Drive the new way.

New IVECO T-WAY: high productivity and safety on off-road terrains

With a complete line-up of AWD and PWD versions and the the 16-speed HI-TRONIX automated gearbox, the IVECO T-WAY features a host of functionalities such as Rocking Mode, Off-road Mode, Creeping Mode and 4 reverse gears to tackle with ease the toughest off-road conditions. The new architecture of the EBS system, combined with disc brakes on all wheels, greatly improves the vehicle’s performance and the driver’s safety in the most demanding applications.

New IVECO S-WAY: high technology and efficiency for on-road missions

The new IVECO S-WAY, with a completely redesigned and reinforced cab, offers a wide choice of Euro III/V diesel engines, a delivering class-leading power from 360 HP to 560 HP Euro III / 570 HP Euro V and superior fuel-saving devices, such as anti-idling feature, Ecoswitch, Ecoroll and Smart Alternator, 12-speed HI-TRONIX automated transmission with the most advanced technology in its category, electronic clutch and best-in-class torque-to-weight ratio.

Lintec & Linnhoff is a global manufacturer and distributor of leading-edge solutions for the asphalt and concrete industries. Under the Lintec, Linnhoff and Eurotec brands, our products include asphalt mixing plants, concrete batching plants, pavement related technologies and specialist concrete cooling solutions. The Lintec containerised asphalt and concrete batching plant series, built in 100% certified ISO sea containers is one of our key technologies.

Contents

18

JUFFALI COMMERCIAL VEHICLES OPENS NEW BRANCH IN DAMMAM

The new location is a part of a growth plan that will reach all Saudi Arabian cities and ensure that Juffali Commercial Vehicles’ objectives are delivered.

22

BETTER PRODUCTIVITY WITH ATTACHMENTS

Auger Torque began its Middle East operations in 2016 with a sole focus on the UAE market. Since then, the company has also established a presence in Kuwait, Qatar, Oman, Bahrain, and Saudi Arabia. Last year saw sales growth of 44% compared to 2021, representing a new record for the firm.

26

BLUE IS THE NEW GREEN

Trychem’s Mehul Parmar tells Plant & Equipment how he and his colleagues are enabling Middle East fleet owners to capitalise on the many emissions-related benefits of AdBlue.

40

VOLVO DELIVERS AFRICA’S FIRST HEAVY ELECTRIC TRUCK

The first heavy battery-electric truck from a major OEM operating in a commercial capacity in Africa was delivered by Volvo Trucks to client Arma in Morocco.

56

BLUMAQ’S SPARES REDUCE DOWNTIME AND INCREASE PRODUCTIVITY

Blumaq explains how, since 1992, it has grown its global operations to manufacture spare parts that are compatible with machines from a broad range of original equipment manufacturers.

MARKET OVERVIEW

30

SCALING NEW HEIGHTS

Representatives from Liebherr and Yongmao speak to Cameron Hubbard about the Middle East’s tower cranes market, and what the future holds for these super-tall machines.

42

BIGGER ISN’T ALWAYS BETTER

Bobcat and XCMG speak with James Morgan about growing levels of demand for mini and mid-sized excavators across African construction markets.

PO Box: 71530, Dubai, UAE | +97145808020 www.mesamediainc.com

Editorial

Contributing Editor Munawar Shariff

Contributing Editor Cameron Hubbard

Advertising

Sales Director Sahar Chaplin +971 55 798 2212 sahar@plantandequipment.com

Artwork

Senior Graphic Designer Adnan Shaik adnan@plantandequipment.com

Accounts

Senior Accountant Pramila CS Kotian accounts@plantandequipment.com

Contributing Editor James Morgan

Assistant Sales Manager Kenny Ann +971 58 829 8247 kennyann@plantandequipment.com

Graphic Designer Dan Fiesta artwork@plantandequipment.com

Social Media

Terms & Conditions

Plant & Equipment shall not be liable for trade names and trade marks used by advertisers. No liability will be accepted for any loss occasioned by the failure of any advertisement to appear from any cause whatsoever, or for any errors therein. Advertisements are accepted subject to availability of space. If it is not possible to insert advertisements in the issue requested, Plant & Equipment will use its best endeavors to ensure that the advertisements are carried forward to the next issue. One month notice is required in writing for the cancellation of any series of advertisements.

No guarantee can be made on the positioning of advertisements unless a contract in writing to such effect has been entered into between Plant & Equipment and the advertiser.

Settlement Terms - Strictly payment in advance.

Copyright: Middle East Strategic Advertising

KONECRANES SUPPLIES MATERIAL HANDLING EQUIPMENT TO LTC GROUP

crane at the site to enhance functionality. In addition, Konecranes will be responsible for the safe and optimized running of the cranes under a 3-year annual maintenance contract, extending a business relationship with LTC Group that first started in 2011.

Konecranes’ equipment and services will be key to Legnano Teknoelectric Company (LTC) Group’s new 30,000m2 manufacturing plant in Dubai, UAE, supporting the entire material flow from incoming raw materials to finished products including transformers.

Konecranes will supply 12 S-series and CXT electric overhead cranes and 9 jib cranes. It will also modernize an existing

LTC Group is the world leader in magnetic cores and laminations for a wide range of transformers and reactors. As it continues to grow its renewable energy sector business, its new facility in Dubai - which will double its production capacity in the region - will play a prominent role in supplying transformers for wind power, photovoltaic, hydroelectric, cogeneration and biomass facilities.

“Our production line uses high quality materials and the manufacturing process needs both reliable and cutting-edge equipment,” said Mauro Mereghetti, Managing Director at LTC Middle East FZCO. “Konecranes’ products and services meet those needs, which made it natural to choose them for this project.”.

METSO OUTOTEC, AMIC SIGN AGREEMENT ON ILMENITE SMELTER PROJECT IN SAUDI ARABIA

ramping up since December 2021. The ramp-up continues and with ongoing optimization works, the furnace 1 has been producing on-spec marketable high-quality chloride slag and pig iron.

As part of this Settlement Agreement, Metso Outotec and AMIC have agreed to enter into a Collaborative Refurbishment and Optimization Works Contract. This contract entails additional value engineering and enhancements for the furnace 2 to ensure sustainable operating performance at higher operating rates. The furnace 2 is expected to start its ramp-up of operations during 2025.

Metso Outotec and Advanced Metal Industries Cluster Company Limited (AMIC), a subsidiary of Tasnee, have signed a full and final settlement agreement in relation to the original engineering, procurement, and construction (EPC) contract, signed in May 2012, on the Ilmenite Smelter Project.

After modifications and construction works, the smelter’s furnace 1 has successfully started operating and has been

As part of the Collaborative Refurbishment and Optimization Works Contract, Metso Outotec will provide the required engineering, technical and project management support and services over an agreed period of time.

The provision, which Metso Outotec has earlier booked for this project, is sufficient to cover the costs related to the Settlement Agreement, including the additional engineering and enhancements for the furnace 2..

MANITOWOC DEALERS FROM THE MIDDLE EAST, AFRICA, AND CIS GATHER IN DUBAI

One of the primary goals of the event was to examine potential for the three areas, namely how Manitowoc's suite of customer support services may assist clients achieve a competitive advantage. Services like online or live training, EnCORE crane refurbishing, and predictive maintenance may help businesses get more uptime and service life out of their cranes, resulting in more profitability.

There were also lectures on Manitowoc's latest innovations, which are intended to increase end-user productivity.

For the first time in three years, regional leaders from Manitowoc and its dealers from the Middle East, Africa, and CIS, gathered in person to share best practices, discuss opportunities for growth, and review the outlook for the lifting segment. The event was held in Dubai, United Arab Emirates.

“The crane industry plays a central role in shaping the cities and communities of our regions, and every year there are bigger and more complex challenges,” said Andrew Youssef, Middle East, Africa, and CIS General Manager at Manitowoc. “At Manitowoc, we pride ourselves on delivering the technology and solutions to meet those challenges, head-on.”.

OPTIMUM PLANT UTILIZATION

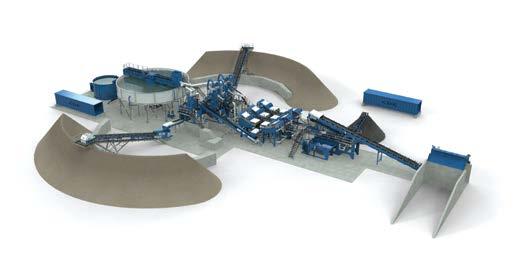

CDE WASH PLANT TO SUPPORT NEXT PHASE OF PIONEERING KUWAIT SEA CITY PROJECT

along the Arabian Gulf. It will have a massive network of canals and waterways, as well as four major marinas, in addition to residential and commercial buildings.

With the next phase commenced, millions of cubic metres of sand and silt will need to be extracted, processed and dewatered to create new entrance channels, waterways and land formation.

CDE, a leading supplier of sand and aggregate wet processing solutions for the waste recycling and natural processing sectors, has announced a new partnership with the La’ Ala Al-Kuwait Real Estate Company that will see it design and engineer a sand washing plant to support the delivery of phase five of its pioneering Sabah Al-Ahmad Sea City (SAASC) in Kuwait.

SAASC is one of the world’s largest real estate developments, located 90km south of Kuwait City in the Al-Khiran region

CDE will commission a new sand washing facility to replace an existing wash plant setup that has reached the end of its operational life to support this. CDE’s solution will enhance throughput by optimizing the plant and increasing uptime. Because of its flexibility to be fine-tuned in response to variable feedstock, the system will be able to alter cut point to ensure optimum plant utilization and product production to support the city’s ongoing development of new coastline and infrastructure.

As part of the latest phase of the project, an estimated 1.3 million cubic metres of beach sand is required by the middle of 2024..

CULTURAL SITES

MEDCO SUPPLIES GENIE AERIAL LIFTS FOR WORK IN MAKKAH AND MADINAH

MEDCO, Genie’s authorized distributor in Saudi Arabia, has started delivering 135 Genie boom and scissor lifts acquired by Al Majal Al Arabi for facility maintenance on holy mosques in Makkah and Madinah. These lifts will be utilized for routine cleaning and maintenance at these critical sites.

The purchase comprises Genie S-60 J and S-80 J telescopic boom lifts, GS E-Drive scissor lifts, and electric Z-60 DC articulating boom lifts.

Each piece of equipment has key attributes that make it the best lift for certain duties at these Saudi cultural sites. For example, the S-60 J and S-80 J telescopic boom lifts are lighter than comparable booms in their class, making them suitable for work on delicate surfaces, while the Z-60 DC articulating boom lifts give up-and-over access for reaching difficult-to-reach regions. Because they are electric, the Z-60 DC machines produce no noise or emissions, making them ideal for indoor use.

Similarly, Genie GS E-Drive scissor lifts enable MEDCO’s customer Al Majal Al Arabi to work indoors or outdoors. Electric scissor lifts are efficient, low-maintenance, and easy to handle, increasing workplace productivity. Because there are 70% fewer hoses and fittings, the risk of hydraulic leaks is reduced to near zero, which is especially important when working on historic sites..

SURGING DEMAND

MODULAR CONSTRUCTION IN THE REGION GETS A BOOST WITH NEW AMANA FACTORY IN SAUDI ARABIA

Leading regional design-build contractor AMANA is consolidating its leadership in modular construction with a new factory in Rabigh, Saudi Arabia. The factory is a response to the surging demand in the Kingdom for offsite manufacturing technologies enabled by DuBox and is vital to successful project delivery for the Kingdom’s raft of ambitious hospitality and entertainment projects. DuBox shifted 85% of construction from its Saudi megaproject sites such as Qiddiya and Red Sea Global’s tourism destinations to its Rabigh factory.

Overall, modular construction reduces the need for manpower by up to 30%, and up to 85% of the construction can be completed off-site, in a factory. Modular buildings can also be constructed within up to 50-70% of the time of a conventional project of a comparable size, with 50% fewer carbon emissions, 50% lesser construction waste and up to 70% improved work safety environment.

At the 70,000sq m Rabigh factory, DuBox designs, manufactures and assembles entire buildings. It can produce 16 modules every day, and the factory has sufficient output to ensure repeatability, learning, consistency in quality and volume savings on procurement..

NISSAN ACCELERATES EFFORTS TO ELIMINATE COUNTERFEIT SPARE PARTS IN THE MIDDLE EAST

CONTINENTAL SHARES MIDDLE EAST

KEY ROLE AND

OUTLOOK FOR 2023

Continental recently hosted a roundtable event on the importance of the Middle East to Continental’s global growth and the continuation of key initiatives with private and public partners across the region. The event was led by Ferdinand Hoyos, Continental’s Head of the Replacement Tyre Business for Europe, Middle East, and Africa, along with Karel Kucera, Managing Director of Continental Middle East.

In line with its long-standing mission to ensure customer safety, Nissan Middle East has taken a bold step to reduce the presence of counterfeit spare parts in the region. Engaging a broad aftersales ecosystem, Nissan has undertaken the development and delivery of counterfeit spare part identification training sessions for authorities, partners and customers across the Middle East.

Nissan’s ongoing collaboration with government entities across the Middle East to grow, with trainings currently deployed to Customs Authorities, Economic Departments and Police in Abu Dhabi, Ajman, Bahrain, and Dubai – with the aim to expand this to wider audiences in Jordan, Kuwait, and Qatar over the coming months. Teams are trained to identify frequently counterfeited items, including spark plugs, brake pads, and oil filters, and detect the subtle differences between a genuine and counterfeit product.

The global automotive counterfeit market continues to pose an imminent risk for drivers, passengers, and pedestrians, reducing the performance and reliability of vehicles in the long run.

Nissan’s aftersales product portfolio in the Middle East, comprises of over three million spare parts, including Nissan Genuine Oil, Nissan Genuine Batteries, and Nissan Genuine Accessories. Nissan’s aftersales network includes eight certified distributors with a total of 101 branches across the region. .

Hoyos provided an overview of Continental Group’s activities, which extend far beyond premium tyres – the extensive portfolio ranges from pioneering technologies and smart mobility of the future to architecture and safe, efficient solutions for vehicles, machines, traffic and transportation.

The event discussed the company’s latest efforts towards this goal and its commitment to developing innovative products and technologies that improve safety on the roads for drivers through dedicated product lines for the Middle East across two brands, Continental and General Tire. These brands utilise pioneering German technology and European manufacturing prowess to bring products that fit the region’s requirements of robustness and durability. This has been complemented by the establishment of BestDrive, a complete tyre fitment solution designed to provide the best advice, service, quality, and value for customers across the UAE..

MOT LAUNCHES SAUDI ARABIA’S FIRST SELFDRIVING ELECTRIC VEHICLE

The Deputy Minister of Transport and Logistics, Dr. Rumaih Al-Rumaih, launched the trial phase of ‘Dhahaina’ (‘Smart’), a new autonomous vehicle (AV) at the Riyadh Business Front. The launch event was intended to boost awareness and increase acceptance of AV technology in society and is the first step-in in a longer process that will see the development of AV legislation, regulations, and supporting systems.

The AV initiative is in line with the Ministry’s efforts to facilitate and embrace contemporary transportation systems. In a statement during the event, Al-Rumaih highlighted the Ministry’s embrace of innovative transportation techniques, and its plans to utilize advanced technologies in the transportation and logistics industry, as per the objectives set in the National Transport and Logistics Strategy. This strategy aims to provide solutions for smart mobility and anticipate the future development of the market. By launching this trial, the Ministry aims to reduce the number of transport-related accidents and fatalities, improve intracity mobility, and minimize the impact of the transportation sector on the environment.

The inauguration occurred at the Riyadh Business Front, owned by the ROSHN Group – which is taking a novel approach to incorporating modern technology into the integrated communities it is building across the Kingdom. ROSHN promotes sustainability by offering pedestrian-friendly streets and eco-friendly modes of transportation for commuting within its communities, while providing connections to a wide range of public and private transportation options that connect its customers to the wider city..

DISTRIBUTION

DYNAPAC SELECTS AL SHIRAWI ENTERPRISES AS ITS DISTRIBUTOR IN THE UAE

For the UAE market, Dynapac recently selected Al Shirawi Enterprises as its distributor. Thani Al Shirawi, CEO of Al Shirawi Enterprises LLC, Victor Fredrick, Deputy Director of the Machinery Equipment Division at Al Shirawi Enterprises, and Thierry Leder, Regional General Manager in the Middle East and Africa at Dynapac, joined the Al Shirawi team at their Al Quoz headquarters to formally sign the partnership.

Al Shirawi Enterprises will be selling the whole Dynapac product line, including soil rollers, asphalt rollers, and paver equipment, throughout Dubai, Abu Dhabi, Sharjah, and Ras Al Khaimah.

Al Shirawi Enterprises is also the exclusive dealer in Dubai and the Northern Emirates for Scania heavy commercial vehicles and luxury coaches, as well as the sole distributor in

the UAE for CASE Construction Equipment, CASE Agricultural Equipment, STILL Material Handling Equipment, Carrier Transport Refrigeration equipment, Kirloskar Power Gensets, and Scania Engines..

EFFICIENT LIFTING

MAMMOET’S MTC 15 ASSISTS THE RED SEA PROJECT’S SHURA ISLAND BRIDGE

Mammoet welcomed the start of 2023 with the delivery of the very first batch of modularly constructed villas for Red Sea Global’s Sheybarah Island Resort. A total of four villas were loaded at Sharjah’s Port of Hamriyah and shipped to the island to be installed.

For the installation, Mammoet used its 650t capacity Demag CC3800 crawler crane positioned on top of Mammoet’s modified barge, ALE 250. The shallow draft of the barge meant that there would be minimal disturbance to the sensitive marine environment of this unique and picturesque archipelago in the Red Sea.

At the construction jetty, the crane loaded and placed the first orb on the barge deck and sailed to the installation area. Once at the location, the barge was positioned using a hyperaccurate GPS system and the barge’s own winches, for precise alignment with the foundation. The barge was then stabilized using a retrofitted 300t spud jacking system provided by Combifloat – Mammoet’s partner for floating and self-elevating marine equipment suitable for nearshore operations. Safe and

efficient lifting, lowering and re-positioning of the barge was achieved through a locally controlled jacking mechanism and a 4-point mooring system.

Mammoet was awarded the contract to transport and install all 73 villa pods back in May 2022. To support the shipment of the villas from the UAE to Saudi Arabia, Mammoet teamed up with P&O Maritime Logistics, a leading provider of critical logistics and marine solutions..

PERFECT COORDINATION

DIRIYAH COMPANY CONCLUDES LARGEST CONCRETE POUR TO DATE

Diriyah Company witnessed its largest volume concrete pour in a single location to date. El Seif Engineering Construction and China State Construction joint venture poured 6100m3 of reinforced concrete for the underground Main Spine Tunnel roundabout foundation slab, which links to four neighboring tunnels, in the southern area of the construction.

The pour was finished in 21 hours, ahead of time, thanks to perfect coordination between the batching plants and logistics teams, using a fleet of 75+ concrete trucks from 5 separate batching plants on-site and 7 pumps. While the initial phase of the pour used concrete from outside sources, the remainder was drawn from on-site batching plants,

including those owned by other contractors, demonstrating a truly collaborative operational partnership..

FAMCO LAUNCHES THE UAE’S FIRST EICHER TRUCK RANGE

Al-Futtaim Auto and Machinery Company (FAMCO), a subsidiary of Al-Futtaim Automotive and a prominent dealer of heavy vehicles, commercial vehicles, and machinery in the UAE, has officially introduced the all-new Eicher Pro 2000 line of Light Duty Trucks.

Powering the logistics and intra-city distribution sector of the UAE, the successful launch reinforces the partnership between FAMCO and VE Commercial Vehicles (VECV), A Volvo Group and Eicher Motors Joint Venture.

Eicher Pro2000 series features a slew of next-generation innovations targeted at dramatically enhancing owner profitability through best-in-class fuel efficiency and uptime. This new line of dependable trucks is outfitted with technologies that assist increase operational economy while also improving driver safety and comfort.

This new range of trucks has been thoroughly tested to deliver best in class performance for customers in the UAE. The Eicher Pro2000 series delivers a power of up to 150HP and is designed to meet application-specific customer needs with variants of Eicher Pro2055XP, Pro2065XP, Pro2075XP, Pro2080XP, Pro2095XP and Pro2080XPT.

With this introduction of Pro 2000 series, Eicher as a brand intends to play a role in the region’s development and would take care of the logistics and transportation needs of the market. This would further enhance the growing contribution of India and is in line with the ongoing effort of strengthening business relationships with the UAE.

Building on successful years of partnership, Eicher is a brand that FAMCO has represented in the UAE for almost a decade now. In addition to supplying the range, FAMCO will also continue to offer the aftersales services and value-added benefits across the leading mobility dealer’s widespread network..

AL MASAOOD SECURES 300 UD TRUCKS ON WASTE MANAGEMENT DEAL

UD Trucks MEENA and Abu Dhabi importer Al Masaood has recently made a significant achievement in the UAE by winning the Abu Dhabi Waste Management Project. This success has come after a highly competitive tender process supervised by Abu Dhabi Municipality, Tadweer, and three subcontractors, Averda, Lavajet, and BEEAH, with UD Trucks securing 300, most of them with service agreements, out of the 420 trucks.

The Abu Dhabi Waste Management Project was divided into four lots, covering Abu Dhabi and Al Ain cities, with the primary objective of improving the waste management infrastructure and services in the region. With rapid urbanization and increasing population, waste management became important for environmental care and sustainability.

JUFFALI COMMERCIAL VEHICLES OPENS NEW BRANCH IN DAMMAM

The new location is part of a growth plan that will reach all Saudi Arabian cities and ensure that Juffali Commercial Vehicles’ objectives are delivered.

Juffali Commercial Vehicles officially launched its newest branch of JuffaliTrucks in the eastern area of Dammam, Saudi Arabia. The new branch is part of an expansion that will encompass all cities in the Kingdom of Saudi Arabia, ensuring that Juffali Commercial Vehicles’ aims, services, and sustainability are met.

JuffaliTrucks is known for its commitment to quality and customer service, and this new branch in Dammam is no exception. The company’s focus on providing high-quality preowned Mercedes Benz and FUSO commercial vehicles, along with their dedication to customer satisfaction, has helped them to establish a loyal customer base over the years.

“We are thrilled to be opening a new branch in Dammam and expanding our presence in Saudi Arabia,” says Heiko Schulze, CEO of Juffali Commercial Vehicles. “We have always been committed to providing our customers with the highest levels of service and quality, and this new branch will enable us to do that even better.”

In addition to selling pre-owned commercial vehicles, the new branch will also offer a range of services to support customers’ needs. This includes maintenance and repair services, as well

as financing options to help customers purchase trucks or buses they need.

“Our ambition and objective are to be the leading used truck brand in the Kingdom of Saudi Arabia. At JuffaliTrucks, you will find a large selection of used trucks, trailers, semitrailers, and all brands, models, bodies, and ages,” says Schulze.

The decision to open a new branch in Dammam reflects JuffaliTrucks’ ongoing commitment to serving customers in Saudi Arabia. The Saudi dealer recognizes the growing demand for quality pre-owned commercial vehicles in the region and is committed to meeting this demand with its extensive range of products and services.

“At all our locations in the Central Region (Riyadh), Eastern Region (Dammam), and Western Region (Jeddah), you will receive the same professional advice and a comprehensive range of services during your truck purchase,” adds Schulze.

The growing demand in used trucks in Saudi Arabia plays to JuffaliTrucks’ capabilities. The business provides a large selection of used semitrailer tractor units with various applications, buses, vans, and used truck bodies. JuffaliTrucks imports and converts European Mercedes-Benz buses and trucks to Saudi requirements in order to give used commercial vehicle choices in Saudi Arabia.

JuffaliTrucks verifies by inspecting vehicles in Europe, upon arrival in Saudi Arabia, and before final delivery to clients in Saudi Arabia.

“In addition to the trade-in of used trucks and the provision of Daimler and Mercedes-Benz after-sales services, we guarantee our customers by checking all the pre-owned trucks in three stages,” says Mohammed Al Wardat, Director of JuffaliTrucks.

“As a result, we have accomplished many achievements and successes in a short period since the establishment of JuffaliTrucks in terms of sales and customer satisfaction, and our expansion plans to cover the whole Kingdom,” adds Al Wardat.

In Saudi Arabia, Juffali Commercial Vehicles is the sole agent and distributor for Mercedes trucks and buses. More recently, the company has also become a distributor for FUSO trucks and buses.

Juffali Commercial Vehicles has a long and successful relationship with Daimler AG, dating back to 1974, when a joint venture between Mercedes-Benz Commercial Vehicles and E.A. Juffali & Brothers established the National Automobile Industry (NAI) in Jeddah to manufacture Mercedes-Benz commercial vehicles in Saudi Arabia.

Juffali Commercial Vehicles, in collaboration with Daimler, offers its clients unsurpassed quality Mercedes-Benz and FUSO products, as well as dependable service and support even in the most distant corners of the Kingdom, through its more than 900 employees.

JuffaliTrucks’ website, www.JuffaliTrucks.com, now allows Saudi buyers to browse and enquire about used MercedesBenz trucks online. Customers may purchase a variety of Mercedes-Benz vehicles, including Actros tractors, Arocs tractors, MCV buses, Tourismo buses, and Travego buses..

Leading digital construction event that focuses on Digital & Sustainable Approaches that Greener

BETTER PRODUCTIVITY WITH ATTACHMENTS

Auger Torque began its Middle East operations in 2016 with a sole focus on the UAE market. Since then, the company has a presence in Kuwait, Qatar, Oman, Bahrain, and Saudi Arabia. Last year’s sales saw the company record 44% growth as compared to the same period in 2021. This year Auger Torque is already witnessing strong demand from the regional oil and gas, infrastructure, and solar industries.

Auger Torque manufactures attachments and distributes them globally in more than 96 countries. In the Middle East region, besides having dealers in the UAE, Kuwait, Qatar, Oman and Saudi Arabia, the company supplies its products through JAFZA into Egypt, Ethiopia, Kenya, and South Africa.

Industries that Auger Torque supplies to are mainly civil, infrastructure, solar, marine, tunnelling, mining, agriculture, and landscaping. This year has begun with a number of active projects in Saudi Arabia (NEOM Project), Kuwait (oil and gas) and in Qatar (post FIFA), where there’s an increase in demand in the solar and infrastructure industries.

Regional challenges

Auger Torque is gradually seeing an improved understanding of the benefits of working with attachments in the Middle East region. “Change is definitely happening albeit at a slow pace if you compare it to the Western and Asian markets,” says Rohan Saldanha, Head of International Business Development- META/ LATAM/APAC at Auger Torque Europe Limited. “It is still a conversion market, where customer awareness is still limited,” he opines. “In a number of cases, access to information/modern technology is limited and where customers are focused on their job at hand, in such situations there is no band width to explore or dabble in newer technologies.”

Over the last seven years, the company has experienced that the general mentality is cost conservation and pricing rather than focussing on the big picture and linking the dots to productivity improvement. However, this is slowly changing.

“We see that when our applications are demonstrated live to customers, they see the wow factor,” continues Saldanha. The company currently has more than 300 customers since 2020 all over the Middle East, Turkey, and Africa (META) region.

Besides customer education, Auger Torque has also seen competition sprout up regionally, however due to the wide array of products in their portfolio other attachment manufacturers don’t eat much into market share and most of the competition is limited to local dealers with no direct presence or limited presence in the market. “For example, in this region, our core product is for drilling and besides us there are several competitors both local, regional and a limited number of international players. The equipment that our competition sells is inexpensive copycat units with mediocre performance parameters and are sold by their dealers who have the sole focus of capturing a quick sale. This leaves customers with a poor overall experience. Hence, customers are looking for reputed and reliable suppliers with a local presence and after-market support,” continues Saldanha.

“What differentiates us from the competition is our principle of being locally accessible as we maintain stock on the ground. We adapt our portfolio to local market conditions and assist

clients when they have a problem. Building trust with both our dealers and customers and being transparent is paramount in establishing a fruitful working relationship for long term business sustainability,” he adds.

Auger Torque/Kinshofer have production facilities in more than 20 countries and each factory produces distinct components for each of the products from their portfolio. Production is also done intra company to help enhance cost synergies. For the META region, the company uses its local experience on its core drilling product and manufactures it in the UAE. “This helps us adapt the product to what the customers want and develop products that are suited for the local ground conditions,” adds Saldanha. More complex products like hydraulic shears, rotators, railway attachments, due to the complexity factor, are produced in their overseas production facilities.

When an order is received in the region, since most attachments are locally maintained at JAFZA, an entry is created on sales force with an aim to have it delivered to the customer within the UAE in three days and in the GCC in 10 days. Non-standard products usually need eight to 12 weeks for production and shipping. “If we see potential for a product or say if based on a recurring requirement for a particular project which involves a number of attachments, the information is relayed to supply chain to account for the demand when it comes to fruition,” he explains. In this case, the products

are produced in component formats and kept in stock. When the order comes in, it is categorised under just-intime production where the partial components are pulled together to assemble the finished product. This reduces lead time and also the risk for the dealer from holding stock for a product which may be high in capital expenditure (CapEx). It also prevents obsolescence in case a sale does not come through.

Besides the civil, infrastructure, marine, EPC, solar, agricultural, and landscaping industries, Auger Torque also provides attachments for the recycling sector. “We provide orange peel and selector grabs and steel shears to cut and recycle steel,” says Saldanha. Drilling attachments are also available from Auger Torque for pre-drilling sheet piles. These are utilized to provide structural support for things like retaining walls. It additionally provides vibro hammers to vibrate the sheet piles in (system solutions). For railways, the company provides attachments that can be fitted on the excavators to lay sleepers and tampers to settle and accompany the ballast stones.

Soon, Auger Torque wants to increase and build on its brand awareness amongst customers in the Middle East. “We are currently working to increase our market reach via our dealer network and want to bring new attachments to service the growing demand in railway, recycling and the renewable energy segment,” he concludes..

Current projects:

• NEOM Green solutions - Saudi Arabia

• Streelight Installations - Oman

• Dewatering Projects - GCC wide

• Tunnel Rehabilitations - Various regions

• Underwater River Dredging Project - India

• Coal Mining - India

• Highway Guard Rail Installations - Qatar

• Solar Post - Helical Pile Installations - UAE

A tough call - Muscat Wastewater Treatment Facility

There was a need for drilling 600mm underground in 12m dense limestone. The problem was that the ground report did not indicate the strata. The requirement was to drill 52 holes at a depth of 12m. The client informed Auger Torque that the machine in use would be a 20-tonne excavator, but on the site the machine was a PC 400. There was no access to hydraulic technicians. This was the first challenge. The earth drill that was shipped was made for a 20 T excavator and the auxiliary line pedal valve was non-functional. So, trying to assist a customer who purchased equipment without planning or a functional carrier machine while being overseas in the UK was quite challenging.

Once on-site, Auger Torque assessed the shortfalls, connected with engineering and logistics, air freighted new hard rock pilot bits in 48 hours, connected with a local hydraulic technician and using the pressure as a gauge, modulated the flow of the excavator and brought it to a level that the earth drill could handle. Meanwhile the client connected the company with a used equipment supplier and got the auxiliary line fixed. By the third day, Auger Torque’s team was in Muscat and began drilling. The first five meters were reached in 20 minutes, the next two meters were tough as there was hard limestone which took an hour to drill through. Overall, each hole was compiled in an hour and 45 minutes to two hours. Due to the proximity of water treatment tanks no rotary percussive method was allowed to be deployed due to the danger of micro fractures in the concrete tanks. Whilst this was a challenging situation, Auger Torque managed to work its way through the issue with the resources available locally while drawing from their tech team in the UK, Australia and the USA resulting in a successful project.

BLUE IS THE NEW GREEN

Trychem’s Mehul Parmar tells Plant & Equipment how he and his colleagues are enabling Middle East fleet owners to capitalise on the many emissions-related benefits of AdBlue.

Regulations concerning the emission of nitrogen oxides, or NOx, are tightening around the world. Formed when fuel is burned at high temperatures, these toxic gases have a detrimental impact on our environment, exacerbate global warming and negatively affect human health. Exposure to NOx can irritate the eyes, skin and respiratory system and, in some cases, even lead to conditions like bronchitis and emphysema.

Diesel-powered vehicles such as cars, trucks and off-highway machinery are major contributors to NOx emissions. The problem is, with so many of these units already in operation on highways and worksites across the planet, it is simply not feasible to ban their use. Instead, industry innovators are working with manufacturers to deliver solutions that ensure our use of contemporary diesel technology does cost the earth.

One such solution is diesel exhaust fluid (DEF), more commonly known as AdBlue. When sprayed into the exhaust

systems of diesel-powered vehicles, this substance reacts with the fumes produced to break down the damaging mononitrogen oxides within. In short, AdBlue represents a practical and effective tool in the fight against NOx emissions.

Owing to its sizeable fleets of heavy-duty, diesel-powered commercial vehicles and construction equipment, the Middle East is ideally placed to capitalise on the advantages offered by this product. To this end, Germany-headquartered Brenntag established Trychem as its UAE-based subsidiary to distribute AdBlue throughout the Middle East.

As Trychem’s Business Unit Leader for Surfactant and Blending Solutions, Mehul Parmar is acutely aware of the benefits that will stem from widespread AdBlue adoption in the Middle East. “When a diesel engine produces exhaust fumes, NOx passes through its catalytic chamber,” he explains. “AdBlue reacts with these gases, converting them into water vapour and nitrogen, reducing NOx emissions by up to 97%.”

“Brenntag entered the Middle East market in 2015, establishing Trychem with a specific focus on AdBlue in the UAE in 2018,” Parmar continues. “Brenntag has now established its own entity in Saudi Arabia and is already active in this market. Further down the line, we intend to supply AdBlue to fleet owners across the Kingdom as well.”

Expansion into the Middle East market could pay huge dividends for Parmar and his colleagues, not to mention surrounding ecosystems. Global AdBlue revenues are on course to reach $44.5 billion within the next decade, according to figures published by Fact.MR, representing a compound annual growth rate (CAGR) of 4% during the period 202333. As regulations continue to become more stringent in Gulf states, the region is likely to account for an ever-increasing share of the international market.

“All diesel engine producers are now focusing on manufacturing and promoting units that meet regulations pertaining to Euro 5 and above, for which the use of AdBlue is mandatory,” Parmar tells Cameron Hubbard. “In addition to banning all imports of Euro 3 vehicles, the UAE government has imposed strict requirements for the use of AdBlue across the Emirates.”

Given the UAE’s status as a regulatory bellwether for the Middle East, it seems inevitable that DEF requirements will become more stringent across the wider region over the coming years. And as industrial activities in the Gulf continue to grow and evolve, companies with large fleets of commercial vehicles and heavy machinery will need to follow suit. “Just

like other lubricants and related products, AdBlue is becoming an essential component of servicing in the Middle East,” Parmar explains.

In a bid to capitalise on this direction of travel, Trychem and its parent company have devised a comprehensive strategy to supply the region. Brenntag is already the largest global distributor of AdBlue and, as such, is well positioned to support ongoing adoption in the Emirates and beyond.

“So far, our primary focus has been the UAE, and we have succeeded in meeting local requirements through our plant in Sharjah’s Hamriyah Free Zone,” Parmar says. “Similarly, we

are setting up an entity for chemical blending in Saudi Arabia to cover demand in the Kingdom. This business is primarily about ensuring strong regional distribution, and we are doing extremely well in this respect.”

The success of Trychem in the UAE has been built largely on Brenntag’s impressive track record manufacturing and sourcing DEF-grade urea at an economical price. “We also have extensive technical know-how and are following ISO 22041 standards for DEF.

“As a result, we have secured a solid lead over competitors in the Middle East, and with the regional adoption of AdBlue set to increase even further, our long-term chances of success are high,” he continues.

“In addition, we have invested in a distilled water manufacturing plant, which allows for backward integration. This makes us very strong compared to our peers in the Gulf, especially when viewed within the context of the strict standards we have implemented to ensure the delivery of a superior product.”

It appears that regional demand is more than sufficient to occupy Trychem for the foreseeable future, but what are the company’s priorities over the longer term? Parmar notes that he and his colleagues remain committed to ongoing innovation and development to help maintain their competitive edge.

“In terms of distribution, we plan to expand our network to cover new sectors – especially the marine industry, whose

vessels require DEF to run,” he explains. “We are already supplying DEF to a number of cruise ships in the UAE. Given the nation’s status as a hub for tourism and cargo shipping, there are plenty more opportunities for us to grow our activities concerning the supply of marine-grade DEF.

“So, demand is continuously increasing, but so too is competition,” Parmar concludes. “We must therefore continue to differentiate ourselves through consistency of supply and the quality of our product. In doing so, we are confident we can continue to outperform our rivals.”.

SCALING NEW HEIGHTS

Representatives from Liebherr and Yongmao speak to Cameron Hubbard about the Middle East’s tower cranes market, and what the future holds for these super-tall machines.

Tower cranes represent a crucial tool in the modern construction arsenal, sharing city skylines with the very buildings they help create. Yet while the surfacelevel makeup of these machines may appear to have remained largely unchanged since their first iterations were introduced back in the mid-20th century, the technology behind these lofty luggers is constantly advancing.

Globally, the tower crane market is witnessing high levels of demand. Valued at $5.29 billion in 2021, the sector is on course to reach $7.59 billion by 2027, representing a compound annual growth rate (CAGR) of 6.2% during the period 2023-2027, according to analysis from Mordor Intelligence. And while Asia-Pacific territories are contributing the lion’s share of this demand, largely due to their sizable populations, the Middle East continues to punch above its weight in terms of its tower crane requirements.

The tower cranes that populate modern metropolises can trace their roots back to 1949, when Hans Liebherr dreamt up a

machine that could support Germany’s post-war reconstruction efforts. Today, the Switzerland-headquartered conglomerate that bears his name continues to pioneer novel innovations within the heavy-lifting space, and the Middle East is proving receptive to these efforts.

Nikolaus Gstinig, Area Sales Manager – Middle East at Liebherr, tells Plant & Equipment: “We are currently seeing a clear upward trend in regional demand for tower cranes, which stems from numerous gigaprojects in markets such as Saudi Arabia and the UAE.”

Singapore-headquartered machinery manufacturer, Yongmao Holdings, is also confident in its ability to capitalise on the region’s development ambitions. Jonas Tan, Sales Manager at the company, says: “There are many projects in the pipeline, but we are still waiting for them to kick off. Delays could be due to rising costs and global financing uncertainty. However, we believe that demand will strengthen in the second half of 2023.”

Encouragingly, gigaprojects are not the only developments driving regional demand for tower cranes. “Liebherr units are represented across a wide variety of project types from lowrise to high-rise buildings, the majority of which relate to the residential and commercial sectors,” says Gstinig. “Our cranes have also been involved in the construction of infrastructure projects, such as the UAE’s Barakah Nuclear Power Plant and Turkey’s 1915 Çanakkale Bridge – the longest suspension

bridge in the world. In addition to the units themselves, we also provide support through Liebherr Tower Crane Solutions, helping to ensure successful operations for end users.”

Yongmao’s cranes are also proving popular on similarly impressive infrastructure developments, as Tan explains. “One of our proudest projects was the Dubai Waste Management Centre (DWMC), the largest waste-to-energy plant of its kind anywhere on the planet.” Commenting on the models that have proven most sought-after among Middle East customers, he continues: “Yongmao is famous for its mid and large-size tower cranes, which are capable of lifting between 18 and 100 tonnes. Our STT series is our most popular flat-top variant thanks to its ease of assembly and low cost.”

Liebherr is witnessing a similar shift towards flat-top cranes, as Gstinig notes. “Our most popular model in the Middle East is the Liebherr 280 EC-H,” he says. “This has long since been the go-to crane for a variety of projects thanks to its hammerhead design, which offers higher loads at maximum radius allowing for lighter-weight construction. However, building styles and requirements are changing and the trend is heading towards flat-top cranes. The Liebherr NC-B 12-70 is fulfilling this need in the Middle East at present.”

To capitalise on current levels of demand and future-proof its offering over the longer term, Yongmao’s research and

development experts are continuously working to maximise the efficiency of their units. “Our new winch design is more energy efficient than our previous system,” says Tan. “Its pin connection uses a hydraulic device to save on labour and time, and because the winch is already attached to the cathead, erection time is also minimised.”

True to its founder’s vision, Liebherr is also investing in fresh innovations to improve productivity and add value for end users. “One of our biggest tower crane-related innovations is our new stronger-fibre rope, which is now produced using a synthetic material instead of steel,” Gstinig explains. “This material offers significant load increases, a longer service life, higher hoisting speeds, reduced maintenance and enhanced safety. Liebherr’s products and innovations within the tower crane segment continue to set new benchmarks in terms of safety and quality.”

So, what are the longer-term priorities for global equipment manufacturers supplying tower cranes to the Middle East?

According to Tan, Yongmao intends to build on its recent track record to take advantage of ever-increasing regional demand.

“Yongmao has been quite successful in the Middle East for more than a decade,” he says. “Over the coming year, we foresee that market demand will increase by at least 20% in the UAE and by up to 250% in Saudi Arabia.”

Gstinig is equally optimistic about Liebherr’s future prospects. “Despite external economic difficulties, Liebherr can look back on a positive overall business performance in the Middle East,” he concludes. “Our team has faced these global challenges head-on, and we are now witnessing positive trends in both Saudi Arabia and the UAE. We are therefore optimistic that Liebherr will experience a bright period over the coming years.”.

Middle East Mega Projects

by Plant & Equipment

by Plant & Equipment

UNITED ARAB EMIRATES

Project: Sequoia Project

Value: USD 2,200,000,000

Arada, a UAE developer, has announced the inauguration of Sequoia, the sixth and last phase of Masaar, its megaresidential woodland project in New Sharjah’s Al Suyoh district.

The Masaar masterplan features 3,000 homes spread over seven gated districts, all of which are linked by a green spine featuring over 50,000 trees. Sequoia is located on the north side of the Masaar master plan. All homes lie within easy walking distance from Masaar Central, the community hub which features ample entertainment, leisure, wellness

Client: Arada Developments LLC

Website: www.arada.com

and fitness facilities along with direct access to its signature forested landscape, outdoor amphitheatre, children’s waterplay area and a skate park.

Homes at the Sequoia district range from two-bedroom townhouses to six-bedroom Sequoia forest signature villas. Smart features come as standard at every Sequoia home while larger villas offer increased privacy, additional lounges, expansive terraces, and pristine swimming pools. All homes in Sequoia will be completed by the end of 2025.

SAUDI ARABIA

Project: Konoz Entertainment City

Value: USD 1,800,000,000

UK-based architecture firm Benoy unveiled its design plans for Konoz entertainment city project, located in Riyadh. The $1.8bn mixed-use project will be developed by Abdullah Al Othaim Investment Company, one of the Kingdom’s largest shopping mall operators. The leisure destination on Riyadh’s Golden Strip will include an entertainment city, a luxury hotel, and residential offerings, in addition to commercial, F&B and retail outlets.

Client: Abdullah Al Othaim Investment Company

Website: www.othaimipo.com

The project includes 50,000sq m of commercial office spaces, a 20,000sq m entertainment city aimed at supporting Riyadh’s tourism and entertainment industry. Other elements include 15,000sq m of green areas, parking for 5,500 vehicles, a 120,000sq m commercial centre, a luxury hotel with 250 rooms, 120 serviced residential apartments, and an additional apartment complex that includes 700 apartments.

OMAN

Project: Establish Green Steel Manufacturing Facility

Value: USD 3,000,000,000

Client: Jindal Shadeed Group

Website: www.jindalshadeed.com

Jindal Shadeed Group will commence work on setting up the proposed 5 million tonnes (MT) green hydrogen-ready green steel complex in the Special Economic Zone (SEZ) in Duqm this year. The green iron produced at the project will be for the purpose of exporting to car factories in the world, factories that produce windmills, and factories that produce household appliances. A project of this caliber would be an added value to the heavy industries cluster in the Special Economic Zone at Duqm and would play a vital role in the development of Duqm as a key industrial hub.

SAUDI ARABIA

Project: Construct Residential Villas

Value: USD 111,520,000

Client: National Housing Company (NHC)

Website: www.nhc.sa

Saudi-based Retal Urban Development Company has inked a conditional development contract with the state-owned National Housing Company (NHC) to develop residential villas in East Albuhirat master plan in Jeddah.

The project will span an area of 98,098.55sq m, and development will begin the day after NHC receives the land and will be finished in 42 months. The residential project will be financed using profits from off-plan sales and internal sources; sales will begin only when the off-plan sale permission is obtained.

UNITED ARAB EMIRATES

Project: Sea La Vie At Yas Bay

Value: USD 545,000,000

Client: Nine Yards

Nine Yards, a real estate development partnership between Ethmar International Holding and Al Nahda International Holding, enters the UAE’s real estate market by launching a unique $545m waterfront project, located at Yas Bay on Yas Island.

The company revealed its first real estate project, Sea La Vie located at Yas Bay, at an exclusive event attended by several distinguished guests. The development will be purely residential with a range of luxury home varieties from 1 to 4-bedroom apartments, lofts, townhouses, duplexes, and penthouses.

BAHRAIN

Project: Hidd Blocks Sewerage Scheme Project

Value: USD 50,000,000

Client: Ministry of Works

Website: www.works.gov.bh

Bahrain’s Ministry of Works is expected to award the engineering, procurement and construction (EPC) contract for its $50m Hidd Blocks Sewerage Scheme project by the second quarter of 2023.

The scope of works includes providing the sewer connection to 144 properties in Block number 109 and 113. The works comprises of constructing a new uPVC and RTR sewer main pipeline of 200mm, 250mm, 300mm, 400mm and 500mm for total length 2,381m; 150mm lateral line for a total length of 1,909m; construction of Type C, Type E, Type H and Type F manholes for a total number of 10, 193, 56 and 49 numbers respectively associated with heavy-duty and medium covers and asphalt reinstatement works. The project is expected to be completed by the end of December 2024.

UNDERGROUND

EPIROC WINS LARGE ORDER IN DEMOCRATIC REPUBLIC OF THE CONGO

at the Kipushi zinc, copper, germanium and silver mine in the Haut-Katanga province in southern Democratic Republic of the Congo. After decades of production, the mine closed for care and maintenance in 1994. Construction started last year to reopen the mine, with late 2024 as target to start production.

Epiroc has won a large order from JCHX Mining and Construction Ltd. for equipment to be used at an underground mine that is reopening in the Democratic Republic of the Congo.

JCHX, a mining contractor, has ordered several Epiroc loaders, mine trucks and drill rigs, including service support, for use

OPTIMUM PERFORMANCE

The ordered equipment, manufactured in Sweden, includes Scooptram ST14 loaders, Minetruck MT42 haul trucks, and Simba production drill rigs. The Scooptram and Minetruck machines will be equipped with Epiroc’s telematics system Certiq, which allows for intelligent monitoring of machine performance and productivity in real-time, and with Epiroc’s Rig Control System, RCS, which makes them ready for automation and remote control.

The Kipushi mine is owned by Kipushi Corporation, a joint venture between Ivanhoe Mines of Canada and Gécamines, a DRC state-owned mining company. The mine will be powered by clean, renewable hydro-generated electricity..

ATLAS COPCO AND AIRLIF COMPRESSORS DELIVER MOBILE COMPRESSED AIR SOLUTION IN SOUTH AFRICA

Atlas Copco Power Technique and long-standing distributor, Airlif Compressors & Pumps, collaborated to deliver a reliable compressed air solution to a foremost opencast mine customer in Mpumalanga, South Africa. The ultra-robust Atlas Copco U110PACE unit was chosen as the ideal partner for the application, having been specially engineered to bring mobility and reliability to even the toughest mining landscapes.

Airlif Compressors is a leading Level 2 B-BBEE supplier to prominent mines and companies in the Mpumalanga region. The company was first approached by Atlas Copco Industrial South Africa 2 years ago to market their range of industrial air products, and has since established itself as a trusted distributor.

Airlif Compressors supplied the U110PACE to the service vehicle manufacturer who was responsible for mounting the uniton to a refurbished water bowser.

The U110PACE has been rigorously tested and proven to weather any terrain, and achieves a consistent, reliable output of compressed air through snow, mud, rain or dust. All units

are equipped with a high-speed fan for optimum performance in high temperatures, and they undergo full footprint data tests to track flow and pressure optimization, contact surface temperature and starting capability.

The U110PACE is part of Atlas Copco’s 8 Series Utility range and is renowned for its compact and box-shaped design; subsequently making it easy to move, lift and mount the compressors onto vehicles..

IVECO PARTNERS WITH AL IMTIYAZ GROUP AS THE NEW OFFICIAL DEALER IN LIBYA

and widespread after-sales support network, long-serving personnel strength, and customer service quality.

“We are delighted to become a partner of IVECO in Libya,” said Ibrahim Musbah Whiba, CEO of Al Imtiyaz Group. “IVECO has a strong presence in Libya, and we strongly believe our new partnership will fuel the growth of IVECO brand to greater levels moving forward. The new range of Heavy, Medium & Light vehicles of IVECO will be available for delivery to customers by early 2023.”

IVECO has partnered with Al Imtiyaz Group for importing transport goods and spare parts as its authorized dealer in Libya. This selection was made by IVECO following a thorough evaluation of Al Imtiyaz Group's reputation and market recognition, taking into account aspects such as a robust

“Al Imtiyaz Group joined the IVECO Official Network in January to import transport goods and spare parts,” said Shahram Falati, Business Director of IVECO Africa & Middle East. “The customers have now the chance to drive the IVECO range and to be supported by the best transport solution across the whole country. Our focus will be on quality and excellent service provided by a strong network.”.

NEW HOLLAND AGRICULTURE CONTINUES ITS PARTNERSHIP WITH CMC GROUP

CMC Motors Group Limited has been a successful and wellknown company in the automotive and agricultural sectors for over 75 years, having operations in Kenya, Tanzania, and Uganda. Today, CMC continues to invest and emphasis its expansion efforts in its domain on farm mechanization.

CMC Motors Group Limited (CMC), New Holland Agriculture’s local distributor in Kenya, has stated that it would exit the mass-market passenger vehicle category in Kenya.

CMC’s strategic shift coincides with the Government’s ambition to restructure and quickly develop Kenya’s agriculture industry. The agriculture industry is the backbone of the East African economy, accounting for around 33% of Kenya’s GDP. CMC intends to extend and continue selling its agricultural machinery portfolio in order to further boost its agricultural sector holdings in the area.

New Holland will continue to supply the same service, products, and components as before. The availability of New Holland products in this region has not changed.

“New Holland has built a strong presence in Kenya, Tanzania, and Uganda through our long-term partnership with CMC,” said Özkan Eren, New Holland Business Director, Middle East and Africa. “We as New Holland are ready to meet the current growing demand in Kenya, Tanzania, and Uganda. We will continue investing in technologies and products that match the specific needs of our farmers and it is certain that we will support our local partner, CMC on their new business strategy to remobilize their focus on agriculture mechanization.”.

HIGH-CAPACITY METSO OUTOTEC TO DELIVER A RELINING MACHINE TO NAMDINI GOLD MINE IN GHANA

SPECIALLY DESIGNED

GUINEA’S WINNING LOGISTICS BOLSTERS ITS FLEET

WITH TWO KONECRANES BARGE CRANES

Konecranes won an order for two Konecranes Gottwald Cranes on Barge from Winning Logistics in Guinea. After on-site commissioning in Q3 2024, Winning will operate a total of ten Konecranes Gottwald Cranes on Barge, loading ships with bauxite off the West African coast.

Cardinal Namdini Mining Limited, a subsidiary of Shandong Gold, has awarded Metso Outotec an order for a SAG mill and a mill relining machine as well as a sizeable wear and spare parts package to be delivered to their gold project in the northern part of Ghana.

The 18MW installed power in the high-capacity SAG mill makes it the biggest gear driven mill in Africa. A 4 tonne 7-Axis mill relining machine with auto-grapple and the highly regarded charge access platform will enable the safe and effective replacement of worn grinding mill lining systems.

Metso Outotec offers the industry’s widest range of horizontal grinding mills, including Premier and Select mills. They can be easily integrated with Metso Outotec mill relining equipment and are supported by the company’s extensive services network to ensure optimization during the mills’ lifetime..

Konecranes Gottwald Cranes on Barge are specially designed and built to ensure uninterrupted material flow on water, even under demanding marine conditions. They can operate in winds of up to 24 m/s and at maximum wave heights of 2.5m, and are built according to Lloyd’s Register Code for Lifting Appliances in a Marine Environment..

ACQUISITION EPIROC COMPLETES ACQUISITION

OF SOUTH

AFRICAN MINING EQUIPMENT MANUFACTURER

Epiroc, a leading productivity and sustainability partner for the mining and infrastructure industries, has completed the acquisition of AARD Mining Equipment, a South African mining equipment manufacturer.

AARD, based near Johannesburg, South Africa, designs, manufactures, services and supports a wide range of mining equipment, specializing in low-profile underground machines for mines with low mining heights. The high-quality products include drill rigs, bolters, loaders, scalers, and more..

VOLVO DELIVERS AFRICA’S FIRST HEAVY ELECTRIC TRUCK

The first heavy battery-electric truck from a major OEM operating in a commercial capacity in Africa was delivered by Volvo Trucks to client Arma in Morocco.

Deployment of heavy electric trucks is now spreading across the world. With Europe and the US among the leaders, the shift to more sustainable transport is kicking off also in other parts of the world. In Africa, the first heavy electric truck is now being delivered in the city of Rabat in Morocco.

“This is a proud moment when we take the first step to more sustainable, electric transport in Morocco and Africa together with our customer Arma and the city of Rabat,” says Martin Nilsson, Managing Director, Volvo Trucks Morocco. “This clearly shows that zero-emissions trucks have a role to play in many parts of the world.”

Arma is decreasing its carbon footprint by electrifying its vehicle fleet, demonstrating again our dedication to the environment.

“Our intentions are clear: we will continue investing in innovations that help reduce emissions and benefit the environment while supporting our customers in meeting their own sustainability goals,” says Youssef Ahizoune, CEO of Arma Group.

The truck is a Volvo FE Electric, one of six all-electric Volvo truck models, already in serial production. Volvo Trucks has the broadest line-up of electric trucks available for commercial transports. The company’s global target is that in 2030, 50% of all new trucks it sells will be electric.

The series-produced, zero-exhaust emission truck will be used for collecting waste by Arma in Rabat. By replacing the existing Volvo FE diesel truck with a Volvo FE electric on a typical route, approximately 30 tons of CO2 could be saved every year.

Morocco has ambitious climate goals, based on large investments in renewable energy. The country is a leader in solar power and home to the world’s biggest concentrated solar power facility, Noor Quarzazate, located 200km southeast of Marrakech.

“Volvo is the first global brand with heavy electric trucks in commercial operation in Africa,” adds Nilsson. “We have the broadest electric truck line up in the industry, which makes it possible to electrify a large part of heavy transports already today.”

“We are proud to be the first company in the waste management sector in Morocco and in Africa to have chosen to invest in sustainable mobility in cooperation with Volvo Trucks,” says Ahizoune. “By taking a step towards the electrification of our truck fleet, Arma is reducing its carbon footprint, showing one more time our commitment to the environment.”.

BIGGER ISN’T ALWAYS BETTER

Bobcat and XCMG speak with James Morgan about growing levels of demand for mini and mid-sized excavators across African construction markets.

When it comes to global development, few regions boast greater potential than Africa. The continent’s construction market is currently valued at more than $380 billion, according to data from Mordor Intelligence, and is on course to achieve an extremely healthy compound annual growth rate (CAGR) of 7.5% during the period 2023-28.

This, of course, is music to the ears of manufacturers supplying machinery to the region – especially those producing earthmoving equipment, which represents a staple on job sites across the continent. In Africa’s largest economy, Nigeria, the construction industry is expected to grow by 2.8% this year alone, according to research conducted by GlobalData. Meanwhile, analysis from MarketResearch.com shows that excavators accounted for the lion’s share of earthmoving sales in the region’s secondbiggest market, South Africa, in 2022.

Yet it could be argued that the most noticeable trend currently taking place within Africa’s earthmoving segment relates to size. Traditionally, larger machines have proved popular in the region thanks, in part, to their capacity, but also because confined worksites were not as common as in markets such as Europe and Asia. But as infrastructure development has accelerated and the population density of urban areas has increased, so too has the requirement for compact and mid-size excavators.

Commenting on the mid-size segment, a spokesperson from China-headquartered XCMG told Plant & Equipment: “At present, we are exporting mid-size excavators primarily to the markets of the Democratic Republic of the Congo, Ghana, Nigeria and Uganda. These machines are used in mines and hydroelectric power stations, as well as for roads, dams and other infrastructure projects.”

Nicolas Dumont, District Sales Manager – Africa at Bobcat, says demand for mini excavators is also on the rise in Africa. “Volumes remain small,” he concedes. “For context, the skid-steer loader (SSL) segment is twice the size of the mini-excavator market, whereas demand for backhoe loaders is 10 times greater. Nevertheless, the requirement for mini excavators is constantly growing; this segment is now approximately 30% larger than it was before the global pandemic.”

Nevertheless, Dumont does not believe this uptick is specifically related to space constraints in African markets. Rather, he contends that it is being driven by a shift away from manual labour. “It’s down to a change in mindset,” he explains. “Decision-makers now understand that, even though completing tasks by hand remains cheap in comparison to the cost of a mini excavator, the productivity achieved by machinery is incomparable.”

In addition to primary markets for mid-sized excavators, XCMG says its earthmovers have enjoyed significant success across a broad range of African nations.

“In Tanzania, dozens of XCMG XE370D excavators were deployed to work day and night at the Rufiji Hydroelectric Power Station project site,” says the company. “Following completion, this facility’s installed capacity reached 2,115MW, which had a significant effect in combating the nation’s energy shortage while facilitating economic development and industrialisation. In the south of the country, XCMG supplied a forest protection and renovation project with several XE370CA units, all of which featured optimised power and hydraulics systems to aid operations in the area’s tropical climate.

“In Sudan’s capital, Khartoum, XCMG XE215C excavators completed more than 6,000 hours of operations at a gold mine without any malfunctions, despite temperatures in excess of 50°C,” the firm continues. “Elsewhere in Africa, our machines supported the development of the Kenya National Referral and Research Hospital (KNRRH), as well as Kenya’s Thwake Dam project. In Ethiopia, 20 XCMG excavators helped deliver a large-scale road project that has dramatically shortened travel times between the north of the country and Addis Ababa, promoting both economic and social development.”

According to Dumont, the two main project types driving demand for Bobcat’s mini excavators in Africa are urban works,

including water, sewerage, fibre-optic and road infrastructure, and agricultural activities such as irrigation and maintenance.

“The Bobcat E50z and E55z models are our top sellers in this region,” he explains. “One of the key advantages of these lines is that they include canopy and enclosed-cab variants with airconditioning, and a number of our competitors don’t offer both choices. We’re also witnessing increasing demand for Bobcat E17z and E27z mini excavators in Africa.”

In terms of mid-sized excavators, the XE215C is among XCMG’s best sellers on the continent. “This machine’s powerful Isuzu BB-4BG1TRP engine and high-end Kawasaki hydraulic system are perfectly matched, guaranteeing reliability and fuel-efficient operations,” says the spokesperson. “Our XE335DK model is also popular in African markets, especially for small and medium-sized mines, municipal developments, water conservation projects, and highway and bridge construction. Its Cummins QSL9 engine boasts a power output

of up to 219kW, offering superior adaptability and efficiency, whereas its specially designed 6.15m boom and 2.7m short arm are ideal for heavy-duty tasks such as crushing.”

It seems that Africa’s fleet owners are growing increasingly receptive to mini and mid-sized excavators, but do equipment manufacturers active in the region expect this trend to continue over the coming years?

Dumont certainly seems satisfied with Bobcat’s long-term prospects. “We are very optimistic about the mini excavator market in 2023,” he explains. “Across Africa, our dealers have been receiving numerous enquiries for these units lately, especially within the 1-to-3-tonne range. Given that historical demand has focused mainly on the 5-tonne segment, this is an encouraging new trend.”

XCMG agrees, adding that its track record of delivery in Africa has left it ideally placed to capitalise on future demand in the mid-size segment.

“Thanks to decades of hard work in African markets, our steel giants have assisted communities across the continent to build beautiful homes,” its spokesperson concludes. “XCMG will continue to invest in technological innovation, delivering more precision products to the market and contributing to China’s ongoing efforts to drive regional development as part of the Belt and Road Initiative (BRI).”.

Africa Mega Projects

by Plant & EquipmentProject: Cast Iron Pipes & Steel Products Production Plant

Value: USD 2,000,000,000

China’s Xinxing Ductile Iron Pipe Company is planning to invest up to $2bn in Egypt’s Suez Canal Economic Zone (SCZONE) to establish a production plant for cast iron pipes and steel products.

The plant would be built over an area of 1.7 million square metres in TEDA Suez (China-Egypt TEDA Suez Economic and Trade Cooperation Zone), which is located within SCZONE in Ain Sokhna. The project, with an annual production value worth $2.6bn, is expected to create 2,100 jobs.

Client: Xinxing Ductile Iron Pipe Company

Website: www.xinxing-pipes.com

The cast iron production facility will be set up during Phase 1 at a total investment of $150m. It would be built over an area of 250,000sq m with annual production capacity of 250,000 tonnes, production value of about $1.2bn per year and employ 616 workers. The steel products plant would be built during Phase 2 at a total investment of about $1.8bn. The export-oriented project, spread over an area of 1.45 million sq m, will have a production capacity of 2 million tonnes annually, employ 1,500 people and have an annual production value of about $1.4bn.

Project: Hydro Power Project

Value: USD 734,000,000

Client: Ministerio Da Energia E Aguas

Website: www.minea.gov.ao

Cuteca is a 203MW hydroelectric project proposed for the Longa river/basin in Cuanza Sul, Angola. The project will be completed in a single phase, with construction beginning in 2024 and commercial operation beginning in 2027. The project, developed by the Ministerio do Energia e Aguas, is planned to generate 873 GWh of power.

Project: Blue Power Energy Solar Park

Value: USD 100,000,000

Client: Government of Ghana

The project will be built in a single phase, with work beginning in mid-2023. The new solar park is anticipated to open for business in 2025. Blue Power Energy Solar PV Park, located in Northern Ghana, is a 100MW solar PV power project that will consist of ground-mounted solar.

Project: Aluminium Smelter

Value: USD 2,700,000,000

Client: Egyptian Company For Metal Constructions

Website: www.metalco.com.eg

The Egyptian Company for Metal Constructions (METALCO) is planning to build a smelter at a cost of nearly $2.7bn to cater for the local and foreign markets. METALCO is currently negotiating with a potential partner for the 600,000-tonne project. The company is studying two possible sites for the project including the Northern Port Said and the Golden Triangle economic zone on the Eastern Red Sea flank of Egypt.

SOUTH AFRICA

Project: Dwarsrug Wind Energy Facility

Value: USD 225,865,000

Client: Mainstream Renewable Power South Africa

The Dwarsrug Wind Energy Facility is a 124MW onshore wind power project. The development is now in the permitting stage in the Northern Cape of South Africa.

The project will be built in a single phase and is planned to be commissioned in April 2024 when construction is completed. The wind energy development will have 70 turbines with 150m towers.

Mainstream Renewable Power South Africa is in charge of developing the project, which is presently 100% owned by Mainstream Renewable Power.

Project: Road Expansion

Value: USD 286,000,000

Client: Kenya Urban Roads Authority

Website: www.kura.go.ke

Kenya Urban Roads Authority (KURA) has entered into an MOU with China’ Sinohydro Corporation Limited for the execution of the project. The project’s feasibility studies, preliminary engineering designs, and environmental impact assessment have also been completed.

Studies, designs, and assessments have been submitted to the National Treasury. The latter on the other hand has granted KURA the approval to proceed with the project preparation. The preparations will be carried out within the existing legal and regulatory framework.

The project will be funded by the GoK in partnership with the Government of China through the Asian country’s Exim Bank.

Project: Geothermal Power Project

Value: USD 144,000,000

Client: Tanzania Geothermal Development Company

Website: www.tgdc.co.tz

The Tanzania Geothermal Development Company (TGDC), a subsidiary of Tanzania Electric Supply Company (Tanesco), is developing the Ngozi geothermal power plant with a planned power generation capacity of 70 megawatts on completion.

The country’s geothermal potential is estimated at 5,000 megawatts electric (MWe), but plans are in place to produce 200 MWe between 2021 and 2025. Of the estimated 70 megawatts total energy expected to be generated from the Ngozi geothermal plant, 30 megawatts will be developed in the initial phase of the project.

TGDC is expected to sell the steam produced from the geothermal wells drilled at the Lake Ngozi site to a consortium comprising the Government of Tanzania.

LOW-CARBON ENERGY SOLUTIONS

CEVA LOGISTICS, ENGIE AND SANEF LAUNCH AN ALLIANCE TO DECARBONIZE ROAD FREIGHT TRANSPORT

refueling trucks. Strategically placed on European motorways, the network will include a specific IT solution to enable transport companies to plan their routes and charging schedules in the fastest and most carbon-efficient way.

In addition, the concept aims at improving working conditions for long-haul truck drivers by allowing them to remain closer to their homes, as they will be swapping trailers at each terminal before turning back. ECTN’s solution will ultimately make the trucking industry more attractive and help alleviate the European truck driver crisis.

Mobilizing the expertise of its founding members - CEVA Logistics, ENGIE and SANEF - the ECTN Alliance envisions building and operating a network of truck terminals with low-carbon energy solutions to transport merchandise along Europe’s motorways. The disruptive system will be tailored to electric trucks’ limited range and charging requirements.

Long term, the terminal network will be open to all shippers and carriers, offering simple access to low-carbon biogas, hydrogen and electric energy solutions for charging and

The Alliance will conduct a proof of concept (POC) in 2023 between the Lille and Avignon metropolitan areas in France to demonstrate the feasibility of the concept before deploying it on a European scale.

Local carriers will carry out the pre- and post-carriage transport to and from the test sites. The POC is expected to provide a rich database for an in-depth understanding of lowcarbon truck use for long-distance haulage and options for decarbonizing road freight transport in Europe..

LIUGONG ACQUIRES HERTZ CHINA

In North America and Europe, renting construction equipment dominates the market, and it is anticipated that China will soon follow suit. In China, rental accounts for more than 90% of the aerial work platform market.