Kemperle represents hundreds of the industry’s top manufacturers and stocks thousands of their superior products. With more than 50,000 products available to our customers, Kemperle’s locations are uniquely equipped to find the products you need.

KEMPERLE PERFORMANCE DRIVEN PRODUCTS

Abrasives | Adhesives | Body Fillers & Polyester Putty | Clearcoats Detailing Products | Hardware | Masking Products | Prep Solvents/Cleaners Primers/Sealers | Reducers | Spray Suits | ...and more

PINNACLE EQUIPMENT

U.S. Importer for Car Bench International

NJ TRAINING CENTER

• Hands-on technical training

• Classroom seminars

ON-SITE MOBILE DEMONSTRATIONS & TRAINING

626 E. Elizabeth Ave Linden, NJ 07036

P: (908) 925-6133

F: (908) 925-4344

414-416 Madison Ave Paterson, NJ 07524

P: (973) 279-8300

F: (973) 279-9030

100 Melrich Rd Cranbury, NJ 08512

P: (609) 860-2800

F: (609) 860-2801

631 Clifton Ave Toms River, NJ 08753

P: (732) 797-3942

Linkedin.com/company/albertkemperleinc

P: (862) 244-4818

F: (862) 244-4822

F: (732) 797-0774 4 Emery Ave Randolph, NJ 07869

Our flagship dealerships are pleased to offer a wide selection of authentic genuine parts so you can repair your customer’s luxury car to the highest quality.

We not only sell WHOLESALE GENUINE PARTS across the tri-state area, but we also offer a knowledgeable team of parts specialists who will find the component you need for a seamless vehicle repair. WE WILL GO THE EXTRA MILE FOR YOU!

AUDI QUEENS

30-35 College Point Blvd. Flushing, NY 11354

Wholesale Direct: 929.297.0788

parts@audiqueens.com audiqueens.com

MERCEDES-BENZ OF BROOKLYN 1800 Shore Pkwy. Brooklyn, NY 11214

Wholesale Direct: 718.258.7055

parts@mbofbrooklyn.com mbofbrooklyn.com

MERCEDES-BENZ OF CALDWELL 1220 Bloomfield Ave. Caldwell, NJ 07006

Wholesale Direct: 973.808.0204

Parts@mbofcaldwell.com mbofcaldwell.com

JAGUAR BROOKLYN 809 Neptune Ave. Brooklyn, NY 11224

Wholesale Direct: 929.583.6492

parts@jlrbrooklyn.com jaguarbrooklyn.com

LAND ROVER BROOKLYN 809 Neptune Ave. Brooklyn, NY 11224

Wholesale Direct: 929.583.6492

parts@jlrbrooklyn.com landroverbrooklyn.com

LEXUS OF BRIDGEWATER 1550 US-22 Bridgewater, NJ 08807

Wholesale Direct: 866.679.7054

parts@lexusbridgewater.com lexusofbridgewater.com

LEXUS OF EDISON 711 US Highway 1 Edison, NJ 08817

Wholesale Direct: 732.593.6860

parts@lexusedison.com lexusofedison.com

“Gary, I wanted to thank you for your continued support for my latest purchase of the Autel ADAS Calibration system. You provided the training we needed and most importantly you provided a direction when calibrations needed a little more technical advice. I’ve had the good fortune of finding you many years ago to supply my necessary computer scan tools to stay current and relevant in this everchanging environment.

I use the analogy of running a business is like being a captain of a ship. My job is steering the ship and plugging the money holes all while navigating into calm profitable waters. After 36 years in business, I can say buying from you and attending many of your Technical Training classes has directly facilitated my continued success in the Auto Repair business.

I’ve owned the Autel ADAS system for over a year. HUGE Success.

Your extensive technical training background has led you to a great business opportunity to provide a valuable needed service that many garages and body shops don’t provide. Most cars leave body shops and repair facilities not getting the necessary Calibrations. The more I know the more I see the opportunity to make cars safer for everyone. One of the lessons I’ve learned is that business owners don’t tell other businesses where their Honey hole is. Buying from you with your training and after purchase support is a honey hole they don’t have to miss out on.”

Bill

Murphy, Owner Auto Clinic -Pepperell, MA

P.O. Box 734 Neptune, NJ 07753

EXECUTIVE DIRECTOR

Charles Bryant 732-922-8909 / setlit4u@msn.com

2023-2025 OFFICERS

PRESIDENT Ken Miller, 821 Collision, LLC (973) 949-3733 / kmiller@821collision.com

COLLISION CHAIRMAN/

PAST PRESIDENT ATTENDING

Jerry McNee, Ultimate Collision Repair, Inc. 732-494-1900 / ultimatecollision@att.net

MECHANICAL CHAIRMAN

Keith Krehel, Krehel Automotive Repair, Inc. 973-546-2828 / krehelauto@aol.com

TREASURER

Tom Elder, Compact Kars, Inc. 609-259-6373 / compactkars@aol.com

SECRETARY

Thomas Greco, Thomas Greco Publishing, Inc. 973-667-6922 / thomas@grecopublishing.com

BOARD

Dennis Cataldo, Jr., D&M Auto Body 732-251-4313 / jr@dnmautobody.com

Brad Crawford, Livingston Collision, Inc. 973-992-5274 / livingston.collision@gmail.com

Gary Gardella, Jr., County Line Auto Body 732-363-5904 / countylineautobody@gmail.com

Dave Laganella, Peters Body and Fender 201-337-1200 / petersbandf@gmail.com

Jeff McDowell, Leslie’s Auto Body 732-738-1948 / chacki@aol.com

Danielle Molina, 821 Collision (973) 949-3733 / dmolina@821collision.com

Ted Rainer, Ocean Bay Auto Body 732-899-7900 / ted@oceanbayautobody.com

Anthony Trama 973-818-9739 / anthonytrama@aol.com

BOARD ALLIED

Joe Amato, The Amato Agency 732-530-6740 / joesr@amatoagency.com

Mike Kaufmann, Advantage Dealer Services 973-332-7014 / mkaufmann@advantageds.com

NATIONAL NEWS

16 AASP Leaders Tour 3M Training Facility in Minnesota AASP/NJ NEWS

18 AASP/NJ Readies for Annual Lou Scoras Memorial Golf Outing in September

17TH ANNUAL LOU SCORAS GOLF OUTING

19 Tuesday, September 17, 2024 Knob Hill Country Club, Manalapan, NJ

NATIONAL FEATURE

20 Under-Indemnification Lawsuit Gains National Attention by Chasidy Rae Sisk

AASP/NJ MEMBER PROFILE

24 Wilson’s Auto Body by Kaitlyn Gavidia COVER STORY

PRESIDENT/PUBLISHER

Thomas Greco / thomas@grecopublishing.com

VICE PRESIDENT/SALES DIRECTOR

Alicia Figurelli / alicia@grecopublishing.com

EDITORIAL DIRECTOR

Alana Quartuccio / alana@grecopublishing.com

SENIOR CONTRIBUTING EDITOR

Chasidy Rae Sisk / chasidy@grecopublishing.com

OFFICE MANAGER

Donna Greco / donna@grecopublishing.com

PRODUCTION COORDINATOR

Joe Greco / joe@grecopublishing.com

CONTRIBUTING EDITORS Charles Bryant • Mario DeFilippis

Bauchner • Kaitlyn Gavidia

Published by: Thomas Greco Publishing, Inc.

244 Chestnut Street, Suite 202, Nutley, NJ 07110

Corporate: (973) 667-6922 / FAX: (973) 235-1963

www.grecopublishing.com @grecopublishing

28 Rising P&M Costs: Can Smarter Billing Help Loosen Insurers’ Purse Strings? by Alana Quartuccio

AUTOMOTIVE RECYCLERS ASSOCIATION OF NEW JERSEY

38 Wharton Insurance Briefs by Mario DeFilippis

Joe Amato, Sr.

Ron Ananian

Jim Bowers

Charles Bryant

Don Chard

Guy Citro

Pete Cook

Ed Day

Dave Demarest

Phil Dolcemascolo

Tom Elder

Bob Everett

Alicia Figurelli

Thomas Greco

Dan Hawtin

Rich Johnson

Mike Kaufmann

Wes Kearney

Nick Kostakis

Jim Kowalak

Keith Krehel

Joe Lubrano

Michael Lovullo

Jeff McDowell

Sam Mikhail

Ron Mucklow

George Petrask

Russ Robson

Jerry Russomano

George Threlfall

Anthony Trama

Cynthia Tursi

Lee Vetland

Paul Vigilant

Rich Weber

Brian Vesley

Glenn Villacari

Stan Wilson

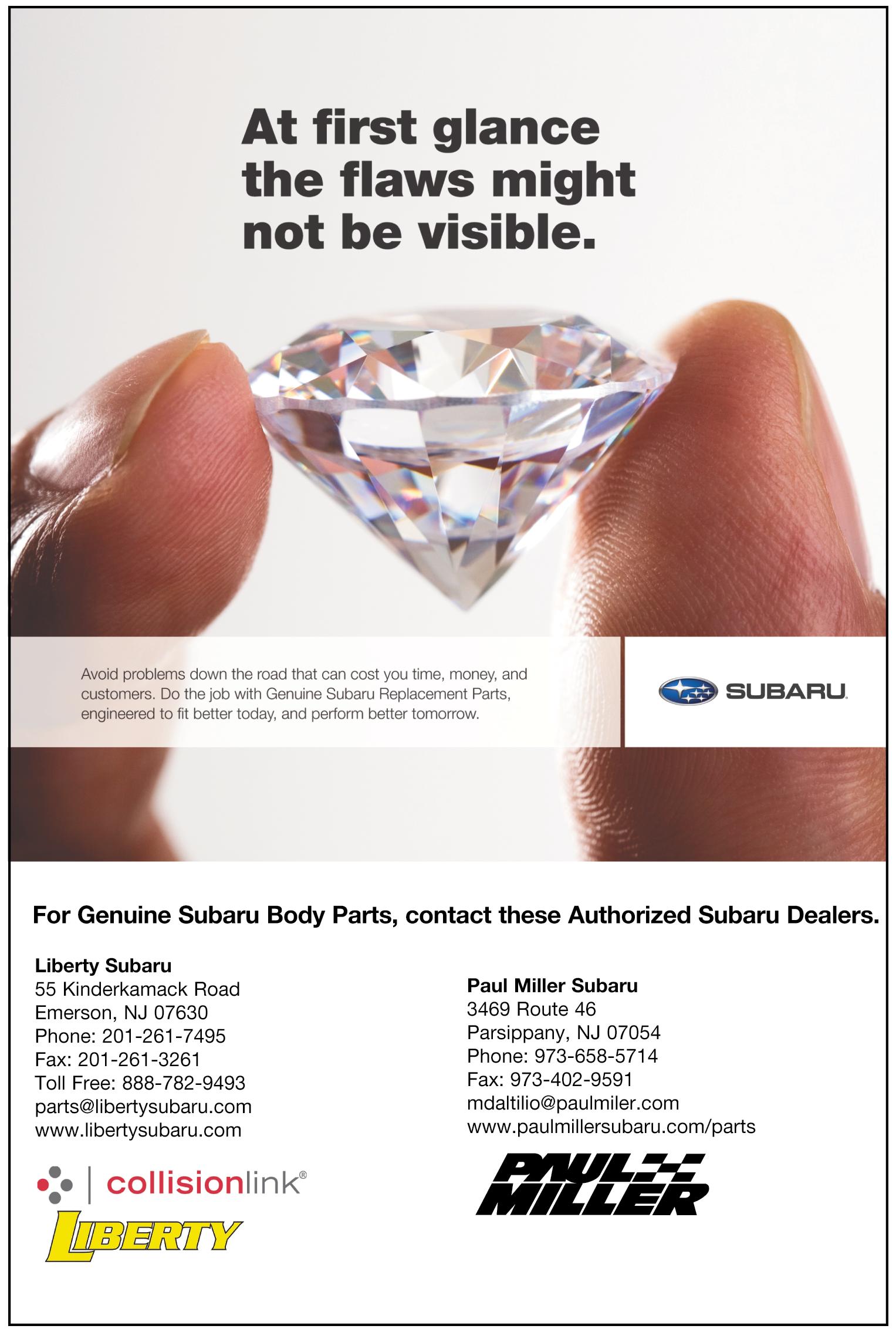

You’ve got the right tools, staff, technology and procedures to give your customers the best repair possible. The missing piece of the puzzle? Genuine Volkswagen Collision Parts. Contact an authorized dealer today and find your perfect fit.

Ciocca Parts Warehouse

8 Minneakoning Road

Flemington, NJ 08822

Toll Free: 800-221-1256

Fax: 908.782.1795

rmuir@cioccadealerships.com www.cioccaparts.com

Paul Miller Volkswagen 118 Morristown Road

Bernardsville, NJ 07924

TOLL FREE: 877-318-6557

LOCAL: 908-766-1600

FAX: 908-766-6171

Email: aaitchison@paulmiller.com www.paulmillervw.com

“Volkswagen“ and the Volkswagen logo are

Douglas Motors 491 MORRIS AVE. SUMMIT, NJ 07901

PHONE: 908-277-1100

FAX: 908-273-6196

TOLL FREE: 800-672-1172

www.douglasvw.com email: douglasparts@douglasautonet.com

Trend Motors 221 Route 46 West Rockaway, NJ 07866

888-267-2821

fax: 973-625-4985 www.trendmotors.com email: dreinacher@trendmotors.com

Crestmont Volkswagen 730 ROUTE 23 NORTH

POMPTON PLAINS, NJ 07444

TOLL FREE: 800-839-6444

fax: 973-839-8146

www.crestmontvw.com email: vwparts@crestmont23.com

If you know anything about me after all these years, it’s that when it comes to having anything to do with fixing things, I am the last person to look to. Especially when it comes to vehicles. Yes, as you know, my motto for 40 years has been, “I can’t fix a tire, but I can write about fixing one.” Sadly, that still holds true. However, after four decades, there may be a glimmer of light.

A few months ago, the lease was up on the Tahoe from hell (the diesel truck that seemed jinxed from the moment I leased it). Now, after so many years of driving, all I wanted was a vehicle that had a great stereo and also saved me money. I absolutely wanted another (nondiesel) Tahoe, but they – and every other truck that size – were just too damn expensive. I wanted to spend less per month, not more. So I called a dealer friend of mine and told him I

was looking for a truck similar to the Tahoe, but I wanted to spend at least $100 a month less. After he laughed at me for a good 10 minutes, he said he’d see what he could do.

He came back to me with a Dodge Durango and something called a Jeep Grand Cherokee Trailhawk. I test drove both, and frankly, I didn’t like either of them. After having a couple of Tahoes and Ford Expeditions, I was spoiled. I liked my big trucks. I felt safe and comfortable. (Or maybe I was just overcompensating! LOL) But postCovid, life is different, and there was no way of getting around the price differences.

I decided to go with the Trailhawk. (I mean, maybe I spent a day thinking about it? When you settle, you don’t waste time.) But that’s not the best part. Again, getting back to my lack of skills, not only did I switch from diesel

by THOMAS GRECO, PUBLISHER

back to regular gas: the Trailhawk was actually a hybrid! I am not a glutton for punishment; I am the Goodyear Blimp of punishment.

The kid who walked me through the process did his best. Trouble was, I forgot everything the minute I pulled onto Route 4. By the time I hit the Garden State Parkway, the car sounded like it was grinding its gears to the bone, and it wouldn’t let me go above 40mph. There I was, rush hour on the Parkway, trying to figure out what the hell was going on while frantically calling the dealership (they closed five minutes after I left) and “MFing” the world. Thankfully, I made it home and brought the car back the next day. Turns out there’s these stupid gears on the steering console that when you accidentally hit them automatically puts the car into some lower gear. What f#$king genius continued on pg. 36

AI is everywhere, even if we don’t always recognize it. Although it has existed in its simplest forms for quite some time, it’s now becoming more mainstream in our everyday lives. Many of us use AI to help draft the perfect email response or even write articles. (Only kidding, this is all me.) Regardless, it is a very powerful tool. Since AI is still in its infancy, the full extent of its potential has yet to be discovered, which is both exciting and frightening.

Our industry is not exempt from the AI revolution, as we are starting to see its implementation with predictive estimating models now in use by companies like CCC. Users can walk around a vehicle and snap a few photos, and AI will generate a preliminary estimate based on predetermined profile selections and a few simple questions about the damage. Pretty cool – albeit potentially illegal for shops to use in NJ. However, it certainly has its usefulness, especially on the insurer side.

I recently attended a negotiation seminar where I learned about another way insurers are using AI: to verify labor rates in a given market. Apparently, insurers are using AI to scrub estimates for labor rates (and likely more) to establish labor rates in a particular market for use in litigation cases. The process is simple – take the totals page from any uploaded estimate, scrub the rates column and generate a report of the current rates in a market. This would make it extremely difficult to argue against, considering it is data from estimates uploaded by repairers!

by KEN MILLER

During the seminar, a possible fix was suggested. It’s pretty simple and could be very telling if implemented: Using your posted door rates in the totals column, then making a bottom-line concession to the agreed price. This way, the information AI is aggregating reflects the actual market labor rate. Easy enough.

I’m not an attorney and don’t give legal advice, but I’m curious about taking this one step further and applying the same logic to labor operations. For those shops that do not itemize every operation performed on a customer’s vehicle – perhaps due to not receiving compensation from the bill payer or making a concession to the customer – every labor operation should be itemized and a value assigned. Any adjustment in cost should be made at the end of the estimate as a

“concession to agreed price” with a negative amount assessed.

This approach is important for several reasons.

It’s the law to fully document all labor performed and parts provided on a customer’s vehicle.

Constantly seeing how much your concessions in labor rates, labor operations and parts are costing your business might inspire you to rethink giving your money away!

By adopting these practices, we can ensure that the data AI uses is accurate and truly reflective of the market, ultimately benefiting our industry.

Offer your employees quality health insurance at an affordable price. The Alliance of Automotive Service Providers has partnered with World Insurance Associates to bring you the AASP Health Plan for members only. Now you can offer your employees quality health insurance at exclusive rates. And it’s fast and easy to enroll!

• Any size business is eligible

• National network of doctors

• Multiple plan designs

• Members-only health plan

• Potentially great premium savings

CONTACT: Joe Amato, Jr. Principal World Insurance Associates 4900 Route 33, Suite 103 Neptune, NJ 07753

O: 732-530-6740 x412

joeamatojr@worldinsurance.com

Terence

terencegorman@worldinsurance.com Call or email us

x162 | M: 646-438-4959

For as long as I can remember, insurance companies have shortchanged collision shops on the cost of repairs and have gotten away with it because that’s the way the negotiations between collision shops and insurers have always been: “Let’s make a deal.” Back in the day, when insurers actually sent an appraiser out to collision shops to inspect the damage on every collision repair that was reported to the insurer, it was common practice for the appraiser to say something to the effect of, “Look, I can’t pay your labor rate, but don’t worry, I will adjust the hours to compensate for the low labor rate.” This practice allowed the insurance industry to control the labor rate and still reach an agreed price with the collision shop making the repairs. I’m not talking about something that took place secretly and only the shop and the appraiser knew that this was taking place. This was the way that collision shops and insurance appraisers reached an agreed price to repair damaged vehicles from so far back that it is hard to even estimate when this practice first started.

From there and as other issues arose that insurers did not want to pay for, more games, as I call them, took place. As an example, when there were certain procedures that certain insurers randomly decided that they did not want to pay for, the appraisers were told to inform the collision shop that they don’t pay for that. Naturally, the shop’s response would be, “What do you mean you don’t pay for that? It must be done, so you don’t have any choice but to pay for it.” When a collision shop took a hard stand and insisted that he or she was not going to abide for performing a procedure and not get paid for it, the games began. In such a situation, it was a common practice for the appraiser to say, “Look, I must follow the insurer’s guidelines, but don’t worry about it; I will work it out by adding an hour or two here and there to compensate for the procedure that the insurer won’t allow me to pay for.” The most common response to this type of activity was, “Okay, I don’t care where you put it, so long as you get to the bottom line, I need to make the repairs.” And that was how it was done!

by CHARLES BRYANT

This method of negotiating an agreed price to repair damaged vehicles seemed to work because it went on for year after year right up until recently; however, at the same time, it allowed insurers to gather the documentation or paperwork to show that many other shops were not charging for the procedure in question, which simply made it easier to refuse to pay other shops for that same procedure by showing that they had not paid for it on many of their estimates. This type of “Let’s make a deal” negotiations has gone on for as long as I can remember, and I have to admit, it has worked for the most part for many, many years, with the exception of a few shops that would take the stance of “Hey, if they are not going to pay for it, I am not going to do it!”

However, with the complexly technical modern vehicles on the roads today, the time has come to eliminate any type of deal making whatsoever. Today’s vehicles are so complicated and sophisticated that the repair shops or the workers performing the repairs must get trained to perform the repairs exactly the way the manufacturer of the vehicle recommends and follow the published repair procedures to the tee, or the vehicle will not be put back to the safe operating condition that it was prior to the accident that caused the damage, period!

The bottom line is the time for the old fashion game of “let’s make a deal” on the cost of repairs must come to a screeching halt. I say this not only because it’s wrong to conduct business in this manner, but because the type of vehicles on the roads today must be repaired

continued on pg. 37

All Makes and Models

24-48 hour Turnaround

Proven Color Match Database

On-site Cosmetic Repairs

Large Inventory of O.E. Replacements

AASP/NJ President Ken Miller (821 Collision; North Haledon) joined fellow leaders of AASP National recently for a tour of the 3M training facility in St. Paul, MN. AASP National leaders learned about the equipment, extensive training and the importance of the proper use of the product while being led through the state-of-the-art 15,000 square foot facility.

Collision repair facilities seeking big solutions to every size job that comes their way need look no further than the Big Bench universal frame machine and bench system. This hybrid drive-on / drive over system is specially designed to accommodate all passenger vehicles as well as select commercial vehicles. Its new pulling tower provides smooth and accurate 180º movement, with optional removable side ramps to cater to vans and extralong sedans, while double safety device and twin lifting arm features ensure that you can trust the accuracy of every lift and adjustment. The basic package includes a 10-ton pulling unit, mountable on any of the four sides of the bench, as well as a pad set, arms for clamp set, high clamps set, electrohydraulic unit and wheel stands set. Additional towers can be added if needed to assist technicians in repair. This universal bench system is the comprehensive solution for most auto body shops.

Whether you’re dealing with a minor fender bender or a major collision, the Big-BENCH is versatile, precise and able to make meticulous adjustments to ensure vehicles are restored to the highest standard. Additional accessories including pulling tower extensions, clamps, anchoring systems, adaptors & convertible ramps are

The Big-BENCH universal frame machine and bench system is designed to handle any size job with accuracy and versatility.

available. Contact Reliable Automotive Equipment today to learn more about the Big-BENCH universal frame system and our wide variety of products, training and support at raeservice.com

AASP/NJ will once again gather the automotive community for a day of fun and friendly competition with the return of the annual Lou Scoras Memorial Golf Outing on Tuesday, September 17.

Following last year’s successful outing, this long standing tradition returns to the Knob Hill Country Club (Manalapan, NJ), which features an immaculate and challenging Mark McCumber-designed course. AASP/ NJ continues to honor late shop owner and association member Lou Scoras of Holmdel Auto Body by hosting the annual event in his memory. A portion of the event proceeds will be applied toward a collision industry scholarship fund.

“I hope everyone puts this date on their calendar and plans to spend it among friends and colleagues on this absolutely beautiful course,” states AASP/NJ President Ken Miller. “Last year’s successful event proved just how

many people love and appreciate the opportunity to put business aside for one day to enjoy some fresh air and camaraderie. It’s also a great way to give back, as we all know how crucial it is to support young talent in this industry.”

The fun-filled day will begin at 11:30am with registration and lunch, followed by a 1pm shotgun start. Following time on the green, the gathering continues at 5:30pm with a cash bar, dinner and prizes. Those unable to participate on the green are welcome to join AASP/NJ in the evening for the dinner and award ceremony.

“Even if golf is not your sport of choice, consider joining us for dinner and take part in some fun interaction,” adds Miller. “I look forward to seeing everyone there!”

Player and sponsor registration is now open. Please visit bit.ly/AASPNJ2024golf for more information. To learn more about AASP/NJ, visit aaspnj.org

TUESDAY, SEPTEMBER 17 Knob Hill Country Club, Manalapan, NJ

PRICING: $195/player ($780/foursome) DINNER ONLY (NO GOLF): $60 ea. 11:30am Registration & Lunch • 1pm Shotgun Start 5:30pm Cash Bar • 6pm Dinner

JOIN US FOR A FUN DAY OF GOLF WHILE SUPPORTING AASP/NJ!

SPONSORSHIPS: REGISTRATION DEADLINE SEPT. 10

Platinum Sponsor Package: $3,500

- 1 Foursome ($700 value)

- 2 Hole Signs ($600 value)

- Your logo on pre-event promotion

- Premium size placement on event signage

- Topmost listing in NJA post-outing coverage

Gold Sponsor Package: $2,500

- 1 Hole Sign ($300 value)

- Large size listing on event signage

- Listing in NJA post-outing coverage

Silver Sponsor Package: $2,000

- 1 Hole Sign ($300 value)

- Medium size placement on event signage

- Listing in NJA post-outing coverage

Bronze Sponsor Package: $1,500

- 1 Hole Sign ($300 value)

- Small size placement on event signage

- Listing in NJA post-outing coverage

Hot Dog Cart Sponsor: $2,500

- Your name/logo included on hot dog station signage

- Listing on event signage

- Listing in NJA post-outing coverage

Lunch or Dinner Sponsor: $1,000 ea.

- Your name/logo included on signage at chosen event (lunch or dinner)

- Listing on event signage

- Listing in NJA post-outing coverage

Longest Drive Sponsor - $750

This year’s outing is dedicated as always to the memory of Lou Scoras of Holmdel Auto Body.

- Listing on event signage

- Company name/logo on signage at contest hole

- Listing in NJA post-outing coverage

Closest to the Pin Sponsor - $750

- Company name/logo on signage at contest hole

- Listing on event signage

- Listing in NJA post-outing coverage

Hole in One Contest Sponsor - $750

- Company name/logo on signage at contest hole

- Listing on event signage

- Listing in NJA post-outing coverage

Hole Sponsor - $300 per sign

- Company name on double-sided lawn sign

- Listing on event signage

- Listing in NJA post-outing coverage

A portion of the proceeds from this year’s event will be put toward a collision industry scholarship fund.

When a vehicle owner brings their car to a shop after an accident, they typically expect it to be repaired, so it’s a tough blow when they learn their vehicle has been deemed a total loss. It’s even more upsetting when their insurance carrier shortchanges them by undervaluing the actual cash value (ACV) of the loss. Yet, that’s a common occurrence these days as demonstrated by the prevalence of allegations, lawsuits and settlements related to under-indemnification.

While shops, vehicle owners and consumer advocates have been bringing these concerns to the forefront for a number of years through a variety of methods, a recent lawsuit in California suggests that this ongoing issue has finally captured the attention of public officials and hopefully indicates that it’s time for these lowball settlements to come to an end.

The Alameda County Consumer Justice Bureau (CJB), under District Attorney Pamela Price, recently filed a lawsuit against Progressive, USAA, CCC Intelligent Solutions and Mitchell International. The suit alleges that, in order to maximize insurers’ profits to the detriment of California consumers, the companies “worked together to create and use automobile valuation software to systematically undervalue ‘totaled’ vehicles and pay California insurance consumers less than the actual value owed under the policies” in violation of a number of California laws, including the Insurance Code, Unfair Competition Law and False Advertising Law.

“A vehicle is the lynchpin to life in California. Many residents live

paycheck to paycheck and go deeply into debt just to buy a car,” District Attorney Price said in the press release issued by her office. “When an insurance company underpays its customers for a totaled vehicle, that can result in missed loan payments, damaged credit scores, impacted borrowing, and the inability to buy a replacement vehicle. That can lead to job losses and even homelessness. California residents and small businesses try their best to follow the law. They expect their insurance companies and affiliates to do the same.”

According to the 69-page complaint filed in April 2024, these insurers not only failed to operate in good faith; they are accused of using specially-designed valuation software created as a means of manipulating and lowering the ACV of total loss vehicles by utilizing a deceptive set of “comparable” vehicles, which allow insurers to lower the reported ACV and coerce customers into accepting lowball settlement offers. Additionally, the complaint indicates that insurers minimize their losses further by reselling the totaled vehicles at auction.

The lawsuit acknowledges that policyholders are only one entity being negatively impacted by this scheme. It also impacts businesses, including car manufacturers and dealers, gap insurance providers, automobile loan institutions and car repair facilities “that lose out on potential repair business when vehicles are systematically totaled instead of repaired.”

Industry leaders weigh in on this

scheme and what the CJB’s lawsuit could mean for collision repairers nationwide.

“The outcome will certainly be interesting, especially if any or all of the plaintiffs are found guilty, as it could catalyze similar actions in other jurisdictions,” suggests AASP/NJ President Ken Miller. “The systematic undervaluation of total losses is not a new issue, and I wouldn’t necessarily view this case as a solution to the problem, even with a favorable verdict. But we can hope! So, until this problem is resolved, let’s try something different. As service providers, we have a responsibility to edify our customers about the total loss process, inform them about the relevant laws and suggest potential tools to help determine a proper valuation. Armed with the correct information, savvy individuals should be able to negotiate equitable settlements with insurers and avoid being taken advantage of.”

“For far too long, here in Massachusetts, we have seen this method aggressively pursued by many insurers in an effort to unjustly mitigate their financial liability and obligation to the vehicle owners,” notes AASP/MA Executive Director Lucky Papageorg. “Using the ‘official’ looking computer-generated reports, which can be difficult to navigate by the typical vehicle owner, insurers successfully deter far too many insureds from challenging the validity of the settlement offer as being fair and reasonable. From my own personal experience when approached by insureds seeking assistance, I have found that the

settlement offers are significantly lower at first, but those that are challenged by the vehicle owner will typically increase significantly.

“We have been educating our member shops regarding what to look for and how they may assist their customers by providing them with information,” he continues.

“I feel that the only way to thwart the underhanded methods of the insurers, in combination with the information providers, is exactly what is happening in California; a lawsuit may take time to be resolved but will shine a light on the collusion between the parties, which is clearly evident and meant to under-indemnify their policyholders. This practice has allowed insurers to unjustly enrich themselves at the expense of the policyholder. I applaud the action being pursued in California.”

“The idea that insurers underindemnify their policyholders isn’t shocking…We’ve all known that something isn’t quite right about how insurers ‘value’ claims for years,”

ABAT President Burl Richards points out. “But it is pretty exciting to see a public official taking note of this egregious wrongdoing and making an attempt to defend her constituents. I’ve often wondered if insurance companies will ever be held accountable for shortchanging customers on total losses and also on repairable claims since they often refuse to pay for the OEMrequired processes and procedures that are necessary to perform safe and proper repairs. It’s great that one state is taking notice of the under-indemnification scheme that shortchanges consumers and makes it increasingly difficult for body shops to run their businesses effectively. Hopefully, this momentum spreads across the country and creates some real change!”

The CJB’s complaint estimates that the underpayment on an individual total loss claim averages $3,000 to $4,000, creating an “aggregate amount of underpayments affecting California insureds [which]

is likely in the billions of dollars,” yet the “unlawful, unfair and fraudulent” scheme continues since it’s unlikely that most insureds will file a lawsuit against their carrier, a fact that insurance companies are well aware of.

“Even if insureds suspect an underpayment, most would conclude that it is not in their economic interest to bring suit against an insurance company defendant over that amount of money,” the complaint points out. “The relatively small amount of any single underpayment and the extremely large amount of the underpayments in the aggregate are some of the insidious aspects of the scheme. An insured should never have to invoke appraisal or sue their insurer to recover money stolen from them by their insurer.”

The lawsuit seeks civil penalties, restitution for California consumers, injunctive relief and associated fees and costs. “Public safety includes protecting consumers from powerful companies that seek only to maximize profits,” District Attorney Price acknowledged in the release. “We are seeking to level the playing field for vehicle owners who face what looks like a rigged game when their car or truck is totaled because a loss of a vehicle can destabilize a person’s life.”

Stay tuned to New Jersey Automotive as this situation unfolds.

All-round solution for auto body shops. The B-Bench features a 13.1 foot frame and 10 ton pulling system, enabling repairs on vans or extra-long sedans. The pulling tower o ers e ortless precision and smoothly moves 180º for accurate adjustments.

Equipped with a double safety device and twin lifting rams, you can trust every lift and adjustment.

Additionally, it o ers a hybrid drive-on, drive-over functionality, with the option of removable side ramps for enhanced versatility and convenience.

INCLUDES

Lift System

Pulling Tower

Pad Set

Arms for Clamps Set

High Clamps Set

Electro-hydraulic Unit

Wheel stands Set

-Large Vehicles?

-Unusual Damage?

-Custom Modifications?

-Specialized Repairs?

*Explore a range of additional upgrades and accessories tailored to meet the requirements of your repair technicians. Contact us today to learn more!

With nearly six decades of experience in the auto body business, Will Wilson of Wilson’s Auto Body possesses extensive knowledge and expertise when it comes to automobiles. From working alongside his father, Will Wilson Sr., to becoming the owner of his own shop, his journey has been one of dedication, hard work and a passion for craftsmanship.

Born into a family deeply rooted in the auto body trade, Wilson’s introduction to the industry began at an early age. “I grew up in body shops for as long as I can remember…. Let’s put it this way: I didn’t receive my first paycheck until 59 years ago. Before that, I was constantly pitching in wherever I could, particularly with projects like hot rods,” he reflects.

His father and his uncle, Fred Wilson, started up an auto body business (Wilson’s Body and Fender Works) before his time in 1947, instilling in him a sense of familiarity and passion for the field. At age 14, he recalls

sitting in on association meetings when his father’s shop was part of the North Jersey Auto Body Association. It was at his father’s shop that Wilson was able to hone in on his skills and develop an interest for the profession. He continued his education at Bergen Tech, graduating in 1970. Having already known the intricacies of collision repair from his upbringing in the shop, he made the decision to study auto mechanics in an effort to expand his wheelhouse of skills. “I already had a good grasp of auto body and wanted to keep learning. I didn’t want to become a mechanic but to develop an understanding of the mechanical systems behind it all.”

Post-grad, Wilson ventured out on his own path in 1971 leading him to various roles, including managerial positions at a number of facilities. Each role afforded him the opportunity to gain knowledge and refine his skills. In doing so, he developed a reputation as a trusted expert in the field.

“I always knew I wanted to be in the auto body business. Surrounded by cars all my life, I was practically raised in my family’s body shop.” In 1993, he felt it was time to make the pivotal decision in purchasing an existing body shop and rebrand it as his own business, Wilson’s Auto Body. As an owner, Wilson infused his own brand of expertise and integrity to earn the trust and respect of customers. Previously located in West Paterson, Wilson’s Auto Body has been a part of the Woodland Park community for 31 years to date. Over time, his commitment to excellence has attributed to the shop’s stellar five-star reputation amongst residents for their quality work and unparalleled customer service.

Integral to this success is the shop’s dedicated professionals. Wilson leads the team which includes

by KAITLYN

manager Brad Albrecht, shop foreman Ed Eder and six employees plus one secretary. They all work to ensure that every repair meets the highest standards. Focused on continuing technicians’ education, the shop has

maintained its I-CAR Platinum Class status. Wilson prioritizes obtaining certifications to ensure a promise to high-quality, knowledgeable and personalized service.

The team undergoes frequent

training to stay at the forefront of the latest advancement in collision repair technologies. “We offer a 100 percent guarantee as long as the person owns the car.” His team prioritizes integrity in every interaction. Technicians are certified in car alignment, measuring systems, aluminum welding and “everything you can think of.” A promise to “high quality work at fair value” is a principle Wilson maintains and highly values. Work comes in through the door via word of mouth, online reviews and participation with DRPs. An unwavering commitment to excellence has fostered a sense of trust amongst locals, reflective of their long-standing relationship with the community.

continued on pg. 39

BMW of Springfield

391-399 Route 22 E. Springfield, NJ 07081

Toll Free: 800-648-0053

Fax: 973-467-2185

bmwofspringfieldnj.com

BMW of Bridgewater

655 Route 202/206

Bridgewater, NJ 08807

PH: 908-287-1800

FAX:908-722-1729

bridgewaterbmw.com

©️2024

Circle BMW

500 Route 36

Eatontown, NJ 07724

Parts Direct: 732-440-1235

Fax: 732-440-1239

wholesale@circlebmw.com circlebmw.com

Park Ave BMW

530 Huyler Street

South Hackensack, NJ 07606

PH: 201-843-8112

FAX:201-291-2376

parkavebmw.com

Paul Miller BMW 1515 Route 23 South Wayne, NJ 07470

PH: 973-696-6060

Fax: 973-696-8274

paulmillerbmw.com

BMW of Bloomfield 425 Bloomfield Avenue Bloomfield, NJ 07003

Parts Direct: 973-748-8373

psantos@dchusa.com

• Audi Parts Professionals are your subject matter experts on collision parts, replacement components and mechanical items.

• Many Audi dealers offer technical service support hotline access that can reduce your repair times and help you meet an on-time promised delivery.

• Installing Audi Genuine Parts contributes towards improved cycle time that makes both your customer and their insurance company happier.

Helping you do business is our business. Order Audi Genuine Parts from these select dealers.

Ciocca Parts Warehouse

8 Minneakoning Road

Flemington, NJ 08822

Toll Free: 800-221-1256

Fax: 908.782.1795 rmuir@cioccadealerships.com www.cioccaparts.com

DCH Millburn Audi

2211 Millburn Ave

Maplewood, NJ 07040

Toll Free: 800.553.9250

Direct: 973.762.0262

Fax: 973.762.2381 www.dchmillburnaudi.com

Paul Miller Audi

179 Route 46 East Parsippany, NJ 07054

Toll Free: 800.35.MILLER

Parts Direct: 973.575.7793

Fax: 973.575.5911 www.paulmiller.com

Bell Audi

782 Route 1 Edison, NJ 08817

732.396.9360

Fax: 732.396.9090 www.bellaudi.com

Town Motors Audi

400 South Dean Street

Englewood, NJ 07631

201.227.6506/6536

Fax: 201.541.0314 www.townmotors.com

Jack Daniels Audi of Upper Saddle River

243 Route 17

Upper Saddle River, NJ 07458

201.252.1500

Fax: 201.254.1552

tbabcock@jackdanielsmotors.com www.jackdanielsmotors.com

Audi Bridgewater 701 Route 202-206 N Bridgewater, NJ 08807

929.600.9156

Fax: 908.595.0237

parts@audibridgewater.com www.audibridgewater.com

Paint and material costs have soared over the past several years. Simultaneously, insurers tightened their purse strings. Although that is not shocking news, where does that leave collision repair shops? Stuck in the middle of a raging, never-ending penny-pinching war, of course!

The above is not likely to change anytime soon, but what can change is how collision repair shops address these issues. That begins with understanding what is happening out there.

“Inflation affected collision repair businesses with parts delays, parts shortages, rising costs and all the inflationary elements that impact our business,” observes Yanni Koutmos of Eagle MMS. “Over the past 10 years, the insurance industry forecasted that claims volume would go down with ADAS and self-driving cars, but claims volume trended in the opposite direction. And severity increased very fast because of inflation. Then other factors played in, like vehicle thefts and natural disasters, and the claim volume just blew up during COVID. At the beginning of the pandemic, cars went off the roads as the world went quiet, but about halfway through COVID, it came back with claims volume being worse than before.

“So these insurance companies were at a net loss ratio between underwriting and selling policies and fulfilling claims,” he explains. “It’s called the pure-loss ratio, underwriting to claim losses. The only reason they maintained any type of profitability is because, in that interim where they were getting whole premium dollars, they invested in the S&P, which was hiking because of inflation. So their investments made money, but their policies didn’t make any money, which means these guys had to get more aggressive. They said ‘no’ to as much as possible and as much

as they could justify. So, while it is the most necessary time for us to invoice, it’s also the most difficult time because inflation didn’t just affect us, it affected them, and they are trying to cover their losses now.”

Koutmos, who worked as a paint technician for about nine years before the pandemic hit, recognized rising P&M costs as a major issue for collision repair facilities long before the pandemic, and he notes its fallout made things worse.

When work began to dry up at the dealership he worked at during the height of COVID, Koutmos threw himself into restoration work. “I started to see a slight increase in the cost of paint. This was nearly five years ago. I had no idea how bad it was going to get at that time.”

Soon after, he found himself embarking on a new venture to help collision shops accurately capture and bill for P&M.

“I was on a road trip with my brother, a software engineer, who was partially frustrated with some of the startups he was working on. He told me, ‘When you start a software company, you need two founders –one person who writes the code and

ALANA

the other who comes from an industry that has a problem.’ He then asked me what problem my industry had, and I told him, ‘Buckle up, we need three car rides to talk about this.’

“When I was doing restoration work, between the time I had quoted the cost on a job to the time I bought the paint, the paint cost had changed precipitously,” he adds about the growing problem.

From there, the brothers started Eagle MMS, a shop materials management inventory and invoicing solution for collision repair facilities that streamlines job costing so collision repair shops have a fair shot at getting reimbursed properly for all these various materials.

“One of the nice things about our software is that it covers all material categories and all manufacturers. We have almost 100 different manufacturers in our database and thousands of parts numbers by all of those manufacturers. Typically, other solutions only focus on what one vendor sells or what one manufacturer makes, so a clip system will only have clips for one make, and your mixing system would have fluid paints just for continued on pg. 30 by

“ It costs them nothing to say. There are virtually no consequences when they

May. “Masking tapes, masking papers, PPS liners and lids. We never write for PPS cups. How many do we use on a typical repair? Three minimum.”

The word “No” is a multi-billion dollar word to the insurance industry. “It costs them nothing to say. There are virtually no consequences when they say ‘no,’ and it saves them billions of dollars a year.”

that make, for example. To properly job-cost a vehicle, you need all of these things, but who wants to run three or four systems to do all that work? So, we put all the data in one place and removed the need for technician engagement because getting technicians to check everything out can be an issue.”

Parts numbers are mapped to an operation, such as spraying a fender or putting on a quarter panel, and every account is set up specifically for the products the shop uses.

Koutmos has been speaking out about the importance of itemizing accurately for proper reimbursement at various industry events, including SEMA and AASP/NJ’s recent Industry Night.

“There are a lot of expensive things we use that don’t come out of the tip of a gun, which is what everyone focuses on,” Koutmos told the AASP/NJ audience this past

There are two sides to negotiating: negotiating on behalf of the customer and then informing the customer about the process, according to Koutmos. “As far as informing the customer, the dirty little secret no one wants to deal with is that the insurance company doesn’t owe for something unless the customer incurred the cost. So unless the customer has incurred some type of financial loss due to the claim, the insurance company doesn’t owe. But the problem is, no shop on the planet wants to bill their customer because no one wants to have a conversation about what vehicle repair actually costs, so we fight with the insurance companies instead. But it’s not our fight because we don’t have a contract with them, and we have to explain that to the customer.”

It all comes down to the fact that it’s not about the shop; it’s about the customer. “They own the car, they’re on the policy, and they actually have the leverage. The problem is, oftentimes, the consumer doesn’t know anything about that, and it becomes up to the shop to educate them on their rights and about the Appraisal Clause. The average vehicle consumer doesn’t know any of that.”

It’s important to keep in mind that what one does today may not change things overnight, but it definitely will lay the foundation for future progress.

“Just because you start implementing a new process, practice or procedure, it doesn’t mean that the whole world will change tomorrow,” acknowledges Koutmos. “You start with small incremental steps, you keep some degree of consistency across time, and when you look back, you’ll see the world does change. It’s small steps, not one big thing that you do. That’s not how business works. Small incremental improvements over a long period of time will find you looking back and seeing how it helped. If you want to make big bucks in this industry, that’s what you have to do. You have to engage in a process. I’m inviting people to engage in a different process. Even though it won’t change the world tomorrow, I’m confident that a few years from now, it will.”

• Our expert parts staff is ready to serve you with over $500,000 in inventory and a fleet of trucks to help ensure same-day delivery on most orders

• We respect your time, and offer a quick and accurate order process to help meet your needs

• Proudly serving the Tri-State area with Audi Genuine Parts since 1970

• Same-day delivery on stocked items, next-day availability on most non-stocked items

400 South Dean Street Englewood, NJ 07631

Parts Direct: 888.779.6792

F ax: 201.541.0314 E mail: audiparts@townmotors.com

Hours: Monday-Friday 7am-7pm Saturday: 8am-5pm

thought of that?! The kid showed me how to put it back in gear, and I was relieved I hadn’t destroyed the car less than an hour after I leased it.

Of course, it took me a few weeks to get the hybrid thing down. Now that I’ve learned how to be like a gas station attendant and plug it in every night, it’s been pretty good. (I get the urge to say “fill ‘er up” every time,

though.) I still miss the Tahoe. But back to my skills! A few weeks ago, the windshield wiper fluid light came on. Great. You all know damn well that I’ve never done that, either. But I was determined to do it this time! I headed to Home Depot like a big shot all ready to grab that container, fly through self checkout and pour that blue shit in.

Home Depot didn’t have any washer fluid.

Here we go… Next stop, Pep Boys. Again, I strutted in, and without even asking anyone, I found that container, grabbed it off the shelf, paid for it and set sail for my driveway. Once home, I went to pop the hood. Hmmm. Now, where can that switch be? It wasn’t on the dash. It wasn’t overhead. Then I remembered: When I put gas in the car the first time, it took me 15 minutes to find the button that opened the gas tank. (On Tahoes and Expeditions, the attendant just pressed the damn door, and it would open!) Wouldn’t you know it, the hood opener was right over there. I pulled on it, and “POP!” It actually opened. I was on my way! I jumped out of the car and went over to the hood. Hmmm. I remembered that there was something important somewhere under the hood, so I stuck my hand in there. (...this IS a car we’re talking about, right?) Unlike other experiences, all I came out of there with was a scratched, greasy, black hand. And the hood only opened about two inches. Again the “MFs” flew, but I was determined. I went back in and finally found it. Boom. The hood popped open. I was orgasmic! (Wait...this IS a car we’re talking about, right?)

Unfortunately for me, under the hood were three or four of those plastic container-looking things. I just knew I was going to put the fluid in the wrong one. But then I saw it! The same image that was on the dashboard light! BINGO! I ripped that top off and started to pour.

After a few seconds, I had to stop. I was spilling more than I was filling. Then I did another thing that probably made hell freeze over: I went into my garage and looked for a tool. I knew someone had put a funnel in

there (must have been the previous owner), and there it was on the shelf, along with bottles and cans of stuff that OSHA probably outlawed in the ’80s. I grabbed it, put it in the container and emptied the fluid into it.

I skipped over to the driver’s seat and turned on the ignition. When I saw that warning light out, I felt like I just had my third kid. I actually completed my first “repair” on a vehicle! Sure, it was not changing a tire, but it was an achievement! And here I am, writing about it.

At least I don’t have to worry about diesel anymore. Just electricity. And gears. Maybe I’ll rent a bike.

properly without straying from or altering the manufacturers’ repair procedures, else the vehicle will not be put back to the safe operating condition that it was in prior to the accident that caused the damage. As a result, the lives of the people operating the vehicle or the passengers riding in the vehicle after the repairs will be in jeopardy should the vehicle be involved in another collision.

Now, let me say that again: The lives of the people operating or riding in a modern vehicle after the repairs will be in jeopardy should the vehicle be involved in another collision. Based on the foregoing, there should be no more negotiating on how the modern vehicle gets repaired. Every repair procedure should be followed!

The problem is, lately, many insurers are not only still attempting

continued from pg. 14

to play the “let’s make a deal” game, but some are now dictating what they will or will not pay for. The AASP/ NJ hotline has recently received reports that certain insurers are now preparing an estimate on damaged vehicles and stating that is all they will pay without even discussing or negotiating the repair procedures or cost of the repairs with the shop performing the repairs. It appears that certain insurers seem to feel that they now have the right to dictate, rather than negotiate the repair cost to repair a damaged vehicle.

If you are a member of AASP/ NJ and run into such a situation, it is strongly recommended that you contact the AASP/NJ hotline at (732) 922-8909 immediately and report the incident.

David Yeager - EL & M Auto (800) 624-2266 / elandmauto@aol.com

Ed Silipena - American II Autos (609) 965-0987 / esilipena@yahoo.com

Norm Vachon - Port Murray Auto (908) 689-3152 / portmurrayauto@yahoo.com

Dillon Rinkens - East Brunswick Auto (732) 254-6501 / ebautonj@comcast.net

President - Rodney Krawczyk Ace Auto Wreckers (732) 254-9816 / aceautonj@comcast.net

1st Vice President - Daryl Carman Lentini Auto Salvage (908) 782-4440 / darryl@las-parts.coms

2nd Vice President - Mike Ronayne Tilghmans Auto Parts (609) 723-7469 / tilghmans@snip.net

Past President - Bob Dirkes Dirkes Used Auto Parts (609) 625-1718 / dirkesauto@gmail.com

The Automotive Recyclers Association of New Jersey

Manual material handling is one of the largest causes of lost workday injuries in the scrap metal industry. About one out of every five injuries happens because someone lifted, carried, pushed or pulled something the wrong way, or lifted beyond his or her capacity.

The most useful part of your body in handling materials safely is not your back or legs, but your head. Untrained workers often do the job the hard way and soon get tired, which leads to possible injury. Below are some suggestions you can incorporate into the training of your employees on manually lifting an object:

• Size up the load. Seek assistance if you think you need it.

• Get close to the load, with one foot alongside the load, and one foot behind it for balance. Get a firm grip on the object, with your palms, not your fingers.

• Test to see that it’s not too heavy.

• Lift by straightening your legs, avoiding quick, jerking motions. Your legs should provide most of the power to lift, not your back.

• Avoid twisting with a load. Use your feet or shift to change direction with a load.

• Lifting comfortably is most important. Judge the most comfortable position for yourself.

Workers should be trained on proper and safe material handling techniques, either manually or by using mechanical means. The use of correct handling techniques is one of the ways to help reduce injuries.

800-221-0003 (ext. 1320) (908) 513-8588 (cell) mdefilippis@whartoninsurance.com

continued from pg. 25

Recently, Wilson became a member of AASP/NJ with Wilson’s Auto Body; however, he is no stranger to the association. “I’ve been in it for years. When I was at Malcom Konner dealership, I was a member,” he recalls. “Additionally, various other shops I worked for were part of the association.” He found himself immersed in a network of peers who share his passion for the automotive industry.

In regard to being a part of the association, his aspirations extend the mere membership. “I’m looking to enhance my expertise through schooling and similar opportunities.” For Wilson, the association serves as a gateway to a number of resources that will further his knowledge in the evolving industry.

“AASP/NJ does a good job of addressing key issues in the industry and I honestly can’t complain. I am always looking to better myself and learn as much as I can. Having been familiar with the association for years, it finally felt time to return, but this time with my shop.”

Reflecting on his career, Wilson acknowledges that his motivation stems from a simple desire “to work hard every day.” From learning the ropes at his father’s shop to his decision to break away and form his own path, his dedication to his craft has remained constant. It is this level of commitment that continues to propel Wilson’s Auto Body forward in tending to their customers; every need and regaining their trust time and time again.

•

•

•