Unbox the future

The year of smart and sustainable packaging

Welcome to the 2024 edition of Packaging Review.

As an annual digital magazine, Packaging Review delves into the latest trends in packaging materials and equipment across diverse industries including food, beverage, pharmaceutical, personal care, and beauty/cosmetics.

The packaging industry stands at the forefront of innovation and sustainability as it navigates through an era of rapid technological advancements and shifting consumer preferences.

One of the most significant trends shaping the future of packaging is the growing emphasis on sustainability. Consumers and businesses alike are increasingly prioritising eco-friendly materials and processes, driving the development of biodegradable and recyclable packaging solutions. Smart packaging technologies are also revolutionising the way manufacturers track and monitor products, and how consumers interact with these products too, enhancing production and supply chain efficiencies as well as consumer engagement.

In our 2024 edition, we explore how these trends are being implemented across the packaging industry. From the latest advancements in food and beverage packaging that extend shelf life and reduce waste, to innovative pharmaceutical packaging that ensures product integrity and patient safety, our articles provide a comprehensive overview of the industry’s evolution.

I hope that the insights shared in Packaging Review inspire you to embrace innovation and sustainability as key drivers of the future of packaging.

Enjoy the

The team

EDITORIAL

EDITOR: Abby Vorster +27 (0)71 359 4519 abby.vorster@newmedia.co.za

LAYOUT & DESIGN: David Kyslinger

ADVERTISING

SALES EXECUTIVE: Anita Raath +27 (0)82 976 6541 anita.raath@newmedia.co.za

SALES EXECUTIVE: C àndida Giambò-Kruger +27 (0)71 438 1918 candida.giambo-kruger@newmedia.co.za

SALES EXECUTIVE: Carla Melless +27 (0)83 260 6060 carla.melless@newmedia.co.za

INTERNATIONAL SALES

Germany/Austria/Switzerland: Eisenacher Medien Erhardt Eisenacher +49 228 249 9860 info@eisenacher-medien.de

Italy: Ngcombroker Giacomo Rotunno +39 370 101 4694 g.rotunno@ngcombroker.com

Taiwan: Ringier Trade Media

Sydney Lai +886 4 2329 7318 sydneylai@ringier.com.hk

CIRCULATION

CIRCULATION MANAGER: Felicity Garbers felicity.garbers@newmedia.co.za

PUBLISHING TEAM

GENERAL MANAGER: Dev Naidoo

GROUP ACCOUNT DIRECTOR B2B: Johann Gerber

PRODUCTION CONTROLLER: Mandy Ackerman

ART DIRECTOR: David Kyslinger

JOHANNESBURG OFFICE

New Media, Building 13, The Woodlands Office Park, 20 Woodlands Drive, Woodmead, Sandton PO Box 784698, Sandton 2146 Tel: +27 11 867 6111

POSTAL ADDRESS PO Box 784698, Sandton, Johannesburg, 2146

Published by New Media, a division of Media24 (PTY) Ltd

MANAGEMENT TEAM

CEO: Aileen Lamb

COMMERCIAL DIRECTOR: Maria Tiganis

BRAND STRATEGY DIRECTOR: Andrew Nunneley

CHIEF FINANCIAL OFFICER: Venette Malone

Interim CEO: MEDIA24: Raj Lalbahadur

and converters of shrink sleeves & flexible packaging

Through an innovative and out of the box approach to our clients’ needs, we are not only willing, but also able to provide practical and efficient cost-saving solutions to most printing and packaging challenges. A pioneering narrow web flexographic printer, ISW specializes in, while not confined to, the manufacturing of highly decorative and complex shrink sleeves, self-adhesive and wraparound labels, and various forms of flexible packaging. By working closely with local and international suppliers, and utilising specially developed in-house processes a multitude of innovative finishes including the likes of thermochromic, glow in the dark, domed, holographic and high lustre metallics along with specialised multi-perforation solutions for promotional items are achieved.

HEAD OFFICE

New Media, Cape Town

11 Shelley Road, Salt River, Cape Town PO Box 440, Green Point 8051

Tel: +27 021 406 2002

Email: newmedia@newmedia.co.za

With the manufacturing plant consisting of 10-colour and eight-colour MPS EPW560’s and a full complement of the latest offerings in finishing equipment for the conversion and inspection of our products, ISW maintains the highest level of quality and is one of only a handful of narrow web printers capable of producing wide lay flat shrink sleeves, achieving a L/F of 276mm from a printed web width of 575mm. By offering assistance and advice with every step from concept to design, production and application; we are there to ensure our clients achieve their desired vision efficiently, affordably and consistently. printers

New closed system for Politainer packaging

Berry Global has introduced a range of special closures and couplings, which can be used in conjunction with its popular Politainer™ combi pack. This provides a closed system to facilitate the safe and easy dispensing of sensitive liquids. It also prevents the liquids from coming into contact with air.

Available in sizes from 1l to 30 l, Politainer comprises a polyethylene container held within a sturdy cardboard outer. The container collapses as the product contents are emptied, which helps to ensure almost complete evacuation of the container while preventing air from entering. This makes it suitable for a diverse range of products, including inks, chemicals, pharmaceuticals, foods, and cosmetics.

After transport, the Jolly and Easy Connect closures and CMB and CPS couplings can be combined to replace the Politainer’s standard cap to avoid oxygen ingress while product contents are dispensed and transferred. Jolly closures are available with various sealing rings, and couplings come in different diameters to meet varying product characteristics, such as viscosity. All the closures incorporate a tamper-evident feature. Jolly couplings for

larger Politainers are available with tubes to ensure full evacuation of the contents.

“We are seeing increasing demand for closed systems for the emptying of our Politainers,” says Klaus Steinmann, key account manager for Berry Blow-Moulding Specialities. “As well as specialist products like inks, chemicals and pharmaceuticals, there are many other applications that require additional protection, including cosmetics and flavourings, many of which are now preservativeand additive-free and contain high-value ingredients.”

The Politainer delivers an up to 75% plastic weight reduction compared to a rigid plastic container of a similar capacity. In addition, empty packs are shipped flat packed with one full truck of empty Politainers equating to eight full trucks of rigid containers – to reduce costs and minimise wasted space. This helps to optimise supply chain efficiency and lessen the need for truckload shipments. •

Award-winning recycled PVC products

Recycled PVC products stole the spotlight at the 2024 Best Recycled Plastic Product of the Year Awards, announced in September at a gala dinner in Cape Town. The event, organised by the South African Plastics Recycling Organisation (SAPRO), saw three innovative products made from recycled PVC dominate the Building and Construction category, impressing the judges with their creative approach to waste reduction and sustainability. Judges for the competition represented Plastics|SA, Polyco, CSIR, Media24 and Waste Plan.

Taking home top honours was NowaTech’s PVC decking planks, made from recycled PVC pipes and bottles (primarily honey and bubble bath bottles), which won Gold in the Building and Construction category. The judges praised NowaTech for

innovative use of recycled materials, noting the product’s durability and contribution to reducing plastic waste.

Winning Silver was an equally impressive product – PVC sewage pipes for low-cost housing developments. These pipes, made from recycled loyalty and gift cards, offer an affordable and sustainable solution for infrastructure development while diverting significant volumes of plastic from landfills.

Tuff Floors, with its range of interlocking floor tiles made from recycled PVC, rounded off the category taking home Bronze. The company was commended for the versatility and ease of installation of the tiles in both commercial and residential projects.

Monique Hinds, CEO of the Southern African Vinyls Association (SAVA), was so excited about the accomplishments of the PVC industry.

“This is a significant achievement for the PVC recycling sector. Despite continued successes in increasing recycling and collection rates for PVC in South Africa, there are still many people who perceive PVC as non-recyclable. Accolades such as the SAPRO Awards are crucial in changing this perception. They highlight industry’s innovation and commitment to reducing waste and unlocking the value hidden in recycled plastics.”

filling equipment

The range of special closures and couplings can be used in conjunction with Berry Global’s popular Politainer combi pack

2024 Clean-Up & Recycle SA Week a great success

The annual Clean-Up & Recycle SA Week , from 16 to 21 September, marked its 28th year of bringing together communities, businesses, and schools to raise awareness about waste management and environmental care. The week culminated in the International Coastal Clean-Up (ICC) Day on 21 September, with hundreds of volunteers clearing litter from beaches across the country.

Douw Steyn, sustainability director of Plastics SA, said there was unprecedented support and participation for this year’s campaign.

“Thanks to generous contributions from our sponsors, we were able to print and distribute a record-breaking 800 000 bags to clean-up coordinators nationwide. We are immensely grateful for the contributions and support we’ve received from the plastics industry, various brand owners, PROs, logistics companies, and NGOs. Their commitment has been vital to the ongoing success of Clean-Up & Recycle SA Week,” Steyn commented.

Plastics SA received an overwhelming response to its call for volunteers to clean up the environment, with over 50 audited cleanups taking place across the country. These were organised by schools, NGOs, municipalities, businesses, industry roleplayers, and community volunteers who were all eager to make a difference where they work, live or play. Beach clean-ups were coordinated along the entire South African coastline, ensuring widespread participation.

Volunteers braved challenging weather, particularly in KZN, where rainy conditions failed to dampen the enthusiasm of participants. One of the highlights this year was the personal involvement of Deputy Minister of Forestry, Fisheries, and the Environment, Narend Singh, who attended the beach cleanup at Durban’s Cutting Beach.

In Cape Town, major clean-ups took place at various sites around the city, including the Milnerton Beach lagoon where around 400kg of waste was cleared from the

beach on Saturday and 394kg on Sunday thanks to Save a Fishie and volunteers who worked their way through clothes, bottle tops and nappies. Captain Fanplastic organised a clean-up of the Liesbeeck River, which Plastics SA sponsored with a schools toolkit in honour of ICC.

Despite the challenges, such as the cost and logistical complexity of delivering bags across the country, the Sustainable Seas Trust and Plastics SA worked tirelessly to ensure that all coordinators received supplies on time.

“Our provincial and ICC coordinators are the real stars,” Steyn said.

A competition was also introduced with the 2024 event, inviting individuals and community groups to showcase their recycling actions or cleanup efforts. The winners of the various categories will be announced in October.

Plastics SA continues to work closely with packaging PROs, providing education, infrastructure, and training to waste collectors, which adds value to collected materials.

Douw Steyn, volunteers and Deputy Minister Narend Singh at Cutting Beach

Smarter futures start here

Africa’s ultimate packaging industry trade show is coming to Johannesburg in 2025.

Propak Africa is set to attract thousands of industry decision-makers with purchasing power and influence.

The future is coming fast and with the rapid and continuous move towards automation and digitisation across industries, companies know they need to invest in smarter solutions, products and services if they want to reap the benefits of staying ahead of the curve.

Companies also know that a good place to find these latest solutions, products and services is at an industry recognised trade show. Trade exhibitions have long been known for their ability to provide a unique platform where latest industry trends and innovations can be showcased to a wide and engaged audience. This is certainly the case for Propak Africa which has built its reputation as Africa’s definitive packaging, printing, food processing, plastics and labelling trade exhibition.

Taking place at the Expo Centre in Nasrec, Johannesburg, from 11 to 14 March 2025, over 400 exhibitors will be showcasing the very best these industries have to offer at Propak Africa.

“It will be four days of unparalleled access to fresh new thinking and ideas that could take your business to the next level,” says Mark Anderson, portfolio director at Specialised Exhibitions, a division of Montgomery Group and organisers of the show. “Industry front runners from across these sectors will use this platform to introduce state-of-the-art technology, advanced equipment and new approaches to packaging. All the latest industry trends will be on view.”

Leading industry players such as Qualitechs, Newmantle, Rotocon, USS Paktech, Filmatic, HG Molenaar, Erema, Cabletech, Userve and IPEX will be exhibiting at Propak Africa alongside many other leading brands.

“Exhibitors will be located across Halls 5, 6 and 7 at the Expo Centre and we will also have some outside stands which better suit some of our exhibitors and their products,” says Anderson. “We are delighted that over 80% of available exhibition space has already

been sold and we are in conversation with additional companies that have approached us wanting to benefit from this opportunity.”

Five-in-one trade show opportunity

Propak Africa incorporates ProPlas Expo, the GAPP Print Expo, FoodPro and Pro-Label Expo.

The exhibition will be leading the way in showcasing packaging innovation, looking at the future of plastics and printing in packaging, highlighting food processing advancements, and displaying the next level of labelling solutions.

“Propak Africa provides an opportunity for exhibitors to gain access to thousands of influential

“It will be four days of unparalleled access to fresh new thinking and ideas that could take your business to the next level”

decision makers and buyers, which in turn leads to the generation of quality sales leads and building brand awareness. It’s where you can get face to face with the right people and prospects across the packaging, printing, food processing, plastics and labelling industries,” explains Anderson. “It’s about finding new customers, gaining deeper customer insight, establishing industry partnerships, and, of course, launching new products and services into the market.”

There were high levels of exhibitor satisfaction at the previous show in 2022. Propak Africa was seen as a value-add to their business and a big part of their marketing strategy; it is also a great platform to bring together industry and customers. The trade show attracted many visitors from Africa with sales leads generated from Zambia, Nigeria, Malawi, Cameroon and Zimbabwe, amongst others.

“We provide personalised support to all our exhibitors to ensure they get the most from their exhibiting experience,” remarks Anderson. “From helping them choose the right stand for their goals and budget, to providing guidance with their planning and brand promotion leading up to the show.”

Technical experts, free seminars

From a visitor perspective, not only are attendees able to see the latest innovations and compare products and brands at Propak Africa, but the trade show also affords them the opportunity to engage with technical experts at the exhibitors’ stands.

There will also be a full programme of free-to-attend seminars with subject experts delivering content rich industryrelated presentations aligned with the show’s theme days.

“We have been working hard behind the scenes connecting with our partners, integrating latest exhibition trends and technologies, and planning our free seminars, theme days and experiential activities. Many initiatives are already in place and with others in the pipeline. It’s going to be an exciting show,” Anderson concludes.

Propak Africa is supported by The Institute of Packaging SA, Packaging SA, Plastics SA and Printing SA. •

Connect with Propak Africa online:

D012-1.pdf 1 2024/09/10 11:04

We’re thrilled to share that we’ll be participating in Propak Africa 2025, from 11 to 14 March. Don’t miss the chance to explore our latest advancements in pump technology. We can’t wait to see you there. Visit us at stand J21 in hall 6.

Tank-free hot melt technology in action

The InvisiPac Hot Melt System can improve end-of-line packaging productivity at any speed, within a compact footprint.

In the fast-paced world of manufacturing, downtime is not only an inconvenience, but also a costly setback that can have a significant impact on productivity, profitability and customer satisfaction. Each minute of halted production translates into lost revenue and wasted resources.

The InvisiPac Hot Melt System offers a revolutionary solution that goes beyond mere possibility and

A standout innovation with many benefits

• Created by leading experts, the Invisipac Hot Melt System offers many advantages:

• No Glue Build-Up: The Invisipac system ensures a consistent and controlled flow of adhesive, eliminating the common issue of glue build-up. This helps to avoid disruptions in production lines and maintain product quality.

• Reduced Risk of Burns: Traditional hot melt systems involve handling molten glue, which can pose a risk of burns to operators. In contrast, the Invisipac system minimizes this risk by keeping the adhesive in a solid state until it is precisely needed.

• Efficient and Precise: The on-demand melting feature allows for efficient adhesive application. The system only heats the necessary amount of adhesive, reducing energy consumption and minimising waste.

transforms downtime into a thing of the past. This cuttingedge adhesive application technology is designed to minimise interruptions and maximise uptime, enabling businesses to maintain seamless operations and gain a competitive edge.

Enhanced safety and user-friendly benefits

Graco’s InvisiPac tank-free melt on demand technology boasts an industry-leading start-up time of merely 10 minutes, significantly reducing start-up energy consumption by 40%. Furthermore, InvisiPac achieves a minimum reduction of 30% to 50% in adhesive usage and effectively prevents unplanned downtime associated with charring, nozzle blockages and hose complications. Collectively, these advantages ensure substantial savings. The InvisiPac Hot Melt System maintains a uniform temperature and viscosity for adhesives. It functions based

“The InvisiPac Hot Melt System epitomises reliability and efficiency within the manufacturing sector”

on a first-in-first-out (FIFO) methodology, which prevents temperature variations and the development of char. Throughout production, material output remains stable, ensuring no downtime.

The integrated module filtering of the InvisiPac applicator prevents nozzle blockages and guarantees a consistent adhesive bead on each box. Additionally, it allows for the monitoring of adhesive consumption, system performance and line data from any location at any time, facilitating the achievement of Industry 4.0 objectives.

The InvisiPac system enhances safety by ensuring that operators do not come into direct contact with the hot molten adhesive, thereby mitigating risks associated with burns, toxic fumes and slippage. When the adhesive within the melter attains a predetermined level, an automatic signal is dispatched to the feeding system, prompting the adhesive to be drawn from the container directly into the melter, all without the need for operator involvement.

This compact device features a hot melt output of 11.3kg per hour, making it suitable for medium to high volume case and carton sealing applications. It is available with four to eight channels, and the melt-on-demand system seamlessly integrates into end-of-line packaging processes.

Efficiency in manufacturing

In the ongoing quest for operational excellence, reducing downtime stands as a paramount objective.

Discover the Invisipac difference

• The Tank-Free™ system provides on-demand delivery of hot melt adhesive for case and carton sealing applications.

• The HM 25C melter dispenses an output of 11.3kg or less per hour.

• The HM10 melter dispenses an output of 4.5kg or less per hour.

• The Tank-Free™ melting chamber efficiently heats the adhesive to the required temperature in approximately 10 minutes, offering the fastest start-up time available for any end-of-line packaging process.

• Using proprietary melt-on-demand technology, the system ensures a continuous flow of hot melt adhesive, which melts rapidly and is dispensed without delay.

• FIFO methodology ensures the adhesive melted first is the first to be dispensed, preventing adhesive char and thermal shock.

The InvisiPac Hot Melt System epitomises reliability and efficiency within the manufacturing sector, offering a solution that not only mitigates downtime but also transforms it into a catalyst for increased productivity and profitability. By leveraging cutting-edge technology, streamlined processes and outstanding performance, organisations can diminish the risks linked to disruptions and refine their operations to attain greater achievements. With the InvisiPac Hot Melt System as a steadfast ally, manufacturers can navigate the challenges of downtime with a dependable partner, acheiving their goal of continuous improvement and sustainable growth.

AxFlow AQS Liquid Transfer is the sole distributor of the Graco InvisiPac Hot Melt System. If you’re looking to minimise downtime in your production processes with InvisiPac, reach out to the knowledgeable team of AxFlow AQS Liquid Transfer for personalised advice and support tailored to your specific operational needs. Let the team help you transform your production line with efficiency and reliability. •

• The patented self-learning feed algorithm autonomously transfers adhesive pellets from the hopper to the melter, eliminating the need for operator involvement. The absence of direct contact with the hot molten adhesive significantly reduces safety risks, including burns, toxic fumes, and slippage.

• The pattern control feature allows for a seamless transition from dispensing a solid bead to a stitched bead at the touch of a button, resulting in time and cost savings.

• Comprehensive reporting functionalities provide essential data to enhance efficiency, lower expenses, reduce downtime, and boost productivity on your packaging line.

Connect with AxFlow AQS Liquid Transfer online

All you need to package your products

Bidvest Data, Print & Packaging provides an array of products and services that are represented in six main categories, including packaging and labelling. The group is committed to delivering efficient and cost-effective solutions to customers while championing ethical and sustainable business practices. These principles extend to the packaging companies within the group, which include Aluminium Foil Converters, Lufil Packaging, Rotolabel, S&N Labels, Masterpack Gauteng and Masterpack Cape, Sprint Packaging and Green Home.

Aluminium Foil Converters

This formidable niche business boasts a wealth of experience in the aluminium foil, film and paper flexible packaging industry. Founded in 1982, Aluminium Foil Converters (AFC) has become the preferred supplier of lidding, closures and wrapping to a range of leading national brands in the dairy, general food, wine and beverage, pharmaceutical, confectionery and agro chemical industries. AFC offers flexographic and gravure printing, laminating, punching, embossing, guillotining and slitting.

AFC is committed to controlling food safety hazards to ensure that its food and pharmaceutical packaging is fully compliant and safe. The company is accredited with ISO 22000:2018 quality food safety management system certifications.

AFC believes in a partnership with its customers whereby valid or reasonable recommendations are adopted with the intention of enhancing food safety for the end user. A pleasant outcome is that customers who audit AFC generally provide positive comments.

Lufil Packaging

This packaging manufacturer has carved a niche for itself by offering a comprehensive range of packaging products tailored for the fast-food segment. Lufil Packaging’s unique positioning allows brands to source all their packaging needs from a single supplier, setting it apart from competitors.

The company’s commitment to sustainability is evident in its approach to demonstrating the circular economy for recycling, ensuring that if a product is not repulpable, then it is biodegradable. Lufil Packaging has also made significant strides in introducing environmentally friendly products. The company now exclusively procures FSC certified materials. In the past, some suppliers struggled to achieve FSC status, but through strategic partnerships, Lufil has helped them become certified. Currently, 90% of Lufil’s products are environmentally friendly, with a strong focus on reaching 100%.

To maintain its FSC and FSSC 22000 V5.1 Food Safety Management System certifications, Lufil has appointed a dedicated quality and food safety manager, who stays updated with any updates to these standards and promptly implements necessary changes in the management system.

By joining the Extended Producer Responsibility (EPR) system a year ago, Lufil proactively adapted to changes in environmental legislation and market demands. The company reports to Fibre Circle, a Producer Responsibility Organisation (PRO), and holds a certificate of good standing from the PRO, affirming its commitment to producing sustainable products.

Lufil is on the brink of launching several exciting projects. One notable development is the creation of an aqueouscoated paper to replace the poly-coated paper currently used for takeaway chicken bags. The launch of this new material is expected in a few months. It will be recyclable, unlike the existing product. Lufil will also begin supplying a large pharmaceutical chain with prescription paper bags from early next year, replacing the plastic bags currently in use.

S&N Labels

A prominent name in the packaging industry, S&N Labels specialises in converting self-adhesive labels and tags. Its extensive product range includes thermal transfer ribbons, price marking guns, tagging tools, and servicing of printers and price marking guns.

Quality is at the heart of S&N Labels’ operations. The company is ISO 9001:2015 certified, underscoring its commitment to maintaining high standards. By sourcing products from the most reliable raw material suppliers, S&N Labels ensures consistent product quality, giving customers confidence in their purchases.

S&N Labels is renowned for its ability to supply high volumes of labels within the required lead times, particularly in the blank label space. This

efficiency is made possible by its investment in some of the best machinery in the industry, which enables the business to meet customer demands swiftly and effectively. Sustainability is a key focus for S&N Labels. The company is FSC certified, reflecting its commitment to the future of our planet. The company continuously seeks ways to reduce waste and recycle as much inbound packaging as possible. Additionally, S&N Labels has minimised the use of plastic cores in its rolls of labels, opting for paper alternatives where feasible.

Masterpack Cape

Masterpack Cape stands as a beacon of excellence in the realm of primary and secondary food packaging. This commitment to quality is underpinned by its BRCGS certification. The company’s adherence to stringent standards is also supported by its Mellow Colour Impression-Proof and Proficient Printer Certifications, ensuring that every product meets the highest benchmarks of quality and consistency. Furthermore, Masterpack Cape holds a AA+ British Retail Consortium (BRC) food packaging safety certification, reflecting the company’s rigorous quality management practices. The AA+ rating is particularly noteworthy as it can only be awarded during unannounced audits. Its recent 2024 audit has set the stage for the eagerly awaited renewal of this prestigious certification, with the next unannounced audit scheduled for 2025.

Connect with Aluminium Foil Converters online

Connect with Lufil Packaging online

Connect with S&N Labels online

Sustainability is a cornerstone of this business. In addition to its longstanding FSC certification, the company recently achieved Programme for the Endorsement of Forest Certification (PEFC) status. This dual certification ensures that all raw materials are sourced sustainably and responsibly. Furthermore, Masterpack’s Fibre Circle EPR programme membership reinforces its commitment to environmental stewardship, promoting sustainable practices across the entire supply chain.

As a commitment to innovation and customer service, Masterpack Cape will be boosting its production capabilities with the installation of its first six-colour UV press. This state-of-the-art equipment will enable the company to produce instantly dry packaging, significantly reducing lead times and enhancing efficiency.

Masterpack Gauteng

Masterpack Gauteng focuses primarily on servicing the healthcare market with folding cartons and package inserts. The balance of this is split between the personal care and confectionery food industries with the supply of folding cartons. A small percentage of the business also feeds the homecare space with cartons and blister cards.

Its capabilities to service such a diverse portfolio of customers include six colour offset printing with full UV options, hot stamp foiling, embossing, PET windows, die-cutting, gluing and leaflet folding. Masterpack Gauteng’s production facility is certified with ISO 9001, FSSC 2200 and FSC accreditations in addition to approval by pharmaceutical customers to produce their products in accordance with the SAHPRA requirements. Masterpack Gauteng is part of the Global Packaging Alliance (GPA), which is a union of nine like-minded companies that share some global customers. Recently the GPA enjoyed a shared win of finding reliable costeffective suppliers of paperboard subsequent to a drought in supply that was followed by the ballooning of prices. The continual sharing of technical expertise also results in efficiency improvements, such as the development of a structural carton design that delivers optimum packing efficiency on automated packing lines.

Sustainability is also important to Masterpack Gauteng. The business will be harvesting rain and evaporative cooler water as a primary eco-project, and it will be completing its migration to LED lighting during the current financial year. In addition, efforts to demonstrate the advantages of paperboard over other packaging substrates as a meaningful biodegradable and compostable option are being ramped up through focused communication campaigns.

Masterpack Gauteng has been working on some exciting projects. One is the development of a more cost-effective solution with increased appeal for ice cream packaging for a boutique ice cream brand. It is also working with a cosmetics manufacturer to define a fact-related method for measuring colour through a documented process of LAB readings. Thanks to contributions from various suppliers included in the process of delivering consistent colour, this development will set the trend in the industry to move from a subjective method of analysing colour to an objective one.

Rotolabel

Based in Cape Town, Rotolabel takes pride in its role as a pioneer in making self-adhesive labelling more environmentally friendly in South Africa. Over the past few years, the business has spearheaded numerous innovations aimed at reducing its ecological footprint and driving positive change in the industry. These innovations include achieving FSC certification, its liner-backing recycling programme, and the launch of CleanFlake™– Rotolabel’s PET wash-off label that enables 100% PET food-grade recycling.

Rotolabel remains at the forefront of sustainable labelling solutions. The company’s journey towards sustainability continues with many more exciting innovations in the pipeline, each aimed at furthering its commitment to environmental stewardship.

As a solution to consumer demand and regulatory requirements driving brand owners to make their products environmentally friendly and recyclable, Rotolabel has collaborated with Avery Dennison to introduce a revolutionary label for PET containers and bottles.

Rotolabel is proudly leading this sustainability-driven change in the South African market, with a 60%+ adoption rate. Despite the company championing CleanFlake™, many PET packs still use incorrect adhesives, resulting in the packaging being downcycled or ending up in landfill.

Sprint Packaging

Sprint Packaging sells over 3 000 commodity packaging lines like styrene to butcheries and retail markets. These traditional, bottom-end packaging solutions and products are crucial to the success of thousands of brands and finished products manufactured nationwide. The company is proud of its national distribution footprint, which services retail service departments such as the deli, bakery, fruit and vegetable, and butchery departments. Sprint Packaging currently provides route-to-market solutions for 265 South African food and packaging manufacturers. Its functional packaging designs not only enhance product visibility but also ensure maximum protection during transportation and storage. With a dedicated team of experts, Sprint Packaging continuously strives to stay ahead of industry trends, providing cutting-edge solutions that cater to the evolving needs of its customers.

CleanFlake™ is a film label with an adhesive that enables true bottle-to-bottle recycling for 100% foodgrade rPET. This scientifically designed adhesive ensures that labels get cleanly detached during the recycling process, facilitating the production of food-grade rPET.

CleanFlake™ has been approved by the Association of Plastic Recyclers and it has received formal approvals from key recyclers both in South Africa and abroad.

Connect with Masterpack Cape online

Connect with Masterpack Gauteng online

Connect with Rotolabel online

Connect with Sprint Packaging online

Green Home

Established in 2007, Green Home is South Africa’s first and longest-running compostable food packaging business. The company’s visionary approach, guided by its founder, has kept it at the forefront of industry trends and innovations.

In the words of Margaret Mead, “never believe that a few caring people can’t change the world. For indeed, that’s all who ever have”. Green Home embodies this spirit, proving that sustainable choices can drive meaningful change. The inspiration behind the founding of the business was straightforward yet profound: if better packaging exists, then it must be used. The founder’s first encounter with compostable food packaging has created a world of possibilities, highlighting the urgent need to move away from non-renewable, petroleum-based single-use plastics. This realisation sparked a passion to explore and develop ecofriendly packaging solutions.

At the heart of Green Home’s mission are two core values:

1. all products are made from plants

2. all products are compostable after use. Its commitment to sustainability is reflected in Green Home’s extensive range of takeaway food packaging, which includes hot cups, clear cold cups, sugarcane takeaway containers, Kraft food containers, cutlery, bamboo cocktail accessories, serviettes, and more. Each product is designed to minimise environmental impact while providing practical solutions for the catering industry.

Green Home’s products are certified compostable, meaning they break down into healthy compost, creating a closed-loop system. This process transforms plant-based packaging into nutrient-rich soil, which in turn supports healthy plant growth. Additionally, Green Home is a founding member of the Organics Recycling Association of South Africa, an organisation dedicated to promoting and expanding the country’s composting and organic recycling market. Together, they are working towards a future with zero organic waste to landfill. •

Connect with Green Home online

The secret to shelf-ready perfection

Discover the transformative power of Industry 4.0 in producing shelf-ready packaging, the ‘silent salesperson’ in retail, blending functionality, aesthetics and sustainability.

We take it for granted in the shops, but shelf-ready packaging has so many features and capabilities – all of which must be balanced to deliver the best possible outcomes for suppliers, machine builders, producers, vendors and, of course, consumers.

Did you know?

Cama is an OEM partner for Rockwell Automation, so control-level familiarity in North America is never a problem.

Packaging equipment specialists need to combine functionality, aesthetics and sustainability, bundling them into a concept that delivers ease of packaging, ease of disassembly/unpackaging, maximised visual appeal, brand championing and optimum sustainability. It’s a scientific test, an engineering project, art form, study of materials and a marketing exercise rolled into one.

A recipe for success

But what makes good shelf-ready packaging? It’s not just what you see on the shelf, but also the machine builder’s domain expertise and packaging design capabilities, coupled with multiple styles of advanced packaging technologies, all of which must be bought together under a holistic viewpoint of the entire product and packaging lifecycle.

Indeed, the developmental process is not simply ‘start to end’. Instead, packaging designers and machine suppliers must look up and down the value chain to ensure that all stages and functions are fulfilled in the best way possible. A feature or choice at one stage can affect another much further down the line, so all possibilities need to be considered. This development process is never a straight line.

Cama’s packaging-design team is recognised globally for its innovative, eye-catching and functional ideas. A free service – which is part of the full capabilities package – has helped some customers reinvent their marketing concepts and while saving other customers tonnes on materials and costs, ultimately delivering stronger packaging that weighs less than its former format.

Always keep the end in mind

Right from outset, you need to consider the end. With sustainability and reduced materials use high on the agenda, you need to keep

an eye on the end of life of any packaging you create. Will it be reused or recycled? This immediately defines the scope for the material selection, not just in terms of type, but also the amount.

The next step is to consider the product being packaged. What shape is it, what is it made of, is it fragile, does it have any unique requirements, how should it be presented? Any one of these points can have a profound impact on the packaging design and type of packaging technology deployed. For this reason, you should consider suppliers that offer a broad range of packaging formats, and not just variations on a theme, which you may have to license.

Machine capabilities are paramount

You need to factor in machine capabilities too. Some products, counts, presentations and packaging styles are suited to top loading, and others to side loading. You must also think about multi-flavour packages – with multiple infeeds – or even bypassing, for bulk packaging and buffering.

Look for a supplier that offers a wide range of technologies, machines and styles, otherwise you will find them trying to adapt you to their limited array of machines and capabilities, rather than the supplier adapting its machines to your specific products and precise packaging needs.

Next you need to look at how the packaging is palletised. Does it offer the best possible layer count? How does it nest together? What sort of weight can it handle? How many layers can you add without damaging the lower levels? Does it need to be displayed on the pallet? As well as greater efficiency, this talks to sustainability, as more boxes per pallet result in lower logistics and fuel costs per product.

When it hits retailers, how easy to use are the tear-offs and have they been designed to tear off cleanly without damaging the rest of the box? In a retail setting time is money. Having to wrestle with poorly designed boxes that aren’t fit for purpose is problematic and retailers are likely to make their annoyances and challenges with your packaging heard.

World-class tech and hardware

The holistic viewpoint mentioned earlier doesn’t just encompass the packaging element of the

“You should consider suppliers that offer a broad range of packaging formats, and not just variations on a theme”

project, it must also consider the current operational and business landscape, where operational data and connectivity are an absolute necessity.

Cama is a world leader in the deployment of Industry 4.0 technology, with its capabilities split into five primary pillars:

1. Digital twin and simulation, virtual commissioning.

2. Digital twin and augmented reality

3. Smart devices, connected machines and system integration

4. Edge computing, data analysis and connectivity

5. Machinery predictive maintenance

Cama’s machines also excel from a hardware standpoint. Its Breakthrough Generation (BTG) concept is setting the standard in secondary packaging, with machines that deliver modular, scalable frameworks that offer easy entry and access, coupled to a hygienic machine design. Within this framework, contemporary automation solutions, including advanced rotary and linear servo technology, are tightly coupled to in-house-developed robotics to deliver the allimportant flexibility and adaptability required by modern packaging operations.

Shelf-ready packaging goes beyond simply housing and protecting a product; it’s a strategic tool that can significantly impact sales and brand perception. This is why it makes sense to employ the best possible people, knowledge, tools and machines for the job; and nowhere is this combination in better supply than at the Cama Group. •

USS Pactech is the local agent of Cama Group.

Connect with Cama Group online:

Go with the float!

EcoFloat White enables the move from white HDPE packaging to transparent PET bottles and containers and combining it with a white, opaque sleeve. The low-density sleeve material supports floatation separation from PET during the recycling process.

CCL Label, a world leader in specialty label, security and packaging solutions, has launched a new version of its established EcoFloat low density polyolefin sleeve material, EcoFloat White.

Guenther Birkner, member of the management team at CCL, comments: “EcoFloat White will enable larger recyclability for dairy packaging – we expect it to be a gamechanger. The dairy industry often utilises HDPE bottles for yoghurt and probiotic drinks packaging or the packaging of similar products. Yet these white HDPE bottles are rarely recycled back into food grade applications for several reasons, including strict food contact regulations. Ultimately, the bottles leave the packaging loop.

“We have seen a large trend to move away from HDPE, in favour of PET, which works well in terms of recycled content for food packaging. We are looking to support this trend with a functional product decoration.”

Closing the loop on milk bottles

“Legislation like the European Green Deal and the Packaging and Packaging Waste Regulation will drive ‘design for recycling’ or eco-design in the coming years. Every industry must develop packaging that is actually recyclable,” explains Marika Knorr, head of sustainability and communication at CCL Label. “Until now, many white HDPE bottles have left the closed loop for food grade packaging and are lost for re-use in a circular sense. By using PET bottles with a white sleeve, dairy brands and

“By using PET bottles with a white sleeve, dairy brands and manufacturers can achieve two benefits at once”

manufacturers can achieve two benefits at once. The whole bottle is fully recyclable, and it is possible to achieve the same look and feel that marketing desires – maximising the messaging and on-pack information provided to consumers. Millions of additional PET bottles will be recycled and turned into a new bottle – giving new life to the packaging.”

Enhanced barrier protection with carbon-free inks

One vital aspect of packaging for dairy products is the light blocking property to keep contents fresh and to maximise shelf life. In the past, the light blocking barrier was often achieved using a layer of black or silver ink. Although this protected the product contents it could be detrimental to sorting and recycling process because the standard near infrared detection system commonly used would have difficulties detecting the underlying material.

“As 80% of recycling is sorting, we needed to make sure that our solution is detectable by standard technology used today in the recycling industry,” says Norbert Fenkart, who heads up the R&D department in CCL’s sustainable sleeve label hub in Dornbirn, Austria. “We use carbon-free inks to

create additional light blocking properties on the sleeve. These work well in NIR detection* where the underlying rigid PET bottle can be spotted and the bottle sorted into the right waste stream.”

The sleeve is also conducive to the crucial sink/float process step in PET recycling because it is made of a low-density polyolefin material that floats. It detaches automatically from the PET bottle flakes and the density separation is seamless and clean – the heavier PET flakes sink to the bottom of the vessel while the floatable material gathers at the top of the vessel and can be easily captured and removed. The recycler is then left with high-quality, clean PET flakes that can be recycled back into food grade packaging, not only for dairy but also other industries. •

*Tests were carried out at the renowned sorting and recycling expert, Interzero

Connect with CCL Label online

MEET OUR PREMIUM & SUSTAINABLE LABELS

Optimised quality control in pharma packaging

As a leading global manufacturer of packaging solutions made from cardboard and paper, the Edelmann Group continuously strives for process optimisation along the entire supply chain. It recently upgraded its EyeC Proofiler 1067 CS to the newer EyeC Proofiler 1050 RS to augment its quality management system.

Since 2023, the Edelmann Group has been using the EyeC Proofiler 1050 RS offline inspection system. It effectively checks the quality of all types of printed products against the original artwork

In 2022, the Edelmann Group, headquartered in Heidenheim, Brenz, Baden-Württemberg, merged its production sites in Wuppertal and Leverkusen into a new site in Burscheid. The new production site focuses on the production of sustainable packaging solutions made from cardboard and paper – such as folding boxes and package inserts – particularly for the pharmaceutical industry.

To meet the increasing demands for individual and high-quality packaging solutions and package inserts, the group’s existing quality management system needed to be developed to accommodate the merger.

It was a challenge to combine the existing testing process while introducing a suitable inspection system for print image control which considers different artworks and printing materials with a grammage ranging from 37g/m² to 450g/m² as part of the quality control process. The aim was to further optimise the testing processes by using a suitable inspection solution. Particular attention was paid to materials with a low material thickness.

The search for an innovative solution

Although Edelmann was already using the EyeC Proofiler 1067 CS for incoming goods inspection, the group decided to upgrade. Working closely with the EyeC sales team, the

previously used pull-through scanner was ultimately replaced by its successor model, the EyeC Proofiler 1050 RS. This model impressed the group with its significantly improved precision and higher performance.

The new system was subjected to validation within the framework of internal and external requirements. The EyeC Proofiler 1050 RS was qualified using DQ, IQ, and OQ, with the validation also taking into account the requirements of 21 CFR part 11 and the Editio Cantor error evaluation list for secondary packaging.

Patrick Herminghaus, quality assurance at the Edelmann Group, emphasises: “On the one hand, the solutions offered by EyeC meet the sometimes-complex market requirements for the pharmaceutical packaging printing industry. On the other hand, EyeC’s support and services have been at a consistently high level for many years. Based on this knowledge and our own positive experiences, we made the decision to continue our cooperation with EyeC and continue to rely on their solutions.”

Improving quality control

In 2023, the EyeC Proofiler 1050 RS was successfully implemented in the quality control testing processes. Since then, the off-line inspection system has been checking the quality of all types of printed products against the print template.

The intelligent algorithm of the robust pull-through scanner compensates for typical fluctuations in the printing process and only shows relevant deviations. The comprehensive inspection of printed products such as printed sheets and package inserts against approved PDF templates enables the Edelmann Group to carry out efficient evaluations, shows precise results and helps ensure the conformity of the printed product.

Thought through to phenomenal results

Overall, the Edelmann Group was able to optimise its quality control with the EyeC Proofiler 1050 RS, increasing the efficiency of its work processes. The group has been successfully using the EyeC Proofiler 1050 RS in its quality control for a year now and has already been able to reduce the risk of incorrect classifications and inspection times.

With this system, the evaluation of printed products can be carried out promptly by sampling the proof against the approved print file. Its implementation has also

capabilities of the new system make it an ideal solution for quality control in the pharmaceutical industry.”

A partnership with future prospects

Due to the positive experiences and results achieved, the partnership between the Edelmann Group and EyeC will continue into the future. Joint opportunities will be explored in more detail to implement value-adding potential for Edelmann’s customers while offering the group increased efficiencies and quality improvements. •

“The EyeC Proofiler 1050 ensures a high level of product safety along the entire process chain”

significantly improved scanning and evaluation times and greatly reduced the number of pseudo-suspicious areas in print image inspection.

With the early detection of printing errors, it is possible to minimise potential costs on a large scale. By enabling the standardised inspection of printed sheets, regardless of the thickness of the printing material, the EyeC Proofiler 1050 ensures a high level of product safety along the entire process chain.

Herminghaus adds: “The introduction of the new EyeC Proofiler RS in Burscheid was crucial for the Edelmann Group to continue to deliver high-quality packaging solutions to the pharmaceutical industry using optimal and high-performance systems. The precise print inspection and extensive

EyeC Proofiler 1050 RS

Leading a revolution from collection to creation

Foster International Packaging, now with a new name and global reach, marking a new chapter in its journey to providing high-performance and sustainable packaging solutions.

In a world where sustainability and innovation are more crucial than ever, Foster International Packaging is proud to announce a significant milestone in the company’s history. Since 1 July 2024, the company has been trading under the Close the Loop brand. This rebranding effort is part of a broader initiative within the global group, which has been expanding and aligning operations under a unified identity.

THE EVOLUTION OF FOSTER PACKAGING

Founded in March 1998, Foster International Packaging has a long history of delivering exceptional packaging solutions tailored to the unique needs of its clients. Over the years, the company has built a reputation for not only meeting but exceeding customers’ expectations, with a strong focus on quality, innovation and a growing commitment to sustainability. The business takes pride in creating lasting relationships with its clients, which has been integral to its success.

Foster International Packaging’s commitment to these values has positioned it as a leader in South Africa’s flexible packaging industry, providing cutting-edge solutions to a diverse range of industries.

INTRODUCING CLOSE THE LOOP

Foster International Packaging’s Australian sister company, O F Packaging, merged with Close the Loop in December 2021 to form Close the Loop Limited. Since then, the group has grown to include 16 different divisions and brands, including Foster International Packaging. The merger also brought

together expertise in packaging and resource recovery/ recycling. With locations across the United States, Australia, South Africa and Europe, the group collects and repurposes products through takeback programmes and provides sustainable and high-performance packaging, which emphasise greater use, recoverability and recyclability.

As the group expanded, it became evident that streamlining its brands and divisions was essential for maintaining consistent messaging under a unified global brand. Establishing a single, cohesive brand was crucial for integrating the diverse locations of the business, to leverage resources across divisions and strengthen the group’s market position.

In 2023, the group began the process of aligning all operations under the Close the Loop brand, and on 1 July 2024, it officially transitioned to trading under the name, Close the Loop. The updated brand you will begin to see in the market embodies the bold and passionate energy that defines Close the Loop. It has been designed to represent the journey of the business to this point and provides an outlook on its exciting future.

The group’s CEO, Joe Foster states: “Close the Loop is not just a new brand - it’s a philosophy and a strategy to streamline our operations and present a unified front to customers, partners, investors and our dedicated team. The work we do to create better packaging products for brand owners while collecting, sorting and recycling difficult product streams may be messy and complex, but our ethos is simple - ’our name is our missionʼ.”

NEW LOOK, SAME BUSINESS

Close the Loop aims to continue the great work it is already achieving in the industries it serves while expanding its sustainability-focused offerings to develop even greater pathways for clients towards a circular economy and closed-loop material chain. The loop symbol of the new brand represents the two key segments in which the company operates, with one side depicting collection and the other creation.

The colours of the new brand are characteristic of the history of the individual businesses while linking to the environment and innovation, symbolising the ongoing evolution of the business and the people within it. All businesses that are part of Close the Loop, including Foster International Packaging, have transitioned to the new Close the Loop brand - with a reinvigorated drive for continual evolution, innovation and growth.

For more information about the rebranding, visit the group website: https://closetheloop.com. •

“Close the Loop is not just a new brand – it’s a philosophy and a strategy to streamline our operations and present a unified front”

Convert to environmentally friendly packaging

KHS has produced a universal adhesive that can be used on practically all outer coatings on aluminium and tin cans. This major development applies to the company’s Nature MultiPack.

Although the universal adhesive innovation may seem like a minor adjustment, it actually constitutes a major development to produce increasingly reliable, future-proof technology for the KHS Nature MultiPack.

The innovation makes it easier for beverage producers to convert to the environmentally friendly style of packaging. Since the system has been successfully established on the market, adhesive demands have increased continuously. The Dortmund systems supplier has answered the call and now enables customers to create appropriate packs with its new one-fits-all solution for beverage cans, while also helping them achieve their sustainability targets.

Finding the right solution

When it comes to circular packaging, KHS helps customers by providing specific advice and developing and implementing environmentally friendly and circular systems, such as its Nature MultiPack. As one of the most sustainable types of secondary packaging, this future-proof technology does away with it completely by holding six beverage cans together with just a few dots of adhesive.

For the innovation to be successful, the KHS team had to find the right adhesive – which was relatively

challenging. Numerous advanced tests were done to determine the ideal amount of adhesive needed to create the perfect balance between high pack stability and easy-to-remove beverage cans. They also had to take into consideration the various coatings can manufacturers use on their containers. There’s a huge variety of can lacquers, running into several hundred worldwide. They often have highly diverse surface properties, from matte to glossy. The discrepancies in chemical and physical properties such as roughness are also enormous.

Universal adhesive eliminates elaborate testing

These dissimilarities affect the effectiveness of the adhesive which is why elaborate testing was initially

“The innovation makes it easier for beverage producers to convert to the environmentally friendly style of packaging”

Images: KHS Group / Reinhold Images

KHS has developed a universal adhesive for its Nature MultiPack which can be used on practically all outer can coatings. This makes it easier for beverage producers to convert to its environmentally friendly style of packaging

Continues next page

“With our further developed adhesive we provide a flexible and cost-efficient solution that meets our customers’ ambitious sustainability targets. Thanks to this resourcesaving technology, it will ultimately score with consumers,” says Dr Matthias Caninenberg, head of Nature MultiPack Technology at KHS

required at the KHS laboratory. For canners interested in the technology, the procedure was very time-consuming. In developing a universally applicable adhesive for practically all outer can lacquers used worldwide, KHS has eliminated the need for elaborate testing.

The new consumable satisfies stringent requirements to ensure stability during transportation, among other things. For this to be realised, the adhesive had to prove its worth on a laboratory scale and in industrial application. The goal of producing a universal adhesive that works on practically all coatings was again exceeded. During qualification and practical application in industrial production, it was shown that the exacting requirements were met.

An accessible eco-friendly technology

The implemented one-fits-all solution enables beverage producers to form the perfect NMP from all standard formats and sizes. Matte and glossy containers can be processed without the need for complex adhesive changeovers. Another benefit is that customers must no longer keep to a given selection of surface lacquers. This makes pack production more flexible and efficient, which

More about our passion for technology motif

KHS’ new advertising motif highlights the company’s passion for technology. KHS puts its heart and soul into developing reliable, future-proof filling and packaging systems – and this is exactly what its current advertising motif ‘passion for technology’ aims to reflect.

The advertising shows a heart made entirely of KHS machine parts. The characteristic parts of a filler are prominent in the design, with the reference to filling equipment and KHS immediately apparent.

The KHS passion for technology slogan rounds off the design and again underlines its objective.

in turn has a positive impact on the supply chain. When removing the need to keep predefined lacquers in stock, costs are reduced and the production process is simplified immensely. Ultimately, KHS has eliminated any barriers to investing in its standardised, environmentally friendly technology.

Connect with KHS online

The KHS Innopack Kisters Nature MultiPack packaging machine is available in a version that outputs up to

per hour and in a high-capacity variant produces a maximum of 90 000 containers per hour.

Bringing global print solutions to Southern Africa

Driven by the profitability of its customers, NSI Label imports, sells and supports digital printing and finishing equipment, software and services to the label and packaging industry of Southern Africa.

NSI Label’s management team has a collective experience of importing and supplying the South African market with specialised manufacturing equipment of over 40 years. Together with its trade partners in Brazil, Japan, China, Taiwan, Germany, Korea and the USA, the business has been able to bring to market innovative, superior manufacturing equipment, usually at highly attractive prices.

Its range of products cater to diverse markets and requirements, from equipment for print users to print resellers looking for either roll-to-roll or sheet-fed applications. Its SMART equipment incorporates CCD camera scanning technology coupled with AI assistance to improve production efficiency and reduce common costs associated with job changeovers.

An award-winning supplier

NSI Label was recently awarded back-to-back African Excellence Awards for the Best Digital Printing Solutions Company in South Africa and for exceptional installations of digital label and packaging systems across Southern Africa. The business is one of a few suppliers that understands that its success is directly linked to the successful implementation and support of the systems it represents and sells.

“We prioritise customer efficiency both in the operation of the equipment, accurate costing and technical problem solving,” says Shawn Bezuidenhout, NSI Label’s managing director. “We not only offer operator training, but also industry advice based on our experience. We understand that many of our customers are not familiar with the label and packaging function, and it is our responsibility to empower them with knowledge to ensure they can continue to focus on their core business. This is because digitally produced packaging should be a complement to their product offering and not a distraction.”

NSI Label’s secret lies in dealing directly with the equipment manufacturers and maintaining a tangible, personal relationship with them. Representatives from the business visit the manufacturing plants and consult with production and design engineers on a regular basis.

“We do not envisage that we can offer quality products and services to our clients while merely maintaining vague virtual relationships with suppliers,” Shawn adds.

“NSI Label was recently awarded back-to-back African Excellence Awards”

Competitive, quality solutions for Africa

People often don’t realise that many top European and American equipment brands are manufactured in Asia. NSI Label’s direct relationships with these manufacturers means that the business can regularly offer South Africans machines that are manufactured in the same factories as well-known global brands by the same team of production engineers, yet at a fraction of the cost of the known brand.

He explains: “We personally visit the production facilities of our manufacturers, and we regularly attend leading international trade exhibitions to ensure that we remain abreast of world trends and cutting-edge technologies.”

The NSI Label head office is based in Midrand, Gauteng, and the team is available throughout Sub-Saharan Africa for onsite technical support for its equipment.

While the company is making great strides in the market offering competitive equipment prices and production costs for its clients, NSI Label’s primary focus remains service delivery.

“We are one of the only local distribution companies that sends our senior technical staff abroad to be trained onsite at manufacturing facilities to ensure the best possible local technical support for our valued customers,” says Shawn. •

Driving economical change in beauty product labelling

In the dynamic world of beauty and personal care, 2024 marks a significant shift towards products that not only enhance personal well-being but also align with global sustainability goals. According to Mintel’s recent Global Beauty and Personal Care Trends Report, consumers are increasingly drawn to minimalist packaging that reflects transparency, quality, and eco-consciousness.

Sophisticated simplicity is one trend that stands out in 2024 as customers demand functional, highquality products with packaging that reflects brand values, transparently lists ingredients, and prioritises sustainable practices.

In South Africa, there is a notable trend towards more economical beauty products with the demand for highend cosmetics slowing down. Grant Watson of Rotolabel observes a change in consumer preferences amidst challenging economic climates, highlighting a strategic pivot in product offerings and market strategies.

“When times are tough, consumers may either opt to downgrade their purchases or reduce product usage, posing potential risks to category growth,” he explains.

To drive innovation, the role of the brand manager has become more important than ever, emphasising the need for labels that aren’t only aesthetically pleasing but also environmentally friendly. Labels are also crucial to secure beauty products and combat counterfeiting – a significant concern in the industry.

Advanced labelling solutions for beauty products

Rotolabel is committed to excellence and customer satisfaction. The self-adhesive label supplier, based in

Image/Client

“Rotolabel’s extensive repertoire of label finishing options extends beyond foiling to include embossing and debossing, silk screening and personalisation,” he adds. “This diversity of finishing techniques caters to the varying needs and preferences of the cosmetics industry, allowing for differentiation and customisation in a competitive market landscape.”

With a variety of label substrates that can be tailored to different applications, Rotolabel helps customers ensure their brands are compatible and their products durable enough to be used in diverse environments.

Equipped to meet rigorous industry standards

Quality assurance and traceability are also of paramount importance in the cosmetics industry. As a label converter, Rotolabel is distinguished by its robust infrastructure and steadfast commitment to quality. The company has implemented 100% quality inspection systems to ensure meticulous attention to detail, and its certifications attest to the team’s adherence to rigorous quality control measures, facilitating complete traceability.

“Rotolabel’s extensive repertoire of label finishing options extends beyond foiling to include embossing and debossing, silk screening and personalisation”

“Quality and traceability are crucial requirements, particularly among multinational brands,” says Watson. The label converter’s project-centric approach effectively meets customers’ diverse needs while its extensive printing capabilities, the expertise of its skilled and experienced account managers and its state-of-the-art infrastructure, enable Rotolabel to consistently deliver premium-quality labels. Ultimately, the company’s value lies in its ability to serve as a strategic and collaborative partner, which enhances a product’s shelf presence and maximises a brand’s impact. It’s the label that captures consumers’ attention and communicates brand identity, making it a pivotal component of product presentation and marketing strategy. •

Connect with Rotolabel online

Eco-friendly innovation for sensitive materials

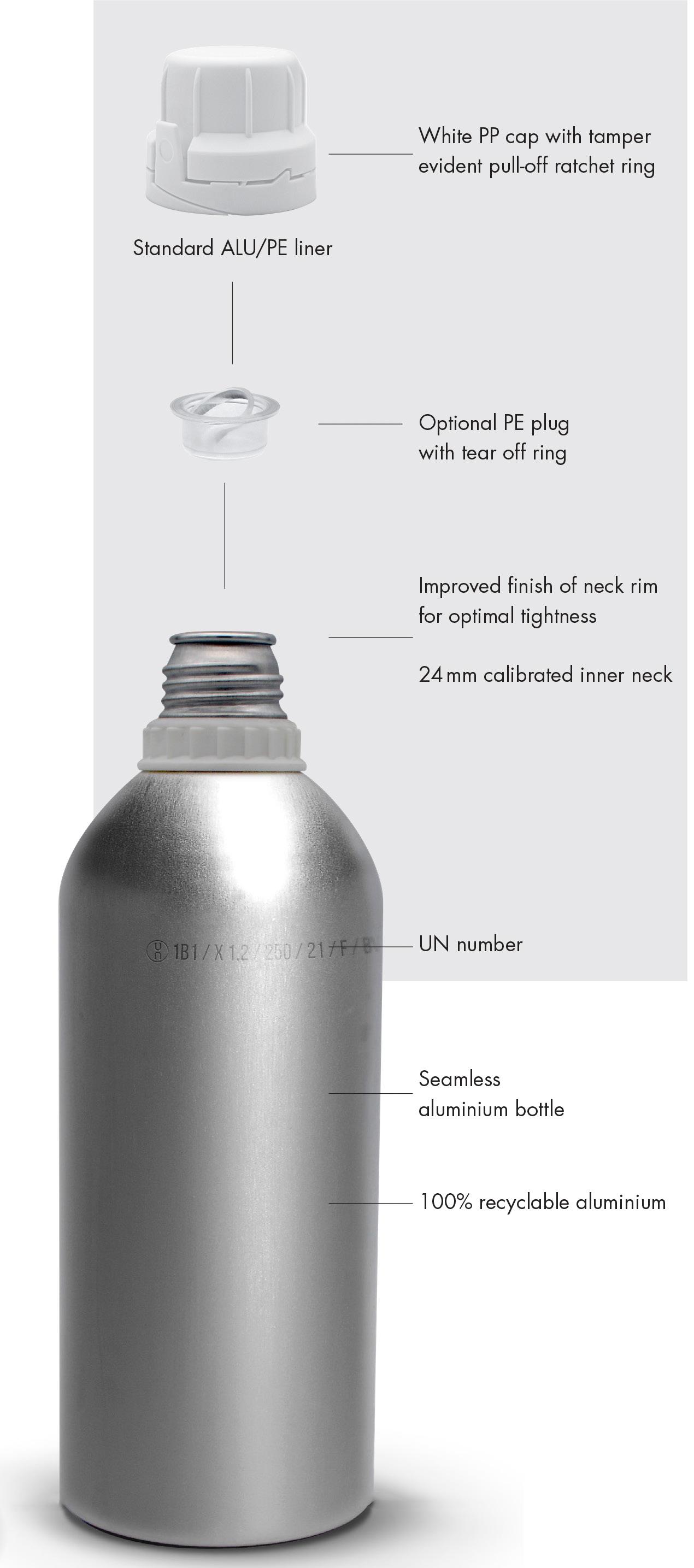

The future of technical packaging lies in solutions that combine performance and environmental respect. Tournaire, with its Omni Plus range, is at the forefront of this evolution, bringing packaging for the most sensitive materials closer to carbon neutrality.

The technical constraints associated with packaging hazardous materials have become more rigorous, and yet environmental requirements are sometimes relaxed. It may be more prudent to opt for packaging with a less controlled carbon footprint, but which ensures better protection of the environment against the hazardous materials within the packaging, rather than non-polluting packaging, which could pose the risk of these substances contaminating the environment.

Although requirements may be slightly more flexible, the main goal remains to protect the environment from hazardous materials and to protect these materials from the environment, while controlling the carbon footprint of the packaging solution. Tournaire ensures that its packaging, approved for the transport of hazardous materials, meets essential safety standards while controlling the environmental impact of its solutions, as evidenced with the innovative Omni Plus range.

High-performance and eco-friendly

Available in South Africa from Sensetek, Tournaire’s Omni Plus range embodies the excellence of sustainable and highperformance packaging. This range is carefully designed using pure aluminum, which meets modern requirements for weight reduction and material minimisation.

The Omni Plus benefits

• Outstanding cleanliness to better preserve your products.

• Larger aperture for easier filling, pouring and 100% emptying.

• User friendly capping and tamper evident ring.

• 100% recyclable aluminium thanks to the removable ring.

• Improved brand identification and anticounterfeiting options.

the need for overwrapping in most cases, reducing the ecological cost of manufacturing. True to its ecological commitment, there is a continued effort to reduce the weight of the range while maintaining its robustness, notably with a 7% reduction in the total weight of the most sold solution compared to its Système Plus equivalent. Aluminum, the central material of Omni Plus, allows for energy-efficient transformation, minimising the ecological footprint of its production. Moreover, the reduction in the number of components used in the packaging solution and their easy separation simplifies the recycling process, contributing to an efficient circular economy.

The design of Omni Plus cans also facilitates their recycling. The separation between plastic and aluminum components optimises the recycling process, reducing environmental

“The Omni Plus range represents an innovative and sustainable response to the challenges posed by technical packaging”

The Omni Plus range represents an innovative and sustainable response to the challenges posed by technical packaging. By reducing packaging weight, enabling reuse and facilitating recycling, Tournaire strives to protect the environment while meeting the strict safety and performance requirements of its customers.

This pioneering and proactive approach places Tournaire at the forefront of modern packaging solutions, proving its unwavering commitment to excellence and sustainability.

Tournaire continues to anticipate its clients’ future needs, offering solutions that combine safety, performance and respect for the environment.

The Omni Plus range is a testament to this vision, marking a significant milestone in the history of industrial technical packaging and confirming Tournaire as a leading player in this field.

Thanks to the Omni Plus range from Tournaire, Sensetek can offer sustainable and highperformance packaging to the South African market. With the lightness, flexibility and infinite recyclability of aluminium, Sensetek offers packaging solutions that not only reduce the carbon footprint but also ensure optimal safety for the most sensitive and hazardous materials. . •

Safeguard quality and safety by preventing cross packing

In the fast-paced world of food and beverage manufacturing, where efficiency and productivity are critical, maintaining quality and ensuring product safety should be top priorities. Cross-packing is a defect that can have serious implications for consumers and manufacturers.

Cross-packing happens when items meant for one package are mistakenly packed into another from primary (sachet) to secondary (carton) to tertiary (boxes) right through to palletising. This mistake can cause several issues, such as:

• Product recalls – incorrectly packed products may need to be recalled, which is costly and time-consuming.

• Customer dissatisfaction – receiving the wrong items can lead to frustration and loss of trust in the brand.

• Legal issues – mispacked products can result in legal complications, especially if they violate regulations or cause harm.

Ensuring accurate packaging is crucial to avoid these problems and maintain a positive brand reputation.

The dangers of cross packing

Cross-packing may seem like a simple mix-up or error in the end-to-end supply chain, but its impact can be far-reaching. Listed below are several consequences of cross-packing: Incorrect product claims – when the wrong product is labelled and marketed as another, consumers can be misled, leading to potential harm or dissatisfaction.

• Undeclared allergens – cross-packing can result in the wrong allergen information on packaging, posing serious health risks to consumers with specific dietary requirements or allergies.

• Consumer confusion and dissatisfaction – receiving a different product from what was expected can lead

to confusion, frustration, and a loss of confidence in the brand.

• Damage to brand reputation – cross-packing incidents can tarnish a brand’s image and erode consumer trust, impacting sales and long-term success.

• Product recall/withdrawal from trade – if cross-packing issues are identified post-distribution, costly recalls

or withdrawals from the market may be necessary to prevent further harm or legal consequences.

• Regulatory sanctions – non-compliance with product safety regulations set forth by organisations such as SON and NAFDAC can result in severe penalties and legal action.

• Reduced sales opportunities – negative publicity surrounding cross-packing incidents can deter potential customers, reducing sales and creating missed opportunities.

Solutions to prevent cross-packing

Food and beverage manufacturers work hard to avoid labelling mistakes, which can harm their brand or lead to costly recalls and legal issues. Cross-packing, where products are incorrectly packaged together, is a common problem that can pose serious health risks and legal challenges. Part of the packaging validation process to prevent this involves reading barcodes or alphanumeric values to ensure all packaging components match correctly. TracePack offers innovative solutions to prevent cross-packing, ensuring the safety and quality of your products.

Advanced production monitoring systems

TracePack’s advanced production monitoring systems are designed to prevent cross-packing. They monitor the production line in real time, ensuring that the right products go into the right packages. If a discrepancy is detected, the system alerts the operator and stops the line, preventing cross-packing.

Quality control and assurance

Quality control and assurance are crucial in preventing cross-packing. TracePack’s systems include rigorous quality checks at every stage of the production process. This includes checking the product before packaging, ensuring the correct labelling, and verifying the final product before it leaves the factory.

Eliminate food and beverage packaging errors

Food and beverage manufacturers take great measures to avoid labelling mix-ups that, at best, damage brand reputation and, at worst, can lead to expensive recalls and

liability. Many companies print and scan 1D and 2D barcodes or text on items to ensure they are labelled accurately and advertise the correct contents. Part of the packaging validation process is to read these barcodes or alphanumeric values to verify that multi-part packaging components, like a top lid and bottom container, match.

Automated inspection technology for frozen pizza sorting and inspection automates quality control by confirming pizza types, verifying ingredient presence, and detecting contaminants. This ensures high standards and minimises waste in a competitive market. Conventional machine vision struggles with the variability in pizza appearance and defects, while AI-enabled technology improves inspection accuracy. TracePack’s deep learning tools can count overlapping toppings, identify acceptable variations and reject non-compliant pizzas.