6 minute read

Discussing why composite

SIMPLE, NO FUSS COMPOSITE DECKING

Charles Taylor, Sales Director at Composite Prime, discusses why composite decking should be used in more projects, and top tips on maintenance and the options available.

Composite products have become well known as a superior product when choosing the right material to install on a project. For anyone looking to make the most out of an outdoor space, composite decking is the perfect solution.

Although traditional timber decking has been the preferred choice of many for years, it’s a high maintenance product which requires annual painting and staining. Composite decking is increasing in popularity as it’s a simple, no fuss alternative due to its unique formula which makes it low maintenance and more durable than traditional products. The plastic content gives the boards a long lifespan without the need to treat or seal the decking, while the wood content enables the product to retain its natural look and feel. This formulation also means that composites don’t need life extending treatments such as sanding or oil, and the boards won’t splinter or rot and can therefore be installed safely in a range of projects.

With people spending an increasing amount of time outside, more investment than ever is being made to improve outdoor spaces from residential gardens to commercial projects. Composite decking is the ideal product to shape outdoor spaces as it is not only a durable investment, but its versatility means that it can be used to create completely bespoke designs which will look great for years to come.

The options available

The HD Deck® range manufactured by Composite Prime is eco-friendly and socially responsible. Made using recycled plastic and FSC® certified oak wood flour, the products are sustainable, ethical and environmentally friendly.

One million plastic bottles are bought every minute around the world, and that number will top half a trillion by 2021, however less than half of those bottles end up getting recycled. As global challenges around plastic waste and the ability to plant forests to meet future timber demands increase, composite provides a sustainable and aesthetic alternative to timber.

HD Deck Dual® decking boards developed by Composite Prime have a reversible two-colour option on

each board which not only saves spaces in warehouses but also offers the opportunity to lay a deck with contrasting colours to create a bespoke finish. The dual-sided board also makes it easy to refresh the deck by simply turning the boards over to reveal the new colour.

The boards are 3D embossed with wood grain to ensure they look natural, and are capped to increase protection against fading, staining and other potentially damaging elements. The boards are low maintenance, slip resistant, durable, sustainable and barefoot safe so even high traffic areas like bars and restaurants will benefit from investing in HD Deck Dual®.

One of the key benefits of Composite Prime is also the ease with which the decking can be installed. Whilst traditional decking options can often be laborious and tricky to take on, requiring specialist tools, the HD Deck® range has a secret clip system that is easy to install. Opting for modern composite decking allows any residential or commercial grade project to achieve a high quality finish which requires minimal maintenance.

For more information about composite decking and the products available, please visit www.composite-prime.com

Recent ‘mystery shopper’ research sponsored by the UK Wood Protection Association (WPA) confirms that understanding amongst many users of preservative treated wood is very poor indeed. When asked if there was a specific treatment specification for timber in ground contact, over 90% of people surveyed said they didn’t know. When asked if they understood what ‘Use Class 4’ means, 72% said they didn’t know. So, how do YOU specify preservative treated wood?!

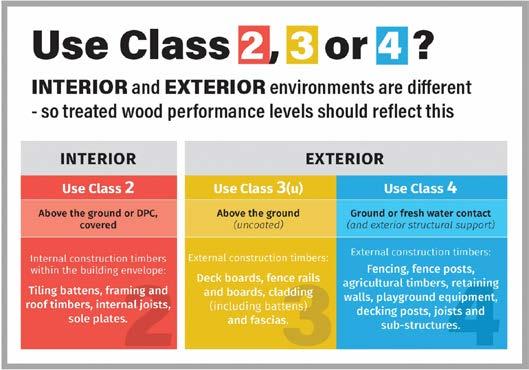

It’s a mistake to assume that all pressure treated wood is the same. Whilst one piece of treated wood may look very much like any other, the level of preservative protection could be very different. That’s because the British Standard for wood preservation, BS 8417, requires that the loading and penetration of preservative impregnated into the wood is tailored to the desired end use. Applications for treated wood are therefore grouped into ‘Use Classes’, the three main being -

The challenge is how best to simplify this message whilst not losing technical accuracy. Therefore, starting this summer, WPA has launched an educational campaign in partnership with the Timber Trade Federation (TTF) & the Timber Decking & Cladding Association (TDCA): For the fencing, garden and landscaping sector, the focus is on promoting the use of the term Use Class 4 for treated wood used in contact with or close to the ground, using the WPA’s ‘Make Sure it’s 4’ logo and communications package.

James Jones Sawmills

For those who need further guidance on what the most critical Use Classes mean in practice, WPA and TTF have developed three new A4 Guidance Notes on Understanding Use Class 2,3 & 4 preservative treated wood. These include a simple explanation of what national standards require for each application, what species are most suitable, what preservative penetration to expect in different treated commodities and the necessary quality control criteria. For those who wish to delve deeper, the WPA website www.thewpa.org. uk contains all you need to know.

Any of the visuals and logos which accompany the Make Sure it’s 4 campaign are readily available, free of charge for all in the timber supply chain to use in their own promotional and educational resources. Simply get in touch via contact@thewpa.org.uk.

Treated Wood Specification & Installation Check List

Establish the Use Class of the timber you need, before ordering. Tell your supplier in writing, that the wood must be treated to that particular Use Class to comply with BS 8417. Ask them to verify that the wood supplied meets your Use Class specification – on the delivery note and invoice or a treatment certificate. When buying from stock always check to which Use Class the wood has been treated. NEVER substitute wood that has been treated for an indoor application for use in an external application – failure is inevitable. Do NOT supply wood that has been treated for external use for what you know will only be internal applications. For wood in permanent ground or fresh water contact, or providing exterior structural support, Use Class 4 levels of protection MUST be achieved. Anything less and service life, structural safety and customer satisfaction will be compromised. When cross cutting, notching or boring treated timber products during installation, ALWAYS apply an end grain preservative treatment to freshly exposed areas – to maintain the integrity of the protection. NEVER put cut ends in the ground, even if end grain coated.

To paraphrase a well known slogan, ‘Stay Alert: Control Treatment Quality: Protect your Business’!