India IB Group expands with Royal Pas Reform > p. 26

Kukuchic

Uganda Kukuchic commissions SmartPro™ single stage incubation for increased capacity > p. 37

Cairo 3A

Egypt Cairo 3A Poultry makes Smart™ investment > p. 18

India IB Group expands with Royal Pas Reform > p. 26

Uganda Kukuchic commissions SmartPro™ single stage incubation for increased capacity > p. 37

Cairo 3A

Egypt Cairo 3A Poultry makes Smart™ investment > p. 18

USA Pilgrim’s Georgia hatchery performance excels with SmartPro™ > p. 16

Poland NaturAgra adopts Smart™ technologies for combined duck and geese hatchery > p. 23

A very warm welcome to the latest edition of Pas Reform Times. We are delighted to share with you our latest news, developments and innovations.

As the world’s only genuinely single-source supplier of fully integrated hatchery solutions, we have much to tell you. In the pages that follow, you will discover inspiring stories on Royal Pas Reform’s new hatchery products, reports from many forward-looking hatcheries around the world, and the latest specialist insights from Pas Reform Academy.

First, though, to recognize that we have all lived and worked through an extraordinarily challenging period. We don’t wish to dwell on the obvious negative impacts of Covid-19 on our lives and our world. Instead, as we emerge from the worst of the pandemic and reflect on our journey through the past year, we want to say how immensely proud we are of our customers for the way they have responded and adapted to the unprecedented business challenges they have encountered. The stories we bring you tell of our customers’ resilience and confidence, and we are privileged to share their journeys.

Supporting our customers through these times has been our top priority. We have focused on rapidly evolving to ensure that we stayed connected. This has led to the virtualizing of our business, not just in our relationships, operations and projects, but also in our digital communications – such as the introduction of our very popular ‘Hatchery Talks’ series of free specialist webinars and podcasts.

We are especially excited to tell you about our new work on incubation and vaccination. Over the years, Royal Pas Reform has achieved global recognition as an innovator and market leader in single-stage incubation, climate control and advanced hatchery automation systems. We continue to lead the field, as 2022 has seen the introduction of SmartSense™ and SmartVac™. We are convinced that both products are game changers for the poultry industry.

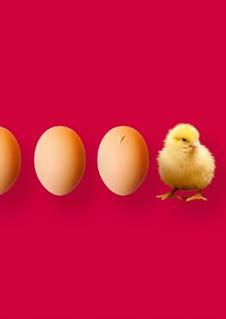

SmartSense™ features a new series of fully connected, datadriven incubators that reliably sense the changing needs of the growing embryo. It uses a constant stream of data, providing real-time information on embryo and day-old chick development, allowing you to adapt to changing incubation demands. This results in ongoing optimization of the incubation process to maximize the number of bestquality chicks.

USA Tyson complex in Humboldt Tennessee chooses SmartPro™ > p. 6

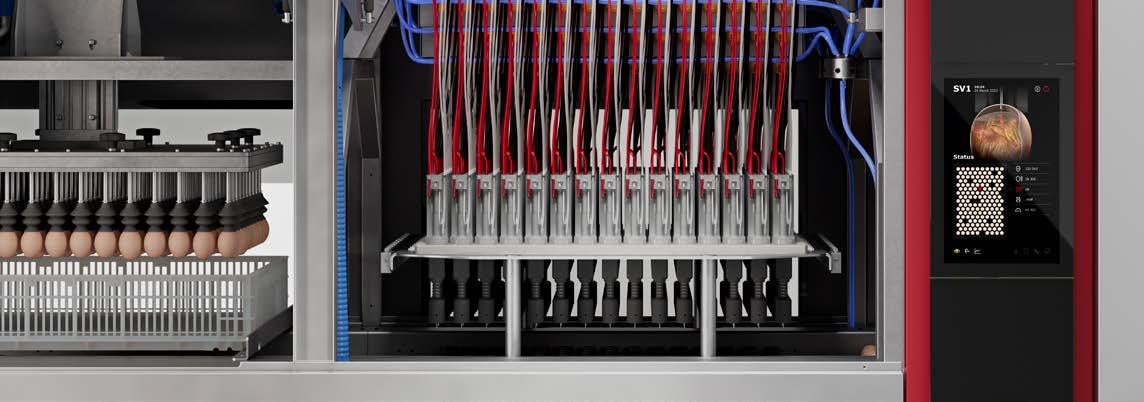

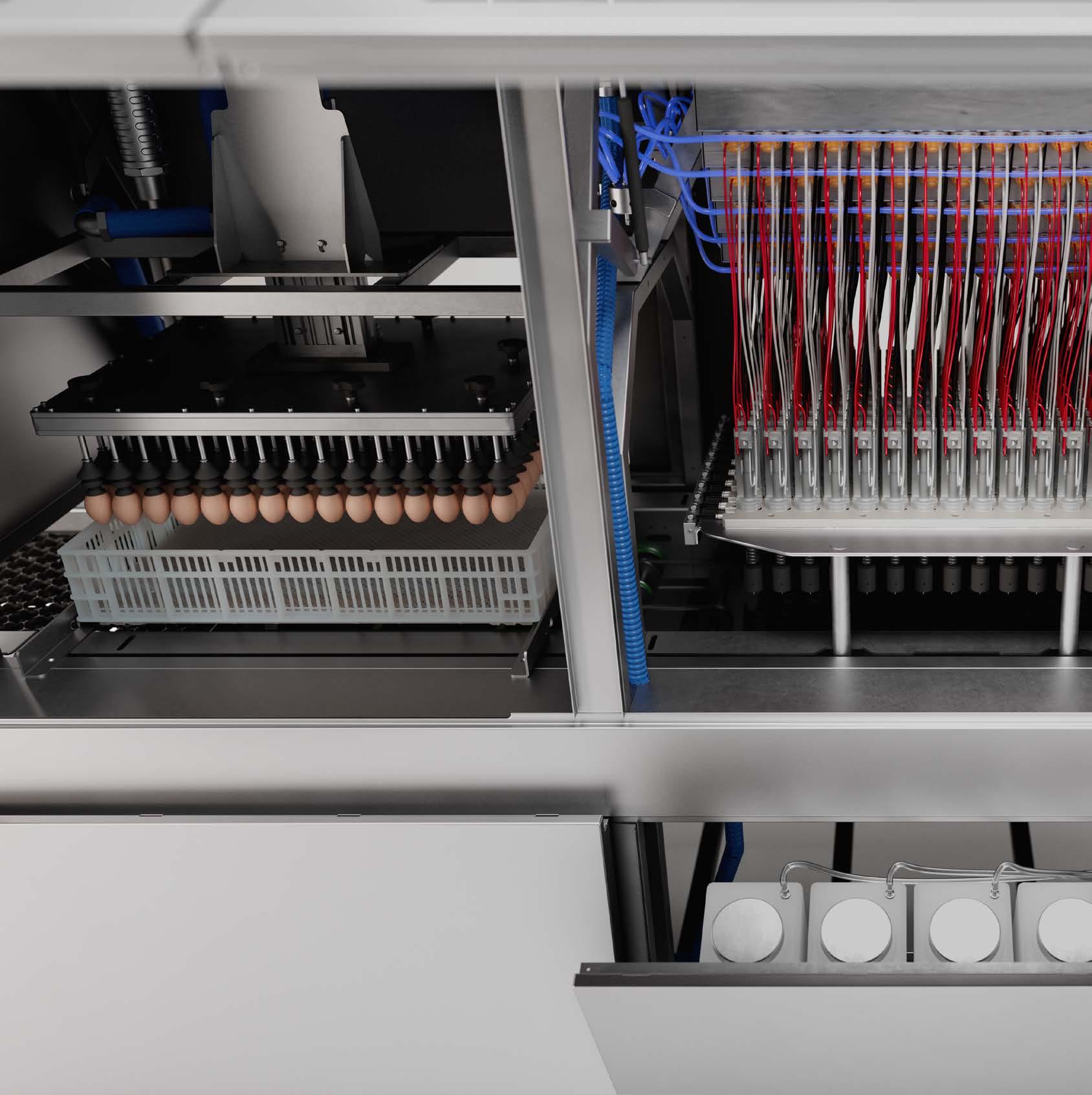

SmartVac™ is a new, patented technology that allows 100% safe, consistent, and accurate in-ovo vaccination and nutrition. It delivers the injectables only into the amniotic fluid, thus preventing possible injury to the growing embryo – to produce chickens with a healthy gut, favorable microbiota and enhanced immunity, resulting in improved field performance.

We hope you enjoy reading this edition of Pas Reform Times.

Until next time!

From all of us at Royal Pas Reform

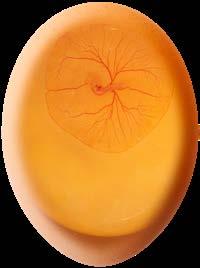

Imagine a future in which connected, autonomous incubators effortlessly hatch the highest number of best quality chicks. Royal Pas Reform brings that scenario a significant step closer with SmartSense™ adaptive embryonic incubation - a new series of fully connected, data-driven incubators that reliably ‘sense’ the changing needs of the growing embryo.

Besides using pre-determined incubation programs for day-old chicks, SmartSense™ also evaluates and meets the current requirements of the embryo in each specific incubator section. We call this ‘Adaptive Embryonic Incubation™’ (AEI™).

SmartSense™, with its industry leading, precise climate control – based on air temperature, relative humidity and CO2 – also features a next generation series of intelligent, high-accuracy sensors in the SmartSense™ trolley. These constantly and non-invasively measure temperature, together with egg weight loss and heart rate averages (both available soon).

The result is that the incubator can automatically adapt the environmental conditions to the actual needs of the growing embryo, further optimizing uniformity and maximizing posthatch performance.

The full SmartSense™ incubation series comprises the SmartSense™ setter and SmartSense™ hatcher, combined with the SmartSense™ trolley, SmartSense™ interface and SmartCenterPro™ hatchery management system.

For more detailed information about SmartSense™ visit www.pasreform.com/smartsense

The SmartSense™ trolley can be positioned and connected inside each section of the SmartSense™ setter without replacing hatching eggs or trays by sensors.

SmartSense™ uses a next generation series of intelligent, high-accuracy sensors for both adaptive incubator control and predictive process information.

A year of breakthrough innovations 1

SmartSense™ – a major breakthrough in developing the hatchery of the future 2

HatcheryTalks™ 4

Tyson, USA 6

Walt Wages joins the Pas Reform North America sales team 6

Ameta, Bulgaria 7

La Cabaña Avicola, Uruguay 7

Efficient data management in the hatchery 8

Paul Smits appointed as new CEO of Royal Pas Reform 8 Masagana Farm, Philippines 9 Allpines, South Korea 9 BH, South Korea 9

Innovative partnership produces practical and smart solutions for Schotman 10

Royal Pas Reform’s SmartStart™ solution delivers better results for Dutch hatchery businesses 11

Kasturi Poultry Farms, India 12

Royal Pas Reform opens its new Polish headquarters in Kościerzyna 12

ZWD Czarne, Poland 13

Optimising hatcher conditions 14 SmartCare™ service and support 14

AgroKush, Kyrgyzstan Republic 15

Pilgrim’s, USA 16

Georgia-based Warrior Systems joins Pas Reform North America 16

Rungta Group, Nepal 17

PT Japfa Comfeed Indonesia Tbk, Indonesia 17

Sun Food International Co. Ltd, Thailand 17

Cairo 3A Poultry, Egypt 18

Royal Pas Reform appoints Basem Mohamed as Service & Installation engineer in Egypt 18

Couvoir Côté, Canada 19

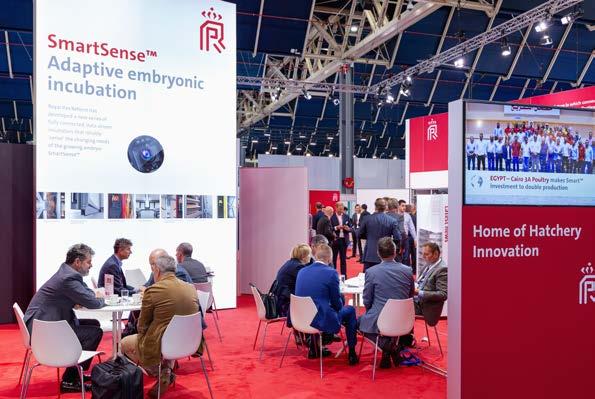

Home of Hatchery Innovation 20

Role of the hatchery in ABF production 22

Royal Pas Reform bids farewell to greatly valued colleagues 22

NaturAgra, Poland 23

Bingo, Bosnia 23

LLC Belgrankorm, Russia 24

Panus Poultry, Thailand 24 We’re in the 2-million club! 24

Sahara Conservation Fund, Niger 25 Agricola Ariztia, Chile 25

IB Group, India 26

Royal Pas Reform welcomes new CFO to the board 26

Widodo Makmur Unggas, Indonesia 27

Agri Plus Sp. z o.o., Poland 27

Delta Masr Group Egypt 27

Getting to the bottom of sex-related first week mortality 28

Royal Pas Reform appoints new agent for Argentina and Uruguay 28

Ross Africa, Zambia 29

Meet our parent company – Hydratec Industries 30

Managing eggs and chicks from young breeders 32 Fiocruz, Brazil 33

Abdu Ali Al-Zailai & Co., Yemen 33

Cahaya Technology Unggas, Indonesia 33

Incupasaje Cia. Ltda, Ecuador 34

Royal Pas Reform appoints Avepork as its agent for Ecuador 34

Siyazan Broyler, Azerbaijan Republic 35

Gerard van den Bergh, Suriname 35

Aviagen America Latina, Brazil 36

Special guest lecture for primary school childeren in Zeddam, the Netherlands 36

Sinokrot, Jordan 37

Avicola Yugoslavia, Peru 37

Kukuchic, Uganda 37

SmartVac™ Next generation in-ovo vaccination and nutrition 38

Hatchery Talks® is a new initiative from Royal Pas Reform –which, through free webinars and podcasts, brings together hatchery professionals from across the world to share the latest insights, trends and tips for best hatchery practice.

Produced and presented by Royal Pas Reform’s specialist teams, Hatchery Talks® provides solutions for the day-to-day management issues that our consultants encounter in their travels to commercial hatcheries in markets around the globe.

Hatchery Talks® webinars are interactive, educational presentations on the latest best-practice recommendations from Pas Reform Academy – allowing participants to interact with a moderator, submit questions and comments, answer polls and download additional literature.

Hatchery Talks® podcasts are bite-sized, 4-minute episodes, which each month focus on a specific hatchery management aspect – making it a valuable, must-listen professional resource for hatchery staff.

Hatchery Talks® is available on all major platforms, including YouTube and Spotify.

On Monday they are…

Balance for perfection Good hygiene practices: a must for the modern hatchery

3 tips to minimize the impact of prolonged hatching egg storage

SmartStart™ post-hatch feeding

Evaluating chick quality with the Pasgar scoring method

Eline Holtslag

Gerd de Lange

Remote consulting under Corona

Lotte Hebbink

In-ovo vaccination and hatchery management

On Monday they are…

Balance for perfection Good hygiene practices: a must for the modern hatchery

3 tips to minimize the impact of prolonged hatching egg storage

SmartStart™ post-hatch feeding

Evaluating chick quality with the Pasgar scoring method

Eline Holtslag

Gerd de Lange

Remote consulting under Corona

Lotte Hebbink

In-ovo vaccination and hatchery management

US-based Tyson chose Pas Reform North America to equip its new, greenfield hatchery complex in Humboldt, Tennessee. Pas Reform North America supplied incubation equipment, hatchery automation and climate control. The SmartCenterPro™ information system provides complete monitoring and control of all these systems.

The hatchery automation consists of farm-to-setter-trolley transfer system, two fully automated transfer candling lines with heartbeat candling and in-ovo vaccination, stackers, de-stackers, SmartCount™ chick counter and separator. To complete the project, a 5-year Smartcare™ preventive maintenance program has been agreed.

Steve Warren, President of Pas Reform North America, comments: “Since the inception of this project, Pas Reform North America have been in frequent contact with Tyson staff, visiting their hatchery operations with our incubation and technical specialists and communicating with them on a regular basis via alternative means. This has been a great way to gain in-depth knowledge of their operations and to help maximize performance. It has enabled us to get to know the Tyson team, and, of course, they have also gotten comfortable with us, our equipment, and company philosophy.”

Barry Vincent, Director

Tyson Foods, says: “Working together with Pas Reform we have been pleased with the expertise they bring to the table with their Total Hatchery Solutions Concept. They manage their projects professionally and in an integrated way, and we think this is an approach that works well for today’s modern hatcheries. The SmartCare™ preventative maintenance program ensures we have joint responsibility for preventive maintenance – as well as proactive hatchery management, which is a great step forward for us. So far, we are very pleased with this new way of working.”

“The hatchery has been operational since end 2020 and the results have been excellent,” says Brandon Womble, Hatchery Manager for the new Humboldt Tennessee project. “We have seen outstanding hatch results and first-week mortality numbers, improved feed conversion, and excellent uniformity to the plant.”

Walt Wages, who joined Pas Reform North America earlier this year in the incubation support team, has been newly appointed as a sales manager. Walt, from Snead, Alabama, had previously gained

seven years poultry industry experience with Koch Foods.

Starting with three years as a supervisor on the processing side at Koch Food’s Debone department, Walt then shifted to live production – as assistant hatchery manager at the company’s newly renovated hatchery operation in Crossville, Alabama. He was instrumental

in the start-up of Crossville, which went 100% single stage on their newly expanded wing. It was there that Walt gained extensive experience with the Pas Reform North America team and products.

Steve Warren, President of Pas Reform North America comments: “In just a few months, Walt has made an

immediate impact, and with his first-class client-side operational knowledge and understanding he will prove to be a valuable addition to the sales management team.”

You can reach Walt at: wwages@pasreform.us and via cell on +1 205-353-1712

of Breeder & Hatchery Operations at Walt Wages joins the Pas Reform North America sales team

Ameta is one of Bulgaria’s largest food companies and a leader in poultry meat production. Part of the German PHW Group, the company supplies a comprehensive range of primarily fresh chicken-meat products, together with some frozen, for both the domestic market and for export throughout the European Union.

Ameta is in a process of integrating new facilities in the northeast part of Bulgaria – to provide the business with further expansion opportunities for the coming years.

Construction of its greenfield ‘White Pines’ hatchery, near Razgrad, started in 2018 and it was commissioned at the end of 2019.

The facility is fitted with a range of Royal Pas Reform’s integrated hatchery systems and equipment, including SmartSetPro™ setters, with a capacity of 124.416 eggs each, and SmartHatchPro™ hatchers, with a capacity of 20.736 eggs each. Also installed is an egg setting line, chickcounting and boxing systems, inline washing machines and a vacuum waste system. Royal Pas Reform also designed and engineered the plant’s HVAC system.

This is Ameta’s second hatchery project with Royal Pas Reform. The first, a 3-stage expansion in Kamchia Shumen, was started in 2007 and completed in 2012.

“The hatchery has delivered great results from the start,” says Tsvetomir Genchev – Investment Project Manager. “Like Ameta, Royal Pas Reform’s quality is the result of its attention to detail.”

“In Ameta, we control all the different levels, with the primary goal of delivering the best product to match our customers’ requirements. We do not make compromises at any stage of the production process and we take pride in on-time execution of orders and delivery.”

Ameta is one of the largest fully-integrated poultry processing and distribution companies in south-eastern Europe. It operates a processing plant, feed-mill, hatchery and breeder and broiler farms. Significant part of its production is exported to Greece, Romania, Italy, Macedonia, the UK and Cyprus. Ameta also supplies the major retailers in Bulgaria, restaurants and meat processors.

“We are delighted to be working with Ameta again,” says Niels Stam, Sales Director at Royal Pas Reform. “They are a progressive and quality led business and our integrated hatchery solution has provided them with optimized production efficiency that delivers the highest number of best quality chicks.”

La Cabaña Avicola, a family company based in the municipality of San Bautista, near Montevideo in Uruguay, has been a pioneer in introducing, promoting and democratizing the consumption of chicken meat in what is predominantly “cattle” country, with a high red-meat consumption profile.

La Cabaña chose Royal Pas Reform’s SmartPro™ technologies for its first-ever owned hatchery. While the company already has a full production chain in place, the decision to invest in a new hatchery was to be sure of having top quality, day-old chicks for its broiler farms.

The hatchery is equipped with SmartPro™ technology and Royal Pas Reform’s customized climate control system. The hatchery will initially produce one-million chicks per year, rising to two million in phase two of the project.

Gabriela Baldi, Managing Director of La Cabaña, says: “This is a very important step for our company and will sustain our aiming of producing top-quality chicken meat for Uruguayan consumers. We have chosen Royal Pas Reform because of both its high-quality equipment and service support, which is considered to be the best amongst its industry competitors.

“We at Royal Pas Reform are very happy with this project,” says Gonzalo Begino, agent for Argentina and Uruguay, “The installation went smoothly, despite the pandemic restrictions at the time. We now are pleased to say ‘welcome to the family’ to La Cabaña!”

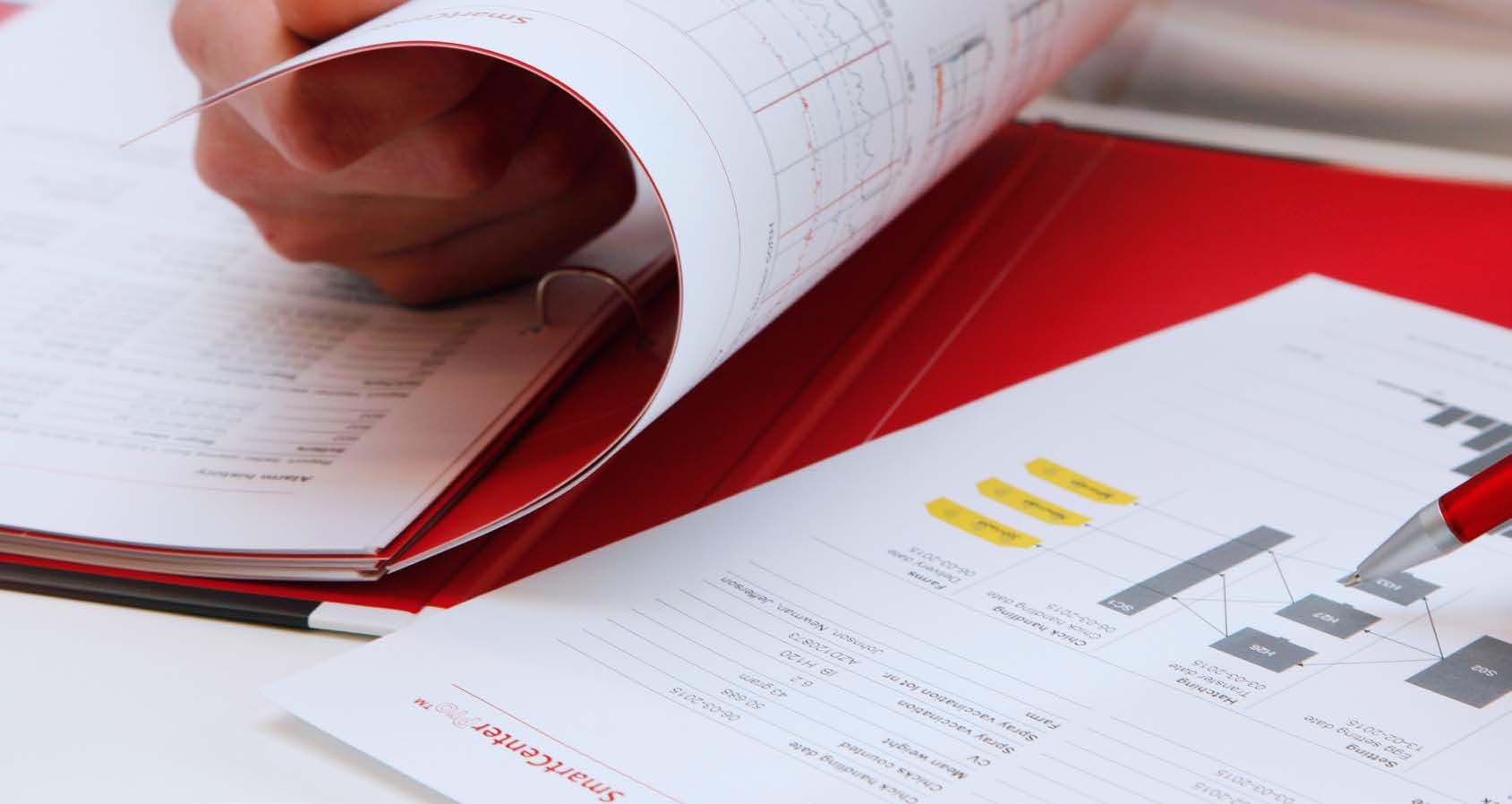

Optimising hatchery performance requires good data management. Data can be stored in various ways, ranging from simple Excel sheets to sophisticated data management software. It is also not uncommon for a large part of the hatchery’s data to still only be on paper. That’s a pity, because this data is much more valuable for data analysis when it is digitally stored in the right way.

Here we look at the most basic hatchery data collection. We assume that in each hatchery for each batch of eggs the following is known:

Flock number, farm, house number, flock age, breed Egg production date

Arrival date in hatchery

Setting and hatch date

Number of eggs set

Number of clears detected during candling

Number of saleable chicks (and ideally also number of culled chicks)

These data can be used to calculate hatch results such as hatchability of eggs set and hatch of transfer. The data is often recorded on separate pages for each hatch day. This might be a great way to report daily production, but it does not allow for deeper analysis such as identification of the best breeder farms, effect of flock age and egg storage time on hatchability, hatchery performance compared to the previous year, comparison of incubation programs, and so on. One has to flip through endless pages and it is difficult to obtain a good overview of historical data.

Set date

21-2-2019 14-3-2019 57600 2 56 A 45 16-2-2019 5184 49795 150 21-2-2019 14-3-2019 57600 2 41 A 47 13-2-2019 5670 48730 250 25-2-2019 18-3-2019 57600 3 23 B 35 20-2-2019 4608 51402 100 25-2-2019 18-3-2019 57600 3 14 B 36 20-2-2019 4896 51650 95

Hatchery data sheets that are generated on a daily and/or weekly basis usually have a dual purpose: they serve as data entry tables and as reports. In addition, data from different hatchery production processes and calculations are put together on one page to obtain a summarising table. Although this may seem efficient, it actually makes data management unnecessarily complex. When preparing these data for analysis you will encounter problems such as multiple data repetitions with differences in detail level, copy/paste errors and non-uniform data entries.

It is more convenient to separate basic data entry tables from daily or weekly summary reports. An example of a basic data entry table can be found in Table 1. As you can see, amounts (#) are used instead of calculations (%). A separate report should contain calculations, e.g. hatch of eggs set, days of egg storage, % first week mortality, and these can be generated daily or on request. Ideally, for quick analysis using a program such as Excel, data entries like those in Table 1 should be made in one large continuous file instead of a new file for each hatching day.

Super-connected!

People do business with people and our involvement in major expos and (virtual) events around the world is a great opportunity to meet up with friends and colleagues, old and new.

Very often data is scattered over several files, as it is here in Tables 1 and 2. If you take a closer look at these tables, you will see that the detail level is different. Keep the data in separate files but use a common column to link the two tables together. In this example you can link them with the ‘Hatch date’ and ‘Flock ID’ columns.

Make the names of the data fields consistent when using different files with overlapping data.

Do not combine basic data entries and daily production reports in one table.

Use amounts and dates when entering data; don’t enter calculations directly.

For simple analysis you can use Excel Pivot Tables or Graphs.

Egg production enterprise Masagana Farm, based in Bulacan in the Philippines, has extended its collaboration with Royal Pas Reform to meet growing consumer demand for table eggs in the Bulacan and Manila areas.

Based on Royal Pas Reform’s integrated hatchery solutions, the family run hatchery started operations in 2020. This was the first phase of Masagana’s strategic development to provide its own supply of layer hens for the company’s highly successful fresh-egg sales operation.

That first phase included 6x SmartSetPro™-2 setters –including Adaptive Metabolic Feedback (AMF™) and Energy Saving Module (ESM™) – and 2x SmartHatchPro™ hatchers. In the second phase, 6 further setters and 2 hatchers have been added, which brings the hatchery’s total capacity to 7.8 million day-old chicks per annum.

Willy Uy, Masagana Farm’s owner, comments: “From the first phase we saw Royal Pas Reform as a knowledgeable partner. They put in the time and the effort to make sure any project they are involved in is a success. We consistently have outstanding service from Royal Pas Reform and excellent performance from their equipment.”

Because of the Coronavirus restrictions that were in place during this development, Royal Pas Reform was not able to send a supervisor from The Netherlands to the Philippines. However, FSI (Filtration Solutions Inc.), Royal Pas Reform’s representative in the Philippines, was able to play a central role in the success of the installation.

“We are very grateful to our partners at FSI for their excellent support in ensuring the smooth and efficient delivery of the project under such challenging circumstances”, says Bas Kanters, Royal Pas Reform’s Sales Director in Asia. “This latest phase – in Masagana’s 30th anniversary year – marks another milestone in the company’s growth journey and we are very pleased to be a part of it.”

Allpines, which was established 40 years ago, has installed 6x SmartSetPro™ setters, 6x SmartHatchPro™ hatchers, and an automated chick counter. According to Allpines’ president, Mr. J.K. Lee, the company chose Royal Pas Reform because chick quality was most important to get a chick supply contract with a big broiler integrator. He had learned that other hatcheries in the area that have Royal Pas Reform solutions, including DY Farms and SungJin, had good hatching results and he was convinced that Royal Pas Reform incubators will give him the required performance.

Fast-growing BH has operated with Royal Pas Reform incubation systems for almost 20 years. Its latest expansion includes 12x SmartSetPro™ setters, 12 SmartHatchPro™ hatchers and an automated chick counter.

South Korea-based hatcheries Allpines and BH have both chosen Royal Pas Reform SmartPro™ solutions for their latest expansion projects. Michaël Kampschöer, sales director Asia, Royal Pas Reform

Schotman hatchery and poultry farms has been breeding chicks in Lichtenvoorde, The Netherlands, since 1950. Innovation is at the heart of its business philosophy and Royal Pas Reform has been a long-term partner in this venture.

Having its own rearing, breeding and broiler farms in the Netherlands and Germany gives the family-owned company flexibility. Schotman works with Royal Pas Reform incubators and the options offered to customers all over Europe include hatching eggs, incubated eggs, regular or slow-growing broilers, and in-ovo vaccination – with or without early feeding.

“We love innovating and taking opportunities”, says Erik Wolterinck, one of the company’s owners. ”We give customers what they ask for. From a standard chick and whether to choose an IB spray or not, the product range has expanded to many varieties. The broiler farmer chooses what suits him and his business and we provide it.”

Brothers Erik and Rob Wolterinck are the third generation of the Schotman family to be breeding chicks. Along with ten relatives, they run agricultural businesses whose main activity is poultry. Over the years the company has grown significantly and today it has a staff of 80.

Internationalization has long been a focus for the business and most of Broederij Schotman’s turnover is now generated abroad.

Schotman and Royal Pas Reform are ideal partners to develop and test innovations. “Innovating together takes you further,” says Rob Wolterinck. We enjoy being among the leaders in the field.”

One of those innovations is SmartStart™ early feeding. With feed, water, and light in the hatchers this is a flexible, practical, and simple system that has been co-developed and tested by Schotman. All the hatchers have been adapted so that SmartStart™ can be used flexibly. “Intelligent lighting is a new feature in the hatcher,” Rob Wolterinck says. “After hatching, the light intensity is gradually increased. With the special feed unit, it takes two minutes to fill the dolley with hatcher baskets with liquid feed – all under perfectly hygienic conditions.”

Schotman now has many customers who order SmartStart™ chicks on repeat. “This means that they are satisfied,” says Rob Wolterinck. “Our tests show that losses in the first week have fallen by 30%. The chicks are really calm and have a good start.”

Three of The Netherlands’ leading hatcheries have adopted Royal Pas Reform’s SmartStart™ post-hatch feeding solution, which is proven to result in a significantly lower 7-day chick mortality. Elshuis, Munsterhuis and Schotman are all hatching chicks from the SmartStart™ system on a regular basis and have reported seeing the businesses benefit.

SmartStart™ is a flexible post-hatch feeding solution that gives newly hatched chicks the earliest possible access to feed, water and light. SmartStart™ promotes the development of robust, day-old chicks and helps to reduce the need for antibiotics. SmartStart™ comprises two key elements that can be applied individually, or together: precision feeding and intelligent lighting.

In 2019, Royal Pas Reform, in collaboration with a European integration, designed and carried out a large field study to test the effect of SmartStart™ on first-week mortality in the farm in a commercial setting. Day-old chicks from SmartStart™ and regular hatchers were housed separately in the farm to monitor results. A total of almost two-million birds were placed during this trial – which was largely carried out during 2019, but which continues to provide new information on a daily basis.

For each trial, the eggs were divided equally over the test and control hatchers, taking into consideration the breeder flock, flock age and egg storage time. The chicks were unloaded from both hatching systems at the same time. The time of chick pulling, processing and transporting them to the farm were also kept equal for both systems. The field trial results showed that the first-week mortality was significantly lower for the SmartStart™ chicks, which was validated by a reputable Dutch university.

“The SmartStart™ system offers a perfect start for newborn chicks,” says Erik Wolterinck of Schotman hatchery and poultry farms. “It is good for the wellbeing of the new-born chicks – as stress can be harmful to their health. Our customers see real differences when the chicks arrive on the farm. They are much more relaxed.”

Kasturi Poultry Farms India (KPF) has chosen Royal Pas Reform to build its new, single-stage integrated hatchery in Dharapuram, Tamil Nadu. The facility, which is expected to be fully operational at the end of 2021, will have a capacity of one-million day-old broilers per week.

The state-of-the-art installation will also feature a fully integrated climate control system and complete hatchery automation – making it one of the most modern facilities in Southern India.

KPF’s ambition is to play a major role in the future growth of Tamil Nadu’s poultry industry. Based in Coimbatore, Tamil Nadu, KPF is an associate company of Venkateshwara Hatcheries Group (Venky’s) and was founded in 2010.

Its plans are taking shape today, and the company has recently made significant investments to expand both its integration facilities – to supply hatching eggs and day-old chicks throughout India and by developing its poultry feed business at KPF’s plant in Dharapuram.

Pradeep Kumar, Director of Kasturi Poultry Farms says: “I have been working with Pas Reform incubation equipment for more than 20 years and we have developed a strong

relationship over this time. When we came to make our investment in these state-of-the-art facilities, it was a logical step for us to go for a single-stage hatchery with the world’s leading single-stage incubation and integrated incubation project specialist. Choosing Royal Pas Reform was the logical choice for us.”

Bouke Hamminga, Royal Pas Reform Director International Sales & Business Development comments: “We are delighted that such an important company as Kasturi Poultry Farms has chosen to work with us. I am sure that, as an integrated hatchery solutions supplier, we can prove to be a leading partner with KPF across the entire Indian subcontinent.”

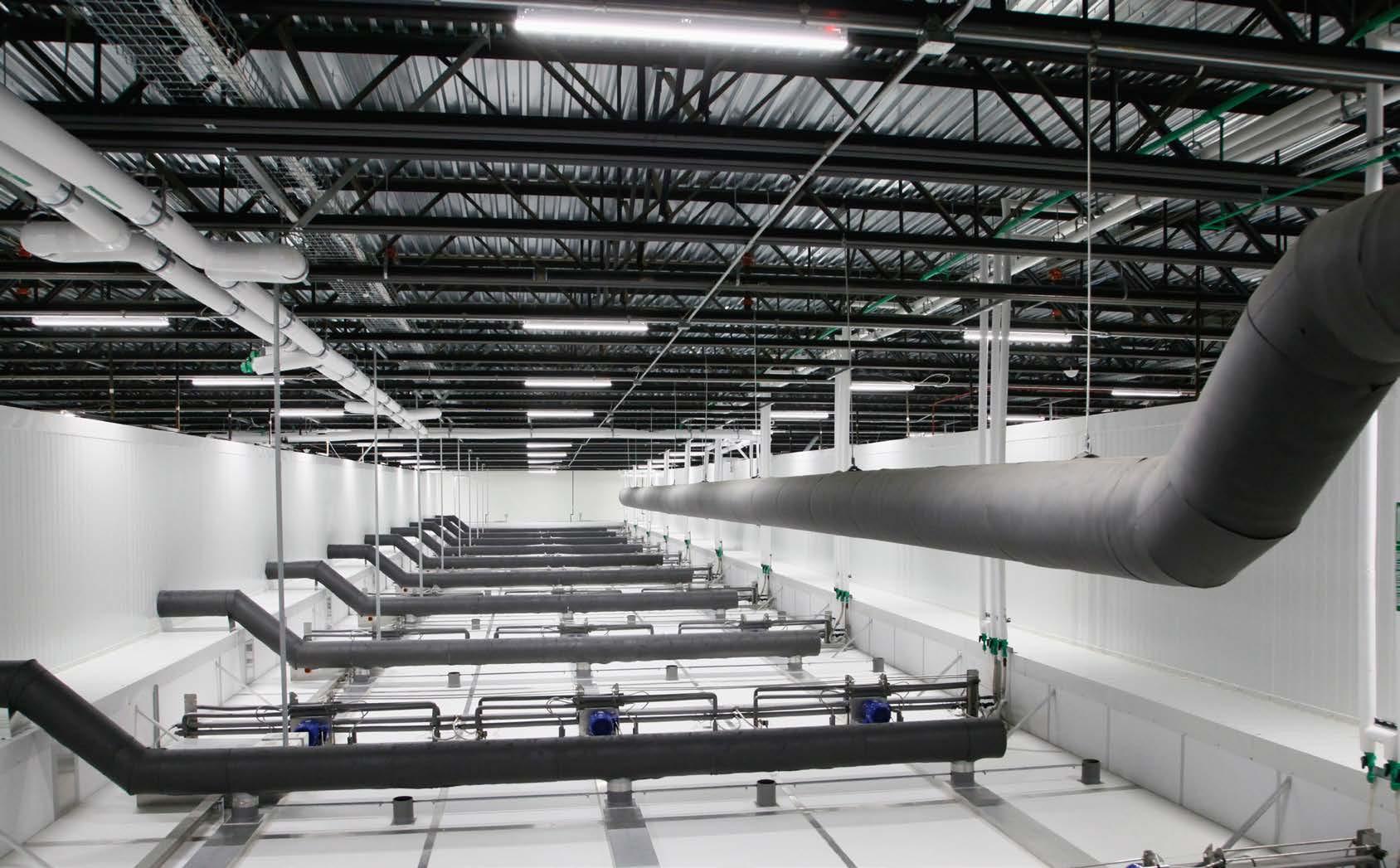

Royal Pas Reform opens its new Polish headquarters in Kościerzyna

Royal Pas Reform is pleased to announce the grand opening of its new business headquarters in Poland. The 800-square-meter facility includes offices for the sales and customer support teams, a warehouse, service and spare parts department and an HVAC production area. A team

of up to 20 staff will be based there.

Located in Kościerzyna, near the northern port city of Gdansk, the launch of the new premises has been driven by Pas Reform’s expanded product and support offerings. It strengthens the company’s already strong presence in Poland – where Royal Pas Reform incubators

at present produce 600 million day-old chicks per year – while also providing important operational and resource efficiencies.

“The decision to open this office was a logical next step in our business growth strategy,” says Jarek Piankowski, Market Director Poland. “The new location and enhanced

operational efficiencies will help us continue to grow and develop to keep pace with our customers’ needs.

“Pas Reform Polska will serve as a service hub for the entire Polish market and allow us to provide superior service along the way: with spares on stock and direct technical support –building on 25 years’ experience

of servicing complete hatchery installations.”

Pas Reform Polska can be contacted by email at jarmaxled@icloud.com, or on mobile at +48 603 957 229.

The thriving family hatchery business ZWD Czarne was founded more than 50 years ago by Jan Wasikowski in Czarne, Poland. Today, the second generation of Wasikowskis are managing the company – proud successors of Jan, who are continuing a thirty-year partnership with Royal Pas Reform.

Marek Lewandowski and his wife Wiesllawa Lewandowski, who is founder Jan’s daughter, (pictured, centre) are building on a strong heritage and using their great drive and energy to lead the company into the future ¬ based on Smart™, future-focused technology from Royal Pas Reform.

Jan Wasikowski started his business in 1967 and ZWD Czarne quickly became known as ‘Jan Wasikowski’s Hatchery’. He adopted Pas Reform incubation systems more than 30 years ago. In 2006, in a bid to increase production inline with growing opportunities in their domestic market, the hatchery took the decision to transfer its operations to single-stage, closed-door, Smart™ technologies.

Over the years, the hatchery has grown organically, with the addition of several smaller extensions. In addition to investment in new setters and hatchers, the company also embraced hatchery automation systems. In 2014, ZWD Czarne installed the intelligent SmartCount™ counting and dosing system, and Pas Reform’s climate control equipment. By early 2019, the setting capacity had increased to 56 million day-old chicks per year.

ZWD Czarne’s partially integrated operations also include parent-stock farms, to produce Ross and Cobb day-old broiler chicks for sale into the domestic poultry meat production market. “Today, our hatchery is fully programmable – to optimize production across a variety of breed and age-related incubation programs,” Marek Lewandowski explains.

Throughout this time, Wasikowski’s Hatchery has received service and support from Royal Pas Reform’s agent in Poland, Jarmax – which provides rapid supply of spare parts from its locally held stock. Royal Pas Reform’s Sales Director Niels Stam says: “We are very proud to have worked with Jan Wasikowksi, and now his daughter and son-in-law, for so long, and we look forward to continuing that strong relationship in the future.”

Hatching is the last part of the incubation cycle and optimal conditions in the hatcher are essential for best hatch results.

Whether a single or multistage incubation system is used, the hatcher is always a single stage machine. Eggs can be transferred from setter to the hatcher between the 15th and 19th day of the cycle, the optimum being days 18-19. Regardless of when the transfer is done, the total incubation time will not change.

A hatcher is a small cabinet, usually loaded to full capacity with eggs, all in their last incubation phase. The embryos as well as the hatched chicks require a lot of cooling and fresh air. As the baskets hamper the air circulation more than the setter trays, a high airflow helps to create a uniform environment. An efficient cooling system and a good supply of fresh air that reaches all parts of the hatcher are therefore necessary for the chicks to survive. The hatching process consists of three periods:

Period 1 - before pipping

• Period 2 - from beginning of pipping until peak humidity

• Period 3 - after peak humidity

Period 1 is simply an extension of the incubation process in the setter. The set points can be fixed, and typical values are: 40-55% relative humidity (RH), 97.5-98.50�F temperature,

Royal Pas Reform’s job is not only to supply fully integrated hatchery solutions, but also to ensure that the equipment continuously delivers the best results for our customers. To achieve this, we have introduced SmartCare™ - a menu of 21 services from which our

customers can tailor exactly the support they need, to maintain uninterrupted performance at every level of hatchery operations.

0.4-0.5% CO2. The actual values depend on the breed, design of the hatcher and local conditions. During Period 2 the leading parameter to be watched in the hatcher is the RH. This is the best indication of when pipping has begun and when hatching is complete. It can be followed by simply watching the graphs, if these are available. Pipping and hatching take several hours. During the process, a hatcher – even if all eggs are very uniform– will contain ready chicks and still closed eggs. As the hatchlings are wet, the RH raises spontaneously (period 2), reaches its maximum and starts dropping after the last chicks have hatched and dry off (period 3).

The time between the first and the last chicks hatching is called the ‘hatch window’. It can last between 12 and 40 hours, depending on the uniformity of the load (age of the flock, storage time), egg prewarming and the uniformity of conditions in the setter. As short a hatch window as possible is desirable. The maximum RH value reached depends on the rate at which the chicks are hatching and the amount of ventilation. Many chicks hatching at the same time can push the RH up as high as 85%. Once the RH peak is clearly over, which will be indicated by a 3-5% reduction in humidity, the initially selected set points can be adjusted. A very slow reduction of temperature (by 0.2-0.30F) followed by more intensive ventilation helps to keep the chicks in a comfort zone. The final temperature is usually around 97.00F and the final CO2 set point 0.25%. The aim is a comfortable environment in the hatcher with sufficient fresh air. The best way to judge the conditions is to closely watch the chicks

Load the machine in a way that provides the most uniform and effective air distribution and flow. This will differ depending on the design of the hatcher.

Don’t open the hatcher during the hatching process unless really necessary.

Aim for optimum fresh air supply; follow the machine supplier’s recommendation.

If operating manually:

- Keep the set points fixed until period 3,

- Correct them very slowly after RH peak,

- Make sure after RH peak that RH doesn’t drop below 55%,

- Observe the chicks’ behaviour (noise, panting) – and respond.

themselves. When they are comfortable they will be calm and silent, and sleep much of the time.

AgroKush, the largest poultry production company in the Kyrgyzstan Republic, has chosen single-stage integrated hatchery systems from Royal Pas Reform for its all-new broiler hatchery in Sary-Kamysh village in the Issyk Kul region.

The integrated new facility includes a hatchery and poultry houses, together with a new feed plant, and a slaughterhouse with a capacity of 3,000 poultry per hour. Initial meat production capacity will be 8,500 tons of live weight per year, rising to 20,000 tons per year when the second phase expansion is implemented.

The poultry farm is fitted throughout with modern European equipment and built in accordance with HACCP and ISO 22000 standards. When fully operational, it will create 200 jobs and have capacity to meet 30% of the domestic market’s poultry meat demand. It will also reduce the volume of poultry meat needed to be imported – increasing the country’s level of food security.

Askat Abdarakhmanov, general director of AgroKush says: “We were looking for an integrated approach to the development of our new hatchery and we favored working with a single-source industry supplier. Royal Pas Reform company met these requirements – as they not only developed the project and supervised installation of the equipment, they remained onsite with us to provide support and training. This approach helped us to achieve exemplary hatch results recently, and we are looking forward to building on this cooperation to scale-up our production in the future.”

Wim Schaafsma, the general director of Pas Reform Russia, is impressed with the commercial and modern approach of AgroKush’s team. He says: “It’s a pleasure to work with such a forward-thinking company, and it gives us further proof that our integrated approach delivers the right strategy for our customers. We wish AgroKush every success in their ambitious plans for future growth.”

Watch the movie!

Wim Schaafsma, general director, Pas Reform Russia

Watch the movie!

Wim Schaafsma, general director, Pas Reform Russia

Pilgrim’s, the second largest poultry producer in the USA, and part of JBS Foods, chose Pas Reform North America for renovation of its hatchery in Talmo, Georgia. The installation includes 11 SmartSetPro™ NF18 setters, with 9 SmartSetPro™ NF6 hatchers, operating on a 54-egg tray platform.

A SmartCenterPro™ hatchery management system provides complete monitoring and control of the equipment and also allows for remote support and advice by Pas Reform Academy specialists.

Joe Steed, Director of Hatchery Technical Services at Pilgrim’s, comments: “Pas Reform North America has been an excellent partner throughout this project. They have been very helpful training our team and strengthening our ability to maximize performance. As everyone knows, there is a learning curve when transitioning to single-stage incubation, and Pas Reform has done an excellent job of making this as smooth as possible for us.”

“The opportunity to bring single-stage incubation to Pilgrim’s Talmo hatchery has been a great experience,” says Steve Warren, President of Pas Reform North America. “We have worked alongside the Pilgrim’s team both during the project concept phase and installation, and we continue to work closely together in the operational phase. Regular visits have proven to be very helpful, and we are excited about the performance we have been able to achieve and what we can still accomplish in the future.”

Pilgrim’s Hatchery Manager, Timothy Taylor, comments: “The renovation has been operational since the first quarter of 2021 and the results have been excellent. We have seen improved hatch results and feed conversion, and our hatchery-performance ranking within the company has improved tremendously.”

Georgia-based Warrior Systems joins Pas Reform North America

Pas Reform North America has successfully completed the integration of the staff and operations of Warrior Systems –a family-owned business based in Gainesville, Georgia.

Until now, the hatchery automation systems delivered

by Pas Reform North America handled only certain types of setter trays and hatcher baskets. The integration of Warrior Systems allows it to deliver and service integrated hatchery projects for any tray or basket size.

The Warrior portfolio includes stackers, de-stackers, separators, vacuum waste systems and

washers for setter trays, hatcher baskets, chick boxes, setter and hatcher dollies and farm trolleys.

Steve Warren, President of Pas Reform North America, says: “The US market will continue to invest in both refurbishing existing hatcheries and building new ones. A large portion of setters, hatchers, climate control systems and automation

equipment currently installed is rather aged. As a result, we see substantial demand coming from the market to develop integrated projects in the coming years.

“We foresaw the need to further enhance our ability to meet customer needsespecially for hatchery automation systems, which are

critical components for a smooth-running hatchery. Now, with Warrior Systems incorporated in Pas Reform North America’s operation, and Warrior’s sales, production and service operations centralized in Pas Reform’s headquarters in Jacksonville, Florida, we can better serve our customers –providing quick and robust service and solutions.”

Nepal-based Rungta Group has chosen Royal Pas Reform to build its new, single-stage integrated hatchery in Hetauda, Bagmati Province. The state-of-the-art installation – with a capacity of thirteen-million day-old broilers per year – includes SmartPro™ incubators, climate control and automation, making it one of t Rungta Group, which is headquartered in Kathmandu, is a large and diverse agri-business. Founded in 1968, the company’s ambition is to play a major role in the future growth of the Nepalese poultry industry, and it has recently made significant investments in a breeder farm and hatchery – to supply day-old chicks throughout Nepal.

Rajesh Roongta, Managing Director of Rungta Group, says: “When we came to make our investment in these state-ofthe-art facilities, our plan was to ensure the best outcomes for our customers. We believe that supplying high-quality broiler chicks ¬ produced in a single-stage incubation process, giving superior post-hatch performance in the field, in terms of growth, mortality and feed conversions – is pivotal for the farmers of Nepal.”

Venkitakrishnan, Royal Pas Reform’s Sales director India & Nepal comments: “This is an important next step in our growth plans for the entire Indian sub-continent. We are delighted that such an important company as Rungta Group has chosen to work with us. I am sure that, as an integrated hatchery solutions supplier, we can prove to be a leading partner for Rungta Group across Nepal.”

PT Japfa Comfeed Indonesia Tbk, one of the country’s leading integrated agri-food businesses, has further expanded production capacity at its hatchery in Tukadaya, Bali by installing a range of Smart™ technologies from Royal Pas Reform. The facility now has a total capacity of 32 million day old chicks per year.

The project was for 6x SmartSetPro™-6 setters, including Adaptive Metabolic Feedback™(AMF™) and Energy Saving Modules™ (ESM™). AMF™ fine-tunes incubation environments to the needs of growing embryos, and Energy Saving Modules™ (ESM™) reduce energy consumption.

In addition, the company has installed 6x SmartHatchPro™ hatchers, including SmartWatch™, Hatchery Automation and Climate Control. SmartWatch™ is a unique tool for hatch-window control, which creates ideal conditions for chicks to hatch – by optimizing the humidity and CO2 inside the hatcher. It monitors and adjusts the hatching process automatically – from the day of transfer, through to the hatching of the last chicks – eliminating any need for human intervention.

Japfa Comfeed launched its Tukadaya operation in 2014, when it installed 12 SmartSetPro™ setters, 12 SmartHatchPro™ hatchers and a full climate control system. A SmartCenterPro™ hatchery information system was installed to monitor and record every incubation cycle. Royal Pas Reform also provided hatchery management training, together with ongoing service and technical support.

Mr. Gusi Ketut Wirata, Japfa Comfeed Indonesia’s east area hatchery lead, says: “We chose to extend our use of Royal Pas Reform’s advanced SmartPro™ single-stage incubation technologies to help us deliver premium quality broilers with high uniformity throughout the integration and achieve a superior retail product.”

Hatchery manager Mr. Mustiko Nur Setyo, has been a happy man since the installation of Pas Reform’s SmartPro™ incubation technologies: “Results are superior and have exceeded our expectations in terms of hatchability percentage and chick quality”, he says.

Japfa Comfeed Indonesia’s core business activities include animal feed manufacturing, chicken breeding and poultry processing, as well as aquaculture farming. It already commands a significant share of the domestic poultry market and is the country’s second largest integrated poultry company.

Thai-based broiler producer Sun Food International Co. Ltd is fueling its next stage of growth with a new single-stage expansions from Royal Pas Reform at its Wangmuang broiler hatchery in Saraburi.

The order includes 12 SmartSetPro™ setters and 12 SmartHatchPro™ hatchers. Royal Pas Reform’s SmartCenterPro™ hatchery information system will provide end-to-end monitoring, control and reporting across every level of hatchery operations – to enhance workflow efficiencies and quality control, and to deliver complete traceability for every hatch.

“With this order, Sun Food is embarking on a two-phase expansion programme that will enable a production increase of 20 Mio day-old chicks,” says Chamlong Termglincham, the company’s CEO.

Established in 1995, Sun Food is today a major poultry producer, supplying quality chicken meat to customers all over the world. Fully integrated with animal feed mills, parent stock farms, hatchery, broiler farms, processing and further processing plants, the company controls every single step in producing nutritious and hygienic chicken meat.

“Royal Pas Reform is delighted to have been selected for this pivotal project in Sun Food’s continuing development,” says Michael Kampschoer, Sales Director Asia of Royal Pas Reform. “We look forward to continuing to partner with Sun Food company to realise its future growth plans.

Steve Warren, President of Pas Reform North America and Warrior System’s founder, Richard Storer

Steve Warren, President of Pas Reform North America and Warrior System’s founder, Richard Storer

Royal Pas Reform maintains spare parts stocks and provides local support in several service locations around the world.

We have recently appointed Cairo-based Basem Mohamed as our new Service & Installation engineer in Egypt.

Basem has a strong technical background and brings with him considerable experience with integrated hatchery solutions from Royal Pas Reform. He will work in close co-operation with ATC, Pas Reform’s representative in Egypt and have the full backing of Royal Pas Reform in The Netherlands.

Cairo 3A Poultry is a fast-growing market pioneer in the Egyptian poultry industry, with a highly advanced and innovative vertical poultry integration model. In a major expansion project, Royal Pas Reform has been appointed to project manage and install an advanced single-stage hatchery based on Smart™ technologies. This will increase meat production capacity to 60,000 tons per year.

Located in the Bahareya Oasis region in Egypt’s Western Desert region, 250 km from Cairo, Cairo 3A Poultry is building a fully integrated poultry city, with farms spread over a vast 11,000 ha site. The company is exclusive supplier and distributor of Hubbard Grandparent stocks in Egypt and supplies day-old parent chicks across the country, as well as frozen, chilled and processed chicken meat.

The new hatchery will incorporate 30 x SmartSetPro™ setters, 30 SmartHatchPro™ hatchers and Royal Pas Reform’s SmartCenterPro™ hatchery management system. It will feature a range of advanced, integrated technologies. This will include a state-of-the-art Adaptive Metabolic Feedback (AMF™) module – to create incubation environments that are fine-tuned to the needs of the growing embryos –, ESM™

Royal Pas Reform appoints Basem Mohamed as Service & Installation engineer in Egypt

Royal Pas Reform appoints Basem Mohamed as Service & Installation engineer in Egypt

(Energy Saving Module) to reduce energy consumption, and SmartWatch™, to monitor and regulate the hatching process.

Royal Pas Reform will also equip the hatchery with a complete line of hatchery automation, including equipment for egg transport, automatic egg candling and egg transfer, chick counting and washing. The climate control system will include a heat exchanger system, air handling units and chick-room coolers/heaters. Royal Pas Reform will also provide the Cairo 3A Poultry hatchery team with full training.

Founded in 2017, Cairo 3A Poultry has full control over all stages necessary from grandparent’s stage all the way to slaughterhouse. The company currently has three grandparent farms, a grandparent hatchery with a yearly capacity of 8.85 million hatching eggs; 12 breeder farms, a hatchery with an annual capacity of 103 million hatching eggs; and 21 broiler farms with an annual meat production capacity of 60,000 tons.

Gregory Vanputte, Royal Pas Reform’s Director Sales & Business Development HAS, comments: “Cairo 3A Poultry is an impressive company that has strong values and an absolute commitment to quality throughout its operations. Royal Pas Reform is delighted that, because of our state-ofthe-art single-stage solutions and advanced installation and service capabilities, we have been chosen as the strategic partner for this expansion.”

The latest chapter in the development story of longestablished Canadian broiler hatchery Couvoir Côté was written this year, when the formerly family run business both completed a major single-stage renovation and expansion project and also joined the Sollio Agriculture cooperative.

Royal Pas Reform was chosen as the development partner for the hatchery, based in Ange-Gardien, Québec, which has been operating for over 40 years. The installation included 12 SmartSetPro™ 2 incubators, 12 SmartSetPro™ 4 incubators, and 14 SmartHatchPro™ hatchers.

“With this capacity we can produce 400,000 broilers per week for the Québec market split over two weekly hatches,” says Sebastien Turner, hatchery operations director at Couvoir Côté. “The actual expansion even has some extra space – to have extra capacity if we need in years to come.”

In addition to the new setting and hatching facility, the project also overhauled the entire hatchery climate-control system – with air-handling units using 100% fresh air, and thus eliminating the need for air recirculation in air ducts in the hatchery. A completely new chilled-water system was also part of the operation.

The majority of the hatchery automation was also replaced. A farm-trolley to setter-trolley unit, stackers, de-stackers, a new transfer/candling and clear-egg removal unit formed part of the project and new washing machines were also included.

The entire operation is connected via a SmartCenterPro™ hatchery management software package – which allows for analysis of results and programs from Côté’s office in Ange-Gardien, and remotely from Zeddam, The Netherlands, or Jacksonville, Florida. A five year SmartCare™ preventive maintenance and hatchery support contract is also included in the project.

Ghislain Gervais, president of the Sollio Groupe Coopératif, Canada’s largest agri-business cooperative, and Sollio Agriculture’s parent organisation said that the acquisition of Couvoir Côté gives the group the strength to extend its position as preferred partner for the Quebec poultry industry.

Gregory Vanputte, director sales & business development HAS, Royal Pas Reform

In the hatchery itself there is never a direct reason to apply antibiotics, as the chicks do not stay here for any length of time. If antibiotics are applied (in-ovo or by injection after hatch) this is done preventively to avoid disease problems or for potential benefits at the farm where the day-old-chicks will be delivered. Furthermore, on the farm itself antibiotics can be administered by feed or drinking water as a preventive measure or as a growth promotor.

This way of using antibiotics is coming under increasing criticism, as it leads to anti-microbial resistance (AMR), which means that bacteria might eventually become resistant to antibiotics. In the long run this causes problems for the treatment of diseases in humans and animals. Many modern poultry companies now aim to produce without using antibiotics, or at least to limit their use to therapeutic purposes only. Some countries have introduced legislation outlawing the use of antibiotics both as a preventive measure and as a growth promotor; in other countries companies are responding to consumer demands for ‘safe & clean’ food.

The question now is what role hatcheries could play in helping to stop the preventive use of antibiotics and to reduce the need for therapeutic use. This is clearly visualized in the figure below. Poultry, for example a broiler flock, will stay healthy if the following two conditions are met:

1. High disease resistance, so the animals are robust and have a high level of immunity

2. Low disease pressure, so pathogens (e.g. bacteria, viruses) are absent or only present at very low concentrations

Under these conditions there is no need to apply antibiotics and the broiler flock will potentially perform very well.

Disease resistance High

Low

Deliver day-old-chicks with high disease resistance by applying Good Management Practices on the breeder farm and in the hatchery. These include:

Provide optimal incubation conditions to ensure strong and vital day-old chicks (with a well-closed navel and wellabsorbed yolk sac)

Apply a good vaccination program on the breeder farm or broiler farm and in the hatchery to ensure a high level of immunity

Avoid stress factors for embryos and chicks, such as overheating, chilling, dehydration and delayed feed access

Keep disease pressure in the hatchery low through Good Hygiene Practices:

Good Management Practice (GMP)

Good Hygiene Practice (GHP)

However, if disease resistance is low and/or disease pressure high, problems are likely to occur on the broiler farm. In this case it is tempting to use antibiotics preventively, as otherwise it is more likely that they will have to be used therapeutically in the event of problems such as increased mortality.

Implement biosecurity measures to prevent pathogens from entering the hatchery; this includes good egg hygiene

Avoid cross-contamination to prevent transport of pathogens within the hatchery

Clean and disinfect regularly to prevent further development of pathogens in the hatchery

Over the past year, all in the Royal Pas Reform family were saddened at the loss of three greatly valued, long-serving colleagues. They were Sales Engineer Sven Bulten, who passed away unexpectedly on September 5, 2020, his 42nd birthday; North America

61;

aged 75 years. All are greatly missed.

Royal Pas Reform bids farewell to greatly valued colleagues Regional Sales Manager Rory Harman, who passed away on February 20, 2021, at the age of and the company’s HVAC specialist Jack Hubbell, who passed away on Friday August 27th, Sven BultenRoyal Pas Reform has completed the installation of a new combined duck and geese hatchery – the first of its kind in Europe – for Warsaw-based waterfowl processing specialist, NaturAgra.

NaturAgra – part of one of Poland’s leading poultry groups, Grupa Drosed, which is wholly owned by one of Europe’s largest fresh poultry producers, French-owned LDC France – wanted to have the newest hatchery with highest standards on the market. In phase one of this greenfield hatchery project, Royal Pas Reform installed 16 SmartSetPro™ 4 setters, 24 SmartSetPro™ 2 setters, and 28 SmartHatchPro™ automated hatchers. The specification included a SmartCare™ contract for ongoing incubation advice. The installation of this equipment and the climate control system and project management was by Jarmax, Royal Pas Reform’s trade agent in Poland.

From February 2022, the goose-hatching season will start –with the full annual capacity of 1.5 millon goslings achieved by the summer. Duckling hatches are due to begin at the same time, with an eventual production target of 12 million ducklings per year.

Sustainability and animal welfare were a central focus in the project’s design. Important factors included a closed vacuum-waste system and sustainable HVAC operation, with heat recovery and energy saving options.

In the duck hatchery, NaturAgra has adopted the welfare friendly SmartCount™ duck counting system, which includes take-off and spray vaccination capability. In addition,

the hatchery features new technology in the form of an egg-washing machine, which removes the cuticle from the duck eggs, to achieve better hatchability. Roldrob chose this after reference visits to Royal Pas Reform’s duck customers, ‘Duck-To farm’ in the Netherlands and ‘Bangkok Ranch’ in Thailand.

Adam Sojka, CEO of Drosed, comments: “I am very confident that we have made the right decision in going with Royal Pas Reform’s SmartPro™ single stage technology. These incubators will help us to deliver excellent quality ducklings and goslings.”

Niels Stam, Sales Director Eastern Europe, says: “We are delighted that NaturAgra chose Royal Pas Reform in the light of very strong competition from sector specialists. It demonstrates that the attraction of our solutions, service and focus on innovation is as strong in the waterfowl sector as it is in the poultry sector. We look forward to working closely with the team at NaturAgra in the future and also to building our reputation in this increasingly important market, worldwide.”

Bingo, Bosnia’s largest supermarket chain, has launched a new, state-of-the-art layer hatchery near the northeastern town of Kalesija.

The installation by Royal Pas Reform, in cooperation with Mrs. Biljana Tomic from its long-term Balkan agent, Iradia, features SmartPro™ single-stage incubation. This includes 12 SmartSetPro™ setters, 8 SmartHatchPro™ hatchers, hatchery automation and HVAC. Bingo aims to produce 2.4 million laying hens per year.

With its headquarters in Tuzla, Bosnia and Herzegovina, Bingo Export-Import Tuzla d.o.o. aims to become a leader in table egg production. In addition, Bingo also exports its products to the countries of Central European Free Trade Agreement (CEFTA) and now plans to start exports to the EU as well.

Irfan Hasanovic, the hatchery manager of Bingo says: “Our mission is to preserve our reputation as the most modern center for egg production in Bosnia and Herzegovina. Using single-stage incubation from Royal Pas Reform greatly contributes in terms of hatchability and chick quality, and we are receiving very positive feedback from our customers.”

Niels Stam, Royal Pas Reform’s Sales Director for Eastern Europe comments: “Royal Pas Reform is delighted to have won this contract. We look forward to continuing to work with Bingo to help its team achieve its plans for further growth and development.”

Rory Harman

Rory Harman

LLC Belgrankorm is part of parent company BezrkBelgrankorm, a large and diversified agri-business established in 1998, which has more than 40 divisions. Located in the Belgorod and Novgorod regions of Russia, its main activities are the production of poultry, pork, beef, milk, grain and animal feed.

LLC Belgrankorm has become the first poultry company in Russia to adopt Royal Pas Reform’s SmartCare™ package–providing five-years’ preventative maintenance and hatchery support.

The new hatchery, at v. Zavidovka, Yakovlevskiy district, Belgorod, was opened in Q1 2020 after both reconstruction of old and construction of new facilities. It is equipped with advanced Smart™ integrated hatchery solutions from Royal Pas Reform. The estimated capacity of the new hatchery is 42 million eggs per year, and as a result the capacity of the entire facility has increased to 92,5 million eggs per year.

Royal Pas Reform supplied, installed and commissioned a range of its single-stage incubation technologies. This includes 20 SmartPro™ 6 setters, 28 SmartHatchPro™ hatchers and the SmartCenterPro™ hatchery management software.

SmartCenterPro™’s track and trace module will record every moment of the hatching eggs and day-old chicks – from the origin of the eggs, to the receipt of chicks at customers’ farms. This includes cycle reports from every hatch, which incorporate individual day-old chick weight estimation and uniformity scoring for each batch produced.

“Agroindustrial holding Belgrankorm is a future-focused company,” said director for eggs production, Andrey Nepokrytov. “This program takes us up to another level. With optimized, efficient and uninterrupted performance in every area of the hatchery we will achieve our goal of producing the highest number of best-quality chicks.”

In 2020 Belgrankorm plans to produce more than 160 million hatching eggs for production over 315,000 tonnes of live weight poultry meat.

“We keep pace with new trends,” says Mikhail Vyacheslavovich Yakushev, general director of LLC Belgrankorm. “We focus on the quality and uniformity of chickens and pay great attention to achieving the highest standards of hygiene and biological safety throughout the hatchery.”

Wim Schaafsma, Pas Reform Russia’s General Director, commented: “We are delighted to work with Belgrankorm again to deliver its advanced integrated hatchery facility at v.Zavidovka. It is a technology led, forward looking company, As the first in Russia to adopt our SmartCare™ package, it now leads the way in harnessing the operational benefits of advanced hatchery care and support.”

Thailand-based

Panus Poultry, which was established in 1997, is a fully integrated poultry company and includes breeder farms, hatcheries, broiler farms, primary processing and further processing plants. A subsidiary of PNP Group, in 2018 Japanese meat processor NH Foods, also known as Nipponham, acquired a 30% stake in Panus Poultry to boost its exports to Japan.

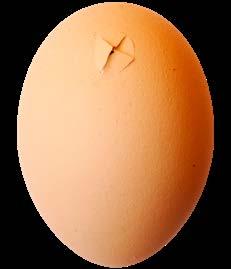

Royal Pas Reform’s timelapse animation revealing the extraordinary complexity of a chick’s embryonic development from fertilization to hatching has now been viewed 2m+ times.

poultry specialist Panus Poultry Co. has installed Royal Pas Reform SmartSetPro™ setters and SmartHatchPro™ hatchers at a major hatchery expansion, located 110km from Bangkok in Phanat Nikhom. Driven by a significant increase in demand for its internationalquality products from Europe and Japan, the hatchery will eventually produce 2.4 million day-old chicks per week.

Watch the movie!

We’re in the 2-million club!

poultry specialist Panus Poultry Co. has installed Royal Pas Reform SmartSetPro™ setters and SmartHatchPro™ hatchers at a major hatchery expansion, located 110km from Bangkok in Phanat Nikhom. Driven by a significant increase in demand for its internationalquality products from Europe and Japan, the hatchery will eventually produce 2.4 million day-old chicks per week.

Watch the movie!

We’re in the 2-million club!

Pas Reform North America has partnered with the Sahara Conservation Fund (SCF) – an international non-profit organization, dedicated to conserving wildlife in the Sahara Desert – to help save the threatened North African rednecked ostrich.

With the exception of a few small savannah populations, the North African red-necked ostrich has completely disappeared from its once vast Sahelo-Saharan range. Pas Reform North America is supporting SCF’s efforts to recover this distinctive, but less known, sub-species of ostrich through the North African Ostrich Recovery Project.

SCF has recently completed the commissioning of Niger’s first solar-powered field hatchery, which is custom engineered to restore and repopulate the ostrich in the wild.

“The survival of the North African red-necked ostrich depends upon this project,” explains John Newby, SCF Fund Director. “Nigeriens who have been caring for the last five breeding pairs of these ostriches reached out to us about how we could help.”

Four shipping containers have been converted into a sustainable camp and architects and engineers for the North African Ostrich Recovery Project created a hatchery – which includes Pas Reform incubators, an incubation lab, office and solar power plant.

The hatchery was fabricated in San Francisco and shipped to Africa for reassembly. Now fully operational, it is equipped to run sustainably – with only minimal water supply from a well one mile away. The first birds are expected to start laying at the end of April. John Newby said: “Through this partnership with Pas Reform North America, we hope to safeguard the future of these unique, flightless birds.”

Steve Warren, CEO of Pas Reform North America says: “We are delighted to support this important conservation project and play a part in helping to ensure the survival of this perilously threatened species.”

Don Manuel Ariztia, founder of Melipilla-based Agricola Ariztia, comments: “We have been working in a very professional way with the Pas Reform team – whether they have come from Europe, or the USA. In both cases, they have helped us greatly with advice based on their in-depth knowledge of incubation.

“We have seen very good results, both with the SmartPro™ NF and the SmartPro™ series. The SmartPro™ NF option suited us very well when that came to market. It meant that we could incorporate Pas Reform’s incubation technology, while at the same time staying with the 54-egg flat. It made the change over seamless and very simple for us to achieve.”

Steve Warren, President of Pas Reform North America, says: ”The SmartPro™NF series has shown great results here at home in the USA. Leading groups like Wayne and Pilgrims are now operating with SmartPro™ NF. We are happy to have made now serious steps internationally as well. This year we have concluded projects in Thailand and we are now extremely happy to have expanded further with Agricola Ariztia in Chile.”

Chile’s Agricola Ariztia has started a new phase of hatchery expansions and renovations at two of its five hatcheries. At the Malvilla hatchery, the company’s largest, Ariztia is renovating and expanding with Smartpro™ NF, on the 54-egg tray produced by Pas Reform North America. Its hatchery in Arica, in northern Chile, will expand with Royal Pas Reform’s SmartPro™ series on the 150-egg tray.

Chile’s Agricola Ariztia has started a new phase of hatchery expansions and renovations at two of its five hatcheries. At the Malvilla hatchery, the company’s largest, Ariztia is renovating and expanding with Smartpro™ NF, on the 54-egg tray produced by Pas Reform North America. Its hatchery in Arica, in northern Chile, will expand with Royal Pas Reform’s SmartPro™ series on the 150-egg tray.

IB Group has chosen Royal Pas Reform as its partner for their multi-location hatchery expansion programme across the Indian sub-continent. These state-of-the-art installations will feature single-stage incubators, fully integrated climatecontrol systems and complete hatchery automation –making them amongst the most modern facilities in India.

IB Group (ABIS Exports India Pvt Ltd) AEPL, which is based in Rajnandgaon, Chattisgarh, believes that adopting a singlestage incubation process – giving superior post-hatch performance, in terms of growth, mortality and feed conversions – is pivotal to producing high-quality broiler chicks.

Mr. Bahadur Ali, Founder & Managing Director of IB Group says: “IBG’s ambition is to play a major role in the future growth of the Indian poultry industry. During the course of 2020 we made a long-term strategic plan with our team, which needed a multiple-location expansion for our hatchery operations.

“It was an obvious step for us to go for single-stage, fully automated hatcheries technology. Choosing Royal Pas Reform – the world’s leading single-stage incubation and integrated incubation-project specialist – was therefore the logical choice for us.”

Bouke Hamminga, Royal Pas Reform Director International Sales & Business Development says: “We are delighted that IB Group – a leading technology driven poultry company in India – has chosen to work with us to deliver its ambitious plans. I am sure that, as a global integrated hatchery solutions supplier, we can prove to be a key partner for decades to come.”

Royal Pas Reform has appointed Marcel Dost as its new chief financial officer. He will lead the company’s global financial activities including accounting and controllership, financial planning and analysis, tax, investor relations and internal audit.

Royal Pas Reform welcomes new CFO to the board

Venkitakrishnan Natarajan, country manager India

Royal Pas Reform welcomes new CFO to the board

Venkitakrishnan Natarajan, country manager India

Poland-based Agri Plus Sp. z o.o. recently started production at its new greenfield broiler hatchery. Agri Plus is part of Smithfield Foods, which since September 2013, together with the WH Group, creates a company that is the largest pork producer in the world. Agri Plus is engaged in the production of pigs, poultry and feed production.

Royal Pas Reform installed 21 SmartSetPro6 high capacity™ setters, 6 SmartSetPro3 and 24 SmartHatchPro™ hatchers, as well as a range of hatchery automation systems, including an egg-setting line, automatic candling and transfer, and a SmartCount™ counting and dosing system and vacuum waste system. In addition, Royal Pas Reform designed, supplied and installed the complete HVAC system.

The hatchery is covered by a preventive maintenance program, delivered by Polish technicians, and a SmartCare™ service program – which now covers all the three of Agri Plus’s sites in Poland. Expert advice is provided by Royal Pas Reform’s Polish incubation consultants.

The facility was already working with 25 year-old Pas Reform incubators and the appointment followed two successful earlier projects with Agri Plus broiler and goose hatcheries in Bielsk Podlaski and Sokolka.

Since 2018, Agri Plus has been developing broiler breeding based on its own model of “Farm Fattening”. It is a safe and stable cooperation offer for Polish breeders.

Kamila Kiczuk, head of all hatchery activities for Agri Plus in Poland, says: “There were several reasons why we chose Royal Pas Reform for our expansion project. Its strong local presence and knowledge, our existing relationship and the results of previous projects were all significant trust factors that contributed to our decision. It is also able to supply spare parts rapidly from its warehouse near Gdansk.

“Also, in previous projects, hatchery automation came from different suppliers. Agri Plus was not pleased with the outcomes, since it could not fully connect all equipment into one central operating computer. Now we can, with the performance efficiency and optimization this gives us.”

Niels Stam, Sales Director Eastern Europe, comments: “We are delighted to extend and deepen our long-lasting relationship with Agri Plus, which is a major European and international poultry producer.

Giza-based Delta Masr Group, one of Egypt’s pioneering agricultural businesses, has chosen Royal Pas Reform’s Smart™ technologies for its all-new hatchery in Alexandria, which will have a capacity of 60 million day-old chicks per year.

Delta Masr Group, founded in 1997 by Mr. Anas Abd Elkhabeer Al Mosalmi, was one of the first companies in Egypt to specialize in broiler poultry farming. Today, the business comprises five distinct sectors – poultry, feed manufacturing, animal production, the agricultural sector, land reclamation, and the grain-trade sector.

Its first hatchery was established in 2001, with a production capacity of 24 million broiler chickens per year. And based on the group’s experience in breeding all available breeds in the Egyptian market, the company has also set up a feed factory under the commercial name Delta Masr Feed Mill, which produces nutritionally balanced feed for all types of poultry.

At the new hatchery, Royal Pas Reform will install 24 SmartSetPro™ 6 setters, 24 SmartHatchPro™ hatchers, and the SmartCenterPro™ hatchery management system to ensure precise, consistent process control. Royal Pas Reform will also supply a full range of hatchery automation and climate control equipment.

Mr. Al Mosali says: “The vision behind our expansion is to provide healthy food for local and external consumers with the highest international quality standards. The new hatchery will allow us to meet market needs, ensure supply security and raise the efficiency of the production process. We chose Royal Pas Reform as a supplier of the best-quality solutions.”

Gregory Vanputte, Royal Pas Reform’s Director Sales & Business Development HAS, comments: “We are delighted to have received this major project commission from Delta Masr Group which has one of Egypt’s most progressive poultry businesses. This new hatchery will provide an important springboard for the company’s continued growth.”

With a capacity of 24 million day old chicks (DOC) per year, the new facility is equipped with incubators, hatchery automation and climate control systems from Royal Pas Reform – designed to produce healthy and highly uniform day-old chicks.

The specification includes 12 SmartSetPro™-6 setters with Adaptive Metabolic Feedback (AMF™) and Energy Saving Module (ESM™), 12 SmartHatchPro™-5 hatchers with SmartWatch™ and climate control.

SmartWatch™ is a unique tool for hatch-window control, which creates ideal conditions for chicks to hatch – by optimizing the humidity and CO2 inside the hatcher. It monitors and adjusts the hatching process automatically –from the day of transfer, through to the hatching of the last chicks – eliminating any need for human intervention.

Mr. Ali Mas’adi, WMU’s CEO says: “With these facilities, the purpose of supporting the national food security program as well as contributing to the welfare of the people of Yogyakarta will be achieved.”

WMU is a leading integrated poultry business, with production facilities spread across Java, including commercial broiler farm, commercial layer farm, feed mill and slaughter house divisions which support its main goal in supplying chicken meat.

“Also by supporting farmers and SME’s of Indonesia, we will grow the business bigger,” says Ali.

Royal Pas Reform’s Sales Director, Bas Kanters says: “We are delighted to be working with WMU in Java. It is a progressive business that is making an important contribution to expanding Indonesia’s poultry market and distribution network.”

Jakarta-based poultry vertical integrator Widodo Makmur Unggas (WMU) has opened its latest broiler breeding farm and hatchery at Tonggor, in the Yogjakarta region of Java, Indonesia, following an inauguration ceremony attended by the region’s Deputy Governor. By Lenise I. de Souza, Incubation Specialist, Royal Pas Reform

By Lenise I. de Souza, Incubation Specialist, Royal Pas Reform

“Why are so many chicks dying in their first week?” I could hear the worry in his voice when I received a call from the manager of a single-stage broiler hatchery in southern Brazil. It was a cold winter (yes, even in this tropical country temperatures can go below 10°C) and he was getting reports of 3-5% of chicks dying in their first week, and in some cases even 10%.

Wanting to get to the bottom of this alarmingly high firstweek mortality, I went to visit the plant, where I learned there was no relationship between setter/hatcher room or breeder flock/line. Stranger still: either males or females were dying, but not both sexes from the same hatch day. Naturally, my first reaction was that something might be going wrong after the chicks had been sexed. Or perhaps transport was the problem? But the manager said they’d looked at these too and could find no correlation.

After tracking & tracing all chick handling procedures after sexing, we realised that the worst cases were when chicks hatched on the Friday but were not delivered until Saturdayso they had stayed overnight at the hatchery. But the records from the chick delivery room showed nothing unusual: temperature and humidity were fine.

It was time to take a look inside the chick delivery room. Once again, the record sheet showed normal environment data. But ... when I stood close to the wall where air was entering the room, I could feel the cold on my bare arms. The chicks on that side were huddled together in their boxes. Measuring their rectal temperature (it was 101-102°F) confirmed that they were suffering from hypothermia. The temperature around these boxes, which contained male chicks, was only 19°C.