Kng JHJ and Fadeyi MO (2021). Mobile cloud computing application solution for waste reduction in the facility management process. Built Environment Applied Research Sharing #08. ISSUU Digital Publishing.

© BEARS reserves the right to this applied research article

BEARS #08 1

Mobile cloud computing application solution for waste reduction in the facility management process

Jun Hui Jason Kng and Moshood Olawale Fadeyi,*

Sustainable Infrastructure Engineering (Building Services) Programme, Singapore Institute of Technology, 10, Dover Drive, Singapore 138683, Singapore

*Corresponding author’s email: fadeyi.moshood@singaporetech.edu.sg

ABSTRACT

The integration of facility management and mobile cloud computing is an innovative and vital undertaking to improve facility maintenance and management. Even though recent studies have proposed various methods of implementing mobile cloud computing, there remains an issue of simplifyingdata structures and maximising productivity. This paper presents a solutionto mobilise corrective maintenance processes. Based on a comprehensive literature review on productivity, lean maintenance, and mobile computing technology, a mobile cloud computing application is proposed to improve information quality and availability. This study proposes a mobile cloud computing system for facilities management staff performing building operations and maintenance using QR codes and cloud computing technologies. The mobile cloud computing system was used in a field experiment at the Singapore Institute of Technology to verify the proposed solution and demonstrate its effectiveness in corrective maintenance practice. The results from the experiment demonstrated the solution's effectiveness in reducing waiting, motion, and over-processing waste, leading to improvement in facility management productivity. The advantage of the proposed solution lies in its ability to transform facility management work processes by maximising usefulness delivered from invested resources, i.e., enhance value delivery.

Keywords: Facility management, Mobile cloud computing, Waste reduction, Lean thinking, Productivity

BEARS #08 2

1.0 INTRODUCTION

The quality of infrastructure in Singapore is among the highest in the world, reflecting high levels of investment supported by years of political stability and general economic prosperity. To this end, the quality of buildings and facilities is constantly being transformed to meet global standards in sustainability and livability. According to Design Build Network (2019), in 2018, the total construction demand peaked at S$30.5 billion, with S$18.5 billion going to the total public sector construction (60% of total construction demand). To keep up with the rapid advancements in the local built environment industry, initiatives such as the Consortium Operation and Technology Roadmap (COTR) and Guide to Smart Facility Management (FM) were launched by Singapore International Facilities Management Association as part of efforts to promote the adoption and implementation of digitalization in the facility management industry (Building and Construction Authority, 2019).

This paradigmshifttowardsdigitalisationhasforcedmanyorganisationstomovefromwidespread traditional culture to modern techniques to forecast future patterns, marking the shift from corrective or planned strategies to preventive and predictive strategies (Konanahalli et al., 2018). This transformation is affecting the facility management sector and its operators that are trying to keep up with it, even if still in a convulsive way since there is clearly a lack of consolidated and shared references and tools (Atta and Talamo, 2020). The success of facility management required systematically storing, transferring, and accessing of data generated from maintenance planning, during and after facility inspections, maintenance, and assessments (Kim et al., 2013).

However, the availability of high-quality data to perform facility management processes is a challenge that the industry is facing. The unavailability of high-quality data can be attributed to many factors, including but not limited to inconsistent data, an excessive amount of data, or the irrelevance of data, leading to massive financial losses annually (Gallaher et al., 2004). Other than the financial losses, the lack of timely and relevant information also results in the generation of waste in terms of lean maintenance (Baluch et al., 2012).

Lean maintenance is a term derived from lean manufacturing, but due to the different nature of the maintenance and manufacturing processes, the principles in lean maintenance differ slightly. Severalstudieshavesuccessfullylistedwastefulactivitiesinmaintenanceprocessesandassociated

3 BEARS #08

them with lean maintenance waste, and most of these activities result from the lack of information (Baluch et al., 2012 and Mostafa et al., 2015).

Due to the substantial loss of information and the growth of technology, mobile cloud computing has become an important research topic in many industries. Mobile cloud computing is a new platform for combing mobile devices to cloud computing systems to create new infrastructure that allows for information technology development. The main objective of mobile cloud computing is providing flexibility and mobility for information (Shamim et al., 2015). Additionally, Appiahene et al. (2018) cited many several sources in claiming that information and communication technology does lead to an improvement in productivity. Productivity, which is generally explained as the output to input ratio, is an important indicator of the efficiency in which organizational resources are being used to achieve certain outcomes (Appiahene et al., 2018).

Syverson (2011) explained that there is no single way to measure productivity, and input can be any observable factor inputs. Since facility management focuses more on time spent on performing tasks than revenue and capital, observable factor inputs for measurement of productivity in facility management can be the waste generated from facility management processes. This study aims to introduce mobile cloud computing into corrective maintenance procedures to reduce unnecessary waste in facility management processes. Addressing this problem will have practical benefits in terms of improving facility management productivity and contributing to the reduction of waste in corrective maintenance processes.

The problem statement for this study is that there is a decrease in productivity in the facility management industry due to the generation of unnecessary waste, primarily in the form of waiting, motion, and over-processing. The root cause of the decrease in productivity stems from (a) having only physical workstations to perform error reporting, resulting unnecessary movement by technicians and facility managers when submitting and retrieving work order information; (b) unnecessary waiting for work order approvals; (c) excessive data entry to transfer information collected during site inspection; and (d) spending more effort to retrieve information because of low quality data.

To achieve this research aim, the research question used to guide this study is, can cloud storage technology improve facility management productivity through the reduction of waiting, motion,

BEARS #08 4

and over-processing wastes. Additionally, some research objectives have been put in place to address this research question, including (a) to examine the impacts of waste in facility management processes on productivity level, and (b) to examine the impacts of using mobile cloud computing to improve productivity in the facilities management processes. This study hypothesises that the proper implementation of mobile cloud computing will increase productivity through reduction of waste in terms of waiting, motion, and over-processing.

2.0 LITERATURE REVIEW

2.1 Productivity

Over the last decades, a massive infusion of detailed production activity data has allowed researchers in many fields to learn about how organisations turn inputs into outputs. Productivity, in essence, is the efficiency with which the conversion occurs (Syverson, 2011). Improving employee productivity has been one of the most important objectives for many organisations, primarily because of the advantage associated with improved productivity, such as favourable economic growth, large profitability, and better social progress (Sharma and Sharma, 2014). Additionally, higher productivity tends to maximise competitive advantage by reducing costs and improving output quality (Bailey et al., 2005). The topic of productivity is worthy of attention simply because it determines the organisational survival and long-term success.

In concept, productivity is efficiency in production: how much output is obtained from a given for a set of inputs. In mathematical terms, the output is divided by a given level of input. Employee productivity can be evaluated in one of two ways, including (a) in terms of output of an employee over a specific period of time, or (b) assessed according to the amount of units of product or services that an employee can handle in a defined time frame (Hanaysha, 2016). The word of caution here is that output should be considered the goods and services’ performance level that is of usefulness to a consumer. The usefulness is the quantity and quality of goods and services’ performance level that is safe and serve the intended function. Whereas input is invested resources may include money, time, manpower, energy or effort, digital solutions, materials, equipment, etc.

Although productivity might seem like a straightforward concept, simply comparing the inputs with outputs, productivity measurement itself is not exactly science; the tools are blunt, and the conclusions are not definitive. These issues stem from the measurement and variables of the inputs

BEARS #08 5

and output. In terms of output, many processes generate more than one output, so the general question would be which output should be used to determine productivity or whether the output should be aggregated to a single output measure.

As mentioned earlier, employee hours, number of employees, or any observable factors can be considered as input (Syverson, 2011). For example, Sharma and Sharma (2014) explained that employee productivity is based on the amount of time that the employee is physically present at the job, besides the extent to which he/she is “mentally present” or efficiently working during the presence at the job, and Ferreira and Plessis (2009) defined productivity as “the time spent by an employee actively executing the job he or she was hired to do, to produce the desired outcomes expected from the employees’ job description”. Due to the complexity of this problem, organisations have resorted to using capital and revenue as the standard approach to measure input and output.

The discussion above has clearly illustrated the concept of productivity and how inaction will lead to stagnation, based solely on the fact that productivity is the output-input ratio. To improve productivity level, the focus of any organisation should be on minimising input and maximising output, which can be achieved in several ways. These include managerial practices, higher quality general labor and capital inputs, learning by doing, product innovation, and information technology (Syverson, 2011). Although the methods to improve productivity levels are defined as separate entities, they are intrinsically interconnected. For context, managers are conductors for the input orchestra. They coordinate the labour, capital, and intermediate factors. The employees they hire are based on the quality of their practices.

The higher the quality of the manager, the better the workforce. A better workforce motivates and inspires employees to be more creative, leading to product innovation (Hanaysha, 2016). The capital controlled by the manager is used to invest in information technology services or processes that can help accelerate the work of employees through enhanced communication and production of higher-value work. Notably, information technology, coupled with a motivated workforce, increases productivity by significantly reducing effort and improving work quality and quantity. This process of developing a highly-skilled workforce and reducing effort is closely linked to the concept of lean manufacturing, with the ultimate goal being a high-quality organisation that can produce finished products concerning the customers' demand with no waste (Dawood et al., 2018).

BEARS #08 6

This concept of lean manufacturing will be explained in the following section.

2.2 Lean Manufacturing and Maintenance

The word lean in lean manufacturing is effectively a time-centric approach for improving processes that focuses on improving overall effectiveness by removing non-value-added operations and waste in the industry (Siregar et al., 2020). Lean is doing more with less, such as using the least amount of effort, energy, equipment, time, facility space, materials, and capital –while giving customers exactly what they want (Womack and Jones, 1996). Waste in lean manufacturing is defined as activities that add cost to a product or service without adding value from a customer’s perspective.

Waste, as defined by Womack and Jones (1996), consists of transportation, inventory, motion, waiting, over-processing, over-production, defects, and under utilisation of people. Hopp and Spearman (2004) suggested that waste can be classified into non-obvious waste, less obvious waste, and obvious waste. They stated that obvious waste is not needed, including excessive setup times, unreliable machines, reworks, and less obvious waste may vary in nature. Examples of less obvious waste are process times, delivery times, process rates, and demand rates.

In recent decades, lean thinking is gaining traction through various sectors. It was originally started as a Toyota production system which describes the manufacturing philosophy of Toyota Motor Corporation. It has successfully extended to many different service industries, such as maintenance service, retail banking, airlines, restaurants, education, food, and hospital (Mostafa et al., 2015). Womack and Jones (2003) hypothesised that lean concepts can be applied to different service industries. They coined the term lean thinking, referring it to “the thinking process of lean inside an organisation and its extended supply chain”. Within the same organisation, lean thinking should be extended from the operations or productions to areas such as the maintenance department. The key behind lean thinking is understanding that all departments are inseparable, and they complement each other to sustain the competitive advantage of the organisation. This concept has to be thoroughly understood before it can be implemented successfully in any department.

Maintenance includes all activities required to keep an asset at maximum operating conditions. These activities are carried out according to certain maintenance strategies (Mostafa et al., 2015). Maintenance strategies should be developed based on the specific system specifications. However,

BEARS #08 7

it should be noted that no perfect strategy exists, and the strategies should be selected based on their advantages and disadvantages (Shahin et al., 2012). Traditionally, maintenance has been more concentrated on corrective maintenance, such as repairs and replacements, with little to no consideration for downtime. However, as more studies have come out to show that 80 – 85% of the total building life cycle costs are generated during the operations and maintenances phase (Munteanu and Mehedintu, 2016), maintenance strategies have shifted to become full scale functions that require flexibility to cope with dynamic business environments. This paradigm shift means that organisations will need to select a strategy or a combination of strategies in order to keep up the building operations.

Based on the classification done by Shahin et al. (2012), the maintenance can be classified according to the time of maintenance activities. Maintenance strategies that are performed after the failure occurrence are the corrective maintenance strategies, and maintenance that is conducted before the failure occurs is the preventive maintenance strategies. The terms above are not definitive, and words such as preventive, predictive, planned, and corrective are all used interchangeably in different literature. This paper will go further in exploring the broad categories of corrective and predictive maintenance.

Corrective maintenance is known as emergency maintenance, failure-based maintenance, firefighting maintenance, or breakdown maintenance (Shahin et al., 2012). The concept of corrective maintenance is to fix it when it is broken. This maintenance process is very primitive, and it has been employed in maintenance operations due to knowledge shortage on the equipment failure behaviour (Mostafa et al., 2015). Corrective maintenance can be carried out immediately by onsite workers or by appropriate maintenance technicians who are contacted to assess and fix the situation. Although this maintenance strategy can be applied to low-value assets, the drive for higher profitability earnings has forced maintenance managers to use more effective and reliable maintenance strategies.

Preventive maintenance is known as time-based maintenance or condition-based maintenance, which is performed before machine failure to keep equipment in a specified condition by providing organised checkup, recognition, and prevention of potential failure (Fouladgar et al., 2012). For time-based maintenance, machinery and equipment are maintained after a fixed operating time specified by the manufacturer, which might not give consideration to the system operating time

BEARS #08 8

and condition. For condition-based maintenance, the maintenance is done based on maintenance records, diagnosis, and performance monitoring either manually or through computing technology, resulting in a higher initial cost (Mostafa et al., 2015).

Although it has been stated that lean thinking processes can be applied to any department, lean manufacturing approaches cannot simply be translated to accommodate to lean maintenance because the business dynamic of asset maintenance and those of production are fundamentally different (Baluch et al., 2012). The authors stated three issues preventing the direct application of lean manufacturing techniques, including the driving forces behind production plans and facility maintenance, the time difference between production efficiency and facility management efficiency, and the difference in data management and collection plan with regards to facility management and production processes. Table 1 below draws up the wasteful activities in maintenance where lean maintenance needs to focus on (Baluch et al., 2012).

Table 1. Maintenance waste with lean maintenance

Lean Maintenance Waste Wasteful Activities

Unproductive Work Effectively doing work that does not need to be done

Delay in motion Wasting time, waiting for parts, machinery, people

Unnecessary motion

Unneeded travel, trips to tool stores or workshops, looking for items

Poor management of inventory Not able to have the right parts at the right time. A complex area that can cause many of the other areas of waste

Rework

Having to repeat tasks, or do additional tasks, as a result of poor workmanship

Under utilisation of people Using people to the limits of their qualification, not to the limits of their abilities

Ineffective data management

Collecting data that is of no use, or failure to collect data which is vital

Misapplication of machinery Incorrect operation or deliberate operational strategies leading to unnecessary maintenance work

The table above has clearly classified the lean maintenance waste and their appropriate wasteful activity, and it also highlighted wastes, such as waiting and motion, that are repeated across several activities. From another perspective, this table demonstrates the broad areas that facility

BEARS #08 9

management is required to manage, and the vast amounts of information required to perform any work efficiently. Wasteful activities in the table can easily be prevented if high-quality information is readily available and easily accessible to facility management staff. According to Watson et al. (2009), high-quality data and information are governed by six dimensions: accuracy, validity, granularity, interoperability, relational, and reducibility. The six data quality dimensions and their corresponding explanations are stated in Table 2 below.

Table 2. Data Quality Dimensions Data Quality Dimensions Explanation

Accuracy

Validity

Granularity

Interoperability

Relational

Reducibility

The degree to which data reflect reality.

The degree to which data measure an intended construct.

The number of individuals, items, or period of time over which data is aggregated.

The degree to which data are integrated across data systems.

The degree to which an information system’s underlying model of a data system is capable of capturing reality.

The degree to which data support the formation of categories of entities.

More often than not, the data quality either stored or generated during the building life cycle meets the standards defined by the six dimensions of data quality. Tereno et al. (2019) cited two studies highlighting data inadequacies resulting in poor facility management performance. The first study, conducted by Jylhä and Suvanto (2015), found similar issues with data quality which were traced to their resulting impacts on facility management performances across four different facility management service organizations. The main waste associated with their study was waiting due to time spent searching for information to perform works.

The lack or poor-quality information stemmed from (a) inconsistent naming, formatting, and data storage; (b) insufficient or overwhelming volumes of data; (c) unreliable data needing validation due to errors or obsolescence; (d) incomplete or obscured information; (e) unavailable information; and (f) irrelevant information. Additionally, the result from Gallaher et al., (2004) study mentioned that an inordinate amount of time is spent looking and verifying specific facility and project

BEARS #08 10

information from previous activity due to inadequate data interoperability.

The second study conducted by Liu and Issa (2012) found that data requirements for efficient facility management operations were insufficient when an issue arises. Their survey respondents identified and classified the types of information needed for the repair of equipment within a work order. They also found other information that was difficult to find in the planning and execution of their work. This information includes (a) equipment operating parameters and spare parts; (b) Mechanical, Electrical, and Plumbing (MEP) information; (c) specifications and warranty; (d) electrical panel information; (d) operations and maintenance manuals; (e) Heating, Ventilation and Airconditioning (HVAC) details; (f) work order history; and (g) up to date as-built plans. Volk et al. (2014) associated missing or obsolete building information with ineffective project management and cost increases in maintenance, retrofit, or remediation processes.

Data accuracy and relevance are the most important factors of information quality in facility management practices. The lack of integrated and readily available information vital for facility operations is indicative of the information integration challenges faced by the industry. The storage of information in different formats and locations and the interoperability of programs and databases amplifies the problem (Saratu et al., 2017). In a study of interoperability challenges, Gallaher et al. (2004) estimated that the total financial loss due to process waste annually was $15.8 billion. About $9 billion was associated with interoperability costs incurred during the building operations phase.

Out of this $9 billion, $6.9 billion was due to the inadequate interoperability for operations and maintenance staff alone. From this $6.9 billion, $4.8 billion was on labour charges for information verification and validation, $1.5 billion was attributed to information delays leading to idled employees waiting for information in order to resolve an FM issue, and operations and maintenance engineers used time valued at $613 million in transferring information into a format that staff members can read and use to perform their activities. The absence of timely and relevant information leads to wasteful activities being performed in facility management processes.

2.3 Mobile Cloud Computing

Cloud computing is gaining popularity as the architecture can be applied to different applications and environments. To satisfy the required demands with low cost, cloud computing delivers

BEARS #08 11

computing as a service and shared resources, software, and information as utility via the internet. Cloud services are delivered through three categories, including (a) Software as a Service; (b) Platform as a Service; and (c) Infrastructure as a Service. Software as a Service aims to provide end-users access to applications, such as Facebook. Platform as a Service offers services for the customers who can develop, test, and run applications through the internet, such as Microsoft Azure, and Infrastructure as a Service provides users with resources such as server, storage, and computation facilities (Al-Janabi et. al., 2017).

Mobile computing technology is a technology that leverages centralised elastic resources from validated network technologies and clouds to provide unlimited mobility, functionality, and storage while serving a large number of mobile devices everywhere and anywhere on the Internet (AlJanabi et. al., 2017). Mobile cloud computing has been defined as a new paradigm for mobile applications where data processing and storage are transferred from mobile devices to controlled and centralised computing systems located in clouds over the internet. These centralised applications are accessed through wireless connection based on a thin native client or web browser on mobile devices (Shamim et al., 2015).

Mobile cloud computing is a talented solution for mobile processing because of several factors, including mobility, portability, and communication. Cloud computing technology has been recognised to enhance the capabilities of mobile technologies. One advantage that has been mentioned across different studies is the ability to enhance data storage ability and data processing (Shamim et al. 2015, Al-Janabi et. al. 2017 and Shaikha et al., 2019). Mobile cloud computing allows mobile users to store and receive large amounts of information through wireless technology previously limited by mobile storage space. The information stored in the clouds is backed up by multiple computers and is always available on demand whenever someone chooses to access it. This increases the reliability of data by eliminating the possibility of losing information on mobile devices, and it increases the availability and accessibility of information.

Today, mobile cloud computing has a wide range of applications in various fields, such as cloud mobile media, cloud storage, learning and education, mobile social networks, mobile gaming, and cloud-assisted Internet of Things, to meet mobile user demands and mobile device capabilities (Shamim et al., 2015). The main objective behind mobile cloud computing includes (a) the delivery of different services, (b) software and processing capacity over the internet; (c) increasing storage;

BEARS #08 12

(d) reducing costs; (e) automating systems and decoupling of services delivery from the underlying technology, and most importantly (f) providing flexibility and mobility of information in different purposes. Mobile cloud computing has also been applied in studies addressing building maintenance management, with most reporting improvements in facility management processes.

Kim et al. (2013) developed a system to support facility management processes such as planning, inspection, assessment, repair, and three-dimensional (3D) visualisation. They concluded that there is a strong potential for mobile cloud computing to improve traditional facility management processes. Lin et al. (2014) developed a system for easy uploading of data into a building information model with a mobile application. They concluded that mobile cloud computing improves the speed at which information can be transferred and how fewer errors were made. Both studies draw similarities in terms of the mobile cloud computing architecture and how this system can be implemented to prevent information loss and streamline information distribution.

The measurement of productivity of any organisation is a rather subjective topic, as the typical expression for productivity is the output to input ratio, and no standardized formula has been developed to quantify productivity. Syverson (2011) mentioned several input factors that can be possible input parameters, including any observable factors. The measure of productivity for facilities management differs greatly from other service industries, as illustrating the output in terms of revenue is impractical. However, the concept of waste in lean manufacturing is a practical way for facility management organisations to identify observable waste or obvious waste, as different facility management activities may be associated with one or more of the eight wastes defined by lean manufacturing. Upon evaluation, wasteful activities performed during maintenance processes occur due to the lack of timely and relevant information, so the provision of the instantaneous and necessary information is key to reducing waste.

Mobile cloud computing has played a big role in improving mobility, portability, and communication by enhancing data storage and data processing. A large amount of data can be stored in the cloud and distributed instantaneously across different platforms, minimising information loss and reducing waste. The provision of timely and relevant information will reduce waste, and observable waste, when used as a variable in the output-input ratio, will result in improved productivity. Motivated by the capabilities of mobile computing technologies and the success of previous studies, this study aims to propose a mobile cloud computing FM solution that aims to

BEARS #08 13

improve the productivity of maintenance works by reducing waste in terms of waiting, motion, and over-processing.

3.0 METHODOLOGY OVERVIEW

There is a need to collect qualitative and quantitative data to justify the results to understand and demonstrate that cloud storage technology can improve the productivity of facility management field workers. Primary data was used for the collection of quantitative data, and a combination of primary and secondary data was collected for qualitative data. For the qualitative data, a combination of literature reviews and interviews were used to collect relevant information. The literature reviews used to substantiate this study contained information regarding productivity, waste in lean maintenance, and cloud computing technology. The data collected from the literature review was used to establish the essential information required by facility managers to perform building operations effectively and the consequences of information loss on an organisation.

Interviews were conducted to collect primary data on facility management processes, primarily in the field of corrective maintenance works. The interview consisted of 10 open-ended questions, and the aim was to get responses from at least two organisations from different service industries. A valid interviewee for the survey was either someone who is currently working in facility management or one who has left facility management for not more than a year. Due to the pandemic, the interviews were conducted online, or answers were submitted via electronic mail. The interview aimed to establish facility management practices, organisational procedures in fault reporting, and challenges faced by facility management staff in retrieving and uploading information. The data collected was used to establish trends in practices and challenges across different facility management organisations.

The quantitative data was collected through field experiments conducted at the Singapore Institute of Technology, an institute of higher learning in Singapore. The criteria for choosing the location of this field experiment were accessibility during a pandemic. The field experiment was conducted to quantify the waste generated in corrective maintenance processes before and after implementing mobile cloud computing applications.

The field experiment was scenario-based corrective maintenance work, and the data that were

BEARS #08 14

collected include (a) number of trips to and from workstation; (b) estimated time spent waiting for the work approvals; and (c) the number of times facility management staff had to perform unnecessary data entries. These three parameters, addressed in the context of getting the job done with no error, were used to establish a baseline for the experiment. The improvements were made based on the results generated. The result from both field experiments will be presented in tabular form in excel, and the values will be compared in terms of percentage waste reduction.

The prototype developed for this study comprises a mobile application with a cloud database for information exchange. The cloud database was chosen mainly for the ability to instantaneously transfer and retrieve JavaScript Object Notation to any mobile device or personal computer. Instead of transferring data from a mobile application to a database and later to a building information model, this study demonstrated how information could be modified, transferred, received, and stored in an online cloud database that manages information in JavaScript Object Notation, similar to how Information Building Integrated System manages its information.

4.0 CASE STUDY

4.1 Details of the Organisation

This study focuses on improving corrective maintenance processes by introducing mobile cloud computing applications to reduce the amount of waste generated, thus improving the overall productivity of the facility management division. This case study is conducted on the facility management division of the Singapore Institute of Technology (SIT), an educational institution in Singapore. This case study consists of an interview and a field experiment, which will be explained in Section 8. The main campus of the university is located in Dover, along with five separate campuses located in the various polytechnics around Singapore.

4.2 Interview

As part of this study to develop a mobile cloud computing application, there is a need to understand the work procedures of the facility management division of the Singapore Institute of Technology. The scope of the interview includes (a) understanding the role of facility management in the institution; (b) getting a broad overview of the software the organization is using to handle work order requests; (c) understanding the standard operating procedures for submission to completion of work order; (d) the average time it takes to resolve a work order; and (e) challenges faced when

BEARS #08 15

performing facility management works.

This interview was administered to the facility manager of the institution and two other facility management practitioners from other service industries to understand the common challenges across the industry. The responses to these interviews were either received as written responses or through online interviews. The response from the interview and the facility manager from Singapore Institute of Technology will be discussed in detail, while the responses from the other practitioners will be used to substantiate the potential benefits inherent in our developed digital solution.

The facility management division in the Singapore Institute of Technology manages a wide range of services, including engineering, environmental, asset management, facilities operations, security, and fire and health. Each of the services is responsible for different aspects of the institution to ensure that the facility is operating smoothly. This interview focused on the facility operations department, responsible for building operations, building maintenance, moving and logistics, addition and alterations, and computer-aided facilities management. The use of computer-aided facilities management includes the use of maintenance management software. Figure 1 shows the facility management division of the Singapore Institute of Technology.

The facility operations team consists of in-house staff, outsourced technicians, and contracted engineers. The inhouse staff is management staff hired directly by the institution to manage the building's day-to-day operations, which includes engaging with internal and external stakeholders, planning for renovation works, scheduling preventive maintenance, etc. The outsourced and contracted staff are provided by the managing agent contracted by the facility management team to carry out miscellaneous works required for the facility's smooth operation. For the facilities operations department, some of the miscellaneous works carried out by the outsourced staff include change of use of space, managing computer-aided facility management software, and performing corrective and preventive maintenance works.

BEARS #08 16

Figure 1. Facility management division at the Singapore Institute of Technology

The outsourced technicians are those that are supplied by the managing agent and are stationed in the institution, and the contracted engineers are those that are only contacted when needed. Outsourced technicians working in the institution are responsible for submitting work orders and carrying out simple work orders, such as performing corrective maintenance on non-specialised equipment. Examples of non-specialised equipment include ceiling lights, faucets, or electrical fans. However, work orders regarding specialised equipment, such as air handling units or laboratory apparatus, will require contracted engineers specialising in the system. According to the facility manager, about 250 work orders are completed each month, so the institution engages many technicians and engineers.

To manage the work orders in the institution, the facility operations team uses a maintenance management system known as maintenance mate, developed by Honeywell. This system has a wide array of functions, including the submission of new work orders, showing locations of assets, and

BEARS #08 17

inventory management. For corrective maintenance works, requests are submitted through the work order page. Information such as description, work order type, asset group, asset name, and location are required to be entered by the technicians. The facility manager is in charge of setting the priority and approving the work. This maintenance mate system is only available at a workstation, and no mobile platform has been developed. Facility operations staff must be physically present at the workstation in order to report and access work orders. Figure 2 shows the user interface of the work order submission page on maintenance mate.

Figure 2. Maintenance mate user interface

After understanding the facility operations departmental structure and the basic functions of the work order entry in maintenance mate, the interview shifted to understanding the standard operating procedure for corrective maintenance work from when a critical facility is discovered to be faulty until its rectification is completed. Figure 3 shows the standard operating procedures for technicians and facility managers for fault reporting. Based on the standard operating procedures, several internal and external factors that resulted in the delay of work order completion were highlighted. Firstly, the inaccessibility of the maintenance management system. The maintenance management system is located on a workstation in the facility management office, and facility operations staff

BEARS #08 18

often found it a hassle to return to the office to submit work orders, especially when they have a busy schedule. This inaccessibility has resulted in many instances of late reporting, ranging from hours up to a day, resulting in a delayed response.

Figure 3. Standard operating procedure flow chart for fault reporting

The second concern is the inaccuracy in data entry. When technicians create a new work order, key information such as the critical facility, the fault, location, and description must be recorded in maintenance mate. Oftentimes, incorrect information is recorded on the work order form, which is a result of inexperience and unfamiliarity. These errors, such as wrong critical facility, incorrect location, and inaccurate description, results in additional works to fault relocation and correct the data in maintenance mate.

Thirdly, troubleshooting duration of specialised systems. When breakdowns and faults occur in specialised systems such as air handling units and laboratory apparatus, the facility manager must get the contracted engineer specialising in the system to troubleshoot the system. The troubleshooting duration may vary due to the contracted engineer’s availability, the complexity of the system, and the availability of replacement components. Therefore, the breakdown of specialised components will usually result in a longer waiting time.

BEARS #08 19

Fourthly, troubleshooting duration of non-specialised systems. One of the many roles of the outsourced technician in the institution is to troubleshoot faults occurring from non-specialised systems. However, the troubleshooting duration for each issue may vary due to the complexity of the issue, the competency and experience of the technicians, the accuracy of the information, the availability of necessary information, and the availability of replacement components. Most of the time spent troubleshooting was looking for accurately diagnosing the critical facility.

Lastly is the approval by the facility manager. After the submission of each work order, the facility manager has to approve the work order before the work can be carried out. The approval of work order depends on the schedule of the facility manager, as approval can only be done through the workstation, the accuracy of recorded information, and the availability of necessary information to help make critical decisions. This delay in the approval of work orders will result in delays for other processes.

Another interview conducted with a facility management practitioner who had experience working in a hospitality establishment shared similar issues. Based on the practitioner, the challenges faced by the hospitality establishment were similar to those of the institution, but more emphasis was placed on the lack of accurate and relevant information and the lack of availability of workstations. The practitioner stated that experience played a huge part in troubleshooting, especially when the fault description is inaccurate and the data available is irrelevant. Additionally, the lack of a workstation meant that technicians had to return to the office after working hours to record all their work. Often, this meant trying to recall what they have done throughout the day, exacerbating the issue of information inaccuracy.

The shortfalls of the work processes highlighted by both interviewees showed how waste is generated throughout the fault reporting and corrective maintenance processes. Simple tasks such as going to the workstation to access the maintenance management system are a bottleneck that happens at every other in the work process. The action of going to the workstation is a form of motion waste, and the time difference between processes such as entering the work order and waiting for approval is unnecessary waiting. Additionally, inaccuracy in data entry contributes to motion, waiting, and over-processing waste, as more effort has to be put in by the technicians to relocate the fault and re-enter the data into the system. Lastly, irrelevant information leads to overprocessing waste, as more works need to be done to locate the necessary information to carry out

BEARS #08 20

the work order.

This interview provides greater insights into how corrective maintenance processes across different organisations generate waiting, motion, and over-processing waste. Using this information, a mobile cloud computing application was conceptualised and developed to minimise and eliminate some of the unnecessary inputs in the corrective maintenance process, which effectively reduces the above-mentioned wastes and improves the productivity of facility management.

5.0 PROPOSED SOLUTION

The proposed solution is a mobile cloud computing platform that aims to increase accessibility to work order and improve data quality and accuracy. The proposed system consists of a twodimensional (2D) barcode system, android mobile devices, and a cloud storage system. The 2D barcode system, such as QR code, was adopted due to the simplicity in implementation and application. With the advancement of mobile technology, many mobile phones are equipped with a camera that is capable of scanning 2D barcodes. Basic barcode scanning features now come inbuilt in most mobile devices, and mobile users can quickly large amounts of information stored in barcodes. For example, the safe entry check-in system implemented by the Singapore government designed for COVID-19 infection tracing requires users to check into any building space using their mobile devices. Users can use the Singpass application to scan the QR code.

The application automatically decodes the information stored in the QR code and automatically populates the information in the application and checks the user into the location stored in the barcode. Another reason for adopting the QR code for this study was to align with the implementation plan and workflow for Integrated Building Information System. The Integrated Building Information System workflow includes a smart tracking system requiring all building components to be tagged with a QR code. The information stored in the QR code will be the unique identifier of the building element, and this unique identifier will be used to access different files in the cloud database.

The proposed mobile cloud computing solution with 2D barcode technology for facility management will help increase information accuracy and consistency, minimise information losses, and reduce lead time when access critical information. By scanning the QR code attached to the

BEARS #08 21

building element, facility management staff can obtain corresponding cloud documents such as building element information, maintenance history, and manufacturer information without the painstaking work of searching through multiple folders just to retrieve minor information. Each component of this proposed mobile computing solution, including the two-dimensional barcode, mobile device, and Cloud Firestore, is briefly described below. The detailed functionality will be explained along with the prototype.

5.1 Two-Dimensional Barcode

Most facility management staff have personal smartphones and tablets that can easily access 2D barcode information. The proposed method for retrieving the unique identifier of each building element is through the implementation of a 2D barcode scanner to decode QR codes as part of the Integrated Building Information System. Three advantages of using 2D barcodes include (a) the ability to create barcode labels with any personal computer; (b) no extra costs required to purchase hardware devices to scan the barcodes since most mobile devices have in- built functions; and (c) the speed at which mobile devices decode the information stored in QR codes.

5.2 Mobile Device

The mobile device used to simulate this application is the Samsung Galaxy S9, which runs on the Android operating system. A mobile application was developed as the front-end user interface for this study, and this is the main point of contact between the users and the database. The application allows users to upload and retrieve real-time information from the Google cloud database, Cloud Firestore. The program was developed in Android Studio, an Integrated Development Environment for android application development, using Java. The libraries required to connect the application to firebase are readily available, so the only additional library required is the Google Vision application programming interface (API), which was used to access the camera and decode QR codes.

5.3 Cloud Firestore

Cloud Firestore is a flexible, scalable, non-sequential (NoSQL) database used to store and sync data for the proposed mobile cloud solution. For non-sequential databases, data fields can be left empty without causing any errors, so new fields can be added or removed anytime without causing errors to the database. Cloud Firestore stores and sends data as JavaScript Object Notation (JSON) from its servers to the mobile application, and the JavaScript Object Notation data format can

BEARS #08 22

easily be translated to human-readable language. Cloud Firestore is a real-time database, so any information changes within the database will be disseminated to facility operations staff instantly. Additionally, the database provides offline support so that the mobile application can work regardless of network latency or internet connectivity. Moreover, the Cloud Firestore has a certain set of rules to manage the accessibility of different users.

Figure 4 shows the mobile application control logic and the connection with Cloud Firestore. The mobile application needs first to authenticate facility management staff to allow them to read and write information from the database. After logging in, the facility management staff can access an array of functions, including (a) submitting new work order; (b) retrieving work order information; (c) updating work order status; and (d) retrieving data for building element. Each of these functions sends a different command to specific files in Cloud Firestore. This process can be divided into different phases, including the input, communication, and output phase. The input phase includes submitting new work orders and updating work order status, and the communication phase is the real-time dissemination and retrieval of work order information. The output phase is the retrieval of building element data necessary to complete work orders.

Figure 4. Mobile application control logic

After establishing the hardware and software components required for the proposed mobile computing solution, the following section will explain in detail how the prototype is developed and the interactions between the mobile application and Cloud Firestore.

BEARS #08 23

6.0 PROTOTYPE DEVELOPMENT

6.1 Interactive Prototype

Before developing the mobile cloud computing application, an interactive prototype was created to visualize the user interface and verify all the necessary functions that must be incorporated into the widgets. The goal of designing this interactive prototype was to provide a modern design on the maintenance mate user interface while providing a seamless technology-human interaction. Moreover, the interactive prototype was used to illustrate the flow of the application, which will reduce development time significantly.

Since the interactive prototype was developed in Adobe XD, any reference to pages of the mobile application in this section will be referred to as artboard, according to the naming convention in Adobe XD. The first step of developing this interactive prototype was to create user stories to understand software features from the end user’s perspective. User stories must not be very detailed, as the aim is to describe the users, understand what they want and why they want it. Ambiguous and simple user stories provide flexibility in software development while avoiding feature creeps, which results in the development of features that the user finds unnecessary.

Figure 5 shows the user stories for facility managers and technicians. For facility managers, they want to access information quickly to update the status of the work order. The acceptance criteria for the facility manager include having a simple user interface to get to the search page, a simple design layout, quick information retrieval, and displaying only necessary information. For technicians, they want to be able to perform fault reporting quickly without returning to the office. The acceptance criteria for technicians include having a simple user interface to access the fault reporting page, quick accessing of work orders, a simple design layout, and simple data fields.

After establishing the user stories, the interactive prototype can be developed to meet the acceptance criteria. The flow of the mobile application is based on the mobile application control logic in Figure 4. The mobile application layout is consistent throughout the artboards to improve communication of information and ease of navigation. Additionally, the icons in the artboard are kept simple so that the design is more intuitive, making users understand and use the application effectively.

BEARS #08 24

Figure 5. User stories for facility manager and technicians

Users must first be authenticated and authorised, and the first three artboards were designed to handle these processes to access the application. Figure 6 shows the landing, login, and register artboards and the interactions between the pages. The landing artboard adopts a time-based transition to navigate to the login artboard. The login artboard contains the sign-up button, which redirects users to the register artboard. The register artboard has an email and password text field, which users must fill up to create an account. After clicking on the register button, users will be redirected back to the login artboard. Back at the login artboard, users can click the login button after entering their information, which brings them to the maintenance request artboard, which is the home page of this application.

Figure 6. Landing, loading, and register artboard

BEARS #08 25

The maintenance request artboard, or the home artboard, is shown in Figure 7. The maintenance request artboard contains a list of outstanding maintenance requests. The design goal of this artboard was to bring user’s attention to important information. The maintenance information artboard contains a list of card views that display key information from each maintenance request, including the unique identifier of the critical facility, the diagnosed fault, the description of the fault, and the date of request. The work order status is colour-coded because the approval process is one of the leading causes of waiting waste in the corrective maintenance process. Users should be subconsciously reminded of the approval status.

An action button is conveniently located at the bottom right corner of the artboard for users to submit new work orders. This button was placed on the first artboard because submitting work orders is one of the main functions of the application, and users should not be wasting time looking for the button. The work order artboard contains four simple fields, including unique ID, fault, description, and image field. Camera icons located in the text and image fields indicate where the information will be populated when the button is clicked, which is more intuitive than placing ungrouped buttons. After users have clicked on the save button, they will be redirected back to the maintenance request page, where a card view will be populated with the new work order.

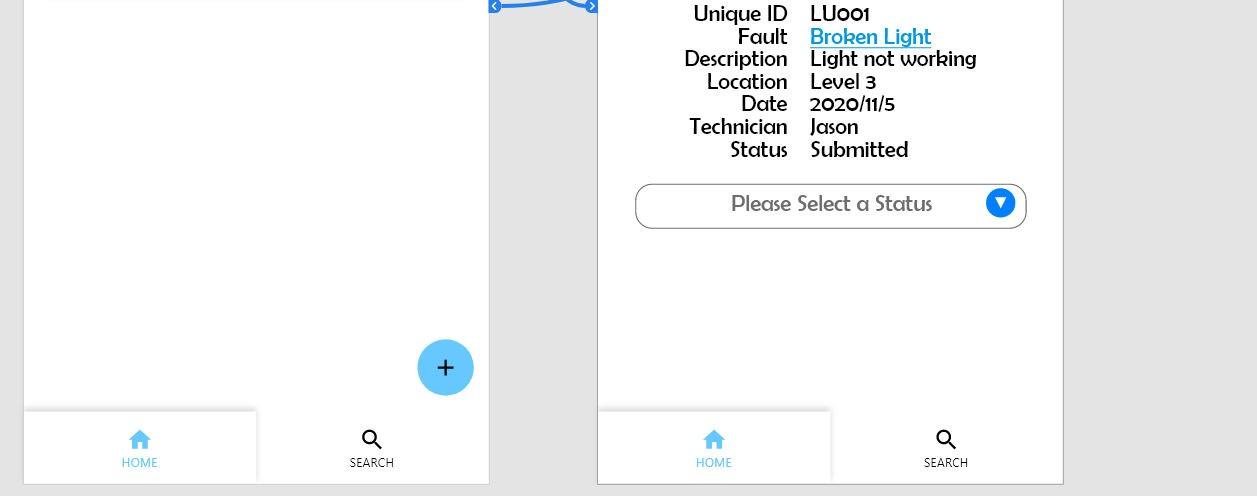

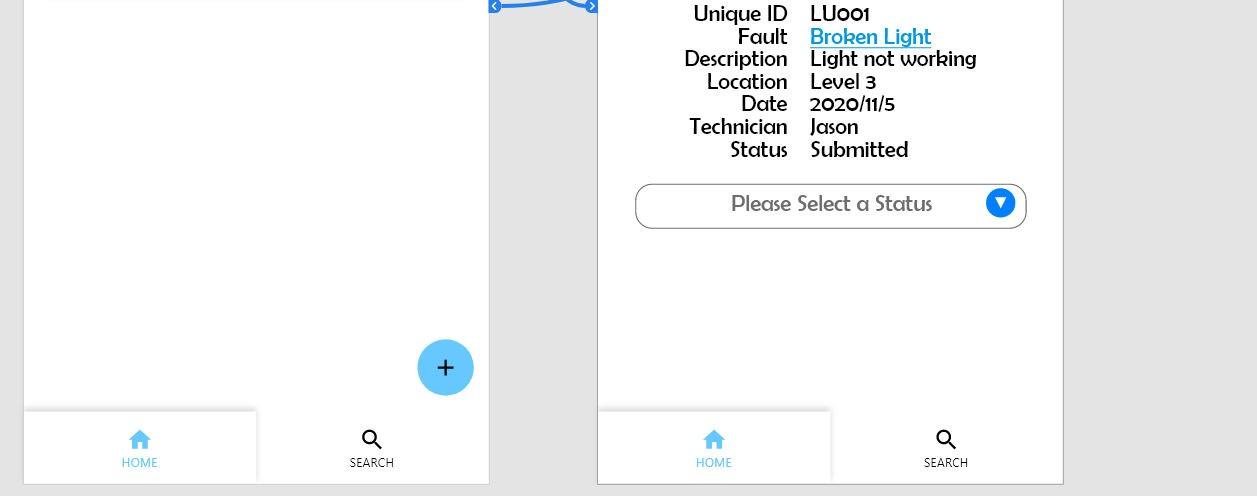

Another important function of the maintenance request artboard is to provide access to the details of the maintenance request. Figure 8 shows the interaction between the maintenance request and maintenance details artboards. The maintenance details artboard contains all other information that is not classified as key information to all technicians but is important for the technician performing the work order. The maintenance details artboard shows the image and location of the fault, the date of fault submission, and the technician in charge. Additionally, this artboard allows users to update the fault field, which is indicated using blue words, and the status dropdown menu. The fault fields can be modified because there is a possibility of an inaccurate initial diagnosis, so technicians have to update the fault during troubleshooting.

This process of changing diagnosis improves data accuracy. The status dropdown menu, located below the current status, allows users to change the status of the work order, with options such as approved, rejected, completed, and closed. Upon updating the status, users can click on the save button at the top of the screen to update all modified fields and be redirected back to the

BEARS #08 26

maintenance request artboard.

Figure 7. Maintenance request and work order artboard

The layout of all the pages associated with maintenance requests, as seen in Figure 7 and Figure 8, are very similar so that less time will be spent picking up the application. Additionally, the naming convention for all fields in the maintenance artboards is consistent to organise the information better. The save button is located at the same position to facilitate ease of navigation. Figure 9 shows the interaction between the new search and completed search artboards, which can be accessed by clicking on the search button on the bottom navigation bar that is located on every artboard.

BEARS #08 27

The new search artboard contains a simple text search field where users can key in the unique ID of the building element to get the information. After the search button at the edge of the text field is clicked, information from the search is populated in the page and placed in one of three card views. The card views categorise information into product specification, maintenance details, and manufacturer contact information, thus providing an organised layout for information storage so users can quickly locate the information required to carry out their tasks. The camera button is used to open the camera function to scan the QR code containing the unique identifier of the building element.

Figure 8. Maintenance request and maintenance detail artboard

BEARS #08 28

Figure 9. Element information sheet

After developing the design and user interface using the interactive prototype, the following section will focus more on how the mobile application communicates with Cloud Firestore, including the authentication and authorisation process, the data structure, and how information is disseminated in real time from Cloud Firestore to all mobile devices accessing the same cloud database.

6.2 Mobile Cloud Computing Application Prototype

The development for this mobile cloud computing application was separated into frontend services, which is the user interface of the mobile application, and backend services, which is the communication with Cloud Firestore. Two other databases were used in conjunction with Cloud Firestore to support the application, including the Authentication database and Image Storage. The function of each of the supporting databases will be explained with the pages they are used for. For clarity, all user interfaces for the mobile application will be referred to as activity in this

BEARS #08 29

section. The first step of using the mobile application is the authorisation and authentication processes, which will be handled using the landing, login, and register activities. The first page of the application is the landing activity, which is programmed to check for existing sessions. If a user is logged in from the previous session, they will be redirected to the maintenance request activity without seeing the login activity.

However, if users were logged out of previous sessions or they have not logged in before, they will be redirected to the login page. New users who have no account will be required to register in the register activity using an organisational email and password. This is the preferred authentication method as compared to anonymous authentication because the authentication database does not store any personal information, so there is no way to identify users if everyone used unique usernames. However, organisational emails usually contain the employee’s name or an employee number, which should suffice as a user identifier.

Figure 10 and Figure 11 below show the interaction between the register activity and the authentication database after the user account is successfully created. Figure 11 shows the authentication console with the user email, date of creation, and last signed-in date. User passwords are encrypted and inaccessible to developers for security reasons. The authentication database automatically generates the user UID, and this UID can be used to store personal documents, but this function will not be used for this application. In the mobile application, a notification will be sent to users when their account is successfully created. After successfully creating an account, users will be redirected back to the login activity, where they can login with their newly created accounts.

Figure 10. Register activity

BEARS #08 30

Figure 11. Authentication database in Firebase

After logging into the application, users will be redirected to the maintenance request activity. On this page, all maintenance requests are listed in card views with all the necessary information. The maintenance request activity is programmed to interact with the “MaintenanceRequest” collection in Cloud Firestore. Figure 12 shows the cloud Firestore hierarchy, which includes the collection and documents. In Cloud Firestore, data are stored in documents, which are organised into collections. In Figure 12, the file path at the top of the page is “/MaintenanceRequest/1604640510735”, which means the user is accessing the data in document number 1604640510735 in the “MaintenanceRequest” collection.

Figure 12. Cloud Firestore hierarchy

Data in the documents are stored JavaScript Object Notations, which are essentially key-value pairs. Figure 13 shows the JavaScript Object Notation from the collection in Figure 12. Every key in the document must be unique, but there is no restriction or limitation to the value, except for the data type. Values uploaded into Cloud Firestore must conform to the required data type, such as String, which are words, or Integers, which are numbers. For example, in “date: 2020/11/06”, the key is “date”, and the value is “2020/11/06”, which is a string. All documents in the “MaintenanceRequest” collection have consistent, unique keys throughout to improve data storage and organisation.

BEARS #08 31

Figure 13. JavaScript object notations

On the mobile application, the recycler view function is used to populate the list of maintenance requests on the maintenance request activity. The recycler view is a more advanced and flexible list view that can display large data sets in a scrolling list. This function is great at handling realtime database such as Cloud Firestore, as it can listen, in real-time, for state changes and perform the necessary actions to accommodate the state changes. State changes refer to the addition, modification, or removal of documents from the database. For example, when data is sent from Device A to Cloud Firestore, the database will instantly push the information to all other devices with this application, without the need to refresh or restart the application.

Figure 14 demonstrates the real time updating of recycler view when there is a state change in the database. A timestamp, highlighted in the red box, is added to the bottom right of the recycler view for illustration purposes. For this example, a new maintenance request was submitted to Cloud Firestore at 13:28:30. Based on the system time highlighted at the top left of Figure 14, it is apparent that the recycler view was updated seconds after the information was sent to Cloud Firestore. Instantaneous data delivery is key to ensuring that all facility operations staff are always updated on the latest maintenance requests, thus reducing lead time.

BEARS #08 32

Figure 14. Real time recycler view update

Figure 14 demonstrates the real time updating of recycler view when there is a state change in the database. A timestamp, highlighted in the red box, is added to the bottom right of the recycler view for illustration purposes. For this example, a new maintenance request was submitted to Cloud Firestore at 13:28:30. Based on the system time highlighted at the top left of Figure 14, it is apparent that the recycler view was updated seconds after the information was sent to Cloud Firestore. Instantaneous data delivery is key to ensuring that all facility operations staff are always updated on the latest maintenance requests, thus reducing lead time.

However, images cannot be sent directly as a key-value pair to Cloud Firestore, as the database cannot store image data type. The workaround to storing an image in Cloud Firestore is to upload the image onto the Image Storage, which would generate a uniform resource identifier for each image, which is a String data type, as seen in the red box in Figure 16. This uniform resource identifier is retrieved by the application and sent as a value to Cloud Firestore and the key “imageuri”.

BEARS #08 33

Figure 15. Submitting work order

Figure 16. Image storage in Cloud Firestore

BEARS #08 34

Figure 17 shows the document page after the work order has been successfully uploaded in the “MaintenanceRequest” collection. The string of numbers highlighted in grey is used both as the document identifier in Cloud Firestore and the image identifier in Image Storage. The string of numbers is generated by getting the system time in milliseconds when the document is uploaded, ensuring that all document identifiers will be unique. In Figure 17, more key- values pairs are present as compared to Figure 15. Additional key-value pairs include the date and time generated form the mobile device, requested personnel which is based on the email used to login to the application, and the default work order status.

Figure 17. Submitted work order on Cloud Firestore

The location value is generated based on the asset information stored in Cloud Firestore. Figure 18 shows the asset information of “LU001”, which is the unique identifier of the building element reported in Figure 15. The file path to access the asset information is “/LU/LU001”, and the application is programmed to concatenate file paths based on unique identifiers. Based on the asset information, the key “location” has the value “Level 4 Office”, and this key-value pair is retrieved from the asset information and sent to the work order. This prevents technicians who are unfamiliar with the building from entering the wrong location. The aim of automatically generating key-value pairs is to improve data accuracy by minimising human errors.

BEARS #08 35

Figure 18. Asset information for LU001 in Cloud Firestore

Figure 19 shows the maintenance details activity after clicking into the maintenance request. As the recycler view is updated in real-time, the application cannot store the document identifier in the device, as state changes can happen very quickly. The application is programmed to detect the position of the clicked object after the user has clicked on the screen and use the position to retrieve the document identifying number to account for sudden state changes. The application uses the get function and the document identifier to retrieve the information from Cloud Firestore. The image can be accessed by getting the value in key “imageuri” as seen in Figure 16 and sending the uniform resource identifier to the Image Storage.

Other than just displaying the maintenance details, the maintenance details activity also allows facility operations staff to update the fault and the work status. To edit the fault, a popup dialog will appear prompting users to modify the fault. To edit the status, users can click on the dropdown menu to select a predefined option, which includes “Approved”, “Rejected”, “Completed”, and “Closed”. After changing the work status or fault, users can click on the save button at the top right of the page to send an update to the database. Compared to writing a new document in the collection using the set function, the application uses the update function to modify key-value pairs. The difference between the set and update function is that the set function replaces all keyvalue pairs within the document, while the update only changes the specific key-value pair. Figure 20 shows the updated status in Cloud Firestore.

BEARS #08 36

Figure 19. Maintenance detail activity

Figure 20. Updated status in Cloud Firestore

Figure 21 shows the recycler view after the status has been updated. As compared to Figure 14, the status has been changed from submitted to approved, and the colour of the text has changed from blue to green. The application is programmed to change the colour of the status based on the status on Cloud Firestore. As mentioned earlier, the changing of work status colour acts as a notification for facility operations staff. This is an integral part of the application as one of the

BEARS #08 37

main goals of this study was to reduce waiting time between corrective maintenance processes.

Figure 21. Updated status in mobile application

After accessing the maintenance details of the work order, facility operations staff will need quick access to building element information to troubleshoot the fault, which can be done through the search activity. Users can navigate to the search activity by clicking on the search button on the bottom navigation bar. The search activity contains a search bar where users can type in the unique identifier of the building element they are looking for, as seen in Figure 22. To make it more convenient, the application has been programmed to copy the unique identifier from the last maintenance detail that was accessed, so users can just paste the unique identifier in the search bar. Additionally, users can click on the camera button to scan the QR code containing the unique identifier of the building element.

Figure 22. Search activity with unique identifier

After clicking on the search button, the application will send a query to Cloud Firestore to retrieve the element information from the database. Building element collections are stored as “LU” or “AHU, " representing the lighting and air handling unit, respectively. This standardises naming convention allows the application to query for the right collection easily. Figure 23 shows the building element information stored in Cloud Firestore. This information storage only contains the

BEARS #08 38

necessary information required to perform corrective maintenance works. Information in this document is manually added through the Cloud Firestore user interface, giving facility managers a higher degree of freedom to decide which information should be added and for what purpose. This page was not designed to replicate the datasheet, as a datasheet still has many technical information that is not required to carry out corrective maintenance works.

Figure 23. Element information in Cloud Firestore

After the mobile application gets a valid response from Cloud Firestore, it will start populating the information from Cloud Firestore onto card views in the Search Activity. The application uses specific keywords such as “product” or “supplier” to categorise information into groups. The remaining key-value pairs which are not categorised together are grouped under maintenance details. Figure 24 shows the search activity after all the element information has been populated.

BEARS #08 39

Figure 24. Element information on search activity

After the facility manager has closed the work order, changes will be made to the user interface. Figure 25 shows the maintenance details activity after the work order status has been changed to “Closed”. As compared to Figure 19, the text colour of the “Broken Light” changed from blue to black, indicating that the field can no longer be modified. Additionally, the dropdown menu is also removed from the page because users will no longer be allowed to change the status of the work order.

BEARS #08 40

Figure 25. Maintenance details activity after closing

Figure 26 shows the building element information on Cloud Firestore after the work order is closed. The data of the “lastWorkOrderClosed” has been updated from “2020/11/05” in Figure 23 to “2020/11/07”. This update is for closing and the opening of the work order, as seen from the key “lastWorkOrderSubmitted”. This function is to help facility managers monitor the response time of each fault.

Figure 26. Building element information after closing

BEARS #08 41

Figure 27 shows the swipe to delete function implemented in the maintenance request activity. The swipe to delete function is just a graphical representation for users, telling them that the document will be removed from the recycler view. The document is moved from the “MaintenanceRequest” collection to the “MaintenanceHistory” collection on the backend. This “MaintenanceHistory” collection acts as an archive folder that the facility operations team can access to search for work order history. Another contingency added in the application is the undo function, which allows users to add the document back to the “MaintenanceRequest” collection if it was accidentally removed.

Figure 27. Swipe to delete function

Figure 28 shows the closed work order in the “MaintenanceHistory” collection after being removed from the “MaintenanceRequest” collection in Figure 12. The “MaintenanceRequest” collection is missing because the only document that was in “MaintenanceRequest” has been moved to “MaintenanceHistory”, and Cloud Firestore has removed empty collections from the database to save space. The “MaintenanceRequest” database will be recreated when a new work order is submitted.

Figure 28. Maintenance history collection in Cloud Firestore

BEARS #08 42

After successfully developing and debugging the mobile cloud computing application, a field experiment was designed and conducted to measure and validate the usefulness of this application in reducing waste in corrective maintenance processes.

7.0 FIELD EXPERIMENT

7.1 Experiment Conducted

A field experiment was conducted after the development of the solution to validate the efficacy of the mobile cloud computing application in improving productivity in facility management. The field experiment was conducted at the Singapore Institute of Technology. The participants selected had previous experience working in a facility management department and were familiar with using an Android device. The hypothesis of this experiment was that the mobile cloud computing application could reduce motion, waiting, and over-processing wastes by at least 30%.

The field experiment was conducted in person at the Singapore Institute of Technology. The field experiment was conducted thrice, and each experiment consists of two parts, before and after the implementation of the mobile cloud computing application. Participants were required to partake in two out of three experiments, once as the person submitting the work order and once as the person approving the work order. Before the start of the experiment, test participants were presented with the operating procedures and briefed on the conduct of the experiment.

Participants were to interpret the operating procedures to the best of their abilities, and the conducting personnel was not allowed to answer any questions during the conduct of the experiment. The conducting personnel, who was responsible for facilitating the experiment, followed the participants throughout the conduct of the experiment to monitor, measure, and record all necessary information required for result analysis and discussion. Prior to the start of the experiment, the critical facility was selected and identified by the conducting personnel, and a QR code has been prepared and displayed on a screen at the bottom of the critical facilities. The conducting personnel also set up all the work order forms and both the information sheet in a desktop folder and in Cloud Firestore, which the test participants were required to access during the course of the experiment.

The field experiment was a scenario-based exercise to replicate how faults were reported in the institution. Two participants, a reporting personnel and approving personnel, were required for the

BEARS #08 43

conduct of each experiment. The critical facility was located along a corridor in Block Innovate, but the exact location was not disclosed in the operating procedure. For the first part of the experiment, the reporting personnel was required to submit a work order on an excel sheet in a laptop, which was used to simulate the workstation.

The laptop was located at the University Tower, which is the location of the facility management office. After submitting the work order, the conducting personnel was to verify the accuracy of the information. Once the information has been verified, the approving personnel would use the details on the work order to locate the critical facility, retrieve the information sheet from the desktop folder, and approve the work order. The conducting personnel was to validate the completion of all tasks before ending the first part of the experiment.