For the second year running the results are in and we couldn’t be happier. Scania has once again been voted the number one* truck brand in the country by the people whose opinion we value the most - New Zealand truckies.

We’re chuffed to have rated highest on all measures, including most preferred, comfort, safety, sustainability, performance, efficiency, service and parts. Thanks again New Zealand. It means a lot.

EDITORIAL DIRECTOR

Dave McCoid

Ph: 027 492 5601

Email: dave@nztrucking.com

EDITOR

Gavin Myers

Ph: 027 660 6608

Email: gavin@nztrucking.com

For all advertising enquiries:

ADVERTISING MANAGER

Pav Warren

Ph: 027 201 4001

Email: pav@nztrucking.co.nz

Mike Devon

Ph: 027 332 4127

Email: mike.devon@nztrucking.co.nz

Maddy McCoid

Ph: 027 336 6811

Email: maddy@nztrucking.co.nz

SUB

Tracey Strange, Faye Lougher

EDITORIAL

Zealand Trucking magazine is published by Long Haul Publications Ltd. The contents are copyright and may not be reproduced without the consent of the editor. Unsolicited editorial material may be submitted, but should include a stamped, self-addressed envelope. While every care is taken, no responsibility is accepted for material submitted. Opinions expressed by contributors are not necessarily those of New Zealand Trucking or Long Haul Publishing Ltd. All rights reserved. This magazine is subject to the New Zealand Press Council. Complaints are to be first directed to: editor@nztrucking.co.nz with “Press Council Complaint” in the subject line. If unsatisfied, the complaint may be referred to the Press Council, PO Box 10 879, The Terrace, Wellington 6143 or by email at info@presscouncil.org.nz

Further details and online complaints at www.presscouncil.org.nz

6 months (6 issues)

One

1

One of the keys to life and business is an understanding of the nuanced differences between adaptation, progress, and advancement. Whether personal, commercial, or societal, chasing every new shiny trinket and labelling it advancement and progress cannot be assured until due assessment is undertaken on whether that progress is genuine or naive. Such critique is at the core of the world’s most enduring companies, according to noted scholars on the subject.

And then there are the environmental, circumstantial, or induced shifts that trigger adaption within the advancement and progress narrative. At times the need to adapt may well redefine both advancement and progress in the medium term at least.

respect we as owners show to those people giving their all to bring this enterprise to life every day, as well as those who support us commercially.

Framed within our own agenda, we could also see an impending slowdown in the economy, and so needed to shore up as best we could for that also.

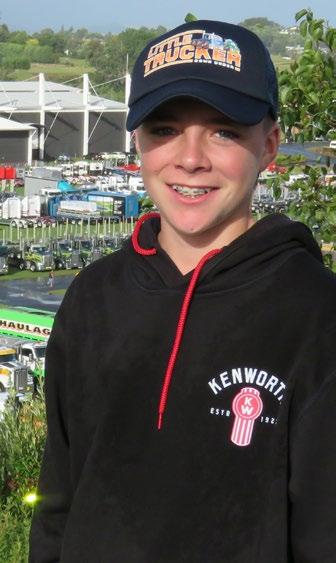

contributors. It will remain our core children’s masthead, now with a monthly print presence, also retaining its own website and social media activity. On top of all this there will be a standalone digital issue produced quarterly.

With every fully electric S.KOe COOL semitrailer box TrailerConnect® telematics is on board.

One of the gifts we received in respect to our current global economic malaise was time. Its impending arrival was well documented, and much of the price we’re paying has its roots in defining naive versus genuine progress in the half decade leading up.

It’s been a wonderful journey. As the old chestnut goes, you never learn a thing about yourself in a boom, and today there’s not a shred of doubt in my mind that I have the greatest business partners anyone could ever hope to have; likewise my respect for the character, integrity, and energy of everyone who breathes the life into Long Haul Publications is without boundary.

We have given subscribers the option of a refund on their outstanding subscription balance, or donation of the same amount to Starship Hospital. Our good mates at Truckin’ Life in Australia have picked up the Australian arm of Little Trucker Down Under, and we’ll continue to share cross-Tasman content, ensuring the masthead retains the down under flavour. A huge thank you to everyone –businesses, transport operators, and readers, for their support of Little Trucker Down Under both past and ongoing.

All S.KO semitrailers are equipped with TrailerConnect® telematics as standard. You have immediate access to the Schmitz Cargobull telematics portal and apps beSmart as well as beUpToDate.

Your advantages are:

- Intelligent dispatching that optimizes tours and on-time delivery while avoiding empty runs.

But it has been a tough year and will continue to be so for some time yet. Every business continues to run the magnifying glass over its costs in what is a small marketplace. As a result, like thousands of other businesses, we’ve had to make some courageous decisions.

- Reduction of process costs for trailer availability, capacity utilization and personnel deployment.

Here at Long Haul Publications, we’ve had a truly interesting and characterdefining year. It started with an internal restructure based on redefining the business, how it was measured, the stress it imposed on staff and a finite marketplace, and most importantly its core values –namely the consideration and

- Efficient fleet management with real-time information on the actual state of the fleet.

For the time being at least, we’ve discontinued printing the Little Trucker Down Under product as a standalone quarterly, bringing the print component within the covers of New Zealand Trucking magazine. As we do with The Business of Trucking section, Little Trucker Down Under will retain its own cover, also retaining Shannon Williams as editor and her band of merry young folk as

- Higher trailer availability - proactive maintenance minimizes downtime and breakdown.

works

It’s a fantastic way to produce informative, entertaining, and shareable industry content. There’s the Keep On Moving Vocational series interviewing industry characters and icons; The Business of Trucking and NRC On Schedule keeping you abreast of business and industry representation; and Blokes Yarning and Chics Chat burgeoning with intellectual might on important topics and issues like, ‘are slash-back stacks superior to straight cuts or curved?’

With every fully electric S.KOe COOL TrailerConnect® telematics is on board.

With every fully electric S.KOe COOL TrailerConnect® telematics is on board.

Your advantages are:

Your advantages are:

We also made the difficult decision to switch off Trucking Radio 24/7 on 31 July this year. After two years – almost to the day – continued rising input costs, and significantly reduced commercial support as a result of the economic downturn, rendered the station non-viable. It’s worth noting the listening audience was continuing to climb steadily.

All S.KO semitrailers are equipped with TrailerConnect® telematics as standard. You have immediate access to Schmitz Cargobull telematics portal and apps beSmart as beUpToDate.

All S.KO semitrailers are equipped with TrailerConnect® telematics as standard. You have immediate access to the Schmitz Cargobull telematics portal and apps beSmart as beUpToDate.

- Intelligent dispatching that optimizes tours and on-time delivery while avoiding empty runs.

- Intelligent dispatching that optimizes tours and on-time delivery while avoiding empty runs.

A huge thank you must go to our commercial broadcast partners who have stayed on supporting the podcasts, making a far more affordable business model sustainable. Contact Pav Warren and her team if you’re keen to be part of this amazing journey.

- Reduction of process costs for trailer availability, capacity utilization and personnel deployment.

- Reduction of process costs for trailer availability, capacity utilization and personnel deployment.

- Efficient fleet management with real-time information actual state of the fleet.

- Efficient fleet management with real-time information actual state of the fleet.

- Higher trailer availability - proactive maintenance downtime and breakdown.

- Higher trailer availability - proactive maintenance minimizes downtime and breakdown.

However, our broadcast division is alive and well. Looking forward and taking so many learnings from radio, our varied, streamed, podcast series continues to ramp up in audience and interest from the industry, and there’s now a list of people looking to talk to us.

Long Haul Publications is now a leaner, more sustainably resourced, and happier business, and New Zealand Trucking magazine continues to be the beast it’s always been.

Telling New Zealand’s road transport story is more important today than it’s ever been, and doing exactly that, across multiple media platforms, better than anyone else, will always be the mission we strive for.

Dave McCoid Editorial Director

-Sustainable: The S.KOe semitrailer is purely electric and has free access to Zero Emission Zones

-Quiet: The electric operation of the cooling unit in combination with the Silence Kit makes day and night deliveries possible

-Time-saving: recharging the battery through the e-axis increases the range and prevents unscheduled stops

-High heating and cooling capacity: The refrigeration circuit in the S.CUe electric cooling unit is identical to the conventional units and has the same excellent performance values

-24 months service and proactive monitoring: the full service contract for cooling units takes into account the special requirements of an electrical cooling unit

-Complete solution: All system components are perfectly matched to each other

- Reduced maintenance effort: The effort for the maintenance of diesel engines is eliminated

-100% SMART: All vehicles are equipped with TrailerConnect® telematics as standard, for controlling and monitoring the vehicles.

• 100% SMART: All vehicles are equipped with TrailerConnect® telematics as standard, for controlling and monitoring the vehicles. COOL semitrailer box board.

• Intelligent dispatching that optimizes tours and on-time delivery while avoiding empty runs.

QR code for legend to

• Reduction of process costs for trailer availability, capacity utilization and personnel deployment.

• Efficient fleet management with real-time information on the actual state of the fleet.

• Higher trailer availabilityproactive maintenance minimizes downtime and breakdown.

Benefits at a glance:

• Sustainable: The S.KOe semitrailer is purely electric and has free access to Zero Emission Zones

• Quiet: The electric operation of the cooling unit in combination with the Silence Kit makes day and night deliveries possible

• Time-saving: recharging the battery through the e-axis increases the range and prevents unscheduled stops

• Complete solution: All system components are perfectly matched to each other

• Reduced maintenance effort: The effort for the maintenance of diesel engines is eliminated

• High heating and cooling capacity: The refrigeration circuit in the S.CUe electric cooling unit is identical to the conventional units and has the same excellent performance values

• 24 months service and proactive monitoring: the full service contract for cooling units takes into account the special requirements of an electrical cooling unit

FAW Trucks (First Auto Works) is set to arrive in New Zealand, with Intertruck Distributors NZ named as the brand’s importer, distributor and master dealer.

“With the popular cabover 9870 model ending and no update from International on the horizon, a replacement cabover was narrowed to three marques. On analysis, it was an easy decision. Our in-depth tour of FAW’s assembly plant in Qingdao, China, provided us with clear insight into their intense focus on quality and to be a leader in global vehicle production,” said Intertruck Distributors NZ company director Comer Board.

“Just on four years ago, FAW approached me to be their distributor, offering 6x4 only. I suggested that when 8x4 RHD variants were engineered for New Zealand, we would be interested. As promised, 18 months later, FAW reconnected with me, offering a rollout of right-hand-drive models. This confirmed they were serious and willing to invest into New Zealand’s small market,” he said.

“We witnessed FAW’s highly automated production facilities and impressive build quality, backed by an extremely motivated workforce using bestpractice methods.”

FAW maintains strict assembly controls to produce 500,000 units annually – 12% of the world’s heavy-duty trucks. The Qingdao assembly plant is one of four in China, and produces 330,000 units per year and continues to expand operations.

“The introduction of FAW is a real game-changer for Intertruck

and more so for our current and emerging new customers,” Board said.

“These are high-quality, greatspec trucks at a very attractive price ticket. They are truly excellent value for money.”

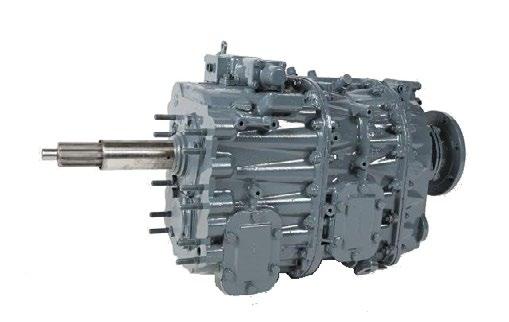

The first model JH6 tractors arrive in September followed by 8x4 rigid trucks. Among their features are a suite of collision warning and mitigation systems, disc brakes, AMT with Intarder, four-point cab air suspension, ECAS rear suspension, highroof flat-floor with under-bunk fridge, a low-roof space cab option, in-dash display with camera and ISRI seats completed in a high-quality cab trim.

Global brands such as Cummins, ZF and FAST transmissions, TRW steering, Wabco and Knorr Bremse brake systems will feature in the trucks.

“After extensive research on FAW’s 13L engine, it made absolute sense to introduce this as our main power plant in heavy-duty,” Board said.

“The JH6, using the same engine, operates in South Africa towing B-doubles in excess of 62 tonnes. Given the already proven JH6 reliability in South Africa and with diesel over 50% of operating costs in that country, the FAW engine delivers the best fuel economy and is fast becoming the preferred choice in many fleets. We will release the FAW CA6DM3 engine at 410kW (550hp)/2600Nm (1917ft/lb), further increasing these specs in 2026.”

Intertruck will be joining the small number of local distributors offering light-, medium- and heavy-duty

choice of model configurations, including a medium-duty urban and job-ready 6x4 steel bathtub tipper. A Cummins-powered 4x2 chassis cab with wheelbase options will suit various body configurations and the container Stinger market,” Board said.

“The FAW light- and mediumduty trucks will replace Foton, a marque Intertruck recently surrendered, as the vehicles compete in that same space.

“Being a New Zealand distributor for 27 years, Intertruck will continue to provide a high level of parts and service support. Our extensive experience, along with the combined appointment of 21 dealers and service providers throughout New Zealand, has been a critical milestone in our success,” he added.

In Manukau, Prestige International will remain as the International dealer in sales, parts and service. All Truck Fix and Diesel Services located in Ōtāhuhu is now the authorised FAW and international parts and service dealer.

“Their location gives our International customers a wider choice for West Auckland and central-city servicing and maintenance requirements,”

now doubled their workshop floor space in readiness for increased business, adding a COF lane in the near future.”

Intertruck has appointed TRT (Tidd Ross Todd) in Hamilton as parts and service dealer for both FAW and International trucks.

CVC (Commercial Vehicle Centre) locations in the South Island are International parts and service dealers.

“Initially, all FAW sales will be channelled through Intertruck’s long-standing and experienced sales team,” Board said.

“They all have an immense knowledge and a complete understanding of the transport industry. Having confidence in making the right choice when setting up new equipment is important; these teams will help guide our customers in this decision process,” he said.

“FAW exports vehicles to over 80 different markets. Launching into New Zealand and Australia with high-quality, fuel-efficient and very affordable trucks, there is no doubt FAW products will be a market disruptor. We are immensely privileged to be on this journey with FAW and look forward to servicing our current and emerging new customers with these premium products.”

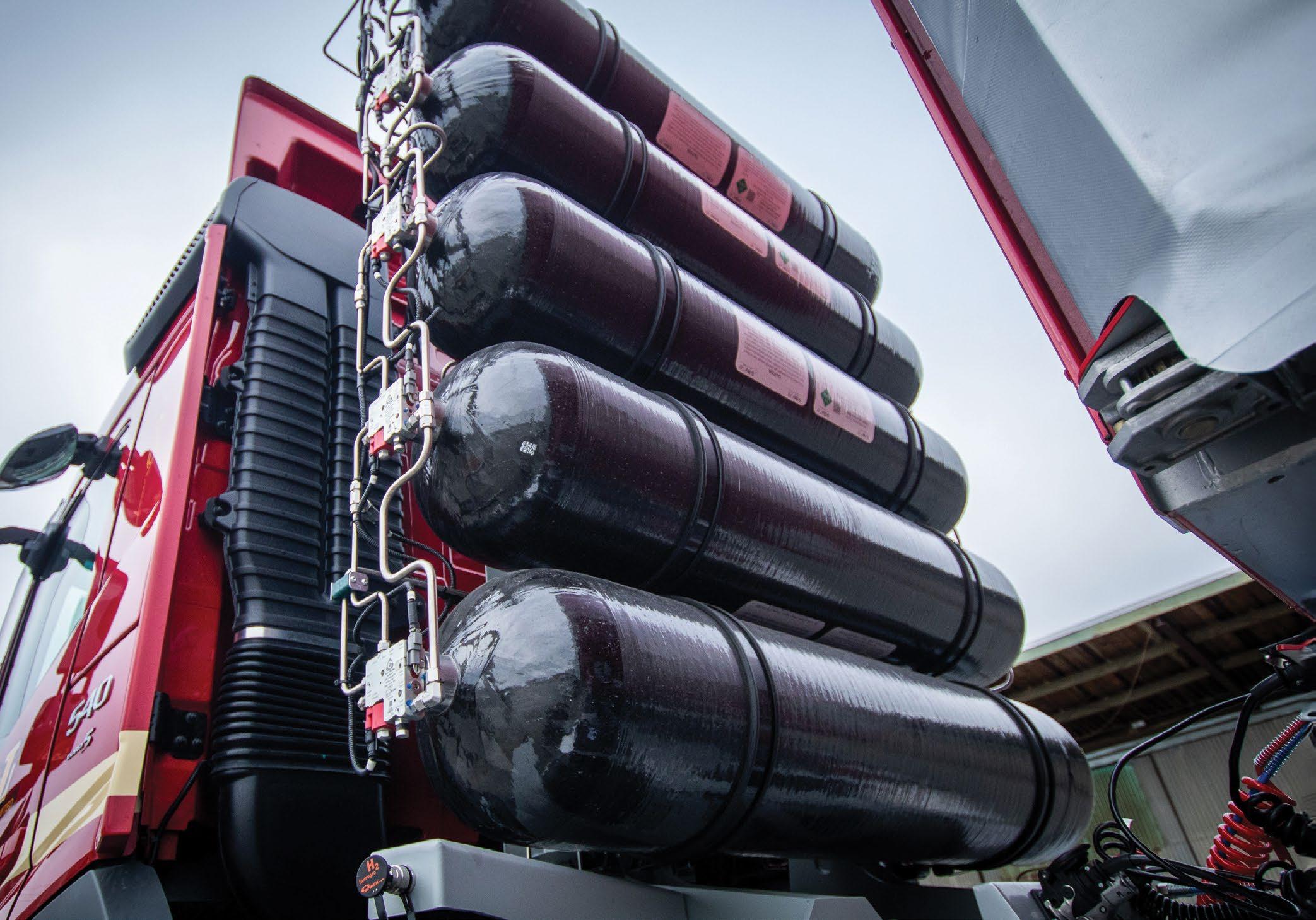

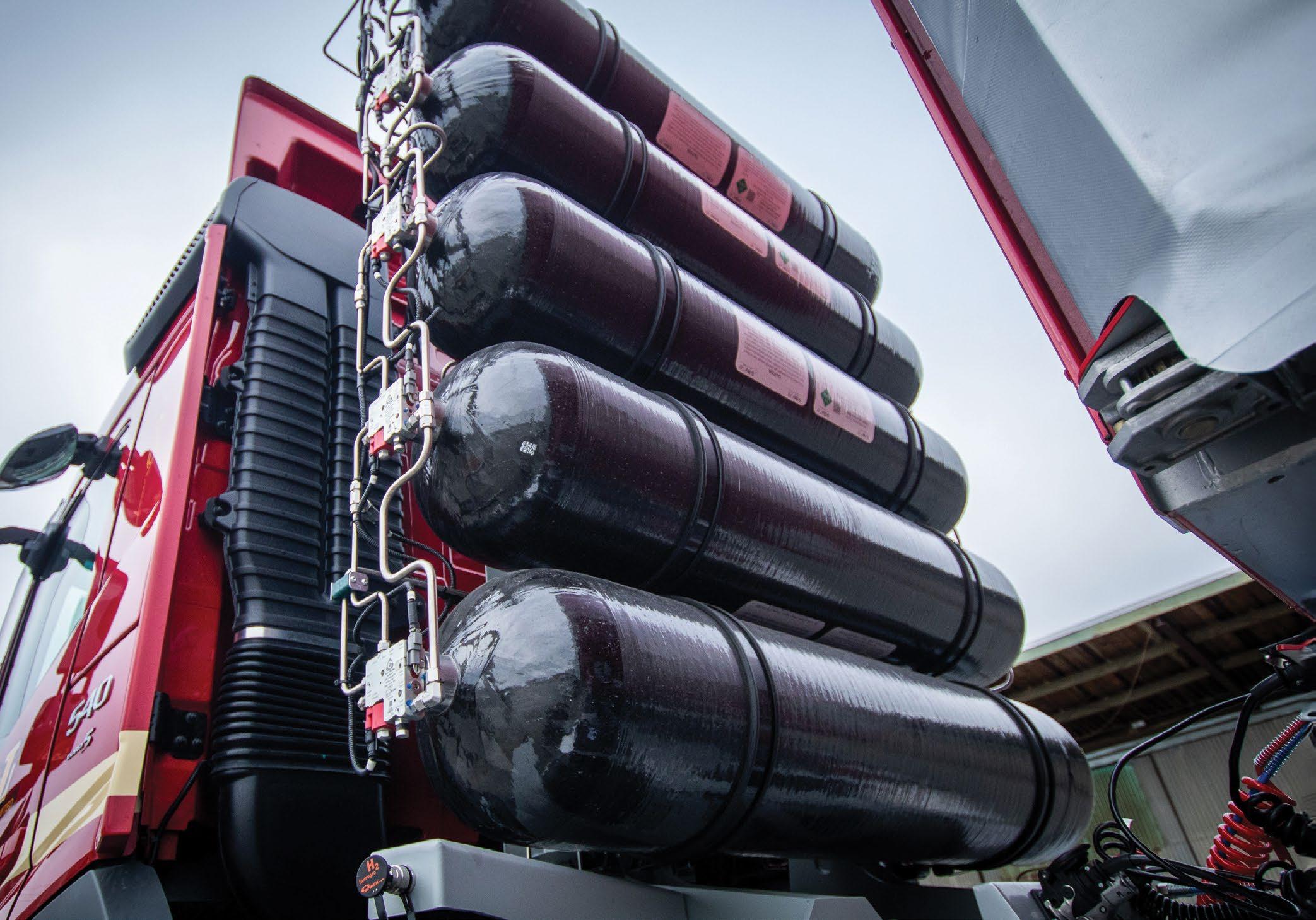

New Zealand’s first Xcient hydrogenpowered fuel-cell electric truck in commercial operation has clocked 100,000km since entering service in July 2022 with NZ Post.

“NZ Post was the first company in New Zealand to trial the hydrogen truck, which aligns with our approach of testing and adopting new technologies,” said NZ Post CEO David Walsh. “It is another step towards our goal of transitioning to net-zero emissions operations by 2050.”

Walsh hoped NZ Post’s early adoption to trial and introduce zero-emission technology to its fleet had encouraged others to also do the same.

“NZ Post’s transport fleet accounts for around 45% of our

emissions so, therefore, NZ Post is focused on opportunities to decarbonise our transport fleet,” said NZ Post group sustainability manager Dawn Baggaley.

Baggaley said the acquisition of the hydrogen truck was made possible with the support of Hyundai New Zealand.

Grant Doull, national manager of hydrogen and eco commercial vehicles at Hyundai New Zealand, said: “The 100,000km milestone

demonstrates that hydrogen can be a reliable and efficient replacement to traditional diesel trucks with a longer range, shorter refuelling time, and a greater payload.”

Andrew Clennet, CEO of Hiringa Energy, said: “Hiringa is delighted to see NZ Post reach 100,000km in their Hyundai Xcient fuel-cell truck. Hydrogen offers enormous advantages in terms of operational efficiency and productivity by allowing

quick refuelling times and high productivity, a perfect match for the needs of NZ Post and their customers.

“By being the first to run a FCEV truck in New Zealand, NZ Post has provided a real-world use case for fleet owners who might be looking to apply for grant funding under the scheme, allowing them to purchase their hydrogen fuelcell truck with confidence in its capability,” Clennet said.

Freight Haulage, an HW Richardson company, recently completed a significant return journey from the deep south to Auckland using a dual fuel truck – which runs on both hydrogen and diesel.

The trip was part of an effort to collect equipment for a hydrogen refuelling site currently being built by HWR in Clifton, Invercargill. Once in Auckland, the truck refuelled with hydrogen at the Hiringa hydrogen refuelling site at Wiri.

The refuelling process at the Hiringa Wiri site was fast, taking around 15 minutes to refuel the truck with 25kg of hydrogen. Once refuelled, the truck drove approximately 450km of its journey back to Invercargill on dual fuel mode – reducing its

diesel consumption by 33%. From there it continued its journey on diesel.

Hydrogen allows for these heavy vehicles to perform their usual work with no, or limited, impact to payload and refuel times, and dual fuel means that there is no range anxiety as the truck continues on diesel when hydrogen is not available.

“Developing both a network and a demand is key to successful implementation of hydrogen as an option for the transport industry, and in the heavy transport space hydrogen offers many advantages,” said Gareth Wishart, general manager technology and innovation at HW Richardson Group.

“Dual fuel is a transitory technology that allows a cost effective retrofit, and the

development of the hydrogen infrastructure, on the path to the 100% hydrogen-fuelled vehicles of the future.”

“Our trials of the dual fuel trucks to test their performance and efficiency are promising, showing the expected 30 to 40% reduction in carbon emissions, a significant reduction in NOx emissions and no loss in power. And we are now progressing to a commercial offering for the dual fuel systems.”

Hiringa is building a green hydrogen refuelling network across New Zealand, with three sites up and running at Palmerston North, Auckland and Hamilton, with a fourth site being built at Tauranga.

Ryan McDonald, head of new business at Hiringa Energy, said the sites are all critical network nodes and once the Tauranga site is completed, the network will have the Golden Triangle freight route covered, while the Palmerston North site is located close to the new Te Utanganui central freight hub being built. The Tauranga site is expected to be up and running in December and is in the Tauriko Industrial Business Park.

“This means we can get freight to Auckland and to Hamilton using these 15-minute fills. Drivers will be able to get in and out really quickly,” he said. “The beauty of hydrogen is that it is a very quick and simple way of getting energy into a vehicle, the refuelling speeds at our stations are akin to a 3000kW EV charger,

without the need to upgrade the local substation”.

Around 15 trucks a day can fill at one of these sites at the moment, with upgrades planned to get that up to 60-80 truck fills per day.

McDonald said the Hiringa hydrogen refuelling network is the perfect scenario for dual fuel trucks as diesel and hydrogen are available at the same location.

“The fill up at Wiri went really smoothly. They literally pulled up, connected the nozzle, pressed the button, filled up and away they went,” he said. (New Zealand Trucking June 2024.)

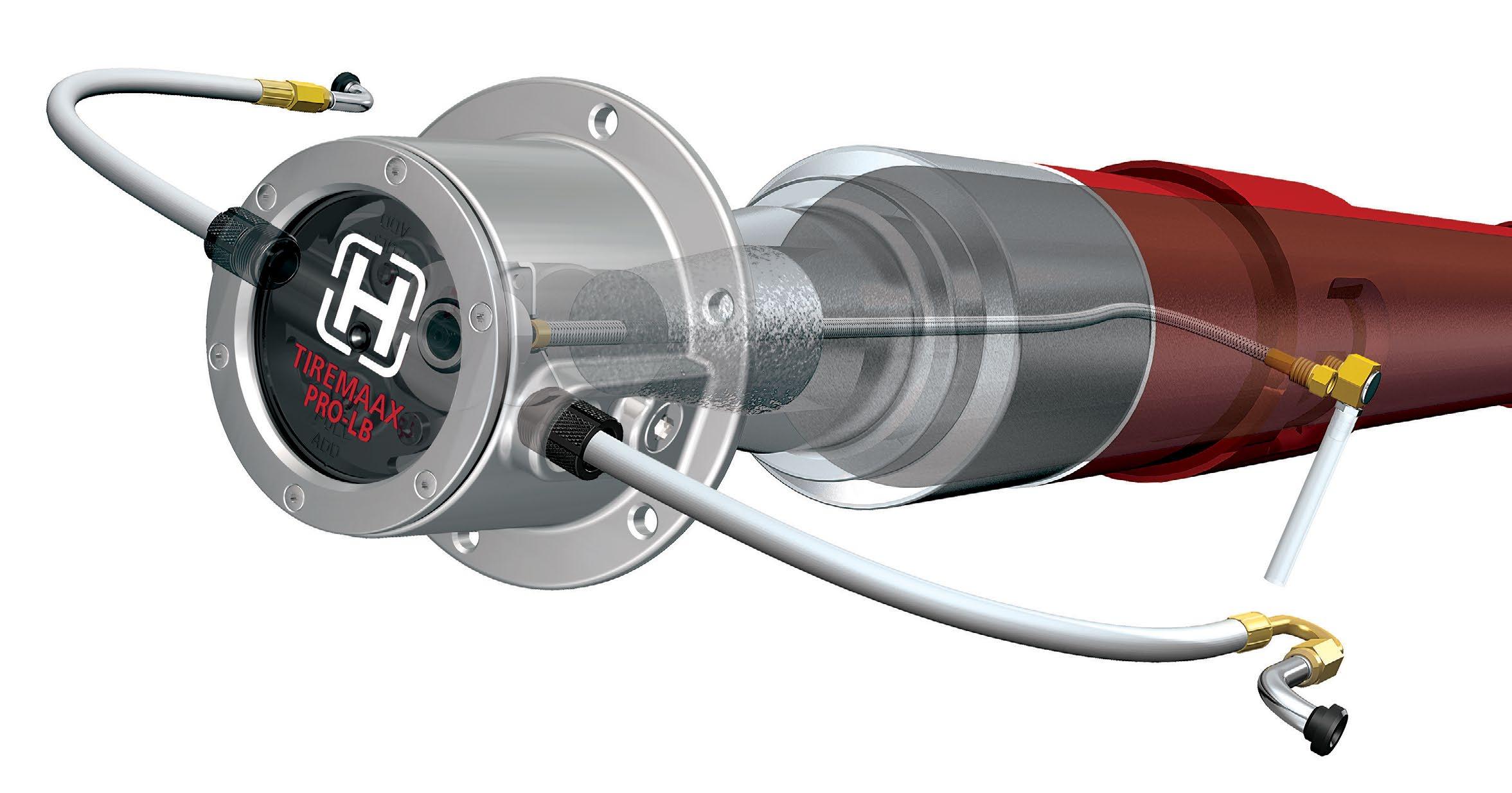

The dual fuel system involves retrofitting a hydrogen system to an existing diesel engine. The hydrogen system includes a frame and tanks, to store the hydrogen and an injection system, hydrogen computer, and in-cab information. Hydrogen is injected to the air intake and during the engine’s intake stroke, mixing with diesel to create a more

efficient and cleaner combustion process and, most importantly, reducing the diesel volumes required.

“The dual fuel approach is seen as a transitional step towards fully hydrogen-powered vehicles,” said Wishart.

“It allows the heavy transport industry to gradually shift to hydrogen without the need for immediate, large-scale asset changes.” (New Zealand Trucking magazine May 2023.)

In partnership with Foodstuffs North Island, Fairfax has announced New Zealand’s first fully autonomous, allelectric, engineless refrigerated trailer. Fairfax said the innovative solution was set to transform how goods are transported across the country while significantly reducing environmental impact.

The Fairfax ZE (Zero Emissions) combines cuttingedge technology from Transcold, Carrier and SAFHolland to create a future in which trucks deliver fresh produce without producing harmful emissions.

“We are incredibly excited

to introduce this revolutionary technology to New Zealand,” said Chris Devoy, CEO of Action. “This is a major step forward in our journey towards a zero-emissions future and demonstrates our dedication to sustainable logistics.”

The heart of the Fairfax ZE is its all-electric eCool refrigeration system by Carrier, powered by a SAF-Holland electric axle. Supplied by Transcold, the design eliminates the need for a traditional diesel engine, resulting in zero tailpipe emissions and reduced energy consumption in standby mode.

Action Group engineer Edd Collins is credited with the idea

behind this environmentally friendly, efficient system. “I was captivated by the potential of combining an electric generation axle with an electric refrigeration unit,” said Collins.

“It’s incredibly rewarding to see our vision become a reality, and I believe this project will set a new standard for efficient and sustainable heavy transport.”

Brad Jackson, Transpecs product sales manager for SAF Holland, said: “Our advanced axle technology, combined with Fairfax’s expertise, has created a solution that sets a new standard for sustainable transport.”

Foodstuffs North Island is

at the forefront of adopting this new technology. “This partnership aligns perfectly with our commitment to reducing our environmental footprint,” said Blair Inglis –fleet safety manager from Foodstuffs NI. “We believe that the Fairfax ZE will play a vital role in ensuring the sustainable delivery of fresh food to New Zealanders.”

Fairfax is looking further ahead to the next phase of its sustainability journey. Plans are in place to integrate hydrogenpowered trucks into its fleet, further reducing emissions and creating a cleaner future for future generations.

Hammar is the world leading manufacturer of Sideloaders, self-loading vehicles for containers and more. A competetive quality solution for container logistics, special transports and terminal handling.

+ Made in Sweden since 1974, delivered to more than 123 countries world-wide

+ Lift, transport and transfer up to 50 tonnes

+ Increase safety and efficiency with grounded containers

+ One vehicle, one driver, anywhere, anytime

New Zealand Trucking magazine has an awesome new digital subscription portal, making it easier than ever to access the magazine wherever you are.

Best yet, existing magazine subscribers have automatic free access!

Not a print subscriber? Or want a digital-only subscription? One-year access will cost just $39.95.

Download issues to read on the go and access your account from any device anytime.

You can also access a back catalogue and, from the July 2024 issue, the Top Truck poster will be included to download and use as a screensaver.

Simply head to the New Zealand Trucking website and register for access or purchase your digital subscription.

Booth’s Logistics has opened new depots in Auckland and New Plymouth to provide greater support across Taranaki and increase its footprint and transport services through Auckland.

“Both of these branches play a key part in our commitment to delivering the best logistics solutions we can and to provide a unique Kiwi-owned nationwide network that connects the regions to all key metro locations and beyond,” said Angus Petrie, general manager – freight.

Booth’s will move its existing Auckland freight hub operation, on Browns Road in Manurewa, to a fit-forpurpose facility at 32 Bell Ave, Mount Wellington.

“Auckland plays a vital role in supporting all aspects of our northand south-bound freight networks, and we are excited to be moving to a facility that allows for greater

Roadlink Tyres in Hawkes Bay is proud to be a member of National Tyre Assistance (NTA) - a network of independently operated stores working together to keep you and your vehicles moving anytime of the day or night anywhere in New Zealand.

capacity and capability but also offers improvements in ease of operation for the benefit of our customers and our team,” said Petrie.

The depot will be led by Maree Smith, who previously managed the Rotorua branch.

The company will move into a crossdock facility in New Plymouth located at 1/220 De Havilland Drive, Bell Block, New Plymouth.

“This facility is part of our ongoing effort to support the regions and improve our service coverage in and out of Taranaki,” said Petrie.

This facility is now fully operational and being serviced daily via Palmerston North and Auckland. New Plymouth customers can access an overnight service across the North Island and a two- to three-day service into Booth’s South Island networks.

Wayne Mehrtens will oversee the New Plymouth branch.

Ia Ara Aotearoa Transporting New Zealand has formally adopted a new constitution and governance structure focused on sector advocacy and delivering member priorities. The new constitution introduces a single national membership structure supported by regional branches and sector groups. This replaces the current system, built around four separately governed

regional associations.

Transporting New Zealand’s national membership will now directly elect board members and sector group representatives at national elections – the first of which will occur in Napier on 4 October. The existing board will remain in place until then.

Transporting New Zealand chair Warwick Wilshier said that the new constitution and

governance structure enabled the organisation to deliver the services members wanted now and in the future and ensured compliance with the new Incorporated Societies Act 2022.

“I’m proud of the comprehensive programme of consultation and engagement that our board, staff, lawyers, regional executives and reference groups have done over the past year to support

this organisational update. We needed to bring our membership with us throughout the process, and we’ve done so,” Wilshier said.

“The last few years have brought significant change for our organisation, with the merger of Road Transport Forum and Road Transport Association New Zealand into Transporting New Zealand in 2021. We remain committed to building sector unity and delivering for our industry,” he said.

“Transporting New Zealand’s new constitution and governance changes will help ensure our organisation remains effective, relevant and fit for purpose. Our members will see an increased focus on advocacy, member discounts and events, and sector priorities.”

The government has introduced legislation that will enable roadside drug testing. The new legislation will permit oral-fluid testing at the roadside for screening purposes so the

hours to reduce the risk of tragic drugged-driving outcomes.

“Oral-fluid testing is common overseas and is an easy way to screen for drugs at the roadside. Our approach will bring New Zealand in line with Australian

Transport Minister

Simeon Brown has announced the government will begin work on a new four-lane expressway between Auckland and Whangārei as part of its Roads of National Significance programme.

The government has agreed in principle to an accelerated delivery strategy that will enable NZ Transport Agency Waka Kotahi to move at pace and deliver the Northland Roads of National Significance as a single expressway between

Auckland and Whangārei.

“An accelerated delivery strategy developed by NZTA includes a progressive publicprivate partnership model that will achieve efficiencies and innovation in planning, procurement, design and construction across the entire roading corridor between Auckland and Whangārei,” Brown said.

It will do this by treating the three Roads of National Significance as three stages of the same project and incentivising the development

partner to deliver excellence in design, construction, financing, maintenance and operation for each phase of the expressway.

“Taking a corridor approach means NZTA will avoid multiple procurement processes. It will also deliver integrated design, construction, maintenance and operations across the entire Northland Expressway and allow greater efficiencies through scale to deliver the project up to 10 years faster than traditional approaches,” Brown said.

The government will also

consider legislation changes that could accelerate delivery and provide increased certainty for delivery partners. Options being considered include changes to the Public Works Act to speed up delivery.

“The Northland Expressway is one of the largest infrastructure projects in New Zealand’s history. We are considering a wide range of funding, financing, and delivery tools to get this project completed as soon as possible.”

We continue with the story of JT Fossey Trucks’ Outlaw series of custom Mack Super-Liners, with Outlaw 7 taking to the road in August. Crimson was handed over to Adam Spicer of Spicer Constructions.

Like the six Outlaw trucks that have come before (see New Zealand Trucking magazine, June 2024), Outlaw 7 is based on a Mack Super-Liner with 58in sleeper, with the Euro-5 MP10 rated at 510kW (685hp) and paired with a 14-speed AMT.

The Tamworth, Australiabased dealer again partnered with key suppliers of choice, with Outlaw 7 boasting a King Bars bull bar, painting by Bel Air Truck Spraypainting, paint and scroll work by Showman Signs, and custom stainless by Bling Man HQ outside of Brisbane.

With Outlaw 7 now on the road, the final three in the series are now in production, with Outlaw 8 (Bronze) due to hit the road in September, Outlaw 9 (Silver) by February 2025, and Outlaw 10 (Gold) in about May. Stay tuned for the grand finale!

ENTER NOW TO BE IN TO WIN A PAIR OF PETERSON’S SUN GLASSES

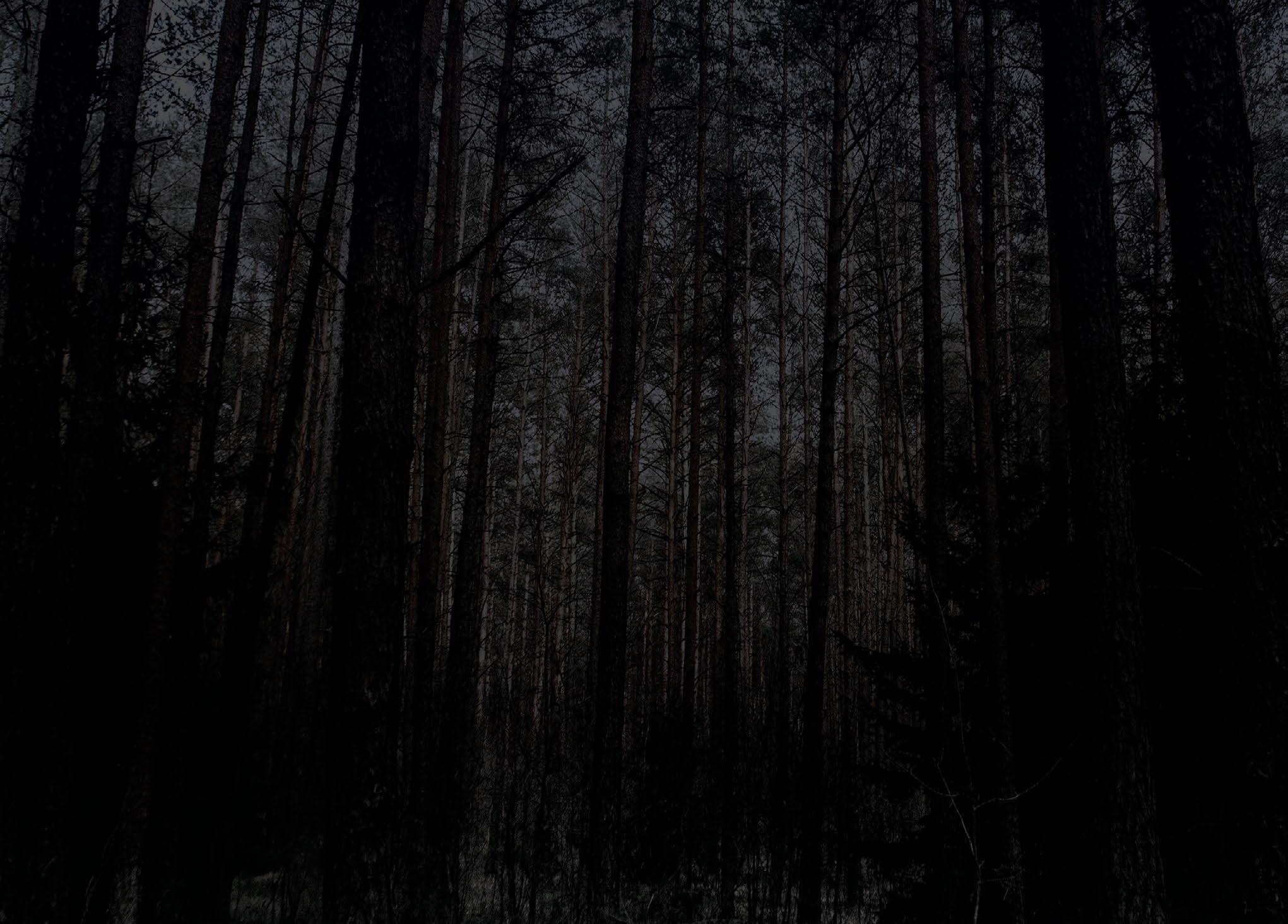

Our winning photo this month comes to us from Zac Munro who drives this sharp T409 Kenworth for the team at McLellan Freight of Balclutha. This shot was grabbed sitting at a loading dock in Kennington, near Invercargill. Well done Mate, your prize is on its way to you. Now get your entries in for the October competition.

Send your best night bling photo as well as contact details into nightmoves@nztrucking.co.nz to enter

Story by Gavin Myers

by Gavin Myers and Dave McCoid

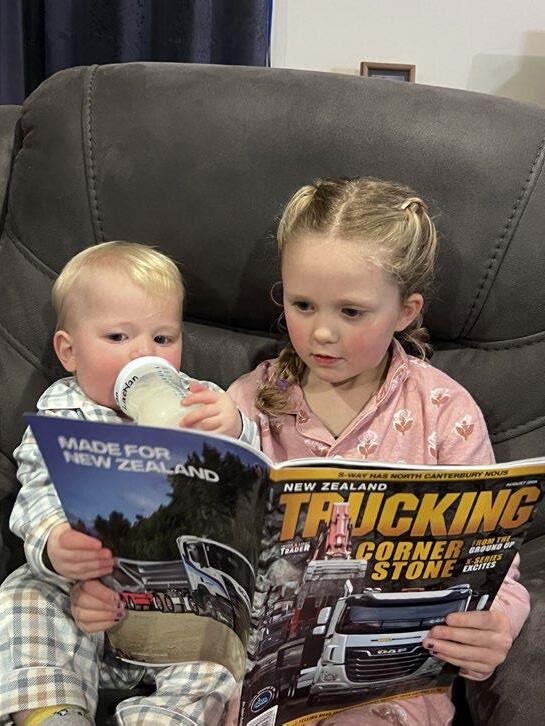

When presented with the opportunity to feature Northchill’s new Volvo FH16 750 Globetrotter XXL, we felt a sense of déjà vu. After all, in the fast-paced world of keeping the nation’s supermarket shelves stocked with life’s essentials, ensuring those runs are as effortless and comfortable as possible for the men and women behind the wheel makes sense.

There we were, standing at the Goodman Fielder Longburn dairy plant loading docks in Palmerston North, with real a sense of familiarity. We’ve been here before; a shiny big-cab Euro in Foodstuffs yellow, its quad-axle MaxiCube reefer in tow butted up to receive its payload for the night, and the name Northchill Ltd Pukekohe sitting discreetly on the side wall of the cab.

In fact, it was exactly four years ago that we featured Northchill’s two then-new DAF XF 530 Super Space Cab Euro-6 models – the first two to enter service locally. The new Volvo is a replacement for one of those big DAFs and while the run, the truck and the driver might all have changed since 2020, the main objective is still to ensure those runs are as effortless and comfortable as possible for the

men and women behind the wheel five nights per week.

But before we depart for our run, let’s back up a little and explore the big-Euro-on-chilled-linehaul task in the world of Graham and Michelle Redington’s Northchill Group. A DAF replacement the Volvo may be, but both brands have a long association with the operation.

“The fleet currently stands at 37 trucks and 45 trailers. We only run Kenworth, DAF and Volvo,” says managing director Graham Redington. “Personally, I’d have a fleet of Kenworths – but you couldn’t get 37 guys here to drive them all … We have drivers here who love Volvos and this helps with driver retention.”

Of the current 37-strong fleet, 13 are Volvos, the oldest still on the job being a 2014 FH12. “We have one that’s done 1,700,000km. It’s

our spare truck. We sold another at 1.7 million and never touched the engine.

“To be fair, they’re probably the pick of the Europeans. They’re good gear, not overly complicated,” Graham reiterates.

The timing and opportunity couldn’t have been better. Blair Stapleton, national fleet sales manager at Volvo Trucks New Zealand, happened to be sitting with a cancelled order on his hands.

“Blair’s good, he’s been awesome,” says Graham. “We grabbed the truck. We still had the opportunity to change the colour at the factory; the timing was perfect.”

Truckies’ truckie, truckies’ company

Driver of Osiris, as the XXL was christened, is Marshall Howl, who’s

Back in the day, the trucks we looked up to were all clean; truckies had pride in the job. Washing the truck is the hardest part of my job. But that’s what I enjoy.

spent two years in the 6x4 DAF on the Foodstuffs run but almost two decades on refrigeration (see page 29, Can’t keep a good man down).

“The DAF was coming up for replacement and they asked me what I want – I’ve never been asked, always just driven what I was given. I suggested the new DAF, but that wasn’t an option, and I didn’t want a Kenworth because I hate swinging off monkey bars to get into a cab … They’ve kept that American tradition and that’s all great, but the Volvos are so easy to get into with all your stuff. And I wanted another automatic because of my arm … From time to time, I’d drive old Western Stars, with a Roadranger direct into the gearbox, and it was hard on my injury,” says Marshall. (More of that injury in the sidebar!)

“As it turned out, this wasn’t an option, it just came up. Actually, this is the third XXL Volvo I’ve had. I had two of them at Cam Arnott, 520s, which was powerful back in the late 2000s,” Marshall says.

“If I work to 65, I might have a couple more chances to get into a different brand!” he jokes.

As we stand with Marshall taking in the big Volvo’s unique details, it quickly becomes clear he and Northchill share the same approach to trucking.

“It’s a real truckies’ company with real trucking-minded people. Nobody there just drives a truck for a job,” comments Marshall.

“I come to work, but this is my life. My passion is my truck, living on the road and achieving something – I can do my day’s work, wash my truck and know that I’ve moved a load from A to B, cleaned the truck and

achieved something. Those are my two responsibilities – get my freight from A to B in a timely, professional manner and keep my truck clean and tidy – that’s all that’s asked of me.

“Back in the day, the trucks we looked up to were all clean; truckies had pride in the job. Washing the truck is the hardest part of my job. But that’s what I enjoy.”

The proof of that stands right in front of us. The truck is poised and spotless, ready for its daily grind. Atop the cab is the same set of LED spotlights that illuminated us to the power of modern lighting technology when we featured the DAFs. Below them is a painted sun visor, and below the windscreen, the normally black plastic section of trim that houses the Volvo badge has also been painted in matching yellow – a neat trick on

the eye that gives the already big cab even more visual height. And it is a big cab …

Riding on a medium-height chassis and standing 3870mm tall, it actually doesn’t reach the greatest height of all FHs. However, the XXL has a visual bulk the others don’t, something extra that adds to its presence. It looks sleek, though, due in no doubt to the wide, neatly integrated cab side skirts and roof aerofoil.

On the chassis’ right sits the exhaust system and a stainless tank. At the left, there’s the AdBlue tank with a factory-optional stainless cover and Roadrunner toolbox behind. Adding an extra sense of ‘tidy’ to the whole look is custom black decking from the rear edge of the chassis rails all the way forward to the connector board.

The additional painting, lighting and fitting were all done in-house –as is maintenance across the whole fleet, by a full-time team of five led by workshop manager Derek McKenzie. “We try to be self-sufficient and pretty much do everything in-house. If a truck gets back in at 4am and something needs doing, we’ll get it done so that the driver is back in his truck for their next shift,” Graham later explains. “We run the Volvo Vcad diagnostic system in our workshop, which is a game-changer when problems do arise.”

At the risk of preaching to the choir, our runs with Marshall are another reminder of how trucking exists to serve the needs of the people – for while they sleep, the overnight freight operations that move their daily essentials are only just kicking into high gear. Anyone who thinks there are a lot of trucks running the length of SH1 in the day would be surprised at what they’d see on an average evening camped somewhere along the route.

Marshall is one of four Northchill drivers permanently on the Foodstuffs north-south run. Monday nights are a shorter run north for Marshall, with a trailer swap at Turangi, while Tuesday to Friday sees two northbound and two southbound trucks passing in the night.

The Longburn dairy plant is the starting point of Goodman Fielder dairy products’ journey to a

supermarket shelf near you. From the outside, the big Volvo sits patiently, but there’s a hive of activity inside the 15.5m MaxiCube reefer. The forklift whizzes in the first few pallet loads, Marshall sets the racking bars for the upper loads, and the process repeats over about 45 minutes until 20 tonne of chilled dairy product is ready for its overnight trip to Wiri.

With a combination tare of 21 tonne, it’s fair to say that the Volvo’s D16G powerplant with its 551kW (750hp) and 3550Nm is overqualified to shift 41 tonne gross. “Coming down from Auckland, we’re carrying only five to 10 tonnes. Definitely 10 on a Friday for the weekend,” Marshall says. Seven-hundred-and-fifty horsepower for 41 tonnes, maximum … we burst out laughing. That’s 13.4kW (18.3hp) per tonne. For context, cast your mind back to the TSL FH16 700 stock unit we featured in June 2022, running at 50MAX and 10.4kW (14hp) per tonne. Even the Kiwitrans Series 4 FH16 600 from our February 2021 issue was running 8.9kW (12hp) per tonne at 50MAX. Again, though, the truck’s arrival was one of pure chance, and Graham’s quick to rationalise the situation: “High horsepower isn’t a thing for us on these runs; we don’t need 750hp. Especially not for what Marshall’s moving. But, it just does it effortlessly and it won’t be using bugger all fuel…” (Early in the truck’s life, that figure is 2.17km/L.)

Besides which, it gives us one last opportunity to have a go in the big daddy of Volvo’s 16L range before it’s replaced by the incoming 17.3L D17 range. There’s no doubt the D16 engine range has done dutifully for the brand, and it’s definitely won a few fans along its 31-year lifespan. Yep, we bet you didn’t realise the D16A debuted back in 1993.

In 750hp guise, it really is a lovely device for forward propulsion. Power peaks between 1600 and 1800rpm, while max torque is on offer from 1050 to 1400rpm with a very gradual tapering off as max power takes over. In the realm of big-six Euros, it doesn’t quite have the same pleasingly deep ‘grumble’ as MAN’s 15.2L D38, but it’s barrel-chested in what one could describe as a typically Scandinavian way – refined purposefulness. At 70db, when under load, it offers up

its own large capacity rumble accompanied by an enthusiastic turbo whistle.

Climbing the Taihape deviation, the 12-speed iShift progressively drops four ratios, allowing the revs to drop right down to around the 1000rpm mark each time. Speed drops to 46km/h in eighth gear, and with the motor in its stride, eighth holds our ascent with the EROAD speed readout ticking up again. By the time we reach 50km/h and 1800rpm, we’re just about at the summit, with no hint that hard work has really taken place. The iShift smoothly

grabs another cog and we’re away again, back up to 90km/h before we know it, with the Desert Road in our sights.

Later, climbing the Hātepe Hill to Taupō, the Volvo drops to 56km/h at 1500rpm in ninth and again gets back into its stride as though it’s pulling off from a traffic light. And, with only 20,000km-odd under its tyres, there’s undoubtedly more in it yet.

“I leave the iShift in auto. They’ve come so far since the ones in the late 2000s that I was used to, where you’d have to hold it in manual. This truck

pulls so well on the hills, and it holds the gears long enough for it to change up, and you carry on pulling,” Marshall says.

“These big-power trucks are great for New Zealand. Our expressways are the closest we have to the motorways of Europe or the States. Otherwise, it’s all hills. Even Transmission Gully, it’s not an enjoyable drive, but it does save going around the coast,” Marshall comments. Our trip over ‘The Gully’ would come a couple of weeks later, when we’d join Marshall for one

of his featherweight AucklandWellington-Palmerston North runs. Approaching Transmission Gully’s biggest grade, Marshall flicks the FH16 into power mode and gives the D16 a boot full. The iShift selects 10th for the climb and our speed briefly drops to 58km/h at 1300rpm, but for the most part, the climb is tackled at 61km/h at 1400rpm. Earlier, the Mangawekas were tackled at a similar 58km/h at 1200rpm, again in 10th. Marshall’s truck is equipped with just the three-stage VEB+ compression exhaust brake, rated at 425kW (579hp).

Northchill’s driving force: Michelle and Graham Redington.

While we’ve run various features on Northchill Group trucks over the years, we’ve never really delved into Graham Redington’s story, and what Northchill is all about. As group managing director, Graham is an approachable but no-bullshit, matter-offact kind of guy. He calls it like he sees it.

And that’s pretty much how one would describe Northchill Group. Its Pukekohe head office is clean, orderly. Fleet photos greet you at the entrance. The team has a cleancut image. They greet you with a friendly handshake and a willing conversation. The sense of purpose is evident in sayings such as, ‘Rule #1 – If we don’t look after the customer... Someone else will’, and ‘Someday you will look back on all the progress you made and be so glad that you didn’t give up...’ painted in large block letters on the office walls.

At Graham’s side as director and head of finance is his wife Michelle. The two established the business in 2007, having returned from Australia after five years. “We bought a tanker business from a guy who carted chemicals. We built that up and sold it, but kept a part of the chemical work. Today, the company runs three acid tankers under Graham Redington Ltd.

“Then, I had a mate at Goodman Fielder transport, and we got into doing milk runs for Goodmans when Mainland/Anchor got split up. So that’s how that came to be, with three

trucks there, and we did that for a time.”

The relationship with Foodstuffs followed, 16 years ago, and refrigerated freight runs are the company’s main line of work today.

“I ran into one of the Foodstuffs board members at the point they were going from company trucks to owner-drivers. So we got in and started there with one truck. It grew to three, and eventually we had 10 runs. We now have seven, which we’re cool with.

Foodies are good people. If you keep a tidy operation, you’ll be there forever,” Graham says. That’s the responsibility of Northchill group operations manager Cory Knox and operations manager Steve Rowe.

In 2021, the diversity in Northchill Group’s work was expanded when Ontour Logistics was added to the fold.

“We brought four trailers off Brendan Main in Thames and then started Ontour Logistics. We tidied it up and have grown it to 15

Northchill has outgrown its current Pukekohe depot, with a move to a new site at Bombay coming up.

concert trailers,” says Graham.

Concert logistics may be a seasonal operation, but it’s full-on work by all accounts, and under the watch of Ontour operations manager Toby McLean. “It’s not something you can just come in and ‘give a go’. Everyone thinks it looks easy, but it’s a lot of planning and hard work. And you have to have guys on the job who know what they’re doing,” says Graham.

Finally, under Northchill Express, the company offers general interisland freight and contract logistics. Those Invercargill-built Stabicraft boats you see on the move? That’s Northchill Express on the job. Northchill Express operations manager Paul Crooks keeps things ticking.

For Graham, trucks are in the blood, no doubt influenced by dad Martyn operating trucks and diggers in Wellington during Graham’s youth. However, his story started with landscaping out of school. “I did that for years, but then moved into transport as a courier and grew from there to the likes of driving interstate in Aussie.”

Today, daughter Hollie is Northchill Group health and safety and compliance manager, and has a promising future in the business.

“She really acts as my PA – she keeps me in check!” says Graham.

In early 2025, Northchill Group will enter the next chapter in its story when it moves into its new 2ha site at Bombay.

“Cruising around, I leave it in auto, and for tight, slow-speed bends like The Sisters or Bulli Point, I’ll set it on stage two. It’s strong enough to hold it in those situations. Stage three does grab,” he explains.

As we’ve experienced before, VEB+ operates quietly, barely

breaking the night-time peace.

On Transmission Gully’s steepest descent, it held a steady 90km/h in 10th at 1900rpm. Earlier, heading down the Taihape Divi, Marshall used a different approach to manage his speed, setting the downhill cruise at a comfortable 76km/h.

In addition, Marshall has at his disposal adaptive cruise control with forward collision warning and emergency braking. “The adaptive cruise is great driving through fog on the expressway. I just set it to max distance and cruise.” The FH is also fitted with lane departure warning and

lane change support, which employs radar sensors at the left-hand side of the cab to check for vehicles in the blind spot. Marshall is a fan of the left-facing camera. Concealed in the mirror housing, it displays a wideangle view down the side of the combination on the central

Most of us will experience a defining moment in our lives, an event that changes things forever in one way or another. Sometimes it’s a decision we make that directly sets the course going forward. Othertimes, it’s an event completely out of our control – being in the right or wrong place at the right or wrong time. For Marshall Howl, that event occurred at 5am on Wednesday, 17 December 2003.

Only 23 years old at the time and driving for Palmerston North-based Clark and Rogers Transport, Marshall was just pulling out of the Ōhakea weigh station when he got caught in a pile up when two other passing trucks connected. His Foden Alpha ended up 50m from the impact site; its cab impacted so hard it was displaced from the chassis.

“I was stuck in it for a couple of hours before they could get me out and into the helicopter to hospital,” Marshall says. “I was put into a coma and woke up on Christmas Day to my dad sitting in the hospital. I had a broken leg, a broken arm, skin grafts, a punctured lung …

and I was in the hospital bed telling the boss I’d be back at work in six weeks. He said, ‘You effing won’t be!’ But the arm didn’t heal as quickly as it should’ve, and they had to eventually reoperate. I spent 10 months off the road, and after psychiatric and driving assessments, I was declared fit to drive.

“Mentally, I have no memory of it. I have no memory of going to work or my runs to Te Kūiti and back that night,” Marshall says. “As such, I have no fear from it. If I did, I might not have gone back driving. How I’m alive is a miracle, but I survived it and got back in the seat. I can hide from it, but I haven’t. Everyone who knows me knows that history.”

Marshall would go back to that same job at Clark and Rogers full-time in 2004. A career truckie, he is a driver to the core, tracing the trucking lineage back generations.

“Dad’s dad, Ron, was a farmer, but was sent to North Africa in the war and drove trucks there. He came home and went back to farming. Mum’s father, Dudley Thompson, had a three-truck transport carriers’ business in

infotainment screen.

“It’s magic. For example, you can watch you’re not going to drag your trailer rounding a kerb,” he says.

Also contributing to good visibility are the FH’s full LED headlights, which provide very good illumination. The LED spotlights ex-DAF are still as good at turning night into day as we remember them being. The job of night driving is made so much more relaxing when you can see properly … “I say, I’m living in the dark, why not have good headlights? It’s a wall of light from the LED spots,” Marshall comments.

The combination of a high cab, with its front spring and rear air suspension, and an average 66db noise level at cruise, means the FH remains one of the industry’s great mile-munchers. “It just cruises along great. You don’t know you’re doing 90,” Marshall comments.

It’s not all perfect, though, as he points out: “I could never hear the fridge motor start up in the DAF. I can in this. And I’m surprised how much firmer it is … it might just need more time to free up.”

But, still, a Series 5 FH Globetrotter XXL cab must be among the top of its class. You have the same 2100mm floor-to-ceiling height as the Globetrotter XL (150mm higher than the standard Globetrotter) and 2170mm interior width, but with 2200mm between the windscreen and rear wall (1950mm for the XL and Globetrotter), the cab is truly voluminous. It also means bed dimensions of 1065 × 2130 × 160mm, which enhances comfort on the two nights per week Marshall sleeps in it.

At his disposal, Marshall has a microwave, fridge/ freezer, telly, and six overhead compartments (with numerous other cubbies, pockets and trays dotted around).

the 1930s and 1940s, two-axle Fords and the like. He sold his business in the late 1940s or early 1950s to what became Manawatu Transport today.

“Dad, Brian, left school and went working for an agricultural contractor, driving trucks and tractors, and he drove a milk tanker between 1965 and 1970 for the Manawatu Co-Op in Longburn. When he and Mum got married, he bought a farm and started that life.”

Marshall has memories of a couple of the farm trucks over the years. “The ’53 OLB Bedford once broke an axle and got stuck down a hill when we were doing a load of hay out of Rongotea. We got the tractor and dragged it home. In 1992, when I was 12, Dad bought a Butterbox International off another farm when we moved to Marton. I used to drive that round the farm as a teenager.”

With truck-driving uncles and cousins, the trucking influence was never far from Marshall. “My family do say I’ve got the truck driver in me. I’ve always been fascinated by it. But I only ever wanted to be a farmer because that’s what I grew up knowing; I wanted to live that lifestyle.”

The two paths would converge during Marshall’s teenage years when he worked for Bruce Gordon Contracting near Marton over three hay seasons.

“They had two little

two-axle trucks and that’s what I learnt to drive on. We’d drive down the farm, on the country roads.”

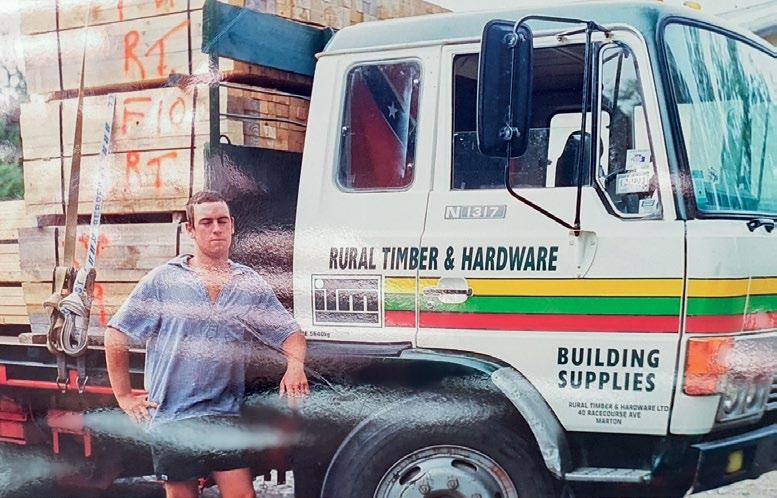

In 1998, at 18, Marshall got his first truck-driving job, taking to the wheel of Marton ITM’s Ford N1317 two-axle, 14-tonner. “The furthest I went on that job was Ohakune. I was out on my own, and for an 18-year-old, that was first-class trucking!”

At 19, Marshall went off to Deca Training in Rotorua to get his trailer license and promptly got a job at Farmers Transport Fielding. “My first day was rough. The guy I was working with fell off the truck, four wool bales high, and died in front of me. That was an eye-opener. I was in the real world with big trucks now,” he says.

The job at Farmers included carting peas into Wattie’s Fielding, which progressed to running trailer loads of veggies to Hawke’s Bay, before moving onto stock trucks. “We had 380 Nissans; they were a big truck!” Marshall recalls. “Farmers Transport was good.”

However, with work slackening off, Marshall began driving stock trucks for a local Rongotea operator Egan Gennills of Egan’s Haulage. “We’d pick up beef calves and have to lift them three decks high in the crate. I’d have 30 to 40 pick-ups, with an agent, a few here and there. Then I would deliver them on my

own, doing long days and half the night. I had a lot of fun working there, coming from a childhood on the farm.”

With three seasons behind him, the drought of summer 2003 meant the stock work dried up, and by July, Marshall was on the hunt again. He went door-knocking and Clark and Rogers had a job, running DB beer on a five-night swap. “That was the job on the Foden Alpha. It was a great truck,” Marshall says.

Having recovered from his accident and with Clark and Rogers selling out to Roadfreighters, Marshall did a short stint with Symons Tankers, running milk from Longburn to Hawera. “I only got six weeks work there … I married in the November and went to Aussie for a week on honeymoon. When I came back, I got two days’ work and they pulled the pin, volumes were down. So, I was looking for a job again.”

Palmerston North-based Cam Arnott Transport helped out with a job for three months over the Christmas period, but within two months, two drivers left, so in 2006 Marshall found himself part of the team full-time, running Yoplait to Auckland and Christchurch from Palmerston North, thus kicking off his career in refrigeration.

When his time there ended four years later, it was back to Symons for another season

before Marshall kicked off an 11-year stint with Hall’s on various runs.

“I took the Taupō swap out of Longburn for Woolworths. I did that for a year and a half but I wanted to move to the dayshift. I covered the South Island run for two months when I got a new day-cab eight-wheeler Western Star, followed shortly after by another with a DD15.

“After the Kaikōura earthquake I was moved to Blenheim, running trailer swaps there for three months. It was good fun and all, Blenheim filled up with North Islanders in the earthquake recovery, but I had two young kids at home, so I went back to Palmy and they gave me the Longburnto-Christchurch swap – via the Lewis Pass to Culverden. I did that for a year and a half; it was probably the best time at Hall’s. It was great.”

Sadly, with the arrival of the Covid-19 lockdowns, Marshall found himself at odds with Hall’s mandates and with his hours reduced to 40 per week, he made a temporary move to Envirowaste running to Bonneyglen landfill at Marton.

“That was a bugger with the mandates at the end. I wasn’t to know at the time, but I could’ve survived the two months before it went away, and avoided six months at Envirowaste. It was a filthy job; the trucks were disgusting. It was all unpleasant. It really pulled me down.”

As fate would have it, at the

point Marshall decided his time at Envirowaste had reached the limits of ‘temporary’, an old friend now driving for Northchill posted to his Facebook about starting a new run.

“I messaged him, and they’d been advertising the job for a month, but only in the Auckland listings, so I hadn’t seen it! I spoke with Cory [Knox, group operations manager], and he basically said: ‘You’ve been at Hall’s 11 years, you’ve got the job!’ I started a week and a half later and have been there two years now.”

At 44, and having run the gambit of driving jobs, Marshall reckons refrigeration is where it’s at for him. “I’ve been on it 18 years in total now. This job is second nature to me – I’ve been going into Longburn since 2006! And that’s what they want, what the customer wants … the experienced drivers they can rely on.”

With two sons aged 20 and 15, there’s always the potential for a fourth generation of drivers in the family. “Their childhood is different to what I had – growing up in town compared to out in the country. The older one is into cars, but I reckon the younger might have an interest. He comes one Sunday a month to Taupō with me.”

A man who’s experienced road transport’s great highs and horrific lows, Marshall Howl is an inspiration in overcoming adversity by embracing it.

We covered the Series 5’s redesigned cab fully in our June 2022 feature of TSL’s FH16 700 Globetrotter XL, so we won’t repeat ourselves too much here. Suffice to say, the Series 5 FH dash still looks fresh, clean and modern four years on from its introduction, with that same sense of being ergonomically designed and built of solid, quality materials. If one were to nitpick, you could say the cupholders are a bit of a stretch from the driver’s seat, and Volvo’s famous birdbath dashtop tray is take-it-or-leave-it – we’ve always loved it, but it’s the latter for Marshall.

With many things in life, there’s always the question of how much is too much? Is an extralarge cab too much to act as a home on wheels just twice a week? Is 750hp too much to move 40-odd tonnes when 530 did the job previously?

And as with many things in life, the answers to those

two questions are a matter of perspective. From the perspective of Northchill, smart, big-cab trucks that are comfortable for their drivers all the time are part of the image.

From Marshall’s perspective, the ease with which the extra power enables him to maintain pace and complete an AucklandWellington-Palmerston North run without troubling the logbook takes the edge off and makes the job that much more enjoyable.

From the perspective of keeping supermarket shelves continuously stocked and the people of the nation fed and happy, the FH16 750 Globetrotter XXL fits in perfectly.

And, as a last jaunt with Volvo’s big 16L, we quite literally couldn’t have asked for more.

As we said in that TSL test, “No matter how often you do it, revisiting the big bangers is always a thrill.” With the new D17 topping out at a Scania V8-beating 581kW (780hp) and 3800Nm, the thrill is set to continue.

Our sincere thanks to Graham and Michelle Redington for allowing us, once again, to feature one of their trucks and sharing the Northchill story. Thanks to Cory Knox and Steve Rowe for helping to organise the runs and clearing us with Foodstuffs and Goodman Fielder.

Thanks, especially, to Marshall Howl for letting us ride along, sharing your story so openly, and for your incredible enthusiasm during and after our time on the road.

To Scott Robinson, Blair Stapleton and the team at Volvo Trucks New Zealand, many thanks for your ongoing support of New Zealand Trucking

Tare: 9870kg (load cert)

GVM: 28,500kg (load certs)

GCM: 60,000kg

Wheelbase: 4285mm

Engine: Volvo D16G

Capacity: 16L

Power: 551kW (750hp) at 1600 – 1800rpm

Torque: 3550Nm at 1050 – 1400rpm

Emissions: Euro-5 via SCR

Transmission: Volvo IShift automatic transmission with overdrive, distribution/longhaul software.

Chassis: 8mm

Front axle: FAL7.5

Front-axle rating: 7500kg

Front suspension: Two-leaf parabolic, stabiliser bar

Rear axle: Single-reduction tandem, 3.09:1

Rear-axle rating: 21,000kg

Rear suspension: Volvo air suspension, stabiliser bar

Brakes: Disc. ABS, EBS

Auxiliary braking: Engine brake, VEB+

Additional safety: ESP package. Adaptive cruise control with forward collision warning and emergency braking. Lane departure warning system, lane change support. Driver alert sensing system. Driver and passenger seatbelt pretensioners.

Additional productivity: Information platform with Dynafleet Support. Telematics gateway with 4G/ LTE & WLAN. Fleet management system gateway. Load indicator software for truck and trailer axle weights.

Fuel: 460L

DEF tank: 90L

Wheels: Alcoa Dura-Bright

Tyres: 385/55 R22.5 (f), 275/70 R22.5 (r)

Electrical: 24V

Cab exterior: Automatic LED headlamps with cornering lights, integrated fog lamps and LED daytime running lights, headlamp cleaning system. Auxiliary spotlights. Rain-sensing wipers. Front underrun protection. Electrical cab tilt. Cab suspension front spring, rear air. Electrically heated and operated flatglass mirrors with front-monitoring camera on passenger side. Aerodynamic roof kit and cab side skirts. Tinted side windows.

Cab interior: Electronically controlled air conditioning. USB Communication Connector (3 ports). Fire extinguisher – 2.5kg. Writing pad. Leather and textile interior trim, leathercovered steering wheel, seat armrests, in-step grab handles. Heated and airsuspended driver and passenger seats. Lower bunk, 815mm wide, semi-firm mattress, premium mattress overlay. Rear upper cab storage – 245L. Underbunk fridge – 33L. Flexible reading lamp (snake light). TV. Electric roof hatch. Extra insulation in cab. Cab parking cooler and heater. In-cab microwave.

Every cover truck holds a special place in the history of New Zealand Trucking magazine. We love to see where their road has taken them.

SEPTEMBER

No.25, Blue Shadow, now tows a flat-deck quad in the Hoskins Transport fleet. Managing director Gint Hoskins says it has been a solid truck since joining the fleet from PBT three years ago.

Volvo FH16 600 Globetrotter 8x4

Currently owner: Hoskins Transport, Oamaru

Current odo reading: 1,500,000km

Current work profile: General freight mainly between Invercargill and Christchurch

Basic original spec: Volvo D16G-600 at 441kW (600hp), Volvo I-Shift 12-speed AMT, Volvo RTS2370B tandem drive set, 3.4:1

What we said in 2014: “There is still a market for flagship models capable of running at maximum weights in difficult terrain and providing the best possible environment for longhaul drivers. In that select company, the new FH Globetrotter has raised the bar yet again and will continue the fine tradition set by its ancestors.”

New Zealand’s trucking industry is not shy of raising awareness about issues affecting its people – and society at large – with many companies using their trucks as mobile billboards to get people thinking and spark conversation about tough subjects. With a recent flagship addition to its fleet, Dirtworks has placed prostate and testicular cancer awareness front and centre.

Story and

photos

by Gavin Myers

It’s amazing how often embarking on a simple journey can lead one down a path to greater things. When general manager Lewis Morgan and director Iydden Wood of Whenuapai-based Dirtworks began a renewal programme for its 18-strong fleet in 2023, they couldn’t have imagined that a year later, they’d be supporting a greater cause.

“We had a real mixed fleet. It was unmatched, looked awful and didn’t show our size or uniformity. So we embarked on a programme to refurbish and paint all the bins and partnered with local signwriter Dr. B Signage and Branding in Westgate to create a cool, modern livery,” explains Lewis.

“But some trucks were around six or seven years old, and maintenance was increasing while utilisation was decreasing. So, in June 2023, we picked up our first new

Fuso Shogun 510, put it in the new livery and loved how it looked. In November, we bought the second, and in February, the third. We saw real benefits from them, driver feedback was great, and it started changing our reputation as well,” he says.

This success led Lewis to place an order with Shannon Pelser at Keith Andrews for four more Shogun 510s, though one would later be changed to an Arocs – something that had a bit more presence and would be able to make a bit more of a statement…

Having previously worked with Barry Hart, Lewis was inspired by Barry ‘s passion and the anti-bullying messages Hart Haulage has used its trucks for. “I thought, ‘What can we do better with the new trucks? How can we use them to better something?’” he says.

The answer hit him in conversation with

one of the Dirtworks team members. “He had a mate that had cancer symptoms for a long time, but being a bloke did nothing about it, and before he knew it, he was told he was past any point of return. I pondered on it and reached out to the CEO of Prostate Cancer Foundation NZ, Peter Dickens. He jumped at the chance to partner with us and get a message out to the industry.

“In conversation with Peter, he spoke about testicular cancer as well. Prostate cancer tends to hit the older generations, and testicular the younger guys … Our driver fleet is around late-40s, average age, and our tip site crew averages in their mid20s.”

“The issue of taking time to be proactive with your health when on the road is really hard. The importance of taking care

Everyone involved with the build of the Arocs has helped make the project a reality.

Making a statement, spreading a message.

of yourself and being aware of the risks is an incredibly important conversation,” says Peter.

With the wheels in motion, everything began to fall into place, Lewis says. John Avison at Steel-Force Pukekohe, who Lewis says had done a stellar job on the Shogun bins, Darryl Blom from Dr. B, and Keith Andrews Trucks all got behind the project and helped to make it a reality.

The messaging currently on the Arocs is an interesting story, too. “Peter’s team sent me artwork for it, and we were just about to press print. I was on LinkedIn and saw the foundation had put out its September appeal, ‘Say something blue to help a mate through.’ I thought, that would really stand out, so we asked if we could pinch it. Darryl created the design, and that’s what we’ve gone with to start. It’s a perfect message with the truck going on the road before September,” Lewis explains.

The plan is to run the livery for six or seven weeks and then revise it to something a little more permanent, speaking to the foundation itself. “It’s a cost we’ll take onboard; it’s worth it for what it is,” Lewis says.

Though it’s only just gone on the road, Lewis says the Arocs has so far been very well received. “I kept it quiet for a while. I wasn’t sure at first how everyone would take it. But I was blown away by the response. There hasn’t been a bad word said about it, only positive.”

The man tasked with spreading the message in the course of his daily work is Steven Paul. A truck driver of 30 years, Steven has been with Dirtworks since 2020, and in that time, has proved himself to be just the man for the job.

“Whenever we put a new truck into the fleet and we choose the driver for it, we look at the way they behave on the road, their pre-starts, attendance, attitude … it’s never on a tenure basis. Steve is a man of few words, but he goes about his business in the right way,” says Lewis.

“We were in the yard, and I told him what we were doing, and he went quiet for a moment. I thought, ‘Okay, he’s trying to figure out how to turn it down,’ but he was actually taking a moment to process it because he has family that is going through prostate cancer right now.

“After a few seconds, he said, ‘Yeah mate, it would be an honour to drive it.’”

Having driven a wide variety of trucks both locally and in Australia, including the series 1 and 2 Actros, Steve says his new Arocs is one of the nicest trucks he’s driven. “Dirtworks is a good crowd, and I pay them respect back and keep my trucks in top condition. After 30 years, I’ve got a lot of friends still out on the road; they’re going to get a shock when they

see me driving this! It is going to get noticed, it’s pretty ‘out there’. For sure, we need more of this out there, men especially are afraid to talk,” Steve comments.

“My father-in-law just finished dealing with prostate cancer. He’s all clear now. When Lewis told me, I thought, with him going through it, it’s been a bit scary. And my dad died of cancer, uncles have had it, and there have been other cancers in the family. So I had no worries about it … why not put the message out there?”

As Lewis says, the more you speak to people, the more you come across people with a connection to cancer. “We talk about six degrees of separation, but this is more like two degrees. But you don’t pick up on these issues until you’re made aware of them. By nature, our industry is heavily male, and they’re in that risk age bracket. So that truck, no matter what job it’s on, will reach an audience where it might just encourage someone.”

Peter adds: “There are a lot of men affected in the transport industry. Through this initiative, Dirtworks is helping us provide services to those men and their families. We just might save lives.”

Says Lewis: “It’s great to be part of something bigger than us. I’m immensely proud of it.”

Other than skin cancer, prostate cancer is the most commonly diagnosed cancer in New Zealand, and testicular cancer is the most commonly diagnosed cancer in male teens and young men aged 15 to 39, according to Prostate Cancer Foundation NZ and Testicular Cancer NZ.

The Blue September fundraiser campaign aims to get Kiwis to say, or do, something blue, to help a mate through. Head to: blueseptember.org.nz to get involved, or make a $3 donation by texting BLUE to 2449

For additional information on detecting, dealing with and beating prostate and testicular cancer, head to prostate.org.nz and testicular.org.nz.

•

•

•

•

•

•

GCA2

•

GCA7

• Unique non-directional traction patterns ensure optimum traction and prolongs tread life.

• Superior sidewall cut resistance.

• Good self-cleaning with groove stone ejector.

• This deep tread is particularly suitable for loaders and dump trucks operating in quarries or mining.

GCA3

• Applications: Articulated dumper, dozer, loader, and graders.

•

•

•

• Non-directional traction and standard tread depth pattern design.

•

•

• Excellent performance supported with heat resistant compounds.

•

•

•

GCA8

Superior sidewall cut resistance. ceptional casing durability.

GCA8

Another beauty from the phenomenal collection of Christchurch’s Richard Lloyd. Alistair Pearson operated this W923S Kenworth on stock as an owner-driver to Steve Mitchell in Darfield. The truck was new to John Pullam and was one of two he owned. Both had Cummins V8 903 engines. The

• Primarily designed for mining, off the road, and muddy surfaces.

Enhanced stability and riding comfort. The extra-deep tread pattern is specially designed for loaders. Excellent performance on extremely rocky surfaces, in open pits, quarries, and underground mines.

• Superior sidewall cut resistance.

• Long tread life, exceptional casing durability.

• Enhanced stability and riding comfort.

Non-directional deep tread pattern designed for muddy and soft surfaces.

Excellent traction and floatation offer comfortable handling.

• Excellent performance on extremely rocky surfaces, in open pits, quarries, and underground mines.

Superior long tread life and excellent puncture resistance.

GCA3

• Unique non-directional traction patterns ensure optimum traction and prolongs tread life.

• Superior sidewall cut resistance.

• Good self-cleaning with groove stone ejector

• The extra-deep tread pattern is specially designed for loaders.

GCA3

GCB5

Low rolling resistance and fuel economy.

• Articulated dumpers, rigid dumpers, loaders, graders.

• With excellent traction and buoyancy performance.

• Outstanding stability and operating comfort, with large pattern plate and long service life.

• Applications: Articulated dumper, dozer, loader, and graders.

• This deep tread is particularly suitable for loaders and dump trucks operating in quarries or mining.

• Non-directional traction and standard tread depth pattern design.

• Applications: Articulated dumper, dozer, loader, and graders.

• Excellent performance supported with heat resistant compounds.

• Non-directional traction and standard tread depth pattern design.

• Primarily designed for mining, off the road, and muddy surfaces.

• Primarily designed for mining, off the road, and muddy surfaces. GCA7

• Excellent performance supported with heat resistant compounds.

GCA2

• Non-directional deep tread pattern designed for muddy and soft surfaces.

• Excellent traction and floatation offer comfortable handling.

• Superior long tread life and excellent puncture resistance.

• Low rolling resistance and fuel economy.

Story by Gavin Myers Photos by Gavin Myers and Dave McCoid

From medium-duty metro models to a full 50-tonne B-traincapable tractor unit, Volvo Truck’s range of electric models has landed in New Zealand.

It was a typical July day in the Waikato – that’s to say, gloomy clouds and persistent rain. There was no chance of that dampening the spirit at Hampton Downs,

though, as Volvo Truck and Bus New Zealand hosted media and customers for continual test-drive laps of the circuit throughout the day.

Now, laps around a racetrack can give only a taste of a vehicle’s capabilities. Still, on first acquaintance, the FL Electric medium-duty and FM Electric heavy-duty models have a lot to offer.

By now, we know the gig … smooth and instant power delivery, near-silent operation and a sense of ease from behind the wheel.

The plucky FL in 4x2 rigid

form (with air suspension on both axles!) is ideally suited to its metro remit. Three steps into the cab via the 90°-opening door. Easily to familiarise yourself with the switchgear. Turn the key as though you’re starting a diesel – and you’re away.

At your disposal is a single electric motor sending its 130kW (175hp) of continuous power through a two-speed gearbox. Power comes from three or four batteries offering 280 to 375kWh capacity. Range, therefore, is quoted as up to 450km. A full charge can be

completed in just 2.3 hours on a 150kW DC charger.

But it’s the handsome FM that gained the most attention. We know the FM well, and the FM Electric is instantly familiar – the only clues being the chassis skirts hiding its six batteries (five optionally) and, less conspicuous, the ‘ELECTRIC’ graphic above the sun visor. With its 50-tonne GCM rating, the FM Electric is powered by three electric motors – offering up to 490kW (666hp) continuous power – coupled to an I-Shift gearbox. Battery capacity ranges from 450 to 540kWh for a range

of up to 300km. The charge time is quoted as two hours on DC.

As with the FL, all axles are air-suspended, but to suit its wider operational brief, the FM is available with low sleeper cab, sleeper cab and Globetrotter cab options.

“The FM (and FH) Electric offers a genuine 50-tonne GCM, 36-pallet B-train configuration – the first EV trucks to offer this option in the country,” says Scott Robinson, national sales manager Volvo Truck and Bus. All Volvo Electric models are available to order now, with up to eight-month lead time (depending on model), says Scott.

The FL is the same truck that was on trial with Fonterra for about eight months in 2022. “We’ve had some uptake with the EVs in trials,” says Scott. “We’ve got one in build at the moment and another three coming for two different companies. One’s for Fonterra Brands, which came off the back of that trial – they just wanted something a bit