COVER STORY

PUMP UP THE V LUME M

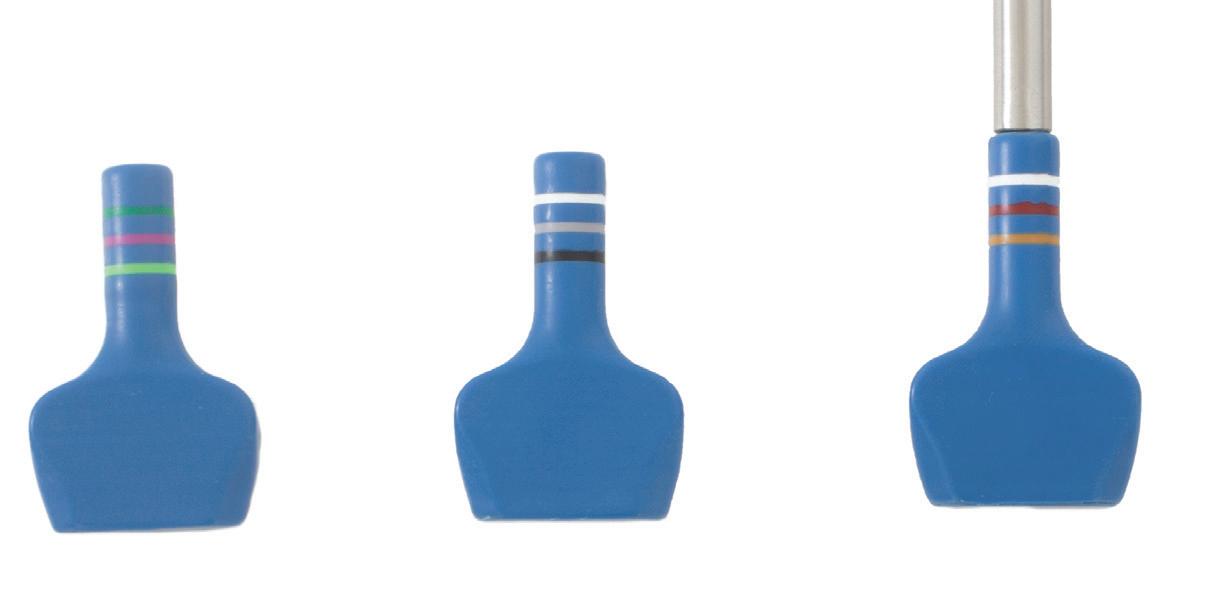

icromoulding typically requires the achievement of truly exacting and sometimes almost impossibly tight tolerances. In many instances the demand is for tiny parts or slightly larger parts with submicron feature sizes. When micron tolerances matter, the customer and micromoulding provider must enter into a close partnership in product development, and it becomes hugely important that the micromoulder owns, manages, develops, and innovates in every aspect of the supply chain. The “get it right the first time” headline over every activity plays to the vital importance of vertical integration, which enhances the quality, compliance, and conformance to design intent. Micromoulders need to understand the critical to quality (CTQ) characteristics to manufacture parts successfully; these characteristics — including moulding, assembly, and packaging — are important to the functionality of the product with regard to end-user experience. In basic terms, the longer the value stream, the more disconnected the value stream, and the more variables can be introduced causing customer issues. Vertical integration supports a shorter value stream reducing silos and suboptimised processes.

ENGAGEMENT WITH A MICROMOULDER FOR A MEDICAL DEVICE PRODUCT DEVELOPMENT PROCESS WILL ULTIMATELY RESULT IN THE NEED TO MANUFACTURE PARTS, OFTEN AT VERY HIGH VOLUMES. MICROMOULDERS NEED TO EXCEL AT EVERY STAGE OF PRODUCT DEVELOPMENT, BUT, AS AARON JOHNSON, VP OF MARKETING AND CUSTOMER STRATEGY, ACCUMOLD, HIGHLIGHTS, THERE ARE PARTICULAR CONTINGENCIES THAT SURROUND VOLUME MANUFACTURING THAT MAKES SUPPLIER SELECTION ESPECIALLY IMPORTANT.

VOLUME MANUFACTURING Variability is the enemy of high-volume micromanufacturing, and so focus needs to be maintained on implementing process controls that drive repeatability all the way from cutting micro tool steel to measurement and validation methods. Typically, medical device OEMs want the highest quality products at the lowest possible cost. Product quality requirements are driven by the Voice of the Customer (VOC), which enables good micromoulders to identify critical medical product characteristics which need to be verified during production. Cost, however, is more than just the price charged to mould a part. It also includes the time it takes to get a product to market, whether defects make it to market, and the levels of supply consistency. Micromoulders should strive to supply the highest quality products, through validated processes, with short timelines to market. Realistically, this can only really be accomplished through vertically integrated processes and utilising process validation. When short-listing potential micromoulding suppliers, from a production perspective there are some key questions that medical device OEMs need to ask to ensure the micromoulder is equipped to achieve often exacting objectives. First, do you design, build, and maintain your moulds? Second, what measurement capabilities do you have on site? Third, what are your methods of validation (DOE, IQ, OQ and PQ)? Finally, what resins do you have experience with in production? The successful manufacture of micromoulded medical products is almost entirely down to the VOC. But it is important to realise that the end user isn’t the only customer — there are customers throughout the entire value stream. The shorter and more centrally located the value stream the quicker concerns can be raised and resolved. ASSEMBLY When dealing with miniaturised plastic medical parts and components, the assembly stage of the product development process must be discussed and considered early in the design cycle, demanding a collaborative and pragmatic relationship between medical device OEM and micromoulder. When dealing with microscale parts and components, the cost of manual assembly is prohibitive and often requires levels of precision when dealing

12

W W W. M E D I C A L P L A S T I C S N E W S . C O M