THE JOURNAL FOR THE MOHAIR INDUSTRY VOLUME 61 2020

WOL & BOKHAAR - internasionale rolspeler www.ovk.co.za

DIE NUWE KOMMISSIESTRUKTUUR

RABAT TERUGBETALING AAN PRODUSENTE

Die rabat sal elke jaar gedurende Maart wat volg op die einde van OVK se finansiële jaareinde aan produsente uitbetaal word. Die finale rabat word dus op die kumulatiewe lewerings wat gedurende OVK se finansiële jaar verkoop is, bereken en nie as ‘n persentasie per skeersel nie. Sedert die inwerkingstelling (01/07/2019) van rabatterugbetalings, is daar alreeds ‘n bedrag van R2.2 miljoen (netto) aan produsente uitbetaal.

LOJALITEITSKORTING

Bona-fide produsente wat hulle vesel deur OVK verkoop verdien verder ook 23.9 sent per kilogram lojaliteitskorting.

BEMARKING & TEGNIESE VELDDIENSTE

U besigheid is vir ons belangrik, daarom is ons bekwame span bemarkers en tegniese veldbeamptes gereed om u as produsent by te staan met ons volledige dienstepakket.

OVK Vesel is ook gereed om u as produsent by te staan met akkreditasie vir RWS en RMS.

HOOFKANTOOR: Ladybrand 051 923 4500 • KLANTEDIENS: 051 923 4598 / klantediens@ovk.co.za

Frans Hugo • 082 854 9468 Bestuurder: Veselverkryging (Wes) Tink Strydom • 082 555 1199 Bestuurder: Veselverkryging (Oos) OVK Port Elizabeth 041 406 7500 VIR MEER INLIGTING EN NAVRAE, KONTAK:

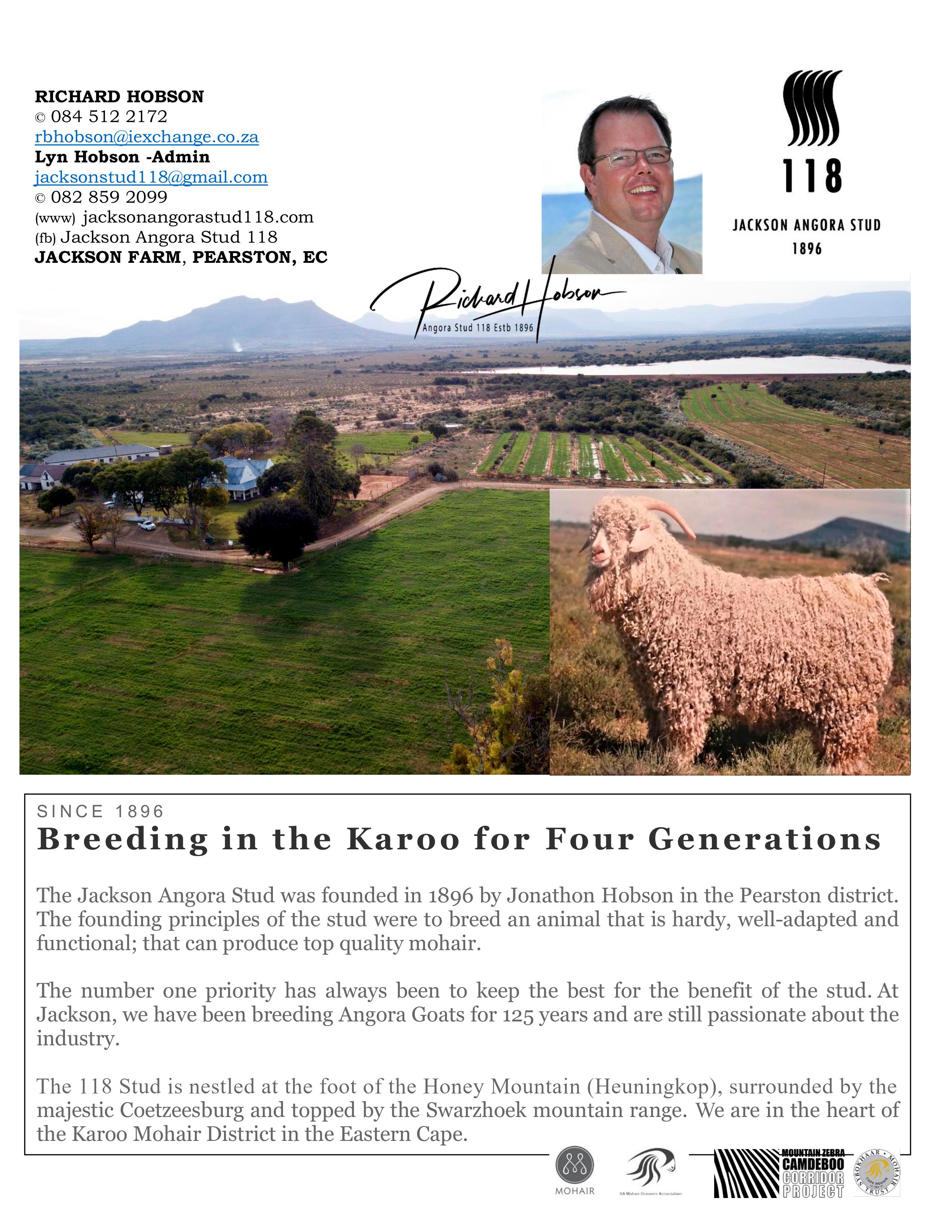

FRONT COVER

Photographer – Riaan Marais

Styling – Gugu Peteni

Model – Heleen Lombard

Location – Blaauwkrantz Farm, Uitenhage

Special thanks to Arthur Rudman and family

THE MOHAIR JOURNAL

127 Fordyce Road, Walmer, Port Elizabeth, 6070

Telephone: 041 581 1681

E-mail: info@mohair.co.za

Website: www.mohair.co.za

Official journal of the SA Mohair Growers Association, Angora Ram Breeders Society and Mohair South Africa.

Editor: Riaan Marais

Contributors:

Marco Coetzee

Cobus de Klerk

Mackie Hobson

George Hope

Lindsay Humphreys

Siobhan Momberg

Gretha Snyman

Pierre van der Vyver

Sanmarie Vermaak

Heinrich Victor

Design and Layout: WalkerDigital.co.za

Printing: Cadar Printers

The Mohair Journal does not accept responsibility for any claims made in advertisements. The opinions of contributors are also not necessarily those of the Mohair Journal.

Mohair Journal 2020 3

Contents Message from the Chairman of the South African Mohair Growers Association, Cobus De Klerk 4 Message from the Editor, Riaan Marais 5 From the SAMGA Office 7 2019 Mohair Report, Marco Coetzee 8 The Sustainable Journey of Mohair 12 Responsible Mohair Standard 14 Best Practice Video Series 17 Rain or Shine 18 Zegna auction and trophy goes to Van Hasselt 20 Van Hasselt rakes in another Miyuki Keori title 21 Webber crowned Daidoh Trophy champion 23 Textile Exchange Sustainability Conference 24 Pitti Immagine Filati 25 Cape Town Yarn Festival 26 Japan Hobby Show 27 China Mohair Fashion Design Competition 28 Mode University Mohair Designs 28 Woven from the Source 30 A Pioneering Spirit 34 Relationships that Empower 37 Semen Freezing and Insemination Trial Results in South African Angora Goats 40 Veterinary Overview 2019 43 New Kid on the Block – The House of Fibre 44 Angora Ram Breeders’ Society 48 Experienced team to lead OVK forward 50 In Memory of 53 Directory: Mohair Management and Contact Details 55 SA Mohair Growers’ Association 57 Angora Ram Breeders Society 59 Spinners 59 Local Manufacturers 61

The 2019/20 year, much like the previous year, was very challenging at a producer level. From April 2019 to January 2020 no rain worth mentioning fell over the production area. The eastern region saw some decent rain in January, February, and March last year, but only part of the western region saw any rain at all. And following March there was little to no rain until August this year.

Producers had no choice but to buy feed for their animals. Some never stopped feeding but were at least fortunate that they could feed less for a short period of time.

A major concern is that producers are chipping away at their financial resources, and we are seeing less and less feed donations. The export ban on mohair due to Foot-and-Mouth disease last year, as well as the Coronavirus pandemic, only added to the negative impact on the 2020 summer season.

The average mohair price at the close of the season stood at R246,07, close to R40 per kilogram lower than last year’s summer average. We were fortunate to see kid mohair prices do well, it was not enough to mitigate the price drop for stronger mohair variants.

However, producers who looked after their animals, and prepared their clips with care, were rewarded with good prices, well above sale averages.

The development of the Responsible Mohair Standard (RMS) escalated in 2019 and 2020, and we were glad to see its implementation earlier this year. We hope to see all producers start their process to become RMS-certified, as there is a great demand for RMS-mohair among manufacturers. Sustainability has become a

Message from the Chairman of the South African Mohair Growers Association, Cobus de Klerk

requirement for many end-users, and producers will have to adhere to these new standards, just like any other export commodity.

We hope the RMS will have a positive impact on prices at mohair sales.

In 2019 a new mohair broker opened its doors. The HOUSE OF FIBRE quickly grew, and now handles the majority of South African mohair. We wish them all the best for the future.

In 2020 the SAMGA office moved from Jansenville to the Mohair International Headquarters in Port Elizabeth and is now under the same roof as the Mohair South Africa team. Having everyone in one location will be to the advantage of the industry.

With the collapse of the world economy and the lockdown restrictions, we could do very little, and as a result, the annual SAMGA Congress could not take place in June 2020.

Between last year and this year, we saw younger producers step into pivotal roles in the mohair industry’s management structures –two younger producers were voted onto the SAMGA management, while another two were voted onto the Mohair Trust. I trust that the younger generation will take the industry to new heights. Mohair regards, J.L.

De Klerk

Mohair Journal 2020 4

My 4-year-old son recently took a headfirst dive from a jungle gym at school, resulting in a trip to the emergency room and three stitches above his right eye. There was a considerable amount of panic from everyone except Charlie himself. Other than a few tears while the doctor was injecting a local anaesthetic, he stayed calm. He asked a million questions while the doctor was stitching him up, and he loved all the attention his stitches and scar attracted.

And while he may have that scar for the rest of his life, in time it will fade and become nothing more than a memory.

Thinking about the incident some weeks later, I found myself wondering how that scenario could have played out had the circumstances been only slightly different. Had he hit something on the way down, fallen differently, or fallen from something higher, Charlie could have lost an eye, injured himself permanently, or worse.

I could not help but draw the comparison between Charlie’s fall and the last few months, not only in the Mohair industry but globally. These thoughts came to me as I was able to visit one of our mohair farms again after the Covid-19 Lockdown travel restrictions were finally lifted. I was taking pictures of baby goats at Dirko Farm near Somerset East. Kidding season is the most special time to be on an Angora goat farm - it symbolises new beginnings in the most beautiful and pure way.

Between the ongoing drought, pressures for improved sustainability from the international market, and the Covid-19 pandemic that all but shut down the entire world, it has been a

Message from the Editor, Riaan Marais

panic-filled, stressful, and in some cases, tragic time. We are still unsure what the future holds, and I don’t think a single person can say they are heading into 2021 without a few scars.

But, all things considered, we need to keep our heads high and look toward the future.

We are grateful to hear that some parts of the mohair production region received some much-needed rain, and our thoughts are with those areas that are still in the grips of the drought.

The launch of the Responsible Mohair Standard (RMS) came at a time when the world’s attention was focused on a global pandemic. However, we are very excited to see it being implemented, and interest in the new standard continues to grow. The industry, along with Textile Exchange and our global stakeholders, pulled together in the most amazing way to push mohair into the future. And the future is looking bright.

And, as always – I hope you enjoy the Mohair Journal as much as I enjoyed putting it together.

Mohair Journal 2020 5

MOHAIR IS ONE OF THE RARE NOBLE FIBRES OF THE WORLD, IT’S SUSTAINABLY PRODUCED IN SOUTH AFRICA WHERE QUALITY AND ETHICS REMAINS THE HIGHEST PRIORITY THROUGHOUT THE PROCESS. 79

P.O.

TEL +27(0)41 486 2430 | FAX +27(0)41 486 2665 www.samil.co.za | yarns@samil.co.za

Burman Road, Deal Party, Port Elizabeth, South Africa

|

Box 3446, North End, Port Elizabeth, 6056, South Africa

Sanmarie Vermaak

What a year! In January 2020 I started working at the Mohair HQ in Port Elizabeth. This was one of the biggest decisions I had to take as a person, but for me, working in the Mohair Industry, this has been the best move I could have made. The SAMGA office works very closely with MSA, and it’s amazing how much can be done when we are under one roof. What a privilege to have a SAMGA office in our headquarters.

At the start of 2020, large parts of our production area were still in the grip of this drought that has plagued the country. Recently large parts of our country received much-needed rain, although some of our production areas are still critical. Luckily during these uncertain times due to Covid-19, our producers could keep head above water with good mohair prices. SAMGA would like to thank our producers for their loyalty in these trying times.

Exciting things happened in the Mohair Industry during the first few months of 2020. Our Responsible Mohair Standards (RMS) have been approved and implemented. From SAMGA we would like to thank Lindsay Humphreys and Dr Mackie Hobson for their hard work getting our own internationally approved standards and for making sure that it is in line with what producers will be able to achieve. Thank you to the producers that already had their audits done. If there are any questions regarding the audits, please feel free to contact your mohair broker. I believe that we can all work together to make our Industry the best Industry for local and overseas markets. All producers need to know that the whole industry gets audited. From the producer all the way through the value chain to the retailer. It is also important to know that being audited is not about a premium but access to the market. Thank you to the brokers that started doing the audits at our producers. To help our producers we made Best Practice videos

From the SAMGA office

that are available on our website, www.angoras.co.za. These videos and manuals will be distributed to every producer as soon as the manuals are finished.

Although we had a rough start this year due to Covid-19, our focus for the rest of the year and next year will be on training the local shearers and farm workers so that they are up to our mohair standards. A very successful farmworkers training day was held in March 2020 in Jansenville. 115 Farmworkers attended the training. The workshop included animal handling, animal health, and mohair classing. A competition was also held amongst the participants recognising the handler whose goat was in the best condition. More of these training days will be held during the last few months of this year. Certificates of attendance were handed out after the training.

I also had the amazing opportunity to start a wonderful journey and relationship with our Empowerment Trust producers. They are so excited to be part of this wonderful industry. Congratulations to the Empowerment Partners that already had their RMS audits done. Thank you Beauty Mokgwamme for including SAMGA in the Empowerment Trust’s operations. I learn so much about our goats and farming from you!

Our industry is healthy and systems are in place so that we can look forward to exciting times ahead. We would like to wish all our producers a prosperous 2020/21 with abundant rain, top quality goats, and mohair.

Please feel free to contact me with any queries on sanmarie@ angoras.co.za; 079 236 7823 or at the Mohair HQ (041) 581 1681

For more information and news from SAMGA visit our website www.angoras.co.za, or visit our Facebook page: Mohair Growers South Africa

Mohair Journal 2020 7

The 2019 Mohair summer season started at the same level as the last sale of the 2018 winter season. Throughout the summer season the demand for finer mohair was high, which was driven by the kid-mohair sector which closed 15% higher than the start of the season. The summer season had its challenges with the foot in mouth decease prohibiting the export of mohair to China for a period of time, which specifically affected the strong adult mohair sector, closing down 7% from the start of the season. Overall, the average market indicator for the 2019 summer season was R285.74 per kg and the market closed 2.4% higher than at the start of the summer season. The highest summer price of R801.10 per kg was paid for a bale of 23-micron super style kid mohair through the official auction system.

When the market opened for the 2019 Mohair winter season, the world economy was in a dip, which impacted the mohair market directly as can be seen in figure 1 The continuous trade war between the USA and China put a lot of pressure on the adult mohair sector as the Chinese buyers’ market was low in confidence which reduced their appetite to purchase mohair. The fine adult sector closed down 16% and the strong adult sector closed down 11% from the first sale of the winter season. The demand and price for the finer mohair remained stable with the kid sector closing 1% higher than the start of the winter season. The average market indicator for the winter season came in at R224.74 per kg, which is 9% lower when compared to the first sale of the winter season. The highest winter price of R551.10 per kg was paid for a bale of 25-micron good style kid mohair through the official auction system.

A comparison of the clip composition between 2018 and 2019 can be seen in figure 2 which indicates some minor changes. Strong adult mohair decreased by 5%, fine adult mohair increased by 3% and kid mohair also increased by 1%.

The buyers’ share of the market, indicated in figure 3 remained

2019 Mohair Report

by Marco Coetzee

Financial Manager

fairly constant from 2018, with top makers taking up 75% of the market and the greasy buyers 25% of the market share.

Italy remains the leader in mohair imports from South Africa importing 38% of the total South African mohair exported. China’s figures reduced dramatically due to the reasons mentioned above but remain the 2nd biggest importer of South African Mohair (18%). Taiwan’s figures increased by 24% and they are now the 3rd biggest importer of South African Mohair (14%). Overall, the export of mohair has reduced from 2018 to 2019 as can be seen in figure 4

The South African mohair clip is estimated at around 2.08-million kilograms for the 2019 year which is 7.14% down from 2018. This is mainly due to the extreme drought conditions experienced over most of the production area. The majority of the mohair production areas have received much-needed rain early in 2020, however, it does take time to recover from such a lengthy drought.

The main focus of the South African mohair industry is sustainability and producing fibres within an ethical environment. The substantial journey of developing an internationally recognised mohair standard, the Responsible Mohair Standard (RMS), started in 2018. Mohair South Africa worked hand in hand with Textile Exchange, a global non-profit organisation, throughout 2019, and finally launching the standard in March 2020. The goals of the Responsible Mohair Standard are to provide the industry with tools to recognise the best practices of farmers and to ensure that mohair comes from farms with a progressive approach to land management, animal welfare, and social responsibility. Beyond the farm, it also aims to provide a system of traceability throughout the entire value chain – from farm to finished product. This is what the International and National brands require to purchase mohair.

Mohair South Africa will continue to treat sustainability as a journey, which we will continue to grow and improve on.

Mohair Journal 2020 8

MSA

Mohair Journal 2020 9 Figure 4 Mohair Exports 2018/2019 Exports 2018/2019 1,200,000 1,000,000 800,000 600,000 400,000 200,000 China Bulgeria Italy Japan Egypt Taiwan U.K. 2019 2018 Figure 1 Mohair Market Mohair Market 700.00 600.00 500.00 400.00 300.00 200.00 100.00 KIDS YOUNG GOATS F ADULTS S ADULTS AVERAGE 2017 W 2017 S 2018 S 2018 W 2019 S 2019 W Clip Composition 2019 Clip Composition 2018 Figure 2 KIDS Y GOATS F ADULTS S ADULTS 20% 23% 32% 24% 19% 23% 29% 29%

3

by weight 2019 Mosenthals New England Samil Stucken Suedwolle 15% 38% 37% 8% 2%

Figure

Buyers

A sustainable fibre. A responsible future.

The Sustainable Journey of Mohair

The Mohair industry has seen a decade of development in two short years – or two very long years, depending on how you choose to see it.

The evolution of consumers has put pressure on the manufacturing sector as a whole, especially on the luxury fashion industry. They are becoming increasingly sensitive to the affect their purchases may have. They want to know the people behind the product, and they want assurance that they are not playing any part in harming the environment and, in the case of natural fibres, the animals involved.

This ever-shifting focus toward the wellbeing of life and land has made sustainability and ethical practices the number one nonnegotiable in the modern world, and the mohair industry could not allow itself to fall behind.

Tackling this issue comes with the understanding that sustainability is not a quick-fix, but rather a journey in ultimately changing the underlying culture of the industry over time. 2009 saw the launch of the Sustainable Mohair Production Guidelines, a solid foundation that gave mohair a competitive edge heading into the future.

A decade later, and with the groundwork in place, Mohair South Africa (MSA) identified the need to adapt further if it was going to drive the required changes within the industry.

The first step in this new part of the journey was to find the right partners that were not only credible and respected internationally, but also had experience in developing and executing standards within natural fibre. Global fashion brands had to be included, as they represent a critical stakeholder within the value chain.

Enter Textile Exchange, a global non-profit that works closely with brands to drive industry transformation in preferred fibres,

in terms of integrity and standards, and responsible supply networks. Working with them immediately took the mohair industry’s progress to a whole new level.

Their approach was progressive, inclusive and thorough. The 24-month process saw engagement with hundreds of stakeholders, which included farmers, mohair traders, processors, spinners, luxury brands from across the world, as well as leading experts in sustainability standards and incredibly valuable input from the South African mohair industry’s own veterinarian Dr Mackie Hobson.

And after two very short (or long) years, the Responsible Mohair Standard (RMS) was officially launched in March 2020.

The RMS

Hanna Denes, senior manager of standards at Textile Exchange, said the core focus of the RMS is healthy and well cared for Angora goats.

“The Responsible Mohair Standard verifies and identifies mohair produced in farming systems that respect animal welfare and the environment. Strong assurance systems are applied and regular audits are performed on farms, before the material is tracked to the final product. The RMS is designed to ensure that animal welfare outcomes are delivered, and that the goats are treated humanely.”

MSA general manager Lindsay Humphreys said that while the journey was not always easy, having the right people to support this cause made it easier, and the end result was well worth the effort.

“We worked closely with the Textile Exchange team and, over this period, our organisation built enormous respect for Textile Exchange and what they stand for.

Mohair Journal 2020 12

Report compiled by Lindsay Humphreys and Riaan Marais, in collaboration with Textile Exchange

“We found that while the journey was a professional one, we developed close relationships with their team and deep respect for their process and approach.”

Every link in the value chain was part of the RMS development, they supported the process, and all those links now have to play their part to ensure the success of the new standard.

Farmers need to adapt their practices in line with the animal welfare, environmental management, and social welfare requirements set out in the RMS, while every other entity between the farm and end-product needs to adhere to their own strict protocols to ensure full sustainability and traceability of the fibre.

To put it plainly, launching the new standard did not flip a switch and instantaneously activate a booming supply of RMS fibre. This is merely the start of yet another journey – one that will need the continued support from all stakeholders.

“Every industry, company, and individual has a responsibility to work towards a more responsible and sustainable future, taking the environment, its animals, and its people into considerations. Sustainability is not a decision, it’s a journey, taken one step at a time,” said Humphreys.

Innovations along the way

With the mohair industry shifting almost its entire focus toward sustainability, some unique opportunities presented themselves to showcase not only the fibre but the Karoo landscape, farming practices, and the people behind the scenes.

Dr Mackie Hobson, the industry’s veterinarian, played an invaluable role not only during the development of the new standards but in assisting mohair producers in understanding what the new standards mean.

Through the South African Mohair Growers’ Association (SAMGA) Dr Hobson was involved in the production of a series of Best Practice videos. These videos explain crucial parts of the day to day activities on an Angora goat farm and are intended as educational material for farmers and farmworkers, to ensure that they adhere to the requirements of the RMS. Subjects like the proper handling of goats, how to administer certain treatments, and the shearing of goats are just some of the important aspects touched on in these videos.

These videos were uploaded onto YouTube and can be viewed by farmers and any interested parties.

With the help of virtual reality (VR) technology, the MSA team was also able to take South African farms abroad. During the 2019 Textile Exchange Sustainability Conference, held in Vancouver, MSA took VR headsets along, allowing conference-goers to ‘experience’ goats being dipped and shorn as if they were on the farm themselves.

This proved to be very popular and more applications for VR are being explored for the future. And on the local front, these tools have been a great addition to the training and development programs the industry already had in place.

The road ahead

But Humphreys, much like all the other roleplayers, realised that launching the RMS was not the end of the journey, merely the start of a new chapter that is still far from complete.

“Once we have achieved our goals, new ones will emerge, and consequently shift our focus accordingly. Long-term commitment to a crucial cause is vital to its success. I am proud to be part of this incredible industry,” said Humphreys.

Mohair Journal 2020 13

Responsible Mohair Standard

Frequently Asked Questions

Why did the industry choose to partner with Textile Exchange and together develop the Responsible Mohair Standard (RMS)?

While all existing Sustainable Standards were considered, the development of a Responsible Mohair Standard (RMS) through Textile Exchange was identified as the best solution to enhance and continue the sector’s sustainability journey, ultimately creating a genuine competitive advantage for local producers.

Textile Exchange is a progressive and inclusive global non-profit that works closely with brands to drive industry transformation in certain fibres, in terms of integrity and standards, as well as responsible supply networks. Textile Exchange developed one of the foremost voluntary wool standards in the world, making them an obvious partner with a solid foundation from which to develop the RMS.

With credibility paramount to the mohair industry, Textile Exchange was seen as the most capable of developing a standard underpinned by strong assurance systems that see regular audits of farms and tracking of material to the final product.

What role-players were involved in making the decision to partner with Textile Exchange in developing the RMS?

Industry consultations included MSA Directors Meetings, Mohair Trust Meetings, and SAMGA Congresses, with representation from a number of industry organisations, including:

» South African Mohair Growers Association (SAMGA)

» South African Wool and Mohair Buyers Association (SAWAMBA)

» South African Mohair Brokers Association

» South African Wool and Mohair Processors Association (SAWAMPA)

» Mohair Empowerment Trust

» Farmworkers Association

» Industry veterinarian Dr Mackie Hobson

It is important to note that whilst SAMGA & Dr Mackie Hobson were consulted with regards to the development of the RMS on-farm standard, the consultation regarding the actual audit process was done independently to ensure the integrity of the process.

What is going to happen to the Certified Sustainable

Mohair standard (CSM)?

While the CSM served the industry well during the first decade of our sustainability journey, it will eventually be replaced by the RMS. The CSM did not meet the need for an independent standard with the right checks and balances. To achieve the necessary credibility, an independent global standard is crucial.

What is the relationship between the Responsible Wool Standard and the Responsible Mohair Standard?

Both standards were developed by Textile Exchange and are very closely related in those aspects not specific to either goats or sheep – such as social welfare and environmental management.

Auditing processes are also very similar, and in the case of farmers who produce both mohair and wool (selling them both through the same broker), audits can be done simultaneously. Certain aspects of the audits are the same for the RMS and the RWS, while other sections will be handled separately.

A single farm may be certified to either or both of these new standards. Separate scope certificates will be issued for RWS and RMS.

What input did the mohair industry have in the development of the guidelines?

The RMS is an initiative entirely driven by the mohair industry to define criteria that will ensure a competitive and sustainable industry in the future. As South Africa is the leading mohair producer globally, it makes sense that we would be the ones leading the sustainability journey, and we are proud to be the leaders of tomorrow in this regard.

With input from the entire industry, from various associations representing stakeholders to highly-regarded veterinarians and companies and brands from throughout the entire value chain, the mohair industry selected Textile Exchange as best suited to develop the RMS. Textile Exchange also invited interested stakeholders to provide input at various stages of their process, with extensive reviews and collaborations taking place.

Mohair Journal 2020 14

Why is social responsibility part of the RMS?

The Social Responsibility section of the RMS is in line with South African labour laws, meaning that producers should be compliant with this section already.

The RMS does not supersede individual countries’ social or labour laws. However, global brands demand assurance that the social aspects of sustainability are supported within the RMS, as this forms part of their minimum requirements for procurement.

What benefits can I expect from being RMS-certified?

The RMS is all about driving longevity and access to the market, as some markets have stopped buying mohair that is not RMS certified.

Are farmers the only ones going through RMS audits?

The producer is the first link in the value chain to undergo an RMS audit. Every member of the value chain thereafter also needs to comply with RMS, undergoing registrations and audits. Processing and spinning facilities also go through extensive auditing processes to ensure they can deliver an RMS product to the market.

How long does certification take and who gives the certification?

Once an auditor has visited a producer’s farm and completed his assessment, the producer will receive a report outlining improvements (as prescribed in the RMS document) before RMS certification can take place. The producer must notify the auditor once he has made the necessary improvements, providing photographic evidence. The auditor will submit the producer’s name for accreditation. Following an administrative process between the broker and Textile Exchange, the producer will be notified once he has been granted RMS-status.

This means, other than the administrative process, the time from the audit to certification will depend on the producer.

How does a producer pass/fail a farm audit?

And how do I address any shortcomings?

Requirements for certification are assigned to different levels: critical, major, and minor.

» Minor non-conformities found during an audit, or for a

farm which has been part of a group for less than 6 months, may have a timeline of up to 1 year to address.

» Major non-conformities found during annual audits will have to be addressed within 30 days, or the producer risks losing certification.

» Critical non-conformities will result in immediate suspension of certification, and producers will need to address the issue as soon as possible.

Do I need to belong to a broker to gain RMS-certification, or can I apply directly?

Growers can become independently certified by contacting third party auditor Control Union directly.

Can I use more than one broker for different fibres?

You can be certified for the different Responsible Animal Fibre (RAF) standards with different brokers – for example, one broker for RMScertified mohair and another broker for RWS-certified wool.

If a farm holds multiple RAF scope certificates, each certification body must be made aware of this situation, and non-conformities must be shared with each applicable certification body and organisation.

If I want to change my broker, what does this mean for me practically?

Choosing which broker to sell through is entirely up to you. If you decide to change brokers, make sure your new broker is RMS-certified, and ensure that you have a clear understanding of their specific procedures.

Is the RMS mandatory?

No producer is forced to comply with the RMS.

The decision to develop and implement the RMS was the result of a clear understanding that the mohair industry needs to deliver responsibly-produced mohair measured against a well-respected and recognised independent global standard to meet market expectations, and that demand would decrease substantially if this did not happen.

To become RMS-compliant is a decision that every producer must make for themselves.

Mohair Journal 2020 15

Responsible Mohair Standard Best Practice Video Series

Aseries of videos depicting some of the best practices outlined in the Responsible Mohair Standard (RMS), has been one of the most valuable tools the South African mohair industry has developed along its sustainability journey.

The series of ten videos, released over the course of three months after the official launch of the RMS earlier this year, addresses issues around the handling and treatment of Angora goats during certain necessary practices, like shearing, dipping, and caring for their horns and hooves.

In the first video released industry veterinarian, Dr Mackie Hobson gives a brief description of the RMS, its development, and why a new international standard is important for the mohair industry.

Hobson, who features in all the videos, was instrumental in the development of the standard and was, therefore, best suited to assist in the making of the Best Practice Video Series.

Sanmarie Vermaak, manager of the South African Mohair Growers’ Association (SAMGA), said these videos are important for the training and development of everyone working with goats on a daily basis.

“These best practice videos are about more than just implementing the RMS; it is about ensuring that we give these animals that we love dearly the best possible treatment. Their wellbeing is our first priority.

“We do our best to provide practical training for farmers and workers as often as we can, but they need something they can access afterward as well. Something they can reference when they are on the farm, and these videos fill that gap,” said Vermaak

Besides farmers and their workers, contracted shearing teams can also benefit from these videos as there is one specifically discussing the shearing process. And seeing as the videos are loaded onto a public platform (YouTube) anyone looking to educate themselves on practices aimed at the wellbeing of Angora goats is welcome to access them.

“All of the videos were shot in English, but come with subtitles in Afrikaans and Xhosa as these are the languages most spoken among farmers and farmworkers in our production region,” said Vermaak.

Videos specifically addressing handling and shearing of Angora goats also come with Sotho subtitles as many of the contracted shearing teams come from the Sotho-speaking regions around Lesotho.

And while these ten videos were identified as crucial areas that needed to be addressed, Vermaak added that more videos could be added in the future if more issues are identified.

“Much like the RMS will be reviewed regularly, we will also review the need for more learning material, and in this particular case, possibly expand our Best Practice Video Series.”

Access the full list of Best Practice Videos on SAMGA’s website angoras.co.za, and click the Best Practice tab.

Mohair Journal 2020 17

Rain or Shine

“However, what you should be focused on is the maths behind weather predictions, and the people on the ground interpreting the figures for you.”

In fact, with weather apps pre-loaded onto most smartphones these days, few things are easier. Chances are if you were to unlock your phone right now, the current temperature would be right there on your screen. And with a simple click or swipe you will have a weekly, daily, or even hourly forecast of the temperature, wind, and rain in the palm of your hand.

In a recent survey conducted by the South African Weather Service, more than 60 percent of the control group got their weather information from mobile apps. Their second choice was forecasting websites, while TV and radio came in at a joint third place.

Garth Sampson, client liaison officer for the South African Weather Service (SAWS), said the survey further indicated that people trusted the forecasts from weather apps to be close to 80 percent accurate.

“While most people use weather forecasts for personal use and to check weather predictions for special occasions, the professions that most regularly make use of forecasts are people in the construction industry and the agricultural sector,” said Sampson.

People making use of forecasts are most interested in the rainfall figures (% chance of rain, amount of rain, and times the rain is expected), followed by the expected temperatures and wind speed.

But with so many apps and websites to choose from, where do you go for your information? Some apps are believed to be more accurate, while others package their forecasts in a more ‘userfriendly’ way.

According to Sampson, some users perceive international forecasters to be more technologically advanced and accurate, while others prefer attractive websites with colourful maps to represent weather conditions.

The variables that impact weather conditions – like air pressure, moisture in the air, wind speed and direction, temperatures, etc. –are measured and the values are run through a mathematical model to provide predictions of what the weather could do in the future.

These predictions are then compared to the weather that was measured on the day, to test the model’s accuracy.

“At the SAWS we use no less than 41 models for our forecasting. Our teams compare the different models to the measured conditions and discard the least accurate models. The forecasts we send out to the public are based on the models that perform the best in recent history, and which we believe will give the most accurate prediction.”

Here is a list of some of the most popular weather forecasting platforms available:

YR

WEBSITE: yr.no

MOBILE APP: Free download on Google Play (Android) and App Store (iOS). Rated 4.4 / 5 with more than 5-million downloads.

A joint operation between the Norwegian Meteorological Institute and the Norwegian Broadcasting Corporation started providing their government with weather reports as early as 1923. In 2007 they launched the platform YR.no, and less than a year later it was the country’s preferred source of weather updates, with 87 percent of the Norwegian public claiming it as their go-to weather website.

Mohair Journal 2020 18

Checking the weather forecast has never been simpler.

Picking the best weather apps to suit your needs

Today YR lists more than 12 million places across the world. Short term forecasts are updated every 3 to 7 hours, while longer-term forecasts are updated twice a day.

According to a Business Insider article from February 2020 more than 3-million South Africans get their weather updates from the Norwegian forecaster. However, it was one of the least accurate platforms, especially when measuring temperatures. Over a fourday period in February YR predicted an average high of 19 degrees (Celsius), while the measured average temperature was 28 degrees.

The website and app are simple to use, comprehensive, and accurate enough for the casual user, but using only one weather model (the European Centre for Medium-Range Weather Forecasting, or ECMWF) makes YR platforms unreliable, especially over the long-term.

ACCUWEATHER

WEBSITE: accuweather.com

MOBILE APP: Free download on Google Play (Android) and App Store (iOS). Rated 4.3 / 5 with more than 50-million downloads. Preloaded on most Android smartphones. Paid versions (Professional/Platinum) available for download from US$ 0.99.

American based forecaster AccuWeather was founded by Dr Joel Myers at the University of Pennsylvania in 1962 and has since become one of the world’s most trusted sources of weather forecasts. Employing more than 100 meteorologists, and drawing information from more than 170 weather models, AccuWeather provides forecasting for 3.5-million locations across the world.

AccuWeather has partnered with 85 percent of major mobile phone manufacturers, and many apps and widgets draw their information from AccuWeather’s database, and in 2017 ForecastWatch named it the most accurate global weather forecaster.

The free app, as pre-loaded onto Android smartphones, is simple to use and provides enough information for the casual user (temperature, the chance of rain, wind speed). For more detailed forecasting the website is more comprehensive and can predict the weather as far ahead 90 days in advance. However, forecasts that far ahead are subject to change multiple times.

WINDY

WEBSITE: www.windy.com

MOBILE APP: Free download on Google Play (Android) and App Store (iOS). Rated 4.7 / 5 with more than 10-million downloads.

Ivo Lukačovič, tech-millionaire from Prague, launched Windy in 2014 to study weather patterns because he loves to kitesurf and ski. However,

after contributing to the disaster prevention efforts of several world governments in recent years, it is believed that Windy has saved countless lives from storms and hurricanes in the last six years.

The platform draws information from four different weather models, including the ECMWF used by YR. Its satellite-style display gives regularly updated forecasts for just about any geographical location in the world, and it is fully customisable to suit the needs of the user. Colour coding for different weather events, and animations to show wind, waves, and pressure systems make it easy to understand.

And while many Karoo-farmer have no interest in where the best waves are for a weekend of surfing, being able to track the weather systems with extreme temperatures, heavy rains, or possible snowfall, could be an invaluable tool.

SOUTH AFRICAN WEATHER SERVICE

WEBSITE: weathersa.co.za

MOBILE APP: N/A

The website is clunky and takes forever to load, and there is no easy-to-use mobile app. But when it comes to accurate weather forecasting within South Africa’s border, it is hard to beat the SAWS.

Business Insider found SAWS temperature predictions to be the most accurate over a four-day period in Cape Town, during February 2020, missing the mark by less than 1 degree. And as Sampson said, where some forecasters use only a few mathematical models to predict global weather, the SAWS uses 41 models just within South Africa.

At the same time, on-the-ground experts across the country are best situated to provide the most up to date weather conditions, dam levels, and issue weather alerts and warnings where needed. According to Sampson only alerts and warnings issued by the SAWS can be used as evidence in court cases where the weather played a pivotal role.

“A simple example can be controlled burning on a farm. Your weather app shows no wind, and suddenly a gust picks up and destroys your neighbour’s crops. He then comes to court and shows a SAWS weather alert for strong winds, you could be held accountable for the damage,” said Sampson.

Without a downloadable app, it may seem like the SAWS is far behind its competitors, but its website is user-friendly on a computer as well as a smartphone. It may not be the quickest way to get your weather forecast, but it might be worth taking the time if you are planning any major operations that could be affected by the weather.

Mohair Journal 2020 19

Business Insider source: https://bit.ly/3bYyxJy

Zegna auction and trophy goes to Van Hasselt

The Ermenegildo Zegna Trophy competition has two divisions. In the first, each entrant’s bale of meticulously curated mohair is classed and given a rating out of 100. This determines the trophy winner.

The second division is determined at a special auction where each entrant’s bale is auctioned off anonymously.

Sometimes the title and the highest price belong to two different entrants, leading to the question: Who is truly the champion?

But in 2019 Van Hasselt Farming left no

room for debate, claiming both the trophy and the highest auction price, walking away as the undisputed Ermenegildo Zegna champion. Their bale of exceptional quality summer kid mohair sold for R1 105.60 per kilogram.

At the prize-giving event, held at Bridge Street in Port Elizabeth, samples from each competing bale were on display. Many of Van Hasselt Farming’s competitors agreed that they were competing for second place, as first place was never in doubt.

Since 1970 the Ermenegildo Zegna

Trophy has been a symbol of the Italian luxury brand’s relationship with South African mohair producers and has become one of the most sought-after titles in the mohair industry.

The top five places, based on the Trophy scoring system, were:

1. Van Hasselt Farming

2. Lategan Junior Farming

3. JH Bosch

And a shared 4th place for Borden Farming and Thornpark Angoras.

Mohair Journal 2020 20

Gay van Hasselt, holding the Ermenegildo Zegna Trophy, celebrated Van Hasselt Farming’s win with the rest of the top ten finalists.

Van Hasselt rakes in another Miyuki Keori title

Van Hasselt Farming claimed the Grand Champion title for the seventh time when the winners of the 2018 Miyuki Keori Mohair Trophy Competition were announced.

Speaking at the awards evening at the Drostdy Hotel in GraaffReinet, Jordi van Hasselt thanked everyone involved for making the competition possible, and in particular his mother for the active role she plays in the success of their farming operation.

The competition, established in 1980, celebrates producers for their ongoing commitment to the quality of the fibre they produce, as well as their dedication to sustainable and ethical practices.

The Miyuki Keori company has dedicated itself to excellence since it first opened its doors in 1905, and in a message to the

participants of the competition, they thanked the mohair farmers for the part they play in supplying the industry with good quality raw products.

“Our goal is delighting consumers with luxury natural fibres such as mohair, and that is only possible through the work done by the mohair producers. And for that we applaud you.”

The full list of winners are:

Grand Champion – Van Hasselt Farming

Reserve Grand Champion – GF Stegmann Farming

Champion Summer Clip – FE Colborne & Sons

Champion Winter Clip – Gert Jordaan Family Trust

Sustainability Champion – Manie du Plessis

Sustainability Reserve Champion – Ben van der Westhuizen

Mohair Journal 2020 21

Jordy van Hasselt received the Miyuki Keori trophy after Van Hasselt farming was crowned Grand Champion for 2018. From left: Billie Colborne(Champion Summer Clip), Gert and Pieter Jordaan, (Champion Winter Clip), George Stegmann (Reserve Grand Champion), Ben van der Westhuizen (Sustainability Reserve Champion) and Manie de Plessis (Sustainability Champion).

Webber crowned Daidoh Trophy champion

One of the mohair industry’s most coveted trophies made its way to Grahamstown after Paul Webber was crowned the Daidoh Trophy Competition champion for 2019. The event, hosted at the Mohair South Africa International Headquarters, honoured producers with the highest average price for their summer mohair clips, with Webber topping the list.

“This is a very pleasant surprise. Last year I wasn’t even near the top, so I am extremely grateful for this award,” said a smiling Webber after receiving the trophy.

A special message from the Daidoh Company congratulated Webber and all the other winners on the night, and thanked all producers for their dedication to producing the finest quality mohair.

“This competition is simply our way of praising all the dedicated mohair producers in South Africa. We thank you for your

commitment to your industry and all the hard work that goes into producing such an amazing fibre.”

The Daidoh Company was founded in 1879 and is one of the world’s leading producers of fine fabrics and clothing, including suits made from the finest kid mohair. In 1992 Daidoh, in collaboration with the Mohair Board, initiated the Daidoh Trophy Competition as an incentive for farmers to produce mohair of exceptional quality.

The top 5 places in the 2019 Daidoh Trophy Competition were:

1. PF Webber

2. Lategan Jnr Farming

3. David Short Farming

4. Borden Farming

5. AR Hobson

And in combined 6th place: Sarel du Plessis, F Froelich & Son, FE Colborne & Sons, McEwan Farms, MW Truter.

Mohair Journal 2020 23

Paul Webber receiving the Daidoh Trophy from MSA director Rothner Bekker

Textile Exchange Sustainability Conference

Another big step along the South African mohair industry’s sustainability journey was attending the 2019 Textile Sustainability Conference, held in Vancouver, Canada. With over 800 textile sustainability experts in attendance, representing leading brands, retailers, suppliers, and more, the conference saw a collective aim to ensure that the industry supports a healthy and sustainable future for our planet.

The mohair industry veterinarian Dr Mackie Hobson, BKB general manager for wool and mohair Isak Staats, and Mohair South Africa (MSA) general manager Lindsay Humphreys were invited to speak at this prestigious event. They shared the valuable knowledge they gained during their experience in the mohair industry, specifically sharing insights into the practical implementation strategies and challenges faced. Their stories, from a South African mohair industry perspective, changed many perceptions about local practices and the industry’s approach to sustainability and ethical farming.

South African mohair and wool were well represented at the conference, with delegates from BKB, MSA, Cape Wools, the South Africa Mohair Cluster, and Stucken in attendance. To better utilise available resources, MSA and Cape Wools shared a stand and represented both South African animal fibres in the Mohair and Wool round table.

When it came to mohair-specific issues MSA hosted its own breakaway sessions with many well-known brands and retailers – of whom many were interested in the development and progress of the Responsible Mohair Standard (RMS). There was also very valuable interaction with the Mohair Council of America, allowing MSA to share their insights and challenges with their US counterpart.

Opportunities for raising brand awareness were abundant. The very recognisable Mohair Mark appeared on every banner and screen at the conference, and MSA launched its virtual farm tours, using virtual reality headsets to put conference-goers on a Karoo farm.

Mohair Journal 2020 24

Pitti Immagine Filati

Pitti Filati is a dynamic platform for buyers, designers, processors, spinners, and the likes to come together and network and establishing relationships in the global yarn industry. It is the “go-to” international trade show for all designers and buyers to draw inspiration from unique yarns and knitting cultures from around the world.

The 85th edition of Pitti Immagine Filati, held in Florence, Italy proved to be an invaluable platform for the mohair industry as the show launched a Sustainable section entirely dedicated to sustainability and its multiple facets. The project was inspired by the growing need worldwide to respect the environment and save resources. This new section was flooded with crowds throughout the entirety of the three-day show, and it was made very clear in which direction future buyers and designers will be paying more attention. The Responsible Wool Standard (RWS) featured prominently, adding to the excitement of the imminent launch of the Responsible Mohair Standard (RMS).

The tradeshow partnered with Textile Exchange, who hosted a meeting where brands, designers, buyers, and processors discussed sustainable practices and traceability, and included Mohair South Africa’s (MSA) general manager Lindsay Humphreys to field questions on the upcoming RMS and the road to its development.

For a fourth consecutive year, MSA had a stand at the tradeshow and followed suit to the sustainable direction the show had taken. Inspired by the textured terrain and soft colours of the Karoo, the stand stood out among many. Spinners from around the world supported the MSA stand, sponsoring sample products and yarns to showcase just how innovative and trend-savvy working with mohair can be.

The stand provided a further platform for conversations focused on the RMS and investigations into allegations of animal rights violations. Many attendees wanted to know what steps have been put in place to ensure ethical practices are implemented throughout the mohair value chain. Thankfully being involved with Textile Exchange, a well-known and trusted organisation, gave designers and buyers a sense of comfort. Many were interested in the development and upcoming launch of the RMS, and communication channels were established to keep brands and retailers informed of the process.

Pitti Immagine Filati 85 fully reflected a fast-growing market that demands clarity in terms of raw materials, the origin of animals, production processes, and consumption.

Mohair Journal 2020 25

For the last four years the Mohair South Africa stand has been a very popular exhibition.

MSA general manager Lindsay Humphreys addressing conference attendees on the RMS and the mohair industry’s sustainability journey.

Cape Town Yarn Festival

Kommetjie played host to the first-ever Cape Town Yarn Festival, that saw 1 500 visitors partake in an array of activities. Online tickets were sold out prior to the event, and tickets at the door sold out quickly.

The event was buzzing with excitement even as visitors queued outside the hall of Kommetjie Primary School to get in. Inside, stalls were set up for yarn lovers to showcase and sell their products. From South African Indie Dyers, imported and local yarns, as well as fibre producers, to lucky draws, demonstrations, and workshops – the event had something exciting for every yarn fanatic.

Mohair South Africa (MSA) hosted a “Dress the Goat” competition, where the public had to register as part of a workshop to enter. The small wire-frame goats were wrapped using sponsored mohair yarn from local spinners, and participants were encouraged to be as creative as possible. MSA sponsored the first and second prize, as well as a lucky draw prize. The winning goat was named Braveheart, dressed by the talented Rachel Ferriman. We look forward to watching this festival grow.

Mohair Journal 2020 26

Japan Hobby Show

The 43rd Annual Japan Hobby Show, hosted by the Hobby Association of Japan, had the Tokyo Big Sight International Convention Centre filled with a range of handcraft and hobby exhibitors. Approximately 30 000 visitors, over a three-day period, had their pick of various activities, including cooking, ceramics, fashion, and needlework.

Mohair South Africa’s stand was set up and managed by instructors from the Japan Handicraft Association, who were well prepared to provide valuable information to visitors and host various workshops on working with mohair. MSA’s own Siobhan Momberg, from the marketing department, offered demonstrations on hand spinning mohair tops into yarns on a traditional spinning wheel. This drew a lot of attention as many attendees had never seen mohair in its various forms – from greasy mohair to tops, and finally spun yarns.

Many people were surprised by the unique qualities of mohair –especially its softness. The popularity of the fibre and stand could be measured by the attendance of constantly full workshops.

Mohair Journal 2020 27

China Mohair Fashion Design Competition

It was a proud moment for Mohair South Africa to present first prize of the competition’s 2019 edition to a very talented designer from South Africa, Leandi Mulder.

Mulder, a Durban University of Technology (DUT) alum, won the award while completing her MA degree at the Beijing Institute of Fashion Technology (BIFT). She was among 50 students, from five Chinese universities, chosen to participate in the competition. While the competition has multiple categories for students to compete in, Mulder was picked as the overall winner of the competition.

In an article written for DUT, Mulder said she is humbled by the award and the appreciation shown for her work on an international platform.

“There are so many talented students at this university, coming from all over China and the rest of the world, so standards are high and the competition is tough. I am therefore working hard and constantly appreciative of this great opportunity that has been very generously presented to me,” said Mulder.

Mode University Mohair Designs

More than 6000 people attended the fashion show and awards ceremony at the 2020 edition of the Mode University Festival, in Nagoya Japan. The festival is a popular proving ground for young, up-and-coming designers, and luxury fashion brands, like Miyuki Keori, use the event to identify talented designers they might want to recruit.

The grand finale is the student design competition. Of the 58 students that entered, only eight knitwear collections were selected for the final fashion show.

Ms Rina Kawamatsu walked away with the Mohair Prize for her collection titled Neon City. Her use of simple designs and bold colours caught the judges’ attention and secured her the top honour.

Mohair Journal 2020 28

South African fashion designer Leandi Mulder

Mulder’s design that secured her as the overall winner of the China Mohair Fashion Design Competition

Mohair Journal 2020 29

Right: Rina Kawamatsu receiving her prize from MSA’s Marco Coetzee

Left: ‘Neon City’ by Rina Kawamatsu won the Mohair Prize.

Above: Mode University always delivers some of the most innovative knitwear designs.

Woven from the Source

We are often told to travel the world, gain experience, and find our passion and inspiration. Local designer Frances van Hasselt did all that, only to realise that what inspired her was just outside her front door.

She found her inspiration in the sunsets over the Karoo, the Swartberg mountains around her hometown of Prince Albert, and the mohair shorn from Angora goats on her family’s farm.

“Growing up my dad used to take me to check on stock. He would try to explain that my interest in ‘fashion’ started in the veld; with rainfall and healthy animals. It made no sense to me at the time, but now I am eternally grateful for the passion and awareness he instilled in me; The importance of having a holistic understanding of where things come from,” Frances said.

Frances has always had a deep affinity with mohair, yet it was only after travelling and working in the fashion industry that she came to realize how incredibly special and unique mohair is. She began to question why one of the world’s most ancient, exclusive, and sustainable natural fibres was relatively unknown, particularly in South Africa, which produces and processes the majority of the world’s mohair.

Frances became determined to produce a local product far removed from the notion many have that ‘mohair is scratchy’, and which instead highlights its unique and desirable qualities. With this in mind, Frances VH Mohair took shape.

The most valuable piece of advice Frances received as a young designer was to create something specific to the South African context. With a completely local supply chain, Frances VH Mohair aims to preserve and develop the skills of traditional artisans; offer sustainable employment and training in an area where jobs are scarce, and beneficiate raw mohair by creating high-value end products.

“Growing up on a Karoo farm, where nature is the defining element, it informs every aspect of what we try to create. Once you look at the tiniest folds of a veld blom (indigenous flower) or the balancing act of dribbling rock formations, the perfection of

nature’s effortless composition is consistently the greatest and most humbling teacher.’’

Four years down the line and Frances VH is a well-known brand specialising in bespoke, hand-crafted mohair products. Their oneof-a-kind rugs, tapestries, and wall-hangings are sought-after art pieces, while more recent forays into knitwear have been celebrated both locally and abroad.

With no physical stores, Frances VH works on a made-to-order, online business model. While growth is part of the plan, Frances is content with doing business at her own pace.

Frances has recently set up a small studio in Prince Albert where clients and creatives from various backgrounds can spend time in the Karoo and get a sense of the landscape, the environment, and the animals.

“We feel strongly that a sustainable, circular economy does not start in factories. The process starts with rain, the delicate ecosystem of the veld, the role of herdsmen, the importance of healthy animals to produce quality mohair. From raw fiber we move into the process of washing, cleaning, dyeing, and spinning until finally, the yarn ends up on the loom. Weaving and finishing are the last few steps of an intricate supply chain.”

Frances believes that once you become attuned to the elements, people, and skills needed to get from farm to fabric you think, design, and manufacture differently – focusing on its simplicity rather than adding too much. You are selective and respectful of the timelessness of that piece. It turns a simple rug into an invaluable ‘homemaker’, passed down to the next generation who will weave their own memories into it.

She feels that whoever they work with – from artists to individuals – needs to have an understanding of where the product comes from, how it is made, and have experienced the Karoo and her many moods.

The past few months have affected every one of us, it has made us all stop and sit with a constantly shifting new world. Frances hopes to see the concept of ‘luxury’ evolving into a more abstract world view – clean air, open spaces, health, and appreciation for

Mohair Journal 2020 30

Frances van Hasselt – picture: Sam Reinders

nature, lengthy, unrushed meals around a table with friends and family, and building homes which make one feel safe, calm, functional, and a reflection of your world.

In the age of heightened technology and doing most of our life through screens, Frances has seen a reactive pull towards handmade, artisanal pieces with tactility, texture, imperfection, and character. “There is a certain comfort and soul that handmade objects have that is felt by users and cannot be replicated in mechanized, mass-made objects,’’ she added.

Frances VH has been fortunate to see demand for their range of products grow and hopes the shift in how people assess and find value in objects is in line with what the brand creates.

Every step of the process from spinning the yarn to carefully trimming the finished rug is carried out by hand by women in rural communities whose skilled craftmanship gives the rugs their unique identity. The quality and scarcity of the raw material, its uniquely South African heritage, and exquisite handcrafted workmanship, combine to create beautiful, bespoke rugs that reflect their Karoo origin and the unique character of each customer.

By incorporating her clients into the process, Frances believes she is playing her part in the ever-growing trend of consumer awareness and sharing the values her father instilled in her as a little girl with the rest of the world.

“We believe that consumers are not only buying products; they are buying stories.”

Mohair Journal 2020 31

Awareness of origin is an ever-growing trend among consumers, FRANCES

VH MOHAIR tells stories of the Karoo through finely crafted mohair products.

For more information on Frances VH Mohair visit their website at www.francesvh.com or visit their Instagram page – francesv.h_mohair_rugs

Frances VH Mohair rugs draws inspiration straight out of the Karoo – picture: Sam Reinders

Frances VH knitwear collaboration with Leandi Mulder – picture: Jacobus Snyman

Frances VH Mohair studio in Prince Albert – picture: Sam Reinders

A Pioneering Spirit

This phrase, made famous by historic American businessman John D Rockefeller, echoes through the illustrious history of the Stucken Group – a name that has become synonymous with mohair and excellence. And while many consider Philip Stucken the catalyst that saw his family’s business establish itself as one of the world’s mohair trading and processing kingpins, the 78-year-old readily shares the credit.

“I became totally engrossed in mohair. It became my second life. And I surrounded myself with the right people – family, customers, friends, and mentors throughout my life. I did not achieve any of this on my own, and this is as much their success as it is mine,” said Philip.

Born in Romania and raised in South Africa, Philip Stucken has spent the last 50 years adding value to the Stucken brand which dates back to its roots as an animal fibre trading company in the German port of Bremen in the mid-1800s.

A century later, the Stucken family’s South African story, and the prelude to their mohair empire, started in 1950 with Philip’s father Rudi.

“This was after the war and Germany at the time was a complete mess. My father’s goal then was to come to South Africa as a pioneer – expanding our company through establishing its own wool buying operation here. We immigrated and started our family’s journey with animal fibres in South Africa,” said Philip.

Initially processing only small amounts of wool, the full-time processing of natural fibres was added to the wool trading business after the acquisition of Gubb & Inggs in the 1970s.

Upon completing his studies in 1973, Philip joined the family business with the same pioneering spirit as his father.

“Our wool trading and processing were in excellent hands. We had a strong team of people run by a widely respected woolman, and I felt like there was little I could add to the wool side of the business. I approached my father with the idea of expanding our mohair activities, and while the idea was met with some scepticism from his colleagues, he liked my enthusiasm and agreed that it was a good idea,” said Philip.

He would never forget the first day walking into the mohair

store. Vaughn Clarke, the biggest and most respected mohair buyer at the time welcomed him with a stern warning: “When trading mohair you either lose a pound or you make a pound, nothing in between.”

At that time Mosenthals were buying 55% of the mohair on offer and 90% of the clip was exported unprocessed.

Philip’s milestones and mentors through the 80’s

A game-changer for the global mohair industry in the early ’70s was the technological developments that made Gubb & Inggs the first mill to process mohair at its origin. Converted Schlumberger wool combs allowed their mill to process mohair more economically than the equipment used by British top makers in the erstwhile specialty fibre hub of Bradford.

In 1984 the Stucken Group acquired its main mohair competitor O.S. Blenkinsop and with it Texas International Mohair. They nearly monopolised the mohair market, until International Mohair Topmakers, the forerunner for today’s SAMIL, set up shop in Port Elizabeth.

Mohair Journal 2020 34

“Do not be afraid to give up the good to go for the great.”

Philip Stucken and Mr S Kawashima at the International Mohair Association Conference in Nagoya, Japan in 1990.

Philip and the King

The good reputation of Gubb & Inggs and their mohair tops made the 80’s the “golden decade” for the Stucken mohair division. “Chairman of the International Mohair Association Tony Hobson persuaded farmers to ramp up production to feed the booming handknitting market. By 1986 local production was up to 11-million kilograms, and we acquired many new customers. Some of them left an indelible mark on my career,” said Philip.

Constantly striving for excellence cemented Philip Stucken and his family’s mohair legacy

“Mr S Kawashima, the King of Mohair in my era, taught me more about the fibre and how to sell mohair in Japan than anyone. I travelled the world with Bernard Verstraete, buyer for worldleading handknitting brand Phildar, buying 600 tons of mohair a year at the time. With my friend P.Y Chen, I travelled to mainland China - due to political trade boycotts I used my German passport, selling SA mohair shipped from Maputo, while my South African competitors stayed at home. When India became a major mohair consumer L.R. Thaker and customer-friend JL Oswal, tried to make me feel at home under very trying circumstances. Finally, Jason Kuo, the most active of agents in Taiwan, brought us the early Far-East adult mohair business - a forerunner to the demand that came from mainland China. In later years the experienced mohair marketing specialist Frank Lin and freshman Carl Zhang took up the mohair rains under the Stucken flag. These people formed part of the Stucken mohair family and contributed to our Group becoming a leading global mohair player,” said Philip.

The 90’s and beyond

The 1990s saw the Stucken Group’s further diversifying with the addition of mohair spinning.

“I felt we were too vulnerable as purely a top-maker, relying on spinners from around the world to buy our product. As luck would have it, Veldspun, a wool spinning, and weaving company next-door to Gubb & Inggs were looking to move their weaving operation but had no interest in taking their old spinning equipment along.

“We offered our friends in Japan, the Okada family, an opportunity to join us in setting up our own mohair spinning facility. They owned the mohair yarn specialist Sanko Keito and brought valuable experience to the table. In 1996 Mohair Spinners South Africa, recently rebranded as Stucken Yarns, opened its doors.”

Nine years later Philip partnered with Tom Gate to establish Specialty Yarn Dyers and in 2010 Pure Cape Textile joined the company and was rebranded as Hinterveld, which manufactures luxury mohair products and exports textiles to leading global brands. This realised his dream of seeing the Stucken Group benefitting from potential synergies along the entire value chain, from trading onward.

Opportunity in tragedy

Philip still vividly remembers the early morning phone call on Easter Sunday in 2015 while on holiday at Bushmans River with his family. The tragic events following a devastating fire at the Gubb & Inggs fibre processing facility will forever be seared into his memory.

“It was, without a doubt, the worst moment of my professional career.

“I remember looking at the wreckage where the mohair combing mill used to be, and I just cried. My mohair baby was gone,” recalled Philip.

Mohair Journal 2020 35

Introducing Mr Bernard Verstraete of Phildar, seated in front of MD David Lawford and his team, to our Mohair Combing Mill in Brady, Texas.

In the 1980’s, PY Chen and Philip Stucken travelled through mainland China selling South African mohair. Here they are in Beijing with the Chinatex raw material buyer.

Looking back, he remembers feeling numb for a few days after the fire, until suddenly meetings were taking place, investigations were finalised, and the way forward became clear.

“We realised life goes on and we need to pick ourselves up again. And more importantly, we realised from the ashes came great opportunity.”

A year later Gubb & Inggs was rebuilt, shifting the focus towards minimising its environmental footprint by lower emissions and reducing energy consumption, making it one of the most advanced facilities of its kind in the world, and once again cementing the Stucken Group reputation as world leaders.

The Group’s drive for improvement and development still continues.

Philip added that an ongoing career highlight is seeing the business remaining in the family, with his nephew Anthony Kirsten and sons Nico and Daniel each heading up a different division within the Stucken Group.

“I have peace of mind that the business will go from strength to strength. It is reassuring, not only for me but for our clients with whom we have built lasting relationships, to see the company is in good hands for the foreseeable future,” Philip said.

The Biggest Deal in the History of Mohair

Transcribed from the notes of Dr Jan van der Westhuizen, member of the South African Mohair Board 1980—1993.

I have often said: Fashion is fashion because it also goes out of fashion. This basic principle came to full expression in the late 70’s and 80’s.

From the 70’s towards the end of the 80’s, average prices increased by more than 400 percent and production grew from 3.8-million kilograms in 1975, to 12.2-million kilograms in 1988. In Europe, knitting yarn shops shot up in virtually every second street and both ladies and menswear rode the high wave.

But as stated, fashion has to change to be in fashion.

Cracks began to show in the demand for mohair. At Mohair Board auctions more and more lots were declared “not sold” and (through the Stabilisation Fund) Mohair Board stock started accumulating to a volume exceeding a full year’s production.

Nearly 100 000 bales of unsold mohair filled every conceivable warehouse and empty space in Port Elizabeth, with almost no consumer demand from the tradition markets.

Fortunately, some personalities find opportunity and potential in such “dormant” stock, and during these doldrums Mr Philip Stucken approached me with an offer to buy a sizeable volume of stock, but well below “reasonable market price”.

Where did this sudden demand come from and what was such a low price level based on?

After several deliberations some mohair stock was sold directly to Mr Stucken and the late Mr Malcolm Claassen (of Samil) for marketing mainly to China. This triggered possibly the biggest flow of mohair into the market ever. Within approximately six months the total stock, as well as continued production, was absorbed – a total of probably 150 000 bales, more than 20-million kilograms.

Since then China was established as a continued mohair market, thanks to the initial plan by Messrs Stucken, Claassen and the Mohair Board.

Mohair Journal 2020 36

The first board meeting of Mohair Spinners South Africa in 1997.

Standing: Andrew Kawalek , Kent Okada (from Sanko Keito), Dieter Mielke, Harry Bonner, Brett Flanagan and David Lawford Sitting: Yasu Shimizu, Philip Stucken, Ted Hoddy, and Werner Romer

RELATIONSHIPS that EMPOWER

Establishing a good relationship with someone who has achieved the same goals you are chasing, can be one of the greatest keys to success.

The Mohair Empowerment Trust emphasised the importance of commercial farmers’ involvement in any of the projects it takes on. It relies on the mentorship provided by successful angora goat farmers, to grow the knowledge of government placed graduates in the industry, as well as to mentor newly established emerging farmers.

The Empowerment Trust is inspired by the support and encouragement of the Wienand family, and their willingness to assist where needed.

Over the past few months, several projects of crucial importance to the development of black farmers and students owed their success to the assistance from the Wienand family.

Brett, along with his sons Mark and Charles, have been closely involved with emerging farmers in the Somerset East area. The Wienands have been farming with Angora goats since the 1940s, and believe their contributions to other farmers, especially emerging farmers, build on the success of the entire mohair industry. They have made substantial contributions to every Empowerment Trust farming project by donating breeding rams, and they have hosted groups of agricultural college graduates looking to learn more about stock farming and the mohair industry.

The Empowerment Trust manager Beauty Mokgwamme said she is very appreciative of what the Wienands have done for the Empowerment Trust and the entire mohair industry.

“In recent months their family has become more like partners to me than just farmers who offer assistance now and then. We have built a comfortable relationship and I hope to see it continue to grow,” said Mokgwamme.

She said she hopes to build more relationships like this in other parts of the mohair production region, as it offers unique opportunities for expanding the Empowerment Trust.

“If you know you have people that are willing and able to assist, it makes it easier to expand around them. Strong relationships with more commercial farmers in the broader mohair region are crucial to the success of the Empowerment Trust.”

In August 2019 Mark Wienand jumped at the opportunity to have four graduates spend a week with him during one of the most crucial times on any Angora goat farm – kidding season.

“We’ve always been keen to have students spend time on the farm with us. We try to show them as much as possible and having them here during kidding was a great learning opportunity.

“In the future, I hope to see these students achieve great things because I sincerely believe they have every chance of succeeding in agriculture,” said Mark.

In March 2020 the Wienand family donated a total of 20 breeding rams to the Empowerment Trust, where each of the ten current farming projects received two rams to improve the genetics of their flock.

Besides improving the quality of each farm’s mohair,

Mohair Journal 2020 37

The Wienand family, near Somerset East, have helped to highlight the importance of what good relationships with upcoming farmers can achieve.

Mokgwamme also saw the ram donation as a way of teaching the emerging farmers about top genetics and giving them something to aspire to.

The Wienand’s also took a special interest in the Empowerment farming project at Brakfontein Farm, due to a close connection with the Saleni family who runs it.

Ntwintle John Saleni started working for the Wienand family around the same time Brett Wienand took up the reigns at the family enterprise. His son, George Saleni, ran the Empowerment project on behalf of their family. However, when Saleni junior tragically passed away in a car accident earlier this year, his father

had to leave the employment of Brett Wienand and take up the position left vacant by his son’s passing.