External Advisory Board Meeting September 30, 2022

Welcome and State of the Center

Giorgio Rizzoni

2

Director Center for Automotive Research

a.m.

3 09:00 a.m. Welcome and State of the Center 09:30

College of Engineering Update 09:45 a.m. Motorsports Teams Update 11:00 a.m. Research Activity Updates 12:00 p.m. Lunch 01:30 p.m. NSF Engines: Electric Mobility Innovation Corridor 02:30 p.m. Closing and Thanks Agenda

News

Leveraging information provided by COTA such as bus routes and passenger demands, CAR is developing prediction tools that use basic measurements collected on buses during service to forecast the energy consumed and the available range of the battery pack.

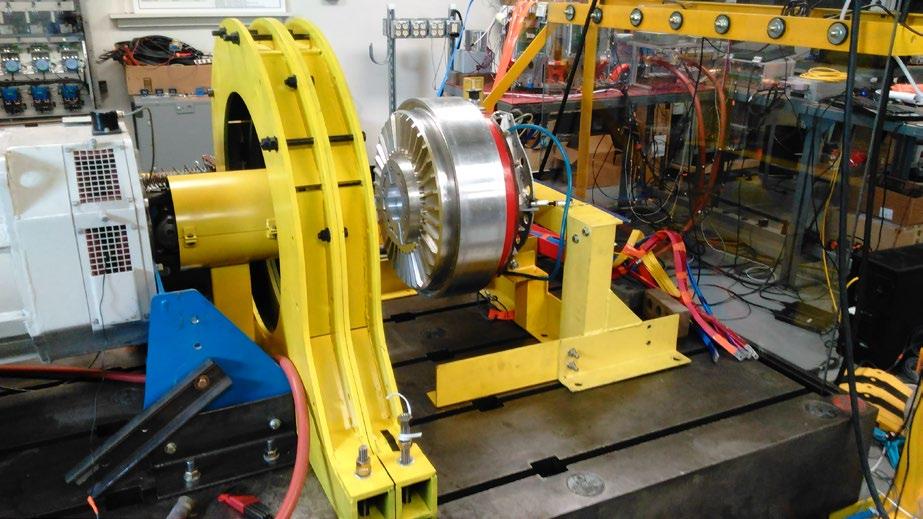

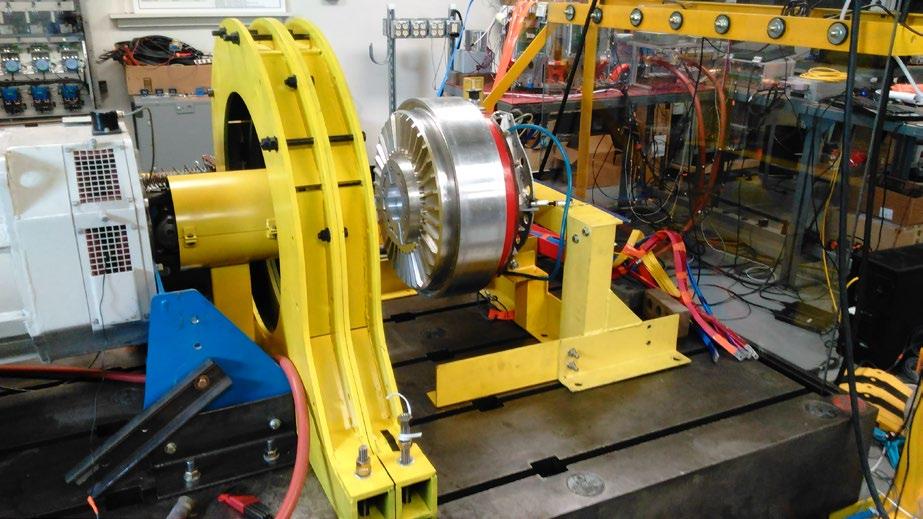

NASA sought the expertise of Research Scientist CG Cantemir to develop a 10 Megawatt Ring Motor concept for their electric aircraft.

For the first time since COVID-19 hit in 2020, the Center for Automotive Research (CAR) has been able to welcome a new group of visiting scholars.

Photo credit: COTA

Photo credit: COTA

Recognitions

Former Research Scientist, Matilde D’Arpino received the CoE Lumley Research Award for her work on projects relating to power conversion and energy storage systems for automotive, aviation, space and grid connected systems.

Associate Professor of Practice Lisa Fiorentini received the CoE Ohio StateHonda Partnership Award for her crucial role in establishing a relationship between The Ohio State University master's program and Honda.

Professor Giorgio Rizzoni has been elected a Fellow of the American Society of Mechanical Engineers (ASME) in recognition of his exceptional engineering achievements and contributions to the engineering profession.

Recognitions

Visiting Fellow Vinith Kumar Lakshmanan received the Young Author Award at the IFAC AAC Conference

Promotions and New Hires

Matilde D’Arpino Research Assistant Professor with joint appointment in MAE and ECE

Qadeer Ahmed Assistant Professor in MAE

Stefano D’Alessandro

Research Associate 2Engineer

Co-Investigator Status

Athar Hanif

Senior Research Associate Co-Principal Investigator

Manfredi Villani

Senior Research Associate Co-Principal Investigator

8

Rehabilitation Engineering

Research Works

Research Interests

9

CAR/SHRS

• Wheelchair predictive maintenance • Wheelchair quality testing standards • Hardware/digital/app design • Technology transfer

• Older adults aging in place and transportation • People with disabilities – community living National and International Research Awards • NAM, NIH, NSF subaward, Japan AMED, NIDILRR • US-India Endowment Fund • Paralyzed Veterans of America Anand Mhatre •2018, PhD, Rehab Science •2011, MS, Manufacturing Systems •2007, BE, Mechanical Engineering

H

Autonomous Manufacturing: Moving from Evolution to Revolution

ybrid

A National Science Foundation Engineering Research Center, Began Sept 1, 2022, $52M NSF support over 10 years*, favorable collaboration and partnership terms. Foundational Components: • Convergent Research • Engineering Workforce Development • Culture of Diversity and Inclusion • Innovation Ecosystem Join us! http://hammer.osu.edu Join the mailing list at: hammer@osu.edu * pending renewal at year 5

Conference

in Automotive

109 Academic Partners 32 Industry Partners 4 National Lab Partners 11 2022 IFAC Advances

Control

14 Countries Represented 72 Students Thank You to our Sponsors!

Ohio State and Wilberforce University partner for EcoCAR EV Challenge

12

Naming of the Center for Automotive Research Facility

The administrative naming of the building at 930 Kinnear Rd. was approved by The Ohio State University Board of Trustees on August 18, 2022.

13

Welcome Zak Kassas, PhD

• Joins Ohio State as a full professor in the Department of Electrical and Computer Engineering

• Will work closely with CAR and ESL

• Leads CARMEN UTC, USDOT University Transportation Center on safety and security of highly automated vehicles

• Led proposal for 2022 UTC competition that will build upon current UTC and expand into cybersecurity

14

Continuing Education

Marcello Canova

Director

and

Education

15

Associate

Graduate

Continuing

Preparing practicing engineers for success in the automotive, transportation, energy and mobility industry

16 Intelligent Mobility Electrification Technologies Sustainable Transportation

Led continuing education programs for engineers at:

Led continuing education topics in:

Educated engineers around the world:

Electrification

Energy

Powertrain

17

India China Italy Brazil France

CAR Annual Report View online @Issuu.com

18

CAR Overview

19

Sponsored Research Expenditures 5 year trend

20

FY18 FY22FY21FY20FY19 $2,000 $14,000 $12,000 $10,000 $8,000 $6,000 $4,000 OSP UNIV Industry StateFederal

Active Sponsored Research Awards

Data pulled as of 9.30.22 59 active awards with 69 collaborating faculty

Student Performance

22

2021 Membership Consortium

Platinum Level

Gold Level

23

CAR Outreach Initiatives

Over the past year, CAR has engaged with more than 5900 individuals

Employed high school and college summer interns who worked with faculty and staff on current research projects

Hosted notable industry and government officials to learn about the biggest advancements in the automotive industry and discuss legislative priorities in mobility

Partnered with AAAOhio, Smart Columbus, DriveOhio, Columbus State and

TRC on Technology Takes the Wheel, a free, educational seminar series that explores autonomous vehicles and their societal impacts.

24

Camp CAR

Introducing the next generation to automotive engineering

As an introduction to crash safety, campers were challenged to roll an egg down a ramp into their hand-built crumple zones. The team that could successfully roll their egg from the highest point without it breaking won!

The campers took a test drive in the Driving Dynamics Lab’s Driving Simulator. In addition to a fun experience, students learned about the importance driving simulators play in building vehicles.

It’s not every day you get to walk through the world’s most advanced wind tunnel! Camp

CAR toured the new Honda Automotive Laboratories of Ohio (HALO) facility, located at the Transportation Research Center Inc. (TRC). The wind tunnel serves three separate state-of-the art testing functions — aerodynamics, aeroacoustics, and racing.

25

College of Engineering Update

Lisa Barclay

Assistant Dean of Diversity, Equity and Inclusion Chief Diversity Officer

26

Lisa A. Barclay, Assistant Dean and Chief Diversity Officer College of Engineering Diversity, Outreach & Inclusion CAR Advisory Board September 30, 2022

The DOI Team: We. Us. Our.

TOPICS OF DISCUSSION

COE by the numbers

Why Diversity Matters Cultural Transformation In Progress

28

Diversity Outreach and Inclusion (DOI)

29 Diversity, Outreach and Inclusion

Support Efforts to Recruit, Retain and Advance JEDI Education and Professional Development Strategic Partnerships and Policies to Advance IE K-12 Outreach and Recruitment KOR Team Student Academic Success SAS Team Inclusive Excellence IE Team

Statistics

30 College of Engineering

FY22 Number of Current Undergraduate Students • College of Engineering: 8,355 • Engineering: 7,789 • Knowlton School: 566 Unit Women (%) % First Gen URM (%) % Pell Eligible Ohio Resident College 2,073 (24.8%) 1,574 (17.9%) 951 (11.3%) 1,648 (18.7%) 6,409 (76.7%) Engineering 1,790 (22.9%) 1,408 (18%) 827 (10.6%) 1,469 (17.9%) 5,949 (76.3%) Knowlton 283 (50%) 166 (29.3%) 124 (21.9%) 179 (31.6%) 460 (81.2%)

College of Engineering Statistics

Number of Current Graduate Students

31

FY22

•College of Engineering: 1,884 •Engineering: 1,723 •Knowlton School: 161 Unit Women (%) URM (%) International Ohio Resident College 531 (28.2%) 154 (8.2%) 878 (46.6%) 670 (35.6%) Engineering 453 (26.3%) 128 (7.4%) 839 (48.7%) 570 (33.1%) Knowlton 78 (48.4%) 26 (16.1%) 39 (24.2%) 100 (62.1%)

College of Engineering Statistics 2021

of

Graduates/Alumni

Current Success Metrics of Undergraduate Students

32

Number

Living

• College of Engineering: 60,243 • Knowlton School: 8,603

• First-year retention rate: 85.8% • Six-year graduation rate: 68.4%

College

Statistics

33

of Engineering

2021 Number of Faculty •College of Engineering: 405 •Engineering: 340 •Knowlton School: 44 •FABE: 21 https://engineering.osu.edu/new-faculty Unit AA/Black Hispanic/Latinx Indigenous URM (%) Women (%) College 13 (3.2%) 18 (4.4%) 0 34 (8.4%) 109 (26.9%) Engineering 9 (2.6%) 16 (4.7%) 0 27 (7.9%) 77 (22.6%) Knowlton 2 (4.5%) 2 (4.5%) 0 5 (11.4%) 22 (50.0%) FABE 2 (9.5%) 0 0 2 (9.5%) 10 (47.6%)

WHY DIVERSITY MATTERSWhy Diversity Matters

34

can see themselves in their

prepares students for the workforce

35 • Greater innovation and creativity • Increased range of skills • Increased pool of talent • Students

leaders • Better

Education within a diverse setting prepares students to become good citizens in an increasingly complex, pluralistic society; it fosters mutual respect and teamwork.

36 • Cooperation and collaboration with JobsOhio • The Ohio State University’s Innovation District • Columbus, OH will welcome Intel • Governing and influential organizations inclusion of DEIJ into assessment of outcomes: ABET, Carnegie Foundation and the American Council on Education • Shifting demographics in the US and volatility of international student enrollment

SHARED VALUES

Integrity and Respect

Diversity and Innovation

Inclusion and Equity

Care and Compassion

Excellence and Impact

37

https://go.osu.edu/enginclusive

Inclusive Excellence

Inclusive Excellence

38

Cultural Transformation: https://go.osu.edu/enginclusive

39 • Elimination of GRE requirement and adoption of comprehensive review process • Improved undergraduate retention and graduation rates • Invested in staff for focused on inclusive hiring and education • 60% of faculty and over 350 full-time staff have engaged with DEIJ professional development • Community of Practice for instructors created • Equity and inclusion language added to annual review section of the college Appointments, Promotion and Tenure

Questions

40

Motorsports Team Updates

41

Ohio State EcoCAR: A Glance Into How Universities Are Driving the Future of the Automotive Industry 09/30/2022

Introduction

Kamryn Russell

Education

Master’s of Science in Mechanical Engineering

Bachelor’s of Science in Mechanical Engineering

Current Role

Project Manager, The Ohio State University EcoCAR Student Projects Team

43

Success

of the

EV Competition

from the EcoCAR Program

1. Brief Overview of Advanced Vehicle Technology Competitions 2. Ohio State EcoCAR

3. Overview

EcoCAR

4. Outcomes

Agenda 44

History of AVTCs

For more than 30 years, the U.S. Department of Energy (DOE) has sponsored 12 Advanced Vehicle Technology Competitions (AVTC) in partnership with the North American auto industry.

More than 27,000 students have graduated from an AVTC 93 universities throughout North American have participated in an AVTC

More than 165 corporations have contributed to an AVTC over 34 years

YEARS OF

Ohio State EcoCAR 33

PARTICIPATION 1990 1995 1999 2004 2008 2011 2014 2018 Natural Gas Vehicle Challenge FutureCar FutureTruck Challenge X EcoCAR: The NeXt Challenge EcoCAR 2: Plugging In to the Future EcoCAR 3 EcoCAR Mobility Challenge

SIX CONSECUTIVE FIRST-PLACE FINISHES

AVTC teams have finished

A History of Success OSU

in the top 3 teams for 13 of the past 14 competition years.

Ohio State won 1st place overall in the final year of EcoCAR 2, in all four years of EcoCAR 3 and the first year of the EcoCAR Mobility Challenge

Results of EcoCAR MC Year 4 2nd Place Overall Communications Awards Outstanding Team & Sponsor Collaboration 3rd Place Communications Presentation Project Management Awards 1st Place Mid-Year Project Status Presentation Technical Pre-Competition & Presentation Awards 1st Place Final Technical Report 1st Place Propulsion Systems Integration Presentation 1st Place HMI and User Experience Presentation Competition Vehicle Event Awards 1st Place Consumer Appeal Sponsored Awards 1st Place AAM Workmanship 1st Place dSPACE Leadership in Validation

Engineering Goals: Increase fuel economy Integrate Connected and Automated Technologies Target the Mobility-as-aService Market Sponsored by the U.S. Department of Energy, General Motors, MathWorks and many others. What was EcoCAR Mobility Challenge? 4-year Advanced Vehicle Technology Competition (AVTC) challenging 11 college teams to rebuild a 2019 Chevrolet Blazer

Vehicle Architecture – Parallel Hybrid 50 General Motors 2.0L Turbocharged LTG 9T50 Transmission Hybrid Design Services 3.5 kWh ESS BorgWarner eGearDrive Denso 32 kW BAS CAV Hardware Processor 1 dSPACE MABx 2 Intel TANK 3 NVIDIA PX2 Sensor A Mobileye Camera B Delphi LRR C Aptiv MRR 1 3 2 A B C B C C C Parker Hannifin 90 kW REM

EcoCAR EV Challenge

Engineering Goals: Increase efficiency of powertrain system Integrate Connected and Automated Technologies Identify and address specific equity and electrification challenges 4-year Advanced Vehicle Technology Competition (AVTC) challenging 13 college teams to engineer a next generation battery electric vehicle (BEV). The EcoCAR EV Challenge: What is the EcoCAR EV Challenge?

EcoCAR

Wilberforce University

54

What is The Competition Structure?

Design and Integration

and Systems

& Simulation

Hardware and electrical system integration

Thermal systems development

High voltage systems

Calibration

Component testing

Design and implementation of a safe, robust, and functional propulsion control system

Developing models used to simulate the vehicle and subsystems

Developing reliable and accurate multisensor vehicle perception systems

V2X communication systems

Autonomous control systems

Project Management & Systems Engineering

Equity and Inclusion

Management of the organization using Agile techniques

Sponsor and supplier interface

Systems engineering

Recruiting & retaining

• Developing university partnerships

Identify inequities in underserved communities through community-engaged research

55 •

•

•

•

•

Systems

•

•

Controls

Modeling

•

•

•

Connected and Automated Vehicle Systems •

•

•

•

•

Diversity,

EcoCAR EV Project Scope

Project Scope

EcoCAR

Propulsion System

Connected and Automated Vehicles

57

Propulsion System

Project Scope 58 EcoCAR

Connected and Automated Vehicles 1. Fully Integrated Propulsion System Architecture 2. Software & Calibration Maturity 3. High Efficiency Energy Management Strategy 4. Propulsion System Fault Mitigation

Project Scope 59 EcoCAR Propulsion System Connected and Automated Vehicles 1. Fully Integrated Propulsion System Architecture 2. Software & Calibration Maturity 3. High Efficiency Energy Management Strategy 4. Propulsion System Fault Mitigation

Project Scope 60 EcoCAR Propulsion System Connected and Automated Vehicles 1. Fully Integrated Propulsion System Architecture 2. Software & Calibration Maturity 3. High Efficiency Energy Management Strategy 4. Propulsion System Fault Mitigation

Project Scope 61 EcoCAR Propulsion System Connected and Automated Vehicles 1. Fully Integrated Propulsion System Architecture 2. Software & Calibration Maturity 3. High Efficiency Energy Management Strategy 4. Propulsion System Fault Mitigation

Propulsion

Project Scope 62 EcoCAR

System Connected and Automated Vehicles 1. Fully Integrated Propulsion System Architecture 2. Software & Calibration Maturity 3. High Efficiency Energy Management Strategy 4. Propulsion System Fault Mitigation

Project Scope 63 EcoCAR Propulsion System Connected and Automated Vehicles 1. Perception System Design 2. Sensor Fusion 3. Path Planning and Control 4. V2X Technology

Project Scope 64 EcoCAR Propulsion System Connected and Automated Vehicles 1. Perception System Design 2. Sensor Fusion 3. Path Planning and Control 4. V2X Technology

Project Scope 65 EcoCAR Propulsion System Connected and Automated Vehicles 1. Perception System Design 2. Sensor Fusion 3. Path Planning and Control 4. V2X Technology

Project Scope 66 EcoCAR Propulsion System Connected and Automated Vehicles 1. Perception System Design 2. Sensor Fusion 3. Path Planning and Control 4. V2X Technology

Project Scope 67 EcoCAR Propulsion System Connected and Automated Vehicles 1. Perception System Design 2. Sensor Fusion 3. Path Planning and Control 4. V2X Technology

Outcomes of EcoCAR

What Does EcoCAR Offer Students?

Participation in AVTCs helps to prepare undergraduate and graduatelevel students for the workforce, providing hands-on experiences that carry them through into their future careers.

Employers are looking for students with these skills, leading to a 100% placement rate with above-average salaries.

Apply knowledge gained in classes to real world projects Network with companies in the automotive industry

Learn advanced automotive technologies and concepts

Work with a diverse and interdisciplinary team

the Start of EcoCAR

(Autumn ‘18)

With community events focused on instilling the importance of higher education and the future of sustainability…

Impact on the Community

6000+ People* Since

Mobility Challenge

*COVID has really impacted outreach activities in the current competition cycle 29 Youth Outreach Events 18 Community Events 20 Influencer Events 12 Publicity Events

Since the Start of EcoCAR Mobility Challenge (Autumn ‘18)

With a majority of our leadership team comprising of graduate

Graduate Degrees

Impact to College of Engineering 4 Conference Papers 3 Technical Conference Presentations 7 Undergraduate Theses 17 Graduate Theses

20

students...

Sponsors

Headline

Leadership

Sustaining Contributor

72

Visionary

Thank you! 73 Kamryn Russell Russell.1114@osu.edu

Formula Buckeyes

EAB 2022 Danny McCray Mccray.112@osu.edu Alexander Hargett Hargett.15@osu.edu Business Director President

Overview

Our Team Competition

75

2023 Outlook Financials

2023 Team Goals • Top 3 Overall at Michigan May IC • Top 3 Design • Sub 4.2 Acceleration • Sub 5.1 Skidpad • Top 3 Autocross • Top 3 Endurance • All controllable cost points • 1st Business Presentation • 1st in class at Pitt Shootout 77

Improvement Plans

2023

• Weight reduction • Engine modeling and tuning • Aero simulation • Camber curves and steering effort • System fail safes and alarms • Shifting system rework • Timeline management emphasizing testing time • Driver training 78

Funding Breakdown

EXPENSES

79 General 17% Chassis 13% Suspension 20%Electronics 9% Brakes 5% Aero 7% Ergonomics 1% Engine 22% Drivetrain 6% PROJECTED 22-23

Total Expected Expenses: $65,592.85 Capstone 15% Alumni 25% Volunteering 11% TREP 18% Sponsors 12% Other Programs 19% FUNDING SOURCES

External Funding

Part / Facility Donations Cash Donations / Discounts

SKF

Composites Envisions

80

• Autoclave • Test Track • Welding Equipment • Henkel • Hexion • B’Laster • Ticon •

•

Alumni

81

Questions? 82

Pantelis Anton Team President

83

Agenda • The Team • Competition Breakdown • Competition Standing • Team Goals • Design Pursuits • Value Baja Buckeyes EAB 84

The Team • 30 members • 7 Subteams • Brakes • Business • DAQ • Drivetrain • Ergonomics • Frame • Suspension & Steering 85

Competition Breakdown

Static Events • Design Presentations • Business Presentation • Cost Reduction Report Baja Buckeyes EAB 86 Dynamic Events • Maneuverability • Suspension & Traction (S&T) • Hill Climb/Sled Pull • Acceleration • Four-hour endurance race

Rochester, NY June 2022

33rd/88 Overall

6th in sled pull

18th in suspension and traction

44th in endurance 59th in acceleration

23rd in maneuverability

35th in the sales presentation 54th in the cost event 24th in design

Baja Buckeyes EAB 87

Team Goals

1

Overall standing

Achieve top 25 overall

2 Project Management Complete the vehicle for reveal day

3

Design

Achieve top 25 in design

Baja Buckeyes EAB 88

Design Pursuits

drive

Weight Reduction

Driver Comfort

Baja Buckeyes EAB 89 4WD Chain

- Dog clutch in gearbox - Custom front gearbox - Custom rear half-shafts - CVT tuning

425 lbs - Chassis tubes and sizing - Half-shaft design - Confidence in loading scenarios

5% female and 95% male - Custom seat and padding - Custom steering wheel and grips - Chassis dimensions - Footbox

ValueApplication

Current Knowledge

Baja allows for the application of current classroom knowledge to real-world problems and designs.

Increased Breadth

Network

Expansion of Knowledge

Baja allows for the increased breadth of knowledge through challenging designs for current problems that expand beyond classwork.

Sponsor, Alumni, and Companies

Students can connect with sponsors, alumni, and other companies, expanding the network of the team and creating industry connections to further the performance of the team in addition to personal development.

Baja Buckeyes EAB 90

Thank you!

sterling K. K. Tool Co.

Buckeyes

Buckeyes

91

Baja

EAB

92

Laura Friedmann Operations Manger

Daniel Seals

Battery Pack Lead

93

95

Goal

Status

Our

Buckeye Current aims to set the world land speed record. Under 150kg, electric class. 96 Our

• At year 1 of 2-year development cycle • Major components selected and purchased • Moving into detailed design & manufacturing phase 200+ MPH

97 Bonneville Salt Flats Wendover, Utah 98.550 mph 166.730 mph 215.964 mph

98 98

MARC GEWERTZ AND SPEED DEMON MEDIA

98

Innovation

Buckeye Current operates at the forefront of the EV movement.

State of the art lithium-ion cells, electric motor, and controls technology

Incorporating industry-standard safety measures

the latest research and simulation knowledge from the Center for Automotive Research

99 •

•

• Leveraging

Battery Pack Mount, protect, and electrically connect cells with appropriate safety measures. • Vehicle simulation drives sizing of battery pack • 585 high-power lithium-ion cells, 491V • Industry-standard safety measures • Design for assembly & service

Powertrain

Mechanical integration & cooling of

and

101

electrified powertrain. • Cooling of electric motor & inverter • Packaging & mounting powertrain components • Manufacturing, testing,

validation

Safely control all electrical components on the vehicle & capture sensor data

voltage component selection &

design

Electronics 102

• High

safety • Low voltage system

• Vehicle controls

Frame Design 103 • Custom chassis • FEA analysis & manufacturability • Suspension dynamics • Accommodate requirements of all vehicle components Custom chassis to optimize vehicle structural stability, aerodynamics, and functionality.

Aerodynamics

designed &

for

above

analysis

104

Fairings

manufactured in-house

speeds

200mph. • CFD

• In-house fairing construction • Hand lay up • Track testing at TRC • Wind tunnel testing at TRC

Team

Demographics 7 Freshman 9 Sophomore 4 Junior 8 Senior 4 Graduate 105 27 Male 6 Female The diverse 33-student team represents both engineering and non-engineering majors. 11 Mechanica l 6 Aer o 1 11 Electrica l1 3 Othe r Chemica l Civil Annual participation is 30-40 students, mostly undergraduate.

Student Involvement, Training, & Careers

Current gives Ohio State students experiential learning that can’t be taught in the

&

106

Buckeye

classroom. • Complex design

manufacturing challenges • Practical applications of theoretical knowledge • Ownership of engineering work Buckeye Current Alumni work at: • Honda R&D, Ford, General Motors, Stellantis, Harley Davidson , Bosch, Rivian, Schaeffler Group, LiveWire, among many others

Our Partners

Connecting Ohio State students with industry since 2010

107

Questions?

you!

108

Thank

Javier Fernandez

110 • 2nd year Masters student • Mechanical Engineering • Contact: Fernandez.302@osu.edu About Me

Goal of the Competition

Overview • Overarching

• The Breakdown of our Competition • The Sub-teams of our team and what they do • Year 1 Accomplishments • Year 2 Challenges • Value of Buckeye AutoDrive 111

Overarching Goal

112 • To develop and test a level 4 autonomous passenger vehicle. • Level 3 = GM’s Super Cruise • Level 4 = Fully autonomous but driver takes over in risky situations

113 • Year 1 = Perception Capabilities • Year 2 = Controllers and Simulation • Year 3 = Exploring Edge Cases • Year 4 = Attaining Level 4 Autonomy Competition Breakdown

Sub-Teams

• Buckeye AutoDrive Sub-teams • Perception • Sensor Integration • Simulation • Planning and Controls • CAN bus • Systems Safety • Hardware Integration 114

and

115 • Handles all the design

creation of the vehicle’s computer vision algorithms. • Object Detection • Lane Detection • Traffic Light/Sign Recognition Perception

Sensor Integration

116 •

In charge of all the sensor integration and fusion needs of the team

•

Also handles the systems interfacing of all the elements in the system.

Simulation

Handles and the design and simulation of the ideal behavior of the autonomous vehicle.

Route Planning

Collison Avoidance

Lateral/Longitudinal Control

117 •

•

•

•

Controls and Planning

In charge of the design and implementation of the controllers of the vehicle.

Behavioral Planner

Motion Planner

Actuator Controls

118 •

•

•

•

CAN bus

Perception to Controls

Controls to Actuators

119 •

In charge of making sure that all elements in our system are communicating with one another.

•

•

Systems Safety

120 •

In charge of generating the necessary safety regulations to make risky situations more:

• Detectable • Controllable • Avoidable

Hardware Integration

121 •

Handles the design and manufacturing of all the necessary covers, mountings, and fasteners.

•

Also takes care of the needed wiring.

1

Accomplishments

122 • Competition takes place at MCity • 2nd overall and 2nd and 3rd in various other challenges (PM, Safety, Simulation, Dynamic) • OSU’s first year in the challenge. Year

123 • Year 2 = Controllers and Simulation • Intersection Challenge • Highway Challenge • Perception Challenge 2 Year 2 Challenges

Goals

124 • 1st place in Static and Dynamic Events • Smoother Integration Phase • Equal focus on all aspects of the vehicle (PM) • Requires finer project planning • Systems Safety Year 2

Value of AutoDrive

• Students get the chance to work in a cutting-edge field of engineering.

• Allows students full creative freedom (Building something from the ground up)

• Great opportunities for job hunting

• Pushes students to expand their knowledge in MAE, ECE, and CSE topics.

125

Sponsors!

126

Presentation to the CAR External Advisory Board September 2022

BSR EAB Presentation | About the Team

Who We Are

• Started in Spring 2021

• Buckeye Solar Racing is a new undergraduate student project team currently designing and building a solarpowered vehicle to compete in national collegiate competitions.

• We plan to race our first vehicle at the Formula Sun Grand Prix in Summer 2023.

Our Mission

• We aim to provide Ohio State students with an opportunity to gain technical engineering, business, and project management experience while furthering awareness of sustainable energy.

BSR EAB Presentation | About the Team Design

Collaborate

Communicate

BSR EAB Presentation | About the Team

Hands-on work

Fabricate new designs

Test and validate existing systems

BSR EAB Presentation | About Solar Racing

BSR EAB Presentation | About Solar Racing

BSR EAB Presentation | The Races

BSR

Presentation | The Races | American Solar Challenge

FSGPASC

3-day track racing event.8-day 1400+ mile competition.

2023 will return to Heartland

Park in Topeka, KS

EAB

FSGP

Motorsports

June 27 – July 2!

BSR

October

Presentation | The Project | Farasi

January-August 2022

September 2022

EAB

II

2021 WMU Solar Car team donates Farasi to BSR.

BSR moves to CAR!

Team works to design vehicle systems. August 2022 Onboarded over 50 new members!

Subteams

Aerodynamics

Electrical

Structural Business

BSR EAB Presentation |

Responsible for aeroshell and canopy development. Aim to minimize aerodynamic drag while optimizing weight and material characteristics working with composite materials. BSR EAB Presentation | Aerodynamics Team Project Teams 1. Canopy 2. Aeroshell Rework 3. Fairings Skills Learned 1. Computational Fluid Dynamics 2. 3D CAD Modeling 3. Hands-on work with composite materials Canopy CFD Analysis

BSR EAB Presentation | Electrical Team

Battery Pack Design

Responsible for full vehicle power delivery and storage systems, driver embedded systems, low voltage componentry, software development, and telemetry.

BSR EAB Presentation | Structural Team Project Teams 1. Chassis 2. Suspension 3. Steering 4. Brakes 5. Power Distribution Responsible for all load-bearing and mechanical subsystems on the vehicle, component packaging, driver ergonomics, and dynamic testing. Skills Learned 1. 3D CAD Modeling 2. Finite Element Analysis 3. Design for Manufacturing 4. Hands-on experience

BSR

Presentation | Business and Operations Team

Focus

and Sponsorship

Media and Outreach

Coordination

rely on the support of the OSU Engineering Department and corporate sponsors for our project to function. The Business Team is always looking for new supporters!

EAB

We

1. Fundraising

2. Social

3. Event

Project Timeline

04

Integration

Chassis received, integrate subsystems, VDR due

Race registration

PVDR due 03

02

Onboarding and Fabrication

Chassis and HV Powertrain

05

Vehicle Rollout Car completed! April 2023

06

2023

Race in our first competition!

Phase 2 Starts Fabrication 01 August 2022

November 2022

February 2023 FSGP

May 2023 BSR EAB Presentation | 2022-23

July 2023

Thank you

Research Activity Updates

143

ARPA-E NEXTCAR

Pete Olin

Engineer BorgWarner

Giorgio Rizzoni

Center for Automotive Research

144

Chief

Director

Intelligent Driving App: Making Driving Green

September 2022

ARPA-E NEXTCAR

• Goal: Improve energy efficiency by leveraging data from connectivity systems (such as enhanced mapping and V2X) to develop look-ahead optimization of propulsion and vehicle control.

• Project Phase I: (2017 2020) demonstrated 20% fuel consumption reduction on a Level 1, 48V mild hybrid + DSF vehicle.

• Project Phase II: (2021-2024) ARPA-E selected 4 teams for more funding.

• Goals:

• 30% reduction in energy use (over Phase 1 base);

• Level 4 automation.

146

Intelligent Driving App: Making Driving Green

Can be though of as next-level Adaptive Cruise Control (ACC) Reduces fuel / energy consumption Improves driver experience

147

(-> But: the app can be applied to any level of vehicle automation)

Intelligent Driving App: What is it?

An embedded software application that:

Is installed in a computing device that is part of the car

Interfaces with vehicle subsystems

• Optimize propulsion energy efficiency by using look-ahead route data.

• Leverages ADAS system data on vehicles with any level of driving automation.

• Provides optimized target values for Propulsion and Vehicle controls.

In-vehicle computing environment

Navigation

ADAS System

Driving App

Controls

Controls

•

•

148

/ Map / Infotainment / HMI Propulsion

Processing Vehicle

Intelligent

Intelligent Driving App: How it Works

Leveraging Route Characteristics to Optimize Vehicle Speed and State Of Charge

data for 48V mild hybrid

Route Information used for Optimization

Currently:

Vehicle location

Stop sign locations

Traffic light locations

Speed limit locations

Elevation/Grade

Road curvature

Intersection turn angles

In Development:

Traffic light, phase and timing

Real-time traffic density

others…

149

Route 19 80 70 60 50 40 30 SOC [%]

•

•

•

•

•

•

•

•

•

•

Simulation

150 Intelligent Driving App: Public Road Test Results Demonstrating 10+% savings Fuel Economy Evaluation In-Vehicle (48V mild hybrid) On-road comparison of: Manual Driving Intelligent Driving Driver selects desired destination, then engages ID system. Summary of Results Fuel Cons. (g) Travel Time (s) Manual Driving 237 249 Intelligent Driving 209 251 RESULTS 12% Reduction 2 sec End Start Route Characteristic Value Course Distance (mi) 2.6 No. of Stops (-) 3 Max Speed Limit (mph) 45 Min Speed Limit (mph) 25 Max Grade (%) 5 Min Grade (%) -5

Driving App: Benefits

energy efficiency improvement

• HEV: 10+% fuel consumption reduction (public road, track, and simulation tests)

• ICE: ~5% fuel consumption reduction (simulation tests)

• BEV: ~2-5% energy consumption reduction (simulation and public road tests)

• Enhances a driver’s ACC experience

• Adds value to OEM HMI/infotainment/navigation system for driver.

• Pulls driver to engage with the vehicle HMI (instead of their smart phone)

Improves Total Cost of Ownership for Fleet operators.

integration with propulsion and ADAS controls.

with TomTom for vehicle horizon information.

Development alliance with OSU CAR.

• Demonstrated

•

• Straight-forward

• Collaboration

•

Intelligent

151

Intelligent Driving App: Commercialization

Seeking industry partners for further development and commercialization

Potential project path

• Integration of the Intelligent Driving app into partner’s vehicle.

• Validation testing to confirm operation and demonstrate benefit.

• In-service operation for longer-term demonstration of benefit over a variety of routes.

• Consider expansion to larger vehicle set.

•

•

152

Commercial Vehicle Research

154

Qadeer Ahmed, PhD Assistant Professor Mechanical and Aerospace Engineering David Cooke Senior Associate Director Center for Automotive Researchrospace Engineering

Research on Commercial Vehicles

CAR

Qadeer Ahmed

@

Single Vehicle Corridor / Small Network

Better vehicles

Powertrain, electrification, control, light-weighting, aero/tires, etc.

Smarter vehicles

Control of speed and/or powertrain using:

sensors & connectivity

automation

Mobility System

Entire Urban Area

Better Mobility Systems

Better deployment of fleet resources

Routing

Fleet selection

Fleet management

15 6

▪

▪

▪

▪

▪

Energy Efficient Mobility Systems (EEMS)

Multi-level approach of research and development (R&D) for insights, tools, and technology solutions at the vehicle, traveler, and system levels

To improve transportation energy efficiency through low-cost, secure, and clean energy technologies

https://www.energy.gov/eere/vehicles/energy-efficient-mobility-systems

157

Challenges in EEMS & Our Focus

Key challenges we focus on:

• Diversity of powertrain types (PHEV, BEV, FCEV, etc.) and respective energy consumption

efficiency

Secure and energy efficient use of

V2X technologies

and infrastructure resource

158

• Powertrain recommendations maximizing fleet

•

ADAS and

• Fleet

deployment and management Toolset: Advanced powertrain models and software simulations Data-driven & physics-based optimization schemes

Super Truck 2 2019-2022

160 OSU Team: 1. Satvik Khuntia, MS Student 2. Athar Hanif, Senior Research Associate 3. Qadeer Ahmed, Project Investigator Class 8 Truck Summary 28 billion gal/year 2.5 million trucks66,000 miles 22% market ST2 Target Strategies Vehicle aerodynamics Engine Downsizing and hybridisation Light weighting and parasitic losses Idle/energy management On Highway - Long Haul - Heavy Duty Overall ST2 Strategies 48 V Mild Hybrid • Electrified Auxiliary load • E – HVAC • E – Hoteling Super Truck 2

Drive Cycle

Load Estimate

HVAC

using

Control

161

Optimal

10 hour idle 2 hour drive 0.5 hour rest 4 hour drive 0.5 hour rest 4 hour drive Composite Drive Cycle Structure

modelling

Physics Machine Learning for driver behavior modelling Dynamic Programming for benchmark solutions Real time implementable strategy developed $5/gal diesel 0.8 gal/hour 10 hour idling Savings: $40 /day/truck 175 lb. of CO2 Vehicle Simulator SuperTruck 2

Co-Optimization of Vehicles and Routes

2021-23

Improve

163 OSU Team: 1. Akarsh Konaje, Graduate Student 2. Sharat Hegde, Research Assistant 3. Manfredi Villani, Research Associate 4. Qadeer Ahmed, Project Investigator

commercial transportation system efficiency Objectives • Improve overall fleet freight energy efficiency • Develop, Implement & Validate cloud based intelligent transportation systems Potential Outcomes • Potential for 25% Freight Efficiency Improvement • Integrates several connectivity technologies which builds potential for future projects, especially, connected vehicle environment mobility future • Powertrain Agnostic: Diesel & e-Powertrain, makes this technology applicable to more vehicles

Our Work & Approach

Powertrain Optimization

ML Models

Target

Increase fleet freight efficiency by

vs BEV

Energy efficient configuration for multiple routes

50 100 150 200 Actual Energy Consumption [kWh] 50 100 150 200 Predicted Energy Consumption [kWh] Energy Consumption Prediction with Neural Network Training Validation Test +/- 10% +/- 20% +/- 30% 50 100 150 200 Actual Energy Consumption [kWh] 50 100 150 200 Predicted Energy Consumption [kWh] Energy Consumption Prediction with Random Forest Training Test Test +/- 10% +/- 20% +/- 30% Energy Intensity Distribution Full Trip (10Hz) 2 4 6 8 10 12 14 Energy Intensity [kWh/mile] 50 100 150 200 250 300 Value Count BEV Conv

:

≥ 8% • Developed a recommender system which provides energy efficient powertrain configurations for a given route • The PRS conducts performance evaluation for exploring the design space and uses machine learning to predict energy consumption for the feasible powertrain configurations • Demonstrated the application for diesel and electric trucks and provided recommendations based on user requirements along with analytical insights on fleet composition

Conv.

Community

Conscious Smart School Bus System 2022-23

Community

School

Hanif,

Miller, CURA,

Ahmed, Project

Cost / Passenger EV range Network Efficiency Travel Efficiency Mobility Energy Productivity Every single dollar is important for a school district in an underserved community. 50 35 10 25 12 % Community needs for a bus selection and deployment Safety Infrastructure Pre- and post- HVAC strategies for the fleet owner climate control strategies Geographical impacts Size of the school district Powertrain performance and neighborhood-aware routing. Existing fleet composition Variety of powertrains Driver constraints Telematics capabilities

Conscious Smart

Bus System Team: Satvik Khuntia, MS Student Joon Moon, PhD Student Athar

Research Associate Harvey

OSU Qadeer

Investigator

Community Conscious Smart School Bus System

Component level and system level modeling

Project Approach

HVAC

Powertrain Energy

E-bus Fleet composition and management

For the student transportation with E school bus

• By considering E school bus operating cost, seamless transportation

• Optimal bus fleet composition

• Optimal bus schedule

Regional Optimization of Application and Infrastructure Architecture in Heavy Duty Vehicle Electrification 2022–25 168 Team Partners

Regional Optimization of Application and Infrastructure Architecture in Heavy Duty Vehicle Electrification

A comprehensive multi-criteria co-optimization applied analytical procedure that brings the operations, BEV powertrain architecture, charging infrastructure, and the grid architecture (energy sourcing, siting, and carbon management) into a common framework, yielding regional specific optimal architecture roadmaps.

Goals

• Analytical tools of battery electric HD truck applications and use-cases to identify optimum vehicle, charging infrastructure, and grid architectures, with economic metrics on applicability, availability, efficiency, affordability, and sustainability

• Assessment of the electrification needs of the freight vehicle network associated with major U.S. shipping ports/rail terminals

• Early-stage vehicle, charging, and grid infrastructure roadmaps to support the above

future or emerging highly

three

freight transport

Figure 1: Optimizing a

electrified

network considers

primary layers – Vehicle, Charging, and Electric Grid Inbound Outbound Electricity fuel Port/term authority Public access D.C. access BEV powertrains Power plant Vehicle arch Charging arch Grid energy arch Freight Sea / Inland waterways Rail New energy sources Operations

Super Truck 3

2022-26

170

Super Truck

Objectives

Salient Features

system

3 171

• To demonstrate next generation medium and heavy-duty vehicles capable of ≥75% reduction of CO2 and tailpipe emissions • Improved freight

efficiency, total cost of ownership, and durability when compared to baseline vehicles

• 18 Class 8 battery-electric and fuel cell vehicles with advanced batteries will be developed • A megawatt charging station will also be developed and demonstrated. • To introduce advanced powertrains with ADAS and connectivity (V2X) features in the heavy-duty Class 8 truck • Adaptive energy-efficient routing to optimize freight efficiency, dispatching, and uptime at the fleet level • Fleet operations with geo fencing, electrical grid, and vehicle charging load management. OSU Team: 1. Muhammad Waleed Khan, PhD Student 2. Ahmed Hussain Safder, PhD Student 3. Manfredi Villani, Senior Research Associate 4. Chris Atkinson, co-Project Investigator 5. Qadeer Ahmed, Project Investigator

Range Prediction Tool for Battery Electric Transit Buses

Marcello Canova

Stephanie Stockar

5 time [h] 50 Speed [mph] 5 time [h] -4 -2 Acceleration [m/s 5 Time [h] -200 200 Pack Power [kW] Model Data 2 Time [h] -400 -200 200 400 Pack Current [A] 2 Time [h] 50 100 SoC [%] Model Data 2 Time [h] 600 650 700 Battery Voltage [V] Model Data Energy Prediction Tool Verification Metric s Energy [kWh] Initial SOC Final SOC Test Data 262.81 92 44 Model 261.65 92 43 Dr.

Dr.

FTA

No Emissions Transit Program

Low and

Proposed Scope Under the New Legislation = > Approved in IIJA 11/15/2021!!! • Capital Investment In Facilities Supporting the Testing of Low and No Emissions Vehicles and Components • Component Assessment Program – Testing For Industry • Directed Research - In support of low or no emission vehicles as well as new and emerging technology components intended for use in low or no emission vehicles.

TVIDC

Transit Vehicle Innovation Development Centers

Organized by the Center for Transportation and the Environment (CTE) and CalStart

Goal: Address the challenges of the continued innovation, development, and adoption of zero emission transit technologies

Transit Agencies

LA Metro Los Angeles, C A

CTA Chicago, IL

MARTA Atlanta, GA

Capital Metro Austin, TX

SunLine Palm Springs, CA

SARTA Canton, OH

AC Transit Oakland, CA

San Diego MTS San Diego, CA

Broward Broward County, FL

CTDOT Hartford, CT Mountain Line Missoula, MT

Foothill Ontario, CA Denver RTD Denver, CO

Lextran Lexington, KY

Transit Manufacturers

GILLIG

Proterra, Inc. ENC

Nova Bus BYD New Flyer of America, Inc.

Research/Industry Groups

The Ohio State University Auburn University Penn State University American Public Transit Ass. (APTA)

Center for Transportation and the Environment (CTE) CalStart

174

FTA Low and No Emissions Transit Program

Directed Research

range

Safety

Early Project Targets

Directed by the Industry and FTA

transit vehicles

Reliability and Interoperability

175

–

–

• Real world

of electrified

• Battery

• Charger

CAR Expansion

176

Photo credit pharmaceutical technology

ADD A HEADING TO MATCH YOUR ICON

Add context here to match your heading and icon.

EV Battery and Alternative fuel Safety Research Opportunities

ADD A HEADING TO MATCH YOUR ICON

Add context here to match your heading and icon.

ADD A HEADING TO MATCH YOUR ICON

Add context here to match your heading and icon.

177

Components of the program • Market research – technology trends, market penetration, standards, best practices • Assessment of installed testing capacity • Needs assessment and recommendations for laboratory expansion

Thank You

Qadeer Ahmed

17 8

Lunch

179

Langlois

Innovation Corridor

180 NSF Engine Electric Mobility

Maureen

Research Development Specialist Giorgio Rizzoni Director Center for Automotive Research

Regional

Engines Program

Innovation

• Flagship program of NSF’s new Technology, Innovation, and Partnerships (TIP) Directorate • Purpose is to grow sustainable regional innovation ecosystems that… Address major societal challenges Accelerate emerging tech in areas critical to national competitiveness Drive durable regional economic growth

The Engines Model – 3 Core Functions

Regional Innovation Engines Program

• Up to $160M, 10yr (Type 2) • Cooperative Agreement • Goal: • Drive durable regional economic growth, maintain US competitiveness in emerging tech areas • Functions: • R&D • Translation • Workforce Development Nascent Phase Emergent Phase Growth Phase

An Innovation Ecosystem is NOT a Center

Engines v Centers (e.g., ERC)

Engines ERCs, etc. Only one per region; whole region involved Partners are best in class, not just regional Tech translation possibly more important than R&D R&D is the main purpose, other functions second Bigger Smaller Higher leverage of federal dollars over award life in partner contributions (not called cost share) Think 4:1? Federal award is main funding Needs a real sustainability plan Needs a sustainability plan Run by full-time CEO Run by university-based PI Can be run by non-universities 99% run by universities The R&D needs to be novel & exciting Highly functional collaborative model across lots of stakeholders Industry very involved in research including providing funding DEIA super important “Culture of innovation” needs to be established Both:

An innovation ecosystem leverages... • Existing R&D assets • Existing workforce, STEM training assets • Venture & philanthropic partners • Government • Of course industry! An innovation ecosystem addresses... • Critical technology needs • Identified societal issues • Gaps in innovation infrastructure • Gaps in workforce preparation

An innovation ecosystem produces…

• New technologies & applied knowledge • Patents, licenses, & products • Capital in-flows • New businesses and entrepreneurs • New & retained jobs • Future-trained workers (All “skill” levels)

ROUGH TIMELINE

August Engage current partners, add others

Assess and initiate establishment of independent non-profit

Form functional working groups for R&D, translation, workforce, DEIA & regional impact

September Working groups active: meetings, studies, focus groups as needed

Develop industry and government engagement strategy for partnerships

Agree on governance structure for non-profit

October Working group landscape analysis and initial recommendations due

Hold 2-d visioning workshop: vision, mission, scope drafted

Complete establishment of nonprofit ahead of LOI submission

Provisional leadership team drafts candidate governance models

ROUGH TIMELINE, cont’d

November 2-day Engine workshop: governance model, DEIA approach, integration

Rough budget drafted including partner contribution scenarios

Begin socializing specific value prop to partners, discuss contributions

December Finalize proposed implementation plan, accord with budget and partners

Identify, vet, socialize CEO candidates

Draft agreements for Engine to function with partners (e.g., contracting, IP, subaward)

<LOI due 12/15/22>

Full draft due for red team 12/15/22

January Finalize and review proposal documents

Receive all letters of collaboration and contribution commitments

<Full proposal due 1/31/23>

February Have a party!!

Thank You!

192

Photo credit: COTA

Photo credit: COTA

Buckeyes

Buckeyes