POMOCA article page 78

THE JOURNAL FOR THE MOHAIR INDUSTRY VOLUME 63 | 2022

3 mohair.co.za |

2021/22 Mohair Market Report

The mohair price over the last 12 years

MET presented at The Agricultural Economics Association of South Africa’s annual conference

Angora Ram Breeders Society's Objectives

Angora Ram Breeders Society - President's report 2021/22

Angora Ram Sales

Veterinary Overview: Disease Surveillance report

Veterinary Overview: Managing Pesticides in the Mohair industry

SAMGA pushes the boundaries

The Purpose of MET - Empowering and Training

Mohair Empowerment Trust - Progress report

How are the Emerging farmers doing?

The House of Fibre - Exciting times for the new Broker

Opening of Bo-Karoo Branch in 2022

BKB Group - The BKB journey of regenerative agriculture

4 MOHAIR | 2022 JOURNAL | mohair.co.za Contents 28 23 09 11 10 Editor's Letter

year full of hope and growth - Report from SAMGA Office

of SAMGA 14 16 17 20 28 18 22 23 30 19 27 34 40 43 45

A

Message from the Chairman

ON THE COVER

Mohair

Featuring Pomoco

Skins

Photo Credit: David Malacrida

Athlete: Matt Schaer

The Empowerment Trust aims to identify emerging farmers on suitable farmland for farming Angora goats.

STUDIO MOHAIR

CRAFTING FOR LIFE.

A crafter’s dream all in one location. With so many options, you can’t help but be inspired for your next crafting project by these beautiful yarns at Studio Mohair.

STUDIO MOHAIR:

041 581 1681

retail@mohair.co.za

127 Fordyce Rd, Walmer, Gqeberha.

FIND THESE YARN BRANDS IN STORE AND MORE:

FOLLOW US

Mohair SA Facebook: @mohairsouthafrica

Mohair SA Instagram: @mohairsouthafrica

Mohair SA Linkedin: @mohair-south-africa

MET Facebook: @MohairEmpowermentTrust

MET Linkedin: @mohair-empowerment-trust

Studio Mohair Facebook: @StudioMohairSA

Studio Mohair Instagram: @studiomohair_msa

SAMGA Facebook: @mohairgrowerssa

Regenerative farming - OVK - The new landscape for mohair and wool farmers

Regenerative thinking and land management - The real estate between our ears

The Herding Academy

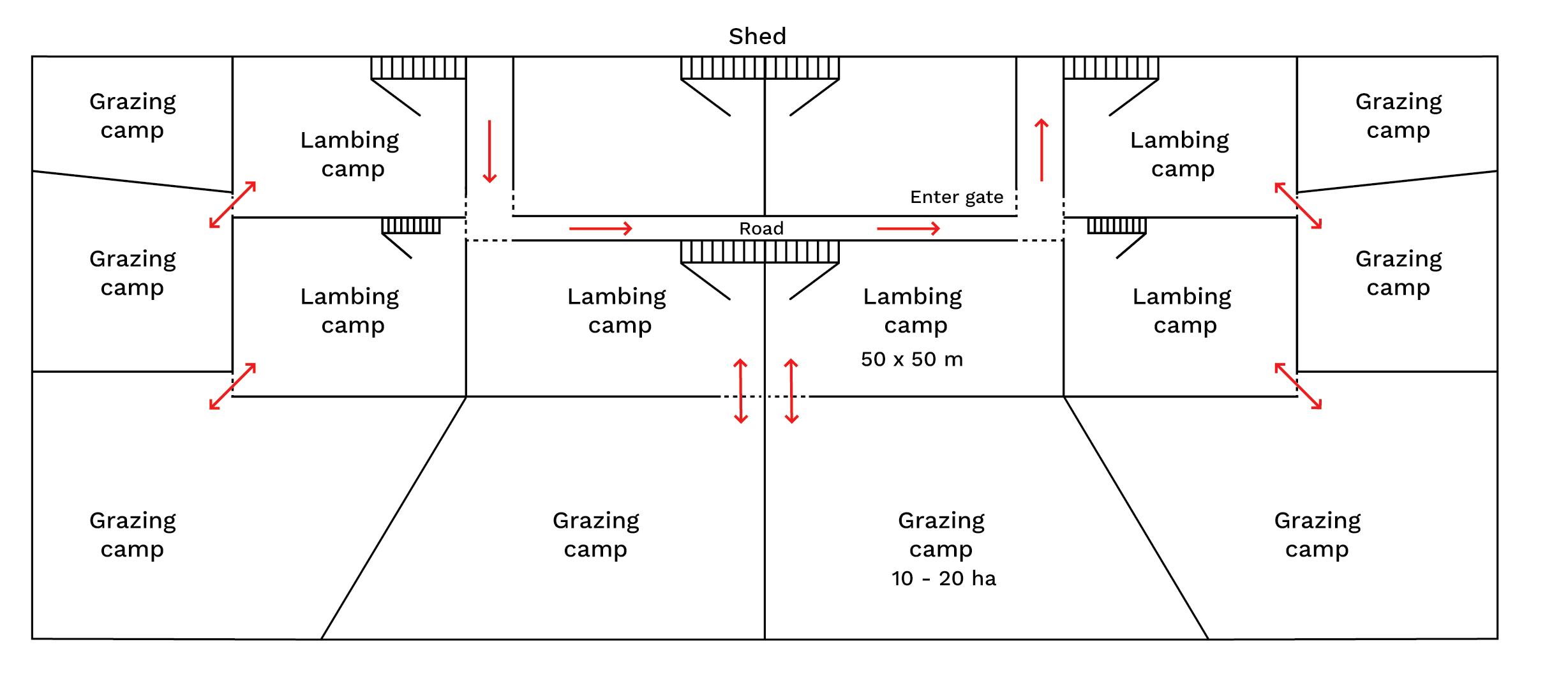

The science of intensive goat farming

Daidoh 22 Mohair competition and award ceremony

RMS - Q&A’s for Control Union Audits

Celebrating 2 Years of RMS certification!

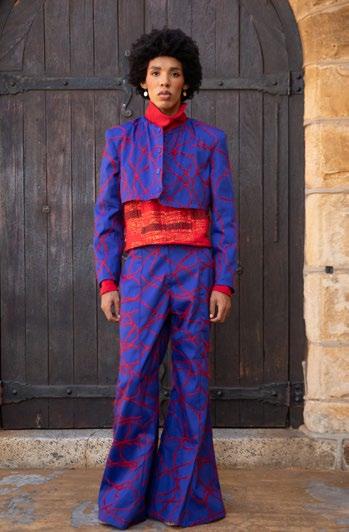

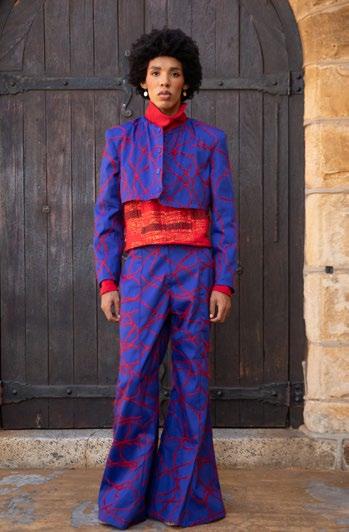

Fashion: GuguByGugu & Burton Miles

Textile Teachings

Mohair Memories

Natural Fibre Connect Conference 2022

EU-SA - Partners for Growth Project & Natural Fibres Roundtable

Tradeshow: Pitti Immagine Filati

Tradeshow: Première Vision

2022 Textile Exchange Conference

Textile Exchange has set a goal to reduce greenhouse gas emissions by 45% by 2030.

78

POMOCA - Our front cover

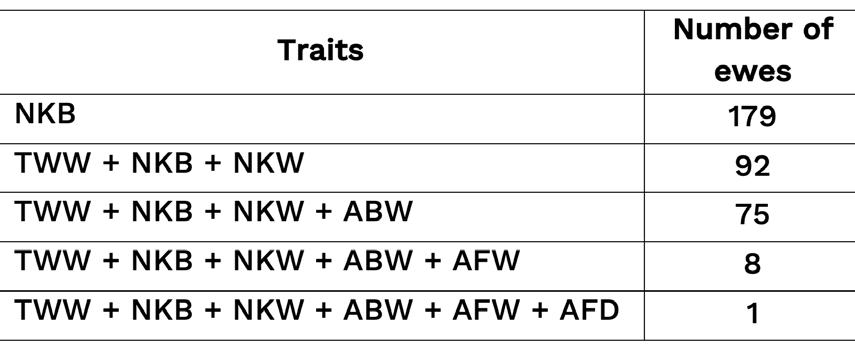

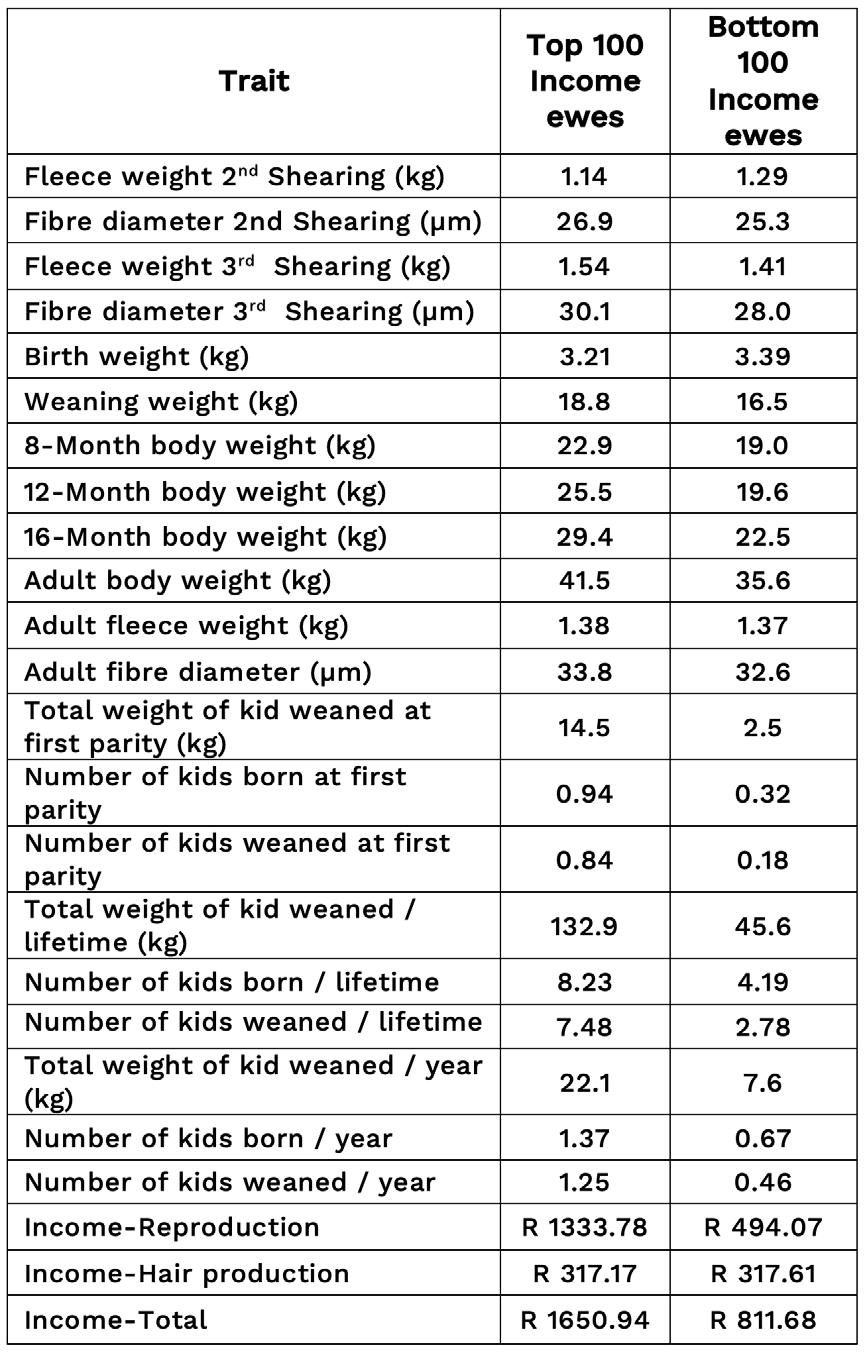

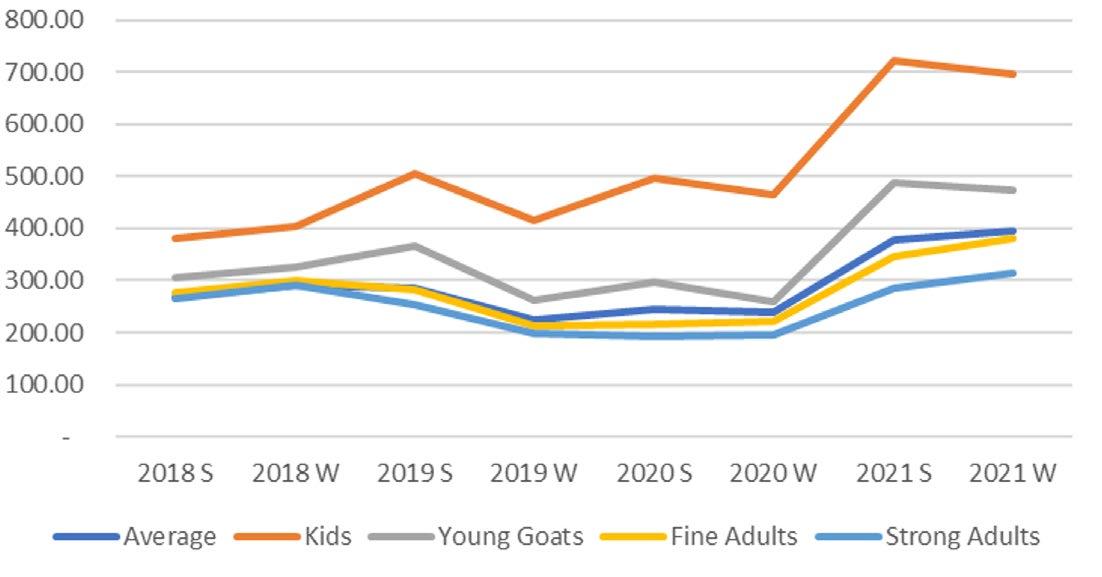

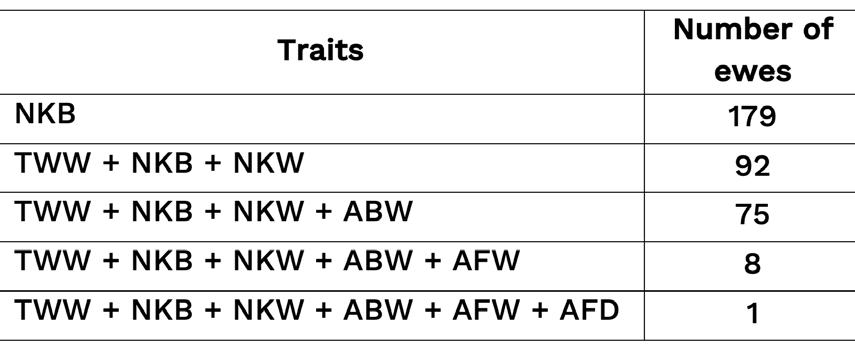

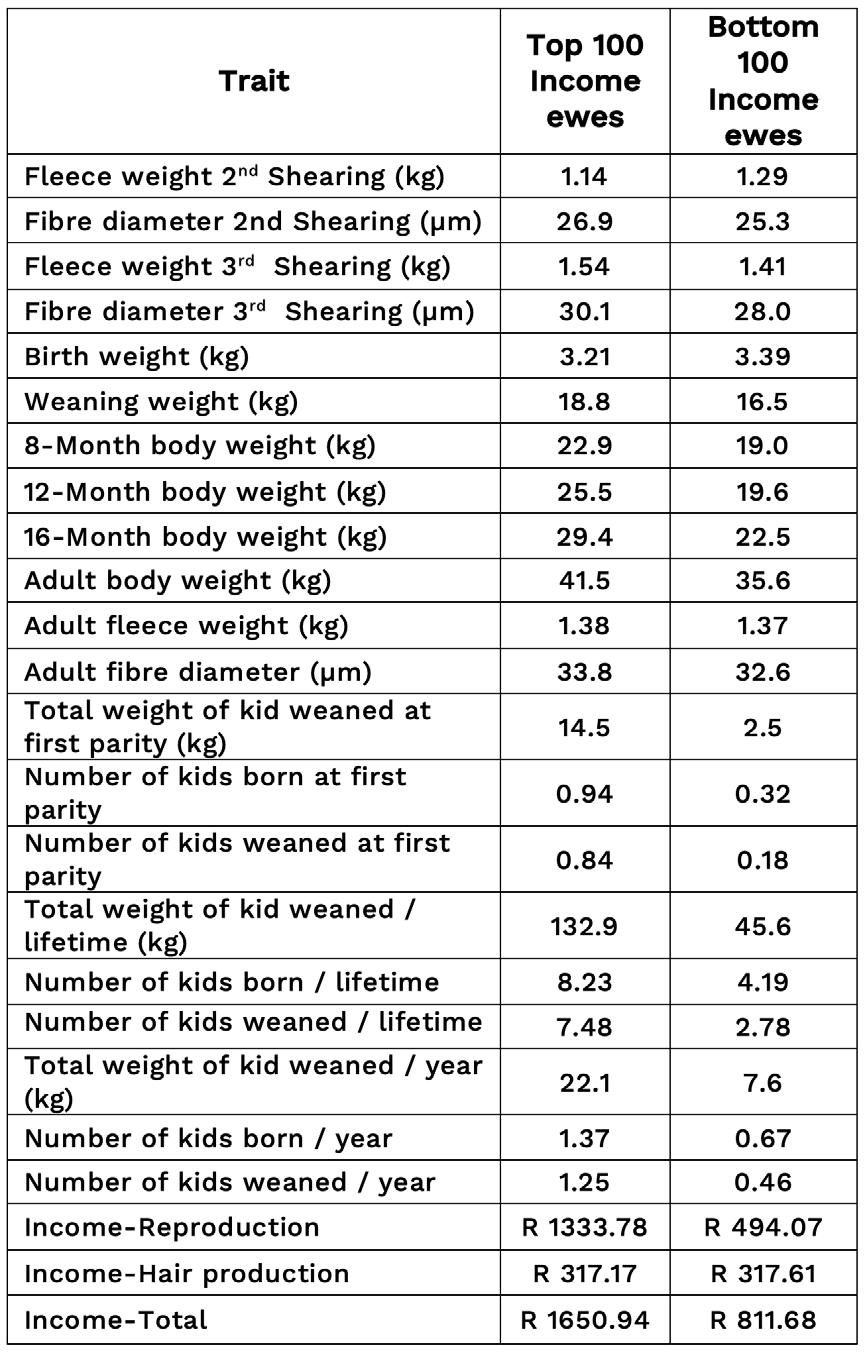

Hair production, reproduction and income of Angora goat ewes that had six kidding opportunities

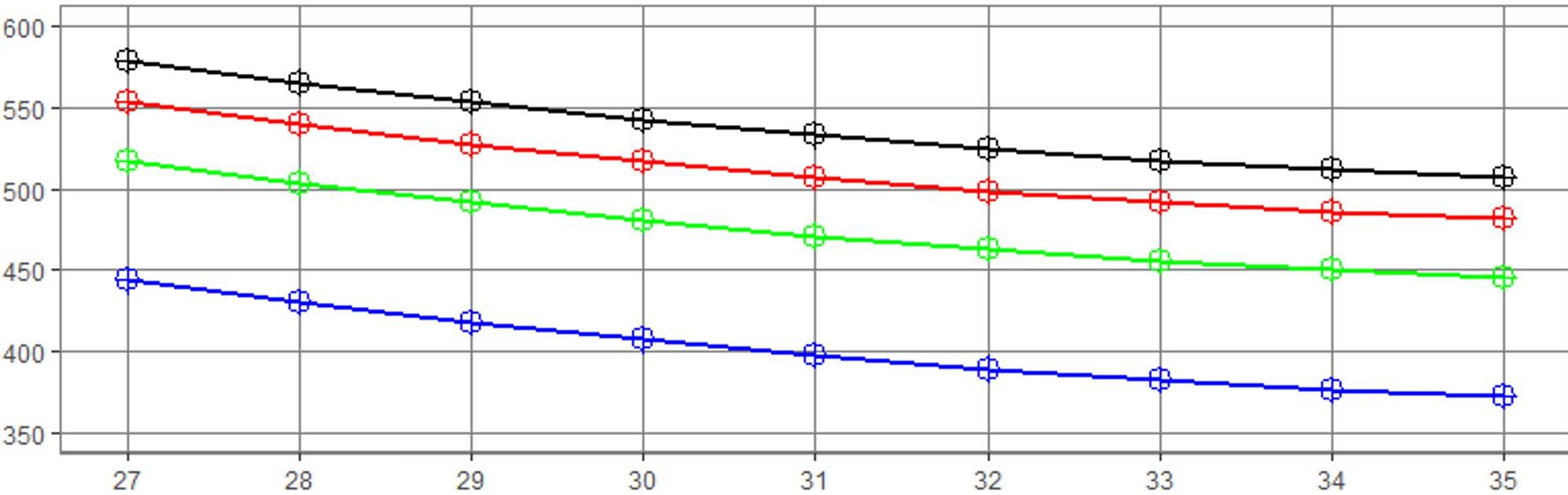

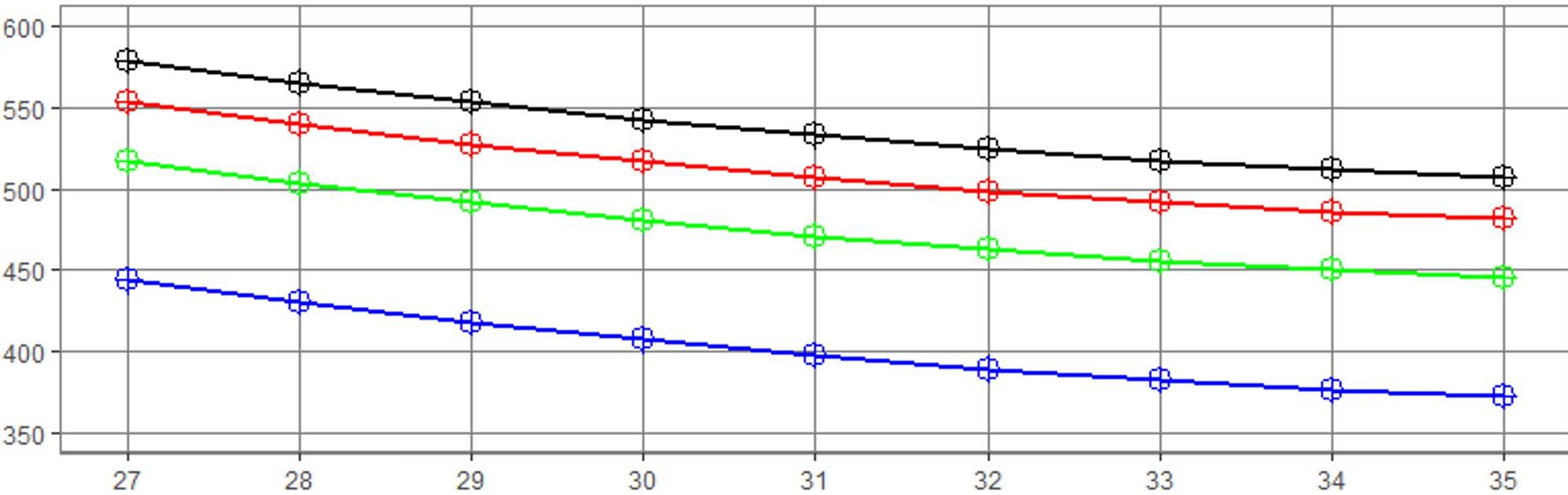

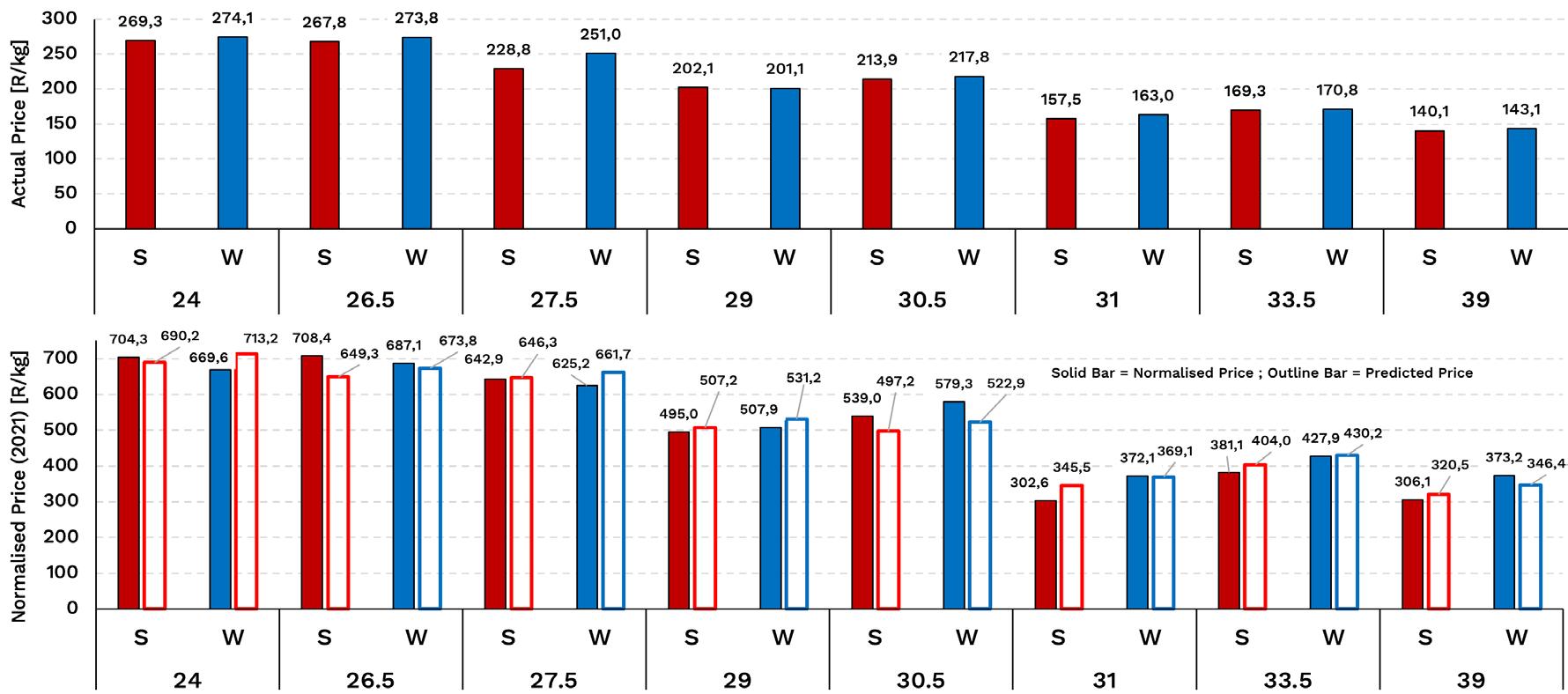

Relationship between mohair auction price and quality and other factors

In loving memory: Billy Colborne

In loving memory: Johannes Hermanus Bosch

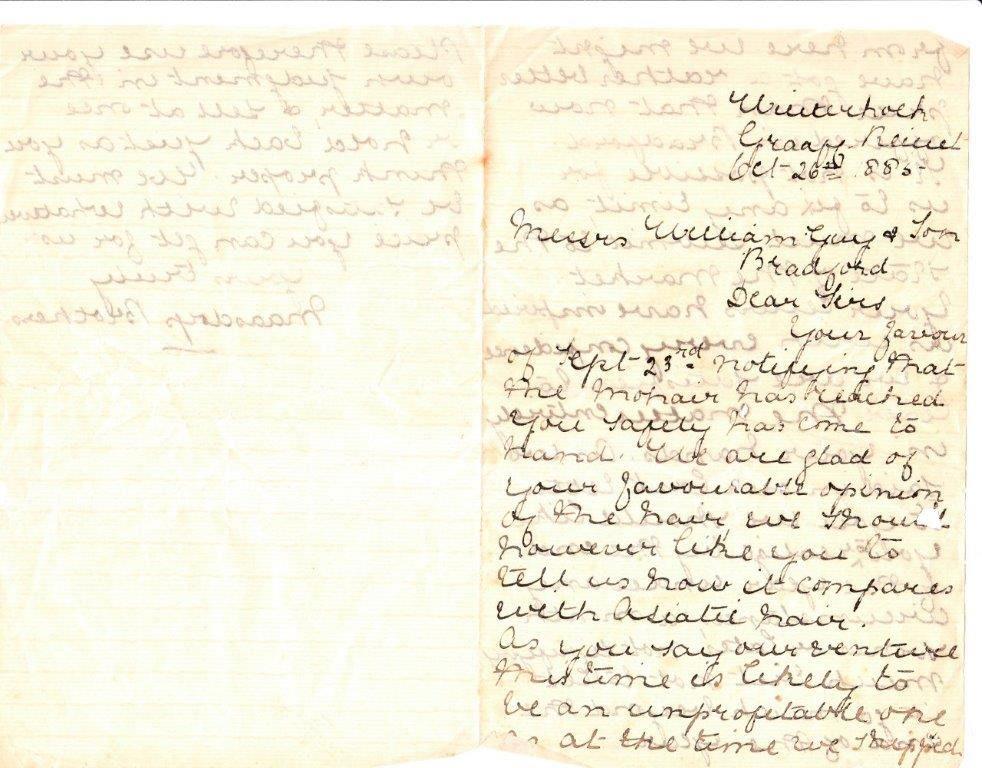

Ox-wagons, mail boats, and mohair

Mohair Directory

7 mohair.co.za | 64 68 74 48 55 68 58 61 65 62 70 71 63 64 50

74 80 86 95 98 97 103 72 73

NATURALLY AT HOME.

Shop the full range of bespoke mohair homeware items from blankets and duvet inners, to floor rugs and throw pillows all in one place. Invest in homeware that will last for generations to come.

STUDIO MOHAIR: 041 581 1681 retail@mohair.co.za 127 Fordyce Rd, Walmer, Gqeberha.

FIND THESE HOMEWARE BRANDS IN STORE AND MORE:

STUDIO MOHAIR

Editor's

LETTER

Mohair SA and the industry at large are going through many changes as we adapt to the needs of the market and world that we serve.

At the core of this change are the Angora goat farmers and their teams, which include the wives and children, farm workers and shearers, all of whom are now viewed through a different lens.

My return to MSA was certainly not business as usual, but to an industry that has progressed over the years.

These changes include the RMS journey, regenerative farming practices being formalised, training of farm workers, the treatment of shearers, the dedicated services of an industry vet and the success of MET.

In addition there has been the planned consolidation of the industry bodies with the intention of being more effective and productive, with greatly improved marketing and communication.

We have the luxury of agricultural schools and the Grootfontein college that specialise in Angora goat farming, which lays the training foundation for the next generation to enter our specialised industry.

We need to preserve this before it’s too late or we need to plan for a private institution that the industry controls.

Succession planning in the trade – brokers to manufacturers – is just as important as it takes time to gain the knowledge and experience necessary to be successful!

Strengthening relationships with the other mohair-producing countries is vital as together we can grow the mohair clip and influence the quality, which is good for the industry overall.

Incorporating the small-scale Angora goat farmers into our fold can impact their lives and increase the volume of mohair that can be RMS-certified in future. The market would value this!

What a privilege it has been to travel internationally and to meet various market segments who have worked with our fibre for generations, and with

designers who speak about mohair’s unrivalled characteristics, with a twinkle in their eyes, as they use it to differentiate garments or items.

Meeting POMOCA in 2022 and observing their use of mohair in their snow-skiing equipment is worth getting excited about and sharing, hence a very different journal cover!

We are stronger together and it makes sense on every level to build and grow our collaborations.

My overriding question, therefore, is how can we help you?

JACKIE GANT Relationship Officer

M: 082 555 6222

T: 041 581 1681

E: jackie@mohair.co.za

9 mohair.co.za |

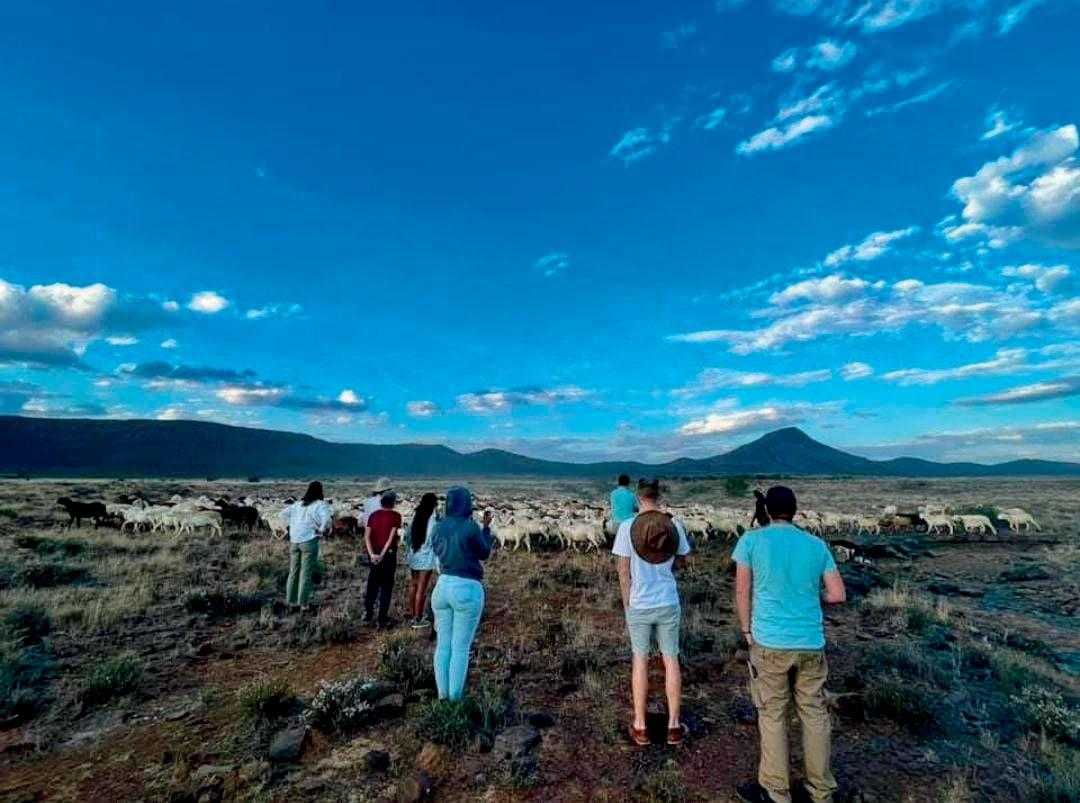

Message from the Chairman of SAMGA

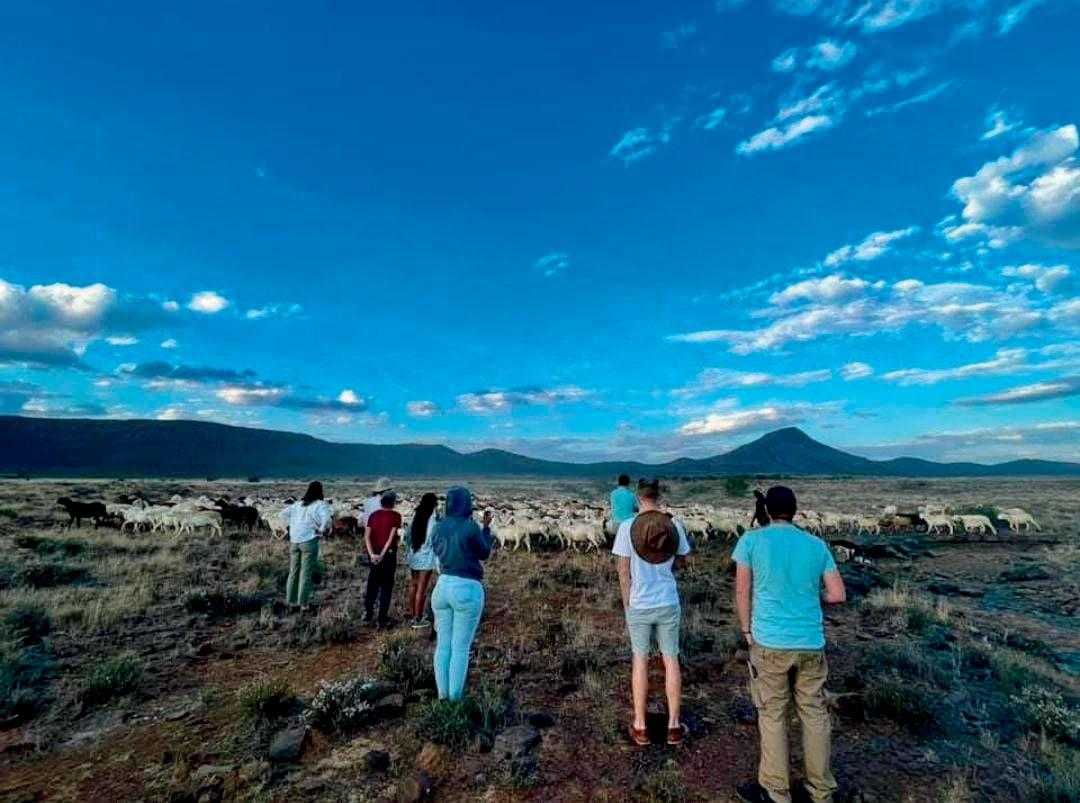

Ibelieve this depicts us as farmers. The crippling drought that most of us endured has, to a large part, dissipated, bringing much needed respite to the majority of the mohair-producing areas. The resolve of the farmers to endure and survive what we came through is quite amazing. Hopefully the drought taught us valuable lessons.

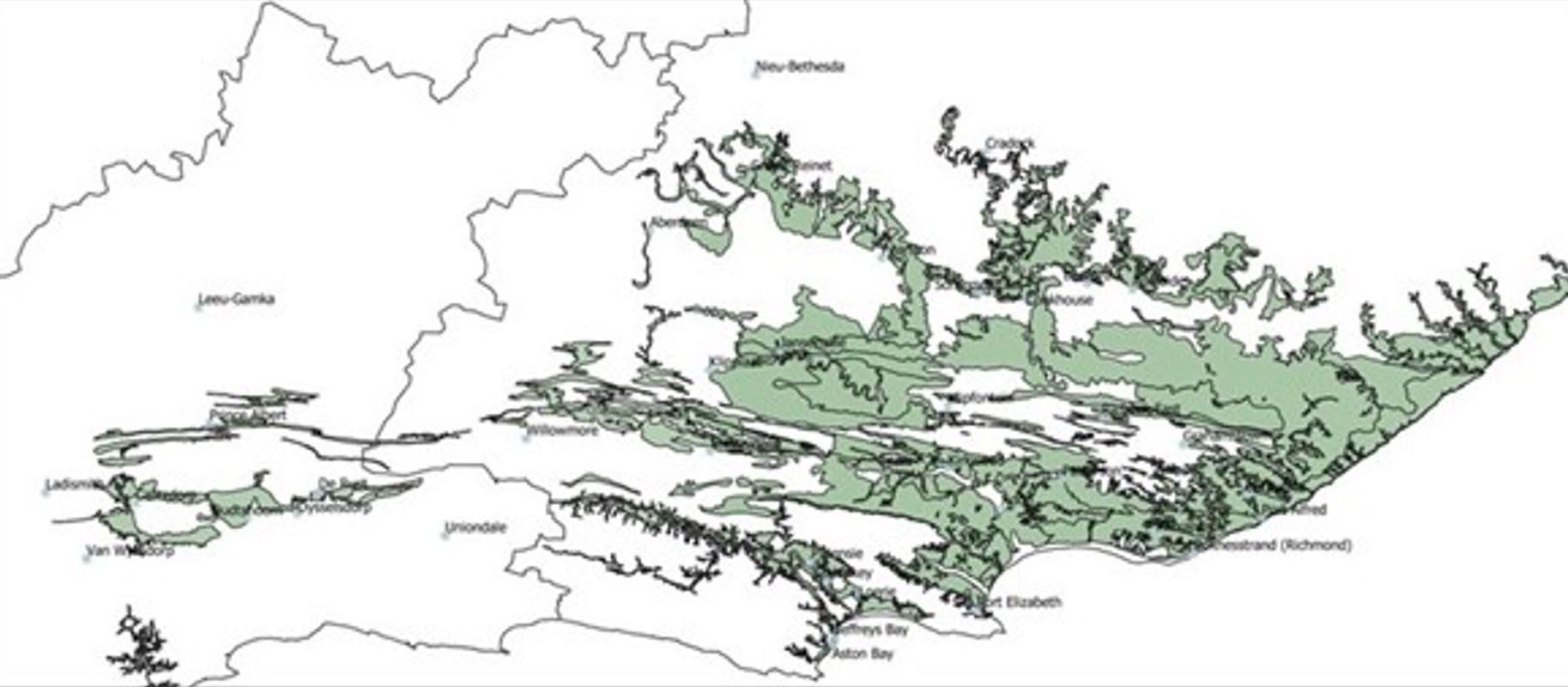

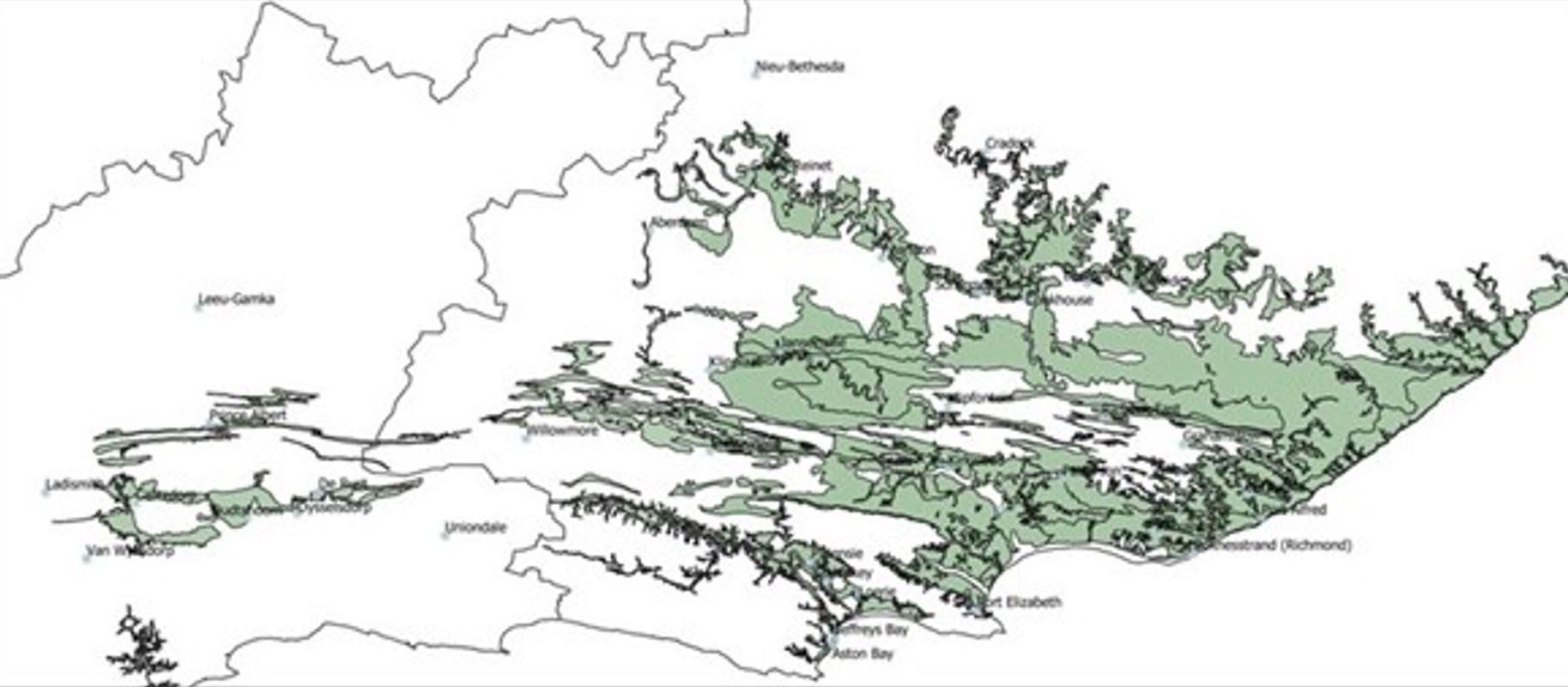

If we are to survive as farmers we will have to farm smarter. Global warming is here to stay. The entire climate is changing – the winds, ocean currents, storm patterns, flooding and droughts. The rise in temperature is but a part of it. We have proven we can survive these stumbling blocks and still grow our amazing industry. It is with great pleasure to see our industry expand in areas not categorised as traditional mohair areas. A producer branch was opened in Carnarvon and there are plans to open further branches in the near future.

It is of utmost importance that we have the whole mohair family under one roof to receive vital information and to be of assistance to everyone.

In this area I would like to thank our manager, Mrs Sanmarie Vermaak, for her hard work in organising the branches, as well as ensuring all producers are equipped to receive valuable information when necessary.

Biosecurity has become an essential part of modern-day farming. Diseases have increased and will continue to do so while global warming persists.

We have come to realise that assistance from our government is sporadic and unreliable. Our industry has undertaken, with assistance from the private sector, to see how we can combat these challenges on our own.

This includes vaccinations and other essential help which is needed by the producer. In this regard, our industry vet, Dr Mackie Hobson, must be commended for his role in ensuring the well-being of our industry.

To ensure the efficient and effective functioning of the mohair industry, we have started a process of stream lining. This was unanimously accepted at Congress this year. It was fantastic to be able to hold a face-to-face congress and it was well supported and enjoyed by the industry as a whole.

Information days, usually held in conjunction with farm worker training, are a popular and important part of our assistance to the producer. Branches that would like to have an information day are asked to contact Mrs Vermaak. It is highly beneficial to everyone attending.

Thank you to our tireless manager Mrs Vermaak for her significant

contribution during the year.

Thank you to Marco Coetzee and the staff of MSA, as well as Beauty Mokgwamme from the Empowerment Trust, for the close working relationship we have received over the year.

Unfortunately we lost Miss Siobhan Momberg this year and we wish her all the best in her new venture.

My thanks go out to the SAMGA committee for their help and support this year, and I am looking forward to working with them in the new year.

Lastly, but most importantly, I would like to commend and applaud my fellow producers for surviving and enduring the crippling drought we have come through.

Hopefully we can start to move forward and start making money, not just a living, doing something we all love – mohair farming.

I wish you all good health and a successful year with good rains.

MARK SHIRES SAMGA Chairman

M: 072 522 0132

T: 041 581 1681

E:

samga@angoras.co.za

10 | mohair.co.za

The mighty drought could not decimate our roots, hidden under the soil from years of suffering. We were plants, we learnt to survive.

– Arjeet Das

“

A year full of hope and growth

Istarted the year 2021/2022 with a prayer that this would be a good year. And what a time we have had so far. We were blessed with amazing rains, unbelievable mohair prices and with a wonderful mohair family that keeps on growing.

During the year we had the opportunity to arrange several farmworker training days. During these days we addressed animal handling, animal health, mohair classing and social development.

We worked closely with some of the local police stations and are thankful for their contribution to these days, teaching our farmworkers about the effect of alcohol and drug abuse.

We were privileged to share our amazing industry with a lot of farmers during information days. Our focus will continue to be training and building our industry.

We had the privilege to welcome a new branch that started in August, 2022 in Carnarvon, known as the Bo-Karoo Branch. We want to welcome each new producer to the SAMGA family. We trust that your farming business will grow from strength to strength.

SAMGA (chairman and manager) and MSA took part in a roadshow, visiting most of our branches to propose and debate the new industry structure. It is wonderful to move around the mohair-producing districts and to meet our producers. We encourage them to attend these meetings as we discuss important information regarding their industry. This is also a platform for each producer to ask questions and to raise their concerns.

At the beginning of the year, we visited new producers in the Western and Northern Cape (Piketberg, Robertson, Van Rhynsdorp and Calvinia). The amazing stories that were told on those visits will always stay with me.

We had the opportunity to form new relationships with two of the agricultural schools in the Western Cape – Augsburg Landbou Gimnasium in Clanwilliam and Oakdale Agricultural School in Riversdale. There are passionate students who are taught discipline and their love for their Angora goats is clearly visible. Both schools participated in the WP Youth Show Competition.

It is with great excitement that we welcome so many new producers to our family. Every day we hear of new producers in all the regions of South Africa. This warms my heart to know that more and more farmers are starting to farm with Angora goats.

The year of 2022 saw all the agricultural shows reopened post-Covid. SAMGA and MSA enjoyed a successful week at NAMPO - Bothaville in the Free State. We also attended a few smaller shows where we showed our products and goats.

We headed to KwaZulu-Natal for the Royal Agricultural Show to see if it

would be viable for us to attend this show in the future.

During September 2022, SAMGA and MSA attended the Nampo Cape show in Bredasdorp for the first time. With our production moving into the Western Cape, we are eager to be visible in that region. I want to take the opportunity to thank each producer and their families for staying positive and for loving our goats. May you and your families be blessed during the coming year. May our industry grow from strength to strength. We look forward to doing more great things together in 2022/2023.

SANMARIE VERMAAK SAMGA General Manager

M: 079 236 7823

T: 041 581 1681

E: samga@angoras.co.za

11 mohair.co.za |

Report from SAMGA Office

INDUSTRY REPORT

13 mohair.co.za |

member of Martyrsford Angora Stud

Proud

www.heritageangoras.co.za

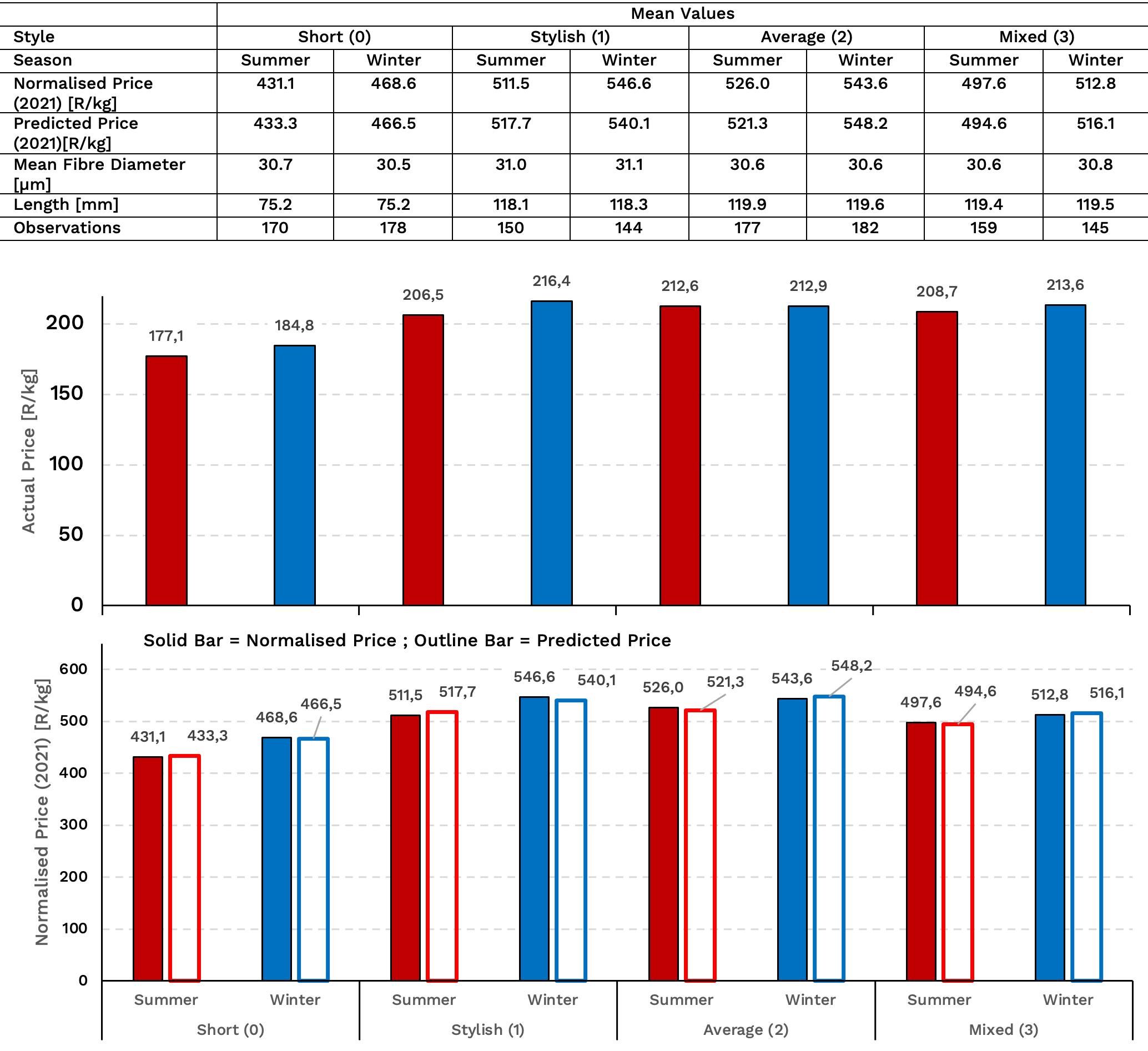

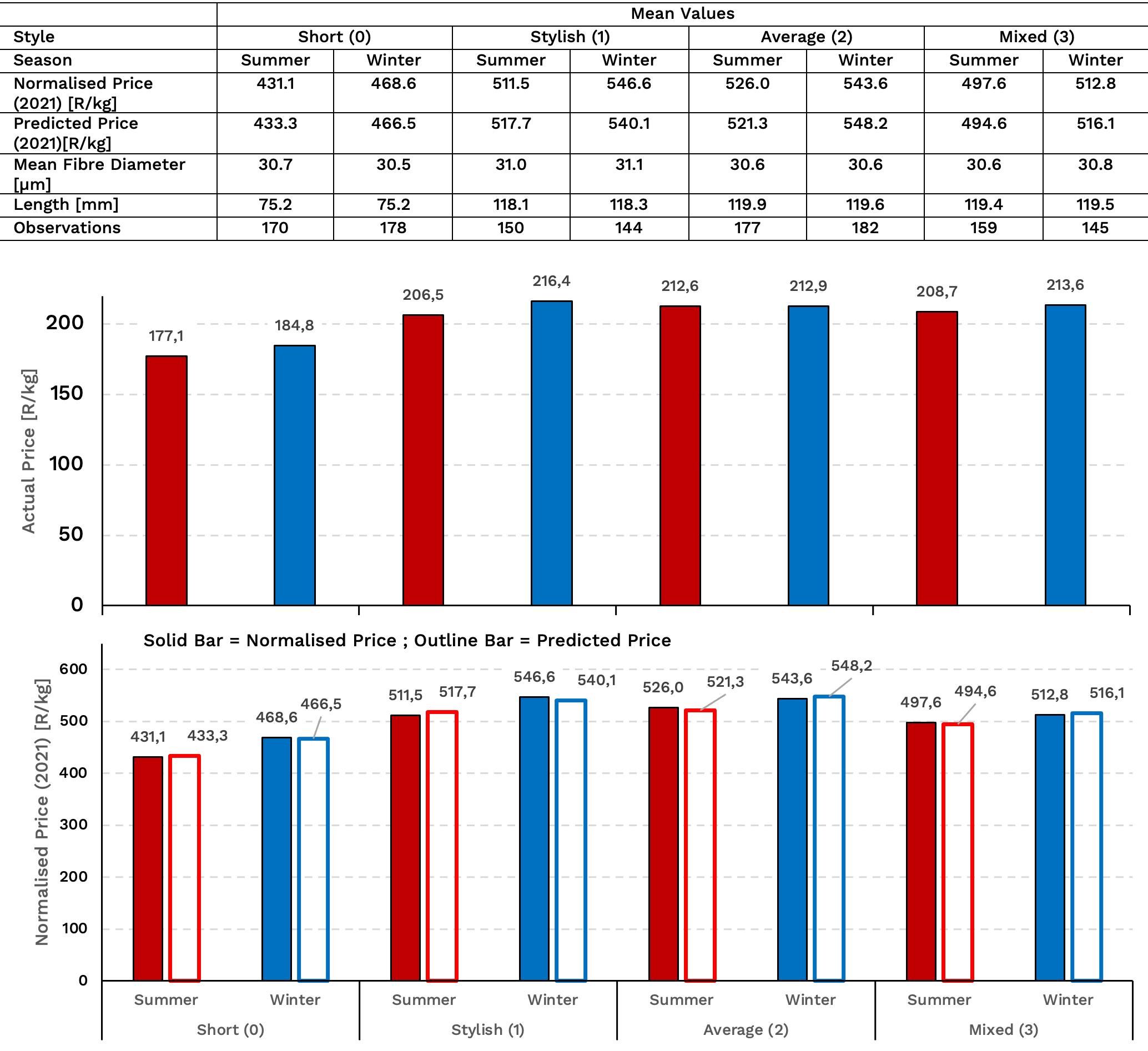

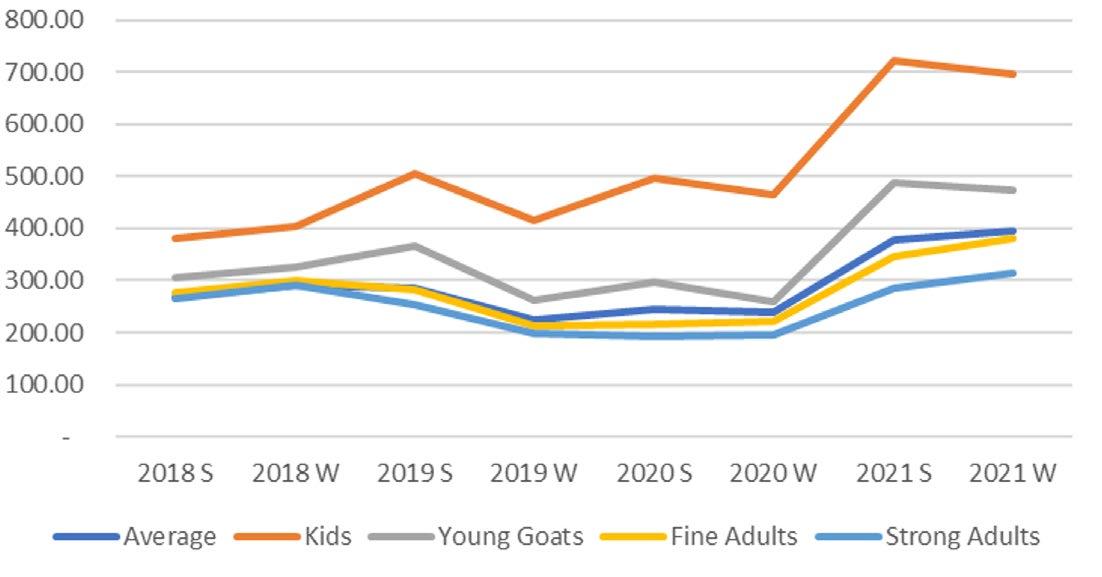

2021/22 Mohair Market Report

The 2021 mohair summer season started off positively for the mohair producers with the price increasing by 25% on the first sale. When the mohair price of the second sale increased by 8%, it was clear that it was going to be a good season and it set the tone for the rest of the year.

The demand for mohair started to increase from the beginning of 2021 and it only got stronger as the year went on. The textile brands and retailers remain under pressure to source materials that are produced ethically and sustainably, and the mohair industry can provide this in the form of RMS (Responsible Mohair Standard) certified mohair.

The start of 2021 saw the first RMS-certified mohair tops enter the market, which saw some brands and retailers that previously banned our fibre returning to the market.

The highest average mohair price for the 2021 summer season came in at R406.93 p/kg and the average mohair price for the summer season was R377.76 p/kg, which is 53% more than the 2020 summer season.

The 2021 mohair winter season started off on a similar note with the price for the first sale increasing by 8%. The second winter mohair sale achieved the highest average price for the entire year of R418.66 p/kg. The average mohair price for the 2021 winter season was R395.07, which is 65% more than the 2020 winter season.

Looking back at the 2021 season as a whole, we saw the average mohair price for the season come in at R386.42, which is 59% more that the average price for the 2020 season. DH Schoeman from the Oudtshoorn area received the highest price for a single bale of mohair for the entire season of R970.00 p/kg. The bale consisted of super style, 25-micron kid mohair.

Figure 1 - A comparison of the clip composition between 2020 and 2021 indicates some changes. Fine adult mohair increased by 3%, kid mohair increased by 1%, young goat mohair increased by 1%, and strong adult mohair decreased by 5%. This indicates that the mohair clip is finer in 2021 compared to 2020. The effect of the long-lasting drought is showing its effect

here. - Figure 2

The buyers’ share of the market changed by quite a bit in 2021, with top makers taking up 76% of the market compared to 83% in 2020, and the greasy buyers taking 24% of the market share. We have also seen a new greasy buyer enter the market in Connacher Wool & Mohair (Pty) Ltd. The competition between all the buying houses to purchase the mohair on offer was clear to see, which played a big part in the increased mohair prices received by the producers. - Figure 3

The year 2021 was a great period for mohair exports, with a 22% increase in quantity compared to 2020. The month of March saw the highest quantity of mohair exported in a single month since 2016 (356 423.10kg).

Italy remains the leading buyer of South African mohair, importing 41% of the total SA mohair exported. China remains the second biggest importer (26%) and the United Kingdom is the third biggest importer of SA mohair (16%). Figure 4

The South African mohair offered on the official mohair auctions is 8% more compared to the previous year. But note that this does not take into account mohair sold outside the official mohair auctions.

A total of 65% of the mohair sold on the official mohair auctions has been RMS-certified, which is a great achievement by our mohair producers and brokers considering the RMS was only launched in March, 2020.

Looking ahead the main focus for the South African mohair industry remains sustainability, traceability and producing fibres regeneratively. The goals of the Responsible Mohair Standard are to provide the industry with tools to recognise the best practices of farmers and to ensure that mohair comes from farms with an advanced approach to land management, animal welfare and social responsibility.

Beyond the farm, it also aims to provide a system of traceability throughout the entire value chain – from farm to finished product.

On the traceability front, Mohair South Africa will continue to collaborate with Oritain, which provides a service that enables you to trace an actual product back to its true origin using advanced science, which is the new benchmark for product traceability. It is always

14 MOHAIR | 2022 JOURNAL | mohair.co.za

Mohair Market 2021

difficult to predict what the market will do from one year to another as there are many variables that can affect the price from season to season.

The South African mohair industry offers a product that complies with the needs of the textile brands and retailers, and if all things remain equal, there is no reason why mohair cannot go from strength to strength. The SA mohair industry remains committed to producing sustainable, traceable and regenerative mohair within an ethical environment.

MARCO

General Manager

M: 073 648 8935

T: 041 581 1681

E: marco@mohair.co.za

15 mohair.co.za |

Clip Composition 2021 Clip Composition

Buyers by weight 2021 Mohair Exports 2020/2021

2020

Figure 01

Figure 02

Figure 03

Figure 04

COETZEE

INDUSTRY REPORT Mosenthals Y GOATS KIDS F ADULT Stucken S ADULT

Suedwolle Connacher

New England Samil

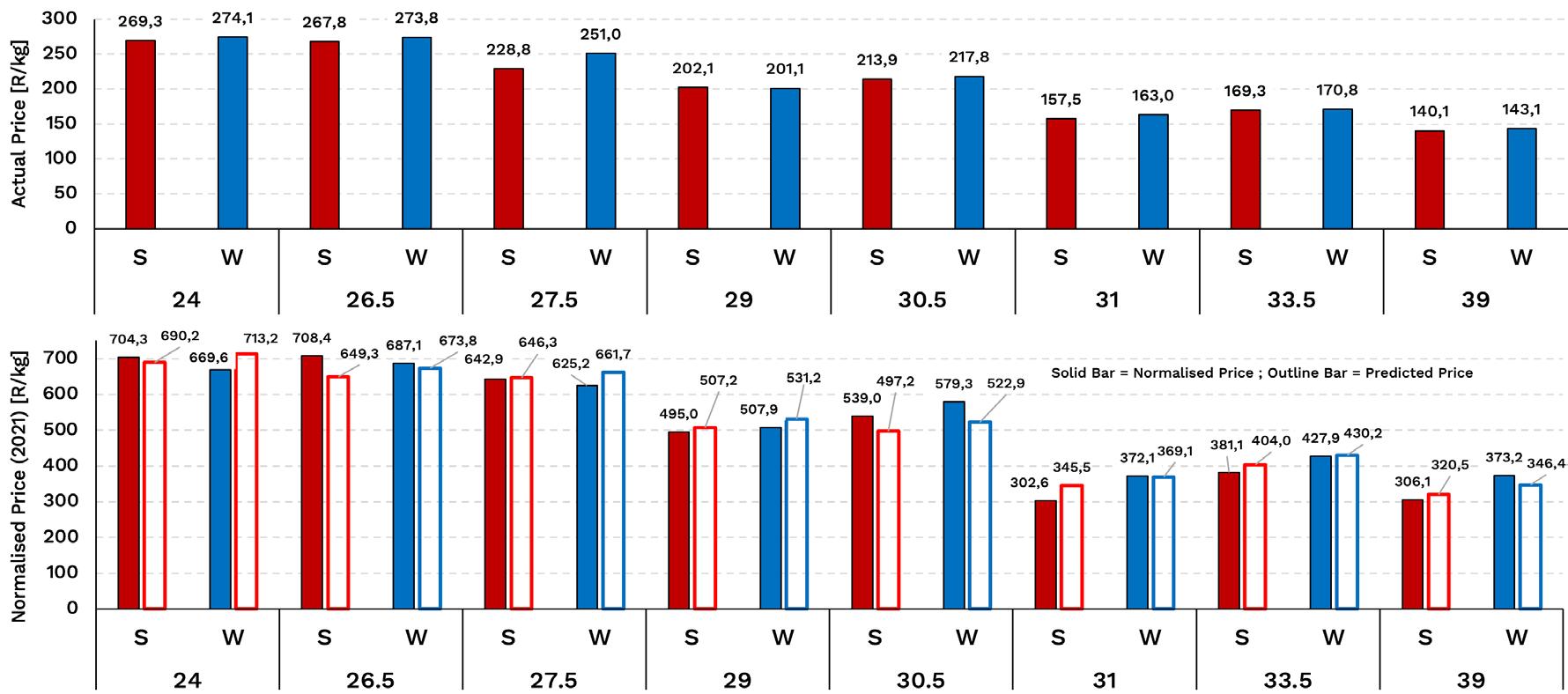

The mohair price over the last 12 years

If you look back 12 years ago, the average mohair price for the summer season of 2011 was R97.70 p/kg. The average mohair price for the season of 2022 was R382.00 p/kg. That is a 290.9% increase in price over 12 years and, on average, a 24.25% increase per year. We are sure that there are not many other industries that come close to these numbers.

From 2011 to 2014, the mohair price increased by 20.4%, only 5.1% per year on average. From 2015 to 2018, the price increased by 137.22%, averaging 34.31% per year.

From the summer season of 2019 to the winter season of 2020, we saw the mohair price decrease by 17.29%. The effect of the PETA expose from May 2018 was felt over these two years as brands and retailers who banned mohair stopped buying the product.

From the 2020 winter season to the 2021 winter season, the average price increased by 65%.

Although the RMS standard was launched in March 2020, the first RMScertified tops were only available to the market from the beginning of 2021. Brands and retailers that had previously banned mohair started buying it again and the demand for mohair during 2021 grew from strength to strength.

In the summer season of 2022 the mohair price increased to a new high of R442.24 p/kg in April. This is the top average price of a sale to date.

During the winter season of 2022 the price started to drop due to various international challenges affecting the world economies, including the war between Russia and Ukraine which directly influenced energy prices, inflation and interest rates across the world.

China’s economic growth was at a low point in 2022 as they continued to lock down the country due to Covid-19 protocols. All these factors influence the purchasing power of our international mohair buyers.

The price did stabilise and start to increase towards the end of 2022, with the average mohair price for the year being R382.00 p/kg, 1% down from 2021.

MARCO COETZEE General Manager

M: 073 648 8935

T: 041 581 1681

E: marco@mohair.co.za

16 MOHAIR | 2022 JOURNAL | mohair.co.za

MET PRESENTED AT

The Agricultural Economics Association of South Africa’s annual conference

in Swakopmund, Namibia on October 2-5, 2022.

The Agricultural Economics Association of South Africa (AEASA) is the professional organisation of agricultural economists in South Africa. It was established in 1961 and held its first annual conference in 1962. AEASA has positioned itself strategically for the 21st century to enable it to be relevant to all agricultural economists, thereby assisting them to serve their communities. The shared vision is that AEASA’s products and services should support all agricultural economists active in the industry, irrespective of race, language, gender, career choice and educational level.

The theme this year was: “How recent value chain disruptions shaped agri-food systems in sub-Saharan Africa”. During the annual conference, the NAMC transformation review committee (TRC) hosted a workshop where industries presented and showcased the transformation work that they have done over the years, as guided by the NAMC transformation guidelines. Workshop theme: “A changing South African agriculture landscape –statutory measures, a tool driving transformation, and inclusive value chain”.

Among the industries, the Mohair Empowerment Trust left a mark of transformation. It is without a doubt that the MET is working hard to ensure transformation within the mohair industry. The objective is to ensure success without chasing numbers (of farmers), allowing for steady growth.

It aims to empower emerging farmers who have access to land that is suitable for Angora goat farming, with good infrastructure, and that will meet the Responsible Mohair Standards (RMS). We received very good feedback after the presentation.

The industries that presented were: Mohair Empowerment Trust

(Ms B Mokgwamme), Potato South Africa (Ms N Xaba), Red Meat and Primary Livestock Cluster (Mr D Olivier), South African Wine Industry Transformation Unit (Mr P Bowes), Raisins South Africa (Ms S Sell).

The MET presentation highlighted our industry’s focus on commercialisation, thanks to empowerment and training. Our videos were very well received and appreciated as they gave the audience the opportunity to hear from the farmers!

BEAUTY MOKGWAMME

Mohair Empowerment Officer

M: 083 443 2392

T: 041 581 1681

E: beauty@mohair.co.za

17 mohair.co.za |

INDUSTRY REPORT

Angora Ram Breeders Society's Objectives

The Angora Ram Breeders Society was established in 1892. The original reason for establishing an Angora stud society was to create guidelines for the improvement of the angora goat. The members of the society created a set of breeding standards that its members adhered to. Rams and ewes were classed according to the standards set out by the breeders society.

Wonderful work was done and a great improvement of angora goats was achieved. Fleece weights were improved and kemp was reduced to virtually zero in our modern animals. Our past stud breeders dedicated their lives to the improvement of angoras and we are eternally grateful for the sacrifices and hard work of these pioneers.

MISSION STATEMENT ARBS

Our mission remains to improve the angora goat and to provide outstanding genetics to our commercial farmers. Our classing standards will ensure that the purity of the breed stays strong, while also enhancing the financial attributes of the angora goat.

RAM SALES

All our sales are held under the auspices of the Angora Ram Breeders Society. This means that the animals on those sales will have to undergo inspection before they are sold on auction. They must all adhere to the minimum standards set out by the ARBS. The classing standards are revisited regularly to make sure that they remain relevant to commercial producers.

VELD RAM PROJECTS

The veld ram projects were originally created because the feeling at that time was that we needed to assess animals in a group on natural grazing. This concept has been a great success and has led to animals being more adaptable and stronger as a result.

Animals are fed a supplement on the veld for six months and undergo strict selection along the way. They will undergo three different selections and rams that are not up to breed standards or that grow poorly are removed from these projects. Up to 30% of rams entered are removed.

This makes the veld concept a very good platform for breeders to test their best animals against other breeders’ stock. Buyers can buy veld rams with confidence, knowing that they have been through rigorous selection. Animals can also be compared on fleece and growth in the same environment.

PREPARED SALE

The annual prepared sale is held in Graaff-Reinet. The rams are prepared by individual breeders on their own properties and then brought to the sale. These rams entered are usually on a higher feeding plane. The benefit of this is that the good and bad traits of that animal are accentuated. The animals are subjected to a strict selection to make sure that they adhere to our classing standards.

PRIVATE SALES

Private sales have become popular in recent times. Most of the private sales are run on the veld ram concept and the rams also run for a minimum of six months together. Rigorous classing also leads to high quality sale groups. Ewes are offered on these sales as well and the same classing standards are applied to these animals.

CONCLUSION

The Angora Ram Breeders Society remains committed to providing the very best genetics to our mohair industry to expand mohair production. Please follow our Facebook page.

18 MOHAIR | 2022 JOURNAL | mohair.co.za

Angora Ram Breeders Society

ARBS President's Report 2021/22

Iwould like to begin my report by offering our condolences to the families of Peter Cawood and Oom Johan Bosch.

Uncle Peter has left a lasting footprint in our mohair industry and served as president of our society and on the SAMGA for many years, while Oom Johan was a much-loved member of the Somerset East community. As we look back at the 2021/2022 season one can only be grateful for the wonderful prices paid on all our sales. Fantastic averages were realised on the sales that have not been seen for many a year.

My personal take is that these are more realistic prices and well deserved for the dedication and effort our breeders have invested. Long may this positive trend continue.

One must, however, temper this excitement with the fact that we are still experiencing a drop in the number of rams entered and sold on official auctions. I hope and trust that we can create a positive increase in the number of rams entered and sold on official sales.

The quality of rams offered on our sales has steadily improved and any flock farmer would benefit from buying these animals.

Strict classing standards are applied to ensure only the best animals reach the sales. Our classing standards are being amended each year to make sure that they remain relevant to commercial farmers as well.

In 2021 we launched a social media campaign to promote our breed society and to create hype around our sales. I would like to convey my hearty thanks to Sean and Julie Hobson, mainly to Julie, for doing a wonderful job.

We will continue with this campaign and work closely with The House of Fibre to market our sales. I would like to thank House of Fibre and their team of field agents for doing a wonderful job of selling our animals.

Thank you, also, to my vice-chairman and the executive for advice and support in a very challenging year.

Lastly, I would encourage all our breeders and flock farmers to keep on promoting our wonderful Angora breed and the wonderful mohair fibre that we produce.

LLOYD SHORT ARBS President

M:

E:

071 347 5854

lloyd@wheatlands.co.za

19 mohair.co.za |

Ram Sale Highest price Stud rams average price Selected flock rams average price Flock rams average price 2020/21 2021/22 2020/21 2021/22 2020/21 2021/22 2020/21 2021/22 Rietfontein Angoras & Guest Sellers - R45 000 - R36 500 - R20 875 - R6 862 Graaff-Reinet Angora Ram Sale R155 000 R70 000 R51 900 R38 429 R13 400 R19 555 R5 800 R8 043 Newlands Angoras & Guest Sellers Ram Sale R61 000 R100 000 R31 750 R49 400 R11 400 R20 100 R6 100 R9 100 Van Hasselt & Guest Sellers Ram Sale R28 000 R51 000 R19 000 R37 600 R14 000 R24 000 R7 900 R13 000 Jansenville Veldram sale R25 000 - R20 000 - R8 500 - R5 000Graaff-Reinet Angora Ram Sale R61 000 R75 000 R34 000 R31 500 R13 600 R15 700 R6 300 R8 500 Noorsveld Mount Stewart Angora Sale - R34 000 - R 8 420 - - -Annual Karoo Angoras & Nelspoort Auction R22 000 R34 000 R17 000 R20 625 R9 156 R17 795 R6 040 R10 065

INDUSTRY REPORT

20 MOHAIR | 2022 JOURNAL | mohair.co.za

L to R: Gary Hobson (buyer), Roche Jongkind (HOF) Neil Quale (seller), Richard Hobson (buyer), Jordi Van Hasselt (seller) Cassie Carstens (HOF), Jakkie Nel (auctioneer)

3. Van Hasselt & Guest Sellers Ram Sale

L to R: Jordi van Hasselt (seller), Gary Willows (HOF) representing the buyers, Cassie Carstens (HOF), Jakkie Nel (auctioneer), Ben van der Westhuyzen & Jackie Pieterse (buyers) not present

1. Graaff-Reinet Angora Ram Sale

L to R: Chris Curtain (HOF), Jannie Lategan, (seller), Reco Pietersen (buyer), Jakkie Nel (auctioneer)

2. Newlands Angoras & Guest Sellers Ram Sale

Back L to R: Hardie vd Heever (HOF), Danie Strauss (auctioneer), Johannes de Jager (HOF), Robert Bosch (buyer), Willie Jordaan (buyer), Roché Jongkind (HOF), Gary Hobson (seller), Ray Hobson (seller), Donna Hobson (seller), Anton vd Mescht (sponsor)

Back L to R: Roland du Toit (seller), Johan van der Schyff (seller), Leon Eybers (seller), Willem Retief (seller), Christian Marincowitz (BKB), Johan Botha (sponsor), Rocco de Villiers (sponsor) Front L to R: Danie Strauss (auctioneer), Izak van der Merwe (seller), Phillip Schutte (BKB), Corne Nel (BKB),

L to R: Michael Bosch & Robert Bosch (sellers), Cassie Carstens (HOF), Jordi Van Hasselt (buyer), Johannes de Jager (HOF), Danie Strauss (auctioneer)

L to R: Ray & Donna Hobson (seller), Jeremy MacLachlan (auctioneer), Neil Quayle

21 mohair.co.za |

(buyer) not present

7. Noorsveld Mount Stewart Angora Sale

4. Graaff-Reinet Angora Ram Sale

5. Annual Karoo Angora & Nelspoort Auction

6. Rietfontein Angoras & Guest Seller

VETERINARY OVERVIEW

Disease Surveillance report

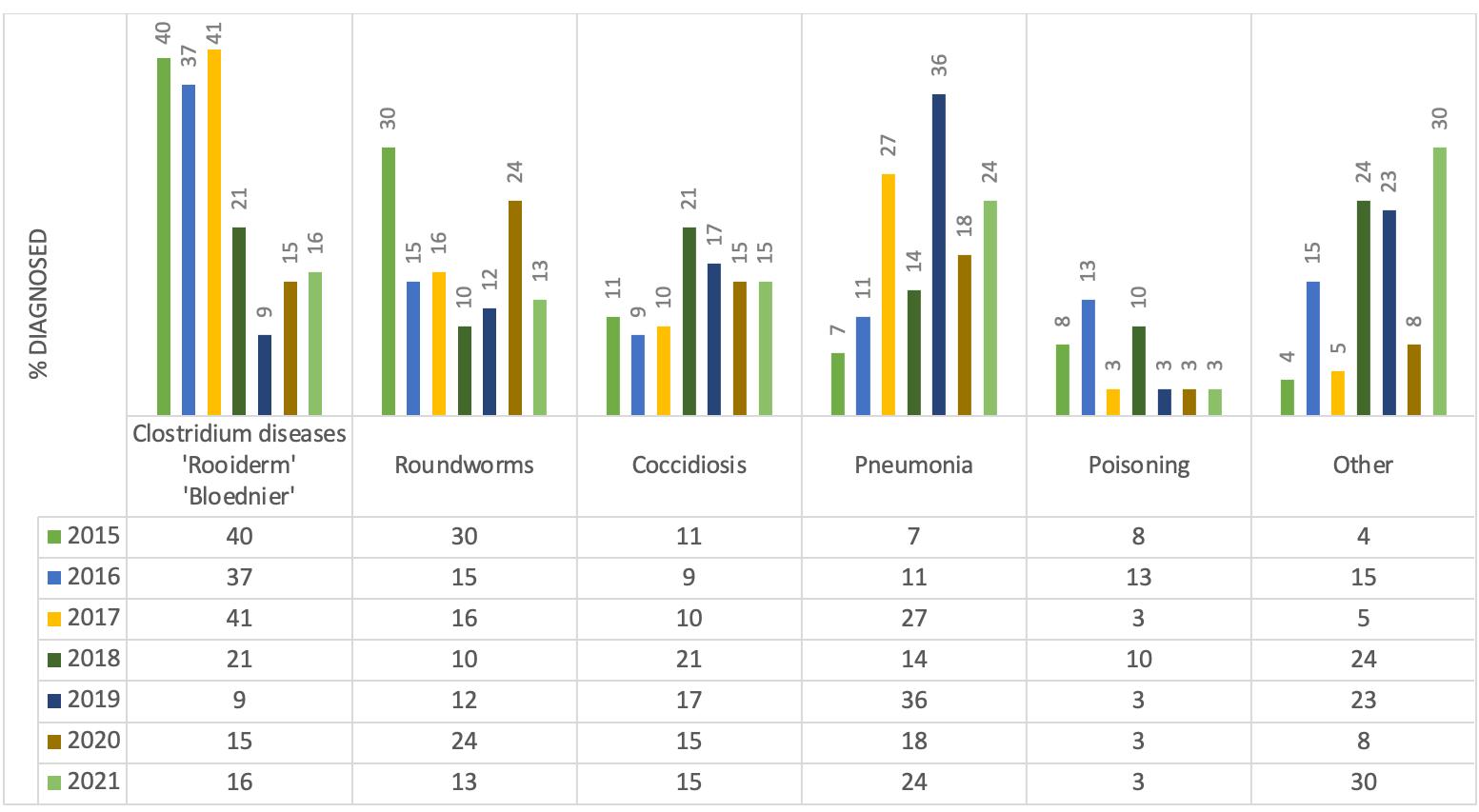

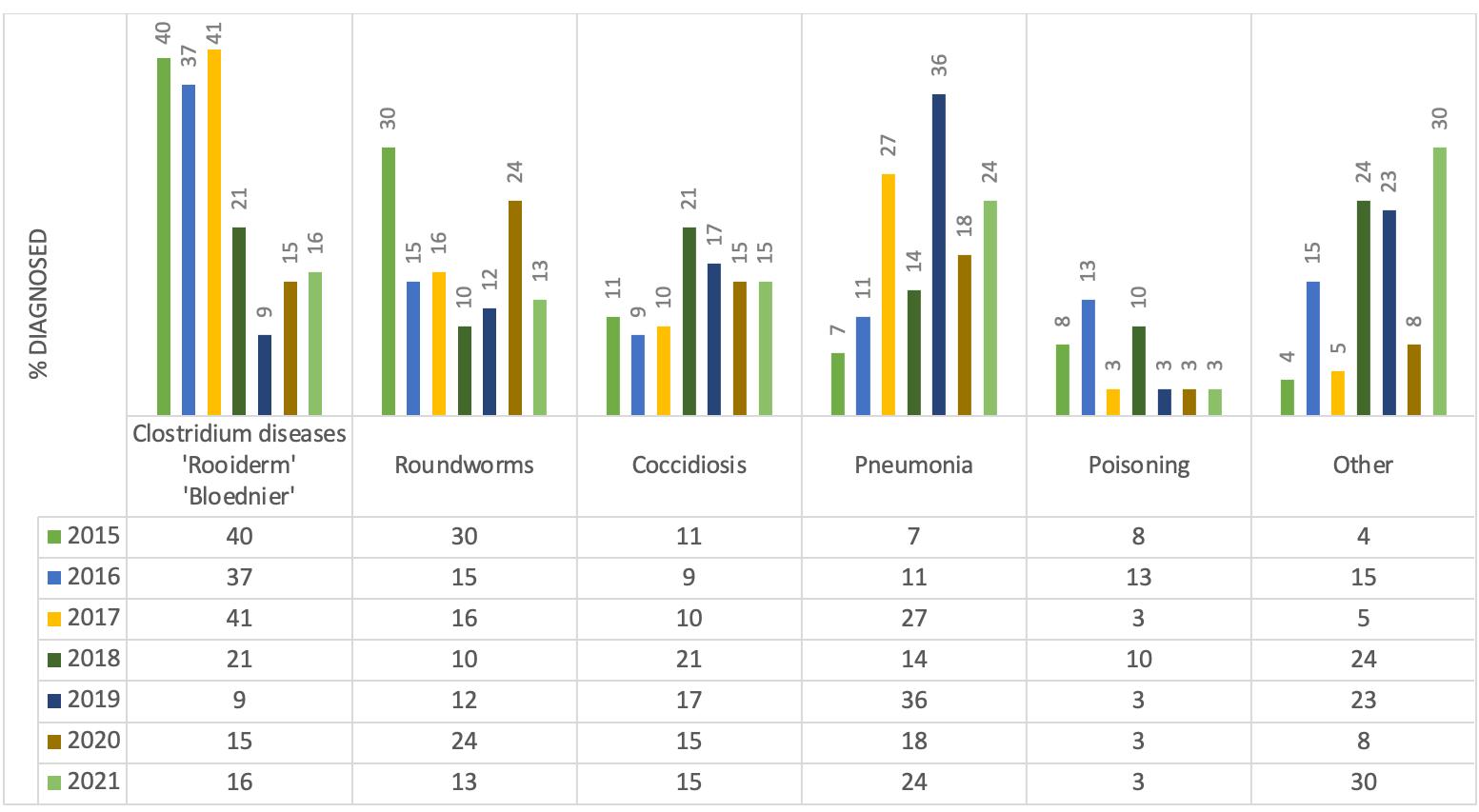

Cause of Mortality

The Mohair SA veterinary disease surveillance programme helps us as an industry to have an early warning system for impending outbreaks. It also enables monitoring and evaluation of the impact of certain diseases, as well as the discovery of “new” diseases. A total of 62 cases of multiple deaths were investigated in 2021. This gives us a window into disease occurrence within the industry.

It is interesting to note the downward trend in the occurrence of the clostridium diseases over the last five years. With the intensive feeding systems during the drought periods this would have been unexpected. It may largely be due to the fact that by far the majority of producers now use multi-clostridium vaccines compared to five or more years ago.

Of concern remains the number of pneumonia cases. These cases are often secondary to stress and underlying internal parasites. More producers need to use Pasteurella vaccination as part of their herd health management programme, as well as reviewing the underlying issues.

The biggest health problems in the industry still remain roundworms and coccidiosis . Although they are not the most frequent direct cause of death on diagnosis, they lead, by far, to the greatest number of losses in life and production. The impact on young weaned kids between January and the end of May each year is huge. Anthelmintic resistance and roundworm management strategies during these periods are of critical importance.

Biosecurity has again been highlighted with disease outbreaks in South Africa and it stresses the fact that producers and the industry need to look after themselves. On farm biosecurity, protocols are a must.

Disease surveillance forms an important part of biosecurity and we are fortunate that Mohair SA has been proactive in establishing a disease surveillance system to support its producers over the years.

MACKIE HOBSON BSc (Agric), BVSc, MRCVS Mohair SA, SAMGA Veterinarian

MACKIE HOBSON BSc (Agric), BVSc, MRCVS Mohair SA, SAMGA Veterinarian

M: 082 860 0406

E: samgavet@gmail.com

W: www.angoras.co.za

22 MOHAIR | 2022 JOURNAL | mohair.co.za

VETERINARY OVERVIEW

Managing Pesticides in the Mohair industry

Producing pesticide free mohair is very important for the global mohair industry. Currently pesticides are regulated by the Oeko-Tex Standard, which is the minimum standard the mohair processors and spinners need to comply with, to enable them to sell their mohair to international buyers.

Prior to every official mohair sale, random samples are taken from the mohair on the auction floor, these are sent to Sisyphus Scientific Solutions in Stellenbosch where they test for pesticide levels. The results of these tests are sent to Mohair South Africa and distributed to our

industry vet, Dr Mackie Hobson, and to the relevant mohair brokers. Should any producer’s mohair test positive for pesticides, Dr Mackie Hobson will contact them to establish why and to assist them to find a solution to this.

We encourage all our farmers to make sure that the products that they use on their valuable Angora goats are in accordance with the Oeko-Tex Standard.

Annually the Mohair Industry publish a list of products that comply with the Oeko-Tex Standard for use by our producers. Ectoparasite Treatment Guidelines can be found at angoras.co.za.

If a producer has any questions or concerns in regards to the above, please contact the Mohair South Africa offices, and we will gladly assist.

MOHAIR SOUTH AFRICA Industry Body (NPC)

M: 041 581 1681

E: info@mohair.co.za

W: www.mohair.co.za

23 mohair.co.za |

INDUSTRY REPORT

25 mohair.co.za | H A

HOM A I R SOUTH AF R ICA

F ACIR

MOHAIR | 2022 JOURNAL

SAMGA pushes the boundaries

In a 2 689km round trip, SAMGA manager Sanmarie Vermaak and Mohair Empowerment Trust officer Beauty Mokgwamme drove to the Western Cape, West Coast and Northern Cape, to visit mohair farmers, a school and field officers.

Roderick and Melissa Smit farm about 45km outside Piketberg and have around 50 Angora goats; Arno and Selma Pienaar farm 110km past Vanrhynsdorp and farm with about 600 Angoras in Namaqualand; and Koos du Toit is in the Robertson area where he recently started farming with Angora goats.

We shared information about the broader mohair industry, discussed what SAMGA and MET’s roles are and worked through the Angora Management Programme, dip and dose drug lists and the best practice videos.

Schools’ programmes are vital for inspiring, educating and training the youth about the Angora goat, mohair and this precious industry in South Africa.

We used this opportunity to visit Augsburg Agricultural Gymnasium, a primary and high school in Clanwilliam. Angora goats are used for youth shows and they have many learners who take part.

Their goats are in great condition and the schoolgrounds and infrastructure are incredible. We have visited this school previously and look forward to walking a road with them.

Our industry is built on relationships and collaborations, and hence we drove through to Calvinia, where we met the OVK and BKB field officers from the area. Great discussions took place and a new SAMGA branch was established.

We encourage all the field agents to think along these lines as it helps to build a stronger producer collective which is good for everyone.

It was a privilege to visit the producers from the western part of our

country. What a positive group of people with tangible passion for their goats. They appreciated the effort made to see them and were grateful for our input.

It was very humbling and a reminder to all that each producer, no matter how far away they are from Port Elizabeth, is a part of the mohair industry and family – and we need to visit family at least once a year.

SANMARIE VERMAAK SAMGA General Manager

M: 079 236 7823

T: 041 581 1681

E: samga@angoras.co.za

27 mohair.co.za |

INDUSTRY REPORT

The Purpose of MET Empowering and Training

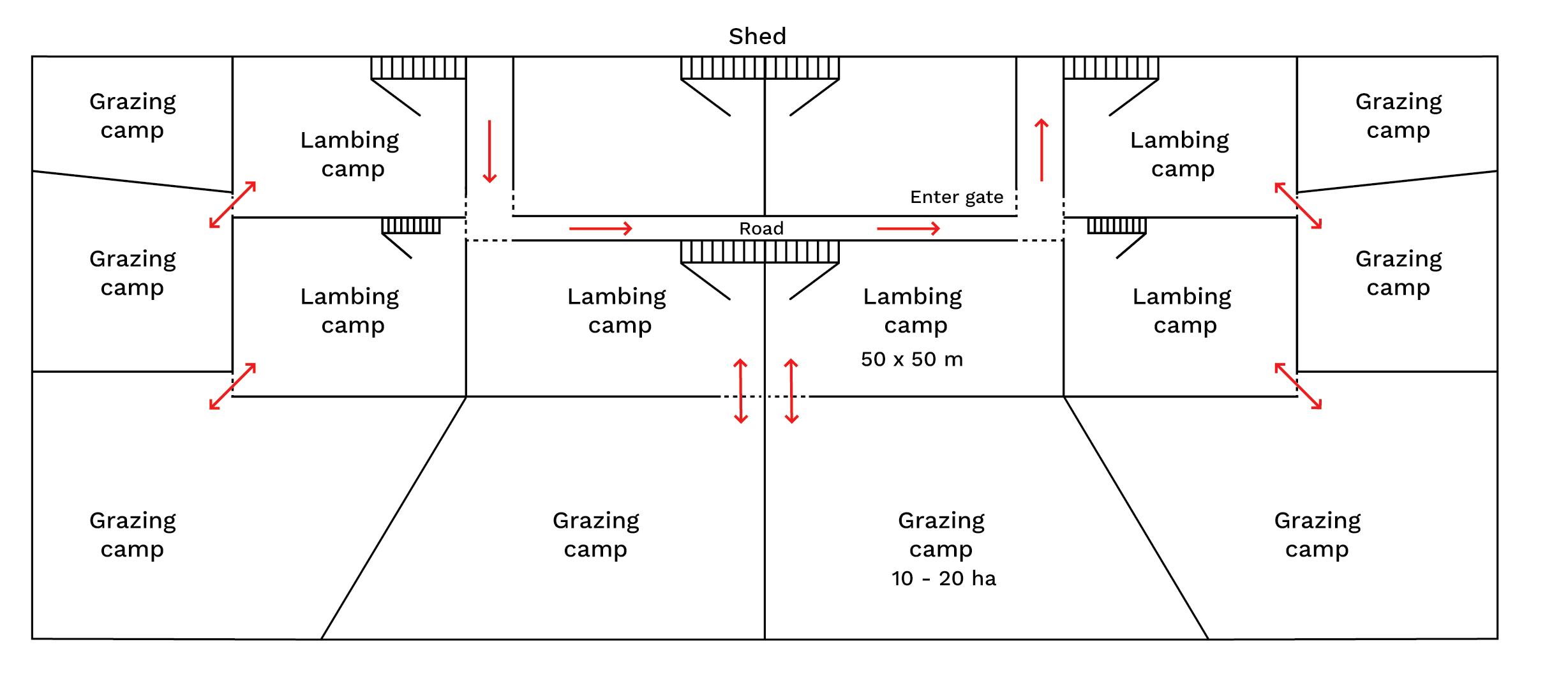

Established in 2010, The Empowerment Trust (MET) aims to identify emerging farmers on suitable farmland for farming Angora goats. The target is to identify and qualify one beneficiary every year.

Strict criteria have been laid down by the trustees of the Empowerment Trust which includes:

• A pre-requisite is that the identified farmer must have access to land (farm), whether their own or rented on a long-term lease.

• A clean criminal record.

Angora goats will be sourced and funded by the Empowerment Trust and will remain the property of the Trust until paid for in full by the beneficiary. The cost of the goats will be covered by the contractual sale of mohair through a recognised broker and will be covered over a period of five years.

The Empowerment Trust partner will sign an interestfree goat loan agreement (memorandum of emerging commercial farmer goat loan agreement) and tripartite agreement to authorise the broker to pay over to the Empowerment Trust by means of a direct deposit 25%

of the total clip income realised by the broker on behalf of the empowerment partner at any of the official mohair auctions to be held for the duration of the agreement. The balance of 75% will be paid directly by the broker to the empowerment partner.

• A maximum of 2 000 goats will be made available per project, consisting of wethers (kapaters), ewes or a combination of both.

• Beneficiaries are limited to a maximum of two per project.

• The Empowerment Trust reserves the right to withdraw from the project and remove the goats should the criteria not be met.

• Regular meetings will be attended by the project management team.

• Mohair grower branches will be encouraged to join the project management team meetings to provide advisory support in terms of mohair production.

28 MOHAIR | 2022 JOURNAL | mohair.co.za

• The potential beneficiary must be willing to make financial inputs to ensure a sustainable farming operation (e.g. covering costs of basic farming supplies needed, such as dips, doses and shearing requisites).

• The Empowerment Trust will engage the relevant government role-players to ensure that the necessary infrastructure needs are met.

• On-farm training will be critical, particularly in terms of financial management.

The objectives of the Empowerment Trust are to promote black economic empowerment within the mohair industry.

• To ensure a sustainable supply of mohair.

• To establish black participants and entrepreneurs.

• To commercialise black and disadvantaged farmers within the mohair industry.

29 mohair.co.za |

INDUSTRY REPORT

Mohair Empowerment Trust - Progress report

The Mohair Empowerment Trust is currently running eight projects involving about 5 000 goats, including two brand-new projects that started recently with their flock of kapaters. A total of six projects were settled between 2019 and 2022. Looking back, we were running about 6 500 goats at one stage and as the partners settled their loans, the goats were officially handed over to the farmers and their contracts ended.

We are excited and proud to see farmers graduating from the emerging level of farming and becoming commercial Angora goat farmers.

The Mohair Empowerment Trust farmers contribute approximately 17 000kg of RMS-certified mohair per annum and we are excited to see the average prices improve with every clip we produce per farm. The Trust continues to give support to its partners and non-partners. All the current partners (except the two new projects) and those who have graduated are RMS certified.

There are many communal and emerging mohair farmers who are not aware of the importance of RMS and we continue to educate and empower these farmers (non-MET partners). We continue to assist our partners with accredited and relevant training to ensure progress on their farms.

MET has attracted a lot of interest and support from local government and banks, and Agri-SETA has supported training.

ACKNOWLEDGEMENTS

We appreciate and value Dr Mackie Hobson’s input and service to our MET farmers. He has assisted us to decrease our animal losses which, in turn, has increased our production.

SAMGA - a special thanks to Sanmarie Vermaak who has ensured that we work closely together in training the farmers and farm workers. We appreciate the support.

Commercial Farmers - Thank you for your mentorship and support that you give our partners.

Brokers - You are our partners in this programme and the field agents have a great positive impact. Thank you.

Buyers - Thanks for buying our partners' hair and respecting what they do.

Mohair SA - Marco Coetzee thank you for your support, help and guidance with the admin and financial matters. The 'Back Office' instills confidence.

Marketing and Communication Team - Thank you for sharing beautiful stories in all mediums. We have gained great traction and attention.

Substrate Design, Ross Charnock Photography and Innova we value you.

MET chairman, Mark Shires and Trustees, we appreciate your support, input, guidance and scrutiny.

Lastly, to the partners and their families we are proud of you regardless of the challenges. We are striving for success together. Keep up the hard work as you journey to become commercial and sustainable agricultural businesses. BEAUTY

M: 083 443 2392

30 MOHAIR | 2022 JOURNAL | mohair.co.za

MOKGWAMME Mohair Empowerment Officer

T: 041 581 1681

E: info@mohairempower.co.za

CURRENT MET FARMERS

Name Farm

Saleni’s Family - Project 2

Lloyd James

Mzwakhe Ndlela

Frank Williams

Ayanda Mehlo

Johnson Mandlendoda

Brakfontein Farm

Driefontein Farm

Eureka Farm

Rietfontein Farm

Krantzkloof Farm

Geluk Farm

NEW MET FARMERS (2022)

District/Area

Kommadagga

Somerset East

Adelaide

Kommadagga

Somerset East

Middleburg, EC

Name Farm District/Area

Marlon de Jager

Mzwandile Tesana

SETTLED PROJECTS

Groottafelkop Farm

Lifford Farm

Aberdeen

Grahamstown

Name Farm District/Area

Linda & Simphiwe Fani

Katie & Simon Miners

Saleni’s Family - Project 1

Leon Barends & Dial Bakers

Harris Family

Wilson De-Bruin & Jackson Mjoli

TRAINING

Doornrivier Farm

Weltevrede Farm

Brakfontein Farm

Irene Farm

Nthwantsho Farm

Tulpleegte Farm

Type Details

SAMGA

Agri-Seta

Annual Grootfontein mohair training

I3A- Partnership

Somerset East

Somerset East

Kommadagga

Graaff-Reinet

Matatiele

Beaufort West

On-farm training, farm workers, youth show – Agricultural school

November 2021 accredited leadership training for all MET partners and July 2021 accredited shearing training by NWGA

55 first-year students

Nov 2 - 4, 2021

Hosted accredited 25-day Agri Enterprises comprehensive mentorship programme from Feb 14 - April 18 2022

Target was rural communal farmers to deliver development and support in the following areas: Middelburg, Graaff-Reinet and Jansenville

41 rural communal farmers graduated

DRDAR Farmers, graduates and officials

31 mohair.co.za |

INDUSTRY REPORT

32 MOHAIR | 2022 JOURNAL | mohair.co.za www.martyrsfordangoras.co.zawww.bordenangoras.co.za www.bordenangoras.co.za

Proud member of

33 mohair.co.za |

Borden Angora Stud

www.heritageangoras.co.za

How are the Emerging farmers doing?

By Sandy Coffey

When Simon Miners was young and growing up in Pearston in the Eastern Cape, South Africa, how was he ever to know that one day he would own and manage his own farm; that he would have a challenging yet flourishing business on the Weltevrede farm in the Smoordrift/ Cookhouse area, with the very animals that he loved as that young boy of 12?

How would his wife, Katie, know that together they would be one of the top MET (Mohair Empowerment Trust) farmers to have graduated to become commercial farmers in the district?

What about Lloyd James? Both his parents were farm workers in Pearston, so he grew up watching them work the land. How was he ever to realise his dream of having his own farm?

And yet today Simon, Katie, Lloyd and the other MET mohair farmers are living that dream.

It’s a sunny wintery day when Beauty Mokgwamme and I make our way from the Mohair SA offices to our first stop – a farm called Tulpleegte, not far from Beaufort West, in the Karoo in the Western Cape.

We are on a two-day trip to catch up with some of these framers, to see how they are doing post-Covid, post-drought and post-locust invasion.

It’s a long drive, but it goes quickly because Beauty is superb company and has a wealth of information to

share. As the mohair empowerment officer, she knows her farmers, she knows Angora goats and she knows mohair.

She shrieks with happiness as we near the farm. Her disbelief at how the land is recovering from the brutal seven-year drought is clear. We stop several times so she can inspect the plants and the ground.

So it is with optimism that we find ourselves at Tulpleegte – it’s a big farm and it’s barren, typical of the dry Karoo region in that area. But our hosts and owners of the farm, Jackson Mjoli and his partner Wilson DeBruin, are warm and inviting. We sit in the shearing shed to chat about where they are now.

After 1994, the government bought 24 farms in the area from commercial farmers to empower small-scale farmers and farm workers interested in obtaining 30year leases. This is how Jackson and Wilson came to apply for their land.

Finding competent black farmers wasn’t the challenge. The challenge was giving them the mentoring and farming support that they needed to continue flourishing.

So exactly how have they all managed to excel?

Enter the Mohair Empowerment Trust, with the aim to identify emerging farmers on a suitable property who have the potential to make a success of farming with Angora goats.

34 MOHAIR | 2022 JOURNAL | mohair.co.za

Yes, there are strict criteria to be met; some might say too strict.

The farmer must have access to land (mostly thanks to the Land Reform and Rural Development), they must be willing to make financial inputs to ensure a sustainable farming operation, and they must agree to “on-farm and off-farm” training, particularly in terms of regenerative farming practices, classing skills, animal health issues and financial management.

The goal is to uplift and empower small scale farmers to become large, commercially viable mohair farmers who will be able to participate positively within the mohair industry and serve in various mohair organisations on a high level.

Someone must run the project. Someone who knows farming, someone who can manage the emerging farmers, and someone who can get this done. Mohair SA was lucky enough to employ Beauty Mokgwamme, who is the empowerment officer. Everyone knows Beauty; I mean, everyone!

But back to Tulpleegte where Jackson and Wilson, Beauty and I walk around a portion of their farm. They are brothers-in-law and friends. Today they are 66 and 62 years old respectively – old in years, but not in spirit.

They met in 2001 in Beaufort West and have been farming together ever since. First it was on a commonage and then in 2014, through the Land and Rural Development Reform project, they were offered this farm.

water management, dipping and disease management, and how to care for the land.

“We now take care of the land first.” They are both fully hands on.

It’s tough being a farmer. Firstly, the seven-year drought was brutal. Many goats died and the land suffered enormously.

This time last year, they only had three kids. But now today, we look around and there is a buoyant nursery with countless kids frolicking in the green veld. The drought has broken.

But just when things were looking up, the locusts arrived.

“When that massive swarm arrived (the size of a huge field), it was terrifying,” remembers Wilson. “We worked up until 7pm each day trying to spray them away. They caused widespread chaos and it was heartbreaking to watch.”

Enter the Responsible Mohair Standard. Launched in March 2020 by Mohair SA and the Textile Exchange, it verifies and identifies mohair practices and farming systems that respect animal welfare and the environment.

It’s designed to ensure that animal welfare outcomes are delivered and that the goats are humanely treated, healthy and well cared for.

It further provides the industry with the tools to recognise the best practices of farmers throughout the value chain. Becoming RMS-certified makes a huge difference to the MET farmers.

“Instead of us seeing goats as an entity, we now see goats as part of the bigger world and how they fit in. The goats are our bosses – we work for the goats,” explains Jackson.

“The first thing we had to change was our mindset. It comes down to realising the impact of everything.

“No-one wanted this farm because it was barren and drought-ridden, but we wanted to take a chance,” says Jackson. “We also knew that the previous commercial owners had made a living off the farm, so there was potential”. They look at each other with pride.

“We had to use our courage,” he adds. And courage is what they have needed.

“I think we got the farm because we submitted a good business plan,” explains Wilson. “We did our homework. And we waited with hope. The day we got the farm was a very exciting one. We couldn’t believe we were now entrusted with this wonderful opportunity.

“As part of the land reform, the government assisted us with fencing, two houses, vehicles and they renovated our shearing shed. This is a 30-year lease. And that was a grant.”

They farmed slowly and deliberately with care, section by section, learning on the way – always through listening to the earth. There were hard lessons to learn.

Their progress accelerated when they were introduced to the Mohair Empowerment Trust at a SAMIL convention in Prince Albert. They were accepted into the trust and their five-year loan consisted of 200 kapaters.

They are the only MET farmers in this area and have been made to feel part of this farming community.

“We love Beauty; she’s black, she’s young, she knows her business and she loves mohair. It is her life and it is our life, so it’s a good match” says Jackson.

And it’s through Beauty that Jackson and Wilson have been exposed to extensive training – rotational grazing,

“Before RMS we might have thrown the dipping poison away down the drain. Now we know it might hurt our children for generations to come, so we dispose of it mindfully and safely.

“We now put the fire extinguishers away, and we make sure the shearers are hygienic and meticulous in their shearing. The RMS has made us much better farmers.”

Regardless of the challenges that they had during the drought, Jackson and Wilson paid off their loan in 2021. They have expressed their need for more goats and MET is evaluating this application.

“Most of the commercial farmers are looking after their land for the next generation,” says Jackson in an ardent tone. “That is what we want. A legacy for our next generation. Something that is theirs for life and beyond.”

He is quick to clarify. “We take nothing for granted. Not our farm, not our health and not our good relationship. We work hard with and for our goats.”

Katie and Simon Miners live on Weltevrede, some four dusty hours away in Cookhouse. We are greeted with great affection, hugs all around when we arrive. Their farm was one of the first to partner with the MET.

Simon was born in Pearston, on Mr Van Niekerk’s farm – his father was a farm worker there – and when he was old enough, he, too, began looking after the goats and watching and learning from his father.

And it was on this farm that he met his wife Katie, whom he married 42 years ago. She was born in

Continues on page 38

35 mohair.co.za |

MOHAIR ARTICLES

“We did our homework. And we waited with hope.”

Somerset East where her father worked on farms in that district and she, too, learnt about goat farming, classing, sorting and how to vaccinate and care for the animals.

When her father got a job on the Van Niekerks’ farm, her destiny was sealed. During this tenure, Simon, through hard work and dedication, had acquired his own goats.

Mr Van Niekerk sold his farm and Simon and Katie had to find space for their 200 goats on a commonage in Pearston. They applied to the Land Reform three times before being successful. Finally they were given the opportunity and were awarded this farm.

“We fell in love with it the minute we saw it,” says Simon. “It was ours, finally something we could call our own.

“It was a day I will never forget, walking onto this farm and into this house. I really did feel as if I was home.”

Home it may have felt like, but it still needed financial and structural attention.

With the help of Robert Turner and Lucky Mokheswane from the Eastern Cape Rural Development Agency (ECRDA), their house was made livable, and they were given funds for input costs for specific farming projects as part of the process.

The department also provided the necessary implements and tools for their farm. But livestock was never part of the deal.

yet!” “I learn something new from my parents every day,” says Sakkie.

He is hungry to be the best farmer he can be and describes some of the challenges.

“There is the fencing, the rising and exorbitant cost of electricity, and water. The rooikat and the jackals are a menace and the current fencing cannot keep them out.

“The farm has been growing vertically and now we need more land and more goats to realise our vision for the future.”

Enter the magic of the MET again. At that time Bongani Ndlovu was working for the trust and as part of his job, he paid them a visit to assess the progress. He was accompanied by the ECRDA employees Robert Turner and Lucky Mokheswane and immediately recognised they were perfect candidates for the MET.

They were awarded a loan of 133 Angora goat ewes which set them on their way. Today they are superbly successful.

They paid back their loan in 2019 and are no longer emerging farmers, but full commercial and very proud farmers.

Katie and Simon work side by side as partners, with different roles. Katie looks after the admin, the notetaking, the record-keeping and the running of the home. Simon prefers the goats and the quiet. When it’s busy, Katie will jump in and sort the mohair as well. They are a formidable duo.

There is a powerful succession plan afoot. Quietly sitting in the corner of the room, we meet Sakkie, –Katie and Simon’s son. At 42 years old, he has been working hard on Weltevrede as well. It will be his one day although Simon “is not ready to stand down just

That is to be 100% self-sufficient, with a smoothly run and fully equipped farm.

Robert Turner tells me why they are well on their way to success.

“They know their goats. They control their finances well and they have repaid all their loans by putting the profit back into the farm to keep it moving forward. And they face their challenges with intelligence and hope.

“They are the number one classers (Simon and Katie class their own hair) in the district. They really are leading the way in professionalism and profit.”

Of course, implementing solar energy will change everything, but it’s prohibitively expensive.

Beauty’s involvement has been pivotal. From the initial loan, to farming advice, financial training, admin support and vaccine programmes, she is pure gold. She has facilitated attendance at numerous training courses that aim to better farming practices.

She has assisted greatly in the animal health, has linked them to other farmers for support and is transparent in how she manages the loans.

“She has done so much for us. I cannot thank her enough. And when she visits, she always brings us snacks!” says Katie with delight.

The RMS accreditation has been crucial in their success. For starters, the accreditation translates into higher prices. And then the understanding and knowledge of how to run a farm with responsible farming practices and how it all works together makes this a valuable process.

As with Jackson and Wilson, the RMS elevates their professional standard and the pride that goes with that. Ultimately the mohair industry quality rises exponentially.

From a macro perspective, it isn’t hard to see how valuable this has been, not only to the industry, but to how it impacts each family on a micro level.

Other MET farmers have similar stories.

Johnson Mandlendoda leases the Geluk farm near Middleburg, Eastern Cape. His chance meeting with Beauty at the local Spar while shopping changed his life forever.

Today he farms 450 Angora goat kapaters and he shares his vision of the future: “We want to be the premier Angora stud breeders in the region.”

Simphiwe Fani leases a farm called Doornrivier. He has been there for nine years. In 2015 he joined MET and paid back his loan in three to five years. Today his daughter has graduated with a degree from the

38 MOHAIR | 2022 JOURNAL | mohair.co.za

“I learn something new from my parents every day”

University of Free State in Bloemfontein.

“I didn’t struggle to pay the fees because my goats paid me,” he says with pride. Lloyd James has a daughter who now lives on the farm. She, too, was educated from the profits of the farm and is the first graduate in their family. This is succession planning at its best. Talking of succession, there is such a sense of pride and the need to leave a long-lasting legacy.

Ntsika Ndlela, who farms for his father on Eureka farm in Adelaide, is poised to take over the farm. He, too, has ambitions but “the old man still has a few years in him!”

“I am still learning from him,” he smiles. “It’s comforting to know that there is a plan once the patriarch has sat down.” “We will rise and fall and rise and fall until we get to the top,” says his father, Mr Mzwakhe Ndlela. Sitting there listening to them, I have no doubt.

Simphiwe Fani has an even bigger vision.

“The big picture for the farm for me is to be able to pay the guys who help me, so they can get a share of the farm too.”

Empowerment can easily be misunderstood and mismanaged. But Jackson puts it perfectly: “Help us out now and then leave us to swim. We don’t want to be holding hands forever. We want to be standing up on our own feet, and when we do, that’s when we help someone else out. “That’s when we all win,” he says as he looks at me in a serious and steadfast manner.

So, how are the MET farmers doing?

Beauty and I reluctantly depart for Gqeberha with a spring in our step. It’s evident that this process, this empowerment, this support from the stakeholders, is not only the demonstration of true empowerment, but it has been critical for the mohair industry.

And ultimately it has been life-changing for the hardworking and dedicated farmers, here in the heart of the global mohair industry.

I am reminded of an old saying: “If you keep your face toward the sunshine, the shadows will fall behind you.”

The Mohair Empowerment Trust farmers could have written that themselves.

39 mohair.co.za |

THE HOUSE OF FIBRE

Exciting times for the new Broker

The “new kid on the block” is not that new anymore (three years old) and The House of Fibre has established itself as the leading international broker of the mohair industry.

In the first seven months of 2022 the core of the news was dominated by three factors.

Fact 01

Exciting times as we moved into a new, state of the art warehouse.

Fact 02

An exciting, innovative marketing and sustainability strategy.

Fact 03

Excellent demand and prices for mohair in the 2022 summer season. We also prepared and sold a substantial portion of the Australian clip, as well as the Lesotho and the UK clips as an international broker.

PRICES

Although it was an excellent season, consistency was key, and this year’s average prices were great all around. The House of Fibre also changed the way of reporting top prices by identifying it per micron and not per agegroup. This way it is far more accurate and fairer. The latest innovative sales report is more compact and gives more accurate information. The best prices for the 2022 summer selling season were:

TWENTY-FIVE MICRON AND FINER PRICE GROUP

• Van Hasselt Farming, Prince Albert at R899.00/kg

• SJ Nel, Steytlerville at R880.00/kg

• Lategan Junior, Aberdeen at R862.10/kg

TWENTY-SIX TO TWENTY-SEVEN MICRON PRICE GROUP

• PH Viljoen, Kleinpoort at R800.00/kg

TWENTY-EIGHT TO TWENTY-NINE MICRON PRICE GROUP

• PCL Michau, Mortimer at R745.00/kg

THIRTY TO THIRTY-ONE MICRON PRICE GROUP

• LR Eybers (PTY) LTD, Rietbron at R600.00/kg

THIRTY-TWO TO THIRTY-THREE MICRON PRICE GROUP

• SC Ferreira, Cradock at R495.10/kg

THIRTY-FOUR MICRON PRICE GROUP

• Die Wieg Boerdery (PTY) LTD, Oudtshoorn at R450.00/kg

THIRTY-FIVE TO THIRTY-SIX MICON PRICE GROUP

• House of Fibre Binning at R408.10/kg

THIRTY-SEVEN MICRON AND STRONGER PRICE GROUP

• Kareekrans Boerdery, Somerset East at R378.50/kg

40 MOHAIR | 2022 JOURNAL | mohair.co.za

PHOTO CREDIT: Samantha Reinders

Our new state-of-art warehouse

On July 1, 2022 The House of Fibre moved to new premises at 7 Metcalfe Street, Deal Party in Nelson Mandela Bay.

This was necessary because the space was limited at the old premises in Paterson Road. With 13 000 square metres of floor space it makes the new warehouse the biggest and most modern mohair-handling facility in the world. Being one of the most sustainable fibres in the world, we followed suit with our building and took the facility completely off the local municipality electricity grid to rely solely on eco-friendly solar energy. We will also harvest the water from the roof to replenish the scarce water resources of Nelson Mandela Bay.

To be completely eco-friendly, the diesel clamp Hyster fleet inside the warehouse will also be replaced by electric Hystersin time. All these specific measures live up to the standards set in the world for responsible, sustainable mohair.

House of Fibre and BKB sustainability and marketing initiatives

Sustainable supply chains are not just advisable but the key to survival and the focus for brands and retailers globally. To emphasise the urgency, it has been reported that retail-related supply chains are responsible for 40% of global greenhouse gas emissions worldwide, and with the current shocking reports on climate change, the time to change or improve practices is now.

The only way this can be achieved is through unparalleled transparency with each partner in the supply chain in aligning strategies on longer term goals, values and the investment of time and money.

To this end, in recognising the responsibility we have as a broker to represent South African mohair farmers in the global market, The House of Fibre, through our dedicated sustainability department at BKB, is committed to engage and support the daily discussions with global sustainability and buying teams.

We are actively building long-term business relationships and identifying collaborative opportunities, bringing the bookends of the supply chain together – you the farmer and the brand purchasing your fibre.

We have actively been assisting brands and retailers in understanding the impact their mohair sourcing has on the environment, the welfare of the animals and the people who work directly with and are supported through

41 mohair.co.za |

MOHAIR ARTICLES

the industry, extremely critical criteria when deciding on which raw material industries to support.

As you can imagine, this process is time-consuming as a retail product may contain a single brand logo, but it takes a giant web of stakeholders (in cases up to 17) to get a product onto a shelf.

In recognising the changing role and responsibility of a broker, The House of Fibre and BKB sent a delegation to Europe in July for the second time this year to actively engage international supply chain partners.

We met with brands, retailers, spinners, processors, and fellow brokers to support the process of collaborating to ensure you, our farmer clients, are represented when critical sourcing decisions on mohair are agreed upon and adopted within buying teams.

Highlights of our trip

1. Italy

We attended Pitti Filati in Florence, a three-day trade show where the leading spinners exhibit latest yarn developments and over 3 000 buyers from brands and retailers make purchasing decisions for the next season. In addition to pre-arranged meetings, BKB was invited by Confindustria Toscana Nord to form part of a panel discussion dedicated to animal fibre production. Lindsay Gurney, our sustainability manager, was given the opportunity to share our group vision and sustainability direction, which sparked interesting conversations bringing new opportunities.

2. France

We attended Premiere Vision in Paris, an event for fashion professionals covering yarns, fabrics, leather, designs accessories and manufacturing. We met with multiple brands and supply chain stakeholders to further identify areas to collaborate.

3. United Kingdom

Textile Exchange, John Lewis & Partners and BKB came together at the John Lewis head office in London to host a brand workshop where we were able to share our sustainability strategy and how it aligns with sourcing goals set by brands and retailers. We further were able to present our property profiling and regenerative plans for The House of Fibre-BKB group.

It was apparent that the overarching focus of brands and retailers for the near future is to source raw material (i.e. mohair) from farms that comply with regenerative programmes that provide scientifically sound reporting systems. The House of Fibre and BKB have developed a mechanism to achieve this and have called it BKB/House of Fibre – Property Profiling. Property Profiling will be offered by BKB and The House of Fibre to willing farmers with a shared objective of being able to capture the impact of their management on land and biodiversity, as well as to support any content claim they need to make in the marketplace (e.g. RWS/RMS and Regenerative).

The profiles help to describe a farm’s natural context and monitor the condition of the resource over time, and to support other vital management systems driving the business.

The monitoring will be closely guided by us and based on scientifically robust measures of accessing regeneration of the farm. This can be built on over time as farming focuses and market requirements evolve. It is

an adaptable, flexible and, most importantly, a realistic mechanism to capture a farmer’s journey and support adaptive management for long-term resilience.

The House of Fibre and BKB sustainability and environmental managers will support this programme fully, as well as our technical field officers, who are undergoing a series of regenerative training to equip them to facilitate this important process.

Very importantly, we believe in a collaborative approach and this programme has been developed in consultation with representatives from the entire supply chain –farmer to brand.

In doing this, we ensure whatever measures are implemented will receive support and buy-in from the international market.

This type of marketing, the world’s first in mohair, will guarantee The House of Fibre maintains the number one spot in the world as a mohair broker.

PIERRE VAN DER VYVER General Manager - House of Fibre

T: 066 056 8125

E: pierre.vandervyver@house-of-fibre.co.za

42 MOHAIR | 2022 JOURNAL | mohair.co.za

PHOTO CREDIT: Bronwyn Botha

Opening of Bo-Karoo Branch in 2022

These are exciting times for the industry, with the growth and expansion of producers exceeding our expectations.

Branches have been established in areas not usually associated with mohair. Last year the North West branch was opened and it continues to grow. The goats have not only adapted, they are thriving.

During the year we attended a well-organised OVK mohair day in Carnarvon, where we were asked to open a branch. The producers in the region were enthusiastic and I am sure they will make a success of their Angora goat farming.

We have further expansion planned for the near future, and I would like to thank our manager, Sanmarie Vermaak, for all the hard work she has put in to ensure the growth and success of the mohair industry.

The importance of establishing a branch cannot be underestimated. Information is vital to the modern-day farmer. The mohair industry is proud of its ability to circulate information among the producers. This is done via the weekly newsletter, the journal and SMSes when necessary.

Another important part of assimilating and learning about the mohair industry is the information day. These are usually done in conjunction with farm workers training. Any branch may contact us if it wants to host an information day.

Also important in establishing a branch is the constant updating of producers’ information, which

is essential for us to assist you.

Last, but not least, are the meetings of like-minded producers to discuss and compare their farming experiences. If you would like to establish a branch in your area, please inform Sanmarie and she will assist in this regard.

MARK SHIRES SAMGA Chairman

MARK SHIRES SAMGA Chairman

M: 072 522 0132

T: 041 581 1681

E: samga@angoras.co.za

43 mohair.co.za |

MOHAIR ARTICLES

MOHAIR | 2022 JOURNAL | Grootfontein Studente Angorastoet 323 Kontak: Hans Greeff Selfoon: 082 788 0308 E-pos: HansG@daff.gov.za Besoekers altyd welkom www.gadi.agric.za Grootfontein Studente Angorastoet is geleë net buite Middelburg Ooskaap by die Grootfontein Landboukollege, wenner en algehele kampioen van die 2016 Nasionale Angoraskou. Waarvoor wag jy? Grootfontein, waar ons kampioene teel. Tuiste van Kampioene!

The BKB journey of regenerative agriculture

Throughout our numerous engagements with brands over the last year, including participation in industry events worldwide, it is glaringly clear that most brands have answered the call to become part of the climate change solution. Many of them have committed to not only reductions in greenhouse gas emissions, but to support regenerative agriculture and biodiversity conservation.

Numerous brands started their climate change journeys with large climate change goals and an intention to test how these could be implemented.

Textile Exchange launched its Regenerative Landscape Analysis at the beginning of 2022, which provided a framework for the fashion and textile industry to understand, communicate and invest in regenerative agriculture. The analysis proved very useful to help navigate the regenerative landscape over the last year.

The key takeaways from the analysis included:

• A transition to regenerative agriculture is fundamental to supporting the long-term health

of the fashion and textile industry, and its success will depend on how these industries can work with farmers to develop more resilient systems to unlock immense social and environmental benefits.

• Regenerative agriculture can't be prescribed. It is contextual and nuanced, and relies on a fundamentally holistic systems approach that puts humans and ecosystems at its core.

• Programmes should be rooted in justice, equity and livelihoods to acknowledge the indigenous roots of regenerative agriculture and past and current racial injustice to underpin future work.

• Regenerative agriculture is about much more than increasing soil carbon levels and calls for the avoidance of carbon tunnel vision. Regenerative systems have shown a myriad of documented interdependent co-benefits related to biodiversity and water availability, as well as quality, climate resilience and livelihoods.

• We need to move out of silos to speed up the transition. It is critical to collaborate and

45 mohair.co.za |

BKB GROUP MOHAIR ARTICLES

PHOTO CREDIT: Bronwyn Botha

create a knowledge-share approach to advance regeneration.

• Understanding these key takeaways and getting to know the landscape around regenerative agriculture in the industry, BKB realised that support needed to be created to not only help brands achieve their goals and provide multiple markets for the fibre produced, but to also support the farmers under our network to implement and/or report on regeneration.

It did become quite clear that while all understood the movement was needed, what was more unclear was how to achieve these goals and how to scale up these interventions to ensure that markets supporting these efforts could still source enough fibre.

For most of the year, it became evident that Land 2 Market and ZQRX were the only certifications that were being recognised for regeneration. The challenge was the scalability, with very few farms being able to achieve the certification off the bat.

Beginning of 2022

Answering the call for regeneration and a reversal of climate change, BKB has spent the last year hard at work trying to bridge the gap between theory and practice, and finding ways that we could credibly communicate the successes of regeneration that brands and consumers could trust.

Most of the wool and mohair farmers supplying BKB operate on natural rangelands. Most of South Africa is considered a brittle environment and relies on grazing and rest cycles to promote vegetation health.

If most of our farmers are grazing on natural rangelands, how much more perfect is the opportunity for regeneration?

Identifying the potential that the wool and mohair industry could have on a movement of regeneration, work was needed to start to understand what it meant, how to support its implementation across the landscape and how to back up the story of regenerative farmers in the market.

This led us on a year-long rollercoaster ride of investigation, trial and error and ultimate adaptation as we navigated the complexity of regeneration and what it meant for our product. Through this, some realisations were made.

REALISATION 1: What does regeneration mean to BKB?

BKB recognises any land management practice that supports the functioning of the four ecosystem processes through the improvement of soil health, water security and improved biodiversity as regenerative. We recognise that there are numerous practices and management tools that farmers can use to improve the health of their rangelands.

REALISATION 2: How to implement regeneration

Regenerative agriculture relies on mimicking the natural functioning of ecosystem processes. Realising this, one has to understand the complexity of the natural world and the variation of what the different ecosystems look like and how they function. This variation is context specific and therefore it is impossible to prescribe the implementation of regeneration. Other factors that influence the context of a farmer's land are their capacity and resources and the unique objectives they each set for their businesses and rangelands. What is well described and tested are the seven principles of regeneration which provide the fundamentals of what are the key factors needed to achieve regeneration and the priority of each in succession.

REALISATION 3: How do you track regeneration?

If regenerative agriculture cannot be prescribed, it is important to gauge the impact that any land management intervention is having on the land. This can be achieved by planning one's land management (grazing planning, fire management and/or rehabilitation interventions), and for each intervention defining indicators to monitor. These indicators need to be

46 MOHAIR | 2022 JOURNAL | mohair.co.za

PHOTO CREDIT: Bronwyn Botha

relevant to the question being asked and need to be comparable over time. Setting a baseline when you start your journey and routinely monitoring the change over time is what truly supports a farmer to be adaptive and protects him/her as they implement a trial-and-error approach and constantly learn as the environment reacts and changes.

End of 2022

A new realisation which became evident at this year’s Textile Exchange conference in November was that regeneration is not a simple process-driven solution and that there is a need to rather support journeys of regeneration.

Probably the most important role-players in this journey within the fashion and textile industry remain the custodians of the land, meaning the farmers.

But while the farmers have the most opportunity to influence the regeneration of the environment, they cannot be expected to do this without support from the industries themselves.