Dairy packaging solutions are the cream of the crop looking to improve e�ciency, sustainability

recognition, let us help.

We can help make your process a success. Talk to our sales team today!

sustainable paper and packaging solutions, Smur�t Westrock is committed you adapt and thrive in today’s environment with e�ective, packaging solutions.

Scan

Sept. 17-19, 2025

You won’t want to miss out on an agenda full of educational business sessions, networking opportunities, and fun activities.

This year’s convention will be held at the MGM Springfield. This hotel combines new construction with revived historic buildings, offering gaming, a 250-room boutique hotel, spa services, retail, and dining.

by following Northeast Dairy Media and the NDFSA.

Scan the QR code and watch your email for the agenda and speaker updates.

DAIRY BLENDER

March 25, 2025

Hyatt Regency Hotel Rochester, NY

BRUCE KRUPKE GOLF TOURNAMENT & CLAMBAKE

July 9, 2025

Golf 8 A.M.-1 P.M. Rogues Roost Golf Course Bridgeport, NY

Clambake 1-7 P.M. Spinning Wheel Event Center North Syracuse, NY

MELINDA AIKEN

EXECUTIVE DIRECTOR

Alex Walsh

BUSINESS OPERATIONS MANAGER Leanne Ziemba

PRESIDENT

Daniel Lausch Lactalis USA – Commonwealth

VICE PRESIDENT

Rebecca Wallick HP Hood

TREASURER

Adam Seybolt Stewart’s Processing Corp.

SECRETARY

Ryan Elliott Byrne Dairy

PRESIDENT

Daniel Seitzer Ecolab

VICE PRESIDENT

Paul Knoerl Pactiv Evergreen

TREASURER

Ryan Osterhout KCO Resource Management

SECRETARY

Bruce Alling Double H

PUBLISHER

Bill Brod billbrod@nedairymedia.com

EDITOR

Courtney Kless courtneyk@nedairymedia.com

CONTENT DIRECTOR

Steve Guglielmo steveg@nedairymedia.com

RESEARCH & DEVELOPMENT

COORDINATOR

Athena Cossette athena@nedairymedia.com

COPYWRITER

Nicole Smith

GRAPHIC DESIGNER

Renate Wood, Robin Barnes

SALES

Tim Hudson thudson@nedairymedia.com

Lesli Mitchell lmitchell@nedairymedia.com

Jake Horodnick jakeh@nedairymedia.com

PRODUCED BY

Northeast Dairy Media

Editorial correspondence should be directed to courtneyk@nedairymedia.com

Advertising correspondence and materials should be sent to lmitchell@nedairymedia.com

An official magazine of the Northeast Dairy Foods Association, Inc., a nonprofit organization. This publication carries authoritative notices and articles in regard to the activities and interests of the associations. In all other respects, neither the association nor the producer of the publication, Northeast Dairy Media, is responsible for the contents thereof or the opinions of the contributors.

The entire contents are © 2025 by Northeast Dairy Media. Nothing may be reproduced in whole or in part without written permission of the publisher. The association and Northeast Dairy Media reserve the right to print portions or all of any correspondence mailed to the editors without liability on its part and no such correspondence will be returned.

Visit The Northeast Dairy Foods & Suppliers Associations online at ndfsa.org for current information on association programs and services, or call the association at 315-452-MILK (6455). Questions and comments may also be sent to the association at leanne.ziemba@ndfsa.org

BY ALEX WALSH, EXECUTIVE DIRECTOR

n 2024, the Northeast Dairy Foods & Suppliers Associations celebrated its 95th anniversary! As we’ve reached this milestone, we want to recognize and celebrate our members who have also achieved success and longevity in business with the first edition of the Northeast Dairy Foods & Suppliers Associations Yearbook.

As a quick history lesson, the Northeast Dairy Foods & Suppliers was originally founded in 1928 in Syracuse, New York, as the New York State Milk Distributors, Inc., strictly representing fluid milk processors and distributors in New York. Over the next 50 years, as the industry in the state continued to expand and diversify, so did the organization’s membership, and in 1978 it became New York State Dairy Foods. It was at this point that the association began advocating and providing member benefits beyond processors and distributors, to dairy product manufacturers, such as cheese, yogurt, and ice cream.

The following decades saw industry consolidation and increased legislative and policy issues in neighboring states that required industry representation, and we became Northeast Dairy Foods Association in 2008, growing the footprint beyond New York to New Jersey and the six New England states.

Today, we’re rebranded as Northeast Dairy Foods & Suppliers Associations, which exemplifies the importance of the close relationship between processors, manufactur-

ers, and distributors, and members that provide products and services essential to the process of producing milk, cheese, yogurt, ice cream, and other products our members manufacture. The organization is comprised of nearly 300 processing, manufacturing, distribution, and supplier members throughout the region and beyond.

As we embark on our 96th year, we look forward with future insights as well as our distinctive history towards continued growth to celebrate our 100th anniversary in just a few short years.

It is with tremendous pride that we celebrate and recognize our diverse membership and your accomplishments. It is your innovation and resiliency that drives and exhibits the strength of the dairy industry that provides healthy and safe products to consumers and serves as a leading economic engine. Agriculture is one of our nation’s largest industries, with dairy being the largest segment of all agriculture, solidifying our members’ importance in the manufacturing and food and beverage space.

We are excited to reflect on our members’ humble roots, where you are today, and the plans you have for the future. Thank you to everyone for your participation and support of our first yearbook, as well as to the associations. It is because of you that we remain a strong, active, and vibrant organization for the membership and the dairy industry as a whole.

packaging solutions are the cream of the crop looking to improve e�ciency, sustainability

recognition, let us help.

formats and needs Sustainable materials

Reduce plastic use with renewable paper-based materials.

E�cient automation

Improve uptime, line speeds and operational throughput.

Connected Solutions

Meet FSMA requirements and improve inventory management.

sustainable paper and packaging solutions, Smur�t Westrock is committed you adapt and thrive in today’s environment with e�ective, packaging solutions.

We asked board members from the Northeast Dairy Foods Association and the Northeast Dairy Suppliers Association the following question: What was your favorite event in 2024 and why? This is what they said.

Daniel Lausch, Director Milk Procurement, Lactalis USA

Always the Clambake.

Nathan Pistner, Vice President of Operations, Byrne Dairy

The Dairy Blender was my favorite event of 2024. The impactful presentations and networking opportunities in a

concise agenda were very efficient; but who doesn’t love a good Tornado Warning during the clambake?

Darren Schochner, Director of Sales, Farmland Fresh Dairies/Bartlett Dairy

The standout event for me in 2024 would be The Bruce Krupke Golf Outing and Clambake. This is a great networking opportunity for all levels of our industry.

Ethan Crist, Corporate Accounts Manager, Veritiv Corporation

The annual clambake remains our flagship event, with tremendous participation. It is one of the best events I’ve ever seen as far as networking, customer appreciation, and visiting with friends, colleagues, and business partners.

Over 90% of organizations are overpaying services but don’t know it and most of the money being wasted is lost forever, not refundable.

Have your expenses reviewed by our team of experts

• No financial risk to our clients

• We are paid from the refunds and/or savings

• We require minimal effort from our clients (2-4 hours from one p

• Initial findings in as little as 2 weeks

• Our objective and unbiased approach ensures we are aligned with clients’ best interests

• No requirement to change vendors

• Over 30 years of subject matter expertise in waste disposal, ut textile rentals, and telecom

CONTACT US TODAY TO START SAVING! Steve Thompson, President steve@integritycostconsulting.com | 315-935-9379

We specialize in cost analysis and invoice verification to help ensure organizations are not wasting their money.

of

By employing experts in each of the fields we review, we are uniquely equipped to find refunds and implement savings without changing vendors

We bill only for the refunds and savings found, and only after a client realizes a benefit. If we don’t generate a financial benefit, there is no fee.

All clients gain peace of mind knowing their bills are accurate and they’re paying the least amount possible.

Verify all line items and codes on vendor invoices

significant financial benefit for minimal effort.

We have reviewed many expense categories for various types of clients.

Below are some of the more common categories that yield savings across all industries (avg % savings shown):

Benchmark costs against proprietary database of over

Negotiate new contracts, if needed, featuring best-in-class/unpublished rates and more favorable

Monitor future invoices in real-time to validate savings and keep costs accurate and controlled

Don’t wait another day to have your expenses reviewed by our team of experts.

In the past nearly 80 years, Nelson-Jameson has seen incredible growth as the single-source supplier to food processing plants. And with its new distribution center in Fairview, Pennsylvania, the Wisconsin-based company plans to continue its growth and serve more Northeast region food processing customers more effectively.

The distribution center in Fairview, near Erie, Pennsylvania, is expected to be operational by summer. Positioned to better serve customers in Michigan, Pennsylvania, Ohio, and the Northeast, this expansion will bring additional delivery routes and a greater inventory of products (the company already had four other distribution centers in Turlock, California; Jerome, Idaho; Amarillo, Texas; and Marshfield, Wisconsin).

“Nelson-Jameson is committed to delivering exceptional service and prioritizing food safety for our customers in the Northeast,” said Mike Rindy, the company’s current president.

“The new Fairview distribution center reflects our continued investment in the Northeast and our unwavering dedication to supporting our customers’ success.”

Rindy added that the facility will be built end-to-end to serve food manufacturers, while maintaining its priority of making positive contributions to food safety for processors and consumers.

“These comprehensive improvements reflect NelsonJameson’s intent to establish Fairview as a future-ready logistics hub that supports growing operational demands, modern infrastructure, and a seamless experience for employees, visitors, and customers alike.”

True to that commitment, and to its roots, Nelson-Jameson prides itself on being a “one-stop shop” for its customers. Whether it’s PPE, ingredients, lab equipment, materials handling, cleaning supplies, parts, tools, or office supplies, the

“Nelson-Jameson is committed to delivering exceptional service and prioritizing food safety for our customers in the Northeast. The new Fairview distribution center reflects our continued investment in the Northeast and our unwavering dedication to supporting our customers’ success.”

– Mike Rindy, President of Nelson-Jameson

company has everything they need to manufacture safe, quality food—nearly 80,000 products, to be exact.

“Our products are sourced from vendors that represent innovation and technology,” said Rindy. “And our category specialists have the food processing and food safety expertise to ensure that the products are being used correctly and are the correct products for the application.”

In all aspects of its business, Nelson-Jameson follows the “Golden Rule” – “Simply Treating Others as We Would Like to Be Treated.” The results speak for themselves. The company has a customer satisfaction score of 8.9/10, and in January, it was awarded a Great Place to Work Certification, with 87% of employees rating the workplace highly (the survey measured leadership credibility, respect, fairness, workplace pride, and a sense of belonging).

“Being certified as a Great Place to Work for the second straight year is an incredible honor because it reflects our employees’ voices and experiences,” said Rindy. “At Nelson-Jameson, we are deeply committed to creating a workplace where every team member feels valued. This achievement reaffirms our belief that kindness and mutual respect are essential to our success.”

When Earl Nelson, Ted Nelson, Herb Jameson, and Bob Dougherty established Nelson-Jameson in a vacant cheese factory in 1947, their goal was sim-

ple: to provide dairy plants with the necessary equipment and supplies. It’s a goal that has since expanded to serving dairy processors across the country.

Since its inception, Nelson-Jameson has achieved several important milestones. Those include the introduction of the Nelson-Jameson Foundation, earning SQF certification at all of its distribution centers and an Ecovadis Bronze Medal for sustainability, and the creation of Next Logistics (part of the Nelson-Jameson family of companies), which has safely delivered products for more than 1.5 million miles with a perfect safety record since 2022.

These days, the company, located at 2400 E. 5th Street in Marshfield, Wis., is led by the fourth generation of the Nelson family and has a staff of more than 300 individuals nationwide. And with the new distribution center in Pennsylvania opening this summer, that growth will only accelerate, and the organization will be positioned to serve the Northeast dairy industry even better.

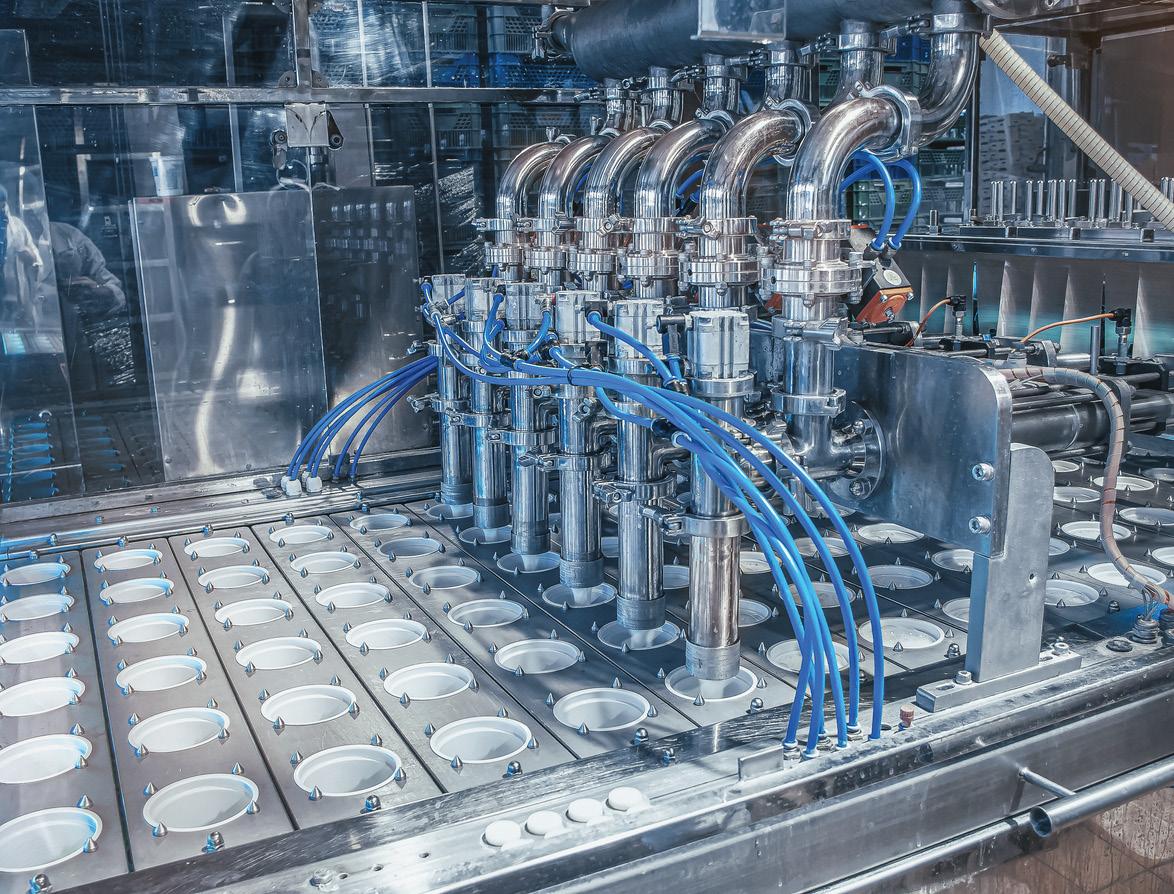

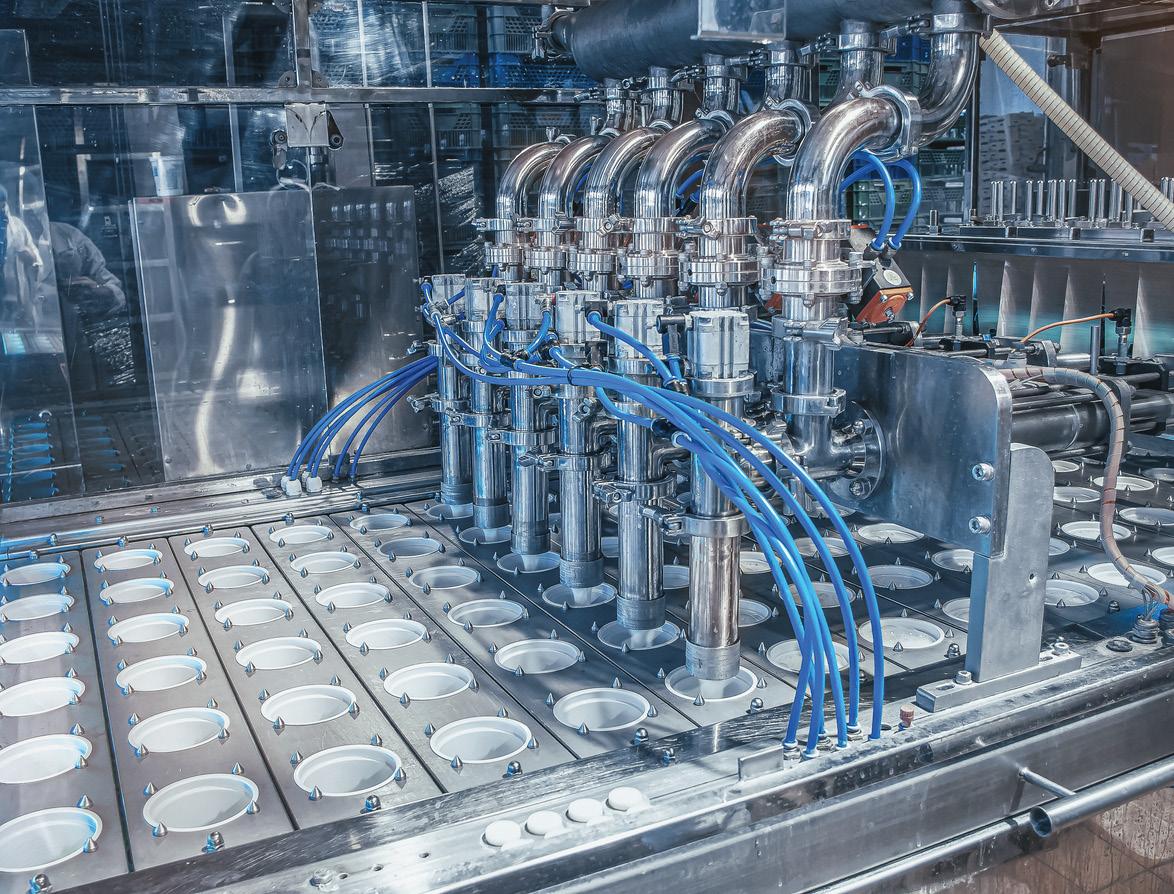

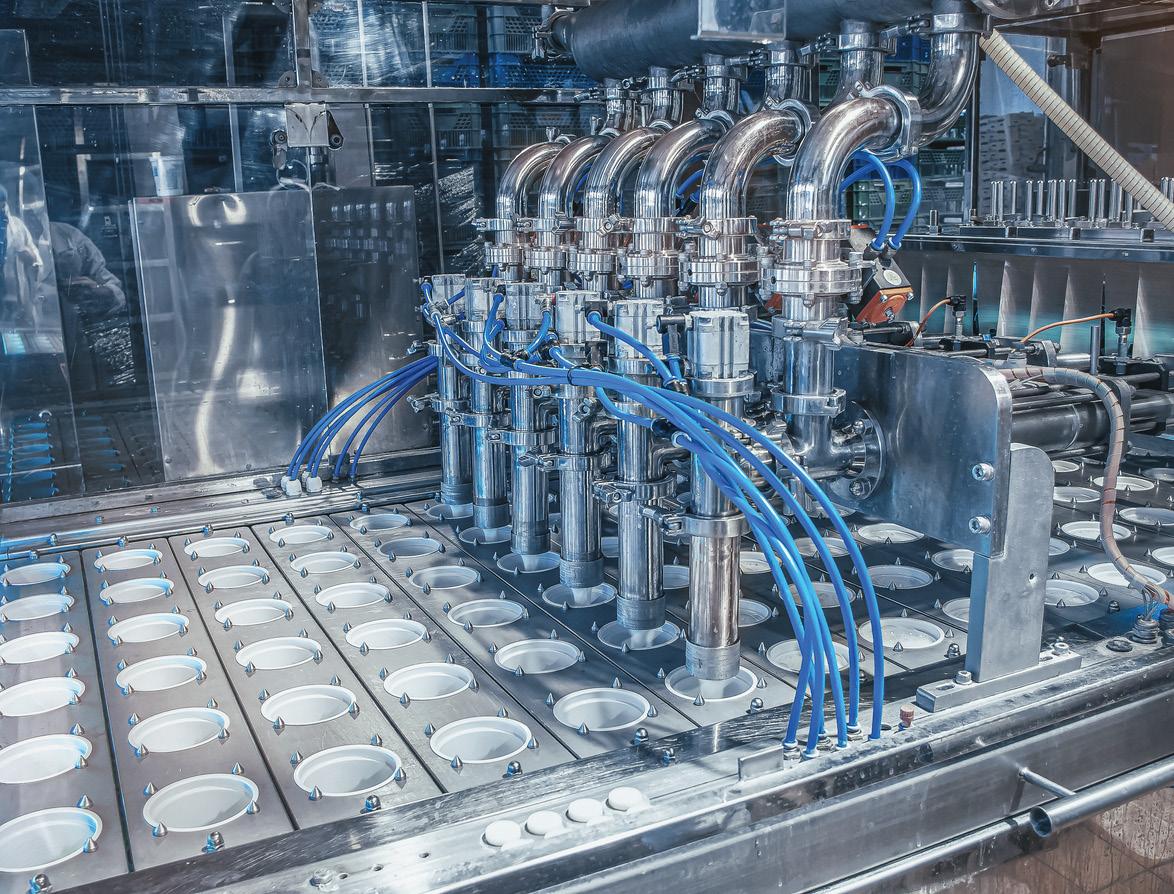

Introducing our new and improved single serve filling machine: N-200 Eco-Pak® . It will help preserve the shelf life of products such as white, flavored milk and juice for school, institutional and single serve markets, filling up to 20,400 cph.

Designed with input from filler operators, the new N-200 features provide:

• Decreased maintenance

• Increased line efficiencies

• Improved performance

• Easy access to machine components

Want to apply our fresh approach to your next product? Visit www.pactivevergreen.com/products/n-200 or call us today at 319-399-3200.

BY GARY LATTA

In late January, the USDA updated its figures for U.S. agricultural output, inputs, and total factor productivity from 1948 to 2021. The results are astounding. Agricultural productivity is measured using an abundance of input and output factors.

The image to the right captures all U.S. agriculture. Data isolating the dairy sector are equally impressive, and reports indicate similar advancements have been made in farming cattle, sheep, poultry, hogs, etc. Note, most university animal scientists measure milk output in kilograms. Most of us are familiar with measurements in pounds (lbs.) and the hundredweight (cwt), with 100 pounds being one hundredweight, etc.

For conversion purposes, one kilogram (kg) is about 2.2046 pounds (lbs.) – most folks round it to 2.205 lbs. One hundredweight (cwt) or 100 pounds, is equal to 45.4 kg. One hundred kilograms is equal to 220.462 lbs., and one thousand kilograms is equal to 2,204.62 lbs., just a little over 22 hundredweights (cwts).

Average milk yield per cow in the U.S. has grown nearly six times since 1940. Many technologies have been discovered and adopted, which have led to this productivity growth. Improvements in animal genetics, nutrition, farm management, and veterinary science are a few of these. Each of these disciplines is a vast science of their own. Only until you venture into topics like bovine genetic progress and nutrition, do you realize the depth of the science behind modern milk production.

One benefit of this growth is the production of more milk with less resources. According to USDA records, the number of U.S. dairy cows peaked at

Source: Professor Josef J Gross, Universität Bern, Veterinary Physiology

Source: An article originally published by UC Davis cited this graph from FAOSTAT

25.6 million in 1944. Today, we have 9.4 million cows. We produced 117 billion pounds of milk in 1944 compared to over 226 billion in 2023. The USDA is forecasting just over 228 billion pounds in 2024, nearly twice the milk of 1944, but with 16.2 million fewer cows. At this point, some researchers, for strange reasons, like to convert this much milk into the number of Olympic size swimming pools it would fill. Though tempted, I’ve resisted.

Looking at the past half century, the U.S. stands alone as champion at the top of milk production per cow. A combination of many technologies is responsible for this impressive performance.

The northeast is blessed with elite agricultural universities whose research and work have contributed significantly to dairy and milk production worldwide. New York’s Cornell University, the University of Vermont, and Penn State are among these. Cornell has been home to several of the world’s leading dairy researchers, like Dr. Thomas Overton , Professor of Animal Science and Director of the PRO-DAIRY Program, and Dr. Dale E. Bauman , Professor Emeritus in the areas of animal biology, food science, and nutritional biochemistry. Dr. Bauman is among modern scientists to champion the concept that by improving production efficiency,

we utilize fewer input resources, and therefore lighten the environmental impact.

In an article titled “Feed Saved - The next step in breeding a more efficient cow?” on the MSU Extension website, Mike VandeHaar, Rob Templeman, and Kent Weigel write, “For years, we have been breeding and managing cows for greater milk production. As cows eat more feed, a greater proportion of their feed intake is used for milk and a smaller proportion is used for maintenance. This is commonly called the “Dilution of maintenance.” Today’s dairy cows produce 5 times more milk than their predecessors 80 years ago, and, although they are also a little larger

and they eat more, their feed efficiency had doubled due to the dilution of maintenance.”

Productivity has come a long way in the last 100 years. In this article on the National Agricultural Library’s website, we see a sharp-dressed dairyman operating the Mehring milking machine at York Roads, Maryland, in 1908. The Mehring is a foot operated machine that is peddled. According to Farms.com, “The treadle system made it instantly attractive. Larger commercial operations appreciated the increased efficiency and ability to milk two cows at once. Smaller mixed farms could take advantage of the low physicality by allowing women and children to milk.” Improvements in both equipment and management have contributed to the phenomenal rise in output per cow while also optimizing the use of resources.

The steady growth in production per cow shows few signs of abating. We can expect the slope and upward trajectory of these graphs to continue. The composition of milk has also changed over time as producers respond to the demand for different products in the marketplace. This could be the subject matter of a future article. The USDA’s long term dairy projections have average milk per cow reaching near 26,540 lbs. by 2033, up from 24,500 lbs. projected for 2024.

Gary Latta is a dairy product specialist consultant for the Northeast Dairy Foods Association, Inc. He has more than 30 years of experience in providing economic analysis, statistics, and information to the dairy processing industry.

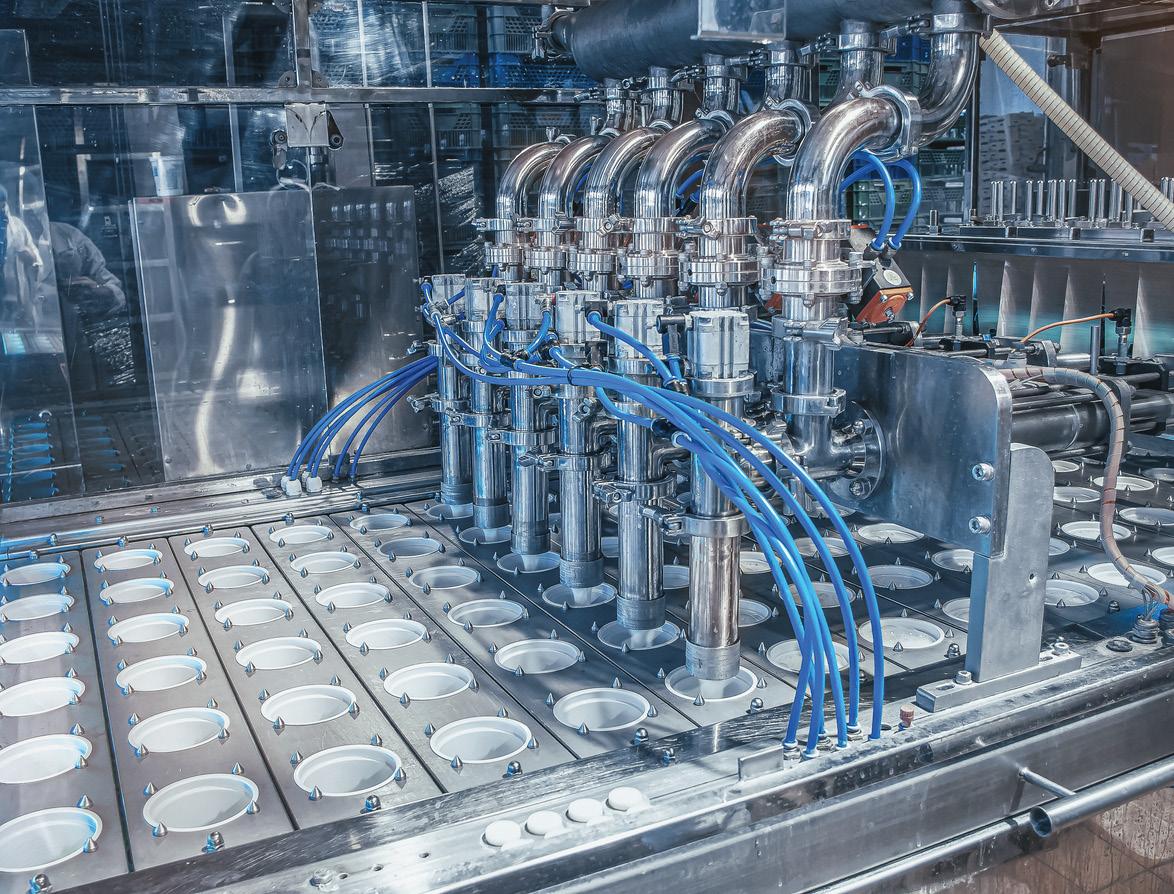

Pactiv Evergreen’s mission, “Packaging a Better Future,” guides all aspects of its operations, from its choice of materials to its organizational goals.

But the company’s past is also a key part of its identity.

Pactiv Evergreen’s filling equipment boasts a rich 143-year history in the liquid packaging industry.

Its origins can be traced back to 1880 with the founding of J.G. Cherry Co. (that company specialized in the handling of fluids, like milk). After a merger with D.H. Burrell and Co., known for producing dairy equipment (including the first cream separator), the newly formed entity, Cherry-Burrell, emerged as a leader in the production of dairy and food processing and packaging machinery.

In the years that followed, the company experienced several shifts in ownership. The first came in 1991, when International Paper, a carton manufacturing company, acquired Cherry-Burrell’s packaging equipment division. Sixteen years later, its Beverage Packaging Division and Blue Ridge Paper Products were purchased by the Rank Group, and the name was changed to Evergreen Packaging. That company and Pactiv, which were both part of Reynolds Group Holdings Limited, merged forces in 2020 and formed Pactiv Evergreen, a publicly traded entity.

“More important than the history that can be traced back through our corporate lineage, though, is our legacy that we have built with our products,” said Gary Nissen, general manager.

The company has several gable top products in its lineup, including standard machines and extended life machines –both are manufactured at a 440,000-square-foot plant in Cedar Rapids, Iowa.

“We are pioneers in extending beverage shelf life (ESL and ELL), clean-in-place advancements, improving speed, and more,” said Nissen.

“Our gable top filling equipment has such a solid reputation that a good deal of our revenue comes from the service and maintenance of the equipment because many customers just don’t want to let these machines go.”

–Gary Nissen, general manager of Pactiv Evergreen

And Pactiv Evergreen is continuing to add to its product portfolio.

“Recent developments for the gable top market include the EH-84, which forms, fills, and seals up to 8,400 standard half-gallon/2 liter cross-section cartons per hour,” said Nissen. “The N-200 providing additional carton sanitization features was also recently introduced, packaging 340 EcoPak® cartons per minute with an optional spout application system. And for the quart/liter cross-section market- the EQ-70 remains competitive with a speed of 7,000 cartons per hour. Our fillers are the industry standard for direct manufacturers and co-packers. Hundreds are installed in the U.S. and Canada with more than 1,300 worldwide. Our single indexing machines provide the highest production per square foot.”

But Pactiv Evergreen’s capabilities extend beyond manufacturing. The company also employs an engineering staff,

tasked with the creation of new products, and a support staff, responsible for maintaining the equipment and providing technical assistance and the delivery of emergency parts.

“Our gable top filling equipment has such a solid reputation that a good deal of our revenue comes from the service and maintenance of the equipment because many customers just don’t want to let these machines go,” said Nissen.

Good equipment isn’t the company’s only focus, though.

As part of its ESG strategy, Pactiv Evergreen is working to “reduce emissions and energ y use,” “minimize water use,” “offer a wide array of sustainable products and materials,” and “design innovative materials and products.”

“Our commitment to sustainability is foundational to our purpose of ‘Packaging a Better Future’ and is guided by our value to ‘Do What’s Right’ to deliver sustainably manufactured products with ethics and integrity,” said Mike King, president and chief executive officer, in a press release. “Every day we strive to operate with respect for the environment and are dedicated to sustainability across our product portfolio, manufacturing, and supply chains.”

Courtney Kless is the Managing Editor of Northeast Dairy Media.

BY DR. GARY KUSTIS

The hiring process is a critical aspect of any organization – and it is the foundation of the company’s success. It is essential to get it right. Unfortunately, many businesses make mistakes when hiring new employees or acquiring new personnel from a merger, which can lead to costly consequences.

In this article, learn about the five most common mistakes companies make when bringing on new talent and how you as the employer can avoid them.

One of the most common mistakes companies make is not preparing their team for their new co-worker. No one likes to be surprised, and equally, no one likes to be “forced” on other people. Your existing team is as important

as the new members you acquire, and tending to both makes the difference between a strong team and high turnover. It’s important both sides are well-informed before the new hire’s first day.

Keep your team in the loop during the hiring process. If possible, invite them to meet the final two candidates one-on-one, and be part of decision-making. This way, they’ll feel more ownership over the outcome. Another useful tactic is a light, but meaningful questionnaire. Ask questions that get to the heart of the new person’s personal interests, office pet peeves, and quirks. This makes them more relatable right out of the gate. Collect the same from your team and provide this information to the new team member—it’s only fair they know what they’re coming into, too.

It’s almost impossible to fully trust someone you don’t know. In the same way you’re trusting a new hire with their responsibilities, they’re trusting you to lead them to success. You’re an especially important part of their career journey. What story do you want them to tell in the future? Do you want to be the terrible manager who taught them everything not to do or the one who showed them good management was possible?

Host a one-on-one “welcome to the company!” meeting at an offsite location (or take them out to lunch on their first day). Use this time to get to know your new hire better, and share your vision for their role in your organization. Be clear about your expectations and how you plan on supporting them in their role.

Interviews are an essential part of the hiring process, but many companies rush through them or don’t take them seriously enough. This can be especially true of second interviews, where many people find that they don’t have much more to ask the job candidates. All of this can lead to hiring someone who isn’t a good fit for your organization.

Take your time with interviews and ask open-ended questions that allow candidates to share their experiences and thought processes. Use behavioral interviewing techniques that focus on past behavior as an indicator of future performance. Consider using a personality test before the second interview and make use of what you learn to inform your questions in that second interview.

Checking references is an essential part of the hiring process, but many companies skip this step, or don’t take it seriously enough. This can lead to hiring someone who isn’t a good fit for your organization.

Take reference checks seriously and ask open-ended questions that allow references to share their experiences with the candidate. Ask about specific examples of how they worked with others, how they managed demanding situations, and how they responded to feedback. Describe the job they are applying for and ask them where they think the candidate may shine or struggle.

Offering competitive compensation packages is essential if you want to attract top talent. Unfortunately, many companies don’t offer competitive salaries or benefits packages, which can lead to losing out on top candidates. The labor situation today is definitely a “seller’s market” so don’t be surprised if you find that you’re paying more for talent than you did just 3-5 years ago.

Research industry standards for salaries and benefits packages in your area and adjust your offerings accordingly. Be transparent about what you’re offering and why it’s competitive. Be sure to also point out the aspects of your com-

pany’s culture that make it a great place to work. Meaningful work and worklife balance have value to people, too.

Avoiding these five common mistakes when onboarding new talent can help ensure that your organization attracts top talent and builds a strong team. By preparing your team for their new co-worker, defining the boss-direct report dynamic, taking your time with interviews, checking references, and offering competitive compensation packages, you can set yourself up for success.

Herbein + Company, Inc. is a member of the Northeast Dairy Suppliers Association, Inc. This article originally appeared on the company’s blog

Microbial contaminants can compromise safety and quality, but QualiTru’s aseptic sampling systems empower you to detect risks early. Monitor critical control points, identify biofilm hotspots, and implement proactive strategies to protect your products and brand.

For more than 40 years, dairy farms and plants have trusted QualiTru Sampling Systems to support safety and quality at every stage of the process.

QualiTru Sampling Enables:

• Early detection of contaminants

• Real-time data for hygiene control

• Improved process monitoring

Call 651-501-2337 to learn about precision sampling in your dairy operation to help ensure top-tier dairy safety and quality.

BY DEVON E. HOFFMAN

If you’ve spent time in the B2B world recently, you may have noticed a new trend.

And I’m not talking about ChatGPT or VR, although those are important and moving quickly, too. Sales and Marketing teams are finally finding ways to become better aligned and work more closely together.

It’s long overdue.

With better alignment, team members can work towards the same goals and boost organizational efficiencies, ultimately leading to more closed-won business.

Historically, Sales and Marketing haven’t really worked well together.

“We gave you leads!” exclaims Marketing. “Why can't you close the deals?”

“Well,” Sales responds, “The leads you sent us were horrible! They were just tire-kickers with no interest.”

And that fight continues until the business folds or the world stops spinning. Whichever comes first.

The main reason for the contention is that Sales and Marketing have typically had their own separate goals.

Marketing is usually focused on brand building and lead generation. They have a long-term vision, and most marketers love trial and error. Especially when it comes to emerging trends or technology, to see if there’s a way for something new to impact the company in a positive way.

For Sales, time is money. Most salespeople (especially ones that are well-seasoned or formerly trained) are very results-driven. “Will this effort get me appointments?” is their primary mindset. Many times, they’re aloof to the inner workings of marketing, especially the backend of a website, the behind-the-scenes management of software, or all that goes into content development.

The fastest route between two points is a straight line, and working out the kinks between the two teams can bring positive change.

Specifically, the connection between the two will:

• Help both teams agree upon what a “quality” lead actually is so the Sales team is only working with the best ones, thus reducing friction and helping close more deals.

• Shorten the sales cycle since there’s less “drop off” when leads are passed from Marketing to Sales and more intel on each prospect.

• Reduce time, effort, and frustration that comes with reporting on different metrics, reporting on the wrong metrics, or managing cross-department communication. Here are a few recommendations on how to better unify your two teams.

The most important way to promote alignment is through transparency and regular communication. That includes from beginning to end – strategic planning all the way through to reporting. There must also be a feedback loop, meaning Sales should provide Marketing with insight into the quality of leads, what drove those opportunities, the status of opportunities, the size of deals, and more. Marketing should allow Sales to support their efforts, too. Here are a few examples of ways to develop more transparency and communication across your Sales and Marketing departments:

• Share Strategies: At the beginning of the fiscal year, Marketing presents its strategies to the Sales team. Additionally, the Sales team presents their strategies to the Marketing team.

• Share Budgets: Make Sales and Marketing budgets available for the opposite department to see. How much is being spent on tradeshows for Sales? How much does Marketing have available to spend on Google Ads? Reveal all the line items and encourage a discussion on how to best optimize available funds.

• Share Processes: Have Marketing members regularly join sales calls and presentations to gain deeper insight into the sales process, customer needs and pain points, and how Sales positions the product. Allow Marketing to offer critiques following those calls.

• Share Brainstorming: Have salespeople join the Marketing team’s brainstorming sessions where campaigns are developed and planned. Salespeople who have a knack for speaking and writing (ideal-

ly, all of them) can offer their talents and assist with content development, article writing, or act as video spokespeople.

• Share KPIs (Key Performance Indicators): Share the metrics you're focusing on and targeting. Track where certain initiatives are intended to drive and see how you’re impacting performance for the following in every stage. Visitor >> Lead >> MQLs >> SQLs >> Opportunity >> Closed Lost >> Closed Won >> Customer

Plan ongoing scheduled monthly meetings, where Sales & Marketing teams come together to review dashboards, goal statutes, and milestones, talk through upcoming promotions, events, and offers, and map out a plan to tag-team upcoming projects.

50-70% of a buyer’s research is done before making contact with a brand. Therefore, one could argue that marketing is equally as responsible as sales (if not more) for helping secure a deal. This truly begs the importance of understanding one’s customers.

What specific questions does the potential customer ask the salesperson when in the sales process, and what answers are given? For the Marketing team, customer insight helps with important decisions, and the Sales team may have already uncovered these insights in their discovery process. They may have customer information that helps Marketing answer the questions: What social media sites to invest in? What targeting can be done within advertising networks? How to organize a website layout? What style, voice, and messaging to focus on with your content?

Sales can also benefit from the data. Pacing, pricing, and packaging can all reflect the buyer’s needs.

Both Marketing and Sales should develop buyer personas and profiles.

By building these profiles together, all team members can weigh in on not only the demographics of buyers but also what goes into their buying processes.

Forrester Research found that highly aligned companies grow 19% faster and are 15% more profitable. That alignment certainly comes from better teamwork, but it also comes from unified systems.

There are many software programs available to help both marketers and salespeople do their jobs more efficiently. Start

by identifying what tools are needed and how both teams can learn and embrace them.

Here are some examples:

• CRM (Customer Relationships Management) and/or Marketing Automation: Consider tools like Salesforce, Pardot, and Hubspot. Having a system that has built-in form capture, lead segmentation, email, opportunity management, forecasting, user behavior tracking, meeting notes, etc., makes it so both teams can access all they need to know about leads and prospects. There’s more transparency on what campaigns are running too.

• Lead Intelligence: Lead intelligence isn’t limited to just sales use. Think about a tool like DealFront- which identifies businesses who are on your website and their pageview history - or ZoomInfo, which provides intent data - giving you contact information of folks who have recently expressed interest in your industry or product. Think about how Marketing can tap into this data for greater market insight, remarketing, or improving conversion rate optimization (CRO).

• Project Management: Software like Wrike or LiquidPlanner is great at helping teams create and manage projects and tasks and also helps with internal collaboration. By reducing meeting time and the number of emails - and helping keep conversations aligned to specific projects - it improves organizational efficiency.

• Person Gifting: Thanks to modern gifting softwarelike Sendosa - you can plan to send postcards, direct mail or personal gifts to prospects in bulk - or based

on specific actions they’ve taken on your marketing campaigns. Timing out gift-giving to specific buying stages can help nudge a lead closer toward a purchase and develop greater brand loyalty.

• Reporting: Both teams need to report on results. By building dashboards in one single system, there’s a greater appreciation for each other’s work and efforts. Use a business intelligence tool like Google Looker Studio that allows you to integrate with other third-party reports and bring multiple data sets into one interface. Doing so makes it easier for all involved to quickly and easily revisit numbers and hold team members accountable.

Marketing’s main responsibility is still to generate awareness, interest, and demand for a brand and its products. Sales’ main responsibility is still to forecast, prospect, work deals, and close business.

In silos, major holes can appear that lead to inefficiencies and lost opportunities. With better alignment, efficiencies are added, sales cycles are shortened, there’s less churn, and more deals are closed.

What’s the investment?

Patience, collaboration, better tools, and an agreement that both teams will work together to make a more significant impact on the business.

You may have heard the term “Smarketing.”

It was coined to describe cohesion between the Sales and Marketing departments.

Organizations that embrace “smarketing” get better results.

It’s not easy. But it’s doable.

Watch your business soar to new heights by letting the collaborative sparks fly, igniting the DYNAMIC DUO of Sales and Marketing!

Devon E. Hoffman joined Site-Seeker in 2016 as a digital marketing assistant. His creativity has driven his ability to create custom, client-focused content. He now supports a number of facets throughout the company, holding the position of Digital Marketing and Sales Specialist Team Lead.

Our weekly email newsletter includes the latest industry news, as well as updates from the NDFSA members.

Two advertising options are available: A spotlight ad (600x300) placed in the body of the newsletter, plus a logo and a 50-word description at the top. A banner ad (600x150) placed in the body of the newsletter.

your sales rep for more information.

INGREDIENTS:

• 8 ounces (2 packed cups) grated extra-sharp cheddar cheese

• 1½ cups all-purpose flour, spooned into measuring cup and leveled-off with knife, plus more for dusting

• 1 tsp. kosher salt

• Scant tsp. crushed red pepper flakes

• 1½ tbsp. roughly chopped fresh herbs, such as rosemary and/or thyme

• 1 stick (½ cup) cold unsalted butter

• 6 tbsp. heavy cream

INSTRUCTIONS:

1. Preheat the oven to 400°F. Set two oven racks in the center of the oven. Line two baking sheets with parchment paper.

2. In the bowl of a food processor, combine the cheese, flour, salt, red pepper flakes, and herbs. Pulse until the mixture resembles coarse crumbs.

3. Cut the butter into ½-inch chunks and add to

the flour/cheese mixture. Pulse until the mixture resembles coarse crumbs, with some pea-size clumps of butter within. Add the heavy cream and pulse until the mixture starts to clump together into a mass.

4. Lightly flour a work surface and dump the dough on top. Dust the top of the dough with flour and use your hands to shape into a rectangle about 1 inch high. Cut the rectangle in half.

5. Dust the work surface with more flour and roll each block of dough into a 8 x 10-inch rectangle about ⅛-inch thick (turn the dough as you go and add more flour as necessary so it doesn't stick). Using a pizza cutter or sharp knife, trim the edges straight without sacrificing too much dough, then cut the dough into thin strips about ¼-inch wide. Transfer the strips to the prepared baking sheets, leaving about a ¼ inch of space between them.

6. Bake the straws for 10-12 minutes, or until lightly golden on top and a rich golden color on the bottom, rotating the pans from top to bottom and front to back midway through. Remove from the pans from the oven and set on a rack to cool. Carefully transfer the cheese straws to a plate and serve.

Many of our members may know Leanne Ziemba as the business operations manager for the Northeast Dairy Foods & Suppliers Associations. But we’ve discovered she also is queen of the kitchen, as she has some delicious recipes that include fresh, wholesome dairy products.

BY GARY LATTA

The Indianapolis 500 is held each year at the end of May. A high point takes place at the conclusion of the race when the winner drinks milk.

In recent years, winning drivers not only drink milk from quart-size glass bottles but also douse themselves in dramatic fashion. Fans and photographers enjoy this moment in victory lane, capturing it on film.

So how did this practice get started? The first driver credited with drinking milk at the Indianapolis 500 was Louis Meyer. Meyer was the event’s first three-time winner, taking the prize in 1928, 1933, and 1936. It was the 1936 victory where history records the first drinking of milk, which was buttermilk.

Legend has it that as a young boy in Yonkers, New York, Meyer’s mother convinced him that drinking buttermilk would be refreshing after physical activities on a hot day. This was advice that Meyer carried with him throughout his life and racing career.

Meyer claimed that he drank cold buttermilk following his win in 1933, and likely he did, but there are no photographs or news reports to support it. However, drinking cold buttermilk from a glass bottle following his win in 1936 is officially the start of the tradition, documented with photographs and film.

Meyer drove his No. 8 race car to the victory circle and sat on the back when someone handed him a bottle of but-

termilk (you can watch it here). The event announcer then said, “Someone has given him a bottle of milk. Well, that race would make anybody thirsty.” Legend has it that an opportunistic marketing person from the dairy industry witnessed the celebratory act and encouraged the Indianapolis 500 promoters to offer future winners a bottle of milk.

The idea caught on, and for a few years, milk was seen being chugged in victory lane after each race. Annual racing was put on hold during WWII. Following the war years, racing was resumed, and so was the tradition of drinking milk. By this time, buttermilk was dropped in favor of regular milk, and then water was offered in silver cups for a few years. In 1954, milk celebrations resumed and have been part of the Indianapolis 500 tradition ever since.

In 1954, the Indiana American Dairy Industry Association offered $400 to the winning driver and $50 to his chief mechanic to pose drinking milk from a glass bottle. Today, those amounts have increased to $10,000 and $1,000, respectively.

Before each race, every driver is polled to determine which type of milk they prefer if they win. The options are whole, 2%, and skim. Each bottle is stored in the track fridge until the winner is announced. Two preselected dairy farmers representing the American Dairy Association of Indiana present the cold milk to the race winner in victory lane. One

dairy farmer is designated “the official” and hands the bottle of milk to the driver. The second dairy farmer is designated as “the rookie,” considered to be in-training, and hands bottles of milk to the winning chief mechanic and team owner. Next

year, “the rookie” will move up to “the official” role, and a new rookie will be selected.

For 2024, the race milk bottle official presenter is Alex Neuenschwander, a fourth-generation Indiana dairy producer, and the rookie presenter is Abbie Herr from Herr Dairy.

“The Indy 500 is all about tradition and I’m excited to be part of the tradition,” Neuenschwander said in an interview with Hoosier Ag Today. “It is such a huge stage for all of the hard-working men and women that are in the industry. I’m excited and humbled to be part of that and to be chosen and by my fellow dairy farmers is a huge honor.”

Gary Latta is a dairy product specialist consultant for the Northeast Dairy Foods Association, Inc. He has more than 30 years of experience in providing economic analysis, statistics, and information to the dairy processing industry.

BY COURTNEY KLESS

ach year for the Q2 issue, Northeast Dairy Magazine talks to Donna Berry (who covers new products and trends for the dairy industry) about what we can expect in the coming year.

In 2024, she believed the emphasis would continue to be on protein and immunity.

“One of the biggest motivators right now in food and beverage is health and wellness and food as medicine,” Berry added. “Consumers are hearing this and they’re reading up on it. They’re recognizing that you are what you eat.”

There was also some pushback on ultra processed foods.

“While some might characterize dairy as being ultra processed, the reality is that compared to other stuff, it’s minimally processed,” said Berry. “So, it’s a really good position for dairy to be in.”

Read on for some of the trends she saw in each segment.

One space where health and wellness weren’t dominating was ice cream.

“Those high protein, low sugar products didn’t have longevity,” said Berry. “Ever since COVID, consumers believe it’s ok to enjoy food and take a little break and have something indulgent. As a result of that, just true, delicious, ‘how much stuff can you put into my ice cream and make it good’ is what is dominating right now.”

As were nostalgic flavors, like cotton candy and butterscotch.

“A lot of those are gearing towards being non-chocolate,

Perry’s Ice Cream has a few new additions to its lineup – and they may feel a little familiar.

The company said the five flavors (Caramel Panda Paws®, Over the Moon, Bee Sting, Fruit Scoops, and Cookie Jar) were inspired by current trends in the space.

“With consumers feeling nostalgic and reminiscent, we focused our flavor development on classic flavors that offer a twist of something new while invoking joyful memories,” said Megan Mergler, associate product manager, in a press release.

because there is a major cocoa bean shortage that does not show any signs of letting up,” said Berry. “Ice cream is clearly one of the categories that has flexibility; you don’t need to have an ice cream that has chocolate in it.”

Berry saw a lot of activity in this space with high-protein and specialty products.

“Milk that is value-added is doing very well,” she said.

One innovation was Organic Valley’s Family First™ line, whole and 2% milks with DHA Omega 3 added.

The lactose-free claim was also “very big.” In April alone, two processors (Prairie Farms and Hiland Farms), unveiled gallon options for consumers.

“One of the biggest motivators right now in food and beverage is health and wellness and food as medicine.

Consumers are hearing this and they’re reading up on it. They’re recognizing that you are what you eat.”

– Donna Berry

Keeping in line with the idea of indulgence and the shift away from viewing fat as unhealthy, products made with whole milk performed better among consumers than those that were low or nonfat.

“Plain old cottage cheese is really booming right now,” said Berry. “The focus is on protein. It is the same thing with yogurt. Greek yogurt has become part of the mix. But some of the more indulgent flavors are also doing quite well.”

When it came to cream cheese (and sour cream), “customers [were] looking for minimal processing, which also correlates to fewer ingredients and cleaner labels,” said Berry.

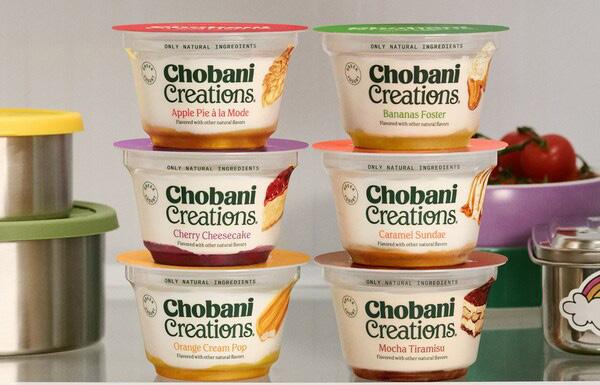

Chobani has a new indulgent option for consumers.

Called Chobani® Creations® Greek Yogurt, the line features six flavors: Mocha Tiramisu, Apple Pie à la Mode, Cherry Cheesecake, Orange Cream Pop, Bananas Foster, and Caramel Sundae.

“By pairing our natural, nutrient-dense Greek Yogurt with dessert-inspired flavors, we’re stretching yogurt beyond the breakfast occasion,” said Niel Sandfort, chief innovation officer, in a press release. “These flavor profiles, whether they be nostalgic like orange cream pop or decadent like mocha tiramisu, hit the spot in terms of food memory, sensory, and satisfaction. With Chobani Creations, we’re giving consumers a permissible, indulgent moment.”

One company that experimented with different flavors was Cracker Barrel Cheese.

In March, it introduced a Truffle Cheddar and Dill Havarti.

“As the appetite for innovative flavor combinations continues to rise, we can’t wait for Cracker Barrel fans and cheese lovers alike to experience our new artisan flavors, promising an elevated snacking experience that exceeds expectations,” said Mallory Loeffler, brand manager, in a press release.

To meet that demand, Tillamook introduced a brick cream cheese free of gums and preservatives.

Berry noted that cheese sales continued to grow in 2024 because, after all, “people love cheese.” Even so, a few new trends emerged. The first was experimentation with flavors – specifically those that were spicy and hot (like peppers).

“When you eat spicy foods with dairy, the dairy helps mellow it out, so you can taste the peppers a little bit better,” said Berry. “So, companies are getting really creative right now in that space.”

They also experimented with different forms of cheese.

“There’s been a lot of activity with the concept of cheese snacking bars,” said Berry. “Instead of it looking like a string cheese or little cubes, it’s more of a bar, so you’re eating it like you would like a granola bar.”

Butter was another space where that experimentation continued, particularly with “different flavors for different uses.” Also doing well was ghee, a clarified butter that was ideal for cooking and frying.

“People are gravitating toward real butter,” Berry concluded.

Refrigerated dairy desserts continued to be one of the biggest opportunities for dairy processors, according to Berry – and they were finally beginning to gain some momentum.

“During COVID, consumers really got used to all of the single serve, grab-and-go concepts,” she added. “And because everyone believes that they can have a treat (there is research that says this), this whole space of dairy desserts and portion control is really resonating with consumers.”

As a result, companies got more and more creative when it came to incorporating different layers and flavors. For example, Rich Foods launched a turtle cheesecake mousse parfait, which its website describes as “perfectly portioned and portable cheesecake mousse on a bed of chocolate crumb, topped with a smooth layer of caramel and sprinkled with chocolate chips and pecans.” And more innovations are sure to follow.

Editor’s note: Thank you to Donna Berry for sharing her knowledge on this topic. You can read her blog at berryondairy.com

Courtney Kless is the Managing Editor of Northeast Dairy Media.

BY COURTNEY KLESS

Bartlett Dairy has a saying: ‘We’re not just milk.’

During its 61-year history, the company has evolved from a milkman service into a regional food and dairy distributor – and it’s been managed by the same family the entire time.

“Milk runs in the veins of the Malave family, but it wasn’t enough to keep up with the demands of our everchanging customers,” said Michael Malave, VP Sales. “The added value to our product mix makes us a key partner to the customers we serve.”

His father, Thomas Malave Sr., established Bartlett Dairy in 1963 with a single truck (at the time, it operated as a doorto-door delivery service and retail route in Queens, New York.). Soon after, Tommy Malave Jr. followed in his footsteps, and together they broadened the company’s market to include stores and restaurants.

By 1990, the decision was made to incorporate the company. That ushered in another era of growth for Bartlett Dairy. Malave’s other sons – Michael, Kenny, Jimmy, and Donald – joined the team, bringing with them a wealth of knowledge acquired during their time at other dairy operations.

“Although the company has grown well beyond the founder’s expectation, it is still a family business,” said Malave. “Throughout the years, each son took a more active role in the family business. This led to its continued growth and success in building one of the largest family-owned dairy distribution organizations in the region.”

Now serving customers in New York, New Jersey, and Connecticut, Bartlett Dairy has stayed true to its roots, specializing in milk (the company’s website boasts that it is

“Milk runs in the veins of the Malave family, but it wasn’t enough to keep up with the demands of our everchanging customers.

The added value to our product mix makes us a key partner to the customers we serve.”

– Michael Malave, VP Sales, Bartlett Dairy

how much it has grown over the years. New hires undergo training directly from the Malave brothers and its team is available around the clock, ready to provide assistance whenever needed.

“often two days fresher” than other brands) and milk products. But the Malave brothers also knew that the business needed to adapt. So, it did.

“By enhancing our portfolio to meet the needs of our clientele, we began distributing other perishable food items to retail and foodservice customers in the region,” said Malave. “We supply syrups, baking ingredients, juices, fresh fruit, soups, paper products, and many other products found in the kitchens that we service.”

And the company is diversifying its offerings again, this time with a line of shelf stable products.

“As always, when adding new products to our brand, Farmland Fresh Dairies, a lot of work goes into it before we get to taste the final product,” said Malave. “It all starts with a vote from the brothers. Then the vision becomes a reality after R and D is done to make sure the product meets the standards of our family values. Once everyone is in agreement, design and packaging is assembled and voted on by the organization. After months of preparation and planning a launch date, we have our new Farmland Fresh Dairies shelf stable product ready for its introduction to the industry.”

Bartlett Dairy’s mission statement contains six core values, but one of them, the commitment to excellence in customer service, is especially important to the company – no matter

“We never miss a beat when it comes to service,” said Malave.

“Growing the business successfully is a shared culture throughout the different departments that make us ‘One World.’ Every employee of Bartlett Dairy has their own talents that they bring to the table. We depend on everyone to roll up their sleeves to support each other and take care of our customers.”

And Malave said the future looks even brighter. The company’s new distribution center is nearing completion and is expected to begin operations soon.

“The brothers wanted to establish a facility within the combines of New York City to better serve our New York metro and New York suburban customers,” said Malave. “Once we open this distribution center, we look forward to growing our business, expanding our product offerings, and bringing jobs back to the community where we were established years ago in a milk plant in Queens, New York.”

Courtney Kless is the Managing Editor of Northeast Dairy Media.

BY COURTNEY KLESS

he Probst Group is deeply committed to two things: clean water and the protection of natural resources.

“Combining our passion for preserving the environment with our unparalleled expertise in wastewater treatment allows us to provide some of the most advanced wastewater treatment solutions in the country,” said Brand Manager Samantha Winchell.

That expertise comes, in part, from knowledge passed down by three generations of wastewater engineers.

Henry Probst was immersed in the world of wastewater treatment as a child, accompanying his father and grandfather on visits to treatment plants.

“He quickly became fond of the unique challenges every facility provided,” said Winchell. “As he grew up, providing technologically advanced wastewater solutions became a passion for him; knowing that he could assist more facilities in effectively treating their wastewater and help protect the

environment at the same time.”

Henry went on to major in Civil Environmental Engineering at the University of Wisconsin – Milwaukee, juggling his studies with employment at ProCorp., a company his father, Tom Probst, founded in 1988 to offer wastewater management solutions to the food and beverage industry.

During that time, the father-son duo also pioneered a few of the earliest processes for enhanced biological phosphorus removal.

Following the sale of ProCorp, Tom and Henry established The Probst Group in 2008, and by 2014, Henry assumed full ownership. In January, the company moved into its new headquarters in Hartland, Wisconsin.

“For years, we’ve made do with spaces that never quite fit. But we dreamed of something better, a place that could truly support our growth and nurture our talent,” said Winchell. “Probst’s innovative office is equipped with cutting-edge technology to enhance communication, streamline processes,

“Cheese, milk, ice cream – they’re all amazing! But dairy processing and production utilize a significant amount of water during the production and cleaning processes, creating process wastewater, which must be treated before it can be discharged. That’s where we come in.”

– Samantha Winchell, brand manager at the Probst Group

reduce our environmental footprint, and ensure that our team has the tools they need to provide the highest level of service to our clients.”

More than 85% of them come from the dairy industry.

“Cheese, milk, ice cream – they’re all amazing! But dairy processing and production utilize a significant amount of water during the production and cleaning processes, creating process wastewater, which must be treated before it can be discharged,” said Winchell. “That’s where we come in.”

During its 16-year history, The Probst Group has created a comprehensive suite of solutions that includes engineering, design, build, operations support, consulting, and assistance with compliance and permitting. Each can be customized to meet the unique needs of the customer (and the facility).

“It’s definitely not a ‘one-size-fits-all’ type of approach,” said Winchell. “It really is our driving force to be your partner for wastewater solutions. Today and tomorrow. We design each system and solution with pride, knowing that we provide our clients with a clear path for process and capacity expansion as they continue to grow in the future.”

Winchell said that as a provider of wastewater solutions, The Probst Group is uniquely positioned to help its clients meet their sustainability goals. But the company also has some of its own.

“We also make a conscious effort to protect the environment through our own actions,” she added. “Our team is passionate about reducing the impact that we leave, and we continue to implement green initiatives and ideas in our workplaces and homes through our Green Team. Some of these efforts include reducing plastic and Styrofoam waste, as you’ll no longer find any disposable bottles in our office, and we’ve outfitted our team and workspaces with reusable, insulated water bottles and ceramic mugs. Additionally, our team participates in a handful of events, such as local river cleanups, to help ensure that we’re protecting the environment.”

The company’s five core values (Be Team Focused; Be Passionate; Be Accountable; Be Kind; and Grow) are at the heart of everything it does.

“Maybe one of the most unique aspects of our culture is the overarching spirit it has created,” said Winchell. “Ask anyone in the company what their favorite part of working here is, and the answer will be a resounding, ‘The people I work with.’ And that mentality combined with our shared values and commitment to the environment and the work that we do allows every member of The Probst Group to feel heard, to challenge something if they disagree, and creates an allfor-one effect; you’ll never hear someone say, ‘That’s not my job.’ And having a great team who works together and enjoys their work transitions directly to the way we interact with our clients, our partners, our vendors, and the community.”

Courtney Kless is the Managing Editor of Northeast Dairy Media.

BY BRIAN BLUFF

In the high-stakes world of pay-per-click (PPC) advertising, success hinges on precision. While the potential for reaching new customers and driving business growth is undeniable, navigating the intricate landscape of keywords, bids, audiences, and ad copy can feel like venturing into uncharted territory. Here's where data steps in, acting as your guiding light and propelling you toward PPC mastery.

Imagine launching an ad campaign without data at your disposal – essentially throwing darts in the dark. Occasionally, you might strike gold, but overall, it's an inefficient and costly approach. Data analysis in PPC illuminates the playing field, revealing:

• Winning Strategies: Data exposes which keywords generate the most clicks and conversions, along with the demographics most receptive to your message.

• Areas for Improvement: Are specific ads draining your budget with minimal return? Data identifies these underperformers, allowing you to optimize or eliminate them altogether.

• Hidden Gems: Data analysis can uncover opportunities to refine your bidding strategy, tailor your ad copy for higher resonance, or adjust your targeting to reach a more qualified audience.

Integrating data analysis seamlessly into your PPC routine is key. Here's how to get started:

• Set SMART Goals: Clearly define your campaign objectives. Do you seek website traffic, lead generation, or immediate sales? Establish Specific, Measurable, Achievable, Relevant, and Time-Bound goals.

• Track Key Performance Indicators (KPIs): Monitor metrics like click-through rate (CTR), conversion rate,

and cost-per-acquisition (CPA) to gauge your campaign's effectiveness in achieving your goals.

• Leverage Analytics Tools: Most PPC platforms provide robust built-in analytics dashboards bursting with valuable data. Tools like keyword planners help forecast performance and inform data-driven decisions. Consider third-party solutions for even deeper insights.

• Embrace A/B Testing: Test different ad copy variations, landing pages, and targeting options to identify what resonates best with your audience. Data will reveal the winning combinations.

While data is a powerful tool, it thrives on proper interpretation. Here are some expert tips:

• Context is King: Avoid basing decisions on isolated data points. Look for trends and patterns that emerge over time – typically at least quarter-over-quarter, or year-over-year for seasonal businesses.

• Consider External Factors: External events, seasonality, and competitor activity can all influence your PPC performance. Factor these elements into your analysis.

• Experimentation is Key: Data analysis is a continuous journey. Be prepared to adapt your strategy as you learn and new information surfaces. Don’t be afraid to do some A/B testing with your ad programs.

By embracing data-driven decision-making, you can transform PPC advertising from a guessing game into a welloiled machine. Leverage the insights data provides to finetune your campaigns, maximize your return on investment (ROI), and ultimately achieve your marketing goals. So, don't be afraid to turn on the lights – data is here to illuminate your path to PPC success!

Brian Bluff is the CEO and co-founder of Site-Seeker.

• ½ cup heavy cream

• ½ cup whole milk

• Juice from two oranges

• Zest from one orange

• 1 tsp. vanilla

• ¼ cup honey

1. In a blender, add cream, milk, honey, and vanilla.

2. Zest one orange, then cut and squeeze two oranges into blender. Blend until well combined.

3. Pour into popsicle molds and freeze for at least 3 hours or until completely frozen.

4. Serve.

Many of our members may know Leanne Ziemba as the business operations manager for the Northeast Dairy Foods & Suppliers Associations. But we’ve discovered she also is queen of the kitchen, as she has some delicious recipes that include fresh, wholesome dairy products.

We partner with associations to amplify the visibility of the association and their members. We help the associations thrive through e ective traditional and digital communications.

SCAN THE QR CODES TO ACCESS OUR MEDIA KITS

IBDEA

2 directories, 4 magazines, 40 newsletters, 12 TV Episodes, 2 Contact Booth Programs, 1 Networking Event, Annual Sponsorships.

1 Directory, 1 Yearbook, 4 Magazines, 52 newsletters, 1 Contact Booth Program, Annual Sponsorships.

We engage members and support associations’ through:

• Print/Online Directories

• Print/Online Publications

• Annual Sponsorship Programs (for members)

• Email Newsletters

• Graphic Design Services

• Video Production

1 Directory, 1 Contact Booth Program, Annual Sponsorships.

1 Networking Event.

• Coordinating Networking Events

• SEO & Content Writing

• Digital Marketing Consulting

Are you an association looking for a partner in success?

Contact BillB@datakey.org or visit datakeycommunications.com to learn more.

LEGISLATIVE REPORT As the 2024 Sessions End, Election Preparations Begin

MEMBER PROFILE QualiTru Sampling Systems is Committed to Innovation, Safety

ASSOCIATION EVENTS Preview of the 2024 Northeast Dairy Convention

HUMAN RESOURCES Exploring Recruiting Trends with KCO Resource Management

BY COURTNEY KLESS

Sustainability has certainly received a lot of attention in the past few years. These are some of the trends that are currently shaping the dairy industry:

The Net Zero Initiative is the dairy industry’s commitment, through the Innovation Center for U.S. Dairy, to reach greenhouse gas neutrality by 2050.

“We’re still 25 years away from that,” said Karl Czymmek, the associate director of Cornell University’s PRO-DAIRY. “As processors and milk handlers look at their systems and try to figure out how to reduce fossil energy, my stance is that that’s going to be a big focus for those groups.”

The initiative also includes a dairy farm component.

“After the milk leaves the farm gates, there’s an additional GHG footprint associated with getting it to the plant, getting that milk heated up and processed, whether it’s into fluid milk or other things,” said Czymmek. “For fluid milk, anyway, around 70-80% of that greenhouse gas footprint is from cradle to farm gate. And so, what goes on at the dairy farm is really important in terms of managing greenhouse gas emissions from dairy.”

The Net Zero Initiative isn’t just about being greenhouse neutral by 2050; it also aims to optimize water quality through improved nutrient management and more efficient water use.

“We are going to pay more attention to water use, I think, especially in irrigated areas, but even in areas where we’re blessed with a lot of natural rainfall,” said Czymmek. “We’re going to have to pay attention to how we’re using water, whether that’s at a plant or at the dairy. I think that’s going to feature more prominently in how we manage dairy farming and dairy processing in the coming years.”

Another important area is animal care.

“The FARM program emphasis on high standards of animal care on dairy farms will continue to be an important focus,” said Czymmek. “There are industry experts in extension, governmental agencies, and the private sector that can help farms keep up with and implement the best animal care practices. This is definitely a topic that’s going to continue to be with us.”

In Europe—and beyond— Czymmek is seeing a growing emphasis on biodiversity (it essentially evaluates how well farmers are maintaining biological diversity in and around their fields).

“We have more questions, I think, than answers, but you have to ask the questions to know the answers,” he said. “I think the good news for New York and the northeast is that many dairies have multiple crops in their rotations; we have different fields and soil types that require different management and sometimes different crops in them. So, we have a decent handle on biodiversity here by virtue of how we handle and manage our soil resources. But we’ll learn more with time.”

PRO-DAIRY is a dairy-directed extension program funded by New York State.

“Our focus is New York state dairy,” said Czymmek. “We have experts in environmental systems, agronomy, forage production and manure management, herd health, farm business management, and a youth development program, where we’re helping young people develop leadership skills while exploring careers in the dairy industry. So, we have a number of experts on staff who focus on these different areas of need, and we work closely with dairy producers and organizations to make sure we are filling important gaps.”

But the organization’s reach goes beyond state boundaries.

“The PRO-DAIRY team works with other Cornell colleagues to prepare a 16-page inset called 'The Manager' for the Progressive Dairy magazine,” said Czymmek.

“Many of us work with colleagues in nearby states to develop programs for dairy farmers, and over time, PRO-DAIRY staff have served on various committees that have a national and even international impact.”

For more information about PRO-DAIRY, visit cals.cornell.edu/pro-dairy

Sustainability is a topic that’s on the minds of many NDFSA members. So, for the third quarter issue of Northeast Dairy Magazine, we decided to ask them more about it.

Sustainability is at the heart of everything Alfa Laval does – and it has been that way for more than 140 years.

“Alfa Laval began its life in dairy, where it created more efficient ways to process milk and has been a leading innovator in separation, heat transfer, and fluid handling since,” said Sheldon Young, sustainability solutions specialist – food and water division. “We see our role as accelerating change for a more sustainable future and design our products to support that goal, using less energy and water, improving productivity, and taking careful consideration to the entire lifecycle of the products we create.”

In recent years, the company has introduced: a revolutionary mixproof and drain valve controller designed to cut water and chemical waste during CIP by up to 95%; an advanced tank cleaning technology that reduces cleaning media and time by up to 60% or more in some cases; and a new centrifuge design for specific applications that low-

ers energy consumption by up to 75% compared to previous models.

During that time, Alfa Laval has also devoted a tremendous focus to its own sustainability journey, committing to becoming carbon neutral by 2030 and setting goals that align with the Science Based Target Initiative.

“Initiatives have been launched at our sites around the world to lower the impact of producing Alfa Laval products, including replacing natural gas as a heating source at applicable production facilities, shifting to renewable electricity, installation of solar panels, and many other projects,” said Young. “We take a proactive approach to sourcing from suppliers with a lower carbon footprint, and carefully analyze how we manufacture and transport our products, seeking methods that reduce emissions.”

Editor’s Note: The information in this article was submitted by members who responded to two questions:

1. What does sustainability mean to your company?

2. Briefly tell us about your company’s efforts in this area over the past five years.

Thank you to all who participated!

As a top provider of sensors and instruments for hygienic process control, Anderson-Negele knows that sustainability is important not only to its operations but to the products and solutions it delivers to its customers.

“Under the slogan ‘Every drop counts,’ we offer a variety of sensors and solutions that enable dairy processors to achieve their sustainability goals,” said Ryan Fitzgerald, head of product management. “Anderson-Negele exists to help reduce product, chemical, and water waste to protect the environment while maintaining safe beverages and food”

Reliable and accurate measurements enable automation and optimization of production processes. With that in mind, Anderson-Negele provides the right products and expertise to help food and beverage manufacturers save energy, reduce material costs, and minimize food waste.

“Over the past five years, we have been consistently examining and optimizing our processes for sustainable production and distribution; however, we can make an even greater impact by helping our customers achieve their sustainabil-

ity goals,” said Fitzgerald. “For example, a dairy processing customer of ours was able to avoid losing 120 liters of milk during each phase transition by switching from time-based control to turbidity measurement on a UHT system. Another dairy reduced its entire water consumption for equipment cleaning by 10% through the optimization of CIP processes with our turbidity and conductivity sensors. In both cases, the reduction of milk and water waste amounted to several thousand liters per year.”

Byrne applies its philosophy of continuous improvement to every aspect of its business.

“Sustainability is no exception,” said Ashley Casey, sales and marketing specialist. “We are constantly striving to implement better sustainable practices throughout our operations and align with industry best practices.”

There’s a lot in motion, especially at the company’s facilities. For starters, Byrne is continually optimizing efficient energy use for the essential utility systems (i.e., water, compressed air, steam, and refrigeration equipment).

And then there’s wastewater. “Our investments in wastewater treatment operations have resulted in improved pre-treatment of our effluent (liquid waste) while using fewer chemicals in the process,” said Casey.

After the milk is processed, the resulting sludge waste is repurposed in various ways; for instance, it can be used as

natural fertilizer by farms or converted into renewable natural gas by municipal treatment facilities.

When it comes to the company’s industry partners, Byrne keeps a close eye on the recycled content in packaging and monitors the key performance indicators for its suppliers’ and customers’ program development.

“Our partnerships with local farms demonstrate commitment to responsible animal welfare practices, conservative use of chemicals, and minimizing over-the-road travel with their proximity to our processing facilities,” concluded Casey.

At CDF Corporation, sustainability is about much more than environmental stewardship; the company places a strong emphasis on social responsibility and economic viability, too.

“Our approach encompasses various practices and goals aimed at reducing environmental impact while supporting the communities in which we operate,” said Kate Connors, marketing manager.

Through several key initiatives, CDF Corporation is actively working to minimize its ecological footprint. For instance, the company is recycling and reusing raw materials during its production processes, installing full-roof solar panel systems at each of its facilities, and developing products that reduce the use of plastics, greenhouse gases, and the resources needed for transportation and storage.

The company also firmly believes that sustainable practices and economic success should go hand-in-hand.

“By focusing on innovations like the Cheertainer®, AirAssist®, and our full range of IBC and Drum & Pail liners — which offers logistical and cost benefits by reducing material use and improving transportation efficiency—we aim to provide value to our clients while adhering to our sustainability principles,” said Connors.

Dart Container has three sustainability commitments: Innovate, Inspire, and Invest.

“Our approach to product development combines first-use performance with sustainable next-life options,” said Bob Motter.

So, Dart Container created the ProPlanet seal to recognize those that adhere to its “highest sustainability standards.” To earn this seal, products must meet at least one of the following criteria: contain recycled material, be commercially compostable, or be designed for recycling.

But the company’s sustainability efforts aren’t limited to product innovations; Dart Container has also earned a significant milestone in its operations.

“Our U.S. manufacturing facilities achieved Operation Clean Sweep Blue recognition, meeting the gold standard for preventing plastic pellet, flake, and powder from escaping into the environment,” the company said. “We’re actively seeking additional innovative ways to further reduce our carbon footprint.”

Ted Reppi, a flow and density consultant, said that Emerson takes sustainability “very seriously.”

The company’s approach is structured around three pillars: Greening Of Emerson, Greening By Emerson, and Greening With Emerson