www.grecopublishing.com Positive Changes, Commitments and Connections from SCRS Handling Demographic Changes in the Workforce CIC HANDLES AIR TO LAND, MATTE TO AI CHAT & WHAT’S TO COME www.wmaba.com June 2024 Volume 17, No. 6 $5.95

Here’s to 241 years of combined service excellence

This year, as Albert Kemperle Inc. celebrates its 83rd anniversary, BASF also celebrates its 158th anniversary. We are proud of our decades of partnership with BASF and years of serving the auto paint and body industry together. Kemperle’s founders would be proud of this relationship and the growth their company has experienced because of it.

Today, as we look forward to many more decades of service to our customers, we find ourselves filled with gratitude. The creativity, hard work, and sense of responsibility of the people working for our two companies have made us what we are today.

Thank you for your many years of loyalty.

626 E. Elizabeth Ave., Linden, NJ 07036

(908) 925-6133

(908) 925-4344 414-416 Madison Ave., Paterson, NJ 07524

(973) 279-8300

(973) 279-9030 631 Clifton Ave., Toms River, NJ 08753

Melrich Road, Cranbury, NJ 08512

(732) 797-3942

(609) 860-2800

(732) 797-0774

(609) 860-2801 4 Emery Ave., Randolph, NJ 07869

(862) 244-4818

2 June 2024

of

Co-celebrating decades

creating chemistry between two industry leaders

Phone:

Fax:

Phone:

Fax:

Phone:

Fax:

Phone:

Fax:

Phone:

Fax:

100

(862) 244-4822 www.kemperle.com

3 June 2024 LOCAL NEWS by Chasidy Rae Sisk 8 MD, VA AND WV STATE SKILLSUSA COMPETITIONS SHOWCASE STUDENTS’ COLLISION CAPABILITIES Skilled students compete. GUEST FEATURE by Brian Griffith 16 THE DEKRA-CERTIFIED SCRS BLEND STUDY, INVOICING AND THE PAINT AND MATERIAL CALCULATOR Are you using the SCRS blend study to your advantage? NATIONAL NEWS by Alana Quartuccio 20 SCRS LEADERS CONVERSE POSITIVE CHANGES, COMMITMENTS AND CONNECTIONS Conversations confirming SCRS’ commitment to collision repairers. INDUSTRY ADVICE: ASK MIKE 32 HOW CAN SHOPS BETTER HANDLE DEMOGRAPHIC CHANGES IN THE WORKFORCE? Dealing with drastically different people. DEPARTMENTS 4 Editor’s Message 6 Executive Director’s Message 7 WMABA Member Application 15 WMABA Sponsors 34 Advertisers’ Index June 2024 CONTENTS 24 COVER STORY by

CIC HANDLES AIR TO LAND, MATTE TO AI CHAT & WHAT’S TO COME Leaving no stone unturned.

Alana Quartuccio

EDITOR’S MESSAGE

AI: FRIEND OR FOE?

I don’t know about you, but to me, it seems like the “future” is being shoved down our throats constantly, and it’s full of acronyms. EV, AV, AI – no thanks! As an older member of Gen-Y (remember when they called us that instead of “Millennials?!”), I’m pushing middle age since I’ll be entering the last year of my thirties later this month, and although my generation is known for embracing technology, I’m over it.

I’ve got a long list of qualms whenever anyone broaches the topic of electric vehicles. They’re expensive, and the infrastructure isn’t there yet – plus who wants to charge for hours instead of spending 10 minutes at the pump? Then add in the dangers associated with accidents, all while questions linger as to

how much “greener” this option really is! Autonomous vehicles? Well, I’m basically the definition of a control freak, so that’s pretty high up on my “heck no” list.

But the concept of artificial intelligence (AI) triggers a whole different level of fear and resentment. Maybe it has something to do with the popularity of movies like I, Robot, A.I. and the Matrix trilogy during my high school and college years, but I always associate artificial intelligence with the idea of computers taking on humanity’s role, usually in a malignant and chaotic way. Yet, every way I turn, it seems AI is being thrown into the mix.

At the most recent Collision Industry Conference (CIC), the subject came up from the perspective of today’s AI uses; instead of being viewed as something

WMABA OFFICERS

PRESIDENT Kris Burton kris@rosslynautobody.com - 703-820-1800

VICE PRESIDENT Phil Rice phil@ricewoods.com - 540-846-6617

TREASURER John Shoemaker john.a.shoemaker@basf.com - 248-763-4375

SECRETARY Barry Dorn bdorn@dornsbodyandpaint.com - 804-746-3928

IMMEDIATE PAST PRESIDENT Steven Krieps steve@gregclineauto.com 304-755-1146

BOARD OF DIRECTORS

703-624-5819

Torchy Chandler (torchy.chandler@gmail.com) 410-309-2242 Tracy Dombrowski (tracy@collisionadvice.com) 571-458-0648 Bill Hawkins (hawkinswilliamjr@gmail.com) 510-915-2283

ADMINISTRATION

EXECUTIVE DIRECTOR

Jordan Hendler (jordanhendler@wmaba.com) 804-789-9649

WMABA CORPORATE OFFICE

P.O. Box 3157 • Mechanicsville, VA 23116

coming soon, panelists made it clear that AI is here now (check out the recap by my talented co-worker on page 24). They also acknowledged that I’m not the only one who has some deep-rooted fears about AI taking over, especially in our job roles. The mention of Grammarly, a free online AI tool to improve writing, made me cringe – the idea that a program can exhibit a skill that I’ve spent 20-plus years honing…well, it’s a little insulting, isn’t it?

So, I decided to give it a try. I downloaded Grammarly and ran a couple of my articles through it. It made a couple minor suggestions, like removing “really” and adding an Oxford comma. Okay, what about if you run something through that wasn’t written by a professional? I inserted a couple of unedited documents written by other people and compared it to the edited versions. Eh, it did a mediocre job actually. It caught most of the actual errors and made a few suggestions for clarity. Did it identify every change that I made when I edited the same document? Nope. Because it’s not a human with decades of experience. But it caught a few things that

HAMMER & DOLLY STAFF

PUBLISHER Thomas Greco thomas@grecopublishing.com

SALES DIRECTOR Alicia Figurelli alicia@grecopublishing.com

EDITORIAL/CREATIVE Alana Quartuccio COORDINATOR alana@grecopublishing.com

MANAGING EDITOR Chasidy Rae Sisk chasidy@grecopublishing.com

OFFICE MANAGER Donna Greco donna@grecopublishing.com

PRODUCTION Joe Greco COORDINATOR joe@grecopublishing.com

www.grecopublishing.com @grecopublishing

4 June 2024

Rodney Bolton (boltonconsulting61@gmail.com) 443-386-0086 Tom Brown (thbrown@ppg.com)

PUBLISHED BY TGP, Inc. 244 Chestnut St., Suite 202 Nutley, NJ 07110 973-667-6922 FAX 973-235-1963 Reproduction of any portions of this publication is specifically prohibited without written permission from the publisher. The opinions and ideas appearing in this magazine are not necessarily representations of TGP Inc. or of the Washington Metropolitan Auto Body Association (WMABA). Copyright © 2024 Thomas Greco Publishing, Inc. Stock Images courtesy of istockphoto.com.

Chasidy Rae Sisk 302.593.7002 chasidy@grecopublishing.com

continued on pg. 29

• Audi Parts Professionals are your subject matter experts on collision parts, replacement components and mechanical items.

• Many Audi dealers offer technical service support hotline access that can reduce your repair times and help you meet an on-time promised delivery.

• Installing Audi Genuine Parts contributes towards improved cycle time that makes both your customer and their insurance company happier.

• Regardless of the age of your customer’s Audi, Audi dealers have access to over 200,000 part numbers. No other supplier comes close.

Helping you do business is our business. Order Audi Genuine Parts from these select dealers.

Audi Bethesda 5206 River Road

Bethesda, MD 20816

Parts Direct: 240.762.5636

Parts Fax: 301.718.1847 www.audibethesda.com

Audi Chantilly 14839 Stonecroft Center Ct.

Chantilly, VA 20151

703.956.2100 Fax: 703.956.2139 www.audichantilly.com

Rockville Audi 1125 Rockville Pike Rockville, MD 20852

Parts Direct: 301.296.2870

Parts Fax: 301.762.5055 www.rockville-audi.com

Audi Silver Spring 3151 Automobile Boulevard Silver Spring, MD 20904

844.413.6929

Parts Direct: 301.890.3015 Fax: 301.890.3748

Email: wholesaless@mileone.com www.audisilverspringparts.com

5 June 2024

strive to make you an Audi

Audi dealers

Genuine Parts fan

EXECUTIVE DIRECTOR’S MESSAGE

It’s Getting Hot in Here... TEAM UP TO COOL IT DOWN!

It’s irony, possibly, that while it’s heating up outside for the season, everything in collision repair is also heating up on all sides. With the Southeast Collision Conference having just taken place, with record attendance, and having this issue full of what just happened nationally at the SCRS and CIC meetings, I’m overwhelmed with the heat coming off local and national discussions.

With our association coming off such a successful show with our partners at the Carolinas Collision Association, it reminds me how much teaming up matters. Repairers in every position –owner to technician – are coming forward with more reasons to get connected to our association and the community we serve.

I am continuing to see multitudes of fresh faces, hoping to get their edge on what is an ever-changing environment. Vehicles, management systems, repair methods and technology are luring folks to our communities where these advancements are discussed. They’re coming for the info and staying for the benefits.

We want to know it all, and know it as soon as possible. Taking information in bits and pieces is no longer enough to keep up. I was astounded by the traffic

we experienced at the Tradeshow in Greensboro, NC, and am energized to continue this momentum through our area and throughout the year. The heat is on me, too! We want to deliver opportunities for you to continue to engage with valuable information, and other shops, to come back with meaningful ways you can improve your business.

I was so impressed with our local submission for the SCRS Blend Study, because it showcases how much it matters that we pay attention to what’s happening in our global community and how much it affects our literal day-

to-day. This is a perfect example of a problem that spans the entire industry, and how one association-led effort can bring it all to light, to discussion, to potential resolution.

Let us keep the heat on as we navigate our industry forward!

Jordan Hendler (804) 789-9649

jordanhendler@wmaba.com

6 June 2024

Beat the heat. BY

Check the WMABA website and newsletters for regular updates and reportsfrom the Executive Director’s perspective.

JORDAN HENDLER

Using Genuine GM Parts for collision repairs is better for your customers, and better for your business. Contact the following dealers for all your Genuine GM Parts needs:

OURISMAN CHEVROLET OF ROCKVILLE

807 Rockville Pike

Rockville, MD 20852

Toll Free: 800-345-4640

Direct: 301-424-5332

Fax: 301-294-6381 www.rockvillechevrolet.com

OURISMAN CHEVROLET

4400 Branch Avenue

Temple Hills, MD 20748

Phone: 301-899-6990

Fax: 301-899-9375 www.ourismanchevrolet.com

7 June 2024 2024 DUES OPTIONS:

KEEP IT GENUINE

INSIST ON GENUINE GM PARTS

LOCAL NEWS

MD, VA and WV State SkillsUSA Competitions Showcase Students’ Collision Capabilities

Each year, talented trade students compete locally in the SkillsUSA State Leadership and Skills Conferences for a chance to showcase their skills on the national stage.

MARYLAND

On April 12-13, the Maryland SkillsUSA Automotive Refinishing and Collision Repair Competitions were held at Mudgett’s Auto Body in Finksburg, MD. Congratulations to this year’s winners!

AUTOMOTIVE REFINISHING WINNERS

First Place: Isaiah Bouchard

(Center For Career & Tech Education; Cresaptown, MD)

Second Place: Roman Bennett

(Thomas Edison High School of Technology; Silver Spring, MD)

Third Place: Jennifer R. Tippett

(Dr. James A. Forrest Career & Tech Center; Leonardtown, MD)

COLLISION REPAIR WINNERS

First Place: Benjamin Kimbark

(Frederick County Career & Tech Center; Frederick, MD)

Second Place: Joselyn Benitez

(Thomas Edison High School of Technology; Silver Spring, MD)

Third Place: Dimas Lima Xoj

(Thomas Edison High School of Technology; Silver Spring, MD)

“Getting involved and helping the next generation is absolutely imperative for our industry,” stressed SkillsUSA-MD Collision Repair Contest Chair Justin Mudgett. “We all know the trades have been contending with a talent shortage, and our only option is to nurture tomorrow’s technicians by connecting with these kids who want to pursue this field as a living. Most of our employees started out as students at the local technical center. That’s where my dad and brother learned this trade, so supporting the school and paying it forward is very important to our family.”

This year’s judges included Stephen Peddicord, EJ Meckel, Josh Gamber, John McDowell, Beth Meckel, Eric Bell, Josh Bissett, Ish Beverly, Tim Gisiner, Nearmon Barrett IV and Carroll Gamber. “This competition couldn’t have happened without them,” Mudgett said. “Judges volunteered their time and talent. We received a lot of support and sponsorships from local independent shops that donated money and prizes to make it all happen because they all understand how important it is to come together to support our community. SkillsUSA is a great way to do something amazing for our industry’s future.”

8 June 2024

VIRGINIA

The Virginia SkillsUSA competitions for Automotive Refinishing, Collision Damage Appraisal and Collision Repair were held on April 19-21 at Caliber Collision in Virginia Beach. Congratulations to this year’s winners!

AUTOMOTIVE REFINISHING WINNERS

First Place: Serenity Lewis

(Northern Neck Technical Center; Warsaw, VA)

Second Place: Noah Spence (Triplett Business & Tech Institute; Mount Jackson, VA)

Third Place: Tanner Culp (Dowell J. Howard Vocational Center; Winchester, VA)

COLLISION DAMAGE APPRAISAL WINNERS

First Place: Daniele Di Nicola (Spotsylvania Career & Technical Center; Spotsylvania, VA)

Second Place: Coby Nesselrodt (Dowell J. Howard Vocational Center; Winchester, VA)

Third Place: Kallie O’Neill

(Washington County Career & Tech Ed Center; Abingdon, VA)

COLLISION REPAIR WINNERS

First Place: James Beazley (Northern Neck Technical Center; Warsaw, VA)

Second Place: Connor Jordan (Dowell J. Howard Vocational Center; Winchester, VA)

Third Place: Layla Wilson (Washington County Career & Tech Ed Center; Abingdon, VA)

According to SkillsUSA-VA Contest Chair Matt Ingram, “Over 50 students from all over the state of Virginia competed in the different events, performing a various array of tasks, such as blending, masking, plastic repair, metal repair, welding and estimating, in addition to taking a written exam. The competition started promptly at 8am with job interviews conducted by industry professionals. Students also had to turn in a professional resume. From 9am until 1pm, students showcased their skills during the physical part of the competition, and the day ended with the competitors and judges enjoying lunch provided by the host shop.”

Ingram expressed gratitude to the “many industry volunteers and judges from different companies, including Caliber Collision, Axalta, USAA Insurance and GEICO Insurance as well as other industry professionals. We are very fortunate in the state of Virginia to have such wonderful industry relationships with companies and individuals who are willing to partner with SkillsUSA-VA to host and sponsor these events at no cost to SkillsUSA-VA.”

WEST VIRGINIA

On March 22-23, the West Virginia SkillsUSA Collision Damage Appraisal and Collision Repair Competitions were held at Fairmont State University (Fairmont, WV). Congratulations to this year’s winners!

COLLISION DAMAGE APPRAISAL WINNERS

First Place: James Marple (United Technical Center; Clarksburg, WV)

Second Place: Aiden Bailey (Cabell County Career Technology Center; Huntington, WV)

Third Place: Grayson Smith (Roane-Jackson Tech Center; Leroy, WV)

COLLISION REPAIR WINNERS

First Place: Tyler Bryant (United Technical Center; Clarksburg, WV)

Second Place: Elijah Terry (Cabell County Career Technology Center; Huntington, WV)

Third Place: Leah Bennett (Fred W. Eberle Tech Center; Buckhannon, WV)

The first place winners from each category will go on to compete at the 2024 National Leadership and Skills Conference (NLSC) scheduled for June 24-28 in Atlanta, GA. More information on SkillsUSA is available at skillsusa.org H&D

9 June 2024 Vans. Born to run. Get your customers back on the road faster with Genuine Sprinter Parts. Call our Sprinter Certified Parts Advisors today to get started. Sprinter Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904 301-890-3060 Fax: 301-890-5473 mbsilverspring@mileone.com Hours: M-F 7:30am-5pm, S 8am-3pm

On to nationals! BY CHASIDY RAE SISK

Audi Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Mercedes-Benz Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Porsche Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Sprinter Silver Spring

Direct: 301-890-3060

Fax: 301-890-5473

Email: mbsilverspring@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

10 June 2024

is our business.

Your business

Free delivery on our fleet of 15 GPS-equipped delivery trucks - delivering all Silver Spring brands on the same truck throughout Maryland, D.C. and Virginia

We use IRF automotive systems including CCC, CollisionLink, OPSTrax, PartsTrader and RepairLink

Highly knowledgeable, experienced and dedicated wholesale specialist team

Large inventory of OEM parts and tires

Contact our dealers for all your Genuine Parts needs!

BMW of Silver Spring

Direct: 301-890-3015

Fax: 240-471-6103

Email: wholesaless@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Herb Gordon Subaru

Direct: 301-890-3065

Fax: 301-847-2239

Email: herbgordonsubaruwholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

Volvo Cars Silver Spring

Direct: 301-890-5456

Fax: 301-847-2239

Email: herbgordonvolvowholesaleparts@mileone.com

Hours: M-F 7:30am - 5:00pm S 8:00am - 3:00pm

11 June 2024 Service. Trust. Genuine Parts. It’s what we do.

Superior service starts with superior parts.

on what Mazda drivers already know-Genuine Mazda parts extend

Designed specifically for Mazda vehicles Get the right part the first time

We're an accurate, trusted resource as close as your phone Give us the opportunity to serve you

Contact these Mazda dealers for all your parts needs:

Safford Brown Mazda Fairfax 10570 Fairfax Boulevard

Fairfax, VA 22030

Toll Free: 800-234-8642

Phone: 703-385-3994

Fax: 703-591-5348

Fitzgerald Mazda 114 Baughmans Lane

Frederick, MD 21702

Toll Free: 800-545-4745

Fax 877-696-1841

E-mail: parts@fitzmall.com www.fitzparts.com

Ourisman Mazda of Rockville 801 Rockville Pike

Rockville, MD 20852

Parts Direct: 301-340-7668

Fitzgerald Mazda of Annapolis 1930 West Street

Annapolis, MD 21401

Toll Free: 866-280-8022

Phone: 410-224-4636

Fax: 410-224-4264 www.fitzmall.com

Phone: 855-417-4511

Fax: 240-499-2488

e-mail: rockvilleparts@ourismanautomotive.com www.ourismanmazdaofrockville.com

12 June 2024

life.

Rely

a car's

An Investment in Success: Wieländer+Schill Welding Equipment Provides Precision, Peace of Mind

What makes an elite collision repair facility? Expert technicians, impeccable attention to detail, unwavering adherence to OEM repair procedures and top-notch customer service. Just as important is the facility’s investment in cutting-edge, quality equipment. Wieländer+Schill’s full range of welders available through Reliable Automotive Equipment (RAE) helps leverage a shop’s investment into efficient, accurate repairs, elevating the overall customer experience while ensuring the vehicle is restored as close to pre-accident condition as possible.

W+S welders help repairers performing a wide variety of welding repairs with simple, self-explanatory, intuitive operation and the highest safety standards. The InvertaPuls IP7-2 offers 2-button handling, dual 3G torches, ergonomic torch removal and narrow housing construction for ease of use in any size shop performing steel and aluminum welding, while the InvertaPuls IP6-2 uses Automatic Cold Transfer technology for a user-friendly MIG brazing experience. Just select your material thickness!

The InvertaPuls IP4-3 is your go-to for steel, brazing and aluminum welding with automatic torch recognition, parameter retention and a 4-roller wire feed for seamless results. With

90 memory spots and 240A current, pulse and double-pulse welding procedures can be performed effortlessly. And shops looking for inverter technology need look no further than the MIG/MAG IM240-I, a powerhouse featuring a 4-roller drive with trim adjustment and D300 wire spool compatibility for ensured precision. Dynamic pulse adjustment guarantees impeccable results on thin sheet metal as thin as 0.6mm.

For more information on the full line of Wieländer+Schill welders and all available equipment, service, training and support through Reliable Automotive Equipment, visit raeservice.com.

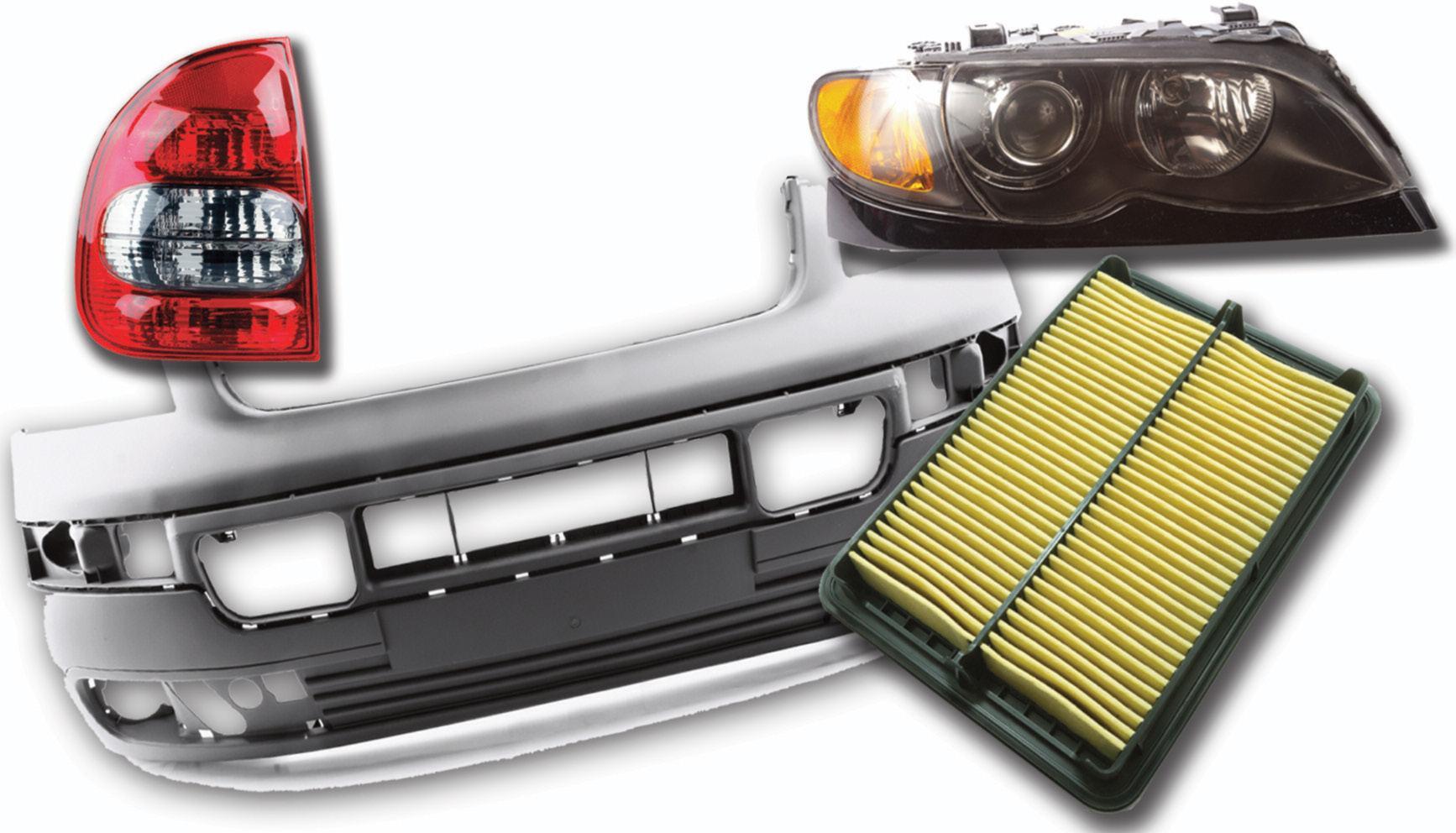

Conquest your Mitsubishi parts needs!

Mitsubishi now offers Genuine OEM parts through our new “Opt-OE” parts program at discounted prices. See Mitsubishi’s Ultra-Conquest parts and prices in the Optional OEM Suppliers category of popular collision estimating systems.

Ultra-Conquest Collision Parts Program Highlights:

• Discounted prices on quality new and unblemished OEM parts

• Automated price and part selection in collision estimating systems

• High parts availability

• Delivery to most major U.S. cities within 24 hours

To find out more about Ultra-Conquest pricing contact your local Mitsubishi dealer. For Genuine Mitsubishi parts, contact these authorized Mitsubishi Dealers.

Fitzgerald Mitsubishi 1930 West Street

Annapolis, MD 21401

Direct: 410-224-4636

Fax: 410-224-4264

E-mail: adamsf@fitzmall.com

Younger Mitsubishi 1945 Dual Highway

Hagerstown, MD 21740

Direct: 800-296-1190

Fax: 301-733-5465 www.youngermitsubishi.com

Buy Genuine Mitsubishi Parts and get the perfect fit at the perfect price. 10% off on all parts orders when you mention this ad.

Available through all participating Northeastern

or

13 June 2024 INDUSTRY UPDATE

Wielander & Schill MIG welders ensure quality welds, every time.

•

area Mitsubishi dealers •

collision

select popular models •

meet

beat aftermarket prices!

Includes the majority of key

components for

We can

14 June 2024

THANKS YOU WMABA WMABA thanks their generous supporters of the Corporate Sponsor Program for 2024! We encourage YOUR SUPPORT of those who SUPPORT US! For more information about the sponsorship program, please contact Executive Director Jordan Hendler at (804) 789-9649 or email jordanhendler@wmaba.com www.wmaba.com BAPS Auto Paints & Supply Certified Automotive Parts Association FinishMaster National Coatings and Supplies LEVEL 1 LEVEL 2 15 June 2024

GUEST FEATURE

LOCAL

CONTRIBUTOR:

THE DEKRA-CERTIFIED

SCRS BLEND STUDY, INVOICING AND THE PAINT AND MATERIAL CALCULATOR

The blend study initiated by the Society of Collision Repair Specialists (SCRS) and certified by DEKRA is undoubtedly one of the most significant and impactful studies completed in the history of auto damage collision repair. Estimates – and ultimately compensation for collision repair – depend on countless time studies, which have determined fair and accurate times for innumerable labor operations involved in collision repair. Every operation, except for those necessitating “repair judgment,” identifies a predetermined labor time which was established through some sort of time study.

Occasionally, the published time for an operation becomes obsolete or inaccurate due to changes in the operation, such as complexity, advances in technology, substrate type or size of the component involved. In the case of blending panels and ultimately refinishing within certain scenarios, the complexity of color prompted the industry to unanimously question the deductions created decades ago when blending and spot refinishing. The complexity of color has become incredible with various rare pigments, translucent colors, quad-coat colors, pastels and matte finishes. Blending into adjacent panels or refinishing within a panel takes a high level of skill and spray gun technique to complete.

Finally, SCRS stepped up and brought

all five of the major North American paint manufacturers, including BASF, Axalta, Akzo Nobel, Sherwin Williams and PPG together with DEKRA, the largest independent North American expert in time testing, inspection and certification. Each manufacturer provided refinish experts for their systems who completed a comparative analysis to determine how long it takes to blend a panel in comparison to performing a full refinish (the study is available for download at scrs.com/blendstudy). The results of the independent study validated what so many technicians have been telling us for many years: It takes more time to blend, and consequently refinish within in many instances, than it does panel-paint…to the tune of an average of 131.59 percent of the allotted refinish time per panel!

I have spent the last 31 years in and around the collision industry. I began my career as an insurance estimator and advanced through various claim positions to estimatics team manager. Insurance staffing migrations to centrals and virtual claim handling practices prompted me to leave that side of the industry and become a repair facility manager for a large dealership and later for an independent MSO. Finally, my career path led me to collision refinish sales where I currently work as a territory manager for a collision refinish coatings company, covering portions of West Virginia, Ohio,

Virginia and Kentucky. I have a tremendous heart and passion for the collision industry and feel we have reached an extremely critical time where repair capacity is shrinking at an alarming rate and not just through retirement of an aging workforce.

Young and talented technicians are leaving our industry every day for less stressful opportunities that offer better incomes. Cutting refinish hours when blending non-damaged panels and blending within repair panels are prime examples of issues that frustrate technicians, unreasonably shrink vital profit margins and result in animosity within repair facilities and toward insurance companies. The paint and material calculation has historically been a simple math equation of the refinish hours on an estimate multiplied by a numerical factor, set by the insurance industry. The reality is that the paint and material rates resulting from insurance industry surveys and other insurance market analysis have unequivocally failed to keep pace with inflation for far too many years.

For my entire career, I have witnessed the frustration and disgust of refinish technicians, repair facility owners and managers over the issue of cutting refinish time on blend and refinish within panels. The DEKRA-certified blending study completed in August 2022 was long overdue. Finally, industry painters have concrete evidence

16 June 2024

BRIAN GRIFFITH

and validation that it takes more time to blend than simply panel paint; however, as I travel throughout my four-state market, very few repair facility estimators, managers and owners are using the results of this study effectively. Accurate paint and material invoicing and adding a negotiated increase based on an “on-the-spot” evaluation in refinish time beyond full refinish on blend panels is a reasonable expectation in the industry now.

Given the results of the study, it’s obvious that deductions on refinish within repaired panels are now negotiable as well. If it takes an average of 131.59 percent of the full refinish time to blend a panel, I cannot imagine a refinish within a full clear situation that would merit any time deduction; however, the onus is very much on the repair industry to change the historic paradigm and collectively embrace the results of the blend study. At the same time, properly invoicing liquid material plays a major role in this issue of refinish deductions and how we move forward as an industry.

From an insurance perspective, there must be some type of calculation for paint and materials other than a final bill and liquid material invoice because many collision-damaged vehicles are not repaired. Instead, the vehicle owner cash settles or trades the vehicle off. Years ago, when the paint and material calculation was established, many repair facilities bought factory packs or mixed paint from a local paint store and did not have their own mixing systems. Colors were not nearly as complex as they are today. Gradually, over time, the industry migrated toward repair facilities housing their own mixing equipment and toners to create the various colors for the vehicles they repaired and painted. In today’s repair facility, painters have an arsenal of refinish technology enabling them to determine the appropriate color to complete the refinishing process in collision repair, also allowing them to accurately measure the exact amount of material used on each individual job to the ounce.

This is significant in relation to blending and spot-refinishing for several reasons. Why would the industry deduct half of the refinish time when blending into a non-damaged adjacent panel or take significant deductions when refinishing within a repair panel, if all parties agree the same basic steps are required for both full refinish and blend, other than the difficulty of effectively performing a color blend in relation to just panel-painting? The allotted time for applying base color within the total panel refinish time is around 10 percent, not 50 percent, and blending is undisputedly more difficult than simply panel-painting. Also, a wet bed of clear base material is typically sprayed onto a panel to blend the color into, so the panel is commonly fully painted with product anyway. The obvious answer is that taking deductions in blending and refinishing within scenarios is the only way, given the current method of establishing paint and materials to capture the base color savings. In a blend or refinish within scenario, base color is not applied to the entire panel.

The current insurer-generated paint and material calculator remains necessary, given all vehicles are not repaired, but I believe the repair industry must transition to job costing their liquid material use on all completed repairs and final bill situations. This removes all incentive to take any paint deduction to achieve a savings for less base color applied for blends, and it will also ensure the initial paint and material calculation is more accurate for customers who cash out. Theoretically, if the industry invoices all liquid used for a repair, CCC, Mitchell and Audatex – in a very short amount of time – will be able to provide very accurate data on the real cost of liquid per refinish hour. They will have an accurate paint invoice and the total refinish hours for each job. A simple math equation will validate an accurate paint and material rate for

the insurance industry.

The blend study has brought new life and excitement to a very volatile and fragile industry. Repair facilities and their technicians should be accurately compensated for the industry to attract and retain talent and for repair facilities to remain profitable and in business. The complexity of color in collision refinish, the cost of liquid and the tools and techniques involved to replicate complex colors have evolved immensely over the last few years. Repair facilities have an excellent opportunity to positively impact the accuracy of the current paint and material calculation and be appropriately compensated for the work and materials used during repairs by simply embracing the results of this very valid blend study. H&D

Genuine Replacement Parts For the Road Ahead.

17 June 2024

Leveraging research to your shop’s benefit. BY

Mercedes-Benz 3301 Briggs Silver Spring, 301-890-3060 mbsilverspring@mileone.com Hours: M-F Parts Advisors Mercedes-Benz Quality Repairs Start With Volvo Genuine Parts. www.volvogroup.com Volvo Cars Silver Spring 3121 Automobile Blvd. Silver Spring, MD 20904 301-890-5456 Fax: 301-847-2239 herbgordonvolvowholesaleparts@mileone.com Hours: M-F 7:30am-5pm S 8am-3pm For over eight decades, the Volvo name has been synonymous with unmatched quality and performance. that legendary Volvo quality starts with Volvo Genuine Parts. For Volvo Genuine parts at the right price, right now, please contact: Subaru and Volvo fax: Fax# is wrong.. 301-847-2239 5:00pm 3:00pmStill reviewing so will advise when all good.

Avoid problems down the road that will cost you time, money and customers. Choose Genuine Subaru Replacement Parts, engineered to fit better today, and perform better tomorrow. Herb Gordon Subaru 3161 Automobile Blvd. Silver Spring, MD 20904 301-890-3065 Fax: 301-847-2147 herbgordonsubaruwholesaleparts@mileone.com www.herbgordonsubaru.com For Genuine Subaru Body Parts, please contact:

www.raeservice.com

For over 30 years, Reliable Automotive Equipment has been the premier OEM Collision Repair equipment supplier. Continue reading for details on our range of OEM certified welders, tailored for diverse automotive needs. Discover the ideal choice for your workshop today!

WHICH INVERTAPULS WELDER

Extremely simple to use entry-level welding machine for steel welding Constructed with durable materials and produces great results on panels as thin as .023 inches. Perfect for standard shop use.

IS BEST

YOUR

SCAN TO LEARN MORE

FOR

SHOP?

torch welding machine capable of performing various welding processes with Automotive Cold Transfer including aluminum welding, MIG

on steel, traditional MIG welding, and pulse welding IM240-i SINGLE PHASE IP6-2 THREE PHASE OEM APPROVALS

Versatile dual

brazing

(800)328-7855

FIND YOUR SPARK.

IP7-2 THREE PHASE

VAS VERSION AVAILABLE

New generation of the IP6-2! Incredibly self-explanatory and dual torch welding machine capable of performing the same welding processes listed under IP6-2. 10-280 AMP’s of welding power professional shop use!

IP4-3 SINGLE PHASE

Cutting-edge triple torch machine capable of steel, brazing, aluminum, pulse and double pulse welding. Has memory of 90 welding parameters. The allrounder for body shop professionals.

*All of the above welders utilize inverter technology to provide better control over the welding arc, increase energy e ciency, and improve welding performance

NATIONAL NEWS

SCRS LEADERS CONVERSE

POSITIVE

CHANGES , COMMITMENTS AND CONNECTIONS

The conversations that took place during the Society of Collision Repair Specialists’ (SCRS) April Open Board meeting confirmed the national group’s commitment to leading the collision repair industry toward positive changes by providing benefits and conducting the necessary research needed to help better the industry.

“We have this opportunity to shape what others see and what they can do,” SCRS Executive Director Aaron Schulenburg reminded the audience as he praised them for taking the time to serve as leaders on behalf of their industry and stressed “how impactful the demonstration of leadership is to those around you.”

One of the strongest arms of SCRS’ commitment lies in its educational programs via the Repairer Driven Education (RDE) series they have been hosting at SEMA since 2010. Recognizing that not everyone can attend the classes in person, SCRS has been sharing captures from the 2023 Ideas Collide Showcase via their YouTube channel in addition to their Consumer Tips and Quick Tip videos, and select classes are available online at rde.scrs.com.

“We have this amazing program at the Show which has been the pinnacle of the work SCRS has done with SEMA. There are many in your organizations who can’t participate at the event,” Schulenburg stated, encouraging all to share the videos.

Registration for the 2024 Repairer Driven Education series is now open at rde.scrs.com. Schulenburg is “excited about this lineup of speakers. We have a tremendous amount of new speakers. We champion new voices who have not yet had the opportunity to participate.”

The program will look similar to previous years with just a few changes; Schulenburg announced the Ideas Collide showcase will be held on Wednesday this year. RDE classes will remain on Tuesday and Wednesday, and although the OEM Summit will remain on Thursday, it will be held in the late afternoon.

Member benefits continue to soar as Schulenburg reported successful growth with its healthcare and 401(k) plans. SCRS also announced a new member benefit with Enterprise that offers an additional five percent off the standard discount. The

program was exclusively put together for SCRS members, and collision shops can use it for personal and professional use. “I don’t believe you’ll find better than what this program offers,” Schulenburg promised.

SCRS recently teamed up with I-CAR to survey technicians to find out what they identify as their biggest needs and wants. “We asked technicians about their experience, what they look for, how they are supported. My take is that there is a lot this industry has to be proud of, but there is also a lot that needs to be improved upon. Can we make it an industry that has more than 15 percent of employers offering healthcare to their workers? We need to do more for the future folks,” he stressed. He outlined some of the biggest complaints technicians brought forth in the survey, such as the lack of healthcare and absence of paid time off. Some suggested the want for 401(k) matching like other industries offer.

Schulenburg reminded all about SCRS’ healthcare program via Gravie which features rich benefits and a cost savings to employers. It’s been well received with positive reviews and continues to pick up more members per quarter. Expanding participation will “give us the ability to influence the quality of benefits.” They have also taken on an additional carrier, Angie Health, in order to make the program available to businesses with as little as two employees. “The Gravie program has a minimum of 10 employees, and some shops don’t have enough employees to meet that requirement, so we looked into how we can serve smaller shops with the same quality and options using national networks.” Through the power of community and the power of the association, the plan can be risked and rated as a 6,000 business entity. “That brings a lot of value to a collision business with 10 employees that couldn’t accomplish that on their own.”

Same goes for the SCRS 401(k) retirement plan, as “the objective is to give small businesses the opportunity to participate in plans that benefit by everyone’s involvement. As the plan grows, all participants benefit from the fact that you have this growing asset class,” Schulenburg explained.

The plan currently has a balance of $27.5 million dollars with

20 June 2024

633 participants. As participants are added, fees decline. Passing the 500 member milestone reduces the price per person when the next fee cycle is met. More information about the member benefits can be found at scrs.com/member-benefits

SCRS continues to produce valuable content that can be shared with technicians as well as consumers. The Media Development Committee reported the completion of 40 new videos to be released via SCRS’ YouTube channel “marketing tools that help make for a more informed audience,” according to Schulenburg.

Referring to the results of the blend study and its outcomes, Schulenburg stressed the need for continued conversations internally.

“We don’t have those discussions often. We don’t sit down with the painter and talk about what is done differently in the paint department with different colors, when it’s a metallic versus a three-stage. If your repair planner has a better understanding of those technical requirements, you now have a better ability to talk about those variations. They now have the ability to talk about how a predetermined position is different than actually evaluating on the spot what that vehicle requires, and they can talk about why this vehicle is different than that vehicle. We leaned into what the overall average difference was when you looked at all the paint manufacturers, all the different colors and all the different methodologies. But if you really look at the research within the study, it also includes what the difference was for a two stage solid versus a two stage metallic versus a three stage. And those numbers were not the same. Those numbers actually reflected variation in the process. If you understand the process, you can talk about why that variation exists, and you can answer these questions in a more informed way. So they address three-stage in the same way that it should follow on the bottom valuation of the specific vehicle and the refinish requirements in question.

“We’ve been trying to find ways to bring facts to the conversation, rather than anecdotes. When you are educated enough to educate someone else and can point to a specific reference to help document it, this is what we have been focusing on.”

Next, SCRS has plans to research and perform a study on structural measuring, the executive director announced. “We believe that setup and measure has this historical kind of approach from the industry that we often hear from our members, just as we did with blends, that doesn’t reflect what the current requirements of modern day vehicles and modern day equipment requires. And so, in our next research project, we intend to look at structural setup, structural measuring and a performance study that analyzes both of those tasks and finds a way to communicate it back to the industry.”

Other meeting activities included SCRS Treasurer Andy Tylka confirming SCRS is “financially health and within budget,” and newly appointed Education Chair Andrew Batenhorst welcomed a team from Pacific Northwest Pollution Prevention Resource Center

“We’ve been trying to find ways to bring facts to the conversation, rather than anecdotes.

When you are educated enough to educate someone else and can point to a specific reference to help document it, this is what we have been focusing on.”

-SCRS Executive Director Aaron Schulenburg

to outline the resources they provide to help shops stay under the regulation threshold when it comes to hazardous materials for the benefit of their employees, environment and the health of their neighbors.

On behalf of the Affiliate Engagement Committee, Tylka reported 40 state representatives from auto body groups across the nation participate with virtual meetings five times a year giving all the opportunity to interact and share ideas. “It takes everyone away from being on their own island and gives all the ability to help each other out,” he stated. Attendees also heard from Justin Lewis (Accurate Auto Body; Redmond, WA) and Jeff Butler (Haury’s Collision; Seattle, WA) of the Washington Independent Collision Repair Association (WICRA), who relayed how they launched their association in 2019 and what they have managed to accomplish in the areas of membership and legislation. Database Enhancement Gateway (DEG) Administrator Danny Gredinberg gave an update on recent activities that continue to lead to positive changes via the three major information providers (IPs). “We have to submit these inquiries because, at the end of the day, we want to get paid fairly for the work we are doing,” Gredinberg encouraged.

SCRS held an election at the conclusion of the meeting which resulted in Todd Hesford (Community Collision Centers) and Andy Tylka (TAG Auto Group) being re-elected to the Board and Josh McFarlin (AirPro Diagnostics) elected to his first term. H&D

Executive Director’s Thoughts

It is always so invigorating to attend the national meetings, and SCRS is one of the best! They are working on so many amazing projects, for the benefit of the industry, and are doing so with help - and in support - of the associations like WMABA. We are so proud our President Kris Burton is on the board representing our area! - Jordan Hendler

21 June 2024 Shaping the industry’s future. BY ALANA QUARTUCCIO

THEY’RE CALLED “ORIGINAL BMW PARTS” FOR GOOD REASON. FOR UNCOMPROMISING PRECISION AND INCOMPARABLE QUALITY, YOUR BMW CENTER IS YOUR ONE-STOP SHOP FOR EVERYTHING BMW.

For Original BMW Parts, contact one of these authorized BMW centers:

BMW of Silver Spring 3211 Automobile Blvd

Silver Spring, MD 20904 866-737-8937

Direct: 301-890-3015

Fax: 301-890-3748

Email: wholesaless@mileone.com bmwofsilverspring.com

Passport BMW 5000 Auth Way Marlow Heights, MD 20746

301-423-0733

Fax: 301-423-2717 passportbmw.com

Richmond BMW 8710 West Broad Street Richmond, VA 23294

800-237-0130

Direct: 804-527-6860

Fax: 804-965-6254

Email: tdailey@crownauto.com richmond-bmw.com

BMW of Catonsville 6700 Baltimore National Pike Baltimore, MD 21228

855-996-2906

410-744-2000

Fax: 410-818-2600

bmwofcatonsville.com

22 June 2024

THERE HAS NEVER BEEN A BETTER WAY TO BUY THE WORLD’S BEST ENGINEERED PARTS.

©️2024 BMW of North America, LLC. The BMW name, model names and logo are registered trademarks.

COVER STORY

Handles Air to Land, Matte to AI Chat & What’s to Come

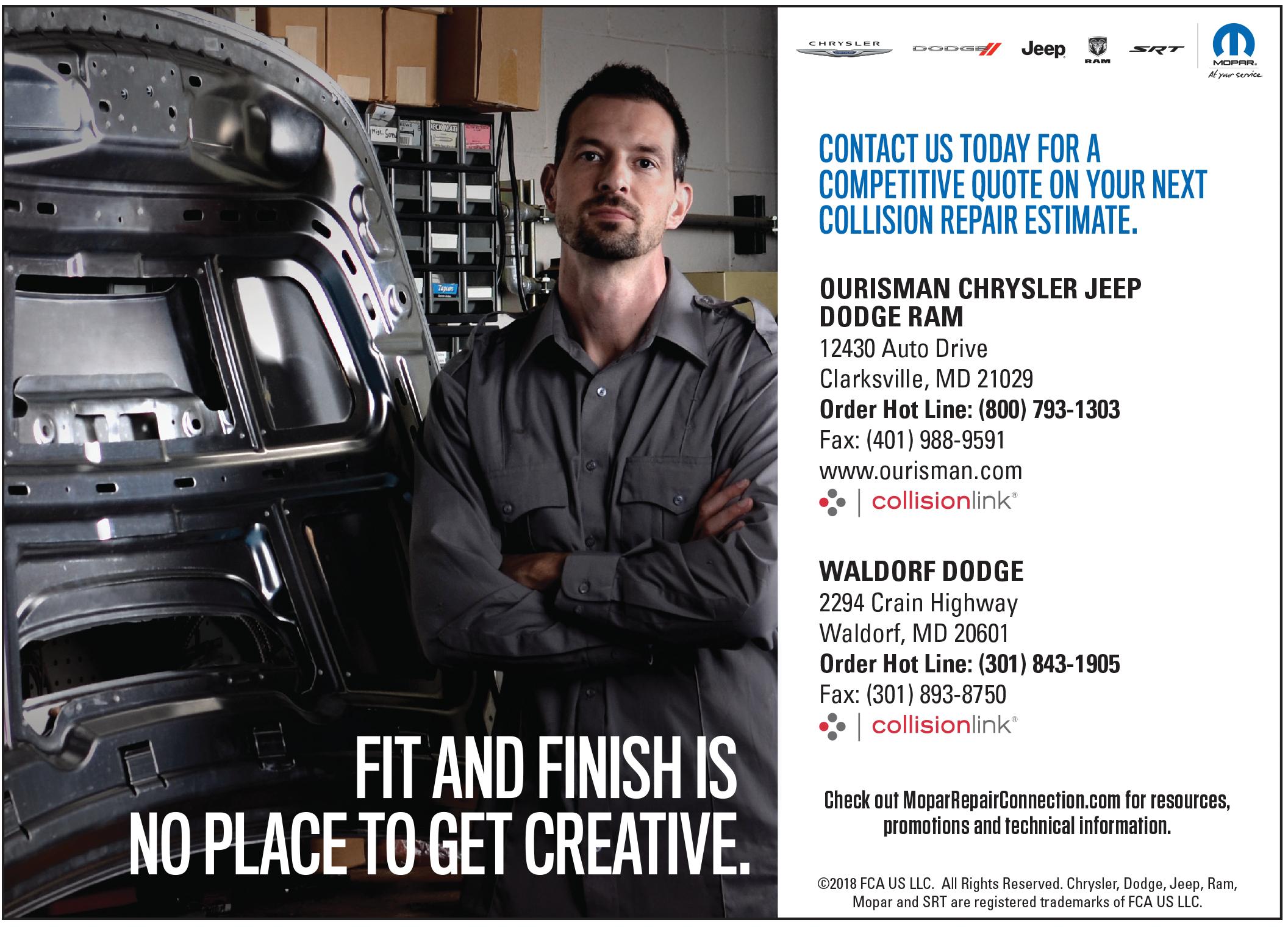

The spring Collision Industry Conference (CIC) left no stone unturned in tackling just about every element of the changes and challenges this industry is facing – and will face for years to come. Technologies like AI are gaining a stronger voice, while data sharing concerns increase, and paint processes and other repair procedures need better solutions toward efficiency.

“I suggest we ask ourselves, what is the ‘greater good?’” Interim Chairman Darrell Amberson queried. “What is the higher goal? What is the normal cause? For many of us, the reason we are here is not only to educate ourselves and for self improvement, but also for the good of the industry. How can we improve our proficiency? How can we gain harmony within our industry? How can we stay ahead of new technologies? How can we adequately staff our businesses? How can we improve safety and provide for the good of the motoring public?

“Think of this empty chair,” he continued, pointing to CIC’s visual representation of the consumer. “It’s the hope and desire of all of us who will spend time on this stage today, that we cause you to think, to challenge some of your perceptions, to broaden your horizons, to frustrate you, to inspire you, to motivate you. We hope to stimulate your emotions and to energize you. We hope to compel you to share your ideas, perspectives and reactions. And we want it to be fun.”

Before the back-to-back presentations got underway, Amberson was joined by CIC Administrator Jordan Hendler and past chairs to introduce “the enthusiastic, driven and energetic” Dan Risley (CCC Intelligent Solutions) as the new Chair for 2024-2025. Risley’s term will begin with the July meeting in Denver, CO.

The conference took flight with the Estimating and Repair Planning Commitee’s compelling discussion about the aligned world of the airline industry. “I think you’ll see that there’s going to be some parallels as far as the repairs, the training requirements and things of that nature,” predicted Danny Gredinberg (Database Enhancement Gateway) as he introduced Kirsten Bossenbroek Spalding (Boeing) whose presentation, “Boeing: From Wheels to Wings,” set out to answer the question, “Is there a difference in repair outcome?”

Much like CIC works for the greater good of collision repair, Spalding shared similar goals the Commercial Aircraft Composite Repair Committee (CACRC) has for the airline industry. “You could swap out the word ‘automotive’ for ‘airplane’ and be having very

similar conversations,” she said, outlining the comparisons she quickly discovered as she began to learn about the collision repair industry.

Whereas, at one time, it appeared all of the airline industry was “along the same learning curve,” an influx of new composites began to change that quickly, according to Spalding. As a result, some parts of the industry were not keeping up or were taking more time to gain familiarity with “metal aircraft structure or pyramidal aircraft structure. And now we’ve got these heavy hyper-efficient composite structures, and we need to make sure that everyone understands the criticality of these processes, especially repairing them and inspecting them. It’s different from what we’ve been used to with metallic structures. We’ve also got a lot of regulatory agency backing in the CACRC, as well, so we published a number of standards through CACRC,” she explained.

Spalding explained CACRC’s “decision tree” in support of the industry’s goals to promote repair and standardization, increasing safety while also reducing cost. Bringing groups together to have conversations also mirrors what the collision industry does.

“Typically, the Federal Aviation Administration (FAA) and NASA are in attendance at all our meetings, and we’ve also got regulators from other countries participating. We’ve got big OEMs, maintenance organizations, repair and overhaul suppliers, parts suppliers and material suppliers. So, we’ve also got some overlap in that space as well. And then we also have support from academia.”

Like with collision repair, it all comes down to focusing on the consumer, Spalding and Gredinberg stressed.

Piggybacking on previous discussions concerning artificial intelligence (AI), Gabriel Morley (DEKRA) reported that the Future Disruptions Committee has been researching AI trends, and instead of continuing the conversation about what AI could do in the future, they decided to focus on what AI can do for the industry now

“At the last CIC, we talked a lot about what AI could do [some day]. But what is it doing today? Because there’s a lot of use cases. AI is being implemented today. And if you’re not getting into it today, that’s going to have some impact down the road for these future use cases that we talked about. We’ve had quite the interesting conversations around AI, what it’s doing, how each of us are using it. We’re discovering new cases of AI and how it’s being used in

24 June 2024

different businesses.”

“I know there are a lot of folks who think that AI is going to take jobs away, but the best thing I can tell you is that isn’t going to be true, at least for a while,” shared James Spears (Tractable). “If a company knows how to leverage AI, it’ll be that company that knows how to leverage the tools and do better,” he commented, indicating that AI could make work life easier by taking tasks away from employees but not actually eliminating their jobs.

Spears referred to AI tools which can help on the business side. “I’ve used a platform called Synthesis that creates training videos,” he added. “It has an avatar; it’s in like 40 different languages. You type in your training script, and you can have a web-based training session within a few minutes.

“I have a lot of technical guys on my team who may not do a lot of business writing,” he continued. “So there’s a tool called Grammarly, which we load up for them, so now when they have to write an email to a client or back to a partner, they have tools to help them tighten up their business writing. It will help you write out your email, to make it more concise, persuasive or direct. This helps a lot of people who have not traditionally had to do this writing in their past to present themselves more professionally.”

AI can also help a shop improve the customer experience.

Ryan Taylor (Bodyshop Booster) called it “exciting times. AI is going to be the tool that becomes just like a part of us for the future. We can hardly imagine doing a math test without a calculator nowadays. It’s going to be like that where we can hardly imagine doing our jobs without some form of AI assisting us.”

Taylor presented the scenario of a customer who needs attention after hours.

“Think about the beginning of that customer journey when they have an accident. How can we instantly be there for that customer? AI can really fill that void for us. A lot of us are off enjoying the weekend. But that customer is in distress dealing with a stressful situation, and they need help. So, from the first point of contact, AI can be a really good co-pilot. Perhaps they visit your website and use an AI-enabled chat bot. Maybe they call your shop, and the AI answers the phone. There are texting AI platforms that can answer questions that your customer service representative or an estimator could answer. It can be trained off of those people who work for you.”

“AI is not going to replace and fix things for you,” Morley pointed out. “You won’t just plug in an AI tool and step away. There’s still going to be human involvement in the process.”

The Parts and Materials Committee sparked a conversation about matte finishes, a growing trend increasing in popularity as more manufacturers have begun to make this luxury option more affordable. “This starts to open it up even more as now people realize it’s more attainable and will select the option,” suggested Aaron Schulenburg (Society of Collision Repair Specialists). “However, that doesn’t necessarily make the process of restoring the finish any easier for the collision repair shops who are responsible for returning that finish upon repair. Shops are more likely to see this in their shops.”

Panelists Thorsten Alstede (AkzoNobel), Bradley Letourneau continued on pg. 26

25 June 2024 Education for the greater good. BY

ALANA QUARTUCCIO

CIC Interim Chairman Darrell Amberson Danny Gredinberg (Database Enhancement Gateway) Kirsten Bossenbroek Spalding (Boeing)

Gabriel Morley (DEKRA)

James Spears (Tractable)

Ryan Taylor (Bodyshop Booster)

COVER STORY

continued from pg. 25

(BASF) and Kye Yeung (European Motor Works) joined Schulenburg in a discussion designed to help shops understand how to contain defects and create a better environment in order to effectively produce this finish to meet customers expectations.

Letourneau suggested that “because there are no standards, and we should expect to see variation, what do we need to do as your finishers to put these back to factory conditions? We need to spend extra time and effort in properly preparing to match the sheen and match the color and above all to do the repair back to OEM specifications.” Ultimately, knowledge is power, and one should have no fear as long as they follow the steps and OEM procedures.

Alstede agreed with Letourneau, adding, “Matte finishes are really not that different from others we’ve worked with.” Focusing on the importance of understanding features and limitations a spray booth operator should have regarding its booth, Alstede reviewed a number of considerations for proper use of matte finish. “Maintaining a balanced pressure in the cabin during the spray paint cycle is actually very important,” he stressed.

Yeung shared his perspective of having to redo improperly done matte finish vehicles in his shop, recommending steps he uses to minimize the need to redo these jobs. One tool he uses is known as a gloss meter. “It measures things in gloss units from zero to 100. The glossiest is zero, and the 100 is matte. They have three cameras in them at 20, 60 and 85 degrees. When you take a sample of a finish, you’ll see that it can differentiate the amount of loss that the human eye can’t detect.”

I-CAR representatives announced they have created a mobile application for their Repairability Technical Support (RTS) portal. “We noticed that techs were trying to use RTS on their phones,” said Nick Dominato. “We realized we needed a better way to get RTS into the hands of the technicians if they have questions about proper repair procedures while working on a vehicle. This gets that information to them in an accessible manner.”

The Data Access Privacy and Security Committee set out to answer the industry’s most pressing questions concerning the collection and removal of data appearing on vehicle history reports with a panel discussion featuring an Experian Automotive executive

and other industry experts.

The panelists covered the subject at great length starting at the collection of data with Ed Pontis of Experian sharing, “Our biggest source comes from the states. We also get data from local police departments, auctions and some from body shops.”

Conversation also explored how parts suppliers are involved when it comes to licensed information.

Pete Tagliapietra (Data Touch) offered food for thought as they have discovered, “Parts numbers end up providing valuable information on determining the severity of damage. Well, when you look at a report from – let’s pick on Carfax for a minute – I’m getting all of the parts information from dealer management systems. And I have the towing companies, and I’m licensing all of the images that the towing companies take at the accident scene, including the VIN. So, I start tying these databases together, and just from the parts information, I now can generate a vehicle damage report. We thought it was all based just on estimates originally, but that’s not the case at all. If I’m a shop owner, I would want you to know that anytime you generate a parts list without an estimate, there’s a good probability it’s still going to end up on a vehicle history report. And it’s going to have a damage assessment associated with it. Once the vehicle history reporting company has the parts list and other pieces of information, they have an algorithm, an AI algorithm by the way, that generates the severity automatically for them that they produce on the report.”

Trent Tinsley (Enterprise Rent-a-Car) asked shop owner Scott Benavidez (Mr. B’s Paint and Body Shop; Albuquerque, NM) about his experience managing customers who have directly blamed his shop for accidents being listed on their vehicle history report. “We’re better equipped now [on how] to tell them,” Benavidez said, referencing situations where customers have blamed his shop due the Carfax date being the same as the date of his shop’s written estimate.

“When they put those two things together, it’s difficult to explain. We’ve been going through this for a long time figuring out that when we hit one button, it turns into 10 people [having access to data], and then those 10 people can send it to another 10 people, and those 10

26 June 2024

Aaron Schulenburg (SCRS) Thorsten Alstede (AkzoNobel) Bradley Letourneau (BASF) Kye Yeung (European Motor Works)

send it to another 10 people, so we have no idea where information ends up. That’s tough to explain to a customer.”

The CIC audience also learned about legislative efforts coming out of associations around the country from local and national leaders. Individual states are pursuing their own bills in relation to specific state-related concerns, such as Texas which has been fighting for legislation to make the Right to Appraisal mandatory in all insurance policies. Meanwhile, Emil Nussbaum of the Automotive Recyclers Association shared that roughly a dozen states around the country are working to create legislation to govern framework on how electric vehicles should be handled, fixed and processed for recycled parts and what that life cycle will look like.

The next CIC meeting will be held July 10 in Denver, CO. Visit ciclink.com for more information. H&D

Executive Director’s Thoughts

This was one of the most in-depth CIC’s I’ve been to yet, and much of what was discussed directly benefits repairers who want to stay ahead of the curve and want to know more ways the industry is poised for change. Even if change isn’t always seen as good, knowing what is coming is far better than meeting it face-to-face on your doorstep. - Jordan Hendler

Suitland, MD 20746

Phone: 301-423-6930

Fax: 301-423-2965

That’s because print advertising works. Especially when it’s connected to a powerful trade association. For over 30 years, Greco Publishing has partnered with the best of the industry to provide trade associations a voice, and to give advertisers a direct outlet to reach buyers.

Today’s shop is inundated with solicitations; advertising with Greco Publishing breaks through the noise to align your company as an association ally, and get you in front of your next customer.

27 June 2024 Only Genuine Nissan Parts deliver the fit, reliability, and performance to meet your shop’s collision repair needs.

original:

real with Genuine Nissan Parts. GENUINE

MAKE ALL THE DIFFERENCE. Contact us for

parts needs: Passport

So keep it

Keep it

NISSAN PARTS

all your

Nissan 5000 Auth Way

YOU

PRINT ADVERTISING WORKS. LET US SHOW YOU HOW. THOMAS GRECO PUBLISHING (973) 667-6922 info@grecopublishing.com @grecopublishing

MADE

LOOK.

Publishing | Event Management | Association AdministratiVE SERVICES | PUBLIC RELATIONS

You’ve got the right tools, staff, technology and procedures to give your customers the best repair possible. The missing piece of the puzzle? Genuine Volkswagen Collision Parts. Contact an authorized dealer today and find your perfect fit.

Alexandria Volkswagen 107 West Glebe Rd. Alexandria, VA 22305

703-684-7007

Fax: 703-684-4138

e-mail: parts@alexandriavw.com

Karen Radley Volkswagen 14700 Jefferson Davis Hwy. Woodbridge, VA 22191

703-550-0205

Fax: 703-643-0081

Ourisman Volkswagen of Bethesda 5415 Butler Road

Bethesda,MD 20816

301-652-2452

Fax: 301-652-2589

e-mail: vwwholesale@ourisman.com

Fitzgerald Volkswagen 114 Baughmans Lane

Frederick, MD 21702

Toll Free: 800-545-4745

Fax: 877-696-1841

e-mail: parts@fitzmall.com www.fitzparts.com

Fitzgerald Volkswagen of Annapolis 34 Hudson Street

Annapolis, MD 21401

Phone: 410-224-4636

Fax: 410-224-4264 www.fitzmall.com

Ourisman Volkswagen of Laurel 3371 Ft. Meade Rd. Laurel, MD 20724

Phone: 301-498-6050

Fax: 301-498-0157 www.laurelvolkswagen.com

Ourisman Volkswagen of Rockville 801 Rockville Pike

Rockville, MD 20852

Parts Direct: 301-340-7668

Toll Free: 855-417-4511

Fax: 240-499-2488

e-mail: rockvilleparts@ourismanautomotive.com www.ourismanvolkswagenofrockville.com Wholesale Parts

28 June 2024

“Volkswagen“ and the Volkswagen logo are registered trademarks of Volkswagen AG. ©2024 Volkswagen of America, Inc.

EDITOR’S MESSAGE

continued from pg. 4

might be beneficial for a non-writer who doesn’t have an editor at their beck and call 24/7.

Maybe AI isn’t the enemy after all. Perhaps, it is just a tool that can be used to make things a little bit easier like those CIC panelists suggested. It may be able to perform certain tasks, but it certainly cannot replace a sentient, experienced professional – not yet at least! And if AI can perform certain administrative tasks and reduce the busywork burden on people and businesses, is that such a bad thing if it allows us to spend more time on the more difficult aspects of the job that actually necessitate our expertise?

I cannot say that this little experiment has made me an AI acolyte, but I’m willing to be a little more open-minded about the benefits it may offer. Just don’t ask me to test-drive an EV. H&D

29 June 2024 chesautoequip.com • 800.604.9653 Providing Top-of-the-line Automotive Equipment CHALLENGER DX77 SURFACE MOUNTED DOUBLE-SCISSOR LIFT CELETTE X-TRAC LIFTING AND PULLING PLATFORM HUNTER ALIGNMENT SYSTEMS WITH ADAS CAPABILITIES PRO SPOT i4s AUTO WELDER Your Automotive Equipment Source! Facility Layout & Design Project Management Equip. & Specs. Training Equipment Installation How Can Our Team Help? View Our Work at chesautoequip.com MAINTAIN AN INFINITE INVENTORY OF ORIGINAL MINI PARTS. © 2023 MINI USA, a division of BMW of North America, LLC. The MINI name, model names and logo are registered trademarks. For Original MINI parts, contact: At your local MINI dealer, we believe that using Original MINI collision replacement parts will speed your repairs and increase your profitability. Original MINI parts assure an absolute perfect fit and function. MINI of Annapolis 25 Old Mill Bottom Road Annapolis, MD 21409 410-349-2565 fax: 410-349-2586 MYMINIANNAPOLIS.COM Crown MINI 8710 West Broad Street Richmond, VA 23294 804-527-6860 fax: 804-965-6254 CROWNMINI.COM Diagnostically speaking, there is no substitute. Contact one of these authorized dealers. Porsche technology. Porsche Genuine Service & Parts. Porsche Silver Spring 3131 Automobile Blvd. Silver Spring, MD 844-413-6929 Direct 301-890-3015 Fax 301-890-3748 wholesaless@mileone.com silverspring.porschedealer.com Euroclassics Porsche 11900 Midlothian Turnpike Midlothian, VA 804-794-3399 Fax 804-794-9771

© 2024 Porsche Cars North America Inc. Porsche recommends seat belt usage and observance of traffic laws at all times.

euroclassics.porschedealer.com

SERVICE, GUIDANCE & LIFETIME SUPPORT ON ADAS AND MORE AT AATI, INC.

by Alana Quartuccio

In today’s fast-paced, technology-driven climate, it takes more than just the proper equipment for automotive repairers to properly perform ADASrelated diagnostics and calibrations. Forward-thinking shops also need an experienced adviser to provide the support and guidance to safely and effectively use these tools to perform the necessary tasks.

Being a teacher and mentor to his clients is exactly what Gary Machiros sets out to do through his business, Applied Automotive Technology, Inc., with offerings that go far beyond “just” ADAS calibration system sales.

Machiros’ 30-plus years of training and repair experience have set him up naturally for this career path. His automotive journey began at the age of 10, working for his father’s gas station in Peabody, MA. By the time he was 20, he was running the family business, Angie’s Service, Inc. (the only gas station on Plum Island in Newbury, MA), which he still does today. The operation has since moved off the island to Newbury and has quadrupled in business; they began performing ADAS calibrations for collision centers in 2020. Currently, the shop performs between 20-40 calibrations per day.

“Back in 1998, General Motors was opening a lot of dealerships all around the world, and they needed a lot of overseas training as a result,” Machiros recalls. “The company that hired me to do the training required that I have a corporation; that was when Applied Automotive Technologies was initially born. I went to the Middle East and taught in Dubai for a while. I also traveled all over the northeast and other parts of the country giving automotive lectures on different systems. Today, we sell equipment all over the country, and people also fly in from different parts of the country to train. We spend a lot of time with them, teaching and training.”

Machiros understands the value in using OEM scan tools and has made it his life’s work to teach shop owners how to use these tools. He’s also expanded to include European scan tool diagnostics in his offerings, selling and training technicians in these operations. Machiros was asked to sell and support Autologic in New England. When Autel US was founded in 2004, he was again asked to sell and support this new revolutionary company. Since 2021, he has been selling and supporting Autel ADAS systems for the automotive aftermarket industry, and training Autel ADAS clients through AATI since 2022.

“When someone buys a calibration system, they will work with our ADAS calibration team members, training on live cars and learning right from the ground floor so they will know how to do it right in their own shop,” he explains. “We take the body shop from knowing nothing about the business and technical side of ADAS to hitting the ground running with everything they will need to do. Our clients get to see and feel everything. We also provide lifetime support. If they ever have a problem, they can call us.”

“We are a training group that sells equipment,” he adds. “You can buy something online, but you will not get any support or business training. What we bring to the table is a great asset to any body shop that wants to get into ADAS calibrations, as we will be with them through their entire ADAS journey, from the day they buy the equipment until forever. We are very special in that regard when it comes to building relationships with body shops, and we do this with shops all over the country. We teach them how to use the equipment and also understand how to properly invoice to be reimbursed by the insurance company, and we are also there to be a problem solver. If something happens, we are there for them.”

30 June 2024

Special promotional feature

31 June 2024 Maxisys COLLISION SIMPLIFIED A WORKFLOW-DRIVEN SOLUTION FOR A COMPLICATED PROCESS MAXISYS ULTRAADAS ADAS BAY MAX LIFT ADAS CALIBRATION. SAFER ALIGNMENTS. ONE MAXIMIZED BAY. MAXISYS IA900AST FOUR-WHEEL ALIGNMENT & ADAS CALIBRATION SYSTEM AUTEL.COM 1.855.288.3587 FOLLOW US @AUTELTOOLS COLLISION CENTERS - CONTACT AATI TODAY FOR A FREE ADAS CONSULTATION WE PROVIDE REAL BUSINESS AND TECHNICIAN TRAINING AT OUR WORKING ADAS CALIBRATION FACILITY APPLIEDAUTOMOTIVETECHNOLOGY.COM | GARY@APPLIEDAUTOMOTIVETECHNOLOGY.COM | 978.420.2138 KEEP ADAS CALIBRATIONS IN-HOUSE SUBLET TO YOURSELF

ADVICE INDUSTRY ASK MIKE:

How Can Shops Better Handle Demographic Changes in the Workforce?

This month, we “ASK MIKE” to share his thoughts on how shops can better deal with changing demographics in the workforce. We at Hammer & Dolly hope you find the following exchange useful, and we encourage you to reach out to us if you have a question for Mike on this or any industry-related matter that he can answer in a future issue.

Hammer & Dolly: If a shop intends to stay in business in the next five to 10 years, it’s likely that owners will need to deal with a drastically different workforce from the one they’ve been used to. Obviously, many of the employees they currently have will be leaving the industry fairly soon due to their age. What are you seeing right now as far as some of the major demographic or philosophical changes in the collision repair workforce, and how are the more successful shops acknowledging those changes and adapting to them?

Mike Anderson: That’s a great question. In the old days, there were three basic ways to get employees. Getting involved in SkillsUSA and other school events was the first way, and the second way was to tap into post-secondary schools. The third way was to take somebody on at your shop through an apprenticeship. That last option was often difficult, because it was sometimes hard to get a tech who earned a flat rate to work with an apprentice because it

could affect their pay.

Today, we have different mechanisms for recruitment, including LinkedIn, Indeed and Facebook. The days of finding people through the newspaper are gone. Obviously, things like SkillsUSA are dwindling, too, because vocational schools are shutting down their automotive programs.

These days, we really need to start with the onboarding process. In the old days, we’d just hire someone and fill out paperwork with them. Now, we need to modernize that process. There’s software called BambooHR that shops can use to run an ad automatically on LinkedIn, Indeed and other sites. People can apply through those ads and send in their résumé that way, which modernizes the ‘interview’ process.

Years ago, we’d interview a person who just wanted to work. These days, it’s more like the potential candidates are interviewing us. You really need to ‘sell’ your company to them – and you do that through your culture and your benefits package.

Benefits packages are very important today. If you look at what the Society of Collision Repair Specialists (SCRS) has done for its members, a shop can now offer health insurance and a 401(k) to employees. Shops also need to look at offering additional benefits. I know some shops that have gone to a four-day workweek or offer flexible hours. There are different things that can be offered to help recruit people.

Today’s generation wants a career path. You need to be able to tell someone, for example, that they can start as a CSR [customer service representative] and later become an estimator. We also need to debunk the myths of this industry, especially if there are parents involved. When I had my collision repair business, we’d invite vocational schools to participate in contests at the shop. Schools

32 June 2024

Vans. Born to run.

Get your customers back on the road faster with Genuine Sprinter Parts.

Call our Sprinter Certified Parts Advisors today to get started.

would send their students, and it was like an NFL tryout. We could see the students’ attitudes and aptitudes.

Sprinter Silver Spring 3301 Briggs Chaney Rd. Silver Spring, MD 20904

Adapting to today’s emplolyees.

WITH MIKE ANDERSON

301-890-3060 Fax: 301-890-5473

The military is another place to look. Every military branch has a website that shows you résumés of people who are getting out. One of them is called the Army Career Alumni Program (ACAP).

mbsilverspring@mileone.com

Hours: M-F 7:30am-5pm, S 8am-3pm

It’s also important to recognize that today’s employees really want feedback – they want to know how they’re doing. Shops should do employee reviews a minimum of twice a year. Quarterly is even better. When I did my employee reviews, I used to give everybody else on the team a questionnaire (FREE download available at bit.ly/AskMikeERQ), so they could offer feedback of their own.

H&D: It’s critical that shop owners and managers be open to feedback. The days of employees simply getting their marching orders are long gone. They need to be encouraged to offer thoughts on how the shop is run. Are you seeing more shops being open to listening to what their employees have to say?

MA: Unfortunately, I don’t see a lot of shops soliciting and receiving feedback from their employees. When Collision Advice was just Tiffany Driggers and me, I would make decisions and didn’t have to solicit anyone’s opinion. As Collision Advice has grown and I’ve brought in other people, I’ve solicited feedback from my team. But when I first started doing that and I’d introduce an idea that my team didn’t like, I’d get defensive, like, ‘What do you mean you don’t like it?’ It is hard for any human being to open themselves up to take criticism or suggestions. That’s probably my biggest area of growth right now. I’m still a work in progress, but I think it’s critical that we all work toward welcoming feedback without getting defensive and that we encourage

Quality Repairs Start With Volvo Genuine Parts.

Mike Anderson is an Accredited Automotive Manager (AAM) and the former owner of Wagonwork Collision Centers, two highly acclaimed shops located in Alexandria, VA. He has served as a member of many industry organizations throughout his career, including the WMABA Board of Directors, the Mitchell Advisory Board, the MOTOR Advisory Board, the ASE Test Review Committee, the National Auto Body Council, the Collision Industry Conference and the Society of Collision Repair Specialists. Additionally, he is a past Virginia SkillsUSA chairman, serves as a facilitator for Axalta Coating Systems’ highly recognized Business Council 20 Groups in both the US and Canada and facilitates numerous courses for Axalta Coating Systems’ Educational Series. He currently offers expert industry consulting via his latest venture, Collision Advice (collisionadvice.com). H&D

For over eight decades, the Volvo name has been synonymous with unmatched quality and performance. that legendary Volvo quality starts with Volvo Genuine Parts.

For Volvo Genuine parts at the right price, right now, please contact:

Volvo Cars Silver Spring 3121 Automobile Blvd. Silver Spring, MD 20904

301-890-5456

Fax: 301-847-2239

herbgordonvolvowholesaleparts@mileone.com

Hours: M-F 7:30am-5pm S 8am-3pm

employees to have their say. It’s part of developing the best culture for your business. Culture is everything – it’s the golden commodity today. Everybody can market themselves and get work, whether they’re DRP or non-DRP. It’s more important to get the right people and show your appreciation to them.

Give your customers the reliability and quality of Genuine Parts.

Contact our team of Mercedes-Benz Certified Parts Advisors today to get started.

Mercedes-Benz Silver Spring

3301 Briggs Chaney Rd. Silver Spring, MD 20904

301-890-3060 Fax: 301-890-5473

mbsilverspring@mileone.com

Hours: M-F 7:30am-5pm, S 8am-3pm

For your Volvo parts needs,

WIN offers education, mentoring and leadership development opportunities to build critical skills for success in the collision repair market.

• Local/Regional Networking Events

• Scholarship Program

www.volvogroup.com

• Annual Education Conference

• Educational Webinars

• Mentoring Opportunities

womensindustrynetwork.com

• School Outreach Program

• Most Influential Women (MIW) Award

33 June 2024

WIN?

Why Join