PAGE 12 SEPTEMBER/OCTOBER 2023 oemoffhighway.com LEADING AGRICULTURE’S TRANSITION TO NET-ZERO Volvo Penta on the challenges facing today’s OEMs & the farming community + 8 Questions on Connectivity in the Era of Electrification

GET FIERCE AT WWW.CAT.COM/MEDIUM-HEAVY-ENGINES © 2023 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow,” the “Power Edge” and Cat “Modern Hex” trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. fierce in fierce conditions. POWERFUL ENGINES THAT DON’T STOP. Cat ® engines provide exceptional power in a smaller, lighter package, so you can upgrade your performance with a durable and proven engine design, even in the harshest environments.

34

WEB EXCLUSIVES

Video Network oemoffhighway.com/videos

OEM Industry Update oemoffhighway.com/podcasts

Premium Content oemoffhighway.com/premium-content

SENSORS & CONNECTIVITY

10 Optimizing Agricultural Sprayers With Inclinometer Technology Learn how this component contributes to precise coverage in agriculture applications

ELECTRICAL & ELECTRONICS

12 Mobile Hydraulics & the Shift to an IoT Environment

Bosch Rexroth’s Enrique Busquets answers 8 questions on connectivity in the new era of electrification

FEATURE SERIES

14 Leading Agriculture’s Transition to Net-Zero

Volvo Penta’s take on the market challenges facing today’s OEMs & the farming community

20 Agriculture Goes Electric

Exploring the benefits, challenges & drivers of electrification

EVS IN CONSTRUCTION

24 Are Electric Construction Vehicle Design Delays Avoidable? Know which factors are slowing down the process & how to solve the problem

AWARDS

26 OEM Off-Highway's 2023

Top New Products

This year's winners highlight the ingenuity & innovation behind some of today's best product offerings

3 OEM Off-Highway | SEPTEMBER/OCTOBER 2023 CONTENTS VOLUME 41, NO. 5 | SEPTEMBER/OCTOBER 2023 14 10 24 12

4 EDITOR’S NOTE EQUIPMENT MARKET OUTLOOK

a Low as Construction Rentals Are on the Rise

6 US Industrial Sector Approaches

OFF-HIGHWAY HEROES

The First Self-Loading Haulers

In August, I had the opportunity to attend the National Fluid Power Association’s Industry & Economic Outlook Conference, where top economists and covered critical data from the fluid power, construction and agriculture equipment markets. These pros are predicting a manufacturing plateau and mild recession in 2024, but suggest 2025 will be an area for opportunity and accelerating growth. For deeper data, turn to page 6 or visit oemoffhighway.com for our monthly update from ITR Economics.

In September, be sure to look for our team at these upcoming industry events and trade shows: The Electric & Hybrid Vehicle Tech Expo and The Battery Show (Sept. 12-14), COMVEC (Sept. 19-21 and The Utility Expo (Sept. 26-28). Please feel free to stop by our booth for a visit, or follow us on social media for up-to-the-minute, on-site coverage.

Meanwhile, we invite you to join us for the OEM Industry Summit, taking place wherever you’re connected, Oct. 31 to Nov. 2. Registration is free, and our lineup of industry experts is set to deliver three days of virtual, educational sessions covering a range of topics from electrification to automation to operator environment — all specially structured for equipment designers and engineers. Register now at oemoffhighway.com or scan the code below for quick and easy access. Take care,

Scan to register!

EDITORIAL ADVISORY BOARD

Craig Callewaert, PE, Chief Project Manager, Volvo Construction Equipment

Roy Chidgey, Business Segment Head, Minerals Projects and Global Mobile Mining, Siemens Large Drives US

Andrew Halonen , President, Mayflower Consulting, LLC

Terry Hershberger, Director, Sales Product Management, Mobile Hydraulics, Bosch Rexroth Corp.

Steven Nendick, Marketing Communications Director, Cummins Inc.

John Madsen, Director Engineering & Product Management, GKN Wheels & Structures

Doug Meyer, Global Director of Construction Engineering, John Deere

Andy Noble, Head of Heavy Duty Engines, Ricardo

Daniel Reibscheid, Business Development Manager, MNP Corporation

Matt Rushing, Vice President, Product Line, Global Crop Care, AGCO Corp.

Allen Schaeffer, Executive Director, Diesel Technology Forum

Keith T. Simons, President – Controls Products, OEM Controls, Inc.

Alexandra Nolde , Senior Communication & Media Specialist, Liebherr-Components AG

Bob Straka, General Manager, Transportation SBU, Southco, Inc.

Luka Korzeniowski, Global Market Segment Leader, Mobile Hydraulics, MTS Sensors

Chris Williamson, PhD, Senior Systems Engineer Global Research & Development, Danfoss Power Solutions Company

EDITORIAL

Editor Kathy Wells kwells@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Senior Editor, Construction Technology, IRONPROS Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Kimberly Fleming kfleming@acbusinessmedia.com

ADVERTISING/SALES

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Sales Representative Greg Schulz gschulz@acbusinessmedia.com

Sales Representative Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Kris Flitcroft kflitcroft@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Service Bethany Chambers

Director, Demand Generation & Education Jim Bagan

Content Director, Marketing Services Jess Lombardo

CIRCULATION & SUBSCRIPTIONS

PO Box 3605 Northbrook, IL 60065-3605, Phone: 877-201-3915 Fax: 847-291-4816 circ.OEMOff-Highway@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo, Data Axle 402-836-2768 | bart.piccirillo@data-axle.com

REPRINTS & LICENSING

Sales Representative Greg Schulz 920-542-1239 | gschulz@acbusinessmedia.com

Published and copyrighted 2022 by AC Business Media. All rights reserved. No part of this publication shall be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

SUBSCRIPTION POLICY: Individual print subscriptions are available without charge in the United States to original equipment manufacturers. Digital subscriptions are available without charge to all geographic locations.

Publisher reserves the right to reject nonqualified subscribers. Subscription

Prices: U.S. $35 One Year, $70 Two Years; Canada and Mexico $60 One Year, $105 Two Years; all other countries, payable in U.S. funds, drawn on U.S. bank, $85 One Year, $160 Two Years.

OEMOff-Highway (USPS 752-770, ISSN 1048-3039 (print); ISSN 2158-7094 (online) is published 6 times a year: January/February, March/April, May/June, July/August, September/October and November/December by AC Business Media, 201 N. Main Street, 3rd Fl., Fort Atkinson, WI 53538. Periodicals Postage paid at Fort Atkinson, WI and additional entry offices. POSTMASTER: Send address changes to: OEMOff-Highway, PO Box 3605 Northbrook, IL 600653605. Printed in the U.S.A.

@oemoffhighway @oemoffhighway @oem-off-highway @oemoffhighway

Published by AC Business Media 201 N. Main Street, Fort Atkinson, WI 53538 800-538-5544 acbusinessmedia.com oemoffhighway.com ironpros.com

EDITOR’S NOTE 4 2023 SEPTEMBER/OCTOBER | OEM Off-Highway

U.S. Manufactured Automotive Vision Safety Products Since 1907

designed and engineered for demanding off-road environments and challenges

Rosco products are made with 115+ years of experience in engineering, automotive vision studies, and vehicle and operator safety.

From tempered mirrors and padded/acrylic visors to AI-powered HD cameras and sensors, Rosco products are ruggedized for the demands of the off highway enviroment.

www.roscovision.com www.roscomirrors.com

US INDUSTRIAL SECTOR APPROACHES A LOW, CONSTRUCTION RENTALS ON THE RISE

In our continued analysis, this month’s data indicates an approaching low for the U.S. industrial sector. On the construction machinery front, higher interest rates, waning corporate profitability and housing market struggles suggest weakness ahead for new orders,

with equipment rentals likely growing in popularity relative to equipment purchases. The following provides a summary of key observations across 13 economic indicators and areas of industry that contribute to today’s global economic conditions.

US Leading Indicator

• The monthly rate-of-change for the U.S. OECD Leading Indicator rose in June.

• The monthly rate-of-change’s December 2022 low signals a possible late-2023 business cycle low for the U.S. industrial sector. However, the preponderance of evidence suggests a later low is more likely. This evidence includes excess inventory of durable goods relative to sales, rapid (though uneven) supply chain loosening, interest rate movements, and money supply tightening.

US OECD Leading Indicator -2.5 -2.0 -1.5 -1.0 -0.5 0.0 -2.1 -2.2 -2.2 -2.1 -1.9 -1.6 -1.3 -0.9 Jun May Apr Mar Feb Jan '23 Dec Nov '22 2023 SEPTEMBER/OCTOBER | OEM Off-Highway 6 oemoffhighway.com/economics EQUIPMENT MARKET OUTLOOK Sponsored by Eberspächer @ROMAN – STOCK.ADOBE.COM ITR Economics is an independent economic research and consulting firm with 60+ years of experience.

Visit oemoffhighway.com to sign up for our monthly ECONOMIC NEWSLETTER. Editor’s Note: Please note that this chart has been modified on the Y-axis to show the trend more easily.

US Industrial Production US Private Nonresidential New Construction

• U.S. Industrial Production in the second quarter was roughly even with levels from the second quarter of 2022. The quarterly average is moving lower.

• Hawkish behavior by the Fed supports our expectation for further decline as interest rates climb. Continued downward movement in the U.S. Total Industry Capacity Utilization Rate also supports probable further decline for Production.

• U.S. Private Nonresidential New Construction in the three months through May rose to $160.9 billion, up 20.2% from the same period one year ago. Growth in quarterly Construction is starting to slow.

• Rising interest rates will hamper demand for new construction starting next year; prepare accordingly.

US Total Public New Construction

• U.S. Total Public Construction in the 12 months through May came in at $391.2 billion, 8.9% above the same period one year ago. Growth is accelerating.

• Annual Construction is expected to follow an upward trajectory, bolstered by funding from the federal infrastructure package. Look to opportunities in areas like water/wastewater and transportation.

A WORLD OF COMFORT

Airtronic and Hydronic Heaters

Eberspächer offers a diverse selection of fuel-operated heaters, including the high-performance Airtronic S3 Commercial/M air heater and the innovative Hydronic S3 Commercial water heater, ensuring driver/operator comfort in any environment.

0 2 4 6 8 10 3.5 4.4 5.2 6.1 6.7 7.3 7.9 8.9 May Apr Mar Feb Jan '23 Dec Nov Oct '22 Annual % change in 12 month moving totals US Total Public New Construction 0 5 10 15 20 25 13.8 13.6 13.9 16.2 18.6 20.8 20.5 20.2 May Apr Mar Feb Jan '23 Dec Nov Oct '22 Annual % change in 12 month moving totals US Private Nonresidential New Construction 0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 3.2 1.9 1.4 1 0.7 0.7 0.4 0.2 Jun May Apr Mar Feb Jan '23 Dec Nov '22 Annual % change in 3 month moving totals US Industrial Production OEM Off-Highway | SEPTEMBER/OCTOBER 2023 7

| MORE AT EBERSPAECHER-OFF-HIGHWAY.COM

Sponsored by Eberspächer

US Farm Machinery Production Europe Ag & Forestry Machinery Production

• Annual U.S. Farm Machinery and Equipment Shipments in May were 12.3% below the year-ago level; the severity of contraction is increasing.

• Volatile food commodity prices and elevated interest rates could hamper demand for farm equipment.

• Annual Europe Agricultural and Forestry Machinery Production was at 11.3% above the year-ago level in May, reaching record highs.

• This industry may contend with downward pressure stemming from high interest rates moving into 2024.

Europe Leading Indicator

• The Four Big European Nations Leading Indicator monthly rate-of-change moved higher in June, though the monthly Indicator value edged lower.

• Growth in Europe faces headwinds in the form of prolonged elevated inflation and rising interest rates; decline in regional industrial activity is likely to extend into at least next year.

Editor’s Note: Please note that this chart has been modified on the Y-axis to show the trend more easily.

US HeavyDuty Truck Production US Mining Production Germany Industrial Production

• Average U.S. Heavy-Duty Truck Production in the 12 months through June was 13.4% above the year-ago level. Growth is slowing.

• Truckload pricing is sharply declining as truck tonnage moves mildly lower, suggesting lower demand; expect headwinds in this industry to extend into next year.

• U.S. Mining Production growth is slowing. The June annual average was 6.7% above the year-ago level.

• General decline in the U.S. Mining Capacity Utilization Rate monthly rate-of-change supports our outlook for further slowing growth for annual Production during at least the coming quarters.

• Germany Industrial Production in the three months through May was at 0.3% below the same three months one year earlier.

• While the auto industry is recovering at a double-digit clip from the supply chain woes of the pandemic, a number of more B2Bfocused industries, like machinery and chemicals, are declining.

0 5 10 15 20 14.6 12.6 15.2 16 16.6 15.2 15.3 13.4 Jun May Apr Mar Feb Jan '23 Dec Nov '22 Annual % change in 12 month moving totals US Heavy-Duty Truck Production 0 2 4 6 8 10 12 10.6 10.1 10.2 8.7 7.5 8 7.5 6.3 Jun May Apr Mar Feb Jan '23 Dec Nov '22 Annual % change US Mining Production -2.0 -1.5 -1.0 -0.5 0.0 0.5 1.0 1.5 2.0 1.7 0.2 -2 0.2 -0.1 1.8 0.4 -0.3 May Apr Mar Feb Jan '23 Dec Nov Oct '22 Annual % change in 3 month moving totals Germany Industrial Production Monthly index Europe Leading Indicator -4.0 -3.5 -3.0 -2.5 -2.0 -1.5 -1.0 -0.5 0.0 -3.9 -3.5 -3 -2.4 -1.8 -1.2 -0.7 -0.3 Jun May Apr Mar Feb Jan '23 Dec Nov '22 0 2 4 6 8 10 12 3.5 4.6 4.6 6 7.6 9.7 10.8 11.3 May Apr Mar Feb Jan '23 Dec Nov Oct '22 Annual % change Europe Agriculture Machinery Production -15 -12 -9 -6 -3 0 3 6 9 12 9.4 7.3 3.2 -0.3 -2.6 -6.1 -9.1 -12.3 May Apr Mar Feb Jan '23 Dec Nov Oct '22 Annual % change in 12 month moving totals US Farm Machinery and Equipment Supplies 2023 SEPTEMBER/OCTOBER | OEM Off-Highway 8 oemoffhighway.com/economics EQUIPMENT MARKET OUTLOOK

US Construction Machinery, New Orders US Defense Industry, New Orders

The most recent 12 months of U.S. Construction Machinery New Orders came in at a record-high $47.4 billion, a 13.2% increase from the year-ago level.

• Higher interest rates, waning corporate profitability, and housing market struggles portend weakness ahead for New Orders, with equipment rentals likely growing in popularity relative to equipment purchases.

US Mining & Oil Field Machinery Production Index

• Annual U.S. Mining and Oil Field Machinery Production ticked down slightly in June but was 6.3% higher than the year-ago level.

• Decline will likely persist in the coming quarters, but it will likely be mild relative to historical downturns due in part to elevated oil prices (provided that OPEC+ continues to cut output as economic momentum wanes).

• U.S. Defense Capital Goods New Orders in the 12 months through May totaled $167.5 billion, 19.6% above the year-ago level.

• Ongoing conflict in Europe will continue to buoy New Orders in at least the coming quarters.

NOKIAN TYRES HAKKAPELIITTA TRI

EXTEND THE ALL-SEASON CAPABILITIES OF YOUR MACHINE

The versatile Nokian Tyres Hakkapeliitta TRI brings the most winter grip to your work. Tough enough for years of extensive use, this specialist tire has excellent braking, accelerating and steering properties.

US OECD Leading Indicator -2.5 -2.0 -1.5 -1.0 -0.5 0.0 -2.1 -2.2 -2.2 -1.9 -1.6 -1.3 Jun May Apr Mar Feb Jan '23 Dec Nov '22 -5 0 5 10 15 20 -4.4 -1 3.4 7.5 8.5 11.6 18.2 19.6 May Apr Mar Feb Jan '23 Dec Nov Oct '22 Annual % change in 12 month moving totals US Defense Capital Goods New Orders 0 1 2 3 4 5 6 7 8 6.7 7 7 6.9 6.8 7.2 6.9 7.3 Jun May Apr Mar Feb Jan '23 Dec Nov '22 Annual % change in 12 month moving totals NUS Mining & Oil Feild Machinery Production Index 0 3 6 9 12 15 10 11.2 11.7 12.3 11.7 12.5 12.8 13.2 May Apr Mar Feb Jan '23 Dec Nov Oct '22 Annual % change in 12 month moving totals US Construction Machinery New Orders OEM Off-Highway | SEPTEMBER/OCTOBER 2023 9 •

Precise control and great efficiency Driving comfort on class on its own Superior traction and lateral grip nokiantyres.com/heavy

Optimizing AGRICULTURAL SPRAYERS With Inclinometer Technology

Learn how this component contributes to precise coverage in agriculture applications

by Todd Harmon

It’s no secret that technology within the agricultural sector is advancing at a rapid pace. New processes and products are seemingly developed daily that have helped to increase yield, decrease waste, and optimize labor hours. This is especially true for agricultural sprayers. The highest-performing sprayers are able to save operators time and money in large part because of one crucial component: the inclinometer.

Spraying fields requires operating on a terrain that is not perfectly flat and level. Dips and divots can result in chemicals sprayed too close or too far away from the crop canopy. This inconsistency spells trouble for end users looking to get the right amount of coverage on the entire field while optimizing their usage of chemicals.

Inclinometers in Spraying Chemicals

Spraying fields requires working on a surface that features a variety of slopes and contours. This constantly changing distance between the nozzle and the

targeted crops provides a necessary platform for inclinometer technology to help each end user prevent overspray and protect the health of their crops.

As the machinery moves over a slope, the inclinometer provides real-time measurements and communicates automatically with the boom of the sprayer. By adjusting boom height, angle or even rate of flow, the inclinometer will constantly provide feedback to bring effective coverage to the crop canopy.

In addition, inclinometers can even turn off chemical spray in situations that would result in a wasted chemical application. This requires establishing a necessary threshold and when that angle is measured, the inclinometer automatically deactivates the nozzles until angle measurement is returned within an acceptable range.

Inclinometer Components

Experts began designing inclinometers as a result of a specific customer request and found that providing advanced features is providing a widely beneficial

solution to OEMs in a variety of industries. Agriculture OEMs looking for an inclinometer solution should ensure that the sensor:

• Measures angles within the degree of accuracy required

• Provides real-time communication while utilizing the necessary output for the system

• Is housed in a rugged casing that can provide IP 69K environment rating for vibration, water and dust resistance

• Features sufficient temperature drift compensation to maintain temperature drift within an acceptable allowance

• Is sized correctly for installation and effective long-term use

And, as is the case for many manufactures, a custom solution may be necessary to provide a tilt-sensing solution that can relay a specific angle range needed for the application. This brings a level of accuracy that a more universal offering may not be designed to measure in its operation.

SPECIAL SECTION 2023 SEPTEMBER/OCTOBER | OEM Off-Highway 10 SENSORS & CONNECTIVITY

Benefits of the Right Solution

Choosing the right inclinometer solution for the necessary application can bring a wide range of benefits for sprayer OEMs and the end users that they serve. A precise and reliable inclinometer will save the end user from wasting expensive chemicals through over spray. Accurate tilt sensing will also adjust flow rate and nozzle automatically — resulting in a more productive and healthy crop yield.

Lastly, a thoughtfully engineered inclinometer will provide the level of durability and reliability needed in environments experiencing high temperature variations, dust, vibration and other environmental hazards.

All in all, the right inclinometer for agricultural sprayer applications will not only save money, but also increase crop productivity and reduce downtime from mechanical failure.

MOBILE MACHINES SENSORS FOR

Position sensors for stroke measurement in hydraulic cylinders

Dynamically compensated inclination sensors for precise angle measurement

Compact safety rotary encoders for position and speed measurement SIKO Products Inc. – www.siko-global.com

SPECIAL SECTION OEM Off-Highway | SEPTEMBER/OCTOBER 2023 11

Functional Safety up to Performance Level PLd CANFIELD CONNECTOR

Todd Harmon is vice president at Canfield Industries.

Mobile Hydraulics & the Shift to an IOT ENVIRONMENT

Bosch Rexroth’s Enrique Busquets answers 8 questions on connectivity in the new era of electrification

As mobile hydraulics continues its transition to electrification, companies are asking about and investing in connected machines that provide valuable, realtime performance data.

To address questions on the topic, OEM Off-Highway sat down with Dr. Enrique Busquets (EB), engineering director at Bosch Rexroth. Busquets is the mobile hydraulics engineering director responsible for regional product and business development for electronics, software, telematics and electrification at Bosch Rexroth North America.

He holds a bachelor’s degree from the University of Texas at El Paso and both a master’s and doctorate degree in mechanical engineering from Purdue University — with emphasis on hydraulic and electronic controls.

Read on for his key insights into market trends and learn what today’s executives need to consider when evaluating this evolving technology.

in monitoring all systems. With the advent of electrics, this becomes even more important for additional layers of safety and control. Moreover, the implementation of electric systems in off-highway equipment eliminates all barriers for automation, which is fully complemented by connectivity. Connectivity should be viewed as a lens through which all machines can be seen and with which more value can be added for the end user.

How can companies incorporate real-time data in their connected solutions?

EB: The use of real-time data is already incorporated into the daily usage of machines in the field. The difference is whether this real-time data is used on the edge or transmitted to a remote location to either add value or make on-the-fly decisions. One of the biggest benefits of our platform is that it allows you to do both and manage the electronic resources freely to optimize each component’s bandwidth.

EB: Automation has been in mobile hydraulics for many years. From mining to agriculture, automated machine solutions have provided a significant amount of value in not only optimizing costs, but entire fleet operations. The challenge is for automation to become more versatile to address the unstructured nature of the environments in which mobile equipment operates. However, we already see several use cases in the field where automation is starting to push the boundaries. For instance, solar filed panel installations have gone autonomous in areas where the sites are remote. In this example, the combination of autonomy and remote monitoring is a key for the success of the entire operation.

What has been the learning curve or shift in training for operators with electric machines?

EB: Connectivity plays a crucial role

What role does automation play in mobile hydraulics? How are managers are monitoring these solutions remotely?

EB: This is still yet to be seen. Different from automotive, mobile applications are usually designed to meet a set of criteria that matches the work to be accomplished. In such cases, the advantages of electrics will become apparent on a case-by-case level, where each application will find the instantaneous torque capability of

@ TREECHA - STOCK.ADOBE.COM 2023 SEPTEMBER/OCTOBER | OEM Off-Highway 12 ELECTRICAL & ELECTRONICS

As operators & executives consider investing in electric solutions, what role should connectivity play in the decision?

by Kathy Wells

electric motors, or the higher efficiency and productivity of those systems advantages at different levels. One aspect that will certainly be an instant impact is the lower serviceable systems and therefore service costs.

How has connectivity improved maintenance & addressed issues faster?

EB: Connectivity in the field usually leads to faster or even remote debugging of errors or service claims. In mobile applications, the complexity of service providers and the inconvenience of a fleet being at a standstill, not to mention the sometimes-exorbitant costs behind such scenarios, makes connectivity a no-brainer. In many mobile applications, we experience small OEMs that do not have a network of dealers or service providers, which are forced to fly personnel all over the country to address field issues. Connectivity will not entirely resolve these issues, but it addresses a portion of them and facilitates service by knowing in advance what is wrong with a particular piece of equipment.

What’s the right balance of implementing hardware, software & the internet to manage mobile machines?

EB: For the field of mobile applications, there is no one-size-fits-all, nor a magic number. Differing again from automotive, mobile applications are extremely diverse. Experience has shown us that anything related to the operator assistance or controls should be handled at the machine level to avoid disruptions by poor network or lack of infrastructure. And any decisions that have to do with a fleet, or decisions that can be implemented over the course of the machine operation, can be moved to the cloud.

Is performance impacted in remote locations where internet capabilities are limited?

EB: Yes, clearly. In some instances, portable devices that provide satellite connection or personal hotspots can alleviate these issues. In other areas, some providers, such as Starlink, will

address the challenges of connecting even in the most remote areas.

How will IoT continue to evolve with the increased adoption of electric machinery?

EB: The benefits of connecting a machine have been in several instances proven with numerous use-cases. Machines which have been electrified, or that are primarily electronically

controlled, are the best candidates to fulfill these use-cases and add value to the OEMs or end users. Therefore, we at Bosch Rexroth believe that the vast majority of mobile electrified equipment will be as well connected.

OEM Off-Highway | SEPTEMBER/OCTOBER 2023 13

Kathy Wells is editor of OEM Off-Highway magazine.

Leading Agriculture’s Transition to NET-ZERO

Volvo Penta on the challenges facing today’s OEMs & the farming community

by Kathy Wells

While agriculture has long grappled with ongoing issues, such as rising costs, labor, and the viability and availability of land, today the industry is facing a new set of challenges. Ready or not, emerging technologies and environmental policies are plowing ahead, and both original equipment manufacturers and farmers are poised to lead the transition toward a net-zero environment.

Volvo Penta is a part of the Volvo Group, a global developer and

manufacturer of heavy-duty diesel engines. For agricultural harvest machines and equipment, Volvo Penta supplies a range of heavy-duty engines designed to withstand the particular demands of the agricultural industry.

Felipe Lopes (FL) is the head of sales, industrial, at Volvo Penta in Brazil, and based in Greater Curitiba, Paraná. Brazil has the most arable land in the world and has almost unparalleled potential for agricultural productivity increase. The country is now a top-five producer of 34 commodities and is the largest net exporter in the world.

In the following conversation, OEM Off-Highway shares insights from Lopes about the issues facing the agriculture industry today and how Volvo Penta is helping OEMs address these challenges.

With your knowledge of the Brazilian market & how it can be indicative of the wider industry, how is Volvo Penta leading the way in agriculture technology development?

FL: Agriculture is the main industry in Brazil. A huge percentage of GDP comes from it and one-third of the Brazilian workforce is employed by agricultural businesses. Today, a sizable percentage of Brazil’s economic exports comes from agriculture. These exports represent one billion people worldwide being fed by the products of Brazilian agriculture. It’s incredibly important.

Volvo Penta has had an opportunity and presence in Brazil, where agriculture is fundamental to the economy, and therefore has become a hub of innovation. As one of the biggest

2023 SEPTEMBER/OCTOBER | OEM Off-Highway 14 AGRICULTURE

POWER TO MAXIMIZE PRODUCTIVITY

The Cummins B4.5 engine delivers the productivity you need to keep your equipment running. With power increases up to 200 hp / 150 kW and peak torque up to 575 lb-ft / 780 Nm the B4.5 enables the replacement of higher displacement engines with no impact on productivity.

©2023

Inc.

Cummins

exporting countries of agriculture products in the world, big agricultural machinery players are present alongside big facilities, big development centers and big projects. Volvo Penta partners closely with agriculture OEMs to seize these opportunities.

What is the most pressing challenge in agriculture equipment right now for both OEMs & end users in the agriculture space, & have you encountered certain challenges in the product development space?

FL: Several conditions affect farmers worldwide, spanning soil condition, fertilizer use, pricing of resources and government regulations. Data is key to optimizing productivity and profit — starting with the engine — in order for farmers to know this information during very high uptime periods.

A key challenge we see today revolves around the Internet of Things (IoT) and electrification (infrastructure). Our end-users’ operations require network connection all over the field, and data acquisition is vital.

How are emerging power trends reshaping agriculture equipment & their applications in the field?

FL: The world is undergoing an energy transition to varying extents. This involves renewable or low to no emissions methods for power. The dominant conversation you’re most likely to hear is around the “silver bullet” when it comes to how one powers their applications/ machines. We cannot rely entirely on electrification and must also continue to explore use of different alternative fuels. Biofuel can be cost-efficient and good for the environment, being a part of the agricultural cycle.

2023

12–18

#systemsandcomponents

www.systemsandcomponents.com

Volvo Penta has strong supporting functions, especially in realizing the use of alternative fuels in agriculture. Biofuel support is strong in Brazil, for instance, but receiving that support entails aligning with environmental, social and governance (ESG) aspects. From a product development perspective, we take pride in ensuring that our engines comply with country-specific ESG, and that the end user meets emissions regulations. There is a big benefit of being a part of the Volvo Group as there is shared knowledge in technologies and regulatory spaces on a global level.

What are Volvo Penta’s priorities in agricultural product development in 2023 & beyond?

FL: We see a responsibility to drive the energy transition through research and development, strong collaborations and guiding our customers.

THE B2B MARKETPLACE OF THE INTERNATIONAL SUPPLIER INDUSTRY FOR AGRICULTURAL MACHINERY AND THE ENTIRE OFF-HIGHWAY SECTOR

■ Over 650 international exhibitors

■ More than 100,000 visitors

■ High-level technical programme

■ ” SYSTEMS & COMPONENTS Trophy” awarded by engineers to highlight innovative products

■ Part of AGRITECHNICA –The world’s no. 1 platform for agricultural machinery

2023 SEPTEMBER/OCTOBER | OEM Off-Highway 16 AGRICULTURE

SYSTEMS & COMPONENTS IS PART OF

NOVEMBER | HANOVER, GERMANY PREVIEW DAYS 12/13 NOVEMBER

We adopt a multifaceted approach to our road to net-zero, spanning alternative fuels with the combustion engine, electrification and fuel cells. In agriculture, there is strong potential to reduce well-to-wheel emissions through the adoption of alternative fuels; given their place in the agricultural cycle.

The key factor to our success will rest on our close partnerships with our customers to meet their business, application and operational needs, through powering and integrated solutions as they navigate this energy transition.

FOR YOUR HEAVY DUTY PLAYGROUNDS

HIGHLY EFFICIENT DRIVE SOLUTIONS FOR HARVESTING MACHINES

USING NAF’S MODULAR SYSTEM:

NAF GEARED BOGIE AXLE – BOTH COST-EFFICIENT AND LOW WEAR – COMBINED WITH THE DIRECTLY DRIVEN FLEXTRAC AXLE® WITH ADJUSTABLE TRACK WIDTH.

OEM Off-Highway | SEPTEMBER/OCTOBER 2023 17

MADE IN GERMANY HANOVER 12.11.–18.11.2023 VISIT US: Hall 15 | Stand A12 CONSENS® CONDITION MONITORING – SENSORED WORKING DIRECT MOTOR ATTACHMENT WITH SPUR GEAR DRIVE OPTIMISED LOAD DISTRIBUTION GUARANTEES LOWER GROUND PRESSURE ON ALL WHEELS NAF’S PBBS® INVENTION

THE LIFTING

BOGIE

REDUCES

EFFECT OF THE

FRONT WHEELS

VOLVO PENTA

Felipe Lopes, head of sales, industrial, Volvo Penta in Brazil

Kathy Wells is editor of OEM Off-Highway magazine.

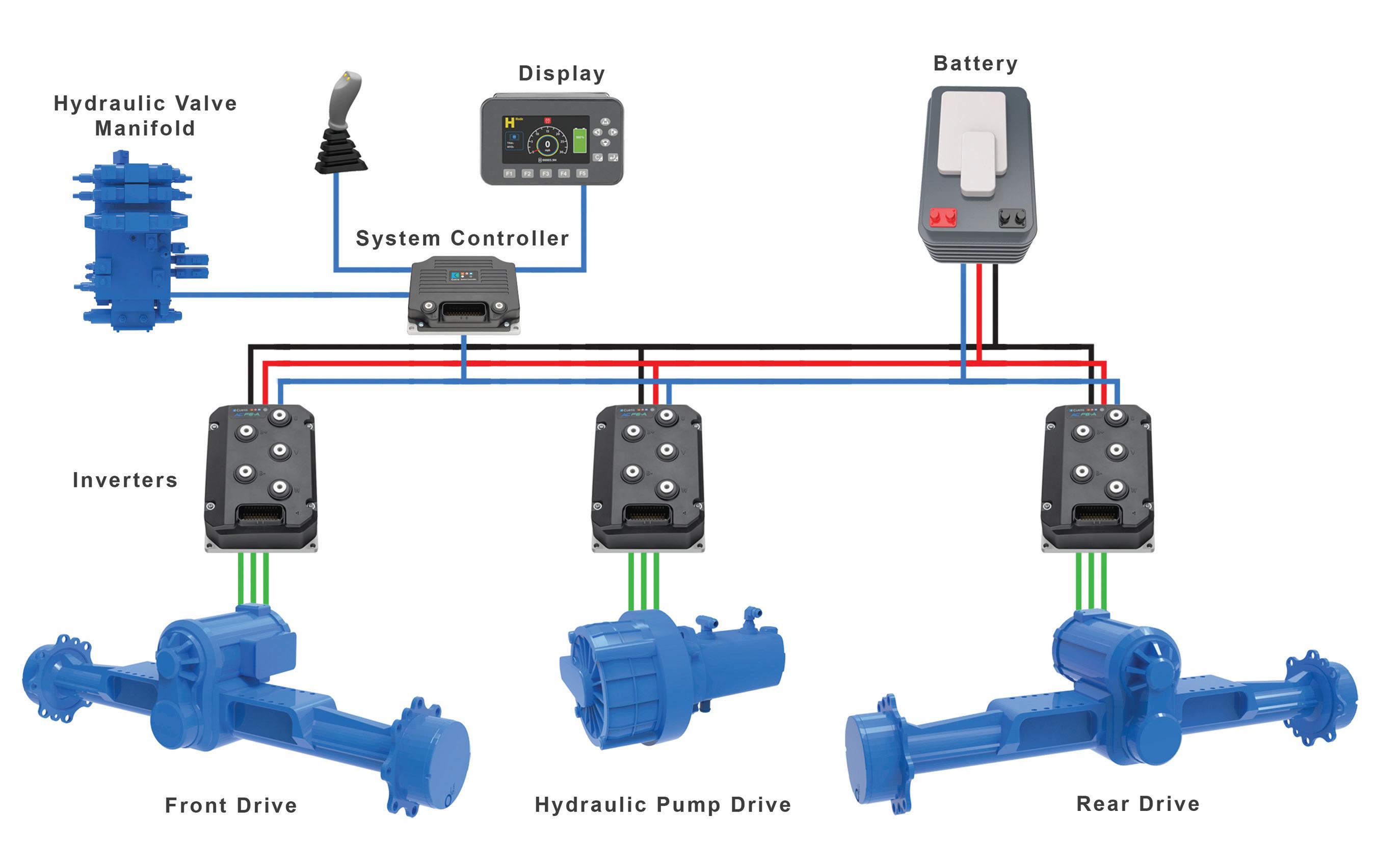

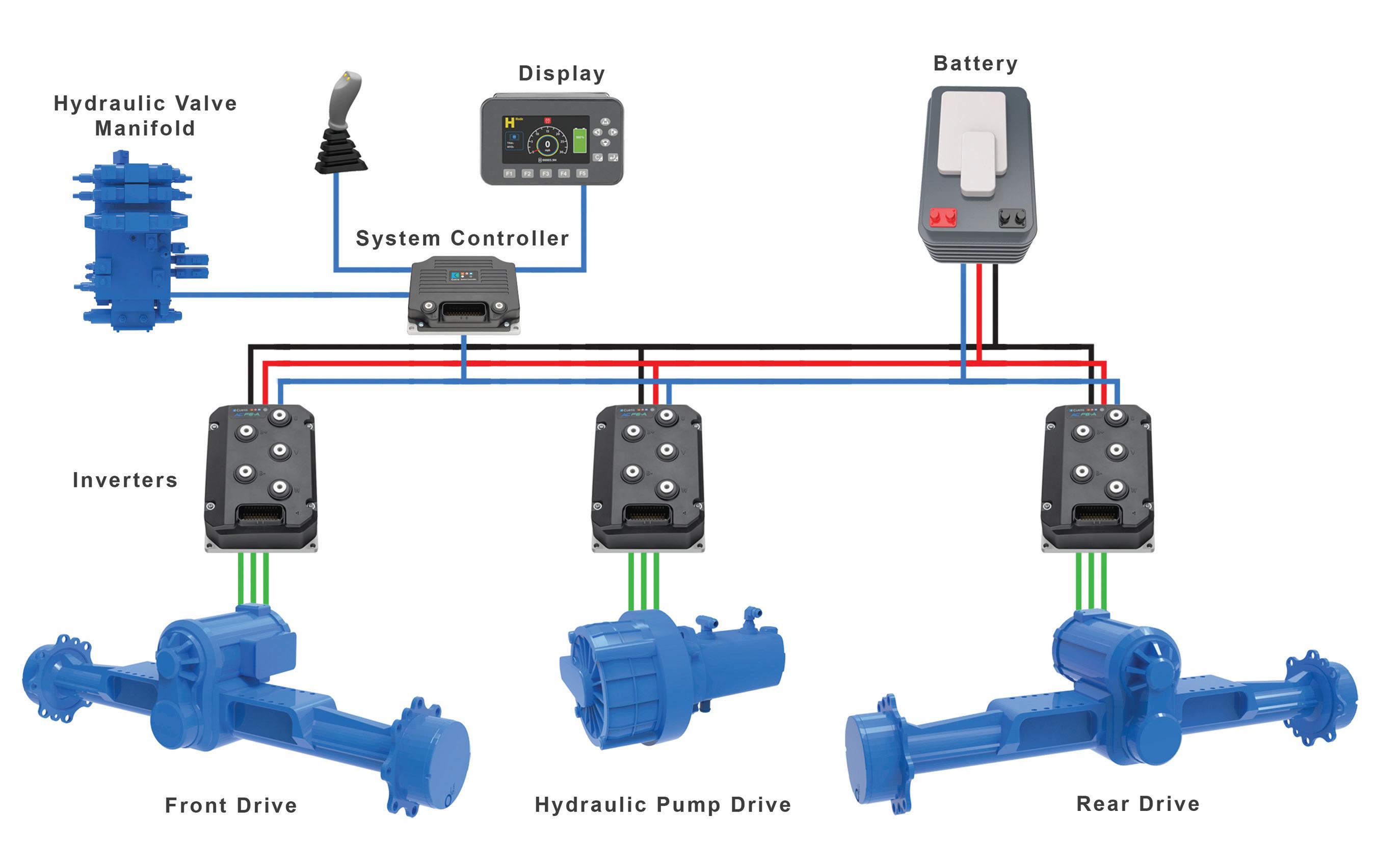

Your Electrification Partner for Agricultural Equipment and Mobile Machinery

For the electrification of agricultural and farm equipment, think Curtis. With over 60 years of expertise with battery-powered vehicles and mobile machinery, and a global record of innovation and product excellence, we are ready to partner with you in the development of your hybrid diesel-electric and fully electric equipment.

Curtis will support your engineering team at every step in the product development process, from initial prototype design through to production release. Highly reliable Curtis motor control inverters and control systems are available in a range of models suitable for every type of application, and are packed with cutting edge features and functions that make system integration simple. We will work with you as needed, whether it is to assist with the design and development of electric traction systems, On-Engine Generator Control or electro-hydraulic control systems.

Get Curtis on your team, and let your mobile equipment benefit from our expertise and the robust, reliable and proven Curtis electrification technology.

See for yourself. We are ready to help you.

Curtis

Instruments

www.curtisinstruments.com

AGRICULTURE GOES ELECTRIC

Exploring the benefits, challenges & drivers of electrification by

Rod Dayrit

Electrification remains the most significant societal transition today, affecting virtually every industry. This is especially true as governments attempt to mitigate the effects of climate change and original equipment manufacturers (OEMs) and fleet operators adapt to changing markets and technologies. With agriculture’s electrification now underway, the industry is following multiple drivers and developments emerging in the past two decades. Government regulations, operational efficiency, greater telematics data availability, lithium battery and charging technology advancements and more substantially contribute to electrification’s progress.

What’s Driving Electrification?

Environmental and health regulations prove to be the most prominent drivers behind the electrification of the agriculture industry. OEMs and fleet operators should expect emissions requirements to become more demanding, such as:

• US Tier IV (approaching Tier V in 2024, with full implementation in 2028)

• Euro 6 (with Euro 7 aiming to be implemented in 2025)

• China VI standards (which are split into VI-a and VI-b)

The increased emissions requirements for agriculture are a result of governments worldwide facing challenges in meeting or sustaining their emissions reduction targets, as originally outlined in climate pledges. Consequently, they are experiencing heightened pressure to address the severe impacts of climate change.

With the electrification of on-road vehicles moving forward under its own momentum, the next target is small and midsized nonroad mobile machinery (NRMM). Bans are increasing for small off-road engines (SORES) for new outdoor power equipment, as seen in California and elsewhere. And agricultural machines won’t be ignored, with the industry contributing an estimated 33% of global greenhouse gasses (GHG) annually.

Moreover, government agencies like the Canadian Centre for Occupational Health and Safety (CCOHS) and the International Agency for Research on Cancer (IARC) recognize gas and diesel emissions’ short- and long-term health hazards (e.g., respiratory issues, carcinogens found in diesel exhaust’s particulate matter).

Similarly, academic research has shown crop health and yields suffer from exposure to internal combustion engines (ICE) emissions. These occupational, environmental and public health concerns will only lead to hastened implementation of those more rigorous requirements.

And given the current agriculture labor shortage, with 40% of new industry jobs remaining open, increased sick days and workers looking for jobs in industries with fewer risks could be devastating for many farms.

Preparation Alongside Reduction

Apart from implementing more stringent regulations to combat climate change, governments understand that

2023 SEPTEMBER/OCTOBER | OEM Off-Highway 20 AGRICULTURE

@DUSAN KOSTIC - STOCK.ADOBE.COM

Challenge Everything

We created solutions that deliver more power, reliability, and fuel savings. Leveraging the R&D resources and proven experiences of the Volvo Group to bring our customers to the forefront of sustainable driveline technologies.

Together, let’s rethink the possibilities and take your operations – and bottom line – to the next level with Volvo Penta´s industry-leading Tier 4 Final solutions.

Lower Total Cost of Ownership

Better Value In The Long Run

Fuel Efficiency

Reduce Your Operational Cost

Service and Support

Global Dealer Network With Local Expertise

Scan the QR code to learn more.

they must prepare for an electrified future. Electric drive is currently the leading alternative energy platform that will replace most ICE, but achieving that transition requires enormous investments. Electrification necessitates accessible charging infrastructure, power grid resilience and similar largescale investments.

For example, the US made $24.5 billion available for EV charging, supply chain resiliency and clean transportation, and California’s CORE program provides funding to accelerate companies’ adoption of electric NRMM. While government regulations and investment are powerful catalysts for electrification, the innovation and

Finding the right telematics fit

Choosing the “right” telematics is a difficult task. TTControl, a joint-venture company of TTTech Group and HYDAC International, shows you what to watch out for along the way.

The Challenge Telematics solutions usually consist of three components: the telematics device, the cloud, and the connection between the two. To successfully develop, maintain and operate a telematics solution, you need a team of 10-20 people to be effective. This investment, however, is not a one-time development effort, but must be sustained. Only few OEMs are willing to make these investments. And is it worth it, considering that most use cases are the same for every machine builder?

Begin your telematics journey and visit us at ttcontrol.com/telematics

How to tackle it

TTConnect was developed with this in mind. Whether you are starting from scratch, looking for a more sustainable approach, or want a new, future-proof solution, TTConnect can help. It is quick to start, supports rapid prototyping with minimal investment and the monthly fee covers updates, new hardware support and more. For further customization, our specialized development team offers expertise in telematics, ECUs, displays, and real-world use cases.

adoption of electric drive go beyond these drivers. Electric drive enables transformative societal shifts, offering numerous merits, particularly by providing farm operators and the agricultural industry with cost savings and enhanced efficiency.

Electric drive offers farm operators and the agricultural industry significant advantages over ICE, leading to newfound efficiencies at both the vehicle and business levels and driving the transition toward electrification.

Low Maintenance & Efficiency

One key benefit of battery-operated agricultural machinery is the reduced need for regular maintenance, such as replacing engine oil or fuel filters regularly. Electric vehicles have a simpler design with fewer moving parts, leading to fewer opportunities for operational issues caused by factors like extreme temperatures and friction (which can affect ICE). As a result, unexpected repairs become less likely, and maintenance tasks are less frequent. The only maintenance required for electric drive agricultural machinery is regular charging. Additionally, electric vehicles eliminate idling and warm-up periods, ensuring that they never waste energy expenses.

Cost Stability of Electricity

Electricity is a more stable and longterm option for agriculture compared to fossil fuels, as its cost structure is less dependent on geopolitical implications. This was highlighted during the RussiaUkraine war, where oil prices fluctuated significantly, resulting in a 42% rise in consumer gas prices within four months in the US and a tenfold increase in Europe. Since then, fossil fuel prices have remained unstable.

In an industry that depends on reliable energy sources, agriculture has the potential to use electricity and alternative energy generation to counterbalance these price fluctuations. Consider, for example, agriculture’s abundance of land. This provides large-scale operations with the ability

2023 SEPTEMBER/OCTOBER | OEM Off-Highway 22 AGRICULTURE

to accommodate alternative energy generation at a massive scale. Solar photovoltaic (PV) panels and wind sources naturally produce energy, leading to self-sustaining energy consumption and more predictable, stable operational costs.

Battery & Charger Advancements

Recent innovations in battery, charger and related technologies have made electric drive equipment viable.

Lithium batteries, in particular, have made a significant impact due to their introduction, cost reduction and availability. Before lithium batteries, fast charging was not possible, which was a major obstacle in electrifying agriculture’s day-long usage of machines in the field. Today’s lithium batteries provide the necessary power output, density, durability and longevity to help electric drive platforms reach the performance levels farmers need.

Nonetheless, a battery is only as good as the charger that keeps it operating efficiently.

Chargers can now be mounted onboard to reduce storage requirements and enable opportunity charging from portable power sources or solar installations. The introduction of more sophisticated charging systems that regulate battery charging is the most important advancement. These systems monitor voltage, usage consistency, poor charging practices, equipment failure flags and more.

With today’s battery and charging capability and insight, fleet managers can optimize operations and resource allocations based on vehicle and energy usage better than ever before.

Agriculture’s Electrified Future

Regulations and health concerns are the driving forces behind agriculture’s electrification, but investment and technology advancements are equally important. While agricultural machines and equipment were not capable of being electrified in the past, with recent innovations, electric agricultural equipment is now a viable option.

Electric drive is becoming increasingly competitive with internal combustion engines, and forthcoming regulations and societal adoption will only widen the gap in electrification’s favor. The last challenges professionals are now solving involve developing charging infrastructure and batteries capable of powering large agricultural machines.

However, with advancements in these areas and better data utilization, the possibilities for electrification are endless, including the potential for autonomous agricultural machinery.

OEM Off-Highway | SEPTEMBER/OCTOBER 2023 23 A PRODUCT YOU TRUST. Being the best in the game starts with a product you can trust. Our full lineup delivers the performance you need to get the job done. Whether you need heavy-duty, solids-handling trash pumps or high-head, high volume dewatering pumps, our products are engineered to get you from job to job – fast. GO WITH A NAME YOU KNOW. GO WITH GORMAN-RUPP. A NAME YOU KNOW. #609 © 2023 The Gorman-Rupp Company. Call Gorman-Rupp at 419-755-1011 or visit GRpumps.com to find a distributor near you. S Series® (Widebase) 10 Series® Super T Series® S Series® (Slimline)

Rod Dayrit is director of business development at Delta-Q Technologies.

Know

Are Electric Construction Vehicle Design Delays AVOIDABLE?

by Geoff Schwartz

The movement toward electrification of construction equipment — once just a concept — is now occurring at a rapid pace. Stricter emissions regulations in the U.S., Europe and China, an increasing number of municipal noise ordinances, and the higher cost of diesel fuel are driving increased demand for electric construction equipment.

In addition, advances in battery electric vehicle (BEV) technology are making electric construction vehicles, especially small equipment such as small loaders and excavators, less costly to produce and more attractive to end users. Lithium-ion battery technology has allowed small construction vehicles to achieve a full day of work on a single charge, and in some cases, two full days

of work. And, thanks, in part, to the lower maintenance costs associated with electrified construction equipment, owners are now able to quickly recover their investments.

The increased demand and improved technologies suggest there will be strong growth in the battery-electric and hybrid-electric off-highway equipment market for the next five to 10 years. In fact, according to MarketsandMarkets, the electric construction equipment market is forecast to grow to $24.8 billion by 2027 at a compound annual growth rate of 22%.

For OEMs, it means the race is on to capture market share. And, for design engineers, it means there is enormous time-to-market pressure. At the same time, equipment electrification presents several new design challenges that have caused delays for many manufacturers.

But are these design delays avoidable? Initially, design delays may have been inescapable due to factors outside of a design engineer’s control, such as a lag in available high-voltage (HV) circuit

protection and power distribution products. However, solutions to the unique design challenges of electrifying construction equipment are becoming more readily available through partnerships with suppliers that have been able to adapt to market trends and have system-level knowledge and testing capabilities.

There have been a couple of factors leading to slower electric construction equipment designs. To begin with, many design engineers have not had experience with some of the special problems and requirements that come with vehicle electrification, such as the increased risk of levitation in HV DC contactor relays or the subsequent need for coordinated circuit protection.

Levitation in DC contactors can occur during an overcurrent condition when the magnetic field created by the current is so strong that it pushes the moving contact away from the stationary contact. The resulting arcing and chattering can damage the contactor to the point of catastrophic failure.

2023 SEPTEMBER/OCTOBER | OEM Off-Highway 24 EVS IN CONSTRUCTION

which factors are slowing down the process & how to solve the problem

GETTY IMAGES 1077973414

This unsafe event is a consequence of the application current going beyond the specification for the relay. This means design engineers need to know the level of current that may cause levitation and make sure the circuit will open before the current reaches that point by specifying upstream circuit protection that will operate fast enough to prevent levitation in the contactor.

Levitation is just one example of how emerging BEV technology, which has increased working voltages and currents, is presenting designers with new challenges. High-voltage DC is more dangerous and harder to interrupt, requiring innovative solutions to distribute, control, and protect application power.

Making the situation more difficult for design engineers is the fact that there are currently no standards for HV fuses or contactors used in construction equipment. And ISO and SAE processes can take three to five years to complete, so the standards simply are not going to come as quickly as they are needed.

When it comes to the electrification of construction vehicles, the lack of standards, as well as a lag in available vehicle-rated HV DC products, has created a “Wild West” scenario. Under these conditions, designers have resorted to practices that have resulted in increased testing times and slower design processes altogether, including:

• Using industrial fuses when HV automotive fuses are not available — While, at first glance, it seems like a reasonable substitution because industrial fuses meet voltage and current specification requirements, the lack of vibration testing for these fuses means no one knows how long they will last.

• Over-specifying and under-specifying — Using overrated parts is a cost drain, and using parts that are rated too low is a potential safety issue. Using low-voltage fuses in HV systems, for example, can lead to dangerous thermal events.

• Matching fuses with contactors without knowing what will happen — Because

of the risk of levitation in HV DC contactors, in some cases, pyrotechnic safety modules (PSMs) may be a better choice than a standard fuse. In other cases, PSMs may be too costly. Ideally, circuit protection should be coordinated with a relay and tested to ensure a balance between nuisance tripping and excessive contact arcing.

While the standards for HV systems will eventually catch up with the industry, and the lag in available products to support electrification is beginning to dissipate, OEMs looking to capture market share will only see success if they prioritize quality and functionality. High-performance designs that win the approval and loyalty of customers beat out rushed products with major design flaws every time.

One phenomenon that is beginning to arise out of the chaos is: In order to avoid delays and costly mistakes, OEMs are partnering with suppliers that have expertise in both high-voltage and automotive applications. Suppliers with system-level knowledge can help OEMs address the challenges of electrification, help them address the special problems of HV DC efficiently, and accelerate time to market by assisting with testing.

Suppliers that have been able to adapt to market trends can offer design engineers more than products that enable electrification. They can offer expertise, customizable solutions and testing capabilities that speed up the design process.

OEMs looking to partner with a supplier on the electrification of construction equipment may also want to consider suppliers that sit on the ISO and SAE committees. These suppliers will have the added advantage of being able to anticipate what the standards will be in the future — making it far easier to stay ahead of what is coming, saving both time and money.

OEM Off-Highway | SEPTEMBER/OCTOBER 2023 25

Geoff Schwartz is the business development manager at Littelfuse Commercial Vehicle Products.

For nearly 40 years, OEM Off-Highway has worked with manufacturers across to globe to identify today’s top product introductions and upgrades and share them with our readers.

Our Top New Products award, returning for its 15th year, is designed to highlight the ingenuity of today’s design teams and showcase the innovation behind some of the latest product launches in the mobile on- and off-road equipment manufacturing space. Read on for the latest information behind several of the industry’s top new releases, including product features, specs and more.

The winners showcased in the following pages have been selected from the best in a global submission process and represent OEMs offering exciting new products in each of the following categories:

• Engines

• Drivetrains

• Fluid Power

• Electrical & Electronics

• Operator Cab

• Engineering & Manufacturing

TOP NEW PRODUCTS: AWARD COVERAGE 2023 SEPTEMBER/OCTOBER | OEM Off-Highway 26

This year’s winners highlight the ingenuity & innovation behind some of today’s best product offerings

by Kathy Wells

TAKE THE LEAD WITH THE NEW CAT® CI3D INDUSTRIAL ENGINE.

Crunching the numbers is all it takes to demonstrate the power of the new Cat® CI3D engine. It’s simple –so we did the math for you. Want the best? You’re looking at it.

Ready for more capabilities, more efficiency and more industry-leading power? Connect with a Cat dealer

I0% LOWER FUEL CONSUMPTION UP TO I000 HOURS BETWEEN SERVICES

20% MORE POWER

0 HOURS THERMAL MANAGEMENT DOWNTIME

SCAN TO WITNESS THE POWER OF THE CI3D

© 2023 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, "Caterpillar Corporate Yellow," the "Power Edge" and Cat “Modern Hex” trade dress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission.

to find

out more on the new CI3D engine.

Winner: Engines

Cat C13D from Caterpillar Inc.

The new 13-liter diesel engine platform is designed for best-in-class power density, torque and fuel efficiency for optimizing the performance of heavy duty off-highway applications. The inline, six-cylinder engine platform offers eight power ratings from 456 to 690 hp with up to 3,200 Nm of peak torque. OEMs can downsize the engine and simplify design, assembly and supply chain requirements across multiple applications. The engine is targeted for a wide range of off-highway equipment and offers up to a 20% increase in power and up to 25% more low-speed torque over the previous generation. It is designed to perform at altitudes of up to 12,000 feet and in extreme ambient temperatures with aids. New engineering improvements include integrating components and reducing the number of leak joints by more than 45%. The upgrades result in lower fluids consumption and extended service intervals as long as 1,000 hours, reducing operating costs and downtime. The engine platform enables the use of renewable liquid fuels, such as 100% HVO, B100 Distilled Biodiesel, and up to B100 Standard Biodiesel. Its core architecture is designed for the future development of natural gas and hydrogen fuel capabilities. By modularizing and eliminating components, its architecture can accommodate configuration adjustments anticipated for future tiers of emission standards in the U.S. and EU without relocating customer connection points.

TOP NEW PRODUCTS: AWARD COVERAGE

Caterpillar

2023 SEPTEMBER/OCTOBER | OEM Off-Highway 28

Cat C13D

Winner: Drivetrains

Brake-By-Wire Solutions from ZF

ZF’s new brake-by-wire system offers a universal solution designed to support the transition from mechanical to intelligent braking technology that is easily scalable, while providing braking safety and driver comfort.

The advanced brake-by-wire solutions provide vehicle manufacturers the ability to control deceleration via an electronic signal that adjusts brake pressure when needed, removing the need for hydraulic lines in the cab. The system is comprised of three components: an electronic pedal, electrohydraulic brake valve and an Electronic Control Unit (ECU).

Together, the system offers vehicle manufacturers ease of installation, electrohydraulic brake valves for precision brake control and adaptable pedal response/brake feel that can be customized to fit a vehicle’s brand identity. It also provides key operator benefits including reduced cabin noise, and passenger car-like comfort for brake feel.

SOME JUDGE ENGINES ON POWER. OTHERS ON TECHNOLOGY.

WHY NOT BOTH?

• EGR-free combustion

• DPF-free after treatment systems

• Reduce maintenance & increase uptime

Because power and technology are what FPT engines deliver, and have been for more than a century. Our engines not only offer options that deliver power from 37kWe up to 515kWe, they also feature the technology that keeps you working in the most extreme environments. Learn more at fptindustrial.com

e

duty power • Eliminate low temp, low load issues

Increase fuel efficiency

• Dep

ndable, heavy

•

ZF OEM Off-Highway | SEPTEMBER/OCTOBER 2023 29

ZF Electronic Pedal Control

Winner: Fluid Power

Thorx CLM 8 S cam lobe motor from Danfoss Power Solutions

Designed for construction machinery with chain drives, such as skid steer loaders, the motor offers better performance, higher efficiency and longer lifetime. The motor features newly developed twospeed technology, which offers 70% shock reduction when shifting speeds. The technology delivers smoother speed changeover with a consistent, quick response time, regardless of temperature. The motor also produces less noise when shifting. Compact construction is another major advantage of the Thorx CLM 8 S motor. By integrating the parking brake rather than bolting it to the rear, the motor is 33% shorter in length than other cam lobe motors, making it the most compact solution in its class. The smaller size results in easier integration and assembly for OEMs while enabling the use of larger, longer-lasting chains. The integral parking brake is the toughest on the market, offering a longer service life. Utilizes a brake design that has been optimized to withstand 100 dynamic emergency stops throughout a machine’s lifetime, 20 to 25 times more than competitive cam lobe motors. The motor offers 5% higher efficiency than other cam lobe motors, with better starting efficiency and performance at low rotations per minute, plus improved mechanical efficiency at high speed. Operators can achieve faster travel speeds or use less power at the same speed while wasting less energy in the form of excess heat.

THE BRIGHTEST DESIGNS IN OEM LIGHTING

Specializing in LED lighting for agriculture, mining, & construction vehicles, J.W. Speaker lights the way to success for industrial OEMs.

With precision, we analyze your unique requirements, embracing challenges, risks, and regulations. By harnessing photometric principles and cutting-edge technology, we transform your idea into market-ready reality.

TOP NEW PRODUCTS: AWARD COVERAGE

SCAN ME

Thorx CLM 8 S cam lobe motor

2023 SEPTEMBER/OCTOBER | OEM Off-Highway 30

Danfoss Power Solutions

Winner: Electrical & Electronics

Vanguard Lithium-Ion 48V 1.5kWh* Commercial Battery (Si1.5) from Briggs & Stratton

The exchangeable design of the 1.5kWh Commercial Battery empowers users to swiftly swap freshly charged packs from application to application and is built to bring efficiency, versatility and reliability to users in multiple industries that require battery power. The integrated Battery Management System constantly measures the pack’s voltage and temperature to ensure safe and efficient operations. When designing the 1.5kWh Commercial Battery, safety and durability were top of mind for Vanguard. The company applied its learnings from other commercial batteries to ensure that the battery’s diecast aluminum casing adds rigidity and reduces vibration and shock response from the pack. The 1.5kWh Commercial Battery is tested to ensure that it is able to withstand the toughest of environments and is durable against the extreme temperatures, abuse, moisture and dirt of jobsites. This makes it a good solution for landscape, concrete and mining applications. The battery features a 1,000-cycle lifespan with virtually no maintenance, so operators can depend on instant power for the job at hand. With a standard charge time of less than two hours, this next-generation battery will have an immediate impact on the off-highway industry as more OEMs realize the many benefits of electrification and look to bring their own battery-powered products to market.

A powerful positioner from ALM delivers up to 40%+ increased welding and assembly manufacturing productivity. You’ll also gain increased safety, quality and ergonomics to ensure maximized throughput is always within reach.

GET YOUR QUOTE AT ALMMH.COM

ALM positioners

Briggs

OEM Off-Highway | SEPTEMBER/OCTOBER 2023 31

Vanguard Lithium-Ion 48V 1.5kWh* Commercial Battery (Si1.5)

& Stratton

www.enmco.com

Winner: Operator Cab

Linux 713/714 Display Series from HED, Inc.

Designed for rugged mobile applications, the new Linux PCAP touchscreen displays allow for use with gloved hands, and are IP67 sealed and sunlight readable. Offering ultra-wide, 80-degree viewing angles from all directions, these displays can be incorporated into a variety of applications, such as a digital dashboard for electric vehicles. Highly configurable with inputs, outputs, touchscreen, video inputs, Ethernet, wireless communication, and can be programmed using today’s popular tools, such as Crank, Qt and CODESYS. The 5- and 7-inch displays offer optional buttons, integrated I/O options, an economical price point that enables OEMs with smaller and/or lower cost vehicles to design a compact, modern display that offers features for a wide variety of applications.

Features include: Linux operating system; Programming tools supported: Crank Storyboard, CODESYS, Open Platform; Cortex A7 ARM Microprocessor running at 800MHz; 4GB eMMC FLASH (option for 8 – with minimum order required); 512MB DDR3 RAM; Sealed enclosure for external mounting; Panel and RAM mount capable; LCD optically bonded to hardened glass lens with AR film; Sunlight readable 5-inch TFT Color LCD display; 800x480 pixel resolution; LED Backlight with 800 cd/m2 (nits) brightness; Ambient Light Sensor; (2) CAN ports; (1) USB OTG (capable of supplying up to 500mA to device): Software updates directly from USB Memory Device, Interface to PC software tools; Low Power Sleep Mode with Wake-Up by following methods: Digital input on connector, CAN traffic, time set by software using Real Time Clock; Optional features include: PCAP Touch Screen that works with moisture and gloves (option); Real Time Clock with internal battery (option, 15 year life); (1) Ethernet 10/100 Base-T (option); (2) Video inputs, NTSC & PAL supported (option), one shown on LCD at a time (not simultaneously), Video Window location and size are programmable with graphics sharing remainder of screen; Wi-Fi and Bluetooth (option), dual-band Wi-Fi 802.11, Bluetooth 4.2 + BLEI/O available (optional); Discrete Inputs and Outputs; Specifications: Operating voltage range: 8-32 VDC; Operating temperature: -40°C to +70°C; Storage temperature: -40°C to 80°CIP; Rating: IP67

TOP NEW PRODUCTS: AWARD COVERAGE

ELECTRONICS LCD HOUR METER/COUNTER COMBO HOURMETER COUNTER T39 MADE IN THE U.S.A e-mail: customerservice@enmco.com TOLL FREE 888-372-0465 2023 SEPTEMBER/OCTOBER | OEM Off-Highway 32

Linux 713/714 Display Series

Winner: Engineering & Manufacturing

Allison eGen Power 130S from Allison Transmission

The Allison eGen Power 130S is the latest product to be introduced to the company’s eGen Power family of fully electric axles. eGen Power e-Axles are designed to fit between the wheels of medium and heavy-duty trucks and buses, replacing the vehicle’s traditional powertrain. eGen Power is a bolt-in solution compatible and easily customizable to current vehicle frames, suspensions and wheel ends, and is well suited to most OEM vehicle assembly processes. Allison has developed a broad portfolio of e-Axles, each purposebuilt to meet the unique demands of its customer base as they evaluate electric commercial vehicle capabilities. Every e-Axle available under the eGen Power family was designed to address the needs of a specific market segment or segment of vehicles. The eGen Power 130S was developed for the Europe and Asia-Pacific regions. Key components of the e-Axle, including new suspension systems, V-rod brackets, banjo housing, brakes, wheel ends and axle spindles, were designed specifically to support the heavier 13-ton gross axle weight rating often required by commercial vehicles in Europe and Asia-Pacific markets.

The 130S uses a single motor to generate 225 kilowatts of continuous power, with a peak power of 325 kilowatts, and 26,000 newton meters of torque at the wheels. It supports a recommended voltage range of 550-850 V. It also features a two-speed parallel axis gear architecture, efficiently meeting application launch and highway cruise demands, while maximizing energy recovery through 100% regenerative braking capability.

High Voltage DC Contactors for EV Applications from Littelfuse

DC Contactors from Littelfuse are a high-current and high-voltage solution for disconnecting DC energy sources in 48V applications requiring continuous run time. Their spacesaving design allows these remoteoperated contactors to be mounted easily in any orientation, making them simple to incorporate into battery electric vehicles, hybrid vehicles, heavy-duty trucks and more.

For stocking information visit waytekwire.com/Littelfuse_HVContactors

OEM Off-Highway | SEPTEMBER/OCTOBER 2023 33

Allison eGen Power 130S

AllisonTransmission

Kathy Wells is editor of OEM Off-Highway magazine.

THE FIRST SELFLOADING HAULERS

Get to know the direct ancestor of today’s elevating scraper

by Thomas Berry

Regardless of its efficiencies in carrying and dumping a load, the efficiency of any kind of hauler is going to be impacted by how easy it is to load. Most often, this is a matter of the loader’s own efficiency. But what about a hauler loading itself?

The earliest self-loading hauler known to this author was the Improved Slusser Excavator, patented in 1866 and built by G. G. Haslup & Bro. of Sidney, Ohio. This machine was a self-loading wagon, modestly described in period sales literature as “The Excelsior of all other Labor-Saving Machines.”

In the 1920s, Highway Trailer Company of Edgerton, Wisconsin, introduced the more direct ancestor to today’s elevating scraper. Highway’s sales literature described it as the “Self-Loading Quick-Action One-Man Operated Rear-Dump Two-Wheel Scraper.” Mercifully for sales and

service staff, plus the telegraphers who handled so much of their communication, it was officially the HTS, with a suffix for its three exceptionally large sizes of its time, 2 cubic yards through 5 1/2 cubic yards.

Unlike more conventional competition, it probably could not be run in multiple behind a single tractor. But as that handle noted, it was controlled from the towing tractor,

eliminating the cost of a second employee on the scraper(s).

Both the Haslup and Highway machines used a mechanism not unlike that in today’s elevating scraper, a mechanism that picked material from the ground and swept it up into the wagon or scraper. Haslup used a slat conveyor, whereas Highway’s “raker” much more strongly resembled what Gene Hancock perfected in the 1950s.

Thomas Berry is an archivist with the Historical Construction Equipment Association (HCEA). HCEA is a 501(c )3 nonprofit organization dedicated to preserving the history of the construction, dredging and surface mining equipment industries. With over 3,500 members in a dozen countries, its activities include operation of the National Construction Equipment Museum and archives in Bowling Green, Ohio; publication of a quarterly magazine, Equipment Echoes, from which this text is adapted, and hosting an annual working exhibition of restored construction equipment. Individual memberships are $35 within the USA and Canada, and $55 elsewhere. HCEA’s next International Convention and Old Equipment Exposition will be held Sept. 22-24, 2023, in Bowling Green, Ohio. HCEA seeks to develop relationships in the equipment manufacturing industry, and offers a college scholarship for engineering students. Information is available at hcea.net, or by calling 419-352-5616 or emailing info@hcea.net.

2023 SEPTEMBER/OCTOBER | OEM Off-Highway 34 OFF-HIGHWAY HEROES

G. G. HASLUP & BRO. ADVERTISEMENT CIRCA EARLY 1870S, HCEA ARCHIVES

The Improved Slusser Excavator, patented in 1866. Note the slat conveyor for loading.

HIGHWAY TRAILER COMPANY SALES LITERATURE, HCEA ARCHIVES

The Highway Trailer Scraper’s HTS sports its “raker” mechanism that foretold today’s elevating scrapers.

hydraulics, HAWE

HAWE Hydraulik is a leading manufacturer of technologically advanced, high-quality hydraulic components and systems. HAWE products are used wherever high-power and maximum precision is required - whether in telehandlers, construction machinery, or agricultural or forestry machines. Partner with HAWE to always have the complete solution! www.HAWE.com | info@haweusa.com | 704-509-1599 Booth S2941 09/26 - 09/28 Louisville, KY HAWE is your complete custom hydraulic solution provider! Industry Leading Performance Proportional directional spool valve PSL-CAN Precise, Flexible and Safe Load-holding valves type OSCA Flexible and efficient Mini hydraulic power pack type HR Energy efficient and Reliable Zero-emission battery system

When great things are being moved with

is involved.

TWINDISC.COM WE PUT HORSEPOWER TO WORK® No matter how you say it or what you call it, Twin Disc designed the perfect PTO that does not require a pilot bearing. We’ve been doing PTOs since 1918 and we continue to be a leader in the industry. Contact our dedicated PTO facility in Lufkin, TX for price and availability. SALES.LUFKIN@TWINDISC.COM DUDE, WHERE’S MY PILOT BEARING?