Enhancing partnering relationships by bringing the best of Symrise german technology to our local production site.

inspiring

In today’s fast-paced business landscape, staying ahead means more than just keeping up. It requires a relentless pursuit of excellence and a commitment to delivering outstanding service to our partners. Here’s how we’ve transformed our operations to better serve you: code of nature

Efficiency and productivity are at the core of our operations. By tripling our productivity daily, we’ve enhanced our capacity to meet growing demands. This boost in productivity signifies our commitment to providing you with faster, more reliable service

We’ve doubled our local production volumes, significantly enhancing production turnaround and overall lead times on all locally produced goods. This achievement means faster access to the products you need, when you need them.

Symrise South Africa site enhancements enables better productivity, and improved working conditions. The site is now a facility we are proud to show our customers

November 2024 marks a wonderful milestone for Symrise South Africa as they celebrate 60 years in South Africa.

9 NEWS

Promoting plastic reusage

Celebrating excellence in SA’s butchery

Simplifying recycling with OPRLS

PVC recycling on the rise

12 EVENT

Prosweets Cologne 2025

Propak Africa 2025

16

COMPANY FOCUS

Celebrating 60 years of success

18

BEVERAGE PROCESSING TECHNOLOGY

Optimising food and beverage production

Endorsing the dairy declaration

Sustainable water strategy

22

INDUSTRY TALK

KHS again wins gold

Advance potato processing equipment

Global sugar reduction trends

27

ALTERNATIVE INGREDIENTS & PROTEINS

Innovative

INNOVATION

Ingredients for diabetes management

Exploring bold colours in savoury foods

Expand your pallete with Exberry

40

CARTON & BOARD

Efficient honeycomb capsule packaging

Tetra Pak, lactalis unveil innovation

Sustainability has emerged as a pivotal theme this year, with companies increasingly focused on reducing their carbon footprint and promoting positive contributions to climate change. A diary date for the upcoming year is essential for those looking to stay at the forefront of industry developments. In this issue we highlight trade shows promising to be key highlights in the year 2025, refer to our diary on page 8 and to find out more about Prosweets 2025, turn to page 13, an essential gathering for those passionate about sweets and snacks innovation, and Propak Africa 2025, where packaging and processing solutions will take center stage, turn to page 14. These events offer invaluable opportunities to network, share ideas, and explore the latest advancements shaping our industry. Also in this issue, we feature insights from Adru van Niekerk, technical director at Nutrochem, who enlightens us on the critical subject of effective allergen management. His discussion highlights the importance of managing allergens to avoid cross-contamination, ensuring consumer safety, and adhering to regulatory requirements. Additionally, we celebrate a landmark achievement by Symrise South Africa, as they commemorate their 60th anniversary. This milestone marks their dedication to growth, innovation, and excellence over the decades, exemplified by the inauguration of their new emulsions plant. It’s a testament to their enduring commitment to industry and our nation. As this year concludes, we extend our deepest gratitude to you, our loyal readers, for your continued engagement and support. We also thank our advertisers, whose contributions make each edition possible. We wish you a joyful and peaceful holiday, abundant with rest and rejuvenation.

Càndida Giambò-Kruger

Account Manager

EDITORIAL

Editor: Kelebogile Nondzaba +27 (0)78 175 9632

kelebogile.nondzaba@newmedia.co.za

Sub-editor: Gill Abrahams

Layout & Design: Tumi Kunene

Cover Image: Courtesy of Shutterstock.com

ADVERTISING

Key Account Manager: Anita Raath

+27 (0) 82 976 6541

anita.raath@newmedia.co.za

Key Account Manager: Càndida Giambò-Kruger +27 (0) 71 438 1918

càndida.giambò-kruger@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien

Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy: Ngcombroker

Giacomo Rotunno +39 370 101 4694

g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

Circulation Manager: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

General Manager: Dev Naidoo

Head of Commercial B2B: Johann Gerber

Production Controller: Mandy Ackerman

Art Director: David Kyslinger

JOHANNESBURG OFFICE

Building 13, The Woodlands Office Park, 20 Woodlands Drive, Woodmead, Sandton PO Box 784698, Sandton 2146 +27 11 867 6111

POSTAL ADDRESS PO Box 784698, Sandton, Johannesburg 2146

Published by New Media, a division of Media24 (Pty) Ltd

MANAGEMENT TEAM

MANAGING DIRECTOR: Aileen Lamb

COMMERCIAL DIRECTOR: Maria Tiganis

STRATEGY DIRECTOR: Andrew Nunneley

CHIEF FINANCIAL OFFICER: Venette Malone

INTERIM CEO: MEDIA24: Raj Lalbahadur

HEAD OFFICE

Cape Town

11 Shelly Road, Salt River, Cape Town PO Box 440, Green Point 8051 +27 021 4062002

Tel: (011) 609 1488 Fax: 086 515 7409 Email: sales@iswshrink.co.za

Through an innovative and out of the box approach to our clients’ needs, we are not only willing, but also able to provide practical and efficient cost-saving solutions to most printing and packaging challenges. A pioneering narrow web flexographic printer, ISW specializes in, while not confined to, the manufacturing of highly decorative and complex shrink sleeves, self-adhesive and wraparound labels, and various forms of flexible packaging. By working closely with local and international suppliers, and utilising specially developed in-house processes a multitude of innovative finishes including the likes of thermochromic, glow in the dark, domed, holographic and high lustre metallics along with specialised multi-perforation solutions for promotional items are achieved.

With the manufacturing plant consisting of 10-colour and eight-colour MPS EPW560’s and a full complement of the latest offerings in finishing equipment for the conversion and inspection of our products, ISW maintains the highest level of quality and is one of only a handful of narrow web printers capable of producing wide lay flat shrink sleeves, achieving a L/F of 276mm from a printed web width of 575mm. By offering assistance and advice with every step from concept to design, production and application; we are there to ensure our clients achieve their desired vision efficiently, affordably and consistently.

Food Pack East Africa Dar-Es-Salaam, Tanzania 23 – 25 January www.mxmexhibitions.com

Diamond Jubilee Hall, Dar-Es-Salaam, Tanzania International Production & Processing Expo Atlanta, Georgia USA 28 – 30 January www.ippexpo.org

UPM Raflatac, a global supplier of sustainable labeling solutions, is expanding its direct thermal (DT) linerless label offering with the launch of its new OptiCut™ WashOff solution. The new linerless label is specifically designed for returnable and reusable plastic food containers, including PP, HDPE and PET crates used in food logistics. Available to customers now, the label launch meets the need for innovative plastic packaging solutions, driven by evolving regulations and consumer demand.

The OptiCut WashOff label, which is compatible with most direct thermal printers and weighing scales, offers excellent washability and easy, adhesive residue-free separation for both industrial processes and home washing machines.

While ensuring excellent washability, the OptiCut WashOff solution meets enduse requirements by offering the same benefits as the entire OptiCut linerless portfolio including:

• Excellent adhesion with a clean cut to a variety of surfaces.

• Minimised service spend.

• Increased efficiency with a longer maintenance cycle.

• Flexibility to print and cut to any length. In addition, all products in the UPM Raflatac OptiCut linerless portfolio are CarbonNeutral® certified by Climate Impact Partners in accordance with The CarbonNeutral Protocol. While UPM Raflatac is working to reduce internal emissions, the unavoidable greenhouse gas emissions from this product have been compensated for through the purchase of high quality carbon credits. This means that partners can promote their printed labels as CarbonNeutral® certified.

“As retailers, HORECA and logistics companies are increasingly shifting towards returnable and reusable containers, we are thrilled to introduce our new wash-off solution for direct thermal printing,” comments Andoni Rodriguez, director, business segment logistics, Retail, Office & Linerless, UPM Raflatac. “With the largest global distribution network for direct linerless products, we are proud to now offer our partners the OptiCut WashOff label. This solution demonstrates our commitment to innovation and to supporting our customers on their sustainability journey.”

UPM Raflatac - www.upmraflatac.com

The 20th Annual Best Business Cleaver Awards took place from October 23rd to 25th, 2024, recognising the most distinguished butchers across South Africa who exemplify excellence in customer service, product quality, and business innovation. For all the winners in the Legends and Consumer Favourite categories across South Africa, please visit www.bestbusiness.co.za.

This prestigious event, which marks two decades of celebrating the nation’s top talent in the meat industry, saw some of South Africa’s finest butchers receive the coveted Titans Trophy, a symbol of their status as the “Best of the Best.”

Crown National was proudly announced as the headline sponsor to the Best Business Cleaver Awards. With over 110 years of experience in supplying superior products and equipment for the meat and food industry, Crown National’s involvement marks a significant milestone for the awards. Their expertise and reputation for quality make them the perfect partner in recognising and supporting the country’s top butchers.

The implementation of On-Pack Recycling Labels (OPRLs) in South Africa was envisioned as a pivotal move to enhance consumer comprehension of packaging recyclability. Introduced in 2019 with support from the World Wildlife Fund (WWF), these guidelines aimed to deliver uniform, clear instructions on managing packaging waste.

Clear guidance for consumers: Annabe Pretorius, Executive: Technical Operations at Plastics SA explains that OPRLs are visual cues directly printed on packaging, designed to inform consumers about the recyclability of a product.

“This streamlined communication was intended to facilitate proper disposal of packaging and boost recycling rates nationwide. Each component of the packaging is covered by the labels, aiming to eliminate confusion and simplify recycling decisions,” she states.

Collaboration and implementation: The guidelines, developed in collaboration with the SA Plastics Pact and partners, encouraged brand owners and retailers to adopt them uniformly. The goal was that consistent application across various brands would clarify how consumers should manage packaging, thereby enhancing recycling rates.

Concerns about current guidelines: Despite initial expectations, Pretorius raises concerns over certain aspects of the guidelines, especially the 30% threshold set to classify recyclability. She highlights that many recyclable products in South Africa fall below this cut-off, cautioning that advising consumers against recycling these items undermines the recycling industry, leads to consumer confusion, and prevents valuable materials from reaching recyclers.

“Plastics SA tracks recycling rates by packaging material, while the OPRL links products to these rates. However, using the 30% threshold as a strict go/no-go criterion seems impractical given the lack of data for

Plastics SA has recently released the country’s latest polymer production and recycling figures for the year ending December 2023, showcasing a positive upward trend in PVC recycling across the country.

According to the new data, South Africa’s total domestic plastic consumption for 2023 reached an impressive 1,983,800 tons, which includes both virgin and recycled materials. Of this figure, PVC constituted 11%, with the majority being used in longterm building and construction applications such as pipes, profiles, floors, and cables. These products, often with lifespans exceeding 100 years, may only enter the recycling stream far in the future, making current recycling efforts notable.

During 2023, South Africa successfully recycled 26,100 tons of PVC, marking a 16% recycling rate in this sector. This achievement represents a consistent year-on-year

increase in recycled PVC, underscoring the effectiveness of focused recycling initiatives and commitment from the Southern African Vinyls Association (SAVA).

“This commendable increase in PVC recycling figures is a clear testament to the collaborative efforts within the industry and the commitment to enhance waste management and recycling in South Africa. From 21,432 tons in 2020 to 26,100 tons in 2023, we are seeing steady progress,” said a representative from SAVA.

PVC packaging, though representing less than 2% of the total market, has seen notable success in recycling efforts. SAVA has directed resources to bolster collection and recycling systems for PVC packaging, which extends shelf life, reduces spoilage, and provides essential benefits to retailers. By developing additional end-markets for post-consumer PVC, supporting recyclers and their collection methods, SAVA is helping to

every individual product,” she says.

Emphasising the crucial role collectors play in the recycling value chain, Pretorius also highlights their responsibility to sort and send materials that recyclers require. “If a sufficient quantity of a specific material is collected, it will generate market demand. This is why we oppose the 30% limit. Our message to consumers should be straightforward: if it’s a clean, mono-layer, mono-material plastic product, recycle it.”

Need for ongoing education: Plastics SA underscores the necessity of continuous education for collectors, recyclers, and consumers. “Newly designed recyclable products, like mono-layer pouches, might not be collected due to lack of awareness. Perfectly recyclable products won’t be recycled if not collected. If waste pickers and collectors assume certain materials are nonrecyclable, they risk losing valuable resources, even when these have been redesigned for recyclability,” Pretorius notes.

A call for clarity: While the original intention of OPRLs was to simplify recycling for consumers and increase recycling rates, this has not always been the outcome. Pretorius questions the effectiveness of the labels in engaging consumers. “Our message needs to be clear: if it’s plastic, rinse it and recycle it,” she concludes.

ensure that PVC packaging remains a valuable resource in the circular economy.

In support of these initiatives, SAVA has invested over R1 million in grants dedicated to recycling projects for both rigid and flexible PVC packaging. To continue advancing these efforts, SAVA invites recyclers to apply for grant funding for 2025. SAVA – www.savinyls.co.za

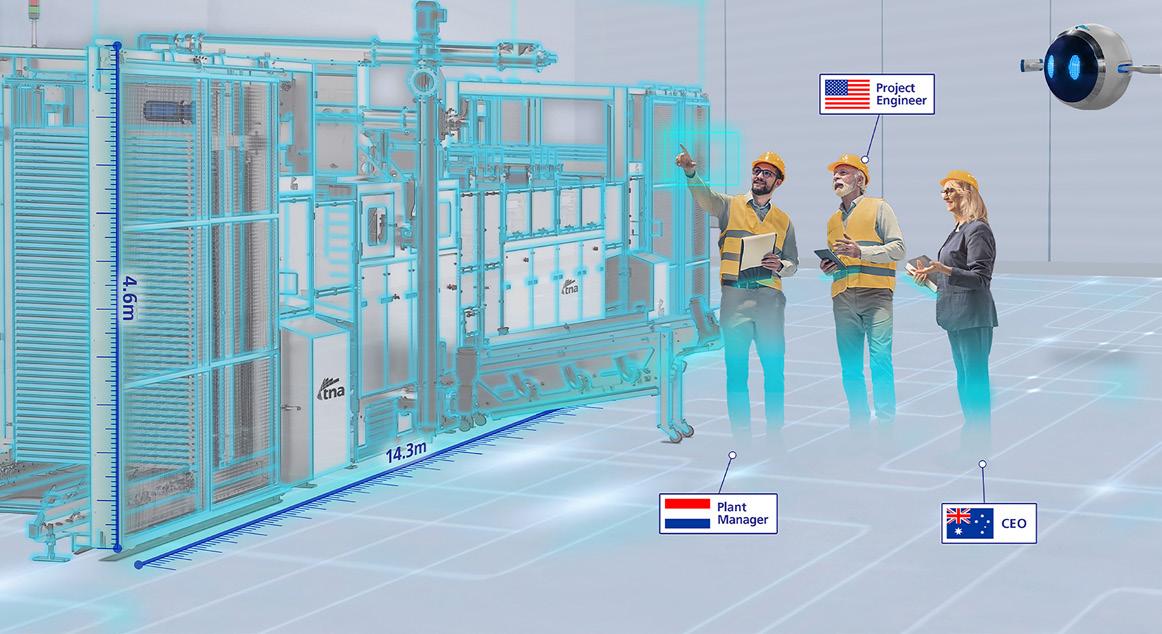

As part of its drive to continue to bring innovative technology solutions to the food industry, TNA Solutions has launched an immersive, interactive digital service, the tna intelliassistTM, to deliver high-impact projects with minimal risks – all while staying on budget. From replacing or integrating capital equipment into an existing line to designing a brand-new facility, the launch marks the first time that a fully integrated extended reality (XR) solution has been available to food manufacturers as part of TNA’s evolution to industry 5.0 solutions. This innovation underscores TNA’s commitment to fostering personalised partnerships, ensuring collaboration and support at every project stage.

The tna intelli-assistTM leverages XR and simulation technologies to enable teams to create digital twins of their

manufacturing site, including equipment, utilities and buildings, and demonstrate how the new additions can best fit into their set-up with minimal disruption and optimal designs. Food manufacturers can use the tool to visualise their plant floor, virtually replace systems and validate manufacturing plans and installations in a low-risk environment. Visualising potential spatial conflicts and utility interferences ensures optimal clash prevention.

To enhance collaboration, tna intelliassistTM also integrates remote meetings into the virtual environment with virtual reality (VR) headsets or through a desktop application. Multiple people can seamlessly join the plant simulation via their preferred medium to preview the project and directly interact with the digital twin, making the process of stakeholder buy-in and troubleshooting more efficient.

“Much of food manufacturing has readily adopted Industry 4.0 technologies due to the efficiency, productivity and repeatability benefits they offer,” explained Natasha Avelange, Global Extended Reality Manager at TNA Solutions. “Building on this with XR allows the human element of food manufacturing to be enhanced, with creativity, productivity and problem solving brought together without barriers. This is the essence of Industry 5.0.

“Food production is an area where there is a continuous drive towards higher output, greater efficiency and continuous uptime. That’s why it’s so important that equipment upgrades or introductions are well-planned and delivered as efficiently as possible. With tna intelli-assist, we’ve innovated a way to significantly shorten project planning time, and improve accuracy, enabling teams to get integration right the first time.”

From 2 to 5 February 2025, ProSweets Cologne will be the central point of contact for all people looking for first-class solutions for professional chocolate production. In addition to process and packaging machines the focus also lies on ingredients at the international supplier fair for the sweets and snacks industry .

They are the undisputed leaders on the German sweets shelf: The average German consumes almost nine kilograms of chocolate products a year, with an upward trend. Whether traditionally produced bars of chocolate with handpicked fruits and nuts or chocolates filled with multisensory taste combinationsmoments full of tasty enjoyment are at the top of the consumers’ list. With tailor-made sweet machines companies can remain agile and quick to react in this constantly changing market.

From the roasting of the cocoa beans, to the rolling and conching, through to the coating and casting, chocolate-makers can find the right equipment at ProSweets Cologne 2025 to process their chocolate creations. With the plants of well-known machine suppliers, including Sollich and Chocotech, which will be on display in Cologne, also small batches of a large variety of sweets can be produced efficiently and hygienically. Many of the solutions presented on-site stand

out because of their consistent hygienic design optimisation to simplify the cleaning processes or fulfil the higher standards for functional sweets and OTC products. The exhibitor Hansella GmbH is planning to present an innovative machine at ProSweets Cologne 2025, which offers maximum raw material efficiency and considerable savings in the cocoa consumption – an industry-relevant and exciting theme in times of rising cocoa prices.

The technology suppliers are more and more frequently going a step further when it comes down to the established machine concepts. The innovative spirit of the machine builders is reflected when ‘out-of-the-box thinking’ is demanded to ensure more flexibility. ConfecVARIO by Winkler und Dünnebier Süßwarenmaschinen (WDS) is such an innovative concept for the production of chocolate, jelly beans and OTC sweets with just one machine type. Thanks to the moulding process in polycarbonate moulds, a clean and efficient technology for the production of fruit gums has been developed here, the roots of which originate from the chocolate moulding process. The ConfecVARIO disposes of a novel, chainless multifunctional cabinet for cooling, warming and storing the moulds. The tempering machines of the model line EX by Selmi are

“With tailor-made sweet machines companies can remain agile and quick to react in this constantly changing market.”

a further example. They are equipped with a removable screw which facilitates changing the coating. They can also process nuts, cocoa nibs and other chunky ingredients together with the mass.

The developments on the raw materials markets – keyword price increases – are also challenging the familiar and established sweets production processes. Cocoa is at the top of the agenda here. It plays a decisive role because it lends chocolate its authentic taste and at the same time determines the texture, colour and aroma of the final product. Cocoa powder helps retain the moisture in bakery products, which leads to a tender crumb. In filled chocolates it provides struc ture and stability by absorb ing the moisture. However, due to the rising global temperatures and the drier climate there is growing concern about the future of this important raw material. One of the product developers’ answers to this development involves adapting the cocoa content in the recipes.

At ProSweets Cologne, suppliers of food ingredients like Prova are reacting to this with a wide range of “cocoa boosters” that intensify the aroma of the chocolate in compounds. They allow the share of cocoa powder to be reduced by up to 30 percent. For example, the extract-free aromas enable the accentuation of whole milk or plain chocolate aromas using very low dosages and adapted solubility.

Natural caramel colours with high stability and a neutral taste profile make up for possible colour losses and guarantee that filled chocolates and chocolate bars retain their attractive appearance in spite of the low cocoa content. Refined with crunchy pieces of fruit, creamy nut pastes or unusual fruit preparations, the reformulated products provide a pleasurable chocolatey experience. A further alternative is chocolate that does completely without cocoa in the recipe – such as ChoViva that was distinguished as a Top Innovation at ISM 2024. The novel chocolate that was developed by the start-up, Planet A Foods, is based on the domestic ingredients oats and sunflower seeds, that similar to cocoa are processed in a fermentation-like way. At the same time, ChoViva has an up to 90 percent lower CO2 footprint compared to conventional chocolate. Such reformulations are a possible option of how to react to the latest challenges on the raw material markets. At the Zurich University for Applied Science (ZHAW) one is going a step further in the search for alternatives. There Prof. Dr. Regine Eibl and Prof. Dr. Thilo Hühn are on the path towards precision fermen-

tation. Their target: To decouple chocolate production and cocoa cultivation by growing the cells of the cocoa beans in bioreactors.

It is no coincidence that Eibl and Hühn have decided to reproduce the most important raw material of the sweets industry in the laboratory. It takes around five years for a cocoa plant to yield its first harvest. On top of that: A quarter of the bean harvest doesn’t pass the quality test in the countries of origin, which means by producing cocoa in the bioreactor, food waste can be avoided. Hühn and Eibl’s team divide the cocoa bean up into pieces and place them on a culture medium. Over the course time tissue forms over the places they have been cut. As soon as there is enough tissue it is placed in a suspension culture in the bioreactor and kept at an ideal temperature so that the cocoa cells can multiply. Freeze-dried and roasted they can subsequently be further produced into chocolate in the classic way. There are already companies like the start-up, Foodbrewer, who intend to bring this innovation out onto the market in the next few years. It is an innovation that fits in with the times: With a view to sustainable food, particularly the younger generation is open to new tastes.

The visitors of ProSweets Cologne can experience which trends will have an impact on the selection of ingredients and processing for the sweets and snacks manufacturers in the “Ingredients” Special Show in Hall 10.1. Here, the future agency Haute Innovations will be presenting the latest and most exciting ingredients and raw materials together with selected start-ups. For example, sugar alternatives originating from the chicory root, the fruit pulp of cocoa beans or Southeast Asian fruits find their way into the recipes.

As automation and digitisation accelerates across industries, companies are recognising the need to invest in smarter solutions, products and services to stay competitive. For those in packaging and related fields, Propak Africa, a leading industry trade show, provides unmatched insights into these latest innovations.

Propak Africa 2025, a premier event in packaging, printing, food processing, plastics, and labelling, will be held from 11-14 March at Johannesburg’s Expo Centre. With over 400 exhibitors, attendees will see thousands of new products showcasing the latest in packaging innovation, from advanced equipment and cutting-edge technology to sustainable solutions. According to Mark Anderson, portfolio director at Specialised Exhibitions a division of Montgomery Group and organisers of the show, the event promises “unrivalled access to groundbreaking insights and ideas that have the potential to elevate your business.”

This show will feature prominent com-

panies from across these industry sectors including Qualitechs, Rotocon, Filmatic, HG Molenaar, Cabletech, and IPEX, among others. With over 80% of available exhibition space already sold, interest continues to grow with companies keen to benefit from the opportunities available to exhibitors.

Propak Africa incorporates four other complementary shows: Pro-Plas Expo, the GAPP Print Expo, FoodPro Expo, and Pro-Label Expo. Together, these provide a comprehensive look at packaging innovations, the future of plastics and printing

in packaging, advanced food processing technologies, as well as labelling solutions that meet changing regulatory and consumer demands.

The trade show offers exhibitors access to thousands of decision-makers, providing invaluable opportunities to generate quality sales leads and build brand recognition. “Propak Africa is where companies can engage directly with prospective new customers, gain an understanding of market needs, form partnerships, Anderson notes.“

Propak Africa 2025 –www.propakafrica.co.za.

Managing allergens is crucial in food production to prevent cross-contamination, ensuring consumer safety and regulatory compliance, explains Adru van Niekerk, technical director - BEng (Chemical) at Nutrochem.

Allergens are substances that can trigger adverse immune responses in sensitive individuals, leading to conditions ranging from mild discomfort to severe anaphylaxis. These allergens are often proteins that cause these reactions. In the food industry, common allergens include nuts, milk, eggs, soy, gluten, and seafood. Contamination by these allergens can occur during food processing, causing severe risks for consumers with food allergies.

The primary concern with allergens in food production is cross-contamination, where allergens unintentionally end up in products that are meant to be allergen-free. This can result in product recalls, reputational damage, and health risks for

consumers. Managing allergens is, therefore, critical to maintaining food safety.

Effective cleaning and disinfection are essential in allergen control. Chlorinated alkali cleaning products, such as Chlorfoam Plus, are highly effective for open plant applications where thorough cleaning of surfaces and equipment is required. The chlorine component helps break down protein-based allergens, ensuring a deep clean. For closed systems, Ultra Cleanse L, used in Clean-in-Place (CIP) applications, is ideal for cleaning allergens from processing lines. In contrast, acid cleaners are generally less effective against allergens because they are

less efficient at breaking down proteins. It is important to note that not all systems are compatible with chlorinated alkali products and care should be taken to ensure materials of construction used, especially rubbers and gaskets, are compatible with chlorine at intended use temperatures.

At NutroChem, we offer a specialised allergen management training programme, which is a value-added service for qualifying clients using our products. This training equips clients with knowledge on best practices for cleaning and allergen control, reducing the risk of contamination and improving food safety compliance.

Nutrochem - www.nutrochem.co.za

• Protect consumers with specialised cleaning solutions designed for allergen control.

• Chlorfoam Plus and Ultra Cleanse L eliminate allergenic proteins, ensuring deep, effective cleaning.

• Minimise cross-contamination risks in both open plant and CIP systems that are chlorine compatible.

• Gain expert guidance through our allergen management training, available to qualifying clients.

• Keep your brand safe, your food allergen-free, and your business compliant.

Symrise South Africa announces 60th anniversary of operations in South Africa, marked by the grand opening of a new emulsions plant. This significant milestone underscores Symrise’s commitment to growth, innovation, and excellence in the region.

“Today, we proudly celebrate 60 years of excellence at Symrise South Africa. This remarkable milestone is not just a reflection of our history, but a testament to our unwavering commitment to delivering solid performance and building credibility within our industry. Over the past six decades, we have established ourselves as a trusted leader in our market, and this longevity speaks volumes about the quality of our products and the dedication we have to customer satisfaction. The strong relationships we’ve fostered with customer partners has been vital to our success.” noted Sofiane Berrahmoune, vice president Symrise Africa, Middle East, Turkey and Russia in Taste, Nutrition and Health Division

"Attendees will have the opportunity to tour the new facility and experience firsthand the innovative technologies that Symrise offers."

In alignment with this momentous occasion, Symrise South Africa has embraced the theme of “Shosholoza” for its customer appreciation event and future strategy. Shosholoza, a term rich in cultural significance, embodies the spirit of moving forward and striving for excellence. This

theme aptly reflects Symrise’s dedication to forging ahead with innovation, growth, and customer-centric advancements.

FUTURE STRATEGY: SHOSHOLOZA

Commitment to Innovation: Symrise is committed to continuously advancing its technological capabilities, ensuring that it remains at the forefront of the fragrance and flavour industry.

Over the past five years, the local team has diligently focused on site improvements and operational efficiencies aimed at future growth. These advancements have included:

On-Time delivery (OTD): Achieving a remarkable 90% consistency rate in delivering products on time.

Increased productivity: Doubling the output of batches produced per shift, enhancing overall productivity.

Inventory optimisation: Successfully reducing Days on Hand (DOH) by half, optimizing inventory and storage.

Cost efficiency: Implementing strategies to reduce cost per kilo, enabling cost savings for customers.

Production volume: Doubling the annual local production volumes, reinforcing Symrise’s position in the market.

The company plans to expand its operational footprint sustainably, aligning with environmental and economic best practices.

Customer-Centric Approach:

By focusing on understanding and meeting customer needs, Symrise aims to enhance customer satisfaction and strengthen partnerships.

Investment in People: Symrise is dedicated to investing in its workforce, fostering talent development and supporting a culture of excellence.

The “Shosholoza” theme is a testament to Symrise South Africa’s unwavering commitment to progress and innovation, guiding the company as it sets new benchmarks for success in the industry. With the opening of the new emulsions plant and the introduction of the Symcloud Double Concentrate Neutral cloud, Symrise is poised for a future of continued achievement and growth.

In the dynamic and ever-evolving Flavour Industry market within Southern Africa, Symrise South Africa has demonstrated exceptional growth and resilience. According to recent market analysis, the regional flavour industry is projected to reach a value of $1.5 billion by the end of 2025, expanding at a compound annual growth rate (CAGR) of 4.7%. Amidst this growth, Symrise South Africa has outperformed its leading competitors, achieving a market share increase of 10% over the last fiscal year. This success is a testament to our unwavering

commitment to innovation, quality, and sustainable practices that meet the diverse needs of our customers. As we continue to lead the way in the industry, we remain dedicated to delivering exceptional flavour solutions that enhance the culinary experiences of consumers across the region.

The 60 year milestone not only marks successful operations but also marks a new chapter of expansion and innovation for Symrise South Africa. Speaking about the companies local progression, Teresa Orlanov - managing director Symrise Southern Africa said, “Our recent advancements at the factory site are not just upgrades—they are a testament to our commitment to innovation and excellence. These enhancements are paving the way for our company to achieve its ambitious growth goals, ensuring we remain at the forefront of industry leadership and sustainable development.”

The new emulsions plant will also see the launch of the Symcloud Double Concentrate Neutral cloud, an innovative product that exemplifies Symrise’s commitment to cuttingedge technology and customer satisfaction. Customer Event and Site Tour: In honour of these achievements, Symrise South Africa is hosting a special event on November 19, 2024, for its valued customers. “As we open our new and improved facility, we are excited to not only enhance our production capabilities but also strengthen our commitment to our customers. This

Symrise is a global supplier of fragrances, flavorings, cosmetic active ingredients and raw materials, as well as functional ingredients. Its clients include manufacturers of perfumes, cosmetics, food and beverages, the pharmaceutical industry and producers of nutritional supplements and pet food.

Its sales of approximately €4.7 billion in the 2023 fiscal year make Symrise a leading global provider. Headquartered in Holzminden, Germany, the Group is represented in more than 100 locations in Europe, Africa, the Middle East, Asia, the United States and Latin America.

Symrise works with its clients to develop new ideas and market-ready concepts for products that form an indispensable part of everyday life. Economic success and corporate responsibility are inextricably linked as part of this process.

advancement represents a significant step forward in our mission to deliver exceptional quality and service. By investing in cutting-edge technology and expanding our capacity, we are poised to build stronger partnerships and drive mutual growth.” Said Shantal Reddy – sales director, Symrise Southern Africa.

Attendees will have the opportunity to tour the new facility and experience firsthand the innovative technologies that Symrise offers. This event is a token of appreciation for the continued partnership and support from our customers.

Symrise South Africa - www.symrise.com

In the ever-changing world of food and beverage production, precise measurement is the foundation of operational excellence.

Meeting strict standards for product consistency, complying with regulations, prioritising worker safety, and preserving the environment depend on accurate measurement. Precision measurement allows for the precise quantification of ingredients, monitors production rates, and streamlines manufacturing processes. This, in turn, leads to optimised use of resources and, ultimately, increased profitability. Since every stage of the manufacturing process relies on accurate measurements for optimal performance, sensors continuously monitor factors such as flow rates, particle size, and temperature, allowing for real-time adjustments and ensuring operational efficiency.

Monitoring tank levels, flow rates, and pressure helps detect and address potential risks proactively, while precise stockpile measurements prevent overloading and overfilling. Optimal measurement practices, from equipment selection to maintenance scheduling, offer substantial cost savings in the long run. By optimising processes through accurate measurement, manufacturers reduce energy consumption, minimise downtime, and extend equipment lifetimes, ultimately improving profitability. With global pressure to reduce environmental impact, measurement plays a crucial role in monitoring water usage, byproducts, and potential pollutants. Real-time data enables swift adjustments, ensuring compliance with regulations and fostering responsible resource management.

VEGA offers specialised measuring instrumentation that is designed to address the needs of the food and

beverage industries. These instruments offer a perfect blend of compactness, flexibility, hygiene, and ease of use without compromising on the renowned reliability and performance associated with the VEGA brand.

The VEGABAR series of pressure sensors and switches caters to various standard pressure measurement applications. Their compact size and flexible design make them ideal for space-constrained environments, while their hygienic construction ensures product purity and simplifies cleaning procedures.

The VEGAPOINT series of level switches offers adaptability and userfriendliness for diverse level measurement tasks. Their intuitive operation and clear status display enable operators to react quickly to process changes, while their robust design ensures reliable performance even during rigorous CIP and SIP cleaning processes.

With a decades-long legacy of innovation, VEGA stands as a global leader in providing cutting-edge measurement technology. Through dedication to precision and reliability, VEGA has redefined the landscape of industries worldwide. VEGA's customised solutions have empowered businesses to optimise processes, enhance efficiency, and ensure the highest quality standards. Driven by a commitment to excellence, sensors and instruments continue to set new benchmarks for accuracy, durability, and performance.

“Precision measurement allows for the precise quantification of ingredients, monitors production rates, and streamlines manufacturing processes.”

The VEGAPULS 6X is the ideal sensor for non-contact level measurement of liquids and bulk solids in simple to merate applications. The optional universal connection for hygienic adapters ensures reduced installation effort and leaner stock-keeping and perfectly fulfils the requirements for hygienic processes in the food, beverage and pharmaceutical industries. With IO-Link, it offers continuous digital data transmission.

VEGA offers advanced and reliable measurement solutions designed to meet the needs of modern manufacturing. From cutting-edge radiometric density measurement to instruments with optimal IP ratings for maximum protection. Partnering with VEGA guarantees improved optimisation, efficiency, and safety. Investing in reliable measurement systems goes beyond just an expense; it represents an investment in the future. By leveraging the power of data and fostering a culture of continuous improvement, manufacturing facilities can ensure responsible resource utilisation, elevate safety standards, and contribute to a more sustainable future.

Compact pressure sensors and switches with 360° custom-colour status display

256 colours

Individually selectable:

Measurement in progress

Sensor switching

Process malfunction

Tetra Pak endorsed the Paris Dairy Declaration on Sustainability at COP 29, reinforcing the dairy sector’s commitment to sustainability.

The Paris Dairy Declaration on Sustainability, an initiative launched by the International Dairy Federation (IDF) and the United Nations Food and Agriculture Organization (FAO) at the IDF World Dairy Summit in October 2024 in Paris, was endorsed by Tetra Pak, a world leader in food processing and packaging solutions, at the United Nations Framework Convention on Climate Change (UNFCCC) Conference of Parties (COP) 29 in Baku, Azerbaijan, on 19 November 2024.

The Paris Dairy Declaration on Sustainability reiterates and reinforces the dairy sector’s commitment to a sustainable transition of the whole value chain within all dimensions environmental, social and economic. The Declaration brings to light the tangible commitments undertaken by dairy operators worldwide towards the various UN Sustainable Development Goals, and sends a clear message to governments, decision-makers and the public on the dynamism of the dairy sector. The

"This endorsement by Tetra Pak exemplifies the dairy sector’s commitment to climate action and the UN Sustainable Development Goals."

Paris Dairy Declaration continues the journey, initiated by the Dairy Declaration of Rotterdam in 2016, to answer the call of the UN 2030 agenda to leave no one behind.

The endorsement took place at the Swedish Pavilion at COP during a bilateral meeting between IDF President Mr. Gilles Froment and Tetra Pak’s Executive Vice President for Processing Solutions and Equipment, Mr. Charles Brand.

“This endorsement by a leading company like Tetra Pak amplifies the impact of the

Charles Brand and Piercristiano Brazzale, Former IDF President

Paris Dairy Declaration on Sustainability and exemplifies the global dairy sector’s commitment to climate action and the UN Sustainable Development Goals (SDGs). We extend an invitation to all dairy organizations and leaders to sign and endorse the Declaration,” said Mr. Gilles Froment, IDF President.

“The Paris Dairy Declaration on Sustainability is an important statement on the dairy sector’s commitment to a sustainable transformation of the whole value chain. Tetra Pak has a long history in the dairy industry, with sustainability at the heart of that journey. Dairy is at the core of our food systems targets where we commit to driving change and being a positive influence on the way food systems can work in the future. We see from our customers a clear desire to drive transformative change. This declaration supports that journey and that is why we are happy to endorse it here today.” added Charles Brand, Executive Vice President, Processing Solutions and Equipment, Tetra Pak.

The purpose of the IDF Paris Declaration on Sustainability is to highlight the tangible commitments made by dairy operators across the various pillars of sustainability— climate, nutrition, health, economic security, and natural resource stewardship— while conveying to governments, decisionmakers, and the public the dynamism and dedication of the dairy sector.

Anadolu Efes is committed to sustainability, aiming for net zero emissions and zero-waste certification by 2030, while reducing water consumption.

Sustainability is firmly anchored in the Turkish beverage company’s business strategy, which includes targets for greenhouse gas emissions (net zero by 2030) and waste generated (zero-waste certification for its malt and beer business by 2030).

A stable supply of water plays a vital role here since a brewery’s business depends on it not only directly, but also indirectly since barley and hops also need water to grow. That’s why Anadolu Efes records the water-stress risk, meaning the balance between the quantity of water demanded and available in the region concerned, for all its beer, malt and hops production sites across the globe. The operations in Türkiye, Kazakhstan, Moldova and Georgia aim to reduce water consumption per beer production by 10% in breweries by 2025 compared to the 2020 baseline. To achieve this, Anadolu Efes pulled plenty of different levers in its production.

Anadolu Efes identified the pasteuriser as one area with considerable potential for water savings and has taken Krones on board to tackle it. “Of course, it would be possible to simply replace the older systems with new ones. But in terms of sustainability, an upgrade is the better solution,” says Jan Golm from the Krones Lifecycle Service team. You must look at how a pasteuriser works to understand how such an upgrade cuts consumption.

Krones – www.krones.com

Your product is your greatest asset. That is why we offer innovative process technology solutions that ensure not only top quality and performance but also the prudent use of water and other resources. The goal: affordable foods and drinks which have been sustainably produced.

krones.com

In an impressive confirmation of the company’s commitment to sustainability, KHS has again been awarded the coveted gold status by rating agency EcoVadis.

The Dortmund systems supplier has further improved over last year’s assessment – now earning 73 points out of 100 in the completely revised evaluation method.

In taking part in the EcoVadis audit, KHS has had its commitment to sustainability, especially within its global value chains, verified since 2012. Increasingly strict requirements – necessitated in Europe in particular by the regulations of the European Green Deal1 – have caused the rating agency to make fundamental changes to its principle of assessment. This has resulted in renewed intensification of all of the rating criteria. The benchmarks in the assessed categories of environment, labour law and human rights, ethics and sustainable procurement have been significantly raised. This has led to greater competition between the participating companies and made the procedure even more demanding with regard to the results achieved to date and their associated rankings. Moreover, annual

SUSTAINABLE TURNKEY SYSTEMS FOR THE BEVERAGE

For over 150 years KHS has aspired to be a reliable partner for sustainable, efficient and durable filling and packaging systems and solutions. In this capacity we find it important to offer our customers in the beverage and liquid food industries technology of the highest quality – not only at specific intervals but also to maintain long-term partnerships, during which we are always at their side. For we are distinguished by our extensive service concept and worldwide network presence that enables us to be on site very quickly indeed. We also continuously subject our products to further development. This allows us to always provide our customers and partners with intelligent systems and solutions which help them to persistently increase their added value in the production process. Together with them we aim to make long-term economy and sustainability a composite part of our entrepreneurial processes both now and in the future.

updates of EcoVadis’ evaluation criteria mean that requirements governing proof of performance during an audit have also been tightened. In short, companies thus need to constantly strive to improve their commitment to sustainability.

KHS GROUP

In this context, KHS GmbH CEO Kai

Acker considers the company’s renewed gold status to be a particularly great success.

“This is a strong signal for the KHS Group and our customers and provides further confirmation of our commitment to the protection of the environment, ethical business practices and social responsibility.” Besides the names of the medal winners, the assessment period and percentile2 are now also published. Of all companies evaluated – regardless of their branch of industry –KHS is therefore among the top 5% with

its commitment to sustainability. The engineering company is thus consistently pursuing its aim to reach net zero within the Group by 2050. “With our second gold award, we’re creating a reliable and credible basis for assessment of our commitment to sustainability for our customers especially,” explains Acker.

EcoVadis is one of the world’s key platforms for the assessment of corporate sustainability achievements. It aims to provide interested parties from various sectors and markets with a reliable summary of the quality of management systems and the associated risk management setup of companies in the supply chain. The EcoVadis database currently contains more than 130,000 rated companies from over 180 countries and 220 different sectors.

Feinschmecker Deli Meats have the reputation for sourcing, manufacturing, packing, marketing & distributing the finest deli cold meats in Southern Africa.

Celebrated by chefs & retailers alike, they are not only big enough to have the commercial capability to supply any outlet, they are also small enough to care about each hand made batch.

The business has existed in its present form since 1983, originally starting out with the name Polony King Foods, however in 2008 the name was amended to Feinschmecker Deli Meats.

All raw materials are procured by the inhouse purchasing department. Most meat is locally sourced from food safety certified abattoirs & meat packers, some poultry and certain cuts of pork are imported.

All recipes and techniques are implemented in the age-old European tradition, mimicking beer’s ‘Reinheitsgebot’.

The range of deli products include whole muscle hams, beef pastrami, turkey products, luncheon loaves, smoked sausages, hot counter items like cooked eisbein and their famous cooked pork ribs.

The company has invested heavily in the capacity of dry curing rooms in recent years,

"Feinschmecker Deli Meats have the reputation for sourcing, manufacturing, packing, marketing & distributing the finest deli cold meats in Southern Africa."

making sure they have the capability to mimic the best dry cured products from Italy, Spain and Germany. Look out for their full range of salamis, coppa, pancetta, bresaola, chorizo curado & black forest ham. Products are sold in two main methods; either packaged in bulk or sliced and prepacked in the state-of-the-art factory. A number of innovative packing machines comparable to the best in the world make for excellent presentation. All delicacies are carefully labelled by hand, using waterproof poly-prop labels which comply with latest labelling legislation.

Recently the technical team have focussed on doing bespoke ready to eat products for specific clients looking for special requests like for an example ingredient to meals or pizzas.

They have the ability to deliver to all major centres around SA. Sales staff are based all around the country and are trained to be deli specialists to assist clients manage their cold counters.

Feinschmecker offers a wide range of charcuterie products, including:

• Salami

• Ham

• Bacon

• Sausages

• Pâtés

Each product is crafted with care and attention to detail, ensuring a superior taste experience.

All raw materials are sourced by our in-house purchasing department. Most meat is locally sourced from food safety certified abattoirs & meat packers; some poultry and certain cuts of pork are imported. We deal with all major spice & casing suppliers to ensure

the best price, product and service levels. It has long been our belief that we will not compromise the quality and integrity of our product by employing ingredients that are not of the highest standard.

Manufacturing

All products, except for Prosciutto Crudo which we import, are produced at our Gauteng factory site. A skilled team of deboners, ham-makers, cutters, salami makers, fillers & others stick stringently to European recipes. No artificial additives or added MSG is used in production.

Products are sold in two main methods. Either packaged in bulk or sliced and prepacked in the highrisk area in the factory. We have a number of stateof-the-art

All raw materials are procured by the inhouse purchasing department. Most meat is locally sourced from food safety certified abattoirs & meat packers, some poultry and certain cuts of pork are imported.

Multivac roll stock machines including a gas-flush packaging machine which is comparable to the best in the world. All delicacies are carefully labelled by hand, using waterproof poly-prop labels which comply with the latest labelling legislation.

A director, a sales manager, sales representatives, merchandising managers and merchandisers look after the sales and marketing of all goods nationwide. This function is never outsourced and is a vital part of the business and the company is represented all over the country. Our sales staff are educated in the fine art of continental delis and train your staff how to manage & run a full-service deli. Relationships with buyers from the various retailers is also key to our success. No sale is ever complete until the end user has consumed the product.

The company is unique in that it is the only high-end producer with a national reach. Gauteng is still the cornerstone of sales, but other regions are catching up fast. All provinces are delivered to weekly. Where own trucks are not used, carefully selected 3rd party distributors are utilised.

Springer Precursor 401: a new yeast extract to develop vegan and natural red meat flavours through Maillard reaction.

Consumers are increasingly demanding when it comes to healthy and natural eating, and manufacturers are responding with new solutions. The natural food flavours market is a fast growing one. It is mainly due to an increasing awareness about the benefits of natural ingredients and due to regulations regarding the use of artificial flavours in food products.

The evolution in the natural beef flavour and plant-based meat markets push manufacturers to be innovative in the provision of red meat flavour. The transition to more sustainable food systems is an important growth factor for both markets.

PRECURSOR 401

Springer Precursor 401 is a perfect yeast extract to create authentic red meat flavours

thanks to its composition and flavour profile: this product has a specific natural combination of amino acids, peptides and key sulfur compounds. This innovative solution contains high levels of free amino acids and especially free glutamic acid, bringing high reactivity and powerful flavour properties. It has many benefits:

It can be used to create your own vegan beef and other red meat flavours.

It is a fermentation-derived ingredient that promotes the transition to more sustainable food systems.

It enables flavourists to use the “natural flavour” label, based on factors such as the production process, ingredient composition, and local regulations, aligning with clean label standards.

This new yeast extract for meat analogues,

processed meat, sauces, snacks and ready meal is an innovative solution for flavourists and food manufacturers who are in search of a natural ingredient for their formulation. Free from animal origin, Springer Precursor 401 is compliant with many diets: Kosher, Halal, vegan and vegetarian.

It allows development of specific beef and red meat notes in a cooking / Maillard reaction. The Maillard reaction is often defined as nonenzymatic browning reaction. While foods are processed or cooked at high temperature, a chemical reaction occurs between amino acids and reducing sugars which generate different flavours and brown colour. It is used almost everywhere from the baking industry to our day-to-day life to make food tasty.

Biospringer – www.biospringer.com

THeat Exchanger (iHX) is a low oil volume model of heat exchanger set to provide a highly efficient, low cost, oil heating solution for food manufacturers.

This next generation heat exchanger is suitable for all manner of snack food applications, including bakery, potato chips, corn products, nut products, French fries, potato co-products and all continuous frying operations.

Heat and Control chief engineer Mick

Heat and Control’s next generation heat exchanger is designed using the latest tech advancements.

Walsh, says development of the new intelligent heat exchanger involved using modern computing technology to innovate, and improve upon, existing heat exchanger technology.

“Using the latest advancements in design and automation in computer code — allowed us to perform the millions of calculations needed — to optimise radiative heat transfer and create an optimised tube bundle design and heating technology, for reduced oil volume,” said Mr Walsh.

“This innovation in design offers a 25% increase in efficiency gains over our previous, base model heat exchanger.

“iHX provides improved oil quality, reduced oil volume, lower fuel costs, and lower emission levels.

“iHX performs at an optimal level because all tubes within the radiative zone use their whole surface area for heat transfer, reflecting heat from the insulation onto the back of tube surfaces which aren’t in direct line of sight to the hot surface.”

The use of heat exchangers in food processing has revolutionised the industry, and their efficient heating performance and reliability make them a superior alternative to steam or thermal heating.

Heat and Control’s iHX Intelligent Heat Exchanger can be used as part of a new equipment line or is easily retrofitted into an existing line.

Heat and Control –www.heatandcontrol.com

As a powerhouse developer and manufacturer of cutting machinery, Urschel delivers targeted results to meet processing goals and optimise profits. Rugged slicers, shredders, dicers, and milling machinery built to exceed expectations.

With a proven track record in the food & beverage industry, BMG provides quality components, technical expertise and superior service. We offer:

• Comprehensive application knowledge and technical support

• Complete solutions from a single source

• A strong global presence

• Thousands of installations in the food and beverage industry

• An extensive, versatile portfolio of premium quality products

• High reliability, efficiency and durability

• Recognised production quality according to global standards

With an extensive stockholding, contact us today on +27 11 620 1500 for your consumable-related enquiries.

Heat and Control’s French fries and potato co-products processing equipment sets the industry standard for dependability, offering rapid and efficient processing of potato products including fries, wedges, and an array of co-products.

Collaborating with experts and strategic partners, Heat and Control delivers comprehensive turnkey solutions — from spud to shipping. The company offers a diverse range of heating options, allowing customers to choose between natural gas, oil, steam, thermal fluid, electric heating, Kleenheat®, and Greenheat. Their fryers boast optimal product handling, uniform oil heating and flow control, efficient fines removal, rapid oil turnover, and clean-in-place sanitation. These features ensure the production of high-quality products with extended shelf life. Heat and Control fryers provide precise oil flow control for even cooking in even the largest fryers. Full control of zone flows and minimised oil volume further enhance operational efficiency and oil quality. With reliability, minimal operator intervention, and highly effective Clean-in-Place (CIP) systems, operating costs are controlled while maximising production.

The Heat and Control French Fry Fryer ensures trouble-free, high-capacity production with precise oil management for uniform cooking and consistent quality. Integrated seamlessly into their full French fry processing lines — already operational worldwide — these fryers boast an impressive processing capacity of over 35 tons per hour of finished product. Heat and Control’s French fry and formed potato product systems are the workhorses of the industry. With options including multi-zone and two-stage

"Multi-zone frying is a great option for processors seeking to customise cooking conditions for different cuts of coated and uncoated French Fries with minimal fryer footprint. "

continuous fryer systems, manufacturers are guaranteed uniformity in their products.

With a specialised two-stage setup, tailored to produce batter-coated fries, but equally suited to uncoated fries, this style of fryer boasts a unique design that maximises production capacity with a minimal footprint: Stage 1: Set coating - Oil velocity control and flexibility reduce damage to the product and coating losses. Controlled oil flow through multiple AccuFlow™ inlets ensures each French fry receives a consistent cooking time. The oil inlet directs fines out of the fryer to safeguard oil and product quality. An outside belt return reduces oil volume, further enhancing oil turnover time. Fines are efficiently removed through multiple outlets, minimising oil degradation. The design of this system includes a drip tray oil flush system and full Clean-in-Place (CIP), ensuring optimal hygiene and reduced fines build-up in both stages. Stage 2: Completes cooking - With the batter firmly set,

fries undergo final cooking in the second stage fryer. Multiple zones of oil inlets and outlets maintain a consistent average cooking temperature, low Delta T, by rapidly adjusting to changes in product load. Oil flow penetrates the pack for uniform cooking, eliminating clusters and quickly removing fines without product damage. Multi-zone frying is a great option for processors seeking to customise cooking conditions for different cuts of coated and uncoated French Fries with minimal fryer footprint. Precise Frying control for product qualityHeat and Control’s unique continuous fryer design gives complete control over product quality. AccuFlow™ oil inlets are proven to offer equal side-to-side oil flow for uniform cooking across all fryer width classes. Multiple oil inlets and outlets enable adjustments to oil velocity, volume, and temperature drop to suit specific products, while efficiently removing fines. Continuous oil circulation between the fryer, filter, and heat exchanger provides precise temperature control and rapid adjustment to changes in product load. A low volume of oil and rapid turnover ensure fresh products with extended shelf life.

Easy cleaning - CIP spray nozzles in the hood and exhaust stack clean all areas above the oil path. Self-locking motorised screw jacks conveniently raise the hood, and conveyors, clear of the pan for complete cleaning and maintenance access. The fryer includes cleverly engineered features which minimise fines buildup from the outset - to reduce overall cleaning time and improve cleaning effectiveness.

Heat and Control –www.heatandcontrol.com

Our value-added systems prepare and cook consistently superior beef, pork, chicken, turkey, fish and other meat products including alternative meat to create a distinctive quality that stands out in the marketplace.

• Preparation + Processing

• Battering + Breading

• Frying + Oil Management

• Branding + Searing

• Cooking, Roasting + Drying

• Coating + Seasoning

• Product Handling

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING.

ADM’s global survey reveals 83% of consumers are reducing sugar intake, with diverse cultural approaches to managing sugar consumption.

Across much of the globe, one thing is clear: nearly everyone is actively reining in their sugar intake. What’s interesting are the various ways in which different cultures approach it. ADM Outside Voice℠ research surveyed 13,900 people in 15 countries across four regions about their purchase behaviors. On average, 83% of consumers are limiting or avoiding sugars in their diets, but the products of particular concern vary widely.

In North America, 69% of shoppers are flipping over pancake syrup bottles to review sugar content and ingredients on labels, while it doesn’t even make the list in the other regions. Sugar scrutiny in non-alcoholic beverages is a global priority, yet research shows that sweetening preferences shift considerably across markets. For example, North Americans prioritise milk alternatives, Europeans are focused on the quality of chocolates and pastries, and, in Latin America and Asia Pacific, snacks and specialised nutrition are top areas for product evaluation.

ADM’s research reveals that a significant majority of the population is reducing their sugar intake, particularly in countries such as Mexico, Spain, Romania and Brazil, where around 90% declare they actively limit or avoid sugars. The importance of low sugar content is so crucial that respondents place it on equal footing with satisfying taste across most of the globe; however, Asia Pacific is an outlier, prioritising quality and health benefits more substantially.

“Our research delivers valuable insights for product development. It serves as a roadmap for formulation strategies, highlighting the most important elements on nutrition labels and ingredient declarations that resonate with shoppers from one category to the next. Furthermore, we leverage this data when partnering with brands as they enter new global markets,” said Diedrich. “For example, we’ve observed that consumers are more

forgiving on calories and sugar tallies in indulgent food categories like confections, ice creams and sweet bakery. However, there is a notable shift toward reviewing the quality of ingredients and sweetening choices in these segments. From this foundation, we can educate brands on the acceptability of ingredients in different regions, which allows them to appropriately balance great taste with label appeal.”

“It’s clear how significant monitoring sugar consumption is, no matter the region. That’s why we have invested in extensive research and analysis to understand attitudes towards sugar, motivations for reading labels, and unique ingredient preferences,” said Sarah Diedrich, senior, marketing director, Global Sweetening & Texturizing Solutions, ADM. “We began this journey two years ago, and it has culminated in the launch of a new interactive insights tool that provides users with an in-depth look at the nuances of consumer behavior across the globe.”

Capturing this comprehensive data is ADM’s new interactive tool, allowing food and beverage manufacturing is a clear. view of how people around the world are navigating their sugar reduction journeys, and the similarities and differences across nations.

JRS FOOD INGREDIENTS

Within the map of the insights tool, country-specific highlights are also shared. For instance, consumers in Poland are more likely to have purchased nutrition bars and sports performance drinks, citing strong athletic and cardiovascular goals more than other European nations. Australians are more likely to seek out sugar-free products rather than offerings with partially reduced sugar, particularly when compared to three other Asia Pacific countries. For shoppers in Mexico, plant-based claims and alternative sweeteners like stevia and agave are sought-after ingredients; and Brazilians hold high regard for products with sustainable sourcing claims.

J. RETTENMAIER & SÖHNE GMBH + CO KG Holzmühle 1 I 73494 Rosenberg I +49 7967 152-332 I food@jrs.de

“These are just a few trends identified in the extensive statistics organised in our new interactive tool, designed to help navigate consumer desires.

VIVAPUR® Functional Ingredients/Systems

› Calorie and Fat Reduction

› Meat or Protein Replacer

› Dietary Fiber Enrichment

› Texture and Structuring

VIVAPUR® Functional Ingredients/Systems › Calorie and Fat Reduction › Meat or Protein Replacer › Dietary Fiber Enrichment › Texture and Structuring

Beneo offers low-glycaemic ingredients that help stabilise blood sugar, support weight management, and promote digestive health. Roné Luttig and Carien Schoeman from Savannah discuss how Beneo’s ingredients align with the goals of diabetes awareness and management. 537 million people are living with diabetes worldwide and close to 50% of diabetics are undiagnosed. It is essential to spotlight innovations that help manage and potentially reduce the risks associated with diabetes. Beneo, a leading provider of functional ingredients, offers solutions that contribute significantly to improving blood sugar management through carefully designed, low-glycaemic ingredients that benefit both consumers and food manufacturers.

One of the standout features of Beneo’s ingredients is their low glycaemic index (GI). Ingredients with a low GI help prevent rapid spikes in blood glucose levels, a critical factor for people with diabetes or those looking to prevent it. Beneo’s ingredients, like Palatinose™ (isomaltulose) and the Orafti® range (chicory root fibre), deliver a more gradual release of glucose into the bloodstream, supporting balanced blood sugar levels. This approach reduces the likelihood of sudden glucose peaks and crashes, enhancing overall blood sugar management.

Palatinose™ (Isomaltulose): This ingredient is a fully digestible carbohydrate that provides energy in a steady and prolonged manner, making it suitable for low-glycaemic products. It’s a particularly great substitute for high-GI sugars, promoting sustained energy release rather than a quick spike.

Orafti® - Chicory Root Fibre (Inulin and Oligofructose): Chicory root fibre is a soluble fibre that is also a prebiotic fibre that aids

November is World Diabetes Awareness Month, highlighting the importance of managing diabetes.

in digestive health and supports balanced blood glucose. Since it’s a soluble fibre, it also contributes to a feeling of fullness, which can help manage appetite and support weight management—factors closely linked to diabetes prevention and management.

One of the critical factors in managing or preventing diabetes is maintaining a healthy weight. Beneo’s Orafti® prebiotic fibres, like chicory root inulin, have been shown to enhance satiety. They help people feel fuller for longer, which may reduce overeating and, by extension, contribute to weight control.

Additionally, these fibres promote a healthy gut microbiome, which plays a role in metabolic health and glucose regulation. Research shows that gut bacteria may influence insulin sensitivity, making these fibres an asset in diabetes management and prevention.

Poor digestive health can impact overall wellness, including blood sugar control. Beneo’s Orafti® chicory root fibres act as a prebiotic, feeding beneficial gut bacteria that support the microbiome. This prebiotic effect has a domino effect on overall health: a healthy gut microbiome is linked to improved insulin sensitivity and lower inflammation, which can help reduce the risk of developing type 2 diabetes.

“For individuals at risk of or managing diabetes, Beneo’s range of functional, low-glycaemic ingredients provides essential support.”

With the rise in health-consciousness and demand for “clean label” products, Beneo’s ingredients provide natural, recognisable options that consumers trust. Ingredients like Orafti® chicory root fibre and Palatinose™ (isomaltulose) are easily incorporated into a variety of applications— from baked goods, confectionary to dairy alternatives and beverages—making them versatile for food manufacturers while maintaining label transparency.

Beneo’s ingredients opens a range of formulation possibilities for food producers looking to cater to the diabetic community. Products that are low in glycaemic index but high in taste are possible with Palatinose™ (isomaltulose) and Orafti® chicory root fibre, allowing manufacturers to create foods that do not compromise on flavour but offer added health benefits.

For individuals at risk of or managing diabetes, Beneo’s range of functional, lowglycaemic ingredients provides essential support. By using ingredients like Palatinose™ and Orafti® chicory root fibres, manufacturers can produce food products that contribute to blood sugar stability, support digestive health, aid in weight management.

Johannesburg: +27 11 856 4500

Cape Town: +27 21 830 5306

Durban: +27 31 313 3338

Email: info@savannah.co.za

Orange and yellow may be popular colours for savoury food, but manufacturers could be missing a rainbow of untapped possibilities with bolder, unexpected shades, according to a new survey from leading natural colours company, Oterra.

The survey commissioned by Oterra reveals that consumers are ready to explore a broader colour palette, hinting at exciting opportunities for creative product development.

“Orange and yellow are traditional favourites among consumers. But our survey has shown greater nuance in consumer tastes that could be converted into new, creative products – and more sales,” says Phil Cook, head of strategic marketing for Oterra.

Colours have long been known to influence flavour perceptions, creating excitement, and driving purchases. However, the survey opens the way for food and drink manufacturers to create products that will appeal to consumers in new ways by matching colour preferences to regions with the associated emotions and

is a world leader in colours from natural sources. It helps manufacturers bring safe and appetizing products to consumers at mealtimes – and any time in between. The deep insights about markets, regulatory requirements, applications, pigments and phytonutrients place Oterra at the forefront of the industry.

“The survey commissioned by Oterra reveals that consumers are ready to explore a broader colour palette, hinting at exciting opportunities for creative product development.”

combining that with consumers’ ages, genders and lifestyle.

The survey asked consumers from around the globe about their colour preferences: from overall appeal to associated flavour expectations, and the emotions they triggered.

“The most interesting results of the survey were the regional variations between perception of colours – with regions preferring different colours for the same types of products,” adds Carel Soo, head of regional marketing for Oterra.

It also revealed that untraditional combinations of colours and products tempted consumers.

“Pink and green sauces were surprisingly popular among consumers, who found them very appealing,” adds Carel Soo. “And red and purple were popular in foods such as noodles and even burger buns.”

One of the surprising facts to come out of the survey was that the same colours provoked different emotional reactions depending on the region, and the intensity of the colour.

Orange was the most appealing shade for seasonings globally, followed very closely by yellow and pink. However, yellow was rated more appealing in Brazil, France, and India.

Black ranked at the bottom of the pile in appeal. Whilst many felt black seasonings were unappealing, they did note them for their elegance and air of mystery.

Consumers love a colourful sauce!

The most appealing colour globally for sauces is yellow, but as with seasonings, there are regional variations. Among the top five colours, red stands out for the US and Europe, purple for Latin America and pink for Asia. While black is still bottom of the pile for sauces, it has the highest acceptance in this application versus the others.

The final category included in the survey was a group of savoury products that are usually not coloured. This included puffed snacks, burger buns, noodles, and gyoza dumplings.

“What’s really interesting with the products that aren’t generally coloured, is that there is a strong acceptance for colours in them,” adds Soo. “There are, of course, regional variations in shade and strength, but there are real opportunities here for manufacturers looking to stand out from the crowd.”

The results of the survey have been made available in a web-based app that uses augmented reality to allow marketers and food and beverage developers to have some fun and experiment with coloured products to test.

Ten countries were surveyed (Brazil, China, France, Germany, India, Indonesia, Mexico, Morocco, United Kingdom, United States) with at least 1000 respondents in each. They were asked questions about 10 savoury applications: burger buns, burger sauces, dumplings, French fries, noodles, nuggets, potato chips, puffed snacks, salad dressings, and savoury dips in different colours.

GNT introduces its firstever paprika emulsion for the EXBERRY® colour range, offering vibrant, clean-label orange shades for diverse food applications.

EXBERRY® Shade Vivid Orange is a water-dispersible colour made from non-GMO paprika. It has a high colour intensity that allows for cost-effective low usage levels and can deliver bright shades in food products including confectionery, dairy, bakery, and plant-based meat.

It can be used to replace paprika oleoresin emulsion (E 160c) and Sunset Yellow (E 110) while supporting completely clear and clean label declarations. EXBERRY® Shade Vivid Orange is created using physical processing methods and without the use of chemical solvents. As a result, it is classified as a food ingredient rather than an additive in many parts of the world and does not require E numbers. It can be described as “paprika oil” under EU and Chinese regulations and “paprika oil emulsion” in Australia and New Zealand. In the United States, it is listed as “paprika (colour).”