Mass Timber

Perkins&Will is committed to mitigating the environmental impacts of our projects, processes, and construction. It is well-documented that buildings constructed with mass timber can achieve lower embodied carbon, consume fewer fossil fuels, avoid process emissions, and promote extended carbon in storage products and sequestration.

With over twenty-five built mass timber projects of significant scale in a variety of sectors, and over thirty years of experience, our expertise runs deep. We have a global team of experts involved in mass timber design, research, and code writing, as well as a trusted network of partners. Our approach to timber construction is rooted in a culture of sustainability and smart business—we believe that timber exists where these two notions intersect.

With the right combination of partners, material sourcing, and design vision, a mass timber project can raise the bar in the cities in which we work, and in the interconnected ecosystem of our planet.

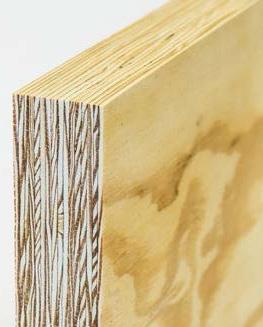

Mass timber is a category of resilient, long-lasting, and sustainable engineered wood products made from different types of fast-growing hardwoods, adjoined with adhesives and fasteners. It includes several types of engineered wood such as cross-laminated timber (CLT), glued laminated timber (glulam), and nail-laminated timber (NLT).

Mass timber carries with it a spirit of optimism and renewal. We continue discovering new applications through material research and sophisticated engineering approaches.

Material: Light-weight, predictable fire-resistance, better thermal resistance, renewable

Design: Pre-fabrication potential, integrated services potential, structural product as interior finish

Construction: Regional variance, composite/hybrid potential, quieter/safer construction

Experience: Biophilic experience, warm interiors

The conversation is international, supporting a global enterprise of carbon sequestration and elevated tenant experience. An ecosystem composed of entrepreneurs, startups, designers, builders, developers, agencies and non-profits has emerged.

CLong-term carbon sequestration

Smaller energy footprint

Reduced GHG (Greenhouse Gas) emissions

Shift to renewable resources

Both resilient and beautiful, timber-built architecture has biophilic properties that can boost human morale, productivity, and sense of well-being. Studies have shown that it can reduce stress and improve concentration.

In health care facilities, the presence of natural materials is associated with faster recovery times, lower pain perception, and positive dispositions.

Hardwood forests are one of the world’s most powerful tools in the battle against CO2 emissions. Every cubic metre of wood stores approximately 0.9 tons of CO2. Trees absorb carbon from the atmosphere as they grow, and wood material is composed of 50% carbon by dry weight.

Buildings constructed with wood will sequester the carbon for the entire life of the building, and longer if the wood is recovered and reused or re-purposed.

economy

One of the most appealing aspects of mass timber as a building material is the relative ease and rapid pace of construction it allows. Projects using mass timber products and off-site fabrication report savings compared to traditional materials and site-built construction.

Wood requires less energy to manufacture than other materials. Researchers universally conclude that raw material acquisition, processing and transportation for wood products need less production energy than the functional equivalent amount of metals, concrete or bricks.

Materials Testing Lab

Gilmore SkyTrain Station

NVIT

2011 VanDusen

Botanical Garden

Visitor’s Centre

1995 District of North Vancouver Municipal Hall

White Rock Operations Building

Centennial Arena

Navel Officer Training Facility

Squamish Li’lWat Cultural Centre

SFU Blusson & Saywell Hall

Kingsway Pedestrian Bridge

Canada Line Stations

Cross Roads

Dockside Green

Laurentian University Vale LWL Centre

UBC CIRS

Samuel Brighouse Elementary School

UBC Earth Sciences Building

Pitt River Middle School

Tall Wood Study

Marine Gateway

SoLo

Evergreen Line Stations

Framehouse

1 De Haro Office Building Great Northern Way Pavilion

Delta Development, Canada’s Earth Tower

Every element of our work celebrates the human experience. Together with our portfolio company, Copenhagen-based design firm Schmidt Hammer Lassen, we have pioneered the application of mass timber across all building typologies. With our clients, we have worked to evoke cultural and emotional responses on a community level. This inclusive strategy applies to our client partners, communities, and strategic choice of building materials.

We wholeheartedly embrace the growing interest in the use of wood in the built environment—timber contributes to a human sense of well-being and is a preferred solution for a resilient future. We are excited to lead the way in this material renaissance, sharing our knowledge and insight with the industry, and pushing the boundaries of sustainable design.

Client: University of British Columbia

Size: 24,500 square meters (264,000 square feet)

Completion Date: 2024

Partners: Schmidt Hammer Lassen

This project is a reflection of the broader natural and cultural setting of the University, and it harnesses the transformative power of health as a core design driver. In order to achieve net-zero carbon certification, our team identifed research opportunities around using wood to develop both a heavy timber structure and modular pre-fabricated facade. The use of local wood is celebrated through an expressed timber structure and cladding throughout the public spaces of the building—echoing the experience of moving through the Indigenous forest surrounding the building.

Social Connectors: Supporting the health and wellness goals of the project, open communicating feature stairs serve each floor. The stairs reinforce the atrium as a community space for the building while placing emphasis on movement and active design.

Client: University of British Columbia

Size: 15,794 square metres (170,000 square feet)

Completion Date: August 2012

Upon its completion, ESB was North America’s largest panelized wood building and the largest application of CLT. The use of glulam beams and columns in a 5-storey building, along with hybrid wood composite floor panels and significant CLT elements, demonstrates the application of wood in large-scale, high performance buildings. A five-story, free-floating cantilevered mass timber staircase is the first of its kind in the world. ESB’s innovative design and construction approaches helped shape BC’s growing legacy of wood expertise.

“The Earth Sciences Building at UBC demonstrates how quickly BC is catching up with Europe in adapting new materials and systems. The seamless integration of heavy timber, cross laminated timber, and full-size Timberstrand® panels proves that wood elements can be the backbone of even the largest structures.”

WERNER HOFSTÄTTER, WOOD FIRST ADVISOR

Client: University of British Columbia

Size: 41,620 square metres (448,000 square feet)

Completion Date: August 2016

The exposed mass timber structure spanning the large atrium and cafeteria creates a warm and inviting space for students that frequent the hallways of UBC Orchard Commons.

The project proved to be both cost effective and aesthetically appealing, by using NLT for the roof deck and glulam for columns and beams. In addition, the lobby spaces in between floors in the two residential towers are connected by 23 sets of NLT stairs—a unique concept of CNC-ing stringers from Douglas Fir 2x12s that further showcases innovative wood design and construction.

Client: University of British Columbia

Size: 5,675 square metres (61,085 square feet)

Completion Date: August 2011

Utilizing wood as a primary building material, CIRS achieves its low-embodied energy and low-carbon impact goals while becoming the first large, multi-story building on campus. Wood allows CIRS to store over 900-tons of carbon, reducing its carbon footprint by more than 90% of the average UBC building. The use of a carbon-sequestering material grown by the sun aligns well with regenerative design principles and net positive performance targets set for this project.

Exposed wood in the auditorium offers a highly desirable and vibrant learning environment. By incorporating wood sourced from BC forests affected by pine beetle, CIRS was able to address a complex, province-wide problem with a simple, elegant solution.

Client: Delta Land Development

Size: 31,494 square meters (339,000 square feet)

By employing local wood from sustainably managed forests as its primary structure, Canada’s Earth Tower will advance the industry by altering market perceptions, providing choice, and putting the performance and environmental implications of construction at the forefront of the conversation.

The tower will source locally manufactured mass timber and will use a hybrid technique of reinforced concrete elevator cores to provide lateral stability to the structure, with engineered wood columns and composite floors comprising the structure of the occupied spaces. Together, this will set a new benchmark for sustainable building performance and wood construction.

“I want Perkins&Will to reach around the corner and create something on this site that is the best response known to man for climate change and buildings.”

Client: Implenia / Ina Invest AG

Size: 34,500 square meters (371,354 square feet)

Completion Date: Under Design Development

Sustainability: Targeting SNBS Platinum and 2000-Watt Society

In the near future, the world’s tallest residential building with a loadbearing wood structure will rise above the ridges in the Swiss city of Winterthur, close to Zürich. In the development of the project, the team identified traditional industrial qualities of the area as a guiding principle for the transformation. The 100-meter-tall tower, Rocket&Tigerli, is designed to create a framework for an active and attractive neighborhood, deeply rooted in historical context

Advancing Typolgoies: A primary aim of the project is to serve as a global benchmark in the reduction of embodied carbon in high-rise construction. Considering timber as a carbon sequestering material, SHL has sought to explore the logic of an innovative construction method developed at the ETH Zurich.

Innovative Solutions: The project breaks with the traditional structural logic of core-and-column, and instead utilizes an LVL timber composite structure to create 2 structural tubes, one at the façade and the other around the circulation which are connected by floors and beams. This achieves programming flexibility, better force distribution and lightness.

Client: Partnership between University of Cambridge, Thornton Tomasetti, Perkins and Will

Completion Date: Unbuilt

When designers at Perkins&Will, researchers at the University of Cambridge, and engineers at Thornton Tomasetti teamed up to explore the concept of a mass timber skyscraper, they sought to prove that a structurally sound tower could be both made of wood and safe enough for residential use.

As conversations in sustainable architecture continue to zero in on mass timber, the first thing that comes to many peoples’ minds is fire resistance. Is mass timber safe? With extensive research, and structural and fire resistance tests, we aim to prove that the answer is “yes”. The next step? To build a full size modular unit in River Beech, using the nodes we’ve constructed and tested. As we continue pushing this concept, we hope to arrive at a sustainable, beautiful solution that pushes materials to their limits.

Rigorous Testing: Our project team traveled to AutoDesk Build Space in Boston to fabricate the large heavy timber nodes designed for structural support. These full scale mockups serve as key components of any life-size module construction that the team tests out next.

Client: KOM-KBH AS

Size: 1,810 square meters office (19,482 square feet), 355 square meters technical basement (3,821 square feet)

Status: Completed, May 2019

Awards: 2019 Office of the Year Award finalist (DK)

Framehouse is a remarkable construction that merges tradition and innovation. The characteristic feature of the exposed frames recurring throughout the three building bodies is inspired by the simple construction of a traditional Danish timber barn, while its innovative spirit is evident in the flexibility and reconfiguration of modern office space.

Framehouse is certified DNGB Gold which is demonstrated from the landscape to the rooftops. River Beech using the nodes we’ve constructed and tested. As we continue pushing this concept, we hope to arrive at a sustainable, beautiful solution that pushes materials to their limits.

Aerial Inspiration: The industrial business area is dotted with repurposed aircraft hangars as well as new construction influenced by their form. While the simple building volumes of Framehouse are a nod to the local context, the building is a rare gem in Denmark—a sustainable and innovative exposed timber structure.

San Francisco, California

Client: SKS Partners

Size: 134,000 square feet

Completion Date: 2021

Sustainability: LEED Gold Goal

1 De Haro was built much like many podium structures throughout the United States, with stacked wood construction on a concrete base. However, 1 De Haro’s wood structure is made of mass timber. By utilizing cross-laminated timber and glue-laminated timber, 1 De Haro is lighter, more sustainable, quicker to construct, and more beautiful than a steel or concrete building. Wrapped in a simple yet finely detailed curtain wall, the warmth and quality of the exposed wood connects to the building’s purpose of supporting local makers.

Located on the triangular site of a former gravel yard, 1 De Haro, is San Francisco’s first cross-laminated timber (CLT) building and California’s first multi-story, fully mass timber building.

The four-story, 134,000 square foot building blends into its urban surroundings while still making a statement. Designed to evoke a jewelry box, its wooden core is wrapped with a glimmering glass curtain wall that illuminates at night. 1 De Haro provides an attractive mix of office and light industrial space that is both sustainable and marketable.

Left:

The exposed wood creates a sense of warmth throughout the building.

Above: CLT panels are lifted into place and then secured throughout the building.

Client: District of Columbia Public Library

Size: 20,786 square feet

Completion Date: 2021

Sustainability: LEED Platinum®

Awards: National Council of Structural Engineers Associations, Awards of Excellence, Outstanding Award for New Buildings <$30M, 2022; Wood Design & Building Awards, Sansin- Sponsorship Award, 2022; WoodWorks, Design Awards, Institutional Wood Design, 2021; World Design Awards, Design Award, 2021; AIA NOVA, Award of Merit in Institutional Architecture, 2021; DBIA, National Awards, Best in Design/ Engineering and Award of Excellence, 2021; NAIOP DC/MD, Best of the Best Building and Awards of Excellence, Best Institutional Facility, 2021; ENR MidAtlantic, Best Project - Excellence in Sustainablity and Award of MeritCultural/Worship, 2021; DBIA, Mid-Atlantic Awards, Excellence in Design and Design Award, 2021, WAN Awards, Gold in Wood, 2021

The design inspiration for the Southwest Library was simple—a series of interconnected gable roofs with tapered sides—but engineering proved to be more challenging. Due to the characteristics of wood being used as the primary structural system, engineering required a completely different “systems” approach beginning with basic engineered wood components— building up the gable form through a series of panels, beams, connections, and structural braces.

As the pieces came together to form components and wood components became assemblies, the profile was realized in rational engineered solution that also guided installation. Engineering the system for installation required that the individual gables be self-supporting prior to placement and the team’s early investment in the engineering sequencing resolved this complex challenge and delivered on the unique architectural form.

Client: Delta Land Development

Size: 380 square metres (4,090 square feet) [house]; 40 square metres (431 square feet) [auxiliary building]

Completion Date: 2020

Wood was chosen as the primary structural building material. It was the obvious choice to reduce the projects embodied carbon footprint and allowed flexibility for prefabrication of the modular panels—the house is a temple to Douglas Fir, a local British Columbia species known for its superior strength and is widely used in mass timber applications.

The building is composed of a limited palette of “noble” materials whose weathering properties are intrinsic to their beauty and whose demands of maintenance to preserve acceptable finishes is limited. The dowel laminated timber walls serve as both the structure and the finish. The choice to use wood primarily reduced the use of more carbon intensive materials, with concrete and steel used selectively where appropriate.

“This is an achievement that all involved can be proud of...a unique combination of measures and outcomes without having to compromise on function and beauty.”

KIRK ROBINSON, SENIOR VICE PRESIDENT, DELTA LAND DEVELOPMENT

Client: Girl Scouts of Greater Los Angeles

Size: 26,059 square feet

Completion Date: 2020

Awards: Wood Design Award, Commercial Wood Design – Low-Rise, WoodWorks, 2022; Merit Award, Education, AIA Los Angeles, 2021; Merit Award–NextLA, AIA Los Angeles, 2018

Camp Lakota is situated on a wooded 55-acre lot in the Los Padres

National Forest. The slope along with the mountain views to the north and winds from northeast play an important role in siting and orienting the new buildings and outdoor decks, while the occurrence of snowfall and the cold climate during the winter months influence the massing and design of the new structures.

Looking to strike a balance between innovation and tradition, the Girl Scouts are modernizing an existing campground by adding 36 new insulated sleeping cabins for year-round use. In addition, an 11,000 square foot dining hall will replace a structure destroyed in a fire.

Cabin prototypes use a flatpacked model, combining higher quality shop fabrication with a compact shipping footprint. Prefinished, insulated SIPS panels are detailed to snap together allowing them to be rapidly assembled on site with standard tools. Building components are packaged and delivered to the camp with minimal trips and disruption to the camp.

Remote Access: The Camp Lakota site is located in the Los Padres National Forest off Frazier Mountain / Cuddly Valley Road. The property is located at an elevation of 5,400ft with sloping topography throughout and organized along a small dirt road.

Client: PCI Developments

Size: 185 square metres (2,000 square feet)

Completion Date: 2018

The pavilion is a concerted effort to demonstrate complex forms and assemblies achievable with wood construction and digital fabrication. Curved NLT prototypes were generated using standard 2x8 lumber and aluminum nails to create a faceted shell—lessons learned from this research were ultimately incorporated into the final grid structure. The bright exterior cladding contrasted by the wood interior offers a warm and inviting space for contemplation and gathering.

Vancouver, British Columbia

Client: Vancouver Board of Parks and Recreation

Size: 1,810 square metres (19,483 square feet)

Completion Date: August 2011

Inspired by organic forms and natural systems, the VanDusen Botanical Garden Visitor Center seeks to create a harmonious balance between architecture and landscape, both from a visual and an ecological perspective. To provide a beautiful and warm environment, the Visitor Centre uses wood products extensively—from the panelized roof structure to the cladding, furnishings, millwork and wall finishes. The roof structure includes 71 distinct panels, each made of over 100 unique curved glulam beams. The panels were prefabricated and pre-installed with thermal insulation, sprinkler pipes, lighting conduits, acoustic liner, and wood ceiling slats. The warmth and beauty of wood contributes significantly to our ability to enliven unusual spaces that may otherwise feel cold and alien.

Client: City of Burnaby

Completion Date: 2008

Kingsway Pedestrian Bridge is a landmark structure connecting Metrotown with the growing commercial and residential areas to the north of Kingsway in Burnaby, British Columbia. The striking doublecurved glulam wood form hovers above the footbridge that crosses Kingsway at McMurray Avenue, blending an elegant design solution and with an inviting passage across a busy intersection.

The project utilizes a steel base yolk frame that support elegant double curved glulam frames; stainless steel rods suspend a precast concrete deck, and a 1/4” coated steel plate serves as the roof.

Concrete support piers, access stairs, LED architectural lighting inset into the steel base yolks and a continuous LED light strip highlight the curves of the roof edge.

Client: SNC-Lavalin

Size: 1,530 square metres (16,500 square feet) per station

Completion Date: December 2016

The Evergreen line stations built upon our success of using wood for Vancouver’s transit system. With tighter budgets and timelines, a refined modular approach with elegant detailing, integrated services, and a signature warm aesthetic helped us deliver design excellence on time and budget.

Client: Rapid Transit Project Office

Size: 2,045 square metres (22,000 square feet) per station

Completion Date: 2002

This station illustrates the potential of sophisticated wood elements to create strong public transit facilities. The station was envisioned as a ‘wood canoe’ that shrouds users with warm wood and glass, protecting them against the elements. By utilizing tapered glulam ribs of the same size and varied lengths of steel section, the project team was able to deliver a simple and costeffective strategy for a seemingly complex geometry. Brentwood has become the region’s flagship station, inspiring several other stations to incorporate wood in the platform canopy to evoke a distinct and unique station identity.