In this issue

Features

10 Advertorial – Discover excellence in PPE pharmaceutical and microbiological testing with Akron Rubber Development Laboratory (ARDL)

12 Renewables – The ASEAN region’s economic growth is fuelling an unprecedented demand for reliable and abundant energy, including fossil fuels and renewable sources, to support its expanding industries

16 Recycling – The Nanyang Technological University, Singapore (NTU Singapore), shares research on re-purposing e-waste plastics to grow “mini tumours” for laboratory testing in healthcare applications; converting hard-torecycle plastic waste into hydrogen and carbon additives for polymer foams used in cushioning and developing a method to break down plastics into valuable compounds using light.

18 Packaging – Highlights: ExxonMobil Chemical collaborated with value chain providers to develop high barrier MDO-PE/PE laminate for recyclable packaging; it also worked with Brazilian packaging converter Videplast for an ionomer-free VSP solution, reducing film thickness for food packaging applications. Meanwhile, Alpla and Zerooo have developed a standardised solution for reusable PET bottles for bathrooms and kitchens

Regulars

1 Industry News

4 Materials News supplements

country Focus: Taiwan is advancing sustainable energy and maintaining semiconductor industry leadership with clear strategies; this month the country will also host Taipeiplas 2024, from 24-28 September at Tainex, Taipei

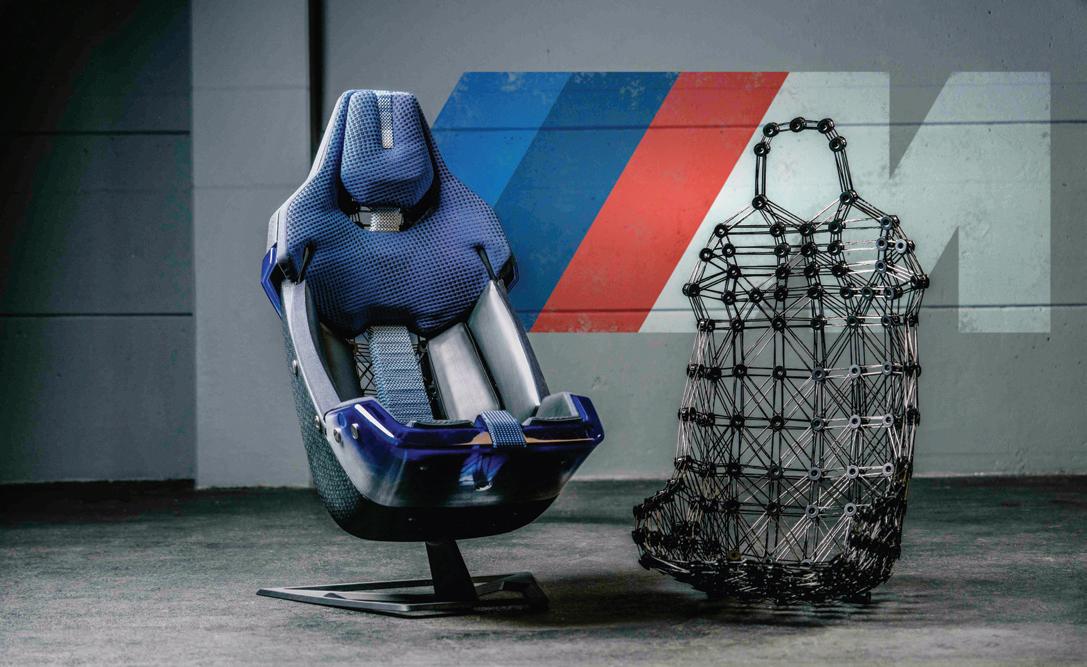

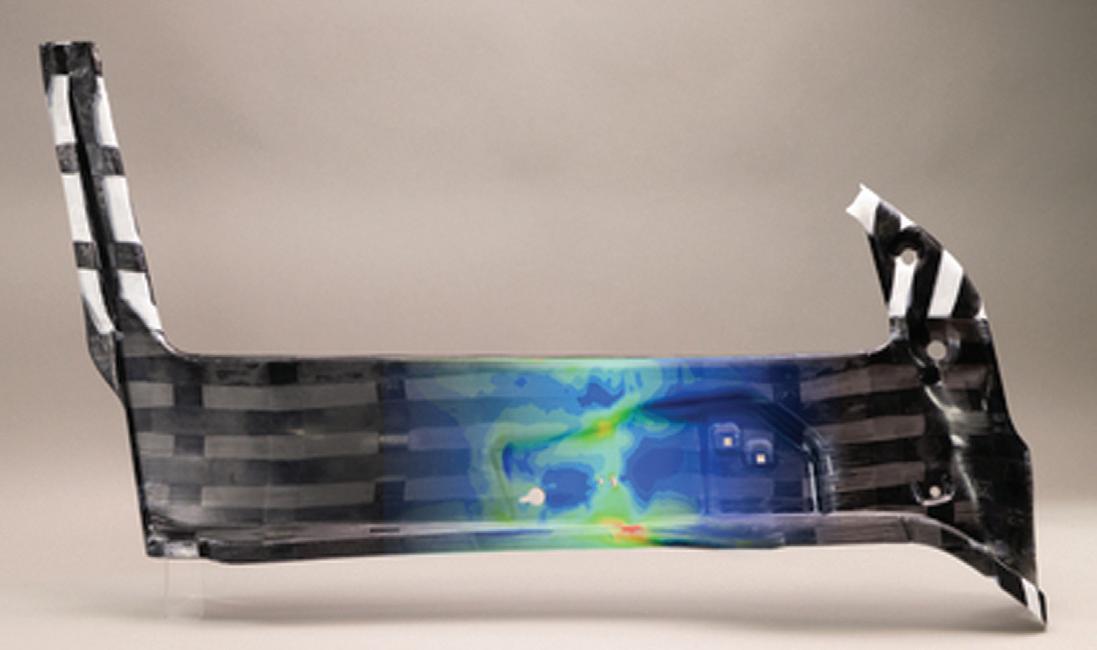

Automotive: OEMs, vehicle makers and parts suppliers all have a vested interest in the sector, with sustainability-driven objectives. Asahi Kasei, Audi, LyondellBasell, Renault, and Antolin as well as BMW, Braskem and others are featured

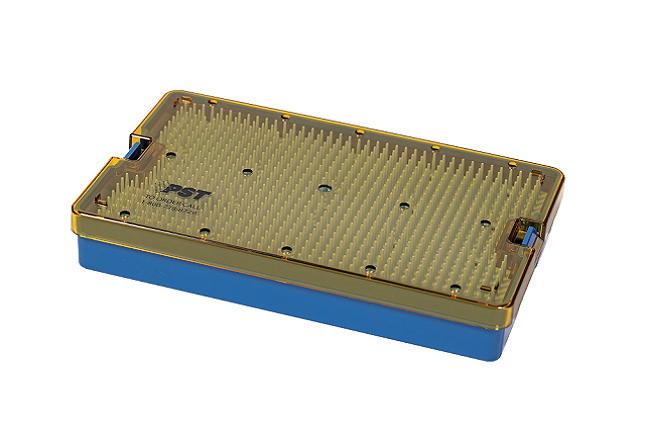

Medical: Leading resin providers are offering advanced materials that improve the production of medical devices, promising to elevate patient care and enhance treatment outcomes

In this interview with Ellen Tan Go, President of PRIA (Philippine Rubber Industries Association Inc.), we find out how the Philippines rubber industry aims to produce competitive products by adopting technology, sustainability practices, and standards, and by connecting with local and global markets

publisher/editor-in-chief

Arthur Schavemaker

Tel: +31 547 275005

Email: arthur@kenter.nl

Associate publisher/executive editor

Tej Fernandez

Tel: +6017 884 9102

Email: tej@plasticsandrubberasia.com

senior editor

Angelica Buan

Email: gel@plasticsandrubberasia.com

circulation

Stephanie Yuen

Email: stephanie@taramedia.com.my

layout/design

Prestige Trading

Email: prestige9a@gmail.com

permits

ISSN 1360-1245 is published 4 (four) times a year in English by Kenter & Co Publishers’ Representatives BV.

Whilst every effort is made to ensure that the information contained in this publication is correct, the publisher makes no warranty, expressed or implied, as to the nature or accuracy of such material to the extent permitted by applicable law.

© 2024 Kenter & Co Publishers’ Representatives BV No part of this publication may be reproduced, stored or used in any form, or by any means, without specific prior permission from the publisher.

PRA is a digital publication that is circulated free to trade readers in the plastics and rubber industry. Please view this link to subscribe/renew your free subscription: http://plasticsandrubberasia.com/register.html

www.plasticsandrubberasia.com www.rubberjournalasia.com www.injectionmouldingasia.com www.eog-asia.com

M&As/Tie-ups/ Investments

• Japan’s Denka Company Limited has invested in Carbon Fly, a start-up company developing carbon nanotubes, through a corporate venture capital (CVC) fund jointly managed with Pegasus Tech Ventures. Terms were not disclosed.

• US materials firm DuPont is acquiring Donatelle Plastics Incorporated, a medical device contract manufacturer specialising in the manufacture of medical components and devices. The transaction is expected to close in the third quarter 2024.

• US firm Dow is acquiring Circulus, a recycler of plastic waste. This transaction includes two facilities, one in Ardmore, Oklahoma, and another in Arab, Alabama, with a total capacity of 50,000 tonnes/year. It is

expected to close in the third quarter of 2024.

• Finnish sustainability fund UB Forest Industry Green Growth Fund (UB FIGG) and German specialty chemicals group Altana are investing in Finnish technology company Nordtreat. It specialises in the development and production of environmentally friendly flame retardants.

• South Korean energy/ chemical firms SK Innovation and SK E&S have merged, encompassing the value chain of both current energy sources (such as oil and LNG) and future energy sources (including renewable energy, hydrogen, and SMR), as well as electrification businesses like batteries and ESS.

• Technology firm Merck is selling its global Surface

Solutions business unit to Global New Material International Holdings Ltd (GNMI) for EUR665 million in cash. The transaction is expected to close in the course of 2025.

• Bangkok-based chemical producer Indorama Ventures has secured a new seven-year loan of US$200 million from the International Finance Corporation (IFC) to help fund the company’s sustainability programs in India, Thailand and Indonesia, and promote a circular economy.

• Additives firm Forward AM has acquired German chemical firm BASF’s additive manufacturing business, including Forward AM’s materials and solutions as well as its Sculpteo service business and leads to the creation of Forward AM Technologies

• Canadian recycling firm Polystyvert has closed

Plant Expansions/Plant Openings

• Australian recycling start-up Samsara Eco and Israelheadquartered nylon apparel maker Nilit are considering setting up a PA6.6 textile-to-textile recycled polymer production site in Southeast Asia, aiming to be operational by late 2026.

• India’s gas utility firm GAIL (India) and

US-based biofuel producer Petron Scientech Inc are exploring setting up of a 500 kilotonnes/year bio-ethylene plant in India.

• VTT Technical Research Centre of Finland and LUT University have opened a pilot plant in Espoo, Finland, to process captured

carbon dioxide into compounds that can replace fossil raw materials in plastic products and chemicals.

• Biotech firm Carbios and Zhink Group, specialising in PET and textiles, have tied up to build a 50 kiltonnes/ year PET recycling plant in China using Carbios’ technology.

the first tranche of a Series B funding for US$16 million, for the construction of its first commercial recycling plant in Montreal for PS waste, expected to start in 2026. Other companies supporting it include Infinity Recycling that led the round, followed by SWEN Blue Ocean, and Earth Foundry, an existing shareholder.

• The former Schenck Process Food and Performance Materials (FPM) group of companies have officially changed their name to Coperion. The transition follows the September 2023 acquisition of the companies by Hillenbrand, the parent company of Germanybased Coperion.

• Chemical firm LyondellBasell is acquiring full ownership of APK AG in Merseburg, Germany, which was under insolvency. Terms were not disclosed.

• Technology provider Lummus Technology and Eastern European oil/gas firm MOL Group are working on the first plastic recycling unit located at MOL’s facility in Tiszaújváro, Hungary. It will have a processing capacity of 40,000 tonnes/year of mixed waste plastics. As well, Lummus has licensed its PP technology to Petronet LNG for a

new US$2.4 billion, 500 kilotonnes/year plant in Dahej, Gujarat, India.

• India’s Bharat Petroleum Corporation has appointed Lummus to build a new ethylene plant in Bina, Madhya Pradesh state, India. Bharat has also selected tech firm Univation's Unipol PE process technology for two world-scale production lines to be located at its Bina Refinery site in Madhya Pradesh. The two units are designed to achieve a combined nameplate production capacity of 1 million tonnes/year of PE.

• Technology firm Wood has been awarded a $US40million engineering design contract by Japanese materials firm Kuraray to build a plant in Singapore to produce Kuraray’s Eval EVOH copolymer.

• A consortium comprising Abu Dhabi-based materials firm Borouge, Abu Dhabi National Oil Company (Adnoc) and Austrian chemical firm Borealis have tied up with China’s Wanhua Chemical and Wanrong New Materials, a subsidiary controlled by Wanhua Chemical Group, to study the feasibility of building a 1.6 million tonnes/year specialty polyolefins complex at Fuzhou, Fujian Province, China.

• Trelleborg Group is building a facility for engineered coated fabrics in Rutherfordton, North Carolina, US, to strengthen its positions in aircraft escape slides, water infrastructure, and advanced materials for healthcare and outdoor products. “

• India’s flexible packaging giant Jindal Poly Films Ltd, part of BC Jindal Group, is adding on a new BOPP line in Nashik, Maharashtra, by 2026 with a capacity of 60,000 tonnes/year.

• Germany’s BASF Catalysts India Private Limited (BCIL), a subsidiary of BASF Environmental Catalyst and Metal Solutions (ECMS), has inaugurated a new R&D lab at its site in Mahindra World City, Tamil Nadu, Chennai, for the development of emissions control catalysts tailored to the needs of the Indian automotive market.

• Chinese battery materials firm BTR New Material Group has opened its new lithium-ion battery anode materials plant in Indonesia. The project's first phase, which involved a US$478 million investment, has a capacity of 80,000 tonnes/year of anode materials. The second phase, scheduled to start in late 2024 with an additional

US$299 million investment, will expand the total capacity to 160,000 tonnes.

• Chemical firm Sabic is to build an engineering thermoplastics compounding plant in China’s Fujian Province. It will primarily produce pelletised Lexan PC and Cycoloy PC/ABS blends.

• Invista Nylon Chemicals (China) Co. has opened its US$240 million PA6.6 polymer expansion at the Shanghai Chemical Industry Park (SCIP). It has doubled the annual capacity of PA6.6 polymer to 400,000 tonnes. Elsewhere, Invista is investing US$17 million to restart its Hexamethylene Diamine (HMD) plant in Ontario, Canada, which was closed in 2009. HMD is a key ingredient in the production of PA6.6. The plant could start production in the first quarter of 2025.

• Trelleborg Sealing Solutions has inaugurated a new R&D facility providing local innovation backed by global expertise in Bangalore, India.

• Henkel Adhesives Technologies India Private Limited has completed Phase III of its Loctite facility in Kurkumbh, Maharashtra, to serve the adhesives, sealants, and surface treatment markets. Henkel has also

launched a second application centre in Thanh Hoa, north Vietnam, to expand its support for sports and fashion brands in AsiaPacific and China.

• US chemical firm Huntsman Corp. has opened a new innovation centre in Tienen, Belgium, for its PU business.

• Specialty materials provider Trinseo has opened a polymethyl methacrylate (PMMA) depolymerisation plant in Rho, Italy.

• Ineos Olefins & Polymers Europe has commissioned a new pilot line that it will use with customers to co-develop recyclable flexible packaging films. It has installed a multilayer, blown film line, supplied by Japanese machine maker Hosokawa Alpine, with Machine Direction Orientation (MDO) at its R&D centre in Brussels, Belgium.

• Japan’s Teijin Ltd has added on a production line for its PC resin Panlite sheet and film, located at its Matsuyama plant in Ehime Prefecture, with a capacity of 1,350 tonnes/year.

• China’s Changhua Chemical is constructing the country’s first manufacturing site for Carnol, a new

line of polycarbonate ether (PCE) polyols with 20-30% fewer greenhouse gases, in Lianyungang. It is targeting commercial volumes of about 80,000 tonnes in early 2025 and will scale to over 1 million tonnes in the coming years.

• Plastics processor Röchling Industrial is investing EUR10 million in setting up a sustainability centre in Germany to process more than 10,000 tonnes/year of plastic waste.

• Thailand-based chemical producer Indorama Ventures Public Company Limited, through its direct subsidiary – IVL Dhunseri Petrochem Industries Limited - and Dhunseri Ventures Limited have formed a joint venture with Varun Beverages Limited, PepsiCo's

second-largest bottling company globally outside the US, to establish two PET recycling facilities in India by 2025. One facility is in Kathua within the Jammu Division in Northern India, while the other is in Khurdha, Odisha. The aim is to reach 100 kilotonnes/year capacity of rPET across all the facilities when combined.

• India’s Reliance Industries Ltd (RIL) is setting up PVC and CPVC manufacturing facilities at its existing locations in Dahej and Nagothane with a total capacity of 1.5 million tonnes/ year, to commence commercial production in 2026-27. It is also expanding its polyester capacity by 1 million tonnes/ year and PTA capacity by 3 million tonnes/ year, also to be built by 2026–27.

Universally applicable –Optimised for your needs.

No matter if you are manufacturing metallised standard food and non-food packaging, easy-to-recycle stand-up pouches from MOPE film or technical products, SML's cast film lines are always optimised for your specific requirements.

Extrusion lines. Engineered to perform.

• Lummus Technology has been awarded a contract by Silleno LLP for an ethylene unit, which will be part of the first PE plant to be built in Kazakhstan, which will convert ethane from the Tengiz oil field into 1.3 million tonnes/year of ethylene.

• China’s Rongsheng Petrochemical has started trials at its polyolefin elastomer (POE) plant in Zhoushan, Zhejiang province. The alphaolefin pilot production facility has a capacity of 300 tonnes/ year of 1-octene or 1,000 tonnes/year of 1-hexene with alternative process conditions.

• BASF will end the production of adipic acid, cyclododecanone (CDon) and cyclopentanone (CPon) at its Ludwigshafen plant

in Germany. The production plant for CDon and CPon will be shut down in the first half of 2025 and the remaining adipic acid production in Ludwigshafen will be closed in the course of 2025, as part of the ongoing strategic review of its production set-up and to ensure competitiveness under changing market conditions.

• Russian petrochemical group Sibur is building a facility for piloting base polymer production technologies in Tobolsk at a cost of more than 6 billion rubles. The facility that will open end of 2024 will have a design capacity of up to 300 tonnes/ year, with possibility to test a broad range of grades of PE and PP to meet the demand for Russia.

Learn more about SML's cast film lines.

Asia turns environmental challenges into sustainable opportunities

Asia's growing waste problem is driving a shift toward a circular economy by repurposing waste into high-value applications, says Angelica Buan in this report.

The global plastics waste problem has reached critical levels, with millions of tonnes generated each year, posing severe environmental and economic challenges. In Asia, the situation is particularly pressing. The World Bank 's report, What A Waste 2.0 - A Global Snapshot of Solid Waste Management to 2050 , projects that waste generation in the Asia-Pacific region will rise from approximately 802 million tonnes in 2016 to 1.1 trillion tonnes by 2030.

Similarly, waste volumes in Southeast Asia have surged since 2000, reaching around 150 million tonnes in 2016, with it to more than double by 2030, according to the United Nations Environment Programme (UNEP) summary report on Waste Management in ASEAN Countries.

In response, Asia is emerging as a leader in innovative waste management, with various initiatives aimed at transforming waste into high-value materials. These efforts include converting plastics into versatile products, from packaging to industrial applications.

As such, these initiatives not only reduce environmental impact but also drive the circular economy, where materials are continually repurposed, minimising the need for new resources.

This shift is crucial for advancing sustainability, as it promotes efficient resource use, reduces waste, and fosters a more resilient, eco-friendly future.

Thailand: versatile bioplastics made from pineeapple waste

Thailand faces severe issues with unmanaged plastic waste, with 2.88 million tonnes of plastic not being recycled each year, resulting in an 87% loss of material value, according to a World Bank circularity analysis. Poor recycling systems, a lack of recycling design, and inadequate source segregation all contribute to low-quality recyclables and feedstock contamination.

Despite these hurdles, Thailand is leveraging its position as a regional bioplastics hub, owing to its strong raw material production and advanced technology across the bioplastics supply chain.

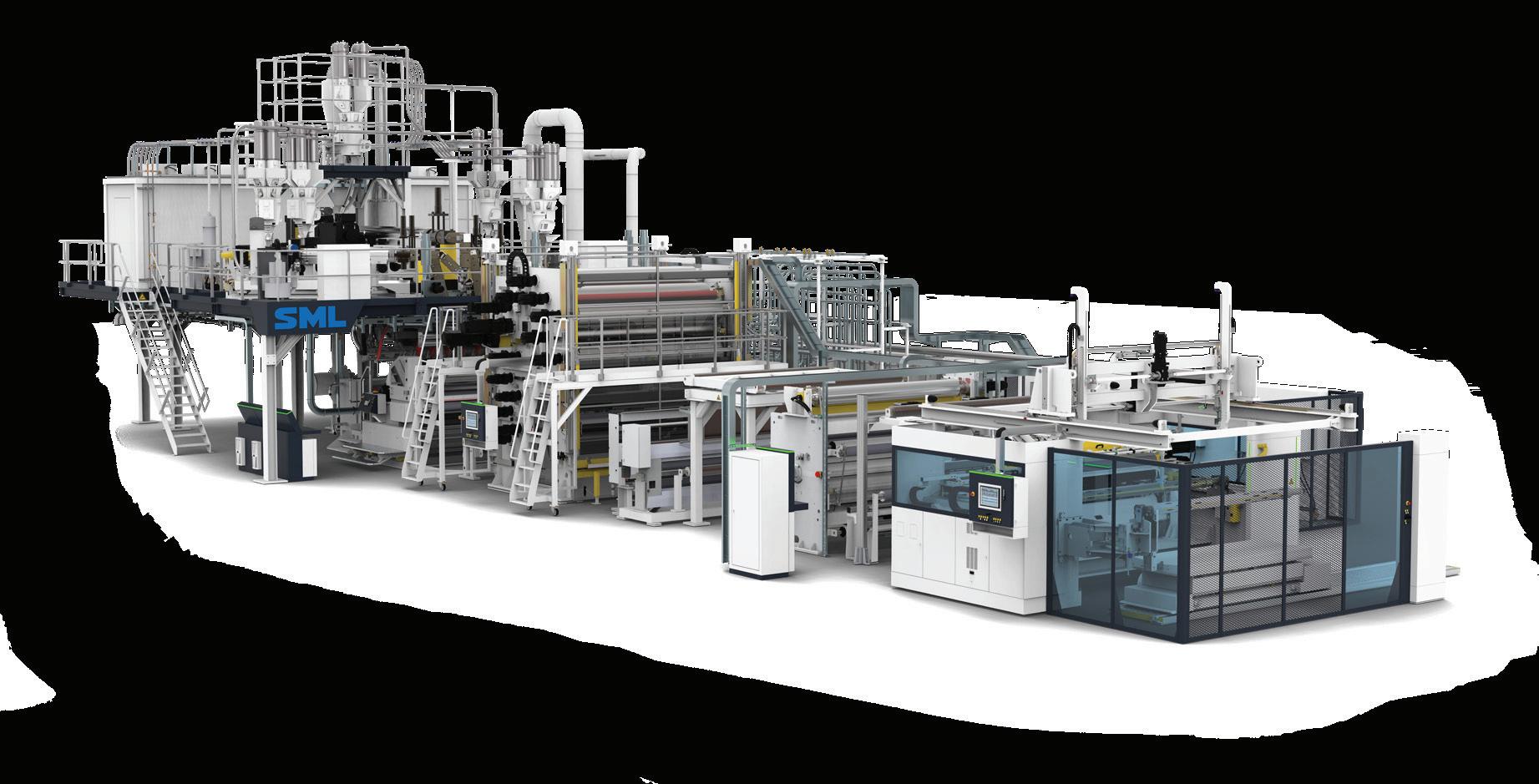

A recent collaborative effort by researchers from Thailand and Malaysia exemplifies this progress. They have developed a biodegradable film made from leftover pineapple stems, offering a sustainable alternative to traditional plastic films.

Led by Associate Professor Taweechai Amornsakchai from Mahidol University, the team created this film using high amylose starch from pineapple stems, combined with glycerol and citric acid to enhance flexibility. The film’s mechanical properties can be tailored by adjusting citric acid levels, making it suitable for various single-use applications where high strength is not required.

materials suitable for a variety of industries

Waste volumes in Southeast Asia could more than double by 2030, according to World Bank

Thai researchers have succeeded in creating biodegradable materials from pineapple leaf fibers, which can be transformed into durable, high-performance

The biodegradable film offers water resistance, heat-sealability, and fully disintegrates in soil within a month. This innovation is expected to reduce reliance on non-biodegradable materials by repurposing agricultural waste, marking a significant advancement in sustainable packaging solutions and promoting the circular economy.

Similarly, the Thai team of reseachers have also made significant strides in sustainable materials by upcycling waste HDPE milk bottles into high-stiffness composites reinforced with pineapple leaf fibres (PALF). This innovative approach has resulted in a 162% increase in flexural strength and a 204% increase in modulus, making the composites not only stronger but also environmentally friendly by sequestering carbon.

The process involves blending rHDPE with PALF and non-fibrous materials (NFM), which are then layered and compressed into composite sheets. The inclusion of PALF enhances the mechanical properties of the HDPE, particularly its heat distortion temperature (HDT), making it suitable for applications like automotive parts where durability under high temperatures is crucial.

The study highlights the potential of using agricultural waste for sustainable composite development, showing how waste can be transformed into durable, highperformance materials applicable across various industries, including the biomedical and automotive sectors, the researchers noted.

Bangladesh: practical farming solution with plastics

In recent years, Bangladesh has experienced a significant increase in plastic consumption. Data suggests that in 2020, the annual per capita plastic use in urban areas rose to 9 kg, tripling from 2005. This increase is largely attributed to the rise in the use of LDPE packaging materials, including plastic bags and wrappers.

Bangladesh's plastic farming initiative, led by MGI, ingeniously utilises plastic bottles for floating farms, benefiting both farmers and the environment

Despite the soaring consumption, recycling efforts have lagged behind. In 2020, only 31% of the 977,000 tonnes of plastic used was recycled. The bulk of this waste consists of single-use plastics, such as shopping bags and wrappers, which have become a major source of pollution.

This mismanaged plastic waste has contributed to severe environmental issues, with pollution affecting urban areas, rural landscapes, and waterways including rivers and canals. It has also impacted the country’s agriculture sector because it is reportedly losing fertile land to rising sea levels and floods, and plastic across its rivers. It has adversely affected farmers’ livelihood and the nation’s food security.

Bangladesh is primarily an agricultural nation and it contributes nearly 14.8% to its GDP as well as employs about 41% of the labour force.

In response to environmental and agricultural challenges, an initiative, known as Plastic Farming, led by conglomerate Meghna Group of Industries ( MGI ), has garnered global praise. This project transforms plastic bottles into floating farms, benefiting both farmers and the environment.

MGI partnered with Bidyanondo Foundation , a local NGO that aids impoverished communities, to train landless farmers in this sustainable practice. They also collaborated with local authorities and farming communities to collect plastic waste from waterways as well as instruct communities on creating and using plastic floating beds for crop cultivation.

Implemented in the landless farming communities of Tungipara, Gopalganj, and Pirojpur districts, the floating farms are constructed using recycled plastic bottles arranged vertically in simple bamboo frames, covered with netting and topped with water hyacinth compost for planting. Crop seeds are planted in the compost. The plastic-based structure is expected to be durable enough for repeated use.

To address microplastic contamination, farmers can utilise water-based fungi, which are found effective in degrading microplastics and widely available in Bangladesh. After two years of R&D, agricultural scientists identified the water-based fungi as a key element in this hydroponic farming method.

Philippines: paving roads with "plastic sachets“

The Philippines is considered a significant contributor to marine plastic pollution, primarily due to its extensive use of single-use plastics, particularly multilayer sachets and pouches. This widespread consumption has earned the country the designation of a "sachet economy," with an estimated daily use of 163 million sachets, according to a 2021 World Bank report.

To address this issue, the government has developed an innovative approach by repurposing plastic waste for road construction. While plastic waste asphalt has been used in various Asian countries, it has also been tested in several locations within the Philippines.

The Philippines' sachet economy takes a U-turn with plastic road plans; the country had its first recycled plastic road, with asphalt made from recycled plastics, through an SMCled initiative

Recently, the Department of Public Works and Highways (DPWH) approved a new initiative to integrate plastic waste into the construction of national roads. This strategy aims to alleviate the problem of unrecycled and hard-to-recycle plastics, including sachets.

DPWH Secretary Manuel Bonoan noted that incorporating waste plastics into road materials can enhance the durability of asphalt pavements.

DPWH has also set standards for incorporating recycled materials into road construction, such as the use of LDPE plastic bag waste in bituminous concrete. The policy promotes shredding LDPE waste and adding it to asphalt concrete to enhance durability and meet DPWH standards.

In 2019, multinational conglomerate San Miguel Corporation ( SMC ) introduced Philippines' first recycled plastics road. This pilot project involved laying asphalt made with recycled plastics on a 1,500-sq m test site at a new logistics centre in Cavite, south of Manila. The test site was selected due to its use as a marshaling area for heavy trucks and equipment.

For this project, approximately 900 kg of plastic waste, equivalent to around 180,000 sachets and plastic bags, were utilised.

SMC's technology partner, US materials company Dow, explained that recycled plastic waste is used as a binder in conjunction with bitumen to produce the asphalt. This method is expected to enhance the durability and longevity of roads compared to traditional asphalt. Pending further testing, SMC plans to use this technology for building roads at its facilities and for major infrastructure projects.

India: new spin on post-consumer recycled plastics with pails

India generates 15 million tonnes of plastic waste annually, but only a quarter of this is recycled due to an inadequate solid waste management system, according to the United Nations Development Programme (UNDP).

To tackle this, it has partnered with Hindustan CocaCola Beverages Private Limited ( HCCBPL ), Hindustan Unilever Limited ( HUL ), HDFC Bank , and the Coca-

Cola India Foundation ( CCIF ) to improve the collection, segregation, and recycling of all plastics. India is one of 12 countries, along with China, Russia, Brazil, Mexico, Vietnam, Iran, Indonesia, Egypt, Pakistan, the US and Turkey, that together account for 60% of the world’s mismanaged plastic waste, according to the Plastic Overshoot Day report by Swiss non-profit firm EA Earth Action.

While waste plastics are typically viewed as an environmental challenge, they are proving to be a valuable resource for companies like US materials firm ExxonMobil in achieving their sustainability goals.

ExxonMobil's new 20-l lubricant pails, launched in India in 2023, feature 50% post-consumer recycled (PCR) content, marking a first for lubricant packaging in the country. This initiative has recycled the equivalent of approximately 2.3 million plastic bottles, as well as jars, and battery casings, into these pails, which are also recyclable.

The company, working with plastic recyclers and compounders, has sourced 115 tonnes of recycled plastic for these pails. This effort aims to set a higher standard for PCR use in industrial-grade packaging.

ExxonMobil says it has conducted extensive tests at its Bengaluru R&D Technology Centre (BRDTC) to ensure that the PCR plastic does not affect the quality of the lubricating oils and that the pails meet quality-control standards for leakage, stacking, handling, and impact.

The company further that it continues to advance initiatives in India to enhance the recyclability of plastic packaging, including developing mono-material packaging solutions.

ExxonMobil's new 20-litre lubricant pails, launched in India in 2023, are the country's first to feature 50% post-consumer recycled content

Recycling medical devices through the thermochemical method

Medical waste being overlooked

Disposable healthcare items are creating enormous amounts of waste, which is incinerated, but in many countries ends up in landfills. The Covid pandemic was an eye-opener to the mountain of medical waste and contributed to an avalanche-like increase in disposable items being used. Worldwide, used face masks alone were estimated to weigh around 2,641 tonnes/day in 2022.

In circular economy policies, medical waste is often overlooked since disposable healthcare items usually consist of several types of plastic that cannot be recycled with today's technology.

In addition, the items must be considered contaminated after use, and so, they must be handled so that risks of spreading potential infections are avoided. When it comes to the production of single-use healthcare items, it is also not possible to use recycled plastic, since the requirements for purity and quality are so high for materials intended for medical use.

Light at the end of tunnel for medical waste

Researchers at Chalmers University of Technology ,

in Sweden, have now shown how mixed waste from healthcare can be recycled in a safe and efficient way, using a technique where the material is heated and converted into chemical building blocks, which can then be used in the production of new plastic.

The technology is called thermochemical recycling and is based on a process called steam cracking. It breaks down the waste by mixing it with sand at temperatures up to 800°C. The plastic molecules are then broken apart and converted into a gas, which contains building blocks for new plastic.

Martin Seemann, Associate Professor at Chalmers' Division of Energy Technology, says the method “destroys bacteria and other microorganisms”.

"What are left are different types of carbon and hydrocarbon compounds. These can then be separated and used in the petrochemical industry, to replace fossil materials that are currently used in production."

Great potential for saving valuable chemicals

To test the technology in real life, the researchers have carried out two different projects in parallel in a test facility at Chalmers Power Central.

Researchers at Chalmers University of Technology, in Sweden, have now shown how mixed waste from healthcare can be recycled in a safe and efficient way, using a technique where the material is heated and converted into chemical building blocks, which can then be used in the production of new plastic

In the first project, a few different product types, such as face masks and plastic gloves, have gone through the process. In the second, a mixture was created that represents the average composition of hospital waste from the region's hospitals. The mixture contained about ten different plastic materials, as well as cellulose.

The results have been consistently positive in both projects, which shows the great potential that exists in the technology.

One of the projects was led by Judith González-Arias, now at the University of Seville in Spain, who says the method “facilitates the recovery of valuable carbon atoms”.

Furthermore, the researchers say this method is the “only” option available, given the strict regulations on medical use materials.

According to Seemann, "The same strict requirements for purity and quality actually also apply to food packaging. This is why the vast majority of plastic collected from packaging is incinerated today, or recycled into items where lower quality is allowed.”

The two projects build on previous Chalmers research, which has shown how mixed plastic waste can be converted into raw material for new plastic products of the highest possible quality.

The technology works well, but other factors also come into play

To scale up the method, new material flows and functioning business models need to be established, in collaboration between the healthcare and recycling sectors. Laws and regulations at different levels may also need to be changed in order for thermochemical recycling to be widely implemented in society.

Seemann adds, "For example, a requirement for carbon dioxide capture, when incinerating plastic, would create incentives to instead invest in more energy-efficient alternative technologies such as ours.”

Many countries have the technical prerequisites for recycling medical waste and other mixed plastic waste through steam cracking. However, regulations and structural conditions vary, which determines how players in waste management, the chemical industry and product manufacturing would need to work together to create functioning value chains in different places in the world.

Sweden lacks volume for thermochemical recycling

In Sweden, there is a great deal of interest in recycling, but single-use items from healthcare do not in themselves create large enough waste volumes for a functioning circular business model. Around 4,000 tonnes of such plastic were put on the market in the country in 2019.

"To build a plant of the size required for profitable thermochemical recycling, you would have to ensure a material flow of around 100,000 tonnes/year before startup," says González-Arias.

She says that new collaborations would therefore be needed between several different players for commercial thermochemical recycling, where healthcare waste could be part of the material flow.

The process would be optimised if a Swedish plant was built in an existing chemical cluster, such as the one in Stenungsund. The Chalmers researchers collaborated with Austrian polyolefins firm Borealis during the development of the technology since it has a steam cracker and related facilities there.

According to Seemann, “The technology is more energy-efficient than some other methods for recycling components in the plastic, such as carbon dioxide capture during incineration to use the carbon dioxide as a building block for new materials.”

The paper Steam gasification as a viable solution for converting single-use medical items into chemical building blocks with high yields for the plastic industry has been published in Resources, Conservation and Recycling.

Ground healthcare items used in the experiments. The material mix includes gloves, surgical gowns, tubing and marker pens, among other things

TaipeiPLAS & ShoeTech Taipei 2024 kick off in September

TaipeiPLAS 2024 (Taipei International Plastics & Rubber Industry Show), a biennial event, will host 400 exhibitors across 1,800 booths, representing a 38% increase from the 2022 edition.

The event, scheduled for September 24-28 atTaipei Nangang Exhibition Centre, Hall 1, in conjunction with ShoeTechTaipei (Taipei International Shoe MakingTechnology Show), marks the return of international buyers after a six-year hiatus due to Covid-19. According to the show organiser, TAITRA, visitors from over 45 countries have registered, including delegation groups from India, Vietnam, Myanmar, and Algeria.

This year's TaipeiPlas will focus on main themes as "Innovative Materials," "Advanced Manufacturing," and "Circular Economy.” All-star exhibitors include Chen Hsong, Chumpower, CLF, Conair, CYKF, Diing Kuen, FCS, FKI, Formosa Chemicals & Fibre, Formosa Plastics, Huarong, igus, JSW, Lung Meng, Maguire, Moretto, Multiplas, Polystar, Siemens, Tenso, Victor Taichung, Wittmann, and YE I. The event will showcase the latest industry advancements, high-performance products for diverse

applications, and circular economy solutions with the addition of three new zones: “Bio, Recycled Plastics & Green Products,” “Composite Materials,” and “Adhesives & Glues.”

Chen Hsong will showcase its all-electric liquid silicone rubber (LSR) injection moulding machine, ideal for medical, electronic, optical, and consumer products. Igus will present its dry-tech bearings, designed to replace traditional metal bearings in extreme environments. Great Eastern Resins Industrial will feature its eco-friendly TPU resins, offering high toughness, strength, bio-compatibility, and a reduced environmental footprint compared to traditional materials.

TaipeiPLAS 2024 will also highlight the industry's sustainable and green supply chain. The “Visionary and Sustainable Development Summit,” held on September 25, will feature experts from BASF, Arburg, Wittmann, Remondis, Victor Taichung, Formosa Plastics, and Eternal Materials, who will share their experiences in low-carbon transformation. Register now at www.taipeiplas.com.tw. For more details, visit the website, follow on social media, or subscribe to the newsletter.

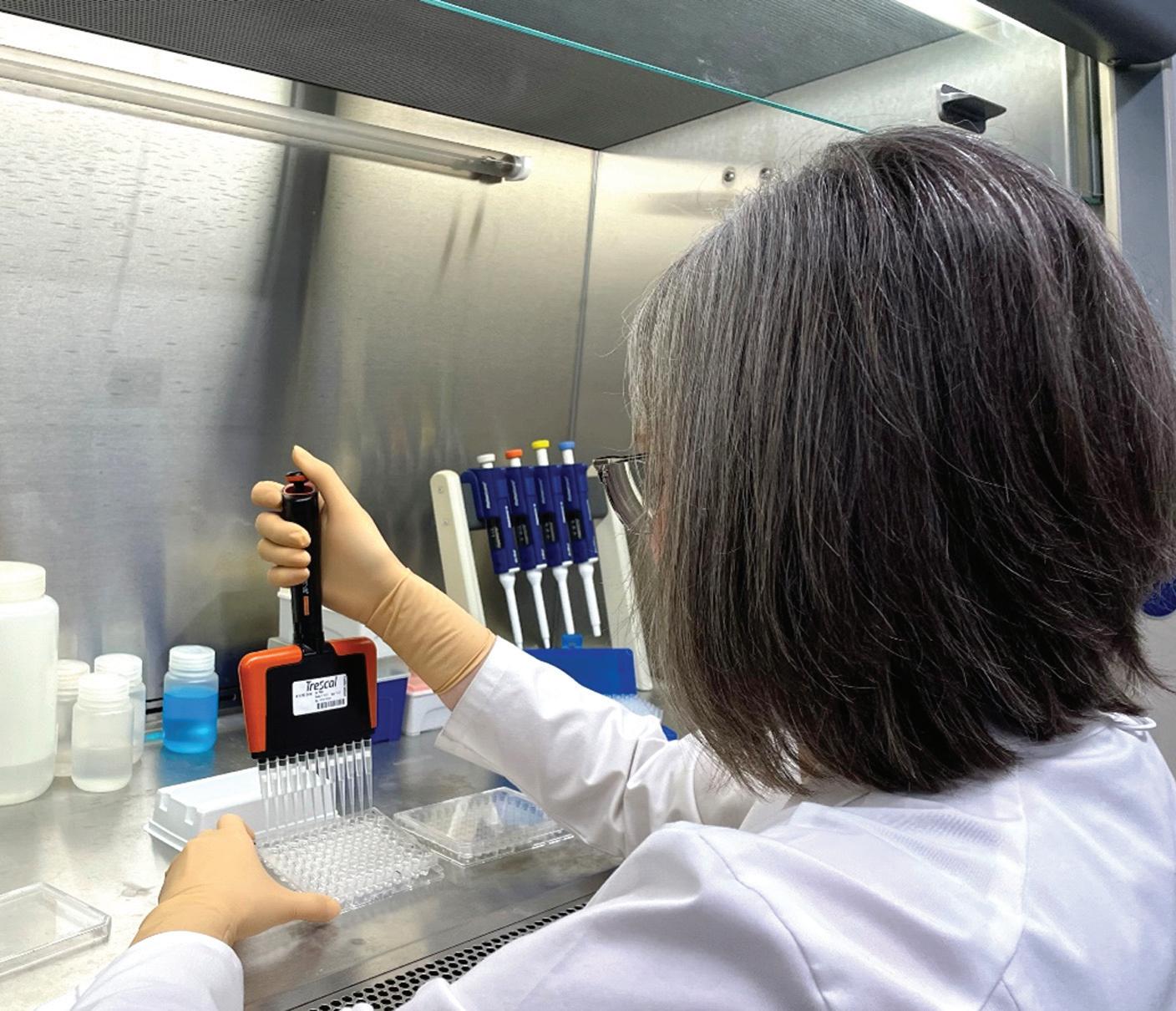

Discover Excellence in PPE Pharmaceutical and Microbiological Testing with ARDL

In the ever-evolving world of the medical and pharmaceutical industries, ensuring the safety, efficacy, and compliance of the Personal Protective Equipment products is paramount. Akron Rubber Development Laboratory, Inc. ( ARDL ) stands at the forefront of this mission, offering unparalleled testing services that set the gold standard in the industry. With decades of innovation, experience, state-of-theart facilities and a commitment to excellence, ARDL is your trusted partner for all your PPE testing needs.

At ARDL, quality is not just a promise, it is a guarantee. The laboratory is certified to the highest standards of quality management and laboratory competence. These certifications ensure that every test conducted meets rigorous international standards, providing you with reliable and accurate results.

ARDL’s Pharmaceutical and Microbiological Testing Services are certified under ISO 9001 (QMS Requirements), ISO 17025 (Testing and Calibration Laboratories QMS) and ISO 13485 (Medical Devices QMS).

ARDL’s data is recognized and accepted worldwide and used for regulatory compliance, compound development and troubleshooting, competitor analysis and supply chain assurance purposes. ARDL offers a wide array of testing services tailored to meet the diverse needs of the medical and pharmaceutical sectors.

ARDL’s expertise includes : ASTM F3267-22 Standard Specification for Protective Clothing for Use Against Liquid Chemotherapy and Other Liquid Hazardous Drugs – Newly Added

ASTM D6978-05(2023) Standard Practice for Assessment of Resistance of Medical Gloves to Permeation by Chemotherapy Drugs

ASTM F1670/1670M-24 Standard Test Method for Resistance of Materials Used in Protective Clothing to Penetration by Synthetic Blood

ASTM F1671/1671M-22 Standard Test Method for Resistance of Materials Used in Protective Clothing to Penetration by Blood-Borne Pathogens Using Phi-X174 Bacteriophage Penetration as a Test System

ISO 16604:2004 Clothing for protection against contact with blood and body fluids — Determination of resistance of protective clothing materials to penetration by blood-borne pathogens — Test method using Phi-X 174 bacteriophage

ISO 10993-5:2009 Biological Evaluation of Medical Devices ( Tests for in vitro cytotoxicity )

ASTM F739-20 Standard Test Method for Permeation of Liquids and Gases Through Protective Clothing Materials Under Conditions of Continuous Contact

ASTM D5712-15(2020) Standard Test Method for Analysis of Aqueous Extractable Protein in Latex, Natural Rubber, and Elastomeric Products Using the Modified Lowry Method

ASTM D6499-24 Standard Test Method for Immunological Measurement of Antigenic Protein in Hevea Natural Rubber (HNR) and its Products

ANSI/AAMI PB70 Standard includes four standard tests to evaluate the barrier effectiveness of surgical gowns, isolation gowns, and surgical drapes (PPE-Info - Standard Details (cdc.gov))

AATCC 42 Impact Penetration2

AATCC 42 Impact Penetration

AATCC 127 Hydrostatic Pressure3

AATCC 42 Impact Penetration

AATCC 127 Hydrostatic Pressure

ASTM F1670 Synthetic Blood Penetration Test (for surgical drapes)

ASTM F1671 Viral Penetration Test (for surgical and isolation gowns)

1 In order of increasing protection

Bacteriophage Phi-X174

2 American Association of Textile Chemists and Colorists (AATCC) 42 Water resistance: impact penetration test determines the ability of a material to resist water penetration under spray impact [AATCC 2000]

3 AATCC 127 Water resistance: hydrostatic pressure test determines the ability of a material to resist water penetration under constant contact with increasing pressure [AATCC 1998]

Consulting and STAT services are available as well as Volume Discounts where applicable.

AdvertoriAl

Expected Barrier Effectiveness

= 4.5 g = 1.0 g = 20 cm = 1.0 g = 50 cm

no penetration at 2 psi (13.8 kPa)

no penetration at 2 psi (13.8 kPa)

Minimal water resistance (some resistance to water spray)

Low water resistance (resistant to water spray and some resistance to water penetration under constant contact with increasing pressure)

Moderate water resistance (resistant to water spray and some resistance to water penetration under constant contact with increasing pressure)

Blood and viral penetration resistance (2 psi)

In a field where safety and compliance are paramount, ARDL stands out as a beacon of excellence. ARDL’s extensive certification, advanced testing methods, and customer-centric approach make it the ideal partner for all your pharmaceutical and microbiological testing needs. By choosing ARDL, you are not just selecting a testing laboratory, you are partnering with a team of experts dedicated to ensuring the safety and efficacy of your products.

Visit www.ardl.com or contact them directly at sales@ardl.com to learn more about how ARDL can support your testing needs. Experience the ARDL difference and discover why they are the trusted choice for leading companies in the PPE medical and pharmaceutical industries.

EnErgy SEctor

Renewable energy gains momentum in ASEAN countries

The region’s economic growth is fuelling an unprecedented demand for reliable and abundant energy to support its expanding industries, says Angelica Buan in this report.

As the Asia-Pacific region expands its economic footprint, securing reliable and abundant energy sources is vital. In ASEAN, rising energy demand is driven by population growth, urbanisation, and industrialisation. Rising industrial activity also intensifies the need to meet growing energy demands while balancing sustainability.

The International Renewable Energy Agency ( IRENA ) in its “Renewable Energy Outlook for ASEAN” report says that the region will experience a 4% annual growth in energy demand until 2025, resulting in a 50% increase from 2014 levels.

ASEAN aims to decarbonise emissionsintensive sectors like transport, industry, and energy, targeting 23% of primary energy from renewables by 2025, despite rising energy demand

Electricity demand alone is projected to double between 2014-2025. To address this growing demand, ASEAN continues to rely on limited domestic fossil fuel resources, leading to a greater dependence on imported fossil fuels.

Rising demand for fossil fuels is also increasing carbon emissions, which contributes to air pollution. Energy-related emissions are projected to rise by 61%, reaching over 2.2 Gt/year by 2025.

To address this, ASEAN aims to decarbonise emissions-intensive sectors such as transport, industry, construction, manufacturing, and energy. The region is targeting to source 23% of its primary energy from modern, sustainable renewables by 2025, even as overall energy demand continues to grow significantly.

Despite the dominance of fossil fuels, transitioning to renewable energy sources is increasingly a priority among ASEAN nations. Key technologies such as green hydrogen, carbon capture utilisation and storage (CCUS), smart grids, offshore wind, and energy storage, along with expanded use of solar, wind, geothermal, and ocean energies, will be critical for achieving net-zero emissions.

Breaking free from coal use

Coal dominates the Asian energy mix, making up 57% of electricity generation due to rising demand.

The International Energy Agency ( IEA ) reports that China alone consumes 50% of the world's coal output and with India, Indonesia, Vietnam, and the Philippines, accounting for over 70% of global coal demand.

However, coal’s contribution to greenhouse gas emissions (GHG) compels countries to transition away from coal. Reducing coal use is imperative for limiting global warming to 1.5°C. Despite this urgency, completely abandoning coal remains a challenge.

Coal accounts for 57% of Asia's electricity generation, driven by rising demand

Reports indicate that while coal use is expected to peak and then decline, coal power plants continue to supply energy to factories, industries, and households due to their low cost and availability. On a brighter note, ASEAN nations are shifting away from coal in favour of cleaner energy alternatives. The region's commitment to reducing carbon emissions and addressing air pollution and climate change is driving this transition toward renewable energy and sustainable growth.

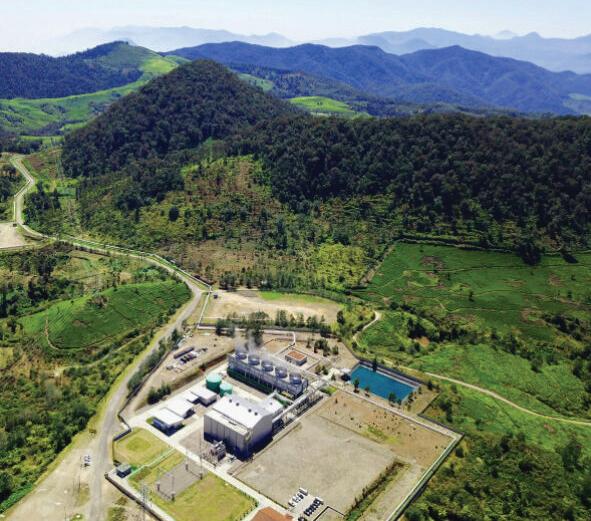

Indonesia: dominance in geothermal energy capability

According to the IEA, ASEAN’s coal demand surged by 13% to 413 million tonnes in 2022, with Indonesia accounting for nearly half of this total. Power generation consumed 71% of this coal. Demand is expected to increase to 528 million tonnes by 2026, largely driven by Indonesia's growing consumption, with a rise to 444 million tonnes projected for 2023.

In 2023, Indonesia became the fifth-largest coal generator globally, surpassing South Korea, according to Ember Climate data. Indonesia’s coal generation surged by 74% from 125 TWh in 2015 to 217 TWh in 2023, with a 7.1% annual growth rate. This growth has propelled Indonesia from eleventh to fifth place, overtaking powerhouse economies like Germany, Russia, Australia, and South Africa.

Indonesia's Batang Power Plant, with a capacity of 2 x 1,000 MW and utilising Ultra Super Critical (USC) technology, commenced commercial operations in 2022

New coal-fired plants are focused on supporting nickel production, vital for electric vehicle batteries and steel. Indonesia, with 42% of the world's nickel reserves and substantial copper, gold, and tin, is investing in expanding nickel production to meet rising global demand. Regarding renewable energy, Indonesia aims for 23% of its energy mix by 2025 and 31% by 2050, as noted by the Minister of Energy and Mineral Resources at the 2022 IEA Clean Energy Transitions Summit.

According to Energy Tracker Asia , Indonesia ranks among the top five Asia-Pacific countries for renewable energy capacity, with 16 geothermal power plants operating across the country. These plants, with capacities ranging from 2.5 MW to 377 MW, are predominantly located in Java and Sumatra. Hydropower and geothermal plants currently contribute 8% and 5% to the country's energy mix, respectively.

The Asian Development Bank (ADB) has provided a boost to Indonesia to maximise its geothermal energy potential, estimated at 29 GW, and its second-largest installed capacity of 2.1 GW. ADB extended a US$300 million loan to PT Geo Dipa Energi (GDE), a state-owned geothermal developer, to expand geothermal power generation by 110 MW in Java. Additionally, ADB will oversee a US$35 million loan from the Clean Technology Fund for this project.

The geothermal power generation project will support the construction of two plants, including one in Patuha, West Java. This initiative aims to enhance GDE’s capabilities in planning and executing geothermal projects and conducting governmentsupported drilling, thereby attracting private sector investment to develop new geothermal sites.

Meanwhile, GDE recently secured a EUR825,000 grant from Germany’s Kreditanstalt für Wiederaufbau Bankengruppe ( KfW ), for drilling two temperature core holes in the Candi Umbul Telemoyo geothermal working area in Central Java, Indonesia.

Malaysia: roadmap for clean energy

The Malaysian government aims to achieve 31% of its total energy mix from renewable sources by 2025 and 70% by 2050, as part of its strategy to reach net-zero greenhouse gas emissions by 2050.

To support this transition, Malaysia has introduced three key policies to boost renewable energy, according to Global Data . These policies include the Renewable Energy Act, the National Renewable Energy Policy and Action Plan, and the Sustainable Energy Development Authority (SEDA) Act.

The Renewable Energy Act 2011 established a feed-in tariff (FiT) system with targets up to 2030 and guidelines for renewable energy tariffs. In 2021, the Ministry of Natural Resources, Environment and Climate Change (NRECC) set a renewable energy target for 2025, aligning with Malaysia's climate commitment to reduce carbon intensity by 2030.

The Malaysia Renewable Energy Roadmap (MyRER) includes assessing installed capacity and resources, setting technology-specific targets, and developing a strategic roadmap.

ADB supported renewable projects, including a geothermal power project to build two plants, one in Patuha, West Java

These efforts have positioned Malaysia as an attractive destination for expansion by major energy technology companies. For instance, Malaysia's largest clean energy firm, Solarvest Holdings Berhad , has secured a RM113 million EPCC contract with P Solar Sdn Bhd to develop a 45 MWp solar farm in Mukim Pekan, Pahang.

This project will generate 57,500 MWh/year of clean energy, offsetting around 36,800 tonnes of CO2 emissions. Scheduled for completion by the end of 2025, the farm is expected to produce nearly 60,000 Renewable Energy Certificates (RECs) to help companies meet sustainability goals.

The solar farm will be equipped with monsoonresistant designs and high-quality panels and inverters, with plans to integrate battery energy storage systems in future phases. Moreover, Solarvest is pursuing further opportunities to further advance Malaysia’s renewable energy capacity, targeting 40% by 2050.

Philippines: alliances to drive renewable energy goals

The Philippines is accelerating its shift to renewable energy, forging key partnerships to enhance its sustainable power efforts, to reduce the nation’s carbon footprint and bolster energy security.

In recent developments, wpd GmbH , a German company that develops and operates onshore and offshore wind farms and solar parks, and is actively engaged in 28 countries around the world, is set to invest over Php392 billion to set up offshore wind farms in the Philippines, in the provinces of Cavite, Negros Occidental, and Guimaras.

In 2023, it was reported that the company sought to register energy projects worth approximately Php55 billion with the Board of Investments (BOI). These projects, totalling a planned capacity of 565.6 MW, consist of onshore wind and solar photovoltaic (PV) power projects in Aklan, Ilocos Norte, Ilocos Sur, Abra, Antique, and Bulacan.

The Aklan project is an onshore wind farm with a total capacity of 75.6 MW. Triconti ECC Renewables Corporation , a German-Swiss-Filipino joint venture based in the Philippines, is collaborating on the planning and implementation of the project. It will comprise 18 Vestas V136 turbines with a capacity of 4.2 MW each, according to wpd. Currently, in the planning stage, commissioning is scheduled for the end of 2023.

The project is part of the "CNP Backbone Extension," a major grid reinforcement and expansion for Cebu, Negros, and Panay. The wind farm will connect to the grid through a new substation being built by wpd and Triconti and the partners are also negotiating a Power Purchase Agreement (PPA) to sell the electricity locally.

The Bremen-headquartered company has already implemented wind energy projects with approximately 2,400 turbines and a total output of 5,150 MW. It is planning additional projects with 12,300 MW onshore, 13,800 MW offshore, and 1,650 MWp solar energy.

Similarly, Acen , a major renewable energy company in the Philippines with a growing presence in Asia Pacific, is partnering with US-based BrightNight for the development of its 1 GWac renewable power portfolio in the country, with an estimated capital deployment of US$1.2 billion over the next five years.

This marks BrightNight and Acen’s second partnership. In 2023, Acen, through its subsidiary, Acen Renewables International ( ACRI ), established a 50-50 partnership with the Florida-headquartered company to develop a 1.2 GW large-scale hybrid wind/solar and round-the-clock renewable power projects in India.

Solarvest's project in Malaysia, set to be completed by the end of 2025, will produce 57,500 MWh/year of clean energy and offset approximately 36,800 tonnes of CO2 emissions

The Philippines' Aklan project is an onshore wind farm with a total capacity of 75.6 MW

AI and interconnectivity propels SEA’s US$6 bn health market

Home to nearly 60% of the world’s population, the Asian region’s digital health market is expected to generate US$66.97 billion revenue in 2024 and reach a projected market value of US$99.57 billion by 2029, according to analysts Statista. The rapid digitisation of health services is leading industry sectors to experience significant growth.

As such, to be held alongside the Medical Fair Asia at Singapore’s Marina Bay Sands (11-12 September), GITEX Global, the world’s largest tech and start-up event, hosted in Dubai, has announced the creation of GITEX DIGI_ HEALTH 5.0 Conference, an AI and digital health expert gathering at the opportune inflection phase of the global healthcare evolution.

The inaugural conference, organised by Kaoun International, the international organising office of Dubai World Trade Centre (DWTC), will convene a premier line-up of international speakers including future health influencers and practitioners in Digital Health, Artificial Intelligence, Telemedicine, Consumer Health, and Patient Care.

Under the overarching theme of Implications of AI and Digitalisation in Disrupting Healthcare, the immersive two-day conference featuring global speakers from over 12 countries will highlight the integration of these technologies.

An expertise of public and private organisations in tech and healthcare will be joining the stage this year.

Headliners include Sutowo Wong, Director of Data Analytics at the Ministry of Health Singapore, Dr Pauline Erica Tay, Director of National Health Innovation Centre Singapore (NHIC), Dr Ossama ElHassan, Head of E-Health at the Dubai Health Authority from the United Arab Emirates, and Hanna Burkhardt, Head of UNICEF’s Venture Fund in Sweden.

Among the innovators, founders, and digital health leaders who will be attending are WeiWei Hong, Director of the healthcare network SingHealth, and Shravan Kumar, Co-Founder and CEO of the Healthcare solutions platform SpeedDoc from Singapore, Chwee Foon Lim, CEO for Asia- Pacific at the world’s largest exoskeleton company Ekso Bionics, headquartered in the United States, Dr Ramon Varughese, Chief Medical Officer of Qualitas Health from Malaysia, and many more.

Medical Fair Asia is organised by Messe Düsseldorf Asia. The showcase will feature 1,000 exhibitors from 62 countries and regions, with a Community Care dedicated area and a StartUp Park presenting highly innovative companies.

“We are delighted to see this co-location with GITEX DIGI_HEALTH 5.0 Conference in Singapore,” said Gernot Ringling, Managing Director of Messe Düsseldorf Asia. “This collaboration complements our event greatly, with Medical Fair Asia’s strengths as a regional sourcing and networking event and GITEX’s expertise as the world’s largest tech event brand.

He added, “With its leadership in biotech and health R&D, Singapore provides the ideal backdrop for this partnership in advancing healthcare and driving the future of digital health across Asia.”

The programme will explore opportunities in a hybrid healthcare future, where AI, IoT, predictive data analytics, and interoperability are transforming patient care systems. Talks and panel discussions will also cover the evolution of telemedicine, the integration of AI diagnostics, VR/AR consultations, and remote monitoring, and the impact of emerging technologies such as blockchain and Web3 on the healthcare sector.

Trixie LohMirmand, CEO of Kaoun International, organiser of GITEX worldwide, said: “Despite the broader worldwide downturn in funding, regional start-ups have attracted significant investments particularly in the digital future health sector where accessible and high accuracy diagnostic medical interventions and solutions are the priorities of future economies.”

To attend the conference from 11-12 September 2024 at the Marina Bay Sands in Singapore, visit the event’s website today and register for a free pass: www. gitexdigihealth.com.

As part of GITEX's expansion into the Asian region, GITEX ASIA — the most international cross sector tech and startup event in Asia—will make its debut in Singapore from 23-25 April 2025. This event strategically positions itself as the premier gateway to the Asian market, connecting the region with a global network of leading tech companies, unicorn founders, investors, AI pioneers, government leaders, and top-tier R&D institutions and academia. Learn more at www.gitexasia.com

Recycling

Living in a plastic world: tackling the plastic pollution problem

With the growing onslaught of plastics pollution, the Nanyang Technological University, Singapore (NTU Singapore) is researching ways of recycling and reusing plastics, as well as addressing major bottlenecks faced when recycling plastics. Researchers have re-purposed e-waste plastics to grow “mini tumours” for laboratory testing in research and healthcare applications; converted hard-to-recycle plastic waste into hydrogen and carbon additives for polymer foams used in cushioning and developed a method to break down plastics into valuable compounds using light.

Plastic pollution has emerged as one of our most pressing environmental issues with the increasing use of disposable plastics. As they are nonbiodegradable, plastics accumulate in the environment, altering habitats and natural processes. Millions of wildlife are also trapped by plastic waste every year.

When plastics break down, they release toxic compounds that contaminate the environment. They also disintegrate into small pieces of plastic called microplastics.

Microplastics are now found all over the globe and are linked to severe health effects such as metabolic disorders and organ damage.

Recycling the way forward

Recycling plastics reduces the amount of plastic waste that would otherwise be discarded and conserves natural resources. However, only about 10% of plastic is currently recycled around the world. The figure is low in part because recycling some types of plastic, such as e-waste and marine plastic litter, is difficult. Chemical reactions that break down plastics into simpler components to be reused are also energy intensive.

From using e-waste plastics to culture cells to developing a greener method that breaks down plastics, researchers at NTU Singapore are solving some of the biggest challenges that stand in the way of recycling plastics and making strides in reducing plastic pollution.

Repurposing e-waste plastics to grow “mini tumours” for laboratory testing

Plastics comprise a large portion of electronic waste (e-waste), and rapid technological advances, and high consumer demand drives its growing use in electronics. According to a UN report, the generation of e-waste is rising five times faster than the official recycling rate figures show. In 2022, e-waste generated 17 million tonnes of plastic globally.

Single-use plastics are also widely used in research and healthcare applications such as cell culture.

Acrylonitrile butadiene styrene (ABS) is an e-plastic commonly used in the housings of devices such as keyboards and laptops. Repurposing plastics such as ABS for high value biomedical applications could be an attractive waste-to-resource strategy for effectively reducing plastic waste.

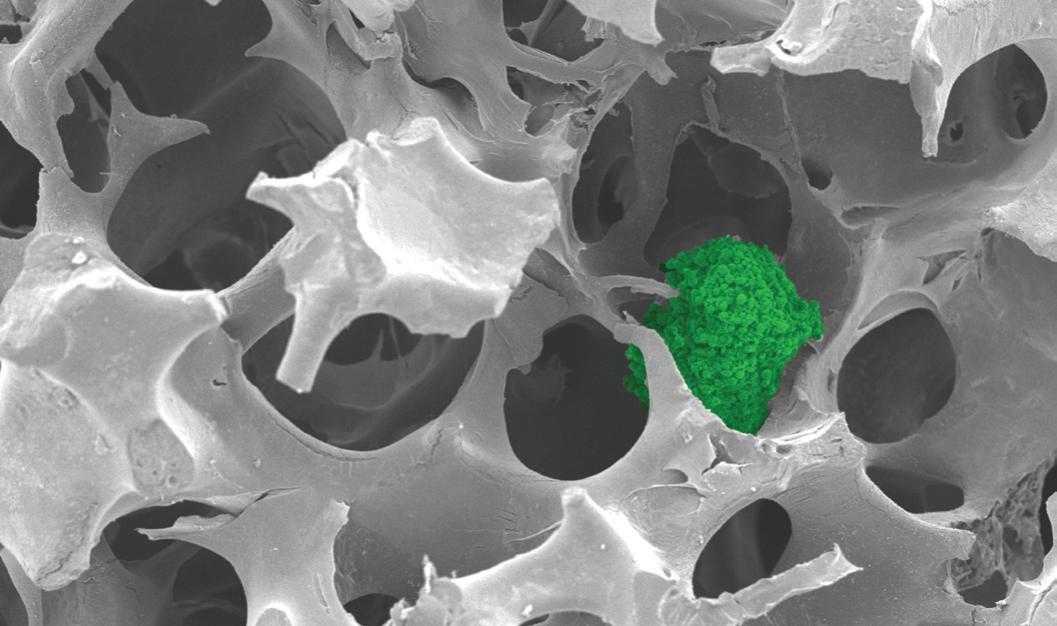

NTU scientists have developed a synthetic matrix to culture cells using ABS from discarded keyboards. The matrix is porous like a sponge and functions as a support structure, providing a framework for cells to attach and grow.

The matrix can culture spherical clusters of cells, called cancer spheroids, whic resemble actual tumours. Due to their 3D shape, these “mini tumours” more accurately represent tumours than conventional cell cultures.

To fabricate the matrix, the scientists dissolved plastic scraps from discarded keyboards in an organic solvent, acetone and poured the solution into a mould.

The matrix supported the growth of breast, colorectal and bone cancer spheroids. The cancer spheroids had properties similar to those grown using commercially available matrices and may be used for biomedical applications such as drug testing.

ABS sponge

“Our innovation not only offers a practical means to reuse e-waste plastics but could also reduce the use of new plastics in the biomedical industry,” said Assoc Prof Dalton Tay of NTU’s School of Materials Science and Engineering, who led the research.

The research was reported in Resources, Conservation & Recycling in 2024.

Converting hard-to-recycle plastic waste into hydrogen and carbon additives for polymer foams

While some types of plastics can be repurposed into new products, it is not as easy to recycle other kinds of plastics. Household plastics, packaging waste and marine plastic litter recovered from the environment are all examples of plastic waste that are difficult to recycle. There are also limited economic benefits to treating mixed and contaminated plastics.

Researchers from NTU explored using difficult-torecycle plastics as a source of solid carbon material for application in polymer foams. The researchers first obtained gas and oil by heating different types of plastic waste at high temperatures (600°C) in the absence of oxygen. Then the gas and oil were heated at over 1000°C to break down the molecules into solid carbon and hydrogen.

The solid carbon can be added to polymer foam to increase its strength and resistance to abrasion for cushioning applications. The foam containing the synthesised solid carbon derived from plastic waste exhibited properties comparable to other carbon-based and conventional reinforcing materials available on the market.

At the same time, the hydrogen produced could be collected and used as fuel.

Published in the Journal of Hazardous Materials in 2024, the research is a milestone in finding a use for plastic waste that previously could not be recycled.

“We have developed a feasible approach to repurpose hard-to-recycle plastics, which is an important aspect of the circular economy,” said lead investigator Assoc Prof Grzegorz Lisak of NTU’s School of Civil and Environmental Engineering.

A bright way to break down plastics into valuable compounds

Although plastics can be broken down by heating them at high temperatures, such processes are energy intensive and generate greenhouse gases, contributing to global warming.

Addressing the need for greener methods of breaking down plastics, NTU scientists have developed a process that can upcycle most plastics into chemical compounds useful for energy storage. The reaction uses light-emitting diodes (LEDs) and a commercially available catalyst and occurs at room temperature. It can break down a wide range of plastics, including PP, PE and PS, all commonly used in packaging and discarded as plastic waste.

Compared to conventional plastic recycling methods, the process requires much less energy.

First, the plastics are dissolved in the organic solvent called dichloromethane, making the plastic polymer chains more accessible to the photocatalyst. The solution is then mixed with the catalyst and flowed through transparent tubes where LED light shines on it.

The light provides the initial energy to break the carbon-carbon bonds in a two-step process with the help of the vanadium catalyst. The plastics’ carbon-hydrogen bonds are oxidised, which makes them less stable and more reactive. After that, the carbon-carbon bonds are broken down.

The resulting end products are compounds such as formic acid and benzoic acid, which can be used to make other chemicals employed in fuel cells and liquid organic hydrogen carriers (LOHCs)–organic compounds that can absorb and release hydrogen through chemical reactions.

LOHCs are being explored by the energy sector as a storage media for hydrogen.

According to Assoc Prof Soo Han Sen of NTU’s School of Chemistry, Chemical Engineering, and Biotechnology, who led the study, the breakthrough not only provides a potential answer to the growing plastic waste problem but also reuses the carbon trapped in these plastics instead of releasing it into the atmosphere as greenhouse gases through incineration.

The method was reported in the journal Chem in 2023.

Recycling

Using light to break down plastics

Mini tumour from ABS sponge

Packaging

High barrier MDO-PE/PE laminate for recyclable packaging

To address the growing demand for recyclable packaging options, US materials firm ExxonMobil says it has successfully collaborated with Hosokawa Alpine , Henkel , Nordmeccanica Group and Univel to develop a high-barrier, recyclable MDO-PE//PE laminate. This advanced packaging solution is engineered to provide excellent barrier properties against oxygen and moisture, and targeted at a range of food products, ensuring optimal product freshness and protection.

The duplex MDO-PE//PE laminate was produced from a high-barrier PE sealant film and MDO-PE printing web. The MDO-PE printing web incorporated ExxonMobil HDPE HD7165L that was specifically designed to produce MDO-PE films. The MDO-PE film was produced on machine supplier Hosokawa Alpine’s five-layer blown film line with inline MDO.

ExxonMobil has developed a duplex high barrier MDOPE packaging solution

The blown PE sealant film was produced using ExxonMobil’s performance PE resins such as Exceed S, Enable and Exceed. Material supplier Evonik ’s TEGOMER 6810, an organo-modified siloxane, was used to help control the coefficient of friction (COF).

Two thin barrier coatings (BC) were then applied on the blown PE sealant film to help deliver outstanding barrier properties: the first layer contains vacuum-metallised aluminium, while the second layer contains 1 gsm of technology firm Henkel’s newly developed barrier coating Loctite LIOFOL BC 1582 RE.

Both functional layers were applied using Nordmeccanica Group's Vacuum & Coating machinery (Nordmet 12F Plus/Super Combi 5000). The MDO-PE film was printed by Univel.

The combination of metallisation and barrier coating to produce a very high PE-content laminate provides ultra-high oxygen barrier properties (similar to aluminium foil3) and excellent moisture barrier properties.

The oxygen-transmission rate (OTR) of the PE-based film was almost two magnitudes lower than the PETmet-based film when measured at 0% relative humidity at room temperature, whereas water vapour transmission rate (WVTR) of both structure was very similar.

The new solution not only meets the functional requirements for a wide range of food packaging applications, from dry goods to liquids, but also offers outstanding stiffness and clarity. This makes it a viable alternative to traditional materials such as PET and BOPP. Additionally, the solution addresses the challenge of maintaining barrier properties while ensuring ease of recyclability, often a limiting factor in conventional packaging materials.

Meanwhile, German machinery maker Reifenhäuser Blown Film has also showcased what it says is the “world’s first’ 18-micron MDO-PE film”. It claims to reduce the thickness of previous films by 25% and enable companies to transition into fully recyclable, low-carbon mono-material flexibles.

The film has been produced on Reifenhäuser EVO blown film lines using the patented EVO Ultra Stretch MDO technology and has been developed and tested for practical suitability in collaboration with raw material manufacturer LG Chem and printing specialist Bobst

The combination of suitable raw materials and Reifenhäuser’s MDO Ultra Stretch technology directly in the line's haul-off, where the film is stretched from the first heat, enables the production of the 18-micron film

Cost-effective solution as an alternative to ionomer vacuum skin packaging

Elsewhere, ExxonMobil has collaborated with Brazilian packaging converter Videplast to develop a vacuum skin packaging (VSP) solution to replace an existing resin that does not contain ionomers, thereby reducing film thickness for food packaging applications.

ExxonMobil has together with Videplast developed a cost-effective vacuum skin packaging (VSP) solution that does not contain ionomers

VSP is a type of packaging where a product is placed on a piece of tray (plastic or cardboard) and a thin barrier film is softened by heat and draped over the product on the tray. Vacuum is applied to ensure the film will cover the entire surface of a product/tray, removing as much air inside the package as possible.

Utilising ExxonMobil’s Exceed XP 7052ML performance PE, the new solution hopes to meet market demands for high-performance, cost-effective packaging that provides protection from food spoilage, leakage, and contamination and extends the shelf life of perishable goods by removing air and providing a tight seal.

The process involves ‘optimal thermoformability’ and a high oxygen barrier, aiming for effective vacuum sealing.

The solution is said to be ideal for packaging small portions of meat, cheese, fish, seafood, and other products requiring high-performance and visually appealing packaging solutions.

Reusable PET packaging for cosmetic brands

Together with packaging and recycling specialist Alpla , start-up Zerooo SEA ME has developed a standardised solution for cosmetics and care products and are now producing reusable PET packaging for bathrooms and kitchens.

From September, the first brands will be presenting shampoo, shower gel, detergent, body lotion and dental care products in 300-ml PET bottles. This reusable and fully recyclable plastic packaging is available

in three colours and is suitable for all caps. A laserengraved 2D data matrix code provides information on the contents of each bottle and its circulation.

Zerooo aims to create reusable packaging that fosters the circular economy in the cosmetics industry. The system from the German start-up SEA ME is said to offer brand manufacturers safe, affordable and sustainable PET bottles, in addition to glass bottles, for the first time. stands for reusable packaging that fosters the circular economy in the cosmetics industry.

The reusable PET bottle is available in clear, milky white and brown versions.

The company states it has created a fully recyclable solution in collaboration with Alpla and ten brand partners. It adds that the reusable PET bottle can be used as a shatterproof alternative for toiletries in the shower, and further formats are planned.

From September, the first manufacturers in Germany will present cosmetics and care products in PET containers from the Zerooo reusable system, with Austria following suit in October. In addition to SEA ME’s own brand, these include sodasan , i+m Naturkosmetik , Speick , Denttabs , 4 people who care and Aveo from Müller

Each Zerooo reusable PET bottle has a laserengraved 2D data matrix code – the zerooo ID – which provides information about the content and circulation history.

“The digital labelling enables transparency and ensures the quality of the bottles. By combining it with the information from the label, it can also be complemented with further product data,” explains Jörg Schwärzler, senior technology manager at Alpla. The reusable PET bottle is reportedly compatible with all automatic return systems, and at the end of their life cycle, the bottles and caps are sorted and recycled.

Alpla says it is promoting closed ‘bottle-to-bottle’ cycles with its own plants, and the Zerooo reusable PET bottle was developed with the SEA ME team at Alpla’s in-house design centre, at the company’s headquarters in Hard, Germany.

Alpla and Zerooo have developed reusable and fully recyclable PET bottles, available in three colours and suitable for all caps

Injection Moulding Asia

Country Focus

Taiwan’s blueprint for a progressive carbon-neutral future

Taiwan is advancing sustainable energy and maintaining semiconductor industry leadership with clear strategies, adds Angelica Buan in this report.

Taiwan is rapidly emerging as a leader in sustainable innovation, combining its economic strengths with a strong commitment to a circular economy. As the 23-million-population East Asian nation advances its green energy initiatives, it is paving the way for its electric vehicle and semiconductor industries to thrive while leading in environmental responsibility, positioning the country as a global leader in both technology and sustainability.

Taiwan plays a crucial role in the global supply chain, leading in the integrated circuit (IC) industry and excelling in consumer goods such as footwear, as well as in textile R&D and production. However, its reliance on imported resources poses challenges to its economic development.

In response, Taiwan unveiled its “Pathway to Net-Zero Emissions in 2050” in 2022, a comprehensive plan focused on transforming energy, industry, lifestyle, and society. Supported by technological innovation and climate legislation, this plan includes 12 strategic initiatives to achieve net-zero emissions, featuring plans for energy transitions, industrial shifts, and green transportation.

Taiwan’s green energy push

Taiwan is making a strategic pivot towards renewable energy, which not only increases the use of wind, solar, and other green energy sources but also helps industries reduce greenhouse gas emissions (GHG), aligning economic growth with environmental responsibility.

According to Taiwan’s National Development Council ( NDC ) 2022 Phased Goals and Actions Toward Net-Zero Transition report, the country plans to boost the share of renewables in its energy mix from 2025 to 2050.

Specific targets include installing 91 MW of hydrogen capacity by 2025; 891 MW by 2030; and 7,300 MW by 2050, aiming for a reduction of 6,700 tonnes of GHG emissions by 2030 through hydrogen alone. To achieve these goals, Taiwan will collaborate with major hydrogen producers, expand hydrogen import sources, and build infrastructure for production, transportation, and storage, including international supply chains and liquid hydrogen stations.

Additionally, Taiwan is advancing blue hydrogen with CCSU testing and localised production technologies and plans to achieve 5% mixed combustion by 2030. The green energy roadmap also focuses on innovative sources such as geothermal, bioenergy, and ocean energy.

For wind and solar PV, the total installations targets by 2050 are 40 to 55 MW and 40 to 80 MW, respectively.

For geothermal energy, Taiwan is eying installations from 20 MW in 2025 to 6.2 GW by 2050, aiming to cut 180 to 620 kilotonnes of GHG emissions by 2030.

Bioenergy targets include 778 MW by 2025; 805 to 1,329 MW by 2030; and 1.4 to 1.8 GW by 2050, with expected reductions of 2.18 to 4 million tonnes of GHG emissions by 2030.

Ocean energy installations are projected to grow from 0 to 0.1 MW by 2025 to between 1.3 and 7.5 GW by 2050, aspires reductions of 0.13 to 1.3 kilotonnes of GHG emissions by 2030.

Taiwan targets a reduction of up to 620 kilotonnes of GHG emissions from geothermal energy by 2030

Taiwan is progressing blue hydrogen development with CCSU testing and aims for 5% mixed combustion by 2030

Injection Moulding Asia

Innovative energy strategies include developing a unified firing system with incentives for coal-to-biomass units, sourcing pellet biomass, and optimising conversion technologies while improving economic benefits through effective use of by-products like ash and biogas residue.

Authorities estimate that NT$4 trillion will be invested in the net-zero transition and zero-carbon technology deployment by 2030, which is expected to generate NT$5.9 trillion in production value and create over half a million jobs.

Journey to a net-zero transportation

Taiwan’s shift to clean energy and a circular economy is driving the growth of a robust electric vehicle ecosystem. By focusing on sustainability and reducing environmental impact, Taiwan aims to lead the global transition to sustainable transportation.

Vehicle efficiency is a major priority, with plans to offer subsidies for replacing old vehicles and promoting high-efficiency models. Regulations are being updated to align with global standards, improving fuel efficiency and optimising public transport.

The increased rollout of electric vehicles (EVs) is anticipated due to these carbon-free initiatives. According to the US International Trade Administration ( ITA ), passenger EVs made up 3.4% of total registrations in Taiwan in 2022, with EV sales soaring 128% from 7,064 units in 2021 to 16,106 units in 2022.

Taiwan aims to achieve 100% electric cars by 2030 and 100% electric motor vehicles and scooters by 2040.

In line with this, Foxconn (or Hon Hai Precision Industry Co Ltd ), a Taiwanese multinational electronics contract manufacturer, plans to deliver over 10,000 electric SUVs in 2024 through its joint venture with Taiwanese automaker, Yulon Motors , focusing on the Model C SUV. The Model B crossover will also be mass-produced for international markets.

Foxconn expects over 9,000 domestic orders, with total sales exceeding 10,000 units. Additionally, 1,555 units of the Luxgen n7 EV, developed with Yulon, were delivered in the first four months of the year.

Foxconn is also entering the commercial vehicle market, with a factory for electric buses in Kaohsiung set to start operations in 2025. The factory will initially produce 500 buses/year, ramping up to 1,000 by 2028.

Expanding EV charging access

With this planned expansion for EV production and sales, Taiwan is rapidly scaling its charging network by establishing stations at highway service areas, transport hubs, tourist sites, and gas stations, as well as in industrial and science parks, exhibition centres, and other key locations.

Foxconn Interconnect Technology Ltd ( FIT Hon Teng ), a subsidiary of Hon Hai, is making notable advancements in the EV sector. Following its acquisition of German manufacturer of sensor, connectivity and automotive electrification solutions, Prettl SWH Group , in 2023 and the launch of the Voltaira brand, FIT Hon Teng has entered the EV charger market through a joint venture with Chinabased EV charging and energy storage systems specialist, XYPower Technology Co .

The new entity, Fxnwing New Energy Technology, merges XYPower’s expertise in EV charging and energy storage with FIT Hon Teng’s manufacturing capabilities. This collaboration aims to deliver high-quality charging and energy storage solutions globally, leveraging the growing EV market.