HARDWOOD MATTERS THE VOICE OF THE HARDWOOD INDUSTRY November 2022 THE OFFICIAL PUBLICATION OF THE NATIONAL HARDWOOD LUMBER ASSOCIATION STRONG ROOTS. GLOBAL REACH. | WWW.NHLA.COM ALLIED ANGLE ENGAGE YOUR POLITICAL MUSCLE plus Converting Social Media Into Sales

Happy National Manufacturing Day! Thank you to those who produce goods and services within the hardwood lumber industry—doors, cabinets, flooring, furniture, lumber, ties, staves, cants, moulding, and more. You are innovative, resilient, and incredibly important to our economy. Thank you for all you do!

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 1 CONTENTS November 2022 • Issue 239 feature 14 Converting Social Media Into Sales by Amanda Boutwell departments 6 One Common Ground Trees are the Answer by Dallin Brooks Executive Director 8 Allied Angle AHUG-Promoting Pennsylvania Hardwoods For More Than 35 Years by Amy Shields Executive Director of Allegheny Hardwood Utilization Group 10 Legislative Log Engage Your Political Muscle! Your Voice Matters by Dana Cole Executive Director Hardwood Federation 12 Member Spotlight Bid Group Technologies 20 Rules Corner Pith - Boxed or Showing by Dana Spessert Chief Inspector WHAT'S INSIDE

ONLINE Follow us 10 20 14 TOP POST OF THE MONTH at facebook.com/NHLAOfficial reader services 4 Chairman’s Message 22 NHLA Job Board 24 Educational Calendar 26 Market Trends

HARDWOOD MATTERS

THE VOICE OF THE HARDWOOD INDUSTRY

National Hardwood Lumber Association PO Box 34518 • Memphis, TN 38184-0518 901-377-1818 • 901-382-6419 (fax) info@nhla.com • www.nhla.com

THE MISSION OF NHLA

To serve NHLA Members engaged in the commerce of North American hardwood lumber by: maintaining order, structure and ethics in the changing global hardwood marketplace; providing unique member services; promoting North American hardwood lumber and advocating the interest of the hardwood community in public/private policy issues; and providing a platform for networking opportunities.

EXECUTIVE COMMITTEE

Jon Syre Cascade Hardwood, LLC Chairman

Bucky Pescaglia

Missouri-Pacific Lumber Co., Inc.

Vice Chairman

Jeff Wirkkala

Hardwood Industries, Inc.

Past Chairman 2020-2022

NHLA STAFF

Dallin Brooks

Executive Director

Amanda Boutwell

Marketing and Communications Manager

Julia Ganey

Member Relations Manager

John Hester Director of Membership and Business Development

Renee Hornsby

Director of Marketing & Communications

Jens Lodholm

Data Administration Specialist

Roman Matyushchenko

ITS Instructor and Associate Dean of Education

Carol McElya

Education Services Project Manager

For advertising contact:

John Hester, Director of Membership and Business Development at j.hester@nhla.com or 901-399-7558 or Vicky Simms, Membership Development Manager at v.simms@nhla.com or 901-399-7557

Amber Signaigo Controller

Vicky Quiñones Simms

Membership Development Manager

Melissa Ellis Smith

Graphic Designer

Dana Spessert

Chief Inspector

MISSION LEADERS

Sam Glidden

GMC Hardwoods, Inc.

Unique Services

Ray White

Harold White Lumber Inc.

Rules

Joe Pryor Oaks Unlimited Industry Advocacy & Promotion

Rich Solano

Pike Lumber Company, Inc.

Structure

Stephanie VanDystadt

DV Hardwoods, Inc.

Membership & Networking

COMMITTEE CHAIRS

Burt Craig Matson Lumber Company

Membership

Rob Cabral

Upper Canada Forest Products, Ltd.

Promotion & Advocacy

Dennis Mann

Baillie Lumber Co. Convention

Tom Oiler

Cole Hardwood, Inc.

Inspection Services

Brant Forcey

Forcey Lumber

ITS/Continuing Education

George Swaner

Swaner Hardwood

Communications & Marketing

Joe Snyder

Fitzpatrick & Weller, Inc.

Rules

2 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM

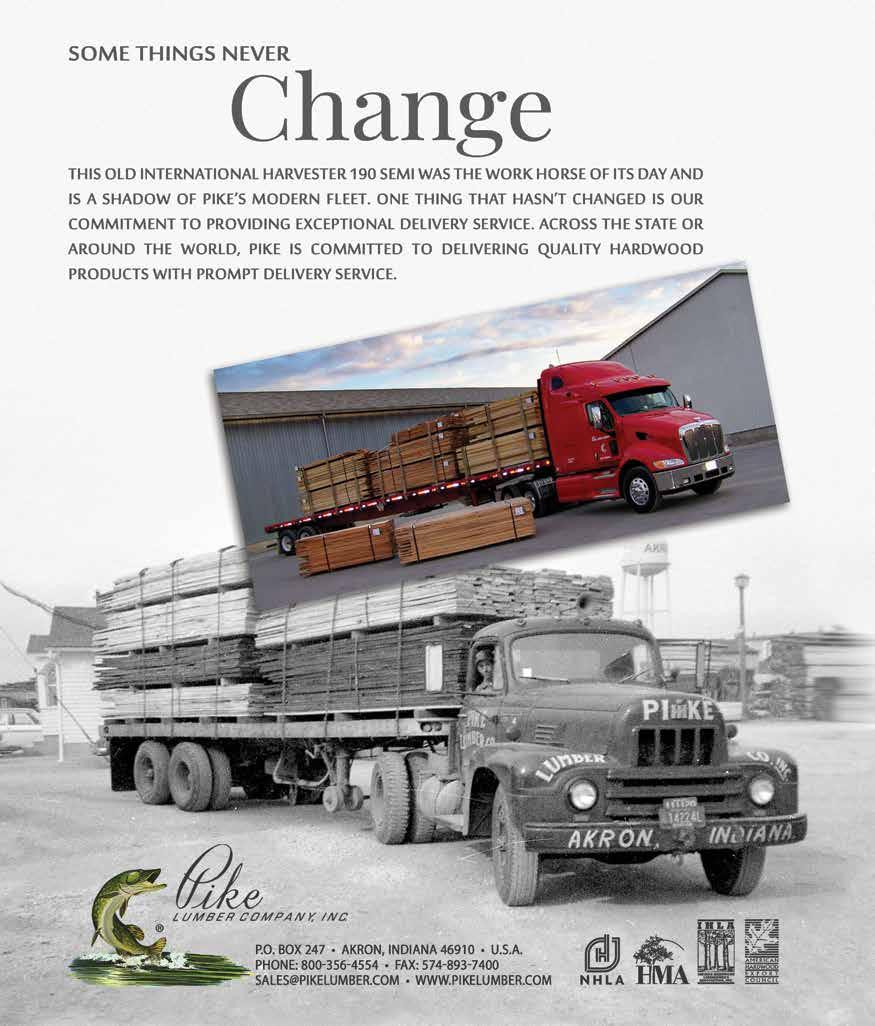

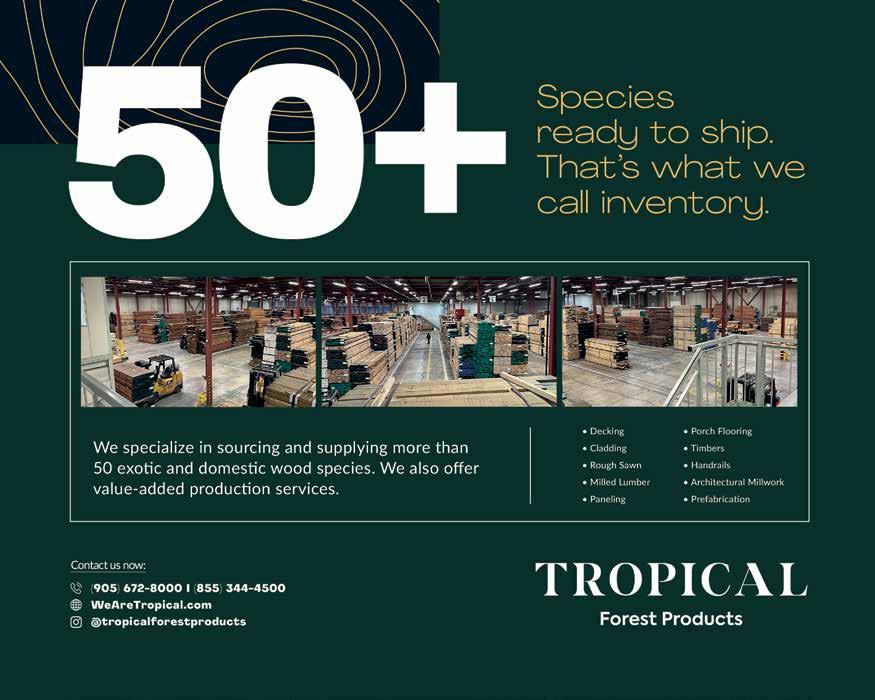

INDEX IFC DMSi/eLimbs/TallyExpress 3 King City Forwarding USA IBC Pike Lumber Company, Inc. BC Tropical Forest Products 21 USNR 7 Wood-Mizer

ADVERTISER

EMBRACE CHANGE

In my relatively short time in the sawmill industry, only 15 years, I have found that nothing remains static. Change is always at our door. The lumber market is up, the lumber market is down. The customer is looking for superior boards, the customer is looking for rustic boards. Logs are available, logs are tight.

In our sawmill, we have found ways to reduce the periodic and seasonal log supply challenges that we see here in the west by investing in standing timber. Embracing a new idea, to change the current unacceptable condition.

How can NHLA do something similar for our membership with regard to hardwood product demand volatility? How can NHLA help our members increase the end-user demand for all hardwood products? How can we work together to explain the hardwood lumber story to our end-user customers and the process in which it is manufactured? Can promotion and advocacy help to stabilize finished hardwood lumber product values? I think yes!

I suspect these questions have been asked before, and I suspect many of you have at least thought about these questions when the values and demand for your products fluctuate with great volatility.

Working individually on these challenges is a daunting and, in my opinion, fruitless effort. But together, as an entire industry, I feel success is achievable. The Real American Hardwood Coalition is prepared and situated to finally promote our industry and tell our story. Their plan of both push and pull marketing efforts, most recently explained at the NHLA Convention in Cleveland, will get our story out into the marketplace explaining the reasons why cus tomers should feel good about hardwood products in their homes and the sustainability story that comes along with the hardwood manufacturing process.

Supporting the RAHC is the change at hand. The RAHC is ready to provide promotional leadership for our entire industry. The website is live, https://www.realamericanhardwood.com/ the plan is prepared, the people are in place, the promotional message is true and genuine, and the industry is ready.

Let us make sure we tell our story to our customers before our industry competitors do it for us!

So, what do we need to achieve such fantastic goals?

Funding, of course, isn’t that what it always comes down to? To achieve success for the whole industry, the whole industry will need to invest in our collective future. Everyone will need to invest a little to successfully defend our products from substitutes such as ceramics, laminates, etc.

4 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM CHAIRMAN’S MESSAGE

BE PART OF BUILDING SOMETHING BIG

Where We’ve Been

It’s no secret, the hardwood industry has been losing market share to products that look like wood, but have none of the natural benefits or authentic attributes of Real American Hardwood™ products. In order to recapture market share and improve industry stability, hardwood organizations united to form the Real American Hardwood Coalition.

Where We Are

The goal is to develop a national consumer promotion campaign on a scale that’s never been seen before. And a lot has been accomplished in a short period of time—including the completion of an extensive consumer research initiative, establishing brand guidelines, registering trademarks, and launching social media profiles.

Where We’re Going, Together

The next steps will have the largest impact on the industry and require buy-in from all industry stakeholders. The Coalition is preparing to launch a comprehensive promotion campaign—including a consumer-oriented website, in-store promotion at top big box stores, a broad media relations campaign, social media influencer partnerships, print and web advertising, and much more.

How You Can Get Involved

Moving the campaign forward and expanding its reach will take the support of the entire industry—for the benefit of the entire industry.

■ Make a voluntary contribution to help fund the consumer promotion campaign.

■ Use the Real American Hardwood logo on your sales and marketing communications, facilities and vehicles, products, and website.

■ Follow @RealAmericanHardwood on Instagram and Facebook, and tag #RealAmericanHardwood in your social media posts.

Visit RealAmericanHardwood.org to learn more and get on board.

TREES ARE THE ANSWER

By DALLIN BROOKS, Executive Director

Iattended a meeting earlier this year where they had several presentations on how the image of forestry is changing by promoting good forestry practices. It was a rah-rah moment, with everyone patting themselves on the back. I raised my hand and asked a simple question. “Is it better to focus on the negative or the positive?”

The milk industry does not talk about how their cows are treated; they brand the positive attributes of milk by highlighting how much we need it. The same goes for beef, chicken, pork, and potatoes. They also kill a living organism but get very little resistance to it. Telling people how nice we treat trees as we cut them down does not give us the positive image we want. To those who care and call themselves environmentalists, we still killed a living organism that they mistakenly think would live forever. Visiting mills, I have seen the old black and white pictures of men standing next to a large tree they cut down. The unwritten boast is “Look! What we did,” before technology, but the other side sees that and says, “Look what you did!” to that beautiful tree.

We can be our own worst enemy with the messages that we share.

WHAT DO OTHERS THINK OF THE HARDWOOD INDUSTRY? My generalized guess goes something like this:

The softwood industry-Hardwood is not part of us because it is not structural or automated.

The loggers-Hardwood is sustainable but more work than softwood.

The hardwood manufacturers-Hardwood from me is better than from him.

The competitive materials-Hardwood requires lots of maintenance and does not last as long.

The environmentalists-Hardwood is deforestation.

6 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM ONE COMMON GROUND

The consumers-Hardwood looks crummy in a few years and needs maintenance.

The contractor-Hardwood is expensive and complicated to install with high callbacks due to shrinking and swelling.

The academics-Hardwood is the best product for carbon sequestration, low carbon footprint, and sustainability.

The architects-Hardwood is wood, but I can get the same look in other materials.

The NHLA staff-Hardwood is not going away and will be used in the future.

The regulators-Hardwood harvesting poses risks to the long-eared bat and other critical organisms.

Like everything that grows, hardwood provides food, logistics, and habitat. Food for many organisms like carpenter ants, hardwoodfocused insects, boring beetles, termites, and decay fungi. Logistics and habitat for the same insects, beetles, and organisms that eat it along with the birds, small mammals, big game, and, yes, even humans. You already knew that, but do:

• The specifiers

• The construction industry

• The competitive materials

• The environmentalists

• The consumers

• The regulators

The Real American Hardwood Coalition is the opportunity for the hardwood industry to tell the whole forest story from our positive appeal. We can help the entire forest industry change perceptions by focusing on how our products encourage forest health, strong rural communities, and economic growth that is better for the environmental goals of everyone.

We have common ground with the die-hard, forest-loving environmentalists. Trees are the answer; we are here to keep them growing, use those maturing past their viability, and provide modern logistics and habitat for them to enjoy. We all need to contribute to the positive message about using Real American Hardwood, as everyone agrees common ground is better.

Dallin Brooks NHLA Executive Director | dallin@nhla.com

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 7

Contact your Wood-Mizer INDUSTRIAL specialist today. Starting at $194,995 © 2022 Wood-Mizer LLC *Price and specifications subject to change without notice. WIDEBANDSAWMILL Features: • Heavy Duty Twin Rail Head Construction with Quad Post Support • Increased Material Drag Back Capability • Wideband Performance, 2" and 3" Available • 6 Ton Log Capacity • HMI Cab Operated Feed Controls with Two-Camera Video System Say HELLO to the WB2000 Industrial Sawmill that combines the increased yield of thin-kerf blade technology with the production demands of wideband sawmill blades. SAY HELLO TO HIGH PERFORMANCE SAWMILLING 844.339.7815 | woodmizer.com IN STOCK CALL TODAY!

AHUG – PROMOTING PENNSYLVANIA HARDWOODS FOR MORE THAN 35 YEARS

By AMY SHIELDS, Executive Director Allegheny Hardwood Utilization Group

By AMY SHIELDS, Executive Director Allegheny Hardwood Utilization Group

Within the 16.6 million acres of forested landscape in Pennsylvania lies the Upper Allegheny Plateau, a region recognized worldwide for its high-quality hardwoods, dominated by black cherry, soft maple and red oak. The Plateau is home to the Allegheny National Forest, the largest concentration of Pennsylvania State Forest and State Game Commission lands, and hundreds of thousands of acres of industrial and Timber Investment Management Organization (TIMO) holdings.

The Allegheny Harwood Utilization Group (AHUG) was organized in 1984 for the purpose of advancing this exceptional natural resource asset, and for expanding the economic development and employment opportunities of the forest products industry within the 14-county “Wood Basket” region of Northwest and North Central, PA. With more than 100 member companies - from landowners and loggers to sawmills, finished goods and by-product producers - AHUG serves all sectors of the forest products community. AHUG is one of three Hardwood Utilization Groups (or “HUGS”) supported through the Pennsylvania Department of Agriculture (via the Pennsylvania Hardwoods Development Council). This unique public-private partnership provides the hardwood industry with direct access to State promotion, workforce and economic development, research, and education resources.

AHUG is a principal source for regional hardwood education, utilizing SFI’s “Project Learning Tree”, industry partners, and the Pennsylvania Woodmobile to deliver working forest, hardwood career and positive industry messaging to thousands of students and adults each year. We coordinate industry training and education forums on topics ranging from 1st Aid/CPR and invasive species management to NHLA lumber grading and global marketing.

Promoting continuous improvement of the industry and its influencing factors through representation and outreach is key to advancing AHUG’s mission. We partner with the USFS in leading the Allegheny Forest Health Collaborative, a 60-member consortium of public and private landowners, forest industry profession-

als and policy makers working in landscape style to address critical forest health issues across the Allegheny Plateau. AHUG facilitates industry participation as a major stakeholder in public lands natural resource planning, working forest messaging and implementation. We host field tours and roundtable discussions to provide opportunities for industry to educate and engage with legislators, agency officials and academia, providing informed input on the programs, policies and regulatory processes that impact their livelihoods.

Promotion of Pennsylvania’s hardwood industry and the high-quality hardwood products they manufacture is a fundamental component of the AHUG mission. We participate in regional, national, and international trade shows, and are proud to be a founding association and current board member of the Real American Hardwood Coalition. AHUG and their sister organization, Keystone Wood Products Association, will be working on behalf of the Hardwoods Development Council to showcase Pennsylvania’s wood products industry and the sustainability of our working forests at the world’s largest gathering of green building professionals – the GreenBuild International Conference & Expo from November 1 – 4, 2022 in San Francisco, CA.

For more information on “GreenBuild 2022” or the Allegheny Hardwood Utilization Group (AHUG), please visit our website at www.ahug.com or follow us on Facebook.

Amy Shields is the executive director of Allegheny Hardwood Utilization Group (AHUG). She can be reached at ashields@ahug.com.

8 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM ALLIED ANGLE

How’s your edger performing? Let NHLA help you become more efficient and more profitable. Our team will evaluate your process from log selection to end product and thoroughly analyze every step in between. The purpose of the program is to identify potential profits that already exist. Contact Chief Inspector Dana Spessert to setup your evaluation today! 901-399-7551 | d.spessert@nhla.com | www.nhla.com THE EDGER IS THE LARGEST CAUSE OF YIELD LOSS IN SAWMILL OPERATIONS. The NHLA Yield Analysis Program has identified an average of $400,000 per company in edger loss.

Engage Your Political Muscle!

YOUR VOICE MATTERS

By DANA COLE, Executive Director of the Hardwood Federation

The 2022 mid-term elections are upon us. Voters will go to the polls on Tuesday, November 8, to vote for 34 of 100 members of the U.S. Senate, 100% of the U.S. House of Representatives (435 strong), 36 state governors, over 6,000 state legislators, and countless local government seats. While the national press likes to focus on who controls the U.S. Senate and House, there is much more to think about than who comes to Washington, D.C. The Hardwood Federation Team works hard for you and your business every day in our nation’s Capitol, but there are also ways you can make a big difference on your state and local level.

First, be informed of the issues that impact your bottom line, whether at the federal, state, or local level. The Hardwood Federation can update you on the federal level through our monthly newsletter and weekly Cheat Sheet. If you are not already a subscriber, you can sign up here Both are also available on our website at www.hardwoodfederation.com.

The next step to successful engagement is to meet with your elected officials. Although the Hardwood Federation focuses on federal issues and federally elected officials, we are big supporters of industry members talking to elected officials and candidates . . . at every level of government. Elected office is like any other business; people move up over time. So, the county commissioner to chat with about the importance of hardwood products to the local economy could end up winning a state House or Senate seat and then moving on to the D.C. level. Educating politicians at every level is vital, not only to make sure they understand hardwood industry concerns when they start but also to ensure that they take those lessons with them and build on them as they work their way up.

Candidates for federal seats will be in their states and home districts for the entire month of October and every day in November until election day. Search them out where you can; town hall meetings, local association and club dinners, parades, fairs, high school and college football games, or make an appointment in their local offices. They will be looking to meet voters and asking for their support on November 8. Or even better, invite them to tour YOUR facility. This can be the most impactful way to make the connection between policy decisions they make and the impacts on business, jobs, and families. Check out the Hardwood Federation’s Facility Tour Guide for information and helpful tips on inviting candidates and giving them an experience they won’t forget.

You know your business better than anyone and are in the best position to educate policymakers about what will and will not support your business’s growth and vitality. But you can also help the Hardwood Federation as we work on issues of national importance. You may recall our talking points from the summer recess. They haven’t changed. But research tells us that it can take up to seven times for a concept to be retained, so don’t hesitate to share our priorities with any candidate you run into, even if it’s already been said!

• Wood Products are Part of the Climate Solution: With the federal government putting a climate twist on almost every policy that takes shape, tell your lawmakers to keep wood products in their toolbox. Hardwood floors, lumber, and other products store carbon and prevent its release into the atmosphere. Lawmakers cannot hear this message often enough. Delivering it repeatedly will make sure that the industry gets credited, instead of penalized, by climate policies moving at the federal level.

VOTE

10 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM LEGISLATIVE LOG

• Protect and Expand International Markets: The hardwood sector is a powerful exporter of products “Made in the USA” and relies on foreign customers to support high-quality jobs at home. To that end, remind your lawmakers of the importance of increased funding for the U.S. Department of Agriculture’s Market Access Program (MAP) and the Foreign Market Development (FMD) Program, which support U.S. hardwood exports.

• Oppose Tax Hikes that Harm American Hardwood Companies: It’s important to communicate the benefits of the small business tax deduction and the flexible estate tax provisions included within the tax reform law of 2017 and oppose any efforts to roll them back.

• Fix the Driver Shortage: Fortunately, the “Infrastructure Investment and Jobs Act” enacted last year addressed some of the challenges related to the driver shortage. Despite this progress, federal policymakers can do more. This includes passage of the LICENSE Act—HR 6567 and S. 3556 - which would help expedite issuing commercial driver’s licenses.

Good luck flexing YOUR political muscle! Like every other muscle, the more you work it, the easier it gets. Let us know how it goes at hardwood.federation@hardwoodfederation.com. We are always looking for feedback from beyond the Beltway. As always, thank you for your support! www.hardwoodfederation.com

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 11 VOTE

". . . meet with your elected officials. Although the Hardwood Federation focuses on federal issues and federally elected officials, we are big supporters of industry members talking to elected officials and candidates . . . at every level of government."

BID Group: THE BRIDGE BETWEEN YOUR GOALS AND RESULTS

In 1924, the world was bursting with new technologies like traffic signals, Duracell batteries, and bulldozers. How fitting that 1924 was also the year that BID Group began. It’s been almost 100 years, and BID continues to provide hardwood lumber industry-leading solutions through a complete range of innovative equipment, digital technologies, turnkey installations, and aftermarket support. Today, BID Group is at the forefront of artificial intelligence and digital solutions.

In the constantly evolving markets of 2022, the hardwood lumber industry has very tight profit margins, increased competition, and elevated pricing pressure. BID Group understands these challenges and offers several ways to tackle them head-on and boost margins. BID is a combination of three unique flagship brands designed to

address customers’ ever-evolving needs and priorities throughout the entire wood processing lifecycle: Comact, Deltech, and OPER8.

Comact is a leader in designing, manufacturing, and optimization of wood processing equipment as well as PLC/Controls for sawmills

12 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM

BID GROUP

MEMBER SPOTLIGHT

Sylvain Dionne, the VP of Customer Experience

and planer mills. Deltech is focused on helping customers reduce energy consumption by designing and manufacturing continuous/ batch kilns, biomass-fueled energy system technologies, and pellet plant manufacturing. Finally, OPER8 is the backbone of BID Group’s vision for Smart Connected Operations and is built by industry experts with decades of experience and the sawdust on their boots to prove it.

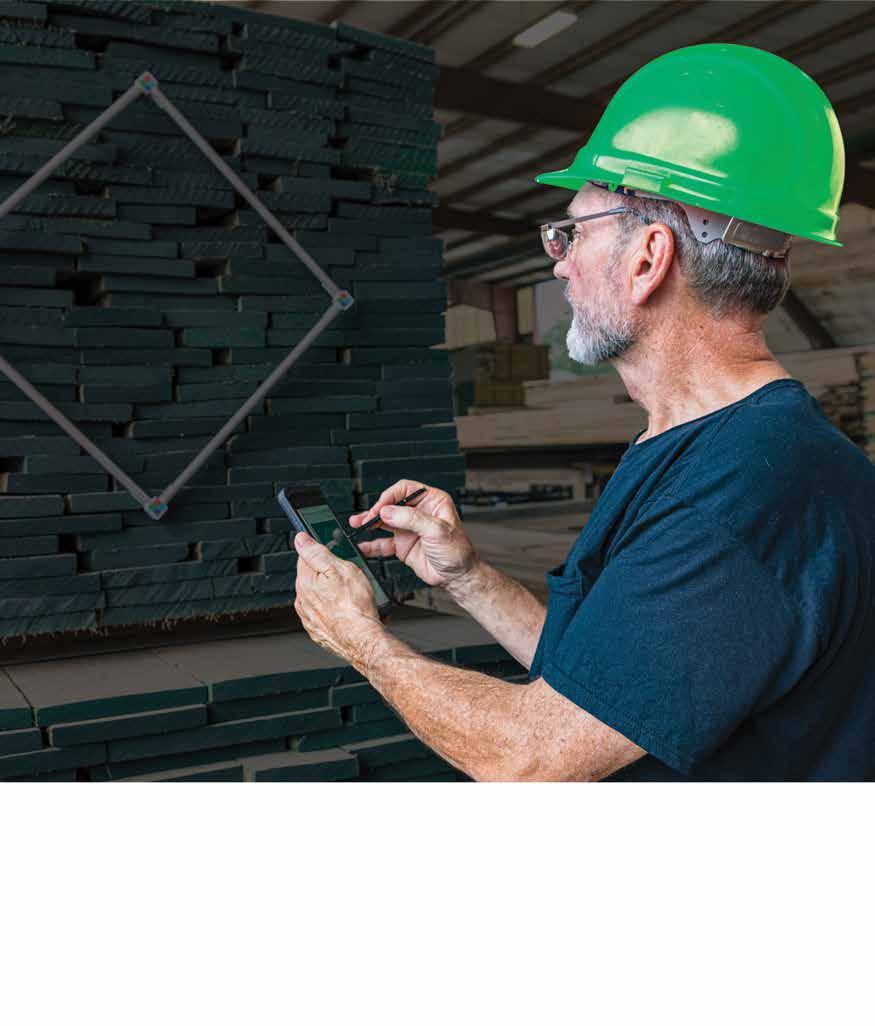

Sylvain Dionne, the VP of Customer Experience at BID Group, proudly said, “BID Group designs, builds, and installs all types of equipment used in the hardwood lumber industry. We also offer the latest and greatest automation and scanning technologies (powered by AI and deep learning), which are part of every product line we deliver. These systems can be delivered with an operating platform, providing a solution to help people manage profitability in realtime. Recently, BID Group has entered the robotic world, so these robots, mixed with our Smart Vision System, can do a lot to help our customers with their daily issues. BID group is highly engaged in the hardwood processing industry, we want to push our technologies and our limits so that our customers can benefit from our products and services.”

Dionne continued, “BID Group is different from our competition because we offer innovative products for the best performance using

“BID Group is different from our competition because we offer innovative products for the best performance using the latest technologies, a devoted specialist team, and a customer-oriented mindset. We take the time to listen to our customers’ concerns, requirements, and expectations and develop individual solutions.”

the latest technologies, a devoted specialist team, and a customeroriented mindset. We take the time to listen to our customers’ concerns, requirements, and expectations and develop individual solutions.”

BID Group is a tremendous supporter of NHLA and the NHLA Annual Convention, sponsoring and exhibiting year after year. Dionne said, “We feel it is important to encourage industry events like the NHLA Annual Convention. We also appreciate the opportunity the Convention provides us to meet with fellow members and customers.”

BID is dedicated to delivering performance, innovation, remarkable service, and results through continuous improvement of its products and services. The company has offices in 18 key locations to serve its global customer base. Today’s innovation from BID Group will lead to a bright future. Imagine what revolutionary technologies they will create in the next 100 years.

BID Group has locations across Canada and the United States. To learn more about BID Group, visit www.bidgroup.ca, call 450-435-2121 in Canada (843-563-7070 in the USA), or email info@bidgroup.ca.

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 13

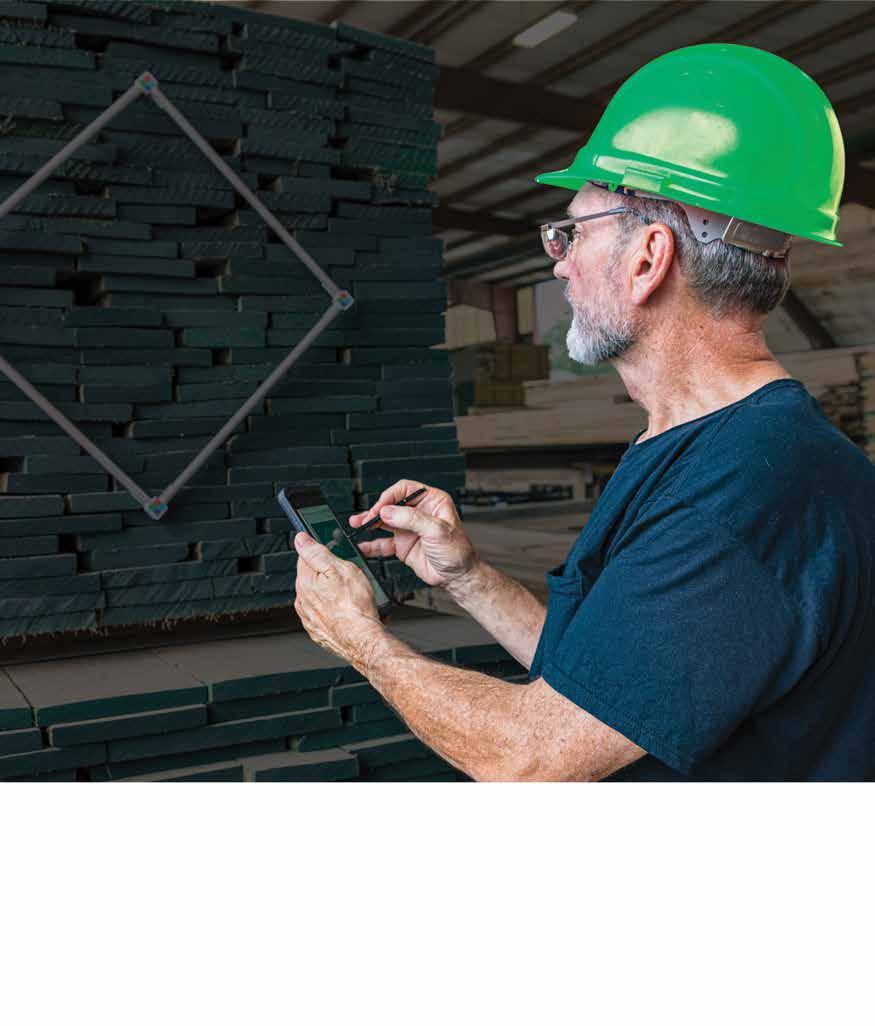

CONVERTING SOCIAL MEDIA INTO SALES

By AMANDA BOUTWELL

By AMANDA BOUTWELL

14 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM

7 STEPS TO CONVERT SOCIAL MEDIA INTO SALES FOR YOUR BUSINESS

1. Research to discover which social media platform is right for your company.

2. Remember that social media is a community.

3. Engage with your audience.

4. Carefully create your social profile on each platform you choose.

5. Give people a reason to follow you by offering engaging, valuable posts.

6. Only publish things your potential customers care about - what interests them.

7. Post frequently

Social media marketing has a long, transformational history. The first social media website was created in 1997, and contrary to popular belief, it wasn’t Facebook! The first social media platform was called “Six Degrees” and was similar to an early LinkedIn. But social media as we know it today didn’t take off until 2004 when Mark Zuckerberg created Thefacebook (which later changed its name to Facebook). By November 2006, Facebook had over 50 million users and announced it would begin selling ads. Thus, the dawning of social media marketing.

It wasn’t long before other social media platforms joined Facebook. Some were successful, like LinkedIn, Instagram, Twitter, Pinterest, YouTube, and TikTok. Others were no more than brief blips on the radar. Today, there are dozens of social media platforms, with a total of 4.2 billion active users. Each social platform provides a unique audience, tone, and focus.

According to the Pew Research Center, social media can constitute 62 percent of a company’s lead generation. It is simply a matter of knowing how to use it effectively. Not all social media platforms work for every company. Each platform serves a different purpose. Some are

meant to highlight photos (like Instagram and Pinterest), while others were created to share videos (like YouTube and TikTok). The most critical step in converting social media into sales for your business is to carefully choose which social media platforms will work for your business. Since the hardwood lumber industry covers a wide range of businesses, what works for sawmills may not be what is best for companies manufacturing equipment.

For example, NHLA Associate Members (those who use hardwood lumber to manufacture cabinets, flooring, furniture, moulding, pallets, and more) could be significantly served by a platform like Pinterest. Pinterest is a visual discovery engine for finding ideas on things like decorating, home remodeling inspiration, and more. Pinterest is where people create an online vision board for what they want. It affords companies in this sector of the hardwood lumber industry the opportunity to get their product in front of 291 million active users (and potential customers) who are actively looking for what they sell. The Real American Hardwood Coalition uses Pinterest to inspire consumers to use real American hardwoods in their dream homes.

Instagram is also a fantastic platform for NHLA Associate Members. It is

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 15

Many companies within the hardwood lumber industry are using social media marketing effectively.”

“

Tony Cimorelli, Marketing Director at Baillie Lumber

said that a picture is worth 1,000 words. On Instagram, beautiful photos of hardwood floors, furniture, and cabinetry speak for themselves, giving would-be customers inspiration for what they want in their homes. Plus, Instagram has over 1 billion monthly active users. How’s that for an audience pool?

Another excellent option for those involved in manufacturing hardwood products is called Houzz. Houzz is a social media platform specialized for home services businesses. You can use Houzz to tap into a network of customers looking specifically for products related to your business. Consumers can make purchases directly

from Houzz, and many contractors use Houzz to buy things like flooring and cabinetry for their custom homes. NHLA Associate member, Koetter Woodworking, does a great job using Houzz to generate sales. For NHLA Active Members (those that manufacture, custom kiln dry, wholesale, or distribute hardwood lumber, plywood, or related products) and Sustaining Members (those that supply services, materials, or equipment), the ideal option may be different. Both do well on LinkedIn because it is the platform most decision-makers at companies use. Facebook can also be an excellent option, and every company has a place on YouTube.

16 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM

“We use LinkedIn because it aligns with our efforts to release important information, increasing our credibility in the industry. We use Facebook because it is a must-have to spread our message and a great platform for sharing informational messages and inter-office fun!

”

Melissa Berry, Marketing Director at Continental Underwriters

To find out which social media platforms your business should be focusing on, you need to identify who your audience is first. You have a leg up if you already know who your customers are. But, if you are unsure, there are many tools you can use, like Google Analytics, to discover where your customers are the most active. You can also look toward role-model companies that are similar to yours. What platforms are your role-model companies on, and which platforms seem to have the most engaged users? Key things to look for include likes, shares, and comments.

The important thing to remember is that you do not need to be on every social media platform out there to convert your posts into sales. Unless you have a dedicated social staff or your company uses a professional service, it is often best to pick just two or three social media platforms. If you operate on too many platforms, your message will be spread too thin, and you won’t have time to make meaningful connections. Remember that social media is a community, and communities are made because of relationships. Forging relationships requires conversation, a natural back-and-forth. If someone comments on your post, reply to them. At the very least, react to what they have said. Relationships you build on social media are what translate to sales.

Many NHLA members do an excellent job on their selected social media platforms. One such member is Continental Underwriters, Inc. We spoke to Melissa Berry, the Marketing Director at Conti-

nental Underwriters, about ways her company uses social media to increase sales. They focus on two platforms: LinkedIn and Facebook. Melissa said, “We use LinkedIn because it aligns with our efforts to release important information, increasing our credibility in the industry. We use Facebook because it is a must-have to spread our message and a great platform for sharing informational messages and inter-office fun!”

Frank Miller Lumber has shined on social media recently with a five-part mini-series that showcases each stage of operation in the sawmill. Not only are they sharing the videos on YouTube, but they are also distributing them across other social media channels. These videos are fantastic educational pieces and show what actually happens in a sawmill.

BID Group is another member that excels at social media. Vicky Drolet, the Marketing Coordinator at BID Group, explained, “We choose to use LinkedIn and Facebook primarily, but we communicate mostly on LinkedIn, as most of our customers are using that

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 17

platform.” Vicky continued, “Social media is important to us because it lets us create relationships with our followers.”

Once you have committed to your chosen social media platforms, it’s time to ensure that your profile is optimized. If you fail to set up your social media profiles properly, it could mean the difference between converting a follower into a customer or never earning their business. Some crucial sections to focus on include your business name (if you have an acronym for a company name, make sure you spell it out), the correct physical address of your business, your phone number, and a link to your website. Including these sections will be critical if someone wishes to reach out after seeing something they liked on your social

postings. Branding of your business should be top of mind. Your profile picture should be your company logo. Finally, the “bio” section (sometimes called the “about” section) should be fun and creative. You don’t want to bore people; you want to encourage them to learn more.

Once your social profile has been set up, it is tempting to publish one post after another, plugging your products and services. While you are encouraged to promote your company on social media, you should find a balance between those posts and posts that are genuinely valuable to your audience. The best way to succeed at publishing valuable content that will convert to sales is to make sure every post has at least one of the four Es. Your posts should be engaging, enlightening, educational, and encouraging. Your brand values must be embedded in everything you share on social media.

Posts that will lead to the most sales conversions will be those that reflect your company culture. Every company has a different personality. For instance, Ally Global Logistics has a video that has gone viral about its Ally Cares program, highlighting several aspects of its culture: charity and inclusion. Ally’s president, Steve Zambo, said, “Ally Cares is an important program to us. With Ally Cares, we give back by setting $1 aside for every load we move. It adds up quickly. Each year, our staff submits what charities they believe should receive the donation. Everyone votes, and the money raised is donated to the charity that wins the popular vote.” The video touches on the four Es and makes people want to learn more about the company.

If your company focuses on providing value to your followers on social, it is practically guaranteed to convert to sales because it builds a relationship of trust. Some ways to provide value on social include posting links to stories your audience would be interested in, polls, and behind-the-scenes imagery that humanizes your business.

A company that is showing its human side on social is BID Group, and people in the hardwood industry are taking notice. Melissa Berry commented, “BID Group does an excellent job on their social media accounts. They post about what is going on out front (informational/educational, how you can help), what they are doing outside (associations/hiring/community service), and what’s going on behind the scenes (employee accomplishments/culture/personal look inside). BID Group’s social media shows a well-rounded company that is real, not just on the screen.”

18 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM

“NWH wants to continue to educate our customers and end-users about the benefits of hardwoods over other materials, and we think social media is one of the ways we can reach them.”

Kelsey Schweitzer, Marketing Manager for NWH

Tony Cimorelli, the Marketing Director at Baillie Lumber, said, “Many companies within the hardwood lumber industry are using social media marketing effectively. I would like to highlight the work of our industry associations. NHLA, AHEC, HMA, and more recently, those behind the Real American Hardwood Coalition, whose efforts help promote the value of using hardwoods and circulate excellent content we can all like and share, which helps everyone in the industry.”

If you want to convert social media to sales, make sure your posts are relevant and interesting to your specific audience. You can learn what your audience cares about by monitoring social media. Simply looking at trending hashtags can give you a myriad of ideas on how to connect what is topical and popular to your brand and your message. Websites like BuzzSumo actively “listen” to social media, the news, etc. Setting up an account can help you keep a pulse on what’s currently important to your audience.

Having social media accounts that are rarely updated can be worse than not having accounts at all. If someone is seeking your business on social and notices that you haven’t posted anything new in months, they may subconsciously feel like you are no longer in business or that you are too busy to care about their needs. Your window of opportunity is small. In today’s give-it-to-me-now world, people don’t have attention spans that last long enough to figure out if your company has what they need. First impressions are more important than ever.

How often you should post varies depending on the social media platform. You are building a community, so your post frequency will make a difference. Generally, it’s better to post too much than to leave vast gulfs between posts. You should try to post at least once every day or two on Facebook, Instagram, and LinkedIn. On Twitter, you’ll need five to fifteen tweets spread throughout the day to remain relevant. The newest hot social platform is TikTok, but it requires a lot of work – at least two original videos per day.

Kelsey Schweitzer, the Marketing Manager for NWH, said, “We have seen many hardwood lumber companies launch social media accounts but quickly fade away. Consistency is the key to success. You don’t have to post every day but keeping accounts current and posting on a regular basis is important to keep people engaged and get the most out of the message you want to share. Companies like Bingaman Lumber, Ron Jones Hardwood, Cormark International, The Wood Yard, Pacific Hardwood, and Advantage Lumber all do a good job on social. People love seeing behind-the-scenes content, and there are some companies in the hardwood lumber industry that do a great job at sharing posts like these.”

Kelsey continues, “NWH wants to continue to educate our customers and end-users about the benefits of hardwoods over other materials, and we think social media is one of the ways we can reach them. As long as people are still using social channels, we’ll continue to be there. This is an industry where people are still becoming

active on social media, so in 5 years, we believe it will be even more impactful than it is today. Being active and consistent today will make sure we are ready and visible when social media becomes more influential in the hardwood lumber industry.”

The bottom line is social media is here to stay and becomes more pertinent to sales each year. If you haven’t joined, you are missing out on potential sales. While it is difficult to measure social media conversions, it is easy to see their importance. Tony Cimorelli with Baillie Lumber says they measure successful social “by looking for positive growth in followers, post engagement, and the number of posts we put up per month.”

Engaging with your customers, building relationships, and developing communities are all part of Sales 101. Social media is no longer a “nice thing to have.” It is a necessity.

Sources:

https://thepaymentsassociation.org/article/the-history-of-social-mediamarketing/

https://eclincher.com/how-to-convert-social-media-leads-into-sales/ www.bramework.com/convert-social-media-sales/

www.bdc.ca/en/articles-tools/marketing-sales-export/marketing/turnfans-into-customers

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 19

YOU CAN FIND NHLA ON Facebook, LinkedIn, Instagram, Twitter, and YouTube. @NHLAOfficial @nhlaofficial @nhla_official @NHLA_Official

PITH - Boxed or Showing

By DANA SPESSERT, Chief Inspector

The NHLA team has returned from Cleveland, Ohio, and one of the best conventions it has held in many years. The convention offered many opportunities for networking, education, and fun. One of my favorite events every year is the ITS Alumni reception. The group seems to grow larger every year, and it’s a wonderful opportunity for our industry friends and fellow graduates to gather and reminisce about their experiences during and after school.

In this month’s article, I want to explain in detail the Pith Limitation in FAS, FAS 1Face (F1F), and Select. In the NHLA Rules Book, on page 14, under the heading of FAS, paragraph 56 states:

“No piece shall be admitted which contains pith, boxed or showing, exceeding in the aggregate in inches in length the surface measure in feet.”

This is one of the shorter sentences describing a Rule, and it is straightforward and to the point. The problem occurs when the pith is boxed, which takes experience to identify. The other issue is handling this on Selects and F1F boards.

To begin, let’s try to identify whether it is going into or coming out of the interior of the board. The rings of annual growth can help answer this question. The rings will be tighter towards the tree’s

20 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM RULES CORNER

center and wider towards the sapwood. So, when looking at the end of the pith, you can usually distinguish which direction the pith is going; turning the board over will help.

Now that we can identify whether the pith is “boxed” or “showing,” we can utilize the NHLA Rule to help us to determine if the limitation has been exceeded. For the FAS side, all pith showing on the face and boxed must be measured to determine if it exceeds the limitation of 1” per Surface Measure foot. On the 1 Common side, measure all that is showing and any boxed pith to determine if it exceeds the 1 Common pith limitation on page 17, paragraph 72 under the heading of 1 Common:

“No piece shall be admitted which contains pith, boxed or showing, exceeding in the aggregate one-half its length.”

In summary, the FAS, FAS side of F1F, and Selects pith that is showing, as well as any boxed, must be measured for this limitation. The pith showing on the 1 Common side is not considered on the FAS face of the board for this limitation. Only the boxed pith is counted on both faces.

Do you have questions about the Rules? Chief Inspector Dana Spessert can be reached by at d.spessert@nhla.com or by calling 901-399-7551.

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 21 Millwide. Worldwide.

"One of my favorite events every year is the ITS Alumni reception."

NHLA JOB BOARD

OUTSIDE SALES

ETT FINE WOODS

This outside sales representative conducts sales in the field via face-to-face interactions with both potential and existing customers. They are responsible for offering the best possible customer experience, working with customers to create the moulding and millwork programs that best serve them.

Responsibilities include developing custom millwork relationships, answering customer inquiries, and providing outstanding customer service for prospecting and developing sales growth.

Skills & Experience Required

This Millwork salesperson should ideally have over 5 years of experience with established relationships in the industry, bringing with them potential customers and the ability to grow a market.

A successful candidate will have strong negotiation skills, strong communication skills, and strong technical knowledge of hardwood lumber, moulding, and millwork.

Salary & Benefits

Salary commensurate with experience, plus an excellent benefits package including 401k with company match, health, vision, and dental insurance, paid time off, and life insurance.

How to Apply

Send your resume to: nhascher@ettfinewoods.com

ETT Fine Woods

1106 Drake Rd. | Donalds, SC 29638

864-379-2111

PRODUCTION SUPERVISOR – DONALDS, SC

ETT FINE WOODS

ETT Fine Woods is seeing a Production Supervisor to oversee an operational department and be responsible for leading an operational team in the production of solid wood lumber products in a safe and efficient manner and take ownership of the existing safety and quality processes. The production supervisor will complete data entry responsibilities and generate reports in a timely and efficient manner. Manufacturing experience and comfort working with computers preferred.

Skills & Experience Required

The nature of the job demands the following skills and qualities:

• Facilitate team development and communication, employee skill

development, problem-solving and resolution, building employee commitment and ownership, and holding employees accountable.

• Drive safety excellence through promoting employee involvement, ownership, and accountability to proactively eliminate hazards.

• Monitor product quality and provide direction to crew members to maximize efficiency.

• Assist with troubleshooting production issues.

Salary & Benefits

Salary commensurate with experience, plus an excellent benefits package including 401k with company match, health, vision, and dental insurance, paid time off, and life insurance.

How to Apply

Send your resume to: nhascher@ettfinewoods.com

ETT Fine Woods

1106 Drake Rd. | Donalds, SC 29638 864-379-2111

SHIPPING SUPERVISOR – DONALDS, SC

ETT FINE WOODS

ETT Fine Woods is seeing a Shipping and Receiving Coordinator who is primarily responsible for shipping and receiving products from production and the warehouse.

Responsibilities include:

• Unloads inbound freight

• Verifies the material matches the order and records any damages or shortages.

• Obtains driver’s signature on a bill of lading.

• Prepares material to be transported to the warehouse.

• Adheres to safety requirements by operating equipment and handling material in a safe and appropriate manner.

• Acknowledges and reports any defects or safety issues to the supervisor immediately.

• Completes required safety training.

Skills & Experience Required

Must be able and willing to work in a manufacturing plant environment, including extended periods of time in noisy, non-air conditioned, or unheated areas. Must be able and willing to work safely and adhere to all safety rules and regulations, including wearing and using appropriate personal protective equipment (PPE).

WWW.NHLA.COM 22 | NOVEMBER 2022 HARDWOOD MATTERS

Here

you will find our current job listings. To see more details or to post a job, visit www.nhla.com/industry-services/job-board.

NHLA JOB BOARD

Salary & Benefits

Salary commensurate with experience, plus an excellent benefits package including 401k with company match, health, vision, and dental insurance, paid time off, and life insurance.

How to Apply

Send your resume to: nhascher@ettfinewoods.com

ETT Fine Woods

1106 Drake Rd. | Donalds, SC 29638

864-379-2111

VICE PRESIDENT OF DOMESTIC LUMBER AND MILLWORK

ETT FINE WOOD

ETT Fine Woods is seeking a Vice President for Domestic Lumber and Millwork. This management position entails overseeing and expanding the domestic sales division. In addition, the position is expected to generate considerable sales of domestic moulding and millwork products, as well as some sales and purchasing of domestic hardwood lumber.

Responsibilities include successfully closing sales, as well as supervisory duties and working with other division managers and other senior leadership to develop the domestic program. The long-term goal of this position is to successfully build long-standing customers and programs for moulding, millwork, and lumber from domestic woods.

Skills & Experience Required

A minimum of 10 years of industry experience and 5 years of experience in sales is required. The successful candidate will offer a great deal of industry experience with established relationships in the industry, bringing with them an established book of business and the ability to grow a market.

A successful candidate will have strong leadership and communication skills, as well as a strong technical knowledge of hardwood lumber, moulding, and millwork.

Salary & Benefits

Salary commensurate with experience, plus an excellent benefits package including 401k with company match, health, vision, and dental insurance, paid time off, and life insurance.

How to Apply

Send your resume to: nhascher@ettfinewoods.com

ETT Fine Woods

1106 Drake Rd. | Donalds, SC 29638

864-379-2111

TIMBER BUYER

HMI LUMBER

HMI Lumber is seeking to hire a Timber Buyer.

Responsibilities include:

• Purchase standing timber or logs within designated regions or counties in Michigan.

• Negotiate the purchase and coordinate the harvest of tracts of standing timber while operating within the company and regulatory guidelines.

• Purchase precut logs and coordinate trucking to the mill.

• Gather names of prospective clients. Turn in all expected paperwork.

• Buyers will also be expected to move work crews, keep track of loggers, and check on completed and in-progress jobs.

Skills & Experience Required

• Grading and Scaling

• Negotiation skills

• Organization and flexibility

Salary & Benefits

• Salary is negotiable.

• A full slate of benefits is available after 90 days.

How to Apply

Send your resume to: mlighthall@hmilumber.com

HMI Lumber

430 Division St. Clinton, MI 49236

517-456-5714

NOVEMBER 2022 HARDWOOD MATTERS | 23 WWW.NHLA.COM

Here you will find our current job listings. To see more details or to post a job, visit www.nhla.com/industry-services/job-board.

NHLA PROVIDES EDUCATION AND TRAINING TO IMPROVE YOUR BOTTOM LINE

NOV

Nov. 15-17

Intro to Hardwood Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Venue: Cumberland Mountain State Park

Location: Crossville, TN

Instructor: Benji Richards, ITS Instructor

Nov. 28-Dec. 9

Inspector Training School

Online Training Program MODULE 1

Two weeks of hands-on training.

Venue: NHLA Headquarters Location: Memphis, TN

Module 2: Online study Module 3: Three weeks hands-on training and final testing at NHLA headquarters.

Instructor: Roman Matyushchenko, ITS Instructor

DEC

Dec. 5-7

Intro to Hardwood Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Venue: Cherokee Wood Products, Inc. Location: Upland, CA

Instructor: Dana Spessert, NHLA Chief Inspector

JAN

Jan. 9-Mar. 3

Inspector Training School

201st Class

Traditional 8-week hands-on training to achieve the certificate of completion in Hardwood Lumber Inspection.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, ITS Instructor

MAR

March 20-31

Inspector Training School

Online Training Program MODULE 1

Two weeks of hands-on training.

Venue: NHLA Headquarters Location: Memphis, TN

Module 2: Online study Module 3: Three weeks hands-on training and final testing at NHLA headquarters.

Instructor: Roman Matyushchenko, ITS Instructor

24 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM Register for classes at www.nhla.com/Education.

ITS CALENDAR

“I enjoyed and was extremely impressed with our 3-day Intro to Grading Hardwood Lumber class. The class was very informative and truly gave me a different perspective on what’s involved in the hardwood lumber grading process. Roman did an awesome job as our instructor. Everyone at NHLA welcomed us and treated us as a part of their family. I applaud everybody involved for a job well done.”

Frank Hooks

APR

April 24-26

Intro to Hardwood Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, ITS Instructor

AUG

Aug. 21- Sept. 1

Inspector Training School

Online Training Program MODULE 1

Two weeks of hands-on training.

Venue: NHLA Headquarters Location: Memphis, TN

Module 2: Online study Module 3: Three weeks hands-on training and final testing at NHLA headquarters.

Instructor: Roman Matyushchenko, ITS Instructor

SEPT

Sept. 6-8

Intro to Hardwood Lumber Grading

Intro class to gain a basic understanding of the NHLA hardwood lumber grading rules and how the rules affect the value of lumber.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, ITS Instructor

Sept. 25- Nov. 17

Inspector Training School

203rd Class

Traditional 8-week hands-on training to achieve the certificate of completion in Hardwood Lumber Inspection.

Venue: NHLA Headquarters Location: Memphis, TN

Instructor: Roman Matyushchenko, ITS Instructor

NOV

Nov. 27-Dec. 8

Inspector Training School

Online Training Program MODULE 1

Two weeks of hands-on training.

Venue: NHLA Headquarters Location: Memphis, TN

Module 2: Online study

Module 3: Three weeks hands-on training and final testing at NHLA headquarters.

Instructor: Roman Matyushchenko, ITS Instructor

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 25

NHLA certified lumber grader at Beasley Flooring Products

HARDWOOD MARKETS MATTER

Hardwood Markets Matter and it is important for NHLA to share market details of the entire Hardwood Industry. We appreciate the support of allied associations and publishers in gathering and sharing this important market information that can help you understand the complete hardwood industry picture.

European demand for U.S. hardwood lumber—which had grown faster this year through July than demand from any other major region—will likely slow considerably through mid-2023. Runaway inflation, the European energy crisis, and the strong U.S. dollar are combining to erode markets for U.S. hardwoods. Although supply constraints from Europe’s ban on Russian lumber appeared to initially increase demand for U.S. Red Oak and White Oak, the war is creating a drag on European economic growth. Already dealing with high inflation, European consumers now face winter energy bills two to four times higher than last year. With the Nord Stream pipeline offline after apparent sabotage, and Russia halting deliveries of natural gas to Italy due to “regulatory changes,” most Russian supplies have been cut off. Even though European nations have been able to refill natural gas storage facilities to within 90% of capacity, the International Energy Agency says supplies could drop to critically low levels by February unless usage is significantly reduced. The EU is discussing mandated conservation measures in member countries, including limiting available energy during peak hours, which will naturally impact wood products manufacturing. Already, even before those potential impacts might be felt, inflation and economic contraction are forcing the cancellation or postponement of projects involving U.S. hardwoods.

Although hardwood lumber prices started declining this summer, European purchasing power has fallen. At the start of October, the euro was worth 16% less than a year earlier, and the British pound was down 17% relative to the U.S. dollar. A German contact pinned at least part of the demand decline in his country on the euro’s steady devaluation. Exports of U.S. hardwood lumber to the 45 nations we count as Europe were 17% lower this July than last, and exporters say markets did not bounce back in August or September. Many economic forecasters now believe Europe has entered a recession that may persist until mid-2023. Accordingly, what was a positive outlook for U.S. exports to European markets just a few months ago has become decidedly negative.

26 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM MARKET TRENDS

0 5 10 15 20 25 Jul-20 Jan-21 Jul-21 Jan-22 Jul-22 Million Board Feet

Hardwood Review, USITC

Monthly

U.S.

Hardwood Lumber Exports to Europe

www.hardwoodreview.com

www.hmr.com

The HMR Demand Index (HDI) is a feature in HMR Executive® that illustrates monthly trends in reported demand from 10 major domestic markets for hardwood lumber. Components of the index are color coded with various shades of blue when demand is slow, they transition to gray when demand is fair, and then to light red and deep red when demand moves from good to strong.

Cabinets

Residential Flrg

Truck Trailer Flrg

Upholst. Furniture

Wood Furniture

Moulding/Millwork

Wood Components

Board Road

Pallets

Railroad Ties

WWW.NHLA.COM NOVEMBER 2022 HARDWOOD MATTERS | 27

Sep-20 Oct-20 Nov-20 Dec-20 Jan-21 Feb-21 Mar-21 Apr-21 May-21 Jun-21 Jul-21 Aug-21 Sep-21 Oct-21 Nov-21 Dec-21 Jan-22 Feb-22 Mar-22 Apr-22 May-22 Jun-22 Jul-22 Aug-22 Sep-22

Quite Slow Slow Fair/Steady Good Quite Good

www.rta.org

WOOD TIE SERVICE LIFE CONSIDERATIONS

Wood crossties and timbers are the backbone of the North American railroad track systems. Using a natural, renewable and sustainable material like wood is environmentally-friendly and touts Built in America. We prolong wood tie service life with preservative application in controlled situations, and have done so for well over a century now. More contemporary practices are also contributing to prolonged wood tie service life,

which starts at the mill, and continues out onto track. Some of these include enhanced sawing solutions and sorting at the sawmill, to quality assurance procedures followed at tie processing yards and treating plants, then on to tie care and installation best practices implemented by railroad personnel track-side.

Prolonging wood tie service life does not take away from railroad tie demand, it’s a safety consideration. Not just for passengers and railroad personnel on track, but the thousands of communities the railroads serve and roll through every day. It is of paramount importance to provide a safe operating environment. Accordingly, it takes around 18-20 million wood crossties annually just to maintain our railroads in North America to keep that level of reliable and safe service.

The Railway Tie Association has been closely tracking (and documenting) tie production, railroad purchases and in-track tie installations since 1987 – a full slate of planning scenarios are available to RTA members. That plethora of statistics renders meaningful information for the entire industry. Bottom line, tie demand is steady, and with less sawmills today versus ten years ago, the supply chain has to become more efficient each year to maintain that equilibrium.

WHAT IS YOUR VIEW OF CROSSTIE COMPETITIVE POSITION RELATIVE TO OTHER HARDWOOD PRODUCTS?

REGARDING YOUR ABOVE ANSWER, PLEASE PROVIDE CONTEXT FOR MARKET, WEATHER OR OTHER CONDITIONS.

EASTERN US

LAKE STATES

Minnesota, Iowa, Wisconsin, Michigan, N Indiana, N Illinois: Lumber markets are down, log prices are too high and the mills are trying to lower log inventory. Mills are very concerned about market prices and hopeful that tie prices will remain steady. If the tie price drops before lumber markets recover, we will likely see a lot of mill closures. Log price is limiting what mills can do.

ATLANTIC

Virginia: Market demand and price for flooring and pallet are dropping

considerably. Red Oak grade lumber demand has fallen off as well. Good logging conditions over the last month.

NEW ENGLAND

New England 1: Fuel prices and labor shortages have loggers struggling. Weather conditions have been poor for logging and the fall mud season has and will keep loggers out of the woods. More Oak and Cherry going into crossties due to the poor lumber market for those species. Pallet cant pricing is stable however demand is starting soften.

Pennsylvania: Competition for ties remains very competitive. Continued dry weather for logging.

28 | NOVEMBER 2022 HARDWOOD MATTERS WWW.NHLA.COM

By AMY SHIELDS, Executive Director Allegheny Hardwood Utilization Group

By AMY SHIELDS, Executive Director Allegheny Hardwood Utilization Group

By AMANDA BOUTWELL

By AMANDA BOUTWELL