Sustell™ makes precise, tailored environmental accountability the new normal across the animal farming value chain, opening the door to accurate reporting, multiple commercial opportunities and more sustainable food systems. From improving farm efficiency to sustainable finance, ecolabeling and credible, accurate reporting, Sustell™ is your solution. Contact us today.

Selko Fylax Grain is a microbial inhibitor that is highly efficacious at low dosage rates saving you money. It is less volatile than straight propionic acid making its effects longer lasting, and it has the added benefit that it also has an inhibitive effect on enterobacteria.

Highly efficacious at low dosage rates of 0.5-2kg / mT

Microbial inhibitor that also has an effect on enterobacteria

Less volatile leading to longer-lasting treatment

United

Tel: +44 (0) 1994 240002

Web site: www.feedcompounder.com

E-mail: mail@feedcompounder.com

Waterlogged fields and extensive crop damage have already cast a massive shadow over harvest prospects, raising serious questions about raw material supplies later this year and maybe 2025 as well.

Although gardeners and reservoir managers will no doubt be pleading for rain as the summer unfolds, the impact of the past few months on the country’s arable crops will be felt well into the future.

The fact that August 2023 to February this year was the second wettest such period for close to 200 years is sufficient to explain the extremely poor growing quality of winter wheat, barley, and oat crops across the UK. According to the Agricultural and Horticultural Development Board (AHDB), only one third of these crops were worthy of being described as either excellent or good when assessed in early April. That compares with a 90% excellent/good rating for the same winter-sown crops when checked in March 2023.

Crops were deemed to be equally ‘mediocre’ in large parts of the EU-27, when assessed last month by the EU crop monitoring service (MARS). This prompted the European Commission to reduce its forecast for 2024 wheat production to a four-year low of 120.8 million tonnes, some 4.8 mt below its earlier expectations.

Ironically, while cereals have struggled to survive the extreme wet and cold conditions of recent months, the invasive arable weed, black-grass, has continued to thrive. There’s a good reason for this of course.

Apparently, black-grass has a ‘ready to go’ mechanism in place to cope whenever fields are flooded, based on having a fully prepared ‘drinking-straw’ root structure. This is in contrast to wheat and other cereal crops which incorporate similar survival systems but have to slowly build their relevant coping root structures once soils become saturated.

The obvious question is how plant breeders might go about transferring the waterlogging resilience of black-grass to the survival and productive benefit of the nation’s cereal crops. That’s the challenge which is being addressed at Rothamsted Research, Hertfordshire, with the goal of making the cereals of the future better able to cope with the multiple weather demands that climate change may bring.

To this end, a comparative study of wheat and black-grass was carried out recently at Rothamsted during which seedlings from both items were grown in flooded pots for up to 21 days.

It was already known that wheat plants have the ability to alter their root structure in response to waterlogging by constructing a drinking straw-like structure called aerenchyma to increase gas exchange from the unflooded tissues down into the flooded roots. While this survival response is effective, the construction process takes time and energy.

What surprised Rothamsted’s researchers, however, was that their black-grass seedlings just kept growing, despite being placed in a flooded environment. This was due to the weed always having its waterlogging survival root structure on standby, just in case.

Researchers are hopeful they can help future-proof tomorrow’s cereals by borrowing the more useful traits from the natural qualities of black-grass. While this is encouraging, it’s clearly a solution which will take time to prove and refine.

Back in the present, with questions remaining over how much damage has already been done to today’s crops, the International Grains Council (IGC) has cut its global grain and stock projections for both 2023/24 and 2024/25, as revealed in its late April report.

Headline figures include 2023/24 global grain production being lowered by 3.5 million tonnes, leading to a sharper fall in 2023/24 carryout stocks than forecast by IGC in March. In total, global grain stocks at the end of 2023/24 are now projected to be 8.4 mt lower than was forecast in March, with wheat taking a 3.6 mt hit in the past month and the maize forecast being adjusted downwards by 4.8 mt.

Currently, therefore, IGC’s projections for 2024/25 show global grain supply and demand remaining ‘finely balanced’ this year with ‘little room for error’. This, the Council added, will keep grain markets sensitive to changing weather reports in the weeks and months ahead.

It’s against this delicate supply/demand background that raw material buyers will be watching the world’s increasingly extreme weather patterns even more closely than normal this year.

According to FEFAC, cereals currently account for 25% of what animals eat in the EU. These are mainly feed grade cereals, of course, not grains grown for human use.

This begs the question of what may happen later in the year when a fair chunk of the 90% of UK cereals which would normally have headed for use in human food production, due to their excellent or good ranking, having to find an animal feed outlet instead. There’s usually a bit of ‘give-and-take’ on standards but only within reasonable limits.

Farmers are also constantly being advised to address Least Cost Formulation (LCF) as a means of supplying the required nutrients to their animals while keeping track of currently available ingredients and the price at which they’re on offer.

Given the prospect that the bulk of UK grains which make it through to harvest this autumn potentially being better suited to feed animals, rather than food or drink outlets, pricing trends for the rest of the year could easily become as volatile as the weather patterns which have got us to this point.

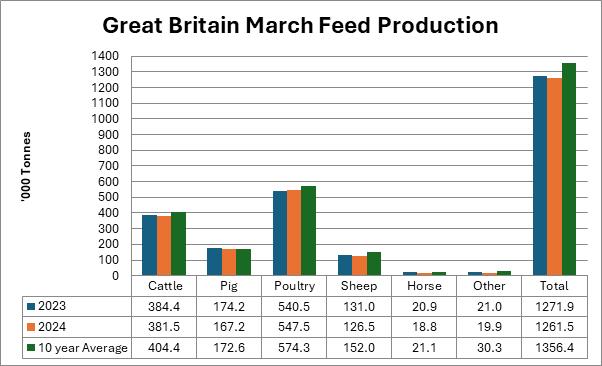

March Production Overview

Total production of compounds, blends and concentrates, including integrated poultry units, during March decreased by 10,400 tonnes or 0.8 per cent from the corresponding month a year previous to 1,262,500 tonnes. This was the fourth year in succession where March feed output had declined and as a result, the current total fell 94,900 tonnes or 7.2 per cent below the decade long average for the month.

Total feed production during the month of March 2024 was made up of: 43.4 per cent poultry feed; 30.2 per cent cattle and calf feed; 13.3 per cent pig feed; 10.0 per cent sheep feed; 1.5 per cent horse feed; and 1.6 per cent other feed.

At 547,500 tonnes of output, total March poultry feed bettered its year earlier production by 7,000 tonnes or 1.3 per cent. However, due to significant drops in output over recent years, the total under review was 26,800 tonnes or 4.8 per cent down on the 10 year average for March.

Integrated poultry feed produced surpassed its year earlier total by a considerable 20,100 tonnes or 10.6 per cent, rising to 210,000 tonnes of production, its second highest level in seven years. Turkey feed production also bettered its year previous return, as it has done for nine out of the past 10 months, in this case doing so by 300 tonnes or 5.9 per cent. Layer compounds was the final subsector to outstrip its respective 2023 total, its output grew by 2,400 tonnes or 2.5 per cent to 99,000 tonnes. Broiler chicken compounds production fell for the fourth March in a row, dropping 14,700 tonnes or 7.5 per cent to 180,600 tonnes. At 27,800 tonnes, poultry breeding and rearing compounds was at its lowest level for the month since 2013, down 1,600 tonnes or 5.4 per cent from a year earlier. Similarly, chick rearing compounds was at its lowest output since 2015 of 10,400 tonnes, 600 tonnes or 5.5 per cent lower than in the March of 2023.

A decrease of 2,900 tonnes or 0.8 per cent brought total cattle and

calf feed compounds down to 381,500 tonnes, its lowest total for the month under review since 2009. Moreover, the current total was 22,900 tonnes or 5.8 per cent down on the decade long average for March.

Total calf feed output was one of only two cattle and calf feed subsectors that bettered its year previous return, doing so by 1,400 tonnes or 12.8 per cent rising to 12,300 tonnes of production. The second was all other cattle blends which, at 33,500 tonnes of production, had increased by a significant 6,400 tonnes or 23.6 per cent from a year earlier. In contrast, output from the sector’s largest category, compounds for dairy cows, fell for the third year in succession to 191,000 tonnes, a decrease of 6,400 tonnes or 3.2 per cent from a year previous. Blends for dairy cow was also down on a year previous, production falling 2,400 tonnes or 3.0 per cent to 78,900 tonnes. At 52,100 tonnes, all other cattle compounds output was at its lowest level since records were kept in their current form; the total under review had declined by 400 tonnes or 0.8 per cent from the previous March low in 2023. Lastly, cattle protein concentrates dropped by 700 tonnes or 7.3 per cent to 8,900 tonnes.

A decline in production of 7,000 tonnes or 4.0 per cent brought total March pig feed down to 167,200 tonnes, the lowest output for the month under review for 7 years. As such, the current total was 5,400 tonnes or 3.2 per cent below the 10 year average for the month.

Despite the significant drop in production from the sector overall, the output of pig growing compounds surpassed its year previous return by 3,000 tonnes or 12.4 per cent and rose to 27,100 tonnes. Pig protein concentrates also bettered their year previous return, up 100 tonnes to 300 tonnes of production for the month. On the other hand, link and early grower feed production for March dropped to its lowest level since 2006; it declined by a sizable 3,800 tonnes or 40.4 per cent to 5,600 tonnes. At 3,000 tonnes, pig starters and creep feed output had decreased by 800 tonnes or 21.1 per cent from a year earlier to its lowest level since 1992. Pig finishing compounds production dropped for the second year in succession, down 3,200 tonnes or 3.3 per cent to 94,200 tonnes. Finally, pig breeding feed fell from its year earlier total by 2,100 tonnes or 5.4 per cent to 37,100 tonnes.

Total sheep feed production was at its lowest level for March since records were kept in their present form in 1992. The current output of 126,500 tonnes was 4,500 tonnes or 5.4 per cent lower than in the respective month a year previous. In addition, the current total was 25,500 tonnes or 18.3 per cent below the decade long average for March.

Although the sector was at its lowest level on record, both blends for breeding sheep and bends for growing and finishing sheep outstripped their year previous returns. The former did so by 500 tonnes or 12.8 per cent up to 4,400 tonnes and the latter did so by 300 tonnes or 5.3 per cent up to 6,000 tonnes. Sheep protein concentrates also increased from a year earlier, up 100 tonnes to 800 tonnes of production. Compounds for breeding sheep fell for the fourth successive year to a record low of 67,300 tonnes, a decrease of 2,200 tonnes or 3.2 per cent from 2023. At 48,000 tonnes, production of compounds for growing and finishing sheep had decreased from year earlier levels by 3,200 tonnes or 6.3 per cent.

At 18,800 tonnes of output, total horse feed was at its lowest level since 2014 and 2,100 tonnes or 10.0 per cent lower than in

the corresponding month a year earlier. Furthermore, 2024’s March production was a considerable 2,300 tonnes or 11.5 per cent down on the 10 year average for the month.

A decline of 1,100 tonnes or 5.2 per cent resulted in total other feed dropping to its lowest level for March since 2008 of 19,900 tonnes. Moreover, due to considerably higher production earlier in the decade, the current total was 10,400 tonnes or 41.4 per cent down on the 10 year average for the month.

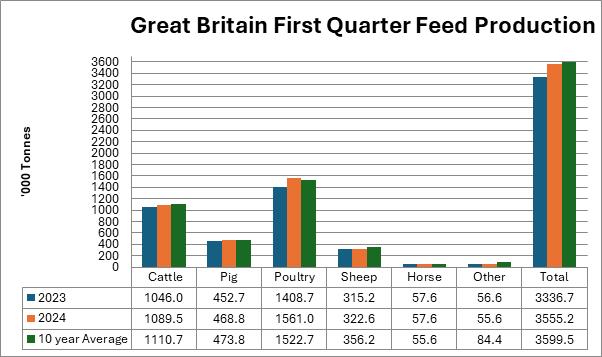

The release of the March feed production statistics brought the first quarter to a close and these figures are analysed below.

Total production of compounds, blends and concentrates, including integrated poultry units, during the first quarter of 2024 amounted to 3,555,200 tonnes, surpassing its year earlier counterpart by 218,500 tonnes or 6.6 per cent. However, the total under review was lower than all but three of the past ten Q 1 returns and therefore dropped 44,300 tonnes or 1.2 per cent below the decade long average for the period.

Total feed production during the first quarter of 2024 was made up of: 43.9 per cent poultry feed; 30.7 per cent cattle and calf feed; 13.2 per cent pig feed; 9.1 per cent sheep feed; 1.6 per cent horse feed; and 1.6 per cent other feed.

At 1,561,000 tonnes, total first quarter poultry feed production exceeded the return of a year previous by 152,300 tonnes or 10.8 per cent. Additionally, the total under review outpaced the decade long average for the timeframe by 38,300 tonnes or 2.5 per cent.

Total production from integrated poultry units was at its highest first quarter level in 12 years at 645,300 tonnes, up a notable 151,000 tonnes or 30.6 per cent from a year previous. Conversely, broiler feed production was at its lowest Q1 output for eight years at 495,700 tonnes, down 16,900 tonnes or 3.3 per cent from the corresponding period a year earlier. Having decreased markedly for the past three years, turkey feed production bettered its 2023 return by 4,900 tonnes or 39.5 per cent, rising to 17,300 tonnes. Both the layer and chick rearing feed subsectors rebounded from decreases in first quarter production a year earlier, with the former increasing by 7,300 tonnes or 2.8 per cent to 265,000 tonnes and the latter by 600 tonnes or 2.0 per cent to 30,000 tonnes. Lastly, poultry breeding and rearing feed output fell

for the fourth first quarter in succession to 76,400 tonnes, a decline of 1,100 tonnes or 1.4 per cent.

A rise of 43,500 tonnes, or 4.2 per cent in first quarter cattle and calf feed production brought the total under review up to 1,089,500 tonnes. Nevertheless, the current total was still 21,200 tonnes or 1.9 per cent lower than the decade long first quarter average.

Protein concentrates for cattle and calves was the only cattle feed subsector that failed to better its year previous Q1 returns, as it dropped 100 tonnes or 0.4 per cent from its corresponding 2023 output to 26,000 tonnes. The all other cattle blends category grew by the most significant proportion in the period under review, rising by 21,200 tonnes or 28.0 per cent from a year previous to 96,800 tonnes. First quarter all calf feed output also increased significantly, up 3,700 tonnes or 8.2 per cent from a year previous to 49,000 tonnes. The remaining cattle feed subsectors all increased steadily from their year earlier Q1 levels: compounds for dairy cows grew by 11,600 tonnes or 2.2 per cent up to 537,900 tonnes; output of blends for dairy cows rose by 2,600 tonnes or 1.2 per cent to 227,000 tonnes; and all other cattle feed outpaced its year previous counterpart by 4,400 tonnes or 3.0 per cent up to 152,700 tonnes.

Following a considerable drop in production between 2022 and 2023, total first quarter pig feed output increased by 16,100 tonnes or 3.6 per cent. However, this rise was not great enough to bring the total under review above the long term average, which it was 5,000 tonnes or 1.1 per cent below.

Pig growing feed production rose sharply from its year earlier first quarter counterpart to 81,200 tonnes, an increase of 17,200 tonnes or 26.9 per cent. The sector’s largest component, pig finishing feed, also bettered its year previous return, doing so by 8,200 tonnes or 3.3 per cent, up to 259,100 tonnes of output for the quarter. Pig breeding feed production also increased, by 2,300 tonnes or 2.2 per cent up to 105,100 tonnes. On the other hand, pig starters and creep feed output was at its lowest level for the period since records were kept in their current form, at 8,100 tonnes, down 1,800 tonnes or 18.2 per cent from a year previous. Link and early grower feed also decreased sharply from the first quarter of 2023 to 14,900 tonnes, its lowest level since 2006 and 9,500 tonnes or 38.9 per cent down on a year earlier.

Total sheep feed bettered its year previous production by 7,400 tonnes or 2.3 per cent and rose to 322,600 tonnes of output for the quarter. Despite this increase, the total under review was 33,600 tonnes or 9.9 per cent lower than the 10 year average for the period.

At 133,200 tonnes, compounds for breeding sheep was the one subsector where production failed to better its year previous Q1 counterpart, falling 3,100 tonnes or 2.3 per cent from its 2023 return. In contrast, blends for growing and finishing sheep and protein concentrates for sheep both grew sharply from their respective year earlier returns: the former’s production increased by 2,100 tonnes or 13.0 per cent to 18,200 tonnes and the latter’s did so by 300 tonnes or 15.8 per cent to 2,200 tonnes. Having declined for three first quarters in a row, compounds for breeding sheep output, at 157,700 tonnes, outpaced its year earlier return by 7,400 tonnes or 4.9 per

cent, however, this was still the second lowest total for the period on record. Finally, blends for breeding sheep surpassed its year previous counterpart by 700 tonnes or 6.6 per cent, rising to 11,300 tonnes for the quarter.

Production of total horse feed matched its 2023 first quarter return of 57,600 tonnes. Output from the current timeframe was nonetheless 2,000 tonnes or 3.6 per cent in excess of the 10 year average for the period under review.

First quarter total other feed production dropped by 1,000 tonnes or 1.8 per cent from the levels recorded a year ago to 55,600 tonnes. Additionally, the total under review was a marked 28,800 tonnes or 41.1 per cent lower than the decade long Q1 average.

With total production from all the sectors bar horse and other feed, surpassing their year previous first quarter returns, it appears as if Great British feed production is on course to rebound somewhat from the sizeable downturn in output in 2023. However, as the poultry feed and horse feed sectors were the only two to better their long term averages there is a big gap to make up before production returns to the heights of four years ago. It will be interesting to see the impact of the incredibly poor weather of the past 6 months affects feed production going forward.

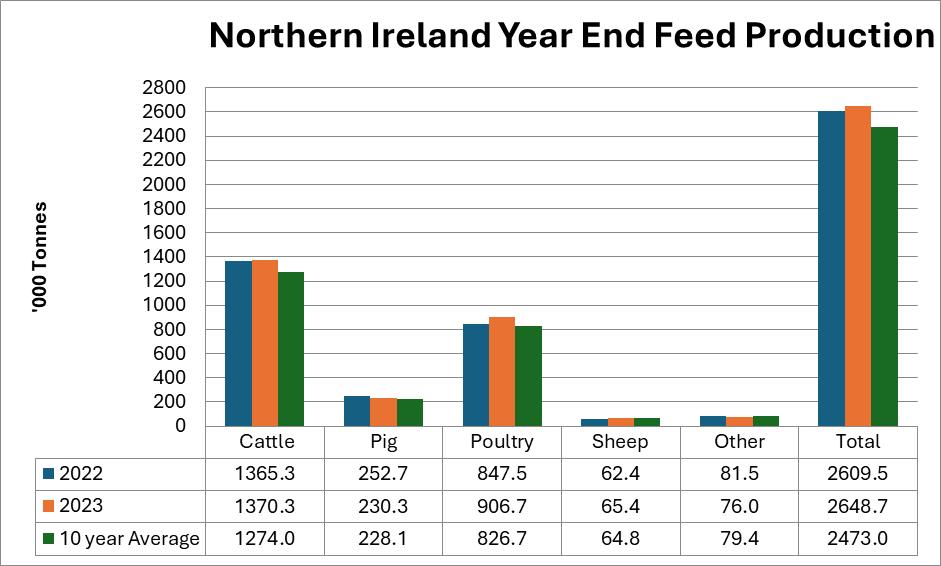

Year End Production Overview

Total production of compounds, blends and concentrates, including integrated poultry units, during the year of 2023 was at a record high 2,648,700 tonnes, surpassing 2022 by 39,100 tonnes or 1.5 per cent. In addition, the total under review was a considerable 175,700 tonnes or 7.1 per cent in excess of the decade long average for a calendar year.

Total feed production during the year of 2023 was made up of: 34.2 per cent poultry feed; 30.5 per cent cattle and calf feed; 14.4 per cent pig feed; 5.6 per cent sheep feed; and 2.2 per cent other feed.

At 1,370,300 tonnes, total cattle and calf feed in 2023 was at its highest level for a calendar year on record and 5,000 tonnes or 0.4 per cent above the previous record return from a year earlier. Moreover, the total under review was 96,300 tonnes or 7.6 per cent greater than the decade long average for the period.

Despite the overall growth in production in the sector, a number

of subsectors failed to match their year previous returns. Production of beef coarse mixes or blends for the period had fallen for the second year in succession, in this instance by 12,900 tonnes or 5.0 per cent to 242,500 tonnes of output. Year end beef cattle compounds production had also dropped for the second consecutive year to 143,100 tonnes, a 7,200 tonnes or 4.8 per cent decrease from 2022. Moreover, protein concentrates for cattle and calves output from the period under review declined from the previous year by a significant 800 tonnes or 26.3 per cent to 2,400 tonnes. On the other hand, both dairy cow compound and dairy coarse mixes or blends were at their highest level for a calendar year since records were kept in their current form. The former surpassed its year earlier return by 8,600 tonnes or 1.4 per cent and rose to 630,600 tonnes of output, while the latter, at 260,800 tonnes, bettered its 2022 counterpart by 11,000 tonnes or 4.4 per cent. All other cattle compounds production for the timeframe increased by 400 tonnes or 8.7 per cent from a year earlier to 5,200 tonnes. Finally, the two calf feed categories outpaced their year earlies outputs: calf milk substitutes rose by a considerable 500 tonnes or 215.0 per cent to 700 tonnes; and other cattle compounds output grew by 5,400 tonnes or 6.8 per cent to 85,100 tonnes.

An increase in production of 59,100 tonnes or 7.0 per cent brought total poultry feed output for the calendar year up to 906,700 tonnes. A record high for the timeframe and the first time that production has surpassed 900,000 tonnes in a 12 month period. Additionally, the current total outstripped the decade long average for yearly production by 80,000 tonnes or 9.7 per cent.

Both broiler feed, at 496,500 tonnes, and chick rearing feed, at 30,800 tonnes, were at record levels for the period under review, surpassing their year previous production by 50,100 tonnes or 11.2 per cent and 2,600 tonnes or 9.2 per cent respectively. After a prolonged stretch of reduced output, production of turkey and other poultry feed in 2023 increased sharply to 31,110 tonnes, which was a rise of 7,100 tonnes or 29.8 per cent from a year earlier; however, the total under review was still low in comparison to the long term average. Layer and breeder feed was the only poultry subsector where production did not better its year earlier total, the 348,300 tonnes of output from 2023 was 600 tonnes or 0.2 per cent down on its 2022 level.

Total year end pig feed production dropped below its year previous output by 22,400 tonnes or 8.9 per cent to 230,300 tonnes. This was the second time in succession that output from the period had decreased sharply from the record high of 2021. Due to significantly lower production in the first half of the preceding decade, the total under review was still 2,200 tonnes or 1.0 per cent in excess of the 10 year average.

All pig feed subsectors fell below their year earlier counterparts in 2023. The largest category, pig finishing feed, decreased by 10,000 tonnes or 9.6 per cent from the calendar year a year earlier to 94,100 tonnes. Pig growing feed output also dropped sharply to

RONOZYME® WX is a leading xylanase enzyme authorized for use in feed for all major monogastric species.

By helping improve digestibility of energy and protein in poultry and swine diets RONOZYME® WX helps deliver outstanding performance in an efficient and sustainable way.

40,400 tonnes, a fall from 2022 levels of 7,000 tonnes or 14.7 per cent. The declines from 2022 returns from the rest of the sector were more moderate but still not inconsiderable: pig link and early grower feed production dropped by 2,700 tonnes or 6.8 per cent to 36,500 tonnes; pig breeding feed output fell 1,500 tonnes or 4.6 per cent to 31,000 tonnes: and pig starter and creep feed decreased by 1,300 tonnes or 4.3 per cent to 28,400 tonnes.

Total sheep feed production in 2023 rose to 65,400 tonnes, an increase of 2,900 tonnes or 4.7 per cent from its year earlier counterpart. Furthermore, the current total outpaced the 10 year average for the timeframe by 600 tonnes or 0.9 per cent.

Breeding sheep compounds were the only category where production dropped below its year earlier return, doing so by 1,000 tonnes or 4.5 per cent to 21,800 tonnes. On the other hand, output of growing and finishing sheep compounds grew by 2,500 tonnes or 8.8 per cent to 30,200 tonnes, its second highest total for a calendar year on record. Coarse mixes or blends for sheep, at 13,300 tonnes, had also increased markedly from 2022 levels which it had bettered by 1,500 tonnes or 12.6 per cent. Lastly, there was around 40 tonnes of sheep protein concentrates recorded as being produced in 2023, a slight increase on a year previous.

A 5,500 tonnes or 6.8 per cent decrease in total other feed from a year earlier brought 2023 production down to 76,000 tonnes. As a

result of this fall, the current total was 3,400 tonnes or 4.3 per cent lower than the decade long calendar year average.

With total production at record highs for a calendar year, the contrast between Northern Irish and Great British animal feed production is stark. The two largest sectors, cattle and poultry, were also both individually at record levels and pig feed was the only main category where production fell below year earlier levels - it was, nevertheless, above the long term average. The industry is looking well set as it entered 2024 and the January figures for Northern Ireland are discussed below.

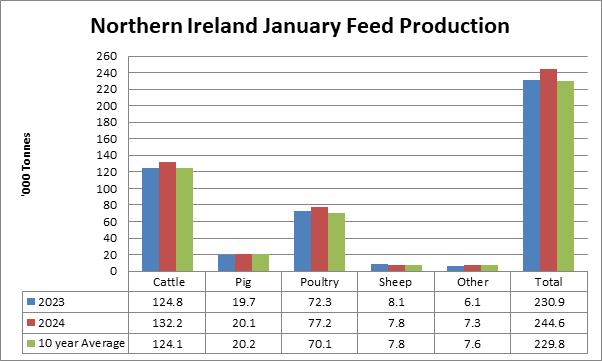

Total production of compounds, blends and concentrates, during the month of January amounted to 244,600 tonnes, an increase of 13,600 tonnes or 5.9 per cent from the corresponding month a year earlier. This was the fourth successive January where total output had risen. Furthermore, the total under review was 14,800 tonnes or 6.4 per cent in excess of the decade long average for January.

Total feed production during the month of January 2024 was made up of: 54.1 per cent cattle and calf feed; 31.6 per cent poultry feed; 8.2 per cent pig feed; 3.2 per cent sheep feed; and 3.0 per cent other feed.

Total cattle and calf feed production in January surpassed its year previous counterpart by 7,400 tonnes or 5.9 per cent and grew to 132,200 tonnes. This was the third highest total on record for the month under review and also 8,100 tonnes or 6.5 per cent greater than the 10 year average for January.

In contrast with the sector’s performance overall, output of beef cattle compounds fell for the fourth year in succession to 14,400 tonnes, a decline from a year earlier of 700 tonnes or 4.5 per cent. Dairy cow compounds production, at 53,300 tonnes, also decreased from its year previous level by 100 tonnes or 0.2 per cent. Beef coarse mixes or blend output bettered its 2023 return by a considerable 5,300 tonnes or 23.3 per cent, up to 28,200 tonnes of production. Both the dairy coarse mixes and blends and other cattle compounds subsectors outpaced their year previous totals: the former rose by 2,400 tonnes or 9.7 per cent to 26,800 tonnes and the latter rose by 300 tonnes or 4.0 per cent up to 8,700 tonnes of output. Production of all other cattle compounds and protein concentrates for cattle and calves were each at 400 tonnes and in line with their year earlier outputs.

At 77,200 tonnes, total poultry feed production was at a record high for the month under review and 4,900 tonnes or 6.8 per cent higher than a year earlier. Moreover, the current total outstripped the 10 year average for January by 7,100 tonnes or 10.1 per cent.

Only turkey and other poultry feed production failed to surpass its year previous counterpart as output fell by a substantial 1,300 tonnes or 45.5 per cent to 1,500 tonnes. On the other hand, both

the layer and breeder feed and chick rearing feed categories were both at record levels for the timeframe under review. The former, at 28,800 tonnes, was 1,200 tonnes or 4.2 per cent up on a year earlier and the latter’s production increased by 600 tonnes or 22.7 per cent. Finally, broiler feed production outpaced its year earlier total for the third year in a row, in this instance by 4,500 tonnes or 11.3 per cent up to 43,800 tonnes.

A growth in output of 400 tonnes or 2.2 per cent brought total pig feed production for January up to 20,100 tonnes. However, in spite of the increase, the total under review was still over 100 tonnes or 0.4 per cent lower than the decade long average for the month.

At 3,000 tonnes of output, pig growing feed had decreased by 700 tonnes or 19. 2 per cent from its year previous level. Similarly, pig breeding feed production had fallen by 100 tonnes or 3.7 per cent from its 2023 return to 2,500 tonnes. However, pig starter and creep feed production rose by 600 tonnes or 24.1 per cent from the corresponding month a year earlier to 2,900 tonnes and pig link and early grower feed increased by 400 tonnes or 12.9 per cent to 3,500 tonnes of output. Each of these totals was a joint record high for the month. Lastly, pig finishing feed production surpassed its year previous total by 300 tonnes or 3.4 per cent and rose to 8,300 tonnes.

Total sheep feed production in January declined by 300 tonnes or 3.4 per cent to 7,800 tonnes; this downturn brought it in line exactly with the decade long average for the month.

Despite the overall drop, more sheep feed subsectors surpassed their year earlier totals than fell below them. Output of growing and finishing sheep compounds increased from its 2023 return by 300 tonnes or 11.3 per cent up to 3,000 tonnes, while breeding sheep compounds production rose by 100 tonnes or 0.6 per cent to 3,600 tonnes. However, production of coarse mixes or blends for sheep dropped to its second lowest level for the month this millennium of 1,200 tonnes, 600 tonnes or 32.6 per cent down on a year previous.

A 1,200 tonnes or 19.5 per cent increase brought total other feed production up to 7,300 tonnes, its highest level for the month In four years. However, this increase was not large enough to bring the total under review above the decade long average for January, which it fell 300 tonnes or 3.6 per cent below.

Modern European agriculture is all about sustainable feed and food production, ideally based on locally sourced raw materials, leaving the lowest possible carbon footprint, with all available waste being used for clean energy generation.

It’s a tall order to tick all these boxes but this is where the industry is headed at present, accompanied by rising pressure being applied to those who don’t match up. This, certainly, is the message being pumped out by the industry’s annual round of specialist conferences and exhibitions, alongside a steady stream of research announcements. Invitations to book now for the top 2024 events before I miss out on my ‘early bird’ discount have filled the email inbox in recent weeks, although the truth is that even the early birds are clearly still going to be paying a hefty amount, often to be told what they’re not currently getting right.

Robotics and Artificial Intelligence (AI) feature prominently in many event headlines, together with exhortations to increase energy efficiency while successfully cutting down on methane and other farm-related emissions.

Studying the various event-linked innovation awards is always worthwhile, first and foremost for information and ideas, but also, in some cases, for a degree of entertainment.

First up is a research development being pursued in Ireland where a team at Munster Technological University (MTU) is bringing a whole new meaning to the idea of squeezing the last drop of juice out of any available asset. In their case, the focus is on freshly cut grass, which they’re subjecting to a biorefinery process to create a pressed grass cake product and three selected grass juices. In addition to maximising pasture management across their very green homeland, one of the team’s key motivations is to help Irish farmers reduce their reliance on imported soya.

The pressed cake, which contains 60% of the protein present in the original grass, is fed to cattle and pigs, while the juices are being trialled for use across a range of livestock feeds, human protein products, and as a feedstock for bioenergy generation.

“Grass is one of the world’s greatest bioresources, accounting for 26% of the world’s total land mass and 70% of the global agricultural area,” research leader, James Gaffey, told Scottish farmers during a recent webinar, pointing out that Europe has 61 million hectares of grassland, all of which he argued is ready and waiting to be put to its proper use.

On-farm trials in Ireland, designed to assess the feeding value of the pressed cake as an alternative to grass silage, have already produced impressive early results. Even though the overall protein concentration of the cake was quite a bit lower than the silage, the MTU team said that consuming the cake results in much higher nitrogen use efficiency than with silage, due to a lot more of the cake-based protein being converted into milk. This, they add, is due to the ‘opening’ of the fresh grass during the biorefining process which is used to ‘unlock’ the higher nitrogen use.

Gaffey also told his Scottish audience that the juices left over, once the cake has been harvested, has great potential as a future animal feed component.

“One of the challenges which livestock farmers face in Europe is to secure sufficient sustainable proteins to feed to their animals,” he said. As a result, we import some 17 million tonnes of protein for animal feeding, around 13m tonnes of which is soya. Much of that soya is travelling a long way to get to Europe, with some of it being associated with land use changes and other impacts.

“Alongside such soya demands of Europe, livestock farmers in Ireland import around 3 million tonnes of animal feed on an annual basis, all of which adds up to a huge challenge for a domestic industry which is seeking to become ever more sustainable in feed for cattle, poultry, and pig production. In addition, the European Parliament recently voted in favour of a proposed protein strategy, much of which focuses on the development of alternative feeds.”

The MTU team’s hope, of course, is that its pressed grass process will create new possibilities for unlocking Europe’s grassland potential, ultimately producing additional proteins without needing any more land to be devoted to feeding livestock or even for there to be any increase in existing grassland output.

There is also evidence that feeding pressed cake to livestock could deliver a methane emissions benefit for Europe’s farmers, a fact which will become increasingly attractive as the continent edges closer to its various 2030 and 2050 net zero targets.

“We’ve discovered that a lot less nitrogen and phosphorus is lost via a cow’s excrement when she’s fed pressed cake in comparison to grass silage,” said Gaffey. “This could potentially yield an environmental benefit, with the ‘bits of work’ done so far indicating that switching from feeding grass silage to giving cows pressed cake could reduce methane emissions by 10%.”

This is very much a ‘watch this space’ development with both partner and competitor implications for our own industry.

The ever-changing face of feeding livestock also showed up in a preview item I was sent by the organisers of the British Pig & Poultry Fair.

Apparently, exhibitors at the Birmingham-based May 15/16 event will be unveiling more than 60 new products, ranging from red LED lighting to calm birds and boost egg production to a special gel which provides (I’m told) ‘quick hydration, energy, and gut protection for day-old chicks’

There is also the promise of a new herbal extract for adding to pig and poultry feeds with the claim that it will ‘enhance appetite, block pathogens, and diminish ammonia odours’.

The prospect that such ideas and inventions will be taken on board by farmers is pretty strong, according to event organiser, Alice Bell, who said that no less than 78% of last year’s 7500 visitors planned to make changes to their business as a result of their day at the Fair. I guess that was 78% of those who bothered to fill in the end-of-day exit survey, but it’s still a figure to take on board.

Congratulations to the nine feed companies who have donated to the University Fund Wageningen (UFW) in The Netherlands, helping to support budding entrepreneurs as they work their way through their PhD studies.

One of the beneficiaries of the 325,000 euros provided by the nine is Evelien Bos, founder of a startup called Pet Panel, which offers a home-based testing service for pet parents to assess which petfood is best for their animals and, just as important, which they prefer.

In addition to having Pet Panel up and running in The Netherlands, Evelien has also been nominated for a Wageningen Entrepreneurship Grant. Awarded annually by UFW, the grant programme targets young entrepreneurs who make a social impact. Finals day is on 22 May.

The company’s offering, which obviously impressed UFW ’ s nomination team, includes both palatability and digestibility tests.

The palatability question is simple enough. Is the feed being provided tasty or not? Pet Panel also points out that while a feed product might be healthy, nutritious, and safe, if pets don’t want to eat it, all these great properties are irrelevant.

To select what pets like therefore, Evelien’s startup offers an acceptance test and a preference test. Acceptance shows the pet in question will eat a specific product while preference shows what it really likes when there is a choice.

Testing for digestibility is a somewhat messier business, being based on the fact that everything eaten by pets, but not properly digested, ends up in their feces.

It’s a measure of the growing number and dedication of pet owners across Europe that a home-testing service like this is in the frame for an entrepreneurs’ award. All credit, therefore, to the nine companies involved with UFW for their awareness of the expanding importance and value of this sector to the feed industry. They’re also, of course, on the inside track as soon as pets make their choice.

A similar indication of market growth potential applies to the following innovation plus entertainment item, courtesy of a promotional blub issued ahead of Petcare Innovation Europe, which takes place in Berlin on June 4 & 5.

Don’t get me wrong, the event’s 10 innovation finalists are all valid contenders for the top prize, to be awarded during the event itself. I was merely struck by the fact that two of the listed finalists have developed premium cosmetics for dogs with, let’s say, challenging hair.

Pet parents are duly being offered a whole new world of shampoos, conditioners, and revitalisers to keep their favoured animals in optimal condition and shape.

Having been brought up on a farm in southwest England with a sheep dog and a gun dog, both of whom were much loved and appreciated for their specialist skills but weren’t big into hair control. I couldn’t escape the image of my father considering which shampoo to give them.

The feed compound message is clear enough, however, namely that the petfood market looks well set for sustained growth in the hands of many very committed owners. Pets, by the way, are also delightfully free from the methane monitoring pressures currently applied to farm livestock or the need to be productive to stay alive.

It also seems, at least in my neighbourhood, that while last year most people seemed to have acquired a dog during lockdown, many of them now appear to have two dogs. Now that really is a significant indication of market growth potential.

Finally, I always like to include a non-feed item in this column, hopefully with a compounder angle for those who wish to find one.

In this context, I was intrigued by a recent press note issued by Rabobank, The Netherlands-based international bank.

“How come animals instinctively eat a balanced diet, but humans appear to have lost that skill?”

The question was posed by Nicholas Fereday, Senior AnalystConsumer Foods, working for RaboResearch Food & Agribusiness.

“We aren’t getting enough protein,” he continued, adding that when we don’t meet our required daily protein intake, we overconsume carbs and fats, leading to weight gain.

Pointing out that for a balanced diet, we need carbs, fats, and protein, as well as salt and calcium, he further explained that unlike carbs and fats, protein cannot be stored in the body. As a result, our body makes it a daily priority to meet our required intake.

“We continue to feel hungry until we meet our protein needs, so we will instinctively keep eating,” he said. “When we undereat protein, we overeat carbs and fats. But today’s food environment is dominated by processed foods that are heavy on carbs and fats, which makes it hard for us to meet our daily nutritional needs. We need to consciously prioritise protein to avoid overeating and achieve a balanced diet.”

Fereday then draws a conclusion for the food industry, which undoubtedly includes us.

“First, there’s an opportunity to reformulate products to increase protein content, potentially improving public health,” he said. “High-protein breakfast options could help consumers prioritise protein at the start of their day to avoid overconsuming fats and carbs during their day. Second, marketing strategies could focus on the benefits of balanced protein intake, aligning with consumer interest in healthier diets.”

His complete argument is obviously longer than this and rather more complex. It’s worth searching for, however, especially in a world where what we eat and how it’s produced has never been so much in focus as it is today.

To ensure the sustainable development of the poultry industry, researchers of this recently published study1 evaluated how technological progress in poultry waste management is key to attaining economic, environmental, and social sustainability.

The poultry industry generates large amounts of byproducts during meat processing, including feathers, viscera, bones, heads, legs, skin, and dead birds on arrival. These materials represent a massive amount of solid waste that should be properly managed to avoid environmental damage and loss of important raw materials that could be used for the feed industry. These byproducts are often rich sources of protein, which, through different technological processes can be extracted and used as functional ingredients in animal feed.

With so many useful ingredients and nutrients, poultry waste can be properly recycled, treated, and reused as feed ingredients, among other options. Before poultry waste is recycled and reused, necessary pretreatment processes are needed, and for the animal feed industry, hydrolysis and enzymatic treatment are gaining ground; in the current study1, researchers evaluated these technological processes focusing on their benefits and limitations, while presenting the economic, environmental, and social sustainability of poultry waste management.

Hydrolysis breaks the peptide bonds of animal carcasses and wastes by putting them in a special solution under high temperature and pressure to denature proteins into amino acids, hydrolyse fats, and dissolve carbohydrates. With hydrolysis, poultry waste can be used to produce value-added products, including high-quality protein and bioactive ingredients for the food and feed industry, bringing additional economic benefits, and helping mitigate the negative effects of poultry waste disposal on the environment. Recent studies2 show that, following processing, poultry secondary products such as keratin and collagen can be used to produce protein feed additives that improve broiler productivity and meat quality. Hydrolysis has the advantage that it is carried out under optimal conditions, has minimised interaction between steps, and can be applied to a wide range of by-products. However, the technique involves high costs and has a longer processing duration which can increase the susceptibility to contamination.

Protein recovery is one of the major challenges during the conversion of poultry offal and feathers into value-added products. However, the use of enzymes for bioconversion helps achieve protein recovery. Bacillus spp. seems to represent a major source of keratinolytic enzymes for feather processing. Keratinase enzyme which can be obtained from microorganisms is a common enzyme used to process feather waste to produce feed hydrolysates and bioactive peptides with high nutritional characteristics. Studies also show that in addition to being used to produce animal feed, by-products generated from enzyme-digested poultry waste can be used to make high-quality meals for aquaculture. Several studies point out that feather degradation mediated by keratinase provides a viable alternative to alkali hydrolysis and steam pressure-cooking of feathers resulting in products of better nutritional properties to be used as animal feed.

Overall, enzymatic treatment is eco-friendly, has low energy demand as it uses low temperature and pressure, has a short processing duration, has high conversion efficiency, and has low waste generation. However, according to the researchers, improvements should focus on lowering the high enzyme costs, improving enzymatic activity or performance and enzyme recycling.

In a new study published in World’s Poultry Science Journal3, scientists confirmed that poultry by-product meal obtained by rendering showed very high protein (63.7%) and fat (24.5%) contents and could be a cost-effective feed ingredient for monogastric animals that would also ensure the efficiency of production. A current phenomenon of black soldier fly (BSF) bioconversion of waste including poultry waste (depending on substrate regulations), has seen improvement in the economics of BSF-based animal feed production. Substrates such as animal manure, food wastes, and sewage sludge have negative values as the generators of such wastes must pay discharge fees. In a recent study4 published in the Waste Management journal, researchers highlighted that substantial economic benefits of BSFbased animal feed production are likely to come from the use of negative value wastes, proper process control, scaling up of the production systems, and coupled with incentive-based government policies. BSF meal is rich in lauric acid, chitin, and antimicrobial peptides, which are reported to have antimicrobial and prebiotic attributes; in line, the researchers suggested that if BSF meal could substitute the use of antibiotics, prebiotics, or conventional feedstuffs successfully, this would greatly improve the economics of BSF meal as livestock and aquaculture feed.

On the other hand, the negative effects of improper disposal of poultry waste on the environment include the release of ammonia and nitrous oxide, the emission of greenhouse gases, and the contamination of groundwater and surface water by nitrates, phosphates, and pathogens. The work published in the Journal of Cleaner Production5 showed that using poultry slaughterhouse

waste in ruminant nutrition as a cleaner product for animal feeding greatly improves environmental sustainability. Similarly, a recent study published in the journal of Environment, Development and Sustainability (2024)6 shows that BSF-based products not only provide a sustainable and eco-friendly source of nutrition but also have the potential to significantly reduce the environmental footprint associated with traditional livestock farming. Studies show that the social benefits of poultry waste utilisation can be multifaceted, and include the reduction of zoonotic infectious diseases, the improvement of air quality, and the creation of more job opportunities.

Drawing from their study, researchers see technological progress in the treatment of animal by-products as an effective and efficient way of contributing to a circular economy for sustainable poultry production. However, the researchers also observed that most techniques used for the conversion of animal waste by-products into value-added products face the challenge of high costs that could hamper efforts to upscale production. It is highlighted that more research should consider the limitations and opportunities to the implementation of each technological process for better utilisation and advancement or invention of new processes, suggesting a thorough identification and comparison of the economic potential and environmental benefits.

References

1. Zhang, Long, Jingzheng Ren, and Wuliyasu Bai. 2023. “A Review of Poultry Waste-to-Wealth: Technological Progress, Modeling and Simulation Studies, and Economic- Environmental and Social Sustainability” Sustainability 15, no. 7: 5620. https://doi. org/10.3390/su15075620Volik, V., Ismailova, D., Volik, Victor, Dilaram Ismailova, Valery Lukashenko, Irina P. Saleeva and 2. V. Morozov. “BIOLOGICALLY ACTIVE FEED ADDITIVE DEVELOPMENT BASED ON KERATIN AND COLLAGENCONTAINING RAW MATERIALS FROM POULTRY WASTE.” (2020).

3. Prabakaran, R., and S. Ezhil Valavan. “Wealth from Poultry Waste: An Overview.” World’s Poultry Science Journal 77, no. 2 (2021): 389–401. doi:10.1080/00439339.2021.1901557.

4. K.C. Surendra, Jeffery K. Tomberlin, Arnold van Huis, Jonathan A. Cammack, Lars-Henrik L. Heckmann, Samir Kumar Khanal. “Rethinking organic wastes bioconversion: Evaluating the potential of the black soldier fly (Hermetia illucens (L.)) (Diptera: Stratiomyidae) (BSF)” Waste Management 117 (2020): 58-80. doi.org/10.1016/j.wasman.2020.07.050.

5. Mehdi Kazemi-Bonchenari, AliReza Alizadeh, Leila Javadi, Mohammad Zohrevand, Nicholas E. Odongo, Abdelfattah Z.M. Salem. “Use of poultry pre-cooked slaughterhouse waste as ruminant feed to prevent environmental pollution” Journal of Cleaner Production 145 (2017): 151-156. doi.org/10.1016/j. jclepro.2017.01.066.

6. Siddiqui, S.A., Süfer, Ö., Çalışkan Koç, G. et al. Enhancing the bioconversion rate and end products of black soldier fly (BSF) treatment – A comprehensive review. Environ Dev Sustain (2024). https://doi.org/10.1007/s10668-023-04306-6.

With products for every kind of mycotoxin, B.I.O.Tox® Mycotoxin Binders can protect your animals from clinical and subclinical intoxications and performance drops.

B.I.O.Tox® Activ8 is specially formulated with activated substances and natural detoxifiers to boost health, performance, and liver function. It is scientifically proven to have a superior binding capacity of Fusarium toxins, especially Deoxynivalenol

Contact us: caiger-smith@biochem.net . +44 7722 019727

biochem.net

The Dairy Group christine.pedersen@thedairygroup.co.uk www.thedairygroup.co.uk

April Milk Supplies Collapse Under the Cold, Wet Spring!

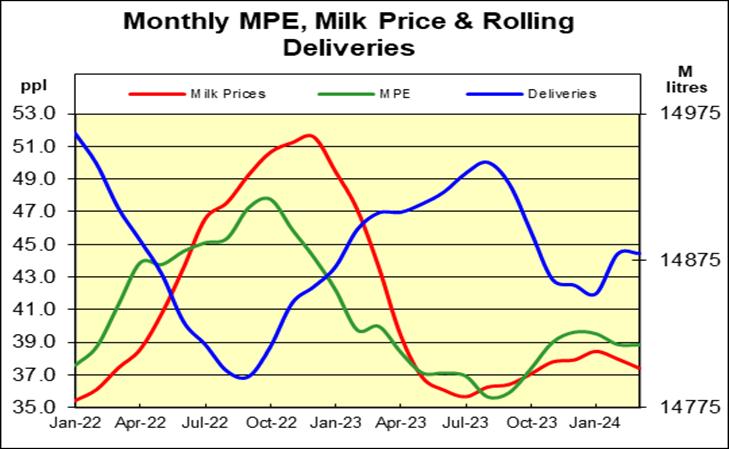

“With milk supplies having tracked the 3- and 5-year averages quite well in recent times there has been little incentive for milk prices to rise, the only exception was September to November 2023 when milk supply dropped around 2% below the averages” says my colleague Nick Holt-Martyn. He goes on to say “this produced a rally in prices that culminated in the January 2024 peak of 38.5ppl, during a 6-month period when farmgate prices averaged 37.8ppl.

While March supply followed that trend (-0.2% & 0% respectively), in April there has been a sudden departure due to the awful weather that has cut grass growth to just 2/3rds of the 5-year average. The relationship between supply and price only comes about when adverse weather causes supply to fall below the long-term trends, more rarely when trends are exceeded. The departure from the trend needs to be significant for the markets to take notice.

The graph below shows the monthly MPE (Market Price Equivalent), Defra Farmgate Milk Price and the Rolling Milk Supply and the direct link between milk supply and milk price. Weak supply or even the risk of weak supply will cause wholesale markets to compete for supply and increase prices. When supply is stable and tracks the longer term averages then prices are also stable, which is where markets have come to in the last 6 months. April might just jolt the markets into life:

Source: The Dairy Group, Defra, AHDB

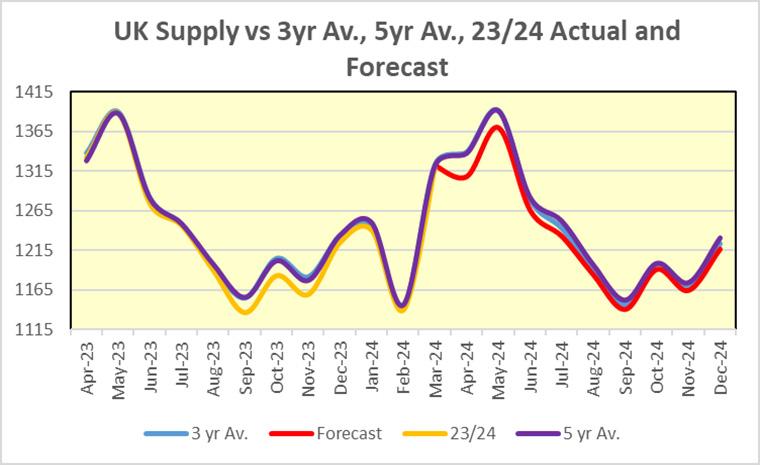

The following graph shows the 3 year and 5 year average UK milk production which essentially coalesce into a single line and adequately portrays the normal position. Against this is set the monthly supply from April 2023 and the forecast up to December 2024. This shows

the departure from the averages in the autumn of 2023 and the current position for April 2024. The April 2024 figure is based on the daily supply figures from AHDB which indicate a supply reduction of around -1.8% compared to April 2023, -2.4% against the 3 year average and -2.2% against the 5 year average. This departure from the normal is more significant than what occurred in the autumn of 2023 and the markets should be taking action to head off a reduction in dairy product supply. The expectation is that supply will recover to the norm as the year progresses if the market responds.

Source: The Dairy Group, Defra, AHDB

Our latest estimate for cost of production for 2023-24 is around 42ppl (-3.4% on the previous year), with a 10% reduction in variable costs (mostly feed) being offset by the 5% rise in Fixed Costs. The weighted rolling Farmgate price has finished the year at an average of 37.3ppl, 4.9ppl (-11.6%) below the cost of production. Livestock sales will make up some of that deficit, but the bottom line is that current milk prices are not sustainable. It is time for dairy markets to wake up and smell the coffee!

Dairy Emissions Manager is the carbon footprint module in MCi. This is a unique web-based tool that utilises dairy herd performance data i.e. herd & production details and feed inputs and resources such as land use, fertiliser, fuel, electricity, plastic and bedding. These are recorded monthly to allow emissions to be reported for any time period. Data collection is flexible either via web entry, via an APP or via a bureau service. Being able to input resources in ‘real time’ allows ongoing benchmarking so producers can monitor emissions and react in a timely manner rather than waiting for a historic year-end report to be produced some months later.

Tom Kimber has achieved an impressive reduction in dairy emissions over the last 3 years. Tom farms in partnership with his parents at Higher Stavordale Farm near Wincanton. The business manages 146 hectares of land with 108 ha of grass and 28 ha of forage maize. This supports a dairy herd of 200 cows (predominately Holstein Friesian with around 20 Dairy Shorthorn) and youngstock. Milk is sold to Barbers and through the family’s farm shop which is also the outlet for most of the dairy-born beef calves, reared and finished on the farm.

Although an annual carbon audit is a requirement of the milk buyer, it is rather historic and Tom sees more value in monthly recording the

Comment section is sponsored by Compound Feed Engineering

data and monitoring the farm’s performance. He says ‘Carbon is a good indication of a farm’s efficiency, so this is a good tool for benchmarking our performance to improve profitability. We are about optimising output, aiming to utilise grazed grass and forage to achieve around 4,000 litres from forage, but so many other resources have an impact on carbon emissions. I use Dairy Emissions Manager to provide a quick and easy way for regularly recording and reporting my dairy emissions. Being integrated into the monthly costings make it very convenient. We can run reports monthly to track my carbon footprint in real time and I work with my consultant to make informed decisions on the effect of resource inputs and output levels. I can also benchmark my resources and identify areas to target which has been extremely helpful.”

Tom has been working with my colleague Richard Lane for almost a decade, initially for nutrition advice and dairy herd costings. In 2017, discussions rapidly broadened into a greater herd focus when more analysis was put on fertility and health which highlighted challenges. Areas of weakness were identified, and a plan of action implemented. Richard was awarded a Trehane Trust Fellowship in April 2021 to produce a report ‘A roadmap for achieving Net Zero in dairy farming practically and profitably’ This work has helped the farm to understand strategies to reduce carbon emissions while increasing profitability as development of Dairy Emissions Manager.

Tom has been recording resources in MCi for over good records it has been possible to backdate carbon calculations with confidence. Since the first year of recording (ending October 2019) carbon was 1.45kg CO2-e per kg ECM, the farm has reduced that figure to 1.23 CO2-e per kg ECM for the dairy unit. Richard says, “Multiple actions have resulted in the reduction and we anticipate reducing to below 1 kg CO2-e with the changes and investments that have already made” Tom comments “We are confident we are on the right track can use Emissions Manager to track our progress towards Net Zero.”

The team have worked on reducing diet protein levels. Richard says “Meeting metabolisable protein requirement is the key, not crude protein %. This winter’s diets have to 16% with good results”. Legumes have grass leys which has boosted silage protein levels, reducing the protein supplementation required.

The introduction of clover into leys with the aim of increasing supply from legumes has led to a review of crop nutrition and subsequently, the amount of artificial nitrogen fertiliser has been reduced. The farm is assessing options to store and use slurry more effectively in the future, using umbilical and trailing shoe applications, thereby further reducing artificial fertiliser and carbon losses.

Following maize harvest, a grass cover crop is established which has proved successful in reducing nutrient losses and enabling zero grazing or an early silage cut before returning to maize. Multi-species leys are being planted across the grazing platform to increase nitrogen fixation from legumes and sequester carbon deeper into soils. Tom says, ’We hope deeper rooting will also help improve soil structure and mitigate some of the effects of climate change’.

My latest book (reviewed by Andrew Mounsey in this issue) was published in April and is already selling well. I’m getting invitations to speak at literary festivals, and press reviews have so far been positive. All this good news has prompted me to flirt with the thought that this book could, like Raynor Winn’s The Salt Path, become an unexpected success.

Winn’s book charted her and her husband Moth’s walk around the Cornish coastline, as they came to terms with his terminal illness, and the loss of their home as the result of a bad business decision. The book’s success put the couple back on their feet both spiritually and as sales grew, financially too. Could my book follow a similar trajectory, and how would I respond if it did?

These thoughts prompted me to remember the story of Michael Carroll, a Norfolk dustman who won more than £9m on the national lottery, and after giving his mother and sister £1m each, blew the lot on cars, drugs, parties and high living. After just eight years, he was back in his old job, emptying people’s bins. This was a very different response. How would you handle a huge windfall? Here are 10 ways you might deal with unexpected success.

1. Be surprised – Rather like buying lottery tickets, if you’re aiming for great success it is unlikely to happen. You have to feel driven to do what you do by something other than the hope of generating wealth. My book was the realisation of a long held ambition, and Raynor Winn’s her way of making sense of personal disaster.

2. Remain objective – So you’ve had a windfall. Remember it’s unlikely to happen again, so don’t start living beyond your means. Reduce your debts, for example, clear your mortgage, have a nice holiday and then take investment advice. Remember that putting money into your pension is both tax efficient, and can make old age more tolerable.

3. Don’t shout about it – The world is full of people who will make plausible arguments to get their hands on your money. Some will be seeking investment in a venture of their own, others seeking charitable donation or philanthropy, and some, sadly will be crooks. It’s good to become charitable, but this is almost always best done via an intermediary such as a community foundation, that knows the local third sector landscape.

4. Don’t rush – If you have a sales role, you’ll know that one of the best ways to get commitment is to create a sense of urgency or scarcity. Nothing is so urgent that you need to jump in quickly to avoid missing out. There’ll almost always be another opportunity that comes along later, that will allow you time to think, reflect and take advice.

5. Avoid addiction – I inherited my late father’s addictive nature. His weaknesses were whisky and cigarettes, mine are exercise and work. But because I know the dangers of addiction, I’m always careful. Others might be less well equipped to deal with temptation, and when you suddenly find you can afford things you previously could not, you can quickly become addicted. Expensive watches seem to be one of the most popular addictions among those unaccustomed to wealth.

6. Create legacy – A friend once said that the only two ways to be remembered were to build a wall or plant a tree. Of course, the reality is that almost everyone is forgotten within three generations, and even if you can endow an art gallery, or can afford to do something similarly flamboyant, your name might not be above the door for as long as you’d like. Better to focus on making a small difference to many lives, because this will almost always be more rewarding.

7. Indulge your kids and parents – We all want to help our children establish themselves in the world, and our parents probably had a part to play in our success. You don’t want to go overboard, but do see what you can do to make the lives of those closest to you more comfortable.

8. Keep learning – I’d never have written my most recent book if I’d not invested a considerable sum in a full-time creative writing MA at the University of East Anglia. This was my first experience of university and it took my writing to another level. I was 64 when I started the course, which proved to me that you’re never too old to learn. If your unexpected success came from your work, then it makes sense to invest some of the gains in becoming even better at what you do.

9. Avoid gongs – I’ve known people go to great lengths to get themselves nominated for an OBE. New found success can encourage you to think that public recognition is important, but in reality, in the 21st century, few people are impressed by the letters you might have after your name.

10. Enjoy the moment – It’s not every day that you enjoy unexpected success, so allow yourself to enjoy the moment and celebrate your achievement. It’s all too easy to persuade ourselves that we are undeserving and even easier to become fearful that everyone is trying to take advantage of your good fortune. Remember that while there will always be bad people, most are genuine and will be pleased that you’re doing well. Life, after all, is all about people.

As I write this month’s column, I pause to check my book’s ranking on Amazon, out of the 3m titles they stock. It continues to sell well, and I heard yesterday that one major distributor had run out of copies and ordered more. However, checking how the book is doing every five minutes won’t influence its success. That depends on the quality of the writing, my publisher’s ability to get the book reviewed in the press, and of course how enthusiastically readers recommend it to their friends. It’s time now for me to start researching my next book, and stop worrying about this one!

Comment section is sponsored by

To

- Ryan Daly, Operations Director

Single platform

Multi location

Full

Order processing

Purchase contracts

Grain intake & processing

Weighbridge operations

Formulations & labelling

Data analytics

Ireland’s Minister for Agriculture, Food and the Marine, Mr. Charlie McConalogue, met recently with members of the Irish Grain Growers Group to listen to their concerns and the current challenges being experienced by tillage farmers.

Commenting after the meeting, Minister McConalogue said: “I was glad of the opportunity to meet with representatives of the Irish Grain Growers Group today and to listen to their concerns. The exceptional weather conditions at the back end of 2023 and into this year has resulted in significant challenges for tillage farmers throughout the country. Thankfully, there has been some return to spring work on tillage farms in the last two weeks with the improvement in weather conditions.”

The minister acknowledged the particular impact of the recent wet weather and the delay in getting spring crops planted. He continued:

“With later spring sowing than normal and the risks associated for farmers, I recently announced that I will work to deliver €100/ha in financial support for crops planted for the 2024 harvest to give confidence to growers to plant crops this year, and to give them confidence in the future of their industry”

The minister acknowledged the difficult year last year for tillage farmers and outlined the additional supports that were provided to the sector in 2023. These additional supports included a top-up of €3m for Protein Aid bringing the total budget to €10m. The Straw Incorporation Measure provided €16.5 million and the Tillage Incentive Scheme provided €8.3 million to growers in 2023.

The €7.147m secured from the EU Agricultural Reserve was topped up with a further €7.147m in State funding.

These funds were used to support growers with un-harvested crops by way of an ‘Un-harvested Crop Support Scheme’ with the remaining funds being used as a once-off flat rate payment on the area of oilseed rape and cereal crops.

In March of this year, the minister also announced an exemption to the crop diversification element of GAEC 7, easing concerns for tillage farmers by allowing them to pick the crops that best suit their circumstances, taking account of the time of sowing, market returns and seed availability.

Minister McConalogue emphasised the importance of a vibrant and sustainable tillage sector in increasing Ireland’s food and feed security while also contributing to climate change objectives. Ireland’s Climate Action Plan 2023 sets out a target to increase the area under tillage to 400,000ha by 2030 as part of agriculture’s commitment to reduce emissions by 25%.

Minister McConalogue concluded: “The tillage sector is an important and integral component of the Agri-food industry and is a sector that I want to see grow and develop. That is why I established the Food Vision Tillage Group in May 2023 to set out a road map for the sustainable growth and development of the sector to 400,000ha by 2030. I recently received the final report from the Group, and I am considering its recommendations.”

Ten years of the Food Fortress programme have delivered an unmatched level of security for the farming and food chain across the island of Ireland, where the production of compound animal feed is concerned.

This was one of the key messages delivered by Food Fortress Director, Robin Irvine, courtesy of his recent presentation to members of the Guild of Agricultural Journalists of Ireland.

He went on to outline significant changes to the governance of the network.

“Originally set up as a partnership between the Grain Trade Association and the Institute of Global Food Security at Queens University we are pleased to announce that the Food Fortress network has now been established as an independent stand-alone business owned and directed by its members - and with a newly appointed board representative of the whole island and both feed importers and compound feed mills.

“Our membership comprises 82 companies and 8 million tonnes of feed production with all of Northern Ireland’s compound production covered - with the comparable figure for the Republic of Ireland around 70% and growing.”

Robin Irvine continued: “We are rapidly moving towards fulfilling the original vision of delivering a testing programme that comprehensively reflects the activities of the entire feed compounding sector across the island.”

Food Fortress is a collaboration of businesses committed to improving the safety and security of the food chain but is also producing significant economic benefits for producers by promoting feed efficiency and hence the performance and profitability of livestock systems and is a major contributor to the reduction of emissions.

Courtesy of a comprehensive programme of strategic sampling and testing – both compound feeds and the raw materials contained within these rations – Food Fortress operates to reduce the risk from the principal contaminants which threaten this chain.

These anti-nutrients include mycotoxins, dioxins, heavy metals and pesticides.

According to Robin Irvine, the Food Fortress programme is the most advanced of its kind anywhere in the world and is supported by the Institute of Global Food Security at Queens University, Belfast.

He commented: “The network was originally formed in the wake of various feed incidents – including the Irish Dioxin crisis which caused significant damage to the reputation of our food sector.

The required lessons were quickly learnt and the result was a decision taken by Northern Ireland’s feed compounders, committing the industry to a comprehensive system of checks and state-of-the-art analysis, where all raw materials and compound feeds are concerned.

“This has evolved into the Food Fortress system that we have in place today. It has been fully operational for the past decade.

“All the raw material importers and feed compounders are contributing to a risk management system that is recognised as best in class the world over.”

Robin Irvine further explained. “The comprehensive analysis of raw materials and compound feeds takes place on a regular and ongoing basis.

“Key to making this happen is the total commitment of the feed compounding and raw material importing businesses that are involved.”

Taking this approach has allowed feed compounders to manage the risk, specifically where mycotoxin contamination threats in animal rations are concerned.

Looking ahead, Robin Irvine also predicted the introduction of tougher regulatory standards, where mycotoxin contamination levels in compound feeds are concerned.

“However, the very real, on-farm, challenge caused by mycotoxins when present at well below guideline limits must be actively addressed by the feed industry,” he said.

Irish Farmers’ Association (IFA) president, Francie Gorman, has highlighted the intense pressure now coming on Ireland’s tillage sector.

He made this comment while responding to recently published figures from Ireland’s Central Statistics’ Office (CSO) figures, confirming that cereal crop output fell by 20% last year.

In 2023, 2 million tonnes of wheat, barley and oats were produced in Ireland, down 500,000 tonnes on 2022. Potato production was down 12% last year.

“It further highlights the urgency of the Tillage Survival Scheme put forward by IFA. We raised this again with Taoiseach Simon Harris on a tillage farm in Kilkenny last week. No time can be lost in putting together a support package that provides some hope for the sector,” he said.

“Tillage farmers have faced a perfect storm since summer 2023, with falling grain prices; input costs remaining high; loss of rented land; and heavy rainfall in the period since,” Francie Gorman said.

“There is no question that our tillage sector is fighting for its very future. The Government says it wants to have more tillage production and this will only happen if they step up and support growers. What was announced recently by the Minister for Agriculture is inadequate,” he said.

IFA National Grain Chairman Kieran McEvoy said in light of the difficulties being experienced in the tillage sector, IFA has proposed in its Tillage Survival Scheme a € 250/ha, five-year payment for tillage farmers.

He added: “It is essential this funding is secured in 2024 to prevent a decimation of the national tillage area.”

Northern Ireland Grain Trade Association (NIGTA) president, Gary McIntyre, has confirmed the exceptional circumstances that have faced the organisation’s members over recent times.

“But as always, we have stepped up and faced these challenges head-on.”

McIntyre reflected on these matters courtesy of his presentation to NIGTA’s 2024 annual dinner.

He added: “We continue to see issues with the supply of grains and raw materials to our market.

“While the current fundamental outlook for supply looks adequate, we live in a world with the highest geo-political tensions seen in a long time.

“We see a European Commission proposal to implement a 95 EUR/T duty on grains and a 50% tariff on oilseeds and products imported from Russia and Belarus.

“Persistent wet weather in Europe continues to hamper spring plantings and is impacting crop development.”

The impact of the atrocious weather on agriculture over the past year was a theme that was reflected throughout the NIGTA president’s speech.

He said: “Twenty-nine days of rainfall in March were recorded in some areas of Ireland and so far, April has continued that trend.

“A further challenge for our industry is to navigate the proposed EU Deforestation Regulation, referred to as EUDR, due to commence on 30th December this year.

“Outside pressure on the EU is mounting to delay as most countries and suppliers are not prepared. However, the official EU stance is still as it was:

“EUDR is to be rolled out as planned and yet we are still no clearer about NI Divergence between EUDR and UKDR

“Every sector within our industry has faced its own unique challenges, but despite the difficult trading conditions, once again you have shown incredible flexibility, agility, and resilience.”

McIntyre continued: “The sustainability agenda remains a key priority for NIGTA, with mounting pressure coming from both policymakers and the marketplace.

“We are acutely aware of the challenges related to air, soil and water quality, and the risk that environmental targets could become our agri-food industry’s licence to operate.

“But we are also focused on the opportunities available within the animal feed and fertiliser sectors to help support our farming customers in reducing their environmental footprint to enhance the green credentials of Northern Ireland agri-food.”

According to McIntyre, NIGTA has been proactive in driving forward better nutrient use efficiency and developing precision nutrition and feeding strategies, by delivering professional advice at farm level, provided by the FAR accredited feed advisers.

“Nevertheless, widespread industry collaboration will be needed to help deliver the ambitious emission reductions required,” he further explained.

“Fortunately, within Northern Ireland, we have an excellent track record of the agri-food industry working together for the common good.”

The tillage clock is ticking for Minister McConalogue Ireland’s farm minister, Charlie McConalouge was handed the final report from the Food Vision Tillage Group three weeks ago. But still, we await his reply.

Surely he can’t be thinking that a few days of decent weather will keep the tillage farmers off his back while he dithers on how to best come through on promises previously made to a sector of Irish agriculture that has been put through the ringer since the last CAP deal was foisted upon it.

Please note that the previous sentence makes no reference at all to the impact of the atrocious weather that has engulfed the country as a whole over the past twelve months.

The Tillage Vision Group was established to address the strategic challenges and opportunities that now confront those Irish farmers who grow crops for a living.

All of this is set against a clear backdrop of two fundamental issues. The first is government’s own recognition of the fundamental role that tillage can play in lowering the carbon footprint of agriculture as a whole.

So much so, in fact, that the national response to climate change targets include a commitment to expand the tillage footprint to 400,000ha. This figure represents a 25% increase, relative to current planting levels.

The other fundamental for tillage farmers goes back to the outworking of the last Common Agricultural Policy (CAP) deal agreed for Ireland.

And this is unfinished business. Tillage farmers believe they were unfairly treated when it came to the most recent allocation of CAP support budgets. And they want Minister McConalgue to rectify this matter courtesy of his response to the Tillage Vision Group report.

And they are absolutely right in expecting an appropriate response from government in this regard.

The last 12 months and more have seen tillage farmers being unable to compete for conacre ground because the current finances of their businesses are on such an unstable footing.

This is all about the creation of a level playing field for all the land based sectors.

And Charlie McConalgue is duty bound to meet this fundamental requirement.

To his credit, the minister has repeatedly asserted that he remains committed to meeting the needs of tillage farmers and has continued to espouse the principles associated with the projected growth in Ireland’s cropping area.

Now he has a chance to put some meat on the bones, where the delivery of these previously made pledges is concerned.

And let’s hope that he delivers his response to the Vision Report at an event attended by key stakeholders within the tillage sector.

Simply issuing a press statement late on a Friday evening wouldn’t really cut the mustard.

The main reason for incorporating enzymes into rations is to improve digestibility and help the animal get more nutrients from the feed provided. To find out more about the role of enzymes in monogastric diets and the factors to consider before including them within formulations, we spoke to Elanco’s nutritional advisor Alex Sly.

What role do enzymes play in pig and poultry diets?