Seventeen years ago, Terry Sroka and Reva Bily “decided to leave the large corporate world of decisions by committee, meeting after meeting and burdensome policies,” they said. The two founded West Point Rack, a Nebraska company that sells exclusively to material handling dealers. “West Point Rack is a smaller company with a highly dedicated staff. This allows us to ‘turn on a dime,’ respond quickly and to innovate whenever the opportunity presents itself,” said Sroka, chief executive officer. “I don’t want to be one of the biggest rack companies out there, just one of the better ones. Our primary goal is to support our dealers, satisfy their customers, earn trust and be the ‘Vendor of Choice’ for rack products and racking systems.” Company president Bily said if an end-user calls, they refer them to a dealer. “There is nothing wrong with selling direct to the end user, but you don’t do both,” Sroka said. “Draw the ‘line’ and stay on one side or the other. In order to build a good relationship with a dealer and to have him trust you, it is necessary that he really believes that you will not go around him and make the sale direct. Dealers are independent businesses that spend time and money to build up a customer base and the last thing they want to see is a manufacturer go around them and sell to one of their prospects who is shopping price.”

Bily grew up on a farm and worked in a packing house and electrical sales before she joined the material handling industry. Customer service is the core of what she does, and the key to growth, she said. Customers want prices and delivery quickly. She tries to get back to a customer with a standard quote in 15 minutes, she said.

The relationship with dealers is built on competitive prices, service and standing behind the product, Sroka said. “If product issues do arise, we address those issues immediately with the goal of creating satisfaction for both our dealer and their customer,” he said.

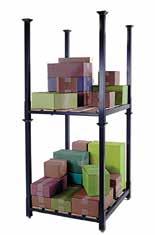

The company sells cantilever racks in light, intermediate, heavy and extra heavy duty configurations, structural pallet racks in galvanized or painted steel and portable stacking racks made to order.

“I always look for things when we do specials,” Sroka said. “Does it have any potential of becoming a standard product? That is how we developed a lot of our standard products.” Specialty products made by West Point Rack include bar cradle trucks, drum racks and handcarts.

West Point Rack has recently added new products to its line of racks. Included is a new line of reel racks, ranging in height from eight to 12 feet.

Vertical racks, which will hold material from 21 inches to 12 feet, feature six-inch deep arms with three shelves made of 14-guage steel. U-Racks, which come with an orange paint finish, can be stacked up to four units high to save space.

“The future looks very positive for West Point Rack,” Sroka said. “Our product base is expanding as is our market penetration. We will continue with the business model and plan that has taken us to this point and will continue to move us forward.”

West Point Rack is one of the fastest growing companies in the industry. Our customers recognize quality products, de pendability of service and competitive pricing.

Our Primary Goal is to support our dealers, satisfy their customers, earn trust and be the “Vendor of Choice” for rack products and racking systems.

We offer a full line of light duty, intermediate duty, heavy and extra heavy duty cantilever racks. We provide multiple configu rations of a wide variety of stacking racks. Our structural pal let racks can be configured for a wide range of applications. West Point Rack has the products that generates solutions for your storage needs.

We also offer specialty products such as bar cradle trucks, drum racks, hand carts and other specialty transport and storage products. Give us a call at 866.245.3630. We may have what you need. Look forward to hearing from you.

Superior Tire & Rubber Corporation has successfully launched the Next Generation line of polyurethane load wheels branded Velocity™. This patent-pending product, redesigned and reengineered, promises to deliver a longer work-life by keeping the bearings and polyurethane cooler through its new innovative hub design.

After a year of trials and almost another year of sales, the Velocity™ has proven to be a game changer. Major warehouses & distribution centers across the US have reported significant longevity and productivity improvements, switching their entire fleets over to reap the benefits. “Heat is the enemy for tires and wheels, shortening work-life of bearings, tire compounds, and the bonding systems of solid tires,” says Joe Peterson, Ph.D.,VP of Engineering & Quality at Superior Tire. “Traditional solid steel wheels don’t effectively dissipate the heat generated during use and they cool slowly even after the vehicle stops. The new hubs help manage the thermal energy generated by the tire, creating a better performing wheel.” Superior Tire’s team of engineers took a common technology found in radiators and computer components and applied it to load wheels, allowing the Velocity™ to limit and maintain a reduced maximum operating temperature thereby prolonging work-life by up to 100% against traditional wheels. They are calling it HeatSink™ technology.

In addition to extending work-life,Velocity™ wheels are approximately 70% lighter than traditional load wheels, not only providing an ergonomic advantage for techs and field staff but also saving in shipping. “The lightweight has no effect on carrying capacity – in the case of traditional solid steel wheels, that excess material is just wasted mass”, states Dr. Peterson. Superior Tire ran dozens of durability tests and found the Velocity™ wheel can easily support more weight than the bearings can hold. A video of one of these tests can be found here:Velocity™ Compression Test

As with any industry-changing technology, there is one caveat – Velocity™ wheels are currently only available for the most popular 5-inch market sizes for Crown, Raymond, and Hyster-Yale Class-2 equipment. Superior Tire is currently in development & testing of 4-inch and 6-inch load wheel variants, with expectations of bringing these to the market in 2023. “This is truly an exciting time on our industry with the overall growth of the market and fleets/operators demanding longer lasting equipment. It’s the perfect time to bring a Next Generation solution to our dealers and OEM partners.”, says Jared Steier – VP of Material Handling Sales and Marketing. “The Velocity™ wheel is a perfect tangible example of our slogan – Engineering Revolution.”

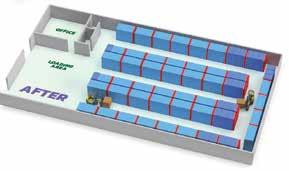

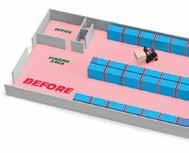

B e f o r e y o u i n v e s t i n u p g r a d i n g t h e i n f r a s t r u c t u r e o f y o u r w a r e h o u s e , f i n d o u t h o w C o m b i l i f t c a n i n c r e a s e y o u r s t o r a g e b y u p t o 5 0 % . W i t h o v e r 2 1 y e a r s ’ ’ e x p e r i e n c e i n v o l u m e o p t i m i z a t i o n , o u r t e a m o f w a r e h o u s e p l a n n i n g e x p e r t s k n o w h o w t o m a k e y o u r s p a c e w o r k h a r d e r f o r y o u C o n t a c t u s t o d a y t o a r r a n g e a s i t e s u r v e y ! O u r w a r e h o u s e d e s i g n c o n s u l t a n c y s e r v i c e i s F R E E a n d w i t h o u t o b l i g a t i o n .

Pallet stacking

warehouse