This three-day course provides a basic understanding of the principles of hydraulics, hydraulic parts, and how these systems operate, providing a firm foundation for working on and troubleshooting mobile hydraulic systems. This course will provide:

• Emphasis on safety, hands-on training and troubleshooting techniques

• Industry-standard content, OE generic and applications for all major brands of fluid power components

• Lectures, discussions, component animations, understanding schematics, and hands-on simulator exercises

April 11-13: Mississauga, ON

April 19-20: EDO of Mexico

August 1-3: Grayslake, IL

November 7-9: Elizabethtown, PA

November 15-16: Monterrey, MX

This will be MHEDA’s first ever convention in fun and lively Nashville! We planned a number of tours around the city where you can enjoy the unique local flavor and energy.

Register now for MHEDA’s 2023 Annual Convention, April 29 – May 3. We look forward to seeing you and providing you with a memorable and productive convention experience! Read more details below or visit our website www.mheda.org/convention2023

Your team is the heartbeat of your organization. No matter how sleek, modern or powerful your equipment or systems appear, they are fueled by humans. Beautiful, messy, imperfect humans.

We are working in an uncertain era of employee fatigue, mental health issues and low morale due to current pressures in and out of the workplace. Are you providing support when and where needed?

As leaders, it is our job to listen, react and plan for a positive and productive work environment.

MHEDA invites you to join us April 29 –May 3 in Nashville for the 2023 Convention, “The Human Factor.” We’ve designed a program to help the material handling business community gain insight on how to better lead during disruption, burnout, supply chain challenges and inflation.

Take a few days to learn from experts who can help you dig through what is impacting the modern workforce, then gain practical strategies you can use to help move your team forward, in harmony.

Beyond the speakers, you will have the opportunity to enjoy the Exhibitor Showcase, where you can learn about the latest material handling products and services. The Showcase provides a personal networking experience where you can meet face to face with suppliers who are there to support and connect with MHEDA distributor Members.

Learn from 14 Education Sessions, Based on Material Handling Business Trends

MHEDA is proud to present you with the opportunity to choose from 14 education sessions at the Convention. Topics are based on the 2023 Material Handling Business Trends, developed by MHEDA’s Executive Committee.

I Love It Here! How Great Leaders Create Organizations Their People Never Want to Leave

Emmy Award-Winner, Author, Drummer and Workforce Expert Clint Pulver demonstrates the ground-breaking WHY of mentorship over old school management techniques and HOW every employee is just one caring person away from a phenomenal success story.

Thrive: Turning Uncertainty into Your Competitive Advantage

Meridith Elliot Powell, Hall of Fame Speaker and Author, will provide you with innovative strategies you need to redefine disruption and turn uncertainty into your competitive advantage.

The US and Global economies are going through turbulent times with inflation, interest rates fluctuations and labor shortages. MHEDA’s favorite economist Brian Beaulieu from ITR Economics provides a look at data-driven analysis of economic trends and offers practical advice.

Listen to expert Demographer Ken Gronbach on how a tsunami of opportunity is headed right for you and why you should formulate business strategies for success based on demographic facts.

Transferring a business can be a very complex, timely, costly, and just plain old exhausting process. Father and son team, Dr. Bart Basi and Roman Basi will present steps to create a Succession Plan.

Former Marine, Speaker and Author Joe Gerstandt distills insights applicable toward leadership, behavior change, culture change, and more effectively creating inclusive spaces and places.

Technologist Scott Klososky will help you learn a four-step model for developing a true market driven digital strategy roadmap that leads to winning market share and improving profitability.

Given the deteriorating levels of mental health, managing our emotional energy is more important than ever. Don Phin, Founder of HR That Works, will share strategies to help address our mental health challenges and those of the people around us.

A myriad of economic nightmares including a global pandemic, supply chain issues, and labor shortages sparked the flame that led to a wildfire of growth in inflation. Dr. Bart Basi, Attorney/ CPA, will discuss inflation challenges in the material handling industry and how you can face those challenges.

Former Marine, Speaker and Author Joe Gerstandt brings a powerful and actionable new clarity to the concept of inclusion, what it is,

why it matters, and how it happens. You will leave equipped to contribute to a more inclusive culture.

Scott Klososky, Technologist, will provide new information to identify and improve the digital fatigue that is growing in the business world.

Don Phin, Founder of HR That Works, will share strategies, insights, and plenty of take-home tools you can put to immediate use, including how to decide who to hire, employee referrals programs that work and how to calculate the true costs of employee turnover.

In a passionate, insightful, and humorous way MHEDA Member John Wieland, CEO of MH Equipment, shares some of his memorable leadership hits and misses – and how that helped shape his ability to lead, keep, and reward leaders.

You in The Driver’s Seat: Strategies to Put You In Control Of Your Life and Career

Business Growth Expert Meridith Elliott Powell will share the secrets every female professional needs to know to advance their career, build their skills and become the leader that organizations strive to promote and keep. Note, this session is presented at the Women in Industry Breakfast.

Visit 90+ Booths at the Exhibitor Showcase

Enjoy walking through the Exhibitor Showcase, where you can learn about the latest material handling products and services.

Build Your Network at the Exhibitor Showcase

The Showcase provides a personal networking experience where you can meet face to face with suppliers who are there to support and connect with MHEDA distributor and integrator members. It’s also a fun environment! Win door prizes and enjoy complimentary food and drinks in the sponsored cafés.

MHEDA will bring together convention attendees for a bonus hour of networking, food, give-aways and more! The Happy Hour will take place in the same ballroom as the Exhibitor Showcase.

MHEDA Convention attendees will enjoy many fun networking events, including local tours, golf tournament, exciting parties and spouse/guest programs.

Nashville is the place to be for live music, authentic Southern eats, and a rocking good time no matter where you go. MHEDA’s 2023 Convention puts you in the heart of it all, with a Broadway location within walking distance. We are offering four fun local activities for you: Bike Tour of Nashville; Tour of the Grand Ole Opry; Golf Tournament at Ted Rhodes Golf Course; and a Goo Goo Candy Making Class!

Memorable Parties

Relax and enjoy good food and great conversation with your industry peers at MHEDA’s Opening and Closing Parties. The Convention opens with an interactive welcome event at Brooklyn Bowl Nashville and will close with a night of live music featuring a popular local band.

Help the local Nashville community when you participate in the MHEDA Give Back event. Great way to feel good while networking with your peers.

MHEDA’s 2023 Convention will take place at the beautiful Grand Hyatt Nashville, located steps from the action of downtown Nashville.

Grand Hyatt Nashville

The hotel features one of the highest outdoor rooftop bars in Music City, a spa, and seven food and beverage experiences. Enjoy a refreshing swim in the outdoor rooftop pool, or lounge on the sundeck featuring panoramic views of Broadway and downtown Nashville. Both are located on the fifth-floor lifestyle level along with the fitness center and spa.

Register Today!

MHEDA looks forward to welcoming the Material Handling business community to Nashville, April 29 – May 3, 2023 to discuss and learn more about “The Human Factor.” Complete event details are available on our website www.mheda.org/convention2023. If you have any questions, please contact us at 847-6803500 or email connect@mheda.org .

www.ProMatshow.com

WOMEN

POWERFUL

ENERGETIC

When I started writing for Material Handling Wholesaler, I originally assumed the reader audience would be only those that have been in the material handling industry for many years like myself. However, what I did not think about was the new and younger workers entering our industry along with the workers that have recently pivoted to our industry for the first time. A mentor of mine once told me, ‘Be a student of the industry,’ so fittingly this month’s edition will be one that I hope serves both the mix of workers entering our industry for the first time along with those that have been in it for many years. Therefore, with that, I thought a good topic for this month would be The Customer Experience, a topic that everyone can relate to whether it be in the B2B or B2C space.

When explaining the customer experience touchpoints of our industry’s service and parts sales to those new or unfamiliar with the material handling space, I often point to parallels in the automotive industry. I ask them, ‘What OEM brand vehicle do you drive? What made you choose where you bought your vehicle? When your vehicle needs service, repair, or parts, how do you choose where to go or who to use for service and parts?’

Knowing they drive OEM brand ‘X’, they know there are multiple OEM dealers of that brand within their town, and they know that there are also many independent service providers and a variety of auto-part stores also to choose from. Understanding this framework makes it easy to translate to our industry when explaining after-sales service and parts for lift trucks and other industrial equipment. So what separates each of the service providers or parts resellers? One of the main differentiators is the customer experience provided by these providers.

Customer experience is not just a ‘buzz’ word in a B2B or B2C business strategy. In addition, it is not just a marketing or communications function. Simply defined, the customer experience refers to how your business engages with your customer throughout their journey of purchasing a product or service. The products or services your company sells to your customer

and your people that provide the product or service from your business to your customer are the two primary interactions your customer has with your company. So, if the product or service that you are competing to sell in your market with your competitors is similar or the same (lift trucks, maintenance services, replacement parts, etc.) then the differentiating factor between the competitors for the interaction with the target customer are your people.

Everyone in your company, no matter the department, will have an effect on your customer experience. These interactions with the customer can be direct or indirect and not limited to only your customer-facing teams (i.e., sales, service, rental, and parts departments). Therefore, it is imperative for all employees within your organization to be engaged with the customer experience vision within the organization.

Let us focus on the customer experience regarding a service repair request. The way a customer can request service has evolved over time. Many organizations have deployed an omnichannel approach to the way a customer can request a service repair aside from the traditional phone call request. This omnichannel experience will include the traditional model but also, appbased options and online platforms.

For example, the use of the company website to submit a service request continues to be more prevalent in our industry. From the use of online chat, and online service request form submission, to the use of messaging apps that link a customer directly with their contact within a service department. As I described in a previous article regarding digital strategy, this truly does bring the B2C experience that your customer expects in their everyday life to the B2B world. What does this experience look like within your organization? Even if you are not equipped with these various mediums, how you interact with your customer from the time of the service request to the start and completion of the repair to the invoicing and collection of payment are all interactions that you can differentiate from the

Solid reputation in the industry for quality and integrity

Convenient, round trip freight, including prepaid, discounted outbound and return shipping

Large inventory of engines in stock ready to ship

At EPS, we’re absolutely committed to delivering the best quality reman engines and parts available anywhere. We also strive to make it easy for you to get what you need as quickly as possible, so you can get back to work. That’s why we provide so many “extras” that are all part of the deal when you do business with us.

➤ Large selection of remanufactured engines ready to ship.

➤ Reman parts, pumps and injectors and overhaul kits available.

➤ One of the industry’s oldest, largest and most reliable suppliers.

➤ Call us for expert advice!

competition and provide an outstanding customer experience.

It is imperative that everyone in your organization values the customer and understands that a positive customer experience will keep your customers loyal to your organization and brand. They must also understand the correlation between the quality of after-sales service your organization provides is a factor in repeat business of service, parts, and equipment sales with your customer.

As I wrote in my December edition, I believe the lift truck industry is currently comprised of a few categories: Factory Stores, Independent distributors, Mega Dealers, and Third Party Service Providers. All four of these are competing for the same end-customer, so recognize that the difference in the quality of the service provided after-sale is the differentiating factor of your customer loyalty and future purchases. Nonetheless, it does not matter big or small, 10 employees or 100 employees, providing a great customer experience is important to the continued growth of your business. Although you may or may not have the resources to deploy a dedicated customer experience (CX) team or officer, your organization’s customer experience vision should be part of the fabric of your onboarding and training of new employees and continuing education for existing employees in all departments within your organization.

Days Apr 10-13 Sales@HessAuctioneers.com PA Auction Co. #: AY2025/AH1856/VB1159

strong units that can take a beating.

Constructed from 5" x 5" x 3/16" square tube with 10" x 10" x 5/8" base plates.

Available in 36" and 48" lengths, 10", 24" and 42" heights.

Time tested diamond mesh partitions have been pre-engineered for easy installation, give an unrestricted view into the cage, and total air circulation.

Low initial cost and maintenance.

Send us the footprint of your project and allow our engineers to assist you on your next project!

CSI: 10605, 102213

Technology changes have been talked about for the last ten years and probably more. Many of you have adopted newer technology by investing in new operating systems, CRM systems, marketing systems, and many apps to improve communication with customers, employees, and OEM personnel. And some of you have only made minor changes because of the cost involved and the lack of OEM suggestions that you do so. And some of you are just “thinking” about changes because you lack the internal talent and professional relationships to help lead the way. Quite frankly, this spread in the way management moves their company forward, where some dive in and move the bar upward, and others just keep juggling the issue until they MUST adapt to the norm, while others just wind up so far behind the curve that they just as well pass the torch on to a new owner with the means to play “catchup”, and hopefully generate a profit on their investment. Unfortunately, these three levels of change management seem to be the norm.

And now there is 2023. And starting in 2023 there will be changes for just about 100% of equipment dealers that will take place whether dealers like it or not. You will either make the changes or stand to lose your business. The reasons for these changes are a result of inflation, interest rates, and a need to provide “green” products and services. Put them all together into your planning file and shake it up and I am sure you will find that changes WILL be made if you hope to stay in business.

Just to give you a little background of what is in store for the industry I suggest you go to U-Tube and find WEALTHION LUCKY LOPEZ. Wealthion is a site that provides quality speakers that deal with economic issues as well as specific industry discussions. In this case, Mr. Lopez is a car industry nut who not only loves cars but the industry as well. He owns dealerships, invests in car loan papers, spends a lot of time at auction houses, and studies new and used auto transactions to the point where he can pretty much foresee where things are going into 2023 and beyond. And after you listen to his

comments you have to basically agree because it all ties together. I have to warn you that this is a 51-minute discussion, but worth every minute of your time. I have watched it three times and can’t stop thinking about it.

No, I am not going to tell you what Mr. Lopez’s final conclusions suggest. All I will say is that car dealers had the best years of their lives in the last couple of years. Made tons of money.

When discussing the lift truck dealer business, we always wind up saying that what happens in the auto dealer business is sure to find its way into the lift truck business. Sometimes these changes are positive and sometimes they are not. But no matter what, both sides share the issues we all do such as inflation, interest rates, lack of personnel, lack of inventory, and fears related to a “recession” that will turn everything upside down.

But the biggest issue every OEM and Dealer in the world had to deal with is the potential switch of the product line into EV. EV will change your entire business model, revenue streams, and costs while trying to figure out how to manage owned gas or diesel units, new units you overpaid for, and used units that everyone wants to buy (for now) when you have shortfalls in your rental fleet. The way I see it transitioning to a high percentage of EV sales and rental assets will be an expensive proposition for most dealers. BUT NOT FOR THE LIFT TRUCK BUSINESS.

Making a change to primarily EV from gas or diesel units will be a killer needing a lot of capital to reach the other side. Lift truck dealers do not have that issue at the same level as other dealers do. You are already in the battery business with the ability to make a switch to lithium batteries that puts you over the hump. Well, how about that? Are you now thinking you are in the clear because of the battery advantage? Maybe not.

All the equipment industry material I read leads me to believe that rental activity is going to increase because users do not want to deal with the “high cost” equipment, interest rates,

personnel issues, and let’s not forget fixed costs and bank covenant issues. And, guess what, they don’t have to because they will let you keep the headaches. Rent they will do. Buying at this time is not high on the list. And don’t be surprised if customers prefer to rent as opposed to a longterm lease, or ask to pay for hourly usage of the units you have on their floor. A flat rate to cover the cost of ownership and a second rate to cover the cost to operate.

It may be that the OEM-Dealer agreements we are used to are about to change. There seems to be a number of OEMs buying other OEMs. There is also a strong consolidation taking place in the equipment rental industry. Companies are looking to expand their rental programs promoting units where dealer networks are not part of the program. In Europe, dealers are becoming service centers for various brands that no longer sell through dealer networks. They sell directly to end users as well as rental companies.

Maybe in the US lift truck dealers do not have to worry about the auto industry, but maybe they do have to think about what is taking place in Europe.

Make sure you closely review the TM Capital 2023 Equipment Rental and Dealer Report that Dean sent out.

The customer is always right. Except when they are wrong, which is most of the time. In sales right and wrong don’t matter.

Keeping the customer satisfied and happy is what matters. What’s the best method of handling the dreaded CUSTOMER COMPLAINT? Try The Personal Touch Method.

Here is a formula I have developed and used over and over. To institute this method, you must first and foremost TAKE RESPONSIBILITY even if the fault isn’t yours, or you won’t be the one who handles it. The customer doesn’t care. He’s pissed. He just wants you to handle it. Now.

Here are 15 Steps to Taking Responsibility when Dealing with Unhappy or Dissatisfied Customers. Not only does this method work, but it provides for self-analysis at the end to prevent the same problem from occurring again. All 15 steps must be used, or the loss of a customer will result.

1. Agree with them at first. (Never argue)

2. Tell them you understand how they feel.

3. Empathize with them. (Site a similar situation, tell them that it makes you mad too, and tell them a similar thing happened to you)

4. Listen all the way out. Make sure the customer has told you everything. Don’t interrupt. Ask questions.

5. Confirm that all is out and that they have said all they want or need to say.

6. Be an ambassador for your company. Tell the customer you will personally handle it.

7. Don’t blame others. Admit you (and or the company) were wrong.

8. Don’t pass the buck. It’s not my job, I thought he said…, she’s not here right now, & someone else

handles that, are words that are never applicable or acceptable to the customer.

9. Respond When something is wrong, people want (and expect) it to be fixed immediately. The customer wants it perfect.

10. Find some common ground other than the problem. Try to establish some rapport.

11. Use humor if possible. Making people laugh puts them at ease.

12. Figure out, communicate, and agree upon a solution or resolution. Confirm it (in writing if necessary). Do it!

13. Make a follow-up call after the situation is resolved.

14. Get a review if you can. Resolving a problem in a favorable and positive way strengthens respect, builds character, and establishes a solid base for long-term relationships. Tell the customer you would appreciate a sentence or two about how the situation was resolved.

15. What have I learned and/or what can I do to prevent this situation from happening again? Do I need to make changes?

It is important to be aware of some practical realities when trying to accomplish the task of satisfying the customer. They are:

• The customer knows exactly how they want it, or exactly what they want, but maybe a lousy communicator and not tell you completely, or tell you in a way that is difficult to understand.

• Remember you’re the customer elsewhere and think of how you expect service when you’re the customer.

• Every customer thinks they’re the only one you’ve got… treat them that way. Make the customer feel important.

• The customer is human and has problems just like we do.

• The customer expects service at the flip of a switch.

• It all boils down to you.

• The customer’s perception is reality.

• How big a deal is it to try to give them what they want?

Customers talk to their associates, friends, and neighbors. Here is the number of people they will talk to based on how well you handle their complaint:

• 3 if you do a good job

• 10 if you do a great job

• 25 if you do a bad job

• 50 if you do a really bad job

• and you will be on the 6:00 news if you do a horrible job (Action9).

When you satisfy an unhappy or dissatisfied customer, and you can get them to write you a review telling you they’re happy and satisfied now, I’d say you have a solid shot at a long-term relationship. If the problem is left unresolved, the customer will surely find your competition.

When a customer has a complaint, you have an opportunity to solidify your relationship…if you handle it properly.

Jeffrey Gitomer is the author of twelve best-selling books including The Sales Bible, The Little Red Book of Selling, and The Little Gold Book of Yes! Attitude. His real-world ideas and content are also available as online courses at www.GitomerLearningAcademy.com.

Following the official ground-breaking ceremony in Kahl am Main near the German city of Aschaffenburg, the extensive construction and installation work on this new spare parts distribution center can now begin. Work will be completed by January 2025. The distribution center is set to house around 22,000 square meters of floor space for the spare parts logistics for the KION brands Linde Material Handling and Dematic. The building complex will be divided into different halls, among them a 30 m tall fully automated high-bay warehouse.

www.kiongroup.com

The American Rental Association (ARA) trade show, The ARA Show™ 2023, has wrapped, and attendance was phenomenal. The largest equipment and event rental trade show and convention in the world was held February 11-15 at the Orange County Convention Center (OCCC) in Orlando, Florida. The number of rental stores that attended the show increased tremendously from the previous show in October 2021. More than 750 exhibitors attended the trade show – many celebrating milestones from firsttime exhibitors to a remarkable 66 years as an exhibitor at the show.

www.ARAShow.org

The Raymond Corporation’s 8910 end rider pallet truck has been named a finalist for an International Intralogistics and Forklift Truck of the Year (IFOY) Award, which recognizes the industry’s best intralogistics products and system solutions from around the world. Adaptability, operator comfort, and sustainability features make the 8910 pallet truck perfect for a range of tasks, especially long hauls. The IFOY Award honors the best industrial lift trucks and intralogistics solutions of the year as selected by a jury of leading international logistics media.

www.rayhmondcorp.com

Mitsubishi Logisnext Americas announced that Cat Lift Trucks will return as the Official Lift Truck Provider for the 2023 Houston Livestock Show and Rodeo™. For 19 consecutive years, Cat Lift Trucks and its local dealer Darr Equipment Co, have played a critical role in the production of the largest livestock exhibition and rodeo in the world. The Houston Livestock Show and Rodeo is a beloved tradition for over 2.5 million visitors and 30,000 exhibitors each year.

As World-Class Designers & Manufacturers of Material Handling Equipment, We Offer:

CUS TOM T RAI LE R S

Th is one-of-a-k i nd wa s ju s t wha t t h e customer ordere d !

G E NERA L PURPOS E

TRAI L ER S

Si ng le e n d fift h whee l , front automotiv e or all w heel steer i n g capab i l i t i es O u r equ i pment i s of heavy du ty, a l l welde d steel c onstruct i o n ca p ab l e o f wit h stan d i n g t h e roug h est p u n is h ment

O u r heavy-duty tran sp orter s c ome eq u i p ped w i t h mai n te n a n ce free batte r y an d c harge r, pe n dant c o n tro l , electrome ch a n i c a l d r i ve and steer w it h laser s ca n b u m p ers as an o p t i o n We ca n b u i l d to your s peci fic atio n s or ask a b o u t o u r standar d mo d e l s

Some materia l han d l i ng jobs are s o un iq u e that o n ly c ustom i zed spe c ialty trai l ers c an be used effi ci entl y We c an design and bui l d a n y size or c apa c ity from t h e "groun d u p " the exa c t tra i ler to fit yo u r spe c ia l n eed s

TRANSPO RT ER S

Give u s yo u r spec s , chances are w e b uilt a s i mi l ar un i t befor e an d wit h m i nor mod i ficat i ons , g et you w hat you n ee d

TRA IL SKID S

Ca n do u ble or even tr i p l e your forklift's ca p acit y Plu s they are extremely maneuvera b l e

O ur p ate n te d PH I LL I P S A uto-D u mp B u c ket wi l l i n crea s e effi ci e n cy a nd red uc e the c o s t of h a nd l i n g almo s t a n y loose i n dus tr i a l mater i a l Our b u c kets are a vaila b le from 1/2 - 20 c u bic yar d s All operat i on s are han d led by t h e c ranema n . It c an n ot be d um p ed i n mi d -a i r or d u mpe d a ccid enta ll y

AGV ’s are c apable of f u lly automat i c o p erati o n a n d are d esi g ned to meet yo u r spec ifi catio n s O ur AGV ’s c an automat ic al l y p i ck u p from a nd deliver loads to m u lt i ple l o c ations C apa ci ties from 1 -20 0 ton s

Par t of the I ndu s tr i a l Sales Group of I r win Car and E q uipment

I

All PH I LLIPS C harg i ng A ttachments h av e ava il ab l e qu ic k di sc onne c t h ydraul i c c oup l i n gs bo l ted to the apro n Hea t resi s ta n t mo d i fi cat i ons are do n e to a n y model of fork l ift for your safe t y

PHILLIPS PRODUCTS

T: 7 2 4-86

F : 7 2 4-86 4 - 8 90 9

Em a il : Da v e F elt at df e lt@ir w inc a r.c o m

MHI announces the four finalists chosen as the most innovative products in each category

Best New Innovation:

• Agility Robotics for Digit a Human-Centric Robot: ProMat Booth S1031

• Berkshire Grey Inc. Project GreyWolfA Berkshire Grey & Locus Robotics Solution: ProMat Booth N6707

• OPEX Corporation for OPEX® Infinity™

AS/RS System: ProMat Booth S2712

• Packsize International Inc. for X5: Booth

S3547

Best Innovation of an Existing Product:

• HAI Robotics U.S.A. Inc. for A42T

Autonomous Case-picking Robot: ProMat Booth N7900

• Vanderlande Industries, Inc. for ADAPTO Shuttle: ProMat Booth S603

• Ideal Warehouse Innovations, Inc. for SLIDE-effect® Dock Bumper: ProMat Booth

S3350

• Geekplus America, Inc. for PopPick: ProMat Booth N7307/N7507

Best IT Innovation:

• Synkrato for Synkrato warehouse digital twin: ProMat Booth N6256

• OneRack for OneRack: ProMat Booth

S2882

• Lucas Systems, Inc. for Lucas Systems Dynamic Work Optimization: ProMat Booth

S3775

• FORTNA for FORTNA OptiSlot DC

Featuring Digital Twin Technology: ProMat Booth S1947

www.promatshow.com

KION GROUP AG finished 2022 with order intake at a high level in a challenging macroeconomic and geopolitical environment. The global intralogistics Group recorded an increase in revenue compared to the previous year, including clearly positive currency effects. Sharply rising costs for materials, energy, and logistics coupled with ongoing supply chain disruptions had a significant impact on both operating segments in the last year, which was reflected in a decline in adjusted EBIT and a clearly negative free cash flow for the Group.

• Order intake of €11.708 billion despite dampening demand (previous year: €12.482 billion)

• Supply chain disruptions coupled with increased costs for materials, energy, and logistics negatively impacted the key financial figures

• Revenue up by 8.2 percent to €11.136 billion (previous year: €10.294 billion)

• Adjusted EBIT of €292.4 million significantly below the previous year’s level (€841.8 million)

• Due to a significant decline in earnings and increased net working capital, the free cash flow of -€715.6 million is significantly below the previous year’s level (€543.8 million)

• Proposed dividend of €0.19 per share at an EPS of €0.75

• Significant improvement in profitability and free cash flow expected for 2023

www.kiongroup.com

Hamilton Caster & Mfg. Co. announced that it has named Mark Lippert as its new President. Hamilton Caster, a 116-year-old manufacturer of heavy-duty industrial casters, wheels, carts, and in-plant trailers, is in its fourth generation of family leadership. Mark succeeds his cousin, David R. Lippert, who retired in December. Mark joined Hamilton Caster in 1995 to lead marketing efforts that have resulted in a brand that has been ranked #1 in brand perception studies for the industrial manufacturing market.

www.hamiltoncaster.com

Felling Trailers Inc.has recently named Joe Pessen as a regional sales manager to serve the South-Central territory. He will be responsible for all sales development, activity, and dealer support within Nebraska, Kansas, Oklahoma, Arkansas, Texas, and Louisiana. As the regional manager for the south-central territory, Joe’s primary responsibilities will be to achieve regional market share objectives with the existing dealer base and develop new dealers in the assigned territory, providing training and product support.

www.felling.com

SIGI has announced the appointment of Dr. Mirka Wilderer to its board of directors. One of the top female executives in the water industry, Dr. Wilderer earned her doctorate in international business from Germany’s Carl von Ossietzky University of Oldenburg. She started her career at Siemens and has most recently served as the Chief Executive Officer of De Nora Water Technologies.

www.southworthproducts.com

KION North America has announced its territory expansion with dealer partner Carson Material Handling. This expansion includes a new location in Campobello, S.C., and involves the acquisition of J&J Forklift Services. Carson Material Handling is authorized to sell the Linde Material Handling and Baoli brands. For almost 20 years, Carson Material Handling has been a fleet management solutions provider throughout North Carolina and North-Western South Carolina.

www.kion-na.com

www.carsonlift.com

Monty Alexander 563 588-3855

Kip Krady 563 557-4493

Dean Millius 563 557-4496

Lift Atlanta is the latest dealer to join the expanding LiuGong North America dealership network in the South. Leaders of the North Georgia-based business said they were looking for a new manufacturer at the end of 2022 and were intrigued by what they heard from current LiuGong dealers and their customers. Lift Atlanta is headquartered in Decatur, Georgia with an additional location in Augusta. The company was founded as a forklift dealer in 1975 by Mitchell Milovich, Lift Atlanta CEO.

www.liftatlanta.com

www.liugongna.com

Plus One Robotics

announces the appointment of Elle Carroll as sales director, responsible for developing new business and expanding relationships within the 3PL and General Merchandise industries. Carroll comes to the company with significant supply chain and robotic solution experience in both sales and engineering. Prior to joining Plus One, she was employed at Berkshire Grey (Bedford, Mass.) as a principal sales solution architect responsible for designing and contracting its robotic solutions at major retailers.

www.plusonerobotics.com

UgoWork™ has announced that it will unveil a brand-new lithium-ion battery management solution at ProMat 2023. To be showcased at UgoWork’s booth (#N6760) alongside its lithium-ion batteries for industrial trucks, payper-use approach, and real-time fleet monitoring services, the company’s lithium-ion battery management solution will put material handling team’s in the driver’s seat for more effective and efficient means to track performance levels and energy usage.

www.ugowork.com

The Women In Trucking Association (WIT) has announced Ashley Leiva as its March 2023 Member of the Month. Leiva is the co-owner of Noemi Trucking in Corpus Christi, Texas. Shortly after graduating high school, Leiva enlisted in the Army. During her 15 years in the military, she was a Sergeant First Class, E7, and worked as a Culinary Management NCO, hauling equipment, food, and personnel to training and danger areas. She trained in many parts of the world, including Indonesia, Malaysia, and Australia, as well as served two tours in Iraq. Leiva is thankful for the support from her family, community, and mentor, Lynette Cervantes, the director at Del Mar College where she obtained her CDL.

www.womenintrucking.org

IMI SalesLeads has announced the February 2023 results for the new planned capital project spending report for the Industrial Manufacturing industry. The Firm tracks North American planned industrial capital project activity; including facility expansions, new plant construction, and significant equipment modernization projects. Research confirms 110 new projects in February as compared to 130 in January in the Industrial Manufacturing sector.

NEW YORK: Wind turbine mfr. is planning to invest $500 million in the construction of a manufacturing facility in COEYMANS, NY. They are currently seeking approval for the project.

The following are selected highlights on new Industrial Manufacturing industry construction news.

Industrial Manufacturing - By Project Type

• Manufacturing/Production Facilities - 98 New Projects

• Distribution and Industrial Warehouse - 71 New Projects

Industrial Manufacturing - By Project Scope/Activity

• New Construction - 34 New Projects

• Expansion - 38 New Projects

• Renovations/Equipment Upgrades - 41 New Projects

• Plant Closings - 14 New Projects

Industrial Manufacturing - By Project Location (Top 10 States)

• California - 10

• Indiana - 8

• Texas - 7

• North Carolina - 5

• Alabama - 4

Largest Planned Project

• Ohio - 8

• Michigan - 7

• Georgia - 6

• Tennessee - 5

• New York - 4

During the month of February, our research team identified 12 new Industrial Manufacturing facility construction projects with an estimated value of $100 million or more.

The largest project is owned by Texas Instruments Inc., which is planning to invest $11 billion in the construction of a manufacturing facility in LEHI, UT. They are currently seeking approval for the project. Construction is expected to begin in Fall 2023, with completion slated for early 2026.

KANSAS: A defense contractor is planning to invest $2 billion for the construction of a 235,000 S.F. computer chip manufacturing facility in BURLINGTON, KS. They are currently seeking approval for the project.

COLORADO: Semiconductor mfr. is planning to invest $880 million for the expansion of its manufacturing facility in COLORADO SPRINGS, CO. They have recently received approval for the project.

SOUTH CAROLINA: Semiconductor mfr. is planning to invest $443 million for the renovation and equipment upgrades on a 300,000 S.F. manufacturing and office facility at 1800 Overview Dr. in ROCK HILL, SC. They have recently received approval for the project. They will relocate their headquarter operations upon completion in Fall 2023.

UTAH: Consumer goods mfr. is planning to invest $400 million for the expansion of its paper product manufacturing facility in CORINNE, UT. They have recently received approval for the project.

GEORGIA: Auto body parts mfr. is planning to invest $300 million in the construction of a manufacturing facility in RINCON, GA. They are currently seeking approval for the project. Completion is slated for 2025.

IOWA: Industrial valve mfr. is planning to invest $75 million for a 36,000 S.F. expansion and equipment upgrades on their manufacturing facility in OSKALOOSA, IA. They have recently received approval for the project.

MINNESOTA: Fluid control equipment mfr. is planning to invest $43 million for a 176,000 S.F. expansion of their manufacturing facility in ANOKA, MN. They are currently seeking approval for the project. Construction is expected to start in the Summer of 2023, with completion slated for late 2024.

NORTH CAROLINA: EV charging station mfr. is planning to invest $41 million for the construction of a manufacturing facility in DURHAM, NC. They have recently received approval for the project.

TENNESSEE: Water heater mfr. is planning to invest $30 million for the expansion of its manufacturing facility in LEBANON, TN. They are currently seeking approval for the project.

Since 1959, SalesLeads, based out of Jacksonville, FL has been providing Industrial Project Reports on companies that are planning significant capital investments in their industrial facilities throughout North America

See more new products online at www.MHWmag.com

WIPOTEC, a manufacturer, and supplier of precision in-motion weighing, track and trace/ anti-counterfeiting solutions, and X-Ray scanning equipment, will showcase its state-of-the-art triple-scale catchweigher at ProMat, Booth #S-237, March 20-23 in Chicago. The company’s HC-FL-T 2 Triple Scale Catchweigher combines three hardware scales into six virtual ones, each capable of operating independently – a feature permitting product gaps as narrow as 10” (250mm).

www.wipotec.com/us

BALYO, the company that specializes in transforming standard forklifts into driverless robots, will be attending ProMat 2023. Robotic experts will be on-hand to discuss BALYO’s full line of driverless forklift vehicles that are helping companies scale up as opposed to out, and showcase tools that simplify the shift from manual to autonomous materials handling.

www.balyo.com

CoEvolution will be exhibiting for the first time at the PROMAT 2023 show at McCormick Place in Chicago from 20-23 March at Booth N7530.

CoEvolution brings with it mainstream robot vendor partnerships (such as with Geek+ and Hai Robotics) and is actively seeking North American partners at PROMAT, including robotics vendors, logistics companies, integrators, and 3PLs. At its 1,500 sq ft booth, CoEvolution will be showcasing its AI-based mobile robot orchestration solution to a US audience.

www.coevolution.ai

ProVeyance Group will be introducing its innovative new FlexExtend Conveyor System at ProMat 2023, which will be held March 20 -23 at McCormick Place in Chicago, Illinois.

FlexExtend is a flexible gravity conveying system with self-tracking skate wheels. The system is designed for low- to medium-volume, multi-sized conveyance operations. This high-flow product can be extended, contracted, or flexed into curves to meet specific material handling requirements.

www.ProVeyance.com

West Point Rack is one of the fastest growing companies in the industr y Our customers recognize quality products, dependability of service and competitive pricing

Our Primar y Goal is to suppor t our dealers, satisf y their customers, earn trust and be the “ Vendor of Choice” for rack products and racking systems.

We of fer a full line of light duty, intermediate duty, heav y and extra heav y duty cantilever racks We provide multiple configurations of a wide variety of stacking racks Our structural pallet racks can be configured for a wide range of applications. West Point Rack h as the products that generates solutions for your storage needs.

We also of fer specialty products such as bar cradle trucks, drum racks, hand car ts and other specialty transpor t and storage products Give us a call at 866 245 3630 We may have what you need Look forward to hearing from you

See more new products online at www.MHWmag.com

Concentric, an OnPoint Group Company, is launching PowerHIVE™, the industry’s first automated forklift battery and charger system, providing on-demand, sustainable, and scalable battery power whenever it is needed. Their newest innovation in equipment power management marries automation with forklift battery systems - eliminating the need to think about forklift charging or battery maintenance.

www.concentricusa.com

Metal fabrication company Penn Sheet Metal, Allentown, Pennsylvania, has cut the time required to stretchwrap its pallet loads of architectural and roofing components and custom decorative building products from an average of 15 minutes per load to 60 seconds or less by replacing manual stretch-wrapping with the automated TAB Wrapper Tornado orbital wrapping machine. The machine is designed and manufactured by TAB Industries that offers a range of automated and semi-automated orbital wrapper.

www.tabwrapper.com

www.pennsheetmetal.com

For more New Products go to www.MHWmag.com

At the Retailers International Leaders Association, (RILA), AutoScheduler.AI introduced the Maken-Ship warehouse optimization platform that optimizes loading products straight off the production line to better orchestrate production, warehousing, and transportation plans.

www.autoscheduler.ai

In Hamilton’s latest line of new industrial wheels, U-Grooved Track Wheels are designed for easy rolling along straight or curvy tracks or pipes. With a capacity range of 1000 –7000 lbs., U-Groove Wheels are a great solution when working with crane cables or pulleys, or using rolling gates and doors.

www.hamiltoncaster.com

Pacline Conveyors has announced the launch of its new Robotics and Automation division, which will focus on integrating Pacline conveyor systems and robotics to offer a greater scope of turnkey solutions for valued distributors, integrators, and end-users. The Robotics and Automation division has its own dedicated facility and will provide efficient conception, design engineering, project management, on-site support, and installation throughout North America.

www.pacline.com

For a direct link to these websites, visit www.MHWmag.com and click on the corresponding display ad under the category you are browsing.

➤ Allied Products

➤ Attachments & Access.

➤ Auctions

➤ Automated Storage Systems

➤ Automatic Identification Equip.

➤ Batteries/Chargers

➤ Container Storage

➤ Controls & Information Handling Systems

➤ Conveyors

➤ Customer Fabricators

➤ Drug Testing Compliance

➤ Dock Equipment

➤ Drum Handlers

➤ Electrical/Electronic Controls

➤ Engines

➤ Finance Companies

➤ Fluid Power Equipment

➤ Insurance Companies

➤ Inventory & Production Control Systems

➤ Inventory And Bar Coding

➤ Lift Tables

➤ LP Gas Distributors

• Pallet Truck Modifications

• Turret Mast Attachment

• Mechanical Attachments

• Special Design Request and Much Much More...

➤ Mechanical Power Transmission Equipment

➤ Non-Powered Floor Equipment & Access.

➤ Other

➤ Overhead Lifting Equipment & Access.

➤ Packing And Equipment

➤ Pallet Jacks

➤ Plant Facilities Equipment

➤ Parts

➤ Plant Yard Equipment

➤ Powered Industrial Trucks

➤ Rack/Shelving

➤ Rentals

➤ Repair Services

➤ Robots, Automated Equipment

➤ Safety Products

➤ Seats

➤ Storage Equipment

➤ Sweepers Scrubbers & Brushes

➤ Tires/Wheels

➤ Training Education/Assoc.

➤ Transportation & Hauling Equipment

➤

➤ Warehouse Management ➤

•

•

•

• Original LIFT-OUT design cuts installation costs in half!

• Fully welded sleeves to hold and capture rails.

• Posts available as Inlines, Corners, or Ends in 18”, 26” and 42” heights.

• Rails available in 2’ – 10’ in 1’ increments.

• Durable steel protection.

• Designed for quick and easy release, but can be bolted together if desired.

• Stronger than typical handrail.

• Top Rail is 42” high and MEETS OSHA FALL PROTECTION if used on a mezzanine.

• Modular hand rail protects employees from entering unsafe areas.

• Easy installation, simply assemble and anchor down.

• Stocked in 4’, 6’, and 8’ sections.

• 42” tall standard.

• MEETS OSHA REQUIREMENTS

• Available in 12”, 18”, and 24” with 4¼”, 5½”, and 8¼” clear opening.

• ¼” material.

• Four mounting holes.

• Accepts ½” anchors, which are available upon request.

• Rack protection creates a visible guide through aisles and saves thousands in damage.

• Available in 36”, 42”, and 48” in either single or double ends.

• Curved end has an 8” I.D. and is 8” and 12” tall.

• Choose floor angle thickness of ½”, 3/8”, or ¼”.

• Two products in one! Keeps flue space clear and prevents damage to walls behind rack.

• Available in 42”, 45” (42” with 3” overhang), 48”, and 51” (48” with 3” overhang).

• Easy installation and creates reinforcement for the rack.

• Flush mount hardware included.

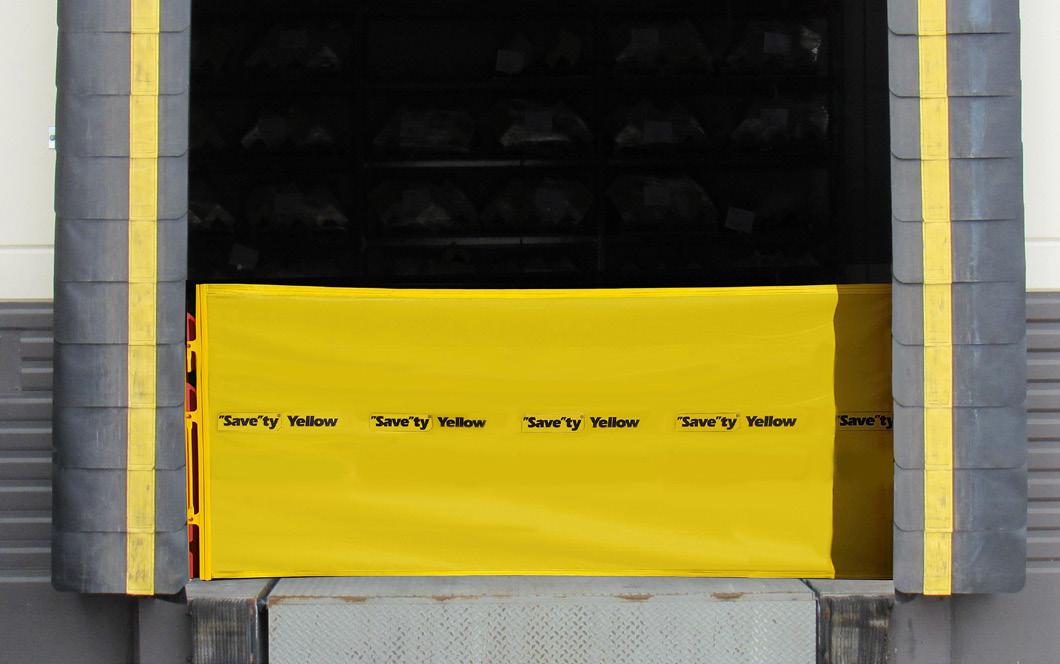

• Protects against unwanted visitors, insects, birds, and debris from entering the work area while allowing air to flow through. 48” tall.

• High visibility, breathable fabric.

• Easy operation, requiring just 3 lbs. of pull force to extend the fabric barrier.

• Accommodates doors from 8’ – 16’.

• MEETS OSHA REQUIREMENTS

• Stop fork trucks from driving or backing off the dock. 42” tall.

• Available in 8’ – 9’ and 10’ – 12’ sizes.

• Includes two 5” steel posts with 12” x 12” baseplates with gussets for strength.

• Reinforced cross bar for strength behind panels.

• MEETS OSHA REQUIREMENTS

Adjustable kickplate and rubber feet

• Choose from 60”, 65”, 72”, 96”, or 120” clear opening.

• Easily pivots to up or down position – requires only 10 - 20 lbs. of lift force.

• Ships mostly assembled – minor assembly required upon receiving. Simply anchor to the mezzanine floor.

• Adjustable kickplate and rubber feet.

• MEETS OSHA REQUIREMENTS

• 6 self-closing arms that operate independently.

• As the pallet is unloaded the top arms close, creating a safety barrier.

• 6’ or 8’ width.

• Includes 8’ tall rack frames and height limiter.

• MEETS OSHA and IBC REQUIREMENTS

Create a real stopping point for pallets! Stops pallets from entering the flue spaces!

•Fits 2.75” deep and 4.75” tall beams.

•Secures waterfall edge wire deck in place.

•Easy installation – slides directly over rack.

•Available in flush mount or with a 3” overhang.

• Reduce damage to your controls.

• Protect any control box mounted to a building column – fan switches, thermostats, and light switches.

• Mounts in minutes with 8 pre-drilled mounting holes. Simply Tek screw to your column and you’re done!

• Available to fit 10” or 12” columns.

• Steel bollards protect a variety of facility assets.

• Surface mount to concrete or direct bury.

• Economy 4½” O.D., Yellow or Red, 5½” O.D. Yellow only, 24”, 36”, or 42” tall.

• Standard 4½” O.D. 42” tall, Yellow with welded top, available with welded eyelet.

• Direct Bury 5½”, 6½”, and 8½” O.D., 84” tall, yellow.

• Square Bollard 4” square tube. 42” tall with painted steel cap.

• Prevent damage to building support columns or mezzanine columns.

• Impact rating: 8,000 lbs. at 5 M.P.H.

• Available in Short, Slim, and Standard. Standard is 42” tall, 24” wide for 6”, 8”, 9”, 10”, and 12”. Yellow is standard, but red, lime green, and orange are available.

• White reflective band standard on lime green and orange.

3” Overhang 2” x 2” Spacing