Dear readers,

In our November-December 2024 edition, the editorial board of Pakistan Food Journal is focusing on the current exhibitions related to the food industry that are held worldwide in the coming months. The economic situation is slowing down the agricultural machinery market at a global level, but the EIMA exhibition, which ended yesterday evening in Bologna, suffered no setbacks and hit an all-time high attendance record. Over 346,000 attendees, including 63,000 foreign guests from 150 countries, came to learn about the most innovative technologies for every type of agriculture. The demand for mechanization remains potentially very high – explain the organizers of FederUnacoma – and the agricultural world needs to immediately recognize the innovations and plan its investments accordingly.

ASIA FRUIT LOGISTICA has announced the dates for its CHINA MEET UP and new CHINA STUDY TOUR and AFL Fresh Produce Golf Cup 2025, two dynamic events taking place in September 2025.

FRUIT LOGISTICA , the world's leading trade fair for the global fresh produce trade, remains the first port of call for professionals from all over the world to maintain and expand their professional networks, discuss new trends and ideas and grow their businesses.

Gulfood Manufacturing 2024 concluded its milestone 10th edition from November 5-7 at the Dubai World Trade Centre, solidifying its position as the world’s premier annual event for the food manufacturing ecosystem. The largest and most impactful edition to date, this year’s event attracted over 2,500 exhibitors from 70 countries, spanning an impressive 1 million square feet across 19 halls, marking a remarkable 30% growth compared to previous editions.

Amina Baqai Editor in Chief

Pakistan Food Journal, November - December2024

SABIC teams up with iyris and Napco to create high-tech durable greenhouse roofing solution using TRUCIRCLE™ polyethylene for Saudi food production initiative

Krones: 360-degree closure inspection for all closure types

GEA: Industrial refrigeration & heating for food processes

Exciting Initiative from Westfalia Fruit in The Netherlands: Driving Sustainability and Innovation with Tattooed Mangos

.18

INEOS Styrolution announces first yoghurt cup in supermarket containing mechanical recycling of polystyrene at food contact quality

Rice export to BD: TCP receives 11 bids

.19

Study reveals link between gut microbes and heart disease, showing benefits of probiotic-prebiotic combination

Exclusive Articles

GEA again listed in the Dow Jones Sustainability World Index – as sole German machinery and plant manufacturer

.22

Krones: Epirotic uses Krones technology to reach a new target group . .24

MULTIVAC: Innovative approaches to the processing and packaging of alternative proteins

Editor-in-Chief

Amina Baqai

Managing Editor / Publisher

Sohail Aziz

Senior Editor / Publisher

Nadeem Mazhar

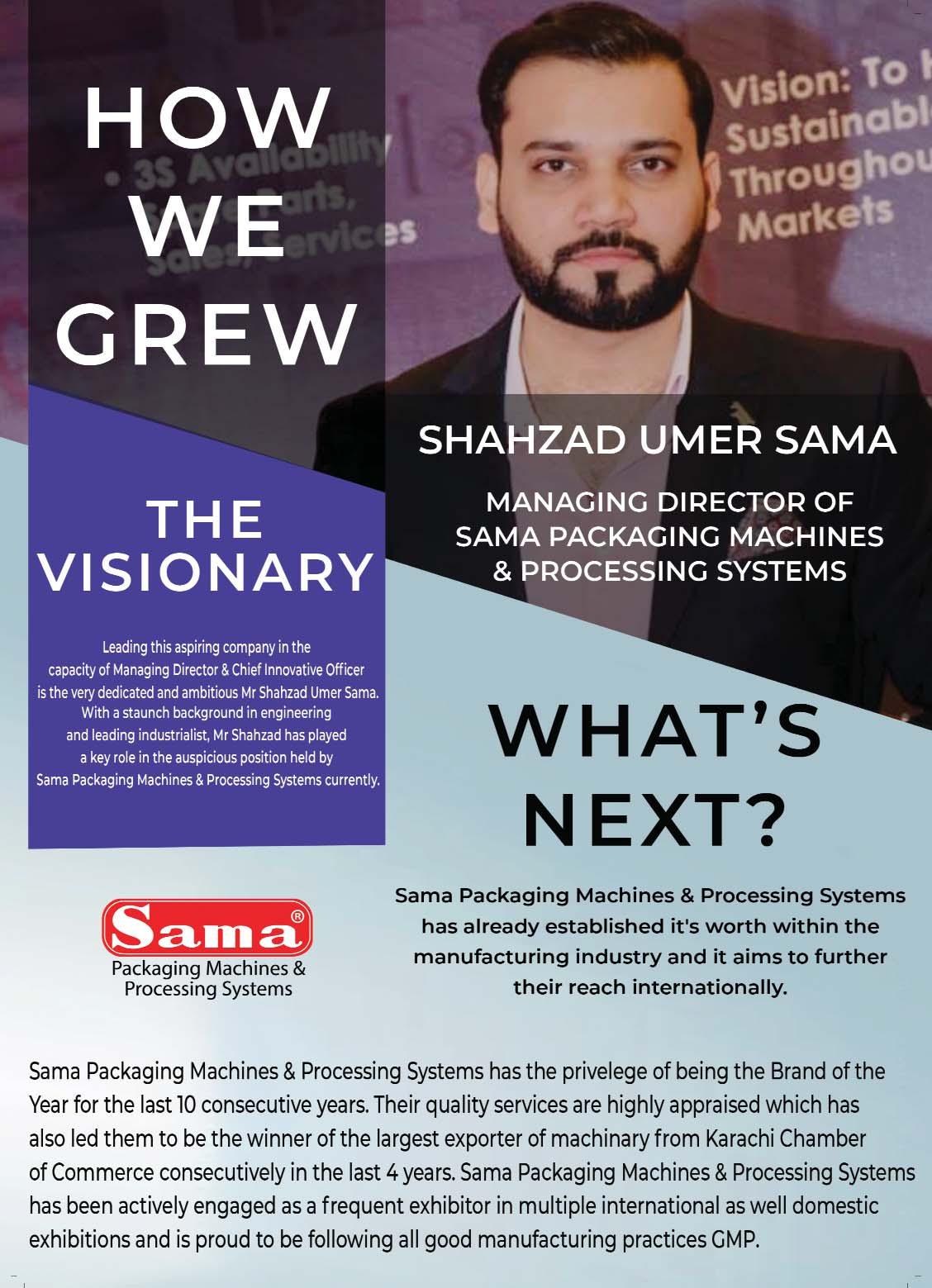

Hony. Editor Shahzad Umer Sama

Marketing Executive Layout & Design Mazhar Ali

Tel: +92-21-34311674, 34303101

Email: info@foodjournal.pk, Url: foodjournal.pk

Printed at Color Plus, Korangi Karachi. Suite B-4, & B-6, 2nd Floor, 64/21, Miran M. Shah Road, M.A.C.H.S, Karachi - Pakistan.

Sidel introduces its breakthrough bottle washer with powerful dual technology – Hydra Ultrasonic

Krones AG: Steinecker wins 2025 German Sustainability Award for “Products: Climate”

Tate & Lyle and BioHarvest announce partnership to drive the future of ingredients through botanical synthesis technology

EIMA International

EIMA International: the “innovation factory” breaks all records

ISM

ISM: Expanded to provide global perspective and connections to sweets and snacks sector

ASIA FRUIT LOGISTICA Announces CHINA MEET UP and Exciting New Events!

FRUIT LOGISTICA

FRUIT

BIOFACH

Gulfood Manufacturing 2024: Celebrating a Decade of Transformative Innovation in Food Manufacturing

.30

.33

Pakistan showcases food industry potential at Gulfood Manufacturing 2024

At Gulfood Manufacturing 2024, PFJ met with ADM’s team: Mr. Bastian Hörmann, the Global Marketing Director and Ms. Greta Leonhardt, Category Marketing Manager at their booth

International Green Week

Date: 17 to 26, January 2025.

Venue: Berlin, Germany.

Fruit Logistica 2025

Date: 5 to 7, February 2025.

Venue: Messe Berlin, Germany.

2025

Dates: 17 to 21, February 2025.

Venue: Dubai World Trade Centre, Dubai

IFTECH Pakistan 2025

Date: 29 to 31, May 2025.

Venue: Lahore Expo Centre.

2025

Date: 02 to 04, June 2025.

Venue: Atlanta, Georgia, USA

2025

Date: 11 to 13, June 2025.

Venue: Shanghai New International Expo Center ( No.2345 Longyang Road, Pudong New District, Shanghai, China)

Asia Fruit Logistica 2025

Date: 3 to 5, September 2025.

Venue: Queen Sirikit National Convention Center, Bangkok, Thailand.

Anuga 2025.

Date: 4 to 8, October 2025.

Venue: Cologne, Germany.

Gulfood Manufacturing 2025

Date: 4 to 5, November 2025.

Venue: Dubai World Trade Centre.

2025

Dates: 10 to 12, November 2025.

Venue: Riyadh International Convention & Exhibition Center, Riyadh, Saudi Arabia

EIMA International 2026

Date: 10 to 14, November 2026.

Venue: International Agricultural and Gardening Machinery Exhibition, Bologna, Italy.

Dates: 23 to 26, March 2027

Venue: Cologne, Germany.

Punjab Agriculture and Livestock Minister Syed Ashiq Hussain Kirmani chaired a meeting at Agriculture House, Lahore, to evaluate the progress of the wheat cultivation campaign and the Chief Minister’s Kissan Package. Secretary Agriculture, Punjab, Iftikhar Ali Sahoo, also attended the session.

Scientists at the Agricultural Research Institute Tarnab (ARIT) in Peshawar have introduced three innovative wheat varieties designed to enhance climate resilience and potentially triple per-acre yields. This breakthrough comes as Khyber Pakhtunkhwa (KP) grapples with significant agricultural challenges stemming from climate change and outdated farming practices.

The Punjab Agriculture Department has announced measures to ensure fair profits for wheat growers in the upcoming harvest season. According to a department spokesperson, the government has set the procurement rate for wheat at Rs 2,800 per maund, providing clarity amidst misleading reports about crop prices.

Rice exports from Pakistan experienced remarkable growth in the first five months of the current financial year, increasing by 35.4% compared to the same period last year. According to the Pakistan Bureau of Statistics, the country exported 2.377 million metric tons of rice, valued at $1.515 billion, between July and November 2024, up from 1.721 million metric tons worth $1.119 billion in the corresponding period of 2023.

The Pakistan Sugar Mills Association (PSMA) has requested the government’s approval to export surplus sugar stocks, citing over 1.08 million tons of excess sugar at the onset of the new crushing season. The appeal was made during a Sugar Advisory Board (SAB) meeting chaired by Federal Minister for Industries and Production, Rana Tanveer Hussain.

In an international tender to purchase 500,000 metric tonnes of rice, Indonesia's state purchasing agency, Bulog, received the lowest price offer of $479 per tonne (c&f) for rice expected to be sourced from Pakistan, covering a consignment of 26,000 tonnes.

Bangladesh has finalized a two-year agreement with Saudi Arabia to import 400,000 tons of diammonium phosphate (DAP) fertilizer annually, aiming to enhance food security amidst rising demand and dwindling arable land. The deal was signed on December 15 in Riyadh between the Bangladesh Agricultural Development Corporation (BADC) and Saudi stateowned company Ma’aden.

European wheat futures extended their upward momentum on Tuesday, closing the year with a 6.6 percent annual rise, driven by strengthening U.S. grain prices and concerns over tightening wheat supply in Russia.

The food industry, a cornerstone of Egypt's economy, contributes 14 percent to the nation’s total exports, according to Minister of Investment and Foreign Trade Hassan El Khatib. Speaking at the inaugural Conference of Food Industries Exporters on Monday, El Khatib emphasized the government’s commitment to enhancing export growth and

achieving sustainable economic development.

France's Agriculture Ministry announced that planting of winter soft wheat, the nation’s primary crop, is projected to rebound sharply for the 2025 harvest. This follows drier weather conditions in November, which averted the rain-soaked planting setbacks experienced last year.

Rice export prices from India, the world’s largest supplier, fell for the third consecutive week, reaching a 15-month low due to the rupee's depreciation and rising supplies.

Poland has recorded a significant increase in mandarin imports from Egypt during the 2023/24 season, with shipments reaching 6.8 thousand tons in the first 11 months—more than double the previous season's total of 3 thousand tons. This growth has elevated Egypt to the sixth-largest supplier of mandarins to Poland, a notable climb from its 10th-12th ranking just a few years ago.

As the winter season peaks, the demand for dry fruits has surged in the capital, with people opting for these nutritious and flavourful items to combat the cold. Dry fruits are widely used in seasonal dishes like Gajar ka Halwa (a carrot-based sweet) and Sohn Halwa (a traditional dessert made with milk, flour, and dry fruits). Bakeries and sweet shops also incorporate dry fruits into their confections to enhance flavour and nutritional value.

The Punjab province is projected to experience a 20% reduction in the per-acre yield of this year’s potato crop due to the ongoing smog and fog conditions. As the primary production zone for potatoes, especially in regions like Sahiwal and Okara, Punjab plays a pivotal role in Pakistan’s annual potato output of approximately 8.3 million metric tons.

The Economic Coordination Committee (ECC) of the cabinet, led by Finance Minister Muhammad Aurangzeb, convened and expressed surprise over an up to 83% increase in the prices of pulses and chicken, despite favourable economic conditions at home and abroad.

Saudi Arabia’s General Food Security Authority (GFSA) announced on Monday the procurement of 804,000 metric tons of hard wheat through an international tender, significantly exceeding the 595,000 tons initially sought.

Prices for greenhouse cucumbers in Ukraine continued their upward trend last month, driven by strong demand and limited market supply, according to analysts. Retail chains and large wholesale buyers remain highly active, fuelling competition and contributing to the price increase.

Soybean, wheat, and corn futures on the Chicago Board of Trade (CBOT) are poised to end 2024 with a second consecutive annual decline, as ample global supplies overshadow market trends. However, year-end weather concerns have provided some support to prices.

Punjab Agriculture and Livestock Minister Syed Ashiq Hussain Kirmani chaired a meeting at Agriculture House, Lahore, to evaluate the progress of the wheat cultivation campaign and the Chief Minister’s Kissan Package. Secretary Agriculture, Punjab, Iftikhar Ali Sahoo, also attended the session.

The briefing revealed that wheat cultivation has been completed on 12 million acres across Punjab, with all resources mobilized to meet the target. Fertilizer supplies, including DAP, are reportedly sufficient and available at controlled prices. Farmers planting wheat on larger tracts of land under the Chief Minister’s ‘Grow More Wheat’ Package can submit online applications until December 15, 2024. Monitoring mechanisms are in place to ensure the availability of highquality seeds and fertilizers in the market.

The Chief Minister’s Kissan Card initiative has gained momentum, with 1,321,000 applications received and 500,000 farmers verified. So far, agricultural inputs worth Rs24 billion have been purchased using the Kissan Card, with

92% allocated for fertilizers. Farmers can withdraw up to 30% cash through the card, making it a transformative project for the agricultural sector.

To further expand access, the target number of Kissan Card holders has been raised from 500,000 to 750,000, allowing farmers in non-digitized areas to participate. The minister lauded the initiative for reducing production costs and ensuring timely access to inputs.

The government is actively monitoring the use of Kissan Cards and overseeing the purchasing process to prevent overcharging or artificial shortages of seeds, fertilizers, and pesticides. Dealers found involved in malpractice face strict action. Farmers can report grievances through the Punjab Agriculture Department’s helpline at 0800-17000.

The minister emphasized the need for stringent oversight to ensure the uninterrupted supply of agricultural inputs, which is critical for achieving wheat production goals and supporting Punjab's farmers.

Scientists at the Agricultural Research Institute Tarnab (ARIT) in Peshawar have introduced three innovative wheat varieties designed to enhance climate resilience and potentially triple per-acre yields. This breakthrough comes as Khyber Pakhtunkhwa (KP) grapples with significant agricultural challenges stemming from climate change and outdated farming practices.

ARIT has developed wheat seeds tailored for both canal-irrigated and rain-fed farming. The rain-fed variant addresses the province’s dependency on rainfall, with 51% of agricultural land reliant on rainwater.

The canal-irrigated seed variety is expected to deliver three times the yield of existing wheat strains, offering a lifeline to farmers struggling with declining production.

KP produces only 1.4 million tonnes of wheat annually, far short of its 5 million tonne consumption demand. Wheat production and cultivation areas have remained stagnant for nearly a decade, fluctuating between 1.247 and 1.47 million tonnes across 0.753 to 0.770 million hectares since 2015.

Senior agricultural scientist Akhtar Ali highlighted the critical impact of climate change on farming, including altered rainfall patterns and seasonal delays. “The yield from current seeds has declined dramatically due to climate challenges,” he said, emphasizing the need for innovation.

ARIT researchers stress that the success of the new wheat varieties hinges on the adoption of scientific farming practices. Altaf Khan, another ARIT expert, explained that modern techniques are essential to achieving the production potential of the newly developed seeds. Additionally, the institute underscores the government’s role in ensuring costeffective access to seeds, fertilizers, and pesticides, alongside raising awareness about climate change's impact on agriculture. Such measures will enable farmers to adapt more effectively to the changing agricultural landscape.

The Punjab Agriculture Department has announced measures to ensure fair profits for wheat growers in the upcoming harvest season. According to a department spokesperson, the govern-

ment has set the procurement rate for wheat at Rs 2,800 per maund, providing clarity amidst misleading reports about crop prices.

The spokesperson emphasized that the recently announced Rs 2,900 per 40 kilograms price applies only to the release of existing government wheat stocks from Food Department warehouses. This measure aims to stabilize flour prices and ensure affordability for the public. The spokesperson reassured farmers that this price does not affect the rates for the new wheat harvest in 2024.

Farmers have been urged to disregard any misinformation regarding wheat prices and trust the government's commitment to fair and transparent pricing. By offering Rs 2,800 per maund, the Punjab government aims to support farmers while maintaining a balance between agricultural sustainability and public welfare.

This initiative is part of the government’s broader strategy to bolster wheat production and secure the livelihoods of wheat growers across the province.

by 35.4% in July-November

Rice exports from Pakistan experienced remarkable growth in the first five months of the current financial year, increasing by 35.4% compared to the same period last year. According to the Pakistan Bureau of Statistics, the country exported 2.377 million metric tons of rice, valued at $1.515 billion, between July and November 2024, up from 1.721 million metric tons worth $1.119 billion in the corresponding period of 2023.

The export of Basmati rice recorded a significant 34.64% growth, with 370,282 metric tons exported, earning $386.116 million, compared to 244,664 metric tons worth $286.778 million in the previous year.

Exports of rice other than Basmati showed a strong 35.67% increase, with 2.006 million metric tons shipped, generating $1.129 billion in revenue, compared to 1.476 million metric tons worth $832.523 million during the same period last year.

The overall food export sector grew by 19.58%, reaching $3.155 billion from $2.638 billion in the previous year. On the other hand, food imports into the country declined by 11.13%, totalling

$2.977 billion, down from $3.350 billion during the same period last year.

This significant growth in rice exports highlights Pakistan's increasing competitiveness in global markets, with both Basmati and non-Basmati varieties driving revenue. The surge also underscores the country's efforts to enhance agricultural productivity and tap into rising global demand for rice.

The Pakistan Sugar Mills Association (PSMA) has requested the government’s approval to export surplus sugar stocks, citing over 1.08 million tons of excess sugar at the onset of the new crushing season. The appeal was made during a Sugar Advisory Board (SAB) meeting chaired by Federal Minister for Industries and Production, Rana Tanveer Hussain.

Despite the PSMA’s request, the government reiterated its stance that no additional export permits will be granted until the allocated export quota of 790,000 tons, approved earlier this year, is fully utilized. As of now, only 186,934 tons have been exported, leaving 603,066 tons of the quota unutilized. The government has set a three-month deadline, starting October 8, 2024, for the industry to meet the export target while ensuring local sugar prices remain stable.

The PSMA highlighted China's annual sugar import demand of six million tons and urged the government to facilitate

sugar exports to China, either through government-to-government (G2G) or government-to-business (G2B) agreements. This, they argue, could capitalize on the surplus stocks and bolster foreign exchange earnings.

During the 2023-24 crushing season, Pakistan produced 6.843 million tons of sugar, with Punjab contributing 4.37 million tons, Sindh 2.022 million tons, and Khyber Pakhtunkhwa (KPK) 447,000 tons. Including carryover stocks of 823,000 tons, the country’s total sugar availability stood at 7.664 million tons.

The domestic consumption report indicates an average monthly offtake of 545,000 tons, combining local usage and exports. Total domestic consumption over the past 11 months was 6.2 million tons.

PSMA officials stated that the local

production cost of sugar is approximately Rs170 per kg, while retail prices range between Rs140-145 per kg—the lowest globally. The international sugar price, as of November 6, 2024, stood at $562 per ton, compared to Pakistan's production cost of $503 per ton, signaling export profitability.

Last month, wholesale sugar prices in Pakistan dropped to Rs6,400 per 50-kg bag, marking a two-year low. Additionally, sugarcane prices rose from Rs350 per 40-kg in the previous year to Rs450 per 40-kg in 2023-24.

The government has directed sugar mills to commence the new crushing season by November 21, 2024, warning of consequences, including the withdrawal of export permissions, for noncompliance. The PSMA was also instructed to clear outstanding dues to sugarcane farmers before the season begins.

PSMA previously proposed a phased export of 1.6 million tons of sugar, predicting potential foreign exchange earnings of $650-700 million in the first phase alone.

The industry disclosed that 85% of sugar is consumed industrially, with the remaining 15% used domestically. Additionally, an 18% general sales tax (GST) applies to sugar, contributing to government revenue.

In an international tender to purchase 500,000 metric tonnes of rice, Indonesia's state purchasing agency, Bulog, received the lowest price offer of $479 per tonne (c&f) for rice expected to be sourced from Pakistan, covering a consignment of 26,000 tonnes.

Two additional offers from Pakistan followed closely, priced at $484 and $485 per tonne, highlighting the country’s competitive edge. Comparatively, price offers from other competitors included $515 per tonne from Vietnam, $511 per tonne from Thailand and Cambodia, $513 per tonne from India, and $517.50 per tonne from Myanmar. The tender requires 5% broken grade white rice from the 2024 crop, milled no longer than six months ago, with deliveries expected between November and December.

Indonesia’s aggressive rice imports are part of its strategy to stabilize domestic prices after a disappointing harvest season. The country’s 2024 rice production is estimated at 30.34 million metric tonnes, reflecting a 2.43% decline from the previous year, with the steepest drop of nearly 15% occurring in the JanuaryApril period. To address the supply shortfall, Indonesia plans to import up to 3.6 million tonnes of rice in 2024 and has announced plans to significantly expand the planted area in 2025. Additionally, the government is considering importing another 1 million tonnes from India next year.

While no purchase has been finalized, price negotiations are underway, and a decision is expected next week. Pakistan’s competitive pricing positions it as a strong contender in the tender, reinforcing its growing role as a key rice supplier to Indonesia.

As the winter season peaks, the demand for dry fruits has surged in the capital, with people opting for these nutritious and flavourful items to combat the cold. Dry fruits are widely used in seasonal dishes like Gajar ka Halwa (a carrotbased sweet) and Sohn Halwa (a traditional dessert made with milk, flour, and dry fruits). Bakeries and sweet shops also incorporate dry fruits into their confections to enhance flavour and nutritional value.

Despite rising prices, dry fruit shops are experiencing high customer traffic. According to sellers, the increased demand stems from the belief that dry fruits help reduce the effects of cold air

on the body. However, prices have risen compared to last year due to increased costs for cultivation, transportation, and labour. Almonds are priced between Rs 4,800 and Rs 5,600 per kg, walnuts cost Rs 1,400 to Rs 1,800 per kg, and cashews, figs, and pine nuts are priced at approximately Rs 3,600, Rs 4,000, and Rs 14,000 per kg, respectively. Among dry fruits, peanuts remain the most affordable and popular option, with prices varying based on the production region—ranging from Rs 640 to Rs 1,200 per kg for peanuts from Gujjar Khan, Chakwal, and Parachinar.

The trend of online dry fruit sales has also seen significant growth, with e-commerce platforms offering competitive prices to attract customers. However, online sellers face challenges, including increased costs and cancelled orders, which negatively impact profitability. An online store owner highlighted that while many customers place orders online, cancellations upon delivery increase the overall costs of operations.

The supply chain for dry fruits spans various regions, including Gilgit-Baltistan, Balochistan, and Punjab, with Lahore serving as the primary market hub. Suppliers source pine nuts from Balochistan, walnuts from both GilgitBaltistan and Balochistan, and peanuts from several regions in Punjab. According to Wazir Hashmat, a supplier from GilgitBaltistan, rising costs at the farmers’ end, along with higher transportation expenses, have contributed to the price hike. Despite these challenges, the popularity of dry fruits during the winter season remains undiminished.

Bangladesh Secures Two-Year Fertilizer Deal with Saudi Arabia to Boost Food Security

Bangladesh has finalized a two-year agreement with Saudi Arabia to import 400,000 tons of diammonium phosphate (DAP) fertilizer annually, aiming to enhance food security amidst rising demand and dwindling arable land. The deal was signed on December 15 in Riyadh between the Bangladesh Agricultural Development Corporation (BADC) and Saudi state-owned company Ma’aden.

BADC General Manager Ahmed Hassan Al-Mahmud emphasized the importance of high-quality fertilizers in sustaining agricultural productivity for Bangladesh’s population of 175 million. "This fertilizer helps us increase productivity by many folds," Al-Mahmud told Arab News, underlining the crucial role of DAP in ensuring food security.

Under the agreement, Ma’aden will supply the fertilizer until 2026 and also provide training for Bangladeshi farmers to optimize fertilizer use. Additionally, Ma’aden has offered to build fertilizer storage facilities in Bangladesh, further solidifying its partnership with the South Asian nation.

The Saudi imports will account for about one-third of Bangladesh’s annual DAP fertilizer requirement, which stands at approximately 1.3 million tons. Moreover, the deal offers a financial

advantage, with fertilizer costing $2 less per ton compared to the global average market price.

“This agreement will save us a significant amount of money,” Al-Mahmud said, adding that Saudi Arabia has been a "trusted and reliable" supplier for over 15 years. He highlighted the logistical benefits, noting that fertilizers from Saudi Arabia take only two weeks to reach Bangladesh, compared to over six weeks from other suppliers like Morocco.

While Bangladesh also imports fertilizer from China and Morocco, the longstanding cooperation with Saudi Arabia makes it a preferred partner. The new agreement reinforces Saudi Arabia’s role as a key contributor to Bangladesh’s agricultural development and food security initiatives.

European Wheat Futures End Year on a High, Gaining 6.6% Amid Russian Supply Concerns

European wheat futures extended their upward momentum on Tuesday, closing the year with a 6.6 percent annual rise, driven by strengthening U.S. grain prices and concerns over tightening wheat supply in Russia.

Benchmark March milling wheat on Paris-based Euronext climbed 1.3 percent to settle at €237.25 ($246.41) per metric ton after a shortened trading session ahead of New Year’s celebrations. The contract reached a six-month high of €237.50 earlier in the session, as the breaching of key technical resistance at €235 spurred buying interest amid light holiday trading, dealers reported.

This annual gain marks a recovery from the previous year, when wheat prices retreated from record highs following the 2022 surge triggered by Russia’s invasion of Ukraine. Earlier in 2024, Euronext wheat hit a four-year low due to abundant global supplies and robust Black Sea exports, which had eased war-related fears.

However, concerns about poor early growth of Russia's winter wheat crop, rising domestic prices, and measures by Russian authorities to limit exports have supported European wheat markets in recent months.

Euronext futures also benefited from a year-end rally in U.S. grain markets, with Chicago corn reaching a six-month high and wheat a two-week peak on Monday. Adverse weather conditions in Argentina and steady U.S. exports contributed to this rally.

Despite the support, export competition continued to weigh on Euronext wheat. Poor harvests in France and Germany have reduced supplies in Western Europe, adding another layer of complexity to the market dynamics.

Egypt’s Food Industry Targets 20% Export Growth Amid Strategic Investment Plans

The food industry, a cornerstone of Egypt's economy, contributes 14 percent to the nation’s total exports, according to Minister of Investment and Foreign Trade Hassan El Khatib. Speaking at the inaugural Conference of Food Industries Exporters on Monday, El Khatib emphasized the government’s commitment to enhancing export growth and achieving sustainable economic development.

The industry currently boasts investments exceeding LE 500 billion, operating 7,500 facilities that generate over 7 million jobs. Despite recent economic challenges, the sector has demonstrated resilience, underpinned by its reliance on locally sourced ingredients and a steady influx of investments.

El Khatib highlighted Egypt’s ambitious goal of raising exports to $140 billion, which would necessitate additional production investments of $40-50 billion. The conference explored strategies to boost export development, with the minister advocating for policies to encourage private sector participation, promote innovation, and enhance local production standards to align with global specifications.

The government’s plan includes streamlining regulations and addressing industry challenges to attract further investments and increase production efficiency. El Khatib underscored the importance of the food industry in driving economic growth, projecting an annual export growth rate of over 20 percent as achievable with the right policies and investments.

With the food sector’s expansion over the last five years and its central role in export strategy, Egypt is poised to leverage its economic potential and global trade competitiveness.

France's Wheat Planting Set to Surge for 2025 Harvest After Favourable Weather

France's Agriculture Ministry announced that planting of winter soft wheat, the nation’s primary crop, is projected to rebound sharply for the 2025 harvest. This follows drier weather conditions in November, which averted the rain-soaked planting setbacks experienced last year.

Farmers are expected to sow 4.51 million hectares of soft wheat, marking an 8.7 percent increase compared to the area harvested in 2024, according to the ministry's latest crop report.

The improved planting outlook comes after November's mild temperatures and reduced rainfall enabled farmers to recover from earlier delays caused by wet conditions. These favourable circumstances contrast with last autumn, when waterlogged fields drastically reduced planting, resulting in the smallest wheat harvest in decades for 2024.

As the European Union's largest grain producer, France’s wheat production plays a significant role in the region’s food supply and global grain markets. The anticipated rebound in planting area offers a promising sign for next year’s harvest.

Rice Export Prices Dip as India's Supplies Surge

Rice export prices from India, the world’s largest supplier, fell for the third consecutive week, reaching a 15-month low due to the rupee's depreciation and rising supplies.

India’s 5% broken parboiled rice was quoted at $440-$447 per metric ton this week, down from last week’s $442-$449 and marking its lowest price since July 2023. Similarly, the 5% broken white rice was offered at $440-$450 per metric ton. Traders in Kolkata cited strong demand from African buyers, who are now benefiting from reduced prices following India’s removal of the export tax on parboiled rice and a $490 floor price on nonbasmati white rice last month.

In Vietnam, 5% broken rice prices remained steady at $520-$525 per metric ton due to dwindling supplies and concerns about an approaching storm in the Mekong Delta region. Traders reported that Vietnam exported 800,000 metric tons of rice in October, a 29.1% increase year-on-year. Additionally, Indonesia’s state food agency Bulog is set to purchase over 80,000 metric tons of Vietnamese rice for delivery in November and December.

Thailand’s 5% broken rice was quoted at $490 per metric ton, stable from last week’s $485-$495 range. Bangkok-based traders noted consistent demand from regular customers, with prices influenced by the U.S. dollar's appreciation after recent elections.

Meanwhile, Bangladesh’s state grains buyer issued a tender to purchase 50,000 metric tons of rice as the country grapples with a shortfall of 1.1 million metric tons caused by recent floods.

The global rice market remains dynamic, with India’s aggressive pricing adjustments boosting its competitiveness, while stable demand and weather concerns maintain steady pricing for Vietnam and Thailand.

Poland has recorded a significant increase in mandarin imports from Egypt during the 2023/24 season, with shipments reaching 6.8 thousand tons in the first 11 months—more than double the previous season's total of 3 thousand tons. This growth has elevated Egypt to the sixth-largest supplier of mandarins to Poland, a notable climb from its 10th -12th ranking just a few years ago.

Poland’s seasonal demand for mandarins, typically ranging between 140 thousand and 170 thousand tons, is on track to reach record levels this year. While Spain remains Poland’s top supplier, its dominance has waned in recent years. Previously accounting for 54-58% of Poland's mandarin imports, Spain's share has dropped to 40-47% over the past two seasons, opening opportunities for other exporters.

Egypt has emerged as one of the fastest-growing sources, quadrupling its exports to Poland since the 2019/20 season. Other countries have also expanded their share, with Turkey boosting exports by 50% to 21 thousand tons and Italy and Greece increasing their contributions by around a third to 15 thousand and 14 thousand tons, respectively.

Mandarins are now Egypt’s second most significant citrus export, following oranges, and the country has been actively diversifying its offerings to meet rising global demand. For Poland, which is seeing increased fruit and vegetable imports to cater to evolving consumer preferences, Egypt’s growth reflects a broader trend of market diversification.

As Polish importers continue to explore new sources for high-quality produce, Egypt’s strong growth trajectory signals its potential to become a more prominent player in the country's citrus market. This diversification also ensures greater stability in supply and competitive pricing for Polish consumers.

Saudi Arabia Secures 804,000 Metric Tons of Wheat in Oversized Tender

Saudi Arabia’s General Food Security Authority (GFSA) announced on Monday the procurement of 804,000 metric tons of hard wheat through an international tender, significantly exceeding the 595,000 tons initially sought.

The GFSA confirmed that the wheat, with 12.5% protein content, is scheduled for delivery between February and April 2025 to the ports of Jeddah, Dammam, Yanbu, and Jizan.

“This purchase reflects the GFSA’s commitment to ensuring sufficient wheat supplies for the Kingdom,” said GFSA Governor Ahmad Al-Fares in a statement. The tender attracted offers from global regions including the European Union, Black Sea, North and South America, and Australia. The sellers retained the discretion to determine the origin of the wheat supplied.

The procurement was conducted on a cost-and-freight (C&F) basis, with all transactions settled in U.S. dollars, the GFSA confirmed. The agency’s decision to purchase above the tender’s initial volume highlights Saudi Arabia’s proactive measures to secure strategic food resources amidst fluctuating global markets.

Ukraine’s Greenhouse Cucumber Prices Surge Due to Strong Demand and Limited Supply

Prices for greenhouse cucumbers in Ukraine continued their upward trend last month, driven by strong demand and limited market supply, according to analysts. Retail chains and large wholesale buyers remain highly active, fuelling competition and contributing to the price increase.

As of today, greenhouse cucumbers are selling for 100-140 UAH/kg ($2.373.31/kg), marking a 20% rise compared to the previous week. This sharp increase is attributed to insufficient domestic stock levels at local farms, which have been impacted by seasonal factors, as well as the inability of imports to fully satisfy growing consumer demand.

Despite stable imports, primarily from Turkey, the volume of cucumbers available in the Ukrainian market has not kept pace with buyer requirements. Sellers have taken advantage of the supply gap by raising prices for both locally produced and imported cucumbers.

Year-on-year, the current price for greenhouse cucumbers is already 20% higher, underlining the growing challenges in meeting demand during the offseason. Market participants expect some relief when the first batches of the new harvest from Ukrainian greenhouse farms arrive, but this is not anticipated until mid-February.

For now, the upward trajectory in prices reflects a broader seasonal dynamic and highlights the dependence on imports during this period.

Soybean, wheat, and corn futures on the Chicago Board of Trade (CBOT) are poised to end 2024 with a second consecutive annual decline, as ample global supplies overshadow market trends. However, year-end weather concerns have provided some support to prices.

Dry conditions forecasted for corn and soy crops in Argentina, coupled with

poor early growth for Russian wheat, may bolster grain markets in early 2025. Yet, expectations of a record-breaking soybean harvest in Brazil—the world’s top supplier—are likely to temper any significant price rallies in oilseeds.

Trade dynamics also remain uncertain heading into the new year, with Donald Trump’s return to the White House potentially reigniting tariffs and Russia, the leading wheat exporter, seeking to restrict shipments further.

In Tuesday's light holiday trading, the most active CBOT soybean futures rose 0.5% to $9.96-1/2 a bushel by 1202 GMT, wheat increased by 0.5% to $5.503/4 a bushel, and corn climbed 0.6% to $4.54-3/4 a bushel.

Despite these gains, the annual performance paints a subdued picture. Soybeans are set to finish 2024 down 23%, wheat 12% lower, and corn off by 3.5%. All three crops experienced their lowest prices since 2020 during the year, with soybeans revisiting that low in December due to favorable rainfall bolstering Brazil's expected record harvest in early 2025.

The easing of the U.S. dollar index in recent weeks provided some relief to grain prices, but robust global supplies and market uncertainties are likely to weigh heavily on prices in the coming months.

SABIC, a global leader in the chemical industry, has joined forces with iyris (formerly RedSea), a sustainable AgriClimate Tech business and Napco National, a vertically integrated Saudi manufacturer of flexible film and packaging products, to create a high-tech durable greenhouse roofing solution using certified circular polyethylene from SABIC’s TRUCIRCLE™ portfolio. The greenhouse roof has been used in the National Food Production Initiative (NFPI), together with other leading champions from the public and private sector in the Kingdom of Saudi Arabia, designed to improve the sustainability of Saudi Arabia’s agriculture and food security in the region.

In this collaboration, SABIC® linear low-density polyethylene (LLDPE) resin is

used in the roofing of large agricultural greenhouses. The polymer material is manufactured with certified circular feedstock from mixed post-consumer used plastics and forms part of the company’s TRUCIRCLE portfolio and services for circular solutions.

The mixed-used plastic is converted into pyrolysis oil in an advanced recycling process, which is then used in the production of new polymer resins, such as LLDPE formulations, with the same purity and quality as traditional virgin plastics at SABIC’s plant in Jubail, KSA. Napco National uses the certified circular LLDPE to manufacture a durable greenhouse roofing film.

Khaled Al-Jalawi, Global Circular Economy Director at SABIC, says: “We

are proud to have collaborated on this innovative project using our TRUCIRCLE material solutions. The agricultural greenhouses, made with certified circular polyethylene from SABIC, utilize advanced recycled plastic, providing significant sustainability benefits. This initiative highlights how SABIC is collaborating with local entities to drive plastic circularity, demonstrating the power of collective efforts to benefit the agriculture industry in the Kingdom and potentially beyond.”

The film made by Napco National using SABIC’s certified circular PE has a thickness of 200 µm. It features good tensile strength and elongation and has successfully passed relevant Elmendorf

tear as well as dart impact testing. The SABIC polymer also delivers high clarity and UV stability. The incorporated, award-winning SecondSky™ technology of iyris adds excellent thermal behavior by blocking near-infrared heat without compromising the transmission of photosynthetically active radiation (PAR).

Chadi Radi, Senior Director for Business Development at Napco National, comments: “We are proud to have sponsored the production of the SecondSky greenhouse film for the Al-Bada prototype farm, utilizing SABIC TRUCIRCLE material which performs very well on our existing PE Film extrusion lines. This collaboration stands as a testament to Napco National’s commitment to sustainable development and innovation. Together, we are shaping a success story that paves the way for a greener future and a more sustainable agricultural industry in the Kingdom of Saudi Arabia.”

As part of this story, SABIC is also the first material supplier in the region to provide certified circular polymers from local production with ISCC PLUS certified feedstock from advanced recycling. As customers are increasingly becoming more conscientious of their environmental footprint, this TRUCIRCLE offering based on local capacities meets with a growing demand for more sustainable and responsible materials.

Further KSA-based collaborators in the extensive value chain of the NFPI include Red Sea Global, a developer of regenerative tourism destinations; Tamala, a local farmers’ cooperative; King

Abdullah University of Science & Technology (KAUST) for analytical studies; Terraxy, a soil regeneration specialist; and the University of Tabuk for analytical reporting on the outcome of the project.

As a first result of the NFPI, a 0.75hectare greenhouse model facility was built on previously fallow, regenerated land at Al-Bada, KSA. The large facility, including a majlis (meeting center), is fully operational, and the first crop harvests have already been delivered to Red Sea Global resorts.

Altogether, the Al-Bada facility is seen by the partners as a solution that could radically transform the lives of Saudi farmers, empowering them to regenerate land in areas where the impact of climate change has made cultivation increasingly challenging. It saves water, energy and

fertigation costs while improving crop yield and quality.

John Keppler, Executive Chairperson of iyris, summarizes the successful NFP initiative: “Saudi Arabia still relies much on imported fresh produce. With this project, we have embarked on a mission to transform the Kingdom’s potential to sustainably improve its food security and secure the future of local food production. The integration of our SecondSky technologies with SABIC’s TRUCIRCLE materials shows how the continued efforts of Saudi companies can transform the agriculture industry and benefit farmers.

As an excellent case study for our farming community, Al-Bada is a fully scalable and replicable model for growing local produce in the Kingdom and potentially beyond.”

The 360-degree closure inspection system has been further developed so that since this year all other plastic closures, as well as aluminium roll-on closures and crown corks, can also be processed.

At the last drinktec trade fair, Krones presented for the first time a new 360degree closure inspection module for its Checkmat series. At the time, it was designed exclusively for tethered caps. The technology has since been developed further and as of this year is now capable of processing all other plastic closures as well as aluminium roll-on caps and crowns.

How it works is both simple and ingenious: The unit itself consists of four cameras that photograph the cap and the bottle neck finish all the way round to provide a 360-degree view. The composite image is then inspected. This process enables the unit to reliably detect the presence, colour and proper placement of and any damage at the closure. What’s more, it can also tell if an irregularity is, in fact, merely a water droplet and thus significantly reduce the number of false rejects.

In addition, Krones offers optional software add-ons that are designed specifically for crowns – and thus ideal for breweries. For example, they can be used to detect any leaks at the closure by evaluating any foam that may be leaking out.

The 360-degree closure inspection also makes it possible to precisely measure the diameter of the crown if desired. As a result, the unit can provide 100% inline inspection, obviating the need for the otherwise customary manual testing in the lab. An optional feature is available for silver-coloured aluminium roll-on closures, too, for continuously monitoring the quality of their application.

The inspection module is equally capable at high speeds as well: In a glass line with crowns, for example, the unit can handle up to 80,000 containers per hour.

While the 360-degree closure inspection unit in the Checkmat series is perfect for inspecting full bottles, Krones likewise has a powerhouse in its portfolio for inspecting empty bottles: Linatronic AI. What makes this unit special is that it uses artificial intelligence and has been trained using a deep learning model. This intelligence, combined with a comprehensive stock of data, enables the unit to precisely detect damage and soiling while keeping

the rate of false rejects extremely low at just 0.3 per cent.

It’s a technology that has proven itself in practice. More than 50 systems are currently in use at beverage factories worldwide. Of course, each new customer brings to the table new products, which add to the database new patterns for detecting material damage or different types of soiling. And that, in turn, further enhances the system’s quality and precision. So, the beverage makers themselves benefit from using artificial intelligence –and the statistics back up that claim: In lines equipped with Linatronic AI, the rate of bottles bursting in the filler averages 65 per cent lower than in lines without it. And that increases not only production reliability and process stability but also makes for far less product waste during ongoing production.

Besides all that, as part of its continuous product development efforts, Krones has also meticulously optimised the machine guards and the integrated belt station and thus further improved cleanability, longevity and ease of maintenance.

A safe, sustainable cold chain requires carefully controlled, low-temperature ranges each step of the way — for both processing and post-processing environments. GEA’s sophisticated, compressor-based process cooling systems are designed to meet these precise condition requirements. This results in thermal-optimal food production environments, ideal product storage and distribution areas, minimization of perishables and extended product shelf life.

Meeting process-critical requirements

GEA’s long and successful history of innovation and leadership in the design and production of world-class industrial refrigeration solutions — which includes compressors; compressor packages and complete, turnkey facilities — provides customers with confidence that their cooling systems can be relied upon to deliver peak performance over the long haul.

GEA is one of the largest suppliers of process technology for the food industry and a wide range of other industries. Our goal is to be the customer’s preferred partner in the industries we serve. As the

world’s population increases, so does the demand for safe, quality food products produced by efficient, sustainable technologies. GEA stands ready to help our customers meet these challenges and serve as a long-term strategic partner.

From privately owned, single-site operations to the largest and most respected food-producing companies in the world, GEA provides customized solutions designed to deliver long-term value. Here are just a few examples of GEA’s applied expertise:

Distribution and storage facility cooling for an international grocer expanding to a new continent;

Energy-saving refrigeration system control technology for a thriving, family-owned regional bakery; Turnkey process cooling facility for a leading producer of a wide range of dairy-based products;

Sustainable heat pump system for a diversified, multi-national consumer and pet food producer.

The heart of our systems

Compressors are the heart of the refrigeration system. GEA’s long history of tech-

nological innovation and product quality in the design and manufacture of compressors and compressor systems provides the confidence our customers require for their operations.

Related to the food cooling process, GEA also has its eye on “green” savings by installing industrial heat pumps. By identifying in which processes waste heat can be recovered and diverted to other processes — like water & brine heating, drying, cooking, blanching, pickling, pasteurization, sterilization, dehydration and cleaning — we help customers work toward achievement of their sustainability goals and save money in the process.

GEA’s ambition is to work with our customers to tailor environmentally sound, sustainable and highly efficient solutions to meet every requirement.

Industry-leading food processors worldwide choose GEA solutions. After understanding your unique challenges and requirements, GEA draws from its worldwide resources to provide you with the optimal, customized solution to maximize results.

Westfalia Fruit, a leading multinational supplier of avocados and a range of fresh vegetables and fruit, is proud to announce the launch of laser etching on mangoes. Driven by its Netherlandsbased operations, this initiative eliminates the need for individual plastic PLU stickers. After extensive testing and trials, the uniquely lasered mangoes have been introduced to customers in Europe.

Mathijs Benard, Head of Operations Central Europe who joined the Netherlands-based team in March this year and who has been heavily collaborating with the German operations team, says: “Since joining Westfalia, my focus has been on improving collaboration and efficiency. The introduction of laser etching, which is almost like a tattoo on the mango, has been an exciting project. Not only does it make the fruit stand out instore, but it also has the potential to save up to 10 million plastic stickers a year. What we can laser on the fruit is only limited by our imagination and customer needs. Currently, we are etching the fruit origin, customer branding, and product reference.”

Strengthening operations and widening capabilities in The Netherlands

The laser project was a collaboration between Westfalia’s capabilities in The Netherlands and in Germany to ensure the fruit’s quality and shelf life were preserved. Customer feedback has been very positive, and the plan is to expand the range further across Europe in the near future.

Wim Destoop, President of Europe, adds: “Mathijs’ role as Head of Operations Central Europe demonstrates the refreshed structure of Westfalia in Europe. By uniting the expertise of our operations in The Netherlands and Germany with the packing capabilities of the former EuroWest facility, we are wellpositioned to ensure continuity and deliver exceptional customer service.”

Also joining the Westfalia

Netherlands team as Head of Commercial is Marcel van der Linden, a seasoned professional with over 30 years of experience in fresh produce, particularly

tomatoes. Marcel remarks: “I’ve certainly joined Westfalia at an exciting time following the acquisition of EuroWest and the combination of the two teams with one clear focus – leading in quality and packing.”

Westfalia's Poeldijk production facilities showcase diverse capabilities. While the company is renowned for its expertise in avocados, these facilities also offer year-round packing solutions for sprouts, capsicum, and other vegetables. “We are committed to providing customers with innovative solutions that showcase our broad services and flexibility,” adds van der Linden, “With state-of-the-art packing lines equipped with robotic technology, we can deliver a variety of pack formats, customized to meet the unique needs of each customer.”

INEOS Styrolution, the global leader in styrenics, announced today the successful completion of a first project with mechanically recycled polystyrene in a yoghurt cup. This milestone achievement was possible by the collaboration of multiple partners along the value chain.

The process of mechanical recycling of polystyrene is taking place in multiple steps from sorting (deep NIR sorting including object recognition) across hot washing and flake sorting to melt filtration and pelletising.

Key in the process is INEOS Styrolution’s “super clean process” which has been registered as a novel technology according to the EU regulation 2022/1616. With this process, INEOS Styrolution achieves food contact quality recyclates which before were only known from PET bottle recyclates.

The recycled material offers the same physical properties as conventionally produced polystyrene, enabling a perfect cir-

cular solution. Intensive quality controls were performed on both the material and the cups. Additionally, detailed analyses are required for the EFSA evaluation of this novel technology. Moreover, the environmental footprint of the recycled material is significantly lower than that of conventionally produced material.

A first consumer test on the acceptance of the recyclate containing cup and the cup color was conducted in spring 2024 in collaboration with Unternehmensgruppe Theo Müller, one of Germany’s leading dairy manufacturers. Several hundred yoghurt cups made from recycled polystyrene were filled and offered to volunteers in an INEOS canteen to evaluate the innovation. Not only did 90% of the testers indicate they would buy the product, but they also shared feedback that a recycled cup could look different from conventionally produced ones. For example, a colour other than today’s plain white would be completely acceptable.

The new technology was presented at the “Dresdner Verpackungstage”[1] (5.6. December 2024) by Lena Lembach, Senior Packaging Development, Unternehmensgruppe Theo Müller, and Dr. Frank Eisenträger, ECO & Market Development Manager, INEOS Styrolution.

Dr. Frank Eisenträger says: “Polystyrene arrived in the champions league of recycled food contact materials. It will enable producers to meet the new requirements of the new EU directive PPWR for packaging and packaging waste.”

Lena Lembach, states: “This is a milestone achievement on our common way to perfect circularity for polystyrene cups and towards fulfilment of the PPWR requirements as well as our own CO2 footprint reduction targets.”

The yoghurts will arrive early next year on the shelves of Lidl supermarkets.

The Trading Corporation of Pakistan (TCP) has received 11 bids for the supply of 50,000 metric tons of long grain white rice to Bangladesh.

The procurement is part of an ongoing effort to meet Bangladesh’s rice import requirements, with TCP evaluating the offers. The successful bidder will be responsible for ensuring timely delivery and meeting the contractual specifications set by TCP.

The state-run grain trader issued an international tender on December 31, 2024 and invited separate sealed bids from Companies dealing in export of Rice, for purchase of 50,000 metric ton Long Grain White Rice (IRRI-6) and 50,000 metric ton Non-Basmati Parboiled Rice both on Free on Board (FOB) Karachi/Gwadar Ports and CIF liner out Chattogram Port Bangladesh Basis through Karachi or Gwadar Port for export to Bangladesh in the shape of break bulk cargo packed in 50 kg polypropylene (PP) woven bags as per specification provided in the bidding document.

The tender was opened on Monday January 6, 2025 in presence of the bidders or their authorized representatives. In response to TCP’s tender, some 11 exporters/traders participated in the tender and submitted bids ranging $498.40 per metric ton to $523.50 per

metric tons for export of 50,000 metric tons Long Grain White Rice (IRRI-6) to Bangladesh. However, no bid was received for the 50,000 metric tons NonBasmati Parboiled Rice.

The bids were required to submit bids a minimum quantity of 25,000 metric ton or multiples thereof with a maximum quantity of 50,000 metric ton for Long Grain White Rice.

As per received bids for the Long Grain White Rice, M/s Kap Impex submitted the lowest bid, offering $468.50 per metric ton FOB and $498.40 per metric ton CIF for the supply of rice to Bangladesh. M/s Jetlee was the secondlowest bidder, with a FOB bid of $459.81 per metric ton and a CIF bid of $499.90 per metric ton.

G M Food ranked third, with a FOB bid of $463 per metric ton and a CIF bid of $502.40 per metric ton. Marvel Agro’s bid was $470 per metric ton FOB and $510 per metric ton CIF. Meskay Teka offered $467.90 per metric ton FOB and $513.90 per metric ton CIF and M/s Jesani’s CIF bid was $515 per metric ton.

Meskay Shahid submitted a FOB bid of $480 per metric ton and a CIF bid of

$517.50 per metric ton, while VMS Trading Co. proposed a CIF bid of $518.92 per metric ton. Garibsons offered $482.50 per metric ton FOB and $521.75 per metric ton CIF and M/s Jhulay Lal’s bid was $478 per metric ton FOB and $523 per metric ton CIF. Conwill submitted the highest bid, offering $482 per metric ton FOB and $523.50 per metric ton CIF.

As per tender’s terms and conditions, validity of received bids is for fifteen 15 working days after opening of bids and the validity of bids can be extendable as per PP Rules, 2004. Sources said that currently TCP is evaluating the received bids and will take a decision in the next few days.

The successful bidders, within four working days of issuance of Letter of Award, for due and satisfactory performance of the contract shall furnish a Performance Bond equivalent to Five Percent (5%) of the Value of Contracted Goods in the shape of a pay order or demand draft or bank guarantee. The performance bond shall be forfeited without notice in case the successful bidder commits any breach of contract or fails to fulfill any of the terms and conditions of the contract.

In a new peer reviewed study published in the Journal of the American College of Cardiology: Basic to Translational Science, Irish researchers have discovered novel links between gut microbes, inflammation and heart disease. Additionally, the study demonstrated that giving a single probiotic combined with a soluble dietary fibre protects against heart disease. The study used Tate & Lyle’s PROMITOR® Soluble Corn Fibre as the prebiotic component.

The study shows the profound impact of the gut-heart connection on cardiac health. For the first time, a human scale model revealed the full extent of the “gut-heart axis,” showing how gut microbe imbalance and inflammation originating in the gut can contribute to heart damage. Excitingly, the study found that a combination of a probiotic and prebiotic—referred to as a “synbiotic”—can significantly reduce heart muscle damage caused by diet-induced cardiac disease.

This research, led by scientists from APC Microbiome Ireland (APC), a worldleading Research Ireland centre based at University College Cork (UCC), and Teagasc (the Irish Agriculture and Food Development Authority), was conducted in collaboration with Tate & Lyle, a world leader in ingredient solutions for healthier and tastier food and beverages. The findings demonstrate the potential of reducing the risk of heart disease - especially in people with poor diets and obesity, half of whom experience cardiovascular issues –by manipulating the gut microbiome with synbiotics.

"This is the first time that a bacteria residing only in the gut has successfully

been used to treat heart disease associated with obesity and high blood pressure, and our synbiotic treatment equals some of the best available cardiac drugs in a human scale model. This work opens new avenues for potentially groundbreaking disease-modifying therapy in patients with obesity, high blood pressure and diet-related heart disease," said Prof. Noel Caplice, an APC Principal Investigator, Chair of Cardiovascular Sciences at UCC, and Consultant Cardiologist at Cork University Hospital.

Prof. Catherine Stanton, Senior Principal Research Officer at Teagasc Moorepark Food Research Centre and an APC Principal Investigator, emphasised the innovative potential of this work: “This study highlights the critical role the gut microbiome plays in our health and physiology. Our results are a testament to

power of harnessing gut microbes to protect against some chronic diseases like heart failure. It’s an exciting step forward in personalised nutrition.”

Dr Kavita Karnik, Global Head of Nutrition, Regulatory and Scientific Affairs at Tate & Lyle praised the innovative work, commenting: "At Tate & Lyle, we are proud to support and partner in cutting-edge research that explores how our dietary fibres, when combined with probiotic strains, can be used to improve health outcomes. It is exciting to see the integral role played by PROMITOR® Soluble Corn Fibre in this unique symbiotic combination. This work creates new opportunities to leverage our science and ingredients to have a positive impact on significant public health challenges such as obesity and associated cardiometabolic outcomes."

GEA Group will be a constituent of the renowned Dow Jones Sustainability World Index (DJSWI) in 2025, too. This places GEA among the world’s most sustainable companies for the second consecutive year. GEA is the only German member included in the index within the Machinery and Electrical Equipment Industry. Additionally, the company will be listed in the Dow Jones Sustainability Europe Index (DJSEI) for the third consecutive year. GEA once again improved its score in the indices’ underlying assessment, which at the same time has become more demanding over the years.

Sustainability as strategic priority

GEA has solidified its membership in the Dow Jones Sustainability World Index, having significantly improved its score in

multiple categories of the Corporate Sustainability Assessment (CSA) conducted by S&P Global, which forms the basis for inclusion. The company’s listing in the Dow Jones Sustainability Europe Index – the European counterpart – has also been renewed. This further bolsters the international technology group’s status as a global pioneer for sustainable and responsible corporate governance. “GEA’s inclusion in the Dow Jones Sustainability World Index as sole German representative for the machinery and plant manufacturing sector is a special honor for us. Our strong position reflects how seriously GEA has taken sustainability for many years now as well as our unwavering emphasis on sustainability as a strategic priority,” says CEO Stefan Klebert.

GEA excels in leading sustainability ranking

The DJSI index family is based on an annual evaluation carried out through the S&P Global Corporate Sustainability Assessment (CSA). In the course of this assessment, S&P examines numerous companies listed in the “Standard & Poor’s Broad Market Index” according to diverse and wide-ranging Environmental, Social and Governance (ESG) criteria. This year, more than 3,700 companies from 49 countries were assessed, with some 1,000 data points recorded per company. GEA’s membership in the DJSWI places it among the top 10 percent of the companies assessed in its industry worldwide. The technology group showed a significant improvement compared with the previous year, upping its score by three

points to a total of 78 out of 100. This means the company achieved the third highest CSA score in the industry “Machinery and Electrical Equipment”.

GEA achieved the highest possible scores in the categories water, energy as well as transparency and reporting. It also scored very well in the risk and crisis management, information security and climate strategy categories. GEA’s ambitious Climate Transition Plan 2040 also contributed to the positive overall result. The company had presented the plan to its shareholders to vote on at its most recent Annual General Meeting in April. At the meeting, the Executive Board succeeded in making GEA the first company in the DAX index family to obtain approval for a

groundbreaking Say on Climate resolution, with an approval rate of 98.4 percent. The new corporate strategy unveiled at the Capital Markets Day in October likewise includes bold climate and sustainability targets. Stefan Klebert: “We are by no means resting on our laurels. As part of our ‘Mission 30’ strategy, we recently adopted additional, even more ambitious measures that advance our purpose of ‘Engineering for a better world’.”

GEA is regularly awarded for its ESG activities. The company has been listed in the DAX 50 ESG Index since 2020. Nonprofit environmental organization CDP gives GEA an “A” for its climate activities, while the company attains an “AAA” in

the MSCI ESG Ratings. Sustainalytics classifies GEA in the group of companies with a low risk of material financial impacts as a result of ESG factors. TIME Magazine and Statista named GEA one of the world’s 500 most sustainable companies this year, ranking GEA number 33 globally and number three in Germany.

¹ The use by GEA of any MSCI ESG Research LLC or its affiliates (“MSCI”) data, and the use of MSCI logos, trademarks, service marks or index names herein, do not constitute a sponsorship, endorsement, recommendation, or promotion of GEA by MSCI. MSCI services and data are the property of MSCI or its information providers, and are provided ‘as-is’ and without warranty. MSCI names and logos are trademarks or service marks of MSCI.

To complement its usual PET bottles, the Greek bottling company Epirotic has recently added stylishly designed cans and glass bottles to its packaging repertoire. The family-owned and managed enterprise aims to gain a foothold in the Greek market for hotels, restaurants and cafés (in some countries abbreviated to HoReCa) with these new containers.

If you tell people in Thessaloniki that you’re headed to Ioannina and the Epirus region you’ll often hear in response: “Ioannina? Yes, it’s beautiful there. You’ll love the landscape.” And the mountains and lakes framing the Epirotic bottling company’s headquarters are a picturesque sight indeed. The Vikos Gorge that is namesake to Epirotic’s own beverage brand is part of that mountainscape. The family enterprise, which was founded in 1990, sells natural mineral water, soft drinks and juices under the Vikos brand and also contract-fills other branded products, making it the Balkans’s biggest bottler. Up till recently, the company had focussed on PET bottles. But that changed with the commissioning of two new lines from Krones.

The next logical step

“Just imagine this: You’re sitting in a nice restaurant, bar or café and order a

drink. A PET bottle would look out of place there. That is why we decided to also fill our beverages into smart-looking cans and returnable glass bottles,” explains Pavlo Sepetas, the son of the company’s founders Petro and Elenia Sepetas and Operations and Technology Director at Epirotic Bottling Industry.Ever since the company was set up, Epirotic has sought to achieve sustainable organic growth, whether in regard to new production facilities or the vertical integration of a preform manufacturing plant. The decision to reach out to new target groups by using two more container types fits in seamlessly with that growth strategy, and so does opting for Krones.“We’ve been working together

with Krones for many years now, starting in 2005 when we installed the country’s first PET bottling line made by Krones, and we are very satisfied. Since then, the number of Krones lines up and running in our plants has grown to seven,” says Pavlo Sepetas. When they set out to expand their horizons, the Epirotic team wanted to have a partner by their side who can draw upon plenty of experience in building and handling returnable-glass and canning lines. But ultimately it was not just Krones’ expertise that won the company over, as Pavlo Sepetas explains: “Planning work for this project began back in 2020. But the coronavirus pandemic forced us to put it on the backburner. When we resumed it in 2021,

Krones won the bid with flying colours: Their quotation was attractive, and the team was incredibly fast. They very quickly submitted an ideal layout for the two lines.”

So far there has been a state-run deposit system in Greece only for PET bottles, cans and non-returnable glass containers. But the country also has a returnable-container system managed by companies without government involvement. The underlying principle is similar, though: Beverage companies sell their products in returnable glass bottles and crates to wholesalers who pay the price for the products themselves and additionally a deposit for the crates and bottles. The same applies to the sale of goods by wholesalers to their customers in the hotel and catering sensor. So, if the customers want their deposit on crates and bottles back, they have to return the empties to the wholesalers who in turn send them back to the beverage producers. That non-governmental system works only because the crates in question can be bought solely from wholesalers – they are not available at retail sales outlets.

It was precisely this layout that set the project apart from others before, as Dimitris Vassos, the plant’s maintenance manager, explains: “The biggest challenge for the planning team was that both lines had to be accommodated in an existing hall. And the raw-materials and finished-goods store located on one side

of that hall didn’t make things any easier because it meant the start and finish of both lines had to be placed at the same end of the hall in order to facilitate the intralogistics involved. Krones provided the best possible solution to all these requirements.”After the contract was signed in December 2021, things once again advanced in leaps and bounds: Both lines were up and running in less than one year, as an enthusiastic Pavlo Sepetas tells us: “Krones is a one-stop shop, which made everything a whole lot easier for us and faster as well. The first machine arrived in our plant on 5 August, and on 31 October, production was already up and running on both lines! That’s impressive.”

The first machine arrived in our plant on 5 August, and on 31 October, production was already up and running on both lines! That’s impressive.

Besides the layout, Epirotic’s stringent quality standards for their own products were a major reason for choosing Krones. The filler the company selected for their canning line is a Modulfill VFS-C with a Modulseam seamer, which are combined in the Modulfill Bloc FS-C. The advantage of the compact block solution is an isolator design that enables a microbiologically hygienic can filling process on a small footprint.

"We are one of only a few companies to use top-quality natural mineral water for soft drinks, too. The water from our region is of great value to us, and we attach paramount importance to hygiene and a consistently high quality of our products. So the filler enclosed in a cleanroom fits in perfectly with our principles,” says Pavlo Sepetas.

For several years now our nutrition has been influenced by the two megatrends of "Health" and the "Neo economy". Animal-based products in particular are greatly affected by this. A variety of different alternatives to milk, cheese and cream etc. have been available for a few years. The per capita consumption of milk and dairy products worldwide is rising very slightly, as reported by Food Outlook from the FAO (Food and Agriculture Organization of the United Nations); this was still 117.4 kilos in 2020, and the prognosis for 2024 is 120.6 kilos. According to Statista Consumer Market Insights, Germany is ranked 4th in the world for sales of dairy alternatives. Many manufacturers of dairy products, both established companies and start-ups, are not just

watching these developments, but are also expanding their product range and becoming involved in this new sub-segment of the market.

These alternative products, which have arisen from this new trend, and which range from the replacement of milk itself right up to cheese, spreads and desserts, impose particular demands on processing and packaging. Subjects such as shelf life and sustainability play a special role here. Manufacturers are faced with several challenges: firstly, there may be a lack of know-how as regards product processing and packaging, as well as the machine technology required, and secondly, there are some issues to be aware of in the branding of the product.

Producers, who also sell animal-based products alongside the alternative protein product, must ask themselves for example, whether highlighting the sustainability of plant-based cheese alternatives could be seen as a criticism of animalbased products. This risk can be avoided by marketing the alternatives through their own new brand. This does however mean, that the benefits of marketing the alternatives through an established and proven brand disappear, and manufacturers have to weigh this up.

Modern approaches for plant-based cheese alternatives

Products, which are manufactured with plant-based ingredients, may differ

from the animal-based equivalent in their processing: Animal-based cheese undergoes a ripening process. This can also be the case with plant-based cheese, if a ripening process is selected with cultures, which consist of a mixture of lactic acid bacteria. There is also a widespread manufacturing process, which does away with fermentation. Here the raw materials are mixed, and the texture and taste are created by means of food technology processes.

Vegan cheese alternatives have a particularly heterogeneous product consistency, ranging from soft to sticky and right up to very hard. This creates a challenge for slicing

accurately to the required portion weight in a way that is gentle on the product. The necessary solutions have to be identi-

fied in discussions between machine manufacturers, such as MULTIVAC, and the producer of the product.

Challenges and solutions: Precise slicing of plant-based cheese alternatives

The choice of blade for the slicer often dictates the first starting point. The serration of the cutting edge can have a positive influence on the slicing quality. And a special coating of the cutting edge or the entire blade may also provide a solution, or alternatively a combination of the two measures. Another factor is the blade speed of the slicer. To achieve the ideal slicing result at the desired output, the application technicians subject the particular product to a thorough test, in order to find the right ratio between cutting edge serration, blade coating and slicing speed, so that an answer can be found to the challenge of consistency.

Experience shows, that plant-based protein products often have a high level of adhesion, and they can be described as "rather sticky". If the wrong parameters are set, this adhesion leads to abrasion, which can have a negative effect on the slicing result and the product placement. The second challenge is that the individual slices stick to each other, and the customer can not remove the product slices singly. The traditional solution is the socalled interleaver, which places interleaving sheets between the individual slices. These are generally however made of plastic, and this creates more packaging waste.

An alternative to interleaving film is the MULTIVAC Sustainable Liquid Interleaver, an innovative spray system used for packing thinly sliced or particularly sticky product slices. Precision nozzles on the spray system atomise a liquid

food release medium, which is both odourless and tasteless and can be tailored to the particular characteristics of the product, for example the fat content. It is applied evenly to the underside of the slices. The adhesion between the individual slices is therefore reduced, but the product itself (taste, smell, colour) however is not altered. This means that there is no requirement for the conventional interleaving film between the slices – and the consumption of plastics during the packaging process can be reduced to the bare minimum. Vegan cheese alternatives can therefore be presented very attractively in the pack, and the individual slices can be removed cleanly by the consumer.

Packaging plant-based dairy alternatives securely

When processing and packaging food products of all types, the objective is to provide optimum protection for the product against external influences, as well as extending the shelf life within the pack. The resulting requirements for the processing and packaging solutions depend on the particular product. Whereas with animal-based food products the focus is mostly on preventing the product perishing, in the case of plant-based alternative products the critical factor is the tendency

towards higher spore growth, which is triggered by the nature of the product. Machine manufacturers must therefore integrate suitable hygiene concepts into their machines.

In order to guarantee food safety up to the point of sale and extend the shelf life, various measures are used during the packaging process. For example, the products are often packed under vacuum or modified atmosphere (MAP, Modified Atmosphere Packaging), either on traysealers or thermoforming packaging machines. The particular requirements of the food product determine, which packaging method is used, and whether the best choice is a vacuum or MAP pack, or even a pack without any gas exchange. The manufacturing process, the desired minimum shelf life, and the preference for the pack design all play a role here.