ChuaCandFadeyiMO(2021).IdentificationandrectificationoferrorsinBIMmodelsusing dynamo.BuiltEnvironmentAppliedResearchSharing#04.ISSUUDigitalPublishing. ©BEARSreservestherighttothisappliedresearcharticle

ChuaCandFadeyiMO(2021).IdentificationandrectificationoferrorsinBIMmodelsusing dynamo.BuiltEnvironmentAppliedResearchSharing#04.ISSUUDigitalPublishing. ©BEARSreservestherighttothisappliedresearcharticle

Camille Chua and Moshood

Olawale Fadeyi,*Sustainable Infrastructure Engineering (Building Services) Programme, Singapore Institute of Technology, 10, Dover Drive, Singapore 138683, Singapore

*Corresponding author’s email: fadeyi.moshood@singaporetech.edu.sg

The productivity of facility managers in delivering healthy and energy-efficient buildings can be determined by the information available for managing the building. Incomplete, inaccurate, and irrelevant information can compromise productivity. In a digitalized architecture, engineering, and construction (AEC) industry, facility managers are required to use building information modelling (BIM) models for their facility management operations. It is not uncommon for facility managers to submit incomplete, inaccurate, and irrelevant as-built BIM models to facility managers, leading to low productivity due to non-usage or usage of the BIM model with errors. Unfortunately, many facility managers do not have automated solutions for identifying and rectifying BIM errors. This study aims to provide automated programming solutions that could help facility managers identify and rectify errors in BIM models with the complexity level of a high rise building and transform the BIM model into a facility management ready model. The investigation on the validation of the developed automated programming solution with built environment professionals suggests that the solutions can considerably reduce the time taken and accuracy for correcting the BIM model and make it facility management ready. The participants' feedback also suggests that the developed solution is satisfying to use, user friendly, and could improve the work process. Lessons and ideas of the developed automated programming solution reported in this paper can help develop solutions that will aid the adoption of BIM models for facility management operations.

Keywords: Facility management, Building information modelling, Computational BIM, Productivity, Dynamo

The low adoption of BIM models for facility management operations is prevalent in the architecture, engineering, and construction (AEC)industry (Edirisinghe et al. 2017; Korpela et al. 2015). Based on the authors’ experience of the industry, facility managers usually find it challenging to adopt BIM models for facility management operations because of incomplete, inaccurate, or irrelevant information that is often in submitted BIM models by contractors to facility managers or building owners. The limited availability of user-friendly solutions that couldefficientlyor effectively identifyand eliminate errors in BIM models and make the BIM models ready for facility management operations are sources of inconvenience and discomfort forfacilitymanagersorbuildingowners.

As a result, it is not uncommon for many facility managers not to make use of and update asbuiltdrawingsforeffectivefacilitymanagementoperations.Despitethegeneralmovementfrom traditionalfacilitymanagementtodigitalisedworkprocesses,facilitymanagersandownersare usually not equipped with the knowledge required to check these models for accuracy and completion.Furthermore,as-builtBIMmodelsusuallycontaintoomuchinformationthatisnot needed duringthe operations stage, leadingto other issues such as extra processingtime. This project aims to reduce these sources of discomfort and inconvenience while providing facility managers and building owners’ awareness of the readiness of the submitted BIM models for facilitymanagementoperations.

Chau and Fadeyi (2020) attempted to develop an automated programming solution that could helpattainaccurateas-builtBIMmodelsforstakeholders'benefits.Thereisaneedtocontinue the initial work by Chau and Fadeyi (2020) for two reasons. The first reason is that the preliminary solutions were developed to check and transform a small section of a two-storey building BIM model for the users' needs. The developed solution lacks complexity commonly attributedtoBIMmodelsinpractice.Thesecondreasonthereisaneedtocreatemorefunctions inthedevelopedsolutionforeffectiveusageinpractice.

ABIMmodel'scomplexitywouldaffectthetests’measuredvariables,includingtheamountof timethatcanbesaved,theaccuracyoftheworkdone,andhowuserfriendlytheusersdeemthe developed solution. In terms of time, the time required for a smaller building versus a fully completedBIMmodelmaydifferdrasticallyduetolongerprocessingtimeneededforthescript

to run and computer to process and time required for the users to navigate around a more complicated script. Thus, the positive time difference between manually checking and automationmaydifferfromthepreliminarywork’sfindingsreportedinChuaandFadeyi(2020). Accuracymayalsobeaffectedasalargerbuildingwouldmeanthattherewouldbemanymore factorstobe considered inthe scriptoftheprogrammingsolution,such asthetotalquantityof assetsandtypesofcomponentsinthebuilding.

As mentioned, the script for a fully completed BIM model would be more complicated than a smallerscalebuilding.Usersmayalsoberequiredtomakemoreselectionsduetothecomplexity and requirementsof acomplexbuilding. Hence, usersmayfind it hardertocompletethe tasks, which would also directly affect the time taken to complete the work's tasks and accuracy becausetheywouldtakealongertimetonavigatethroughthescriptandaninaccurateselection would cause the resulttobe inaccurate aswell. User-friendliness isalsoimportant because one of the key motives of developing an automated programming solution is to help the facility managers and owners that are not fully equipped with the skills to easily check submitted asbuiltBIMmodelsforaccuracy,completeness,andconsistency.

The second reason relates to the lack of completion of all the functions forthe solution. Some functions were not developed due to its complexity and lack of programming knowledge to develop them previously. Additionally, there is a lack of customisation in the preliminary solution for the users to make more specific choices. For example, regular tables, chairs, and decorative sculptures were grouped in the same category of furniture. However, different facilities deem different types of assets as critical assets. Critical assets are subjective and can be defined in two general ways. First, they are assets that are of high value to the owner and require extra care. Secondly, they are assets under the management of facility managers that requireregularmaintenanceormayaffectthefacilitiesoperationsiftheyarenotwellmaintained.

Forexample,ifthefacilityisamuseum,thedecorativesculpturemaybedeemedashighvalue critical asset. In such cases, users of the developed automated programming solution need to have the authority to make specific selections to exclude suchcomponents frombeingdeleted during the transformation of a submitted as-built BIM model. Once the scripts for all the functions of the developed solution is completed, they must be tested to validate their effectiveness against traditional methods. The solution needs to be fully developed and tested on a full-sized completed BIM model that is more realistic and similar to actual conditions to

representthedevelopedsolution'seffectivenessaccurately.

Thedevelopedsolution'ssuccesswillbedeterminedbasedontheefficiency,effectiveness,and user-friendliness it provides. Efficiency means the developed solution's ability to increase efficiency in the workprocesses by reducingthe amount of time needed tocomplete the same amountofworkwhileallowingcustomisationsbytheusers.Timetakentocompletegiventasks and participants’ perception of the solution in improving their work process will be used to assesstheefficiencythedevelopedsolutionprovides.

Effectiveness means the ability of the developed solution to increase the work's effectiveness by increasing the level of accuracy of the work done. The number of problems found and the number of tasks done correctly will determine the level of effectiveness. User-friendliness meanstheuser’susabilityofthesolutionbydesigningittobesimpleenoughforinexperienced users to navigate through multiple selections. Feedback by the users would be analysed to determinethesatisfactorylevelthedevelopedsolutionprovidesthem.

Ahigh-risebuildingconsistingofthevariousMEPsystemswasusedtosimulateanactualasbuilt BIM model in this present study. Required information for the respective components, such as roominformation and asset information, were also entered into the model to ensure it meetsthenecessarydevelopmentlevel.AnarchitecturalBIMmodelandMEPBIMmodelwas developed tonear as-builtBIMconditionsaspossible.ThecompletedBIM Modelconsistsof a total of 20 floors inclusive of a rooftop and basement – See Figure 1 to 3. The building is a luxurious condominium that is 19 storey high inclusive of 15 residential floors, 3 floors of commonareas,andarooftopusedtohousemechanicalequipment.Commonareassuchasthe playandsittingareaswerefullyfurnished,andMEPsystemsinstalledasnecessary.

InthearchitecturalBIMmodel,thereareatotalof1218rooms.Alltheroomshavebeengiven a standard form of naming and numbering. The room numbers are unique for each room as theyserveastheuniqueidentificationofthatspace because therecanberoomswiththesame name in the entire building, such as lift lobbies, risers, and more. The list of room naming abbreviationsusedforroomnumberingscanbefoundin Supplementary Information A-i.The

roomschedulesshowingthenecessaryinformationwerealsocreatedfortestingpurposes.The fulllistoftheroomscheduleforthemodelscanbefoundinSupplementaryInformationA-ii.

Variousdisciplines,includingHVAC,plumbingandsanitary,electricalandfireprotection systems,weredrawnontheMEPBIMmodel'ssamefile.AlistofassumedcriticalandnoncriticalequipmentforthisprojectcanbefoundinSupplementaryInformationA-iii.Allthe informationforallcriticalequipment,variousdisciplineswereaddedintothemodelwith referencetoageneralassetinformationrequirement(AIR)forthisproject.TheAIRcanbe foundinSupplementaryInformationA-iv.Inthisproject,thereisatotalof447equipment, with362beingmechanicaland85beingelectricalequipment. Figure1:OverallarchitecturalBIMmodel(Left)andMEPBIMmodel(Right)usedforthisstudy

Figure2:Typicalfloorplansampleinthedesignedhighrisebuildingusedforthisstudy

Figure3:ExamplesofsomemechanicalequipmentdrawnintotheBIMmodelusedforthisstudy

The provided solution is an automated programme used to automate the work processes and completethetasksneededtoprepareBIMmodelsforfacilitymanagementoperations,suchas the extraction of information or integration into a centralised platform. See Supplementary Information B forvideosofthedynamobasedautomatedprogrammingsolution.Thesolution comprisesoftwocomponentstopreparetheas-builtBIMmodelforoperationsusage.Thefirst component is to automate the workprocesses needed to checkthe qualityof theas-built BIM modelgivenbythecontractors.Anyproblemswiththequalitywouldbegeneratedintoareport and given to their contractors for rectification. For example, the BIM model's information to bedeliveredattheendofaprojectwouldbestatedintheEmployer’sInformationRequirement (EIR) andwouldbemadeknowntothecontractoratthe startof theproject.

If the submitted as-built BIM model’s requirements and quality did not meet the owner's expectations, it is the contractor’s responsibility to make the changes before the client’s acceptance. This will help to ensure the quality and integrity of the submitted as-built BIM model. The second component is to automate the work processes to transform the dense asbuilt BIM model to a lightweight BIM FM model. By saying lightweight, it is to ensure only the information needed during the facility management operations stage is included. This is becauserequirementsforaconstructionmodelaredifferentfromthoseusedduringthefacility management operations stage. Unless the owner has requested a second model apart from an as-builtBIM modelinthe contract,itwouldnotbe the contractor’sresponsibilitytopreparea separate BIM model. This process would include keeping necessary information from the asbuiltBIMmodelwithanyneworfacilitymanagementrelatedinformation.

Removing any unnecessary materials will help users to navigate through the model more efficiently and effectively. Through automation of the two components, it would help to simplify and streamline the work needed to prepare the BIM model for facility management operationsusage. If thesolutioncanhelpusersincreasecompletenessofwork done correctly, a higher level of facility management operations accuracy can be attained. Also, if the time requiredtodothesameamountofworkreduces,theworkprocesseswillbecomemoreefficient andeffective.Lastly,simplifyingtheworkprocessestocompleteallthenecessarytasksisalso animportantaspectforusers.

The solution willbe developed using dynamo programming, where the basis uses the python programming language. Dynamo is a visual programming software installed with Autodesk Revit.Itallowsuserstocreatevariousprogrammestoautomatedifferenttaskswithouthaving theneedtodevelopaseparateapplicationprogramminginterface(API)tointegratewithRevit. Developing an API is not easy due to the complexity of the requirements and the level of permissionsneeded.Dynamomakestheuseofnodestoexecutevariouscommandsandstrings toconnectthemtoformaprogramme.Dynamohasanin-builtlibraryofnodesforallusersto explore and authors across the community also share their own customised nodes online for alltouse.

The list the functions required in the proposed automated programming solution is shown in Table 1. Explanation of each function’s scope of work and its final script is also listed accordingly.ThefunctionofcheckingfortheMEPsystemscolourcodeisnotincludedbecause the colour code presented by the Building and Construction Authority (BCA) is a set of recommended colour code. However, different contractors would use their own set of colour code systems in practicefor their identification purposes. The colour code presented by BCA didnotincludealltheessentialsystemsforalltheMEPdisciplines.Forexample,chilledwater supply and return systems as well as condenser supply and return systems. Moreover, there seemstobenopatterninthecolourcodegivenwheresomesystemsusetheduplicatedcolour, whichshowsnopurposeincolourcodingthe systemforfacilitymanagementpurposes.Thus, itisremovedfromthe listoffunctionsofadevelopedautomatedprogrammingsolution.Only in the future, if colour coding of the MEP systems is mandatory and useful for facility managementpurposes, shoulditbe included.

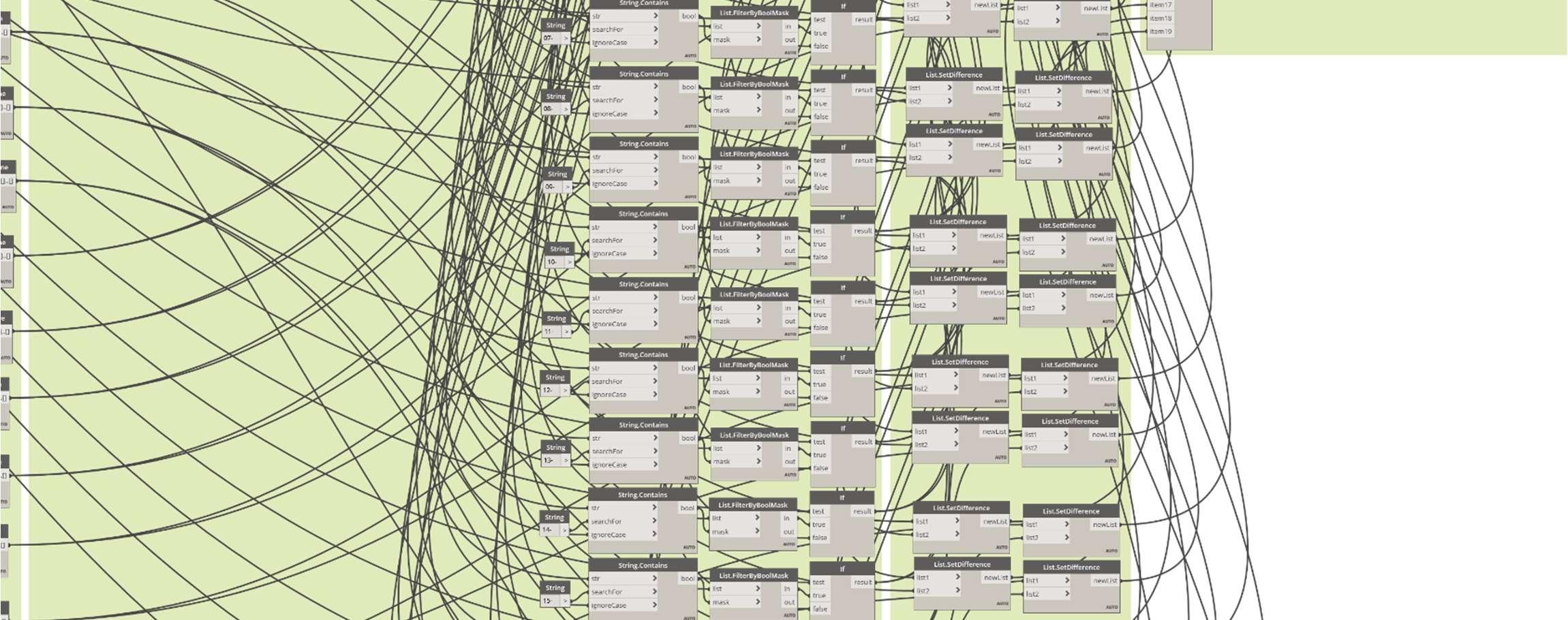

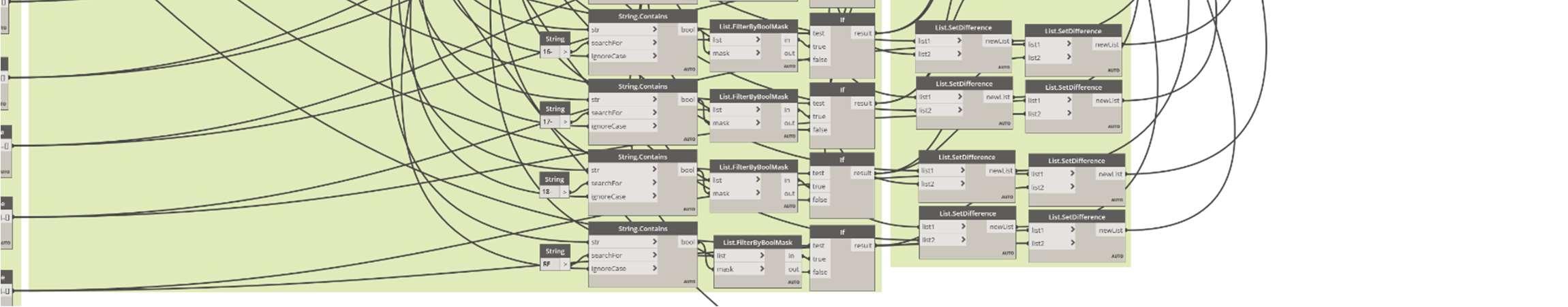

In each of the scripts, various steps are grouped accordingly into boxes of green and orange. The orange boxes are steps thatwillrequire user’sinput before running the programme while the ones in green do not require user’s actions. For all actions that require user’s input, the boxes would be shifted to the left. Each function’s scripts will be made up of multiple subfunctions to complete the different tasks to achieve the function's objective. As a BIM model for differentbuildings and the requirementsforevery projectisdynamic, the scripts designed arebasedontheassumptionsofgeneralrequirementseveryprojectshouldmeettoachievethe optimaloutcome.

A CheckRoom Boundaries

B Checkfor DuplicatedRoom Numbers

C CheckforExtraor Missing Equipment

D Checkfor Duplicated EquipmentLabels

E Checkforcritical interferences

F CheckInformation Fields–Without existing information

Archi Checkforproblemsofanyroomboundariesissues 1.1CheckRoomBoundaries

ExtractelementIDof roomswithproblems

Archi Checkthatallroomnumbershavebeenfilled 1.2CheckforDuplicatedRoomNumbers

Checkthatallroomnumbersarenotduplicated ExtractelementIDof roomswithproblems

Abilityforuserstoselectwhichfloortocheck

MEP Checkforanyextraormissingequipmentbasedon existingequipmentlistofassets 1.5CheckforExtraorMissingEquipment

ExtractlistofmissingassetsfromBIMmodel

ExtractlistofextraassetsinBIMmodel

Abilityforuserstoselectwhichfloortocheck

MEP Checkforanyduplicatedequipmentlabels 1.6CheckforDuplicatedEquipmentLabels

ExtractelementIDof duplicatedequipmentlabels

Abilityforuserstoselectwhichfloortocheck

Abilitytogenerateareport ofwhichsystemsare different

Archi& MEP Checkforinterferencesforcriticalassets

Archi:1.3CheckforCriticalInterferences(Archi)

MEP:1.7CheckforCriticalInterferences(MEP) ExtractelementIDof componentswith interferences

Archi& MEP Checkallrequiredcorrespondinginformationfor eachroom/equipmenthave beenfilledup(Based on AIR)

ExtractelementIDof rooms/equipmentwith missinginformationforeachparameter

Archi:1.4aCheckInfoFieldsWOExistingInfo

MEP:1.8aCheckInfoFieldsWOExistingInfo

G CheckInformation

Fields–With existing information

Abilityforuserstoselectwhichfloortocheck

Archi& MEP Checkallrequiredcorrespondinginformationfor eachroom/equipmenthave beenfilledup(Based on AIR)

Compareinformationbetweenexistinglistof informationinexcelandBIMModelfor differences

Abilityforuserstoselectwhichfloortocheck

Archi:1.4bCheckInfoFieldsWExistingInfo (Archi)

MEP:1.8bCheckInfoFieldsWExistingInfo (MEP)

Component2: TransformingofAs-builtBIMModeltoBIMFMModel

H Update Informationinto BIMModels (Import&Export)

Archi& MEP

Abilitytoexportinformationfrommodelinto editableexcelfile

Abilitytoimportinformationfromexcelinto model

Abilitytoselectspecificparametersinsteadof entireschedule

Abilityforuserstoselectspecificfloorsforaction

Archi: 2.1aUpdateInfointoBIMModels(Archi)_Export 2.1bUpdateInfointoBIMModels(Archi)_Import

MEP: 2.1aUpdateInfointoBIMModels(MEP)_Export 2.1bUpdateInfointoBIMModels(MEP)_Import

I Removalof UnwantedItems

Archi& MEP

Abilitytoallowuserstoremoveunwanteditems suchasdrawingsheets,schedules,non-critical assets

Abilityforuserstoselectspecificitemsinsteadof entirecomponent

2.2RemovalofUnwanted Items

J LightenBIM ModelFiles

Archi& MEP

Abilitytoallowuserstopurge BIMModel completely

Abilitytoallowuserstocompactandoverwritethe existinglargerfile

2.3Lighten BIMModelFiles

Also, anarchitectural BIM model and MEP BIMmodel wouldhave different parameters and elementsthat need tobe worked on. Thus,the same functionsforcomponent1would be split into architectural and MEP discipline while in component 2, the first function, ‘Update InformationintoBIMModel’ wouldalsobesplitintoarchitecturalandMEPdiscipline dueto the different parameters involved. ‘Removal of Unwanted Items’ and ‘Lighten BIM Models’ wouldusethesamescriptforbothdisciplinesastheparametersinvolvedtoattaintheobjectives isthesame.

In component 1, the purpose of the scripts developed is to ensure that facility managers or owners can check the quality of the as-built BIM models received from the contractors and ensurethat thequalityattainedmeetstheir projectrequirementsandstandardrequired.Thisis toallowrectificationworksbytherightpartybeforeitistoolate.Ensuringanaccurateas-built BIM model is also important for subsequent uses of this model for facilities management purposes.

Figure4showsthedynamoscriptforfunction‘1.1–Checkroomboundaries’.Therearethree mainstepsinthisscript.Inthefirststep,theprogrammewouldattainalltheroomsintheBIM modelandcheckforroomswithanarea=0.Thisisbecausetheareawouldbezeroforthethree types of room problems; Not enclosed, Redundant, and Not Placed. Then, once these rooms withproblemsarefound,theircorrespondingelementID,level,roomname,androomnumber wouldbeextractedandorganised intoanexcelsheettobeexported.

Attaining the element ID would help the user search for the specific room in the BIM model easily,anditisauniqueIDthatisautomaticallytaggedbyRevit.AsshowninStep3a,theuser wouldberequiredtoinputthenameoftheexcelfilereport.Afterrunningthe programme,the excelsheetwouldautomaticallypopout.AnexampleoftheexcelreportcanbeseeninFigure 5.Withoutthisfunction,userswouldhavetomanuallycreateandchecktheroomscheduleand extracttheroomelementIDmanually.

Figure6showsthedynamoscriptforfunction‘1.2–Checkforduplicatedroomnumbers’.As roomnumbersareuniqueforeveryroom,unlikeroom nameswhere differentroomscanhave

the same name, room numbers are important to identify the room correctly in a building. In thisscript,therearefivemainstepstoachievetheobjective.Inthefirststep,usersarerequired toselectthefloorsthattheywouldliketocheck.Theycanselectspecificallyformultiplefloors thattheywould like to check instead of the entire building, reducing the time forthe script to loadiftheydonotneedthewholebuildingtobechecked.

Users are to select ‘true’ for floors they want and ‘false’ for floors to exclude. In the second step,theselectedroomsbasedontheusers’inputwould begatheredandputintoalistinStep 3.InStep4,theprogrammewouldlooktosegregateroomswithmorethanoneoccurrenceinto different lists. The informationgathered would thenbe exported into anexcel sheet report, as showninStep5.InStep5a,usersarerequiredtoinputthenameoftheexcelsheettobesaved. After running the programme, the excel sheet report would pop up automatically, and an example ofthereportisshowninFigure 7.

Figure 8shows the dynamo scriptfor function '1.3 – Check for critical interferences (Archi)'.

Inthisproject, the criticalelementassumedfortheArchitectural modelisthefurniture.There are five main steps in this script. In the first step, the users are required to select the other elements to check their furniture with. Users are to select ‘true’ for elements to include and ‘false’ to exclude. In the second step, the selected elements based on the users’ input will be extractedandgo throughinterferencechecksinStep3b.

TheelementIDsofthoseelementswithclasheswillbeextractedandinputintoanexcelsheet report in Step 3c. Users would also have to input the name of the excel sheet report that they wouldlikeinStep3a.Afterrunningtheprogramme,theexcelsheetreportwouldautomatically popup,andanexampleofthereportisshowninFigure9.Withoutthescript,userswouldhave to conduct the check manually using the function inbuilt in Revit and manually extract the elementIDfromtheHTMLfilereport.

Figure 10 shows the dynamo script for function ‘1.4a – Check information fields without existinginformation’.Thisfunctionaimstocheckthatalltheinformationcorrespondingtothe rooms have beenfilled up as required. In this script, it alsoallows users to check specifically the floors that they would like. In Step 1, users would have to select ‘true’ for the floors to

includeand‘false’toexcludetheotherfloors.Inthesecondstep,theprogrammewouldgather theselectedroomsbasedontheusers’inputandinputthemintoa listasperStep3.InStep4, the programme would check the rooms' corresponding fields for any empty field and export the rooms’element ID ofthose with problems intoanexcelsheetreport inStep 5b. Usersare alsotoinputthenameoftheexcelsheetreportinStep5a.Anexampleoftheexcelsheetreport isshowninFigure11.Withoutthisautomatedprogramme,userswouldhavetomanuallycheck fieldbyfieldinthe roomscheduleforanymissingroominformationandmanuallyextractthe elementIDofthose rooms.

Figure12showsthedynamoscriptforfunction‘1.4b–Checkinformationfieldswithexisting information’. This function aims to compare existing information inside an excel sheet with the information inside the BIM Model and find the differences. Apart from the model's information, theretends to be anothercopy of theinformation onhand. Hence, it isimportant to identify the differences between these two to clarify with the contractors, which is the accuratecopy.Thereare4mainstepsinthisscript.Inthefirststep,theprogrammewillextract alltheroom’scorrespondinginformation.

In Step 2a, the user would need to select the excel file to import into the programme for comparison, and Step 2b will extract and identify the information. In Step 3, the programme will find the differences and export the information into an excel sheet report in Step 4b. Wherein 4a, the user would need to input the name of the excel file. Figure 13 shows sample excelsheetreportofScript1.4b.Figure14showsexample ofexcelsheetofexistinginformation andRevitroomscheduleinformation.Withouttheautomatedprogramme,userswouldhaveto manually compare the information cell by cell to find the differences, which would increase thetimeneededandchancesforhumanerrors.

Figure4:Script1.1–Checkroomboundaries

ProblemsWithoutProblems

ElementIDLevelRoomNameRoomNumberElementIDLevelRoomNameRoomNumber

1805433Level53BRLIVINGSPACE05-3R-LR-011642159Level3-WithFurnituresOnlyMBR03-2R-BR-02 1805459Level5STORE05-4R-SR-011642162Level3-WithFurnituresOnlyMBRWIC03-2R-WIC-01 1805819Level7BR107-3R-BR-011642165Level3-WithFurnituresOnlyMBRWC03-2R-WC-02 1807805Level93BRLIVINGSPACE09-3R-LR-011642177Level3-WithFurnituresOnlyBR103-2R-BR-01 1835081Level13RoomB1-CA-ELEC-021642180Level3-WithFurnituresOnlyBR1WC03-2R-WC-01 1835136Level13RoomB1-CA-ELEC-031642615Level3-WithFurnituresOnlyDINING03-2R-DN-01 1642633Level3-WithFurnituresOnlyENTERTAINMENT03-2R-ENT-01 1642636Level3-WithFurnituresOnlySTORE03-2R-SR-01 1642639Level3-WithFurnituresOnlyCMWC03-2R-WC-03 1642642Level3-WithFurnituresOnlyKITCHEN03-2R-KC-01 1642645Level3-WithFurnituresOnlyMAIDRM03-2R-MR-01 1643636Level3-WithFurnituresOnlyLAUNDRY03-2R-LD-01 1643966Level3-WithFurnituresOnlySER.BAL.03-2R-BAL-02

Figure5:SampleexcelreportforScript1.1(Left)androomschedule(Right)

1102584 1102583 1102585 1102584 1102707 1102706 1102720 1102719 1102933 1102934 1102935 1102936

Figure13:SampleexcelsheetreportofScript1.4b Figure14:Exampleofexcelsheetofexistinginformation(Top)andRevitroomscheduleinformation (Bottom)

Figure15showsthedynamoscriptforfunction‘1.5–Checkforextraormissingequipment’. The purpose ofthisfunctionis tocheck the BIMmodelforanyextra equipmentthatdoesnot belong in the model or missing equipment that should be in the model but was not drawn in against an existing list of equipment for comparison. By comparing the mechanical and electricalequipment against the excel sheet, when the excelsheet showsextra equipmentthat cannot be found in the model, those refer to ‘Missing Equipment’ while those that are not in theexcelsheetbutareinthe modelarethe‘ExtraEquipment’.

Users are also allowed to conduct the check based on selected floors only. In the script, there arefivemainsteps.Inthefirststep,theuserwouldhavetoselect‘true’forthefloorstoinclude inthecheckand‘false’forthefloorstoexcludefromthecheck.Then,inStep2,theprogramme would extract all the selected equipment elements from the model based on the users’ indication. Followed in Step 3a, the user would have to select the excel file of the list of equipmentforchecking,whileinStep3b,theprogrammewouldimportthelistandcategorise themintothefloorby floor basis. InStep 4, the programme willsearchformissing, andextra equipment as previously explained and export the gathered information into an excel sheet report.

The way itworksfor electricaland mechanical equipmentis thesame. The excel sheet report wouldhavetwosheetswherebyoneisforelectricalandtheotherformechanical.Anexample of the excel sheet report is shown in Figure 16. Without this automatedprogramme, it would be very difficult for users to search for the missing or extra equipment in the BIM model accuratelyduetotheas-builtBIMmodelscale.

Figure15a:Script1.5–Checkforextraormissingequipment-Part1(Note:Theelectricalportionofthescriptisnot showninthisfigureastheyareexactlythesame).

Figure17showsthedynamoscriptforfunction‘1.6–Checkforduplicatedequipmentlabels’. This function aims to check the equipment in the BIM models for any duplicated equipment labels.Oneofthecommonmistakesinanas-builtBIMmodelishavingduplicatedequipment labels. Equipment labels are a unique label to all the critical equipment in the building for identification purposes. In this script, there are five main steps. In the first step, users are to select the floors they would like, and the programme in Step 2 would extract the selected equipmentbasedontheirinput.

The extracted equipment from the various floors would then be gathered into a list in Step 3 andinputintotheprogrammeatStep4tosearchforduplicatedlabels.Theinformationwould thenbe exportedintoanexcel sheet report in Step5b, whereusers wouldfirst input the name oftheexcelsheetinStep5a.AnexampleoftheexcelsheetisshowninFigure18.Withoutthis programme,userswouldhavetomanuallysearchforitintheMEPschedulefortheduplicated labels. This would increase the chances of inaccuracy due to human errors, and also the time takenwouldincrease.

Figure19showsthedynamoscriptforfunction‘1.7–Checkforcriticalinterferences(MEP)’. Thepurposeofthisfunctionistocheckforanyinterferencesonthecriticalequipment.Inthis project, the general assumption for critical equipment includes mechanical and electrical equipment.Inthisscript,thereare3mainsteps.

In the first step, users are to select the elements to check against the critical equipment. This wouldhelpthesearchtobemorespecificandachieveonlytheresultsofinterest.Then,inStep 2, the selected elements and the critical equipment would be extracted. The elements would thengo through checkfor any interferencesand input intoan excel sheet report. Users would alsoberequiredtoinputthe nameoftheexcelsheettheywant.Anexample oftheexcel sheet isshowninFigure 20.

Figure 21 shows the dynamo script for function ‘1.8a – Check information fields without existing information (MEP)’. This function aims to check that all the information corresponding to the critical equipment have been filled up as required. In this script, it also allows users tocheck specifically the floors that they would like. In Step 1, users would have to select ‘true’ for the floors to include and ‘false’ to exclude the other floors. In the second step, the programme would gather the selectedequipment based on the users’ input and input themintoalistasperStep3.

InStep4, theprogramme wouldcheckthe rooms'correspondingfieldsforanemptyfieldand export the equipment’s element ID of those with problems into an excel sheet report in Step 5b. Users are also to input the name of the excel sheet report in Step 5a. An example of the excel sheet report is shown in Figure 22 below. Figure 23 shows an example of missing informationintheMEPscheduleidentifiedwiththeprovidedautomatedprogramme.Without this automated programme, users would have to manually check field by field in the MEP schedule for any missing equipment information and manually extract the element ID of the equipment.

Figure24showsthedynamoscriptforfunction‘1.8b–Checkinformationfieldswithexisting information(MEP)’.Thisfunctionaimstocompareexistinginformationinsideanexcelsheet withtheBIMModelinformationandfindthedifferences.Apartfromthemodel'sinformation, theretendstobeanothercopyoftheinformationonhand.Hence,itisimportanttoidentifythe differences between these two to clarify the contractors' accurate copy. There are four main stepsinthisscript.

In the first step, the programme will extract all the critical equipment corresponding information.InStep2a,userswouldneedtoselecttheexcelfiletoimportintothecomparison programme. In Step 2b, users would need to extract and identify the information inside, and the programme will find the differences. The information will be exported into anexcel sheet reportinStep3-SeeFigures25to27.Theuserwouldalsoneedtoinputthenameoftheexcel filethattheywant.Withouttheautomatedprogramme,userswouldhavetomanuallycompare the informationcellbycell to find the differences, which wouldincrease the time neededand chancesforhumanerrors.

EquipmentTypeinExcelthatisdifferentfromBIMModelFloorinExcelthatisdifferentfromBIMModelRoomNameinExcelthatisdifferentfromBIMModelEquipmentLabel/MarkinExcelthatisdifferentfromBIMModelControlPanelinExcelthatisdifferentfromBIMModelBrandinExcelthatisdifferentfromBIMModelEquipmentModelinExcelthatisdifferentfromBIMModelCapacityinExcelthatisdifferentfromBIMModelSerialNumberinExcelthatisdifferentfromBIMModel

DomesticWaterTransferTank3RoomUnitsFCU-04-3R--01LMCP-B1-06ProjetsPFH-41S35281CMHFanCoil FCU-05--4R-01-PFH-42S41.2kWCondensUnitFCU-06--2R-03Daikin230/1/5117.12kWD05589300

CU--06-3R-02LMCP-07--01230/1/5217.13kWD06589322

FCU-07--4R-06CS3H-45MM-AH32012D0657936 CU-07-3R-001D07589251

FCU--08-2R-04D09581926

FCU-16-4R--01D175893589

FCU-17-3R-011D1858944 CH--RF-01D1858945 D1858946

DomesticWaterTransferPumpB1PlantRoomDWTP-B1-02LMCP-B1-04GrundfosModelA45kWGF64793312/20/2020

DomesticWaterTransferPumpB1PlantRoomDWTP-B1-03LMCP-B1-04GrundfosModelA45kWGF57983212/20/2020

DomesticWaterTransferTankB1PlantRoomDWTP-B1-01LMCP-B1-04GrundfosModelA45kWGF37985812/20/2020

CarparkExhaustAirFanB1CarparkCEAFB1-02LMCP-B1-01SystaAirAXC(A)1250-115000CMHSA64718112/20/2020

CarparkExhaustAirFanB1CarparkCEAFB1-01LMCP-B1-01SystaAirAXC(A)1250-215000CMHSA64718212/20/2020

CarparkFreshAirFanB1CarparkCFAF-B1-04LMCP-B1-06SystaAirAXC(A)1250-315000CMHSA64718312/20/2020

CarparkFreshAirFanB1CarparkCFAF-B1-03LMCP-B1-02SystaAirAXC(A)1250-415000CMHSA64718412/20/2020

CarparkFreshAirFanB1CarparkCFAF-B1-02LMCP-B1-02SystaAirAXC(A)1250-515000CMHSA64718512/20/2020

CarparkFreshAirFanB1CarparkCFAF-B1-01LMCP-B1-02SystaAirAXC(A)1250-615000CMHSA64718612/20/2020

JetFanB1CarparkJF-B1-02NILProjetsPFH-41S35280CMHPJ47108112/20/2020

JetFanB1CarparkJF-B1-01NILProjetPFH-40S35280CMHPJ47108212/20/2020

JetFanB1CarparkJF-B1-08NILProjetPFH-40S35280CMHPJ47108312/20/2020

Figure2:SampleexcelsheetreportofScript1.8b Figure26:SampleofexistinginformationinputintoDynamoprogramme

Figure27:InformationfromBIMmodel'sMEPschedule

Figure 28shows the dynamo scriptforfunction ‘2.1a –UpdateInformation intoBIM Models (Archi–Export)’.Thepurposeofthisfunctionistoallowfacilitymanagersorownerstomake updatesintotheBIMmodelusingmorecomfortablesoftware,excel.Userscanalsoexportthe information they require for any other use as necessary. The first part of this function is to exporttheinformationfromtheBIMmodel.Inthisscript,therearefivemainsteps.Inthefirst step,userswouldberequiredtoselect‘true’toincludethefloorsoftheinformationtheywant and ‘false’ to exclude the rest. The elements will then be extractedby the programme in Step 2basedonthe selectedfloorsandgatheredintoalistinStep3.

Userswouldalsoneedtoselectthecorrespondingparameterstheywanttoinclude inStep4a, and the programme will extract the related information of the selected elements in Step 4b. Lastly,theuserwouldneedtoinputthenameoftheexcelsheetinStep5a,andtheprogramme in Step 5b will export all the gathered information. The excel sheet containing the exported informationwillpopupautomaticallyintheexcelwindowsafterrunningtheprogramme.This excel can then be edited as necessary and imported back to the BIM model using the next dynamoscript,‘2.1b–UpdateinformationintoBIMmodel(Archi–Import)’.

After users make the edits they require, this dynamo script will allow them to upload the information back into the BIM Model. The dynamo script for function ‘2.1b – Update informationintoBIMmodels(Archi –Import)’ isshownin Figure 29. In this script, thereare threemainsteps. Inthefirststep,userswouldbe requiredtoselectthefileto beimportedinto theprogramme.Inthesecondsteptheinformationwillimportedandread.Inthethirdstep,the programme will use the element ID to match the corresponding information according to the rightparameters.

Figure29:Script2.1b–UpdateinformationintoBIMmodels(Archi-Import)

3.2.3MEPdiscipline:UpdateInformationintoBIMModels–Export

Figure30showsthedynamoscriptforfunction‘2.1a–UpdateinformationintoBIMmodels (MEP–Export)’.Thepurposeofthisfunctionistoallowfacilitymanagersorownerstomake updatesintotheBIMmodelusingmorecomfortablesoftware,excel.Userscanalsoexportthe informationtheyrequireforanyotheruseasnecessary.Thefirstpartofthisfunctionisto exporttheinformationfromtheBIMmodel.Inthisscript,therearefivemainsteps.Inthefirst step,userswouldberequiredtoselect‘true’toincludethefloorsoftheinformationtheywant and‘false’toexcludetherest.TheelementswillthenbeextractedbytheprogrammeinStep 2basedontheselectedfloorsandgatheredintoalistinStep3.

UserswouldalsoneedtoselectthecorrespondingparameterstheywanttoincludeinStep4a, andtheprogrammewillextractthecorrespondinginformationoftheselectedelementsinStep 4b.Lastly,theuserwouldneedtoinputthenameoftheexcelsheetinStep5a,andthe programmeinStep5bwillexportallthegatheredinformation.Theexcelsheetcontainingthe exportedinformationwillpopupautomaticallyintheexcelwindowsafterrunningthe programme.ThisexcelcanthenbeeditedasnecessaryandimportedbacktotheBIMmodel usingthenextdynamoscript,‘2.1b–UpdateinformationintoBIMmodel(MEP–Import)’. DifferentscriptsforarchitecturalandMEPdisciplineareduetothedifferenttypesof parametersinvolved.

Afterusersmaketheeditstheyrequire,thisdynamoscriptwillallowthemtouploadthe informationbackintotheBIMmodel.Figure31showsthedynamoscriptforfunction‘2.1b–UpdateinformationintoBIMmodels(MEP–Import)’.Inthisscript,therearethreemainsteps. Inthefirststep,userswouldberequiredtoselectthefiletobeimportedintotheprogramme.

Inthesecondstep,theinformationwillbeimportedandread.Inthethirdstep,theprogramme willusetheelementIDtomatchthecorrespondinginformationaccordingtotheright parameters.

Figure 32 shows the dynamo script for function ‘2.2 – Removal of unwanted items’. This functionaimstoallowuserstoremoveunwanteditemsintheirBIMmodelthatisnotnecessary forfacilitymanagementoperationspurposes.Asallprojectsaredynamic,thisscriptwillenable users to choose exactly what to remove. In this script, there are two main parts. In Step 1a, userswould beaskedtoselect‘true’forcategories thatthey wouldliketodeleteallelements, andStep1bwouldextractallthoseelementsanddeletethem.

InStep2a,usersaretoselecttrueiftheywouldliketodeletesomethingfromthatcategoryand select the specific item. Up to 5 oreach category can be deleted in one run. Inaddition, users can re-run the same programme. The programme will extract all the specific items and delete theminStep2b. ThisfunctionisimportanttoremoveunnecessaryitemsfromtheBIMmodel thatwould notbe relevant duringthe facilitymanagement operations stage. After running the programme, users can check the BIM model to see if all the unwanted items have been removed.

Figure 33 below shows the dynamo script for function ‘2.3 – Lighten BIM model files’. The purpose of this function is to lighten the BIM model by purging further and compacting the file.InStep1,theprogrammewillpurgethefilecompletelyuntilzero.Withouttheautomated programme,userswillhavetopurgecontinuouslytoreachzero.InStep2,theprogrammewill ‘save as’ the file and automatically replace the existing file with the compacted BIM model file. Users can check the BIM model file in the location where the file has been saved to see thatthesizeofthefilehasdecreased.

Asmentioned,testswouldbeconductedafterdevelopingthesolutionstovalidatetheoutcomes ofthe solutionandhoweffective ithashelpedtomeet the needsoftheusersandtheproject’s objectives. The complete integration of architectural and MEP models would be used as part of the test. The test participants are also equipped with basic knowledge and skills in using Autodesk Revit and little knowledge in using Dynamo. All participants have actual work project experiences in using Autodesk Revit and navigating through BIM models. Two tests were conducted to validate the two different components of the solution. The tests were conducted on a one by one basis meetup. Due to some participants not having the required software, Revit, on their own personal laptop, and to ensure that the laptop's technical specificationswouldnotaffectthetest'saccuracy,theactualsessionofthetestthroughmeetup wasconductedinsteadofusingZoomsessionsbecauseof COVID-19restrictions.

All the necessary materials for the tests were prepared and organized properly in a folder for each participant. Afacilitator wouldfacilitate the session byprovidinginitial instructionsand recording the time used for each test. After the tests, the necessary deliverables were saved back into the folder for results analysis subsequently. In each of the tests, participants were givenaninstructionsmanualstatingthevarioustaskstheyhadtocompleteandthedeliverables they would have to deliver. The instructions manual and other reference documents required forthetestswouldbeprintedfortheparticipantforeasyreferenceduringthe test.Foreachof thetests,participantswererequiredtoattemptittwice.Thefirstattemptinbothtestswasmade without using the solution, and the second attempt to complete the list of tasks in the instructions’manual.

In the first test, participants were asked to find all the problems from the as-built BIM model given, as stated in the instructions manual, by conducting the required checks. In contrast, in the second test, participants were asked to transform the as-built BIM model into a BIM FM model by removing the unnecessary elements and updating necessary components, as mentionedintheinstructionsmanual.Theproblemsandtasksrequiredtocompleteareplanted throughoutthebuildingondifferentfloorsfordifferenttaskstoensurethattheywouldhaveto spend time navigating through more complex models and ensuring the system also tests the additionalloadingtime requiredforDynamorunthrough the fullbuilding. Refer to Figure 34 to 37forthetestinstructions.

Figure3:Instructionmanual-Part1

Figure36:Instructionmanual-Part3

Figure37:Instructionmanual-Part4(end)

Twovariables,timetakenforeachparticipanttocompleteeachtest'sattempt,andthenumber of tasks completed correctly, were measured from the tests. The measurement of time is to validate if the solution can achieve higher efficiency by taking a shorter amount of time to completethe same number oftasks. Forthe number of taskscompletedcorrectly, thepurpose is to validate if a higher level of accuracy can be achieved using the solution. It was done by comparing the number of tasks the participants can complete correctly in two tests. Subsequently,theresultsofthetestswereanalysedbycomparingthetimetakenandthedegree ofaccuratetasks’completionforeachattempt.Thismeasurewasusedtodeterminetheresults ofthetestsinthefollowingsection.

Participants used the BIM given model to complete the required tasks listed in the manual as possible. The size of the BIM model is similar to actual projects in the industry to ensure the resultsattainedfromthetestsandvalidationofthedevelopedautomatedprogrammingsolution would be authentic. For the first test, participants were required to locate all the planted problemsinthe model,andanexcelsheetwasgiven tothemtorecordtheproblemsfound. In the second test, participants had to complete as many tasks as possible to transform it into a BIM facility management (FM) ready model. 55 minutes was given for the first test for each attempt, while 15 minutes for each attempt was given for the second test. After the sessions, therecordedanswersintheexcelsheet,timetakenforeachtask,andattemptandtheBIMFM model from the second test were “marked” to determine the number of correctly completed tasks. The results were then analysed using the time difference for each participants’ results, percentageoftimesavings, mean,andvariances.

InTest 1,the aim wastochecktheas-built BIMmodelsforaccuracy, andthefollowingtasks were given. For architectural discipline, four main tasks were tested. In the first task, participantswererequiredtochecktheroomboundariesforanyproblems,whichinclude‘Not Enclosed,’ ‘Not Placed’, and ‘Redundant’ rooms. In the second task, they were required to check for any duplicated room numberings. In the third task, they checked for information fields thatare tagged to each room butwithoutexistinginformation. The purpose is toensure that all information fields are filled for all the rooms in the building. For the last task, they checked the BIM model information against an existing set of information. The purpose is to comparetheinformationbetweenbothandfindanydisparities.

There are also four main tasks for the MEP discipline. In the first task, participants were required to check for any extra or missing equipment in the BIM model. In the second task, they checked for any critical interferences, which refers to any clashes against the building's critical equipment. The third task required the participants to check each critical equipment's informationfieldswithoutanyexistinginformation.Thepurposeistoensurethatallimportant fields are filled up for critical equipment. The last task required them to checkinformation in the BIM model against an existing set of information. The purpose is to compare the informationandlookforanydisparities.

In Test 2, theaim was to transformtheas-built BIM model to BIM FM ready model with the following tasks given. For the MEP discipline, the participants were required to update information into the BIM model. The purpose is to test for time and accuracy of transferring thenewsetofinformationgiveninexceltotheparticipants'BIMmodel.InformationforMEP critical equipment is important for facilities management usage. Two main tasks were given forarchitecturaldiscipline.Thefirstisfor participantstoremove unwanteditems. Inthistest, participants are expected to remove different categories of items. Some categories are to remove all of its elements, while for some, only specific elements of that category are to be removed. The last test is to lighten the BIM model files through purging and compacting the files.Itisimportanttonotethatinpurging, itisexpectedtopurgethemodelmultipletimesto be able to reach 0 items left to be purged. The dynamo script used for these two tasks is the sameforMEPdisciplinesastheparameterswouldbematchedaccordinglytothetypeofmodel openedautomatically.

Information five main factors considered to lower any influences of uncertainty in the results isprovidedinTable2.

Table2:Testenvironmentalfactors

S/N Factor Description

1 Equipment MeasuringEquipment:

Thesameequipmentwasusedtorecordthetimeforallthe attemptsbytheparticipants.

Computerusedfortests:

2 Operator

The same computer, mouse, and mousepad were given to the participants to complete the tasks. The purpose is to ensure that the specifications and performance of the computerisconsistentnottoaffectthetimeneeded.

The same facilitator conducted the test and take charge of giving the same set of instructions and record the time to ensure fairness of the tests. The facilitator also facilitates any breaks required by the participants andmakes decisions regardingthetime measured accordingly to the situations. That is, time taken during the break isnotconsideredinthereportedtimetakentocompleteatask.

3 Environment The following environmental conditions were considered for the indoorenvironmentusedbyeachoftheparticipants.

Thermal Comfort: Each indoor environment used were airconditioned at a temperature deemed comfortable by each of theparticipantsasdifferentindividualswillconsiderdifferent temperaturesandhumiditytobecomfortable.

Indoor Air Quality: Each indoor environment had good perceivedairqualitybytheparticipantsandfacilitator.

Lighting: Sufficientlightingandcomputer’sscreenbrightness to set to the perceived acceptable level of the participants to ensure participants would not be affected by any glare or strainingoftheireyes.

Noise: The test were conducted in a comfortably enclosed space away from noisy establishments and factors such as trafficsandrenovations.

Stress: Eachoftheindoorenvironmentusedhadconsiderably low amount of distractions but not a completely isolated that maycauseunnecessarystresstotheparticipant.

4 TestTaker

Remindersshallbegiventotheparticipantstoensurethattheywill getenoughrestandhealthyenoughtotakepartinthetests.Factors affecting the participants’ condition of mind mayindirectlyaffect the reliability of the test results. Additionally, participants taking thetestshallbedeemedtohavesimilarlevelsofproficiencyinthe BIM authoring tool and experiences with the as-built BIM model toensureconsistencyintheresults.

5 Method As mentioned, the same set of instructions manual containing all the tasks required of the participants would be given to them to ensureconsistency.

Fivepeopleparticipatedinthetestingofthedevelopedscript.Thesamplesizeisgoodenough forthepurposeofvalidatingthedevelopedsolution.Themainpurposeistodemonstratehow the developed solution could help verify submitted as-built BIM models and their transformationinBIMmodelsreadyforfacilitymanagementusageina promptmannerover the traditional manner (without the developed solution) of performing the tasks. Thus, the provisionofobjectivedatadoesnotnecessarilyrequirealargesamplesize.

Aquickfeedbacksessionwasconductedwiththetestparticipants.Thepurposeistodetermine their opinions on the user-friendliness of the developed solution, their satisfaction with the developed solution, and impact of their work process. Finding from this survey is subjective and should be treated as an indication, not a confirmation of how people will perceive the developed solution's user-friendly nature. The confirmation of the user-friendliness can only be achieved through feedback gotten from people using the developed solution for their everydayfacilitymanagementpractice.

The time taken for participants to complete the tasks was collected. The accuracy of the completion for each task was noted. This is because participants may complete their tasks quickly but not necessarily complete the task of finding all the errors or completely transforming the as-built BIM model to the BIM FM model correctly. The demonstration of the developed automated solution can be found in the link in the supplementary information section B. The demonstration video is provided for better appreciation, visualization, and understandingofthedevelopedautomatedsolution.

Inthefirsttest,participantsareexpectedtocompleteeighttasksgivenintheinstructionmanual twice. The first attempt to be made without the solution and the second attempt with the solution. In the first attempt, participants are to record the details of the checks in the excel sheet given, while in the second attempt, the excel sheet report that would be generated automaticallywouldbothbeusedfor“marking” subsequently.

Table 3 shows each participant's time to complete the eight different tasks on both attempts, withandwithoutthesolutionforthefirstcomponent.Thetimetakenwasrecordedinseconds, andthetotaltimetakenforeachattemptofalltheeighttaskswerecomputed.Forthefirsttest, eachparticipantwasgiven6minutesforeachtask.AsshowninTable3,itcanbeseenthatfor certain tasks, participants actually made use of all the time given for the attempt without the solutionbutarestillunabletocompletethetaskgiven.Ingeneral,itcanbeseenthatthereisa large decrease intime when the participantsuse the automated solution forthe 2ndattempt to completetheeighttasks.

Table3:TimeTakenforeachparticipanttocompleteTest1onbothattempts

Task14.501.134.681.204.631.284.021.183.831.17

Task25.833.426.003.555.383.525.023.354.923.47

Task33.120.853.350.973.031.002.970.922.680.97

Task46.000.775.330.805.720.856.000.805.330.78

Task56.003.156.003.026.003.326.002.886.003.12

Task66.004.706.004.986.004.806.005.006.004.85

Task73.371.923.872.053.082.023.331.952.921.97

Task86.001.256.001.286.001.276.001.286.001.18

Total40.8217.1841.2317.8539.8518.0539.3317.3737.6817.50

Table4showsthetimedifferenceandpercentagesavingswhenusingthedevelopedautomated programmingsolution.Itcanbeseenthatthe5participantswereabletosavea rangeof20.18 minutes to 23.63 minutes out of the given 50 minutes for each attempt given. It was also observed that the percentage time savings for each participant ranged from 53.6% to 57.9%. Based on the mean, an average of 22.19 minutes and 55.7% of time savings were obtained using the developed automated solution. This shows that the solution effectively reduces the amount of time needed to check the as-built BIM Model. Additionally, the variance of the percentage time savings was 2.9%. The variance reported is acceptable for well-defined constructionjobs(±3–5)andresearchanddevelopmentjobs(±10–15)(Lewis, 2006).

Table 5 shows the number of problems each participant found in the 8 different tasks on both attempts, with and without the solution for the first task. The total number of problems that shouldbefoundforeachtaskisin the 2ndcolumnfromthe left. The greencellsshowthatthe

participantscould find all the problems ineach task within theallocated time given. The cells in red are those whereby participants cannot completely find all the problems within the time frameorareunabletogetthecorrectproblemsthatshouldbefoundforeachtask.Thepurpose oftabulatingthenumberof problemsfoundcorrectlyforeachparticipant'staskistocheckthe accuracylevelofworkdonebyeachparticipantforeachattempt.Itisevidentthatwiththeuse of the developed solution to complete the task, all participants could find all the problems requiredcorrectly.Whereas,intheattemptswithoutthesolution,allparticipantscouldnotfind alltheproblemsrequiredaccurately.Duringthetestswithouttheuseofthedevelopedsolution, it was observed that participants were not able to find all the problems for some of the tasks despite using the full amount of time given. There were also cases where participants did not getthecorrectelementIDoftheelementwithaproblem.

Table4:Timedifferenceandpercentagesavingswhenusingautomatedsolution

Time Difference (Mins)

% Savings

Time Difference (Mins)

% Savings

Time Difference (Mins)

% Savings

Time Difference (Mins)

% Savings

Time Difference (Mins)

% Savings

Time Difference (Mins) %Savings

Task13.3774.813.4874.383.3572.302.8370.542.6769.573.1472.32 Task22.4241.432.4540.831.8734.671.6733.221.4529.491.9735.93 Task32.2772.732.3871.142.0367.032.0569.101.7263.982.0968.80 Task45.2387.224.5385.004.8785.135.2086.674.5585.314.8885.87 Task52.8547.502.9849.722.6844.723.1251.942.8848.062.9048.39 Task61.3021.671.0216.941.2020.001.0016.671.1519.171.1318.89

Task71.4543.071.8246.981.0734.591.3841.500.9532.571.3339.74 Task84.7579.174.7278.614.7378.894.7278.614.8280.284.7579.11 Total23.6357.9023.3856.7121.8054.7121.9755.8520.1853.5622.1955.742.9

Table5:No.ofproblemsfoundforeachtaskbyeachparticipant

Note: The total number of problems that should be found for each task is in the 2nd column from the left

Table 6 shows the total number of problems found for each attempt by each participant. The percentage increase in accuracy after using the solution to complete the tasks was also calculated.Basedonthetable below,itcanbeseenthatafterusingtheautomatedsolution,all participants were able to increase the level of accuracy in the work done. The percentage increase in accuracy ranges from 26.4% to 54.26%. The average percentage increase in accuracy achieved is 40.6%. This shows that with the automated solution, a higher level of accuracywasabletobeachieved.

Table6:TotalNumberofproblemsfoundbyeachparticipantineachattempt

Inthissection,participantsareexpectedtocompletethe3maintasksgivenintheinstruction’s manual twice, where the first attempt to be done without the solution and the second attempt with the solution. In both attempts, participants' completed BIM model would be used for judgingthenumberoftasksdonecorrectly.

Table 7 shows the time taken for each participant to complete the 3 tasks given on both attempts, with andwithout the solutionfor transforming anas-built BIMmodeltoa BIM FM model. The time taken were recorded in seconds, and the total time taken for each attempt of allthe3taskswerecomputed.Forthissecondtest,participantsweregiven5minutesforeach task.Itisevidentthatallparticipantswereabletocompletethetasksfasterusingthedeveloped solution.

Without Solution With Solution Without Solution

Task15.703.106.003.256.002.976.003.025.773.13 Task25.623.286.003.155.682.975.383.025.023.03

Task32.571.082.871.102.671.052.771.032.680.98 Total13.887.4714.877.5014.356.9814.157.0713.477.15

ThedifferenceintimetakenfortheparticipantstocompletethetaskofmakingtheBIMmodel readyfor FM withand without the solution is shown in Table8. The percentage time savings were also calculated based on the time difference. The mean time difference and percentage savings were also calculated to determine the average time saved by using the automated solution. Lastly, the 5 participants' percentage savings variance was also calculated to determinehowspreadapartthe resultsare.

The 5 participants were able to save a range of 6.32 minutes to 7.47 minutes out of the given 15 minutes foreach attempt given using theautomated solution. It was also observed that the percentagetimesavingsforeachparticipantrangedfrom46.2%to51.3%.Basedonthemean, an average of 6.91 minutes and 48.81% of time savings were obtained using the automated solution. Thisshowsthatthesolutioneffectivelyhelpedthe participants reducetheamountof time needed to transform the as-built BIM Model to a BIM FM model. Additionally, the varianceofthepercentagetimesavingswas4.7%.Thevariancereportedisacceptableforwelldefinedconstructionjobs(±3–5)andresearchanddevelopmentjobs(±10–15)(Lewis,2006).

Table8:Timedifferenceandpercentagesavingswhenusingautomatedsolution

Table 9 shows the number of completed sub-tasks for each of the 3 different tasks by each

participant, with and without using the solution. The total number of subtasks for each task is shownonthe2ndcolumnfromtheleft.Thecellshighlightedingreenshowthattheparticipants wereabletocompleteallthenecessarysubtasksasexpectedfromeachtaskwithintheallocated time given. The red cells are those whereby participants cannot complete the subtasks for the specifictaskwithinthetimeframeorareunabletocompleteitcorrectly.Thepresentedresults show the level of accuracy forthe work done by each participant in both attempts. The use of the automated solution to complete tasks led the participants to complete all the necessary subtaskscompletelyandcorrectly.Whereas,whenparticipantscompletedthetaskswithoutthe solution, all tasks were not completed accurately. Moreover, the time taken was also longer thanusingthesolution.

Table9:No.ofsubtaskscompletedcorrectlyforeachtaskbyeachparticipant

Table 10showsthe totalnumber ofsubtaskscompleted foreach participant'sattempt,and the percentage increase in accuracy after using the solution to complete the tasks was also calculated. Itcan be seen that after using the automated solution, all participants were able to increase the level of accuracy in the work done. The percentage increase in accuracy ranges from 11.5% to 34.6%. The average percentage increase in accuracy achieved is 21.5%. This showsthatwiththeautomatedsolution,a higherlevelofaccuracycanbeachieved.

Participantswereaskediftheyperceivethesolutiontoimprovetheirworkprocess,i.e.,ithelps themcompletetheirtasksmoresimplyandeasilythantheusualtediousmethods.Basedonthe participants'responses,asshowninFigure38,4outof5participantsrated4onthescaleof5 while1participantrated5.Ascaleof1meanstheleastimprovementsand5meansthemost improvements.Thisshowsthatparticipantsfeltthatthesolutionwasabletohelpsimplifythe workprocessesneededtocompletetheirtasks.

(Note:1means“leastimprovements”and5means“mostimprovements”)

Participantswereaskediftheyfindtheautomatedsolutionuserfriendly.Basedontheresults obtained,asshowninFigure39,alltheparticipantsratedthesolution4outof5,with1being theleastuser-friendlyand5beingthemostuser-friendly.Thisshowsthattheparticipantsfound thesolutiontobeuser-friendlyenoughbutalsodoeshaveroomforimprovements.

(Note:1means“leastuser-friendly”and5means“mostuser-friendly”)

Participantswereaskediftheyperceivethesolutiontoimprovetheirsatisfactionwiththework process.Basedontheresultsobtained,asshowninFigure40,alltheparticipantsrated4out ofascaleof5,with1beingtheleastsatisfiedand5beingthemostsatisfied.Theresultsshow thattheusersaremostlysatisfied,butthereisroomforimprovement.

Figure40:UserSatisfaction

(Note:1means“leastsatisfied”and5means“mostsatisfied”)

Thetestsconductedprovidedinsightintotheeffectivenessofthedevelopedsolutions.The developedsolutionreducesinvestedtimeandimprovestheusefulnessintermsofimproved accuracyindoingthegiventasks.Additionally,thepost-implementationsurveyconducted providessuggestionsonpossibleusers'perceptionofthedevelopedsolutiontoimprovethe workprocess,user-friendliness,andsatisfactionlevel,albeitthereisroomforimprovement.

Theabilityofthesolutiontoincreaseefficiencyandeffectivenesswouldmeanthatvalueorientedproductivitylevelscanincrease.Value-orientedproductivityoccurswhenthereisan increaseinthenumberandusefulnessofgoodsandservicesdeliveredfrominvestedresources.

Valueoccursifusefulnessisdelivered.Increasingoutputwithlittleornousefulnessfrom investedresourcesmeansproductivityisdeliveredwithnovalue.Thisstudysuggeststhe developedsolutionensureslittleinvestedresourcesintermsoftimewhileincreasingthe numberofaccurateworkdone,i.e.,increasedoutputandusefulness.

Ifthesolutioncouldonlyreducethetimeneededtocompletethesameamountofworkbutnot itsaccuracy,theworkoutputwouldnotbeuseful.Thismaybedetrimentaltothenextpartof

theworkprocesswhentheBIMmodel'swronginformationisusedformaintenancepurposes. Additionally, the work process must be simple and user friendly enough for the users. The discomfort and inconvenience brought by a solution would also compromise the delivered usefulness. A complicated work process and difficult to use interface or complex navigation willconfusetheuser,causingunnecessarywastageoftimeandpossibleerrors.Thedeveloped solutionreportedinthispaperdoesnothavethese poorcharacteristics.

Each participant was given only 6 minutes to complete a set number of problems to find or sub-tasks. Participants were generally unable to complete their tasks without the use of the developed solution but were able to complete their tasks with the solution. Participants were abletocompletetheirtasksaccuratelyandatamuchshortertimewhentheyusedthedeveloped solution for the given tasks. If the participants were to sit continuously to find the problems withoutusingthesolutionandwithouttimeconstraintsasdoneinthistest,thepercentagetime savings when compared with the use of the solution scenario would be much higher because they would need more time to complete the work accurately. Almost 2 hours were given to each participant to complete the given tasks in the investigation reported in this paper. Participantscannotbeexpectedtoconcentratecontinuouslyformultiplehourstodothetasks. The tasks are tedious, and participants' concentration level would significantly decrease if givenamuchlongertimethan2hours,ultimatelyreducingtheresults'accuracy.

The developed dynamo script (solution) can run through all the selected elements in the complex BIMmodeltotestforthe problemsin ashorterperiod. Thisisagood representation of the developed solution's ability and the benefits it can give the users to meet the project's objectives, which is to be able to prepare the BIM models for FM use efficiently, effectively whilebeinguserfriendly.Thebenefitsprovidedbythedevelopedsolutioncanultimatelyhelp streamlinetheworkprocessneededtopreparetheas-builtBIMmodelsforFM purposes.

It is important to note thatthedevelopedautomated solution reportedin this paper should not beseenasaready-madesolutionforanyproblemsrelatedtothelowadoptionofBIMmodels for facility management operation. The same applies to any root cause related to incomplete, inaccurate, or irrelevant information often in submittedBIM models by contractorstofacility managersorbuildingownersandtransformationofas-builtBIMmodelstoFMreadymodels.

The authors made this word of caution because many industry professionals focus more on

providinga solutiontoaproblemmorethansolvingaproblem.Asolutionshouldbeprovided to the root cause of a problem, not the problem. Two problems may be similar, but the root cause or context of the root cause may differ. Industry professionals should let the root cause and its context drive how a solution is developed and applied. Some ideas or lessons on how to develop a solution to the root cause of a similar problem could be gained from previous worksorexperiences.Still,theyshouldnotbeseenortakenasaready-madesolutiontosolve anycurrentproblem.

The reported project aims to develop a solution for facility managers and building owners to effectivelyandefficientlycheckcompleteas-builtBIMmodelsandtransformthemintoanFM operationallyreadymodel.Thefirstobjectivewastodevelopanautomatedsolutionthatcould helpfulfilltheproject'saim.Thesecondobjectivewastoexaminetheefficiency(time-saving), effectiveness, and user-friendliness of the developed automated solution in identifying incomplete,inaccurate,orirrelevantinformationinBIMmodelsandmakingthemodelsready forFMoperations.

Therewasaconsiderablereductioninthetimetakentocompletethecheckingofas-builtBIM models for completeness, relevance, and accuracy with the developed automated solution's adoption. The study participants completelyand accurately identifiedall the errors relatingto informationcompleteness, relevance,andaccuracy, plantedin theBIMmodels. However, the participantseithercompletelyutilisealltheallocatedtimeorspendmoretimethanthesolution adoptionscenarioinidentifyingtheerrorswithoutcompletingseveraloftheirtasksaccurately.

There was a considerable reduction in the time taken to transform the as-built BIM model to BIMFMmodelstoadoptthedevelopedautomatedsolution.Thestudyparticipantscompletely and accurately identifyall the BIM models' errorsthatcould hinder the transformation within the restricted period. However, the participants either completely utilise all the allocated time or spend more time than the solution adoption scenario in creating FM ready BIM models withoutcompletingseveralof theirtasksaccurately.

Theparticipantsinvolvedintestingthedevelopedautomatedsolutionsperceivedittoimprove the work process, user friendly and satisfying to use. Despite the reported potentials of the

developedautomatedprogrammingsolution,itshouldnotbeseenasaready-madesolutionto a similar problem and root cause. Two problems may be similar but the root cause or context of the root cause may be different. Nevertheless, lessons and ideas can be gained from the projectexperiencereportedinthispaper.

The Singapore Institute of Technology funds this project through a SEED grant (R-MOEA403-G008). Ms. Camille Chua did the project work and writing of this paper as part of her Master of Engineering Technology in Sustainable Infrastructure Engineering (Building Services) degree. Dr. Moshood Olawale Fadeyi guided the development of the developed automatedsolution andexperimentaldesignand execution. Dr. Fadeyi also contributedto the developmentofthisarticle.

ChuaCandFadeyiMO(2020).Theuse ofdynamotoautomate theprocessneededtoprepare building information modelling (BIM) models for facility management and operations. Built EnvironmentAppliedResearchSharing #01.

Edirisinghe,R.,London,K.A.,Kalutara,P.,&Aranda-Mena,G.(2017).Buildinginformation modelling for facility management: are we there yet? Engineering, Construction and ArchitecturalManagement,24(6),1119-1154.

Korpela,J.,Miettinen,R., Salmikivi,T.,&Ihalainen, J.(2015).Thechallengesandpotentials of utilizing building information modellingin facilitymanagement:the case ofthe Center for Properties and Facilities of the University of Helsinki. Construction Management and Economics,33(1),3-17.

Lewis. J. P. (2006). Fundamentals of Project Management: Fundamentals of Project Management(Worksmart Series).NewYork:Amacom

SupplementaryInformationA

Supplementary Information A-i to A-iv

https://www.dropbox.com/s/45s29bdeyporcrp/Supplementary%20Information%20Ai%20to% 20Aiv.pdf?dl=0

SupplementaryInformationB

Downloadtheslidesinthelinkbelowtoviewthevideosofthedevelopeddynamo scripts.

Dynamo scripts

https://www.dropbox.com/scl/fi/fcz754yg3xq8yyvjyaa8w/Supplementary-Information-BDynamo-Scripts.pptx?dl=0&rlkey=fpfst888j43wlvsu1i0gy73fh