5 minute read

ADDITIVE VS. SUBTRACTIVE

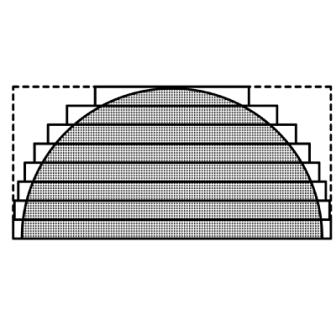

It seems like we reached the era of 3DPrinting were more and more companies rise up developing new kind of 3dprinters, bigger, faster or with complete new materials. But one thing stays mostly always the same. The printed layers are nearly always visible for the human eye . Good engineered machines could decrease the layer height to microns but that affects the fabrication time or the size of the object. So talking about big scale additive manufacturing we could wether take the visible lines as a design statement or we have to find ways to get rid of them .

But 3D-Printing gives also the freedom to produce forms which were impossible or very difficult for cncmilling . It is also a forceless fabrication method and much easier to program compared to cnc-milling strategies.

Advertisement

The future definitely belongs to 3dprinting but besides improving the machines and processes we also have to find feasible solutions on the way SUBTRACTIVE

CNC-milling is a well established fabrication method for prototyping out of a wide range of materials as well as fabricating parts with a high accuracy for the industry as mass production tool. It is one of the most precise fabrication method and is used for big scale as well as production of small pieces.

But the disadvantage of CNC-milling is that mostly by fabricating complex freeform shapes, much material is wasted because the prefabricated materials are coming in standardized shapes . That also affects the millingtime and the wear and tear of the tools. It also needs much programming effort to get to the final shape.

COMBINATION

So the combination of both methods could be very senseful . Mostly the advantage of the one is the disadvantage of the other. So by combining both we can get all the advantage and getting rid of all disadvantages .

We can create parts with walls via 3Dprinting instead of full volumes like in CNC-milling . We can also create inner structures with the advantage of 3Dprinting .

Much amount of material will be saved and milling waste can be looped back and used for 3D-printing. So we can create a closed material loop without wasting material.

We can create high accuracy parts with trusted accuracy for connection points and fittings. We can get rid of the visible printing lines and get a high quality surface finish close to injection molded parts.

We can decrease the production time by using rough printing instead of rough milling .

We can repair things instead of throwing them away and we can always correct while fabricating using both methods together. ROUGH PRINTING

CNC FINISHING

Types of hybrid manufacturing

Having 2 methods in one setup which are based on additive and subtractive methods we have the freedom to combine these in different ways. According to the shape and function of the piece which should be manufactured we consider the decision between AM and CNC translates from a binary workflow to a more continuous workflow where we can choose the most efficient way of producing by combining both methods.

The different types or workflows of hybrid manufacturing depend on the particular application which it is planned for. It could be driven by time efficiency as well as reducing the amount of material . But also novel dimensions are coming now in the field of view. It could improve structural properties or new kind of designs which where not possible with just using on of these both methods.

“ By having these both methods you have always the tool to correct the errors of the previous without any human interaction . “

Milling + 3D-Printing

This combination could be useful to let the milled part work like a mold for the 3D-printing process of a specific shape or to use the 3d-Print as a kind of coating on top of structural inferior materials

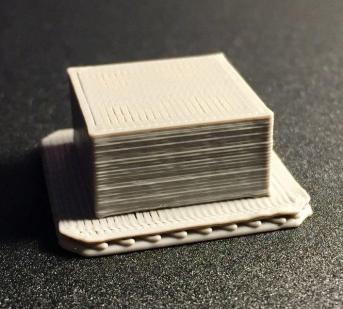

3D-Printing + Milling

This could be one of the most important economical proofs of hybrid manufacturing. Instead of roughing a big amount of material out of a big stock to create a model out of, 3Dprinting can be used for a rough-printing. This intermediate step before the final milling finish can save a lot of material and time .

3D-Printing + Milling + 3D-Printing …

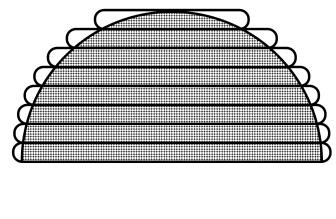

This method is often used in the metal industry where a part is first printed and then milled accurate and on top of that another 3d-print is attached to get milled again. It could be seen as a close loop. And this shows the big benefit of combining both methods over and over again to find new ways of structural improvements as well as a new way to fabricate parts which were difficult to fabricate before.

Milling + 3D-Printing + Milling

This is the method we describe later as our proof of concept. We are milling a mold with the robot to print directly on that mold. We try to print very rough, fast and with a advanced printing strategy supporting the tensile strength of the object we want to create. Afterwards we mil again over the surface to get a nice surface finish without visible printing-lines and for accurate outline dimensions and accurate working areas for the connection of other attachment parts. This method is probably the most effective in terms of producing small series of products or prototypes and gives also the possibility to brake out of the planar layer printing to the idea that we can create the physical layers over and over again and always different . Because 3d-printing just needs any surface and didn't care if it is straight, uneven or a freeform.