8 minute read

Event previews

OTC Asia 2020

Date: 24-27 March 2020 Location: Kuala Lumpur, Malaysia

Advertisement

The biennial Offshore Technology Conference Asia (OTC Asia) is where energy professionals meet to exchange ideas and opinions to advance scientific and technical knowledge for offshore resources and environmental matters. Founded in 1969, the Offshore Technology Conference (OTC) organises the world’s foremost events for the development of offshore resources in the fields of drilling, exploration, productions, and environmental protection. The flagship OTC is held annually in Houston, Texas, U.S.A. OTC events are brought to you by organisations that cover all aspects of the offshore energy industry.

2020.otcasia.org

Date: 24-25 March 2020 Location: Johannesburg, South Africa

Transforming the operational performance of Sub-Saharan Africa’s oil & gas industry through adopting digital technologies. The Oil & Gas Digitalisation Summit Sub-Saharan Africa will welcome the oil & gas sector to Johannesburg in March 2020 and will place the oil & gas industry at the forefront of a new age. The conference will help chart a roadmap for developing more resilient and robust producers across the continent, less affected by global price fluctuations and future-proofed to withstand external shocks (which the O&G industry is prone).

Over the course of two days, the conference will demonstrate how adopting technology can positively facilitate national content strategies that build capacity across SSA and enhance development of the SME sector and add value to national economies across the continent.

www.oilandgasdigitalisation-ssa.com

Date: 21-23 April 2020 Location: Singapore

SecurityWeek’s Industrial Control Systems (ICS) Cyber Security Conference is the largest and longest-running event series focused on industrial cybersecurity. Since 2002, the conference has gathered ICS cyber security stakeholders across various industries and attracts operations and control engineers, IT, government, vendors and academics.

Over the years, the focus of the conference has shifted from raising awareness towards sharing security event histories and discussing solutions and protection strategies. The conference series now includes two editions, the flagship U.S. Event which takes place each October, and a Singapore/APAC event which takes place each April.

The events cater to the energy, utility, chemical, transportation, manufacturing, and other industrial and critical infrastructure organisations.

Both events address the myriad cyber threats facing operators of ICS around the world, and will address topics covering ICSs, including protection for SCADA systems, plant control systems, engineering workstations, substation equipment, programmable logic controllers (PLCs), and other field control system devices. The majority of conference attendees are control systems users, working as control engineers, cybersecurity professionals, in operations

management or in IT. Industries represented include defence, power generation, transmission and distribution, water utilities, chemicals, oil and gas, pipelines, transportation, data centres, medical devices etc. Other attendees work for control systems vendors, security products and services companies, associations, universities and various branches of the US and foreign governments.

www.icscybersecurityconference.com

Data files Logistics firms to get active on boosting Zone 2 safety

Logistics operations using ATEX lift trucks in Zone 2 should be using active gas detection to improve safety and protect people, warns Pyroban. In Zone 2 it is important that drivers know when a potentially explosive atmosphere is present so that the cause of the flammable atmosphere can be investigated and rectified. Active gas detection systems on lift trucks can play a vital role in this, significantly improving onsite safety.

Some 3PLs have been slow to adopt this active approach assuming that it is better to operate ATEX lift trucks that use passive, Ex d protection methods so that trucks can work through a gas or vapour release. However, active gas detection ensures that drivers know there is a problem and can act upon it accordingly.

Pyroban’s most popular active gas detection solution for Zone 2 areas is system6000™ which involves converting the truck at the Pyroban UK factory in as little as six weeks. system6000 combines gas detection with various explosion protection methods and is suitable for all brands and types of diesel and electric materials handling equipment working in logistics operations, such as VNA, pallet, picking, counterbalance and reach trucks, and more.

With system6000, the driver gets visual/audible warnings followed by automatic equipment shutdown at certain levels.

www.pyroban.com • +44 1273 456825 • sales@pyroban.com.

EEMUA Publication 186 - A Practitioner’s Handbook for potentially explosive atmospheres

EEMUA 186 offers guidance for safe installation, inspection and maintenance work in potentially explosive atmospheres.

EEMUA 186 focuses on ignition caused by electrical and mechanical sources and interprets relevant parts of international and European standards, directives and regulations.

EEMUA 186 covers application design engineering and duties of the Responsible Person (IEC standards). It includes separate chapters on fuel filling stations, hazardous areas in water and waste water, and mechanical ignition sources.

Closely associated with the CompEx® training and competency assessment scheme, this easily navigable resource is available to purchase at:

https://www.eemua.org/Products/Publications/Print/EEMUAPublication-186.aspx

ATEX certified pressure regulators

ATEX certified pressure regulators for air, gases and liquids from ID Insert Deal Srl are available through their UK distributor, Measure Monitor Control. There are 54 different models of ATEX certified regulators and filter regulators covering a range range from 1/8” to 2”.

The primary regulators suit inlet pressures up to 400bar for air, gas or liquids and at the opposite end of the scale, the tertiary regulators offer control ranges down to 5mbar.

Also ATEX approved are another 30 different models of relief valves, filters, lubricators and manifolds to deliver a comprehensive package of solutions for pressure control in hazardous environments. 316L stainless steel, brass and aluminium constructions are available up to DN100

Heaters Communications

ATEX

Training ..Safety First..

Cable Glands

ROTRONIC Intrinsically Safe sensors and measurement transmitters with analogue outputs are suitable for use wherever there is a risk of explosion due to dust or gas in the environment.

HygroFlex5-EX transmitters and probes from ROTRONIC conform to the latest international ATEX standards. The transmitter is Intrinsically Safe (secondary side) , there are two channel outputs, the housing is heavy duty. Interchangeable probes are available for all applications, including those at pressure and low dew point.

Technical datasheet available Tel: 01293 571000 Email: instruments@rotronic.co.uk Web: www.rotronic.co.uk

with a range of elastomers to suit all common industrial gases and liquids from -60 to +300degC.

See the ID Insert Deal range at stand AF104 during Air Tech 2020 21-23 April at the Birmingham NEC.

Also at stand AF104 will be the new S230 series triple certified dew point sensor from SUTO iTEC GmbH that measures from -100ºCtd to +20ºCtd up to 1.5MPa and can be supplied with either ATEX, IECEx or GB3836 certification. This groundbreaking instrument employs dual sensors to deliver a very wide accurate measuring range.

The S231 is based on the same technology and carries equal certification options for hazardous environments but with a narrower measuring range of -50ºCtd to +20ºCtd for gas pressures up to 35MPa.

www.measuremonitorcontrol.com +44 (0)1443 772500

SAFETALKST-1 EX MOBILE

APPLICATION: 3G/4GAndroid6.0 SIZE: 127 X 63 X 27 MM

SPECIFICATION: • 8GB Internal • 32 GB Expandable • -200C to +600C Amb. • • 1 10 00 00 0 m mA AH H b ba at tt te er ry y

Temp. CAMERA: 5MPRearCamera WEIGHT: <200 gms PROTECTION: Ex ib IIC Gb T3 tb IIIB Db IP67

FCGFlameproof ControlGearsPLtd.

Mumbai,India +912223663200

RP@fcg-india.com www.fcg-india.com

Control Panels

Buyers Guide

To advertise in the Product Datafiles or Buyers Guide contact Kathryn Startin on +44 (0)1732 359990 or kathryn.startin@imlgroup.co.uk

AUTOMATION CONTROL & TECHNOLOGY

Southampton SO40 9AH +44 (0) 2380 665544 enquiries@trant.co.uk trant.co.uk

Your Total Solutions Provider

Specialists in design and custom build of a wide range of Hazardous Area Equipment Registered OEM for Technor Marechal

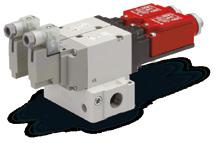

SeriesVP/VG SMC - Meeting tomorrow’s machine safety standards today ISO 13849-1 Safety Standard Compliant Valves – Series VP/VG

As the introduction of international machine safety standards continue to accelerate at full throttle, the issue of manufacturing safety is now a critical consideration for all system operators and designers. SMC is committed to help and support equipment manufacturers and end users with the safe design of their equipment and machines in three ways:

By: • developing and increasing its range of safety components • providing technical support and guidance in the selection process • supplying reliability information about its products - B10 and MTTF data

Category 2

Residual pressure release valve

The detecting function of the main valve position detects a mismatch between the input signal and valve operation.

Safety limit switch

Category 3, 4

VP542-X536

When the dual residual pressure release valve is used, if one of the valves fails to operate, the other one releases residual pressure.

Dual Residual Pressure Release Valve VP544-X538

Residual pressure release valve w Residual pressure release valve q

With Soft Start-up Function VP544-X555

Residual pressure release valve w Residual pressure release valve q

Dual Residual Pressure Release Valve VG342-X87

Safety limit switch

Soft start-up valve