4 minute read

Demystifying IoT/Industry 4.0 and the Role of electrical Contractors

DEMYSTIFYING IoT/INDUSTRY 4.0

AND THE ROLE OF ELECTRICAL CONTRACTORS

InDuSTRY 4.0 IS OPenInG uP MAnY OPPORTunITIeS FOR eLeCTRICAL COnTRACTORS. One AReA TO COnSIDeR IS unInTeRRuPTIBLe POWeR SuPPLIeS (uPSs) AnD THe VALue THeY BRInG In An InTeRneT OF THInGS (IoT) WORLD.

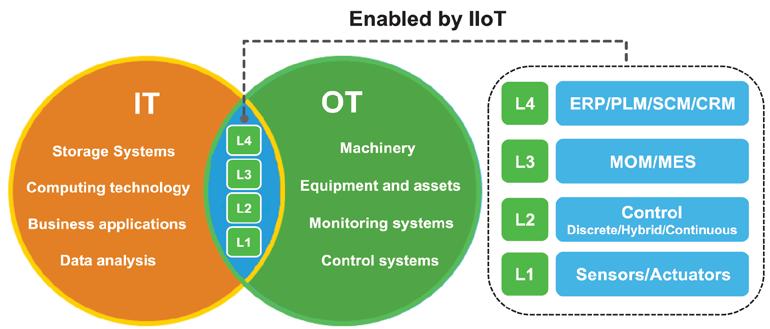

Industry 4.0 is all about automating industrial processes for efficiency and scale. Historically, automation has been accomplished by combining various means of mechanical, hydraulic, pneumatic, electrical, electronic, and IT. But Industry 4.0 will take automation to another level, one where machines talk to each other to get things done.

not only will robots coordinate tasks, but they will also integrate forecasting, production scheduling and supply chain management for a dynamic and efficient production environment.

More efficient, sure, but dynamic?

Yes. The day will come when the device being manufactured will communicate with the production environment, giving instructions on configuration and options, resulting in each device being “custom mass produced”. This, of course, will be enabled by adding significantly more IT capacity. And I am not talking about just leveraging centralised cloud computing. I am talking about edge computing.

IoT applications require reliable infrastructure

To understand why, you need to grasp how a typical IoT application works. First, it relies on some sort of device – a sensor or a machine running IoT

Cloud Computing located farthest from on site edge networks providing greater compute, network and storage resources

Local Servers on the edge providing highly available resources and low latency access close to edge devices at the site

Edge: Industrial Internet of Things Real-time data processing

So, what is edge computing?

In the race to digitally transform, many companies are adding a serious number of IoT sensors, meters, and high-definition video into their operational processes. Think proximity sensing and contact tracing for public transportation, IoT soil sensors in agriculture, or IoT sensors communicating with robots in manufacturing.

By massively scaling their metering, sensing, and video capabilities,

the companies will be generating big data. Integrating, interpreting, and analysing this data for their benefit is key, and it requires IT in the form of compute and storage. This is an opportune time for most companies to consider a local micro data centre in the control room of the manufacturing site; this solution is the secret sauce of Industry 4.0 for manufacturing. All that infrastructure is aimed at delivering benefits such as improving the speed and accuracy of supply chains, improving quality management, enabling predictive maintenance programs and more. But here’s a line from a recent Forbes article that really struck me: “The most critical success factor all these use cases depend on is secure, scalable and reliable end-to-end integration solutions that encompass on-premise, legacy and cloud systems, and platforms.” The word “reliable” is the one that caught my eye, because it is spot on.

software, for example – that collects and transmits data. In a manufacturing environment it might be data about the health of machines while in a bakery. It might be sensors that monitor oven and refrigerator temperatures. The device then sends that data to some sort of collection point. For a small or medium business, that is likely a small server or appliance located on premises, which then sends the data to a cloudbased service provider or other form of centralised collection point. That is where applications exist that make sense of the data and deliver actionable intelligence back to the business. The whole setup only works if all the components that play a role are functioning as they should. Having stable and clean electrical power, of course, is fundamental to their reliable function.

This is where electrical contractors come in.

When doing a job for almost any company today, have a conversation about the kind of equipment that will be on site. Find out if the company is using some form of IoT equipment (even if they do not use the term IoT). If so, explain the importance of reliable power to the proper functioning of that equipment and how an uninterruptible power supply (uPS) offers power protection in the event of a utility power outage. That includes clean and stable power, as the uPS acts as a filter thanks to its double conversion technology. Industry 4.0 is a game changer that will further automate industrial processes. edge computing is an integral part of the system, enabling reliable delivery of IT capabilities in extreme proximity to the operation. Opportunities abound.

The key for electrical contractors is to start a conversation, and get customers thinking about the value their IoT applications are delivering – and why they warrant reliable power protection.

Karthik Iyer

Sales Manager – Industrial & Commercial Segments Karthik.Iyer1@se.com