INSULATION | AIRTIGHTNESS | BUILDING SCIENCE | VENTILATION | GREEN MATERIALS 2 009597010-08.eps NBW=80 B=20Issue 45 £5.95 UK EDITION SUSTAINABLE BUILDING Bonny in Clyde River Clyde Homes cracks the safe on decarbonising social housing Seal of office Ireland’s first passive certified office building United ambitions UN pushes for radical sustainable building action FROM SMALL SCREEN TO DEEP GREEN Charlie Luxton’s visionary new sustainable office

Aereco’s range of demand controlled ventilation products have been securing the quality of indoor air for nearly 40 years. Easy to install and maintain, they provide an ideal solution for homes new and old.

ALDES GROUP

Design

Editor Jeff Colley jeff@passivehouseplus.ie

Reporter John Hearne john@passivehouseplus.ie

Reporter Kate de Selincourt kate@passivehouseplus.ie

Reporter John Cradden cradden@passivehouseplus.ie

Reader Response / IT Dudley Colley dudley@passivehouseplus.ie

Accounts Oisin Hart oisin@passivehouseplus.ie

Art Director Lauren Colley lauren@passivehouseplus.ie

Aoife O’Hara aoife@evekudesign.com | evekudesign.com

Contributors

Lenny Antonelli journalist

Toby Cambray Greengauge Building

Energy Consultants

Talina Edwards Envirotecture

Sally Godber Warm

Marc Ó Riain doctor of architecture

Matthew Tulley Solid Carbon Storage

Jason Walsh journalist

Print

GPS Colour Graphics www.gpscolour.co.uk | +44 (0) 28 9070 2020

What is there to say? As I write these words the news has been confirmed that July was the world’s hottest month on record. And there is a palpable sense of change all around us. While much of southern Europe was burning, in Ireland it doesn’t really feel like we’ve had a summer. While the fires were raging in Italy and Greece, in Ireland it was a washout – July was the wettest month on record.

While of course we shouldn’t conflate climate with weather – a favourite trope of the morally bankrupt, immorally wealthy fossil fuel schills that have corrupted the discourse on climate over the years – this kind of disconnect may be a harbinger of what is to come. The question that occurs: does a warming world necessarily mean a warmer UK and Ireland?

The answer may well be yes, but there is uncertainty here. The reason? The Gulf Stream system – or more accurately, the Atlantic Meridional Overturning Circulation (Amoc) – may be on the verge of collapse, due to impacts such as the increasing melt of Greenland’s glaciers into the Atlantic. In a worst case scenario this may potentially occur by as early as 2025. If that were to come to pass, what would the consequences be in this corner of the world?

Here the science isn’t settled, but the options on offer range from more rainfall and stronger storms, to much colder winters and much hotter summers. Ireland and the UK have the same latitude as Labrador in Canada – which Benjamin Franklin, who first charted the Gulf Stream, described as the “Land of the Eskimauxs.” Do we have to therefore consider the possibility of a markedly different climate, including potentially prolonged deep freezes and hot summers? One architect friend mused to me about using Newfoundland weather files to

stress-test their building designs.

While I say all of this, it’s important not to lose sight of our – at least for now – relatively privileged position in the kinds of disruption we face. I was consoling a Washington DC-based friend earlier, while he dealt with a flooded basement and storm-downed trees, and he gave some useful perspective. “I, like everyone who isn’t poor in the developed world live a charmed life,” he said, “so little to really complain about over a few hours mopping.”

Nevertheless, while we mustn’t ignore the issue of climate justice, we must build or retrofit now without due consideration for the climate and extreme weather variables our buildings may face – be it cold snaps, heat waves, oscillation between droughts and torrential rain pour, or just the insidious impact of increased horizontal rain and the impact of storms.

If I stop to reflect on the UN Environment Programme’s Buildings Breakthrough target, which says that “near zero-emission and resilient buildings are the new normal by 2030” I find them profoundly useful: they encapsulate the two heads of the monster that we must slay. We must mitigate, by cutting emissions to as close to zero as possible. But we must also adapt, and make our buildings – even our entire built environment, our ways of life – as resilient as possible in the face of such menacing uncertainty.

I must apologize for such a downbeat opening to this issue, which, as it turns out, is filled with stories to inspire hope: real buildings and initiatives that are the kind of medicine an increasingly climate-sick world needs. As luck would have it, that medicine tastes good.

Regards, The editor

Official partner magazine of:

• The Association of Environment Conscious Building

• The International Passive House Association

• The Passivhaus Trust

ph+ | editor’s letter | 3 PASSIVE HOUSE+ EDITOR’S LETTER Publisher’s circulation statement: Passive House Plus (UK edition) has a print run of 9,000 copies, posted to architects, clients, contractors & engineers. This includes the members of the Passivhaus Trust, the AECB & the Green Register of Construction Professionals, as well as thousands of key specifiers involved in current & forthcoming sustainable building projects. Disclaimer: The opinions expressed in Passive House Plus are those of the authors and do not necessarily reflect the views of the publishers. editor’s letter ISSUE 45 Publishers Temple Media Ltd PO Box 9688, Blackrock, Co. Dublin, Ireland t +353 (0)1 210 7513 e info@passivehouseplus.ie www.passivehouseplus.co.uk

CONTENTS

19

BIG PICTURE

Talina Edwards of Envirotecture describes an extraordinary off-grid passive house which uses straw and a range of low embodied carbon building materials to blitz regulatory requirements on fire, while delivering year-round comfort levels that the neighbours can scarcely believe.

NEWS

UN pushes for radical sustainable building action; design and performance centre stage at UK Passivhaus Awards; and AECB 2023 Conference to focus on providing solutions for building in an age of climate chaos and biodiversity collapse.

24

COMMENT

Dr. Marc O Riain writes about an extraordinary Dublin project from 1994; Sally Godber writes about a new organisation offering passive house training at scale; and Matthew Tulley reports on a recent trip to Ireland, where a delegation of UK retrofit stakeholders visited to see what lessons could be learned.

CASE STUDIES

From small screen to deep green

Charlie Luxton’s visionary new sustainable office

The new Oxfordshire studio of Charlie Luxton Design, the practice of the well-known TV presenter and architectural designer, is deeply impressive for its exhaustive attention to sustainability across every facet of the project, from energy use and embodied carbon to the reuse of materials and the ecological restoration of the three-and-a-half-acre site. It’s a gorgeous building, too.

4 | passivehouseplus.co.uk | issue 45 CONTENTS PASSIVE HOUSE+ 24 COVER STORY 36

08

16 08

Bonny in Clyde

Scottish housing association cracks the safe on decarbonising social housing

How do you solve a problem like decarbonising social housing, and do so rapidly, en masse, in a manner that lifts vulnerable people out of fuel poverty while delivering warm, healthy homes? River Clyde Homes may be about to pull off the seemingly impossible.

Hope springs external

High end passive house scheme lands in Killiney

What happens when one of Ireland’s most seasoned passive house builders and a renowned design-led architecture practice collaborate? They create a head turning, high density passive house scheme that showcases the aesthetic possibilities of external insulation.

Seal of office

Ireland’s first passive certified office building

While the passive house standard has had a lasting impact on the design and construction of new homes in Ireland, progress has been slower in commercial property. With the business world under increasing pressure to take meaningful climate action while providing better working conditions for staff, one new office building in the southeast may be a sign of things to come – and a beacon for a UNaffiliated project.

INSIGHT

Banking on sustainability

Why a pillar bank is financing verified green homes

Last year Irish banking behemoth AIB launched discounted development finance for homes certified to the Irish Green Building Council’s rating system, the Home Performance Index. But what was behind the move, how is it being received and does this indicate the finance industry is getting serious about green homes?

MARKETPLACE

Keep up with the latest developments from some of the leading companies in sustainable building, including new product innovations, project updates and more.

Flash floods and porous materials

While the most dramatic impacts of climateinduced flash flooding abounding on social media this year are all too obvious, other more insidious effects also pose risk to everything from agriculture to porous materials, as Toby Cambray explains.

ph+ | contents | 5 PASSIVE HOUSE+ CONTENTS ph+ | contents | 5 64

44 54

36

64 68 70 44 54

BIG PICTURE

PASSIVE & ECO BUILDS FROM AROUND THE WORLD

If you were choosing how to build in a bushfire-prone region of Australia, you could be forgiven for skirting over the possibility of packing your walls with straw. Talina Edwards of Envirotecture describes an extraordinary off-grid passive house which uses straw and a range of low embodied carbon building materials to blitz regulatory requirements on fire, while delivering year-round comfort levels that the neighbours can scarcely believe.

1. Huff’n’Puff Haus – a strawbale Passive House

The Huff’n’Puff Haus is a new off-grid, energy efficient, natural and healthy passive house for retirement that is designed to be adaptable, bushfire and climate resilient. It is a contemporary strawbale house that is off-grid with completely self-sufficient power, water and waste.

Located in the southern part of Australia, it is a few hours’ drive inland from Melbourne in ‘high country’ in the Strathbogie Ranges, Tangurung country. The temperate climate means winter temperatures drop to freezing overnight, but summer highs can reach 40+ C.

It was designed to settle unobtrusively into the natural landscape.

8

We have owned the land (55 acres) since 2000 and dreamed about this for years.

When our clients initially approached us back in 2015, we’d just started learning more about the passive house standard and the importance of understanding building science for keeping a home comfortable and healthy – and energy efficient, which is a consideration for living off-grid. What started as a conversation about a resilient and sustainable strawbale home in a rural location, soon offered us all a

new exciting challenge - was it possible to achieve certified passive house (with a low operational carbon footprint) whilst using materials with low embodied carbon too (with more bio-based materials like straw and timber)?

The whole team was eager to explore this possibility and make it a reality. Thankfully, there’s now a growing awareness about the importance of upfront carbon.

3. Bricks, timber or straw – which is best?

The strawbale walls we used were prefabricated “situp” panels made by John Glassford and team at Huff’n’Puff. No big bad wolf or three little pigs here – this house will be strong and resilient for many years to come. The wall panel frames are crammed full of straw and sealed up for delivery – and it was observed they looked like a stack of coffins.

Being 350 mm – whereas a typical Australian wall frame is 90 mm thick – they are strong. The timber used for the framing is plywood, and this was very fortunate during the Covid materials shortages when typical timber studs were in very short supply.

Straw has excellent insulation values, is a waste-product from the farming industry, and as it’s a natural bio-based material it’s low in embodied carbon.

Once erected on site, the panels were temporarily wrapped up again to protect them from weather and from any curious rodents.

ph+ | huff’n’puff big picture | 9 BIG PICTURE HUFF’N’PUFF

2. The brief

4. The wrong orientation?

An interesting siting challenge was that this regional location has lovely 360-degree outlooks, however the best views to the distant horizon are to the south. In the southern hemisphere, we want to maximise solar gain from the north during our winters, while ensuring the building is appropriately shaded from the harsh summer sun.

Traditional principles of “solar passive

design” limit south-facing glazing as they lose too much heat from the home in winter. However, by looking at the building holistically and using PHPP as a design tool, we were able to test the performance impacts of adding (or removing) these southern windows and optimising the design to ensure every room in the house gets to enjoy the views – while not negatively impacting the internal comfort.

From an architectural design perspective, this was exciting news to realise that with passive house there aren’t necessarily “rules of thumb” that apply in every scenario – so our creativity as designers is not limited. In this case our clients desire to embrace those views, meaning we could have large windows to both the north and the south as we’d checked that it would still perform as intended.

5. Biophilic design

Internally, the straw panels were finished with lime render which formed the internal airtight layer. The exception to this was the two bathrooms, as these were wet areas. They had internal Intello membrane installed so they could be lined with cement sheeting, waterproofing and tiles.

The lime render really contributes to the biophilic design of the home – the texture and natural colour is lovely. Sustainable timbers were also chosen to complement the render, creating a simple, calm colour palette.

Deep sills are another benefit of the lime-rendered straw, framing the triple glazed windows, and creating shelves in some locations – or enough space to sit in the window and enjoy the views in all directions to the countryside.

HUFF’N’PUFF BIG PICTURE 10 | passivehouseplus.co.uk | issue 45

The intention was for this home to be safe, healthy, natural and non-toxic, with low embodied energy, durable and fireresistant materials. Due to the remote rural location, the threat of bushfire is real in hot dry summers, and due to a changing climate.

At the time we were also learning more about the Living Building Challenge and more ethical and responsible material choices – and we wondered if it was possible to have a certified passive house with no plastic. We realised this was potentially possible with rendered strawbale walls but could’ve been trickier to detail for the

ceiling airtight layer. We opted for Intello for the underside of the roof trusses, with a suspended ceiling to run the MVHR ducting through.

Our clients wanted to ensure their home was built to a higher ‘bushfire-prone’ standard than the building code required. While the rendered-strawbale may have been suitable, the roof design would have needed to change with larger eaves if we’d wanted to protect external rendered walls. As this wasn’t aligning with the design concept of a long house reminiscent of an old woodshed in the paddock, and the additional bushfire protection we

were aiming for externally, we tried to source non-combustible magnesium oxide boards for cladding. However, thanks to the pandemic and supply issues, this unfortunately wasn’t to be, and we had to choose a non-combustible cement-sheet cladding instead.

Its neutral colour with clean lines does look lovely. This meant the external face of the strawbale was wrapped with a vapour-permeable membrane, with a ventilated cavity behind the cladding in a way more like typical lightweight walls would be constructed.

7. Views for days

This home sits quietly in its place. It’s modest in size, selfsufficient in use, and a healthy home to live in harmony with the landscape.

While it is relatively small (TFA 171 m 2) in comparison to typical new Australian homes (240 m 2), inside it feels incredibly spacious and with connection to the distant horizon in every direction, and bright with lots of natural daylight. It is a real retreat from the harsh elements all year round.

Our clients have shared how they love watching the sky change colours, and how this paints the landscape in varying beautiful ways – depending on the time of the day, the time of year, where they are in the house and the direction they’re facing.

This was a conscious design decision: to create space for contemplation and enjoy the views, to be able to chase the sun when desired, or to be able to seek shade and shelter from the winds when required too.

Photos: Marnie Hewson

ph+ | huff’n’puff big picture | 11 BIG PICTURE HUFF’N’PUFF

6. Bushfire-prone area and external materials

www.proctorgroup.com 01250 872 261 contact@proctorgroup.com @proctorgroup PRODUCTS IN FOCUS Wraptite, a strong robust external air barrier designed to keep buildings airtight and dry. Easy to install, it combines the best properties of a vapour permeable membrane and an airtight membrane in one affordable, self-adhering product. Also available in UV

8. That’s something a bit different. Who will build a straw passive house in a rural location?

The site is reasonably remote, with not a lot of local builders servicing the area – particularly not ones who were familiar with straw bale construction or passive house performance. This led us to working with Huff’n’Puff straw “Sit-up” panels (a prefabricated strawbale company) who could make the wall panels off-site and deliver them all boxed up ready to be erected.

Then with the expertise of a great team of builders, Hedger Constructions, who care about quality and were very open to learning something new, we had a successful outcome.

9. Flexibility and adaptability

The house design balances the integration of passive solar design principles with the site constraints and local climatic conditions – view, orientation, site slope, sun, wind and rain. It has also been designed with a zoning of spaces unlike a typical family home, creating a flexibility of use with one wing of the house occupied by its permanent residents while the second wing can adapt to fulfil the needs of visiting family and friends when required. The ‘guest’ wing is within the same thermal envelope but separated by an external timber-lined covered entry/hallway space. This creates a sheltered transition between outside and inside, whilst also creating privacy between the homeowners and their guests. Our clients have shared how well this is working for them and their visitors – making the home feel a lot larger than it is by utilising these outdoor spaces as extra rooms.

10. Thermal envelope and airtightness

The floor plan for this house is relatively long and thin (37 m long by 6.7 m wide), with the roof trusses spanning the full width in the north-south direction. This meant the house could be constructed with the floor, external walls and roof structure all up, insulated and airtight before any internal walls were built. This simplified things for the builders internally with installing the MVHR and dealing with other services.

You don’t often see a whole house’s thermal envelope volume in one space like this, without the visible interference of internal partitions. It did create a distorted sense of size during the construction process but was clever to construct it in this way.

ph+ | huff’n’puff big picture | 13 BIG PICTURE HUFF’N’PUFF

HUFF’N’PUFF BIG PICTURE 14 | passivehouseplus.co.uk | issue 45

One of the design intentions was to keep the house size more modest, but create great functional use of all the space, while maximising the views, and creating a warm and welcoming space to be in.

There are appropriately sized eaves to the north to shade the house from the harsh summer sun while ensuring the occupants can enjoy natural daylight and views to the landscape all year round.

Our clients’ neighbours commented on this as they live in a typical ‘wooden tent’

11. Why the odd roof pitch?

This home is off-grid, which means it’s completely self-sufficient for power, water and disposing of waste on site. There is no gas connection (or bottled LPG gas), so it is an all-electric home with enough solar PV and batteries to run the home and charge electric vehicles too.

The roof of the house was designed with an asymmetrical gable, so the north-facing pitch was steeper – a more appropriate angle to harvest that renewable energy from the sun, maximising the solar collection. The carport is at the western end of the house, which creates an asymmetrical double gable profile and adds a little fun and a modern twist to the roof line.

with little insulation, single glazing, and no external shading. In an attempt to keep cool in summer they close all the curtains and keep the house dark. It was a stark contrast for them to visit a home that was perfectly comfortable inside despite the sweltering heat – and still light and bright and a joy to be in!

Our clients also told us how their home was the ‘talk of the town’ while under construction, as everyone was curious about this “big, long shed with small windows”.

Yet when the neighbours visited, they all commented on how deceptive appearances could be from afar, and how truly beautiful this home feels to be in. (We know that a passive house’s beauty is more than skin-deep.)

The last word should go to our clients: “We are delighted to be in the house,” they said. “It really is wonderful. Thank you for your skill and thoughtfulness in designing our lovely home.”

SELECTED PROJECT DETAILS

Architect and interior designer: Envirotecture

Builder: Hedger Constructions

Prefabricated SIP supplier: Huff-n-Puff Strawbale Constructions

Passive house consultant: Alex Slater

Passive house certifier: Detail Green

Stylist: Belle Bright

Windows: Logikhaus

Ventilation: Fantech

Cladding: Cemintel Barestone

Airtight membranes: Pro Clima

12. Beauty is in the eye of the beholder

ph+ | huff’n’puff big picture | 15 BIG PICTURE HUFF’N’PUFF

UN pushes for radical sustainable building action

The United Nations is pushing for a rapid drive to make the world’s buildings sustainable – aided by an international coalition centred in the Wexford town of Enniscorthy.

The Enniscorthy Forum has signed a memorandum of understanding (MoU) with the UN Environment Programme (UNEP) on a broad collaboration to accelerate the global transition to decarbonised, high performance buildings – including the UN’s Buildings Breakthrough target of making “near zero-emission and resilient buildings the new normal by 2030.”

Founded to support the UN sustainable development agenda, the forum has launched a global network, the Buildings Action Coalition (BAC), with a membership comprising community-centric organisations, global industry players, and academia – and set to include Zero Ambitions Partners, a new sustainability communications and strategy consultancy co-founded by Passive House Plus editor Jeff Colley.

The MoU between the Enniscorthy Forum and UNEP was announced at a major ministerial summit hosted by the forum on 27-29 June in Enniscorthy. The MoU includes a collaboration with UNEP’s Global Alliance for Buildings and Construction (GlobalABC) on the Buildings Breakthrough target. Led by the French and Moroccan governments, 16 countries have signed up to date.

Mark Radka, chief of the energy and climate branch of UNEP, said: “We are delighted with our newly formalised relationship with the Enniscorthy Forum and look forward to a strong and enduring partnership that helps raise the performance of buildings and the built environment on a global scale. Experts from Ireland helped initiate the UN’s High Performance Buildings Initiative and this prompted creation of the Enniscorthy Forum. UNEP values and appreciates the Irish government's support for the Enniscorthy Forum and the activities of its Buildings Action Coalition.”

The Enniscorthy Forum is supported by the Irish government and the summit was attended by senior industry figures, government officials, community-based organisations, and leading academics from around the world. Participants called on the Irish government to endorse the Buildings Breakthrough target, and the initiative has been placed on the government’s agenda for review and consideration.

Speaking at the event, Yves-Laurent Sapoval, senior advisor to the director general of planning, housing and nature at the French ministry

of ecological transition, affirmed support for the initiative: “We consider improving the performance of buildings and the built environment to be imperative if we are to achieve the objectives set forth in the Paris Climate Agreement, and we look forward to working with the Enniscorthy Forum to accelerate achievement of tangible progress through the GlobalABC towards the Buildings Breakthrough target.”

The Passive House Institute was among a number of organisations from either side of the Atlantic which formally joined the coalition to coincide with the summit, alongside Building Energy Exchange, Building Innovation Hub, Built Environment - Smarter Transformation, Onion Flats, Passive House Canada, passivhausMaine, Passive House Network, River Clyde Homes, and South West College. Meanwhile, the Association for Environment Conscious Building (AECB), The Energy Coalition, Passive House for Everyone, Passive House Massachusetts, A2M, and Zero Ambitions Partners signed letters of intent to join the BAC.

The BAC aims to advance the cause of high-performance building and a more sustainable built environment, and accelerate tangible action on decarbonisation and improving quality of life everywhere, by developing a pan-continental forum to share the experience and expertise from some of the world’s foremost experts in the field.

The BAC’s knowledge-sharing and anti-gatekeeping ethos is being driven by its coalition partners. By promoting and demonstrating the transformative benefits of high-performance buildings it is pushing for a quicker adoption of

best practice methods in planning, design and construction across the world.

Zero Ambitions Partners co-founder Jeff Colley and Enniscorthy Forum CEO Barbara-Anne Murphy signed the letter of intent in a ceremony at Enniscorthy Castle on the occasion of the summit.

“We recognise the potential for the Buildings Action Coalition to make a major contribution to raising the performance of the world’s buildings and the built environment,” said Colley. “There is real substance in the coalition’s approach. Strong engagement with the UN sends out a significant positive signal, but the focus on engagement with grass-roots organisations will make a real difference.

“We’re excited to join the coalition to offer our help in raising awareness, recruiting, setting priorities for strategic communications, and assembling the required resources.”

Enniscorthy Forum CEO Barbara-Anne Murphy said: “We look forward to welcoming Zero Ambitions Partners to the coalition. They are extremely effective at outreach and information sharing, which is precisely the kind of support this initiative needs now.

“We have a significant programme underway to mobilise resources and disseminate knowledge, experience and best practices to transition towards high performance building. Given their competence in strategic communications, Zero Ambitions Partners will have an important role to play.”

Scott Foster, an adviser to the Enniscorthy Forum and former director of the Sustainable Energy Division of the UN in Geneva, said:

“Improving the performance of buildings and the built environment is the one action that can deliver integrated solutions at scale in a timely fashion to produce tangible outcomes on economic, social, and environmental resilience, quality of life, and climate, among other desirable outcomes, and in the process advance employment, innovation, and investment.

“This launch is an exciting development for the Enniscorthy Forum and is proof that small local organisations can achieve big things with the right support, the right partners and the right vision. The Buildings Action Coalition has far-reaching ambitions to help transform the built environment worldwide.”

For further information visit www.enniscorthyforum.org •

16 | passivehouseplus.co.uk | issue 45 NEWS PASSIVE HOUSE+ NEWS

(above l-r) Pictured are signatories including (top row) Passive House Massachusetts president Hank Keating; A2M founder Sebastian Moreno-Vacca; AECB CEO Andy Simmonds; River Clyde Homes director Richard Orr; Passive House Pennsylvania director Dave Parker (representing Passive House Network); Building Energy Exchange executive director Richard Yancey; (bottom row) passivhausMaine executive director Naomi Beal; Enniscorthy Forum CEO Barbara-Anne Murphy; Passive House for Everyone! co-founder In Cho; and Passive House Institute head of training Susanne Winkel.

AECB conference: building, climate chaos and biodiversity collapse

AECB CEO Andy Simmonds will update delegates on the association’s new collaboration with the UN-affiliated Buildings Action Coalition, and describe how this may afford the chance to accelerate the en masse decarbonisation and greening of buildings in the UK and internationally.

Prof Newman will give a plenary talk on the first day on urban forestry, drawing from his work on climate change, diet and sustainable livelihoods.

As with all AECB events, knowledge transfer will be at the forefront with thought-provoking talks and case studies from fantastic speakers, AECB experts and carefully-selected suppliers together with hands-on technical workshops, an exhibition area and plenty of time for questions and discussion.

The AECB 2023 Conference will focus on providing solutions required for building in an age of climate chaos and biodiversity collapse.

Headline speakers for the two day event on 29-30 September will include broadcaster and ecological architectural designer Charlie Luxton, natural resource, climate change and climate finance consultant Prof Steven M Newman, building physicist Prof Robert Lowe, and energy and climate research fellow Dr Lai Fong Chiu.

On the first day of the event, which will be hosted at the School of Natural Building at Tod College in Todmorden, West Yorkshire, the AECB will update delegates on a whirlwind of activity by the association in recent months including developments with the AECB’s CarbonLite suite of standards for new build and retrofit, on how the new standards can complement the passive house standards to create a practical, evidence-based route to decarbonisation for all buildings.

Charlie Luxton – whose deep green retrofit for his architectural practice is profiled in this issue of Passive House Plus - will give a plenary on the second day giving his thoughts on low energy buildings, embodied energy and the circular economy.

Luxton’s talk will be followed by a joint plenary by Prof Lowe and Dr Chiu on systems shocks and peak oil.

A number of interactive, hands-on and technical workshops will enable delegate to get to grips with selected topics in more depth such as the AECB standards and schemes, biodiversity and food, building climate resilient buildings in the Global South, software and the use of ‘natural’ materials in theory and practice.

The full programme is available at https:// aecb.net/aecb-conference-2023/ with discounts on registration offered until 1 September. •

Coalition forms to develop net zero carbon standard

Across-industry steering group has joined together to develop a standard for verifying UK buildings as net zero carbon.

Buildings are directly responsible for around a quarter of carbon emitted by the UK, according to the UKGBC’s Whole Life Carbon Roadmap. There is therefore no credible pathway to net zero for the UK economy without tackling emissions associated with the construction and operation of the UK’s building stock.

While significant progress has been made in defining what ‘net zero’ means for buildings in the UK, a process of market analysis showed a clear demand for a single, agreed methodology. The UK Net Zero Carbon Buildings Standard is intended to enable industry to robustly prove their built assets are net zero carbon and in line with the UK’s national climate targets. Leading industry organisations BBP, BRE, the Carbon Trust, CIBSE, IStructE,

LETI, RIBA, RICS, and UKGBC have joined forces to champion this initiative. The standard will cover both new and existing buildings and will set out performance targets addressing operational energy and embodied carbon emissions to align with the UK’s 2035 and 2050 emissions targets. It will also cover the procurement of renewable energy and the treatment of residual emissions, including carbon offsetting. •

ph+ | news | 17 PASSIVE HOUSE+ NEWS

(above) Broadcaster and ecological architectural designer Charlie Luxton will be delivering a plenary talk; (below) Todmorden, West Yorkshire.

Photo: Tim Green

Design and performance centre stage at UK Passivhaus Awards

Apioneering co-housing scheme, a cubeshaped self build, a cork and polyester-insulated retrofit to a 1970s house, a glulam timber school, and a curved college building were the winners at the 2023 UK Passivhaus Awards.

While awards for buildings tend to focus on newly completed projects in spite of the absence of post occupancy data, the Passivhaus Awards instead require entrants to demonstrate proven performance over time – and eagle-eyed readers may recognise some of the winners from previous issues of Passive House Plus.

Over 200 people attended the awards on 5 July, which were sponsored by Ecology Building Society, Knauf Insulation and Munster Joinery.

The competition was fierce, with an inspiring array of exemplary projects on display.

For the first time there was a tie in the residential new build category, with two markedly different joint winners: Ostro Passivhaus and Cannock Mill Cohousing.

Designed by Anne Thorne Architects, the groundbreaking Cannock Mill Cohousing is a wonderful example of what can happen when communities manage to forge an alternative to speculative housing development: a 23-unit cellulose-filled timber frame scheme in Colchester, Essex which simultaneously combats loneliness and climate change, and featured in issue 40 of Passive House Plus.

Paper Igloo Architects’ Ostro Passivhaus in Stirlingshire, which featured in issue 37, is a striking example of how great design can overcome even the most onerous self-imposed

restrictions: the woodfibre-insulated, cubeshaped building could barely have had a better form factor, but the fenestration and beautifully-detailed diagonal Siberian larch cladding and reveals give this project a real visual flourish.

With polyester clothes and Cork interior décor conjuring images of the 70s, it seems fitting that both materials should find a home in a retrofit to a house built in that decade: Bowman’s Lea. The Harry Paticas-designed retrofit to a London townhouse, which won the retrofit award, uses recycled polyester to insulate the loft, and cork internal wall insulation.

The winner in the non-domestic category was passive house stalwarts Architype’s Hackbridge Primary School, a beautiful, passive house plus-certified school near the pioneering experimental green housing scheme BedZed. The building, which is achieving net zero operational carbon, includes a cellulose-insulated panelised structural timber frame with glued laminated timber (glulam) columns and beams and a Larsen truss – a system which uses timber boarding to frame out the external insulation zone while minimising the use of timber.

Meanwhile Hamilton Architects’ Erne Campus won the people’s choice award. The curved new home for South West College, Enniskillen, generates four times more energy on-site than it uses. The world’s first educational building - and currently the largest building – to be certified to the passive house premium standard, Erne Campus is also BREEAM Outstanding certified.

The shortlisted projects included a number of other exemplary projects, such as:

• Tooley Foster’s Foleshill Health Centre, Coventry – the first NHS certified passive building;

• Roger Burton’s Chester Road Passivhaus, Stockport – a timber frame home with a large PV array and only electric convective heaters. The project was commended;

• Michal Rudnicki and Huff & Puff Construction’s Parc y Rhodyn, Wales – a straw-filled structural insulated panel (SIPs) house in Wales, that also meets the One Planet Development policy and is entirely off-grid;

• A D Practice’s Harpenden Enerphit Plus, Herts – a PV-roofed deep retrofit published in issue 43 of Passive House Plus

• RDA Architects’ Modernist Enerphit Plus, London – a sensitive retrofit to a 1960s modernist house published in issue 44 of Passive House Plus

• Mark Siddall’s Shepherd’s Barn. Durham – an Enerphit Plus retrofit using the box within a box approach – with a cellulose-insulated timber frame built within original and rebuilt stone walls.

To view all winners and finalists, visit https://tinyurl.com/UKPHA23 •

18 | passivehouseplus.co.uk | issue 45 NEWS PASSIVE HOUSE+

(above) Bowman’s Lea and Hackbridge Primary School, two of the winners at the 2023 UK Passivhaus Awards.

Bowman’s Lea photo: Harry Paticas/Agnese Sanvito Hackbridge photo: Architype/Jack Hobhouse

Cynicism and inspiration

It’s common for people who’ve taken passive house designer or tradespeople courses to say it has transformed how they think about buildings – that once you’ve seen it, you can’t unsee it, and that it fundamentally affects your approach on any projects. Sally Godber , director of leading passive house certifier Warm explains how one new community interest company, Coaction Training CIC, hopes to mobilise the industry.

Currently, energy literacy within our industry is so low that to enact the level of change we need, legislation alone – when it comes – is not going to be enough.

Within every project, irrespective of the client’s sustainability aspirations, there are a multitude of opportunities to make improvements. I’m not just talking about the big-ticket items like triple glazing, but rather tweaking a construction so it can be built without thermal bypass occurring, or reducing hot water pipe lengths that would otherwise contribute to overheating. Many of these low or no-cost opportunities are missed because no one is aware of the issues. We need a workforce who have the technical understanding to spot and address such issues.

Many construction professionals that I talk to feel frustrated that they can’t do more to enact change, but they’re wrong. All of us, no matter what our role, have the ability to improve the performance of the buildings in which we’re involved. I’ve found two key ways of using the knowledge I’ve gained from working in passive house which don’t rely on a strong sustainability brief from the client:

1. Stealth: With the right knowledge there are all kinds of modifications that can be applied to design or construction that might seem small but will make a tangible difference that you can do now. For example, our trainer Rupert Daly says: “in timber frame projects I specify the insulation width to be the same as the void between studs, so it’ll fit well without needing to be cut”. This means the construction team is set up to do a good job, and the risk of air gaps which severely reduce the performance of the insulation is minimised. It’s a small but signifi-

cant change, and you can read more about how insulation fails through thermal bypass from another of our trainers Mark Siddall in his recent paper, ‘Thermal bypass risks’.

2. Informing the client and team of the impact of their decisions. I was recently told by a supplier of structural insulated panels (SIPs) that their thermal bridging was “such a tiny number we didn’t think it needed worrying about”. I was able to put them right and gave them the opportunity to improve. Clients don’t always want to go for improvements, but you might just be surprised.

Hopefully, these examples make it clear that you don’t need to wait for the right client or project to come around, although we want that to happen too. All you need is the right knowledge and that’s exactly what we’ve developed. Our Coaction (formerly CarbonLite) training courses are a direct response to this situation. We know passive house gives you the key to really understand building performance. After all, it was developed specifically to address the ‘performance gap’ between design aspirations and real building energy performance.

So, who needs this training? Well, everyone. Energy performance doesn’t fall into the lap of any single role; pipe fitters, architects, clerk of works, are all undertaking activities that have an impact, so they all need some understanding of the issues. For the record, I’ve seen firsthand great solutions come out of multi-disciplinary teams tackling a problem that would usually be pigeonholed in one person’s court, and I guarantee it’s much more fun. We offer a range of courses at different levels; there’s something for everyone.

Passive house training at scale is the leg

up that the industry needs, irrespective of what our building regulations are up to. This is of course challenging, as we’ve got twenty-five trainers and there are a lot of people to train, but it’s also the exciting bit. We’ve assembled a collective of experts across a spectrum of disciplines, to give a variety of opinions with a common drive for change in our industry.

The opportunities to make real change, and in particular, to work more collaboratively are all waiting, we just need you to join in! n

COLUMN SALLY GODBER

ph+ | sally godber column | 19

All of us, no matter what our role, have the ability to improve the performance of the buildings in which we’re involved.

An early green building in a changing Ireland

It’s fair to say that green building wasn’t a thing in early 90s Ireland, which makes one extraordinary Dublin project from 1994 all the more remarkable, as Dr. Marc O Riain writes.

Almost 30 years ago, designers and researchers set out to create a modern ‘green’ building on a vacant lot in the centre of Temple bar at the outset of its regeneration. I, at the time, was street-painting across from Trinity and had a good view of the queue that formed a day before the apartments went for sale. Word on the street was one could get paid for holding a spot in the queue for potential buyers of the eight apartments. So, what made the Green Building an instant hit?

Supported by €3m in European funding in 1994, Tim Cooper with Murray O'Laoire Architects developed a design for the Green Building. It was described in a 2007 feature in Construct Ireland, the progenitor magazine of Passive House Plus, as “an innovative mixed-use development of offices, apartments and shop units laid out around a six-storey central courtyard designed as a semi-external atrium space with a glazed operable roof. The atrium's roof is oriented southwards and designed to naturally ventilate and light the building”.

The building was designed with a low glazing factor and high interior radiant panel surfaces supplied by low temperature solar water heating. It was cooled in the summer by drawing cold air up through the atrium at night using canyon and stack effect ventilation. The building benefitted from its compact apartment units’ mid terrace location, thus reducing surface heat loss. The envelope uses a mineral wool external insulation sys-

tem coupled with south-facing double glazed windows and triple glazing on the north face.

Although the roof initially featured wind turbines combined with solar electric panels (PV), the turbines would be later decommissioned because they were not successful. “The problems have been two-fold: firstly, their vibrations were heard in the penthouse apartments causing some discomfort for residents and, secondly, they failed to reliably produce power due to turbulence,” Walsh wrote.

The PV panels were another matter. The PV energy production (3,000 kWh/a) met 75 per cent of associated heat pump electrical demand (4,000 kWh/a) when built. Although grid connected, surplus electrical energy was fed back to the grid for free, as there was no associated purchase tariff at the time. “When we first put them in (PV panels) we couldn't grid connect,” Cooper told Walsh in 2007. “So, we had to put in the massive accumulator and a stack of inverters. That is now all redundant. The grid-connected photovoltaic alone is much more efficient than the photovoltaic and turbines were together, before".

Space heating and domestic hot water was driven by a ground source heat pump and evacuated solar tubes on the roof. The vertical ground source heat pump runs at a very efficient 5:1 co-efficiency of performance, which is impressive even by today’s standards. Interestingly Cooper reports that bedrock temperatures in Dublin have risen 2.5 C in the past 28 years since the bore-

hole was first measured, either a reflection of global warming or urban heat island effect. Whatever the reason, it must be improving the heat pump efficiency.

This early Irish example of low energy building design had a blend of passive and active solutions. Of the active solutions the PV and ground source heat pump would appear to function well with the internal thermal mass of the building fabric. It was definitely a signpost for things to come, as building standards in Ireland had just been introduced in 1992 and energy efficiency standards under Part L of the Building Regulations, didn’t differ too much from the 1974 elective standards. It would be the Kyoto protocol in 1998 which would drive the European Union to introduce the Energy Performance of Buildings directive in 2002 which would have a direct impact on the design of our buildings going forward. It is perhaps only today, almost 30 years later, that we have caught up with the Green Building in Dublin. It is a testament to the visionaries who brought this new ground in a very conservative country which itself was on the brink of change. n

Dr Marc Ó Riain is a lecturer in the Department of Architecture at Munster Technological University (MTU). He has a PhD in zero energy retrofit and has delivered both residential and commercial NZEB retrofits In Ireland. He is a director of RUA Architects and has a passion for the environment both built and natural.

20 | passivehouseplus.co.uk | issue 45

DR MARC Ó RIAIN COLUMN

Photos: David Ruffles

GROUND BREAKING U-VALUES FROM AS LOW AS 0.47W/M2K

UNPARALLELED CHOICE OF PASSIVE CERTIFIED PRODUCTS – OUTWARD OPENING, INWARD OPENING, UPVC, ALUMINIUM, ALUCLAD

T. 01789 473 987 E. info@munsterjoinery.co.uk

T. 01789 473 987 E. info@munsterjoinery.co.uk

WINDOWS & DOORS

WINDOWS & DOORS

WINDOWS & DOORS

WINDOWS & DOORS

T. 01789 473 987 E. info@munsterjoinery.co.uk

www.munsterjoinery.co.uk

www.munsterjoinery.co.uk

T. 01789 473 987 E. info@munsterjoinery.co.uk

www.munsterjoinery.co.uk

www.munsterjoinery.co.uk

UK retrofit meets Irish retrofit

With the UK’s nearest neighbour setting ambitious targets to deep retrofit a quarter of its housing stock by 2030, a delegation of UK retrofit stakeholders visited Ireland to see what lessons could be learned, as Matthew Tulley writes.

As we all know, removing a lot of fossil fuel use from our homes will need a lot of them to be retrofitted. Ten of us came over from the UK to see how Ireland have been getting on with the job. Retrofit is complicated, there are a lot of options to consider and for many homeowners it’s a journey into uncharted and dangerous waters. This is why the 17 Irish one-stop-shops have put the customer at the centre of their approach.

The visit started off with talks and a meal with one-stop-shop directors and project designers. Caroline Ashe from Kore Retrofit Ltd said how they help homeowners select which measures are right for them and then specify the retrofit. They then de-risk by selecting and monitoring the contractors, and carry out quality control checks throughout and at the end of the retrofit.

The following day we visited a ‘work in progress’ in Thurles, Co. Tipperary, where we saw a terrace house retrofit nearing completion. This had a typical set of challenges, with mostly external insulation, but also internal insulation on one side where the neighbour-

ing property had an extension that didn’t match up on height and depth. Because the whole house was also being refurbished at the same time, the new bathroom and kitchen could accommodate the change in inside wall thickness of the internal insulation. There were comments about the air source heat pump in the small rear yard, but as in many properties there is little choice on where to install – and behind the new triple glazed patio door you couldn’t hear it at all. The retrofit is transforming a cold and draughty home into a lovely new, comfortable place to live.

We also visited a much larger detached renovation a bit outside of town – we were asking about the metal strip at the base of the external wall insulation and whether it would be a thermal bridge. The tradesmen reminded us about mice and rats in the country – and the importance of the design being vermin proof! Again, this retrofit was part of a major re-design of the home so it was a full building site – definitely not something that could be lived in through the retrofit. On other jobs where it was just external insulation and air-

tightness, windows, ventilation and a heat pump, then it was all done around the homeowner living there – just one day away while plumbing was connected up.

The Templemore Arms Hotel had a lovely private room for soup and sandwiches and a ‘question time’ format with estate agents from Sherry FitzGerald Gleeson, and a local project manager. We heard that there is now a significant premium on both rental income and property values from homes with A or B Building Energy Ratings (BERs, the Irish equivalent of EPCs) – and a home that is retrofitted will not remain empty for long. The high cost of retrofit is more than recovered in property values in Ireland.

We finished off at TUS (Technological University of Shannon) hearing about heat pump performance, since all of the retrofits done by one of the leading one-stop-shops, Electric Ireland SuperHomes, are free of fossil fuels. We also learned about the quality assurance processes used by the contractors, and the site visits by the project managers of the one-stop-shops. There is independent quality assurance also done on a sample of retrofits by KSN Energy on behalf of the state agency responsible for retrofit grants, the Sustainable Energy Authority of Ireland (SEAI). We had heard from SEAI via a video link after breakfast. SEAI provide significant grant funding for retrofit but also have adopted SR 54, Ireland’s code of practice for retrofit, and commission KSN to ensure the standards are maintained.

It was a busy day and a half, but we mixed pleasure with business. We were well looked after at Abbey Court Hotel who were pleased that ‘in person’ events have returned after Covid. Most also joined the optional excursion to the music session in Paddy Rohan’s (every Wednesday evening) – a very traditional Irish pub including a grocers shop in the front part. As one of our visitors said: ‘Thank you so much for sharing your time and knowledge with such energy and openness. The visit was inspiring and informative in equal measure, and has greatly increased our collective understanding of the possibilities for retrofitting the UK’s aging housing stock.”

For more information contact m.tulley@ solidcstore.org n

MATTHEW TULLEY COLUMN 22 | passivehouseplus.co.uk | issue 45

(Above) The UK delegation during a tour of an Electric Ireland SuperHomes deep retrofit in Thurles, Co. Tipperary.

IN BRIEF

Building type: Steel barn converted into 204 m2 office and recording studio

Method: Flat pack I-beam timber frame, wood fibre insulation, material reuse and biodiversity focus

Location: Oxfordshire

Standard: Uncertified passive house Energy use: Beyond net zero. Net export of 1,400 kWh from Jan to mid July 2023, excluding EV charging.

Embodied carbon: Meets LETI 2030 target and RIBA 2025 target

See ‘In detail’ panel for more information.

FROM SMALL SCREEN TO DEEP GREEN

CHARLIE LUXTON’S VISIONARY NEW SUSTAINABLE OFFICE

The new Oxfordshire studio of Charlie Luxton Design, the practice of the well-known TV presenter and architectural designer, is deeply impressive for its exhaustive attention to sustainability across every facet of the project, from energy use and embodied carbon to the reuse of materials and the ecological restoration of the three-and-a-half-acre site. It’s a gorgeous building, too.

By Lenny Antonelli

25

If you’re a fan of architectural TV shows, you will know Charlie Luxton from programmes such as Building the Dream, Homes by the Sea, and Building a New Life in the Country. What you may be less aware of is the sheer depth and breadth of his knowledge of — and commitment to — sustainable building.

Charlie heads his own small practice, Charlie Luxton Design (CLD). When the firm decided to build a new studio just outside the village of Hook Norton in Oxfordshire, it was a chance to push the envelope across a swathe of sustainability metrics in a way that is often difficult when working for a client. “If I’m going to do a project for me, I have to make it a massive education piece,” he says.

His commitment to environmental protection stretches back to his childhood in Australia, when protests to save some of the

country’s old growth forests made a lasting impression on him. He moved to a farm in England at the age of nine and says playing in streams and climbing trees helped to foster his love of nature.

Charlie and his wife Kate, who is CLD’s studio manager, were finishing their own house next door when this three-and-a-halfacre plot came up for sale. It had been used to keep horses and had a steel-framed barn surrounded by heavily grazed paddock. The CLD team had been working in Charlie and Kate’s old thatch cottage down the road, but this site offered the perfect opportunity to create a purpose-built studio.

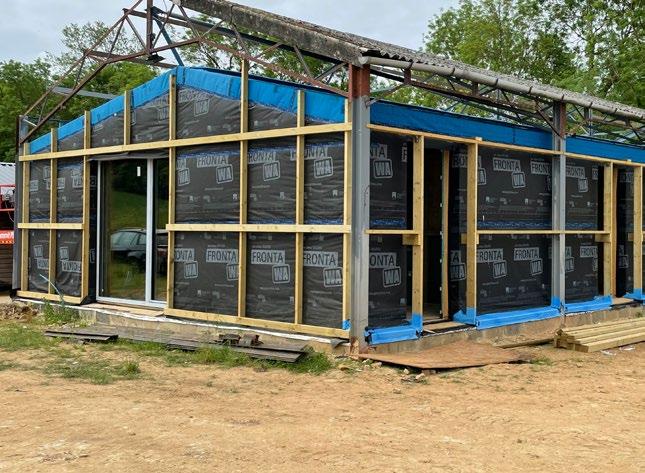

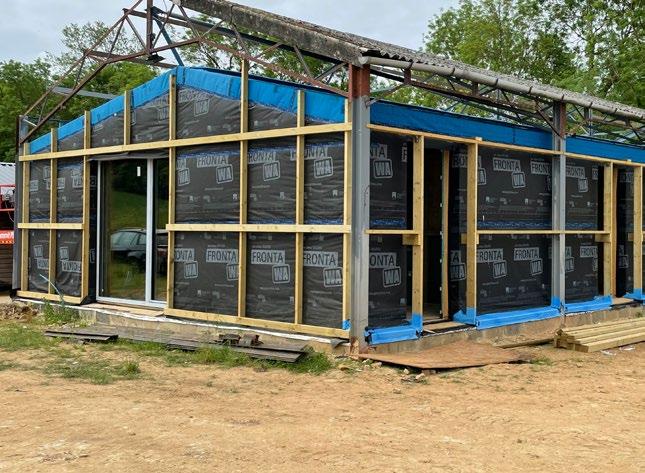

Building-within-a-building

From the outset, Charlie was keen to make use of the existing barn. “We stripped it back very carefully and engineered it so we could work with the existing concrete slab,” he says. “We took down the walls, took all the wood out of the stables for reuse, and basically tried to design a [new] building that could use as much of the existing structure as possible.”

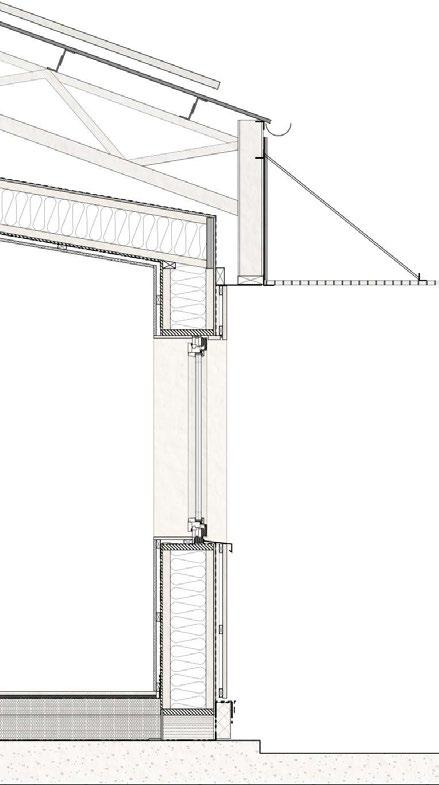

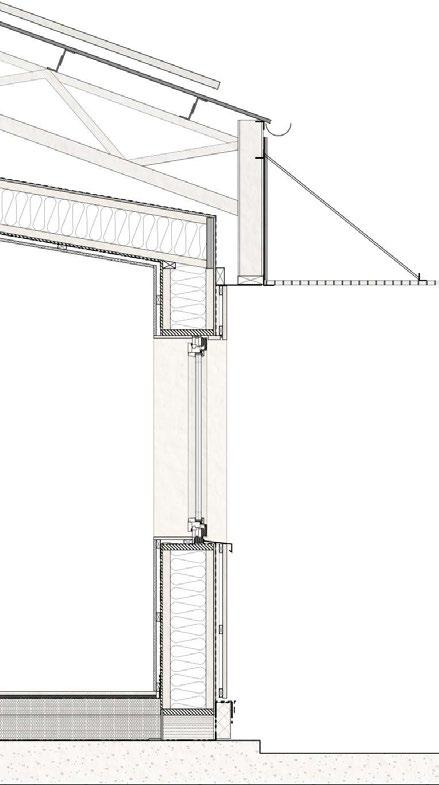

Building on the existing slab required extra thick walls to spread the load of the new studio. But with a goal to get close to the passive house standard and a preference for natural insulation, the walls were always likely to be quite thick.

Charlie served as principal contractor and recruited as many local trades as he could. The team laid a thin layer of levelling screed and then set out to build a new timber-framed studio within the structure of the old barn.

“The idea was very much to build a building within the building,” he says, “so that we didn’t put any additional load on the frame, because the frames of those buildings are really only designed to take themselves, and the wind.”

But the barn did provide a sheltered space within which to build the studio. The CLD team chose a timber I-beam system from German wood product specialist Steico. Each of the beams was digitally modelled and precut before being delivered to site. It’s a low-waste system Charlie had grown to like on previous projects.

“The thing about going with these precut systems is you can get an entire building on one lorry,” he says, and this was one of many ways he sought to reduce the carbon footprint of the build.

Steico laminated veneer lumber (LVL) — a mass timber product that takes dozens of thin layers of wood and glues them together to create a structural timber panel — was used for posts and beams, and around the building’s Internorm timber aluclad triple glazed windows. Durelis VapourBlock, a structural chipboard that also provides airtightness and vapour control, frames the

walls and roof internally, and serves as the main airtightness layer too. The walls and roof were pumped with blown cellulose insulation (Charlie brought his local labourers down to PYC Systems in Welshpool for training in how to install it), and then lined internally with Fermacell board, which is made from recycled gypsum and paper.

The team clad the structure in dark, powder-coated standing seam steel and British-grown larch and fitted a cap of EPS insulation — salvaged from another project — above the LVL ridge beam to stop thermal bridging down through the steel joist hangers. “We were really careful about that level of detailing,” Charlie says. The roof is finished with a 20 kW solar PV array.

Design for reuse

Inside, the team fitted 250 mm of EPS insulation over the existing slab. This was laid without any glue so that it could be easily reused in future. “We planned it all out on a computer so that we could do it with as few cuts as possible,” Charlie says. The team also used a hot wire cutter to cut the insulation as cleanly as possible, to stop microplastics from breaking off. The floors are finished with boards made from English elm.

An obsession with minimising the environmental impact of materials permeated the whole project. “We really tried to reuse as much as we can,” Charlie says. Timber reclaimed from the horse stables was reused for internal finishes. An oak-framed sliding door was salvaged from another project and re-purposed as an internal screen. Old walkways from the site were reused as solar shading. Recycled furniture and second-hand appliances were specified throughout. Outside, rather than completely dig up the concrete yard, the team simply broke up some areas of concrete and planted within it.

Charlie says that thinking about how to reuse materials at scale was one of the big takeaways from the project. “How do you use the things you’ve got to make the buildings you need?” he asks. “And how do you do that at scale? How do you find the materials, log the materials, test the materials, certify the materials?” These are some of the next big environmental questions for the building sector to get to grips with.

The CLD team also thought about how the building, and its components, might be used long into the future. “We sort of tried to imagine how you might minimise disruption for other phases of the life of the building,” he says. The building has been plumbed for future conversion to a house, and it’s been framed so that more doors can easily be installed in future. Cladding and roofing were also fixed to be easy to remove.

26 | passivehouseplus.co.uk | issue 45 LUXTON CASE STUDY

1.

2.

3.

4.

5.

6.

7.

8. Insulation

9.

20 kW PV array

Corrugated metal skin

Reclaimed walkaway as solar shading

Existing and adapted steel frame

Steico timber inner frame

Internorm triple glazed windows

Existing concrete slab

above slab

Void for services & ease of construction

Minimalist heating

The finished studio achieved an airtightness score of 0.3 air changes per hour and is within the parameters for passive house certification. The building is both heated and cooled, when needed, by an air source heat pump that warms or cools supply air being drawn into the building through a Passive House Institute-certified heat recovery ventilation system from Airflow, the specialist ventilation supplier who suggested this project to Passive House Plus for this article. The system, along with the lighting system, is managed by a building automation system from Wiise.

It’s a fairly minimal approach to heating, and Charlie says it keeps the building sufficiently warm on all but the three or four coldest days of the year. But while the building was wired for infrared radiators to top up the heating, he decided against putting them in. “Given how little we would use it, I suspect the embodied energy would make no sense whatsoever,” he says.

So instead, on freezing winter mornings, an old electric radiator, covered in paint, is wheeled to provide some extra heat, and Charlie says this works well.

And what about comfort on hot days? The heat pump provides cooling too, and on the hottest day of 2022, when temperatures in Oxfordshire exceeded 38 C, the temperature in the studio was a warm-but-acceptable 26 C. An external shade limits solar gain from the high summer sun to the south-facing studio space.

The 20 kW solar PV array provides electricity to the studio, to two electric cars, and to Charlie and Kate’s own house next door. So far this year, as of 12 June, the three buildings have used 11 mW of electricity in total, but only 2.4 mW of this was imported from the grid, with the rest — almost 80 per cent — coming from solar power. Charlie is planning to install a battery next year.

Studio space

And what about the spaces inside? What kind of studio did a group of architects and designers want to create for themselves to work in? Kate says that while the old thatched cottage was a pleasant space, it wasn’t really suitable for an office. “For clients coming, it was slightly weird,” she says.

For the new studio, the team wanted to have an open plan working area that fostered collaboration, but also separate rooms for calls, meetings, or quiet working. And with its light filled spaces and warm timber finishes, the new studio is certainly a beautiful space to work in.

“I know the team love coming here,” Kate says, “post-Covid there has been a culture of working from home, but we didn’t suffer from that. The guys wanted to get back into the office and be all together, and I think having this building is a huge part of that.”

She adds: “It’s a place that we want our clients to come to, we want to have meetings here, we want to share it with people.”

CLD does not use the whole building — about one third of the footprint is a music studio for writing and rehearsal, rented by a friend of Charlie’s, and some work was needed during the build to ensure this would be acoustically separated. “You can hear a little bit of drumming, but nothing bothersome, actually it’s really quite nice,”

ph+ | luxton case study | 27

Finished photos: Ed RS Aves | Other photos:

In the seven years since the Luxtons bought the site, it has gradually become richer in wildlife, and noticeably louder with the sounds of nature.

Charlie Luxton Design

WANT TO KNOW MORE?

The digital version of this magazine includes access to exclusive galleries of architectural drawings. The digital magazine is available to subscribers on passivehouseplus.ie & passivehouseplus.co.uk

SUSTAINABLE BUILDING MATERIALS FROM FOUNDATION TO RIDGE

Sustainability Prize 2023

OF THE SUSTAINABILITY PRIZE

Creating quality low energy architecture requires a dedicated, knowledgeable team from initial concept right through tofinishing touches. Ecomerchant is a key part of that team for Charlie Luxton Design.Our valuesalign, creating good buildings that perform and last whilst respecting our environment.

28 | passivehouseplus.co.uk | issue 45

WINNER

Charlie Luxton

Principal, Charlie Luxton Design

Black Barn Studios by Charlie Luxton Design Winner of Architects' Journal

www.ecomerchant.co.uk info@ecomerchant.co.uk +44 (0) 1793 847 444

he says.

The needs of this space were factored into the design of the building management systems by Wiise. When musicians press record in the studio, the ventilation system – which is inaudible to the occupants but may be detectable in recordings – is temporarily turned off.

Rewilding the site

Outside, the team’s attention to detail extended well beyond the boundaries of the building. The site was heavily cropped and packed with hardcore and rubber crumb, and as soon as they got the site, Charlie wanted to start restoring biodiversity.

This included planting over seven hundred native trees — particularly elm, alder and black poplar — plus new areas of wildflower flower meadow, and native scrub with crab apple, dog rose, hazel and rowan.

Charlie estimates that it will take about twenty years for the surrounding site to sequester, in the soil and new vegetation, the building’s carbon footprint (excluding the PV array – see embodied carbon section below) of sixty-seven tonnes. He says this is based on back-of-the-envelope sums, but he’s having more detailed calculations performed soon, and developing a longer-term biodiversity management plan.

He says that in the seven years since they bought the site, it has gradually become richer in wildlife, and noticeably louder with the sounds of nature. “Last year waking up at certain times of day and in certain weather was extraordinary,” he says. “That’s just been joyous to be honest with you… the sense of wellbeing it gives you to bring a land back to biodiversity health. It just feels amazing.”

The project was a winner of the sustainability prize at the 2023 Architects’ Journal Small Projects Awards. “That was a real vindication of what we’ve done and what we’ve worked towards,” Kate says. “To get that industry recognition was so exciting and we feel incredibly proud of it.”

I asked Charlie what the biggest challenge on the building was, but he says it all went pretty smoothly. “It went really well if I’m honest,” he says. “Do you know why? Because it was incredibly rational. And that’s the biggest lesson I think is, we just need to make things a lot simpler, to make all of our buildings a lot simpler.” He says that simpler buildings mean quicker and cheaper builds, less travel to site, lower embodied energy, and more flexible and longer-lasting buildings. It makes it easier to deliver airtightness and eliminate thermal bridges, too.

“And I think it’s actually really liberating to say I can make a really simple building, and if I concentrate and work really hard on that, it can be beautiful.”

ph+ | luxton case study | 29 CASE STUDY LUXTON

5 2 1 8 3 7 9

4 6 10

1 Charlie Luxton in the old building. The slab and steel frame were retained, and some blocks were reused; 2 levelling screed to existing slab; 3&4 Steico I-beam frame going up; 5 Caberfloor chipboard on 100 mm Platinum EPS, including channels cut for 75 mm semirigid Airflow ducting, with a further 150 mm EPS beneath; 6 25 mm battens on Durelix Vapourblock airtight vapour control board and Pro Clima airtight tapes, after the Steico Zell woodfibre insulation was blown in; 7 Fermacell boards; 8 Luxton and the Airflow Flexi DV1600 MVHR system; 9 Panelvent under Solitex Fronta vapour permeable breather membrane; 10 battened and counterbattened wall awaiting the powder coated corrugated iron cladding and roofing.

Advertise with us.

It is always a pleasure to work with the Passive House Plus team. They provide a wealth of information, support and time to provide the best advert. Launching a new product is never easy, but in the space of only two months we’ve received over 150 enquiries through two issues of the magazine and all have been very fruitful. We have been quoting straight after the magazine is out. A lot of the customers enquiring have genuine current projects and this is reflected in how many respond to our follow ups.

It is no doubt in my mind that this team are one of the best I have dealt with out of the many publications we use. They deliver and they deliver quality!

- Elizabeth Assaf, owner, Urban Front

To enquire about advertising, contact Jeff Colley on +353 (0)1 2107513, or email jeff@passivehouseplus.ie

www.passivehouseplus.co.uk

30 | passivehouseplus.co.uk | issue 45 LUXTON CASE STUDY Ÿ COP: 3-12 Ÿ MVHR Ÿ heating Ÿ cooling Ÿ hot water Ÿ for superinsulated & airtight homes C E R T I F I E D C O M P O N E N T s e n d u s f l o o r p l a n s f o r a q u o t e i n f o @ t o t a l h o m e . c o . u k 0 3 4 5 2 6 0 0 1 2 3 | t o t a l h o m e . c o . u k AS SEEN ON THE STREET h p v s e r i e s E F F I C I E N T R E S P O N S I V E C O N V E N I E N T H E AT P U M P V E N T I L AT I O N A I R - C O N D I T I O N I N G I S S O Y E S T E R D A Y . . . T H E F U T U R E I S H E A T P U M P V E N T I L A T I O N

Embodied carbon

By Jeff Colley

Embodied carbon calculations were conducted by passive house consultant Richard Bendy of The Healthy Home, using the AECB’s PHPP-based embodied carbon calculation tool, PHribbon. I amended these calculations to consider the effect of different product specifications in a couple of high impact areas. The project was then compared against the embodied carbon targets for offices in the RIBA 2030 Climate Challenge, and the LETI 2030 design targets.

The scope included the whole building, with the exception of reused/recycled items such as the retained concrete slab, steel frame and blocks for a first course of blockwork, along with brise soleil made from a recycled walkway. Groundworks were not included. Fixed furniture and equipment – including reused appliances – were also omitted, as were external works, along with ductwork, pipes, electrical fittings, and the Mixergy hot water cylinder, but the vast bulk of the building was included.

In the absence of quantified data on construction process-related emissions, the calculations rely on the default assumption in the RICS methodology, where construction process emissions are derived based on the value of the project. In this case, the construction process-related emissions, which are taken to represent 23 tonnes of CO2e, are likely an over-estimate, given the care taken by the project team to minimise emissions throughout the build.

In several cases, where the specified product didn’t have source data – such as an Environmental Product Declaration, default data, or CIBSE TM65 calculations in the case of building services – data was taken from EPDs or Product Eco Passports on similar products, to produce an indicative result. Most notably, this was the case with regard to the PV array, EPS insulation, air-to-air heat pump and heat recovery ventilation system.

Based on the precautionary principle, in the case of the building’s large PV array, where the specified product didn’t have an EPD, a similar product a with high embodied CO2 score was included in the calculations.

On this basis, the building scored a cradleto-grave total of 814 kg CO2e, meaning it meets the RIBA 2025 target for offices.

As Passive House Plus has shown previously, this total was dominated by the large PV array, which contributes a whopping 59.3 per cent of the total – albeit based on a panel with an EPD showing a high embodied carbon score, given the absence of an EPD for the actual panels used. If the roof mounted array is omitted, the total is just 332 kg CO2e/m2. This ignores the energy generated by the array, and is based on the conservative requirement set by RICS that any replacement materials/technologies within

CASE STUDY LUXTON

W D C o O B 0 0 0 0 n @ m -W 004 0 5 Q W K A M M W W S o T W S e b w o d R O 5 B P 2 0p P 2 D W W W 0 D W W W D W 2 LocationincorporatingReproductionOrdnancearightpropertySurvey 0 25 50 M 1 2 6 5 6 7 7 4 3 1. Black Barn Studio 2. Writer’s Retreat 3. Site entrance 4. Parking 5. Existing concrete yard adapted for planting 6. Native woodland 7. Wild flower meadow & grassland 6 WIDER SITE PLAN 1. Black Barn Studio 2. Writer’s Retreat 3. Site entrance 4. Parking 5. Existing concrete yard adapted for planting 6. Native woodland 7. Wild flower meadow & grassland Wider Site Plan Charlie

31

Luxton Design

Detail Study

Roof Construction:

Photo voltaic panel

0.7mm corrugated metal sheet

Existing steel frame

Ventilated void

Solitex Fronta Quattro breather membrane

12.5mm Panelvent

300mm Steico I-Beam & blown woodfibre insulation

Duralis Vapourblock board, taped for airtightness

25mm service void

12.5mm Fermacell board, finished & painted

Wall Construction: UK grown larch vertical cladding

50 x 50mm treated softwood counter batten

50 x 50mm treated softwood batten

Solitex Fronta Quattro breather membrane

12.5mm Panelvent

300mm Steico I-beam & blown woodfibre insulation

Duralis Vapourblock board, taped for airtightness

25mm service void

Floor Construction:

20mm English Elm wood floorboards

22mm Glued Caberdeck

100mm HP EPS 100 (laid for re-use)

150mm EPS PREMIUM 100 (laid for re-use)

Fully taped radon membrane

20mm levelling screed Existing concrete slab

SELECTED PROJECT DETAILS

Client, architect, main contractor:

Charlie Luxton Design

Passive house consultant:

The Healthy Home

Structural engineer:

Varndell Engineering

Quantity surveyor:

Andrew Bird Associates

Electric contractor:

AMR Electrical Contractor

Airtightness tester: Aldas

Life cycle assessment:

The Healthy Home

Building system supplier: Steico

Wood fibre insulation: Steico

Floor insulation (EPS): Kay-Metzeler

Windows & doors: Internorm, via At-Eco

Liquid airtight membrane: Blowerproof, via Ecomerchant

Airtight tapes & membranes: Pro Clima, via Ecomerchant

Corrugated metal roofing: Sandford Roofing

Fit out: Hook Norton Construction

British elm floorboards: Sutton Timber

Heat pump: Panasonic, via Airflow

MVHR: Airflow

Solar PV: Aspey Energy

Building management system: oxone, via Wiise

Landscaping: Katie Guillebaud

Garden Design

Breathable sheathing board: Panelvent, via Ecomerchant

Insurance: The Build Store

Hot water cylinder: Mixergy

Lighting: Darklight design

Sanitaryware: Duravit

Insulating blowing machine and training: PYC

the 60-year study period for the building must be assumed to have the same embodied carbon emissions as the initial one – a highly questionable assertion given the rate of decarbonisation in industry. Based on the projected lifespan of 25 years in the EPD for the default PV array chosen, this meant two replacement arrays were included.

It is worth adding, however, that if the value for what is currently the lowest emissions PV array on the market was used – the Sunpower Maxeon 3 – the totals for the PV array would have dropped by 73 per cent –or a cradle-to-grave total of over 26 tonnes, versus almost 98.5 tonnes. While this massive reduction owes mainly to the panel’s low carbon manufacturing – notably including the wafer and ingot being manufactured in Norway, using hydroelectric power – it’s also due to the panel’s higher output. For this calculation, 103 m2 of Maxeon 3 array had the same output as 120 m2 of the high carbon array that was assumed.

While thinking in terms of cradle-to-grave impacts is key, there is an argument that greater emphasis should be placed on reducing emissions now, provided it doesn’t lock in avoidable emissions over the lifespan of the building via operational energy use and avoidable repair or replacement of components. For this reason, LETI has set upfront embodied carbon emissions targets, alongside cradleto-grave and operational energy targets.

On this basis, the building fares very well, registering a total of 217 kg CO2e/m2, comfortably beating LETI’s 2030 target for upfront embodied carbon target for office buildings of 350 kg CO2e/m2.

It’s also worth noting that because both RIBA and LETI – quite reasonably – have separate embodied carbon and operational energy performance target, the extra carbon

invested in reducing emissions over time is counted, but the carbon saved through energy efficiency and generation of renewable energy isn’t. It may be the case that the upfront carbon pays back very quickly, which is precisely why it makes sense to have embodied carbon and operational energy targets, rather than trading one off against the other.

One factor which substantially helps: LETI’s targets don’t count roof-mounted PV arrays, instead regarding them as part of the grid, which drops the upfront total by 157 kg CO2e/m2

Based on LETI’s definitions of upfront emissions alone – excluding the PV array – the biggest embodied carbon total comes from the standing seam galvanised steel cladding at over eight tonnes – an estimate which would have increased if the impact of the vertical steel ribs on surface area of materials was considered.

While LETI’s targets don’t permit CO2 sequestered in materials to be offset against the emissions released upfront, the reliance on timber and wood fibre insulation means that at the point of practical completion, the building’s materials had absorbed and stored 176 kg CO2e/m2 – over 80 per cent of the upfront total.

Another factor significantly affecting the cradle to grave totals is the life cycle assessment requirement to consider the sequestered CO2 in the building’s timber and timber-based materials as effectively being released into the atmosphere at the building’s assumed end of life. 35.9 tonnes of CO2 stored in the building become 40.8 tonnes at the end of life, through a combination of the emissions being assumed to be released, and the extra carbon spent in transporting and processing the materials at that stage.

ph+ | luxton case study | 33 CASE STUDY LUXTON