INNOVATION IN IMPLANTS

Thermoplastics: the cool kids of medical 3D printing METALS SUCH AS TITANIUM SEEMED TO BE THE LAST WORD IN MEDICAL MANUFACTURING. NOW, IMPLANTS 3D-PRINTED WITH MEDICAL-GRADE POLYMERS OFFER NEW POSSIBILITIES, SAYS KUMOVIS.

T

he discussion about medical 3D printing with polymers has long since grown beyond surgical models and rapid prototyping. Medical R&D activities indicate that longterm applications such as implants, which previously relied on metals and conventional production methods, are likely to be challenged by 3D printed polymer implants in the coming years.1 It has taken years of trials, testing and constant process development to fuse 3D printing technologies and thermoplastics into solutions that open up new opportunities for both medical device companies and hospitals. Possible applications range from trial implants and instruments to short- and long-term implants. The safety and performance requirements of the manufacturing process and 3D printed products vary depending on the local regulatory peculiarities and fields of application. ADDED-VALUE MEDICAL DEVICES Instruments and trial implants, for example, come into contact with patients’ blood during surgery; this, however, is just a temporary contact. And whereas the risks of applications such as these are low compared with implants intended to be permanent, their potential in terms of costs, functionality and ergonomics is all the higher.

Permanent polymer implants also have great potential. These products must meet the industry’s requirements for mechanical properties and those for biocompatibility, including considerations of the long-term interaction with the surrounding tissue. There are already first projects to 3D printing interbody fusion cages from polyetheretherketone (PEEK) or polyetherketoneketone (PEKK), including solutions that help cells adhere to them (Figure 1). HOW TO IMPROVE OSSEOINTEGRATIVE BEHAVIOUR Medical device companies have sound reasons to use metals such as titanium to manufacture implants and instruments. Biocompatibility and mechanical properties have values that meet the high demands outlined above. Titanium, moreover, shows good osseointegrative behaviour; there are, however, polymer alternatives. Meeting the osseointegration challenges of polymer implants requires new developments. First, polymers modified for osteoconductive properties are on the rise.² Second, the 3D printing process combined with post processing can positively affect bone ingrowth. With its 3D printed macrostructure, the Kumovis Improved Implant Interface allows for enlarging the surface of medical devices, thus supporting bone ingrowth. At the same time, this technology coupled with post-processing enables nutrients to travel through capillary effects using a selective microstructure. Coating technology enables adding hydrophilic surfaces to polymer implants. To supply cells — both on the surface and inside the implant — with nutrients, the adaptation of porosity through 3D printing plays a major role. Moreover, applications pointing to tissue engineering could be feasible if new resorbable polymers and the associated processes prove themselves in testing.

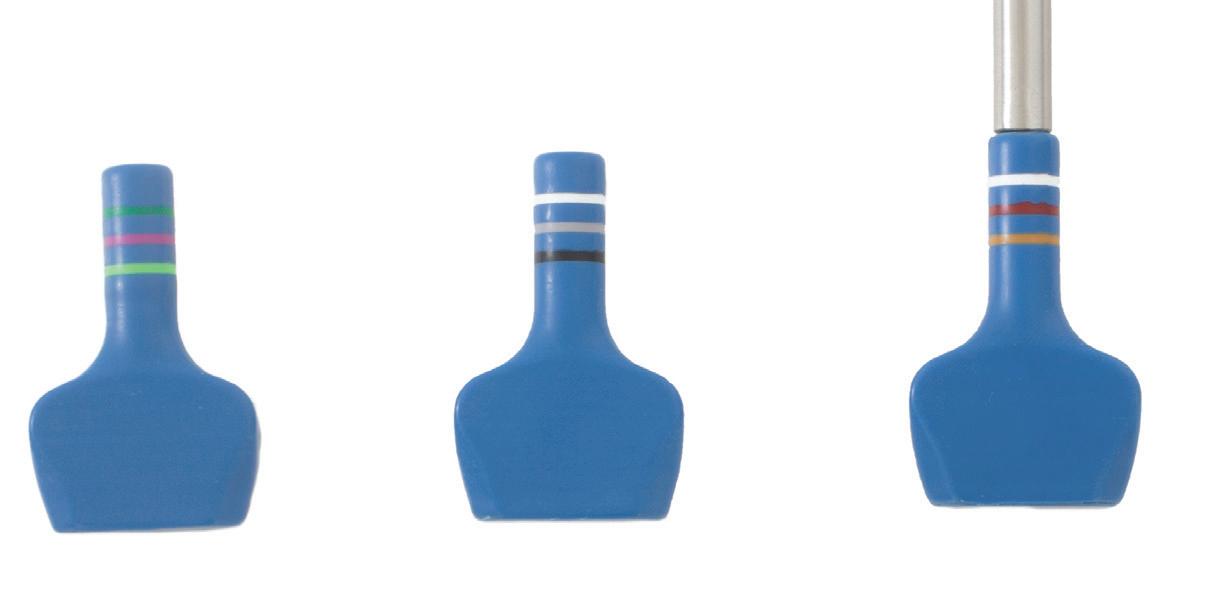

3D printing trial implants with polymers such as polyphenylsulfone (PPSU) can save medical device companies up to

14

50% on manufacturing compared with milled titanium. Furthermore, a PPSU variant with X-ray contrast agent makes the trial implant visible in the X-ray image during the operation. Polymer trial implants are also lighter than their metal counterparts. And individual colour coding of the trial implant makes visible, at a glance, its size and application area.

WHICH POLYMERS TO USE FOR MEDICAL 3D PRINTING Besides using metals, healthcare professionals opt for high-performance polymers for 3D printing. Important medical-grade thermoplastics include the following: • PEEK: a high-performance polymer that has been used in medical

W W W. M E D I C A L P L A S T I C S N E W S . C O M