P1 C NNECTION

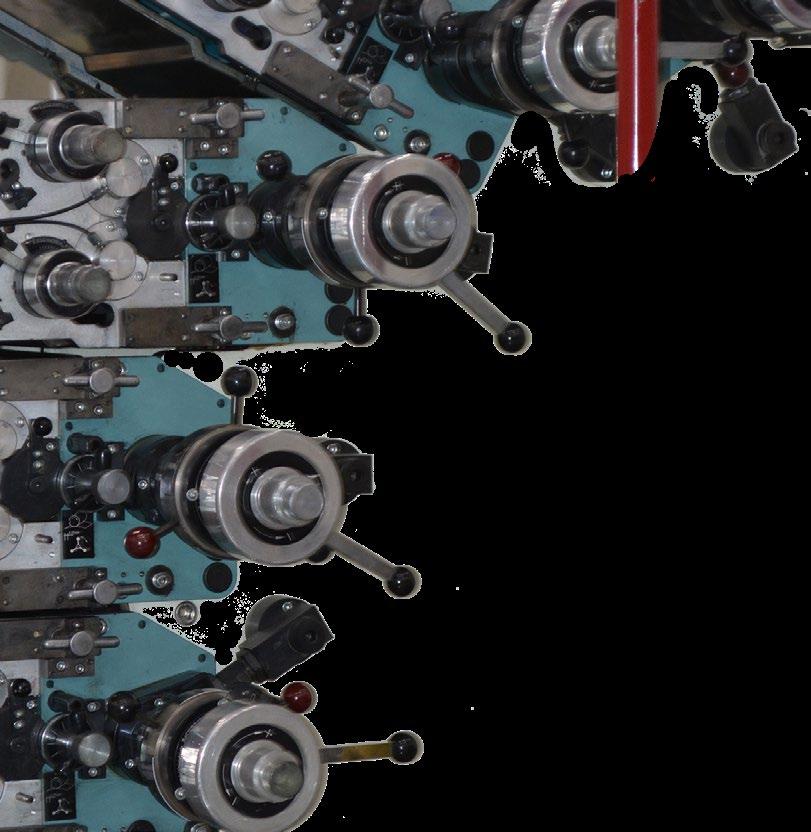

P1 Millwrights have come a long way, baby! Impressive project, personnel, and revenue growth propels the division into a new era.

I

t seems like just yesterday we wrote this article about the Millwright Division of P1 Construction in 2018.

And the Millwrights have come a long way, baby - with impressive project, personnel, and revenue growth.

Most recently, the Millwrights' success was evidenced by numbers released by Local 1529 – the Kansas City Millwrights union.

The numbers measured Kansas and Missouri Millwright hours, combined over the past four years (2019-2022). And P1 Millwrights led the charge in combined Kansas and Missouri hours.

“Our team will be the top millwright contractor in hours logged for both Kansas and the Kansas City area,” Millwright Team Leader Jim Nisely said. “We are on target to work over 110,000 man hours in 2022.”

In Kansas, P1 Millwrights were second only to IMI of Topeka, with 99,954 hours, and in Missouri, P1 Millwrights came in second to Burns Boys Co Inc., with 221,685.

But just like every success story, it’s the people behind what’s on the paper who make it happen.

The Millwrights became a division of P1 around 2014, following one of P1’s all-time

largest projects, the relocation of the National Nuclear Security Administration’s Kansas City Plant, managed by Honeywell. At the time, it was Millwright Team Leader Jim Nisely with just six field associates.

Today, the Millwright team consists of: one senior project manager, two project managers, two project engineers, three engineers, 18 foremen, and, in 2022, around 65 Journey man/Apprentices in the field.

Millwright Project Manager Marques

Nisely says three factors made the growth and success happen: Jim’s passion and tenacious leadership, P1 executive leadership’s commitment to the Millwrights, and attracting the very best talent in the field.

“From day one, Jim has given a massive amount of time and effort in getting us where we are,” Marques said. “I consider myself fortunate to learn from the example he has set for us all, and benefit from his mentorship, which took me from the field to project man agement. I do not know a person that is more driven or works harder than he does.”

“P1 ownership’s commitment and investment to the division has been critical,” Marques said. “They have always been willing to support and provide the resources necessary to complete our projects and help grow the division.”

A WINNING TEAM

Pictured

Leadership,

2nd Place 2nd Place

But Marques emphasizes that without the talent out there performing the work, the success couldn’t happen at all.

“The biggest reason for our success in building the division has been, and always will be, having the most talented and strongest field lead ership in the area,” he said. “Our sustainability comes from these guys –their attention to detail, and the hard work and long hours they put in.”

“We would put our field team’s skills against anyone in the country. It’s an honor to work with such good men.”

So why does such good talent flock to P1? Marques says one reason is the way P1 treats their field experts.

“P1 gives us what we need to do our job. They get the trucks, they pro vide the tools. Some of the guys coming from other firms are amazed – they’ve never been give the tools to do the job. They come here, they have everything they need,” Marques said.

“Whether you’re a Millwright in a grease pit, or a sales person in an office, when your company makes your job easier, you’re going to excel at it.”

Foreman Tom Sparks echoes that sentiment, and adds that the professionalism of the team is all about attitude.

“I believe the only thing that we are truly in control of is our own attitude,” Tom said. “How we react to situations that come up is totally up to us. If we work hard at keeping a positive attitude, our crews will stay positive.”

And holding on to the best field personnel means attracting – and keeping – customers. P1 Millwrights have had long-standing relationships with customers like

CertainTeed Building Products, Central Plains Cement Plant, Ply Gem Building Products, Hill’s Pet Nutrition, and JM Smucker Pet Food.

The Millwrights have taken on multi-million dollar projects with a customer base that continues to grow.

“It’s the reliability our field leadership provides,” Marques said. “We provide customers with the labor quality they need to complete their projects.

You give our Millwrights something to do, and they do it. No one has to make sure we’re working or make sure it’s being done right - it is.”

Marques says assigning the right talent to the right project is critical to this kind of success – a luxury the Millwrights sometimes have with their diversely talented team.

“Millwrighting is such a broad trade. We work on power house turbines, we put conveyors in. We install equipment. We touch many different industries,” Marques noted. “Some guys have specialties in some areas, some in others. We try to match those to the project.”

The Millwright division also operates independently in key areas, performing their own estimating, and using the skills of Project Manager Wes Trammell to handle manpower scheduling in addition to his other responsibilities.

“We have averaged 60-65 in the field all year, and even got up to almost 80 at times,” Wes said. “That’s pretty amazing, considering the labor issues in our industry.”

Jim says Millwright growth has also been fueled by the in-house engineering capabilities.

“We have added two design detailers to help control the load put on Senior Engineer Dave McPherson,” Jim said. “Although we partner

with other engineering firms, having detailers Justin Shrack and Yaser Almuarifi on our team has given us more flexibility to control scheduling and increase our in-house capabilities.”

And of course, the dollars don’t lie. Millwright annual revenue has gone from $8,391,643 in 2019 to a forecasted $27,800,000 in 2022.

P1 Vice President Glenn Shain, who has worked with Jim and the team from the beginning, marvels at how the division has grown in just a short time - and the value of developing symbiotic relationships with other P1 divisions.

“In just a few short years, our Millwright team has jumped from supporting other divisions in their work activities to a position of lead ing other divisions into exciting new work opportunities,” Glenn said.

Marques notes that Director of Business Development (then Operations Manager) Steve Hinshaw was integral in helping sell the Millwright capabilities internally to other P1 divisions.

“Jim and his team are uncovering many new full MEP opportunities lead by the millwrights fabricating, setting, and moving critical equipment and structures for new customers,” Glenn added.

“These projects bring our piping and electrical teams into supporting these customers with full facility solutions.”

“It has been a great joy to watch this team explode in its impact to our construction business plan and we are excited for the many additional opportunities for growth ahead for them.”

This was the P1 Millwright’s first amusement park ride, but it probably won’t be their last! Although the project had some setbacks due to pieces not fitting correctly, the P1 crew was able to assist the customer with corrections and capture all the documentation for change order purposes. This made it easy for the customer to get money back from the manufacturer. P1 Millwrights were instrumental in the installation of two theaters, two structures, and eight ride units. FlyOver uses immersive, state-of-the-art technology that gives riders the unmistakable feeling of flight. Participants sit with their feet dangling before a 52.5-foot-wide spherical screen, while the visuals whisk them away on an exhilarating journey above the iconic Las Vegas strip. Special effects combined with the ride’s motion create the ultimate flying ride.

Millwright capabilities shine in large industrial settings like Hill’s. P1 Millwrights have worked on multiple projects at Hill’s, including: MSCC3, which included conveyor Installation and integration; design, fabrication and installation for equipment access platforms; and integration of mixing and making equipment; MIH, which included batching equipment installation; pneumatic conveyance installation; and structural design, fabrication and installation; and SRP3 (Omaha, NE), which included electrical trestle structural fabrication.

Another industrial success, the Smucker twin screw extruder project included relocation and installation of new extruder equipment; installation on pneumatic conveyance systems for the project; and design detailing, fabrication and installation of access platforms.

Tired of hearing us talk about how great P1’s singlesource capabilities are? Too bad.

“All trades under one roof” is exactly what’s turning a job with some challenging physical constraints into another P1 success story.

According to Project Manager Casey Sheafer, the Kansas confidential mission critical data center expansion project had some items that required careful consideration and dedicated design leadership – and P1 was up to the task.

The P1 team installed three megawatt generators, 1,000 feet of electrical duct banks, and two 4,000 amp services, for a contract amount of $14,000,000.00.

Capabilities included Virtual Design and Construction (BIM); electrical, pipe, plumbing, and sheet metal fabrication; Millwrights; electrical, HVAC, plumbing, and mechanical construction; and commissioning.

Casey says the knowledgeable P1 team was able to help lead project decisions to ensure proper placement.

“P1 helped drive a lot of the decisions in our submittals and shop drawings, thanks to multi-trade expertise,” he said.

Next, the team found themselves applying some creativity to work within the tight space.

“There was a lot of underground conduit and mechanical work, and concrete foundation work,” Casey said. “We had to come up with a design to fit everything in the limited space.”

Electrical VDC Specialist Justin Underwood notes that when VDC embarks on a project, there’s more to just creating the drawings and handing them off to fabrication or the field.

“We had to work back and forth with the foreman and project manager to understand the design we’d have to come up with,” Justin said. “There’s lots of collaboration between VDC and the field on what those drawings should look like, and how to route the elements the way the foreman needs it.”

Justin says the goal is to create something that fits the way the foreman would install it even if VDC and fabrication weren’t part of the process.

“We spend hours in meetings on how to route it, and the best preferred methods,” Justin said.

Justin adds that the electrical modeling was more time-consuming due to “redundant wiring”, which is common in data centers.

“Redundant wiring means there’s an “a” side and “b” side, so conduit to a piece of gear has to be done twice,” Justin explained. “If one side fails, the other will pick it up, to ensure there will never be loss of power.”

VDC brought multiple trades to the table on this project, including plumbing, sheet metal, and electrical.

“This was one of the more rare projects in which we had so many trades from P1 on board,” Justin said.

And both Casey and Justin agree: that is the ideal situation.

“Being a single-source provider with the opportunity to have those multiple trades on one job means we can communicate verbally within seconds since we’re all together, rather than send an email to an outside contractor,” Justin said.

“We were able to have Turner in the same room with the multiple disciplines of VDC and get quick turnarounds on changes,” Casey added.

P1’s single source value-add on this project extends to P1 Millwrights, who set the massive equipment, and P1 Service will join P1 Construction and select third party vendors to perform the commissioning when the project is ready.

“Critical environments like data centers have a major commissioning process,” Casey explained. “It includes all the prechecks for electrical and mechanical. Then, over a week, there is a full-system check where the utility drops power to the building, batteries kick in and are tested, generators kick in and are tested, etc. It’s a pretty long process.”

P1 single-source to the rescue again, tackling tight timelines and tight spaces for a project done right!

ervice Coordinator Susan Watson has always believed that “life is what you make it,” and with this attitude, her life and career path has definitely been full of adventure.

Susan is the youngest of five children and grew up in Missoula, Montana. After finishing high school, she got a job at the Super America gas station and joined the Sheriff’s cadet program.

The cadet program taught young men and women about law enforcement as a potential career. As a cadet, she did security work at events and worked at the World’s Fair in Banff in the public exhibit buildings. She was able to go on field trips to crime scene investigations, ride-along with officers, and visit other police departments to learn about being a deputy.

As it turned out, she decided that law enforcement wasn’t a career she wanted to pursue, and, after getting laid off from the gas station, found herself unemployed and scouring the want ads.

“I replied to an ad in the local paper and drove 200 miles to Spokane Washington where I was hired to work on a crab boat out of Dutch Harbor Alaska,” Susan said.

She was 25 years old and set off to be a deck hand in the Bering Sea. If you have ever watched “Deadliest Catch” – that was Susan’s life for six months.

“We caught live crabs and loaded them to the processing ship and I’m here to tell you,” Susan said, “Hell is not hot!”

She said it got to 70 below with the wind chill and the only thing keeping them warm was the intensive physical labor. Susan and her colleagues wore coveralls and rain gear along with big heavy boots with cleats on them so they didn’t slip on the deck.

“You work non-stop. You only get to sleep when you are traveling to the next area, so you work about 18-20 hour days,” Susan said. “It’s hard work but I liked it because it was so different.”

She spent most of the time out in the middle of the Bering Sea, but when she was able to go to land, it was small Alaskan fishing villages inhabited by indigenous people.

“Going into those little villages was like walking into the past. There were no trees and everyone lived off the land for the most part. It was unlike anything I had ever seen before and it was amazing to experience that,” Susan said.

At the end of the crabbing season, she went home for two weeks, and then went back for the salmon season, which lasted about two months.

When salmon season was over, she moved on to the next adventure: working on a residential construction crew, which led to a job in the logging industry.

“In logging, you work year ‘round, but the winter is when the trees are cut, so it doesn’t damage the ground, and in the spring you go back through and plant trees,” Susan explained.

Susan had the job of a Hooker. The Hooker works on forested slopes, cutting the limbs off and then wrapping chains around the logs. Cables were then hooked to the chains and the logs were pulled up the mountain to be loaded on to trucks.

Then other companies would come through and put the limbs in piles to dry where they would be burned in the fall.

She had been logging for about three years when her then-boyfriend was hired on with the railroad.

“He told me I would love it, so I applied and was hired to be a switchman where I worked out of the train yard and switched out boxcars,” Susan said.

She did that for a few years but after dealing with seasonal layoffs, she applied for a position as a dispatcher. She returned to her Missoula, Montana roots for the job, but after five years, she was transferred to another state.

Susan and ten friends decided to move to Sioux Falls, SD with the I&M Rail Line.

Susan was in South Dakota a couple of years when one of her coworkers told her he was applying to the Kansas City Southern Railway. She made a call to KC Southern to get some information, ended up applying for one of the available positions herself, and flew to Louisiana to interview.

“After I got the job, the railroad came in and packed up my stuff and moved me,” Susan said. “I lived in Shreveport, Louisiana for five years and then the job moved to Kansas City, so they came and packed me up and moved me again.”

That was in April of 2009, and she was able to buy her first house in Gladstone, MO where she has been…wait for it… ever since!

After 26 years at the railroad, her position was eliminated and her experience as a dispatcher brought her to P1 as a service coordinator.

“I’ve had a lot of jobs during my life that were challenging and exciting and now I get to work at P1 and I just love it,” Susan said.

Susan says she really enjoys the working environment that P1 offers.

“Everyone works hard, absolutely, but everyone is very friendly and treats me like I’m important and my role here is important,” Susan said. “This is the reason I enjoy coming to work every day.”

Susan and her husband Karl are still newlyweds! They were neighbors in Montana, and had lost touch over the years, but in 2018 they were able to reconnect on social media and got married in January 2021.

Susan says they enjoy playing pool, doing puzzles, watching TV and tending to outdoor plants and flowers in the summer, and, of course enjoying time with Jillie, the family dog. Susan and Karl share their home with Susan’s sister Julie, who came to live with Susan after a medical crisis in 2020.