INSULATION | AIRTIGHTNESS | BUILDING SCIENCE | VENTILATION | GREEN MATERIALS Issue 44 £5.95 UK EDITION SUSTAINABLE BUILDING Military precision West Country barn conversion brings low carbon comfort for army family Down under wonder Australian passive house built around a tree Cold comfort Are energy ratings predicated on cold homes?

1960s Lambeth modernist gem gets Enerphit treatment

MODERN LOVE

sustainable

The Ecodan multi-award-winning range of air source heat pumps from Mitsubishi Electric are ideal for new or retrofit passive house projects. Ecodan is the sustainable, low-carbon alternative to traditional fossil fuel central heating systems with market-leading, ultra-quiet sound levels, smart controls and remote monitoring via our MELCloud App. Enjoy comfortable heating, proven cost savings and reduced CO 2 emissions. The renewable heating alternative ecodan.me.uk/ph44 Review our CIBSE TM65 EMBODIED CARBON CALCULATIONS DATA SHEETS QUHZ-W40VA CIBSE TM65 Embodied Carbon Mid-level Calculation Including Operational Carbon Benchmark Estimate Type of product Capacity of equipment (kW) Product weight (kg) of the product weight? (Y/N) Service life of the product (years) Type of refrigerant Refrigerant GWP Refrigerant charge (kg) Energy consumption of the factory per unit of product (kWh) Product Complexity Total = 4,374 (kg CO e) QUHZ-W40VA Product Information A2W Heat pump 15 R744 1 1.15 14.08 Category 3: High Organisation: 29th of September 2021 Residential Product Marketing Mitsubishi Electric embodied.carbon@meuk.mee.com Operational carbon data for heating requirements, according to heat pump at medium temperature (55ºC), average climate conditions and equivalent Electrical grid according to Greenbook forecast for residential use. (source: gov.uk, IAG spreadsheet toolkit for valuing changes in greenhouse gas emissions, Gas network according to SAP 10.1 carbon emissions factor (source: BRE Group, SAP-10.1-01-10-2019, Page 171) 5,000 10,000 15,000 20,000 25,000 30,000 35,000 with Refrigerant Leakage (kg CO Operational Carbon Estimate (kg CO Potential carbon savings vs a gas boiler ecodan.co.uk Embodied Carbon Result with 'Mid-level TM65 Calculation' Method: 618 (kg CO e) 3,756 (kg CO e) Operational Carbon Result: ecodan.me.uk/tm65 NEW Industry first DATA

Build a

future

Publishers Temple Media Ltd

PO Box 9688, Blackrock, Co. Dublin, Ireland

t +353 (0)1 210 7513

e info@passivehouseplus.ie www.passivehouseplus.co.uk

Editor Jeff Colley jeff@passivehouseplus.ie

Reporter John Hearne john@passivehouseplus.ie

Reporter Kate de Selincourt kate@passivehouseplus.ie

Reporter John Cradden cradden@passivehouseplus.ie

Production / IT Dudley Colley dudley@passivehouseplus.ie

Accounts Oisin Hart oisin@passivehouseplus.ie

Art Director Lauren Colley lauren@passivehouseplus.ie

editor’s letter

Close your eyes and imagine your least favourite part of your least favourite song. And now imagine the record is scratched, so it’s playing in a hellishly unending loop. You’re welcome. My hope is that I’ve set a sufficiently low bar and that the broken record I’m about to play will seem like sweet relief.

I’ve lost count of the times over the years that I’ve argued in this letter that we must adopt evidence-based approaches if we are to make buildings sustainable. It may seem to suck the romance out of life, but quantification is essential to this, and for that to happen we need metrics. Those metrics must be robust, and they must be understood. Parroting numbers, without understanding and contextualising what they mean, is futile.

found a – hopefully – engaging way to explain what may seem unspeakably dull or obtuse: the thermal comfort assumptions in energy performance calculation methodologies.

Let me try to convey the meaning in this case: You design a house to achieve an A rating, and ensure that it’s built in accordance with all the requirements to hit that seemingly superlative standard. The house is marketed as an A-rated home, and the lucky homebuyers move in, expecting to reap the benefits of a cosy home with low energy use. Then the utility bills arrive, and the trouble begins.

Design

Aoife O’Hara aoife@evekudesign.com | evekudesign.com

Contributors

Lenny Antonelli journalist

Hamish Bresnahan Alexander Symes Architect

Toby Cambray Greengauge Building Energy Consultants

Chris Croly BDP

Simon Jones Air Quality Matters

Marc Ó Riain doctor of architecture

Peter Rickaby energy & sustainability consultant

David W Smith journalist

Jason Walsh journalist

Print

GPS Colour Graphics www.gpscolour.co.uk | +44 (0) 28 9070 2020

Cover

Lambeth Enerphit

Photo: Timothy Soar

It’s challenging attempting to publish meaningful articles about sustainable building – articles that we hope will help inspire and inform our readers to make new and existing buildings fit for this new Anthropocene era, this confluence of climate emergency, biodiversity emergency, housing emergency, geopolitical emergency, bloody omni-emergency. Our task is to take complex subjects – in a range of related areas where continuous research is advancing humanity’s understanding at the leading edge – and make it somehow digestible, explicable so that people can have the confidence to apply these learnings on actual buildings. It’s not just a matter of keeping up with the latest evidence. It’s about explaining it.

If you’re explaining, you’re losing, according to B-movie actor and deregulation poster boy Ronald Reagan. But we must resist the Gipper’s advice, trust that our readers are sufficiently resolved to hear us out, and explain ourselves in the simplest way possible, short of dumbing down.

So how does this manifest itself, in practical terms, and how does it relate to the earlier bleatings about metrics? In this issue, it’s in having the audacity to publish a feature article on an EN standard, and trusting that our readers will stay awake and understand the significance of the issue, and find that we’ve

The energy crisis sparked by Russia’s invasion of Ukraine has helped bring matters to a head, but the problem is simple: the A-rating for the home was built on a model which assumes miserly heating levels – a whole house average of less than 15.6 C for sixteen hours per day for one notional house which complies with Ireland’s nearly zero energy building (NZEB) standard. And the UK assumptions while more generous, were still woefully inadequate.

The problem is that it’s not enough to have metrics. We need realistic targets too, and we need to ensure building users understand what they’re getting. We said we’d give you an A-rated house. We didn’t say it would be a comfortable house.

Worst of all, energy performance is one of the areas where we have the best understanding of the evidence. For over 30 years, the passive house standard has shown a route to essentially solve the energy, comfort and indoor air quality issues – though in this issue you’ll find a Dublin office building showing an intriguing alternative approach – so we have no excuse for not getting this right. True, there are many other areas of sustainability where we still have a way to go in terms of establishing, bedding-in and clearly explaining evidence-based metrics. But time is of the essence: we must play the notes we do know and learn the ones we don’t, before the record stops.

Regards, The editor

Publisher’s circulation statement: Passive House Plus (UK edition) has a print run of 9,000 copies, posted to architects, clients, contractors & engineers. This includes the members of the Passivhaus Trust, the AECB & the Green Register of Construction Professionals, as well as thousands of key specifiers involved in current & forthcoming sustainable building projects.

Disclaimer: The

in Passive House Plus

ph+ | editor’s letter | 3 PASSIVE HOUSE+ EDITOR’S LETTER

opinions expressed

are those of the authors and do not necessarily reflect the views of the publishers.

ISSUE 44

Passive House Plus is an official partner magazine of The Association for Environment Conscious Building, The International Passive House Assocation

The

About

and

Passivhaus Trust.

CONTENTS

BIG PICTURE

This issue features Pepper Tree Passive House, a small secondary dwelling attached to a young family’s home in the Australian Illawarra region.

NEWS

WorldGBC launches green building policy principles for governments, Scotland to mandate passive house for new homes, and experts say TrustMark’s new Licence Plus scheme undermines retrofit standards.

COMMENT

Dr Marc Ó Riain writes about the emergence of the passive house standard; and while poor practice remains stubbornly persistent in parts of the industry, understanding why and how this persists could be a catalyst for change, argues Dr Peter Rickaby.

28

CASE STUDIES

Visionary vernacular

Passive inspired Dumfries home puts users first Can a low energy building be truly sustainable if it doesn’t fully consider its occupants needs? The latest offering from one of Scotland’s leading green designers uses passive house knowhow to signal the way to pragmatic, modest, occupantcentric architecture.

Military precision

West Country barn conversion brings low carbon comfort for army family

Designing a building to the passive house standard for the first time is one thing. But trying to do so when the client is a soldier, the design must accommodate the frame of a barn, and you’re straining to get it built precisely on schedule, during a pandemic, is quite another.

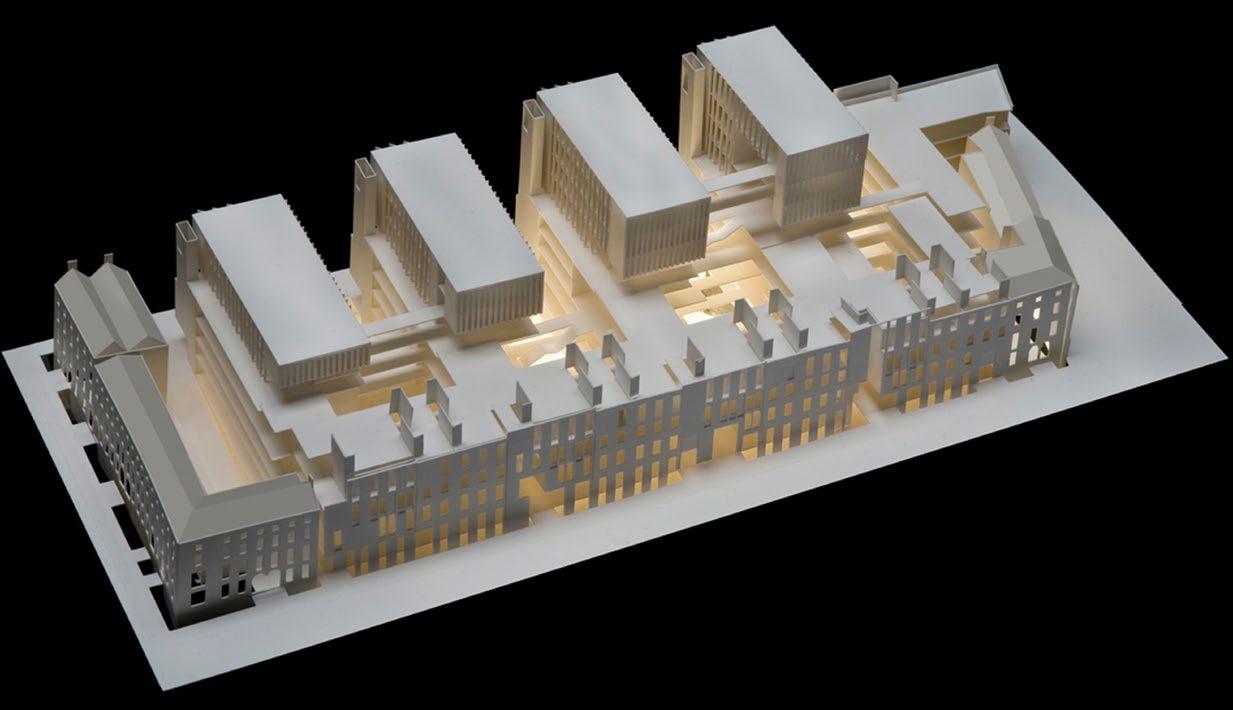

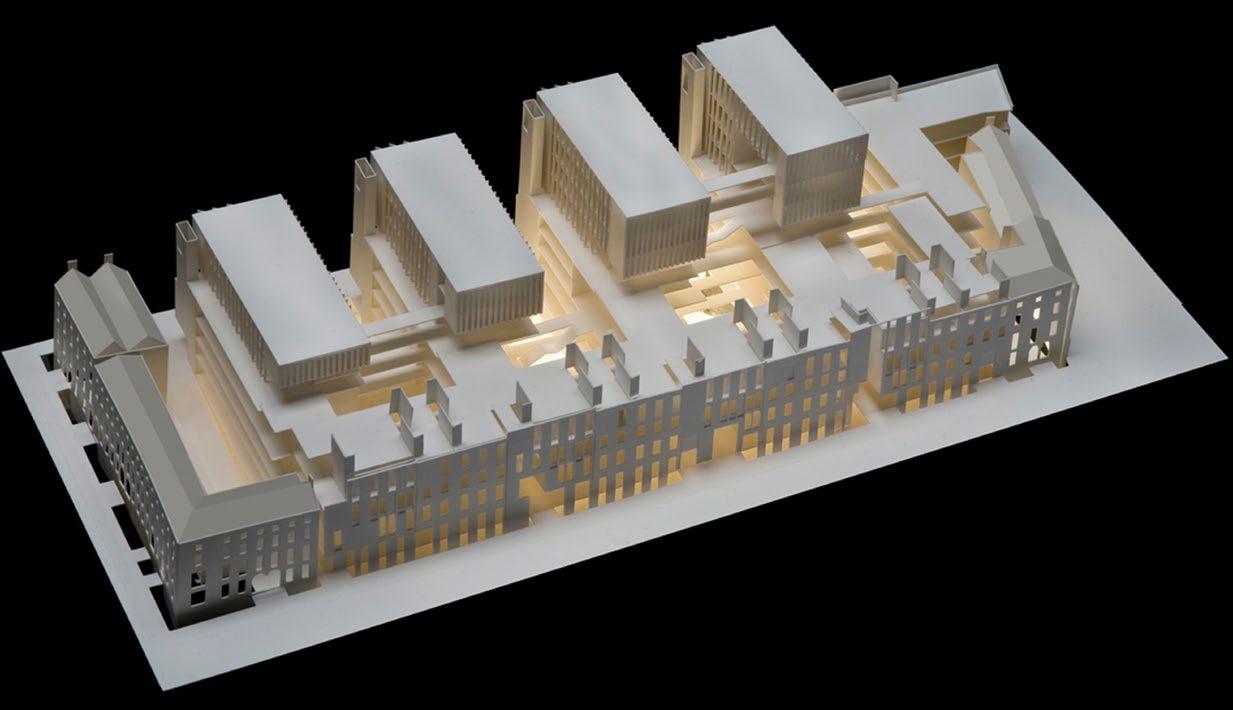

Modern love

1960s modernist gem gets Enerphit treatment

Where does the balance lie between conservation of buildings, energy and nature?

One deep retrofit to a London modernist house may point the way ahead, bringing light, form and avant garde energy performance to old ideas about contemporary living.

4 | passivehouseplus.co.uk | issue 44 CONTENTS PASSIVE HOUSE+

8 18 28 24

18 38 8 48

58

Adaptation sensation

Landmark Dublin building pioneers dynamic adaptive comfort approach

Sometimes a building comes along that asks challenging questions. Chris Croly, building services engineering director of BDP, describes one such example – a building designed to tackle the specific energy profile of offices, while trialling an innovative, dynamically-controlled approach to adaptive comfort.

INSIGHT

Cold comfort

Are Ireland and the UK’s energy ratings predicated on cold homes?

Passive houses aside, attempts at low energy building have a long and inglorious history of using more energy than predicted, with a key reason being “comfort taking”, where occupants take back the benefit of energy efficiency by cranking up the thermostat. But is it rather that energy ratings are assuming miserly heating use –and temperatures that fail to meet the requirements of a new EN comfort standard?

MARKETPLACE

Keep up with the latest developments from some of the leading companies in sustainable building, including new product innovations, project updates and more.

What goes around comes around

Why the history of refrigeration points to the future of heating

As efforts to decarbonise buildings gain pace, heat pumps powered by an increasingly clean grid are looking like an irresistible force. While reducing emissions from operational energy use rightly remains front and centre, embodied carbon is the next target – including the heat pump’s refrigerant. Toby Cambray goes back to refrigeration’s beginnings to find a route to a low carbon future.

ph+ | contents | 5 PASSIVE HOUSE+ CONTENTS ph+ | contents | 5 38 48 58

70 72 COVER STORY 77

BIG PICTURE

PASSIVE & ECO BUILDS FROM AROUND THE WORLD

While genuine efforts to address aspects of sustainability are becoming common in construction projects, all too often those efforts remain couched in an oil age mindset – typified by the likes of a remotely located passive house McMansion with two SUVs in the driveway.

But sometimes a building comes along where, rather than feeling incongruous, energy targets like passive house are manifestly functioning as part of a well-rounded conception of sustainability, using resources sparingly to deliver a home that is at once modest and delightful – a blueprint for an architecture fit for the Anthropocene.

Hamish Bresnahan of Alexander Symes Architect explains the practice’s work on one such project: Pepper Tree Passive House

1. Introducing Pepper Tree Passive House

Pepper Tree Passive House is a small secondary dwelling, attached to a young family’s home in the Australian Illawarra region, perched on a steep site and elevated into the canopy of the site’s 60-year-old pepper tree. Built to the passive house standard, sustainability is at the core ethos of the project – embodied between the natural material palette, high performance design and strong biophilic connection.

The ambition of this project was to do more with less. While light touches to the existing home were made to improve its thermal performance, building the new secondary dwelling to the passive house standard has created a future proofed refuge to escape to in future peak temperature days.

9

2. An ambitious upgrade

Adam Souter approached Alexander Symes Architect with the ambitious project, looking to upgrade his family’s Unanderra home as well as use the opportunity to showcase the technical expertise of his emerging construction firm, Souter Built.

Adam is passionate about the future of sustainable housing in Australia, trying to implement sustainable change to the way we build, one house at a time. A certified passive house tradesperson, Adam and his partner Ame Rooke-Jones wanted to create a sustainable, healthy space to raise their three kids.

3. Preserving nature

From the outset, the intention of the additions to the home was to protect the pepper tree and explore the potential of high performance, future-proofed technologies that are respectful of our natural environment and a step towards regenerative architecture.

PEPPER TREE BIG PICTURE 10 | passivehouseplus.co.uk | issue 44

4. Work / life balance

The brief was developed to envision the secondary dwelling as a 24-hour space; used as a home office by the family’s growing business during the day, and a short-term stay cabin at night that would give visitors an experience of the higher quality of space that the passive house standard affords, all while creating a future-proofed studio with western views to Mount Kembla and the treetops outside. Pepper Tree Passive House gives the clients a perfect space to work while being able to create a distinct separation between work and home life, without the lengthy commutes and empty building hours experienced in a traditional workplace model.

5. Year-round views

The west-facing views over the suburb’s tree canopy toward Mount Kembla are one of the key elements of the site. The timber alu clad triple-glazed full height windows ensure that these views are enjoyed year-round without the significant compromises to thermal comfort that would be experienced with a typical window system, thanks to the harsh western afternoon sun of the local climate.

Subservient to the existing pepper tree, the U-shaped form of the new building creates a high ratio of external envelope to internal volume which proved difficult to achieve airtightness, especially given the project was Souter Built’s first passive house project. They succeeded though, achieving 0.51 ACH @50 Pa on the final blower door test.

ph+ | pepper tree big picture | 11 BIG PICTURE PEPPER TREE

Photos: Barton Taylor

Section BB

Section AA

6. Seeking approval

There was an extensive coordination process with the local council, because of the unique form and building makeup that isn’t commensurate with standard secondary dwellings.

Under current legislation, the size of secondary dwellings is measured to the external wall finishes. Although the detached studio is under 60 sqm in internal floor space, there was great difficulty in getting the council to approve the proposed works as the highly insulated walls meant that they were thicker than a standard build, thereby increasing the perceived footprint. This is something that architect Alexander Symes still believes needs addressing, as the current legislation punishes higher performing building envelopes.

7. Subtle upgrades

Although the clients were also looking to upgrade their Illawarra home, the existing house functioned well for their needs already.

Instead of extensive alterations and additions, light touches were made to the existing home to upgrade its thermal performance – including new external insulation and timber cladding, repainting the existing concrete tiles lighter to reduce heat gain and the addition of a 12 kW building-integrated photovoltaic pergola.

Wrap around decks were added to the existing home to strengthen its ability to connect with the gardens, and improve the usability of the entire site. New recycled timber fencing to the front garden provided space for chickens and an edible garden.

PEPPER TREE BIG PICTURE 12 | passivehouseplus.co.uk | issue 44

ph+ | pepper tree big picture | www.blauberg.co.uk | 0116 216 0650 Sustainability, 99.9% recyclable components. Unit adapts to any wall or ceiling space Multi-angle duct connection adaptable to any space Rotating condensation drain Ultra slimline 21cm deep Just the width of this magazine

8. Celebrating the natural environment

From the project’s outset it was critical for the design to use both materials and landscaping in a way that strengthened the biophilic connection to the pepper tree, as well as regenerate the biodiversity of the site. Despite the small building footprint, it was critical to the project’s success that the site’s natural environment was dis-

turbed as little as possible.

The building’s two cantilevered wings each host an extensive roof garden, filled with a variety of drought tolerant native plants, collecting excess rainwater to be used in the dwelling, and helping to blend the building into the site.

The choice of charred Shou Sugi Ban

timber cladding behind the existing street trees adds to this effect, while removing the need for ongoing maintenance over the material’s lifecycle. Internally, timber products with non-VOC finishes were used, reducing total embodied energy while still providing a warm material palette.

9. Reclaimed materials

To reduce the amount of new materials used and total embodied energy of the project, Adam constantly saved materials that otherwise would have gone to waste as part of the work of Souter Built, stockpiling a catalogue of reclaimed materials to be used on the project.

Adam’s constant innovation in holistic material approach is exemplified throughout this project, such as salvaging the structural timber from the demolition of a 100-year-old home in Bondi (which became Pepper Tree Passive House’s external staircase) as well as ensuring all leftovers from Souter Built’s concrete pours of the last few years were poured into empty buckets (which became the external pavers for Pepper Tree Passive House).

PEPPER TREE BIG PICTURE 14 | passivehouseplus.co.uk | issue 44

www.ecomerchant.co.uk

Ecomerchant isanessential partofourteam-helpingus deliverPassivhausstandardswith naturalmaterials.

Ecomerchant isanessential partofourteam-helpingus deliverPassivhausstandardswith naturalmaterials.

PaulMallionFRICS

PaulMallionFRICS

CertifiedPassivhausDesigner ConkerConservationLtd.

CertifiedPassivhausDesigner ConkerConservationLtd.

ph+ | pepper tree big picture | 15

www.ecomerchant.co.uk info@ecomerchant.co.uk +44(0)1793847444 SUSTAINABLE BUILDINGMATERIALS FROMFOUNDATION TORIDGE

info@ecomerchant.co.uk +44(0)1793847444 SUSTAINABLE BUILDINGMATERIALS FROMFOUNDATION TORIDGE

10. Form and function

The northern wing houses the living, office and kitchen spaces with a breakfast bar, carefully framing a view of Mount Kembla. Recycled sandstock bricks line the floor and wall area where direct sunlight from the northern highlight windows projects during winter, acting as a thermal battery.

The more private southern wing contains the bedroom, laundry and bathroom, ensuring the total volume of the building is only as big as it needs to be to protect the existing pepper tree. The floating deck between the two wings has been carefully scribed around the pepper tree, providing a meditative retreat immersed in the tree canopy.

11. Performs as designed

A life-cycle assessment was conducted that showed despite the higher amount of embodied energy associated with passive house construction, due to the small, high performance building envelope, low-embodied carbon material selection and significant on-site generated & exported renewable energy, the building’s environmental footprint is 64 per cent less than a comparable built-as-usual home in the same climate zone.

The use of Shou Sugi Ban recycled hardwood cladding means that no re-oiling of the timber is required, and protects the timber from pests and rot.

Between the passive house standard and the 12 kW photovoltaic system installed, the whole home uses 94 per cent less grid energy than a comparable five-person home in the same climate zone. This ensures the young family has energy security, and is not susceptible to grid electricity market increases. The home will also be a bastion against unpredictable future climate peaks – during the recent cold snap the space was a comfortable 20 C internally while outdoor temperatures were below 1 C (without using any internal heating).

16 | passivehouseplus.co.uk | issue 44

New Licence Plus scheme undermines retrofit standards, experts say

TrustMark defends scheme & says it creates a pathway to PAS 2035

By Lenny Antonelli

Leading retrofit experts are concerned that TrustMark’s new Licence Plus scheme for domestic retrofit installers and contractors threatens to undermine years of work to improve retrofit standards.

TrustMark launched Licence Plus in September last year to “enable more quality retrofit energy efficiency improvement installations to be made to the millions of homes across the UK”. The scheme is intended to demonstrate the “competency and quality” of participating installers to deliver retrofit.

However, key figures in the retrofit sector expressed concern that the introduction of the scheme would put the existing BSI Retrofit Standards Framework, and in particular the PAS 2035 standard, on the backseat and pose a threat to retrofit quality.

Some members of the BSI Retrofit Standards Task Group that Passive House Plus spoke to felt that Licence Plus had been introduced following political pressure to develop a less onerous alternative to PAS 2035.

PAS 2035 was developed by the BSI to help safeguard homes and occupant health from the consequences of bad retrofit, following the 2016 Each Homes Counts review into retrofit failures. Licence Plus appears to omit a number of PAS 2035 quality control elements, such as the need for a risk assessment, retrofit design and post occupancy evaluation.

“We know from retrofit failures that remediating the consequences can take a long time and cost much more than it would have done to do the work properly in the first place. Failures also erode public confidence in the retrofit industry,” said Peter Rickaby, former chair of the BSI Retrofit Standards Task Group. “In this context, it is depressing to see that with the Licence Plus scheme TrustMark is abandoning nearly all the public protection mechanisms enshrined in PAS 2035 in the face of in-

dustry push-back and political expediency.

It is difficult to avoid the conclusion that TrustMark has lost sight of its mission and is not to be trusted.”

Meanwhile Julie Godefroy, CIBSE’s head of net zero, said: “Licence Plus does not require compliance with PAS 2035/2030. Instead, it risks reducing the drive for upskilling and sending confusing and contradictory messages to homeowners. Developing skills and competences is an investment which will return multiple benefits. Government and public bodies procuring works should demonstrate their commitment to developing a skilled and competent retrofit industry, through supporting PAS 2035/30, in order to deliver safe, comfortable, and low energy and low carbon homes.”

Passive House Plus understands that many members of the task group did not hear about Licence Plus until it was presented to them one week after it was first launched on the TrustMark website, and felt undermined after years of work to develop retrofit standards.

“It's disappointing to see that Licence Plus appears to be a move away from a whole house approach to retrofit,” said Marianne Heaslip, technical director of People Powered Retrofit. “Retrofit requires joined up thinking if we're to avoid some of the disasters of the 2010s. This is why PAS 2035 is so valuable. Rather than trying to ignore the complexities involved in retrofit, I hope the industry changes tack and instead embraces this challenge. Not only because this is necessary technically, but also because that's how we'll get new people involved in rewarding roles and achieve the skills and understanding we need to do this work well.”

A ‘transition’ to PAS 2035

Responding to questions from Passive

House Plus, a spokesperson for TrustMark said that Licence Plus would enable installers who have demonstrated their competence “to engage in a transition adoption of whole house fabric-first retrofit”.

“The Licence Plus Scheme (LPS) does not replace or compete with PAS 2035 but aims to support new businesses with a positive adoption of aspects of its principles and work within a consumer protection and oversight process so that they can more readily transition towards it,” the spokesperson said. However, critics said there is no clear mechanism for how this transition is to take place.

The TrustMark spokesperson said that businesses can only become Licence Plus registered through their scheme provider (i.e., a certification body or trade association), which “builds in another layer of trust”.

The Licence Plus scheme will use the Reduced Data Standard Assessment Procedure (RdSAP) process to produce an Energy Performance Certificate (EPC) for each dwelling. “This helps to identify staged improvements that can be incorporated into the homeowner’s project to create a plan of future improvements,” the spokesperson added.

He said Licence Plus would “create a pathway for tradespeople to engage with oversight, audit, and compliance processes where they might not have previously done so, and added that, “TrustMark is pleased to be working with the Retrofit Standards [sic] groups to look at how we can achieve the best outcomes to transition to a place where the PAS 2035 ideal is realised.”

However, some members of the BSI Retrofit Standards Task Group pointed out to Passive House Plus that TrustMark did not work with the group in drawing up the scheme. •

18 | passivehouseplus.co.uk | issue 44 NEWS PASSIVE HOUSE+ NEWS

Scotland to mandate passive house for new homes

Scotland’s minister for zero carbon buildings is proposing to make the passive house standard, or a new Scottish equivalent, the minimum energy efficiency standard for new build homes from the end of 2024.

It follows Alex Rowley MSP’s proposal last year for a Domestic Building Environmental Standards Bill, which aimed to introduce the passive house standard into Scottish law, and which received support from across the political spectrum.

The Scottish government has now said it will give effect to the proposal through its own legislation by the end of 2024. Patrick Harvie MSP, Scotland’s minister for zero carbon buildings and a Scottish Green Party MSP for Glasgow, said: “I look forward to working with Mr Rowley – and with colleagues across parliament – to continue supporting improvements and enhancements to energy and environmental standards across our new housing stock, and delivering our vision to make all homes in Scotland warmer, greener and cheaper to run.”

The Green Party in Scotland supports the SNP-led government through a power sharing deal. The shared policy programme between the two parties, published in September 2021, expressed “explicit support for passivhaus and equivalent standards” and says that all buildings that apply for a building warrant from 2024 onwards must use “zero emissions heating as the primary heating source and meet significantly higher

energy efficiency standards”.

Passive House Plus understands that Alex Rowley, a member of Scottish Labour, will be involved in the drafting of the bill, and that the Passivhaus Trust has also been consulted.

A consultation on Mr Rowley’s proposal last year received 629 responses, with 80 per cent being fully supportive, 13 per cent partially supportive and only six per cent opposed.

“A move to the Passivhaus ‘gold standard’ for all new-build homes would be radical, ambitious, practical and forward-thinking,” Rowley wrote when proposing his bill last year. “It would future proof homes and prevent them from having to be retrofitted in the near future, upskill the construction sector and make Scotland a leading player with exportable skills and knowledge.”

One group who voiced their objection, though, was Homes for Scotland, a representative body for the country’s home building sector. The group’s submission said that the proposal was “not required” as the “current direction of travel” in the building regulations would improve energy efficiency and thermal performance. The group said that proposing new standards without allowing adequate time for transition would lead to a “significant reduction” in the number of new homes built in Scotland.

The Royal Incorporation of Architects in Scotland, meanwhile, was partially supportive and called for a “flexible Scottish equivalent to the Passivhaus Standard”. It said that any

new energy efficiency standards should be implemented through the existing framework of building regulations.

Writing in the construction magazine Project Scotland, solicitors Keith Emerson and Andrew Leslie cautioned that two years “was not a lot of time to formulate new standards, educate all parts of the industry on it and implement these changes.”

They also wrote that building to the passive house standard typically costs 5 to 10 per cent more. However, while specific research for Scotland is not available, a 2019 paper by leading passive house expert Dr Shane Colclough and chartered surveyor Martin McWilliams concluded that the extra cost for a developer to build a three-bed dwelling to the passive house standard compared to the 2012 English building regulations was £1,984, or £1,368 for a new build social house, figures closer to one per cent of building costs. Previous research by Colclough and colleagues found that the extra cost of building a passive house in Ireland, where minimum energy efficiency regulations for buildings are tighter, was as low as 0.1 per cent.

The Passivhaus Trust, meanwhile, said in 2019 that “best practice” passive house construction would cost 8 per cent more, but that this could be reduced to four per cent once the standard is adopted at scale. n

ph+ | news | 19 PASSIVE HOUSE+ NEWS

Passive house isn’t just about efficiency – it’s about social justice

The potential of the passive house standard to change the world isn’t restricted to tackling climate change – it’s about social justice too.

Speaking at the 26th International Passive House Conference in Wiesbaden, Passive House Plus reporter Kate de Selincourt spoke about the role of highly energy efficient buildings in enabling lower-income communities to live in a healthy environment. "So much of the passive house is about health and well-being," said de Selincourt, who had researched the human consequences of the energy crisis in the Cold Proof series of articles in issue 43 of Passive House Plus.

De Selincourt told the conference that a growing number of British people are unable to heat their homes properly. Low-income families and elderly people have been living in winter in cold and damp buildings with room temperatures of 15 C – and sometimes even below 10 C, leading to enormous suffering and health threats. De Selincourt also told the audience about the gratitude of residents when they move into homes that meet the passive house standard. "The heat stays in the house for a long time, and the demand for heating energy is generally low. The whole lives of these people are changed," de Selincourt said. A separate series of lectures was devoted to the topic of social housing, with projects from around the world.

The conference covered other benefits of passive house projects, such as delivering good indoor air quality in buildings with vulnerable occupants such as schools and health care buildings, and protecting the power grid against overloading.

Around 600 international participants attended the three-day conference, which was held in Wiesbaden and online. Excursions took visitors to impressive projects such as the passive house district Bahnstadt Heidelberg and the first certified passive house hospital in Frankfurt.

"It is motivating to see that a high level of energy efficiency is having a ripple effect around the world. Here we have heard about impressive large projects, also in the area of energy retrofits, which are changing lives for the better for inhabitants in the long term," said Jan Steiger, member of the management board of the Passive House Institute.

Nora Steurer of the Global Alliance for

Buildings and Construction (GlobalABC), a network associated with the United Nations, pointed out that global CO2 emissions in the building and construction sector rose by five per cent in 2021 compared with the previous year. The decarbonisation of this sector must therefore be "enormously accelerated." This requires a structural change, according to Steurer. Passive House Institute founder Prof Wolfgang Feist and director Dr Benjamin Krick highlighted the urgency of the conference’s theme, Efficiency NOW! "Unless the heating demand of buildings is reduced, the power grid won't suffice if the majority of our buildings are equipped with heat pumps", explained Krick.

Delegates also learned of Enerphit retrofit projects in Germany, Ireland, Spain, Poland and Denmark, and large scale projects such as the 18-storey Ken Soble Tower in Hamilton, Canada, which is providing 146 healthy and affordable apartments with low energy costs to the predominantly elderly residents. In northern Mexico, where summer temperatures can reach 52 C, one project provided crucial information on the feasibility and cost-effectiveness of Enerphit retrofits in emerging economies. A workshop on the EU outPHit project focused on large-scale and fail-safe deep retrofits using prefabricated components. Municipalities were invited to attend a workshop specifically tailored to their needs, which also presented the outPHit concepts for quality assurance in retrofits to the Enerphit standard. •

with us.

It is always a pleasure to work with the Passive House Plus team. They provide a wealth of information, support and time to provide the best advert. Launching a new product is never easy, but in the space of only two months we’ve received over 150 enquiries through two issues of the magazine and all have been very fruitful. We have been quoting straight after the magazine is out. A lot of the customers enquiring have genuine current projects and this is reflected in how many respond to our follow ups.

It is no doubt in my mind that this team are one of the best I have dealt with out of the many publications we use. They deliver and they deliver quality!

- Elizabeth Assaf, owner, Urban Front

To enquire about advertising, contact Jeff Colley on +353 (0)1 2107513 , or email jeff@passivehouseplus.ie

at the 26th International Passive House Conference about the human consequences of the energy crisis – and how the passive house standard can help.

20 | passivehouseplus.co.uk | issue 44 NEWS PASSIVE HOUSE+

(above) Passive House Plus reporter Kate De Selincourt spoke

www.passivehouseplus.co.uk

Advertise

WorldGBC launches green building policy principles for governments

The World Green Building Council (WorldGBC) has launched a set of principles aimed at guiding national governments to develop effective building policies and programmes to accelerate a decarbonised future.

The principles, developed by WorldGBC with its network of 75+ green building councils, were released ahead of the G7 ministers’ meeting on climate, energy and environment on 15–16 April, and take into account sobering analysis from the latest Intergovernmental Panel on Climate Change (IPCC) report, and the conclusion that there is a rapidly closing window of opportunity to implement policies that will keep the world within the 1.5 C warming limit.

Many of the priority topics for the G7 ministers meeting can be addressed by buildings — from achieving both energy security and net zero, to advancing the transition to circular economies. Worldwide, buildings are responsible for 37 per cent of energy-related carbon emissions and 34 per cent of energy demand. With such a significant environmental and carbon impact, leaders and policymakers must recognise the built environment as a key agent of change to close the 1.5 C gap.

WorldGBC and its network have launched “Global Policy Principles for a

Sustainable Built Environment”, to support policymakers around the world to adopt a holistic approach to built environment sustainability, and ensure that new and updated policies and legislations deliver the transformative action needed to reach the Paris Agreement and the UN’s Sustainable Development Goals.

The principles are structured around seven key focus areas: carbon, resilience, circularity, water, biodiversity, health, equity and access. These areas are supported by detailed policy levers to show how they can be effectively implemented through regulation, information and incentives. Despite being the largest contributing sector to carbon emissions, the building and construction industry is still not on track to achieve total decarbonisation by 2050, meaning the gap between actual climate performance of the sector and its pathway to decarbonisation is widening.

This creates a dual challenge for the built environment — with markets in Asia and Africa expecting their building stock to double by mid-century. Meanwhile other regions are grappling with the challenges of renovating energy inefficient buildings.

Cristina Gamboa, CEO, WorldGBC, said: “Our sector is in a strong position to deliver resilient development that integrates

mitigation and adaptation measures, whilst also addressing other pressing societal issues, including energy security, resilience, health and equity. In this global stocktake of the Paris Agreement year, and ahead of countries submitting updated nationally determined contributions (NDCs) in 2024, it is crucial that political leaders take bold actions to strengthen and implement building policies that deliver transformative change.”

By supporting the delivery of these principles, governments will be sending a clear signal to the market that decarbonised built environments are a priority, therefore enabling industry to deliver more innovative solutions. But governments must take a holistic approach, embracing public funding and influencing financial investment decisions and tools that consider carbon mitigation, resilience and green buildings. WorldGBC and its green building council network invite governments to use “Global Policy Principles for a Sustainable Built Environment” as a tool to review and update existing legislation; as well as offering their support within a local and global context.

Download the report here: https://tinyurl. com/WorldGBCreport. •

Must listen: Zero Ambitions Podcast

Over the past two years Passive House Plus editor Jeff Colley has been moonlighting as co-host of Zero Ambitions, a weekly podcast that wrestles with the challenge of how to deliver the scale and ambition of decarbonisation and sustainability in buildings required to avoid a hellish future. The focus is very much on keeping listeners engaged and informed – with a necessary dose of gallows humour.

Jeff’s co-hosts are user experience experts Alex Blondin and Dan Hyde (co-founder of Passive House Plus’s progenitor, Construct Ireland), who help to ensure the podcast couches the technical minutiae that Jeff loves in a manner that might chime with different

kinds of users – designers, tradespeople, policymakers and building users.

Some recent highlights:

• Learning from our mistakes: looking back at ten retrofits, ten years later, with retrofit pioneer Marion Baeli (PDP, Passivhaus Trust)

• Systems design for passive houses, radon research as a proxy for ventilation, and some further education. With Dr. Barry McCarron (PHAI, CREST)

• Passive house can lead to more than just houses: community engagement, control pathologies, and propagating systemic change. With Helena Fitzgerald (Department of Economics at the University of Limerick)

• Unconventional approaches to space heating: infra-red, ceramics, and the necessity for good design. With John Morehead (Wain Morehead Architects)

• EPCs are just a ritual (pt. 1): fundamental flaws in how we assess energy performance and how we got here, with Adrian Leaman and Bill Bordass (UsableBuildings.co.uk)

• Retrofit, energy ratings, and improving Europe's energy performance, with Ciarán Cuffe MEP

The podcast is available wherever you listen to podcasts. But you can find all ninety-five episodes here: https://tinyurl. com/zeroambitionspod. •

ph+ | news | 21 PASSIVE HOUSE+ NEWS

22 | passivehouseplus.co.uk | issue 44 www.cupapizarras.com Scan to request your FREE sample!

Book review Show Me the Bodies: How We Let Grenfell Happen, by Peter Apps

Review: Simon Jones

porter, Peter Apps, is a forensic review, as it stands today, of the evidence presented at that inquiry. And it is an indictment of the entire sector.

But it is the account from those that were there that night and the stories of the community that lived in Grenfell that lifts this book to another level. Each chapter starts at a point in time in the evening and sets the scene as the disaster unfolds, followed by powerful personal testimonies and stories of the lives it touched and destroyed.

It is an emotional rollercoaster of the shock of the events, the heartache of the lives it ruined, and anger at a system that let Grenfell happen. I found myself shaking my head in disbelief one minute, taking a minute to compose myself another (that's crying like a baby), to wanting to break something.

of June 2017, our government got what it had asked for”.

From the first chapter, this book smacks you in the face and doesn’t let up. It’s a story of loss and unbelievable bravery, it’s a story of neglect and obfuscation at a grand scale and ultimately a story of failure to protect the vulnerable including families and children.

It’s a story that everyone involved in the built environment should read, think about for a while, read again, and imprint in their memory.

The entire industry needs to ask itself the question, what kind of culture creep takes a company to a place that these found themselves in? And what systems can it put in place to make sure it never happens again?

On 14 June 2017, 72 people needlessly died in what was to become the UK’s worst housing disaster. For anyone watching at the time, as flames ripped up the sides of the high rise building in West London, it was clear something had gone horribly wrong, and what followed in the years afterward through the subsequent inquiry and investigations, sent shockwaves through the sector – shockwaves that should change everything.

I, like many, followed the inquiry as it happened, facilitated largely by the excellent reporting of Peter Apps, deputy editor at Inside Housing, a publication with a focus on social housing.

I was shocked by the testimony, and being from industry, was particularly interested in how something so extraordinarily flammable could find itself on the outside of any building, let alone a tower block. The answers, as they were coming out from the inquiry at the time, were explosive.

This book "Show Me the Bodies: How We Let Grenfell Happen", by the same re-

But this disaster was foretold by many, from industry experts to the residents of the flats themselves. Warnings to the local authority about the state of disrepair of many of the safety systems that would ultimately hinder rescue efforts on the night, went unheeded.

It’s hard to even begin to explain the industry's part in what led to the products being used on the high-rise, which ultimately turned Grenfell into a towering inferno. With one manager's response to questions about the products fire safety, years beforehand, saying they could “go fuck themselves”. An employee of another describing a test on its product as a "towering inferno", buried the testing and marketed it for use on high-rise buildings. There were failings, all the way to the top of the system itself, with the false reliance on declining deaths by fire used as an excuse for inaction and the citing of unreasonable burdens and costs to industry. As one senior civil servant put it when pressed to justify its failure to tighten fire safety rules, “show me the bodies.”

As Apps notes in the book, “on the 14th

And as a society, this book asks uncomfortable questions of us all. Ultimately, how did we let Grenfell happen? And this time, this time, will we learn the lessons? •

ABOUT THE REVIEWER

Simon Jones has been in building services, air quality and the built environment for nearly two decades and has consistently been a voice for better standards and approaches in the industry. He has built up a reputation of integrity and knowledge in that time across the ventilation and indoor air quality sector.

ph+ | news | 23 PASSIVE HOUSE+ NEWS

Cynicism and inspiration

In spite of everything we know about how to build and retrofit high quality low energy buildings, poor practice remains stubbornly persistent in parts of the industry. But understanding why and how this persists could be a catalyst for change, argues

Dr Peter Rickaby

Readers of this column may have detected some cynicism in recent editions. After years promoting energy efficiency and retrofit, a little cynicism seems appropriate, especially about the chances of the UK government rising adequately to the challenge of climate change. However, my cynicism is more broadly based than that: it has been reinforced by recent projects and by Peter Apps’s book Show me the Bodies, about revelations from the Grenfell Tower enquiry. Apps paints a picture of an industrial culture of lying, cheating, and minimal compliance

and reporting on defects in a block of over 250 flats in south London owned by a housing organisation. The block was designed over ten years ago by a leading housing architect and a leading M&E consultancy, who adopted the passive house standard. Unfortunately, the housing organisation chose to procure the building via design and build, from a contractor who appears to have been incompetent at best. The design air permeability was changed from 1 m3/m2h@50Pa to 4 m3/m2h@50Pa, the wall U-value as built was 40 per cent higher than specified (be-

with or avoidance of regulations, combined with government complacency and wilful inaction in the face of uncomfortable truths. In short, focusing on the bottom line and ignoring the health and safety of everyone else.

Recently, I have been assisting a couple who bought a house from a housebuilder and have never been able to heat it adequately. In winter, they wear anoraks at home, and cannot invite friends and family to visit. After years of fruitless argument between my clients and the housebuilder, we used airtightness testing and thermography to show that the house is riddled with thermal bridging and thermal bypass, and with the help of a solicitor we finally nudged the housebuilder into offering limited remedial work. Then the housebuilder argued that further thermography to demonstrate that the proposed work has been effective is unnecessary because it is not required by Building Regulations. Wait – what? This is not about Building Regulations. Does the housebuilder care so little for its customers that it couldn’t just admit that the house is not fit for purpose, apologise for the defects and promptly correct them?

Another project has involved investigating

cause wall ties and fixings were not allowed for), the windows and external doors didn’t fit properly, the never-serviced MVHR systems were the cheapest available, and the ductwork leaked. In the as-built SAP/EPC assessments the air permeability of every flat was recorded as exactly 4 m3/m2h@50Pa, a barely credible result that doesn’t seem to have attracted the attention of the building control body. Recent testing suggests that 7 m3/m2h@50Pa would have been more accurate. To compound the mess the housing organisation is now procuring remedial work through another design and build process.

Finally, my colleagues at the UK Centre for Moisture in Buildings have been receiving requests from housing organisations for training about condensation, damp and mould (CDM). Of course, we are pleased to provide such training, but it is difficult to avoid the conclusion that the sudden interest is driven by the tragic death of Awaab Ishak, the loss of £1m funding by his family’s landlords, and the consequent sacking of their chief executive. There has been mould in social housing for decades, and it has either been ignored or dealt with by blaming

residents’ ‘lifestyle’ and perhaps installing an inadequate ventilation fan. If the objective of social housing is to provide accommodation for low-income families, how can mouldy housing that they cannot afford to heat properly be considered fit for purpose? Peabody’s ground-breaking CDM strategy for Thamesmead showed five years ago that a risk-based approach and good ventilation can deal with the problem. Cynicism is not helpful, of course, unless it drives effective action. I have said before that what the building and housing industries need to help them rise to the challenge of climate change is inspirational leadership. So, to finish on a positive note, there has always been plenty of that around, even if it hasn’t been as effective as we might like. Colleagues have undertaken and disseminated research and demonstration projects, written and published guidance, developed and delivered training, contributed to reviews, written technical standards, developed and implemented improvement strategies, and delivered cutting-edge retrofit. Organisations such as the Passivhaus Trust, the Good Homes Alliance, the Sustainable Traditional Buildings Alliance, the London Energy Transformation Initiative, the Architects Climate Action Network and the amazing Make a Difference network have many energetic and inspirational members. But why is exhausting work needed to counter the lazy, complacent bottom-liners who pushback? That’s life, I guess, so I’m minded to repeat some Latin advice from my late father: “Nil illegitimae carborundum” (which, very loosely translated, means “Don’t let the bastards grind you down”). n

Dr Peter Rickaby is an independent energy and sustainability consultant, and a retrofit consultant with Savills social housing team. He helps to run the UK Centre for Moisture in Buildings at University College London, where he is an Honorary Senior Research Fellow. He is also helping Rise International with research into sustainable building materials for Lesotho. The views expressed here are his own and not necessarily those of Savills, the UKCMB, UCL or Rise International.

DR PETER RICKABY COLUMN 24 | passivehouseplus.co.uk | issue 44

I’m assisting a couple who bought an unheatable house from a housebuilder. In winter they wear anoraks at home, and can’t invite friends to visit.

The road to Damascus: The Passive House Standard

Set against a 1980s backdrop of abundant, cheap, dirty energy and reckless “greed is good” free market capitalism, a quiet revolution in low energy building was brewing in Germany, as Dr. Marc O Riain writes.

All the development of active and passive low energy buildings throughout the 20th century, much of which has been discussed in this column previously, was leading somewhere. From Solar 1 MIT in 1933, through to the first ‘Zero energy house’ in Copenhagen (1974), Bentley’s double wall construction (1976), the development of heat pump technology in the Phillip’s experimental house (Aachen 1975), the discovery of thermal bridging and thermal bypass by the Princeton House Doctors (1977), and the combination of heat recovery ventilation with a high degree of tightness and super-insulation in the Saskatchewan Conservation House (1977). Pioneering projects like these provided the deep research precedents required for the development of the passive house standard by Wolfgang Feist and Bo Adamson in 1988.

The voluntary German building energy performance standard was primarily centred around passive solar, thermal comfort, super-insulation, airtightness and mechanical ventilation with heat recovery (although not exclusively), and thermal bridge-free construction. Supported by government subsidies, Bott, Ridder and Westermeyer Architects developed a four-house terrace to the passive house standard in 1990. Each unit was 156 m2 and 50 per cent of the cost of the build was met by the Hesse state government.

The standard set quantitative performance targets for designers to meet to achieve a very low whole building energy use. The system synthesized most of the previous passive strategies with MVHR into a quantifiable design process. Interestingly, active solar (potentially due to cost) was not a core part of this strategy in 1988, but later welcomed by Feist as a suitable renewable component.

The passive house is only really ‘passive’ in the sense that the design approach takes a “passive-first” approach to energy conservation, leaving the building with a small amount of fixed primary energy balance (120 kW/m2/yr) to then be met with active systems. It might be better defined as a hybridised low energy or zero energy house.

This standard attempts to isolate the enclosed habitable environment from the external environment irrespective of the building’s location, making the standard globally appli-

cable, using local climate data sets. Criticisms of some aspects of passive house highlight issues with space heating capacity in colder environments (Straube 2009) and overheating in the summer (Goncalves et al. 2022, Mitchell & Natarajan 2019, Finegan 2022).

In a similar strategy to the Lo-cal House of 1976, designers must use high performance glazing (<0.8 W/m2k) and achieve thermal bridge-free design (identified at Twin Rivers - Nisson and Dutt 1985). The standard allows for shading devices to moderate summer overheating, employing natural shading such as deciduous trees or building integrated shading (again, similar to the Lo-cal House). The highly technical system is based on knowledge of building physics, a level of sophistication or specialization not commonly found in architectural education (Tzonis 2014) and as a result not abundant in architectural practice.

By 2016, there were only 3,000 certified passive house designers worldwide, with 323 in Ireland out of 2,507 registered architects at the time (Maguire 2016). The passive house standard, and its Excel-based planning software, requires the building designer to become familiar with local climactic conditions, mechanical systems, solar heat gain calculations, and thermal bridging calculations. The key energy performance standards are 15 kWh/m2/ yr for heating and cooling demand, and/or 10 W/m2 heating/cooling load, with remaining loads attributable to lighting and process loads, leaving a total overall building primary energy demand of 120 kWh/m2/yr for all energy loads – including a significant aspect absent from national methodologies such as DEAP and SAP: unregulated (plug) loads.

In 1996, an economical planning package was developed to demonstrate payback periods based on unit costs of energy plus inflation (Passivhaus 2016). In 2011, the institute introduced a standard for building retrofit, called Enerphit. While it relaxed standards for space heating demand (25 kWh/m2a) and airtightness (1 ACH @50 Pa), the overall whole building performance remained the same (120 kWh/m2a).

Passive house is the single most popular voluntary low energy design process in the world, with an estimated 60,000 (as of 2016) certified passive houses built worldwide (Passipedia 2015). The weakness of the system is

perhaps the need for so much training and the lack of intuitive design software. For architects passive house offers a measurable, quantifiable results-based matrix for design decision-making. It offers a clear, if complex strategy, that can inform the design process.

Several factors combine to limit the standards wider adoption due to cost and time-constraints: its detailed application software (PHPP), optional use of ‘localised’ climate data and in some instances use of secondary software (Trnsys, Therm, WuFi) to validate inputs. The standard is voluntary whereas national energy performance standards are mandatory, meaning one might or not achieve regulatory compliance by meeting the standard without additional measures, further limiting practice adoption.

At a very strategic level, passive house is both an insightful and useful design approach that every architect and engineer should learn in college. It teaches us to understand aspects of the whole building as an energy performing unit. Since Tomás O’Leary’s first passive house in Ireland in 2004, the growth of the standard has been both exceptional and global, influencing the EU definition of nearly zero energy buildings (2010) and the subsequent member state adoption in to building codes.

The passive house standard has been a valuable education, policy and practice tool, that has resulted in a complete modal shift in the design and construction of our buildings, and has the ability to eliminate fuel poverty through energy conservation while mitigating CO2 released into our atmosphere. In the lee of an energy crisis we have become far more aware of the importance of energy efficient buildings and the passive house standard. n

Dr Marc Ó Riain is a lecturer in the Department of Architecture at Munster Technological University (MTU). He has a PhD in zero energy retrofit and has delivered both residential and commercial NZEB retrofits In Ireland. He is a director of RUA Architects and has a passion for the environment both built and natural.

26 | passivehouseplus.co.uk | issue 44 DR MARC Ó RIAIN COLUMN

UNPARALLELED

GROUND BREAKING U-VALUES FROM AS LOW AS 0.47W/M2K T. 01789 473 987 E. info@munsterjoinery.co.uk www.munsterjoinery.co.uk

& DOORS

CHOICE OF PASSIVE CERTIFIED PRODUCTS – OUTWARD OPENING, INWARD OPENING, UPVC, ALUMINIUM, ALUCLAD

WINDOWS

IN BRIEF

House type: 107 m2 bungalow

Method: Wood fibre insulated timber frame infrared heating

Location: Dumfries and Galloway

Standard: AECB CarbonLite Building Standard

Heating & hot water cost: £90/month*

* Estimated space heating and hot water cost, based on Ofgem’s energy price guarantee for October 2022.

See ‘In detail’ panel for more information.

£90 per month

VISIONARY VERNACULAR

PASSIVE-INSPIRED DUMFRIES HOME PUTS USERS FIRST

Can a low energy building be truly sustainable if it doesn’t fully consider its occupants needs? The latest offering from one of Scotland’s leading green designers uses passive house knowhow to signal the way to pragmatic, modest, occupant-centric architecture.

By John Cradden

29

It’s been shown clearly over the last few years that passive house design lends itself relatively easily to a variety of building forms thanks to the versatility of PHPP software.

But every so often, a combination of tight budgets and less than ideal form factors present a challenge that gives even those architects passionate about the standard a reason to rethink their approaches, without jettisoning the efficiency, sustainability, and attention to detail that fully certified passive houses demand.

Beechtrees, a lovely, modest larch-clad, zinc-roofed house in Scotland built by seasoned Dundee-based passive house designer Kirsty Maguire, is one such case.

It’s built to the AECB CarbonLite Building Standard, which is based on passive house and uses the same software (PHPP), but with less onerous targets for energy performance.

Located in a rural area in the middle of Dumfries and Galloway, a large region in the southwest corner of the country, it’s an unusual and innovative build that doesn’t try to ape a traditional farmhouse, but still strongly reflects the local vernacular of metal roofs and timber cladding of the neighbour-

ing farm buildings. The inspiration Kirsty Maguire took from around the site is infectious: the link building between the living and bedroom wings has the same colouring as “a beautifully weathered barn with a rust red roof,” and a similar nearby shed.

Built for two retirees, Tony Francis and Zoe Roberts, as their forever home, it’s also single-storey, meaning it will be easier for the couple to navigate in future years. That comes at an energy cost as it increases the building’s surface area to volume ratio or ‘form factor’. Future-proofing the house to allow for the occupants’ changing needs in this case means more walls, roof and ground floor per square metre, and therefore more surfaces through which heat is lost. The form factor is also not helped by the H-shaped floor plan, designed to give the couple two courtyards.

It’s designed essentially so that the external spaces are conceived as external rooms, as the clients spend a lot of time outdoors,” said Kirsty Maguire.

The courtyards each exploit the light at different times of day, a bit like a sundial. According to Maguire, the east courtyard, opening from the kitchen, is perfect for

sitting outside with a morning coffee. As the sun moves around, it hits the south side with the pond and vegetable garden, bathing the outdoor dining table in sunlight from late morning until evening. It has a generous living space with a cathedral ceiling in the main part of the building. The

30 | passivehouseplus.co.uk | issue 44

bedroom wing is similar but more private and set back, and there’s a welcoming entrance space linking the two.

What the whole space gains inside and outside as a result of this clever design is clearly worth the concession – if you can call it that – of building to the AECB CarbonLite Building Standard instead of passive house.

A quick look at the building fabric specs shows that Beechtrees has exactly what you’d expect to see in a passive house: the U-values for walls, roof, floor and windows, the thermal bridging and the airtightness, and the Zehnder heat recovery ventilation system. It also has infrared heating for the little warmth that’s required and an air source heat pump – using the ultra-low global warming potential (GWP) refrigerant R290 – for hot water.

Named after the mature deciduous trees from the site, Beechtrees is all about timber. As many trees were retained as much as possible, with the felled trees being turned into cills and shelving by a local craftsman. The building’s superstructure is timber frame, with Steico wood fibre insulation in walls and roof, and triple glazed timber windows. The project’s broader sustainability efforts extended into other materials too. Reclaimed materials are used as well, such as paviours, and the drystone dyke

was rebuilt by Tony using stone from site.

It’s reasonable to argue that if the budget was more flexible, a greater investment in wall insulation, for instance, could have brought the overall energy performance closer to the passive house standard, but other choices took priority, according to Maguire.

“That relationship to the [external] spaces on the site was really key to the layout of the building,” she said. “As a result, we’ve got these two wings and a link, which does make the form factor higher, and therefore there’s a point in time where you can keep putting more and more insulation in but there’s a balance [to be struck]. And that’s where we used PHPP – to start to identify where that balance is, and where you can still get good performance.”

The wall insulation in Beechtrees is far from skimpy, with 240 mm of Steico Flex wood fibre insulation fitted between the timber frame, with a further 100 mm of Steico Special Dry wood fibre boards wrapping the frame externally, delivering a U-value of 0.127. Nonetheless the design allows for more: an extra layer of insulation could be installed very easily by simply removing the timber cladding at some point later, giving this dwelling a highly satisfying degree of cheap and easy future-proofing.

Besides the lower energy targets, the key difference between the AECB and the pas-

sive house standard is around certification. In a nutshell, certification for a passive house can only be awarded by an independent certifier, while the AECB relies on self-certification by the designer or consultant.

According to the AECB website: “The AECB self-certification process is designed to make explicit the project’s claim to be a low energy design and to provide the consumer with a degree of protection under trading standards – without the AECB having to get involved in quality control

ph+ | beechtrees case study | 31 CASE STUDY BEECHTREES

WANT TO KNOW MORE? The digital version of this magazine includes access to exclusive galleries of architectural drawings. The digital magazine is available to subscribers on passivehouseplus.ie & passivehouseplus.co.uk

Tony and Zoe were adamant the house shouldn’t be too big for their needs or have any wasted space, and no clutter. “We have no space that’s underutilised, and no junk”.

and legal matters.

“This approach puts the responsibility for performance claims clearly with the person signing the certificate and a duty of care on the client to ensure that the consultant is competent and suitably insured.”

Kirsty Maguire herself is a big advocate

of passive house certification, and recently undertook passive house certifier training, becoming the only Scottish-based consultant to have this. Having designed several certified passive house projects over the last decade, Kirsty says with Beechtrees she made sure the quality assurance process was

the same, along with the details and the general approach to the project.

Which was surely music to the ears of Tony and Zoe, who were introduced to the passive house concept by their daughter, and were inspired enough to make enquiries that quickly led them to Maguire’s door and the start of an in-depth but by all accounts very amicable and free-flowing discussion about what they wanted. Their brief was for an environmentally sustainable and warm home that maximised the access to the outdoor space around the site so that they could enjoy the garden and walk their dogs and entertain family, and also recycle as many of its elements as possible.

“There were quite a lot of things we put on the brief,” says Zoe, “such as being able to have the doors open when we’re cooking, and positioning the house so we could make the most of the private bit of garden… we needed a mud room for the dogs – a place where three filthy Labradors can go and shake.”

They were also adamant that the house shouldn’t be too big for their needs or have any wasted space. “I think we were very keen to have no clutter. We were ruthless before we moved in about throwing things out that hadn’t been used. And thankfully we have no space that’s underutilised, but neither do we have any junk.”

Kirsty’s experience and a highly communicative approach to working with Zoe and Tony, allied with the enthusiasm and commitment of a local contractor undertaking one of his first passive house-in-

BEECHTREES CASE STUDY

North east elevation

North west elevation

formed projects, meant that Beechtrees succeeded – even exceeded – expectations in terms of meeting their quite specific demands.

“Kirsty is so kind of efficient and pedantic, in the nicest possible way, about detail that she and her assistant really pushed us hard to make decisions before it even got out of the ground, such as things about light switches, outside lights, positioning of inside lights, colour of the kitchen, colour of the tiles,” said Zoe, who even admits to

getting a “wee bit stressy” about it as the process went on, “but oh my goodness, did we realise the value of that during the build”.

They’re also full of praise for Kirsty’s choice of contractor, David Broatch of Broatch Construction, a firm based just 20 miles away, even though he had limited previous experience of working on passive houses.

“They had never built a house like this before, and... Kirsty must have had some intuition about them,” said Tony, who was sceptical that they would take on the job with the limited budget they had, “but she was right. They really wanted to get it right. And they concentrated so hard on doing that.”

It was clearly a transformative experience for Broatch, because he has gone on to completely change his business focus as a result of this project, heading into passive house in a big way. The firm has recently completed building a home for the daughter of wellknown passive house architect Jonathan Hines, managing director of Architype, on the strength of Kirsty’s recommendation.

Adding to the highly positive build experience was the efficient sourcing of ma-

terials just before the chaos of the Covid pandemic, so that the only supply issue was bathroom tiles, which Tony and Zoe sourced elsewhere in order to keep to the schedule. Only the windows and doors were a little late, but this added just three weeks to the projected 16-week build time.

The choice of timber frame construction was a simple decision given timber frame’s dominant position north of the border, so expertise and skills were easy to find. “We’ve got obviously great joiners across everywhere who are familiar with it so it’s a sort of standard way of doing things up here for buildings at this scale.

Kirsty also describes Beechtrees as a bit

ph+ | beechtrees case study | 33 CASE STUDY BEECHTREES

2 1 8 3 7 9

1 The house is named after the mature deciduous trees from the site; 2 Isoquick insulated foundation system and timber frame; 3 400 mm Steico Flex wood fibre insulation in the bedroom wing; 4 airtightness taping at window; 5 heat recovery ventilation ducts in void inside airtight layer; 6 threshold detail; 7 & 8 salvaged tiles; 9 Greencoat PLX standing seam roofing system.

5 4 6

We needed a mud room for the dogs –a place where three filthy Labradors can go and shake.

Drone photography: Ali Yassine

Putting people and theplanetfirst

Putting people and theplanetfirst

Environmentallyfriendlybuilding productsfromrenewableresources

Environmentallyfriendlybuilding productsfromrenewableresources

Insulation

CERTIFIED SAFETY

CERTIFIED SAFETY

STEICOBuildingSystem

STEICOBuildingSystem

Sheathingandsarkingboardsfor new-buildandrefurbishement

Sheathingandsarkingboardsfor new-buildandrefurbishement

Flexibleinsulationbattsmade fromnatural wood fibres

Flexibleinsulationbattsmade fromnatural wood fibres

woodfibresorcellulosefibres

Airinjectedinsulationmadefrom woodfibresorcellulosefibres

Insulationsystemsforrendered facadesorcurtainwalls

Insulationsystemsforrendered facadesorcurtainwalls

LightandefficientI-joistsforwall, floor,androofconstructions

LightandefficientI-joistsforwall, floor,androofconstructions

STEICOaretheworldslargestproducer ofintegratedconstructionand insulationsystemsmadefromwood. Wehavebeenmanufacturingecological andenvironmentally-friendly constructionmaterialsforover30years.

STEICOaretheworldslargestproducer ofintegratedconstructionand insulationsystemsmadefromwood. Wehavebeenmanufacturingecological andenvironmentally-friendly constructionmaterialsforover30years.

Findoutmoreabouthowyoucanmake adifferenceat: www.steico.com

Findoutmoreabouthowyoucanmake adifferenceat: www.steico.com

Laminatedveneerlumberwithhigh load-bearingcapacity

Laminatedveneerlumberwithhigh load-bearingcapacity

SupportedbyourUKinsulation distributors:

SupportedbyourUKinsulation distributors:

Sealingsystemforthebuildingshell

Sealingsystemforthebuildingshell

34 | passivehouseplus.co.uk | issue 44 BEECHTREES CASE STUDY

Construction

Sealing

Construction

Sealing Insulation

of a dream project. “We had great clients, really fantastic to work with, really good at making decisions, and great ideas. We also had really good colleagues in the design team so we could work together quickly in a straightforward way.

“And then working with the contractor was fantastic,” she added. “They would come to us with the potential of how to make things even better than we had so we can learn from them as well and keep that discussion flowing. The work that they did was in accordance with drawings and beautifully done, and it was on time, on budget during Covid. I’m not quite sure what more we could have asked for really.”

It’s rare that a client is less than delighted with any project worthy of being featured in this magazine, but Tony and Zoe exude

a particular pride in what their two-bed home represents in terms of its modesty, efficiency, sustainability and, above all, a dwelling that’s tailor-made for them right down to the last detail and with no attic or any kind of wasted space. And of course, a very comfortable home.

Having lived all their lives in old houses with nooks and crannies, big sandstone walls that Tony describes as “just big sponges full of water”, they now live in an “almost perfectly controlled environment”.

“We’ve got the air circulation system in the heat exchanger, which brings in fresh air, collects the warmth from the house and pumps out the stale air. We’ve got fresh air to breathe; even if we don’t open a single door or window, we’ve got lovely fresh air, of the right temperature.”

SELECTED PROJECT DETAILS

Client: Zoe Roberts and Tony Francis

Architect: Kirsty Maguire Architect Ltd

M&E engineer: Luths Services

Civil/structural engineer: Narro Associates

Energy consultant: Kirsty Maguire

Architect Ltd

Main contractor: Broatch Construction

Quantity surveyors: McGowan Miller

Construction Consultants

Mechanical contractor: Paul Heat Recovery Scotland

Airtightness tester/consultant: Thermal Image UK

Wood fibre insulation: Steico, via Ecomerchant

Insulated foundations: Isoquick

Airtightness products: Ecological Building Systems

Windows and doors: Green Building Store

Flooring: Howdens

Roofing: Greencoat PLX

Infrared panels: Trotec

Hot water heat pump: Vaillant

Mechanical ventilation: Paul Heat Recovery Scotland

Heating controls: Heatmiser

They’re particularly pleased with the work of a local furniture maker, Philip Wilson, who cut down the beech tree that obviously inspired the house’s nomenclature and then created beautifully rustic shelves and windowsills with the wood, all finished with a very distinctive blue resin. “It’s terribly, terribly original and just so beautiful to look at.”

Viewed purely from an energy performance perspective, Beechtrees could have pushed the envelope a little more with still more insulation or a more compact form. But energy performance and thermal comfort are not the only requirements to consider, and this thoughtful, skilfully designed house makes a strong case for allowing a little leeway, and is tailored to meet the needs of its owners throughout their later years.

ph+ | beechtrees case study | 35 CASE STUDY BEECHTREES

A complete low energy solution for internal wall insulation

Suitable for traditional solid stone and brick walls, Retro EcoWall combines the breathable, insulating and sustainability benefits of natural materials to optimise thermal performance and manage moisture.

Diasen Diathonite Thermactive.037 Lime and cork insulating plaster

Gutex Thermoroom Adhesive Adhesive mortar for Thermoroom

Gutex Thermoroom Natural wood fibre insulation boards

Lime Green Solo One coat lime finishing plaster

Reinforcing Mesh Embedded within Lime Green Solo

Auro Natural Paint Breathable natural paint

Discover our solutions online at ecologicalbuilding systems.com

36 | passivehouseplus.co.uk | issue 44 BEECHTREES CASE STUDY

1 2 3 4 5 6

1 2 3 4 5 6

Building type: Single-storey detached property.

TFA 107 m2

Site type & location: Site in a hamlet on the outskirts of Thornhill village, Dumfries and Galloway

Completion date: February 2021

Budget: £261,000

Number of occupants: 2 adults and 3 dogs

Energy performance standard: AECB

CarbonLite Building Standard

Space heating demand (PHPP): 32 kWh/m2/Yr

Heat load (PHPP): 17 W/m2/yr

Primary energy renewable (PHPP): 87 kWh/m2/yr

Heat loss form factor: 5.5

Overheating (PHPP): 2 per cent of year above 25 C

Energy performance certificate (EPC): B82

Airtightness: 0.42 ACH @50pa

Embodied carbon: Not calculated. Similar to Dundee passive house published in issue 38 of Passive House Plus, although without the PV array.