INProgress Partners

SMACNA & SMART—Building a Future Together

Stadiums show the world that SMACNA and SMART are in it to win it.

December 2022

December 2022 - Volume 16, Number 7

3 WE ARE BUILDING IT... AND HERE THEY COME

Stadium work, legislation partnerships, and men and women supporting women in trades—these are just a few of this issue’s topics that demonstrate the ways we are building the industry together.

INProgress Partners

JOSEPH SELLERS, JR. ANTHONY KOCUREK

Co-Publishers

KAARIN ENGELMANN editor@pinpmagazine.org Editor-in-Chief

JESSICA KIRBY jkirby@pointonemedia.com Editor

POINT ONE MEDIA INC. artdept@pointonemedia.com Creative Services

Partners in Progress is a publication of the Sheet Metal Industry LaborManagement Cooperation Fund.

4

PLAYING THE LONG GAME

Stadium work brings SMACNA contractors and SMART Locals together to show the world what the sheet metal industry can do.

7 RELATIONSHIP MANAGEMENT

Fire life safety legislation in Albuquerque, New Mexico, is a major win achieved collectively by SMACNA New Mexico and Local 49.

10 HEAVY METAL SUMMER ROCKS BOSTON & ST. LOUIS

HMSE camps in Boston and St. Louis bring contractors and Locals together to improve recruitment.

All contents ©2022 by the Sheet Metal Industry Labor-Management Cooperation Fund, P.O. Box 221211, Chantilly, VA 20153-1211.

Find Partners in Progress online at pinp.org or at issuu.com/ partnersinprogress. An archive of all issues is available. Issues may be downloaded and printed for no fee.

For comments or questions, email editor@pinpmagazine.org.

12

TRADESWOMEN BUILD NATIONS

More than 3,100 tradespeople and leaders, including SMACNA and SMART representatives, attended the Tradeswomen Build Nations event.

16 MOVING BEYOND WORKPLACE CONFLICTS

You can’t change others, but you can change your point of view. Here are five principles for improving relations and six steps to resolving conflict.

18 HOW TO BE MORE DECISIVE IN YOUR LIFE AND LEADERSHIP

We aren’t all born decisive, but we sure can learn the skill. Discover how being more decisive can change your work and life for the better.

20 MY JOURNEY: ADMIR “OTTO” IBRADZIC

Office work was not for Amir “Otto” Ibradzic, but the sheet metal industry certainly is.

2 » Partners in Progress » www.pinp.org

CONTENTS

Future Together

SMACNA & SMART—Building a

SH EE T ME TA L AI R R AIL TR AN SPO RT AT ION

12

While walking alone through a cornfield in 1989’s Field of Dreams, Kevin Costner’s character, Ray Kinsella, hears a strange whisper: “If you build it, they will come”. That experience would send some of us running out of the haunted field as fast as we could, and it would leave others scratching their heads trying to figure out what “it” is that we are supposed to build. Fast-forward through some movie frames, and Ray discovers “it” is a baseball field. Ray takes a leap of faith, and when he builds the field, whole teams of dead baseball players show up to play.

Ray’s corn field stadium was pretty simple. Today, stadiums are $100 million dollar plus ventures that provide tremendous amounts of work and pride for sheet metal contractors and workers throughout the United States and Canada. It’s a given that it takes great labor-management collaboration to win coveted stadium work. Contractor and union representatives share requirements for becoming the successful bidder and performer on high-profile stadium projects that will be admired by sports fans for decades to come in “Plaing the Long Game” on page 4.

Labor and management in the sheet metal industry are not limited to building ductwork or showcase stadiums. We also build relationships. SMACNA New Mexico and Local 49 provide a great example of the way persistence and partnership can pay off. Industry leaders from New Mexico describe their joint efforts to educate state legislators and prove that labor and management can work together across political lines to secure fire life safety. Learn more in “Relationship Maintenance” on page 7.

© Can Stock Photo / Keifer

With record amounts of work projected in many jurisdictions, one of the most compelling needs is for SMACNA contractors and SMART Locals to work together to recruit the best potential talent for our industry. Learn how SMACNA Chapters, contractors, and Locals in Boston and St. Louis ran highly successful Heavy Metal Summer Experience camps in their areas this past summer in “Heavy Metal Summer Rocks Boston & St. Louis” on page 10.

When you’re the only person (or one of few) on a jobsite who looks like you, being in a room of 3,100 allies can be a very powerful experience. Tradeswomen Build Nations is the world’s largest gathering of tradespeople and leadership—find out how SMACNA and SMART represented at the 2022 event in “Tradeswomen Build Nations” on page 12.

Internal relationships likewise require building and nurturing. Doing that with difficult employees and co-workers presents a unique challenge. Workplace coach Joel Garfinkle shares his insight on how to deal with difficult co-workers and move beyond conflicts in “Moving Beyond Workplace Conflicts” on page 16. One of the important qualities of great leaders is decisiveness,

but many of us suffer from “analysis-paralysis” from time to time. Decisiveness may not be an innate, inherited trait, but that means it can be practiced and improved. Learn why being decisive does not always mean being perfectly right. Turn to page 18 for tips on “How to be More Decisive in Life and Leadership”.

Office work is certainly not for everybody. My Journey on page 20 features an apprentice in Waterloo, Iowa, who realized during engineering school internships that he did not like working in an office because he was more of a hands-on person. His discovery led him to a more fulfilling career in the commercial HVAC industry.

As we wrap 2022’s final issue of Partners in Progress, we are thankful to all those in labor and management who worked together to improve our industry in 2022. Our staff and the staff and the leadership of SMART and SMACNA wish all our industry partners a joyous holiday season and a healthy and prosperous 2023. ▪

BE4ALL CALENDAR 2023

This 2023 BE4ALL calendar is a tool for your members/ employees/colleagues to learn more about the different cultures and faiths that make up our ever-evolving industry. Each month highlights several important holidays/observances your peers may take part in and even a few that might be less familiar. In addition to noting the exact date of the observance, an explanation of that particular day’s significance and history can be found directly below the calendar.

Please post this calendar in a public space, such as a break room, lunchroom, or other communal meeting areas. By doing this, we hope you can use this resource to start meaningful conversations that will enable you to learn more about your colleagues and develop a new understanding of the different cultures, ethnicities, and faiths that make up the sheet metal industry. If you want to learn more about a particular day, scan the QR code so you can travel to the BE4ALL website where you can learn more about the history and tradition associated with a specific observance. ▪

Partners in Progress » December 2022 » 3

We are bulding it ... and here they come.

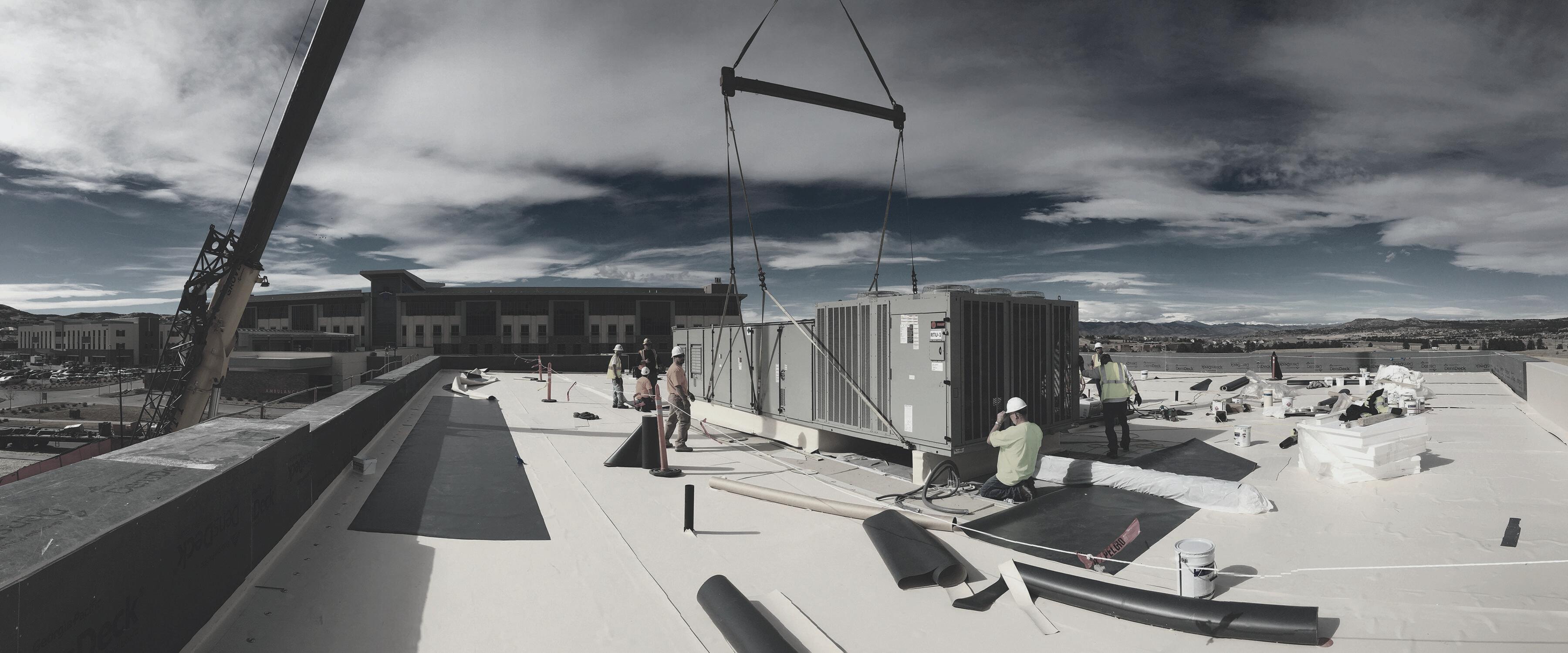

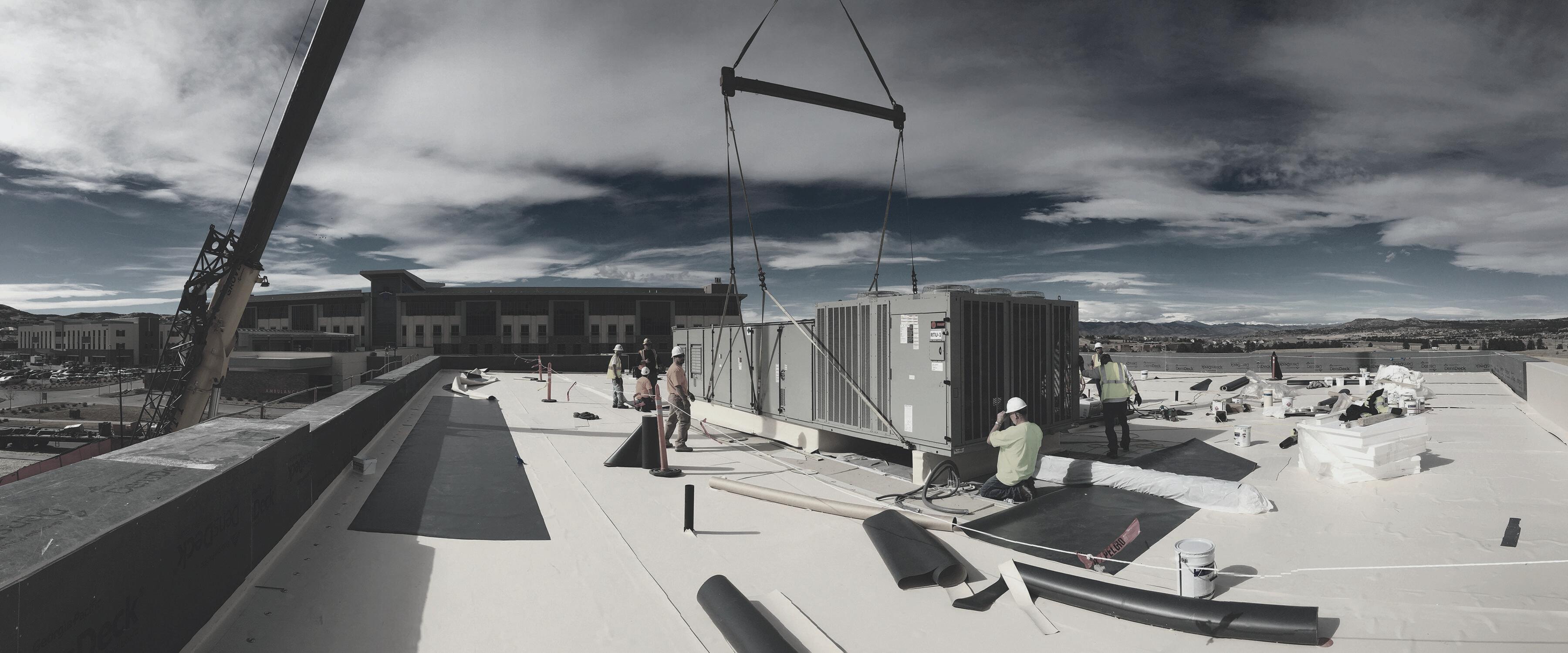

Playing the Long Game

By / Robin Brunet

In this post-pandemic climate of pent-up demand, and despite inflation and supply chain issues, stadium projects are big business in many jurisdictions of the United States and Canada. Indeed, they are a boon for SMACNA contractors and the SMART workforce.

Steve Hinson, business manager/president of Local 105, which serves various Southern California counties, including Los Angeles, says,“Our members have been involved in at least five major projects during the past five years, including SoFi Stadium in Inglewood and, more recently, the adjacent Intuit Dome, which broke ground in 2021. Whenever we hear of stadiums builds, we get right in front of the decision makers to make sure the appropriate humanpower is deployed.”

L. William Zahner, president and CEO of A. Zahner Co., says that stadiums mean long-term employment for both architectural and mechanical sheet metal crews. “Securing these projects takes effort and can be frustrating, but it’s well worth it,” he says. He adds that the high-profile nature of stadiums allow the sheet metal trade to show the world what it can do.

ACCO Engineered Systems sales manager Matt Taylor agrees that stadium projects—including SoFi, the Stub Hub Center, and the Crypto.com Arena—are essential for his company’s success. “Work at SoFi began in 2017, lasted three years, and enabled us to use some of our most experienced people, as well as hire locally,” he says.

That 70,000-seat stadium was designed by HKS Architects, is covered by a canopy of translucent ETFE membrane and 34,789 unique, perforated panels courtesy of A. Zahner Co., and includes a 5,000-ton central plant, over 1.7 million pounds of sheet metal ductwork, and 4,000 tons of VRF systems from ACCO.

SoFi and similar projects demonstrate that stadiums demand the absolute best sheet metal design, fabrication, and installation. “Not only are they massive, but also they are enormously complex,” says SMACNA Western Washington Executive Director Julie Muller-Neff. “Plus, as energy efficiency takes on new levels of meaning in the construction sector, the standards to which stadiums are built are rapidly evolving. Climate Pledge Arena in Seattle is a prime example.” The 740,000-square-foot, multipurpose facility completed in 2021 is the world’s first International Living Future Institute certified zero carbon arena.

SMACNA-Western Washington’s Hermanson was the mechanical contractor, using Local 66 crews to help create a stadium powered exclusively by renewable energy, including on-site and off-site solar. Plumbing, fitting, and sheet metal requirements—including installation of 1 million pounds of sheet metal and 200,000 linear feet of pipe—had to be fulfilled in an existing arena that was completely gutted except for the roof.

With the coming surge in the renovation and construction of sporting venues—including Highmark Stadium in New York, the Rogers Centre in Toronto, and stadiums in Kansas, Nashville, and St. Louis—what is the recipe for procurement of these projects and their construction success?

“In the context of sheet metal, it is vital to have skilled labor available,” Zahner says. “Since I can state confidently that my

company has the skills and the volume to get big jobs done on time, I get my foot in the door.” Another advantage Zahner offers is that the company manufactures everything it installs. “ACCO has helped build major sport facilities along the West Coast by working with trade partners and engineering groups to bring flexibility into the mix, which is crucial because these facilities have diverse systems and frequent sequence changes,” Taylor says.

Maintaining well-trained crews is another important part of the procurement process, Zahner emphasizes. “The number one consideration is safety training, as a lot of work is conducted at great heights—and any construction manager will be scrupulous about this,” he says. “OSHA certification lays the groundwork. SoFi crews were trained to either OSHA 10 or 30 standards, but it’s also indispensable to have ITI training for crane work, rigging, lift planning, and more.”

Taylor echoes Muller-Neff’s observation that training must address stadium design that is evolving to accommodate more sustainable systems. “For example, a lot of new arenas require flexible duct ‘socks’ that wrap around the entire perimeter of the facility,” he says.

Partners in Progress » December 2022 » 5

Playing the Long Game

“As more and more stadiums are built to the standards of Climate Pledge Arena the more intensively crews will have to be trained in order to secure such work…Goals—such as net zero carbon—affect everything from mechanical overall down to the fasteners of building envelopes,” says Western Washington Sheet Metal JATC’s executive administrator Jeff Reinhardt. “Fortunately, organizations such as ours contribute to our workforce being one of the best trained in the industry.”

However, according to Zahner, even the most experienced sheet metal company with the most thoroughly trained crews will not prevail without productive labor-management relations. “Good union relationships enable me to get crews at size in any jurisdiction, not just my home base of Kansas City,” he says. “Locals want projects to succeed, and this enthusiasm disseminates into the workforce.”

Muller-Neff agrees. “Good relations are essential in stadium work because these projects have all sorts of rules and regulations that require the expertise of both parties to find solutions—and to pivot quickly when required,” she says.

There’s no magic to fostering great relationships, just the requirement of forthrightness. “Open and honest communication between the two parties is important,” Hinson says. “At Local 105, my predecessor Luthor Medina pushed for it very hard, and we continue to emphasize it because we’re well aware that to get anything done we need to be on the same page.”

The Local 66 JATC is a testament to the benefits of labormanagement cooperation. “Our mission statement is to bring both parties together for the development of a highly skilled and competitive workforce for our evolving sheet metal industry,” Reinhardt explains. “With six members from labor and six from management governing our activities, we’re able to continue providing training that is specific to many areas of industry, such as lift certifications for stadiums.”

Zahner echoes the sentiments of his colleagues. “When all the elements are in place, stadium work fulfills a lot of objectives,” he says. “It’s a showcase for sheet metal specialists. It gives young talent considerable training and on the job experience, and it’s a great way for labor and management to come together.”

“And last but not least, the fact that our work will be admired by stadium patrons for decades to come is enormously fulfilling and will compel us to continue seeking such work, well into the future.” ▪

Robin Brunet’s journalism has been published in over 150 magazines, newspapers, websites, and other media across Canada and the United States since 1982. He is also the best-selling author of two books: Red Robinson: The Last Deejay and Let’s Get Frank, as well as the upcoming The Last Broadcast

6 » Partners in Progress » www.pinp.org

Relationship Maintenance

By / Natalie Bruckner

The great strides on fire life safety legislation that labor and management have made in Albuquerque, New Mexico, will be a game-changer for everyone.

It has been a long and bumpy road, but the efforts of Local 49, SMACNA New Mexico, the Mechanical Contractors Association of New Mexico, SMACNA contractor Energy Balance & Integration LLC, and many others are finally paying off.

Effective October 7, 2022, a temporary emergency rule has been issued to the New Mexico Administrative Code (NMAC) to read that all smoke and fire dampers will be inspected by an Authority Having Jurisdiction (AHJ) or a contractor with an ANSI accredited program that is certified to inspect smoke and fire dampers.

In addition, amendments have been made to sections 1, 8 and 9 of 10.25.2 NMAC, which means inspections of the mechanical operations will now be conducted alongside fire control system inspections.

“Currently, the fire control systems generally get inspected, but the mechanical system does not, and that is what our legislation is going to correct,” Kocurek says. “The fire control

systems only sense the fire and smoke, the mechanical system and smoke control equipment receives that signal to actually go to work. It has to go hand-in-hand.”

According to Isaiah Zemke, business manager-financial secretary-treasurer at Local 49, “The rulemaking was made possible due—in part—to relationship maintenance and upkeep with the governors’ staff.”

Rather than fight this battle alone, labor and management collaborated, educated, and enlisted the help of those who were beginning to understand why inspection of the mechanical parts of smoke and fire dampers is such an important issue. “We worked together to overcome the barricades in the fire marshall’s office and actually teamed with the proper contacts, while also engaging the Construction Industries Division of New Mexico,” Zemke says.

It was with this united front they were able to gain access to various legislative leaders and educate everyone from the rule makers to individuals on the issue. This ultimately resulted in a win, not just for the industry, but also for building occupants, who can now feel safer, should a fire break out.

Partners in Progress » December 2022 » 7

Fire life safety legislation was a major win for labor and management in Albuquerque, New Mexico

Overcoming misconceptions and misinformation was a major hurdle for those involved in this endeavor. Some believed that advocacy for the amendment was a case of political opportunism, gaining more work for union contractors.

“There were governmental agencies that were against our process,” Zemke says. “So, we decided—at one point—to step back and consider who would be best to get on our team and work alongside us. This was greater than SMACNA New Mexico and Local 49 just promoting work.”

As labor and management and other members of the advocacy team worked together raising awareness among those outside of the industry, “It became clear that we were trying to advance an ‘industry’ issue, not a political issue,” says Ronda Gilliland-Lopez, executive director/administrator at the Mechanical Contractors Association of New Mexico.

Kocurek adds that this shift in thinking was integral to their success. “First and foremost, any proposed initiatives have always been for the health and safety of the citizens of New Mexico. Second, they are designed to improve and strengthen the mechanical industry,” he says. “That battle took a while, but we did this by reminding community leaders that Local 49 and SMACNA New Mexico are a team.”

That’s not to say there weren’t misconceptions around the relationship between labor and management. “There was a need to break down old political barriers,” Kocurek explains. “Many legislators think only in terms of labor versus management and union versus non-union issues, which generally translates to Republican versus Democrat. However, many were surprised to see labor and management working together for an industry issue.”

The team agrees that while trade unions and signatory contractors may have some disagreements on personal political issues, they stand united as industry partners on industry issues. “That alone is breaking old barriers,” Kocurek says.

While there may still be a long road ahead to overcome this stereotype, Zemke says, “The goal is one day to be able to

walk into Democrat or Republican representative offices and discuss ‘industry’ issues without being tainted by preconceived political issues, and that can only be done through exemplary partnerships like this.”

Political advocacy was not the only effort this partnership engagned in to advance this issue. “Using the JATC, we conducted awareness sessions with some AHJ personnel,” Kocurek says. “We would show them how extensive our training and knowledge base is in mechanical fire life safety and smoke containment systems, and how we can provide a complete verification of the fire life safety systems covering all aspects. Nobody knows the mechanical aspect of these systems like we do because we actually install them as part of our everyday work.”

Work on fire life safety doesn’t end here. The team has a goal to get as many AHJ to the training centers as possible. “This is how we will educate them on how the mechanical systems actually work,” Zemke explains. “We will assure them we are working together with them to cover all bases in the inspection and verification of fire life safety systems, in all our public buildings, and in as many private buildings as possible.”

Ultimately, the team has a big vision, and that is to have the mechanical inspection certifications available just as they are with elevator inspection certifications. “We eventually want all buildings to have certification updated every four years as the building codes and NFP codes already state they should be,” Gilliland-Lopez says. With such a strong labor-management partnership, it is likely they will reach their goal.

Natalie is an award-winning writer who has worked in the United Kingdom, Germany, Spain, the United States, and Canada. She has more than 23 years experience as a journalist, editor, and brand builder, specializing in construction and transportation. When she’s not writing, you will likely find her snowboarding, mountain biking, or climbing mountains with her rescue dog.

▪

Relationship Maitenance 8 » Partners in Progress » www.pinp.org © Canstock / garumna

Heavy Metal Summer Rocks Boston & St. Louis

By Sheralyun Belyeu

Students from diverse backgrounds graduated from the Boston Heavy Metal Summer Experience camp in 2022. SMACNA St. Louis and Local 23 are already planning a camp for 2023.

Paul Heimann, vice president and controller of Welsch Heating and Cooling, has his eye on the future. “We’ve all heard that thousands of people are ready to retire out of the trades,” Heimann says. “We have to actively recruit young people to replace the workers we’re losing, and we have to get them quickly so they can receive training and mentoring from those leaving the workforce. We only have a small window of opportunity.”

Bob Butler, president of SMART Northeast Regional Council in Boston, agrees. “Recruitment work is crucial for the future,” he says. “If we don’t have the best people out there, we’re going to miss the boat.”

Welsch Heating and Cooling in St. Louis and J.C. Cannistraro Mechanical in Boston piloted Heavy Metal Summer Experience camps this year to give high school students real-life experience in sheet metal. “At first, I thought it might be a disruption to our operations to host this camp,” says Matthew Cannistraro, J.C. Cannistraro’s operations manager of manufacturing and fabrication. “But actually, the people who work in our fabrication facility were excited to work with the campers. It was received as a tremendous opportunity to pass down some of their knowledge and experience to the next generation.”

It didn’t take long for the contractors to organize solid camp experiences. “We were ready less than two months from the time we got the go-ahead,” Heimann says.

SMACNA made it easy to succeed by providing a detailed HMSE Playbook with suggested schedules, permission forms, and releases. “Everything we needed was in there,” says J.C. Cannistraro sheet metal mechanic Shamaiah Turner of Local 17.

Partners in Progress » December 2022 » 9

© Canstock / Denchik

Cannistraro relied on Turner to pull the camp together quickly. “In addition to my job in the field, I help J.C. Cannistraro with some diversity and equity inclusion projects, as well as perform outreach work to schools,” says Turner, who is also recording secretary for the SMART International Women’s Committee and a trustee on the SMART Recruitment and Retention Council. After just five days of camp, she saw student attitudes changing.

“They could see a viable path for their future,” she says. “One student invited a relative to the graduation. He wanted me to explain that he could make money working in the trades. This relative was adamant that he would have to go to college. I pressed upon the family that the student can go as far as he wants in the trades. And if he wants to go to college later, he will actually be able to afford it.”

Finding Campers

Locals and SMACNA used community connections to advertise the HMSE camp. Local 36 Director of Marketing Jeff Bradley is on the St. Louis School Business Partnership Board. “We reached out to different area high schools to get a good cross section of the St. Louis metro area,” he says. “As a Local, we dove in and did whatever we could to make sure Heavy Metal Summer Experience was a success.”

In Boston, J.C. Cannistraro has a corporate partnership with Big Brothers Big Sisters of Eastern Massachusetts. “We recruited students from Madison Park Vocational Technical High School, which is in Boston,” Cannistraro says. “We also worked with MASS Girls in Trades, which has a network of vocational technical schools around the region. The organization was able to get the word out to a broader audience.”

The result was a diverse group of campers. “One of the inspiring things about the camp was watching the students interact with each other,” Cannistraro says. “They had different educational experiences, different family backgrounds, different neighborhoods. And they all came together to have fun for a week.”

Future Years

After seeing HMSE in action, the participants are thinking about the future. Three campers from this year have texted Cannistraro’s Diversity and Community Outreach Manager, Amy Cannistraro about working for the company next summer. She is exploring wider work options for teens.

“We would bring them on as paid employees,” she says. “We have had high school interns over the years, and we want to formalize and strengthen our high school internship opportunities. We want to ensure that there are opportunities in all areas of the company, not just the office but also in the shop.”

Heimann and Bradley have already started planning for the 2023 HMSE camp because they want enough time to add

Heavy Metal Summer Rocks Boston & St. Louis

new projects and ideas. The planning committee will include the Local business manager and SMACNA executive, any contractors that want students to tour their shops or worksites, and the JATC. “We can’t operate without SMACNA, and SMACNA would have a hard time operating without us,” Bradley says, “especially with the quality of training that our instructors can provide in the JATC.”

The objective is to include a welding activity in the next camp. “I’ve started reaching out to vendors to ask if they would donate the proper PPE for the student campers,” Bradley says. “We’re also going to add a field day and take students out to a job site.”

Bradley contributed to the HMSE Playbook with feedback based on his experiences this summer, even adding the instructions for a simple clock project he designed for the 2022 camp. “The Playbook is a live document, so the process was quick and easy,” he says. “We just submitted feedback to Angie Simon, and she updated it.”

Heimann’s ideal HMSE graduation ceremony would include a job announcement. “I want to bring a contractor on stage to say he’s hired a camper to do a little work and introduce a student who is starting his placement,” Heimann says. “I think I can get that on the news and get people asking about what’s happening here.”

Local 36 hosted the St. Louis graduation ceremony at the union hall this year, and in 2023 Heimann wants to add a tour of the JATC for parents. “I think it would be an eye-opening experience for people to visit the school and see what our capabilities are,” he says.

Heimann is considering ways to offer camp-type experiences to adults. “There are some great nonprofit organizations that help people get their lives back on the right track,” he says. “I think we ought to partner with rehabilitation centers and see if we can recoup some of those we missed the first time. With wages starting at $25 an hour, it’s a pretty good start to changing a life.”

See hmse.org to view video highlights of some past camps.▪

A Colorado native, Sheralyn Belyeu lives and writes deep in the woods of Alabama. When she’s not writing, she grows organic blueberries and corrects misspellings of her name.

The HMSE Playbook

The HMSE Playbook is a 125-page manual developed to share with interested contractors or JATCs to aid them in hosting camps at their facilities. It provides sample applications, permission releases, and video and media releases, as well as sample schedules, projects, and lessons learned.

“We tried to think of everything they might need to run the camp,” says Angie Simon, co-founder of HMSE. “I have received feedback from numerous camps last summer that the playbook was very valuable to help them plan their camp—it is designed to be a ‘Easy Button’ for the camp hosts.”

The Playbook details the curriculum and sample itineraries based on Western Allied Mechanical’s and Hermanson Company’s inaugural camps, and includes several photos of classroom and shop activities, projects, and exceptionally happy-looking students.

“We anticipate HMSE camps in about 30 locations around the nation next summer ,” Simon says. “Last summer we had about 170 students, and next summer I anticipate 425!”

Learn more at hmse.org

Partners in Progress » December 2022 » 11

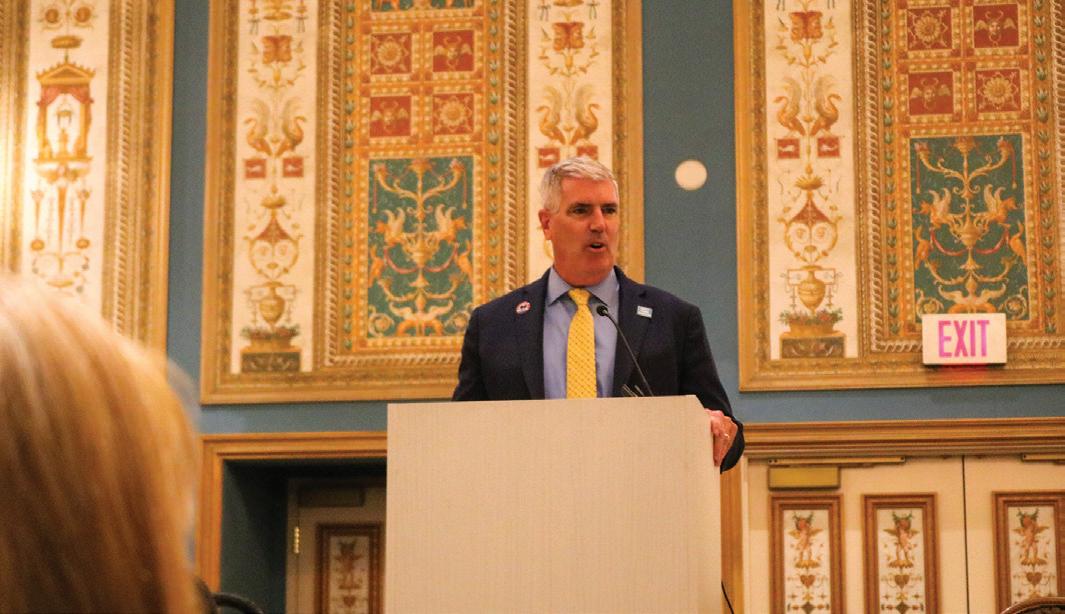

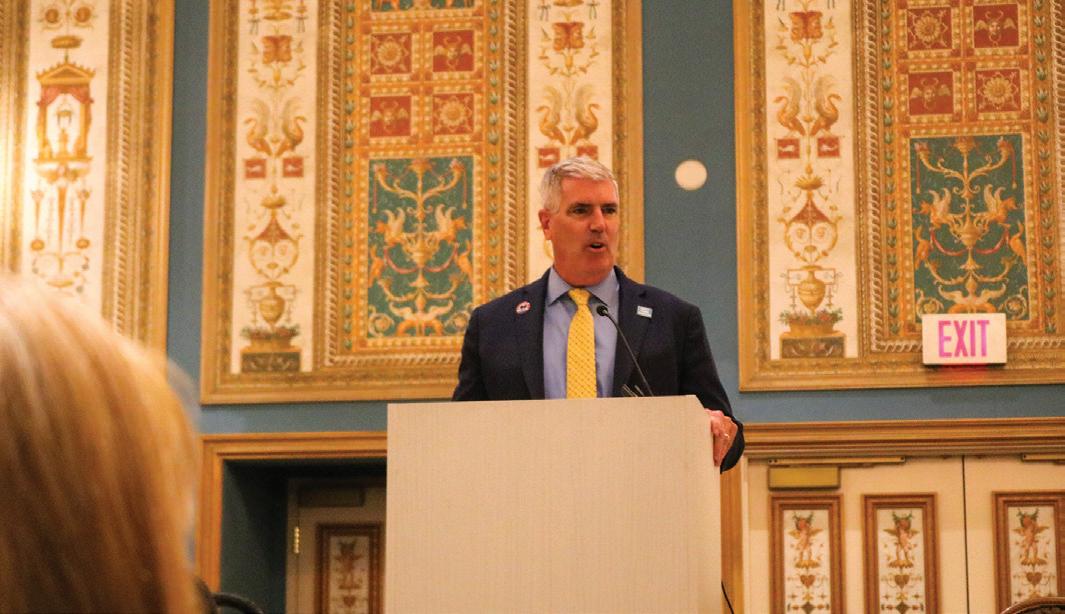

Tradeswomen BUILD NATIONS

Tradespeople, union leadership, and contractors gathered at the 2022 Tradeswomen Build Nations event—the largest gathering of tradeswomen in the world. Hosted by North America’s Building Trades Unions (NABTU), the annual event brings more than 3,000 trades industry representatives together, this year representing 48 states and 10 provinces.

By / Jessica Kirby

The three-day Tradeswomen Build Nations (TWBN) conference featured two formal plenary sessions, a banner parade on the Las Vegas strip, and over a dozen workshops on a range of topics addressing unique and critical issues of tradeswomen in the workforce.

“The impact of TWBN and its exponential growth is phenomenal,” said NABTU President Sean McGarvey. “There is nowhere on the planet where more building trades members gather each year than at this conference, and this year almost

every general president in the building trades attended.”

The sheet metal industry represented well. SMACNA held its Women’s Summit with 50 attendees in Las Vegas on the Thursday before TWBN started, to encourage SMACNA attendees to stay and attend both events.

Angie Simon, past SMACNA national president and advisor to the board of Western Allied Mechancial in California, attended and was most impressed by how many allies (male supporters) attended the event. “SMART General President Joe

Sellers and his top people, as well as many business managers and JATC trainers, were there to support the SMART women,” Simon says.

“There were about 10 SMACNA folks who stayed for the Friday and Saturday events,” she adds. “This included SMACNA CEO Aaron Hilger. SMACNA attendees were also invited to the SMART reception on Friday.”

Simon heard from the men who attended that TWBN was eye opening. “They heard stories and attended panel discussions

that made them even more aware of what their female sisters have had to endure being the only women on a jobsite,” she says. “So, for their awareness, it is excellent that they attended. For the women, it was a chance to celebrate their successes, not feel so alone, and bond and network with other women working in the trade. Plus, the educational content was solid.”

Samara Sampson has been active in Local 285 since she started her apprenticeship in 2016. She sits on the SMART IA Women’s Committee and chairs Local 285’s Women’s Committee. She’s had her eye on TWBN since 2019. In 2022, she got her wish.

“I’d heard of the electric energy and the powerful feeling of being in a room full of tradeswomen when we are all so used to being one of few or the only,” she says. “I was looking forward to getting the chance to network with other women within the industry.”

Sampson agrees that the best part of the conference was seeing so many brothers and allies in attendance. “They were excited to be a part of the change and enjoyed the conference’s energy,” she says. “Our brothers need to be at these conferences to see what we face and how we work toward change. Some people need to be involved to be able to understand. We are all a part of this industry, and we must work together toward a better future for everyone.”

Attendees also included four tradeswomen and three office staff from Local 280, representing SMACNA-British Columbia members Ridge Sheet Metal, Viaduct Sheet Metal, and Boston Sheet Metal.

Sheila Sadler has been a sheet metal worker at Viaduct Sheet Metal for 18 of her 19 years in the trade. A stay-at-home mom straight out of high school, Sadler was out of the paid workforce for a decade, which proved a disadvantage when her marriage ended.

“I had a minimum wage job and still had to depend on my children’s father for help,” she says. “I didn’t want to be that any more, so I looked to the trades.”

The trades discovery program at British Columbia Institute of Technology (BCIT) led her straight to sheet metal, and she never looked back. “I love metal work and having a good, stable job to raise my kids,” she says.

Partners in Progress » December 2022 » 13

Similarly, Nikki Pasqualini of Ridge Sheet Metal has been in the sheet metal industry for five years and entered from high school. “Sheet metal was something I knew nothing about at the time, but when the opportunity arose, I took it and became the first ever female to work as an apprentice at Ridge,” she says. “The future potential and benefits were a driving factor in this decision.”

Sadler still loves her job 19 years later, so much so that when she heard about TWBN, she was immediately interested. The idea of meeting other women in trades and getting eyes on proof she is not alone was a big draw. She wanted to find out about the challenges women face collectively and maybe even make a difference.

“I wanted to find out what I could do to make it better for everyone coming into trades and learn ways to keep women in the trade,” Sadler says. “I am also interested in ways to bring women into the trades and help them find jobs that could change their lives for the better.”

Pasqualini attended because to become more involved in the union and the industry, and she also wants to learn how to be more of an advocate for her fellow tradeswomen.

“I wasn’t too sure what to expect, although I was told it would be an empowering experience,” she says. “The convention exceeded my expectations. The amount of powerful and strong women in one room just blew me away.”

For Sadler, the meeting in the Great Hall was the event highlight. “It was the most powerful experience I have ever felt,” she says. “The pride that was in that room was overwhelming. I felt connected to 3,300 people all at one time. I have goosebumps thinking about it.”

That feeling resonated throughout the weekend, and among women and men in all trades who attended the event. “People on the street could feel the energy when we went on a small walk about,” Sadler says. “It was amazing to see and feel.”

One of Pasqualini’s favourite parts of the conference was the banner parade. “Having over 3,000 women march, union strong and proud down the strip, was such an amazing experience,” she says. “The crowd watching cheered for us and chanted

14 » Partners in Progress » www.pinp.org

Tradeswomen Build Nations

© Can Stock Photo / Ghen

with us. As someone who has not had the opportunity to work with too many women, it was breathtaking to see the amount of support there is out there.”

Among many lessons gleaned at the event, Sadler learned that daycare is a huge issue in the industry because the days start early and daycare hours don’t often align. This poses a difficult barrier for single parents, most of whom are women.

“We need a better support system for retaining these workers,” Sadler says. “We are here to help fill the jobs that the industry so desperately requires and to take care of our families, the same as any other construction trade.”

Another key takeaway was from the workshop titled, “Bullying and Harassment—Don’t Be That Guy”. “Bullying and harassment still happen in many work places, especially for women and apprentices in trades,” Pasqualini says. In many instances, co-workers who are bystanders to bullying do nothing to help or deflect because they are afraid of retaliation.

“ʻSilence is compliance’ is a phrase that stood out for me,” Pasqualini says. “As tradespeople, we need to work on how we treat each other because times have changed, and this is not a man’s job or a woman’s job. This is our job.”

For future attendees, Pasqualini recommends taking the time to listen to people’s experiences and stories, which can be a good source of learning how to navigate future situations.

“Be open to networking and making connections,” she says. “It’s hard, but it will be worth it. Finally, don’t be afraid to speak up and tell your story.”

Sampson says events like this are important opportunities for contractors, owners, and union leadership to work together to express support for the workforce.

“It’s important that labor and management leadership support individuals attending this event because it shows a genuine interest in an equitable future within their union or company,” she says. ▪

Jessica Kirby is editor-publisher for Point One Media, a small but sturdy family-owned trade magazine creator representing some of North America’s most successful construction associations.

Partners in Progress » December 2022 » 15

”

The crowd watching cheered for us and chanted with us.

As someone who has not had the opportunity to work with too many women, it was breathtaking to see the amount of support there is out there.”

“

—Nikki Pasqualini, Local 280

Moving Beyond Workplace Conflicts

Steps for resolving disagreements and improving relationships with coworkers

By Joel Garfinkle

By Joel Garfinkle

Sir Winston Churchill and Lady Astor, two prominent British politicians, experienced one of the most hostile relationships in Parliament history. Their interactions were constantly filled with conflict, sarcasm, and caustic remarks, each intending to pay the other back in full for past transgressions.

Once, during a legislative session, Lady Astor became so upset with one of Churchill’s decisions that she shouted, “Sir Winston, if you were my husband, I’d poison your tea.”

To which Churchill quickly retorted, “Madam, if you were my wife, I’d drink it.”

If your work life sometimes feels like a session of the oldschool British Parliament, take heart. You can’t change your coworkers, but you can change your point of view about them—and about yourself. Here’s the reality: In today’s “dogeat-dog” work environment, many people needlessly put each other down instead of building each other up. Positive, uplifting, and encouraging words have been irresponsibly exchanged for

negative, piercing, and destructive ones. Following the five guidelines I outline below will help you move beyond tension and discord and into a healthier, more productive way of relating to colleagues.

Five Principles for Improving Relationships with Difficult People

Spend the next 30 days incorporating these five guidelines for improving relationships with difficult coworkers and other unflattering individuals into your daily life, and I guarantee you’ll experience a dramatic and positive change in your work environment. Each of these principles will make a dramatic difference:

1. Practice acceptance.

See and accept others for who they are. Notice their strengths and talents, rather than their imperfections and shortcomings. Look beyond physical appearance to find the real person.

2. Be fully present.

When someone comes up with a new idea, listen without judging. Look for the possibility in each new suggestion. Look for ways it can work instead of reasons why it won’t.

16 » Partners in Progress » www.pinp.org

“The harder the conflict, the more glorious the triumph”

— Thomas Paine

© Can Stock

Photo / tillydesign

3. Treat your coworkers as equals.

Develop a “we’re all in this together” mentality. Instead of trying to outshine everyone around you, cultivate team spirit. Remember the old adage, “There is no I in TEAM.”

4. Change your perspective.

Your point of view is valid, but others may have equally valid opinions and ideas. Try viewing things from their perspective instead of yours. This enables you to better understand who they are, what they think and feel, and why they behave as they do.

�5. When all else fails, remember someone who reached out to you.

Not every difficult relationship will turn around overnight. In certain situations, we can benefit from the advice of R. J. Rehwinkels, who said, “The only people you should try to get even with are those who have helped you.”

Evaluate your relationships. Where are they headed? You might need to initiate some tough conversations to get things back on track. Be the first in your circle of friends and colleagues to get even only with those who have helped you. It can make a real difference to building positive relationships at work.

As you begin to implement these guidelines, you may still find yourself immersed in long-brewing conflicts that you need to address head-on. Read on for a step-by-step process on how to handle them with grace and skill.

5 Steps to Resolve a Conflict

Client Martina Asks: Lately, my office has become Conflict Central. We can’t have a productive meeting because someone always leaves in a funk when his or her idea gets rejected. There’s a lot of door slamming and loud voices. People who used to socialize together after work aren’t even speaking. Worst of all, our productivity is in the tank. As a team leader, I feel a lot of responsibility to do something about this. I’d like to be the person who turns the team around and gets our projects back on track. What do you suggest?

Coach Joel Answers: Conflict has become a way of life in many organizations. In fact, a whole industry has been created around training people on how to resolve it. Just Google “conflict resolution” and you’ll see what I mean. But a lot of these triedand-true theoretical methods are not particularly effective. Some people thrive on conflict and love to create more of it. If you have one or more of those on your team, your job is going to be challenging.

How about this? Instead of seeing conflict as a negative, a big problem to be solved—how about looking at conflict as an opportunity to become even better than you are?

Martina seemed unconvinced, but she was willing to go along—for a while, anyway. Here’s the outline of actions steps that we put together for her to deploy.

Step 1: Develop an internal support team.

Gather around a table with a few team members who you know are not happy with the current situation and would welcome an opportunity to take part in turning it around. Look for people who are open to using conflict as an opportunity to get better, not just a problem to be solved.

Step 2: Clearly define the problem

The problem is not that Joe’s a jerk who won’t go along with anything, or that the workload is too heavy or that the boss’s expectations are unrealistic. Just as married people are seldom really fighting about the budget, work teams are seldom really fighting about the workload. What they both want is control and recognition. The problem is that nobody is yet able to see conflict as an opportunity and share control to build a better organization. It’s your job to show them how.

Step 3: Make your adversaries part of the solution.

Not everyone will see the possibilities. But you must, first of all, respect those whose opinions differ from yours. Invite them in. Give those who are willing to work together a seat at the table and get everything out in the open. During this kind of communication, the key ground rule is “no argument.” The key tool is listening, with the aim of letting the other person know he or she has been heard.

Step 4: Capture ideas and pick the top 5.

Every person at the table will have ideas. Some will have merit; some will not. Make sure that your brainstorming session doesn’t deteriorate into an “us against them” free-for-all. Choose ideas from all different perspectives—ideas that are positive and will keep momentum going, not short-term solutions that will put a bandage on an open wound.

Step 5: Team up to move up.

Take your top five ideas and let each participant choose to be part of an implementation team that puts one of them into action. Develop a timeline for completion and an interim schedule for progress reports. In short, the secret to conflict resolution is not “Can’t we all just get along?” The secret is giving people a project to work on where their ideas and creativity are respected and where they can see the results of their efforts.

What’s the biggest conflict in your workplace right now? Start making a list of steps you can personally take to turn this conflict into a big step forward for your team and for the company.

▪

Copyright ©2005-2022 Joel Garfinkle, All Rights Reserved. Joel Garfinkle is recognized as one of the top 50 coaches in the U.S., and the author of seven books, including Getting Ahead: Three Steps to Take Your Career to the Next Level He has worked with many of the world’s leading companies, including Google, Deloitte, Amazon, Ritz-Carlton, Gap, Cisco, Oracle, and many more. Visit Joel online at Garfinkle Executive Coaching.

Partners in Progress » December 2022 » 17

How to Be More Decisive in Your Life and Leadership

By Gregg Vanourek

By Gregg Vanourek

“Should I stay or should I go?” —The Clash

We make many decisions every day. Many are trivial, but some are consequential and taxing. Which career to pursue (or transition into). When to make a big move. Who to live with, work with, or hire. Whether to start a new venture.

To live and lead well, we must get good at making decisions. On the leadership front, do we want leaders who wallow and waffle? Or leaders who move forward despite uncertainty; home in quickly on the key issues; actively gather input before deciding; involve others in decisions; invoke their experience, judgment, wisdom, and gut instinct; and remain calm under pressure?

There’s a lot at work with making good decisions. The neurological mechanics of decision-making are breathtaking. When we make decisions, we’re using the brain’s prefrontal cortex for what’s called “executive function.” We’re drawing upon an array of cognitive processes, including: attentional control, cognitive inhibition, working memory, cognitive flexibility, reasoning, problem-solving, differentiation between conflicting thoughts, value determinations (good, bad, better, best, worse, worst), prediction of outcomes, and more.

No wonder so many people sometimes struggle with indecisiveness—wavering between different courses of action and having trouble deciding and moving on—and its related problem of “analysis paralysis.”

Truth be told, getting good at decision-making isn’t easy. This isn’t a new challenge. Even Aristotle mused about the absurdity of the idea that “a man, being just as hungry as thirsty, and placed in between food and drink, must necessarily remain where he is and starve to death.” Indecisiveness indeed.

The challenge can be even more complex with making decisions in organizations. As expected, there’s much room for improvement here, as well. According to a McKinsey Global Survey, only 20% of respondents say their organizations excel at decision making. What’s more, a majority report that much of the time they devote to decision making is used ineffectively. Clearly, we have work to do.

The Problem with Indecisiveness

“Indecision may or may not be my problem.” —Jimmy Buffett

Indecisiveness has many drawbacks—and sometimes costly and painful consequences. For example, indecisiveness can:

• make an already difficult situation worse;

• create delays that have spillover effects, impeding important progress;

• cause frustration;

• reduce productivity, effectiveness, and credibility;

• inhibit innovation;

18 » Partners in Progress » www.pinp.org

© Can Stock Photo / nasir1164

• bring about stress;

• lead to team and organizational stagnation, breakdowns, and failures; and

• prevent us from realizing new opportunities.

“Indecision is the greatest thief of opportunity.” —Jim Rohn

When making decisions, we can experience “choice anxiety”—feeling distressed because we can’t seem to determine what’s right, with the fear of making the wrong decision shutting us down. Psychologist Barry Schwartz talks about the “paradox of choice” and claims that the freedom to choose, while sounding nice, is actually one of the main roots of unhappiness today, in part because we live in such abundance. Choice overload leads to anxiety. We fear making the wrong choice or fear missing out on the “right” choice.

Schwartz cites an intriguing “jam study” in which a store gave one set of shoppers a range of six jams to consider, and another set of shoppers a range of 24 jams. In the end, shoppers were ten times more likely to purchase jam from a range of six jams than from the much larger set. Ten times. Choice overload can easily lead to not making a choice. We simply walk away.

Another big problem is second guessing—when we keep revisiting previous decisions and agonizing over whether we should change them. It’s an unproductive and frustrating doom loop.

Causes of Indecisiveness

There are many causes of indecisiveness. Here are 11 of the leading causes:

1. personality (e.g., our levels of neuroticism and anxiety);

2. fear of making the wrong choice: we’d rather not decide than risk making the wrong decision, due to loss aversion;

3. fear of failure, rejection, or loss of social status;

4. lack of confidence;

5. excessive risk aversion;

6. lack of clarity about what we want or where we’re going;

7. conflicts between our own preferences and the expectations of others;

8. decision fatigue (a state of mental overload and depletion from making many decisions);

9. family or cultural conditioning (such as excessive punishment for making mistakes);

10. lack of accountability for indecisiveness; and

11. a history of perfectionism.

How to Be More Decisive

Thankfully, there are many things we can do to become more decisive. Note that decisiveness doesn’t mean making hasty, impulsive, or rash decisions. It means making decisions quickly, firmly, and effectively. Here are 22 tips and techniques for developing our decisiveness:

1. Recognize that decisiveness isn’t a set trait, and that decision-making is a skill that can be practiced and developed.

2. Acknowledge that indecisiveness is a form of selfsabotage, only making things harder for ourselves and others.

3. Become clearer about what we want—including clarity about our personal purpose, core values, and vision of the good life.

4. Build our confidence (the good kind, which is earned through hard work and disciplined attention to growth and development), since this is a key factor in decisiveness.

5. Develop systems to make as many decisions as possible habitual, routine, or automatic—such as having a regular reading or workout routine at a certain time on certain days (this helps us avoid decision fatigue and frees up cognitive resources for other decisions).

6. Increase our self-awareness so we know under what conditions we work and decide best (and worst).

7. Recall that most decisions involve uncertainty, which tends to come with anxiety, and learn to expect and account for that.

8. Develop mechanisms for coping with anxiety and stress, since these contribute to indecisiveness.

9. Recognize the difference between fear and actual danger, noting that our fears are often exaggerated versus the actual dangers we face.

10. Recognize that being decisive isn’t about always being right (instead, it’s about being able to make clear decisions—even tough ones—quickly, firmly, and confidently despite uncertainty).

11. Distinguish between irreversible and reversible decisions. (Jeff Bezos wrote about this in his 2015 letter to shareholders with the distinction between one-way doors, where there’s no going back, and two-way doors, which you can simply “reopen and go back through.” He lamented that too many big companies use one-size-fitsall decision making, treating all decisions like one-way doors and, in the process, slowing everything down.)

12. Get curious and investigate why we avoid making decisions.

13. Build our decisiveness and decision-making courage by working to make decisions more quickly and more boldly—and then take stock of how things turn out.

14. Start small and make less consequential decisions more quickly at first, building from there to bigger decisions.

15. Divide bigger decisions into smaller ones (or a series of steps) that are less intimidating and more manageable.

16. Summon more urgency into our lives, since time is precious and wasted time is a common regret.

Partners in Progress » December 2022 » 19

17. Set deadlines for making decisions.

18. “Don’t let the perfect be the enemy of the good,” as the expression goes. Look for the point where we have enough information to make a reasonable decision instead of waiting until we have nearly all possible information, variables, and scenarios accounted for. Focus on pursuing learning and growth instead of perfection when making decisions.

19. Recognize that we can’t control our future and that we can’t make perfect decisions.

20. Use the “only option test”. Imagine that only one of the two options were possible and then see how it feels, and then imagine that the other option was the only possible one and see how it feels. Next, consider whether we have two good options and it doesn’t really matter so much which one is chosen.

21. Focus only on the most important things and don’t get caught up in the rest, thereby reducing the total number of decisions to make.

22. Pray on or sleep on important decisions, summoning deeper wisdom and grace.

“If you were omniscient and had a time machine, you would know everything you need to know about the [the results of your decision], but the problem is that we don’t have either of those things, so we don’t have perfect information when we’re making a decision.” —Annie Duke

The key isn’t just decisiveness. What we really want is skills for making good decisions. It’s about both decision-making quality and decisiveness. Surely it’s easier to be more decisive when we know we have a good decision-making process. So what does that look like?

How to Get Better at Making Decisions

A good decision flows from a good process for deciding. Here are several ways we can get better at making decisions:

• Look into whether there’s more information readily available that would be important for making a good decision—or not—and gauge whether we have enough of the right kind of information to decide.

• Get input on decisions from trusted friends and colleagues.

• Evaluate the likely impact of a decision before making it.

• Invoke our intuitive sense (gut instincts) as well as our reason and logic when making important decisions.

• Distance ourselves from the situation (e.g., project forward decades into the future and think about which choice will serve us the best over time).

• View the issue from a different perspective (e.g., ask ourselves what we’d advise our best friend to do in the situation at hand).

• Look for innovation solutions such as creative combinations or trials. For example, when I was in graduate school, I did two different summer internships to get a feel for both opportunities—and learned that neither was a good fit for me.

• Get feedback and coaching or mentoring on decision making.

Final Thoughts

One of the keys to decision making and decisiveness is learning to trust ourselves more. Without self-trust, all of this can fall apart quickly. We don’t need to be perfect. We just need to apply ourselves consistently at getting better.

Once we make a decision, it’s important not to dwell and not to agonize. We must let go of the myth of the one perfect decision and focus more on making the best of the decisions we’ve made. Focus more on developing and using a good decision-making process instead of on whether any decision is “right” or “wrong,” and then trust in that process to serve us well over time.

Refuse to live in a state of regret: Take full responsibility for our choices and move on. Make changes when needed. Give ourselves credit for doing our best.

Finally, consider this: If we can get good at making decisions and being decisive, it will help us with everything we do. There’s incredible leverage that comes from improving this. Wishing you well with it.▪

Gregg Vanourek is a writer, teacher, speaker, and coach on leadership and personal development. He is co-author of three books, including LIFE Entrepreneurs: Ordinary People Creating Extraordinary Lives (a manifesto for integrating our life and work with purpose and passion) and Triple Crown Leadership: Building Excellent, Ethical, and Enduring Organizations (a winner of the International Book Awards). This article was reprinted with the author’s permission.

20 » Partners in Progress » www.pinp.org

How to Be More Decisive in Your Life and Leadership

/ indomercy

© Can Stock Photo

My Journey: Admir “Otto” Ibradzic

Former

By / Tara Thoman-Gettman

By / Tara Thoman-Gettman

Admir “Otto” Ibradzic is a fourth-year sheet metal worker apprentice with Local 263 at Waldinger Corp. in Cedar Rapids, Iowa. Ibradzic’s parents emigrated from Bosnia to Germany, where Otto was born, before settling the family in Waterloo, Iowa, when he was two years old. After graduating from high school, he moved to North Liberty, where he lives with his wife.

“I attended college at the University of Iowa for engineering, where I did some internships for engineering positions,” he says. “I realized during those internships that I was more of a hands-on kind of guy and didn’t like the office much, so I decided to pivot and join the trades.”

Ibradzic knew he wanted something well-rounded across multiple trades and chose HVAC. “While my job title is technically sheet metal worker, I deal with mostly commercial HVAC. This mainly includes ductwork and setting the equipment,” he says.

Ibradzic is pleased to enjoy good wages and health and retirement benefits while he completes his training over the next five years.

“I had zero construction experience when I joined the trade,” he says. Each year his training will focus on another aspect or area of the trade. So far, he’s learned how to form ductwork, how HVAC systems function, and how the systems work together.

“You learn about the industrial aspect of the trade, as well, where we are taught how to weld on food-grade materials,” Ibradzic says. “We do a lot of maintenance at the different plants around the Cedar Rapids area, like General Mills, Quaker, and Ingredion.”

His skills are already helping him stand out in the sheet metal industry, thanks to an annual contest where competitiors are graded on class-based knowledge and workpersonship. “I actually competed regionally last year down in Kansas City at the Local 2 JATC where I placed first for HVAC in the region,” he says.

On-the-job training is the key to truly learning the trade, Ibradzic says. “I can’t speak for all companies, but at our company, you are paired with a journeyperson who shows you the ropes,” he says. “They teach you everything you’ll learn in school and more.”

From learning proper tool use to how to adapt to different jobsite conditions, Ibradzic appreciates how interacting with other trades has taught him how to work together toward a common goal. ▪

This article originally appeared in The Gazette, Cedar Rapids, Iowa.

Partners in Progress » December 2022 » 21

engineering student finds rewarding career in the trades

Help Spread Awareness About Careers in Sheet Metal

The SMART-SMACNA Best Practices Market Expansion Task Force has launched a recruitment initiative to help address the industry's labor shortage.

The Brand Ambassador program attracts new recruits to the sheet metal trade by leveraging the positive experiences of apprentices, journeypersons, and other members of the industry who love the trade.

Brand Ambassadors spread the word about the advantages of SMACNA and SMART careers to their friends and family on social media.

Anyone interested in being a Brand Ambassador simply uses the hashtag of our recruiting campaign, #MJMG, on their social media accounts. Exemplary Brand Ambassadors will receive $100 Amazon gift cards.

Industrial Athlete™

GET THE SMART-SMACNA BRAND AMBASSADOR PROGRAM STARTED IN YOUR AREA

info@industrialathleteofficial.org @industrialathleteofficial @industrialathltofficial

details

resources visit

For more

on other recruiting

pinp-materials.org

By Joel Garfinkle

By Joel Garfinkle

By Gregg Vanourek

By Gregg Vanourek

By / Tara Thoman-Gettman

By / Tara Thoman-Gettman