As we reach the conclusion of another year, it's both a time for reflection and a moment to look forward to the future. This final print edition marks an important milestone for us, as we transition to a fully digital publication starting in 2025. Our magazine will be published online in May and August, offering even richer content to inspire and inform our dedicated readers. Throughout 2024, there have been significant challenges, particularly the ongoing cocoa shortage which has made waves across the food and beverage manufacturing manufacturers

EDITORIAL

adapt,

looking for alternative ingredients and strategies to meet consumer demand. The ripples of this shortage are felt far and wide, influencing everything from the price of chocolate bars to new, exciting recipes in pastry lines, see page 6 for more on this story. We owe an immense debt of gratitude to you, our loyal readers, for your steadfast support through the years. Your engagement and passion have been a guiding light for us. Additionally, we extend our heartfelt thanks to our advertisers; your partnership and support have been invaluable in enabling us to bring quality content to our audience. As we embrace the holiday season, we wish you a restful and joyful break. May this time be filled with peace, happiness, and a touch of indulgence from the culinary delights that make this season special.

Warmest wishes,

Kelebogile Nondzaba

Ngcombroker

Editor: Kelebogile Nondzaba +27 (0)78 175 9632

kelebogile.nondzaba@newmedia.co.za

Layout & Design: Itumeleng Kunene

Art Director: David Kyslinger

Cover image: Shutterstock.com

ADVERTISING

Key Account Manager: Anita Raath +27 (0) 82 976 6541 anita.raath@newmedia.co.za

Key Account Manager: Càndida Giambò-Kruger +27 (0) 71 438 1918 candida.giambo-kruger@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien

Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy:

Rescuing sweet potatoes

Cocoa farmers hoard produce

Nestle says goodbye to loved coffee creamer

Provisur’s latest machine innovations

Advanced potato processing equipment

Metpac and Trashfortreats join forces

Bake it better masterclass launch

Propak Africa 2025

High productivity baking solutions

Beta-glucans can win over hearts in a beat

Beverages industry blends

Keep winning with Vega

Pumps driven food processing success

Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

General Manager: Dev Naidoo

Production Manager: Mandy Ackerman

Art Director: David Kyslinger

JOHANNESBURG OFFICE

Building 13, The Woodlands Office Park, 20 Woodlands Drive, Woodmead, Sandton PO Box 784698, Sandton 2146

Tel: +27 11 713 9000

POSTAL ADDRESS PO Box 784698, Sandton, Johannesburg 2146

Published by New Media a division of Media24 (Pty) Ltd

MANAGEMENT TEAM

MANAGING DIRECTOR: Aileen Lamb

COMMERCIAL DIRECTOR: Maria Tiganis

STRATEGY DIRECTOR: Andrew Nunneley

CHIEF FINANCIAL OFFICER: Venette Malone

HEAD OF HR: Leone Fouche

Interim CEO: MEDIA24: Raj Lalbahadur

HEAD OFFICE

11 Shelley Road, Salt River, Cape Town

Tel: +27 21 406 2002

Email: newmedia@newmedia.co.za

PO Box 440, Green Point, Cape Town 8051 www.newmedia.co.za

Europe Recyclable Flexible Packaging

Vienna Austria 10 - 11 December www.ami-events.com

Food Pack East Africa

Dar-Es-Salaam, Tanzania

23 – 25 January www.mxmexhibitions.com

Diamond Jubilee Hall, Dar-Es-Salaam, Tanzania

International Production & Processing Expo

Atlanta, Georgia USA

28 – 30 January www.ippexpo.org

February

ProSweets / ISM

Cologne, Germany

2-5 February www.ism-cologne.com

Fruit Logistica Berlin, Germany 5-7 February www.fruitlogistica.com

Ishida Europe has extended its range of QX Flex tray sealers with the launch of a new model, which meets market demands for a compact, high-performance solution. The innovative model also maximises output, capacity and flexibility for medium- to high-volume production lines.

Sustainability is an integral part of Multivac’s strategy. For 60 years, the company’s packaging solutions have ensured that sensitive products globally can be processed efficiently, as well as being packed hygienically, reliably and attractively.

Rotolabel is passionate about the environment and focuses on minimising any negative ecological impact of its products. The company subscribes to the four Rs of packaging sustainability: responsible sourcing; reduction of materials; recyclability and increased recycled content

Interested in advertising in

If you are a supplier to the packaging industry, this will be an ideal opportunity to showcase your product offering and create additional brand awareness within the food, beverage, pharmaceutical, cosmetics, personal care, and home care manufacturing sectors.

In the complex ecosystem of food production, distribution, and consumption, the challenge of food waste continues to pose a significant threat. As leaders in the food rescue industry, we at SA Harvest recognise that the most effective solutions often emerge from the power of collaboration. A recent successful food rescue operation involving sweet potatoes from Du Toit Agri exemplifies this principle, highlighting how partnerships can transform potential food loss and waste into nourishment for thousands.

The origin of surplus: Dutoit, established in 1893, has over 130 years, has a long-standing history of delivering high-quality fruit and vegetables across South Africa. Despite their extensive experience and efficient farming operations, even seasoned producers can face challenges with surplus. This year, Dutoit encountered an unexpected excess of sweet potatoes, a result of preparing more stem cuttings than needed for the next planting season.

To prevent this valuable crop

from going to waste, SA Harvest stepped in to help. Initially meeting to discuss fruit rescue, the collaboration quickly expanded to include sweet potatoes, ensuring they were put to good use rather than lost.

Mobilising for impact: The need to swiftly move such a large quantity of sweet potatoes provided an opportunity to demonstrate the agility and impact of strategic partnerships.

SA Harvest, leveraging its robust logistics network and warehouse footprint, initiated a coordinated rescue operation. This entailed putting out a call to FWJ Logistix, a company with a storied legacy of four generations in

Ghanaian cocoa farmers are withholding their produce, anticipating higher prices, which is exacerbating the global cocoa supply deficit.

A dozen farmers, buyers and officials from state regulator Cocobod confirmed the practice, with some blaming it for a slowing of bean purchases but many link it to a statement from one of the country’s prominent political leaders.

An industry sources told Reuters that farmers were reacting to comments by Vice President Mahamudu Bawumia, who told supporters of the ruling New Patriotic Party four weeks ago that the government would raise prices for farmers.

“I have more than 300 bags, but I won’t sell,” said a cocoa farmer in south-central Ghana, who asked not to be named. “I will only sell after Christmas. We want to see if

they will increase the price as they said.”

Bawumia, who is running for the presidency in the Dec. 7 elections, has since said his comments had been misunderstood.

However, local media quoted Bawumia as saying the government would bring the farmers’ price on par with Ivory Coast’s.

Speaking to Reuters, Bawumia said there would only be a price adjustment in the case of a “significant difference” between the two countries’ prices.

Cocobod CEO Joseph Aidoo told local media that the farmgate price will be raised if the Ghanaian cedi currency depreciates, eroding farmers’ income. Despite that, Samuel Adimado, president of Ghana’s cocoa buyers’ association said the current price was optimal for farmers and would help Cocobod clear its debts.

Cocobod has highlighted that Ghana lost more than a third of its 2023/24 cocoa output to smuggling.

logistics, who unhesitatingly stepped forward. With trucks returning to Cape Town empty after delivering solar products, FWJ Logistix offered to transport the sweet potatoes from the Du Toit packhouse to SA Harvest’s Cape Town warehouse.

To facilitate the transport of such large volumes of loose sweet potatoes, SA Harvest’s long-standing partner CHEP supplied a total of 206 agri bins crucial for the operation. The coordinated effort saw three interlink trucks transporting the sweet potatoes from the packhouse in Prince Albert Hamlet to Cape Town.

In a bid to boost farmer incomes and deter smuggling, Ghana raised the fixed farmgate price by nearly 45% to 48,000 cedis (just under US$3,000), per metric ton for the 2024/25 season, which opened in September.

However, Ivory Coast, Ghana’s neighbour and the world’s biggest cocoa grower, raised its price to 1,800 CFA francs ($3.00) per kilogramme, just slightly above Ghana’s.

Both countries, accounting for more than 40% of the world’s cocoa exports, are currently signatories to an agreement to cooperate on production, research and sales policy to help raise cocoa prices and improve the livelihoods of cocoa farmers in Africa.

Source: www.foodbusinessafrica.com

Cremora, a brand deeply rooted in South African households for over 77 years, will now be managed under the banner of Lactalis, which is expanding its presence in the local market.

Despite the sale, the global company emphasized its commitment to the region’s economic development and its focus on long-term sustainability in Southern and Eastern Africa.

Cremora is currently manufactured at two Nestlé plants in South Africa, located in Babelegi and Potchefstroom, both of which are included in the deal.

According to a Nestlé spokesperson, there are no jobs that will be affected as part of the transaction. The brand has also been produced in Zimbabwe at a plant in Harare, but this site will cease production of Cremora after the deal.

Instead, the Zimbabwe facility will focus on producing other Nestlé brands, including the Everyday creamer and Cerevita breakfast cereal.

While Nestlé is exiting the Cremora business, it emphasized that the decision to offload Cremora is part of a broader realignment strategy aimed at keeping its business in East and Southern Africa competitive and sustainable

in the long run.

Nestlé noted that it operates five production facilities in South Africa, producing a range of goods from beverages to milk products, ice cream, and confectionery, and that the sale of Cremora will not impact its broader operations.

In Zimbabwe, the Harare plant remains Nestlé’s sole facility, but the company assured that this site will continue to play a key role in its future investment and sustainable development efforts.

Mota Mota, Nestlé’s regional head of communications, expressed confidence that the brand is being passed on to capable hands at Lactalis.

“We believe that Cremora is in good hands with Lactalis,” he said, adding that the transition will serve the best interests of employees, customers, and consumers alike, ensuring Cremora continues to deliver quality products under new ownership.

The acquisition by Lactalis South Africa is pending regulatory approval, and financial terms of the deal have not been disclosed.

Lactalis, a global dairy leader based in France, already has a significant footprint in South Africa. It operates in several regions across the country, including the Western Cape, Eastern Cape,

Gauteng, and KwaZulu Natal.

The company’s portfolio in South Africa includes well-known brands like Président, Parmalat, Melrose, Steri Stumpie, and Bonnita.

Herman Janse van Rensburg, the general manager for Lactalis South Africa, stated that this acquisition aligns with the company’s ongoing strategy to diversify its product offerings and better meet the preferences of South African consumers.

“We look forward to welcoming our new colleagues to the Lactalis family as we continue to build on the rich heritage of Cremora,” van Rensburg said, noting that the goal is to ensure a seamless transition for customers and consumers.

“With the sale, we are set to build on the legacy of Cremora, ensuring that the beloved creamer remains a staple in South African homes.”

Source: www.foodbusinessafrica.com

Heat and Control’s French fries and potato co-products processing equipment sets the industry standard for dependability, offering rapid and efficient processing of potato products including fries, wedges, and an array of co-products.

Collaborating with experts and strategic partners, Heat and Control delivers comprehensive turnkey solutions — from spud to shipping. The company offers a diverse range of heating options, allowing customers to choose between natural gas, oil, steam, thermal fluid, electric heating, Kleenheat®, and Greenheat. Their fryers boast optimal product handling, uniform oil heating and flow control, efficient fines removal, rapid oil turnover, and clean-in-place sanitation. These features ensure the production of high-quality products with extended shelf life. Heat and Control fryers provide precise oil flow control for even cooking in even the largest fryers. Full control of zone flows and minimised oil volume further enhance operational efficiency and oil quality. With reliability, minimal operator intervention, and highly effective Clean-in-Place (CIP) systems, operating costs are controlled while maximising production.

The Heat and Control French Fry Fryer ensures trouble-free, high-capacity production with precise oil management for uniform cooking and consistent quality. Integrated seamlessly into their full French fry processing lines — already operational worldwide — these fryers boast an impressive processing capacity of over 35 tons per hour of finished product. Heat and Control’s French fry and formed potato product systems are the workhorses of the industry. With

"Multi-zone frying is a great option for processors seeking to customise cooking conditions for different cuts of coated and uncoated French Fries with minimal fryer footprint. "

options including multi-zone and two-stage continuous fryer systems, manufacturers are guaranteed uniformity in their products.

With a specialised two-stage setup, tailored to produce batter-coated fries, but equally suited to uncoated fries, this style of fryer boasts a unique design that maximises production capacity with a minimal footprint: Stage 1: Set coating - Oil velocity control and flexibility reduce damage to the product and coating losses. Controlled oil flow through multiple AccuFlow™ inlets ensures each French fry receives a consistent cooking time. The oil inlet directs fines out of the fryer to safeguard oil and product quality. An outside belt return reduces oil volume, further enhancing oil turnover time. Fines are efficiently removed through multiple outlets, minimising oil degradation. The design of this system includes a drip tray oil flush system and full Clean-inPlace (CIP), ensuring optimal hygiene and reduced fines build-up in both stages.

Stage 2: Completes cooking - With the batter firmly set, fries undergo final cooking in the second stage fryer. Multiple zones of oil inlets and outlets maintain a consistent average cooking temperature, low Delta T, by rapidly adjusting to changes in product load. Oil flow penetrates the pack for uniform cooking, eliminating clusters and quickly removing fines without product damage. Multi-zone frying is a great option for processors seeking to customise cooking conditions for different cuts of coated and uncoated French Fries with minimal fryer footprint.

Precise Frying control for product qualityHeat and Control’s unique continuous fryer design gives complete control over product quality. AccuFlow™ oil inlets are proven to offer equal side-to-side oil flow for uniform cooking across all fryer width classes. Multiple oil inlets and outlets enable adjustments to oil velocity, volume, and temperature drop to suit specific products, while efficiently removing fines. Continuous oil circulation between the fryer, filter, and heat exchanger provides precise temperature control and rapid adjustment to changes in product load. A low volume of oil and rapid turnover ensure fresh products with extended shelf life.

Easy cleaning - CIP spray nozzles in the hood and exhaust stack clean all areas above the oil path. Self-locking motorised screw jacks conveniently raise the hood, and conveyors, clear of the pan for complete cleaning and maintenance access. The fryer includes cleverly engineered features which minimise fines buildup from the outset - to reduce overall cleaning time and improve cleaning effectiveness. .

Heat and Control –www.heatandcontrol.com

Everything you need to move your product from A - Z

Ideal applications:

• Snack foods

• Prepared foods

• French fries

• Fresh produce

• Pet food

• Nuts & Trail Mix

• Crackers

• Confectionery

Smart and flexible conveying that keeps your line running smoothly. We provide a wide variety of innovative and dependable conveying and product handling systems to move product through the line as efficiently as possible. info@heatandcontrol.com I

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

Shepstone Gardens was the scene of an elegant and inspiring afternoon this weekend, as SASKO, Moirs, and Safari launched a new chapter for Bake It Better with a Masterclass series led by renowned pastry chef Teddy Zaki.

This exciting partnership with Zaki, celebrated for his artistry and culinary skill, represents a transformative step for Bake It Better, positioning it as South Africa’s ultimate baking hub. Designed to inspire and equip bakers of all skill levels, the series promises a journey of technique and learning.

Bake It Better was founded with a clear mission: to uplift South Africa’s baking community by creating an inclusive space for bakers to learn, share, and enhance their craft. SASKO, Moirs, and Safari recognised the growing enthusiasm for home baking and developed this platform as a one-stop destination for baking enthusiasts seeking inspiration, support, and connection. Whether a seasoned baker or just starting out, Bake It Better offers everyone a chance to elevate their skills and explore new baking possibilities.

Teddy Zaki, the visionary behind Just Teddy patisserie, brings a wealth of expertise to the series. Known for his unique blend of South African, French and Middle Eastern patisseries , Zaki has earned his place among South Africa’s top pastry chefs, admired for his precision and artistry.

His cookbook, Just Teddy – Petals from Paris, has received recognition in the Gourmand World Cookbook Awards. Through this new partnership, Bake It Better aims to introduce bakers to refined techniques and delightful recipes, beginning with a high tea

“SASKO, Moirs, and Safari recognised the growing enthusiasm for home baking and developed this platform as a one-stop destination for baking enthusiasts seeking inspiration, support, and connection.”

theme that reinterprets classic treats with a local twist.

The launch event, titled “High Tea – But Better,” captured the spirit of the upcoming series. Guests enjoyed a selection of South African tea-time favourites, each with Zaki’s distinctive flair.

With Shepstone Gardens as the backdrop, the luncheon provided a glimpse of the six-part masterclass series, where Zaki will lead bakers through recipes such as Milk Tart Choux Swan, Cherry Lemon Delights, and the Ultimate Fruit Scone. The series will also offer a special session on high tea plating, sharing his insights on crafting visually appealing tea-time displays.

“The Bake It Better platform has always been about learning and connecting,” says Nomsa Khanyile, Marketing Director at Pepsico. “With Teddy Zaki leading this

Bake it Better is packed with recipes, advice, tools, and techniques designed to help you become a better baker.

Masterclass series, we’re bringing a new level of inspiration and expertise to our baking community, helping them bring something special to their kitchens.”

Reflecting on the launch, Zaki shared his excitement about reaching a wider audience: “Baking is about creating memories and sharing joy. This series is dedicated to making those moments memorable. Each class delves into flavours, techniques, and presentation to make high tea both accessible and memorable. I’m thrilled to collaborate with Bake It Better and share these skills with South African bakers.”

The six-part Bake It Better Masterclass series is now available on the platform, inviting bakers to join Zaki on a baking journey that blends tradition with creativity. Each session offers step-by-step instruction, expert tips, and a sense of community, helping bakers to refine their skills and discover new baking adventures.

To learn more about the Bake It Better Masterclass series and join South Africa’s baking community, visit www.bakeitbetter.co.za

As automation and digitisation accelerates across industries, companies are recognising the need to invest in smarter solutions, products and services to stay competitive. For those in packaging and related fields, Propak Africa, a leading industry trade show, provides unmatched insights into these latest innovations.

Propak Africa 2025, a premier event in packaging, printing, food processing, plastics, and labelling, will be held from 11-14 March at Johannesburg’s Expo Centre.

With over 400 exhibitors, attendees will see thousands of new products showcasing the latest in packaging innovation, from advanced equipment and cutting-edge technology to sustainable solutions.

According to Mark Anderson, Portfolio Director at Specialised Exhibitions a division of Montgomery Group and organisers of the show, the event promises “unrivalled access to groundbreaking insights and ideas that have the potential to elevate your business.”

This show will feature prominent com -

panies from across these industry sectors including Qualitechs, Rotocon, Filmatic, HG Molenaar, Cabletech, and IPEX, among others. With over 80% of available exhibition space already sold, interest continues to grow with companies keen to benefit from the opportunities available to exhibitors.

Propak Africa incorporates four other complementary shows: Pro-Plas Expo, the GAPP Print Expo, FoodPro Expo, and Pro-Label Expo. Together, these provide a comprehensive look at packaging innovations, the future of plastics and printing

in packaging, advanced food processing technologies, as well as labelling solutions that meet changing regulatory and consumer demands.

The trade show offers exhibitors access to thousands of decision-makers, providing invaluable opportunities to generate quality sales leads and build brand recognition. “Propak Africa is where companies can engage directly with prospective new customers, gain an understanding of market needs, form partnerships, elevate brand awareness and launch new products,”

Propak Africa 2025 –www.propakafrica.co.za.

Provisur Technologies is a full-service provider of innovative machinery and integrated production systems for industrial food processing. The company’s DMC (Defrosting. Marinating, Cooking) business unit is home to the Lutetia® brand, one of the world’s leading names in defrosting, marinating, and cooking technologies.

Tempering meat products is usually a lengthy process in which the frozen food loses its liquid content and active protein. Lutetia® tumblers use technologies that counteract the drip loss of meat. In the rotating drum of the tumbler, frozen meat IQF or in blocks is defrosted by steam injection under vacuum. The advantage of this patented technology is that the meat juice consisting of water and proteins is retained in the product through direct temperature control. Due to reduced drip loss, the weight loss that occurs during conventional defrosting is reduced. At the same time,

the process stops microbial growth and therefore increases product safety.

Defrosting in a Lutetia® tumbler is ideal for a wide range of meat – poultry, beef, and more – and is best suited to goods that are subsequently processed for cooked or marinated product. Lutetia® tumblers are available in a wide range of sizes from T1 to T7. Manufacturers will find the perfect machine to match their capacity and yield targets, with the help and advice of the Provisur, Lutetia sales experts.

In addition to defrosting in the tumbler, Lutetia® has a second technology: defrosting in the chamber. The patented technology inside the chamber makes it ideal for fragile products such as fish, or heavy block. For defrosting meat, the chamber is perfect to ensure “fresh look” once the product has been defrosted.

Lutetia® smoking solutions use cooking chambers to efficiently produce semi or fully cooked smoked products of consistent high quality.

Lutetia has also developed a unique smoking application using their tumbler, the application is not only based on smoking but use a combination of different process to match the perfect result. In fact, a major European supermarket chain has approved the smoking of meat products using Lutetia® systems as well as large European meat manufacturing companies. These deliver the best smoke penetration, enabling customers and consumers to obtain products perfectly adapted to their tastes and requirements.

Provisur’s PROactivation® technology is a patented method to produce cured meat and dry products, achieving maximum quality in a shorter time. While conventional methods such as air-drying require three to twelve months of maturing and drying, PROactivation® shortens the entire process to around two to four weeks. This leads to shortened storage time which in turn leads to significant savings in terms of storage space as well as an increase in flexibility when responding to market needs. The process enhances the raw material and creates products that are delicious in taste and texture.

Complete lines, integrated systems, robust machinery: With Lutetia® tumblers and chambers, manufacturers have all the advantages of a complete and flexible solution that includes tumblers and injectors as well as filling and loading systems. Years of knowledge and experience combine to make Lutetia® a world-leading brand, and with

their experts who have mastered important parameters which make the difference to help reduce cycle times, improve product quality and maximise throughput.

“Our integrated Lutetia® line minimises labour and labour costs and therefore improves efficiency,” explains Stéphane Kulikowski, sales director at Provisur for Lutetia brand. “Our robust systems are almost maintenance free and extremely easy to clean. We are proud of our worldwide aftersales service which is second to none. When our customers get in touch with us, they know that one of our experts will be on hand to help within a very short timeframe. In fact, there is

a constant two-way interaction between us and our customers.”

Innovation based on collaboration: Provisur has two Innovation Centers, one in Illinois, USA, and one in Plailly, France, that play an integral role in the company’s customer support. Customers can test and collaborate with Provisur experts to create the solutions they need to boost their business. Both centers are equipped with all the latest food processing equipment and technologies and allow the company’s clients

Provisur® Technologies of Chicago, Illinois, USA, with numerous branches in Europe, specialises in innovative industrial food processing machines as well as integrated production systems for a wide range of end products. Several well-known and time-honored brands, which are among the technology leaders in the sector, operate under the umbrella of the company. With its product portfolio, divided into the areas of Slicing (Cashin®, Formax®, Hoegger®), Further Processing (Weiler® and Formax®), DMC (Lutetia®) and Separation (AM2C®, Beehive®, Hoegger®), Provisur provides food processing companies with maximum efficiency solutions for requirements of any size.

to make informed decisions about investing in new systems, developing new products, or refining existing products.

Provisur - www.provisur.com

With almost 100 years’ experience in working with the food industry, IPCO can supply everything from premium quality steel bake oven belts to high productivity cooling systems for confectionery and chocolate products.

The company also supports food processors through consultancy services to help deliver new levels of efficiency and reliability to production processes. IPCO has sales and service offices in more than 30 countries, with trained and equipped service teams on the ground and available to provide a quick response to any service or repair requirement.

IPCO is the world’s largest supplier of carbon and stainless-steel belts to the bakery and confectionery industries, working with OEMs and end users alike. Steel belts are designed to provide years of reliable service and help businesses maximise both productivity and profitability. Key benefits of a steel conveyor belt include excellent thermal conductivity and outstanding durability; with good maintenance a working life of 20 years is not unusual. Being lighter than mesh belts, they are also a more sustainable choice, requiring up to 30% less energy to heat as they reenter the baking chamber.

A high quality bake oven belt will have certain mechanical properties – flatness, straightness – ‘engineered in’ at the production stage to ensure that it runs through the oven as it should. Consistency of colour is important too; dark areas absorb heat while light, shiny areas reflect it, so uneven belt colour could result in an uneven bake. This also has to be engineered into the belt. A flat, smooth surface ensures clean release at the end of the oven with minimal risk of damage to fragile products. And when

“The company also supports food processors through consultancy services to help deliver new levels of efficiency and reliability to production processes.”

cleaning is required, steel is easier to clean than other materials.

IPCO is also a major supplier of confectionery cooling equipment. Belt-based cooling operations make use of the exceptional heat transfer properties of the material to ensure quick and controlled solidification. In a typical system, the molten product is deposited onto a continuously running stainless steel belt and transported through the cooling tunnel. Cooling is carried out either by means of chilled air applied from above the product, chilled water sprayed onto the underside of the belt, or a combination of the two.

The inherent smoothness of the belt results in clean discharge of candy and other sticky products from a cooling line, leading to a better quality product and less waste. This ease of release means that delicate products can also be processed successfully.

This expertise has resulted in the development of a comprehensive range of chocolate forming/moulding equipment,

To access video, check out the Food Manufacturing Digimag.

with systems designed for the production of industrial ingredients – chips, chunks, drops and blocks – and decorative products such as shavings, rolls, pencils, blossoms and many more.

The production of instant coffee is another major applications for IPCO’s systems, with its freezing lines now being used by all of the world’s major producers.

After roasting, the coffee is milled and turned into a slurry, similar to soft ice. This is fed onto the steel belt and frozen by means of cold air blasted over the product at high velocity to guarantee rapid and uniform heat transfer. The combination of impingement technology and the excellent conductivity of the steel belt enables freezing times to be reduced by as much as 50% compared with conventional methods). Product quality is also enhanced, as the smooth, temperature-controlled freezing process ensures that the colour and flavour of the coffee is maintained.

Another food process for which steel belts are ideally suited is the drying of fruit and vegetables. Based around perforated belts, these systems enable controlled dehydration by the flow of air through the product, resulting in reduced process times. The use of modular, multi-stage drying units allows time/temperature curves to be optimised for products as diverse as potatoes, carrots, apples, orange peel, celery, garlic and tomatoes. Special systems for sensitive products have also been developed, enabling the drying of cut strawberries, blueberries, pineapple, mango and more. Delivering an end product with a highly uniform moisture content, IPCO dehydration systems are capable of handling partially frozen products and can also be used as a pre-dryer for microwave plants.

IPCO – www.ipco.com/bake

Our solid and perforated steel belts have helped bakeries produce premium quality products for almost 100 years.

Flat, straight, durable and easy to clean, they provide a baking surface that’s ideal for everything from rich, chewy all butter cookies to traditional biscuits and crackers.

We can also support you with a wide range of conveyor components covering everything from tensioning, drive stations and drums to tracking systems, break points and graphite stations. Talk to your local IPCO service team and we’ll work with you to improve the performance, productivity and reliability of your oven through process enhancement and system upgrades.

High productivity wide belts up to 3500 mm.

Maximum versatility – bake more on an IPCO steel belt.

Energy efficient – lighter belt means lower carbon footprint.

High power laser cleaningfaster, cleaner and greener than traditional cleaning.

Installations, upgrades (mesh replacement), repair, maintenance and spare parts.

Beta-glucans are the perfect solution to enhance snacks by introducing dietary fibre and heart health advantages. By incorporating this plant-based ingredient, they become eligible for approved health claims. Make hearts glow with joy and discover how these benefits can be translated into practice.

Most consumers worldwide understand the connection between heart health and their overall well-being.1 For example, 63% of consumers worldwide show interest in products that support heart health, even if they don’t have specific health concerns. 2 As a result, providing snacks with approved health claims presents a compelling opportunity for manufacturers.

To achieve this in an easy and affordable way, incorporating beta-glucans from barley into recipes is the way to go. Barley beta-glucans are viscous, soluble, fermentable dietary fibres with scientifically proven benefits for heart health. Because of this, they also enable fibre enrichment and corresponding claims.

Beta-glucans generate a high viscosity, which makes the food thicker and slows its passage through the gastro-intestinal tract. This delays the uptake of glucose from food, lowering the blood glucose response.3 In addition, the high viscosity lowers the uptake of bile acids and thereby reduces blood cholesterol concentration 4, helping to cut the risk of coronary heart disease.

Snacks enriched with these functional ingredients provide advantages not only for consumers but also for producers. With more than 120 scientific studies demonstrating the beta-glucan health effects from cereals,

“Beta-glucans are the perfect solution to enhance snacks by introducing dietary fibre and heart health advantages.”

official bodies including EFSA, the FDA and Health Canada have approved corresponding health claims.5

The BENEO-Technology Center developed multiple recipes with beta-glucans that can carry high fibre and other health claims depending on local legislation, like “Barley beta-glucan has been shown to lower/reduce blood cholesterol. High cholesterol is a risk factor in the development of coronary heart disease”. This claim can be used for foods that provide at least 1 g of barley beta-glucan per quantified portion. The beneficial effect is obtained with a daily intake of 3 g barley beta-glucan. One of those developed recipes are mouth-watering multi-grain biscuits. Not only do they offer health benefits, but also a desired texture and great taste.

BENEO, a leading producer of functional ingredients, offers barley beta-glucans in the

form of Orafti® ß-Fit, a clean label, non-GMO, vegan-friendly wholegrain barley flour with a beta-glucan content of 20% on dry matter. Orafti® ß-Fit can be used in a wide variety of applications. Some snack solutions can include baked goods like biscuits, muffins, cookies and cakes as well as extruded cereals. Also in dairy and dairy alternatives it can serve as a clean label texturiser.

BENEO’s customer technical support manager, Dr Isabel Trogh, sheds even more light on this versatile ingredient: “Orafti® ß-Fit is a cost-effective ingredient that offers technical advantages alongside health benefits for consumers. As well as having a neutral colour and taste, it is pH and temperature stable. When reformulating recipes with Orafti® ß-Fit, in some cases, small adjustments, like adding a bit more water, might be necessary. But most applications allow for a simple 1:1 replacement of the original flour ingredient, e.g., wheat flour, with our wholegrain betaglucan rich barley flour.”

Discover the full recipe of our instant noodles with Orafti® ß-Fit and other recipes, get inspired for your next product innovation. *References available on request

A proven way to a healthier heart.

Orafti® β -Fit is nature’s affordable solution.

At BENEO, we know that consumers have a heart for healthy food choices. That’s why we’re taking traditional foods to a heart-healthy level with an affordable source of beta-glucans. Orafti® β -fit is a wholegrain barley flour, offering 40% total fibre with 20% beta-glucans. This ingredient is proven to reduce LDL cholesterol, which lowers the risk for coronary heart disease significantly, enabling EFSA and FDA approved health claims. From pasta and cereals to breakfast biscuits or sourdough bread, our versatile ingredient makes healthy food creations easy.

Want to know more about Orafti® β -Fit? Scan here!

www.beneo.com

Berry Global’s European Flexibles division has reported a significant 36% year-on-year increase in the use of post-consumer recycled (PCR) polyethylene (PE) across its industrial, consumer (noncontact sensitive), and agricultural film products.

This achievement reflects Berry’s dedication to driving sustainable packaging solutions and helping customers meet their environmental goals.

The steady growth in the use of recycled content, a trend that has continued since 2021, demonstrates Berry’s proactive approach and commitment to sustainability.

Berry Global has set a goal to use 30% circular plastics across its FMCG packaging products by 2030. Berry’s target aligns with its participation in global sustainability initiatives, such as the Ellen MacArthur Foundation’s circular economy targets.

Berry has incorporated the additional 4,386 tonnes of PCR content into a variety of their flexible film products. This includes primary packaging applications such as Form-Fill-Seal and Heavy-Duty Sacks used in construction and chemical industries and Single-WoundSheet for horticulture, peat and insulation products. The recycled content is also used in secondary and tertiary packaging, such as collation shrink films for the food and beverage sector as well as stretch wrap and stretch hood pallet protection films for logistics and transportation. Additionally, Berry have begun to incorporate the recyclate into agricultural stretch wrap, supporting sustainable practices across multiple industries.

COMMITMENT TO SUSTAINABILITY

“Our technical expertise in integrating recycled plastics, supported by substantial investments in our advanced recycling

“The steady growth in the use of recycled content, a trend that has continued since 2021, demonstrates Berry’s proactive approach and commitment to sustainability.”

facilities in Steinfeld, Germany and Heanor, UK, has allowed us to produce packaging solutions with increasing levels of recycled content – without compromising on performance,” said Tony Nawar, VP and General Manager of Berry’s European Flexibles Packaging Business.

“As sustainability continues to shape the new packaging landscape, we are proud to work with our customers to deliver highperformance solutions that strike the balance

Berry Global has a long history of manufacturing rigid, flexible and nonwoven products for our customers around the world. With over 250+ locations around the world, we can produce and deliver products efficiently to your own manufacturing needs.

At Berry Global Group, Inc. (NYSE: BERY), we create innovative packaging solutions that we believe make life better for people and the planet. We do this every day by leveraging our unmatched global capabilities, sustainability leadership, and deep innovation expertise to serve customers of all sizes around the world. Harnessing the strength in our diversity and industry-leading talent of over 40,000 global employees across more than 250 locations, we partner with customers to develop, design, and manufacture innovative products with an eye toward the circular economy. The challenges we solve and the innovations we pioneer benefit our customers at every stage of their journey.

between sustainability and functionality,” Tony added.

Importantly, Berry Global also reassures its customers of the integrity of its recycled content claims by securing RecyClass certification across many of its products. This independent, third-party verification provides full traceability of the recycled materials used, ensuring transparency and trust in the company’s sustainability efforts.

As part of its drive to continue to bring innovative technology solutions to the food industry, TNA Solutions has launched an immersive, interactive digital service, the tna intelliassistTM, to deliver high-impact projects with minimal risks – all while staying on budget. From replacing or integrating capital equipment into an existing line to designing a brand-new facility, the launch marks the first time that a fully integrated extended reality (XR) solution has been available to food manufacturers as part of TNA’s evolution to industry 5.0 solutions. This innovation underscores TNA’s commitment to fostering personalised partnerships, ensuring collaboration and support at every project stage.

The tna intelli-assistTM leverages XR and simulation technologies to enable teams to create digital twins of their

manufacturing site, including equipment, utilities and buildings, and demonstrate how the new additions can best fit into their set-up with minimal disruption and optimal designs. Food manufacturers can use the tool to visualise their plant floor, virtually replace systems and validate manufacturing plans and installations in a low-risk environment. Visualising potential spatial conflicts and utility interferences ensures optimal clash prevention.

To enhance collaboration, tna intelliassistTM also integrates remote meetings into the virtual environment with virtual reality (VR) headsets or through a desktop application. Multiple people can seamlessly join the plant simulation via their preferred medium to preview the project and directly interact with the digital twin, making the process of stakeholder buy-in and troubleshooting more efficient.

“Much of food manufacturing has readily adopted Industry 4.0 technologies due to the efficiency, productivity and repeatability benefits they offer,” explained Natasha Avelange, Global Extended Reality Manager at TNA Solutions. “Building on this with XR allows the human element of food manufacturing to be enhanced, with creativity, productivity and problem solving brought together without barriers. This is the essence of Industry 5.0.

“Food production is an area where there is a continuous drive towards higher output, greater efficiency and continuous uptime. That’s why it’s so important that equipment upgrades or introductions are well-planned and delivered as efficiently as possible. With tna intelli-assist, we’ve innovated a way to significantly shorten project planning time, and improve accuracy, enabling teams to get integration right the first time.”

In an impressive confirmation of the company’s commitment to sustainability, KHS has again been awarded the coveted gold status by rating agency EcoVadis.

The Dortmund systems supplier has further improved over last year’s assessment – now earning 73 points out of 100 in the completely revised evaluation method.

In taking part in the EcoVadis audit, KHS has had its commitment to sustainability, especially within its global value chains, verified since 2012. Increasingly strict requirements – necessitated in Europe in particular by the regulations of the European Green Deal1 – have caused the rating agency to make fundamental changes to its principle of assessment. This has resulted in renewed intensification of all of the rating criteria. The benchmarks in the assessed categories of environment, labour law and human rights, ethics and sustainable procurement have been significantly raised. This has led to greater competition between the participating companies and made the procedure even more demanding with regard to the results achieved to date and their associated rankings. Moreover, annual

SUSTAINABLE TURNKEY SYSTEMS FOR THE BEVERAGE INDUSTRY

For over 150 years KHS has aspired to be a reliable partner for sustainable, efficient and durable filling and packaging systems and solutions. In this capacity we find it important to offer our customers in the beverage and liquid food industries technology of the highest quality – not only at specific intervals but also to maintain long-term partnerships, during which we are always at their side. For we are distinguished by our extensive service concept and worldwide network presence that enables us to be on site very quickly indeed. We also continuously subject our products to further development. This allows us to always provide our customers and partners with intelligent systems and solutions which help them to persistently increase their added value in the production process. Together with them we aim to make long-term economy and sustainability a composite part of our entrepreneurial processes both now and in the future.

updates of EcoVadis’ evaluation criteria mean that requirements governing proof of performance during an audit have also been tightened. In short, companies thus need to constantly strive to improve their commitment to sustainability.

In this context, KHS GmbH CEO Kai

Acker considers the company’s renewed gold status to be a particularly great success.

“This is a strong signal for the KHS Group and our customers and provides further confirmation of our commitment to the protection of the environment, ethical business practices and social responsibility.” Besides the names of the medal winners, the assessment period and percentile2 are now also published. Of all companies evaluated – regardless of their branch of industry –KHS is therefore among the top 5% with

its commitment to sustainability. The engineering company is thus consistently pursuing its aim to reach net zero within the Group by 2050. “With our second gold award, we’re creating a reliable and credible basis for assessment of our commitment to sustainability for our customers especially,” explains Acker.

EcoVadis is one of the world’s key platforms for the assessment of corporate sustainability achievements. It aims to provide interested parties from various sectors and markets with a reliable summary of the quality of management systems and the associated risk management setup of companies in the supply chain. The EcoVadis database currently contains more than 130,000 rated companies from over 180 countries and 220 different sectors.

The evolving beverage industry in East and Southern Africa: A Fusion of tradition, innovation, and growth.

The beverage industry in East and Southern Africa is witnessing rapid growth as it blends cultural heritage with contemporary innovation. Traditional beverages are cherished for their authentic flavours, while new products continue to emerge, capitalising on regional trends and health-conscious consumer demands. This dynamic market is shaped by a distinctive mix of modern preservatives and sweeteners, all contributing to the flavour, shelf-life, and appeal of beverages. Here’s a closer look at how the beverage landscape is evolving, fuelled by both tradition and innovation.

The modern beverage industry is embracing natural, health-focused ingredients, often inspired by traditional beverages but adapted for today's market. Here’s a breakdown of the key trends and ingredients:

Sweeteners: In line with the global move toward health consciousness, the beverage industry is shifting away from traditional sugars and artificial sweeteners to natural, low-calorie options. Stevia is becoming a popular sweetener, offering a healthier alternative with a lower glycemic index, ideal for consumers seeking lowsugar beverages.

Stabilisers: Consistency and mouthfeel are essential in beverages, and stabilisers play a crucial role in achieving this. Gaur gum is commonly used, especially in fruitbased drinks and juices, to give a smooth texture and prevent ingredients from separating. Xanthan gum is also frequently used in plant-based and dairy alternatives, providing a creamy texture and enhancing product stability. Traditional drinks like Mahewu and Uji benefit from stabilisers, which help retain their consistency even in larger, commercial production settings. Natural preservatives: Preserving

The deep-rooted beverage traditions in East and Southern Africa offer a range of local drinks that have been part of the cultural fabric for generations. Key traditional beverages include:

Uji (East Africa) – A fermented porridge-like drink made from millet, sorghum, or maize, valued for its tangy taste and health benefits. This breakfast staple’s preparation has evolved with the use of modern stabilisers to improve consistency and shelf-life.

Mageu/Mahewu (Southern Africa) – This refreshing, fermented maize drink is a staple

freshness without compromising on health is a priority, so natural preservatives are increasingly replacing synthetic ones. Citric acid and ascorbic acid (vitamin C) are favoured for their natural preservative qualities and antioxidant properties, often used in fruit juices and teas.

Plant-Based and dairy alternatives: Driven by rising interest in plant-based diets, alternatives like almonds, oats, and coconut milk are expanding rapidly in urban centres. These beverages often include stabilisers like gum acacia to enhance texture and appeal to a wide range of consumers, including those who are lactose intolerant or vegan.

Growth Drivers: A Youthful Demographic and Rising Middle Class: A youthful population and expanding middle class across East and Southern Africa provide a solid foundation for the beverage industry's growth. The younger demographic is more open to experimenting with new flavours and formats, and they tend to be early adopters of international trends like energy drinks, flavoured sparkling waters, and plantbased beverages. Additionally, the rising middle class in countries like Kenya, South Africa, and Ethiopia is increasing demand for premium beverages as disposable income grows.

in South Africa, Zimbabwe, and Zambia. As a traditional drink, Mahewu is celebrated for its tangy flavour and nutrient density, and many commercial versions use stabilisers to maintain its consistency and probiotics for added health benefits.

Amarula (Southern Africa) – Made from marula fruit and now popular globally, this cream liqueur captures the fruity richness and has been commercialised with sweeteners and natural stabilisers to maintain its flavour and creamy consistency. These traditional drinks continue to be celebrated and produced, preserving the local ingredients and flavours that define them. However, the use of modern ingredients has made it easier to package and distribute these beverages to a wider audience.

The beverage industry in East and Southern Africa holds immense potential, balancing a rich tradition of locally made beverages with new opportunities driven by innovation. Companies in the region are increasingly embracing cultural heritage by adapting traditional drinks for the modern consumer. Amidst the rapid evolution of the beverage industry in East and Southern Africa, Bragan Ingredients continues to adapt to new trends and demands. By offering a diverse range of high-quality ingredients, we support beverage creators in crafting innovative, consumer-driven products across Sub-Saharan Africa, meeting the tastes and preferences of an ever-changing market.

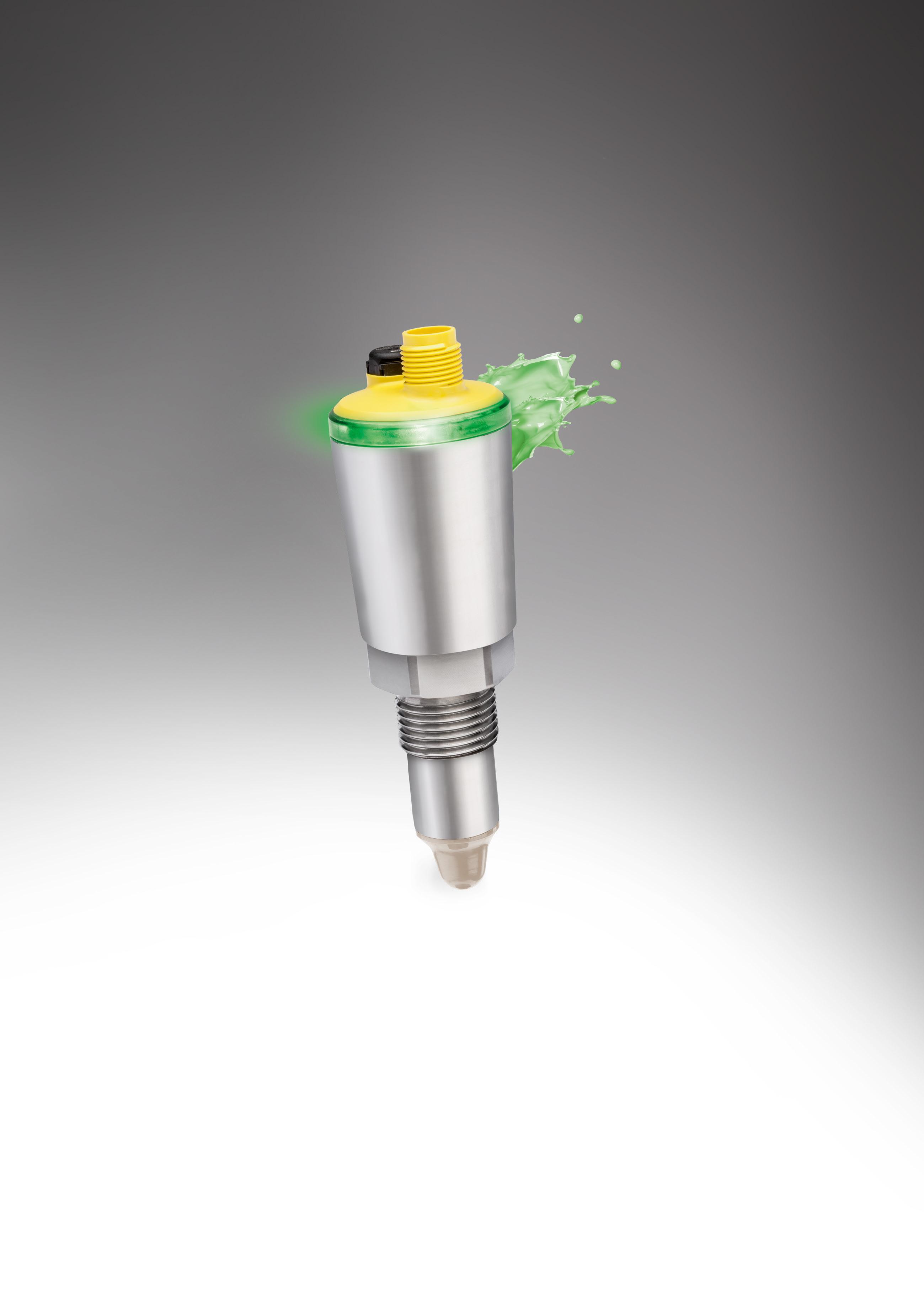

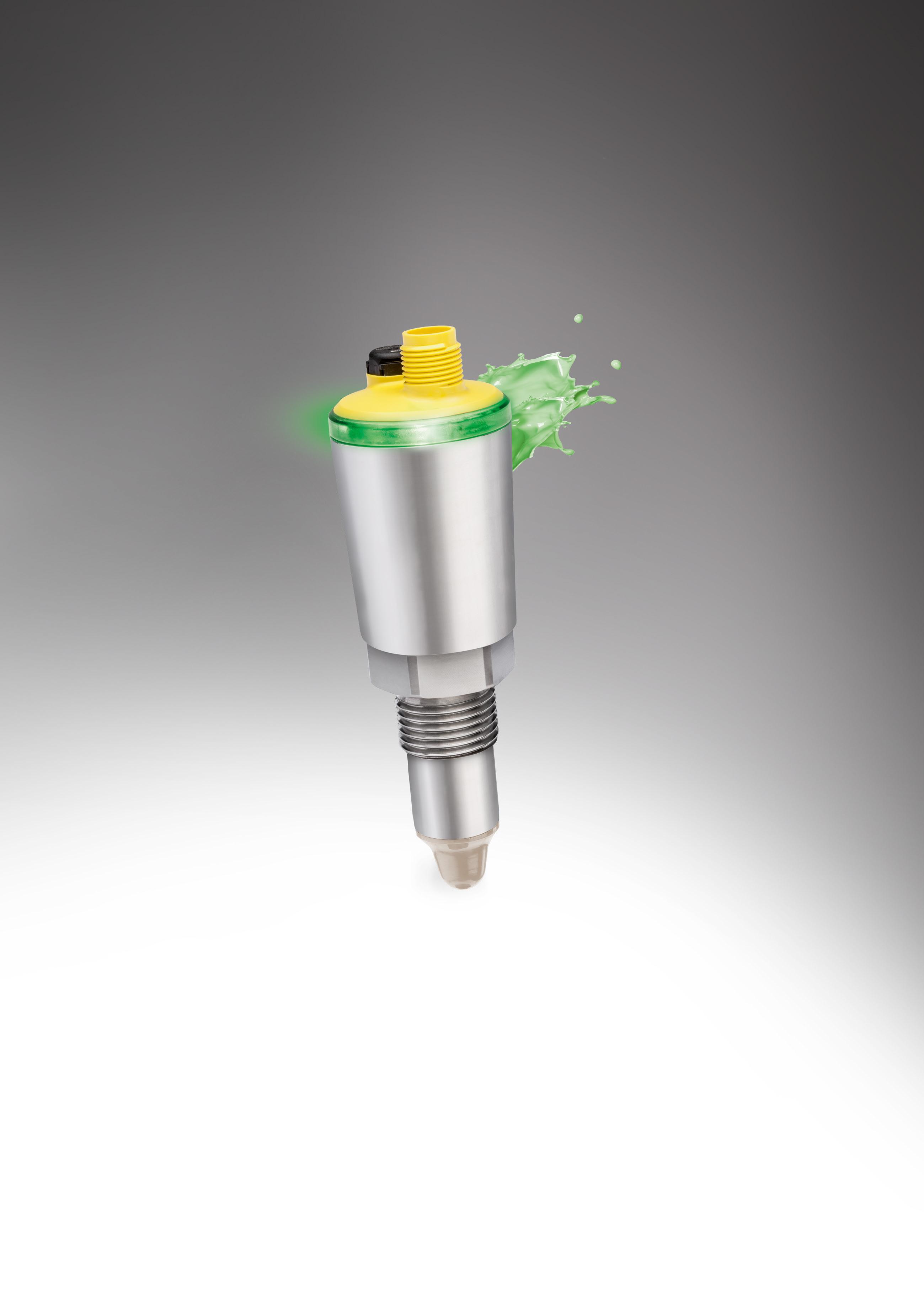

In chewing gum manufacturing, precise control of temperature, pressure, and tank levels is crucial. Radar technology ensures accurate measurements, enhancing efficiency.

“Radar technology stands out as the most effective method for measuring levels in reaction tanks equipped with agitators”

When manufacturing chewing gum, the key ingredients used are manufactured utilising chemical reactions that take place in a specialised vessel equipped with a unique agitator. The agitator is typically designed with blades that move in a precise manner to achieve thorough mixing. The vinyl acetate molecules combine to form extended chains, resulting in the creation of the polyvinyl acetate polymer. This process usually necessitates the presence of a catalyst and specific temperature and pressure conditions, ensuring adequate exposure of the reactants to each other and controlling the reaction temperature uniformly.

Maintaining precise control of temperature, pressure, and tank levels is crucial during the polymerisation process. Radar technology stands out as the most effective method for measuring levels in reaction tanks equipped with agitators. At a confectionary manufacturer, the VEGAPULS 6X continuously monitors the level of the reaction mixture within the vessel.

Accurate measurement is essential for adhering to the recipe and ensuring the correct amount of reactants is added to

achieve consistent production. It also helps prevent overfilling of the reaction vessel, which can result in spills and safety hazards during production. Proper filling levels can significantly impact the mixing efficiency of the agitator. Thanks to its false signal suppression feature, the VEGAPULS 6X provides accurate level measurement unaffected by the agitators in the tank. Additionally, offering non-contact measurements eliminates the risk of contamination or damage to the sensor from the sticky reaction mixture. Precise level measurement ensures consistent product quality and minimises waste. The VEGAPULS 6X offers measurement down to the vessel bottom and accurately measures even in media with a low dielectric constant. The polymerisation reaction is exothermic, typically falling within the temperature range of 60°C to 90°C. The VEGAPULS 6X can operate under the harshest process conditions, from -196°C to 450°C. The VEGAPULS 6X is designed for effortless setup. All the settings can be customised in advance for specific applications, making the instrument ready for immediate use. The display and adjustment modules are intuitive and easy to comprehend. It also comes with Bluetooth for wireless communication with the VEGA Tools App.

Compact capacitive level switches with 360° custom-colour status display

Individually selectable: 256 colours

Measurement in progress Sensor switching Process malfunction

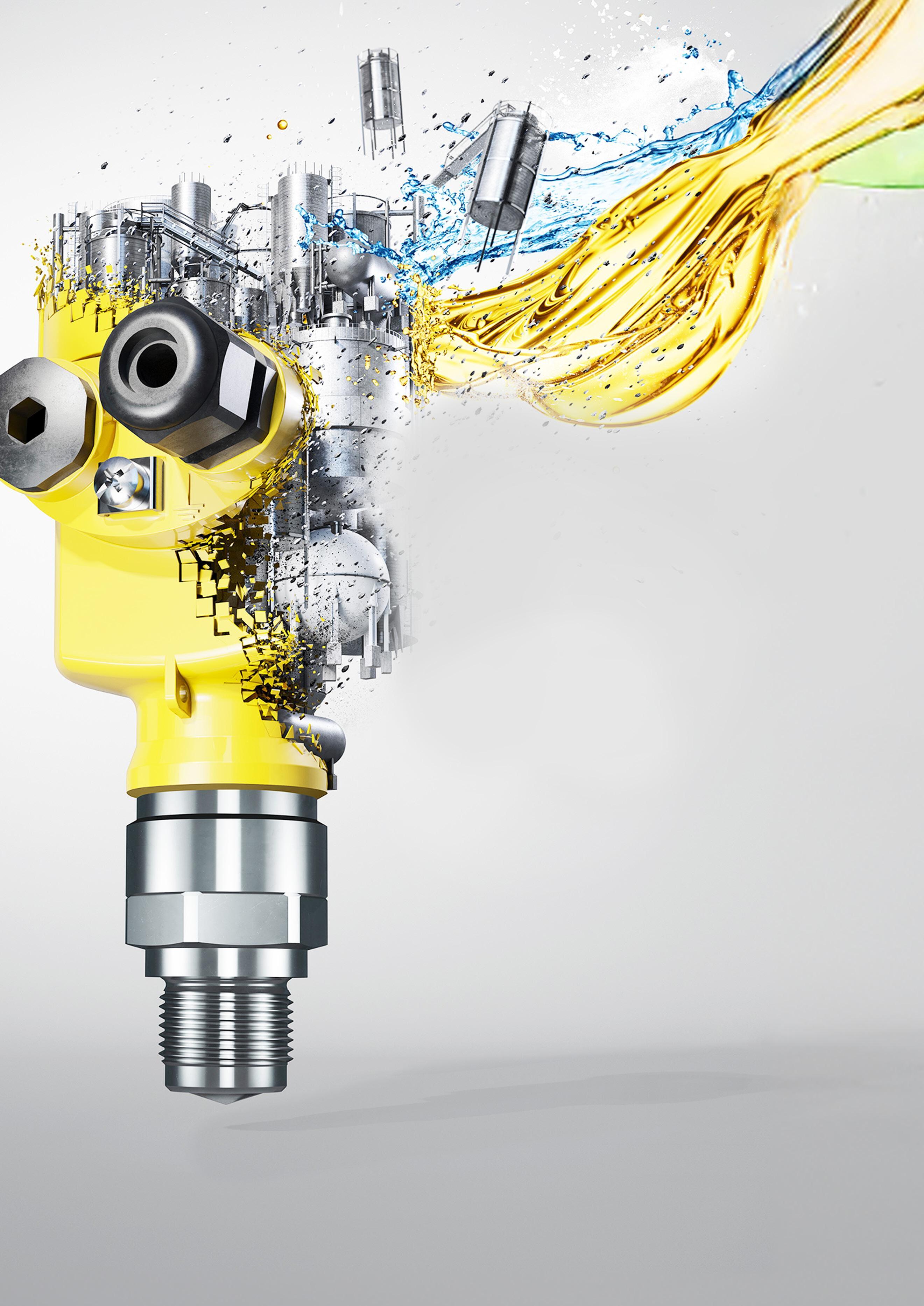

The agro-processing industry offers significant opportunities. Innovative pump technology can enhance food safety, quality, and production efficiency for processors, explains Eddie Le Roux, Hygienic Pump Specialist for Verder Pumps South Africa.

The agro-processing industry has ranked high on many business opportunity lists for some time, from the Department of Trade & Industry’s Sector Opportunities list to SME South Africa’s Top 10 Thriving Industries for South African SMEs in 2024. Food and beverages manufacturing as a sub-sector accounted for 23% of South Africa’s total manufacturing output, or R 537 billion, in 2018. Despite major headwinds in the form of the COVID-19 pandemic, a depressed economy, climate change impacts

and changing consumer demands, the agriculture and agroprocessing sectors are still expected to create almost 1 million direct and indirect jobs by 2030.

This emphasis on growing agroprocessing – and food and beverages processing as a sub-category – amounts to a lot of pressure on food processors. To remain profitable and achieve environmentally sustainable production facilities in the face of increasing

competition will require innovative solutions to industrial processing operations.

Transforming raw ingredients into consumable food products and ensuring preservation, flavour enhancement, and safety is a challenging game for longstanding market players and new entrants alike. Adopting recent innovations in pump technology to improve the quality, safety, and variety of processed foods is an often-missed opportunity to stay ahead.

Fit-for-purpose pumping solutions represent

It’s the only one of its kind in the country to target decision makers in the manufacturing of food, beverages and their related industries. It o ers incisive and authoritative reports on all aspects of the process, from raw material sourcing, to manufacturing and packing, right down to the distribution and marketing of nished goods. FOOD REVIEW informs readers about the introduction of new ingredients, equipment, products and packing, and provides objective commentary on cutting-edge local and international market trends and issues.

To contribute editorially contact

Kelebogile (Lebo) Nondzaba kelebogile.nondzaba@newmedia.co.za

+27 (0)78 175 9632

For advertising enquiries, contact Anita Raath

anita.raath@newmedia.co.za

+27 82 976 6541 or Candida Giambo-Kruger

+27 (0)71 438 1918

candida.giambo-kruger@newmedia.co.za

"Fit-for-purpose hygienic pumping solutions that have been designed and built to eliminate any risk of contaminants during production are necessary for producers who want a competitive edge."

an opportunity for improved shelf stability, environmental improvements, cost reduction and production capacity improvement. They are integral to every food and beverage processing facility – from fruit and vegetable canning, to processing soy-based and vegan food products, to fruit juices, beer, wine and more.

First and foremost, choosing the right hygienic pumping solution as well as the processing method, is crucial. Cleanability requirements must be designed to meet international and local hygiene standards –including clean in place (CIP) and sterilisation in place (SIP) – as these can present many challenges for processors. Aseptic processing, for example, requires well-coordinated

operations, as well as highly sterile and controlled environments. This is where hygienic pumps with a modular design can be integrated, allowing for streamlined disassembly, cleanability and reassembly.

Cross-contamination risk – particularly in fermentation processing facilities such as breweries and dairy processing – can be mitigated against through careful selection of equipment to maintain the highest hygiene standards.

Fit-for-purpose hygienic pumping solutions that have been designed and built to eliminate any risk of contaminants during production are necessary for producers who want a competitive edge.

agroprocessing industry to create jobs, and to do so in a sustainable way, the importance of high-quality, fit-for-purpose pumping solutions cannot be overlooked.

Innovations that ensure that food is safe, shelf stable and tasty depend on processes that are reliable, repeatable and error-free and equipment that is equally reliable and safe. Integrating the right pumping solution is critical to food safety and sustainable production, reduces downtime and total cost of ownership – due to fewer breakdowns and need for repairs on equipment/machinery –which then results in less stock holding requirements in terms of spares.

As the food and beverages industry responds to meet demands created by the need to ensure food security, grow the

We offer a wide product portfolio to meet all the challenges in the food and beverage industry. Our pumps are used in the dairy industry, breweries and wineries and many other food applications.

Because the technical aspects of selecting the right pumping solutions for specific applications can be complex, food and beverage processors should look to a trusted and reputable brand that can offer not only a wide range of pumping solutions but solutions that are long-lasting, costeffective and efficient – because they are 100% fit-for-purpose for the application.

Verder - www.verderliquids.com

MetPac-SA, the Producer Responsibility Organisation (PRO) championing South Africa’s metal packaging recycling industry, in partnership with [dot]GOOD, South Africa’s foremost cause-marketing agency, is proud to announce the expansion of the Trash4Treats competition to 25 schools in Gauteng in partnership with Mr Bin and 10 schools in Kwa-Zulu Natal in partnership with Phoenix For The Planet. This is in addition to the schools in the Western Cape with who are already engaged in the 2024 interschools competition.

“The Trash4Treats project aims to instil a strong understanding of recycling and waste management by directly involving students in the collection and recycling of post-consumer metal packaging. By hosting an inter-schools competition we are not only able to provide a platform for schools to raise essential funds, but learners also get to experience the principles of a circular economy firsthand. By transforming what would otherwise be waste into a monetary resource, learners learn the profound impact of their actions on the environment and their community,” explains Kishan Singh, CEO of MetPac-SA.

The Trash4Treats competition engages learners by encouraging them to collect metal cans, amongst other recyclables, which are then recycled to generate funds for their schools. In recognition of their efforts, learners are rewarded based on the number of cans collected—every 25 cans bring a reward. The competition also

features a pledge system, which further motivates learners to participate and embrace sustainable practices.

This ambitious initiative was first launched in the Western Cape in 2019 and continues to foster environmental stewardship and community engagement among primary school learners by raising awareness about the high recycling value of recycled metal packaging. Learners and teachers must bring clean and sorted recyclables to school. In return, schools are provided with posters as well as igloo bins and bulk bags to collect and store recyclables. Schools that collect the most recyclable waste per capita will win a portion of R60 000 for upgrades to their school.

The expanded competition was launched in Gauteng with school activation days taking place between 30 July and 29 August 2024 at participating schools Diodi Primary School, Thobeka Primary School, Ditawana Primary School, Emisebeni Primary School, and several others from Soweto, Naturena, Malvern, and Sydenham. The KZN launch took place from 19-23 September 2024 at schools such as Allingham Primary, Palmview Primary, Olympia Primary, and Northview Primary in Phoenix.

Shilpa Rama-Madhav, senior account manager at [dot]GOOD, says the Trash4Treats teams have worked diligently to educate learners about the importance of recycling and community cleanliness. “Our objectives are to educate, motivate, and equip the learners and teachers, and by extension their communities, with knowledge and practical tools for a sustainable recycling environment. We also aim to continuously increase the tonnage of waste collected and diverted from landfill, with a key focus on metal and metal packaging,” she says.

The activation days at schools are filled with vibrant energy, as learners sing, dance and engaged actively in their learning. This dynamic approach not only makes recycling fun but also embeds lasting values in the learners.

Emphasising the educational value of the initiative, Shilpa states that the initiative has proven to be a powerful tool for education and community development, fostering a sense of responsibility and environmental awareness among young learners.

Metpac SA - www.metpacsa.org.za