Built-in storage for additional arms.

Double action lever for fast arm changes.

G1 arm included.

Additional arms available to address almost every repair.

Collapsible boom extends up to 8' in the air.

Electrode automatically retracts in less than 2 seconds.

Lightweight gun weighs less than 25lbs.

Our flagship dealerships are pleased to offer a wide selection of authentic genuine parts so you can repair your customer’s luxury car to the highest quality.

We not only sell WHOLESALE GENUINE PARTS across the tri-state area, but we also offer a knowledgeable team of parts specialists who will find the component you need for a seamless vehicle repair. WE WILL GO THE EXTRA MILE FOR YOU!

AUDI QUEENS

30-35 College Point Blvd. Flushing, NY 11354

Wholesale Direct: 929.297.0788

parts@audiqueens.com audiqueens.com

MERCEDES-BENZ OF BROOKLYN 1800 Shore Pkwy. Brooklyn, NY 11214

Wholesale Direct: 718.258.7055

parts@mbofbrooklyn.com mbofbrooklyn.com

MERCEDES-BENZ OF CALDWELL 1220 Bloomfield Ave. Caldwell, NJ 07006

Wholesale Direct: 973.808.0204

Parts@mbofcaldwell.com mbofcaldwell.com

JAGUAR BROOKLYN 809 Neptune Ave. Brooklyn, NY 11224

Wholesale Direct: 929.583.6492

parts@jlrbrooklyn.com jaguarbrooklyn.com

LAND ROVER BROOKLYN 809 Neptune Ave. Brooklyn, NY 11224

Wholesale Direct: 929.583.6492

parts@jlrbrooklyn.com landroverbrooklyn.com

LEXUS OF BRIDGEWATER 1550 US-22 Bridgewater, NJ 08807

Wholesale Direct: 866.679.7054

parts@lexusbridgewater.com lexusofbridgewater.com

LEXUS OF EDISON 711 US Highway 1 Edison, NJ 08817

Wholesale Direct: 732.593.6860

parts@lexusedison.com lexusofedison.com

Our team is committed to helping you succeed in your automotive business. Investing in our

“Gary, I wanted to thank you for your continued support for my latest purchase of the Autel ADAS Calibration system. You provided the training we needed and most importantly you provided a direction when calibrations needed a little more technical advice. I’ve had the good fortune of finding you many years ago to supply my necessary computer scan tools to stay current and relevant in this everchanging environment.

I use the analogy of running a business is like being a captain of a ship. My job is steering the ship and plugging the money holes all while navigating into calm profitable waters. After 36 years in business, I can say buying from you and attending many of your Technical Training classes has directly facilitated my continued success in the Auto Repair business.

Your extensive technical training background has led you to a great business opportunity to provide a valuable needed service that many garages and body shops don’t provide. Most cars leave body shops and repair facilities not getting the necessary Calibrations. The more I know the more I see the opportunity to make cars safer for everyone. One of the lessons I’ve learned is that business owners don’t tell other businesses where their Honey hole is. Buying from you with your training and after purchase support is a honey hole they don’t have to miss out on.”

AATI Today

Bill Murphy, Owner Auto Clinic -Pepperell, MA

P.O. Box 734

Neptune, NJ 07753

EXECUTIVE DIRECTOR

Charles Bryant 732-922-8909 / setlit4u@msn.com

2023-2025 OFFICERS

PRESIDENT

Ken Miller, 821 Collision, LLC (973) 949-3733 / kmiller@821collision.com

COLLISION CHAIRMAN/

PAST PRESIDENT ATTENDING

Jerry McNee, Ultimate Collision Repair, Inc. 732-494-1900 / ultimatecollision@att.net

MECHANICAL CHAIRMAN

Keith Krehel, Krehel Automotive Repair, Inc. 973-546-2828 / krehelauto@aol.com

TREASURER

Tom Elder, Compact Kars, Inc. 609-259-6373 / compactkars@aol.com

SECRETARY

Thomas Greco, Thomas Greco Publishing, Inc. 973-667-6922 / thomas@grecopublishing.com

BOARD

Dennis Cataldo, Jr., D&M Auto Body 732-251-4313 / jr@dnmautobody.com

Brad Crawford, Livingston Collision, Inc. 973-992-5274 / livingston.collision@gmail.com

Gary Gardella, Jr., County Line Auto Body 732-363-5904 / countylineautobody@gmail.com

Jeff McDowell, Leslie’s Auto Body 732-738-1948 / chacki@aol.com

Danielle Molina, 821 Collision (973) 949-3733 / dmolina@821collision.com

Ted Rainer, Ocean Bay Auto Body 732-899-7900 / ted@oceanbayautobody.com

Anthony Trama 973-818-9739 / anthonytrama@aol.com

BOARD ALLIED

Joe Amato, The Amato Agency 732-530-6740 / joesr@amatoagency.com

Mike Kaufmann, Advantage Dealer Services 973-332-7014 / mkaufmann@advantageds.com

PRESIDENT/PUBLISHER

Thomas Greco / thomas@grecopublishing.com

VICE PRESIDENT/SALES DIRECTOR

Alicia Figurelli / alicia@grecopublishing.com

EDITORIAL DIRECTOR

Alana Quartuccio / alana@grecopublishing.com

SENIOR CONTRIBUTING EDITOR

Chasidy Rae Sisk / chasidy@grecopublishing.com

OFFICE MANAGER

Donna Greco / donna@grecopublishing.com

PRODUCTION COORDINATOR

Joe Greco / joe@grecopublishing.com

CONTRIBUTING

Nick Kostakis

Jim Kowalak

Keith Krehel

Joe Lubrano

Michael Lovullo

Jeff McDowell

Sam Mikhail Ron Mucklow

George Petrask

Russ Robson

Jerry Russomano

George Threlfall

Anthony Trama

Cynthia Tursi

Lee Vetland

Paul Vigilant

Rich Weber

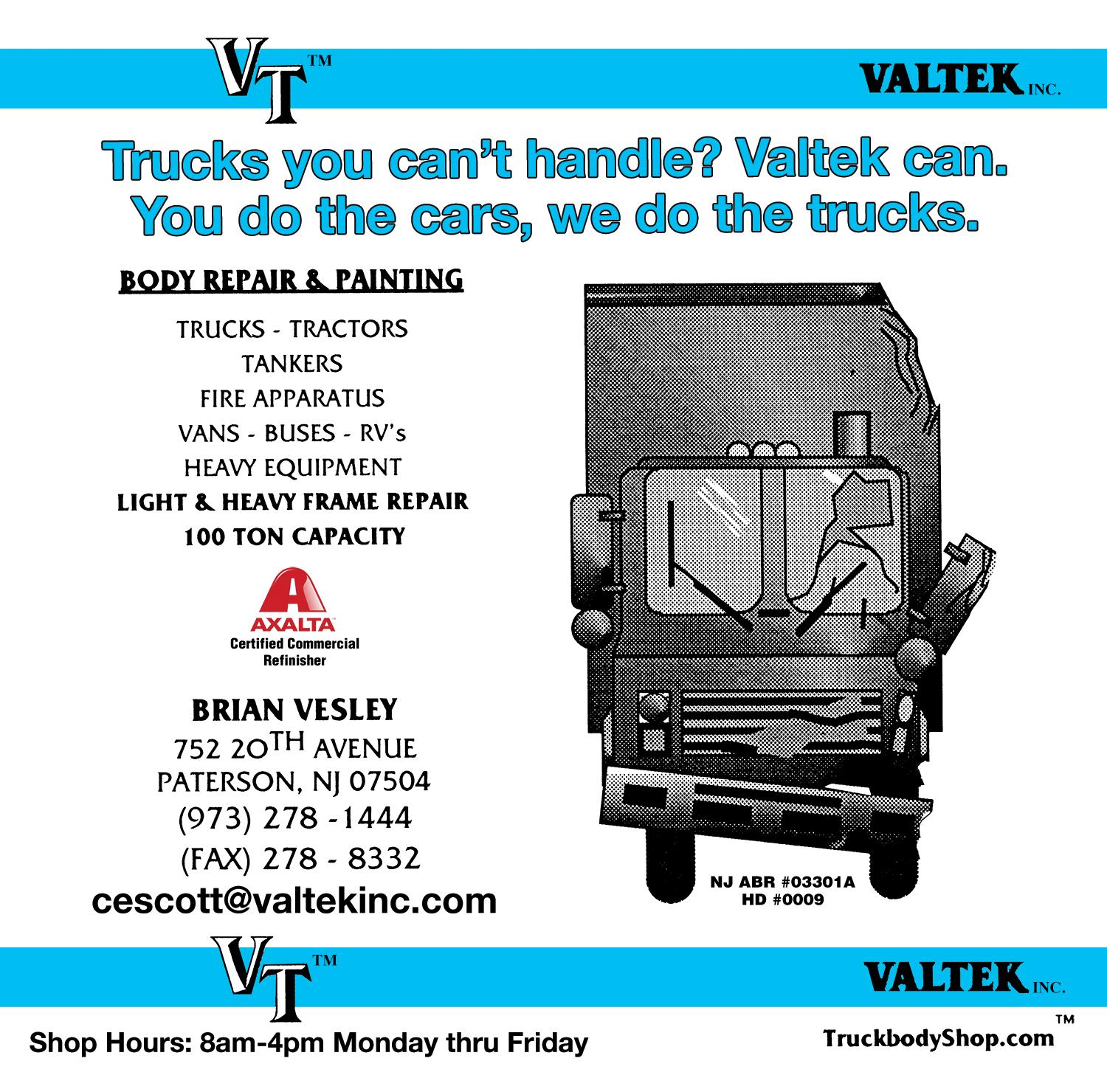

Brian Vesley

Glenn

Stan

Kemperle represents hundreds of the industry’s top manufacturers and stocks thousands of their superior products. With more than 50,000 products available to our customers, Kemperle’s locations are uniquely equipped to find the products you need.

KEMPERLE PERFORMANCE DRIVEN PRODUCTS

Abrasives | Adhesives | Body Fillers & Polyester Putty | Clearcoats Detailing Products | Hardware | Masking Products | Prep Solvents/Cleaners Primers/Sealers | Reducers | Spray Suits | ...and more

PINNACLE EQUIPMENT

U.S. Importer for Car Bench International

NJ TRAINING CENTER

• Hands-on technical training

• Classroom seminars

ON-SITE MOBILE DEMONSTRATIONS & TRAINING

626 E. Elizabeth Ave Linden, NJ 07036

P: (908) 925-6133

F: (908) 925-4344

414-416 Madison Ave Paterson, NJ 07524

P: (973) 279-8300

F: (973) 279-9030

100 Melrich Rd Cranbury, NJ 08512

P: (609) 860-2800

F: (609) 860-2801

Linkedin.com/company/albertkemperleinc

631 Clifton Ave Toms River, NJ 08753

P: (732) 797-3942

F: (732) 797-0774 4 Emery Ave

NJ 07869

P: (862) 244-4818

F: (862) 244-4822

There are a lot of things that fascinate me in today’s world. More so than anything else, the bitching and complaining I see on social media not only fascinates me; it also drives me nuts.

There’s no escaping it. On the national level, I see all these protests and all these people causing trouble because of one issue or another. Right or left, it doesn’t matter. The first question that always comes to my mind isn’t, “Hmmm, what are they protesting?” It’s actually, “Don’t these assholes have to work?”

Now look, I have said this before. I have always hated protestors, whether I agreed with them or not. Yes, I know about their rights, yadda yadda yadda. But what about the rights of the truck drivers and civilians whose roads they are blocking? Why do one group’s rights supersede another group’s? Where is that in the Constitution? Go the f@#k home and vote! Or run for office. Do SOMETHING that matters – instead of making me have to spend five hours getting across the George Washington Bridge. Or how about these idiots who go around yelling and screaming about what a horrible a country we live in? Seriously? My dad used to get furious when he’d see these people. I guess the apple didn’t fall far from the tree. I remember when we were kids, there was a saying: “America: Love it or leave it.” Try getting away with saying that THESE days. You would be called a racist, a bigot or worse. But I never understood that. I mean, if you hate something so much, why would you stay? It’s like all these celebrities who say they will leave the country if

by THOMAS GRECO, PUBLISHER

Trump gets elected. Didn’t they say that in 2016? Last I looked, Cher was still living in Malibu. (I don’t really know if Cher lives in Malibu, but I “believe” she is somewhere in California…see what I did there?)

Take my hometown. Every year, our taxes go up, and every year, it’s the same people bitching and moaning, saying, “Once my kids graduate...” or “Pretty soon I won’t be able to afford to live here...” blah blah, freaking blah. But they never leave!

And here’s the catch. Earlier this year, Realtor.com ranked our town 34th in the top 100 hottest real estate markets in the nation. Last week, the same site listed it as the top home buying town in Essex County. Four years ago, the average price of a house was $394,000. Now, it’s $665,000! Houses are selling on the average of anywhere from $34,000 to $144,000 over asking price!

So unless their house is a total piece of crap that they haven’t taken care of, they could sell it, take their tens of thousands in profit and their bitching and complaining and move the hell out of here! And please don’t let the door hit you on the ass on the way out.

I will never understand it. Yes, my taxes are high. Yes, we have some problems in our school system. But unless my business fails, I am never leaving here, and I will never complain about it. And if God forbid that DID happen, and I were to sell my house, I would make THREE TIMES what I paid for it. Yeesh.

In the immortal words of famed philosopher, the Wicked Witch of the West, “What a world.”

From a young age, I was taught the importance of “doing the right thing” – a principle that has guided my decisions throughout my life. Whether it was caring for my family, supporting friends, serving the community or putting the needs of employees and clients first, I’ve always strived to prioritize others. As a self-employed individual, living by this value came naturally. Helping others felt fulfilling, and there was always enough time and money left to provide for my family and sustain a profitable business.

However, when I entered the collision repair industry in 2017, I quickly learned that “doing the right thing” carried new and complex implications. Though I had been around the industry for decades in various roles, owning my own shop was an entirely different experience. At first, we thought doing the right thing meant running our shop like most others: taking the keys, battling with insurers, fixing the car to the best of our ability and minimizing the client’s involvement. But it didn’t take long to see that continuing down this path could lead to the downfall of our business.

Recognizing this, we turned to a professional business consultant who helped us see that our well-

by KEN MILLER

intentioned approach wasn’t truly serving the best interests of our customers, employees or ourselves. The only parties benefiting seemed to be third-party bill payers, when they were involved. With the consultant’s guidance, we learned that the right thing to do was to involve the customer in every aspect of the repair process – from selecting parts to understanding specific procedures and even navigating insurance issues. By embracing this new approach, we began doing right by everyone involved: the client and their vehicle, our shop and our employees.

In this industry, the temptation to follow what’s popular rather than what’s right is a constant challenge. For those of us committed to integrity, we understand that what’s unfamiliar is often met with skepticism. Nevertheless, it’s our duty to cut through the noise and misinformation to do what’s right - for our customers, our employees and the industry as a whole.

It’s important to remember that every business has its own model, and different doesn’t necessarily mean wrong. The key is ensuring that we are all striving to “do the right thing.”

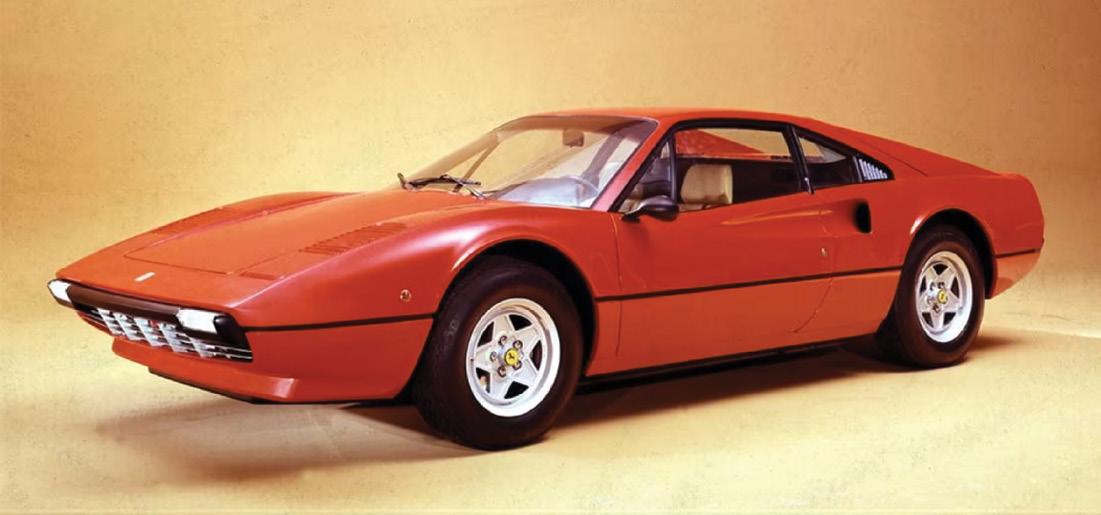

For the eight years (1980 – 1988) that the series Magnum P.I. was on television, Tom Selleck could be seen driving around the streets of Oahu, HI in a bright red (is there any other color?) Ferrari 308. I am not sure how inconspicuous he could have been during “sensitive investigations,” but heck, this is one beautiful car that I would like to own someday, if only my wife would let me.

For the TV show, per my research, each season would use one or two new cars, and the prior year’s models were sold off, usually sporting the license plate “Robin1.” This was in reference to Robin Master, the alleged owner of the estate where Magnum resided and the actual owner of the 308 Ferrari that Magnum would “borrow,” pretty much all the time. Production of the 308 began in 1975, and it replaced the Dino 246GT and GTS.

The 308 was mid-engined and drove the rear wheels through a five-speed manual transmission (no automatic available). Suspension was independent at all four wheels with four-wheel disc brakes and unassisted rack and pinion steering. The frame was of tubular construction, similar in construction to the Dino, its predecessor. The engine was a V8 with double overhead cam (DOHC), and the engine was transversely mounted – crankshaft perpendicular to the car’s length. The early 308 bodies were constructed with fiberglass with a corresponding weight savings of about 330 pounds. This changed to steel in 1977 and remained steel until the end of production, with a final quantity of 808 cars constructed of fiberglass.

Various configurations have been available through the years:

308 GTB – Berlinetta – Hard top fixed roof conventional coupe.

308 GTS – Targa top – This model had a removable one-piece hard top that covered both driver and passenger, and when removed, the rear roof and window stayed fixed while the occupants received a “convertible” feel complete with loud wind-driven noise, poor climate control and no discernable radio at speed. Fortunately, upon installation of the Targa top, the car once again became “tame.” The Targa top is a nice feature, and when installed, it provides a quieter ride than a conventional rag top. By the way, T tops are common in some Corvettes, etc., like Targa tops, except that they come in a pair, one half over the driver and the other over the passenger seat with a frame between the two halves.

308 GT4 – Which was marketed as a two-plus-two – meaning it actually had a rear seat. As crazy as a fourseater sports car may sound, once you have a child or an occasional third passenger, it makes the car much more versatile and able to be used more often, as I can attest.

KEITH KREHEL

The GT4 had a longer wheelbase as expected, to allow for rear seating.

208 GTB/GTS – This model is similar in style but had a smaller engine (under two liters), producing a dismal 155 HP and was made exclusively for the Italian market as vehicles sold in Italy above two liters were subject to a much higher 38 percent VAT (value added tax) versus the standard 18 percent VAT tax for those below. These vehicles are regarded as the slowest Ferraris ever made – a dubious honor. By the way, the Italian public not only paid this VAT but were already paying a hefty income tax as well.

As the 308 was built for a decade, the horsepower varied a bit depending on year, fuel systems, emission controls and country of destination (see chart). Fuel injection, when introduced, improved emissions but hurt performance. In 1982, four-valve technology was introduced – “quattrovalvole” – which helped recover some needed horsepower lost to prior emissions controls. Total production was about 12,443 units, including the 300 (anemic) 208s made. The 308 was replaced by the 328 GTB/GTS in 1985 with a much more powerful engine.

In my opinion, the Ferrari 308 has become an icon largely due to its Magnum P.I. exposure. Thomas Magnum was lucky that Robin Masters allowed him to borrow it so often.

bodies command more money.)

It’s that time of year again!

New Jersey Automotive’s annual survey opens October 1 until November 1 giving our readers – yes, that means YOU! – and all Garden State automotive service providers an opportunity to speak your mind about all the things you experience day to day in this ever-changing world of collision and mechanical repair. This annual survey has not only become an anticipated activity to take part in year after year, but the information obtained reveals several

interesting facts about the industry, and that information – published every December in New Jersey Automotive – becomes a reliable resource.

For example, it’s no secret that the industry is beginning to age out, and last year’s survey revealed 98 percent of survey takers reporting their oldest employee had a birth date prior to 1973. In 2022, that number was only 86 percent.

It’ll be interesting to see what the 2024 survey will reveal about EV preparedness. Recent survey results

showed that more repair professionals are becoming less interested in taking on the task of repairing these vehicles – which is likely due to inability to train accordingly or perhaps they are finding the investment isn’t worth the pay-off. In 2022, more than half of those polled believed they were ready to fix these vehicles; that percentage dropped down to 26 in 2023.

Of course, it’s always enlightening to see which insurers repair shops seem to have the most issues with. Will State Farm, Allstate and Progressive top the list yet again?

The survey only takes a few minutes to complete, so do yourself, your neighboring shop and the whole industry a favor and take the time to share your point of view. (Remember, comments remain safely anonymous as New Jersey Automotive will not publish respondents’ names.)

Survey results will be published in the December 2024 issue of New Jersey Automotive. AASP/ NJ members can visit aaspnj.org to take the survey, or watch their inbox for details. Shops interested in taking the NJA survey can email info@grecopublishing.com with the subject line “Industry Survey.”

All Makes and Models

24-48 hour Turnaround

Proven Color Match Database

On-site Cosmetic Repairs

Large Inventory of O.E. Replacements

When performing aluminum repairs, preventing crosscontamination is crucial. Aluminum is highly sensitive to contamination, especially from steel. If you don’t prevent steel dust from settling on aluminum-intensive vehicle surfaces, galvanic corrosion will occur and weaken aluminum components. When aluminum exterior surfaces like the hood, roof or door panel are exposed to steel dust, galvanic corrosion can damage a paint job. Aluminum dust also is explosive when exposed to a spark.

A clean room minimizes the risk of cross-contamination by providing a controlled environment free from airborne dust, metal shavings, and other contaminants. This ensures that the aluminum repair process is conducted in optimal conditions, prevents surface damage and helps maintain the integrity of the repair as required by OEMs.

The RAE Body Repair Station features a curtain that has special light reflection as well as fire approved properties. This will isolate your aluminum work area from nearby bays. Accepted by leading OEM certified collision repair facility programs, the body repair station features an e-glass curtain that meets fire retardation standard EN-13501-1 (required by OEM certification programs across the globe). A builtin viewing window meets standards for eye protection of workers outside the aluminum bay. LED lighting helps provide ideal lighting conditions when performing intricate

repairs, while a specially-coated welding curtain separates and protects the surrounding area from the aluminum bay. Please contact Reliable Automotive Equipment to learn more about how we can help you perform aluminum repairs safely, efficiently and cleanly. Visit Booth #32135 in the South Upper Hall at SEMA for more information on our full line of collision repair equipment, products, training, service and more.

The RAE Body Repair Station isolates your aluminum work area from nearby bays.

Offer your employees quality health insurance at an affordable price. The Alliance of Automotive Service Providers has partnered with World Insurance Associates to bring you the AASP Health Plan for members only. Now you can offer your employees quality health insurance at exclusive rates. And it’s fast and easy to enroll!

• Any size business is eligible

• National network of doctors

• Multiple plan designs

• Members-only health plan

• Potentially great premium savings

CONTACT: Joe Amato, Jr. Principal

World Insurance Associates 4900 Route 33, Suite 103 Neptune, NJ 07753

O: 732-530-6740 x412

joeamatojr@worldinsurance.com

Terence

terencegorman@worldinsurance.com Call or email us

x162 | M: 646-438-4959

Two’s company, three’s a crowd, but four on the sidewalk is not allowed! The simple childhood proverb offers a lot of wisdom in terms of business contracts, especially in the collision repair industry where it’s not uncommon for confusion to exist when it comes to which entities a repair facility owes its loyalty: the customer who brings the vehicle into the shop or the insurance company that typically compensates for the repair. But when another type of business – a vendor – recently decided to insert itself into the equation, collision leaders and business owners around the country immediately made their objections known.

In July, GEICO Insurance announced that it had reached an agreement with asTech, a diagnostics and calibrations service provider, to standardize pricing for GEICO Auto Repair Xpress (ARX) direct repair facilities utilizing their services as a ways of mitigating the variety of price points that have emerged for these operations. Claiming that the partnership was intended to “reduce friction,” the insurer indicated that the new initiative will speed up reimbursement “for an OEM or OEMcompatible scan if [shops] correctly follow the Rules Engine process in selecting the appropriate scan for the vehicle.”

Days later, industry leaders and advocates aired their apprehensions at the Collision Industry Conference (CIC) as shop owners objected to any vendor entering into an agreement with an insurance company on their behalf. Although representatives from asTech were on hand and tried to quiet concerns by insisting the agreement would streamline processes and work in the customer’s best interests, the overarching response seemed to suggest the beliefs that the agreement would undermine shops’ independence, jeopardize repair

quality and compromise free market pricing.

By the end of the month, GEICO released an updated standardized pricing sheet which reflected increases for the listed operations; however, nothing within the new communication did anything to alleviate shops’ fears as collision repairers ponder whether the vendor’s action will result in a domino effect that will deteriorate facilities’ ability to prioritize quality and safety over cost.

Will the industry’s reaction quiet other vendors’ attempts to follow suit, or are we just waiting for the other shoe to drop?

One of the largest concerns expressed by shops since the agreement was announced comes down to the possibility that a vendor entering into a standardized pricing agreement with a third-party entity on behalf of their customers sets a dangerous precedent that similar businesses may follow. Aaron Schulenburg, executive director for the Society of Collision Repair Specialists (SCRS), reports receiving many inquiries from the industry about “this new relationship and agreement. It is unclear to me why a vendor would enter into an agreement, and create standardized pricing for their customer, with another business who is not a party to that service agreement. I absolutely think it is rightfully concerning that vendors are seeking standardized pricing directly with insurance companies, whose only relationship in the scenario is to indemnify a consumer for a loss.”

AASP/NJ President Ken Miller (821 Collision; North Haledon) agrees that this situation could potentially be very problematic. “It is early in the process to understand the potential impacts on setting precedent, but it’s hard to imagine a scenario where this will be good for repairers.”

“This is a conflict of interest that

includes a lack of transparency,”

AASP/NJ Collision Chairman Jerry McNee (Ultimate Collision Repair; Edison) offers. “It will set a dangerous precedent for a vendor to enter into a standardized pricing agreement on behalf of their customers with a thirdparty entity as we lose that lack of control within our business; there is no such thing as ‘one size fits all.’

“Establishing standardized pricing agreements for scanning processes can send misleading messages to insurers and impact shops’ ability to collect for nonincluded operations,” he continues, suggesting that the “misleading perception can lead to unrealistic expectations and pressures on shops to conform to these standardized prices, regardless of their specific circumstances and costs, and will likely cause an undervaluation of services because standardized pricing will not accurately reflect the complexity and variability of scanning tasks. This will result in shops being undercompensated for more laborintensive or sophisticated operations that fall outside the standardized scope.”

Miller also expresses concern that such standardized pricing agreements could send a misleading message to insurers about the ability to streamline scanning processes, suggesting it could make it appear that these processes are simple due to the “small price tag being attached to these operations. Those of us who have a more comprehensive understanding of scanning and analyzing vehicle data know there can be much more to it than ‘plug it in and clear the codes.’”

He furthermore expects that this situation could make it more difficult for shops to collect for non-included operations. “I’m concerned about the broader range of services being discussed in this deal, such as ADAS calibrations, initializations, zero point resets, etc. Besides the obvious issues with setting prices for many of these operations, I see too many failure paths for this to be a practical solution and too much potential liability for shops.”

“Repair facilities are so used to bill-payers using what they establish to be prevailing prices as a limiting factor in indemnification,” Schulenburg contributes. “And it’s not about whether the price today is acceptable or not; it’s about the act of negotiating for another business. For context, businesses that actually perform diagnostic and calibration work enter into purchase and service agreements with vendors, such as asTech. Those agreements typically have commitments between both parties and often stipulate obligations around terms and conditions and pricing.

“So, could the new terms, new pricing and new included or nonincluded agreements affect what those businesses were otherwise effectively capturing or the terms that they had agreed to with their service provider?” he asks. “I believe they could.”

McNee points out the challenges related to “negotiating with a bill payer who has no knowledge of the task at hand,” comparing it to “dealing with a kindergartner writing in crayon that just says no or ignores line items requested.” He suggests standardized pricing will make it more difficult for shops to justify additional charges since “insurers will argue the standardized pricing covers all necessary tasks, making it harder for shops to receive appropriate compensation. With this pressure to adhere to standardized prices, shops will feel compelled to cut corners or reduce the quality of their services, compromising safety and service.”

To ensure a fair market, shops are prohibited from setting rates, so McNee queries, “Is this not an antitrust violation? How does this not fall under regulatory and legal scrutiny? Should standardized pricing agreements attract attention from regulatory bodies due to potential anti-competitive practices or consumer protection issues?”

Although Schulenburg stresses that he does not have the legal expertise to answer these questions, he expanded upon the list of reasonable concerns. “This

agreement seems to give asTech the ability to determine whether aftermarket or OEM scan tools are needed on a job. That raises a lot of concerns. First and foremost, in the asTech mechanical product – which is different from the collision product – they continue to rely only on OEM tools and not the rules engine. So, it begs the question: is the departure from OEM tools only happening in the collision repair space because of the interaction with an insurance company that is indemnifying the cost of the loss? It raises concerns over why vendor recommendations carry so much influence, when manufacturer recommendations are so often dismissed by insurance companies, and it also raises concerns about selfcertification of results.

“asTech is documenting that their ‘asTech OEM Compatible scans are certified to be equivalent to scans performed by an OEM scan tool,’ but it simply appears that they are certifying it for themselves,” he points out. “I don’t know what that term ‘OEM compatible’ means, but I think it raises concern over how this is being pitched to the industry, to the insurer and to the consumer in contrast to how it has to be recognized in the estimating system. My understanding is that as an integrated partner with CCC, they must classify the scans as either aftermarket or OE for the CCC validation coding, and I understand the only options are OEM or aftermarket. So it raises the concern, how does a so-called ‘OEM-C’ scan get represented in the diagnostic workflow? I would presume as aftermarkets so why call it something other than that? If not all scans or tools are created equal, then does any company simply get to ‘certify’ that their product is the ‘same,’ ‘comparable’ or ‘equivalent’ as OEM? How does the market deal with that?”

The arrangement between GEICO and asTech has certainly elicited numerous scrutinies, but across the industry, the prevailing question seems to be whether this situation is the beginning of a new trend among vendors, or if the industry’s reaction

Lithium-ion batteries, while e cient and powerful, can be prone to thermal runaway if damaged or improperly handled. This could result in a fire that is di cult to extinguish, posing significant danger to the entire repair area. Protect your workers and shop with our fire containment blanket.

High-performance fire protection blanket for hybrid and e-vehicles. This non-flammable blanket is certified to consistently withstand temperatures up to 2012 °F and can endure short-term temperatures up to 2462 °F, preventing flame spread and buying crucial time for emergency responders. It can be swiftly deployed by two individuals within 1 minute, thanks to its excellent air permeability and lightweight nature. Ensure safety standards in repair shops with our top-tier fire protection solution!

MITIGATES DAMAGE AND MINIMIZES RISKS DURING REPAIRS

PROVIDES RELIABLE PROTECTION FROM POTENTIAL BATTERY HAZARDS

CAPABLE OF WITHSTANDING EV FIRES EXCEEDING 2000°F

will prevent other vendors from following this example?

Schulenburg “hope[s] this is a one-off misguided effort that simply lost sight of who the actual customer was, not the start of a trend.”

“The development of standardized pricing agreements by vendors sets a new trend that other insurers will adopt because standardized pricing agreements will be profitable for insurers and their vendors,” McNee

fears. “If shops accept them without significant backlash, other insurers will adopt this model. If shops follow the money and lower their standard, who benefits? Insurance companies and their vendors. Can you afford to do scans and calibrations at these prices? None of us can, and shops are not doing themselves or this industry any favors by continuing to bury their heads in the sand.”

Miller expects “that others will

try to copycat this, but only time will tell if it will be successful; however, I believe it will difficult to stop this because this was initiated in the DRP network, and unless the shops are willing to terminate their DRP agreement, they have little to do but follow the mandates. In the ‘cancel culture’ world we live in these days, it would certainly send a strong message if it went the other way because of the industry’s response.”

Although asTech neglected to respond to inquiries from New Jersey Automotive on this topic, two of the company’s competitors weighed in to share their viewpoints on vendors negotiating pricing contracts with insurers, the message this scenario sends to insurers and whether they believe other diagnostic and calibrations providers will follow this example.

“It is in the best interest of a vendor to behave as a partner with their customers – in our case, the repairers,” insists Josh McFarlin (AirPro Diagnostics). “When a customer comes to you and decides to use your products and services, I think that, at a minimum, they should be part of any discussion about pricing/revenue that is going to impact them.”

“The insurer is not the customer, and the vendor has no business other than pricing the product they sell,” Tommy Ames (1Source ADAS and AutoEsolutions) shares, as he notes, “This didn’t feel like information that asTech wanted to make public, and it came across as very collusive. Engaging in a contract and forcing shops to use a set pricing schedule should never happen. The next obvious step is to engage in aggressive steering to drive business to shops utilizing the endorsed option.”

When it comes to standardized pricing, Ames emphasizes that excluding repairers from the conversation definitely creates the potential for misleading information to be conveyed. “This isn’t the way pricing should be standardized; to standardize pricing, you need all parties involved and multiple parties

from all areas, not just the biggest vendors or the biggest shops. There is way more to the scanning process than just a piece of paper.

“In the end, shops aren’t going to lose money,” he predicts. “They will just bill for every little detail. You can cut my scan prices down, but then I will start charging for battery support, documentation, inspection, test drives and on-site tech fees. The same services will ultimately cost more in the end.”

So, will other vendors follow asTech’s example?

“It depends on the industry’s reaction, ultimately,” Ames believes. “Right now, there are a lot of gripes and threats. But until it affects either company’s bottom line, then yes, others will follow suit. I’m sure other insurers are watching to see how this works.”

“Obviously, it is hard for me to say what other vendors are going to do, and I think it is too early to really speculate,” McFarlin says. “The only data point we have so far is that it seems like a lot of repairers feel the need to be very vocal about their dissatisfaction with the announcement, and many of them are demonstrating that dissatisfaction by looking for a new vendor…someone who will treat them as a partner. I will say that this has served to strengthen our resolve to remain focused on working closely with our customers to make sure they receive the best possible service, a pricing model that fairly represents the work performed, and that they have

all of the documentation they need for the work that is performed.

“We work in a complicated industry made up of complex relationships between the carriers, the vehicle owners, the repairers and the vendors,” he observes. “While it does not surprise me that this happened (many would be quick to say that this was ‘always just a matter of time’) – and I think it is easy to believe that this is just the beginning – I do feel that the reaction from the repairer community may cause others to pause on following the same path. Time will tell.”

We maintain a comprehensive inventory of high-quality, genuine OEM

Email or call today to speak with our highly knowledgeable parts staff!

LAND ROVER PRINCETON 1125 US-206 • Princeton, NJ 08540

609-921-7788 Visit us at www.landroverprinceton.com!

BMW of Springfield

391-399 Route 22 E. Springfield, NJ 07081

Toll Free: 800-648-0053

Fax: 973-467-2185

bmwofspringfieldnj.com

BMW of Bridgewater

655 Route 202/206

Bridgewater, NJ 08807

PH: 908-287-1800

FAX:908-722-1729

bridgewaterbmw.com

©️2024

Circle BMW

500 Route 36

Eatontown, NJ 07724

Parts Direct: 732-440-1235

Fax: 732-440-1239

wholesale@circlebmw.com circlebmw.com

Park Ave BMW

530 Huyler Street

South Hackensack, NJ 07606

PH: 201-843-8112

FAX:201-291-2376

parkavebmw.com

Paul Miller BMW 1515 Route 23 South Wayne, NJ 07470

PH: 973-696-6060

Fax: 973-696-8274 paulmillerbmw.com

BMW of Bloomfield

425 Bloomfield Avenue Bloomfield, NJ 07003

Parts Direct: 973-748-8373

psantos@dchusa.com

• Audi Parts Professionals are your subject matter experts on collision parts, replacement components and mechanical items.

• Many Audi dealers offer technical service support hotline access that can reduce your repair times and help you meet an on-time promised delivery.

• Installing Audi Genuine Parts contributes towards improved cycle time that makes both your customer and their insurance company happier.

Helping you do business is our business. Order Audi Genuine Parts from these select dealers.

Ciocca Parts Warehouse

8 Minneakoning Road

Flemington, NJ 08822

Toll Free: 800-221-1256

Fax: 908.782.1795 rmuir@cioccadealerships.com www.cioccaparts.com

DCH Millburn Audi

2211 Millburn Ave

Maplewood, NJ 07040

Toll Free: 800.553.9250

Direct: 973.762.0262

Fax: 973.762.2381 www.dchmillburnaudi.com

Paul Miller Audi

179 Route 46 East Parsippany, NJ 07054

Toll Free: 800.35.MILLER

Parts Direct: 973.575.7793

Fax: 973.575.5911 www.paulmiller.com

Bell Audi

782 Route 1 Edison, NJ 08817

732.396.9360

Fax: 732.396.9090 www.bellaudi.com

Town Motors Audi

400 South Dean Street

Englewood, NJ 07631

201.227.6506/6536

Fax: 201.541.0314 www.townmotors.com

Jack Daniels Audi of Upper Saddle River

243 Route 17

Upper Saddle River, NJ 07458

201.252.1500

Fax: 201.254.1552

tbabcock@jackdanielsmotors.com www.jackdanielsmotors.com

Audi Bridgewater 701 Route 202-206 N Bridgewater, NJ 08807

929.600.9156

Fax: 908.595.0237

parts@audibridgewater.com www.audibridgewater.com

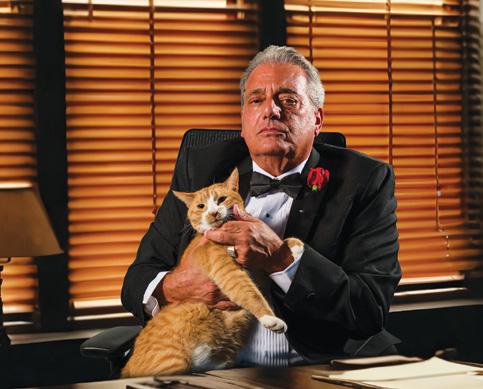

For five decades, Eddie Day has been a prominent and highly respected figure in the automotive repair industry. During that time, he built one of the most successful collision repair shops (Collision Restoration; Fairfield) in the state as well as serving as President of AASP/NJ, and he was a key figure in the merging of the state’s four automotive repair associations. Affectionately known as “The Godfather” to his friends and peers, earlier this summer, Eddie surprised just about everyone when he sold his shop and retired. New Jersey Automotive sat down with “The Godfather” and discussed his 50 years in the industry. So sit back and enjoy Eddie’s journey. Leave the cannoli.

New Jersey Automotive: How’s retired life treating you?

Eddie Day: You know, everyone tells me that I sound and look relaxed. Do I miss the business? No. I thought I would miss it more. I definitely have to keep busy with something because I get anxious. But do I miss being responsible for 25 people? Do I miss 13 insurance companies with 13 different rules? No, I don’t. Not a bit. I mean, it hasn’t been that long, but so far, it’s been great.

NJA: Is it what you thought it would be?

ED: No, I thought I was really going to be messed up, that I would be anxious and grieving and all that shit. But honestly, my office took it much harder than I did because we were closer than most families. It was a tough breakup for the employees. But I needed peace of mind. It was time.

NJA: All right, let’s go back. When did you first realize you loved cars?

ED: My family thought I was a special needs kid because of my illnesses. So my mother was smart enough to know that school was not going to be the answer; I wasn’t going to make it. I didn’t have the confidence, even though she did her best. Toys back then were very rudimentary, very simple. I took every toy apart to see what was going on inside. And then I got to the point where I could actually put the stuff back together, and it worked. So my mom bought an old car, put it out in the driveway and went to a little auto parts store and bought these little SK tool kits. That’s how I got started.

NJA: So you graduated high school, and what happened? Did you go right into the industry?

ED: I was in the industry before that. I was 14 years old working at Koch and Testa Auto Body in Montclair. I got the job through what Bloomfield High School used to call cooperative industrial education. You know, the slow kids. (Laughs) You have to understand, downstairs in the mechanical shop, it was like its own subculture. The kids from the Key Club didn’t even walk through the f#$king hallway. The mathematics class certainly wasn’t there. Okay? They were hard line dopes like me who couldn’t add two and two, but we could put a whole car together.

NJA: What was that like?

ED: Every shop teacher was Italian. They were World War II veterans, and they didn’t take any shit from anybody. They put you against the wall. They would literally pick you up off the ground. I’m not kidding. Frankie Stell – we called him Frankie Bear – Frankie Bear would go to the toughest guy on the first day of class, grab him by the shirt and pick him off the ground to let everybody else know, “Don’t f#$k with me during the year.”

NJA: Wait, that was a teacher?

ED: That was a shop teacher. Frankie Stell. A great guy. His voice quivered when he got pissed off at you. He’d say, “Eddie, I think you’re a nice kid, but I’ll knock your f#$king head off if you talk in my class.”

NJA: Tell me about that first day walking into Koch and Testa Auto Body.

ED: An old German perfectionist metal man. He wouldn’t let you do anything. I remember there was a ’66 Pontiac Bonneville there. This was 1973 or 1974. So that was kind of a new car then. It was dark maroon metallic, a real fine metallic. I remember him sanding it. He painted the right side rear quarter. He polished it. And that’s when I knew I wanted to do this. I just knew. He ran liquid ebony over it, which was a product we used 30-40 years ago, with a tie-on wool bonnet. And then he used cornstarch for a finish. He dusted cornstarch on it and buffed it out. It was like glass. I remember thinking, “Holy shit, what a cool way of doing business.”

NJA: How long were you there?

ED: I was there every summer for three years. And I worked my ass off. He never raised my hourly rate. The minimum wage was $1.75 an hour. So I worked four hours a day, five days a week, and I took home $30. He made me sand with this Coleman gas, and your hands would split open. But you didn’t complain. Then he found out I had an illness. I was taking medication for it. He fired me a half hour later.

NJA: Why?

ED: He thought I was going to have a seizure. He took me into the compressor room, that old piston compressor, you know. And he fired me.

continued from pg. 29

So, I put whatever tools I had on my bike and rode home. I got home, and my mother ran over. She asks, “What are you doing home? You’re supposed to be working.” I said, “I don’t know. I got fired.” “What’d you do?” I said, “I took my medication in front of Joe for the first time, and he fired me because I told him I was epileptic.” She said, “You made two mistakes. Number one, you told that man you had an illness. I never liked him. He was a cold German, and I never liked him, and you trusted a stranger with your personal information. Number two, I’ve driven you to work in the snow, and I remember passing body shops – you should have stopped in one of those f#$king shops for a job.” She was right.

NJA: So did you?

ED: I went back and worked at Caldwell Auto Body. The owner was a happy-go-lucky guy. He drank during the day, but he was a nice guy. The place was two by two. It had undercoating all over the floor because he used to undercoat for Claremont Cadillac. The place was a mess. But he made his living.

NJA: When did you decide to open up your own shop?

ED: Well, I worked for HR Auto Body, and then I worked in little garages all over the place. At the time, you could rent a garage, and nobody really bothered you. There was no room in the garage. They were usually so small that when you had a big car, the garage door would land on the bumper. If you painted a car, you’d paint the right side, wait a day later, turn around, paint the left side. There was no room to paint the whole car. Then I started working at Derio Oldsmobile in West Caldwell for a guy named Tony. I was in Florida on vacation when President Reagan fired the air traffic controllers. I was stuck there for a week. When I got back, Tony fired me. I put my tools in the trunk of the car, and I drove away. It’s amazing, the toolbox fit in the back of my car, right? I put the top down, and I drove home.

An hour later, my friend Paul Kaufman called me. He wanted his car painted. He found a garage in

Bloomfield. It was a shack. It had no running water, no heat, no bathroom. I would go to the McDonald’s on Broad Street if I had to go to the bathroom. It had a little, tiny air compressor. It had an extension cord. I had used fluorescent lights hanging up all over the place. I had carpet on the doors to keep the place warm. I had two kerosene heaters. And that’s where I started my own business. From there, I worked, worked, worked. Then I met a guy, and I shared a garage in Fairfield with him. I went there with $200 and a toolbox. I had no money. I used his checkbook. I never took a dime from him. I’d put my name next to every check, and I’d pay him back at the end of the week. I remember Matty from Muller Brothers sold me my first 55-gallon drum of thinners. It had my name on it. I felt like I had made the big time. I got credit. I got f@#king credit, you know? Matty started me off in the business. Great man.

NJA: What year was this?

ED: It was May of ’86. That was Ed’s Auto Body/Collision Restoration in Fairfield.

NJA: Was the shop an immediate success?

ED: No. I did wholesale work. I did work for some guys, some shyster that did auction work, but I used to work until 12, one o’clock in the morning. My first wife brought me Thanksgiving dinner and Christmas dinner there. I’d work outside with a drop light. The guy that rented the building to me drove by with his wife at one in the morning, and I was working with a drop light on this old black Bonneville. She turned to him and said, “You finally found another goddamn animal.” That was me.

NJA: But wasn’t the ’80s supposed to be the golden age of auto body?

ED: Oh, no, no, no. We did well. It was too early. I made money. I worked my ass off. It was me and a helper in a two-bay shop. It was the tiniest little shop. I rented the back of the mechanical shop. Then the town shut me down. They wanted a spray booth. I put the spray booth up, but I never got a permit. Then they shut me down again.

NJA: You often talk about the end of the ‘80s being the gold rush.

ED: Well, I think there were a lot of shops that were still doing business the old-fashioned way. There was a lot of money going around. People weren’t afraid to spend money on their cars. They restored stuff. I was probably working cheap because I was a kid. But I worked hard and made money, yeah, of course.

NJA: And then later in the ’80s you became involved with AASP/NJ. How did that come about?

ED: Around 1989 I think, Champion Bumpers’ Steve Bollander brought me into the association. But I really wasn’t ready.

NJA: What made you become interested in it?

ED: I wasn’t smart enough. I needed to know more. I think the shops that join and take part in the association are the smartest people in the industry. That’s why I joined. I wanted to know more.

NJA: You join the association, you’re learning, getting training and sharing ideas, and within four or five years, you’re the president.

ED: I wasn’t ready for that, either! (Laughs)

NJA: What are your memories from that time?

ED: I have trouble with public speaking. I struggle with it. But then again, I was good in a small setting. But as president, it brought a lot of attention I never expected. Because of that title, I met my direct repair partners, and my business took off.

NJA: When you became president, everyone in the association wasn’t exactly on the same page like they are now. How did you get through those muddy waters?

ED: It was tough because you had shops that had a different view on being insurance related. They were telling me that I was going to go out of business. And I remember in the back of my head, saying to myself, “They don’t know it, but they’re going out of business.” Because the guy with the checkbook is the guy you have to connect with. Whether you want to be a rebel or not, being completely isolated from the insurance industry is a death sentence. Look, at least 60 percent of our members have always been direct in one way or another. Or they’re doing fleet or dealership work. They’re being fed by somebody. Maybe I got it a little bit earlier. But I knew that those insurance relationships were important. Especially in the location I was in. My shop was tough to find. Today, if you want to find me, you put in your phone, and a red line drags you right to the shop. People will find you. It’s easy. But back then, it was contentious. Obviously, the Board stuck together, whether one was DRP or not. We represented everyone without judgment. We always said each shop had to make their own business decisions. We stood behind that then, and the association still does today.

NJA: Then a couple years later, you were past president, but you were very much involved in the merger of the four state associations.

ED: I started going to some of the other associations’ dinners and meetings. I became very close with Nick

Kostakis, Lee Vetland, Joe Lubrano and several other guys from Central and South Jersey. They were great people. They were smart, decent human beings. I knew they wanted the best for the industry. We knew we couldn’t accomplish what we needed to accomplish being splintered into four separate associations in four different corners of the state. So we sat down, and I remember being at the table, and I couldn’t even talk. My mouth was so dry. Then Nick called me and said, “Let’s bring this to DEFCON 5. Let’s get this done.” Because it wasn’t going to happen. We were hitting too many stumbling blocks. He, I, Lee and Glenn Villacari wouldn’t let it die. I remember Lee saying, “All you’re going to have is your trade show and your walkie-talkies.” He was being a little insulting. I said, “What does your association do for money? Golf outings?” We went at it, me and Lee. Of course, we eventually became so close I did his eulogy when he died. But that was huge. It was probably the biggest thing that happened in the industry, in not only New Jersey, but across the country. Because right now, if we’re not the top state auto body association in the country, we are absolutely top two or three. No doubt. That was the foundation of that.

NJA: You were always involved in the NORTHEAST® Automotive Services Show committee. But then when we moved it back to New Jersey in 2009, you took on a more prominent role.

ED: It was so exciting. We loved it. Watching it grow was fantastic. We had great ideas. We seemed like we had the perfect brain trust to make that grow.

NJA: Did you ever foresee it becoming as big as it has?

ED: No. I mean now it’s second only to SEMA in the country. You know why it worked out? Because when we took it back to Jersey; we had enough balls to say, “Let’s wing it. Let’s give it a shot.” And that took a lot of f#$king nerve. That took balls to move into that big space. Then we met the people at the Meadowlands. They were great. We knew right away that it was going to be strong. But it

• Our expert parts staff is ready to serve you with over $500,000 in inventory and a fleet of trucks to help ensure same-day delivery on most orders

• We respect your time, and offer a quick and accurate order process to help meet your needs

• Proudly serving the Tri-State area with Audi Genuine Parts since 1970

• Same-day delivery on stocked items, next-day availability on most non-stocked items

400 South Dean Street Englewood, NJ 07631

Parts Direct: 888.779.6792

F ax: 201.541.0314 E mail: audiparts@townmotors.com

Hours: Monday-Friday 7am-7pm Saturday: 8am-5pm

You’ve got the right tools, staff, technology and procedures to give your customers the best repair possible. The missing piece of the puzzle? Genuine Volkswagen Collision Parts. Contact an authorized dealer today and find your perfect fit.

Ciocca Parts Warehouse

8 Minneakoning Road

Flemington, NJ 08822

Toll Free: 800-221-1256

Fax: 908.782.1795

rmuir@cioccadealerships.com www.cioccaparts.com

Paul Miller Volkswagen 118 Morristown Road

Bernardsville, NJ 07924

TOLL FREE: 877-318-6557

LOCAL: 908-766-1600

FAX: 908-766-6171

Email: aaitchison@paulmiller.com www.paulmillervw.com

“Volkswagen“ and the Volkswagen logo are

Douglas Motors

491 MORRIS AVE. SUMMIT, NJ 07901

PHONE: 908-277-1100

FAX: 908-273-6196

TOLL FREE: 800-672-1172

www.douglasvw.com email: douglasparts@douglasautonet.com

Trend Motors 221 Route 46 West Rockaway, NJ 07866

888-267-2821

fax: 973-625-4985 www.trendmotors.com email: dreinacher@trendmotors.com

Crestmont Volkswagen 730 ROUTE 23 NORTH

POMPTON PLAINS, NJ 07444

TOLL FREE: 800-839-6444

fax: 973-839-8146

www.crestmontvw.com email: vwparts@crestmont23.com

was scary. Especially when we got sued by the trade show manager we fired.

NJA: But you were the only one on the committee who wasn’t sued. Why was that?

ED: Well... (Laughs) The rumor was he was going to also sue me. So I called him and told him I felt left out. He said, “What do you mean?” I said, “I feel left out. Do you really want to alienate me like this? I want you to sue me.” And he kept asking, “What do you mean?” I said, “I’m waiting for the lawsuit.

I’m going to wait for the certified mail. I wish you would sue me. I really do.” Again, he asked “Why???” I said, “I don’t know. That remains to be seen what the outcome of the lawsuit is going to look like, my friend.” (Laughter) I never got sued. (Laughs) Now, that could be perceived as threatening. But it wasn’t. I’m an insecure guy, and I don’t want to be left out. That’s all. (Laughter) He sued the rest of the committee, but he didn’t sue me.

NJA: You’ve spent almost 50 years in the industry. You are a key figure in AASP/NJ’s history. We have seen you walk into the NORTHEAST show and meetings and it’s like you are the “Godfather” of the Jersey collision repair industry. What are your thoughts on the association after 40 years working in it?

ED: I have so many great memories of this association and this industry. I met some of my closest friends in the world. Brothers. You know? And I still talk to 50, 60 percent of them. People I can walk up to at the NORTHEAST show and give a big sincere hug. It’s like being in combat. There’s a little bond when you go through a lot of the same shit. You know what I’m saying? When you’re crawling, it’s like being in a foxhole with somebody. It’s like a war reference, I guess you can say. You’re in the trenches with the same problems. So when I look back, I think of all the great people I’ve shared that foxhole with.

NJA: What are the biggest changes you’ve seen in the industry in the last 40 years?

ED: DRP and certification were the biggest changes. The push for DRP and the push for high-end certification, which is a very small market that I was in. There’s only seven or eight shops that do what I did. And it took a lot of balls and a lot of money. And I did it. I started it at 59 years old. It was a younger man’s game because there’s a lot of shit you’ve got to go through. With the right administrative staff in the office, you can do it. But it’s tough. There’s a lot of politics. You have to create a solid relationship and a strong level of trust between you and the dealership. And some guys are just like, nope, nope, just like straight out, nope. For me, I think the certifications were the turning point in my business. No doubt.

NJA: How many certifications did you have when you sold?

ED: Volvo, Polestar, Jaguar, Land Rover, Tesla, Maserati, Porsche, Mercedes-Benz, just finishing BMW. So eight. C8 Corvette because it’s a restricted car also. So nine. Nine high-labor-rate certifications.

NJA: What would your advice be to a shop that would want to do something like that?

ED: Hold on to your hat. Batten down the hatches because it gets really, really, really hard. And programs like Land Rover and Porsche are the toughest. It’s a lot of work. Anybody that does it, I give them a lot of credit.

NJA: Pre-certification, you were very much a DRP shop. Obviously, that’s always been such a controversial topic. But yet, you’re one of the few shops that was never really criticized for that. Why do you think that was?

ED: Initially I was. But I don’t know. I think it has to do with how they respected what I did and the work that I did. I always helped other shops when they asked. I was never a hog with my work or my knowledge. So I didn’t get criticized for being a DRP. Not too much. Under their breath, maybe. But, you know, everybody kind of got it 20 years later, right? Then everybody else joined. I always say, maybe I just got it earlier than the guy who complained about it.

NJA: There’s a trend here. You were on the DRP train early. You were on the certification train early…

ED: I always read the trade publications. I would sit and read every issue of New Jersey Automotive and Body Shop Business. I would go to the training at the trade show, and I’d listen. These guys were smarter than me, and I was aware enough to realize I could learn from them. That is the problem with a lot of shops. Their goddamn egos. Because they think they got it wrapped up. If they had it wrapped up, they’d be certified for eight high-paying

continued on pg.

David Yeager - EL & M Auto (800) 624-2266 / elandmauto@aol.com

Ed Silipena - American II Autos (609) 965-0987 / esilipena@yahoo.com

Norm Vachon - Port Murray Auto (908) 689-3152 / portmurrayauto@yahoo.com

Dillon Rinkens - East Brunswick Auto (732) 254-6501 / ebautonj@comcast.net

President - Rodney Krawczyk Ace Auto Wreckers (732) 254-9816 / aceautonj@comcast.net

1st Vice President - Daryl Carman Lentini Auto Salvage (908) 782-4440 / darryl@las-parts.coms

2nd Vice President - Mike Ronayne Tilghmans Auto Parts (609) 723-7469 / tilghmans@snip.net

Past President - Bob Dirkes Dirkes Used Auto Parts (609) 625-1718 / dirkesauto@gmail.com

The Automotive Recyclers Association of New Jersey

Recently, we have received a number of problems with workers’ compensation annual audits. There are several classifications of insurance that can apply to your operations, such as auto dismantling, scrap dealer, clerical, sales, auto repair and store auto part sales/counter person. It is very important that you have each employee classified properly and understand the workers’ compensation guidelines. The area that has been the biggest problem is the classification of a counter person versus clerical person. Technically, if there is no physical separation between the counter person and a clerical (internet sales, bookkeeper, etc.) person, they will classify the clerical person ($0.17 rate) as a counter person ($4.29) rate, which is an extremely higher rate.

Proper classification, physical separation and understanding the guidelines are all important items to have prepared prior to your appointment with the insurance company’s auditor. You should contact your insurance agent prior to your audit and review the job duties of each of your employees for proper classification.

If you have any questions, please contact me.

OEM directors. But their egos keep them from listening to somebody else’s point of view. Don’t let your head get too big. It will hold you down. Try to play nice with your competition. But if your ego is in the way, that’s not going to happen.

NJA: A lot of people would say that the insurance companies are treating shops worse than ever these days. Did you see that on the way out?

ED: It started getting hard again. They left us alone during COVID. Everybody thought that was going to continue. So a lot of guys were changing their business tactics and charging over and above and all that stuff. The insurance companies…they’ve got attorneys and psychologists that sit and tell their employees how to get into the body shop’s head. They’re very smart. They adapt 1,000 times faster than we do.

NJA: I know you love being Italian almost as much as fixing cars.

ED: I had a very Shakespearean great-grandfather. So, we have a Romeo and a Juliet, a Hector and a Leo. These are all Shakespearean names. And my Uncle Romeo was the black sheep of the family. He was the wiseguy of the neighborhood of the North Ward in Newark. And he was feared and rightfully so. Because I heard the hardship my grandparents went through, yet they came here with an American flag on their lapel. My great-grandfather would say, “This is the greatest country in the world, but the greatest culture in the world was in Italy.” The one that contributed most to the world, including the Renaissance, right, the beginning, out of the Dark Ages, was Italy. So, yeah, how can you not be proud? What other country produces Bugatti, Lamborghini, Maserati, Ferrari, Versace, Armani, right? I mean, there’s no other country in the world that’s produced something so loved as Italian food, right? Listen, before we got to this country, a meal was a piece of meat with animal fat poured on top. That was a f#$king dinner, okay? (Laughs.) So, yeah, of course, I grew up very proud. I had a very old-fashioned house. My grandparents lived with us and spoke broken English, but they loved this country unconditionally. They were incredibly patriotic, and they sent their sons to war. And the most died…more Italian Americans fought and died in World War II than any other ethnic group.

NJA: When the pandemic hit, we started doing a podcast together called “Out of Body Experiences.” During those podcasts, we repeatedly brought up the fact that you’d never sell your shop. You love repairing cars too much. But then earlier this year, going back to our theme here, you got an offer you couldn’t refuse.

ED: As they say in the movie, yeah. I think this is going to be like Haley’s Comet. Listen, there’s certain companies, consolidators, that will buy anything. Certain ones like run-

down, shitty, poor quality, bad-reviewed shops because all they can do is lift it up, right? All they can do is fix it, right? The company that acquired us wants to be the cream of the crop. My building’s not beautiful, never was, but they wanted my brand. That’s why they called me. I had two people pitching me at the same time. But I liked the way they talked. We broke bread, and we sat down. They were good guys. Really, they’re compassionate. My employees didn’t want that much change that quick, but I said to them, when I leave, this is going to get better. Again, ego out of the way. “No one can do it like Eddie did.” Bullshit. They’re more efficient than me. Their job cost program was stronger. Their accounting was easier. Their process was near perfect.

So really, it was about timing. I’m 66 and a half years old. A dear friend in the industry said to me, “My father died on the job, Eddie Day. Our industry is going through something right now. You’ve got to jump on it. Don’t die on the job.” I’m very blessed it worked out.

NJA: What will you miss most?

ED: The thing that I will miss most is my customers. Being able to satisfy the toughest customer. Keeping that Google rating at 4.9. Satisfying that tough customer who comes in screaming. And my people, of course, my people. We sat down for breakfast and lunch every day. We ate together every day. Nobody ate over the desk. It was a family. But it was time.

NJA: What do you see as the future of the collision repair industry?

ED: The spirit of that small shop is never going to end. That guy is going to make it work. I never counted that fivecore shop out, ever. Because I think they’re the f#$king backbone. Let’s go back to World War II, right? They’re the boots on the ground. If they watch their money, that five-core shop is always going to make a decent living. There’s always going to be a little overflow for that guy. As for the technology, sub it out to the dealer, let the dealer fix the broken wire and put the light out, bring it back, add your 25 percent, get your tow bill. So technology is not a problem because you become a problem solver. And the problem solving is what? Find somebody that can fix it. That’s how you problem solve. Find somebody smarter than you. I’m a firm believer of being around smarter people than me, which lately, is easy to find. (Laughs)

•

•

•

Pro Spot’s 5 Series Spot Welders. The most sophisticated spot welders in the world now have the most versatile boom system, the Ergo Lift Assist

9' High, 5' Low, 51" Reach

Pivots Left to Right 180 °

Fits Through Doorways

Easy Movement Between Vehicles

Balanced and Safe

Ergonomic