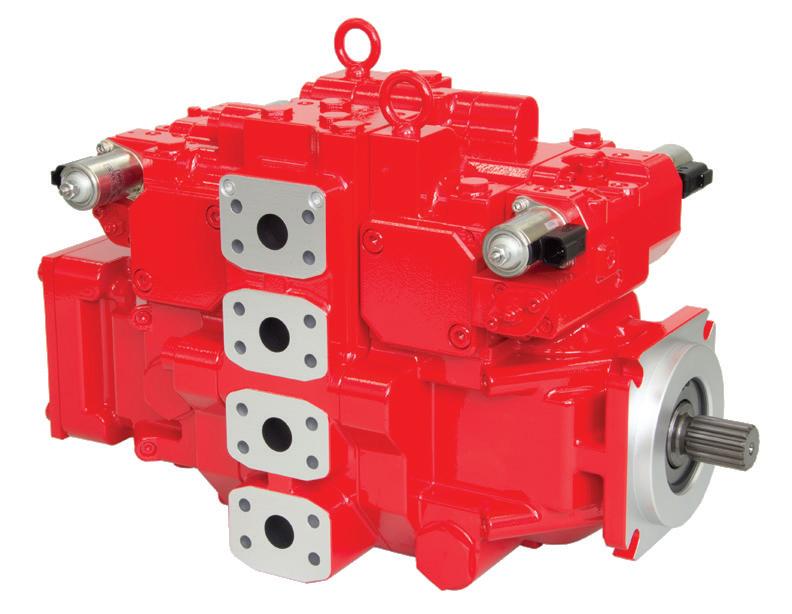

WHEN YOU NEED IT RIGHT AND YOU NEED IT NOW, CALL SUNIE. From order entry to product shipment, Sunie and the team at Twin Disc’s Lufkin, Texas, facility care for your order to ensure you receive a product that exceeds your expectations.

With an intense focus on land-based power transmission products, standard power take-offs, hydraulic power take-offs, mechanical clutches and pump drives are produced and shipped from Lufkin, Texas, with industry-leading delivery times. An experienced, friendly team that’s homegrown in Texas provides quick responses, flexibility and customer service that can’t be beat.

Fast. Focused. Friendly. From deep in the heart of Texas. Explore more at TINYURL.COM/LUFKINOEM

ELECTRONICS

20 Trends in Electric Construction Equipment

Experts expect the industry to reach a tipping point in 2025, where the majority of heavy equipment will move away from diesel engines to electric or hybrid, and this trend will continue to grow in the coming years.

ON-HIGHWAY UPDATE

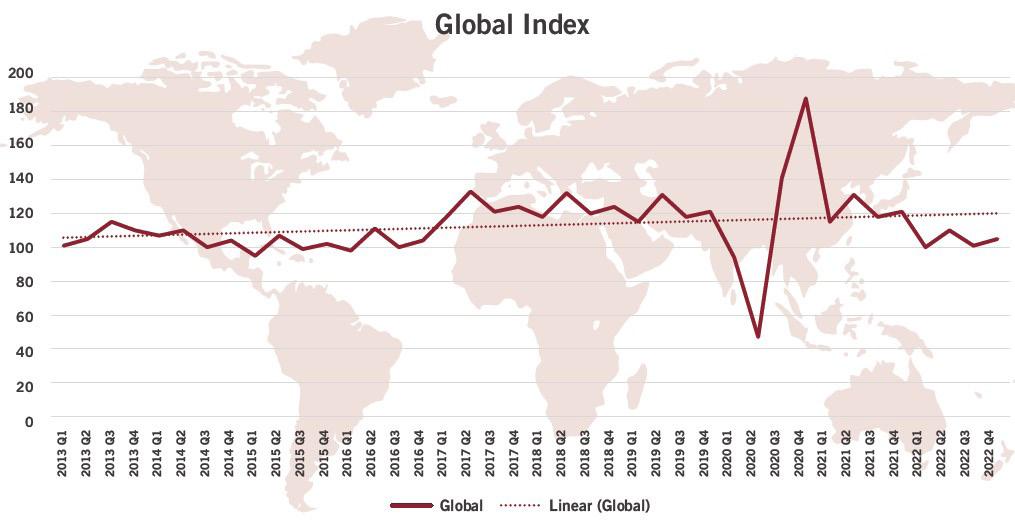

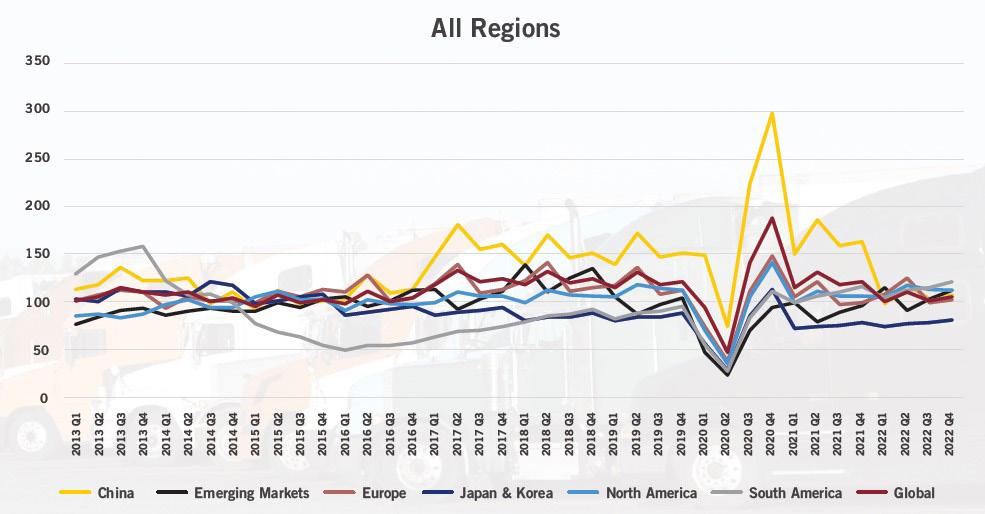

24 Power Systems Research Truck Production Index for Q4 2022

The PSR-TPI measures truck production globally and across several regions.

In 2020, the end of CONEXPO-CON/AGG (CONEXPO) marked the shutdown of, well, everything. This year, CONEXPO marks the regathering of the industry for what will surely be a celebration. I know that I am looking forward to my first time attending the show. I hope to see you there at one of our booths (North Hall, N12839, or South Hall, SL80012).

As we have been saying since October, bauma was a great preview of what to expect at CONEXPO. During bauma, we saw exhibitors featuring electrification, connectivity and alternative fuel technology. The tour with the Moog team during bauma included extreme connectivity and automated excavator work. We are looking forward to seeing more of the same in March 2023 as the whole AC Business Media publishing team heads to Las Vegas.

In this CONEXPO and International Fluid Power Exposition (IFPE) issue, we cover some of the new technologies that you will see during the event and what industry experts think you can look forward to from the show (page 10). One technology featured is JCB’s new hydrogen combustion engine, which I was thrilled to see in person during a media trip to the company’s headquarters in England. I also saw the engine in operation in a load all operating in a quarry near the headquarters. You can learn more from the article on page 16.

Also, be sure to check out the product sections for CONEXPO (page 28) and IFPE (IFPE section page 19) to learn a little more about what you’ll see in Vegas.

Can’t attend? Follow our social media platforms for frequent updates, including videos, images and reports, on what our team is experiencing live during the event.|

Craig Callewaert, PE, Chief Project Manager, Volvo Construction Equipment

Roy Chidgey, Business Segment Head, Minerals Projects and Global Mobile Mining, Siemens Large Drives US

Andrew Halonen , President, Mayflower Consulting, LLC

Terry Hershberger, Director, Sales Product Management, Mobile Hydraulics, Bosch Rexroth Corp.

Steven Nendick, Marketing Communications Director, Cummins Inc.

John Madsen, Director Engineering & Product Management, GKN Wheels & Structures

Doug Meyer, Global Director of Construction Engineering, John Deere

Andy Noble, Head of Heavy Duty Engines, Ricardo

Daniel Reibscheid, Business Development Manager, MNP Corporation

Matt Rushing, Vice President, Product Line, Global Crop Care, AGCO Corp.

Allen Schaeffer, Executive Director, Diesel Technology Forum

Keith T. Simons, President – Controls Products, OEM Controls, Inc.

Alexandra Nolde , Senior Communication & Media Specialist, Liebherr-Components AG

Bob Straka, General Manager, Transportation SBU, Southco, Inc.

Luka Korzeniowski, Global Market Segment Leader, Mobile Hydraulics, MTS Sensors

Chris Williamson, PhD, Senior Systems Engineer Global Research & Development, Danfoss Power Solutions Company

EDITORIAL

Editor Lori Ditoro lditoro@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Dave Haglund

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

Sales Representative Mark Gates mgates@acbusinessmedia.com

Sales Representative Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: 877-201-3915 Fax: 847-291-4816 circ.OEMOff-Highway@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

REPRINTS & LICENSING

Sales Representative Greg Schulz 920-542-1239 | gschulz@acbusinessmedia.com

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication shall be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

SUBSCRIPTION POLICY: Individual print subscriptions are available without charge in the United States to original equipment manufacturers. Digital subscriptions are available without charge to all geographic locations.

Publisher reserves the right to reject nonqualified subscribers. Subscription

Prices: U.S. $35 One Year, $70 Two Years; Canada and Mexico $60 One Year, $105 Two Years; all other countries, payable in U.S. funds, drawn on U.S. bank, $85 One Year, $160 Two Years.

OEMOff-Highway (USPS 752-770, ISSN 1048-3039 (print); ISSN 2158-7094 (online) is published 6 times a year: January/February, March/April, May/June, July/August, September/October and November/December by AC Business

Media, 201 N. Main Street, Ste 350., Fort Atkinson, WI 53538. Periodicals

Postage paid at Fort Atkinson, WI and additional entry offices. POSTMASTER: Send address changes to: OEMOff-Highway, PO

@OEMOffHighway

@OEMOffHighway

@oem-off-highway

Published by AC Business Media 201 N. Main Street, Fort Atkinson, WI 53538 800-538-5544 www.ACBusinessMedia.com www.OEMOffHighway.com www.IronPros.com

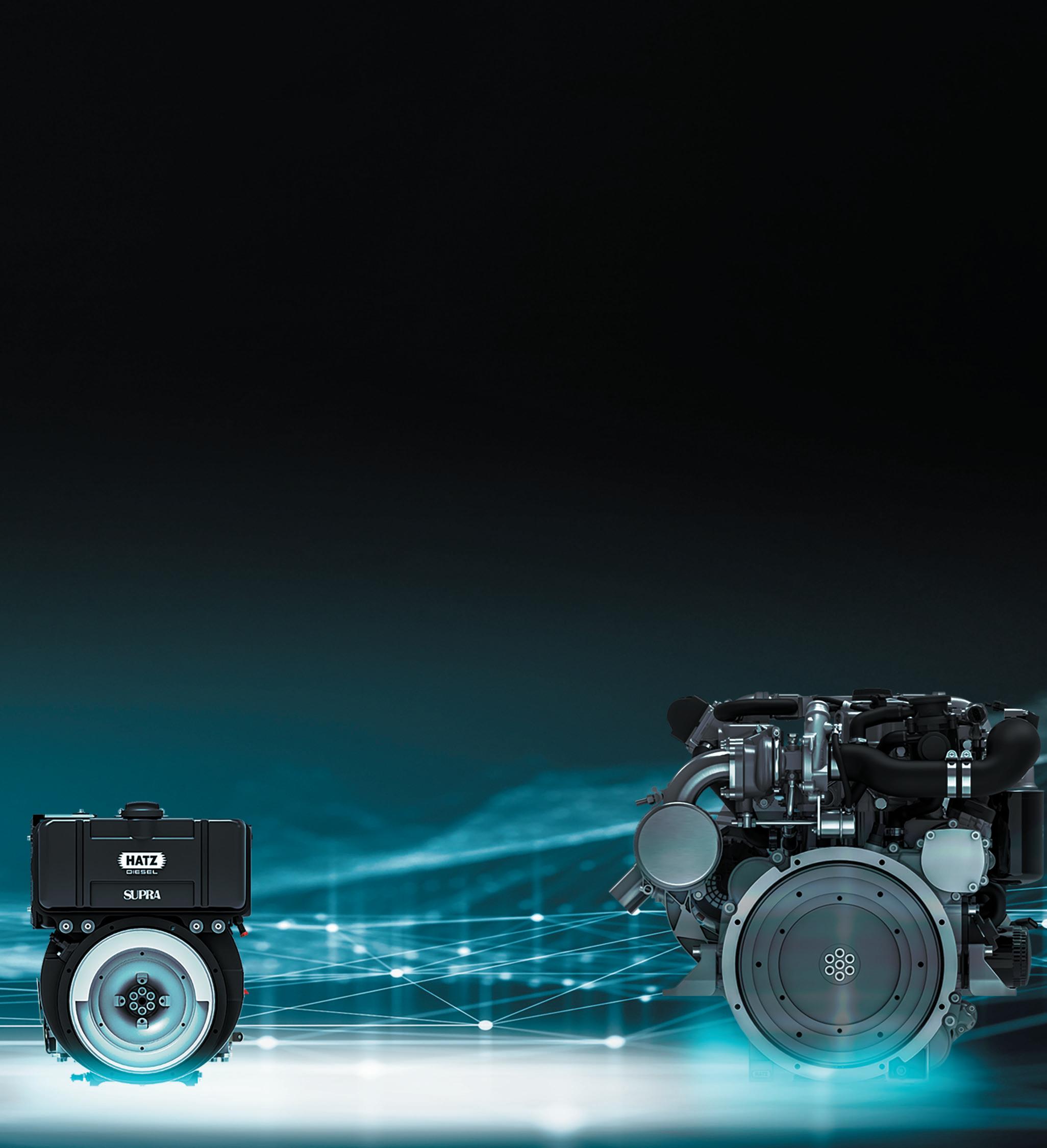

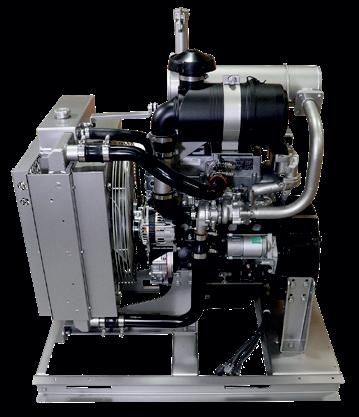

For nearly 150 years, Hatz and cutting-edge diesel technology remain synonymous. As Hatz moves forward into the future and expands its performance, systems, and products we continue to offer new solutions to solidify our position as a manufacturing partner of choice. We continue to develop our digital and IoT presence, our electrification, and hybridization technologies, along with advanced designs and alternative fuels. All supported by an extensive network of Hatz Service Centers.

Visit us at Hatznorthamerica.com

While this number increased, the U.S. leading indicator decreased, but most other indicators in this report are above previous levels.

As 2022 ended, the U.S. leading indicator moved down. However, new machinery orders in the U.S. in November reached a record high of $43.2 billion, up 15.5% from the November 2021 level. Several other numbers were up including U.S. farm machinery production, North American rotary rig count and U.S. Total Public Construction.

• The U.S. OECD leading indicator moved downward to end 2022, on a monthly value basis and monthly rate-of-change basis.

ITR Economics is an independent economic research and consulting firm with 60+ years of experience. QUESTIONS?

economics@oemoffhighway.com

• Rate-of-change decline in the indicator suggests U.S. industrial production will move along the back side of the business cycle through at least the third quarter of this year.

• U.S. industrial production in the fourth quarter was 2.5% above the fourth quarter of 2021.

• Leading indicators, ranging from macroeconomic indicators to utilization rates to tightening financial conditions, signal rate-ofchange decline is likely to persist for production into at least late this year.

• U.S. private nonresidential new construction in the three months through November came in at 14% above the same three months of 2021.

• Given the size and scope of nonresidential construction projects, spending tends to lag the macroeconomy by roughly one year. We expect the slowing growth that is currently characterizing the macroeconomy to manifest in construction spending by the end of this year.

• U.S. total public construction in the 12 months through November came in at $360.6 billion, up 3.4% from the year-ago level.

• Public funding for the federal infrastructure package has begun to be announced. Federal funding will likely buoy public construction spending in the coming years.

• U.S. farm machinery and equipment shipments in the 12 months through November were 1.9% above the year-ago level.

• Elevated interest rates could mute domestic demand for farm equipment, while a strong U.S. dollar could favor imports and reduce demand for U.S. exports.

• Europe agricultural and forestry machinery production in the 12 months through November was 4.4% above the year-ago level.

• Annual production is at the highest level since before the Great Recession. Uncertainty over the reliability of Ukraine food exports may bolster other European countries’ agricultural sectors in the near term.

• The four big European nations (France, Germany, Italy, and United Kingdom) leading indicator monthly rate-of-change ticked up in December. More data will be needed to confirm a rate-ofchange low for the indicator. The monthly value declined mildly to end the year.

• Recovery in the automotive sector may buoy European industrial production in the coming quarters, but leading indicators are pointing decidedly downward.

• U.S. heavy-duty truck production for 2022 was 10.7% above the 2021 level.

• Lower freight prices, along with higher borrowing costs, may hinder demand for investment in newer trucks.

Editor’s Note: Please note that this chart has been modified on the Y-axis to show the trend more easily.

• China large diesel bus production in the 12 months through November was at 16.5 thousand units, 24.2% lower than one year prior.

• China is rapidly electrifying its transport networks, suggesting limited demand for diesel buses in the country.

• In the three months through November, German industrial production was 0.2% below the same three months of 2021.

• Leading indicators such as Markit Economics’ Germany Purchasing Managers Index suggest business cycle decline will persist for German industrial production as the country continues to contend with energy uncertainty.

• Annual U.S. construction machinery new orders in November totaled a record-high $43.2 billion, up 15.5% from the year-ago level.

• Signals from the housing market suggest annual new orders are likely to peak in the near term. Spending stemming from the federal infrastructure package could provide some opportunity.

• The North America rotary rig count averaged 911 rigs in 2022, up 47.2% from the 2021 level.

• Oil and gas firms continue to contend with supply chain disruptions and elevated pricing, contributing to a lack of investment in the sector.

• Annual U.S. defense capital goods new orders in November totaled $166.2 billion, 4.9% above the year-ago level.

• Elevated global uncertainty bodes well for defense spending. The U.S. defense budget increased for FY2023.

Giotto and Leonardo have been first choice customizable displays for manufacturers of agricultural and earth-moving vehicles for many years now. Today the two successful displays have been upgraded and based on the Linux operating system and the Qt framework.

NO NEED TO RECODE

With the new version of Giotto and Leonardo featuring Linux and Qt tools, OEMs have the possibility to reuse some existing applications on MTA hardware without the need to recode them from scratch.

SOFTWARE ADVANTAGES

Thanks to Qt, the new displays will enable future-proof and best-performing applications’ development.

HARDWARE FOR TOUGH ENVIRONMENTS

Giotto and Leonardo are built to resist the rugged conditions and harsh environments typical of construction applications.

Have a look at our range of products at www.mta.it

Find us at booth S62617

The industry certainly remembers the last time it gathered in Las Vegas for CONEXPO-CON/AGG (CONEXPO) in 2020. At the end of the event, the world shut down because of the COVID-19 pandemic. We are all grateful to gather again to learn from each other and see all the new technology. Among many ways to gather and network, the event will feature an all-new community zone. Dave Turin of Discovery’s Gold Rush and Dave Turin’s Lost Mine and Aaron Witt, founder of BuildWitt, will headline a conversation at the show’s all-new Community Zone Tuesday, March 14, from 1 p.m. to 2 p.m. The Community Zone is an area in the Festival Lot of the show where construction pros can gather to network, grab some refreshments and participate in different events. Every day, the CONEXPO-CON/AGG Community Zone will feature live music, influencer meetups, a concession area to purchase snacks or beverages and simply a spot where attendees can relax and recharge.

Here what industry influencers are saying about CONEXPO 2023.

“The ACBM team and I are incredibly excited, as always, to attend another CONEXPO event – and this year in particular. Despite some of the slowdowns in markets, materials and supply-chain expectations, there is a palpable amount of new product development and innovation that is going to be showcased at the event. The opportunity for efficiency and improvement through new executions from the equipment community is greater than ever before, and the timing is perfect to learn what new marketplace integrations can do for our business in 2023 and beyond.”

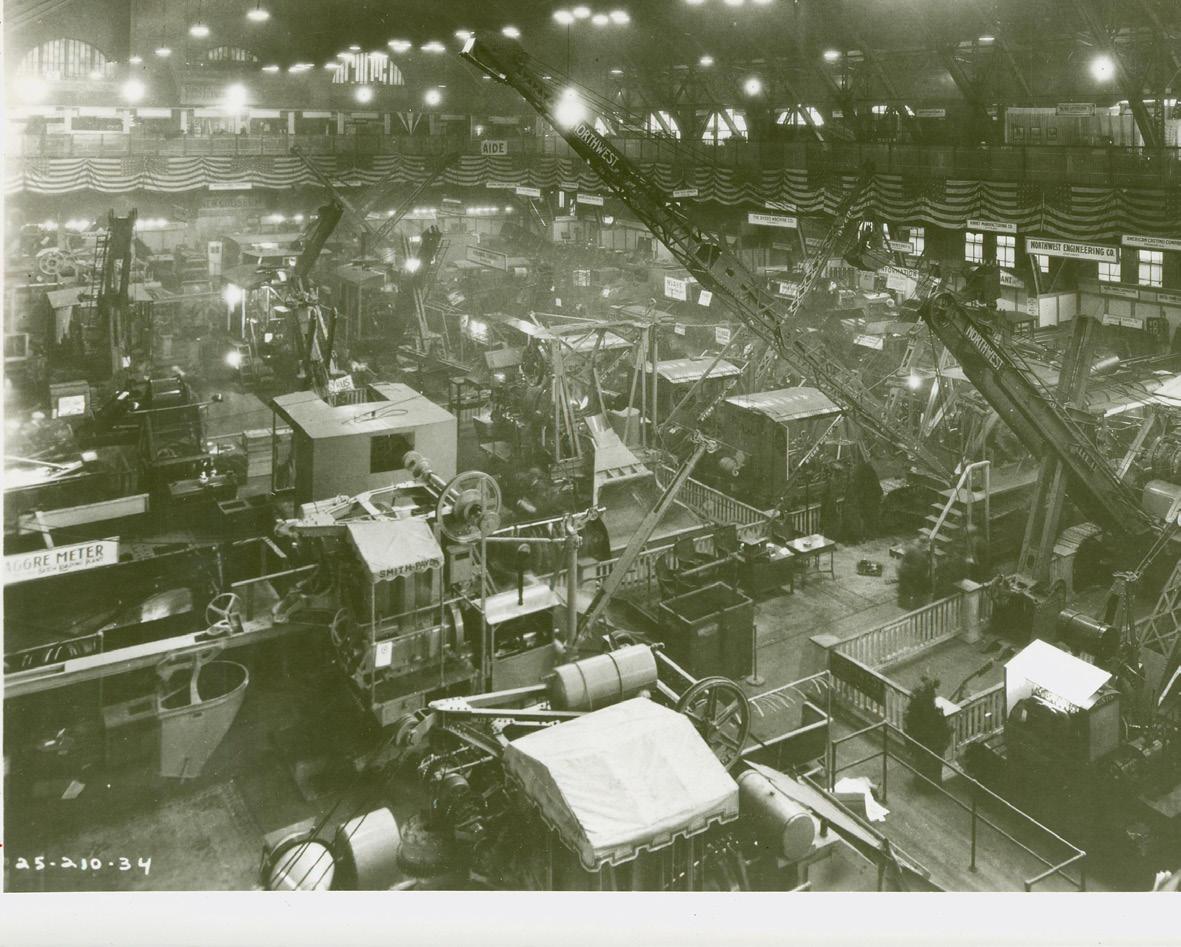

The OEM Off-Highway team and other industry influencers weigh in on what they look forward to during the construction industry’s largest trade show. by Lori Ditoro, EditorAttendees check out equipment in the North Hall in 2020.

“The exhibit includes the unveiling of a new high power internal combustion engine, as well as the leading-edge lithium-ion battery technologies under development. We will also showcase Caterpillar’s technical services and market expertise leveraged by the global Cat dealer network to

maximize the efficiency and extend the lifecycles of off-highway equipment, including Cat remanufactured and service replacement engines.”

“JCB is excited for our return to CONEXPO because it presents an opportunity to discuss our ‘Off Road to Zero.’ We are pleased to detail to attendees how we see hydrogen as not only the ideal zero-carbon fuel source for our machines but also how it offers zero compromise to its diesel counterpart with the added benefit of zero emissions.”

Schwandt, Chief Revenue Officer,

“CONEXPO is the largest construction trade show in North America. Every three years, the construction community at-large comes together in Las Vegas to showcase their equipment, products and services, displaying innovation in new product launches and technology unlike any other. (continued)

The power behind it all.™Amy

“We are looking forward to connecting with customers and contractors alike and we will be covering this event with real-time interviews, press coverage, targeted promotional efforts, daily news updates and so much more.”

—Amy Schwandt, AC Business Media

There are over 28 million reliable, eco-friendly, durable and technologically advanced Isuzu engines worldwide. Our Tier 4 and Stage V engines and power units are clean, quiet and fuel-efficient - meeting critical requirements in agricultural, construction, forestry and rental markets. Contact your local Isuzu Distributor to experience technologically advanced power today! Ask about our new gen-set ready power units! www.IsuzuEngines.com

CONEXPO is a must-attend event and is a game-changing experience for anyone in the construction industry. Visit us at booth #12839 in the north hall or Booth 80012 in the south hall and we will help guide you on how to make the most of your experience while you’re in Las Vegas.”

“We have lots of customers exhibiting our

engines at CONEXPO,” said Tasker. “We will be meeting with our customers, distributors and dealer networks, as well as unveiling new products. It’s the biggest show in North America from a construction equipment perspective, so it’s incredibly important to us. CONEXPO is really our landmark show in 2023.

“We will have some exciting developments to share at the exhibition as well as the opportunity to see different machines being built by the customers that are exhibiting our end products,” Tasker said. “It will be really fascinating to experience the depth and breadth of offerings being developed by this industry. I am always amazed by the different machines on display at CONEXPO.”

“I can’t wait for CONEXPO 2023. It is THE key event for the businessto-business verticals we serve across our company. We are anticipating an exceptional 2023 CONEXPO. People in this industry tend to mark time in three-year cycles because of CONEXPO. The last three years have been difficult for everyone. I can’t wait to put it behind me!”

“At Trelleborg Wheel Systems, we look forward to participating

at the 2023 edition of CONEXPO, which is recognized as the largest trade show here in North American and an important meeting point for professionals in the construction machinery industry. Our tire experts will be present at Booth 43375

in the West Hall to advise customers on the right tire for their specific application and needs from Trelleborg and Mitas products.

Overall, CONEXPO offers a complete overview of the market in all its breadth and gives us the chance to bring live to visitors how our tires are engineered with specific tread patterns, advanced tire structure and specialty compounds for an improved performance, even in the most demanding environments.”

Ben Chiswick,

Ben Chiswick,

“As a company focused on electrified propulsion systems, it’s exciting to see new technology developments taking hold as the industry evolves toward a future of electrification. It’s also fascinating to see the array of approaches that suppliers and OEMs are taking to integrate sustainable technologies and processes and how they’re shifting traditional mindsets to meet both industry regulations and the demand for electrified solutions. Events like CONEXPO are a great place to see and learn about some of the changes that are taking shape firsthand.”

Many manufacturers have decided that their journeys to zero emission offhighway equipment will require multiple power sources. Fossil fuels are not the future. For assets with sizes and requirements that work well with electric power, battery-electric is the solution. However, the materials required to manufacture batteries are not readily available and access may become an issue.

Others have begun with renewable biofuels for larger, more powerconsuming assets. However, while

biofuels produce lower carbon and other emissions than diesel, they do not drive equipment to the magic number zero. So, what are manufacturers to do? The team at JCB believe they have the solution: An engine designed and optimized to combust hydrogen, which we learned about and got to see when we toured the JCB properties.

During three chilly days in January, the JCB North America team brought media members to their North England manufacturing and test facilities.

We toured the museum at the main headquarters, which presented a full history of the JCB brand and growth since its beginnings 75 years ago.

The family and leadership team were on display in pictures, including Joseph Cyril Bamford’s private office, which is typically closed during museum visits. We were honored to be allowed inside. In addition, we saw several historic pieces of equipment, including the backhoe loader and a backhoe loader drivetrain.

As we moved to the next stop, we began the journey to zero emissions.

At Kevin Quarry, the team presented their 100% electric, zero emission equipment that operates on batteries and was launched in 2019. During the presentation, we saw the:

• 19C-1E Electric Compact Excavator

• 505-20E Telehandler

• 66-40E Electric Teletruk/Forklift

• HTD-5E Electric Dumpster

Each asset’s compact design allows it to operate well in small or tight spaces, including indoors. Its smaller footprint is also what allows the equipment to be powered by a lithiumion battery that requires no maintenance. All these machines’ batteries can use the JCB Universal Fast Charger which decreases the different machine charging times to around 1 hour and 40 minutes (charging can take more or less time depending on the piece of equipment).

While these machines provide adequate work using electric power, larger machines require more power than electricity can provide. What needed to be the next step on the road to zero?

The JCB team decided on an excavator because it has high energy demand and is required to work many hours. To operate these machines using battery power, end users would need to produce huge amounts of power with diesel generators, defeating the benefit of the zero-emission electricity. They considered all future fuels—including E-fuels, ammonia and hydrogen—and decided hydrogen was their fuel. It is plentiful, has three times more energy than diesel and can be transported as a gas under high pressure or liquified in refrigerated trucks.

The JCB designed, built and tested a fuel-cell powered excavator. Prototype I was a 30-kilowatt-hour (kWh) fuel cell. Then they built Prototype II, a 20-ton, 70-kWh fuel cell. The architecture included:

• Fuel Cell

• Large cooling pack (much larger and more complicated because the coils are tiny and can be blocked by dust and other particulates from the environment)

• Hydrogen tanks

• DC-DC converter

• Power electronics

• Power batteries (one battery pack; starts on the battery then the fuel cell recharges the battery)

After testing, the team decided that the fuel cell prototype was too complicated, not robust and too expensive. It would work more effectively in smaller vehicles. Even though this technology wasn’t chosen, the team still has the 20ton, fuel-cell excavator operating at Wardlow Quarry in England.

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites. Sturdy and resistant, reliable and safe, able to combine comfort and high performance.

BKT is with you, even when work gets tough.

RAISING YOUR EFFICIENCY.

Increase your welding and assembly manufacturing productivity by up to 40+% with a powerful positioner from ALM. Built for increased ergonomics, safety and quality improvements, to give your efficiency a lift.

In 2020 and after the decision regarding the fuel cell technology, Chairman Lord Anthony Bamford challenged the JCB engineering team to decide what they would do to get to zero emission technology. Electric power for smaller equipment was decided. However, larger equipment needed a different direction. They needed a different hydrogen solution. Lord Bamford challenged the team to produce a hydrogen-combustion engine by the end of 2020.

The four major challenges to designing specifically for hydrogen combustion were:

• Hydrogen and air mixing—Using a gas as fuel required a uniform mixing of fuel and air.

• Air compression—Forcing the air into the mixing/combustion chamber or cylinder required a turbocharger.

• Spark ignition—Better sparkplugs were necessary.

• Steam management—Since the only emission from the hydrogen combustion was steam, corrosion could occur.

While these were the major challenges, Tom Beamish, principal engineer, JCB, discussed that this engine is not a conversion. The engine was designed from the ground up to be optimized for hydrogen combustion. While it’s not rocket science, it uses the same fuel and similar combustion principles as NASA … so maybe it does use a little rocket science.

In addition to the four major challenges already mentioned, Beamish mentioned several other engineering factors that had to be overcome:

• All materials that contacted hydrogen had to be carefully examined.

• A whole new control system for the engine was used.

• The spark system is new.

At Wardlow Quarry, we also saw the hydrogen-combustion load all machine in action. The architecture of this machine includes:

• Hydrogen tanks

• A refueling point

• The hydrogen engine

We also got up close to the refueling capability from a portable tank already planned for end users. Refueling seems as simple as adding gasoline or diesel to current equipment.

This hydrogen-combustion engine will make its North American debut during CONEXPO in the South Hall, Booth S83751.

Read more: https://oemoh.co/wrcaw4

Experts expect the industry to reach a tipping point in 2025.

by Mourad Chergui, Delta-Q Technologies

by Mourad Chergui, Delta-Q Technologies

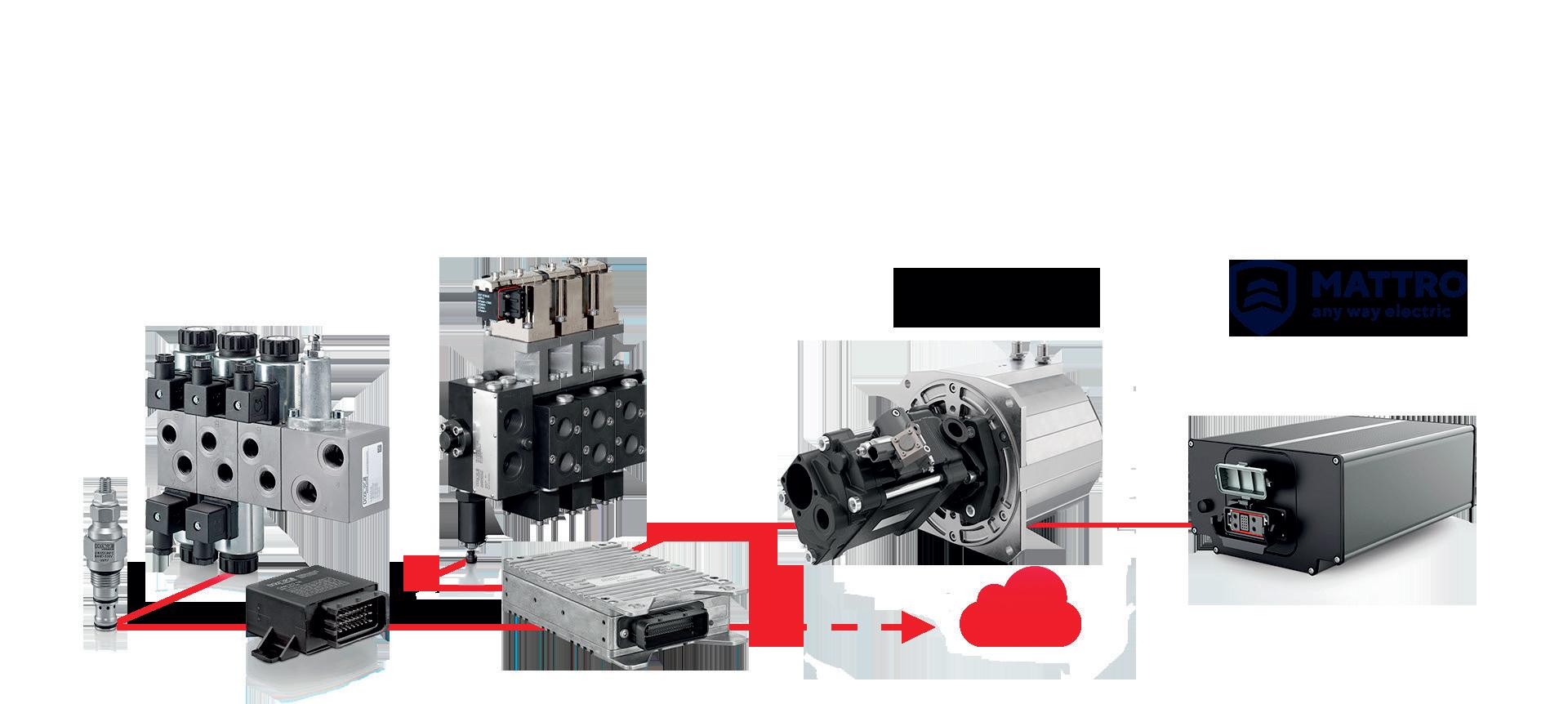

The construction industry is rapidly transitioning to electric solutions, driven by stricter emissions regulations and high fuel costs. Experts expect the industry to reach a tipping point in 2025, where the majority of heavy equipment will move from diesel engines to electric or hybrid. This trend will continue to grow in the coming years. Some current trends in construction vehicle electrification include international regulatory pressures, the exponential growth in suppliers and services catering to the demand for electric construction equipment and new technologies that provide options for original equipment manufacturers (OEMs).

The trend toward battery-powered construction equipment is international, driven by tighter emission regulations. Governments and regulatory bodies are enacting tougher standards for non-road diesel engines used in construction, making it difficult to operate dieselpowered equipment. For example,

the European (EU) Stage V Emission Regulations and China VI Emission Standard represent global trends to reduce exhaust emissions from nonroad mobile machinery. In addition to emission regulations, many governments, right down to the municipal level, are introducing low-noise requirements, especially in residential areas.

The high cost of diesel fuel is also a significant factor driving the trend toward electric solutions. As fuel prices continue to rise, OEMs want to help end users looking for ways to reduce costs and stay competitive. Electric construction equipment offers a more efficient and costeffective solution,because it consumes less energy and has lower operating costs.

The battery-powered trend is on track to accelerate in the coming years as governments worldwide enforce regulations and promote clean energy.

Another trend in the construction equipment industry is that electrification is becoming more cost-effective as supply

and demand increase and technology improves. As fuel costs continue to rise and other diesel-powered equipment expenses remain high, the benefits of using electric construction equipment are becoming more apparent and alternative-powered technology is becoming more attractive.

Advances in battery technology and electric motor efficiency have also led to lower production costs of electric construction equipment, making it a more accessible option for OEMs of all sizes. While the initial costs are currently higher for electric equipment than diesel counterparts, lower maintenance and operating costs offset the difference.

Additionally, governments and organizations are providing subsidies and incentives for using electric machinery, including construction equipment. As a result, battery-operated construction machinery is becoming more affordable and accessible, making it a viable alternative to traditional diesel-powered equipment.

As the construction industry continues to grow and evolve, so do the suppliers and dealers that support it. With increasing demand for electrified equipment and a growing need for sustainable and cost-effective solutions, companies are developing and producing more components and software to meet these demands. This shift is particularly significant for manufacturers of traditional internal combustion engine (ICE) parts, that are experiencing significant disruption as electric vehicles become more mainstream.

Dealers are also poised to experience significant changes in their operating models. Electric construction equipment has fewer parts and requires different service than ICEs. Dealers are facing a change in their offering of products and services that might include supporting and servicing batteries and recharging vehicles. In a 2021 survey of off-highwayequipment dealers by McKinsey & Co., 78% of respondents see the chance

to sell new products and services for electrified equipment as the most significant opportunity presented by the energy transition in off-highway vehicles.

More advanced battery technology plays a crucial role in the adoption of electric construction equipment. The latest advancements in battery technology have led to improvements in energy density, power output and durability, which in turn have enabled the use of electric power in larger and more demanding equipment.

One of the most popular types of electric construction equipment is the compact excavator, which has been available as an electric vehicle (EV) for a long time. However, as battery technology improves, manufacturers are developing the capability to electrify larger equipment, including cranes, and mining trucks. In addition, with the increase of batteries to power larger equipment for more extended periods,

The Mosaic Modular Lighting system gives OEMs the freedom and versatility to create impactful, affordable designs by using standard lighting modules. OEM designers can incorporate a wide range of multifunctional DOT and ECE standard LED’s into custom bezels to reduce cost and expedite time-to-market.

OEMs can choose from a broader range of electric options that can handle the most demanding tasks.

Recent advancements in battery technology have also led to faster charging times, which are critical for operators who need their equipment back in operation as quickly as possible. Faster charging times allow electric construction equipment to have more hours of operation. Charging solutions have advanced along with chargers. Chargers are designed closely with battery and equipment manufacturers and are strictly examined, even in intense conditions, to ensure a prolonged battery life. With enhanced flexibility, chargers can be portable for easy access to an electrical outlet.

As the adoption of electric construction equipment grows, the need for reliable and accessible charging infrastructure is important. Construction companies

operating in remote or inaccessible areas will increasingly turn to solarpowered EV charging or portable power storage and charging as a solution. Solar-powered charging solutions can be set up quickly and provide a reliable power source. Portable power storage and charging solutions enable the use of construction equipment in remote areas, with trailer-mounted batteries and EV charging stations becoming more

common on work sites. The growing adoption of solar-powered EV charging and portable charging for off-grid construction sites offers a green solution for construction equipment. |

Read more: https://oemoh.co/gfff5k

High quality, designed, tested and manufactured in the USA , our range of single, 3 and 5-piece wheels allow for ease of tire fitting, increased productivity and e iciencies for a wide range of light & heavy duty machinery, We work with our customers and partners to design innovative solutions for the current and future needs of the world’s essential industries.

Typical applications include: Backhoe loaders, skid steer loaders, telehandlers, wheel loaders, dump trucks, excavators, motor graders, forestry machinery Learn more www.moveero.com

FORVIA Hella: Custom solutions for customer segments such as trucks, buses, construction machinery, agricultural vehicles, and more

Bi-LED low beam and high beam headlamps

Excellent high beam and low beam from one single headlamp module

Design freedom thanks to modular system

For the most diverse applications and the highest demands

New C240 LED combination headlamp

All important light functions combined in one LED headlamp: Low beam, high beam, position light, daytime running light and direction indicator light

Unmistakable, extraordinary design

Suitable for heavy duty demands thanks to sturdy material

Work Lamps

Intelligent work lamp with smart functions

Individual light adjustment for more safety, comfort and productivity

Uses the existing wiring harnesses thanks to power line communication (PLC)

Easy upgrade from conventional work lamps

Warning Lamps

Flat and compact design Available as flashing or rotating variant

Long lifetime

www.hella.com/soe www.hella.com/construction www.hella.com/mining

The Power Systems Research Truck Production Index (PSR-TPI) increased from 101 to 105, or 3.7%, for the three-month period ended December 31, 2022, from Q3 2022. The year-over-year (Q4 2021 through Q4 2022) loss for the PSR-TPI was, 122 to 105, or -13.2%.

The PSR-TPI measures truck production globally and across six regions: North America, China, Europe, South America, Japan & Korea and Emerging Markets.

This data comes from OE Link, the proprietary database maintained by Power Systems Research.

Global medium and heavy vehicle production is expected to decline by 15.8% in 2022 when final numbers are available in Q1 2023, primarily due to a significant drop in heavy truck demand in China. Global MHCV demand is expected to improve by 4.6% in 2023 even with concerns of a slowing global economy. Ongoing supply chain disruptions along with generally higher inflation and a risk of COVID-19 variants returning are also a concern moving forward.

Global medium and heavy vehicle production is expected to decline by 13% this year primarily due to a significant drop in heavy truck demand in China. A slowing global economy along with continued supply chain disruptions will continue place pressure on demand moving forward.

See you in Vegas – it’s always a pleasure to meet the people that inspire us. Together, let’s look at solutions for your upcoming projects. More precision, less effort – more profitable.

www.liebherr.com/conexpo March

Medium and heavy commercial vehicle production will be mixed this year due to a variety of issues. In China, truck overcapacity continues to hinder demand while the Russian-Ukraine war is significantly impacting demand and production in Eastern Europe. The global supply chain will remain a problem through at least the end of this year for all regions. There is serious concern about a major slowdown in the North American and European economy as a direct result of higher fuel and energy prices and overall inflation which doesn’t appear to be going away anytime soon.

Medium and heavy commercial vehicle production will be mixed in 2022 due to a variety of issues. In China, truck overcapacity continues to hinder demand while the Russian-Ukraine war is significantly impacting demand and production in Eastern Europe.

While the global supply chain is showing improvement, it will remain a problem in 2023 for all regions. There is serious concern about a major slowdown in the North American and European economy as a direct result of higher fuel and energy prices and overall inflation which doesn’t appear to be going away anytime soon.

Medium and heavy commercial vehicle production is expected to increase by 12.5% in 2022 over last year primarily driven by improved Class 8 truck production. While not back to prepandemic levels, the supply chain has seen improvement during the past few months. Within the Class 8 truck segment, PSR expects truck demand to remain strong into the first part of next year as a result of significant pent-up heavy truck demand.

While commercial vehicle demand is expected to decline slightly in 2023,

production levels are expected to remain strong through at least the first half of the year.

Commercial vehicle production is expected to improve by 2.3% in 2022 over 2021 and further improve by 4.8% in 2023 primarily due to continued pent up vehicle demand.

However, higher inflation, particularly energy costs and higher interest rates along with continued supply chain issues will put negative pressure on demand throughout the year. Another concern is the ability of the various manufacturing plants to remain open during possible power shortages.

After relatively low vehicle demand over the past few years, medium and heavy commercial vehicle demand in South Asia continues to be strong and production is expected to rise by 18.6% in 2022.

Production is expected to further increase by 12.9% in 2023 as the trucking companies continue to replace their older vehicles. In India, the focus is moving toward more infrastructure spending which is good for the vocational market.

After exceedingly elevated levels of MHCV production in Brazil in 2021, overall production in South America is expected to increase by 6% in 2022 before declining by 11.7% this year. Emission regulations Proconve 8 or P8, equivalent to Euro VI, are now in effect in Brazil. The legislation considers MHV to be all CV vehicles above 3.8 tons. The additional vehicle cost of the P8 emission technology will likely have a negative impact on Brazilian truck demand this year. Other factors such as higher interest rates will also place pressure on truck demand moving forward.

Medium and heavy commercial vehicle production in Japan and South Korea is expected to finish flat in 2022 compared to 2021. However, commercial vehicle production is expected to increase by 4.8% this year. Concerns surrounding a slowing global economy along with continued supply chain disruptions will likely impact vehicle demand this year.

Demand for medium and heavy commercial vehicles declined sharply in 2022 primarily due to a slowing economy and the affects from COVID-19 related lockdowns. Also impacting demand was the implementation of the vehicle scrappage scheme in 2020 and 2021 along with a truck prebuy ahead of the China VI emission regulations implemented in July 2021 which resulted in a relatively young truck fleet in China. MHCV production is expected to improve by 7.7% this year over 2022.

The next update of the Power Systems Research TPI will be in April 2023 and will reflect changes in the TPI during Q1 2023.

Chris Fisher is the senior commercial vehicle analyst at Power Systems Research. Jim Downey is vice president – global data products at Power Systems Research.

The logo that officially kicks off the BKT tire family specifically tailored for electric vehicles (EVs) was unveiled just a few weeks ago at SIMA. E-READY specification is the beginning of a path toward solutions suitable for electric mobility. It also underscores BKT’s commitment to sustainability. By stylizing the new logo, BKT seeks to showcase its aptitude for anticipating market needs through the robustness of its advanced technology.

How does a tire intended for an electric vehicle differ from a conventional one? There are many differences. Trials and field tests have revealed that, to equip an electric vehicle, designers will have to consider several factors that characterize electric mobility including:

» Weight

» Engine structure

» Range

» Noise

www.oemoffhighway.com/22671134

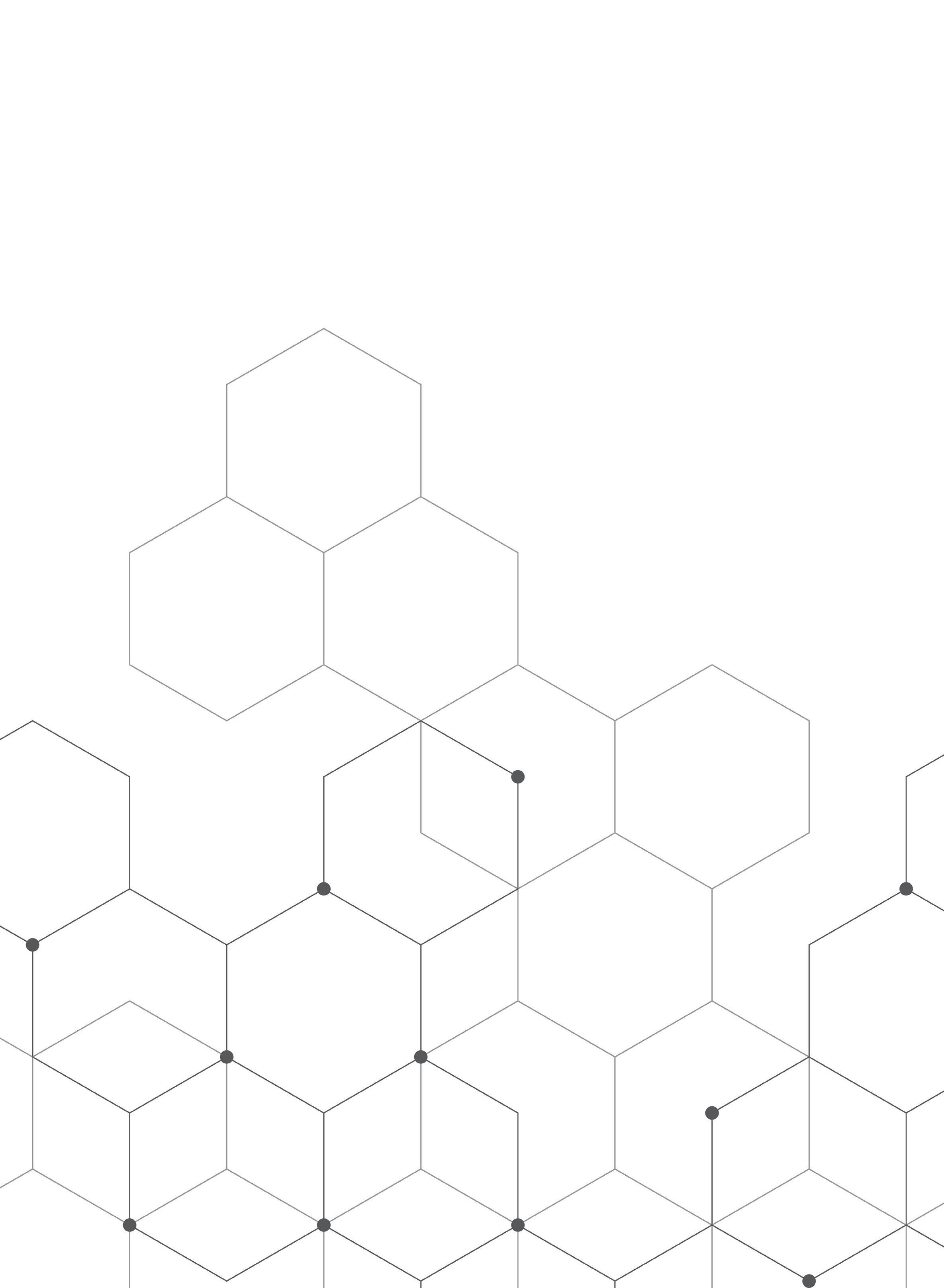

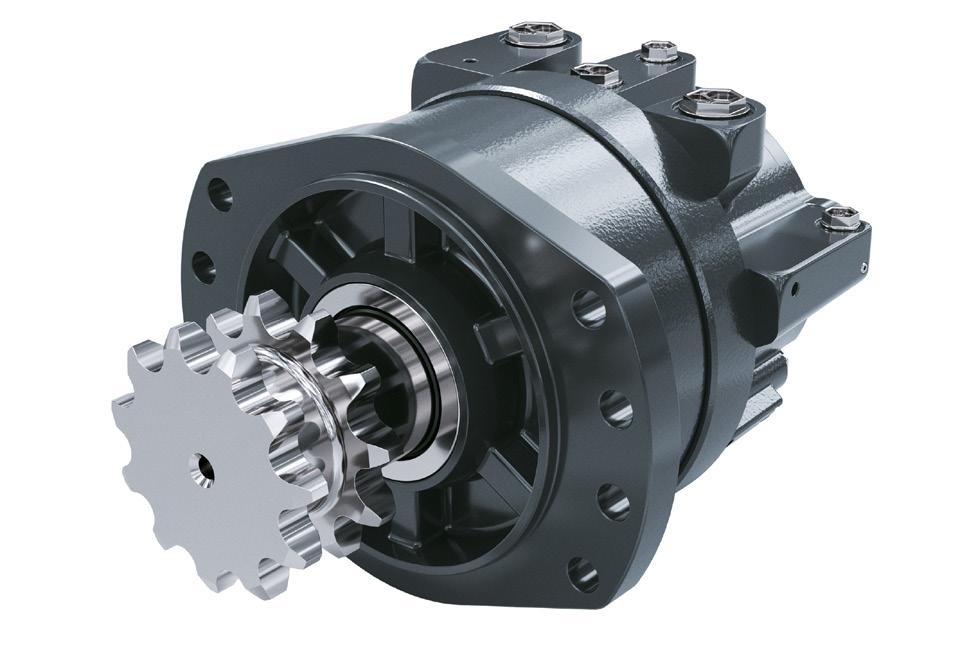

Dana Incorporated announced that it will launch a hydrostatic driveline for telehandlers in North America. The system’s modular architecture enables customers to easily transition to a hydrogen or battery-electric vehicle design. The new driveline will be showcased at the CONEXPO-CON/ AGG 2023.

Developed for telehandler applications lifting up to 12,000 pounds, Dana’s new driveline comes equipped with a compact Spicer 312 dropbox for high-power hydrostatic motors. This new hydrostatic dropbox functions as a continuously variable transmission without torque interruption and delivers enhanced performance with precise movements at low speeds, reduced fuel consumption, and an integrated spring applied hydraulic release parking brake.

www.oemoffhighway.com/22684410

J.R. Merritt Controls is adding the Merritt Evolve joystick to its lineup, which offers a range of customization options. Featuring a new performance-driven handle design, face plates and other aspects that can be customized to meet specific application needs. Key features of the joystick include:

» Spring return handle action in single- or dual-axis operation

» Can be supplied with j1939, canopen, or a hall effect output

» Constructed for use in harsh environments

» Enables left- or righthand mounting

The Merritt Evolve Joystick will debut during CONEXPO-CON/AGG 2023.

https://oemoffhighway.com/22697582

CrossControl offers the CCpilot V1000 and CCpilot V1200 for construction, agricultural and industrial machines. The displays are compact and can be used to monitor operations. With sizes from 7-in. to 12-in., the products can be deployed as a modular display platform for original equipment manufacturers (OEMs)

that build equipment of different size and complexity.

The displays are supported by an open software platform, which means OEMs and system developers are free to choose from different toolchains including Qt, HTML5 and CODESYS. The platform features a windowing framework for Linux. This approach allows for the creation of a human machine interface (HMI) system that can deploy multiple independent applications in parallel. For example, based on this technology OEMs, system integrators and designers can create an HMI system with an in-house developed app for base machine control and instrumentation, a sourced app for steering or navigation and a separate vision system app.

The platform supports dynamic window size, resolution and frame rate and is agnostic to camera brand. Building on from displays with connected cameras, the platform enables computer vision with object detection for process guidance, automation, augmented reality and safety and offers additional performance with an optional internal AI accelerator.

With software capabilities and hardware, CrossControl’s display computers provide a future-ready platform for machine intelligence.

www.oemoffhighway.com/22644109

Smaller than our fullsize G3-C grip. Compatible with our standard and angled JHL joysticks.

www.OTTO-Controls.com

Bridgestone Americas (Bridgestone) introduced the M863 all-position radial tire designed to help deliver outstanding performance and increased durability for on- and off-highway fleets. The new tire provides a simple solution to equip tough trucks, concrete mixers, dump trucks, construction fleets, logging trucks and more with a product proven to deliver more miles per tire.

The 4-belt construction on the M863 delivers durability and a premium casing for maximum retreadability. Other key features include:

» Stone rejector platforms: Help prevent trapped stones from pushing deeper into tread grooves and piercing belt layer, damaging and exposing belts to rust.

» Block sipes: Promote traction by slicing through water for a solid grip on wet roads.

» Stabilizing tie bars: Help reduce block squirm to fight irregular wear and extend tread life.

» Wide flow-through grooves: Evacuate water effectively for solid wet traction.

www.oemoffhighway.com/22684533

Trackunit is demonstrating its latest range of Internet of Things (IoT) construction equipment, tools and apps to increase site; personnel; and equipment safety, productivity, and sustainability based on data insights.

Trackunit’s technology solutions reduce loss and theft across the project site and rental yard. In 2023, it will continue to expand the platform to support OEMs, rental operators’ and contractors’ growth in 2023 and beyond. https://oemoffhighway.com/22697589

The mammoth construction equipment trade show now known as CONEXPO-CON/AGG has a rich history that parallels and embodies the evolution of the highway and heavy construction industry and its machinery.

It all started in 1909, at the Ohio State Fairgrounds in Columbus with the Road Show of the American Road Builders Association (ARBA). Held as a sidelight to the ARBA Convention, it was the world’s first construction industry trade show.

Forty exhibitors, in an area that many large single exhibitors now exceed, showed state-of-the-art steam (as in steampowered) rollers, 8-ton capacity dump wagons and concrete mixers capable of churning out 8 cubic yards an hour. Salesmen also showed static and operating scale models of machinery.

The event became simply The Road Show. While held irregularly and at different locations, the opportunities it presented for manufacturers to introduce new machinery as technology advanced led to its growth in size and attendance.

In 1929, The Road Show came into its own, overshadowing the ARBA Convention. Held at the Cleveland Armory, about $5 million worth of exhibits arrived in or on roughly 500 railroad cars.

While the 1932 show in Detroit was noted for its depressioninduced lack of heavy equipment, trucks, smaller equipment and road materials dominated.

Back in Cleveland, the 1936 show introduced motion pictures as sales tools for many exhibitors, with one even setting up a small theater. The 1938 show, again in Cleveland, was the first with outdoor space, a total of 6 acres indoors and out, with attendees from 26 countries.

Ending an 8-year hiatus due to World War II, the 1948 show at Soldier Field in Chicago was a landmark. More than 1,000 carloads of machinery worth $15 million was viewed in 770,000 square feet by 63,000 attendees from 40 countries. It was the first many shows in Chicago that gave it the name Chicago Road Show.

Expansion beyond road construction inspired a name change to the Construction Equipment Exposition in 1960. Finally, it was named CONEXPO in 1975, the last to be held in Chicago. The show ‘s time in Las Vegas began in 1987, with 308 exhibitors, 907,000 square feet and 115,000 attendees.

A discussion of the equipment innovations introduced at CONEXPO and the Road Shows would require a book.

However, if a machine was new on the market, especially if it introduced a technological breakthrough like the first truckmounted crane (1920), Hug Roadbuilder construction truck (1932), the world’s largest crawler tractors of their time (1948), the Koehring 505 hydraulic backhoe and Skooper hydraulic shovel (1963), Michigan 675 wheel loader (1975) or Cat D7E electric drive crawler tractor (2008), you could count on it being at the show. |

The Historical Construction Equipment Association (HCEA) is a 501(c)3 non-profit organization dedicated to preserving the history of the construction, dredging and surface mining equipment industries. With over 3,800 members in 25 countries, activities include publication of a quarterly educational magazine, Equipment Echoes, from which this article is adapted; operation of National Construction Equipment Museum and archives in Bowling Green, OH; and hosting an annual working exhibition of restored construction equipment. HCEA’s 2020 show will be August 28-30 in Concordia, KS. Individual memberships within the USA and Canada are $35 for one year, $65.95 for two years and $99.95 for three years, and $45.00 US elsewhere. HCEA seeks to develop relationships in the equipment manufacturing industry, and offers a college scholarship for engineering and construction management students. Information is available at www.hcea.net, by calling 419-352-5616 or e-mailing info@hcea.net. Please reference Dept. OEM.

ON THE COVER Products

19 IFPE 2023

08 6 Considerations for Ergonomic Joysticks

The science behind designing a joystick for maximum operator comfort, configurability and durability.

12 On-Road

OEMs of small off-road vehicles need a plug-and-play solution to add durable on-road signaling capabilities to their equipment.

04 Sometimes Change Looks Very Familiar

Engines have changed over the last 30 years. But, emissions excepted, the things OEMs and end users require haven’t.

16

IFPE 2023 will see the introduction of several new products and technologies geared toward OEM needs. 19 12

16 Securing Future Electric Motor Supply Needs

Regardless of one’s opinion of the viability, performance, or economics of electric vehicles, it is clear the world is inevitably transitioning from combustion engines to electric power..

There is a saying attributed to French author Jean Baptist Alphonse Karr, “plus ça change, plus c’est la même chose.” Often translated as “The more things change, the more they stay the same,” it’s remembered because, more often than not, it tends to be true.

It’s certainly true of today’s dieselpowered construction equipment and the engines that are chosen by the original equipment manufacturers (OEMs) who build them. Those engines are marvels of technology—smaller, lighter and more fuel efficient than the generation they’re replacing while meeting the world’s most stringent emissions standards.

The engines have changed over the last 30 years. But, emissions excepted, the things OEMs and end users look for haven’t. They want efficiency, reliability and support along with the most transparent emissions compliance possible. How those four attributes are ranked on what the equipment is intended to do and where it’s going to be sold.

Engines have changed over the last

years.

by Robert Bezner, Perkins EnginesSullair engineers had an ambitious goal in mind for their new mid-range series of lubricated rotary screw air compressors. They wanted a machine that was half the size and weight of the legacy model it was replacing, with no sacrifice in performance. Meeting that goal demanded advanced compressor and control technology and an engine with high power density.

They chose a 300-horsepower (hp) engine, primarily because of its very high power density. The engine also met Sullair’s expectations for performance in harsh environments, ease of maintenance and overall reliability.

Sullair selected this 300-hp engine because of its very high

Sullair selected this 300-hp engine because of its very high power density, its performance in harsh environments and the ease of maintenance and overall reliability.

power density, its performance in harsh environments and the ease of maintenance and overall reliability.

The Sullair Mid-Range Series is the result of extensive customer feedback that indicated a need for a smaller, more powerful machine. Sullair’s rotary screw technology and unique electronic spiral valve coupled with the power-dense engine easily provided the capacity and control needed to meet both the size and output requirement.

30

But, emissions excepted, the things OEMs and end users require haven’t.PERKINS ENGINES

Taylor Power Systems had a different set of expectations for their new 750-kilowatt (kW) stand-by generator. They ranked reliability at the top of the list because their products are used to support critical infrastructure. In addition to

reliability, the other goals for the system included a small footprint, easy servicing from either side and a competitive price.

Taylor Power had recently collaborated with an engineering team that resulted in a special version of a small diesel for an unusual application. That engine had a 3,000-hour service interval.

Based on that experience, the engineers approached an engine manufacturer about the possibility of powering the new 750-kW generator set with a diesel engine with expanded capabilities to increase power density. The

resulting engine was a 750-kilovolt-amp model with very high power density and an improved air filtration system that allows servicing from either side to meet the Taylor Power design requirement.

Emission compliance may be the most recent change OEMs and end users must deal with, but it’s also the most far reaching in terms of both technology and geography. That’s why it was a top concern for the Liftking engineers who designed the company’s new 16M rough terrain forklift.

Because Europe and North America are major markets for the 16M forklift, Liftking engineers wanted an engine that met the emission standards without sacrificing power. They chose to power the 16M with a 134-hp engine

Parker enables its partners in the off-road machinery industry access to unsurpassed people, technology and expertise that work together to develop electrification solutions with maximized system efficiency in work and traction applications for a quieter, cleaner tomorrow. parker.com/electrification

that meets both EU Stage V and U.S. Environmental Protetion Agency (EPA) and CARB Tier 4 Final emission standards. While emission compliance was a top concern, the Liftking engineers favorably considered their previous performance, maintenance and global support experiences with the manufacturer in reaching the 16M decision.

Liftking engineers chose to power the 16M with a 134-hp engine that meets both EU Stage V and U.S. EPA and CARB Tier 4 Final emission standards.

McElroy Manufacturing chose the same engine for its new iSeries TracStar tracked, hydraulic fusion machines, but for a different primary reason. TracStar machines are a key technology for modern thermoplastic pipelines, and they are used in remote locations and harsh environments all over the world.

The iSeries offers three levels of control ranging from manual to fully automatic operation. This control flexibility is a reaction to the industry’s ongoing shortage of qualified operators, making the iSeries more easily used by operators at all experience levels.

Along with the advanced control systems, McElroy engineers wanted to update the iSeries engines to Stage V and Tier 4 Final compliant models. So, for McElroy, the decision was driven by:

• The engine manufacturer’s authorized distributor support was available virtually everywhere an iSeries machine might be operating

• Global emission compliance

• The engine’s performance

These examples are among many thousands of decisions that have been made by OEMs over the last few years to embrace changing market conditions, emission standards and emerging Environmental, Social and Governmental matters. Change may really be the only constant, but it’s consequences often tend to look very familiar.

Perhaps Karr was onto something. | Robert Bezner is North America regional marketing manager for Perkins Engines.

•

•

•

•

•

•

By using

by Mark Vandersluis, SuperGrip Controls

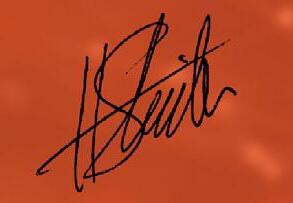

The No. 1 cause of workplace injury is overexertion, which can happen while lifting, pushing, pulling, holding or carrying objects. In recent years, these injuries cost businesses $13.7 billion, or 23.5% of the overall national burden, according to the Workplace Safety Index. To prevent overexertion-related injuries, it is recommended that companies provide their employees with ergonomic equipment. This article details six considerations when designing and choosing a joystick.

Ergonomics is the design of a product to match the individuals that use it. However, because everyone in the world is unique, ergonomics can be subjective. Anthropometry, the science that defines physical measures of a person’s size, form and functional capabilities, according to The National Institute for Occupational Safety and Health, is a way to quantitatively define the ergonomics of the demographic for the product.

The first step is to identify the demographic being targeting and

determine what physical dimensions are important for the application. In joysticks, these are generally the arms, hands, thumb, wrist and fingers.

By using anthropometric databases, smallest and largest physical dimensions for a population are evaluated, and a product is designed that can be used comfortably by both. By using inhouse 3D printers, rapid

ergonomic equipment, you’re not only prioritizing operator comfort and preventing injuries, but you’re also increasing

prototypes can be developed and shared with expert users early in the design process to validate the dimensions and get feedback specific to different industries, machines and applications.

The faceplate (see Figure 1) is a design that reflects user feedback. After accounting for a range of thumb lengths and sizes and considering feedback from expert users, this dual-angle faceplate moves the upper controls closer to the

user’s thumb. This reduces the need to reach, which improves control and minimizes thumb strain. The faceplate angle also matches the natural resting position of a thumb.

A triangular shaped faceplate, a feature of some handles, matches the natural arc of the user’s thumb, so they can easily reach the faceplate functions. The spacing between components has been optimized to prevent accidental activation with and without gloves.

In some applications, such as a single, centrally positioned joystick, a handle that can be used with either the right or the left hand can be useful. While in other applications, right and lefthand specific handles provide better comfort and control. When it comes to ergonomics, right and left-hand specific controls are superior.

In development of some joysticks, through studies and feedback sessions, the natural position of a user’s wrist

COME AND SEE US!

From March 14 to 18, 2023, “Smart actuation for smart applications” is our theme at the international trade show for the latest innovations and expertise in the fluid power, power transmission and motion control industries. Get a close-up look at our electrified, connected and sustainable products: Off Highway Solutions with an outstanding performance and a very small installation space.

We look forward to hearing your thoughts and showing you why we are the ideal development partner for your future projects.

Christoph Thomas Mathew Alagna CHIEF EXECUTIVE OFFICER, CUSTOMER OFFICER, THOMAS GROUP MAGNETE USA, LLC

MAGNETE USA, LLC

DIRECTOR OF SALES

DIRECTOR OF SALES

SOUTH 3-4 · BOOTH S-81741

when holding a joystick is inclined inward by approximately 10 degrees relative to the forearm.

As shown in Figure 2, this was taken into account in the joystick and this angle was built into the grip. This provides a more comfortable operating position and simplifies the cab design and installation process by eliminating the need for complicated mounting platforms or armrests.

One piece of feedback during development was that many ergonomic right and left handles are directive, forcing users to hold the handle in one way. In real-use situations, being able to change the grip style can help prevent fatigue and injury.

With some joysticks, this feedback was included, and handles were designed to be comfortable in different hand positions.

Position sensors for stroke measurement in hydraulic cylinders

Dynamically compensated inclination sensors for precise angle measurement

Compact safety rotary encoders for position and speed measurement

SIKO Products Inc. – www.siko-global.com

Configurability is another key characteristic of an ergonomic handle because different applications need different controls.

Multiple faceplate and trigger control options allow designers to select the perfect layout for the application.

In some joysticks, new high-visibility LED buttons have been introduced. They are visible in full sunlight but can be adjusted to the right brightness for the application to reduce strain on the user’s eyes. The RGB LEDs can be configured to any color, customized to provide user feedback and are available with a custom graphics, making machine use intuitive and efficient.

An ergonomic handle’s benefits are useless if the handle cannot withstand the environments in which it’s used. For this reason, durability is crucial when choosing any handle.

Joysticks must undergo stringent testing to the highest industry standards to make sure they perform in the most extreme situations. For example, some joysticks are tested to withstand temperatures between -40°C to +85°C, high amplitude vibration and shock, salt fog exposure, and cycled to 5 million cycles or 20 million operations.

Some joysticks are fully enclosed, rated to IP69K above the panel and IP67 below the panel. This means the entire joystick is waterproof and protected from dust, dirt and liquids.

Ease of use is an important benefit. Many design techniques are available to ensure a joystick’s handle helps reduce operator fatigue and the risk of repetitive strain. For example, using an intuitive trigger rather than buttons or rollers better fits an operator’s natural motion. Capacitive operator presence sensing that does not require mechanical activation should be included. |

OEMs of small off-road vehicles need a plug-andplay solution to add durable on-road signaling capabilities to their equipment. A new all-in-one device provides the answer.

by Chris Do Vale, APEM

by Chris Do Vale, APEM

Avariety of smaller vehicles are designed primarily for off-road use. Whether intended for work or pleasure, these machines—including lawn and garden equipment, tractors, recreational vehicles and commercial equipment— may occasionally need to move on-road for brief periods. Original equipment manufacturers (OEMs) supplying this equipment often need a way to provide some on-road controls and signaling functionality without undergoing extra development costs.

For these common design situations, there is a simple and economical plugand-play switching device option, enabling OEMs to easily provide the standardized basic functionality needed for safe on-road driving. This vehicle instrumentation and control solution can be ideal for manufacturers to provide basic on-road capabilities an off-road vehicle.

On-road vehicles typically need a few basic signaling controls:

• Horn momentary pushbutton

• Headlight and running light controls (parking, low beams and high beams)

• Turn signals (left, right and cancel)

Anyone who has operated a registered, roadworthy car is familiar with these essentials, which are used almost every time the vehicle is operated. However, what is the best way to add these devices to an off-road vehicle, where the functions are only used intermittently? And what is the best way to ensure that these controls work reliably under all conditions, since many off-road vehicles have open cabs or cockpits, which expose the controls to environmental extremes?

Designers can select and arrange individual outdoor rated buttons and switches for the task, but this adds complexity and increases installation cost. Also, the resulting look-and-feel may be inferior to what a user commonly experiences with on-road vehicles. A better approach is necessary, one provided by a new solution.

To address these and other concerns, an all-in-one standardized component has been needed and is now available. This device combines all the key functions into a single unit, and it provides the user interface format familiar to drivers everywhere (see Figure 1). Any device considered for this service must meet the following requirements. A large, red momentary-push horn button is easily seen and accessed by the operator.

The multiposition rotary switch allows users to select headlight and running light options or to turn off the vehicle lights. A three-position lever allows users to select or cancel left and right turn signals. All three functions are indicated with universal markings, so the legends are recognizable by any user.

Proper sealing is critical to ensure these types of signaling device can survive the elements. Designers should verify the device is rated for IP67 according to IEC 60529, which means it is protected against solids and dust intrusion, and it can remain immersed

“All contacts should be capable of operating at a standard vehicle voltage of 12 volts DC, with a current carrying capacity of 10 amps or 15 amps, and no greater than 25 megaohms of resistance.”

in water while under pressure for short periods of time.

Furthermore, because vehicles may be operated in environments ranging from deserts to the arctic, a wide operating temperature range is needed, for example -40°C to more than 85°C (-40°F to more than185°F).

Devices made from polyamide (PA) nylon are a good choice for this service because they offer superior wear and impact resistance, combined with good temperature stability.

Many vehicles use a relatively standard instrument/gauge hole size of 2-1/16 inches (52 millimeters) diameter, so designers will find that a signaling device

which can be installed in this size dashboard or panel cutout simplifies planning and installation.

From an electrical standpoint, all contacts should be capable of operating at a standard vehicle voltage of 12 volts DC, with a current carrying capacity of 10 amps or 15 amps, and no greater than 25 megaohms of resistance. This ensures that the contacts can directly operate common loads, or they can reliably energize interposing control relays.

For best installation convenience and reliability, the device should be provided with a short pigtail connectorized with

The new Load-Control Valve for Winches, series LCW, offers up to 40% lower pressure losses compared with commercially available valves. Other advantages are in particular the reduced pilot oil consumption and the integrated pilot pressure bypass valve. bucherhydraulics.com

an automotive-type plug, intended to mate with an associated socket. The plug and socket must have a locking mechanism and sealing provisions to properly resist the vibration and moisture that can be experienced in offroad operation.

For the moving elements of the switches, an electrical life of at least 10,000 cycles should be specified, established through conservative testing, which implies a much longer useful life. As with many other industrial and marine applications, designers must specify that the devices are sized and rated to meet the need but provided durability where it counts so they can handle some mistreatment while remaining functional (see Figure 2).

OEMs for all types of consumer, commercial and industrial small, off-road vehicles already invest significant effort in developing their products. Simply because these vehicles move, there is a good chance that many may need some amount of on-road capability, which includes the requirements for operators to use a horn, turn signals and lighting.

By selecting a thoughtfully designed and suitably rated plug-and-play signaling control device, these OEMs can deliver this capability in a safe, reliable, and useful manner for their customers, without incurring the significant expense and risk of custom design |

CO-LOCATED WITH CONEXPO-CON/AGG (two shows, one price)

The International Fluid Power Exposition (IFPE) is the place where engineers meet to:

Spark new ideas with in-depth technical conversations with other engineers.

Discover solutions current suppliers can offer to your unique challenges.

Find new partners among suppliers pushing the envelope on what fluid power can do.

Including Bosch Rexroth , Danfoss Power Solutions , Parker Hannifin , Poclain , IFM Efector , Hawe Hydraulik , Husco , and 375+ more!

Join your peers from these OEMs: Caterpillar Inc

Volvo Construction Equipment

∙ Liebherr

∙ CASE Construction Equipment

Komatsu

John Deere Construction

Doosan Bobcat

KOBELCO Construction Machinery USA

∙ LBX Company

“ There’s no other show in the world I think that brings the OEM machine manufacturers and the suppliers as close together as this show. It’s a good place to meet and learn about what’s going on. In the Americas, in the Western Hemisphere, this is the show for fluid power.”

KEN ROSENBECKER SALES MANAGER NORTH AMERICA | WIPRO INFRASTRUCTURE ENGINEERING

IFPE only happens once every three years!

SAVE 20% OFF REGISTRATION Register now at IFPE.com and type AD20 in the Promo Code box

MARCH 14-18, 2023 LAS VEGAS, NV, USA

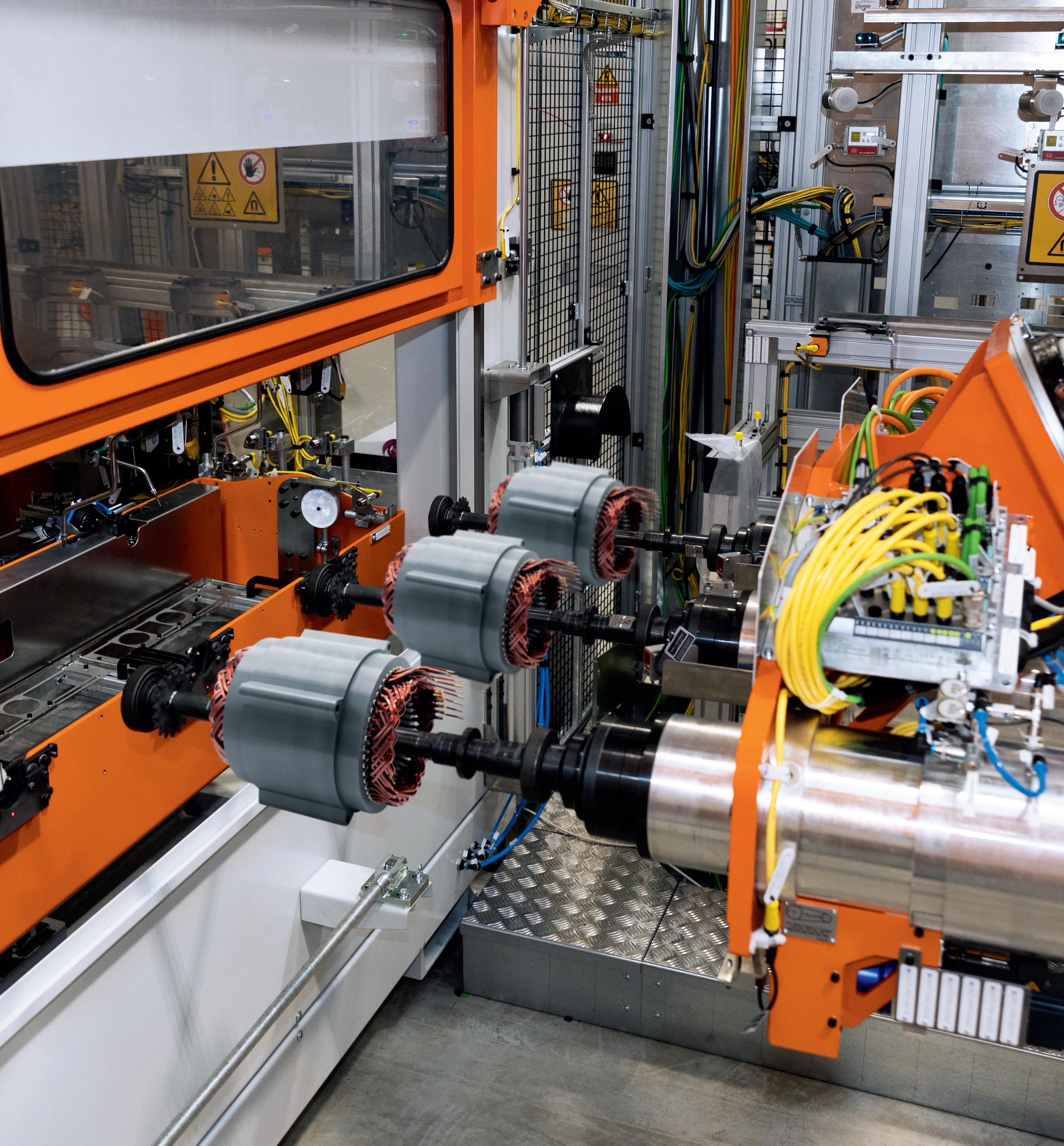

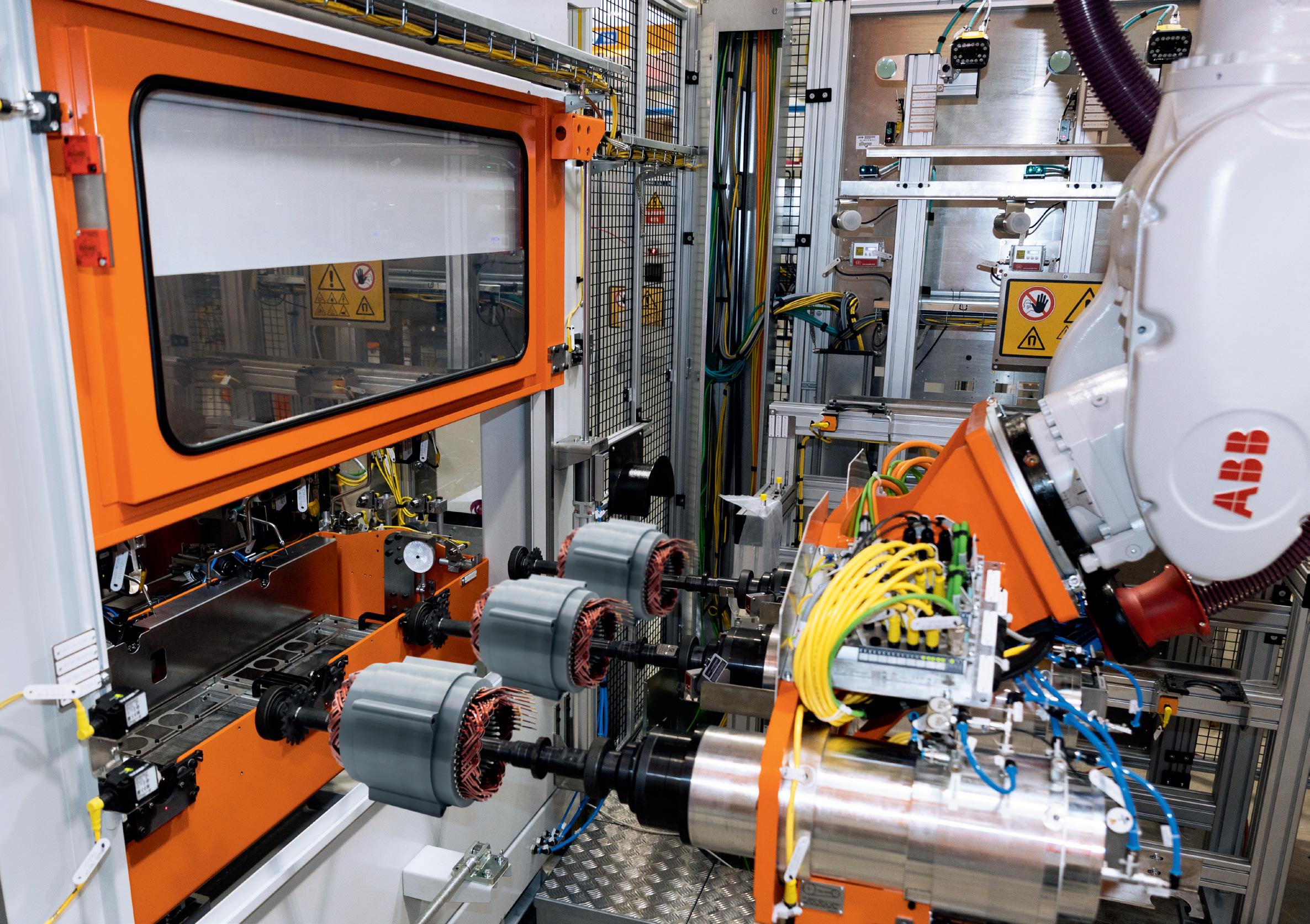

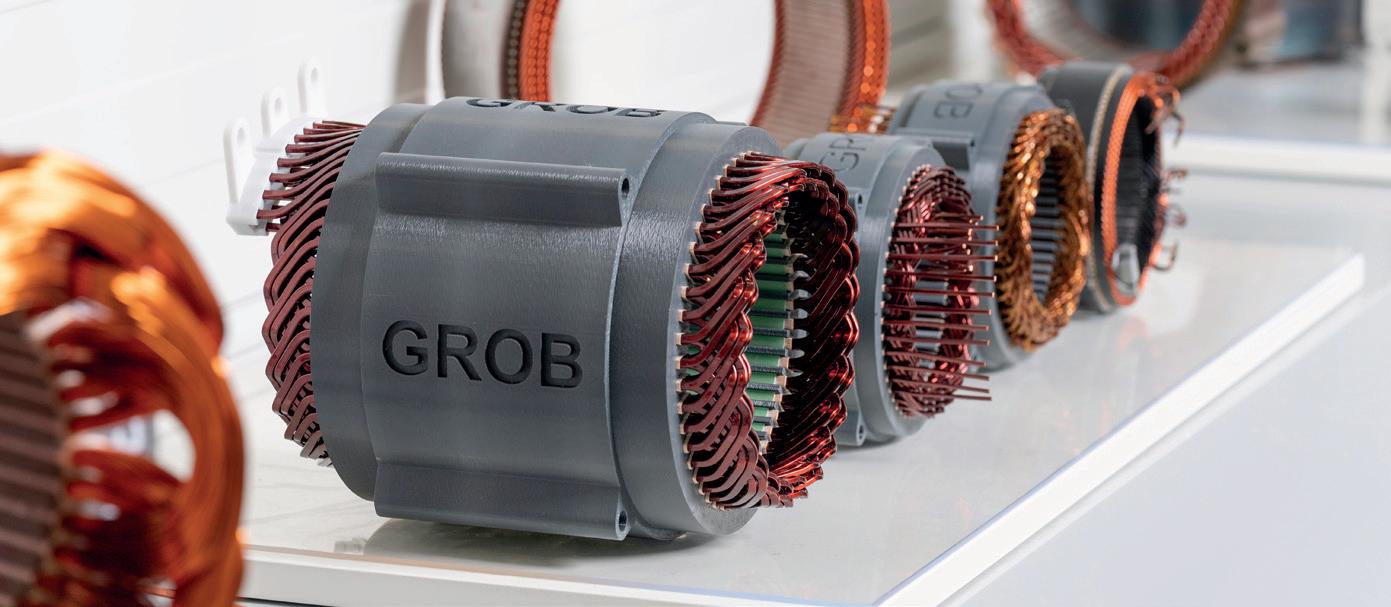

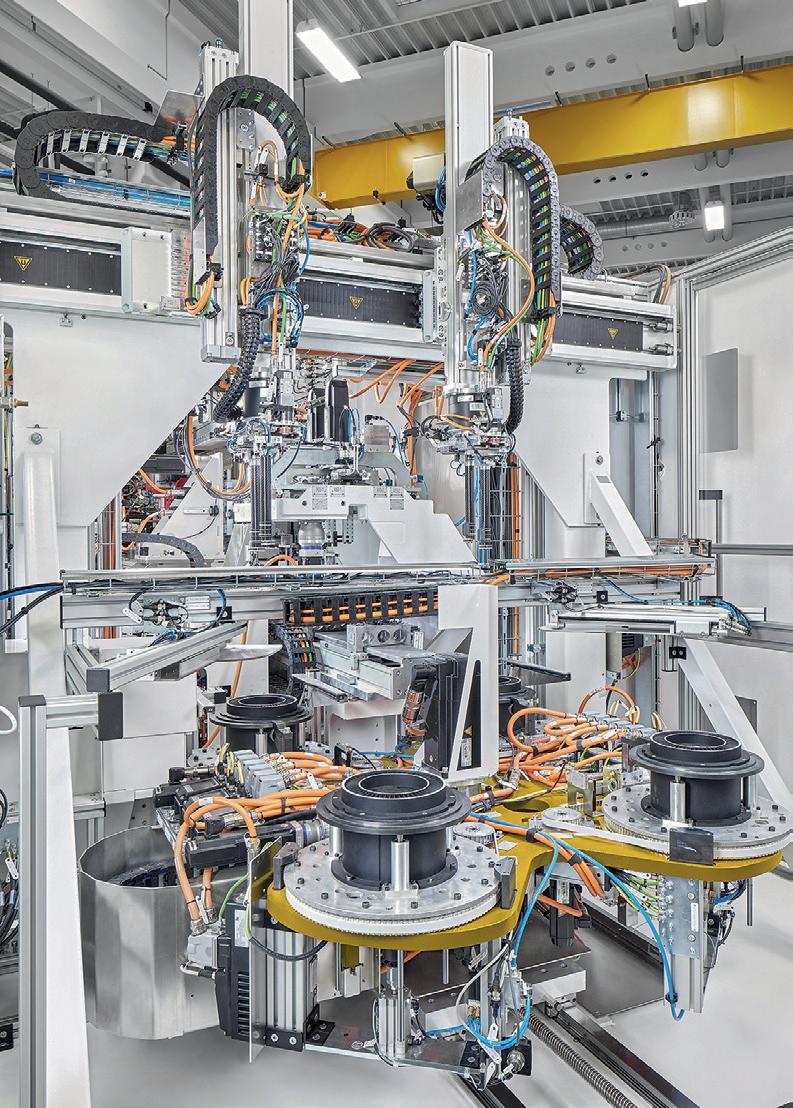

by Glenn Oshel, GROB

by Glenn Oshel, GROB

It’s no secret that most light vehicle OEMs have committed to fully electric fleets within the decade. Regardless of one’s opinion of the viability, performance or economics of electric vehicles, the world is transitioning from combustion engines to electric power. This movement is being felt in the construction equipment field and will only become more and more prevalent in the coming years.

In a short period, electric motors for passenger vehicles have evolved to offer balances of speed, acceleration and efficiency. Heavy construction and agricultural equipment have more and different requirements. Speed is replaced by torque. Acceleration is replaced by power. But the beauty of electric motors is that they perform differently by changing voltages and currents. Many design characteristics can help maximize performance metrics.

In fact, several motor types are wellsuited for the construction industry.

Synchronous permanent magnet motors (think wheel loaders) and asynchronous Induction motors (think fork trucks) are well-understood and commonly used. Several variations are available.

Synchronous reluctance motors, for

example, can give the performance of the permanent magnet motor, without the magnets. No one motor is best for all applications.

Whatever the type of motor the vehicle requires, original equipment manufacturers (OEMs) are increasingly facing difficult decisions to produce

their own motors or purchase them from Tier I suppliers. Uncertainty in the electric market and rapidly changing technologies, make this decision difficult and fraught with very expensive risks.

This article presents basic considerations for make-buy decisions of electric motors and strategies for in-house production that adapt to changing demands and technologies.

All traction motors have three principle assembly commodities: the stator; the rotor; and the complete motor assembly (for example, housing, bearings and gears). Three primary sourcing strategies for motors are available:

1. Purchase the complete motor assembly from a Tier I producer. This can be the OEM’s own design or an off-the-shelf unit of the supplier’s design.

2. Purchase the rotor and stator from a Tier I supplier, and the OEM

assembles them into the motor assembly. The stator and rotor can be produced to the OEM’s own design or designed by the supplier or other third party.

3. The OEM designs and assembles its own stator, rotor and motor.

Deciding to purchase motors or manufacture them in-house really starts with the OEM’s knowledge and experience of designing efficient electric motors. Many OEMs starting to venture into electric powertrains often lack the proper resources to confidently design their own motors. For them, the clear choice is to purchase finished drive units from a reputable Tier I supplier. Normally, the OEM can work with the Tier I supplier to customize the performance metrics to meet the application.

If the OEM has team of experienced motor designers, then any sourcing strategy can be pursued, and the commercial side of the decision becomes the primary driver.

In-sourcing motor production is capital intensive. Depending on the type of motor, stators are the most expensive and difficult component to produce. For this reason, every consideration must be made for the design of the stator. In order of investment, a coil-wound stator requires the least investment; a continuous hairpin stator is the next most expensive, and a hairpin stator is the most capital-intensive solution. That said, traditional hairpin stators dominate most design choices and have a number of functional benefits.

Likewise, capital investment in rotor assembly depends on the type of rotor. Generally, induction rotors use axially inserted conductor rods and are the most economical to assemble. Permanent magnet motors depend on many individually-placed magnets in multiple laminate stacks. Often, hundreds of these magnets could be in a rotor. The method to secure the magnets (interference fit, adhesive or overmolding) also has an impact. Overall, permanent magnet rotors require a larger investment than induction rotors.

Kawasaki is a world-leader in pump efficiency and performance. Inside our range of products you’ll find some of the most efficient axial piston pumps available on the market today. Our engineers understand our customers’ needs, each pump has been designed to deliver high performance across a diverse range of applications.

However, choosing an induction or permanent magnet rotor should based on the application, not cost.

Besides the stator and rotor design, the second consideration is production demand. Demand should not be thought of as maximum annual units. The projected fluctuations year-to-year

are important for making decisions.

If some years have a drop in demand, will the OEM be comfortable paying for equipment not fully used in those years? In these cases, some OEMs choose a hybrid approach. They in-source the stable portion and contract with a supplier for the overflow demand.

Considering changing market demands makes it challenging to right-size production systems. Some motor manufacturers offer multiple production lines that fit OEM needs regardless of capacity. New OEM entrants first purchase low volume systems. These systems are beneficial for several reasons:

• They become a training lab for the customer.

• The customer can produce its own prototypes.

• They have just enough capacity to produce any special niche motors.

The market is changing fast and the transition to electrified construction equipment is inevitable. With selfappraisal of resources and skill levels, OEMs can prepare to make the best decisions for the types of motors to and their production.|

Glenn Oshel is key accounts director, e-mobility, GROB Systems, Inc.

Read more: https://oemoh.co/7f7szr

The latest Curtiss-Wright Tractor Inverters (CWTIs) are for use in hybrid and pure-electric applications for on-highway and off-highway commercial vehicles.

The latest models launched as 420-kW vehicle-grade traction inverters for single or dual motor applications. Both models operate with multiple motor technologies, including AC-induction, permanent-magnet-synchronous and interior-permanent-magnet (IPM) types, to ensure improved range, longer battery life and lower operating costs. www.oemoffhighway.com/22314666

SignalFire Wireless Telemetry announced the addition of the new DIN RANGER to its family of sensor-to-cloud cellular data transmission products. This new DIN-rail-mountable, DC-powered version of the RANGER is for applications with existing power and panel boxes.

The DIN RANGER requires less than 2.5 mA of external DC power, while also offering more inputs and outputs. Because of the low-power features of LTE-M & NB-IoT cellular technologies, the DIN Ranger integrates with Modbus RTU devices, offering an always-on, bidirectional connection with a cloud application over cell networks. These products use the open MQTT/Sparkplug standard, which is quickly becoming the preferred protocol for distributed industrial sensor networks. The RANGER is also offered as hardware only—untethered to the cloud.

www.oemoffhighway.com/22340209

Gearmatic added a line of hydrostatic track drives to the company’s product mix with torque output ratings from 12,539 pound-foot to 162,264 lb-ft (17,000 Nm to 220,000 Nm). The TD Series offers different gear ratios and mounting options among the 11 models, providing a full-line solution of new or replacement drives for tracked vehicles in industrial applications.

Built for performance and reliability, the heavy-duty TD Series is designed for easy installation, minimal maintenance and universal fitment with ISO and SAE hydraulic motors. The compact profile is ideal for space-critical mounting configurations while increasing the overall efficiency of the undercarriage.

PACCAR Winch planetary gear boxes feature a main bearing system with high load carrying capacity. All TD Series models feature a spring loaded, hydraulically released multi-disk parking brake with braking torque set in accordance with specific application needs. The sealed design prevents moisture and dirt from infiltrating the drive. Gearmatic TD Series track drives are available for new fitments and retrofit applications.

www.oemoffhighway.com/22366490

Briggs & Stratton announced the launch of the new Vanguard 7 kWh Diecast Commercial Battery. The 7 kWh pack comes as an answer to OEMs’ requests for a flexible battery solution that can be used in a wider variety of applications. With this latest addition, Vanguard offers a competitive range of battery power solutions.

www.oemoffhighway.com/22353977