Semiconductor

Think What’s Possible

Page is a powerfully imaginative and collaborative architecture and engineering firm: one that’s ready for today and designed for what comes next. We pair form with function, reason with emotion, and ideas with expert implementation. At Page, the potential of what’s possible is paired with the practicality of how to make it happen. Our purpose is designing places smarter, while improving the experiences of those who work, live, and learn in them. From thought to finish, Page experts—of all disciplines—see the big picture, figure the best way forward, and deliver solutions in inventive and amazing ways. Imagine that.

Visit our website at pagethink.com

We start with your vision. We design for the future.

Page Serves The Following Core Markets:

Academic Advanced Manufacturing

Aviation

Civic/Community/Culture

Commercial & Mixed Use

Government

Healthcare

Mission Critical

Science & Technology

Page Advanced Manufacturing Expertise

Automobile

Electric Vehicles

Energy Storage

Lithium Battery

Microelectronics

Solar

Tool Hookup

Water/Wastewater

Design is the crux of what we do. Throughout the generations, Page has promised, and delivered, design that makes lives better. We believe buildings are important for what they do and for the positive impact they make on individual lives.

That’s why we have a solution-driven project focus that results in life-enhancing buildings and places. Our multidisciplinary services allow complete integration from conceptualization to engineering to interiors and more, resulting in an improved client experience and final product.

We recognize that good talent can be applied to complex projects regardless of industry. And good talent becomes great when it gains experience in a variety of situations. We create crossover teams so that individuals can work on different projects and share their own expertise and insights with other team members. Our collective commitment to visionary design is reflected in our portfolio of successful, complex projects.

Our work spans the globe, from more than 25 U.S. diplomatic campuses to mission critical facilities in the Middle East to five-star resorts in Africa and beyond. Since Page has multiple offices in the U.S. and affiliates abroad, we have the capability to staff projects onsite as well as set up “follow the sun” workflows to increase efficiency.

While Page is distinguished by our portfolio of successes, we also are distinguished by our full spectrum of architectural and engineering design services. This allows us to provide an integrated “total design” single team approach. Our clients benefit from the highest levels of interdisciplinary coordination, quality control and quick response demanded on today’s highly complex and technically sophisticated projects.

This we believe. As agents for positive change, we are driven by the ideals we hold dear. In the delivery of our services, we are guided by three core values:

Creativity

Think curiosity/innovation/ imagination/optimism/originality.

Collaboration

Think sharing/community/ camaraderie/civility/teamwork.

Commitment

Think integrity/respect/giving/ discipline/rigor.

Architecture

Page is known for their well-researched program-driven solutions aided by integrated multidisciplinary expertise and a strategic mindset. We bring global thinking and experience to bear on projects that build communities. Our portfolio reflects a commitment to visionary design, a record of innovation and fresh ideas and most importantly, demonstrated success with complex projects.

We develop a uniquely created design for every project that reflects the building type, client, need and location. We take pride in knowing that a Page project is one of the best possible solutions to the needs of its multiple stakeholders from owner to operator to neighbor.

Engineering

Our in-house engineering experts lead development of the latest industry design codes and standards. Page engineers contribute to progress in safety, wellness, sustainability, energy and carbon neutrality, and increase our impact by working across disciplines. We use a combination of custom tools and Building Information Technology solutions to visualize and communicate how occupants and operations interface with complex integrated building and process systems. Adoption of advances in renewable energy, microgrids, Internet of Things and high-performance systems demonstrate our commitment to socially responsible design. Our multidisciplinary mechanical, electrical, plumbing, fire protection and process engineering practice areas work collaboratively with design and construction partners to bring your concepts to reality.

Process Engineering

Page engineers and designers have worked with a variety of clients on developing comprehensive design layout and equipment integration to support manufacturing needs. We create process flow diagrams, section details for space management, tool and instrument specifications, and coordinate with vendors to determine the needed infrastructure for successful equipment installation. We work with clients through a comprehensive programming process to understand their manufacturing flow and process needs, and design systems that ensure safety and manufacturing standards are met, or exceeded. Through our work with advanced technology clients we have an acute sensitivity to the need for precision, accuracy, and compliance with each clients unique production needs.

Combining planning, architecture, interior design, industrial engineering, and predictive analytics, Page is able to help clients achieve maximum efficiency in process and aesthetics. Applying creative thinking to process and design, Page often saves clients significant time and expense in developing product manufacturing solutions. From vehicular circulation on a difficult site to the ergonomics of a work area, Page understands and excels at creative problem solving within the product manufacturing market.

Lab Planning / Design

Page specializes in challenging projects for demanding clients throughout the globe. Laboratory facilities are among the most intricate and complex projects.

The unique challenges posed by highly toxic petrochemical corrosion labs, sterile environments for pharmaceutical manufacturing, biohazard high-containment suites, precise environmental control of animal laboratories are commonplace obstacles overcome by our dedicated technical team of architects and engineers every day. Page has specialists equipped with a thorough understanding of the safety standards and scientific equipment requirements foundational to the success of all laboratories.

Workplace Design Strategy

As an interdisciplinary firm that stretches across multiple market sectors, Page has a depth of experience in our portfolio that covers manufacturing facilities to office space. Our clients range from aerospace manufacturers, to global technology companies, to federal government clients. We are on the cutting edge of advanced manufacturing practices, as well as Class-A office space trends.

Today’s workplace should be designed to a company’s culture and mission. Page dives deep to understand our client’s culture, mission, and project goals to help them create a workplace that will support and often enhance their culture. The dynamic workplace is the workplace that best supports a company’s goals. It is flexible, open ended and agile, it integrates people process and technology. The workplace is constantly transforming and evolving in response to technology, economic drivers, cultural shifts and emerging values specifically related to principles of environmental sustainability.

Lines are blurring between what was once a hard line between manufacturing space and office space. Today, the value of co-locating them allows various pools of knowledge to interact together resulting in true innovation.

Programming

To support clients before and beyond traditional professional services we have a dedicated strategies and analytics team that develop and employ a broad array of tools, techniques, and processes to help our clients make informed project decisions. Our in-house team brings expertise, energy, and passion to clarifying client challenges and opportunities sometimes before the nature of or need for a facility or real estate project is confirmed.

Our team members collaborate with Page and consultant specialists, designers, engineers, and clients to clarify goals, assemble information, and evaluate alternatives. Their understanding of business dynamics and organizational complexities allows them to efficiently and effectively facilitate productive discussions and target research. Custom data exploration and visualization differentiates our deliverables, not just to explain and summarize findings, but often also serving as interactive decision-making tools that help bring clients and their stakeholders into the evaluation process.

Building Sciences

Page approaches sustainable design through the interdisciplinary lens of building sciences to create higher performing, healthier, more resilient buildings. As one of the first signatories of AIA 2030 Commitment, we are invested in leading the industry towards carbonneutral buildings and advocating for resilient solutions to help our clients prepare for the future. We believe that intention requires rigor and through our data driven and integrative process, we collaborate early and often to ensure designs are informed by our building performance analysis.

Commissioning

Page recognizes the level of investment and importance of facilities that function as designed from the day they open. Our Commissioning service provides this assurance to owners and operators as well as minimizing costly construction rework. This is accomplished through a collaborative process that includes the building owner, design professionals and the general contractor under the guiding hand of the Commissioning Authority.

Page also performs Testing, Adjusting, and Balancing (TAB) in accordance with NEBB standards. We are an independent testing firm with absolutely no affiliation with manufacturers, factory representatives, vendors/providers, contractors or installers of HVACrelated equipment and systems.

Planning / Urban Design

We help our clients evolve, grow, and prosper because our process is informed by research, cutting-edge technology tools, and an appreciation for the unique culture of the people, organizations, and places we serve. Our interdisciplinary team of master planners, urban designers, architects, landscape architects, and programmers are dedicated to supporting the ongoing evolution of our urban areas, encouraging appropriate development and redevelopment suited to the particular conditions of each site we aim to transform.

Through urban districts, institutional campuses, innovation districts, long range development plans, master plans, streetscapes and transit-oriented communities, our teams integrate the building blocks of community, sustainability, and resilience into innovative solutions.

Advanced Manufacturing Integration at all levels.

Top 5 Green Design Firms,

Manufacturing & Industrial

Engineering News Record, 2023

Semiconductor Design

Engineering News Record, 2024

Design

Engineering News Record, 2024 #6

Page entered the field of advanced technology and microelectronics in 1981 with the design of Motorola’s MOS-8 wafer fabrication facility at its Ed Bluestein Campus in Austin, Texas. As the world of microelectronics has evolved, so too has Page’s philosophy on supporting the growing industry. At Page, we have expanded our teams and services to provide more comprehensive design and engineering expertise that keeps pace with the rapidly changing needs of the client. By establishing trust and long-term relationships with our clients, we gain institutional knowledge of their best practices and specific manufacturing advances, allowing us to grow alongside them, working collaboratively to retrofit and advance their existing facilities, and design better, more adaptable new facilities.

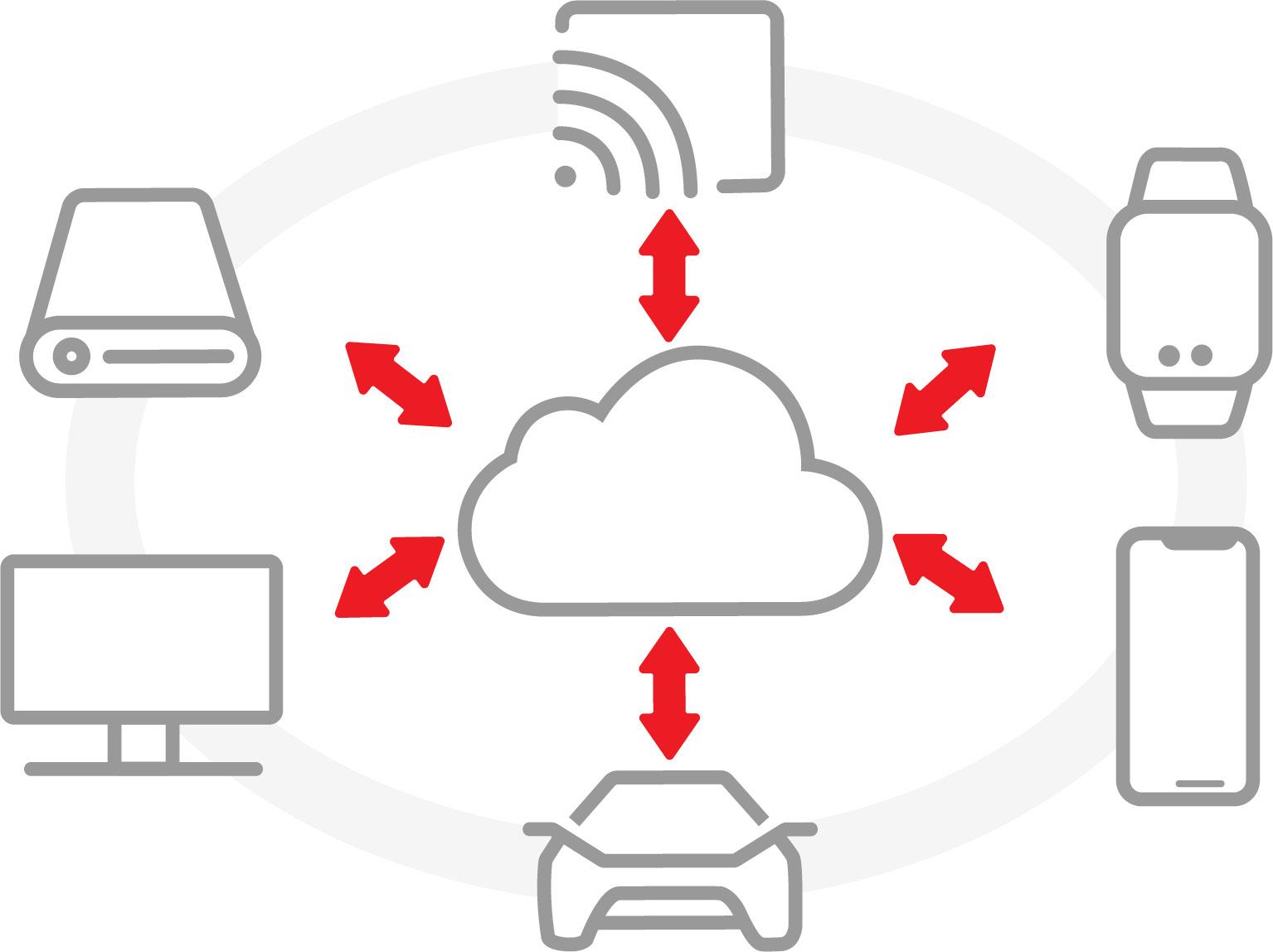

Page is heavily invested the semiconductor industry through our support and leadership of the International Roadmap for Devices and Systems (IRDS) Yield Enhancement (YE) teams, which consists of sub teams for Ultrapure Water, Ultrapure Chemicals, Ultrapure Gas, Air Molecular Contamination, and Critical Components. This team also works directly with More Moore Device Design Team which is leading the future of semiconductor device technology needs. The Yield Enhancement Teams are focused on identifying gaps and challenges and developing solutions as well as determining the roadmap for future device manufacturing needs. The IRDS community shares innovation, research, and resources to understand what the latest semiconductor manufacturing capabilities are, and to connect investment of the supply chain back to the needs of the manufacturers who use those components in their end products. Semiconductors are the basis of many of the devices we use every day in the growing network of the Internet of Things—from cell phones to laptops to drones and selfdriving cars. Engagement in IRDS helps keep lines of communication open between manufacturers, engineers, designers, end users, and everyone in between.

The Internet of Things (IoT) is powered by microelectronics, which drives development and growth across multiple related industries. Page is actively engaged in industry leadership organizations, helping to keep lines of communication open between manufacturers, engineers, designers, end users, and everyone in between. This unique insight helps our design teams stay current on latest industry trends and developments, and informs best practices in new and upgraded facility design.

This forward-looking approach to the microelectronics industry is carried through in our approach to designing fabs and manufacturing facilities. We look ahead, not just to next year, but 10 or more years down the road. Our design philosophy goes beyond just water, chemical and air processing, and the nuts and bolts of building a manufacturing facility; we get to the heart of where these devices are made, on a molecular level.

Page’s internal structure further supports this integrated approach. In 1942, Page became one of the first Architectural firms in the nation to integrate Engineering services within a single design organization. Today, the firm offers the complete range of Architecture, Interior Design, Strategic Consulting, and Planning capabilities together with in-house Civil, Structural and MEP Engineering services as a single, fully-integrated “total design” team. Our approach provides the highest levels of interdisciplinary coordination, quality control and quick response as demanded on technically sophisticated projects— while allowing our managers a single point of authority and control in committing the full resources of the design team in order to ensure that our commitments are met.

Similarly, Page is a diversified firm, with expertise in multiple market sectors. Our clients benefit from Page’s depth of portfolio and crosssector experience, which provides our designers and engineers with unique insights and unconventional solutions to design challenges. This exposure to how different industries addresses similar problems to provide our team with a broad project delivery perspective and more open-minded and innovative approach than single-focus firms that specialize only in a limited number of building types. Working collaboratively with companies in diverse business sectors, from small professional service providers to Fortune 500 companies, our multidisciplinary design professionals strategically plan and create spaces which help our clients accomplish their mission.

The Page team takes a holistic approach to the microelectronics and related industries and how that applies to our clients. We leverage this unique perspective and expertise to each individual client, finding the best solutions and design innovations for your specific project needs.

Advanced Manufacturing Team

Integrated Design Team

Page is a diverse design firm drawing from the expertise of our employees in architecture, sustainability, design, branding & graphics, and engineering. We believe our commitment to creativity and collaboration offer our clients a complete project team approach that results in coordinated, well-designed projects. At Page, we promise design that makes lives better. Our promise is that simple, and our delivery is all the more powerful for it.

We Want to Partner with You

We love what we do. We are a team of passionate designers who enjoy working together. We have a strong team and it shows through our collaboration with our clients and through the success of the project. We design to our client’s needs and vision, not prescriptively. This shows in the variety of work we produce. We are knowledge seekers and innovators, which make your project intensely exciting to us.

Over 126 years proud

Page is a full-service firm, providing professional consulting engineering design, architecture, and construction administrative services, for a variety of project types. We have been working in the advanced technology, microelectronics industry, and advanced industrial manufacturing for over four decades, and we have expanded our teams and services to provide more comprehensive design and engineering expertise for these advanced facilities that keeps pace with the rapidly changing needs of our clients. We establish long-term relationships with our clients, building institutional knowledge of their best practices and specific manufacturing advances.

Our seasoned engineers and designers have worked on major greenfield and renovation projects around the world, with a forwardlooking approach to facility design that emphasizes adaptability to accommodate the inevitable changes in manufacturing and microelectronics. We leverage this unique perspective and expertise to meet each individual client where they are, finding best solutions and design innovations for each client’s specific needs.

Page is actively involved with industry organizations who are leading the developments and advancements in the field of advanced microelectronic devices, and pioneering the next generation of devices and systems.

We work together as a single firm in a shared pursuit of excellence.

Page One: From Good to Exceptional

In 2013, Page announced to the world that we had made changes reflecting our then-new generation of leadership such as a new organizational structure, the opportunity for every employee to become an owner and a new way of working. This included a “one firm, one voice” approach supported by firmwide processes across all offices to improve project delivery. A few years ago, we elevated this concept with an initiative called Page One.

Page One identified opportunities for offices, practices and other organizational elements to further collaborate across the firm in a shared pursuit of excellence. The tagline “From Good to Exceptional” reflects the continuous mission to evaluate our actions on an ongoing journey with no defined endpoint. As we leverage Page One to improve our communities, reduce our environmental impact and lead with integrated design, we create operational models for others in our industry to follow.

We developed measures to evaluate progress and provide rigor to our intentions. They are based on our defined firm values, conversations with colleagues and research into evolving best practices.

These measures are organized into six categories, or pillars, that align with industry data gathering and recognition. By intentionally aligning our work with the pillars, we have clear, focused intentions and documentation of our progress:

Firm Strength

We seek people with capabilities and business acumen to give us the knowledge, competitive edge and financial health to create exceptional work on behalf of our clients and communities.

Design

We emphasize generating unique solutions across project types, systems, scales, geographies and client sectors by prioritizing rigor, economy, elegance and ingenuity.

Environmental Responsibility

We consider the impact of buildings on our environment and take responsibility for lessening it through regenerative thinking, processes, and solutions.

Social Responsibility

By intentionally nurturing diversity across origins, backgrounds, skillsets, experiences and more within our teams, we bring a wide range of creative inspiration and expertise to bear on solutions for clients and communities.

We are committed to ensuring our projects make lives better for users, their communities and society.

Research & Tools

We facilitate the dedicated exploration of new ideas and development of proprietary tools to improve our work processes and yield better design solutions.

Efforts to increase our institutional knowledge on key topics or issues involve the systematic collection, organization and creative analyses of information.

Professional Practice Leadership Page supports professional development and growth within our firm and in our industries through knowledge sharing and service on professional organization committees and boards.

SAN FRANCISCO

PHOENIX

LOS

Foundation of Page One:

§ Commitment to transparency and nurturing trust

§ Assessments of operational conditions

§ Analysis of systems in and out of Page

§ Evaluation of potential opportunities with a broad viewpoint

§ Integration of feedback from outreach

§ Conduct research and support innovation

§ Support of a collaborative framework that embeds rigor

Semiconductor

The semiconductor industry is driven by innovation, reliability, and speed that allows us to remain connected to an ever-evolving technology world.

At Page, our forward-thinking design process molds the manufacturing configuration into flexible, built environments by simplifying structural grids, harnessing reliable power sources, and balancing repetitive mechanical and specialty process systems into a complex environmentally controlled facility. Tracking and verifying key design metrics is paramount to our success for establishing a clear path to make informed decisions to solve complex challenges.

By immersing our clients into our design process, we can collectively identify emerging technologies, materials and environmental systems to create the best possible solution.

Confidential Semiconductor Client

Page has been performing work on this confidential semiconductor campus for over 15 years. Page was part of the design team for the Semiconductor Fab A2, which at the time of its construction, was the largest wafer fabrication facility in the United States. The 1.6 millionsquare-foot, 300MM plant includes 350,000 square feet of Class 100 cleanroom (including over 55 piping systems); 225,000 square feet of office support area; expansion to the existing central utility building; and miscellaneous structures and support facilities. The new Fab A2 project was located adjacent to the existing semiconductor facility Fab 1, and the Page team had to take considerable steps in sequencing design and construction packages to maintain existing operations of that facility during construction of the A2 project. The four-story office building housed the client’s USA Headquarters offices, a commercial kitchen, a 1,000-seat employee cafeteria, auditorium, meeting spaces, and a data center.

Since the completion of Fab A2, the Page team has performed numerous maintenance projects, upgrades, and improvements to both Fab A2, Fab 1, the central utility plant, and other miscellaneous campus needs. Page’s long-standing relationship with this client has established us as trusted experts for the company’s internal processes, standards and systems.

Location Austin, Texas

Project Size

1,600,000 Square Feet

Services Provided

Architecture

MEP Engineering

Process Engineering

Structural Engineering

Interiors

Confidential Semiconductor Manufacturer, Multiple Projects

Proprietary Waste Neutralization System

Page provided project management, design and engineering services for a $75M, first of its kind, 2.0 MGD acid waste neutralization treatment system, utilizing membrane bioreaction. Project included a chemical support building and lab. Mechanical scope included a 500 ton chilled water distribution, HVAC and Fire protection, and the process engineering included nitrogen, air, and water processing.

Gas/Chemical Layout and Facilitization

Page provided project management, design and engineering services for a $8M gas/chemical equipment layout and utility facilitization project that was based on client functional area and process needs.

Facility Upgrade Services

Page provided project management, design and engineering services for a $10M facility upgrade, driven by a client process upgrade. Scope of work included upgrades to bulk nitrogen, oxygen and helium systems, as well as Ultra Pure Water and cooling water systems.

UPS Power Upgrade

Page provided project management, engineering, and design services for a $20M UPS Power Upgrade at two of the client’s primary factories. The project required the installation of additional UPSs to provide a secondary power source on the existing distribution panels in order to achieve 100% redundancy within the entire UPS system.

Location Arizona

Project Size

Confidential

Services Provided

Architecture

MEP Engineering

Process Engineering

Structural Engineering

Life Safety

Telecommunications

Security

Instrumentation and Controls

Confidential Semiconductor Manufacturer FAB 28/28A

Page was the prime A/E working with Hensel Phelps Construction in a design/build partnership to completely retrofit a 500,000-square-foot fab, central plant and process support facilities and convert it to 14 nm technology. The existing fab was a high-volume semiconductor manufacturing plant, which ran 300 mm wafers on a 45 nm process technology. This project converted the older fab to the new 1274 process.

The scope of work was to design the necessary base building conversions and additions to accept the new process tool requirements and existing tool upgrades required to produce the new products. Major architectural / MEP / FP renovation components included upgrades to the building structural systems which included new process system support structures, reconfigurations of fab and subfab level support spaces, a 700,000 CFM smoke exhaust system, upgrades to the recirculation air system and distribution, AN ISO 150 class 3 100,000-square-foot cleanroom gut and redo including the 16’-tall Automated Material Handling System (AMHS) bays, complete electrical upgrade, and new fire protection systems.

Page provided project management, architectural, engineering and process engineering design, construction documentation, and onsite construction administration support. The design phase for the project began in late April 2014 with construction overlapping the design phase starting in early August 2014, establishing a just-in-time design package issuance. The majority of the construction was completed in August 2016 with substantial completion. The final completion date was January 2017 for the Hensel Phelps contract with the client. The entire project documentation was designed in 3D/BIM utilizing Revit software including laser scanning of all existing facilities provided by Hensel Phelps that were used as the baseline 3D models for all renovations.

Location

Kiryat Gat, Israel

Project Size

500,000 Square Feet

Services Provided

Architecture

MEP Engineering

Process Engineering

Structural Engineering

Life Safety

Telecommunications

Security

Instrumentation and Controls

Confidential Client Semiconductor Wafer Fab2

Page was the prime A/E working with Austin Commercial Construction in a design/build partnership to build a new construction 1.6 millionsquare-foot 300mm wafer FAB, with 300,000-square-feet of ISO 5 (Class 100 Turbulent) Cleanroom. The FAB2 is 30% larger than the first FAB built in 2006, also designed by Page and built by Austin Commercial. The scale of FAB2 required two mechanical wings, one on the north and one on the south ends of the cleanroom, to allow for split air scrubber filtration plants. To minimize downtime risks, the two FABs run independently of each other, and FAB2 required a new industrial wastewater filtration plant, deionized water purification, bulk chemical storage vessels, bulk gas plant and a high voltage power substation, provided by Oncor, the public utility company.

The new FAB is designed to achieve Gold LEED certification by leveraging the innovative concepts to reduce, reuse & recycle water, and design-out energy usage equipment throughout the facility. Other innovations include split temperature chiller plant, heat recovery from the compressed dry air systems and chillers, use of premium efficiency motors, reflective roof, highest efficiency fan filter units, make-up air energy recovery run-around coils, minimized pipe / duct friction and more than 95% construction waste recycling. Located in “Tornado Alley”, the FAB incorporates hardening techniques to the building and system elements to protect itself from ultra-high winds, hail, flash flood rains and hurricane forces.

Page provided Code and Zoning consultation services, Design Management, Civil, Architectural, Structural (CSA), mechanical wet central plant and distribution, mechanical cleanroom make-up air systems, electrical high-voltage substations & distribution, fire protection sprinkler system, fire alarm notification system.

Location Richardson, Texas

Project Size

1,600,000 Square Feet

Services Provided Architecture Interiors

Mechanical Engineering

Electrical Engineering

Civil Engineering

Structural Engineering

Fire Protection Engineering

Confidential Semiconductor Client B39

CUP and B51X

B39 CUP

A new 58,000-square-foot Central Utility Plant (CUP) and associated trestle to support the B51 R&D wafer fabrication facility at the Boise site. This CUP acts as a multi-function building and housed the UPW pre-treatment process, UPW Makeup Water treatment, HFW treatment, IW neutralization, future Fab Metals Waste treatment, Concentrated metals plating waste treatment, compressed air, chilled water, hot glycol, and hot water boiler plants that supply building services to the CUP and fab. The building is designed as a high bay with service platforms to access equipment. The chilled water and hot water systems are the primary building services the CUP provides to B51 and B51X. Additional house systems were included in the design to support make-up air, pre-treatment and waste treatment, but not limited to: hot glycol system, process vacuum, instrument air, and house vacuum. Other facilities were added including nitrogen, power, network, potable water, non-potable water, and sanitary sewer. The water and waste treatment were designed for source water and UPW pretreatment, IW neutralization, reclaim water treatment, and hydrofluoric waste treatment/sludge processing. Exhaust systems for the building have dedicated general exhaust, acid, and ammonia scrubbers.

The services leaving and entering the B39 CUP are routed on a facilities trestle between B51X and the new CUP. Trestle design incorporate pyrophoric gas lines along with building services. An environmental chase from the pyrophoric bunker will be needed and designed to connect to the trestle. The design encompassed both B51 and B51X, the modular design of the trestle and allowed for future fabrication expansion. The trestle is enclosed and heated to maintain at 65 degrees Fahrenheit.

Location Boise, Idaho

Project Size

58,000 Square Feet

Services Provided

Architectural

Mechanical Engineering

Electrical Engineering

Process Engineering

Instrumentation and Controls

Fire Protection Engineering

Confidential Semiconductor Client B39

CUP & B51X

B51X

The Page design scope for this project was to build out the remaining unfinished portion of the building to ISO Class 5 turbulent flow ballroom which will enable an additional 54,000 square feet of cleanroom. The design included provisions to ensure the existing operating fab was not affected during the construction phase. The design also included the incorporation of catwalks in the interstitial and coordination with the AMHS systems in the cleanroom. This scope included implementation and extension of the cleanroom air management systems as well as the electrical systems to support the building equipment.

The scope also included the design and buildout of the associated Central Utility Plant (CUP) B39 systems which services Building 51. This includes provisions for additional chilled and hot water systems supporting the building as well as CDA, waste treatment, and UPW. This additional equipment required close coordination and space management to add platforms and pads in and around the existing equipment.

Location

Boise, Idaho

Project Size

54,000 Square Feet

Services Provided

Architectural

Mechanical Engineering

Electrical Engineering

Process Engineering

Instrumentation and Controls

Fire Protection Engineering

Confidential Semiconductor

Manufacturer Bulk Silane and Specialty Gas Distribution

Bulk Silane

The team engineered the design for a SiH4 backpad equipment/ISO trailer arrangement. The design included utility piping to VHFS and DVPs located at the backpad, a fire protection deluge system for ISO module trailer and Y-cylinder from POC. Page designed and facilitated an S-DOC abatement unit for the SiH4 purge vent, and a blower ventilation system that provided a 200 feet per minute face velocity over the area of the open panel VHFS modules.

In addition, the team provided a CFD simulation model to show the bulk silane system met all codes and requirements in regards to ventilation and airflow.

FAB 8.1 Phase 2 Extension Specialty Gas Engineering and BIM Modeling

Specialty Gases Distribution Systems and BSGS design included BIM Modeling, gas room equipment arrangements, gas room facilitation, gas distribution and support equipment facilitation, global distribution lines up to DVB’s, VMB’s, DVMP’s, VMP’s and including facilitation of DVB’s and VMB’s. In addition, the design included the electrical facilitation of the HPM Gas Rooms that included general lighting, convenience outlets, LSS, safety showers, fire protection, and HVAC. Furthermore, a code compliance assessment was performed in order to verify all code requirements for the specialty gas systems to address building and fire code issues in the design.

Location Malta, New York

Project Size 103,500 Square Feet

Services Provided

Confidential Semiconductor Manufacturer Austin Campus Renovations

Page has been working with the client since the 1980’s and is provided updates and renovations for their 80-acre Ed Bluestein Campus, located at 3501 Ed Bluestein Blvd in Austin. The total building space for this most recent project, “ATMC Expansion” comprises over 81,000 square feet, with over 47,000 square feet of it being new or retrofit cleanroom spaces. The campus has semiconductor fabrication cleanrooms located in three buildings with original construction completed in 1995 and 1998. The project consists of the renovation of an existing semiconductor fabrication facility in Austin, Texas. Clean room areas such as Class Probe, Implant, X2 Cleans, Yield Enhancements, Gown Room, and Clean Link corridors have been repurposed to assist in additional production capacity for the facility. Greater than 31,000 square feet of ISO class 3, 4, or 5 clean room square footage has been converted/ added to existing fabrication facility.

Renovations include full architectural cleanroom buildout, structural/ vibration, mechanical, electrical, and process mechanical upgrades. Fire protection engineering design services include renovation and modification of existing and new wet-pipe and dry-pipe sprinkler systems, coordination of fire suppression systems with the clean room environment. Also, the design provided upgrades to the existing fire alarm system including additional audile notification zones, VESDA smoke detection systems.

Additional code consulting services for NXP include fire analysis of planned new fabrication support equipment, firestopping system review for penetrations through fire rated construction, UPS battery room expansion, and fire alarm notification system improvements.

Location Austin, Texas

Project Size

81,000 Square Feet

Services Provided Architecture

MEP Engineering

Process Engineering

Fire Protection Engineering

Instrumentation & Controls

Image courtesy of the client.

Confidential Client / Office / Manufacturing Facility | Phase 2

Marcy

Nanocenter Master Plan

The Client is building a $1 billion, 200 mm silicon carbide wafer fabrication facility at the Marcy Nanocenter, the largest facility of its kind in the world. The project will be located on 56.25 acres at the northern end of the 398-acre Marcy Nanocenter site -the project will include: Fabrication building: This 454,000-square-foot building will be built on four levels, creating a footprint of about 150,000 square feet. It will include about 112,000 square feet of cleanroom space.

Administration building: This four-level, 85,000-square-foot building will sit on an approximately 25,000-square-foot footprint. It will include open office space, a cafeteria, a gym, common space, a main lobby entrance and a clean gown room. Central utility building: About a 100,000-square-foot, two-level building, taking up about 75,000 square feet of space on the ground, with the facilities boiler and chiller plants, main electrical distribution equipment and other facility infrastructure. It will support the fab through an above-ground utility trestle.

SUNY Polytechnic Institute / CNSE

Master Plan

Goals: SUNY CNSE (Albany, New York) required a Master Plan to guide the expansion of its Albany NanoTech Complex, which has rapidly become the anchor of New York State’s Tech Valley. The Complex offers highly specialized facilities -housing some of the world’s most advanced equipment-that have attracted more than 300 global partners in industry and government.

Strategies: The Plan provides a strategic framework for 3 major phases of work, adding more than 1 million square feet of cuttingedge facilities, more than doubling the size of the NanoTech Complex.

Phase 1: NanoFab Xtension (NFX) 320,000 SF

Phase 2: Zero-Energy Mixed-use Facility (ZEN) 350,000 SF

Phase 3: NanoFab Xtension 2 (NFX2) 220,000 SF

SUNY Polytechnic Institute / Nanofab Xtension (NFX) Building | Master Plan

Phase 1

The prominently sited NFX Building communicates the power as well as the promise of new technologies under development. A world leader in nanoscience R&D and education, SUNY Poly’s NFX Building houses more than 120 wafer processing and inline metrology tools.

Class 1,000 cleanrooms support research and manufacturing of the most sophisticated, next-generation computer chip manufacturing tools for the latest chip wafer production. Specialized design features support heavy manufacturing tools and mitigate vibration during semiconductor fabrication. 300mm advanced lithography platforms support 193nm immersion lithography development and EUV lithography development. Advanced wafer platforms enable planarization, copper plating, etch development, ion implantation, thin film development and wet cleaning technology.

The design includes a pedestrian walkway and utility umbilical with floor-to-ceiling glass walls, constructed over an adjacent active highway and connecting to the NanoFab North facility.

500,000 SF New Construction | 50,000 SF 300mm Wafer Cleanrooms | 2 Data Centers | 5,000 SF Metrology Labs | Automated Material Handling System | 20,000 SF Offices and Conference Rooms Services

Location Albany, New York

Project Size See above

SUNY Polytechnic Institute / Marcy

Nanocenter and Master Plan

SUNY Polytechnic Institute’s new 360,000 square foot state-of-the-art computer chip fab at the Marcy Nanocenter will be home to AMS AG’s advanced sensor manufacturing - more than $2 billion in initial private investment, and generate more than 1,000 new jobs in the Mohawk Valley. The groundbreaking marks a major milestone in the governor’s Nano Utica initiative, which is now projected to create at least 4,000 jobs over the next decade, and includes research and development at the Computer Chip Commercialization Center (QUAD c) in partnership with General Electric.

The wafer fabrication facility will be staffed and operated by AMS AG to support the company’s high performance analog semiconductor operations which have a global marketplace in products ranging from smartphones, tablets and other communications devices, automakers, audio and medical equipment manufacturers and others. AMS sensors are used in hundreds of mill ions of devices to recognize light, color, gestures, images, motion, position, environmental and medical parameters and more.

“Today marks an exciting milestone in the transformation of the local economy,” said Governor Cuomo. “Through the Nano Utica initiative, we’re bringing an unprecedented focus to the Mohawk Valley, and jumpstarting a high-tech manufacturing industry that will create thousands of good-paying jobs in both the immediate and long-term future. This is another sign of how Upstate New York’s best days are ahead, and I look forward to seeing construction move forward.”

Location Utica, New York

Project Size

36,000 Square Feet

Services Provided Master Planning Programming Manufacturing Architecture

Page Select Advanced Manufacturing Clients

Advanced Micro Devices (AMD)

Confidential Electric Vehicle Manufacturer – Nevada & Texas

Confidential Semiconductor Manufacturer – Phoenix

Confidential Semiconductor Manufacturer – Austin

Confidential Semiconductor Manufacturer – Central Texas

Confidential Semiconductor Manufacturer – Idaho

Confidential Semiconductor Manufacturer – New York

Confidential Semiconductor Manufacturer – North Carolina

Confidential Semiconductor Manufacturer – North Texas

Confidential Solar Module Manufacturer

Continental Structural Plastics

DuPont Photomasks (Toppan)

Entegris

Finisar

Fujifilm

FUJITSU

Hospira (Abbott Labs)

Hughes Research Laboratories

IBM Corporation

Janssen Pharmaceuticals

K&N Engineering

Keysight

L3 Technologies

NEC Electronics

On Semiconductor

Photronics

Sachem

SEMATECH Corporation

Sandia National Labs

Sony Spansion

ST Microelectronics

Tokyo Electron

TriQuint Semiconductor

The University of Texas at Austin

Versum Materials

VPX Canning

pagethink.com