INSULATION | AIRTIGHTNESS | BUILDING SCIENCE | VENTILATION | GREEN MATERIALS Issue 43 £5.95 UK EDITION SUSTAINABLE BUILDING “It’s a lovely house to live in now” One Cork family’s story 5 years post retrofit Our friend electric Hertfordshire passive retrofit may turn a profit Demountable homes Cardiff homeless families scheme aims for net zero COLD TRUTHS The health threat homes may pose in an energy crisis OFF GRID WHIZZ KID Canadian retreat takes architectural route to zero energy COLD TRUTHS The health threat homes may pose in an energy

www.cupapizarras.com Scan to request your FREE sample!

Publishers

Temple Media Ltd PO Box 9688, Blackrock, Co. Dublin, Ireland t +353 (0)1 210 7513 | t +353 (0)1 210 7512 e info@passivehouseplus.ie www.passivehouseplus.co.uk

Editor Jeff Colley jeff@passivehouseplus.ie

Reporter John Hearne john@passivehouseplus.ie

Reporter Kate de Selincourt kate@passivehouseplus.ie

Reporter John Cradden cradden@passivehouseplus.ie

Reader Response / IT Dudley Colley dudley@passivehouseplus.ie

Accounts Oisin Hart oisin@passivehouseplus.ie

Art Director Lauren Colley lauren@passivehouseplus.ie

editor’s letter

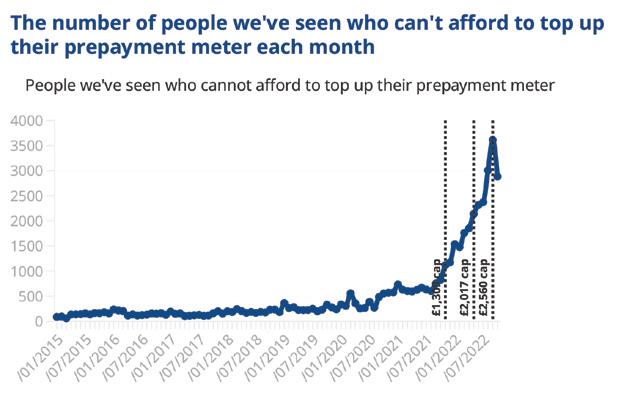

As I write these words, it is precisely 20 years since the team at Temple Media Ltd went to print for the first time. The publication was this magazine’s predecessor, the stealthily titled green building magazine Construct Ireland (for a sustainable future), which we published till the opportunity came up to rebrand as Passive House Plus and expand into separate Irish and UK editions. When I think back over the millions of words we have published over the years in thousands of articles on how and why to make buildings energy efficient, it is galling in the extreme to think of the situation before us this winter. Tens of thousands of vulnerable people will very likely die, in miserable conditions that Dickens himself would scarcely believe, unable to afford to heat or power their homes, unable to afford to bathe, and unable to afford to wash or cook food – assuming they can afford to buy it in the first place.

lack of understanding of the fact that breathability is really about a building’s ability to sweat out moisture, rather than air. Or there’s the shameful argument of landlords attempting to blame the presence of dangerous mould in social housing on tenant behaviour. How dare they have the audacity to wash and dry clothes indoors, or to want to eat cooked food!

Design

Aoife O’Hara aoife@evekudesign.com | evekudesign.com Print GPS Colour Graphics www.gpscolour.co.uk | +44 (0) 28 9070 2020

When I think of these horrors – which Kate de Selincourt’s articles in this issue, Cold Truths Part 1 and 2 so viscerally describe – I cannot help but think back to some of the arguments we have heard and the obfuscation we have faced over the years when advocating for higher energy performance standards. There’s the argument that passive house is too expensive, akin to a Mercedes that most people would love to buy in an ideal world when what they need is a Ford – an argument which looks extremely foolish when you consider the growing chasm between the heating costs of typical homes and passive houses, and an argument which has been debunked by research showing that building to the passive house standard can add as little as 0.01 per cent to construction costs. There’s the surprisingly stubborn nonsense that buildings should be breathable, not airtight – an argument which betrays a

In truth, we have known for a long time how to make buildings comfortable, healthy, green, and cheap to run, and protect vulnerable people against the mortal threat posed by the convergence of a cost of living crisis, energy crisis and winter weather. While I don’t take comfort in anyone’s misery, it’s hard not to feel a strange kind of hope in the fact that people with deeper pockets are feeling the pain of higher energy costs now – even if it only means a lighter bank balance, rather than an existential threat to their lives. Fuel poverty has caused enormous suffering for decades. If sympathy for the suffering of vulnerable people wasn’t sufficient to drive a push for the en masse uptake of evidence-based approaches to low energy building and retrofit, perhaps the empathy borne from experiencing a fraction of that suffering will be?

As I write these words, I’m painfully aware that the urgent priority must be to put measures in place to protect vulnerable people in the here and now. But we are a species that has form in failing to look forward, so we must also use the sheer unmitigated awfulness of the current situation to win hearts, minds, and wallets, and convince policy makers, industry, building owners and the public of the need to transform our building stock, so that we never face such awfulness again.

ph+ | editor’s letter | 3 PASSIVE HOUSE+ EDITOR’S LETTER

Contributors

Toby Cambray Greengauge Building Energy Consultants

Cillian Collins Perkins&Will Catrin Maby energy researcher and consultant Marc Ó Riain doctor of architecture

Peter Rickaby energy & sustainability consultant David W Smith journalist Cover SoLo house, British Columbia Andrew Latreille

Regards, The editor

ISSUE 43

Publisher’s circulation statement: Passive House Plus (UK edition) has a print run of 9,000 copies, posted to architects, clients, contractors & engineers. This includes the members of the Passivhaus Trust, the AECB & the Green Register of Construction Professionals, as well as thousands of key specifiers involved in current & forthcoming sustainable building projects.

Disclaimer: The opinions expressed in Passive House Plus are those of the authors and do not necessarily reflect the views of the publishers.

About Passive House Plus is an official partner magazine of The Association for Environment Conscious Building, The International Passive House Assocation and The Passivhaus Trust.

CONTENTS

BIG PICTURE

This issue features an off-grid prototype house in British Columbia, designed and constructed to demonstrate an innovative approach to future building.

NEWS

The AECB launches two new levels of retrofit standards; Ashden Awards winners showcase climate solutions; and Climate Change Committee says decarbonising buildings is the most important issue.

COMMENT

Dr Peter Rickaby examines the UK governments inaction on retrofit; Dr Marc Ó’Riain asks if nuclear power can overcome the high-profile failures of its past; and Dr Catrin Maby suggests that general builders could be the frontline in promoting and delivering home energy retrofit.

26

CASE STUDIES

Phit the bill

All electric retrofit may turn a profit in energy crisis

A passive house, by its nature, requires a much smaller amount of energy than a typical home, and when its heating demand is met by electricity, and you cover it in solar PV panels, you can start to see the potential for a whole new generation of passive homes that are semi-independent of the electricity grid. This is the case for Carrstone House in Bedfordshire, which generates so much solar energy it had to be registered as a power station.

Safety net Demountable homes for homeless families aim for net zero

At times the need to put roofs over the heads of vulnerable people and the need to tackle climate change and unsustainable resource use can seem in direct opposition. But one new Welsh scheme shows that doesn’t have to be the case.

4 | passivehouseplus.co.uk | issue 43 CONTENTS PASSIVE HOUSE+

6 26

20

38

14 38 6

Northern comfort

Belfast developer finds path to passive at scale

In trickier housing markets, the instincts of house builders have often tended towards building to the worst legal standards required –or worse. One award-winning new project in Belfast’s suburbs is showing that it doesn’t have to be this way – and that developers can thrive by pitching homes designed to ensure comfort and low bills at increasingly energy-conscious consumers.

Five years post retrofit

Cork family describe a home transformed How do you take a painfully cold, unhealthy house and make it comfortable and affordable to heat? Five years ago, one Irish family decided enough was enough, and took decisive action to transform their period property into a cosy, healthy home where the heating system ticks along without the homeowners touching it.

INSIGHT

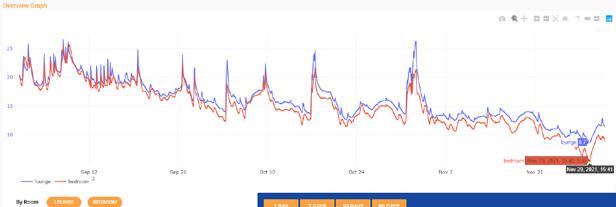

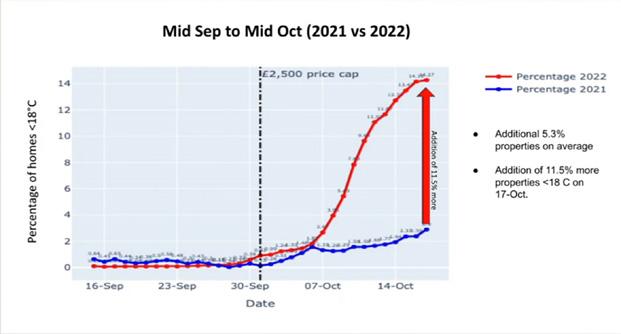

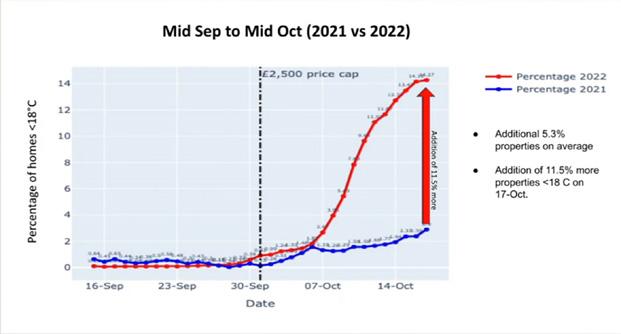

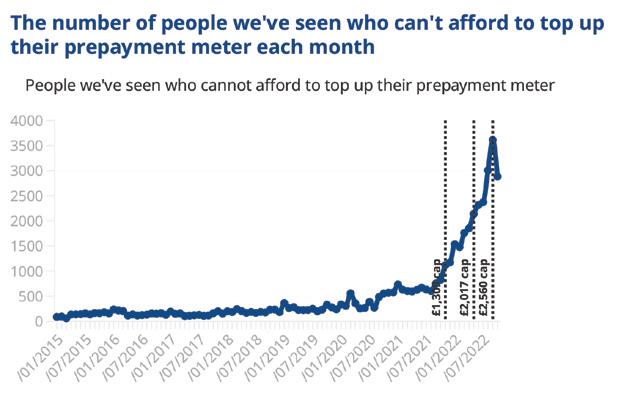

Cold truths: What the energy crisis will mean for building occupants this winter

While most people will feel the squeeze as a consequence of the energy crisis, for vulnerable people spikes in energy prices may be a matter of life and death. In a two-part mini-series of articles in this issue, Kate de Selincourt peers into the void to see how vulnerable people may respond to high energy prices, and what the impact will be for their living conditions and their health.

MARKETPLACE

Keep up with the latest developments from some of the leading companies in sustainable building, including new product innovations, project updates and more.

Awaab Ishak’s death shows that building physics are a life and death matter

Advances in building physics in recent years are leading to an ever-increasing understanding among experts of the risks that a litany of pollutants can pose to building occupants. But this has not stopped vulnerable people from living – and dying - in substandard buildings that exacerbate these risks. Urgent action is needed, Toby Cambray explains, to better communicate and decisively tackle the risks buildings can pose to their occupants.

ph+ | contents | 5 PASSIVE HOUSE+ CONTENTS ph+ | contents | 5 48 58 66 58 66

76 82 48

BIG PICTURE

PASSIVE & ECO BUILDS FROM AROUND THE WORLD

Given the need to slash the emissions released in the construction and operation of buildings while protecting against the risk of volatile – and potentially disrupted –energy supply, what lessons can we learn from off grid low energy buildings from more extreme climates? Cillian Collins, senior architect with Perkins&Will, describes an extraordinary prototype project in British Columbia.

1. Introducing SoLo

Located in SoLo Valley in the Coast Mountains north of Whistler, British Columbia, SoLo is an off-grid prototype designed and constructed to demonstrate an innovative approach to future building – by generating its own energy and minimizing its carbon footprint.

SoLo fulfills a brief both as a single-family home and as a corporate retreat and prototype intended to demonstrate an approach in how to build future alpine settlements in British Columbia that will adapt to extreme weather patterns.

Now more than ever, in the face of the current climate crisis and depleting natural resources, we must choose to build differently and expect buildings to counteract their negative consequences. SoLo investigates a path forward through its deliberate choices and priorities. The project started with an overarching set of principles and goals that would lead every decision: eliminating harmful materials used in both construction and finishes; minimizing energy consumption through a high-performance building enclosure system, appliances, and fixtures while also generating energy on site; and reducing greenhouse gas emissions, both in operation and embodied in the construction.

ph+ | solo valley big picture | 7 BIG PICTURE SOLO VALLEY

The design allows the inhabitants to celebrate the natural beauty of the valley and provides an immersive connection with the raw beauty of the surroundings.

A platform on stilts raises the house up off the ground, minimizing the footprint and amount of excavation required on the landscape, as well as reducing the need for concrete. Mass timber is used to create a compact, pure form for habitation, with the CLT serving as both a structural element and interior finish for walls, roof and floors, reducing the need for interior materials. Given the valley’s extreme climate, it was critical to have an ‘enclosure-first’ approach to ensure energy efficiency and outstanding comfort. A layer of mineral wool encapsulates the mass timber structure to create the thermal boundary and simplify thermal bridge free detailing. A fixed structural module based on CLT sizing is used to formulate the programmatic requirements, sized to allow ease of prefabrication and delivery.

The south façade makes use of building integrated photovoltaic panels (BIPV). Although there is a reduction to the system efficiency with the panels being installed vertically as opposed to at an optimum angle, this configuration eliminates any risk of snow load buildup throughout the winter and serves a double duty as the cladding on this façade.

SOLO VALLEY BIG PICTURE 8 | passivehouseplus.co.uk | issue 43

3 7 9 10 8 11 4 6 5 2 Building Assembly Standing Seam Metal Roofing 2 Glulam Columns 3 2x6 T&G Exterior Siding 4 1070mm x 1700mm PV Modules 5 Steel Structure Platform Timber (DLT) Mineral Wool Insulation 8 Weather Barrier 9 Passive House Certified Curtain Wall 10 Glass Guard 11 Timber Deck Addition To

the challenges

the site’s

seasonal construction

prefabrication

was

was

negate

posed by

remote location and

window,

was an obvious fit. This

essential to allow for a quick erection of the building during the summer season while decreasing the amount of equipment and materials needed to be delivered to site—reducing the project’s embodied carbon footprint. A local contractor with passive house experience and prefabrication expertise (BC Passive House)

commissioned to prefabricate building elements off-site. Minimizing site disturbance, the modular prefabricated home is set on a light structure above the uneven terrain. This reinforces its relationship to the site as a ‘visitor’, allowing nature and the site to remain the focus.

essential Building Assembly 1 Standing Seam Metal Roofing 2 Glulam Columns 3 2x6 T&G Exterior Siding 4 1070 mm x 1700 mm PV Modules 5 Steel Structure Platform 6 Dowel Laminated Timber (DLT) 7 Mineral Wool Insulation 8 Weather Barrier 9 Passive House Certified Curtain Wall 10 Glass Guard 11 Timber Deck Addition Passive House Wall Assembly IN OUT Passive House Wall Assembly From Interior to Exterior 1 DLT (Dowel Laminated Timber) 2 Air Barrier—Vapour Permeable 3 24” Mineral Wool Insulation filled between TJI Supports 4 38mm x 89mm Strapping with Mineral Wool Insulation 5 Moisture/Weather Barrier 6 130mm x 128mm Glulam Columns 7 Support Railing and Clamps 8 1070mm x 1700mm PV Panel Module 9 Triple-Pane Passive House Certified Window Temperature: THERM Simulation

2. An ‘enclosure first’ approach 3. Prefabrication was

4. Off grid self sufficiency

As an off-grid system, the building was required to be self-sufficient. With the added challenge of an extreme climate, the passive house standard was set as a goal with an aim of realising significant energy savings while also creating a comfortable indoor environment. By reducing the operational energy demand, on-site energy generation became feasible to implement.

The building uses solar energy as the main energy source through a 32 kW PV array (103 panels mounted vertically on the south façade) that feeds a 96 kWh battery pack. A storage shed composed of two 20 ft long shipping containers accommodates electrical equipment including a fuel cell, 12 hydrogen cylinders, Tresvolt batteries, invertor and electrical control panels. The 5 kW fuel cell and 120 kW hydrogen cylinders provide back-up power when there is no winter sun or peak use exceeds battery capacity.

In an ideal off-grid system, the batteries would store enough energy to power the development for one day, and then the PV array would generate enough to recharge the batteries each day. Balancing storage, production, and demand without oversizing costly equipment required careful consideration. Satisfying peak electrical demand during the winter using only PV panels and battery storage would require an unreasonably large and costly PV array and battery system, which would be underused in the summer.

As a result, the system is sized for average annual demand. In this scenario, the batteries reach their low-level limit more frequently, more efficiently using the capacity of the batteries and significantly reducing the required battery system cost. However, this increases the backup requirements during the winter. The use of a hydrogen fuel cell is currently being trialed to serve as a back-up generator, to minimize carbon emissions in operation.

Complementing the home’s solar generation, the house processes its wastewater and collects and treats its own drinking water. Provisions were also made for the future installation and connection of wind power.

In a time of rising energy costs this frugality is equally applicable in an ‘on-grid’ context.

ph+ | solo valley big picture | 9

Photos: Andrew Latreille

Structural materials typically account for approximately half of the material in a building and represent the single largest opportunity to reduce embodied environmental impacts. Materials used in SoLo were carefully designed to maximize their structural capabilities and minimize the project’s environmental impact. Wood was chosen as the primary structural element to reduce embodied emissions. It is expressed and exposed intentionally throughout the project to authentically showcase the types of mass timber products used. The key structural materials used in the project include:

• 341 m3 of wood: dowel laminated timber (DLT) wall and roof panels, glulam beams and columns, nail-laminated timber (NLT) and cross-laminated timber (CLT) floors.

• 89 m3 of concrete: cast-in-place concrete foundation and footings.

• 3.6 m3 of steel: beams, columns, and decking of the raised platform, and steel rod brace frames.

Post-construction, Perkins&Will and Integral Group undertook a whole-building LCA of the project to understand the embodied carbon associated with structural, architectural, mechanical, electrical, and plumbing (MEP) systems, and on-site renewable energy systems.

When accounting for biogenic carbon using wood within the LCA model, it highlighted that the structural materials were not the largest portion of the project’s global warming potential (GWP). Instead, the architectural and interiors components were the largest contributing category, with insulation being the prime contributor. This is a by-product of taking an envelope first approach using highly insulated assemblies, designing a project with a compact form, and limiting materials such as concrete and steel.

The project team found that the renewable systems (required in an off-grid setting) accounted for the majority of GWP by MEP systems. Batteries are responsible for the largest portion, closely followed by the PV Panels and PV Inverters.

It is a nuanced discussion as there are several overlapping design and performance considerations when it comes to balancing resiliency and occupant comfort. We must consider sizing of mechanical systems, procurement of sustainably harvested wood products and the local energy supplies, i.e., how is energy supplied at a district level? And what will the environmental impact of this infrastructure be as we strive to accommodate a growing population?

Further information on the LCA analysis of the project will be released in the coming months.

10 | passivehouseplus.co.uk | issue 43

5. Celebrating wood & reducing embodied carbon

The next generation of heat pumps: The new Vitocal 150-A

With a flow temperature of up to 70°C, the new Vitocal 150-A is ideal for retrofits. It achieves its high efficiency by using R290 (propane) refrigerant, which is particularly environmentally friendly with an ultra low global warming potential of 0.02 (GWP).

With a flow temperature of up to 70°C, the new Vitocal 150-A is ideal for retrofits. It achieves its high efficiency by using R290 (propane) refrigerant, which is particularly environmentally friendly with an ultra low global warming potential of 0.02 (GWP).

It achieves its high efficiency by using R290 (propane) refrigerant, which is particularly environmentally friendly with an ultra low global warming potential of 0.02 (GWP).

The compact design saves up to 60 percent of the space required and reduces installation time by up to 90 minutes, compared to conventional heat pumps.

The compact design saves up to 60 percent of the space required and reduces installation time by up to 90 minutes, compared to conventional heat pumps. R290

GLOBALWARM

The compact design saves up to 60 percent of the space required and reduces installation time by up to 90 minutes, compared to conventional heat pumps. R290

GLOBALWARM

ph+ | solo valley big picture | 11

R290 GWP 0,02

NG POTENTIAL (GWP100 gem IPPCAR6)

GWP 0,02

NG POTENTIAL (GWP100 gem IPPCAR6)

GWP 0,02

GLOBALWARM NG POTENTIAL (GWP100 gem IPPCAR6)

6. Certification

In a climate that typically ranges from -30° C in the winter to +35° C in the summer (up to 44° C in the area’s recent heat dome), the difficulty in obtaining the passive house standard is exacerbated. The project location also added a degree of difficulty as the valley has limited solar access due to mountains to the south.

Passive House Planning Package (PHPP), the energy modelling software used for passive house certification, influenced the design both in siting and tendency towards a more compact form in early massing. However, two competing design criteria briefs emerged; firstly, a double height space in the living area that would accommodate a gathering space (for the building’s use as a corporate retreat) with an expanse of glass facing north-east towards the views, and secondly, raising the building out of the ground creating additional exposed soffits.

These conditions placed emphasis on the performance of the building envelope to reach classic passive house certification. It was evident through PHPP modelling that while reaching the 15 kWh/m 2a threshold for certification via space heating demand was possible, it would have been to the detriment of other design criteria outlined above. Third-party certification was still important to validate the approach, and as result, PHI Low Energy Building certification was pursued and achieved instead, blending the goals of design and performance. The project realized a heating demand of 23 kWh/m 2a and an airtightness result of 0.6 air changes per hour at 50 Pa. This is the first building certified under the Passive House Institute umbrella within Perkins&Will and is paving its way with lessons learned for current and future projects.

7. Research

SoLo is a prototype. Not just in terms of construction methodologies, but also as a testing ground for improved and optimized design processes.

The project team leveraged an internal innovation incubator micro-research grant to investigate outstanding questions that may not usually have the bandwidth to be investigated in day-to-day project work. In this case, the project team created a research report: “Increasing understanding of the role of thermal bridging in building performance and the design process”, co-authored by Cillian Collins, Alysia Baldwin & Aik Ablimit.

Although successful in achieving PHI Low Energy Building certification (heating demand less than 30 kWh/m 2a), this project fell short of achieving the 15 kWh/m2a space heating demand target for full passive house certification. If the lower space heating demand had been met, passive house plus certification could have been achieved due to the level of PV generation applied.

Throughout the project design, the team considered several factors to achieving the lower space heating demand number including:

• How much double height space can we have?

• How much northeast glazing can we have while balancing performance, views, and daylighting? What is the optimum amount of south-facing glazing?

These questions were resolved intuitively throughout the design process with the validation of assumptions through PHPP modelling and juggling the energy balance of the window sizing with heat loss vs solar gain, as well as the balance between window and PV sizing.

However, there is a potential benefit from the power of computational design that would allow designers to review and weigh up the impact of interlocking design parameters on often competing performance metrics such as energy, daylighting, cost, views, etc. This was the topic of another research paper: “Computational design for Passive House projects”, authored by Cheney Chen & Cillian Collins. For more information on this paper, please visit: tinyurl.com/58p8xeat

8. Takeaways

The innovation of SoLo lies in taking technologies that already exist and synergizing them in a way that creates a replicable formula: one that creates high-quality, high-performance buildings that maintain design quality and aesthetics, while focusing on occupant health and wellness. The future potential of this project lies in bringing all these approaches together and scaling them from a single cabin in the woods to high-rise mixed-use projects in urban centres. By tackling both embodied and operational emissions through the adoption of new construction methods consisting of mass timber, modular/prefabrication, passive house design principles, and clean energy generation, buildings can counteract their negative consequences and act as a source of repair.

SOLO VALLEY BIG PICTURE 12 | passivehouseplus.co.uk | issue 43

ph+ | solo valley big picture | 13 TheCOP26housegoesbeyond zerocarbontodemonstratehow beautiful,affordable,healthyand comfortablehomescanbe developedwithminimalimpacton theenvironmentthroughouttheir lifecycle.Ecomerchant’ssupport, expertiseandproductrangewas keytodeliveringtheultra-low carbonlevelsrequiredusingnatural andsustainablebuildingmaterials. PeterSmithRIAS RoderickJamesArchitectsLLP DesigneroftheCOP26House PassivhausDesigner www.ecomerchant.co.uk info@ecomerchant.co.uk +44(0)1793847444 SUSTAINABLE BUILDINGMATERIALS FROMFOUNDATION TORIDGE Ecomerchantareproudtobepartners,sponsorsand supplierstotheCOP26House. TheCOP26Housestores(sequesters)twotimesmore carbonthanemittedtopracticalcompletion. BeatstheRIBA2030ClimateChallengetargetbya substantial22%. Panelisedsystemusingnaturalmaterials,constructed inlessthan8weeks. AllianceforSustainableBuildingProducts(ASBP) 2022AwardsFinalistInnovationCategory. ChosenbyGrandDesignsashostvenuetothe nextseriesofGrandDesigns:TheStreet.

Decarbonising buildings “most important issue”

– Climate Change Committee

Decarbonising buildings is “probably the most important issue” in the UK’s efforts to reduce greenhouse gas emissions, according to the UK’s independent authority on climate change.

Delivering the first keynote speech at BE-ST Fest in Glasgow, Climate Change Committee (CCC) CEO Chris Stark said: “The built environment – buildings, what we do with those buildings – is probably the most important issue in addressing our emissions and in how we tackle climate change.”

Set up under the UK Climate Change Act to advise the governments of the UK on what they should be doing about climate chance and the targets they should be setting, the CCC’s view is that energy efficiency is the “golden thread” to decarbonising buildings.

“We’ve got this challenge of increasing the number of buildings rated EPC A to C, getting to the point by about the mid-2030s when you’ve got roughly 90 per cent of buildings in the UK at least at the C level,” said Stark. “That makes this a huge national mission. If we don’t do that, the problem is too big.”

Stark said the emphasis should be on rolling out energy efficiency measures to “reduce the size of the problem before we focus on the next stage,” and that government policy was on the right track a decade ago. “In the early 2010s – about 2012 – we were installing over two million measures a year, then the policy rug was pulled away by Ed Davey of all people,” he said. “In the modelling we’ve done for net zero, we increase rapidly those installations over the late 2020s, getting to a peak just about 2030 when we’re back to 2.5 million installations a year, and then it drops off again as we move on to the next challenge of decarbonising heat to those buildings.”

Stark said the emphasis should then shift to the blanket uptake of low carbon heat, rising from about 10 per cent of buildings today, to 100 per cent by 2050. “To do that, heat pumps really are the core of it,” he said, adding that this will require “massive growth in heat pumps to the point we’re installing about a million a year by 2030, up to two million a year [by the mid-2040s] which is broadly what we do with gas boilers today.”

Stark said that the CCC’s modelling has about 20 per cent of properties taking low

carbon heat from district heating networks by the middle of the century.

“It can be done,” Stark told delegates at the 25 October event. “We’re talking about an extra quarter of a million people in your sector (by the mid-2030s) across the UK to deliver that hugely beneficial outcome.”

Meanwhile, the second keynote speaker at BE-ST Fest, Christina Gaiger, president emeritus of the Royal Incorporation of Architects of Scotland (RIAS), warned about the prevalence of ad hoc solutions in retrofit. “There is still current investment right now in systems which are not appropriate,” said Gaiger. “We are still building homes that will need to be retrofitted in the future. That is the reality of where we are and if we don’t own that, we’ve got no possibility of driving that conversation forward.”

Gaiger pointed out the added stresses placed on building in the 21st century. “The built environment is going through the climate emergency as well,” she said. “All of our buildings are having to stand up to more than they’ve ever had to stand up to before. They’re also going through the energy crisis and the cost-of-living crisis because not heating a building changes its performance –it wasn’t designed to be not heated.”

Part of the challenge, Gaiger told the 500-strong audience of industry professionals and policy makers, is getting architects to focus attention on seemingly mundane but crucial concerns. “Building maintenance is so, so important,” she said. “Building maintenance isn’t sexy. But […] if I could encourage anyone to do one thing it would be to look

after their building and invest in maintenance, because maintenance is green.”

BE-ST Fest, an industry summit focused on zero carbon construction and organised by Built Environment – Smarter Transformation (BE-ST), is the culmination of a month-long festival of the sustainable built environment, showcasing best practice and highlighting emerging opportunities.

Hosted at BE-ST’s Innovation Campus near Hamilton, attendees also heard from a broad range of speakers including Passive House Plus editor Jeff Colley. The event was expertly hosted by architect and ACAN founder Sara Edmonds.

BE-ST CEO Stephen Good said: “Real climate change is happening now – earlier this year we saw UK temperatures exceed 40C for the first time. There has been a lot of talk about how to make change, but we need to take that one step further and start putting plans into action to protect our planet for future generations.

“Our role as an innovation centre is to provide the connections, infrastructure and culture needed to solve the sector’s most pressing challenges, and BE-ST Fest is all about bringing together experts and leading voices that can support businesses to break the status quo,” said Good. “We cannot afford to wait.”

Several of the speakers at BE-ST Fest were interviewed by the hosts of the Zero Ambitions Podcast. Visit www.be-st.build/ be-st-fest/ to listen back, and view videos from the event. •

14 | passivehouseplus.co.uk | issue 43 NEWS PASSIVE HOUSE+ NEWS

(above) Climate Change Committee

CEO Chris Stark speaking at BE-ST Fest.

AECB launches two levels of retrofit standards

The Association for Environment Conscious Building (AECB) has introduced a new retrofit standard catering for hard-to-treat homes and cases where homeowners want to take urgent action on climate change but are not currently able to commit to a deep retrofit.

In a move designed to broaden the application of retrofit standards and acknowledge increasingly compelling environmental arguments for the use of heat pumps for space heating as the electricity grid decarbonises, the AECB has introduced the tiered Level 1 and Level 2 Retrofit Standards. In brief, Level 1 is designed to support a rapid transition to low carbon heating and requires reasonably light touch improvements to insulation and airtightness levels and the installation of mechanical ventilation, with heat pumps designed to run at low flow temperatures. Meanwhile Level 2 is effectively a rebrand of the AECB’s pre-existing retrofit standard and requires more significant fabric improvements.

AECB CEO Andy Simmonds said: “We’ve challenged ourselves on the deep retrofit agenda. Deep retrofit is a very meaningful, useful thing to be doing, but it’s not the only thing we should be doing. We clearly need to be getting off fossil fuels rapidly. Heating by electric heat pumps offers an easy and potentially cheap route when combined with relatively light fabric retrofit, so it’s not an intrusive approach.”

Simmonds added that the tiered approach would require Level 1 retrofits to be designed with a long-term plan and the potential for future upgrades in mind. “One of the things we’ve been worried about in the past is people doing shallow retrofits which lock out future improvements,” he said. “So, the standard we’ve developed is designed to not block that second deeper retrofit. We’ve been looking at what happens if you have two waves of retrofit - a Level 1 [becoming] a Level 2 over time. Level 1 is either a step towards a deeper retrofit or those buildings may well be sitting there operating at that level for 10 or 20 years.”

Simmonds said the Level 1 standard recognises that switching from fossil fuel heating to heating by heat pumps is “the single easiest and cheapest measure to reduce both operational and embodied carbon whilst keeping homes warm. As such for many buildings it may not require the deeper fabric retrofit measures needed to achieve

the AECB Level 2 Retrofit Standard – but it does require good ventilation measures.”

The Level 1 standard has been designed to ensure appropriately designed heat pump installations without worsening heating bills – short term issues with energy prices notwithstanding. However, it is assumed that many properties will later be taken to Level 2 to further reduce operational carbon and energy bills, and to again improve on building occupants’ health and comfort.

Simmonds said that for Level 1 & 2 retrofits there should be a clear focus on minimising upfront carbon emissions from materials used in the retrofit.

The Level 1 standard is predicated on running heat pumps at low flow temperatures via existing radiators and additional radiators or underfloor heating, as required, in order to have a sufficiently large heating emitter to enable the heat pump to run at reasonable efficiencies. The Level 1 standard also requires pragmatic building fabric improvements, including a relatively modest airtightness target of 5 m 3/hr/m2 at 50 Pa, and ensuring at least reasonable insulation and glazing standards where possible, along with either a heat recovery ventilation or mechanical extract ventilation system. Meanwhile the Level 2 standard is effectively a rebrand of the AECB’s pre-existing retrofit standard, which adds a space heating demand target of 50 kWh/m2/yr, and tightens the airtightness target to 2 m3/ hr/m2 at 50 Pa.

The retrofit standards follow the same approach as the association’s badge for new build, the AECB Building Standard, in that they rely on the software used to design buildings to the Passive House Institute’s suite of new build and retrofit standards, the Passive House Planning Package (PHPP). As per the AECB Building Standard, the AECB Level 1 and Level 2 Retrofit Standards set less onerous targets than the equivalent passive house standards, and while the passive house standard requires independent certification, the AECB standards rely instead on self-certification, backed up by random auditing from AECB experts.

Instead of the situation where building owners seeking to retrofit find that the Enerphit standard may be beyond their reach and are left without guidance and standards to pitch for, the new retrofit standards could be conceived of as part of a spectrum with Enerphit, meaning that AECB

standards can be achieved where Enerphit isn’t practical, or that building owners and industry professionals can migrate from AECB standards to Enerphit over time, projects permitting.

Sally Godber, director of leading passive house certifier and trainer Warm welcomed the introduction of the new standards, and said they’d be particularly useful for people keen to take immediate action on climate.

“For the private residential market, for people who don’t have a massive budget to put into a retrofit, this is the guidance they need,” she said. “This is something which is achievable in a relatively shortterm time frame. For individuals who are freaked out, you can give them something really meaningful in terms of a long-term plan and some actions they can take now. Those kinds of conversations you have with friends and family, this is what I’ll be steering them towards.”

Godber praised the new standards’ tiered approach, and the requirement with Level 1 retrofits to plan for the possibility of further, deeper interventions. “It’s absolutely crucial that any retrofit standard has the end in mind and doesn’t lock in problems. They’ve got that which I think is really great.” Godber has found less considered approaches to retrofit all too common. “We’ve reviewed so many retrofit projects where problems have been locked in. They haven’t got the energy savings or comfort they wanted, and they have to undo the retrofit measures that were already done.”

Godber said that any retrofit standard must have the end goal in mind. “How you deal with the likes of eaves details – the details that can only be done once,” she said. “I hope that will inform choices, and that retrofit plans will be used to avoid lock in.”

In something of a policy vacuum on meaningful deep retrofit planning, Godber said the AECB’s standards offered hope.

“There isn’t the leadership in the UK to push the fabric first and heat pump agenda. This standard allows for that critical mass for homeowners to do something rather than waiting for policy change,” she said.

“I’m inspired by the AECB thinking of the question of what is practically achievable – what’s realistic. It makes it achievable to make inroads into our existing building stock in a meaningful way.”

Visit www.aecb.net/aecb-retrofit-standard for more information. •

ph+ | news | 15 PASSIVE HOUSE+ NEWS

Ashden Awards winners showcase climate solutions

Ashden CEO Harriet Lamb said: “In a time of skyrocketing energy bills and political instability we can’t wait for government to make all the necessary changes. These sector leaders are magnificent examples of tenacity and innovation in action, driving forward with scalable solutions to some of UK society’s most pressing issues.

farmers in regenerative agriculture, builders in retrofitting skills, and giving EV batteries that would otherwise go to landfill a second life, are all initiatives that are necessary for the decarbonisation of the UK,” said Lamb.

Organisations tackling the UK cost of living crisis and providing a new generation with the skills for green jobs have been recognised in this year’s international Ashden Awards.

The three UK winners, which were among eight global winners, were announced at a ceremony at the Royal Geographical Society in London, hosted by broadcast meteorologist Laura Tobin.

Musician, producer, visual artist and climate action advocate Brian Eno also took part in an on-stage conversation with Ashden’s CEO Harriet Lamb, to discuss the climate crisis and the importance of extending the learning from the trailblazing climate innovators celebrated at the awards.

The diverse group of Ashden Award winners from the UK includes retrofit training provider B4Box, who won the Ashden Award for Low Carbon Skills, supported by Garfield Weston Foundation. B4Box train disadvantaged people in North England to retrofit homes and reduce energy use, emissions, and heating costs in a part of Manchester severely affected by fuel poverty.

Stockport-based Vectar Studios won the Ashden Award for Greening All Work, supported by LinkedIn. Vectar make film and TV sets from engineered cardboard with comparable strength to MDF but 90 per cent lower carbon footprint, slashing emissions and cutting waste. The sets, which are a sustainable alternative to timber-built sets, have been used by broadcasters around the world and are being trialled by ITV’s Coronation Street.

Scottish company Renewable Parts Ltd won the Ashden Award for Energy Innovation, supported by Impax Asset Management. The Argyll-based company are the first business in the global wind turbine industry to refurbish components so they can be used again. Their circular model is helping decarbonise the supply chain and has stopped more than 100 tonnes of waste going to scrap.

The winners were chosen from over 200 applicants by judges, including housing experts, energy sector specialists and award sponsors.

“Across a range of industries, they show that the transition to a low carbon future is exciting and can be positively impactful in so many ways – transforming the building and wind industries and even film and TV – they are showing that ingenuity is the key to decarbonisation in the UK. This move to low carbon jobs also presents huge opportunitiesthe green transition is not about giving things up, it’s about creating jobs, giving people new skills, and creating a more positive future.

“There is a desperate need for the UK government to put in place the policy infrastructure, and desperately needed funding, to supercharge these exemplars showing how we can meet climate targets and bring a whole host of benefits to so many.”

Runners up in the UK included: FarmEd, Oxfordshire, who are helping shape the future of the UK’s agricultural sector by raising awareness of regenerative farming that enriches the soil whilst removing CO2 from the atmosphere; Greater Manchester’s Low Carbon Academy, who are providing local people with the green skills and a range of qualifications needed to retrofit homes and carry out other energy efficiency measures; and in the north and east of England, Connected Energy are the only organisation in the UK to repurpose second-life electric vehicle batteries for use in commercial scale energy storage projects.

“The runners up in the UK also showed huge potential for replication and scalability country-wide and we want to celebrate them too for their incredible work. Training

Ashden Award winners in the global South, including four from Africa and one from Indonesia plus runners up from India and Peru were also celebrated at the London ceremony.

Two Kenya companies won international awards. Kakuma Ventures won the Ashden Award for Energising Refugee Livelihoods, for creating clean energy, internet connections and new jobs for refugee camp residents. SokoFresh won the Ashden Award for Energising Agriculture, for its sustainable cold storage for smallholders, matched with help getting products to market.

There were joint winners of the Ashden Award for Energy Access Skills: ground-breaking Togolese training centre Energy Generation for empowering entrepreneurs to create solutions for Africans by Africans, sparking opportunities for women; and Zimbabwe’s Zonful Energy, who provide solar training for rural young people, through collaboration with colleges and NGOs, alongside connections to jobs.

The Ashden Award for Natural Climate Solutions was won by Indonesia’s Alam Sehat Lestari (ASRI), who work with Indigenous communities, replanting trees in deforested areas and promoting sustainable forms of income to reverse illegal logging.

Since 2001, over 240 innovators in the UK and global South have won an Ashden Award. Ashden uses its network to amplify their voices and raise awareness of their work. To maximise impact, the climate solutions charity also makes connections with funders, investors, policymakers and others, providing a global platform to showcase their initiatives. •

16 | passivehouseplus.co.uk | issue 43 NEWS PASSIVE HOUSE+

(above) B4Box multi-skilled operative Orianne Landers completing a double-glazing window upgrade on a retrofitted property in Stockport, Greater Manchester.

Photo: Andy Aitchison/Ashden

(above) Keynote speaker, musician and climate action advocate Brian Eno spoke about society being “in a golden age of intellectual activity… we’ve seen the destructive phase, but now we’re in the biggest movement in human historythe climate movement. People are re-building everything.”

AECB Conference focuses on practical decarbonisation

The first in-person event of the Association for Environment Conscious Building (AECB) since Covid, the 2022 AECB Conference, focussed on practical solutions to decarbonising buildings.

The event on 30 September offered delegates the chance to get hands-on experience of carefully considered assemblies with the potential to deliver low energy, healthy buildings at scale while minimising the use of precious resources and impact on the environment.

Under the conference theme “Building for a Future” – a title which referenced the pioneering green building magazine set up by AECB founders Keith and Sally Hall in 1989 – the event kept conference-style presentations to a minimum, with plenary discussions by AECB CEO Andy Simmonds and Passive House Plus editor Jeff Colley followed by hands-on tours of carefully considered construction and retrofit assemblies.

The event was held at the brand new Centre for Advanced Timber Technology at the New Model Institute for Technology and Engineering (NMITE) in Hereford, a mass timber building which will serve as new hub for sustainable building education and upskilling ranging from third level courses to CPD events.

In his plenary speech, Simmonds described the evolution of the AECB’s standards, including the AECB Building Standard for new build, the AECB Level 1 and Level 2 Retrofit Standards (as described on page 15 of this issue), and three standards which are not certifiable, but rather serve as guidance: the AECB Water Standard, the AECB Lifetime Carbon Standard and the AECB Daylight Standard. “We’re going to be developing training to help people deploy all of these standards,” said Simmonds.

Simmonds also contextualised the construction assemblies by outlining a set of principles reflecting the thinking behind the AECB’s approach, including – avoiding building if possible; building near sustainable transport; retrofitting first; avoiding making buildings too big; making the building adaptable; making components last as long as possible; specifying the most environmentally benign

components possible; making the building as high performance as possible; and designing with future climate in mind.

Jeff Colley’s plenary speech focused on demystifying embodied carbon calculation, aiming to equip delegates with the key terminology, the key reference documents, and to describe the elements and stages of building life cycle assessment in simple terms.

A carefully curated list of sponsors was chosen for the event, focusing on companies whose products and solutions embodied the principles outlined by the AECB, as reflected in the built assemblies.

A deep retrofit assembly designed by Andy Simmonds was based on a real Simmonds Mills Enerphit project featuring an innovative cellulose-filled I-beam system to build an extension and externally insulate the existing building. This assembly was sponsored by key partners on the actual Enerphit project. Platinum sponsor Partel provided an innovative external airtight system for the project, and described the system to delegates, and the hygrothermal simulation and post occupancy moisture monitoring they undertook. Gold sponsor Green Building Store provided a triple glazed window for the assembly and described the weather tightness, airtightness, and thermal bridging detailing of its installation.

A second AECB assembly focused on a mock-up of a 1930s cavity wall house with suspended timber floors. Platinum sponsor Ecological Building Systems used this assembly to demonstrate a new solution to naturally insulate and airtighten the suspended timber floors.

A proprietary assembly focusing on the role of properly detailed wood fibre insulation to enable internal wall insulation to traditional buildings without posing moisture risks was provided by platinum sponsor Steico, while gold sponsor Ecococon built an assembly of their pioneering modular straw bale build system. Delegates also had the opportunity to tour the Department of Education’s GenZero mass timber classroom building.

As part of the pre-conference pack delegates had access to a recording of a pre-conference webinar with Q&A by Professor

Kevin Albertson, of MMU Business School titled “The Great Squeeze: The current economic paradigm shift and its implications for greening our design and construction business models.”

The AECB assemblies were built with CLT offcuts standing in for existing masonry, led by expert green builder Tim Hulse of Ecovert Solutions. “Having built the Chestnuts deep retrofit, Tim Hulse was the obvious person to help create the construction assemblies at the AECB conference,” said Simmonds. “I asked him to work with two young local carpenters – 27-year old Fraser Williams and 17-year old Raimi Wye – to get this done in a tight window. Very grateful to Tim for volunteering and very impressed with the way Fraser and Raimi rose to the challenge in a very short period of time, to do such a good job.”

Simmonds also singled out NMITE and the event sponsors for praise. “This feels like a new type of event – where even the sponsorship is carefully curated and tied in not just to the ethos of the AECB, but to the themes behind the event – and to a centre for timber-based building,” said Simmonds. It’s very encouraging to find a venue – a new regional hub for sustainable building – that has such a compatible vision, and to find suppliers in the industry willing to sponsor and help realise that vision.

The AECB commissioned videos of the event, including descriptions of the assemblies demonstrating retrofit strategies, as well as Steico and Ecococon’s assemblies, by green building multimedia specialist Ben Adam Smith. To view them visit www.youtube. com/@aecbnet •

(below) Delegates inspecting the sustainable building and retrofit assemblies at the 2022 AECB Conference.

ph+ | news | 17 PASSIVE HOUSE+ NEWS

18 | passivehouseplus.co.uk | issue 43 NEWS PASSIVE HOUSE+

Exeter's leading-edge leisure centre provided inspiration for UK Conference

main contractor on St Sidwell’s Point, was a Gold sponsor of the conference, which enabled public sector attendees to attend for free.

Passivhaus Trust chief executive Jon Bootland said: “Following Exeter’s lead, passive house is gaining traction among local authorities and is being used to deliver comfortable and energy saving schools, social housing, leisure centres, and other buildings that avoid the ‘performance gap’. We were delighted to welcome a large number of public sector delegates to the conference.”

Passivhaus Trust research and policy director Sarah Lewis said: “St Sidwell’s Point is a fantastic beacon to the construction industry, illustrating that passive house can be applied to any building typology and can work for large and complex buildings. We take our hats off to the project team and to Exeter City Council for their vision in delivering the project. With energy bills soaring, passive house buildings, including leisure centres, make total sense.”

This year’s UK Passivhaus Conference was held in Exeter, reflecting Exeter City Council’s record for developing buildings to the passive house standard over the last decade, including the new St Sidwell’s Point leisure centre and Edward’s Court extra care unit, as well as more than two hundred new council homes. St Sidwell’s Point is the UK’s first leisure centre built to the passive house standard and puts Exeter on the world map for passive house. The project was a central focus of the two-day conference, with a masterclass presented by members of the design and construction team as well as tours of the project, and Jessica Grove-Smith, from the Passive House Institute in Germany, speaking about passive

house swimming pool design.

The conference also included largescale keynote case studies including Hounslow Council’s masterplan to build 967 homes to the passive house standard and Exeter University’s ambitious passive student accommodation plans. Addressing the cost-of-living crisis and fluctuating construction material costs, the conference also included a section on ‘how to deliver cost-effective passive house’. Ambitious plans for widescale passive house training of architecture students and others were also announced at the conference.

The conference attracted 200+ in-person delegates and over 250 online delegates in the ‘hybrid’ conference. Kier Construction, the

Thermal bypass paper published

The Passivhaus Trust has published a new technical paper on thermal bypass – the phenomenon where air movement across, within and behind insulation increases heat loss, causes discomfort and enables mould growth.

The paper reviews the literature on thermal bypass, contains over 150 references, and identifies practical actions that can be taken to prevent thermal bypass having a significant impact upon performance. The paper has received peer review by informed practitioners and academics, and was authored by seasoned passive house architect and building physics expert Mark Siddall of LEAP.

Siddall said that understanding and preventing thermal bypass was an important aspect of addressing the performance gap between theoretical and real-world energy performance. “Thermal bypass is largely unregulated and can increase heat loss ten-fold,” he said.

Relevant to new build and retrofit projects, the guide draws upon a sound evidence base which reveals simple practical steps policymakers, developers, certifiers, designers, and constructors can take to create successful high-quality, high-performance, and robust buildings at speed and scale to meet climate targets.

The Passivhaus Trust said people who read the paper will gain new insights, build confidence and discover how to make informed, intelligent decisions that will improve the health, well-being and energy security of building occupants and owners, reduce carbon emissions and fuel poverty, close performance gaps, avoid costly mistakes, and protect the building fabric from moisture damage.

In the paper Siddall identifies different types of thermal bypass including closed loop, open loop wind washing, and open loop air leakage (including infiltration or exfiltration).

Phil Bialyk, Exeter City Council Leader, said: “Exeter has a very proud record of creating passive house buildings – and everything that has happened since we started on this journey has proved that the decision was the right one. We now have a leisure centre, extra care facility and scores of new council houses built to passive house standard, which means we are lowering our carbon emissions and saving energy at a time of rapidly rising fuel costs.”

In addition to Kier Group’s Gold sponsorship, the conference received sponsorship from Silver sponsors Aldas, Ecology Building Society, Iso-quick and Passivhaus Homes, and Bronze sponsors Ecological Building Systems and Max Fordham. •

The Passivhaus Trust state that by contextualising an understanding of thermal bypass, this paper provides a comprehensive and technical demonstration of how passive house reliably closes the performance gap. “If thermal performance gaps are to remain within an acceptable tolerance, then continuous insulation should be encapsulated on all sides by uninterrupted, unbroken air and wind barriers,” the trust said.

The paper makes the case for the application of the passive house standard at scale to provide a robust solution that delivers high performance construction, energy savings, carbon emissions, comfort, and health and well-being that owners, investors, and occupants can rely on both now and in the future.

To read more visit www.passivhaustrust.org.uk/guidance.php to download the paper. •

ph+ | news | 19 PASSIVE HOUSE+ NEWS

(above) Delegates touring St Sidwell’s Point passive house certified leisure centre at the 2022 UK Passivhaus Conference.

Photo: Kier Construction

Will

Recently, I attended a ‘Delivery Summit’ about the National Retrofit Strategy published by the UK’s Construction Leadership Council (CLC). Participation was by invitation only. The event was held at the Department for Business, Energy and Industrial Strategy (BEIS) conference centre and co-hosted by the CLC and the Green Construction Board (GCB). The invitation raised my hopes that we might finally get a domestic retrofit programme for the UK.

No such luck – no ministers or senior officials from BEIS’s retrofit team attended, the only BEIS staff present were junior officials from the CLC and GCB secretariats. The event was identical to at least four such meetings I have attended in the last ten years. All were held in departmental basement conference rooms, involving group discussions with ideas written on post-it notes and stuck on wall charts. Approximately thirty people were present, some of whom were also at the previous events. Words like ‘the usual suspects’ come to mind, but some who attended the first event have probably retired by now. The main theme of the discussion was promotion of a national ‘retrofit hub’, an enduring call that government has never responded to, from people who seem to have few other ideas. At the first such event I suggested that what we need to drive retrofit is some inspirational leadership (perhaps a retrofit Tzar), but there has been no response to that either.

However, much has happened in the last ten years. The Green Deal, the Green Deal Home Improvement Scheme and the ill-conceived Green Homes Voucher Scheme have come and gone. The Energy Company Obligation (ECO) has replaced CERT and CESP, and the Local Authority Delivery Scheme (LADS) and Social Housing Decarbonisation Fund (SHDF) have begun to make some impact on public sector housing. We’ve had the Each Home Counts review and introduced TrustMark and the PAS 2035 retrofit standard to raise domestic retrofit quality and protect householders against the consequences of bad retrofit.

Despite all this activity, and the promises made at COP 26 last November, the need to retrofit twenty-seven million homes, 67 per cent of which are owner-occupied, seems to have captured not one iota of the current Government’s attention. Have they not noticed that twenty-seven million retrofits over twenty-eight

years means delivering five every working minute? Or that most householders are not even aware of the need to retrofit? Or that unless we reduce the demand for heat by 60 per cent (through insulation) there is no chance of supplying enough zero-carbon electricity to power all the heat pumps, even if we quadruple offshore wind capacity (or the capacity of other zero-carbon power sources) as is suggested by the government’s own Heat & Buildings Strategy? The silence from ministers is deafening. The reason for the silence seems to be that in the UK Conservative Party, after the Daily Mail’s idiotic ‘conservatory tax’ claims, and the failures of The Green Deal and the Green Homes Voucher Scheme, domestic retrofit is seen as politically toxic. Ministers won’t go there: they don’t have the courage to tell householders the truth about the challenge we face and what it will cost, and they certainly won’t be telling us to improve our homes. Let the market deal with it. Heat pumps will save us. Meanwhile the country swelters in heatwaves, loses crops in droughts, drowns in floods, burns up in wildfires, and continues to build new homes that will need to be retrofitted before 2050. Those of you who know your Douglas Adams might agree that our current politicians deserve the same fate as the Marketing Department of the Sirius Cybernetics Corporation*.

There are some signs of change. After decades of irresponsible complacency about climate change the building professions have woken up to the need for action. The Low Energy Transformation Initiative (LETI) and the Architects’ Climate Action Network (ACAN) are impressive campaigns and have produced excellent technical guides. But LETI and ACAN rely on unpaid work by committed young professionals, with little support from their employers, clients, professional bodies or industry leaders. They provide inspiration, but their efforts are too little, too late. Even the CLC and the GCB don’t seem to provide much leadership, and other industry bodies produce reports in which almost every paragraph begins with the words ‘The government must…’ (Really? Have they not noticed that nobody is listening?)

After a thirty-five-year career promoting energy efficiency in buildings and housing, through consultancy, training, guides and standards, and five years of working only on projects that might make a difference, I am beginning to wonder why I bothered. Kim

Stanley Robinson’s novel The Ministry for the Future suggests that climate action will be driven by climate catastrophes and green terrorism: ‘Crash Day’, when two hundred airliners are brought down to stop people flying – a chilling idea. In that context civil disobedience looks tame, so I’m beginning to think that the Insulate Britain and Don’t Pay movements deserve more support. Although, as a colleague of mine remarked, if only the people who glue themselves to motorways would glue some insulation to walls instead.

Post script

After I submitted my copy for this column, the UK Government announced a consultation about 'ECO Plus' – a £1 billion funding programme aimed at delivering simple, 'low-risk' improvements (e.g. loft insulation, heating controls) to middle-income households, with the proposal to adopt the abysmal TrustMark Licence Plus process rather than PAS 2035. We should probably be grateful for small mercies, but loft insulation and heating controls were being promoted by Government twenty-five years ago, and although not all homes have them, most do. £1 billion also sounds like a lot of money, but it is approximately 1/500th of the money we need to spend, collectively, to retrofit the UK housing stock in support of the net zero carbon target. And finally, are there any low risk retrofit measures? ECO Plus abandons all the consumer protection features of PAS 2035, painfully and expensively learned via Retrofit for the Future, CoRE, RE:NEW and the Each Home Counts review, leaving homes and their occupants unprotected against retrofit risks and cowboy installers. Words like 'too little, too late' and 'it will all end in tears' still come to mind. n

* In The Hitch-hiker’s Guide to the Galaxy, the Marketing Department of the Sirius Cybernetics Corporation were the first against the wall when the revolution came.

DR PETER RICKABY COLUMN 20 | passivehouseplus.co.uk | issue 43

Dr Peter Rickaby is a retrofit consultant with Savills social housing team, and chairs the BSI Retrofit Standards Task Group. The views expressed in this article are his own, and not necessarily those of Savills or of BSI.

With a decade of government inaction on retrofit, Peter Rickaby wonders, is it time for more radical action?

we ever insulate Britain?

indoor air for nearly 40 years. Easy

Does nuclear have a role to play in decarbonising energy?

We stand in the transition between two energy paradigms; last centuries obsession with oil and gas consumption, and this centuries transition to renewable energy. However, there is an energy gap between the supply of renewable energy and the decommissioning of fossil fuel plants. International exogenous factors, like the war in Ukraine, have created unexpected shortages in energy supply.

The UK and Ireland’s main import is natural gas for electricity supply (50 per cent and 57 per cent respectively) and gas is only up to 55 per cent efficient at producing electricity, with coal, peat or biomass having a similar low efficiency with high transformation losses. Electricity generated from wind and hydro is 100 per cent efficient. But the trouble is we don’t have enough renewable energy production and we don’t have a backstop to buffer the grid as traditional power plants come to the end of life. So, what will fill the gap?

Ireland and the UK achieved 36-38 per cent of total domestic demand from renewables in 2021. In response to COP 26, Ireland and the UK have targeted 80 per cent and 100 per cent renewable delivery of electricity demand by 2030 and 2035, respectively. However, the mass scaling of renewables means that we are taking fossil fuel-based energy stations offline, or not extending their lifespans. Therefore, we have a massive gap to bridge up to 2035.

James Lovelock, the man who postulated the GAIA theory of a self-regulating Earth, argued that nuclear power was a green solution since it was relatively compact, had little or no atmospheric emissions, produces little waste, and is confined and self-degradable; thus, it avoids increasing the greenhouse effect. So why do we have a hang up with using nuclear energy?

Public opinion might have been influenced by a calamity of large nuclear accidents globally which appeared to be covered up by operators and national governments. The Windscale fire in northwest England in 1957 resulted in a 200-mile radius radioactivity contamination which did not respect any national boundaries. The Three Mile Island nuclear accident in 1979 was the worst in US history, resulting in a de-prioritisation of nuclear power generation

in the US. The Sellafield reprocessing plant (formerly Windscale) accidentally discharged 20 tons of uranium and 160 kg of plutonium into the Irish Sea in 2005. But perhaps the worst nuclear accident experienced in Europe was Chernobyl in 1986. The trans-boundary nature of fallout was global in scale and raised huge environmental concerns of the potential catastrophic consequences of a nuclear accident. It is worth remembering that there is a 1,000 square mile exclusion zone as a result of the Chernobyl accident. Consider a similar exclusion zone from a similar accident in Sellafield or nearby at Heysham 1. The UK and Ireland would largely be an exclusion zone for habitation.

duction capacity. France has also closed nearly all its gas and coals plants leaving it dependant on Germany for 50 per cent of its imported energy to cover the renewable energy gap. In turn Germany is dependent on Russia.

The war in Ukraine has exposed a worldwide energy deficit. Take out one main provider of natural gas and every country and its people end up paying on the double. Since February 2022, the price of domestic oil and electricity has nearly doubled, at 89 per cent and 80 per cent respectively.

So, were we too hasty to reject nuclear as a clean fuel to support a renewable transition? Or is the technology beset with too many socio economic/environmental risks and too ex-

Since February 2022, the price of domestic oil and electricity has nearly doubled, at 89 per cent and 80 per cent respectively

Is the risk worth it? After the Fukushima Daiichi accident in Japan in 2011, a number of countries made policy decisions to phase out nuclear power because of such risk factors. As a result, in 2019, nuclear power provided only 7.5 per cent of Japan’s electricity (down from 33 per cent in the 1960s). Germany, which planned to shut down all nuclear power by 2022, has retained two as a response to the energy crisis in 2022. In total 65 reactors have been shut down worldwide since 2011. Meanwhile in France 69 per cent of the domestic electrical energy demand is met by nuclear power, compared to 21 per cent in the UK and 0 per cent in Ireland. However, both France and the UK’s nuclear infrastructure is aging badly. Decommissioning costs for the UK’s degrading nuclear facilities is predicted to be €260bn to safely secure the 700,000 cubic metres of radioactive waste, while France’s EDF estimates that their decommissioning costs will only be €54bn. The average age of France’s 56 nuclear power plants is 37 years meaning a lot are nearing or in extended lifespan. Interestingly, climate change and higher temperatures in France are making it harder to cool nuclear power plants, impacting efficiency and pro-

pensive to decommission to be a valid option? Given the length of time it takes to build a nuclear reactor, or even a small modular reactor, and the shortfall in energy production from existing reactors as they get older, it is unlikely that nuclear energy is the panacea to bridge the renewable energy gap. n

A fully referenced version of this article is online at www.passivehouseplus.co.uk

One zero carbon energy source has historically been vehemently opposed by environmentalists. But can nuclear power overcome the high-profile failures of its past, asks Dr. Marc O Riain , or has the technology missed the boat?

Dr Marc Ó Riain is a lecturer in the Department of Architecture at Munster Technological University (MTU). He has a PhD in zero energy retrofit and has delivered both residential and commercial NZEB retrofits In Ireland. He is a director of RUA Architects and has a passion for the environment both built and natural.

22 | passivehouseplus.co.uk | issue 43 DR MARC Ó RIAIN COLUMN

UNPARALLELED CHOICE OF PASSIVE CERTIFIED PRODUCTS – OUTWARD OPENING, INWARD OPENING, UPVC, ALUMINIUM, ALUCLAD GROUND BREAKING U-VALUES FROM AS LOW AS 0.47W/M2K T. 01789 473 987 E. info@munsterjoinery.co.uk www.munsterjoinery.co.uk WINDOWS & DOORS

Mainstreaming retrofit – a massive missed opportunity

The scale of the retrofit challenge facing the UK and Ireland will require an army of tradespeople to upgrade homes – leading many to the conclusion that a new retrofit industry needs to be built from scratch. But is a more realistic answer staring us in the face – a thriving existing industry of trusted local tradespeople, asks Dr Catrin Maby OBE.

In delivering home energy advice and retrofit programmes, there is an important practical distinction between types of measures. On the one hand, there are those that you can do as one-offs, because they can be dropped into or onto the existing structure and services relatively easily – such as putting insulation in the loft, fitting draught strips to doors and windows, installing cavity fill insulation, upgrading a boiler and heating controls, and installing solar panels. On the other hand, there are measures which are much more intrusive, both to the occupants and to the

room, the floor above the side ‘entry’, and the suspended timber floor to the front living room. In those days, we were also replacing gas fires with gas central heating. So, the work involved carpentry, plastering, decorating, plumbing and gas work. Later on, I coordinated a retrofit programme for a group of local authorities in Gloucestershire, and the mix of skills needed extended further to include solid fuel and biomass heating, solar thermal, PV and heat pumps – and working with stone as well as brick.

I started to doubt the value of energy retro-

These ‘general builders’ play a key role in terms of what work is decided upon in practice, they are potentially even more influential when recommended by others, and so start from a position of trust. They could be the frontline in promoting and delivering home energy retrofit – so we need to make sure that they have the necessary up-to-date knowledge and skills to do so. But it turns out that there is no clear definition of this as a trade in the UK – and hence no specific qualification or educational pathway. Qualifications and college courses are specific to individual trades, such as carpentry, joinery, bricklaying, electrical services and so on. The builders I spoke to had developed a wide range of skills, but had to source their learning in multiple ways, building up from being a carpenter perhaps, or bringing transferable skills from engineering or project management.

building: solid wall insulation, replacement windows, and underfloor insulation.

Something else stands out about this second set of measures: there are often details which require a wider set of building skills than those of the installer trained for a single measure. This is even more obvious when you try to tackle sloping ceilings and the range of traditional window types to be found in UK and Irish housing. You also need to see the totality of the building to seek out the potential cold spots, take care to ensure adequate ventilation, and consider moisture movement, concerns frequently highlighted by those involved in retrofitting older buildings. This is further complicated by the fact that older homes tend to have had bits added to them over time, so that each one is different.

Back in the nineties in Birmingham, I worked with the council’s urban renewal department to update their approach to energy efficiency in renewal area programmes. By exploring all the nooks and crannies of some of the big old town houses, I was able to point out several features that could easily be insulated, such as the attics on each side of a loft

fit as a ‘green’ industry, separate from everyday building work on existing homes. Surely we were missing major opportunities for retrofit when people were getting other work done? I decided to research this as a PhD, as I wanted to understand home energy retrofit from the perspective of mainstream building tradespeople. Earlier research by Gavin Killip indicated that the UK home ‘repair, maintenance and improvement’ (RMI) market was a thriving, multi-billion pound, demand-led industry.

Investigating the characteristics of the contemporary RMI industry, it seems that it is dominated by sole traders and microbusinesses, tending to work in a limited geographical area, and getting much of their work through word of mouth and community networks. What my interviewees told me was that they collaborated through informal networks to bring together the different trades needed for each project, so avoiding the risk and hassle of having permanent employees. But this requires someone to coordinate each job, to bring people together and liaise with the customer – and that someone is thought of just as a ‘builder’, offering general building services.

Anecdotally, builders are currently all flat out with work, in spite of the disastrous economic climate. The demand for RMI work is huge – and we are doubtless still missing opportunities every day to maximise the energy retrofit that could be included in this work. We should be creating a tailored qualification for the role of an energy retrofit-skilled home RMI builder – and celebrating it as a key job for a young person to train for. One which I suspect will keep them busy for the next 30 years. n

A fully referenced version of this article is online at www.passivehouseplus.co.uk

DR CATRIN MABY COLUMN 24 | passivehouseplus.co.uk | issue 43

Dr Catrin Maby OBE has worked on home energy advice and retrofit since setting up an energy advice service for London tenants in the 80s, going on to help local authorities to develop energy efficiency aspects of housing renewal programmes, and affordable warmth and climate change strategies. From 1999 to 2015 she led Severn Wye Energy Agency, and she has since worked on research and policy in the UK and EU, including PhD research on the role of mainstream building trades in retrofit. She is a Monmouthshire County Councillor, and cabinet member for climate change and environment.

General builders could be the frontline in promoting and delivering retrofit – so we need to make sure they have the knowledge and skills to do so

A Complete System Approach

Designed by Passivhaus experts, the PH15 system includes all the technical elements, training and key components to enable you to build in a cost-optimized and low-carbon way.

PH15 marries modern methods of construction with existing UK labour skills to create a flexible and scalable route to net zero housing. Adaptable to diverse house types and external finishes. We work with you from an early stage to ensure you meet your net zero goals.

Discover more at phhomes.co.uk

Littlepits, Buckinghamshire Certified Passivhaus Plus 0.1 ACH at 50 Pa BOPAS Buildoffsite Property Assurance Scheme

Reimagining timber construction for a net zero future

PHIT THE BILL

ALL ELECTRIC RETROFIT MAY TURN A PROFIT IN ENERGY CRISIS

A passive house, by its nature, requires a much smaller amount of energy than a typical home, and when its heating demand is met by electricity, and you cover it in solar PV panels, you can start to see the potential for a whole new generation of passive homes that are semi-independent of the electricity grid. This is the case for Carrstone House in Bedfordshire, which generates so much solar energy it had to be registered as a power station.

By David W Smith

By David W Smith

IN BRIEF

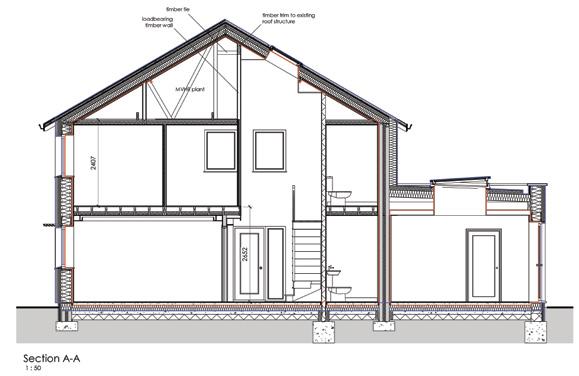

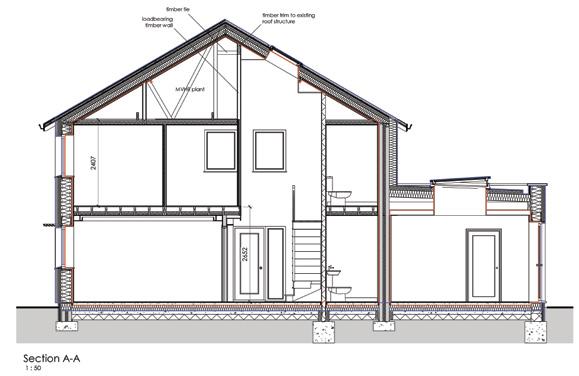

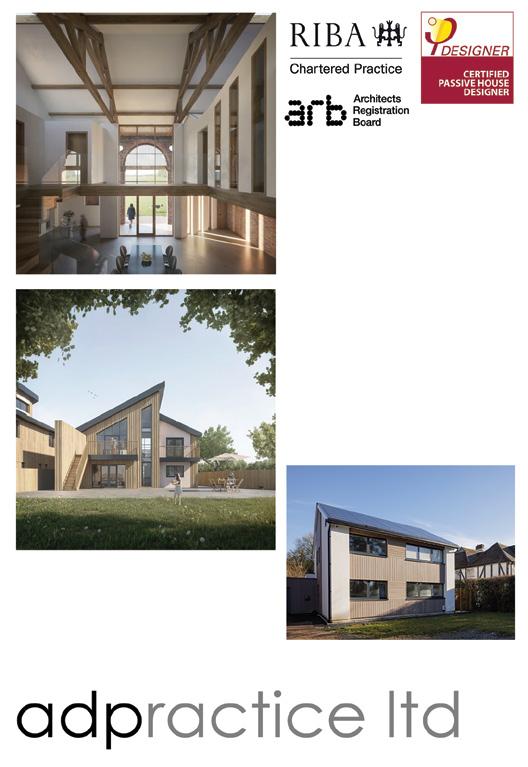

Building: : Deep retrofit & extension of 151 m2 detached 1960s house

Method: External wood fibre insulation, timber frame, air-to-water heat pump

Location: Harpenden, Hertfordshire

Standard: Enerphit Plus (certified)

Heating cost: £23/month*

* Based on monitored energy use for space heating – adjusted to current UK energy price cap and ignoring PV reduction. See ‘In detail’ panel for more information.

per month

HARPENDEN CASE STUDY

£23