❖❖ STAMPING Alignment jig Valve Gears How they work Copper Boiler Alternative boiler for Fire Queen Pickering We visit a very productive club on the Yorkshire moors THE ORIGINAL MAGAZINE FOR MODEL ENGINEERS Vol. 230 No. 4718 2June – 15 June 2023 Join our online community www.model-engineer.co.uk

Published by Mor tons Media Group Ltd, Media Centre, Morton Way, Horncastle, Lincs LN9 6JR Tel: 01507 529589 Fax: 01507 371066

© 2023 Mor tons Media ISSN 0026-7325

www model-engineer co uk

EDITORIAL

Editor: Mar tin R Evans

Deputy editor: Diane Carney

Designer: Druck Media Pvt Ltd

Club News: Geoff Theasby

Illustrator: Grahame Chambers

Publisher: Steve O’Hara

CUSTOMER SERVICES

General Queries and Back Issues

01507 529529

Monday-Friday: 8 30am-5pm Answerphone 24hr

help@classicmagazines co uk

www classicmagazines co uk

ADVERTISING

Group adver tising manager: Sue Keily

Adver tising: Angela Price

aprice@mor tons co uk Tel: 01507 529411

Ad production: Andy Tompkins

By post: Model Engineer adver tising, Mor tons Media Group, Media Centre, Mor ton Way, Horncastle, Lincs LN9 6JR

PUBLISHING

Sales and distribution manager: Carl Smith

Marketing manager: Charlotte Park

Commercial director: Nigel Hole

Publishing director: Dan Savage

SUBSCRIPTION

Full subscription rates (but see page 726 for offer): (12 months, 26 issues, inc post and packing) –

UK £128 70 Expor t rates are also available, UK subscriptions are zero-rated for the purposes of Value Added Tax

Enquiries: subscriptions@mor tons co uk

PRINT AND DISTRIBUTIONS

Printed by: William Gibbons & Son, 26 Planetary Road, Willenhall, West Midlands, WV13 3XB

Distribution by: Seymour Distribution Limited, 2 East Poultry Avenue, London EC1A 9PT

EDITORIAL CONTRIBUTION

Accepted photographs and articles will be paid for upon publication Items we cannot use will be returned if accompanied by a stamped addressed envelope and recorded delivery must clearly state so and enclose sufficient postage In common with practice on other periodicals, all material is sent or returned at the contributor’s own risk and neither Model Engineer, the editor, the staff nor Mortons Media Ltd can be held responsible for loss or damage, howsoever caused The opinions expressed in Model Engineer are not necessarily those of the editor or staff This periodical must not, without the written consent of the publishers first being given, be lent, sold, hired out or otherwise disposed of in a mutilated condition or in other unauthorised cover by way of trade or annexed to or as part of any publication or advertising, literary or pictorial manner whatsoever

Vol. 230 No. 4718 2 June – 15 June 2023

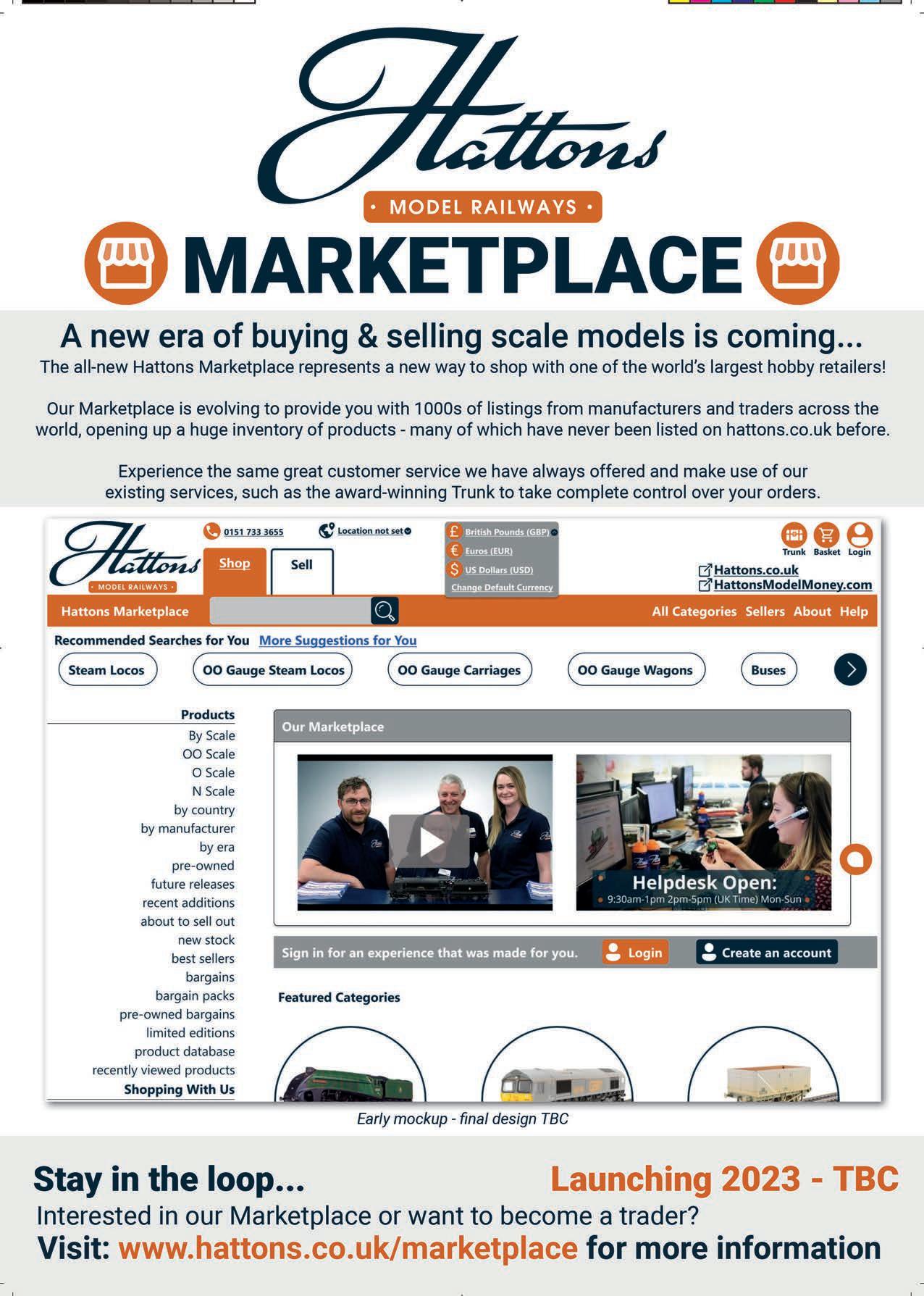

728 SMOKE RINGS

News, views and comment on the world of model engineering

729 WE VISIT PICKERING MODEL ENGINEERS

John Arrowsmith discovers an extraordinarily diverse club on the Yorkshire moors

734 THE EATING OF ELEPHANTS

Steve Goodbody argues that anything is possible if you take it a bite at a time

737 LNER B1 LOCOMOTIVE

Doug Hewson presents a true to scale 5 inch gauge model of Thompson’s B1

740 RADIAL VALVE GEARS AGAIN

Duncan Webster explores the subtleties of valve gear operation

745 BASIC OSCILLATOR STEAM ENGINE IN CAD

Luis Trincão leads us through the creation of a 3D CAD model of an oscillating steam engine

748 A COPPER BOILER FOR FIRE QUEEN

Luker presents a copper boiler for Fire Queen, as an alternative to stainless steel

753 BOOK REVIEW

Roger Backhouse reads Stewar t Har t’s book: Making Model Victorian Stationary Engines

http://www facebook com/modelengineersworkshop

http://twitter com/ modelengineers

& SAVE UP TO 49%

See page 726 for details

754 A NAMEPLATE STAMPING JIG

Graham Astbury finds a way of making sure his letters line up

759 CLUB DIARY

Future Events

760 KMYCA – A NEW RAISED MINIATURE RAILWAY

Luc Hoorelbeke tells the story of the relocation of the Koninklijke Model Yacht Club’s track in Antwerp

764 BEER HEIGHTS LIGHT RAILWAY SIGNALLING

Mike Hanscomb describes the signalling system at the Beer Heights Light Railway at Pecorama in Devon

767 RAILWAY BRAKING FOR MODEL ENGINEERS

Bob Bramson explains the science and the practicalities of stopping trains

772 CLUB NEWS

Geoff Theasby compiles the latest from model engineering clubs around the world

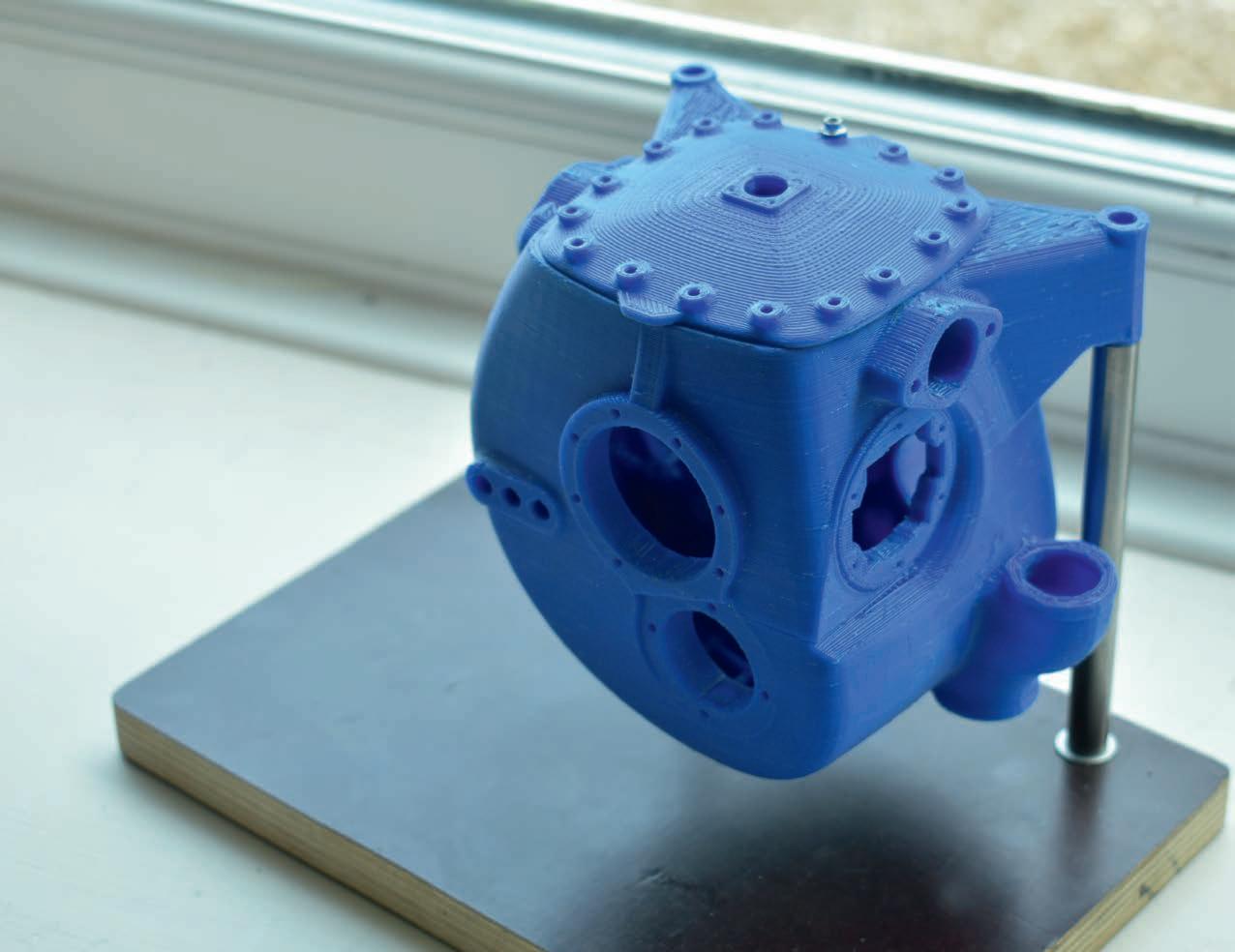

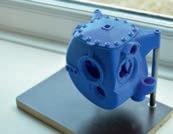

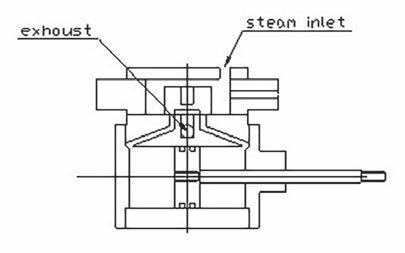

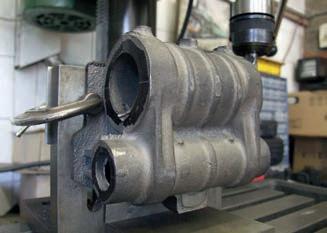

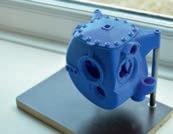

An engine gearbox pattern 3D printed to check for clearance and fit (photo: John Arrowsmith)

www.model-engineer.co.uk

N

. . .

O

T H E C O V E R

This issue was published on June 2, 2023 The next will be on sale on June 16, 2023 ❖❖ S TA M P I N G A gnmen g Valve Gears How hey wo k Copper Bo ler A ternat ve boi er or Fire Queen Pickering We vis a very p oduc ve c ub on the Yo ksh re moors THE OR G NAL MAGAZINE FOR MODEL ENG NEERS –Jo n o r on ne ommunity www mo e -e g nee co uk

SUBSCRIBE

723 www.model-engineer.co.uk 737 729

748

MODEL MAKING METALS

1/32in. to 12in. dia. bright steel, stainless steel, bronze, spring steel, brass, aluminium, silver steel, steel tubes, bolts, nuts & screws, tap dies + drills, white metal casting alloys. Fine materials, chain, plastic.

Lathe milling machines and equipment, new and secondhand.

Mail order nationwide and worldwide callers

Mon.-Fri. 9 - 5pm. All cards welcome. Send now for a FREE catalogue or phone Milton Keynes Metals, Dept. ME, Ridge Hill Farm, Little Horwood Road, Nash, Milton Keynes MK17 0EH.

Tel: (01296) 713631 Fax: (01296) 713032

www.mkmetals.co.uk

email: sales@mkmetals.co.uk

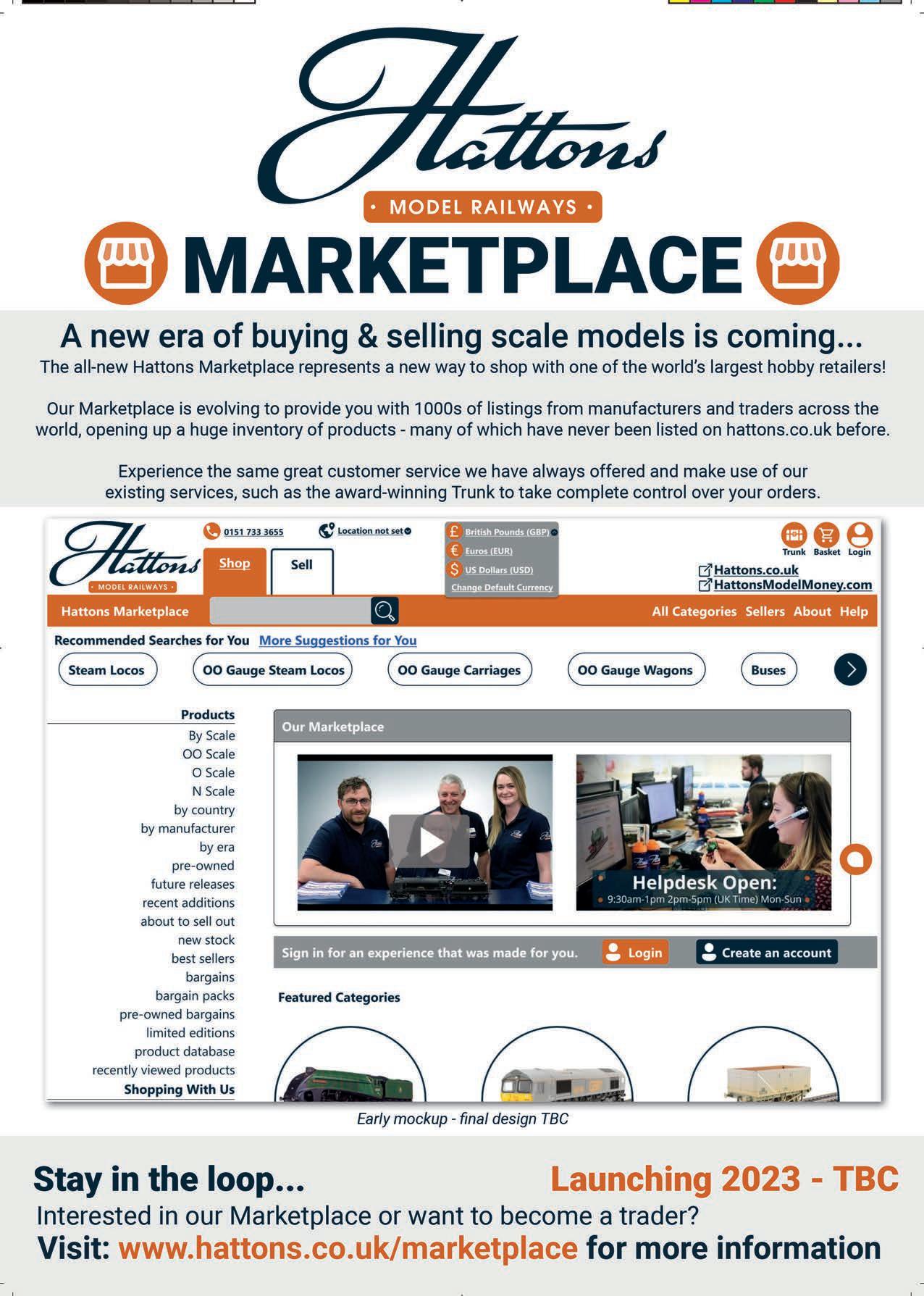

P R I N T O N LY Q u a r t e r l y d i r e c t d e b i t fo r £18.00 1 ye a r d i r e c t d e b i t fo r £65.00 1 ye a r c r e d i t / d e b i t c a r d fo r £70.00 P R I NT + D I G ITA L Q u a r t e r l y d i r e c t d e b i t fo r £21.00* 1 ye a r d i r e c t d e b i t fo r £82.99* 1 ye a r c r e d i t / d e b i t c a r d fo r £84.99* D I G I TA L O N LY 1 ye a r d i r e c t d e b i t fo r £49.00* 1 ye a r c r e d i t / d e b i t c a r d fo r £52.95* *Any digital subscription package includes access to the online archive Enjoy 12 months for just £65 GREAT REASONS TO SUBSCRIBE > Free UK deliver y to your door or instant download to your device > Great Savings on the shop price > Never miss an issue > Receive your issue before it goes on sale in the shop SUBSCRIBE AND SAVE L MAGAZINE FOR MODEL ENGINEERS V 9 N 70 4 - 1 m ou online community www m del-enginee c uk EDERATION AGM d Autumn Rally at Little Hay Midlands Show First impressions ❖❖ THE ORIGINAL MAGAZINE FOR M V 3 4 11 J n our n ne c mmu SCOT IMLEC 2023 We invite entries for this year s efficiency compeition We visit a bobb ❖❖ THE ORIGINAL MAGAZINE FOR MODEL ENGINEERS 4712Jo n ou on ne commun ty mode -eng nee L i n co l n s h i r e L i n e Exploring the history of the Lincolnshire Coast Light Railway h u r c h the 150th the s EC 2023 rd to the small ficiency competit on We V t Rye d a l e We tak p Nor th Yorksh re SAVE 49%

w w w.classicmagazines.co.uk /MEDPS 01507 529529 and quote MEDPS Lines open Monday to Friday 8 30am – 5 00pm GMT Offer ends December 31, 2023 Subscriptions will start with the next available issue Direct Debit payments will continue on the agreed plan unless you tell us otherwise To view the privacy policy for MMG Ltd (publisher of Model Engineer), please visit www mortons co uk/privacy Please visit www classicmagazines co uk/terms for full terms & conditions

Jaw Regrinding - Pete Barker

DIANE CARNEY Assistant Editor

Great Central Railway

The Great Central Railway is trying out a new timetable for its award-winning heritage trains The aim is to encourage visitors to visit the locomotive footplate and meet the driver and fireman

Trains run between Loughborough and Leicester Nor th and when they reach their destination, the heritage steam or diesel locomotive moves to the other end of the train for the return journey, a process known in railway slang as ‘running round’

General Manager o f the Great Central Railway Malcolm Holmes said, “We know so many of our visitors now have no direct memor y of steam locos when they ran on Britain’s railways but are still fascinated by them By changing our timetable and allowing trains to wait for longer at Leicester Nor th we want to encourage families to stand on the footplate of a steam engine, feel the heat of the fire and meet our engine crews It’s par t of our drive to make ever y visit rewarding and full of memories ”

An extra ten minutes was added at Leicester Nor th station so visitors alighting to stretch their legs get the chance to experience the line’s heritage steam and diesel locomotives in person

The timetable change was trialed during services over the Coronation Bank Holiday weekend It will be used again on the last Bank Holiday in May (the 29th) and again for a special gala event celebrating fifty years of trains on the heritage line over the weekend of 17th and 18th of June.

Malcolm concluded, “We hope to inspire new generations to come and

volunteer with us and learn to drive locomotives themselves Once upon a time it was said everyone wanted to grow up and be an engine driver and we want to awaken that passion!”

Summer Events

Now that the summer has arrived, the usual events will soon be upon us and it’s time to make sure that your diaries are updated with those you’d like to attend (see the Club Diary on page 759) Firstly, there are two of the locomotive efficiency competitions –LittleLEC for locomotives under 50lb and IMLEC for larger locomotives LittleLEC this year is hosted by the Swansea Society of Model Engineers at their Derwen Fawr track on the 10th and 11th of June. See www littlelec co uk for more details IMLEC is hosted by the Bristol Society of Model and Experimental Engineers at Ashton Cour t from Friday July 7th to Sunday July 9th - see www imlec uk These are both exciting events and provide a great oppor tunity to see a wide variety of locomotives in action Other popular events include the Welsh Rally at Heath Park, Cardiff (June 9th-11th, see www.cardiffmes.co.uk) and the Weeting Rally near Brandon, Suffolk (July 14th to July 16th, see www weetingrally co uk)

The Weeting Steam Engine Rally and Country Show has become a major show and features a wide range of agricultural machinery and traction engines

Fire Queen

Copper Boiler

Luk e r ’s l o c o m o t i ve d e s i g n s

( B a l l a a ra t a n d , c u r re n t l y, F i r e

Q ue e n ) fe a t u re s t a i n l e s s -

s t e e l b o i l e r s T h e s e p re s e n t

d i f fi c u l t i e s f o r m a n y

b u i l d e r s , fi r s t l y b e c a u s e t h e c e r t i fi c a t i o n re q u i re m e n t s m ay b e ra t h e r o n e ro u s ( d e p e n d i n g w h e re t h ey l i ve )

a n d s e c o n d l y b e c a u s e m o s t

b u i l d e r s p ro b a b l y h ave l i t t l e o r n o e x p e r i e n c e o f T I G w e l d i n g T h i s l a t t e r p o i n t i s n o t a m a j o r o b s t a c l e i f t h e b o i l e r i s to b e ‘ b o u g h t i n’ b u t t h e f o r m e r p o i n t m ay s t i l l p re s e n t d i f fi c u l t i e s M a n y b u i l d e r s d o l i ke to m a ke t h e i r o w n b o i l e r s t h o u g h a n d t h ey w i l l b e f a m i l i a r w i t h t h e c o n s t r u c t i o n o f c o p p e r b o i l e r s h e l d to g e t h e r w i t h s i l ve r s o l d e r Luk e r , t h e re f o re , t a ke s a b re a k f ro m t h e F i r e Q u ee n b u i l d a n d o f fe r s , s t a r t i n g i n t h i s i s s u e ( p a g e 7 4 8 ) , a d e s i g n f o r a c o p p e r b o i l e r f o r F i r e Q u ee n

Model Engineer 2 June 2023

Mar tin Evans can be contacted on the mobile number or email below and would be delighted to receive your contributions, in the form of items of correspondence, comment or ar ticles.

tons co uk 728 LittleLEC

MARTIN EVANS Editor

07710-192953 MEeditor@mor

Welsh Rally

IMLEC

Weeting

Rally

We V i s i t t h e Pickering Experimental Engineering and Model Society

John Arrowsmith visits another club in North Yorkshire well-known for the quality of its work.

My visit to PEEMS - the Pickering Experimental Engineering and Model Society - was an eyeopening experience in as much as I have never before had such a wide variety of engineering ar tefacts and equipment presented to me by club members as I did here Indeed, I had a veritable model engineering exhibition put on just for me, such that I did not know what to look at first t as an incredible display of everything from full size vintage motor cars down to small oscillating engines,

P A R T 1

all presented in the most professional way Before we get onto the details, a little about the club itself would be appropriate. PEEMS is a club that does not own any land or buildings or have any sort of railway track on which to focus its operations It was started about 20 years ago with a group of like-minded individuals who were interested in engineering but not railways as such Located in Pickering itself, the members use the workshops and facilities provided by Mike Sayers

and with 40 members at the moment they have a very wide range of skills and interests The workshop spaces available are on a par with a good sized engineering works. Simply, there’s just about everything that might be required to build quality models from, as I said, full size to small oscillating engines, but more of that later

For more formal events and meetings the club has use of a large room in the Hungate Centre in the centre of Pickering, not far from the North Yorkshire Moors Railway station It was in this

729 M E V I S I T S www.model-engineer.co.uk >>

building that they had put on a mini exhibition just for me and I have to say it was an impressive display of work which I enjoyed tremendously Members hale from different parts of Yorkshire, as well as the local area, with one member travelling up from Surrey to attend events

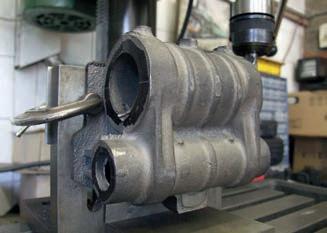

arri ed on a fine, sunny morning to find a small selection of exhibits, all set up to show how they operated, along with some static models under construction or full size examples of their type just for ie ing he first specimen on show was a new steam powered motor cycle engine

block under construction by Paul Windross This beautifully machined piece of work has all been made in his home workshop using a Myford lathe as his main machine tool (photo 1) It is intended that this power unit will be installed in a two or three wheeled vehicle to hopefully power a

UK record attempt machine

The engine itself is a full size version of Paul’s 129 33 mph tethered Hydroplane At the moment the engine is only fi ed together for testing and running on air The steam generator and burners are currently under construction

Next in line on this display

730 Model Engineer 2 June 2023

The steam powered motor cycle engine block being built by Paul Windross

An Atkinson Cycle Engine built by Mel Doran

This Atkinson Differential Engine was also the work of Mel Doran.

This stationary 20 cc OHV V-Twin 4 stroke I/C engine was designed and built by Brian Rees.

Mel Doran built this example of a Gardner O Hot Tube Gas engine

1 2 3 4 5

was the half size replica, built by Mel Doran, of a Gardner ot ube as ngine built from castings supplied by the Anson Engine Museum (photo 2 Mel also had a finely built

example of an Atkinson cycle engine on show (photo 3) alongside his example of an Atkinson differential engine (photo 4 rolific builder, rian Rees demonstrated his self

designed and built example of a stationary cc , t in four-stroke I/C engine - another high quality machine (photos 5 and 6) The late Tom Pascoe was a great friend of Mike Sayers and on his passing the family wanted Mike to have one of Tom’s models and this four cylinder I/C engine just shows the sheer quality of Tom’s model making skills (photo 7)

Moving on from the outside demonstration area I was shown into one of the club’s display rooms where an

amazing selection of work was on show. Much of it was the tooling for the well-known 4½ litre Bentley engine built by Mike Sayers (photo 8) including the wooden former for the radiator (photos 9 and 10) ome of the igs and fi tures were works of art on their own, for example the engine to supercharger coupling (photo 11) and the little blower rotor test rig for use with the Bentley engine (photo 12); superb or manship n the ne t table were some of the patterns

731 M E V I S I T S www.model-engineer.co.uk >>

Brian starting his OHV engine with an electric drill

A 4 cylinder I/C engine built by the late Tom Pascoe, now owned by Mike Sayers

The Blower rotor test rig

One of the superb components used on the Bentley

The well-known Bentley turbocharged engine built by Mike Sayers

The wooden forming block for the Bentley radiator

The front radiator casting

11 12 6 7 8 9 10

and formers used in making the radiator (photo 13 ther exhibits in this room included a fine three cylinder n ani ero engine (photo 14) and, made using a modern 3D printer, an example of a gearbox, produced to see how it would loo and fit hen made for the engine (photo 15).

I then went into the workshops and here was an almost complete manufacturing plant capable of facilitating the most complicated and accurate work Lathes, milling machines, grinders, sheet metal work machines, welding equipment and a host of all the necessary associated small tools and fittings collets and muffler furnaces etc It’s no wonder that the members here can produce such fine or to such high standards with all this equipment available When you have models like the 1929 4½ litre supercharged Bentley engine in one-third scale built by Mike Sayers standing in the adjacent showroom, how can you not have the incentive to produce top class work? It is probably the finest model

engineers’ workshop I have ever had the pleasure of visiting I have shown some of the smaller models that were working outside but to then be shown the full size examples that have been refurbished or built in this space was another revelation The two seater, three litre Bentley motor car circa 1924 (photos 16 and 17) had just 4 or 5 pieces available to start the re-build This process started in 1987 and took 10 years to complete Since completion t he car has toured widely including the West Coast of the USA It has also graced many rallies and shows in the UK with its presence. Next to this was an equally impressive Riley Lynx This again had been rebuilt from just a collection of bits Although the chassis and engine was sound, all the body work and wings have been made here and this took 15 years to complete Today it looked an absolute picture (photos 18 and 19) If that was not enough perhaps the twin cylinder 1928 1000cc Ind ian motorcycle would take your fancy It was described as a box of old bits and pieces when it arrived; no loo at it t ust oo es quality (photo 20) Alongside these exceptional examples were three more motor cycles that have been ‘through the or s he first of these was a 1937 Rudge 500 which was bought at auction with a broken frame and worn out engine It has a bit of history in that in 1990 it was ridden at the Royal Tournament by the

732 Model Engineer 2 June 2023

A selection of tools and formers used for building the Bentley engine

A 1930 3 litre Bentley 2 seater completely rebuilt in the main workshop

The 3D printed gearbox housing to check dimensions and ft

The dashboard of the Bentley

The Riley Lynx sports car again completely rebuilt in the workshop

13 14 15 16 17 18

An Anzani 3 cylinder aero engine

Motor Cycle Display team

(photo 21) Next in line was a 1962 Norton 650SS which was bought as a wreck and threw up many other problems during the refurbishment (photo 22) Both these bikes

were rebuilt by Jonathon Milner The third bike in this collection was a 1957 elocette aliant hich has been restored by Rob Davey t is fitted ith a ater cooled elocette engine obtained from a Police LE bike

enquiries are still ongoing It also has various additions and works to get to this standard (photo 23)

I m u s t m e n t i o n a m o d e l e n g i n e t h a t w a s r e s i d i n g i n t h e w o r k s h o p T h i s i s a m o d e l o f t h e e n g i n e f r o m

t h e c a r w h i c h w o n t h e v e r y f i r s t B r i t i s h G r a n d P r i x M i k e h a s b e e n g i v e n f u l l a c c e s s t o t h i s e n g i n e w h i c h h a s b e e n s t r i p p e d d o w n c o m p l e t e l y A f u l l s e t o f d r a w i n g s h a s b e e n m a d e a n d n o w t h e e n g i n e i s s l o w l y c o m i n g t o g e t h e r I t l o o k s l i k e l y t o b e a n o t h e r m a s t e r p i e c e t o a d d t o t h e c o l l e c t i o n ( p h o t o 2 4 )

So where do we go from he re, having exhausted all the models, tools and equipment at this location? The group, including my wife and I, were then taken into Pickering where another display of models and equipment had been set out for us It was like a one man model engineering exhibition, but all that will be revealed in Part 2 in the next issue of Model Engineer

733 M E V I S I T S www.model-engineer.co.uk

The Riley engine compartment

A 1935 Rudge motor cycle ex Motor Cycle Display team.

A Velocette Valiant motor cycle circa 1957.

The Norton 650 SS bike.

A new Grand Prix engine under construction.

A 1928 Indian twin cylinder 1000cc motor cycle

1937(56) London Div Signals

To be continued 21 22 23 24 19 20

T h e E a t i n g o f E l e p h a n t s

Steve Goodbody

In the late spring of 1985, the c field club s ne rail ay at entley ildfo l ar and Motor Museum has officially opened for business ith his ob oy also finished, and the e el e aminations a fast receding memory, and ith the school summer holidays no in session, the si teen year old author had settled do n for t o months of late mornings and intensi e lethargy. his, ho e er, did not last long.

Summer holidays

am, it appears, utterly incapable of rela ing at least in the sense that most people interpret the ord o nothing can t it still fidget mpty my mind thousand thoughts run through it o reiterate, am not one of life s rela ers, at least not in the classical sense, and by the third day of my summer holidays ne this for a fact

ertainly, there ere the usual ee ly acti ities –household chores, club meetings, and of course entley at ee ends – and se eral portable trac and traction engine e ents dotted through the summer to loo for ard to in addition, but, after cleaning the already spotless or shop for the third day in a ro , it suddenly hit me as, for the first time since embar ing on Bluebell seven years before, bored o this came as a bit of a shoc , for d been loo ing for ard to a period of doing ery little after the intensity of the e aminations, or at least so d thought, but no that d tried it, reali ed that didn t li e it at all o, hat li ed as building things a nd hat needed, beyond all doubt, as a ne pro ect ut hat to build ell, it had to be another locomoti e, for that as here my primary

interest and enthusiasm lay nd, spoiled by the many intensi e but en oyable days spent dri ing fully loaded passenger trains at entley, and ha ing by then gained e perience ith a ide range of engines on our ground le el trac , ne that ideally anted a se en and a quarter inch gauge locomoti e the si e and po er of the larger engines being more suited to the tas urthermore, if as honest, preferred the indi idualistic charm of narro gauge prototypes to the more purposeful appearance of their standard gauge brethren nd, of course, it had to be capable of being built ith the tools already to hand, because as still a schoolboy on a ery meagre budget, and the finished product had to be capable of being manhandled out of the bac garden or shop and up our one in four dri e ay hen it as finished h yes, and it mustn t be too comple as anted to finish it ithin four years fi e at the most o ay, si at the outside if should end up doing le els and going to uni ersity

o, in summary, as loo ing for a se en and a quarter inch narro gauge locomoti e, capable of being built on a small d ardian round bed lathe capacity not quite eight inches diameter and eighteen inches bet een centres , ithout a milling machine, and light enough to manhandle and t ransport around the house and aimed to finish it ithin

si years at orst case

n my youthful nai ety could see no potential conflicts ith any of these goals they all seemed perfectly reasonable to me and so, retrie ing a stack of recent Model Engineer maga ines from the shelf abo e my riting des ,

began to flic through the ad ertisement pages to see hat designs ere on offer

Introducing Elidir

o , the increasingly patient readers may recall that Bluebell, the gauge pot boiler based around a Mamod stationary engine and described in the first episode of this series, o ed her general appearance to the ale of heidol ail ay s engines depicted on a postcard purchased during a family holiday to ales during the mid s and sa ed for posterity in the author s boyhood scrapboo ell, during that same holiday, and then on a similar trip to no donia in the inter ening years, e had isited se eral more of the reat ittle rains of ales, as they ere then and still are collecti ely no n, and had been utterly smitten by one particular saddle tan locomoti e bearing the nameplate Holy War hich had gracefully trundled its ay up and do n the line beside the la e at ala hat, thought, as a ery pretty engine er the years, as my rail ay no ledge gre , learned that Holy War as but one of a ariety of similar engines manufactured by the unslet ngine ompany of eeds from the late s to the ery early s, many of hich had or ed humdrum li es ferrying materials around the slate mines of orth ales, and than fully se eral had either been restored or ere preser ed and a aiting restoration nd, to my eyes at least, hether ith cab or ithout, a more attracti ely proportioned locomoti e ould be hard to find

nd by no m sure that you, prescient eader, ha e an in ling as to here this is heading, don t you or,

734 Model Engineer 2 June 2023

P A R T 15 – A N E W S TA R T

Continued from p 711

M E 4717 May 19

fnds some things are best tackled in small helpings

placing the most recent stac of Model Engineers upon my des , opened the ery first page of the une issue and there, under the large font heading Elidir, as a line dra ing of an engine hich loo ed ery much li e Holy War urriedly, re ie ed the summari ed specifications in the ad ertisement and, although impossible to confirm ithout the dra ings, it appeared that Elidir, in addition to being a design based upon my ideal locomoti e, might actually meet my other goals in addition ith boredom replaced by e citement, it seemed the search for a ne pro ect might be o er before it had really begun photo 89 nd so, after a brief consultation ith mum and dad to confirm their illingness to host yet another locomoti e pro ect, dashed off a letter to Messrs ee es o ham td, enclosed a cheque for the princely sum of t enty one pounds and fifty pence plus postage and , and began to count the days until a set of Elidir dra ings arri ed by return post nd, in eager anticipation of my ne t pro ect, probably ga e the or shop yet another clean in the meantime

An ounce of planning

n my opinion, there are ery fe things as satisfying as poring o er a good set of dra ings hen draughted ell, the depicted ob ects leap from the t o dimensional page into a fully formed

three dimensional mage in my mind the designer s aims and intentions being ob ious suspect that most model engineers are li e that. nd, in the ideal case, the designer, in addition to presenting their intentions clearly and unambiguously on the page, ill also ha e thought carefully about each part s manufacture and assembly, and this attention to detail ill ma e all the difference to the builder o , ith Rob Roy, hile the dra ings and the design ere ery good o erall, recalled se eral errors hich had caused a great deal of head scratching once the parts ere made, and some asted effort hen those parts had to be re made into something that ould fit and or n short, Rob Roy had taught me to isuali e, chec , re chec , and sometimes e en s etch, each part along ith its neighbours before cutting any metal

nd so, as opened the ele en ne ly arri ed Elidir dra ings for the first time, as unsure hat to e pect My first impression as that the dra ings ere clear and uncluttered, a good sign because any errors or omissions ould hopefully be more ob ious in re ie also noticed that the parts had the ump off the page into three dimensions quality, something surprisingly difficult to achie e but highly desirable and encouraging to the builder ut ere they accurate i e a ill oy, began searching for missed dimensions, inconsistent dimensions, impossible assemblies, and anything else hich might present a problem ith the design or its construction. nd, after a day of this, had found e actly none reathing a sigh of relief, mo ed on to the crucial question – could I actually build it ith dra ings in hand, retired to the or shop to consider ho ould machine each of the larger parts, starting ith the biggest lumps of al l, the cylinders o , at t o and a quarter inches bore and ith a t o and a half inch stro e, reali ed that the si e and eight of each cylinder casting ould be roughly one third of a completed Rob Roy – not something to be ta en lightly, if you ll pardon another pun preading the appropriate dra ing across dad s ood or ing bench,

began to plan each machining step, measuring the lathe carefully to ensure the cylinder castings ould fit in each of the necessary configurations and, after a full day of head scratching and pondering, concluded that, hile it ould be a tight fit and d need some creati e setups and ha e to ma e an ad ustable fly cutter to do the ob, should be able to accurately machine the cylinders on my little lathe ith the tools at hand y the end of the follo ing day, d re ie ed each of the dra ings in a similar fashion and concluded that there as only one part on the entire engine hich simply could not machine ith the tools at hand the large diameter ring hich connected the boiler to the smo ebo his, reasoned, as a relati ely minor problem and one needn t orry about for three or four years and, as it turned out, as e actly fifty percent correct ith this conclusion but that ill e entually become clear nd so, ha ing con inced myself that Elidir s design as sound, and that could probably build it ith the limited tools in my or shop, and feeling that the result ould be orth the effort, ordered the chassis steel and prepared to embar on my ne t pro ect. nd, ith fe distractions or obstacles to get in the ay, by the end of the holidays the basic chassis as, to all intents and purposes, complete photo 90

735 E L E P H A N T S www.model-engineer.co.uk >>

The June 1984 Model Engineer advertisement behind the author’s next project, Elidir, a 7¼ inch narrow-gauge Hunslet locomotive designed by Alan Ruston

By the end of the school summer holidays in 1985, Elidir’s basic chassis had taken shape

89 90

t this point too the opportunity to line up all three engines for a photograph, one of only t o occasions hen that has happened, and it as only then, ith the three of them sitting side by side on the grass outside the or shop, that truly began to reali e the scale of the tas upon hich d embar ed photo 91 .

Slippery slopes

o , as is so often the case hen doing a long and tedious ob hac sa ing and filing the frames to shape being that summer s prime e ample my mind occasionally anders into a dangerous ‘What if?’ onderland, a quagmire filled region here pro ects tend to become stuc , or unstuc , depending upon your interpretation of the phrase ou no the sort of thing one minute you re happily building an Elidir to the published design, the ne t you e decided to relocate the handbra e column to the other side of the cab, and to add holes for an e tra bra e shaft, and to dra up plans to incorporate a steam cylinder and a acuum cylinder and a acuum reser oir in the space behind the boiler, and all because you thought to yourself in a ea moment

during your fourth consecuti e day of frame filing hat if added steam bra es to the engine li e ill s Dart, and acuum bra es li e eoff s Lorna ouldn t that be fun nd, ust li e that, and not for the last time, the What if? Wonderland, to gi e it a catchy moni er, turned the scope of an already large pro ect into something e en larger.

ut that as a problem for the future, for ith the e el results published and deemed satisfactory, and ith the alarm cloc blaring at ten to fi e each morning so that could al the t o miles to catch the bus to righton for le el studies, and ith the return ourney getting me home after se en o cloc each e ening, and ith home or piled on top of it all, the summer holidays e entually ended and a ne school term began. nd, after ust one ee of this performance, and no ing that there ere t o full years of it to come, and ha ing neither the time nor energy to thin about Elidir bet een the endless cycle of college, home or and sleep, began to suspect that my si year orst case timeline might ha e been a little optimistic

h ell, thought, it s not the end of the orld if it ta es

an e tra couple of years to complete

Postscript to Par t 15 or those unfamiliar ith the ritish state education system of the time, and begging forgi eness to our cottish readers because belie e that their system as not quite the same, let me briefly and some hat o er simplistically e plain ho things or ed, for it is ery different to the system employed in other countries, most notably the irstly, after finishing primary school at age ele en, students entered a secondary school here, o er the course of the ne t fi e years, their focus steadily narro ed to perhaps eight or ten sub ects until, at the end of their fifth year, they sat their Ordinary-level (hence, O-level e aminations hich ere graded accordingly. rior to ta ing those le el e aminations, students ould choose a reduced number of sub ects, typically no more than three or four, hich they ished to study for an additional t o years to Advanced-level (hence, A-level , and ould apply to a school or college hich taught those le el courses for study n turn, the selected establishments offered

places on the desired courses contingent upon students achie ing certain le el grades in the ey preparatory sub ects entually, and to complete the picture, at the end of their le el studies students under ent a similar process should they ish to study for a uni ersity degree n this case, uni ersity places ere offered to students based upon their le el e amination results ne consequence of this system, and one hich my merican colleagues find hard to belie e, is that students typically began focusing on a particular discipline from the age of thirteen or fourteen and, by age se enteen, their long term career specialisation as largely set he second consequence as that, ith college and uni ersity places being based e clusi ely upon those one time e amination results, a great deal hinged upon the results of those le el and le el e ams

n short, le el and le el studies ere considered enormously important, and that is hy they generally too precedence o er the author s model engineering acti ities along the ay nnoying, isn t it

736 Model Engineer 2 June 2023

Standing beside Bluebell and Rob Roy, Elidir’s size was becoming apparent to the author.

To be continued 91

L N E R B 1 L o c o m o t i v e

P A R T 21 – M O R E O N C Y L I N D E R S

We will now make a star t on machining the cylinders. Obviously, I have not done this myself so the photos are all supplied by others The full size cylinders are blind bored from the front and, as I said in my last ar ticle, I am making mine bored straight through You can choose for yourself what you do with yours I have co-opted the assistance of Geoff Whittaker for the photos of the machining as his were much better than mine The B1

would just like to illustrate the tender which John Bruce is building for his B1 The first four photos photos 129, 130, 131 and 132) are of his completed tender

737 www.model-engineer.co.uk >>

Doug Hewson presents an authentic 5 inch gauge version of Thompson’s B1 locomotive.

Continued from p 701, M E 4717, May 19

A few views of John Bruce’s B1 tender (Photos John Bruce)

cylinders are not the same as my Class 4 but the methods Geoff used were, I thought, ver y good Before I get into that, a few words on tenders and I 129 130 131 132

underframe Photograph 133 is a nice photo of a green B1 photographed at Elgin East shed in hen as ust fi e years old his is a with single plate sides and no visible rivet s around either end of the smoke box and neither are there any rivets visible on the front buffer beam I just hope that the lads preparing the engine remembered to remove that gallon tin of oil from the front buffer beam! I thought I would include this photo to give you a little inspiration

On to the cylinders, then he first stage in machining the cylinders is shown in photo 134 where Geoff was machining with a slab cutter on the milling machine and, as you will see, the ports emerge d on the machining

738 Model Engineer 2 June 2023

LNER B1 seen at Elgin East shed. (Photo by Rail Online).

Facing off the back of the cylinder block

The cylinder block is mounted on an angle plate for boring all the way through

Machining the top face of the cylinder block

Adding a counterbore at the end of the cylinder

136 137 133 134 135

Note that these cylinders are ¾ inch longer than mine were but I hope you will get the idea Once the back plate was machined the cylinder was clamped horizontally on the milling machine on a substantial angle plate and then the top of the back plate could be machined photo 135) Note the centrelines which Geoff has scribed on the faces of the cylinder Now we come to the boring of the cylinders and photo 136 shows the set-up used for this job Once t he boring has been done the cylinder was then mounted on a mandrel to face the opposite end

Before you remove the cylinder from the mandrel there is another little job that you should do and that is to bore a little bit more out at each end photo 137) It needs boring out by an extra 40 thou x 3/16 inch at each end I have never heard of anyone needing to rebore their cylinders out during the lifetime of their engine but that is the correct way to do the job, just in case you should ever need to. However, there is another very good reason why you should do this and that is that you can then make a sleeve from tinplate, about an inch long, and use this to insert your piston; oil it well and then the rings will slide in very nicely without anything snagging

You can now hone the cylinders To do this I did not use any fancy rig but I just used a wooden plug, long enough to

reach through the cylinder, and left it about ¼ inch under the bore size I put a saw cut down the centre, wrapped a piece of medium Emery tape round the plug, and then held it by hand and pushed it backwards and forwards through the bore until it was nice and shiny inside

Job done Photograph 138 shows the plug which I made for honing my Y4 cylinders

Photograph 139 shows the hone in use. I would also recommend using a good glo e on your hand Ed’s note: please take great care if using this method. Use of a proper honing tool held securely might be a safer option!)

Photograph 140 shows my Y4 piston with rings on it ready for going into the cylinder and photo 141 shows the piston pushed in as far as it will go

Photograph 142 shows the

sleeve which I made from a tin to push the piston home ready for drilling the crosshead To

NEXT TIME

739 L N E R B 1 www.model-engineer.co.uk

Plug made for cylinder honing

Y4 piston with rings.

Using the plug to hone a cylinder

Piston pushed into the bore.

ee e in se to fnish the o

We make the valve liners

138 139 140 141 142

be continued

R a d i a l Va l v e Gears Again

P A R T 1

Introduction

Duncan Webster sheds light on what is often seen as a complex subject.

Why again I hear you ask, well this is the third round of articles I’ve written on the subject in the past 40 years or so Not that I’m obsessed, but I do find them fascinating, and Mr ates eeps on changing things ma ing it difficult to get some old computer models to run The earlier articles were either flawed (ref 1) or full of complicated maths (ref 2) With more widespread availability of soft are a lot of the design can be done very accurately by dra ing, although some maths will be unavoidable For the more difficult bits little stand alone computer programs are available I have also included some more obscure valve gears.

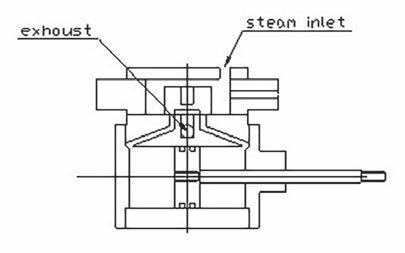

Terminology

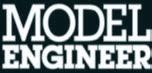

Figure 1 shows a schematic cross section of a double acting locomoti e cylinder ith slide valves and fg 2 shows piston valves The principle of operation is the same for both It is possible but unusual to have piston valves with the exhaust port in the middle of the valve chamber and steam entry from both ends This

was used on the rebuilt Bulleid Merchant Navy locomotives, probably because the cylinders were already in existence This is known as outside admission (as opposed to the normal inside admission) Slide valves are almost always outside admission. The only difference as far as the valve gear is concerned is that to admit steam to the left hand end of the cylinder with outside admission the valve is mo ed to the right, ith inside admission it is moved to the left To avoid repetition I will discuss outside admission hereafter, ust pointing out hat ould change for inside where appropriate

When the piston is at either e treme of its stro e, admitting steam ould ha e no turning effect on the crank These positions are known as dead centres With our cylinder as sho n in fig let s thin about the left hand end of the cylinder only, ith the piston tra elling to the left To allow the steam to exhaust the valve is displaced to the left At some point the al e has mo ed to the right to close the exhaust and the remaining steam ill begin to

be compressed This is known as the point of compression rosaic lot e engineers or reasons which will be explained later, just before the dead centre, the al e begins to open to allow steam into the cylinder This is the point of admission, and the distance the valve is open when the piston reaches dead centre is the lead Radial al e gears gi e constant lead The piston now sets off to the right, and part ay along the travel the steam valve is closed, the point of cut-off The trapped steam then expands producing useful or until as the piston approaches the right hand dead centre, the exhaust opens, the point of release The reader will have noted that for part of this time the port is closed to both steam and exhaust. The movement produced by all mechanisms driven by eccentrics, cranks etc approximates to a simple equivalent eccentric, so the only way to allow this to occur is to ma e the al e longer than the distance between the outer edges of the ports, or shorter than this distance for inside admission This is as shown in figs and

740 Model Engineer 2 June 2023 Outside admission slide valve Inside admission piston valve

Fig 1

Fig 2