When Cows Reach the Sky

AMERICA’S LOWEST CARBON DAIRY ETHANOL PLANT WILL USE MILK PERMEATE TO POWER PLANES

22 SUSTAINABILITY SPOTLIGHT: GINGRICH MEADOWS

24 MSU RESEARCHERS

STUDY TAR SPOT

AMERICA’S LOWEST CARBON DAIRY ETHANOL PLANT WILL USE MILK PERMEATE TO POWER PLANES

22 SUSTAINABILITY SPOTLIGHT: GINGRICH MEADOWS

24 MSU RESEARCHERS

STUDY TAR SPOT

A nearly old as time process that begins with fermentation, is going to help cows reach the sky. America’s lowest carbon dairy ethanol plant in Constantine, Mich. will upcycle milk permeate, a byproduct of the ultrafiltration process, to produce ethanol that will power planes.

22 SUSTAINABILITY SPOTLIGHT: GINGRICH MEADOWS

When we talk about farm sustainability, we often overlook the most crucial element—the sustainability of the farmer’s own well-being. On Gingrich Meadows Dairy, in Leroy, Mich., they are continuously looking ahead and trying new things to not only make their farm more sustainable, but their quality of life better.

Tar spot is a corn leaf disease capable of causing severe damage to infected crops. Dr. Martin Chilvers and graduate student Peyton Phillips at Michigan State University have been diligently researching this fungal disease and educating producers on effective management strategies.

“Without a doubt the most rewarding part about working in the

MARTIN GRINNELL, HEALTH AND SAFETY INTERN (PAGE

BY EMILY KITTENDORF-KING

Innovation and sustainability take center stage in this issue, highlighting groundbreaking advancements that are reshaping the dairy industry. From America’s lowest carbon dairy ethanol plant to cutting-edge agricultural research, we're excited to showcase the progress driving our industry forward.

Featured in this issue is one groundbreaking new technology, America’s lowest carbon dairy ethanol plant in Constantine, Mich. The facility will transform milk permeate, a dairy byproduct, to ethanol that will be used for sustainable aviation fuel, powering jets and airplanes. The groundbreaking for the plant took place this summer and many from the MMPA team had the chance to celebrate the success and partnership between MMPA and Dairy Distillery that made the project possible (pg. 18).

These unique innovations that revolutionize the industry aren’t possible without sound science. In this issue, learn from Dr. Martin Chilvers about his team’s efforts with tar spot in corn and what research has taught us about the disease (pg. 24). Flip to page 22 to learn about technology innovations that Gingrich Meadows Dairy has adopted to become more sustainable. In the spirit of change, a new school year is underway and MMPA wished their summer interns well as they start the new semester. Learn more about them and their take on working in the dairy industry on page 14.

NO. 2

(USPS # 345-320) is published bimonthly by the Michigan Milk Producers Association, 41310 Bridge Street, Novi, MI 48376-8002. Periodicals postage paid at Novi and additional mailing offices.

POSTMASTER: Send address changes to Milk Messenger, PO Box 8002, Novi, MI 48376-8002.

President and Chief Executive Officer

Sheila Burkhardt, Chief Corporate Affairs Officer

Emily Kittendorf-King, Editor & Advertising Manager

Mikayla Bowen, Editor messenger@mimilk.com

Publication Designer Stacy Love rezudesign.com

Printing Foresight Group, Stacey Trzeciak staceyt@foresightgroup.net

Publication Office

MMPA Milk Messenger P.O. Box 8002, Novi, MI 48376-8002 p: 248-474-6672 f: 248-474-0924 e: messenger@mimilk.com w: mimilk.com

Established in 1916, MMPA is a member owned and operated dairy cooperative serving dairy farmers in Michigan, Indiana, Wisconsin and Ohio.

An Equal Opportunity Employer – F/M/V/D

Subscriptions: mimilk.com/subscribe MMPA members - 50¢ per year

Non-members - $5 per year

Circulation: 2,600 (ISSN 0026-2315)

he Dairy Distillery Alliance project in Constantine, Mich., is making significant progress. Our early August groundbreaking event officially marked the start of construction, allowing us to recognize and celebrate our partners and vendors who are turning this concept into reality.

The project will include America’s lowest carbon-intensity dairy ethanol plant and a wastewater treatment plant. The ethanol plant will convert milk permeate, a byproduct of ultrafiltered milk, into two million gallons of ethanol per year. The wastewater treatment plant will manage the waste stream from both MMPA’s Constantine processing facility and the new ethanol plant.

There were many key partners that assisted with the project to make it all come together from partners with expertise in wastewater equipment systems, designing and building the distillation equipment, general contractor, lending partners, legal and a bank who specializes in USDA-backed financing.

Since December 2023, we’ve been working on the engineering and design for the wastewater and distillation systems, and we began environmental testing and permitting in January 2024. Construction officially started on July 6, 2024, with site work and foundation phases now underway. The distillation tanks are scheduled for installation by the end of August, followed by the buildings. We plan to have the wastewater plant operational by the end of December 2024, with the ethanol distillation expected to come online by June 2025.

We’re currently in the process of hiring a plant manager to oversee operations as construction wraps up. The plant is expected to employ 10-13 people and will operate 24 hours a day, seven days a week.

Originally, the project’s revenue model focused on selling liquid ethanol as an energy source for the vehicle fuel market. However, we’ve since identified a promising opportunity to partner with Lanza Jet, which is pioneering the production of lowcarbon jet fuel. This partnership could become a significant part of our long-term strategy.

Throughout this process, we’ve engaged multiple departments within the Michigan Milk Producers Association, including the Constantine team, plant engineering and operations, accounting and finance, human resources, and government relations and communications. We appreciate their support and the support of our member owners.

The excitement is building as we move closer to making this project a reality. Thank you to everyone involved for your vision and support in bringing value back to the dairy farm and contributing to a sustainable future.

The Lab Pasteurized Count (LPC) measures the number of bacteria that survive the batch pasteurization temperature of 145º F for 30 minutes. While most plants use the high temperature short time (HTST) method of pasteurization instead of batch pasteurization, the LPC (and similar tests such as the spore-shock test) are tests that can easily be performed in a laboratory environment with a minimal amount of equipment. Some processors use these tests to predict the ability of milk to meet their post-pasteurization shelf-life goals, with many fluid processors seeking code dates of 21 days post-pasteurization. Many producers use LPCs for both monitoring and troubleshooting of their farm quality program.

We perform the test by measuring five mL of milk into small sterile vials and then heating the vials to 62.8 degrees Celsius for 30 minutes in a water bath.

The bacteria that cause elevated LPCs are commonly found in the environment and make their way into the milk supply through many avenues. Maintaining clean milking equipment, clean cows and a clean milking environment are essential to produce milk with low LPCs. Rubber and soft plastic components of milking systems should be replaced regularly before wear is evident. Filters should be changed after 3-4 hours of milking. One part of the milking system that is often overlooked is the vacuum system. Vacuum lines may be cleaned by drawing some of the cleaning in place (CIP) solution into the vacuum lines on a periodic basis.

Your MMPA member representative can assist you with developing process that reduce the risk of high LPCs. Using tools such as the LPC helps MMPA to maintain current raw milk and product customers and opens avenues to develop relationships with other customers.

The samples are then cooled in an ice bath and plated on Petri film. The plates are incubated for 48 hours, and the colonies are counted. The best results don’t have any colony growths, indicating low LPC counts and fewer heat-resistant bacteria.

farm it would be worth looking into why they’re high. Your MMPA member representative is a great resource to help you find the common trouble areas. We always start with the rubber components. A few things in the system were inking, which can cause elevated LPCs. Items like line gaskets, hoses and seals, even vacuum supply lines, can cause high LPCs so we try to clean those out too and replace the pulsation lines sooner than we used to. Running a cleaner with the detergent cycle helps us clean the stainless-steel lines very well. We sometimes get a buildup of milk fat or milk stone in our automatic takeoff sensors. While MMPA doesn’t offer premiums or penalties for LPC values, we feel like it’s in our best interests to ship the best quality milk as we can so that we produce a product that we’re proud of.

America’s lowest carbonintensity dairy ethanol plant breaks ground in southwest Michigan, adding to the needed biofuel supply and helping lower the dairy industry’s carbon footprint.

On August 6, 2024, the Michigan Milk Producers Association (MMPA) and Canadian Dairy Distillery celebrated the groundbreaking of their innovative $41 million ethanol plant in Constantine, Michigan. The event featured remarks from key figures including MMPA Board Chairman Doug Chapin, MMPA President and CEO Joe Diglio, and Dairy Distillery CEO Omid McDonald.

“I’ve been inspired by MMPA dairy farmers and their commitment to sustainability,” Dairy Distillery CEO Omid McDonald said. “Our partnership with MMPA represents a groundbreaking innovation in the dairy sector. Utilizing milk permeate to produce low carbon ethanol is an innovative solution to reduce carbon footprint and provide dairy farmers more value from their milk.”

As a result of their partnership, the new facility will transform 14,000 tons of milk permeate, a dairy byproduct, into

2.2 million gallons of ethanol annually. When blended with transportation fuel, the permeate ethanol will offset 14,500 tons of carbon a year, equivalent to 5% of carbon footprint of the milk processed at Constantine.

“The Dairy Distillery Alliance marks a significant step forward in our sustainability journey. By transforming milk permeate into ethanol, we are not only reducing waste but also contributing to a cleaner environment,” MMPA President & CEO Joe Diglio said. “This project highlights our commitment to innovation and sustainable practices within the dairy industry. It’s a testament to the dedication of our members and partners in striving for a sustainable future. We are proud to lead this initiative that benefits the communities we all work and live in.”

The project received $2.5 million in funding from the Michigan Strategic Fund, showing the state’s commitment to the future of clean energy. Lending partners for this renewable energy project include Pathward®, N.A. and CoBank. Ethanol production at the plant is planned for 2025. The Dairy Distillery Alliance was initially announced last

spring, marking the beginning of this groundbreaking partnership.

“The efforts at Michigan Milk Producers Association and Dairy Distillery in Constantine, Mich. are a prime example of how innovation and partnership and collaboration can meet the important needs of expanding producer economic opportunities, providing a value-added product, and addressing the need for low carbon renewable fuels,” said John Berge, Acting Deputy Administrator, United States Department of Agriculture (USDA). “The investment that USDA made through the Inflation Reduction Act will result in those important outcomes for Michigan dairy producers. We are proud of that and hope this becomes the first of many of these types of projects.”

Below, L-R: Omid McDonald, Founder & CEO, Dairy Distillery; John Berge, Acting Deputy Administrator, United States Department of Agriculture, Farm Services Agency; Doug Chapin, Board Chairman, Michigan Milk Producers Association; Joe Diglio, President & CEO, Michigan Milk Producers Association; Mark Honeysett, Village Manager, Village of Constantine; Brenda Stewart, Regional Senior Business Development Manager, Michigan Economic Development Corporation; Nate Engle, Director of Community Engagement, Michigan Department of Agriculture & Rural Development; and Steve Carra, 36th District State Representative, Michigan House of Representatives.

The Michigan Milk Producers Association (MMPA) is pleased to announce the appointment of Aaron as its new Chief Financial Officer (CFO). In his new role, Anticic will be responsible for managing and overseeing all financial activities of MMPA, ensuring the organization’s long-term financial stability, and supporting its strategic vision.

Anticic brings a wealth of experience to MMPA, having spent over 13 years at Mastronardi Produce, one of the largest produce companies in the world. Starting his tenure at Mastronardi as a financial analyst, Anticic advanced to the position of VP Finance, most recently leading the finance team at the Mastronardi BerryWorld Americas joint venture. During his tenure with Mastronardi Produce, Anticic built and led various accounting and finance teams which played a central role in the development of strategy and in managerial decision making throughout the organization.

“We are excited to welcome Aaron to our executive team,” said Joe Diglio, MMPA President & CEO. “His proven track record in financial leadership and experience with the agriculture industry will be invaluable as we continue to strengthen and grow our cooperative. We are confident that Aaron’s expertise and vision will greatly contribute to the future success of MMPA.”

Aaron holds a Master of Business Administration with distinction from the Richard Ivey School of Business in London, Ontario, Canada. He lives in the Metro Detroit area with his wife and children. In addition to his CFO role with MMPA, Anticic has been appointed as an officer of the MMPA Board of Directors.

“I am honored to join MMPA and work with such a dedicated team,” said Anticic. “I look forward to leveraging my experience to support MMPA’s dairy-farmer owners by ensuring the cooperative’s financial health and contributing to its strategic initiatives.”

In July, USDA began accepting applications through its Emergency Assistance for Livestock, Honeybees and Farm-raised Fish Program (ELAP) to provide financial assistance to eligible dairy farmers who incur HPAI-related milk losses. The per cow milk loss payment due to H5N1 will be determined based on an expected 21-day period of no milk production when a cow is removed from the milking herd, followed by seven days when the cow has returned to milking but produces 50% of the normal amount of production. To apply, producers should contact the Farm Service Agency at their local USDA Service Center.

USDA is actively recruiting farms in Michigan and Ohio to participate in a voluntary program to test bulk milk tanks on dairy farms. The Dairy Herd Status Program offers producers another option to qualify for interstate dairy cattle movement while further reducing H5N1 virus spread, increasing surveillance and expanding knowledge of the disease. Interested producers can begin enrollment by contacting their APHIS Area Veterinarian in Charge or State Veterinarian.

SIEGLER DAIRY FARM LLC*

DAIRY LLC*

AUTHORITY*

EDWARD & PATRICK BOLDAY*

TIMOTHY MATER*

KENNETH K NIELSEN*

BRADLEY STINE*

THOMAS J SCHULTZ*

MK FARMS LLC*

DANIEL L WILLIAMS*

GARY & ROBERT KING*

BREEZY ACRES LLC*

GALLAGHER DAIRY FARM INC*

RICHARD J FETTIG*

TERRY & ERICH LAUTNER*

HORNBACHER FARMS*

STARWARD FARM*

DAVID J LEAVINE*

FOLKERSMA FARM LLC*

SHERWIN WILSON*

DE SAEGHER DAIRY INC*

REETZ DAIRY LLC

BROWN DAIRY INC

REBA ZIMMERMAN & SONS

CLOVERDALE FARMS LLC

LEMAJRU DAIRY FARM LLC

THOMAS & FRANCIS THEMM

ERIC R BLEICH

PRIME LAND FARM

YOLONDA MARKEY

LAWLER DAIRY FARM

B W HULETT FARM INC

J & A KOEBEL FARM LLC

EDWARD & DARLENE

GINGERICH

TIMOTHY P DEMARAY

NAAMAN MARTIN

GUCWA FARMS LLC

LAMB DAIRY FARM LLC

D MISHLER ALVIN D BONTRAGER

MMPA board members Aaron Gasper and Amy Martin attended the National Council of Farmer Cooperative’s Washington Conference in August, alongside MMPA President & CEO Joe Diglio and MMPA Chief Corporate Affairs Officer Sheila Burkhardt.

The conference brought farmer co-op leaders from around the country to talk to policy makers about two pressing policy issues facing cooperatives and their members in the coming year—the need to extend Section 199A tax provisions before they expire and the need for a new farm bill.

In total, the conference included 135 meetings with legislators on Capitol Hill. During the conference, attendees heard from Senator Mike Crapo (R- Idaho), the ranking member of the Senate Finance Committee who will play a key role in negotiations next year to extend expiring tax provisions. While the senator expressed his support of extending Section 199A, he did note that the exact contours of the debate would be heavily influenced by the results of November’s elections. In addition, they heard from ABC Washington Bureau Chief Rick Klein, who provided his perspective on the state of presidential race, and Dr. John Newton, chief economist for the Senate Agriculture Committee, who looked at how the worsening farm economy made passing a new farm bill even more pressing.

At the beginning of July, the U.S. Department of Agriculture issued a recommended decision to amend the Federal Milk Marketing Order (FMMO) pricing formulas. The draft rule follows three years of efforts by the National Milk Producers Federation (NMPF) and its member cooperatives, including MMPA. Changes included in USDA’s recommended rule include:

• updating milk composition factors,

• discontinuing the use of barrel cheese in the protein component price formula,

• updating dairy product make allowances,

• returning to the higher of Class I mover with an accommodation for extended shelf-life milk, and

• updating the Class I differential price system.

NMPF is encouraged that USDA’s recommended decision incorporates much of its proposal. USDA’s approach recognizes the complexities of milk pricing and aligns largely with the comprehensive strategy developed by dairy farmers and their cooperatives over the past three years. Once the proposal is officially published in the Federal Register, it will undergo a 60-day commentary period. A final producer vote is projected for early 2025.

For more information please visit www.nmpf.org/fmmoupdates.

NMPF’s comments note that dairy should remain a distinct food group, with at least three servings recommended for older children and adults, and corresponding amounts for younger children in the next Dietary Guidelines for Americans.

NMPF also states that including plantbased alternatives as substitutes for dairy beyond fortified soy would be a disservice to the American people because there is little to no science supporting the nutritional equivalence of plant-based alternatives. The comments urge extreme caution in recommending plant-based dairy alternatives beyond fortified soy as substitutes for dairy products in the dairy group.

“Dairy foods have been well-studied over decades, and the evidence for the benefits of the dairy food matrix, including nutrient bioavailability and impacts on health outcomes, is wellestablished. By contrast, we are aware of few, if any, studies that have similarly tracked and identified health outcomes for highly processed plant-based

dairy alternatives. These products vary tremendously in their nutrient content, and in contrast to dairy foods, FDA has not established Standards of Identity for any of the alternatives, so there is no requirement that they meet any particular nutrient content.”

NMPF also encourages the DGAC to review the growing body of science that shows dairy foods have beneficial or neutral effects on chronic disease risk at all fat levels. “The scientific evidence supports removing low-fat and fat-free limitations on dairy recommendations, although consumers should certainly be able to choose these varieties if they enjoy them or they need to limit caloric intake,” NMPF said in its comments. The guidelines have significant effects on nutrition in the United States because they form the basis of federal nutrition policy and programs; they also helps guide health promotion and disease prevention initiatives at the federal, state and local levels. The DGAC is expected to release its scientific report with recommendations to USDA and HHS for updating the guidelines in the fall.

Internship: Human Resources

College: Michigan State University

Year in School: Incoming Senior

Major: Advertising Management, Minor in Professional and Public Writing

Dream Job: Executive Media Planner for Ford Motor Company

What previous experience did you have that helped prepare you for your internship?

My classes have greatly prepared me for this internship, even though my hands-on experience in HR is limited. The tasks I’ve worked on—such as presentations, policy writing, infographics, and handbook revisions—align closely with my coursework. Last semester, I took a writing class focused on drafting policies and enhancing a company’s media reach and communications. It’s been incredibly beneficial, and it’s great to be able to apply those skills in this internship.

How did this MMPA internship experience fit into your future career goals?

Even though I know what I eventually want to do, I’m not exactly sure what my next steps are after graduation. This internship is perfect because it gives me experience in my field while letting me explore different areas.

What was your favorite experience working as an MMPA intern?

I genuinely loved meeting everyone and making new friends. The people in the Novi office can attest to how I’ve made an effort to connect with everyone. Being naturally social, I find it inspiring and incredibly helpful to meet so many people who are passionate about their work, as it helps me figure out my own career path.

Brighton, MI

Internship: IT Technician level 1

College: Michigan State University

Year in School: Junior

Major: Computer Science

Dream Job: Cyber security, penetration testing

What previous experience did you have that helped prepare you for your internship?

I had an internship last summer working in IT.

How did this MMPA internship experience fit into your future career goals?

It helps me gain more experience in IT, which is a steppingstone to getting into cyber security.

What was your favorite experience working as an MMPA intern?

Going to visit the plant down in in Middlebury. It was cool to see the process of how the cheese is made.

How did this MMPA internship experience fit into your future career goals?

My goal this summer was to do something different, this internship provided me with that opportunity. I have been able to experience another area of the industry.

What do you like most about working in the dairy industry?

The people! Whether I am here working at MMPA or out working with a dairy farm during class time, I love seeing the passion people have for this industry. It is so inspiring to see people be proud of what they have worked for and continuously strive to do better.

What was your favorite experience working as an MMPA intern?

I love being able to see a different part of the industry that we do not get to cover enough in school. In just the first couple of days here I was able to learn so much about all the different processes in the plant.

Internship: Health and Safety Intern

College: Accounting/Finance

Year in School: Junior

Major: Business Administration

Dream Job: 100% Grass Fed, Organic Dairy Producer

What previous experience did you have that helped prepare you for your internship?

Working as a farm hand for one of our producers when I was in high school gave me crucial insight into how the dairy industry operates. I think it’s important to have a good understanding of the entire “life cycle” of milk when you work in the industry, and having years of hands-on experience with the first step in the process has proven invaluable during my time here.

How did this MMPA internship experience fit into your future career goals?

I believe that having a solid understanding of accounting is incredibly valuable no matter what business or business function you work in. I once was told by a lifelong dairy farmer that farming is first and foremost a business. Being that accounting is often referred to as the language of business, becoming fluent in it is incredibly important to me.

What do you like most about working in the dairy industry?

Without a doubt the most rewarding part about working in the dairy industry is knowing that the work I’m doing will benefit dairy farmers and the dairy industry in some way. Dairy farmers are some of the most hardworking and kind people I have ever met. Anytime I can do something to give back, I am beyond happy to do so, whether it’s in the milking parlor, behind the wheel of a tractor, or in the office.

Internship: Food Systems Fellowship

College: Michigan State University

College of Veterinary Medicine

Year in School: Rising Second Year

Major: Doctorate of Veterinary Medicine

Dream Job: Large Animal Veterinarian

How did this MMPA internship experience fit into your future career goals?

This internship opened me up to the world of regulatory work which provided me a new opportunity to scope out for when I am finally able to practice as a veterinarian. Working with regulatory agencies from co-op to state inspectors is an important aspect of being a veterinarian, especially one who wants to work with biosecurity regulations. My ability to take charge of being the biosecurity expert for the field representative team has provided me more opportunities to build my communication skills and learn more about how producers think regarding their disease management protocols which I can take back with me to build better relationships when I become a veterinarian.

What do you like most about working in the dairy industry?

I have loved getting to know producers and learning more about the regulations on how to ship milk.

What was your favorite experience working as an MMPA intern?

My favorite experience has been working with field representatives like Emily Patton to help producers learn more about biosecurity and how they can start implementing plans on their own farms.

BY EMILY KITTENDORF-KING

Anearly old as time process that begins with fermentation, is going to help cows reach the sky. What started as a solution to upcycle milk permeate, a byproduct of the ultrafiltration process, became an answer to improving dairy farmer’s economics and contributing to the dairy industry’s sustainability goals. The unique solution was the result of an unlikely partnership between a Canadian-based vodka company, Dairy Distillery, and America’s 10th largest dairy cooperative, the Michigan Milk Producers Association (MMPA).

“At the time when MMPA reached out to us looking for a better value from their byproduct, we were making vodka from milk permeate,” Omid McDonald, Dairy Distillery Founder & CEO said. “After some phone calls and meetings, we realized that the amount of permeate that MMPA’s Constantine, Mich. plant produces would yield millions of bottles of vodka which would be hard to sell. We then turned to look at using permeate to make biofuel. That’s where this project came from.”

While the volume of vodka would have flooded the market, there is a strong need for low-carbon biofuel. From the idea’s inception, pieces of the puzzle have continued to come together.

“The ability to solve a problem for milk permeate and create a way to add value was the first win,” Brad Parks, MMPA Director of Strategic Initiatives explained. “The second is that the project let us build a state-of-theart wastewater treatment plant that will use the biogas produced when manufacturing low carbon fuel to fuel the treatment processes.”

The new wastewater treatment facility removes the Constantine plant’s reliance on the municipality’s wastewater treatment facility and lets the new plant be run nearly carbon neutral. The only question that remained, was cash flow.

“I wondered how competitive we were going to be on the revenue side of ethanol,” Parks added. “But then the opportunity came along where the airline industry expressed interest in utilizing all of the ethanol that we would produce for sustainable airline fuel. That became the third win. Our revenue side is locked up long term and we have a more secure economic model.”

The win-win-win will benefit MMPA’s member owners and has resulted in breaking ground on the lowest carbon dairy ethanol plant in America. The success of the official groundbreaking of Dairy Distillery Alliance’s 2.2 million gallon ethanol plant in August though, didn’t come without its challenges.

“It’s been a lot more complicated than what we envisioned,” Parks said. McDonald added, “I call myself a seal, used to jumping through hoops, but this is a big project. We knew it wouldn’t be simple. It’s a first of its kind, it’s something new, but what we are doing together in Constantine is worth all the hassle.”

The list of what they both consider red tape includes securing grant money, partnering with agencies and contractors, and working with state and federal agencies. Thanks to teamwork between the two organizations, the red tape is behind them.

“Dairy Distillery brings the distillation expertise on operating an ethanol plant, and we’re bringing the ability to generate milk permeate, which feeds the plant,” Parks said. “We both

bring expertise and knowledge to the partnership that the other doesn’t have.”

The partnership between Dairy Distillery and MMPA may seem happenstance, but Parks is quick to point out that “our organization has a desire to innovate and look at things in a new way, diversify what we make and expand our footprint. We’re always on the lookout for opportunities. That goes a long way. You can call the project luck, but you can also say we were on the lookout for that.”

Despite the new and unique use of the Dairy Distillery Alliance innovation, when it comes to the distillation process to produce the ethanol, the milk permeate ethanol plant relies on science experimented with during the 1970s oil crisis.

“The process is almost as old as mankind,” McDonald explained. “With fermentation, the yeast we have eats the lactose, converts that into alcohol and then we use standard distillation to purify that alcohol to ethanol. From there, it can be used in cars or in planes.”

In Constantine, 14,000 tons of milk permeate will be piped under the road from the dairy plant to the ethanol plant annually, requiring no additional transportation. From there, the permeate will fill fermentation tanks before going onto to be distilled. The distillation process requires heating the mixture of water and alcohol until the alcohol vapor evaporates through the still. Then, it gets dehydrated to 99 percent alcohol.

With fermentation, the yeast we have eats the lactose, converts that into alcohol and then we use standard distillation to purify that alcohol to ethanol. From there, it can be used in cars or in planes.”

The final product will be sent via rail car to become sustainable aviation fuel.

“Constantine’s dairy-based ethanol is going to power planes and milk permeate has the potential to reduce the carbon footprint of air travel by 50%,” McDonald said. “This project is part of the dairy industry’s bigger message that dairy is sustainable and getting even more sustainable. Dairy production’s carbon footprint in the U.S. has been decreasing consistently for a decade, and this is just one more step.”

The low-carbon ethanol plant will offset 14,500 tons of carbon a year, equivalent to 5% of Constantine’s carbon footprint for milk processing.

“Traditional gasoline emits 88 grams of CO2 for every megajoule of energy it produces, corn ethanol emits 55 grams of CO2 per megajoule, and Constantine’s ethanol is going to be around 12 grams of CO2 per megajoule,” McDonald explains. “Because the grass that the cow ate was carbon that was captured when the cow eats it, we capture that sugar, so essentially the ethanol is taking the carbon out of the atmosphere and putting it back in, so it’s neutral, and that’s the goal.”

The sustainability message is one that MMPA is carrying forward. Beyond being good for the environment, the value-added ethanol also provides a diversified revenue stream that will benefit member-owners.

“This project shows how we can turn environmental responsibility into an economic opportunity,” Joe Diglio, MMPA President & CEO said. “By converting milk permeate into ethanol, we’re not only upcycling a dairy byproduct, but also creating a new revenue stream for our memberowners. This project is a win for the environment, a win for our cooperative, and a testament to our commitment to leading the dairy industry into a more sustainable future.”

The ethanol plant is expected to be in commission mid-2025, while the wastewater treatment facility is on track to begin operation by end of the year. Looking to the future, McDonald and Parks are excited about the possibi lities.

“It takes someone to take the first step and MMPA has done that in Constantine,” McDonald said. “Others are now looking at doing the same at their facilities. The need for low carbon energy is one that’s just going to grow, and the amount of milk permeate being produced across the world is growing as well.”

McDonald added, “Once we have shown that we can make a value for MMPA and achieve the carbon reduction that we’re on target to achieve. Then, the sky’s the limit.” Quite literally. What started as McDonald’s self-considered “far-fetched idea” has turned around and proved the impossible. “I never thought cows would fly.”

BY MIKAYLA BOWEN

MMPA IS COMMITTED TO COOPERATIVE SOCIAL RESPONSIBILITY AND SUSTAINABLE BUSINESS PRACTICES THROUGHOUT OUR ENTIRE SUPPLY CHAIN. AT THE FARM LEVEL, MMPA MEMBERS ARE ALSO ON A SUSTAINABILITY JOURNEY. WE’RE CHECKING IN WITH A HANDFUL OF MEMBER FARMERS LEADING THE CHARGE WITH THIS SUSTAINABILITY SPOTLIGHT SERIES.

When we talk about farm sustainability, we often overlook the most crucial element—the sustainability of the farmer’s own well-being.

On Gingrich Meadows Dairy, in Leroy, Mich., they are continuously looking ahead and trying new things to not only make their farm more sustainable, but their quality of life better.

Brothers Eric Martin and Brandon Gingrich are on the same page when it comes to their definition of sustainability. “Sustainability is maintaining practices that allow you to continue operating your business with no end date. That’s for the animals, the land and quality of life,” stated Brandon.

Eric added, “You also have to practice things that work for you. You need to sustain your land, because if it’s not profitable or your cows aren’t profitable, you’re not going to have a great quality of life. Happy cows make milk, so you have to keep the cows happy.”

1,500

The farm has made it a priority to reduce the amount of labor needed for it to operate. In 2012, eight robots milked 450 cows, but not in an efficient manner, so in 2016 two 16-stall parlors replaced them. Fast forward to February of 2024 and the farm replaced the 16-stall parlors with eight robots.

“The 16-stall parlor didn’t work for us,” stated Brandon.

“We couldn’t keep employees in the parlor and the parlor was starting to be unreliable,” added Eric. “With robots there is a higher level of job satisfaction. With more content employees, the cows are happier.”

There is also a level of consistency with robots that Gingrich Meadows appreciates.

“There is consistency every single time with the robots,” Brandon said. Eric added, “We’re not getting different prep and lag times or different teat dip rates. There is no challenge with teaching employees the importance of proper prep procedure. Cows also go undisturbed most of the day and they’re not being pushed into a hot holding area.”

The implementation of activity monitoring collars in 2012 has also saved the farm a great deal of labor.

Eric described, “Our heat detection system helps us breed off of more natural heats. We’re not synching up cows all the time and giving as many shots, which is also labor intensive and expensive. We have also noticed since the robots have been installed that our heat detection has increased.”

Gingrich Meadows cares a lot about the welfare of their cows and has made great efforts to produce quality forages that benefit the animals’ gut health.

“For five years now, we have been trialing alternative forages to replace

“With robots there is a higher level of job satisfaction. With more content employees, the cows are happier.

alfalfa. We spend four weeks out of the year chopping and putting up alfalfa, so to improve our quality of life and the digestibility of the forage, we explored alternatives.”

Alternative forages have been effective in improving the farm’s time management and animal welfare, while also allowing the added benefit of double cropping.

“Mastergraze is a tillering corn with many shoots that acts like corn when you plant it, but feeds like sorghum. We have fed it for three years now and it has increased digestibility by 2530% compared to alfalfa. We have also had success with a male sterile forage BMR sorghum Sudan grass. One of the reasons we like the alternative forages is that it treats the cow’s gut better. We do get less pounds of milk in the bank, but we don’t burn them out and we maintain elevated butterfat and protein levels,” Brandon explained.

Although the alternative forages are annual crops, the farm spends less time in the field and are able to harvest a second crop.

Brandon stated, “You can double crop with it so we’re actually getting more tons per acre than alfalfa. Our goal is to always have a living plant in the soil to tie up the carbon, which is how we’re using cover crops- to help build the soil and to feed the next crop.”

The farm has also experimented with biologicals that have significantly reduced their need to add nitrogen and urea to their fields.

“We’ve done some test strips with biologicals, and we’ve gained nitrogen in our fields right out of the program. It’s allowed us to reduce the need of urea fertilizer,” stated Brandon. “Resources on Earth will not be here forever, you’ve got to find ways to be sustainable and biologicals are something we utilize to be sustainable.”

For many generations Gingrich Meadows have been on the forefront of trying new things and being progressive. Brandon and Eric agree, “That’s part of sustainability, you have to do what works best for you. Just because that’s the way it’s been done for the last 60 years doesn’t mean that’s how it has to be done today.”

BIOLOGICALS: CROP PROTECTION AND SEED TREATMENT PRODUCTS DERIVED FROM LIVING ORGANISMS, NATURAL MATERIALS, OR NATURALLY OCCURRING PROCESSES. THEY ARE USED IN AGRICULTURE TO IMPROVE THE HEALTH OF FOOD CROPS AND PROTECT THEM FROM PESTS, DISEASES, AND WEEDS.

FORAGE SORGHUM: A TYPE OF SORGHUM THAT’S BEEN BRED FOR FORAGE PRODUCTION AND IS OFTEN USED AS AN ANNUAL HAY OR FORAGE CROP. IT CAN BE USED AS A COVER CROP TO PREVENT SOIL EROSION AND IMPROVE SOIL FERTILITY.

SOURCE: U.S. DEPARTMENT OF AGRICULTURE

VERIFICATIONS

MMPA sustainability survey, FARM* Animal Care and FARM* Environmental Stewardship evaluations, Comprehensive Nutrient Management Plan, and Michigan Agriculture Environmental Assurance Program verified.

MMPA SUSTAINABILITY MISSION

To continually strive for a more sustainable future for our community, our environment, our economy’s health, and for the lives and world around us.

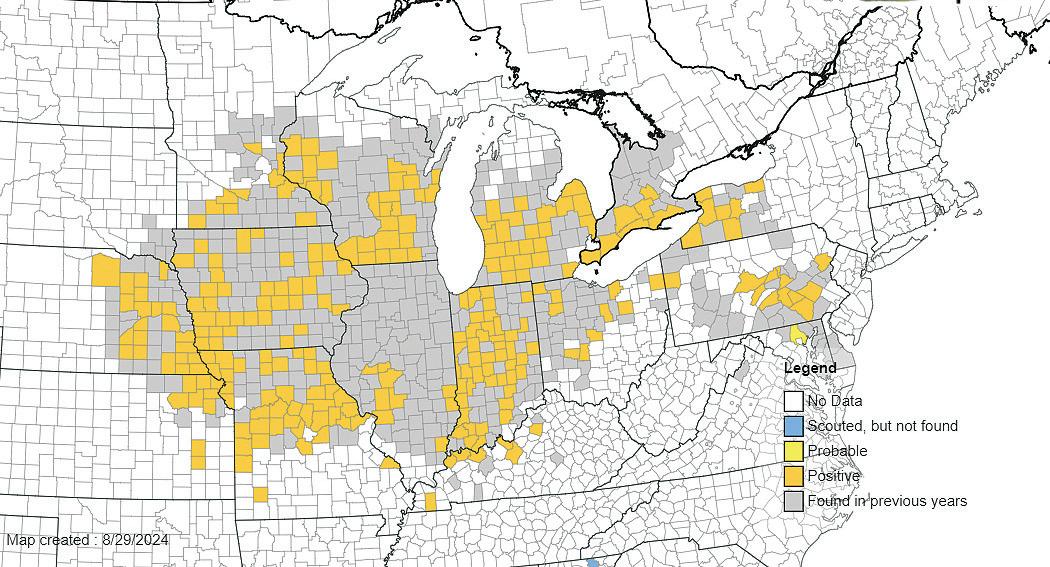

Michigan State University (MSU) researchers have been studying tar spot in corn fields since its first appearance in Michigan in 2016.

Tar spot is a corn leaf disease capable of causing severe damage to infected crops. Dr. Martin Chilvers and graduate student Peyton Phillips at MSU have been diligently researching this fungal disease and educating producers on effective management strategies.

“We had severe epidemics in 2018 and 2021,” stated Dr. Chilvers. “The fungus thrives in cool, wet conditions. Disease modeling work with colleagues at UW-Madison has resulted in an improved understanding of the conditions and the development of the Tarspotter app which is a decision support system, that helps to predict conditions favorable for disease development.”

Frequent moisture events and increased awareness have led to early detections of tar spot across the region, including Michigan, in the 2024 season. While warm July conditions slowed its progress, tar spot is now easier to find into August and September, with disease pressure increasing in some fields. Weather conditions for the rest of the season are going to be key to its development.

Tar spot is caused by the fungal pathogen Phyllachora maydis. P. maydis and can only infect green corn tissu. The fungus survives on infected corn residue through the winter and releases spores in the spring that can infect new plants. It is not seed transmitted, though can be moved on infected leaf tissue.

“We map tar spot every year and from this work we can see it’s travelling 10’s of miles per season, including moving into states where it has not previously been reported. It produces many spores that become airborne and are carried by the wind,” explained Dr. Chilvers.

It is reasonably simple to identify tar spot as the lesions are relatively distinct, consisting of a matte black raised spot that is embedded within the leaf and will not rub off the leaf surface. Tar

BY MIKAYLA BOWEN

spot thrives in cooler, wet weather conditions, so it is important to be scouting fields during these conditions.

“It is very important to be checking your fields, especially when weather conditions are favorable for the fungus,” stated Dr. Chilvers. “Fungicide cannot be applied as a preventative measure, and once a field is infected the disease can spread quickly.”

Bug feces, scientifically called insect frass, are often confused with tar spot, however these are easy to distinguish as frass will dissolve and wipe off the leaf with some water, while tar spot will not.

“If farmers are unsure whether tar spot is present in their fields, they can send a sample into the MSU Plant and Pest Diagnostic Services,” Dr. Chilvers stated. “Occasionally other diseases are

confused for tar spot, we’ve even had fields unnecessarily sprayed when bug poop has been mistaken for tar spot, so be sure of your diagnosis.”

It is important to identify tar spot as early as possible as it can result in rapid dry down of the plant and result in decreased nutritional content compared to a healthy disease-free plant.

“The disease can rapidly dry down the corn plant and result in lost starch,” Peyton explained. “With the rapid dry down yields are reduced and the lignin increases as the starch content is reduced.”

Tar spot is not known to produce any mycotoxins or cause harm to ruminant animals during digestion. However, under high disease pressure, tar spot can overwhelm plant defense responses leading to the rapid dry down of the crop, resulting in lower yields and a reduced nutritional content.

Use of hybrids with tolerance/resistance to disease is the cornerstone of disease management. A hybrid with partial resistance to tar spot will greatly help slow disease development and has the potential to negate the need for a fungicide.

“Unfortunately, no hybrid is immune to tar spot, but there is significant variation in hybrid susceptibility”, stated Dr. Chilvers. “If you want to minimize damage from tar spot it is very important to select a corn hybrid with tar spot resistance.”

It is not recommended to use tillage as a preventative management practice. Although tar spot does survive on residue, the spores can travel many miles in the wind, negating any benefit from tillage.

Dr. Chilvers explained, “In the severe tar spot epidemic years of 2018 and 2021 there were numerous fields that hadn’t been in corn for years that were severely impacted by tar spot.”

Any value in tilling fields will be short lived as spores blow in from outside fields. Crop rotation is an important tool for disease and insect management, however, variety susceptibility and weather conditions play a much larger role in disease development.

“If you practice crop rotation it doesn’t mean you’re going to escape tar spot because it can blow in from outside,” stated Dr. Chilvers.

Tar spot can rapidly dry down the plant to the point where it can no longer be harvested or is missing vital nutritional content. When considering harvest timing it is important to scout fields to know the severity of the disease

“

Unfortunately, no hybrid is immune to tar spot … If you want to minimize damage from tar spot it is very important to select a corn hybrid with tar spot resistance.”

during a given growing season. Always remember to check pre-harvest intervals after making a fungicide application as most fungicides need to be applied 30 days before silage harvest.

Depending on the timing of disease onset and weather, a fungicide application somewhere from VT/ R1 (tassel and silking) through to R3 (milk) is typically the best timing. Early vegetative applications tend to have little effect on suppressing tar spot epidemics and later timings might interfere with harvest if the pre-harvest interval is too long. Applying fungicides at the VT/ R1 growth stage is also ideal for mycotoxin suppression in silage, however, could possibly be too early for optimum tar spot control depending on the year and disease pressure.

MSU continues efforts to develop data sets to train and test the tar spot disease forecasting app “Tarspotter” developed with colleagues at the University of Wisconsin-Madison. The Tarspotter app is free to download and can be found on smartphone app stores (a version is also available via Field Prophet).

Tarspotter can be used to assess tar spot disease risk based on weather variables for multiple pinned locations within the app. When using the app keep in mind that is still important to scout fields to see if disease is present and be mindful of crop growth stage. Funding for this work was also made possible by the Corn Marketing Program of Michigan and the National Predictive Modeling Tool Initiative through the USDA.

Dr. Chilver warns, “Although we have seen greater disease suppression with two fungicide applications, this is not always profitable. In fact, some years a fungicide may not be needed. In general, we recommend the use of a fungicide product with mixed modes of action, this typically provides better disease suppression than a single mode of action product.”

Dr. Chilvers and his team are also weary of the development of fungicide resistance in the tar spot fungus. By using a mixed mode of action fungicide, it should slow the development of fungicide resistance.

“Each year we conduct fungicide efficacy trials to assess current and new products and combinations,” Peyton described. “We have tested various fungicide products and there are a couple that do perform a little bit better, but really it comes down to application timing. That’s the more important factor.”

If you do decide to make a fungicide application, be sure to leave check strips and pencil out the costs and benefits, otherwise you will never know what your return on investment is.

The Michigan Alliance for Animal Agriculture (M-AAA) is a partnership among the state’s animal agriculture industries and MSU focused on advancing the Michigan animal agriculture economy. M-AAA’s partnership with MSU allows scientists such as Dr. Chilvers and his team to continue researching relevant crop diseases in Michigan.

“Sample analysis testing can be very expensive, so without the help of M-AAA none of this would be possible,” said Dr. Chilvers. “We’ve generated an awful lot of data through analysis testing, which has been really cool. Now we’re just working through getting it organized and analyzing it for publication to share with the growers.”

MMPA is proud to partner with M-AAA to support research, extension and seed grant projects that will enhance Michigan animal agriculture.

ADAPTED FROM THE USDA FARM SERVICES AGENCY FACTSHEET

Overview

Authorized by the 2018 Farm Bill, the Emergency Assistance for Livestock, Honeybees and Farm-Raised Fish Program (ELAP). ELAP provides emergency assistance to eligible producers of livestock, honeybees and farm-raised fish. The program covers losses due to an eligible adverse weather or other qualifying loss condition. ELAP is administered by the USDA’s Farm Service Agency (FSA). Effective for the 2024 program year, FSA has updated ELAP eligibility regulations to include:

• Milk losses due to the Highly Pathogenic Avian Influenza (HPAI) H5N1 virus in dairy herds with H5N1 Infection supported by at least one positive test confirmed by USDA Animal & Plant Health Inspection Service a (APHIS) at National Veterinary Services Laboratory (NVSL).

• Eligible producers must have had reduced milk production as a result of removal of adult dairy cows from the milking herd due to H5N1 infection.

Producers can apply to receive ELAP assistance at local FSA service centers. For 2024 program year losses, the application period will end Jan. 30, 2025. To apply, producers need to submit the following to FSA:

• Proof of herd infection through a confirmed positive H5N1 test (based on USDA’s APHIS H5N1 case definition) on individual animal or bulk tank samples confirmed by APHIS at NVSL;

• A notice of loss indicating the date when the loss is apparent, which is the sample collection date for the positive H5N1 test; and

• An application for payment certifying the number of eligible adult dairy cows removed from production, the month the cows were removed from production, and the producer’s share in the milk production.

The final date to file a notice of loss and application for payment for eligible losses is 30 days after the end of the prior calendar year, which is January 30.

USDA continues to work with the Food and Drug Administration, Centers for Disease Control and Prevention, and State veterinary and public health officials to investigate H5N1 among cattle. APHIS continues to provide confirmatory testing for samples from livestock as well as guidance for producers, veterinarians, and state animal health officials. Learn more at https://www.aphis.usda.gov/livestockpoultry-disease/avian/avian-influenza/ hpai-detections/livestock.

LEARN MORE

For more information about ELAP, visit fsa.usda.gov/ELAP or contact your local FSA office. To find your local FSA office, visit farmers.gov.

Who is eligible to receive Emergency Assistance for Livestock Honeybees, and Farm-Raised Fish Program (ELAP) benefits due to H5N1 losses?

Producers who have risk in milk production from dairy cows, have suffered decreased production from the removal of adult dairy cattle from the milking herd due to the Highly Pathogenic Avian Influenza A (HPAI) H5N1 virus, and have received a positive test from USDA’s Animal and Plant Health Inspection Service (AHPIS) National Veterinary Services Laboratories (NVSL).

How will producer payments be calculated?

Producers will be compensated for 21 days of zero production of milk and another 7 days of 50% of production, based on the month of removal and the production of milk for that month according to USDA’s National Agricultural Statistics Service (NASS) monthly production records at the All Milk price for that month.

How does a producer apply for ELAP H5N1 assistance?

Producers should contact their local USDA Farm Service Agency (FSA) office to complete a notice of loss form (CCC-939) and an application for payment form (CCC-939H5N1). To find your local FSA office, visit farmers.gov/service-center-locator.

What information does a producer need to provide FSA?

To apply, producers need to submit the following:

• Proof of herd infection through a confirmed positive H5N1 test (based on USDA’s APHIS H5N1 case definition) on individual animal or bulk tank samples confirmed by APHIS’ NVSL;

• A notice of loss indicating the date when the loss is apparent, which is the sample collection date for the positive H5N1 test; and

• An application for payment certifying the number of eligible adult dairy cows removed from production, the month the cows were removed from production, and the producer’s share in the milk production. The final date to file a notice of loss and application for payment for eligible losses is 30 days after the end of the prior calendar year, which is January 30.

A producer must also submit a positive H5N1 test from APHIS NVSL confirming infection in their dairy herd and agree to provide milk production records, if requested, to support the eligible number of adult dairy cows removed from production.

Checkoff Strategy Focuses on Dairy’s Link to Brain Health

The first 1,000 days of a baby’s life encompassing pregnancy through the child’s second birthday is critical for brain development. Nutrition is a large driver of brain development and helps with overall success of life for a child. Checkoff organizations Dairy Management Inc. (DMI), National Dairy Council (NDC), Innovation Center for U.S. Dairy, U.S. Dairy Export Council, Newtrient, GENYOUth and the 16-team state and regional network are joined by MilkPEP to collectively elevate awareness and understanding of dairy’s contributions to the 1,000-day period. The strategies for elevating this awareness include media partnerships, social media strategies, Health & Wellness partnerships, collaborations, Pediatric Care Specialist engagement, and Checkoff-produced content.

Megan Maisano, director of nutrition and regulatory affairs for NDC, is confident this collective strategy will resonate with health professionals and consumers given its solid scientific foundation. She notes an AAP statement identifying 14 essential nutrients for early brain development, with dairy providing seven of them.

“At the end of the day, every parent and care provider just wants their child to reach their full potential and do better than the generation before,” Maisano said. “Good nutrition during pregnancy,

lactation and early childhood plays a foundational role in enabling a child to grow, learn and thrive. Dairy is an affordable, accessible food group that contributes really important nutrients, especially in those early years.”

Link to article with more information: https://www.usdairy.com/media/pressreleases/checkoff-strategy-focuses-ondairys-link-to-brain-health

The “Sundaes for Good” Ice Cream Social on the Circle returned to the heart of downtown Indianapolis in July to celebrate National Ice Cream Month and support another important community leader. Each year, proceeds from the event benefit a local organization, partnering this year with Boys and Girls Clubs of Indianapolis. Over $7200 were raised for the group, building an important relationship with inner-city youth to be activated throughout the year. Local celebrities show up to scoop ice cream, mascots from Indy sports teams interact with visitors, and the Purdue Dairy Club brings cows to the city streets to share about dairy farming with the public.

Continuing almost two decades of tradition, world-renowned cheese sculptor Sara Kaufmann spent the

first weeks of the Indiana State Fair carving into almost two tons of cheese. This year’s sculpture centered around the Art of Fun, featuring dairy-fied works of art like the “Mooona Lisa” and an appearance from Buttercup the cow in “American Gothic”. Over 1,400 pounds of cheese created a media buzz that reached 4.6 million viewers. The story of sustainability was also shared throughout the many lifestyle pieces - at the end of the fair, the cheese goes to BioTown Ag to be recycled in the digester and converted into energy.

Do you know a teacher who’s looking for a low maintenance classroom pet? Encourage them to sign up for the free Adopt a Cow Program to virtually adopt their very own Indiana, Ohio or Michigan dairy calf! Registration for this school year ends September 15.

Throughout the year-long program designed for grades 3-5, teachers will receive bi-monthly progress updates, photos of the calf, student activity sheets, suggested lessons that follow Common CORE standards, and opportunities to virtually tour the farm and ask questions to the dairy farmer. This national program is made available to local schools by ADAI, ADA Mideast, UDIM and through a partnership with the Center for Dairy Excellence Foundation of Pennsylvania. Learn more and sign up at DiscoverDairy.com/Adopt-A-Cow.

UNITED DAIRY INDUSTRY OF MICHIGAN

ADA Mideast is a proud partner of Ohio State Athletics, providing an opportunity to promote dairy to more than 150 million people via TV and radio broadcasts, digital marketing and social media throughout the year.

This fall, ADA Mideast is leveraging its partnership with Ohio State Athletics to promote chocolate milk. Through the NCAA NIL program, OSU Offensive Lineman Donovan Jackson is being featured in a campaign sharing how chocolate milk makes him “Built Like a Buckeye” and gives Ohio State fans a chance to win chocolate milk for year. The campaign, which includes a video, is being promoted with online ads and social media.

For more than 60 years, ADA Mideast has sponsored and coordinated the butter cow display at the Ohio State Fair. This year the iconic butter cow and calf wore butter medallions and proudly stood next to life-size butter sculptures of four elite athletes as they flipped, jumped and zoomed to glory. The display, sculpted from 2,000 pounds of butter donated in part by DFA, was featured in 619 news stories on TV, radio, online and in print, reaching more than 401 million people and making it one of our most popular displays yet! Most of these news stories also included messaging about dairy

farmers’ commitment to producing highquality milk which nourishes athletes and everyone in their communities.

Eighteen educators participated in a STEM-focused experience hosted by UDIM, which explored the science and technology behind the dairy industry. They visited an agronomy farm, a cheese and whey processing plant, and participated in a virtual farm tour. They also engaged with experts who discussed cow care, dairy nutrition, genetics, technology, milk quality, milking processes, and methane digestors. Teachers were impressed by farming advancements and environmental stewardship. One teacher noted, “Seeing all the changes in the dairy industry over the last twenty years was eye-opening!”

UDIM recently supported the Children’s Hospital Cereal Drive in partnership with Gleaners Community Food Bank, aiming to solve child hunger in the community. UDIM, with the help of some partners, collected over 81,000 servings of cereal at the Royal Oak Kroger. Over $20,500 was also donated through virtual food drives, which enabled Gleaners to purchase milk to go with the cereal donations. Your team at UDIM helped get an additional 80,000 servings of milk. This year’s cereal drive collected 906,750 servings of cereal and over 200,000 servings of milk!

No one wants to think about a crisis on the farm, but they can happen when you least expect it. And where do you even start to plan? Your dairy checkoff organizations, American Dairy Association Indiana, American Dairy Association Mideast and United Dairy Industry of Michigan are equipped to help you plan for and handle a crisis. With past experiences and crisis preparedness training, we are here to help you prepare. For further information, or to set up a planning meeting for your farm, contact your state staff below.

Indiana Allie Rieth rieth@winnersdrinkmilk.com, 317-443-2296

Michigan: Jolene Griffin jolene@milkmeansmore.org, 224-567-1894

Ohio: Erin Brown Erin.Brown@drink-milk.com, 740-487-6816

Getting Started:

Find your farm on Google Maps or use an aerial photo to identify buildings, label them for emergency vehicles. Keep copies around the farm and give a copy to each member of your farm management team and family.

Set up a meeting with local emergency responders. Show them around your farm, share your crisis plans with them.

Keep extra supplies of water, non-perishable food, batteries, etc. on-hand. Stock up for weather events and resist the urge to use them on normal work days.

Contact local checkoff staff to set up a crisis planning meeting. We will walk you through crisis situations to create a plan for your farm.

The Freeliners column is open to current MMPA members who wish to advertise—at no charge— goods or services relating directly to their dairy farm operations.

• An item submitted will be published for no more than two consecutive issues (one issue, unless otherwise requested). After that, it will be withdrawn.

• It will be published again for no more than two consecutive months only if the member resubmits the item by writing or calling the Novi office.

• Reference to a name of a firm or other commercial enterprise with which a member is involved will be deleted, with permission of the member.

• If the member does not wish such deletion, he/ she may choose to have the item published as a Classified Ad at the regular per-line rate.

• Freeliners must be received by the 10th of the month preceding desired month of publication.

FOR SALE: POLLED HOLSTEIN, JERSEY AND NORWEGIAN RED BULLS. AI bred from very functional dams. Many young bulls to choose from. Hardy and healthy with strong feet and legs, raised on pasture. Competitively priced. Young beef bulls also available. For pictures and pedigrees call or text 906-287-0746.

FOR SALE: 4-TON FEED BIN WITH FLEX AUGER. Call 810-728-6237.

FOR SALE: DAIRYPLAN C-21 SOFTWARE SYSTEM WITH COMPUTER. Call 810-728-6237.

FOR SALE: H&S 5126 SIDE SLINGER MANURE SPREADER. Call 989-551-5977.

FOR SALE: NICE HOLSTEIN, JERSEY AND HOLSTEIN/ JERSEY CROSS HEIFERS. All sizes. Call 260-705-8185.

FOR SALE: 400+ SCR COW COLLARS. Some in almost new condition and under warranty. Best offer. Contact Kevin at 989-277-2880.

FOR SALE: USED MILKING EQUIPMENT. 2- 15 hp 3 phase vacuum pumps, 1-2 year old Mueller 3 phase cooler, 1 newer single phase cooler, 2 older single phase coolers, and much more not listed. Call or text Cameron at 810-404-5993.

WANTED: MICHIGAN DAIRY FARMER LOOKING FOR 500-COW +/- HOLSTEIN HERD. Call 517-290-7696.

FOR SALE: 7 BOUMATIC FLO-STAR CLAWS. A milk pump motor for sale. Call or text for info and price at 734-915-4332.

Cost for classifieds is $25 for the first 35 words and then $5 for each additional word. Payment due with order. All ads must be received by the 10th of the month preceding desired month of publication. MMPA neither sponsors nor endorses products or services advertised in the Milk Messenger

O PPERMAN GROOVING: We can fix your scabbled floors. Diamond sawed grooves, no hammering or cracking of concrete. No hoof damage. Call Opperman Grooving Inc., Portland. 517-647-7381.

DAVIDSON CEMENT GROOVING, INC: No water needed. Wider, rougher grooves for better traction. We also offer texturing for your previously grooved floors. Three operators will travel Michigan and other states. No interest payment terms. Est. since 1987. Call 1-800-365-3361.

CONCRETE GROOVING BY TRI-STATE SCABBLING, home of the 2” wide groove. Best traction, lowest prices. 800-554-2288. www.tristatescabbling.com

A SURE WAY TO KEEP YOUR COWS UPRIGHT! Concrete grooving/texturing provides high quality traction in new and old concrete, fast service. NIENOW GROOVING. Call Cliff at 989-635-1494.

FOR SALE: NEW & USED MILK TANKS. We stock all sizes, makes, models. Special prices to co-op members, corporate & private farms. Contact us anytime day or night. Special on 2000 gal. Muellers for $13,900 & up. 2700 & 4000 gal. Muellers call for quote. 800-558-0112.

STRAW & DRY HAY (LARGE & SMALL BALES).

Feed Oats, Feed Barley and Corn Silage. Delivery Available. 989-723-1886 or 989-277-1414.

ALFALFA HAYLAGE (EXCELLENT & FAIR GRADES) & CORN SILAGE. 989-723-1886 or 989-277-1414.

NEW KATOLIGHT PTO GENERATOR, 60 KW, keep everyone warm and producing if there is a power outage. Call Brent at 248-770-5122.

SEED CORN - “Minnesota 13” Open Pollinated 85 Day Yellow Field Corn Seed. High Protein, High Yield, High Fat, Fast Drydown. Great Digestibility! 80,000 graded seeds $100.00 JanksSeeds.com 989-284-5052.

BARN WHITE WASHING AND CLEANING WITH HIGH PRESSURE AIR: Serving all Michigan and Indiana. Miller Spray Service, Inc. 574-825-9776.

FOR SALE: Used BouMatic 10 HP oilless vacuum pump with motor, $3,400 OBO, Ag Bagger Model G6000 10 ft. tunnel $11,000. OBO. Can email pictures for both. “Zareba” AC 20-mile electric fencer $40 plus shipping. Cheboygan, MI. 231-625-2036.

The MMPA Farm Supply Store has brought in a new line of nitrile gloves. Currently, we stock small, medium, large and extra-large sizes of the 5-mil premium blue nitrile gloves. Each box contains 1000 gloves with ten boxes to the case.

PRICE: $4.32/BOX STOCK NUMBERS:

.......................... 699961

....................... 699962

H0w to Order MMPA Merchandise from the FARM SUPPLY STORE

Call in your order: Main Line: 989-317-8370 Toll Free: 877-367-6455

Orders (Novi): 800-572-5824 then dial 2

3 Fax in your order: 989-317-8372

These are SERVICE personnel only. Order your supplies through your hauler.

Ben Chapin, Remus, Member Services Director

Steve Lehman, Ithaca, Raw Milk Compliance

989-289-0731

989-330-1638

Doug Soehnlen, Member/Superior Supply Representative 330-575-4643

Joe Packard – Area Supervisor

248-520-3481

Brandon Ewers, Coldwater 231-414-4539

Alyssa Stace, Elkhart, IN, Animal Care/Sustainability 269-967-7351

Emily Patton, Lansing 248-880-3785

Christy Dinsmoore – Area Supervisor

Carley VanNorman, Ruth, MI

248-513-7920

248-826-6294

Chelsea Smith, Falmouth, MI 231-519-2455

Sarah Michalek – Farm Sustainability Manager ..............

Deb Gingrich, Leroy, Animal Care/Sustainability

Rachel Brown, Charlotte, Sustainability Coordinator

Novi (Monday-Friday, 8 a.m.-4:30 p.m.)

In Michigan

Toll Free

Ovid (Daily, 6 a.m.-10 p.m.)

Constantine (Daily, 7 a.m.-10 p.m.)

248-305-0537

248-520-3580

248-826-7243

Main Office

Local line

800-572-5824

800-233-2405

989-834-2515

800-391-7560

Farm Supply Supervisor

Main Line

989-317-8370

Toll Free 877-367-6455

Orders (Novi) 800-572-5824, then dial 2

Fax 989-317-8372

Farm Supply Sales Representative

Jake Riley, Mt. Pleasant

248-912-5070

John Lehman, Elsie, Bulk Tank Calibration................................ 248-444-6775

248-474-6672

Toll free 800-572-5824

President and Chief Executive Officer

Joe Diglio ext. 202

Chief Financial Officer

Aaron Anticic ext. 277

Chief Corporate Affairs Officer

Sheila Burkhardt ext. 208

Chief Operations and Business Development Officer

Greg Soehnlen ext. 341

Director of Strategic Initiatives

Brad Parks ext. 341

Laboratory Supervisor

Teresa Farmer ext. 219

Quality

Sudeep Jain ext. 305

Member Services

Emily Keranen ext. 203

Human Resources

Kelly Kerrigan ext. 301

Commodity Sales

Molly Costaris ext. 209

Communications

Emily Kittendorf-King ext. 234

Corporate Controller

Jeannie Strain ext. 312

Member Relations

Jessica Welch ............................................................................... ext. 303

Canton, Ohio Plant Manager 330-477-4515

Constantine, Michigan

Dave Davis, Plant Manager .................................................. 269-435-2835

Ovid, Michigan

Glen Kienitz, Plant Manager 989-834-2221

Middlebury Cheese Company, Middlebury, Indiana Plant Manager 574-825-9511

If you are unable to reach your assigned member representative, please contact the representatives listed in your area. Your assigned member representative is listed on your quality statements or can be found by visiting mimilk.com/contact/field-staff and searching by your producer number.

Officers

Doug Chapin, Board Chairman

Tony Jandernoa Board Vice Chairman

Eric Frahm, Treasurer

Joe Diglio, President and CEO

Sheila Burkhardt, Secretary

Aaron Anticic, Assistant Treasurer

Greg Soehnlen, COO

Todd Hoppe, General Counsel

Directors-At-Large

Aaron Gasper, Lowell, MI 616-291-4092

Bruce Benthem, McBain, MI 231-920-1615

Kris Wardin, St. Johns, MI 989-640-9420

District Directors

1 Paul Keener Ashland, OH 330-988-0139

1 Kurt Steiner Creston, OH 330-464-1219

2 Brian DeMann Martin, MI 269-720-7637

2 Brian Preston Quincy, MI 517-376-1350

3 Doug Chapin Remus, MI 231-349-4059

3 Amy Martin LeRoy, MI 231-388-0496

4 Eric Frahm Frankenmuth, MI 989-652-3552

4 Corby Werth Alpena, MI 989-464-5436

5 Tony Jandernoa Fowler, MI 989-593-22245

5 Scott Lamb Jeddo, MI 810-327-6135

In autumn’s glow, the Holstein stands, on stubbled corn, in golden lands.

The trees behind, a fiery show, of crimson, orange, and yellow glow.

Her black and white in contrast bright, as dark skies loom with storm in sight. A breeze picks up, the leaves take flight, while nature braces for the night.

“ We want access to the best genetics available that fit our dairy, so we have enrolled in the NxGEN® program. Sires that excel in health traits, DWP$, and NM$ are selected for matings. Strategic-breeding plans, including genomic testing, allow us to accelerate genetic progress while managing heifer inventories, which all play a role in the improved health and reproduction for the herd.”

Jeremy Natzke

Wayside Dairy, Greenleaf, Wis.

“ Using NxGEN keeps us on the front line of what Select Sires has to offer, which translates to more genetic success. CentralStar has managed our mating program and has done a good job keeping it simple, while using genetically-superior bulls that excel for health and fertility traits.”

Tony Schmitz Schmitz East Branch Dairy, Fond du Lac, Wis.