Oxford dictionary has narrowed down the top word of 2022 to metaverse, #IStandWith, and goblin mode. But I want to throw another potential contender into the hat for this year — net zero. Or maybe even electrification.

It feels like almost every day I read something related to either of these terms. The federal government just announced a new grant that would put $5,000 back into the pockets of homeowners that make the switch from oil heat to an electric heat pump

The Atmospheric Fund releasedastudythat looked at the Greater Toronto and Hamilton Area’s carbon emissions in 2021. According to the report, the two regions increased their carbon emissions by 2.2 million tonnes, or 4.5 per cent, in 2021. “Emissions profiles stayed similar across the region. Buildings are still the top source of emissions, primarily due to the use of natural gas for heating and hot water,” according to the report. “Natural gas emissions in buildings increased by 1.7 per cent, a source of emissions despite the warmer winter and proven, cost-effective mitigation strategies that exist today.”

And these two articles were just published on our website within the last week. I could go on and on with examples to prove how much of a hot topic net zero has become in the last few years.

Yet even though it's a hot topic, we've got a

longwayuntilwe'reclosetomakingour2050 net zero goals.

At the Heating, Refrigeration and Air Conditioning Institute of Canada (HRAI)’s annual conference in Ottawa from Sept. 18-20, both electrification and net zero were the main focuses. One of the speakers was asked whether or not netzero targets were achievable. They stated that some of the targets might not be met by the hoped date, but that doesn’t mean that deadlines shouldn’t be set. If there were no deadlines in place, then the industry wouldn’t have a path to try to follow We’d rather arrive late to the party rather than not at all.

Additionally, the Net-Zero Advisory Body, an independent Canada-based advisory group, released a report as to how the built environment can achieve net zero. It included supporting the elimination of fossil fuel combustion for heating, efficient building envelopes, efficient appliances and system within buildings, and the use of low carbon and net-zero building materials. The good news for the building sector is that the technologies exist today. It’s time to start implementing them.

November/December 2022 Volume 32, Number 8 ISSN 1919-0395

Publisher

Mark Vreugdenhil (289) 638-2133 ext.1 Cell: (416) 996-1031 mark@plumbingandhvac.ca

Editor

Leah Den Hartogh

(289) 638-2133 ext. 2 Cell: (289) 830-1217 leah@plumbingandhvac.ca

Francesco Lo Presti (289) 638-2133 ext. 3 francesco@plumbingandhvac.ca

Roy Collver, Ron Coleman, Mark P. Evans, Bill Hooper, Glenn Mellors, Bruce Nagy, Greg Scrivener

Design and Production

Tim Norton/Janet Popadiuk production@plumbingandhvac.ca

All articles and photos by Plumbing & HVAC staff unless noted.

PLUMBING & HVAC Magazine is published eight times annually by Marked Business Media Inc. and is written for individuals who purchase/ specify/approve the selection of plumbing, piping, hot water heating, fire protection, warm air heating, air conditioning, ventilation, refrigeration, controls and related systems and products throughout Canada.

Marked Business Media Inc. 286 King Street W, Unit 203, Oshawa, ON L1J 2J9 Tel: (289) 638-2133

Postmaster: Send all address changes and circulation inquiries to: Plumbing & HVAC Magazine, 286 King Street W, Unit 203, Oshawa, Ontario, Canada L1J 2J9. Canadian Publications Mail Sales Product Agreement No. 43029513. Postage paid at Toronto, ON.

Annual Subscription Canada: $40.00 plus applicable taxes, single copy $5.00 plus applicable taxes. Annual Subscription United States: $60.00 U.S. Annual Subscription foreign: $90.00 U.S.

Copyright 2022. The contents of this magazine may not be reproduced in any manner without the prior written permission of the Publisher.

A member of:

• Canadian Institute of Plumbing & Heating

• Mechanical Contractors Association of Canada

• Ontario Plumbing Inspectors Association

• American Society of Heating Refrigerating & Air Conditioning Engineers

• Heating Refrigeration and Air Conditioning Institute of Canada

• Refrigeration Service Engineers Society of Canada

in the 2025 editions of the National Model Codes. Any code changes introduced into new editions of the National Model Codes will apply to new houses and buildings. For the new editions to become law, they must be adopted by a province, territory, or other authority having jurisdiction.

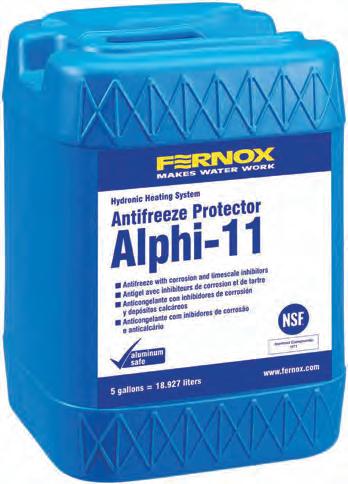

While there are numerous proposed changes within the public review document and each one could be highlighted, industry members should be made aware of two proposed changes in the National Plumbing Code 2020. The first proposed change relates to the protection of potable water from contamination. References to the NSF/ANSI/ CAN 61 standard, “Drinking Water System Components - Health Effects,” would be added to mitigate the risk of consumption of potablewaterthatischemicallycontaminated.

The second proposed change would require that discharge pipes be connected to relief valves on hot water tanks. This would mean that a pressure-relief, temperature-relief, or combined temperature- and pressure-relief valve be connected to a discharge pipe that runs the length of the hot water tank, with the rationale that this could help prevent serious injuries.

By Francesco Lo PrestiThe Canadian Commission on Building and Fire Codes (CCBFC) is seeking code users and stakeholders to participate in the fall 2022 public review of proposed changes to the National Model Codes, which includes the National Building Code of Canada (NBC) 2020, the National Fire Code of Canada (NFC) 2020, the National Energy Code of

Canada for Buildings (NECB) 2020, and the National Plumbing Code of Canada (NPC) 2020.

Participants can provide feedback on the proposed changes until Dec. 23. Following the public review, all comments received will be considered by the relevant code development committees, and recommendations on the proposed changes will be made.

If approved, the changes will be included

Additional proposed changes related to the building environment include Proposed Change 1677, which revises Table 9.23.10.1. to clarify that 38 mm by 140 mm studs spaced at 400 mm can be used in exterior walls only supporting a roof or a roof plus one floor.

Proposed Change 1756 will clarify requirements for the current practice for heat transfer requirements with respect to fenestration systems by introducing a new standard specific to the assessment of surface temperature for condensation evaluation of exterior wall systems.

spending more to fill their tanks with gas,” explained Freeland, as part of her speech to the House. “This is a challenging time for millions of Canadians—for our friends, for our families, for our neighbours.”

According to CIPH and MCA Canada, the government is likely wagering that the Bank of Canada is raising interest rates to reduce inflation and create a “soft landing” for the economy “That thinking is optimistic, but the minister of finance has committed to measuring today that will help those who need help the most,” explained the two associations in a joint statement.

Apprenticeship loans will be permanently interest-free in Canada after the release of the Fall Economic Statement on Nov. 3.

By Leah Den Hartogh

By Leah Den Hartogh

The Canadian economy is expected to fall into a recession in early 2023. According to the Fall Economic Statement (FES), which was released on Nov. 3 by Chrystia Freeland, deputy prime minister and minister of finance. And there is some positive news in sight for Canadians the Bank of Canada expects inflation to decline to 3 per cent by late 2023. Currently, it sits at around 6.9 per cent.

“While inflation is lower in Canada than in many of our peer countries, I know that fact brings little comfort to Canadians paying higher prices at the checkout counter, or

The FES lists inflation as the top global economic challenge largely due to imbalances between supply and demand. These imbalances stem from a series of global supply shocks combined with rebounding demand, which is driving up prices for goods and services. “It’s important, as both the Deputy Prime Minister and the Minister of Finance, that I’m honest with Canadians about the challenges that still lie ahead. Interest rates are rising as the central bank steps in to tackle inflation and that means our economy is slowing down,” states Freeland. “It means business is no longer booming in the same way it has since we left our homes and went back into the world.” As Freeland puts it, the upcoming global slowdown is unavoidable.

As part of the FES, there are several changes coming to the housing market, which will aim to “make housing more affordable.” The statementreiterateslegislationthatwaspassedin parliament in June 2022 that implemented a two-year ban on non-Canadian purchasing residential property in Canada, effective Jan. 1, 2023.

Following the release of the Fall

Totally reinvented fire tube technology from the ground up and we continue to advance our compact boiler performance to the highest levels

• Patented stainless steel fire tube heat exchanger— designed to reduce high stress point welds

• Advanced user interface with intuitive text display and Quick Dial Wheel

• Smart controls with Setup Wizard to simplify boiler start up and trouble-shooting

• AFUE 95.0%—Energy Star certified

• Compact, light weight, wall hung design saves space over traditional floor standing boilers

• Built-in 3 zone pumps or 3 zone valves powered connections

• Optional NaviLink® Wi-Fi remote control

• Common venting up to 8 units and cascading up to 16 units

• Up to 15:1 turndown ratio

To learn more about the new NFB-H high capacity boilers visit Navieninc.com

The leader in condensing technology...does it again.

Economic Statement, the federal government has stated they plan on tabling new legislation. This would create a new Tax-Free First Home Savings Account, and doubling the FirstTime Home Buyers’ tax credit. Additionally, the government stated that they would like to “ensure that profits from flipping properties held for less than 12 months are fully taxed, starting in 2023, with certain exceptions for unexpected life events. This measure will ensure that investors who flip homes pay their fair share, and play a role in lowering housing prices for Canadians.”

There are many exciting elements to the fall economic statement. However, for some, there are a few that deserve the spotlight specifically. “The two most exciting announcements today for CIPH and MCAC are the elimination of interest

on the Canada Apprentice Loan and new investments to modernize National Research Council facilities. Minister Freeland has telegraphed other major investments to come that will ensure Canadian businesses and workers are well-funded for the energy transition, but those investments will come in the spring when they are more likely to stimulate the economy,” shared CIPH and MCAC.

There is hope that the removal of the interest on apprenticeship loans will help keep tradespeople in the classroom and finishing their ticket. Additionally, the National Research Council is receiving $962.2 million over eight years towards the council’s scientific infrastructure.

It appears that most within the industry are content with the direction the fall economic statement has Canada leading. The Heating, Refrigeration, Air Conditioning Institute of Canada (HRAI) welcomes the measures included in the statement that will support

a net-zero initiative. “These include a 30 per cent tax credit for investments in low carbon heating technologies, such as air source heat pumps, ground source heat pumps, active solar heating and electricity storage technologies,” shared Martin Luymes, VP of government and stakeholder relations at HRAI, in an email. “More importantly, the industry acknowledges the government’s commitment to investing in the workforce of tomorrow, via the Sustainable Jobs Training Centre and via efforts to beef up immigration efforts focused on skilled trades. These investments will assist the HVAC/R industry in meeting the challenges of the transition to a low-carbon economy.”

The Sustainable Jobs Training Centre is set to develop curriculum, credentials, and on-learning for 15,000 workers to upgrade or gain new skills for jobs in a low-carbon economy, with areas of high demand such as low-carbon buildings and retrofits taking priority.

Our mission? Offer safe products, manufactured in Canada, that stand out in the market by their outstanding performance, their sustainability and their components increasingly more environmentally friendly. Our automated plants enable us to revolutionize the industry with competitive products that meet your daily hot water needs !

For more information, contact your local representative.

North America’s largest HVAC/R trade show has announced the winners of its coveted Innovation Awards. The International AirConditioning, Heating, Refrigerating Exposition, or better known as the AHR Expo, will return to the Georgia World Congress Center in Atlanta, Georgia, from Feb. 6 to 8.

The Innovation Awards is broken into 10 industry categories, including building automation, cooling, heating, indoor air quality, plumbing, refrigeration, software, sustainable solutions, tools & instruments, and ventilation.

“The awards program experiences growth year-on-year,” said

Mark Stevens, show manager of the AHR Expo. “This is a direct correlation to just how fast our industry is growing through innovation. The awards are a key indicator of how HVAC/R is being called upon to solve worldwide issues at a rapid pace. We aim to highlight this innovation trajectory and honour those that are pushing the bar to create real solutions to difficult problems.”

Entrants are evaluated based on overall innovative design, creativity of the product or service offered, product or technology real-world application, as well as overall potential market impact, reports the show.

Building Automation: Cielo WiGle Inc. (Bo oth #C6700) — The Cielo Breeze Max is a smart thermostat for mini-split, windows, and portable air conditioners. It is equipped with an auto-detection algorithm that automatically detects any air conditioner brand or model, making it universally compatible with over 200 brands and over 5,000 air conditioner models. It works with a 5V adapter or can be hardwired through 12/18/24 volts AC or DC. Max is compatible with Amazon Alexa, Google Home, SmartThings, IFTTT, and Siri shortcuts.

Cooling: Chemours (Booth #C6425) — Chemou rs introduces its Opteon XL41, a non-ozone depleting, low global warming potential refrigerant replacement for R-410A in residential and light commercial air conditioning and scroll chiller applications. It provides 78 per cent GWP from R-410A, while remaining compatible with all R-410A residential and commercial applications and lubricants.

Heating: Copeland (Booth # B1839) — Copeland’s new ZPSK7 scroll compressor is a product line of 1.5 to five-ton two-stage compressors ideally suited for residential and light commercial HVAC applications. These compressors can operate at 100 per cent capacity or as low as 65 per cent capacity based on heating/ cooling demand. When partial load is needed, bypass ports inside the compression chamber open, which partially unloads the compressor. When demand increases, the modulation control valve is activated, sealing the bypass, and shifting capacity to 100 per cent.

Indoor Air Quality: Belimo Americas (Booth #B315) — Belimo’s new room sensors can measure temperature, humidity, dew point, and CO2 with or without an ePaper touch display. Integrated near-field communication provides easy field adjustability, commissioning, remote display capabilities, and troubleshooting even without power. Non-powered configuration allows it to be set up before installation.

Plumbing: Caleffi (Booth#B3317) — The PresCal HP piston-type pressure reducing valve by Caleffi ensures stable water pressure control while withstanding inlet pressure or punishing downstream water hammer. It’s ideal for staged pressure control or more demanding applications that are fraught with extreme pressure fluctuations. The high-range model serves as a first stage PRV in a two-stage application. The lowrange model serves as a second stage, or as a stand-alone PRV for pressure spikes.

Refrigeration: Retail Solutions (Booth #B1839) — The Copeland ZFW variable speed scroll solution includes brushless permanent magnet motorbased scrolls, and variable frequency drives targeted for low-temperature, stationary refrigeration applications. It has a speed range of 1,000 to 7,000 rpm and is universally applicable for fans, pumps, and other electric motors. Available with A1 refrigerants and, moving forward, A2L approval by 2024.

Software: cove.tool (Booth #B4561) — Built for mechanical engineers, the loadmodeling. tool establishes peak cooling and heating loads to design and size the mechanical system using the EnergyPlus engine. As it is web-based, mechanical engineers can access the tool anywhere, including results, which means large files won’t have to be shared manually. Multiple engineers can also simultaneously work on the platform.

Sustainable Solutions: Taco Comfort Solutions (Booth # B1639) — System M is an air-to-water heat pump system that can provide heating, cooling, and domestic hot water. The outdoor heat pump integrates with Taco’s indoor HydroBox to provide a complete system with only six pipe connections required. A plug-n-play appliance, its packaged design makes installation less intrusive, with no refrigerant or gas lines needed.

Navac (Booth #C6364) — Navac introduces its new NEF6LM BreakFree power flaring tool. It is designed to perform reliably in harsh environments and is equipped with a rechargeable battery. Navac’s BreakFree tool delivers fully automatic flaring operation and reduces the refrigerant leaks in HVAC systems.

Ventilation: SmartD Technologies (Booth #5948) — SmartD’s Clean Power VFD integrates wide-bandgap semiconductors into its multi-level inverter architecture and combines them with patented modulation algorithms to produce a pure-sine wave electrical signal without the need for external filters.

“Wearethrilledtocelebratethisyear’swinners aswellastocontinuetochampioninnovation among our industry professionals,” said Stevens. “In the last few years, HVAC/R has taken on a wider audience outside of our direct industry stakeholders. It is refreshing to welcome an understanding of the value HVAC/R brings to the world in essentially every factor of daily life.”

Submissions are judged by a panel of thirdparty judges made up of ASHRAE members. Entrants are then evaluated based on overall innovative design, the creativity of the product or service offered, application, and potential market impact.

Each winner will also be eligible to win Product of the Year, which will be announced during the show.

In order to qualify for the Innovation Awards, exhibitors must have products featured at the show. Exhibitors are permitted to submit one product per category. However, the same product may not be entered in multiple categories. Funds raised from the entry fees of the competition will be donated to the Atlanta College and Career Academy, and Atlanta-based technical high school. The 2022 AHR Expo in Las Vegas raised $25,000, which was donated directly to workforce development program and was used to support a local dual-HVAC high school.

The climate within a geographical area will determine when an HRV or ERV is the best choice for the installation.

By Francesco Lo PrestiThe most basic approach to improve the indoor air quality within a space is to open the windows and let in some fresh air. According to Gord Cooke, president of Building Knowledge Canada, “The first building code stated in as many words, thou shalt have windows in every room and people should leave the windows open most of the time”

This standard has been a fairly common practice for getting fresh air inside a home. And as much as this principle will likely be here to stay, as we all know, times change and evolve. Better solutions have come about with the improvement of mechanical ventilation.

Since 1995, the National Building Code of Canada has had comprehensive requirements

for continuous mechanical ventilation devices to provide fresh air capacity year-round. Around 22 years later, with the adoption of energy efficiency requirements within the Ontario Building Code, heat recovery ventilators (HRVs) became effectively mandatory in all new homes.

When HRVs are brought up in conversation, it is only natural to get into energy recovery ventilators (ERVs).

When discussing ERVs, we first need to understand the overall history of heat exchangers. “HRVs were referred to as heat exchangers and the first ones developed in Canada for residential applications were always associated with energy-efficient housing programs such as the R-2000 program. So, you’d have a sheet metal box with one fan taking stale stinky air out of

Continued on page “17”

the house and one fan bringing fresh air in from outside through the heat recovery core, recovering approximately 70 per cent of the waste heat from the exhaust air,” explains Cooke. “ERVs use the same two fans and pull new air into a home while taking stale air away, but in addition to recovering the temperature difference between the two air streams, the ERV core was able to transfer moisture from one air stream to the other which was an advantage specifically in hot, humid weather to reduce cooling loads”

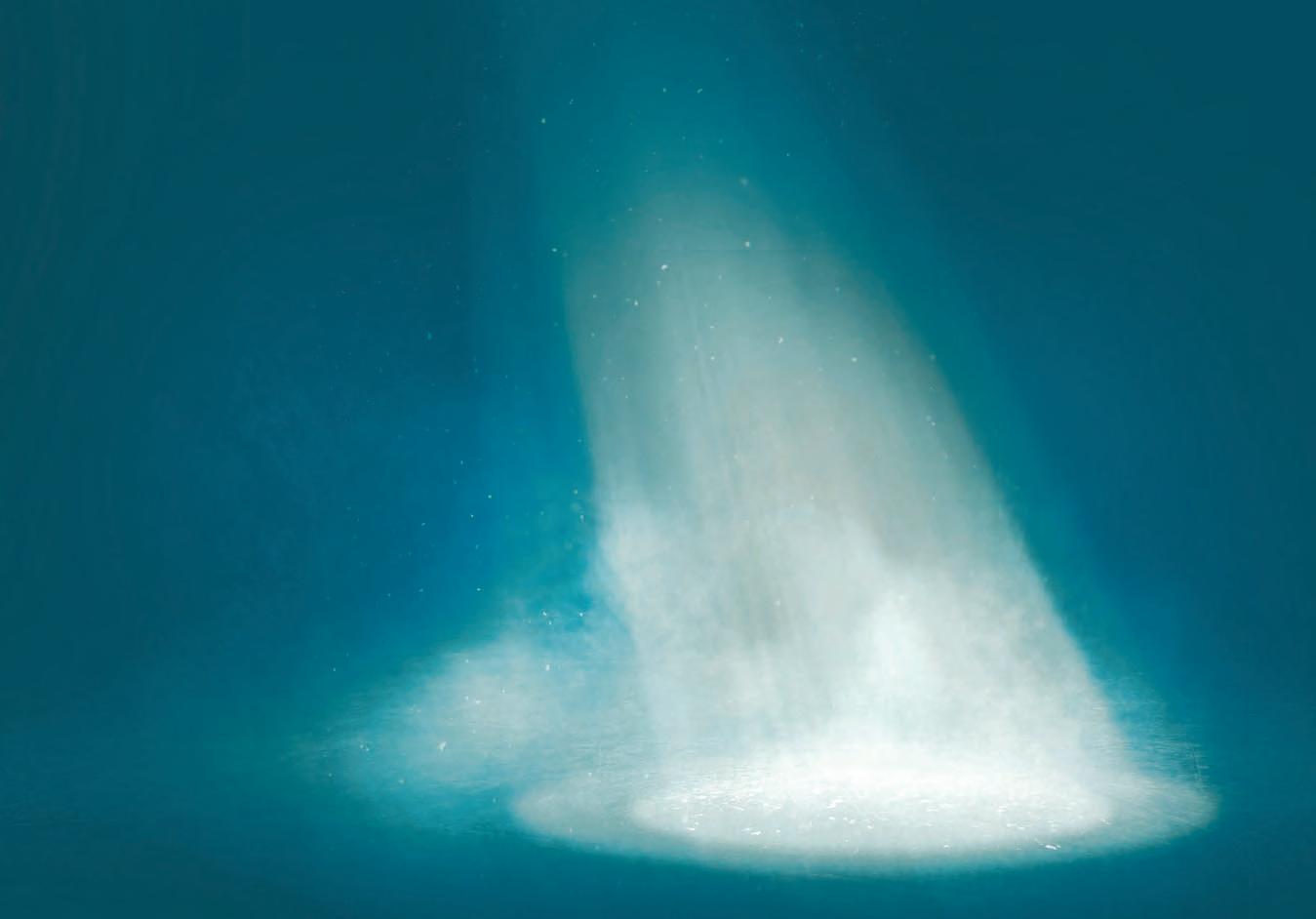

Both systems are very similar in construction and operation. However, the main difference between ERVs and HRVs is that essentially, “HRVs core can exchange heat, whereas an ERVs core can exchange both heat and moisture between the air streams,” explained Bruno Poitras, North American product manager of indoor air quality solutions at Fantech. Looking under the hood of an ERV system, “The core in an ERV is made of a permeable material that

recovery ventilators can exchange both heat and moisture between the air streams. Photo provided by Carrier

Miltenburg, Carrier’s residential product manager, explains, “It all depends on your climate. Typically, ERVs are used more in warmer climates. Traditionally, Canada has

instead. Ongoing research may change the currently recommended zones, but it’s best to follow the manufacturer’s specifications.”

allows moisture to move from the higher humidity stream to the one with lower humidity, equalizing the incoming air’s humidity,” explains Poitras.

This or that With ventilation required in all homes, some customers may ask, “Which system should I use? An HRV or ERV?” As Jean-Paul van

fewer zones to use ERVs. There are a few zones that allow adequate energy transfer. For example, these zones would be in the southern areas of our provinces, and coastal provinces. But once we get further up north, we have shorter summers and less humidity in the air, and the ERV may not be used to its potential or be subject to the core freezing, and that’s where an HRV could be used

When it comes to which is the better choice for an application, the home’s needs to come into play, “Whether it is an HRV or an ERV, it will depend on the circumstances of the home and the climate conditions. Several factors must be taken into consideration — the number of people living in the home, the number of washrooms, and the amount of water used,” said Christian Romeroll, vice president of the HVAC division and sales at Napoleon. “For example, for a family with three teenagers who utilize a high amount of water, the home will need a unit with a higher number of CFM to correctly transfer ventilation and control humidity in the house.” He adds that HRV and ERV sizes range between 90 and 150 CFM. Continued on page “19”

Flat out ask their customer, how often do you want fresh air in your home? In most cases, they will answer all the time, and that’s when you inform them about ERVs.Energy

An ERV can be seen in a home’s mechanical room as one part of a total home heating and cooling system.

Continued from page “17”

When trying to promote the benefits of an ERV system, an essential thing any contractor can do “is flat out ask their customer, how often do you want fresh air in your home? In most cases they will answer all the time, and that’s when you inform them on ERVs,” said Cooke. The benefits of an ERV system are apparent. They provide “fresh, clean air inside of a home. ERVs are recovering around 70 to 80 per cent of the temperature in the winter and around 60 to 70 per cent in the summer,” said Cooke. ERVs can be used in both seasons as, “The cold fresh outside air is humidified in the winter, preheated by the outgoing, warm interior air. In the summer, the fresh, warm, humid outside air is precooled and dehumidified by the outgoing air-conditioned interior air,” said van Miltenburg.

A home is always vulnerable to contaminated indoor air quality. “For the most part, the air outside is fresher than inside. Inside air becomes contaminated by various elements, for one, us humans. Then you have the various materials being spread throughout the house. Like your deodorants, pet dander, and also the toxins coming from carpets, paints, etc.,” adds Cooke.

The air found in homes is becoming staler and this is also a result of innovation, as “Homes are more airtight than ever, but this also increases the potential to have stale indoor air, and this is where HRVs and ERVs can help balance this out,” said Romeroll.

When trying to weigh the benefits of installing an ERV system, it’s crucial to understand which type of system you will install, as they all serve different purposes depending on the home’s needs. There are three types of installs regarding HRVs ERVs — “First, you can do a simplified install, which is ideal when you have a fully furnished heat pump that is fully ducted to your home. HRVs would be ideal in this scenario. Then you have a partially dedicated install, which an ERV would work best as you will pull from the bathrooms and the kitchen. Those often have more moist air. Lastly, there’s the fully dedicated install, where essentially, you’re pulling from the same areas, but you’re distributing the air from the HRV or ERV directly into the living spaces,” explained Poitras.

While ERVs can provide homeowners with many benefits, the system can present some challenges for the contractor during the installation, especially in retrofit projects. “For example, when an HVAC system has already been set up, the contractor has to plan and think about where to put the ERV system and its connections,” explained Cooke.

Even in the more basic installs, both HRVs and ERVs require new ducting and low-voltage control systems, explains van Miltenburg. “You must plan where to put the drains, upsize existing fresh air intake, route new exhaust, and ensure you’re using properly insulated ductwork.”

Additionally, there are telltale signs homeowners should know when it comes to the maintenance of an ERV system, “If your system’s filters are dirty, your house will have no ventilation and you can tell when you get that musty smell. Also, suppose your unit is running at a higher speed, in that case, let’s say in the summer, sometimes your system can over-ventilate, and you’re going to notice your floor or building materials begin to swell because there is too much moisture inside the home,” explained Poitras.

No matter which system you choose, the first and most important thing to remember is your customer’s needs. “It’s about the relationship between a contractor or dealer and the homeowner. Homeowners want information, choices, and they want their needs met. Our job is to provide our customers with just that. We provide information, choices and help homeowners through dealers and distributors figure out what’s best for their needs,” said Romeroll. :

If you are old enough to remember playing in the streets till the streetlights came on, then you must remember playing red light–green light. It was our introduction to learning when it was safe to run, walk, and, most importantly, when to stop. Throughout this article, we are going to use this analogy to manage the ability to grow our business. We will learn when to grow aggressively, when to grow cautiously, and when to slow it down to a crawl.

Remember from the last issue, our quest is to build new past customers. So, walk and capture as many long-term customers as you can. The customers that can bring in $10 a month for the next twenty years are more valuable than the one-off ones. Monthly pay is the way to play.

Continued on page “23”

- PROductive with fast installation

- PROvides for 95% of applications

- PROactive with dedicated support

- PROmote an iconic, trusted brand

Learn about the industry’s most exciting new development at www.GEAppliancesAirAndWater.com/unitary

Our goal is to convert as many of the maintenance visits into “monthly club members” or MCMs. If your first-year goal is to complete two hundred maintenances at $150, that equates to $30,000 in revenue. If you convert 50 per cent into MCMs, that is an additional $9,000 per year or $39,000 in year one; do that for the next 10 years at the same rate of conversion, and the five-year revenue is a staggering $285,000.

This does not include any extras or replacements. Based on 500 MCMs, you should be able to count on an additional $425,000 in replacement opportunities per year.

Cash on-site customers are only your customer until you walk out the door. Our ex-utility, now retailers, figured this out a long time ago. They captured over 50 per cent of the households in Ontario. Do the math. That leaves half of the homes still up for grabs. By having the customer become an MCM, the relationship has a certain amount of bonding.

What should an MCM package look like? It could look like discounted rates, modified ranking in scheduling, or additional monthly specials. Be creative and think like a retailer. At this point, you should have your maintenance plan, your MCM package, and even multi-level incentives. Now what?

if they sign-up for an MCM. Then collect the fees and paperwork. Not every repair can be solved with a tune-up, so train accordingly. We don’t want $300 repairs turning into $150 maintenance.

A typical example may sound something like — “The cause of the failure is due to a dirty flame sensor. The fee to remove and clean the flame sensor is $X. However, the dirty flame sensor is a sign of a lack of maintenance. It also indicates that other areas of the furnace need attention. I suggest that rather than spending $X to just clean the sensor, for an additional $50, we could perform a complete tune-up on the entire piece of equipment. How would you like me to proceed?”

Wait and listen. If approved, then proceed and invite them to stay while you do the work. Conclude with, “Now that we have the unit tuned up, I highly suggest that this be performed on an annual basis so as not to create an untimely call out again. We have an MCM plan that is only $10 a month and it comes with all these benefits plus a tune-up once a year. The good news is that you can save $50 on today’s visit by taking advantage of this offer. How would you like to proceed?”

Assess your program with your staff to ensure everyone under your roof believes that the product you are presenting is a huge benefit to the customer. Seeing is believing and believing is seeing.

If you think it will be a cakewalk, it will not. It is a major cultural shift for everyone. Switching from the get-in/get-out mentality is a change of our basic nature, especially for the veteran technicians that might be on staff.

As technicians, we were trained to fix everything and maintain nothing. When we get to the home, typically, we would head straight to the basement to fix the problem. After, you’d leave and head onwards to the next call, while revenue is collected by the office.

Business has shifted and this approach doesn’t work anymore. We need to build relationships and communicate effectively with our customers, limit our service calls to no more than five per day, and engage the customer on the importance of scheduled maintenance. Nowadays, the technician should invite the customer into the basement, create an invoice before the repair is completed, explain the possible savings if they have an MCM, and offer a deep discount on the tune-up

from page “23”

So what if they say no? Once the technician returns with the service order and cheques, have your customer service representative reach out — “I noticed you didn’t take advantage of the $50 savings yesterday. Before I process this invoice, would you like to reconsider? I would simply apply the payment to the invoice and the balance would prepay your plan for five months. Your first payment would come out on the 15th, six months from now.”

After a year of practice, the MCMs will start to grow and grow! It is not unusual for a company to have 4,000 to 5,000 MCM customers. They have a very strategic way of using MCMs to drive revenue. They don’t just schedule them based on a calendar date but strategically on their departmental needs.

Once you have an established number of MCMs, go through and colour-code them. Red for equipment under five years of age, yellow for equipment six to 10 years, and green for equipment that is over 10 years old.

When the company is steady in all departments, this should be when red MCMs receive their visits. This is for when there are several MCMs due, and you want to put technicians on full-time. But this does leave the opportunity to sell add-on products.

During slow service times, look to yellow to fill up the service schedule. These are the MCMs that are going to drive service. At this point in the equipment’s lifespan, they are starting to age and reach the end of its warranty period. Preventative warranty service would be in the best interest of the customer. Add-ons are always an opportunity.

When installations are slowing down, green MCM equipment is coming to the end of its useful life. This is the time to start talking about replacements, heat exchangers failing, or expensive parts now out of warranty. If the unit checks out, leave the customer knowing that they are still in the clear. Your closing statement should be something like this — “I

would highly suggest you start to budget for a new system in the not-so-distant future. For now, you are good to go.”

More than anything else, make sure the customer believes that your work is done with their best interest in mind. The benefits will soon return to you tenfold! :

Glenn Mellors was born into a plumbing family and started in the industry in 1973. He entered the HVAC side of the business in the 80s, working in wholesale, and then joined Lennox in 1992. In 2008 he joined the ClimateCare Cooperative Corporation, an Ontario contractor group, where he is director of training and implementation. Glenn can be reached at gmellors@climatecare.com.

One way of categorizing monthly maintenance plans is by giving them a colour code based on the age of the system.

Three new thermostat models have been released by AprilAire, Madison, Wisconsin, under its new line of indoor air quality (IAQ) thermostats, the S86 series. Paired with a fan circulation mode, it also features a progressive recovery option to ensure proper temperatures for the start of an event or a Heat Blast option to raise the room temperature 3F to 5F. The S86 series includes multi-stage universal, multi-stage universal with IAQ that offers ventilation, dehumidifier or humidifier controls, and a Wi-Fi multi-stage universal with IAQ. AprilAire www.aprilaire.com

Saniflo’s, Cambridge, Ont, Sanicompact toilet can be installed quickly and easily, anywhere in the home with no venting required. In addition to handling toilet waste, the toilet can pump water away from a nearby sink. It combines a macerating pump and a tankless toilet bowl into one single fixture. The toilet operates with only 1 to 1.28 gallons of water per flush. Saniflo www.saniflo.ca

SharkBite, Vaughan, Ont, introduces new pushto-connect PEX technology with the SharkBite EvoPEX. Ideal for new residential plumbing systems, the EvoPEX requires no tools to install and can be rotated after installation. A green visual indicator on the connector appears when the tubing has been inserted to the proper depth. sharkbite www.sharkbite.com

Oatey, Cleveland, Ohio, introduces its new SquareDrain point drain, which is an extension of its QuickDrain total shower solution. The point drain system is designed for both curbed and curbless applications. Ideal for residential uses, it features a patented universal flange adaptor. Once installed, the drain system allows for easy maintenance with a debris basket and cover key included. Oatey www.oatey.ca

So far, I have been focusing exclusively on hydronic heat pumps, both air-to-water and geothermal. But I felt it was time to break the thing up a bit. This time around, I wanted to dive into some of the most common hydronic misapplications or “party fouls,” that I have seen over the years.

Right out of the gate, I wanted to highlight the consequences of oversizing equipment. Oftentimes in the field, I will come across projects where for whatever reason the principle “bigger is better” has been carried out. That only counts with Monster Trucks

turndown. It is sized for the domestic load, not the heating load, which is typically smaller. The turndown on modern boilers means that when the home needs 14,000 btu/h, the boiler can modulate. And when we have domestic calls, it can ramp up and quickly charge your indirect hot water heater.

These are in no particular order and intended to help technicians think on their feet and come up with their own scenarios, which I hope you will share via email with me. I have made a list of hydronic installation party fouls, but I am quite sure the list could easily have been significantly longer.

and ice cream cakes. Oversizing equipment happens frequently, and typically, people will use the turndown ratio as the reason why the oversized boiler won’t hurt anything.

I quite frequently see homes that are going to get a complete hydronics package, and the boiler ends up being 115,000 btu/h with a 10:1

As soon as a swimming pool comes into play, we immediately see people bumping the boiler up to a 399,000 btu/h boiler. So, what’s wrong with that? Well, we immediately just made the project much more cost-prohibitive — bigger venting, bigger pumps, bigger pipes, and more expensive replacement parts.

The reality is that you don’t need anywhere near that big of a boiler, much less a second boiler to heat the pool. Remember, in the

Bigger doesn’t always mean better when it comes to sizing hydronics.

Michael Ridler

There is also the belief by some that plastic pipe is safe without glycol and that it won’t fail since it can’t expand and burst in concrete. That is simply not true.

summertime, your boiler that was heating your home is now chilling in the basement and looking for a summertime hobby. Why not heat your pool with it?

In my own home, I have a pool that is roughly 25 ft. by 15 ft. and a six-ft average depth. That makes the total pool volume roughly 16,875 gallons. Lifting the water from 50 F to 70 F over a day would take 93,825 btu/h. No need for a second boiler, much less a bigger boiler.

The one that always boggles my mind is when someone thinks they don’t need glycol in the system. On two separate occasions, a contractor friend of mine ran into garage radiant floor circuits without glycol. The way

that some try to get around the lack of glycol is by continuous circulation of the pumps. If there was a power outage, they would be able to quickly discover why this solution doesn’t work.

There is also a misconception that plastic pipe is safe without glycol and that it won’t fail since it can’t expand and burst in concrete. That is simply not true.

If that were the case, we would not see jobs with burst pipes in concrete. When a plastic pipe filled with fluid freezes inside, a concrete slab may not be able to expand uniformly, which will result in damage such as splitting in the plastic tubing.

Even if the concrete did have a void where the pipe can expand, you assume wrongly that the pipe cannot have an ice dam form inside

it, which would build pressure to the point where the pipe will fail.

To put this one to bed, CSA B214-21, Clause 13.3, requires freeze protection in hydronic systems when installed in locations where it can freeze. The hydronic system needs to be designed around end users not understanding how the system operates. And remember that one day the homeowner may sell the house one day, and the new homeowner might not inherit this knowledge with the sale.

Continued on page “31”

One of the things I like to do when I get invited to go to a job site with a contractor is doing a few checks. The one that commonly is overlooked is the outdoor reset. I know that on some boilers, the outdoor reset can be a huge pain to set up, but as boilers get more and more advanced, it is getting much easier.

Modern condensing boilers can have their outdoor reset settings programmed quickly. Even the most novice technician will end up with a boiler that is adequately saving fuel and delivers comfort.

Without utilising outdoor reset, we forget that we are impacting comfort. The number one thing that we are supplying with our systems is indoor environmental quality, or in more simple terms, comfort. If we are pumping out 140 F water when we only need 100 F water, we will overheat spaces, which will impact comfort and reduce system efficiency.

For every 4 F, you reduce your boiler water temperature, you can expect to see savings of one per cent. This might not seem like much, but amplify that over 10 years and keep in mind the skyrocketing costs for fuel.

It is not even a matter of the cost of the reset controls at this point since most modern condensing boilers typically come with the sensor. In scenarios where you are doing a retrofit and can not get a wire to the right side of the building, there are some well-designed wireless sensors in the market.

Piping a heat pump like it’s a boiler is another common installation mistake seen in the industry. Oftentimes where we go wrong is with the application of the math for sizing piping on a heat pump. I went into more detail about this in a previous article (Heat Pumps are not Boilers in September 2022).

Let’s take a 60,000 btu/h boiler. To size the tubing, we first need to figure out the flow rates using a typical Delta T of 20 degrees. By doing this, we get 60,000 / (500x20), which equates to six GPM. This fits almost perfectly with a 3/4-inch copper piping at 3 .94 ft. per second.

Where things go wrong with a hydronic heat pump is mistakenly assuming that you can achieve a 20-degree Delta T. Many hydronic heat pumps can only lift the water five to eight degrees. If we redo that formula for a hydronic heat pump, 60,000 / (500x8) = 15 GPM.

If we try to feed 15 GPM through a 3/4-inch piece of copper, we have a flow velocity of 9.83 ft. per second, which is far exceeding the flow velocity suggested for the copper pipe on a hydronic system.

Best of all, you have inadvertently put a choke point into your system, which in many cases results in catastrophic equipment failure. Many times a year, I am forced to condemn a hydronic heat pump system that has been piped this way.

A lot of manufacturers will publish their flow rates in their manuals, so I’d suggest referring back when need be.

I can tell you that just about every item listed here has happened to

Some technicians try to get around using glycol within the system by continuous circulation of the pump, but the dilemma with this approach is that if there is a power outage, the pumps would stop operating and the likelihood of freezing within the piping drastically increases.

me firsthand, and in some cases from doing them myself. Together as an industry, we need to recognize our strengths, work on our weaknesses, and collaborate to positively grow the industry.

There are so many talented designers and installers reading this article, and I would love to see you engaged and involved, not only just in installations, but in guiding training and the future of our industry. We will go into some more party fouls in Part 2. :

Michael Ridler is a technical services manager at Eden Energy Equipment. He started out working for a Ont-based HVAC company and now focuses on providing field support and technical training to contractors, engineers, and builders on heat pumps, boilers, and all things hydronics. He can be reached at edenenergymike@gmail.com

Presenting a collective brand family of mini-split and VRF products. What does this mean to our distributors and contractors? All Halcyon products will now be referred to as AIRSTAGE H-Series, and all VRF products will remain AIRSTAGE V-Series and J-Series. With exciting things to come, AIRSTAGE takes promise for the future.

Visit fujitsugeneral.com

General Pipe Cleaners, McKees Rocks, Pennsylvania, announces a new solution for clearing tree roots and other stoppages in three-inch to 10-inch lines up to 100 ft. long with the Speedrooter 92. Power cable feed drives and retracts cables up to 20 ft. per minute and a guide tube boosts cable efficiency and operator safety. The cable size can be adjusted by turning the knob atop the feed with no screwdriver or special tool required. It features a braced frame at key stress points, 1/2 hp motor, toolbox, and 100 ft. of 3/4-inch or 5/8-inch Flexicore cable.

General Pipe Cleaners www.drainbrain.com

Ridgid, Elyria, Ohio, introduces the AC840080 18V 8.0Ah max output EXP lithium-ion battery. It utilizes advanced intelligent electronics to communicate directly with the battery cells to optimize performance when paired with brushless tools. This battery features ThermaGuard technology, which uses these electronics and oversized heat sinks to protect the cell’s performance. This battery is compatible with all Ridgid 18V tools.

Ridgid www.ridgid.com

Teledyne Flir, Wilsonville, Oregon, announces its Flir One Edge Pro, a wireless thermal visible camera for mobile devices. Unlike its predecessors, the Flir One Edge Pro doesn’t need to be physically connected to its companion mobile device nor does it have separate models for specific operating systems. It has a spring-loaded clip designed to allow operators to attach the camera to many types of mobile phones and tablets. Its MSX patented image enhancement feature overlays the edge detail of the visible camera onto the thermal image.

Flir www.teledyneflir.com

alternative to sheet metal return air frames

Filtered and windowed models keep system clean during rough-in

and trusted since 1992

‘Anywhere you can pan a joist space, you can use our Thermopan.’

Our Mechanical Contractor Hub was built for you thermopan.ca

Linesets, PVC, PEX and more UV protected for outdoor use

‘So easy, one person can hang a lineset.’

Solstice N40 (R-448A) offers 5-10% lower energy consumption, a 68% reduction in global-warming-potential and lower environmental impact on the planet. Solstice N40 is approved for use by all major compressor and component manufacturers, and is a near-drop-in replacement for R-404A, allowing for easier installations and conversions. Talk to us today to find out more.

For more information visit: https:www.honeywell-refrigerants.com or Call 800-631-8138

When energized, a solenoid causes the valve to close, which allows hot gas to flow in the opposite direction up the suction line.

By Greg Scrivener

By Greg Scrivener

Evaporator pressure regulators are pressure regulators used in the suction line, leaving an evaporator to control the pressure. This means that they are inlet pressure regulators. They take the pressure input from the inlet piping and open/ close the valve to maintain a set pressure. The valve outlet pressure always has to be lower than the inlet pressure otherwise there will be no refrigerant flow. There are a couple of reasons why you may want to control the suction pressure in an evaporator.

In commercial refrigeration, these valves are most commonly referred to as evaporator pressure regulator (EPR) valves and occasionally as ORITs (based on a common model nomenclature). In industrial refrigeration, they are usually only referred to as suction pressure regulators or simply suction regulators.

Recall, of course, that by controlling the pressure in the evaporator, we are controlling the temperature in that evaporator. This type of

control may be desirable or necessary for several reasons, including preventing ice formation on an air evaporator and minimizing defrost, preventing freezing in a chiller, or controlling the temperature of the evaporator to minimize product impact.

Continued on page “37”

Figure 1: Here is an example of a basic refrigeration system with no EPR valve.

By controlling the pressure in the evaporator, the technician is ultimately able to control the temperature in the evaporator.

Continued from page “35”

First, let’s take a look at the simple refrigeration system in Figure 1. In this system, the evaporator pressure, and therefore the temperature, is only a factor of the refrigeration system balance. If there is a decrease in load at the evaporator, less refrigerant will boil. The compressor has to move the same amount of refrigerant as the evaporator boils for the pressure to stay constant. That way if the evaporator reduces how much refrigerant boils, the pressure will drop until the flow balances. This happens because as the refrigerant pressure falls its density also decreases. Since the compressors we use are constant volume pumps, a lower density means less mass is moved through the compression each stroke or cycle. The condenser will reject the heat that was absorbed in the evaporator combined with the heat that was added during the compression.

In many refrigeration systems, the basic system described above works perfectly fine because as soon as there isn’t a load at the evaporator, the temperature is low enough that the system shuts down (or that evaporator shuts down at least). However, in some cases, this decrease in pressure and temperature is not acceptable. Consider an application with sensitive products like flowers. In some of these applications, we want to make sure that the air temperature off of the evaporator never decreases below a certain point. In order to do that, we can add a pressure regulator in the suction line, as shown in Figure 2.

This pressure regulator functions by adjusting

to match the inlet pressure setpoint. Mechanical valves use a spring and bellows so that when the pressure drops below the setpoint, the valve is completely closed. As the pressure increases above the setpoint, the valve opens, depending on its sensitivity, until it is fully open.

Figure 2: Here is a basic refrigeration system with an EPR valve.

Using R507 as an example, if we set our EPR from Figure 2 at 76 PSIG, we would be assured that the evaporator coil never reached a temperature below 32 F. In fact, it would be at almost exactly 32 F whenever it was running, and this provides very consistent air temperature leaving the coil. Consider a water chiller as opposed to an air coil in this application. The evaporator temperature mustn’t go low enough to freeze the water. Water chillers also often must operate in a very large range of capacities and have compressors with unloaders and other capacity control. This means they are at fairly high risk of being in a situation where there is an imbalance between the compressor and evaporator that causes the pressure to decrease.

Similarly, it is usually desirable to reduce the amount of frost that builds up on an evaporator. In the case of an air conditioner that isn’t designed to handle any frost, an EPR can be used to maintain adequate suction pressure to prevent frost from forming at all. Employing an EPR in this way for air conditioning is not typical since most air conditioning systems can operate fine without this extra control but they are used on some specialty air conditioners. It is more common to see EPRs used on a system with multiple evaporators operating at different temperatures, as shown in Figure 3. It is possible to refrigerate a space

Continued on page “39”

Strategically employing EPR valves can improve the operation of complex refrigeration systems.

Continued from page “37”

to 35 F using a -20 F coil. However, the amount of frost that collects on a coil increases with a decrease in the coil temperature, and coincidently, this also results in low humidity in the space since more water is removed. In order to prevent this, an EPR can be used to maintain a higher temperature in the coil.

Figure 3: An EPR can be used to maintain one evaporator at a higher temperature.

Other than the obvious fact that using an EPR increases the cost of the system, there are two main drawbacks to using an EPR. The first is that there is always an energy penalty when you use a pressure regulator on a suction line. At full load, you have introduced a pressure drop that wouldn’t otherwise exist in the line, and if you recall the rule of thumb, for each 1 F SST equivalent in pressure drop, there is about a two per cent energy penalty. For our R507 example, that means if this regulator introduced a 1.5 psi pressure drop (which it likely would), there would be a two per cent energy penalty. The other drawback is a bit more subtle and applies mainly to systems with high peak loads. It is sometimes desirable to float suction pressures down to increase the refrigerated capacity of the evaporator. This can be done in modern refrigeration controls by decreasing suction pressure set points, which allows more compression (either with capacity control on a single compressor or by adding compressors). This option is not possible with standard EPR valves.

EPR valves are available with many options. Probably the most common is a combination EPR/suction stop valve that is used for hot gas

An EPR valve doesn’t always need a suction stop solenoid.

defrost. These valves include a solenoid that, when energized, causes the valve to close so that hot gas can flow in the opposite direction up the suction line. Hot gas valve groups will be a topic of a future article since there is not enough time to go into detail here.

Strategically employing EPR valves can improve the operation of complex refrigeration systems; while using EPR valves on every circuit is common practice in both industrial and commercial applications, there is a substantial energy penalty that ought to be considered. There are additional complications when using these types of valves with pumped liquid; things can become even more challenging when electronic suction regulators are used since they behave differently in power outages. As is often the case, there is a delicate balance between operation and energy and lots of things to consider. :

Greg Scrivener is the lead refrigeration engineer and a partner at Laporte Consultants, Calgary, and works throughout Canada and the U.S. He is a professional engineer and journeyperson refrigeration mechanic. He can be reached at GScrivener@laporteconsultants.com.

After three decades, Marie Li-Ying will be retiring and will be taking a welldeserved break.

After 30 years of working within the refrigeration sector, Marie Li-Ying announces her retirement from Honeywell.

By Leah Den Hartogh

By Leah Den Hartogh

t’s been quite a ride,” stated Marie Li-Ying, business manager of fluorine products at Honeywell. “I’ve enjoyed every minute of it. You’ve got the highs and lows, and interestingly, being with the same company for such a long period of time, I’ve been able to see how business has changed over the years.” Li-Ying has been with Honeywell for 30 years as she announces her retirement.

Overhercareer,shehasputplentyoftime and effort into volunteering at associations, including her work at Refrigerant Management Canada (RMC) It was her work with this association, managed by the Heating, Refrigeration, and Air Conditioning Institute of Canada (HRAI), that she received the Warren Heeley Environmental Achievement Award in 2021. She was instrumental in the creation of RMC, which is essentially an environmentally responsible program. It manages the disposal of Canada’s stocks of surplus halocarbon refrigerants for the refrigeration and air conditioning industries.

“You are well deserving of this award. On behalf of HRAI, we wish to thank you

Additionally, the work she has been a part of during her tenure at Honeywell has been something she is quite proud of, especially the amount of money the company has invested in research and development. “Overall, when you look at what the company has done with this new product, the HFO or hydrofluoro-olefin, it’s equivalent to like 688 million barrels of oil that you’re removing from the atmosphere.”

She initially joined Honeywell in the midst of the phasing out of CFCs. “It was quite hectic

very few could probably say that they have done everything that they’ve set out to do. “That goes part of always learning and wanting to do more,” she said. “I’m always surprised and humbled that anyone would ask me to be a role model.”

for the countless hours that you have spent volunteering your time and for helping Refrigerant Management Canada with our simple, easy to use, industry-wide collection program for the final disposition of the end of use of refrigerants in a safe manner,” said Caroline Czajko, director of environmental services and the manufacturing division at HRAI, in a video awarding the honour to LiYing.

According to Li-Ying, Refrigerant Management Canada is the first of its kind, worldwide — “Other companies, other countries have looked at it and it’s become something to be proud of as Canadians.” She is currently the past chair of the board of directors and previously was the treasurer for RMC.

initially and then it would slow down,” said Li-Ying. “It makes you feel good when you’re part of an industry that’s looking ahead at the environment in general. The sustainability of the product and what we can do to make sure that the carbon footprint that we’re leaving is responsible as well.”

Being able to pay-it-forward is something that Li-Ying has tried to embody in both her personal and professional life. During our conversation, she remained quite humble regarding the work she has done for the industry over the past three decades.

It’s to no surprise that she said that she hadn’t quite accomplished all that she could have in her career. But she did remark that

Growing up in a Chinese family, she said that oftentimes the males of the family took on the more dominant role, but that her grandmother was unique and ahead of her time. “Even as a female, you need to do the best you can and support yourself. You’re not supposed to be dependent on anyone just because you’re female,” said Li-Ying. “My mom and my grandmother were very great role models.” When she first started in the industry, she often found herself being the only woman in a lot of her roles.

It hasn’t always been easy juggling a healthy work life balance, especially over the pandemic,butsheislookingforwardto some“me time.” She and her husband are thinking about doing some renovations to their home. There has also been some planning to do some travel. “We love to see exotic places. We’vedoneafairbitof Europe,butwehaven’tdone much of Asia. So, we’re looking forward to doing more travelling.” :

A long-time volunteer within the HVAC/R industry, Li-Ying has worked closely with HRAI for many years.

It makes you feel good when you’re part of an industry that’s looking ahead at the environment in general.

Navac appoints Bryan Schwartz to the newly created position of national training manager. He will be responsible for training development programs, in-person and remote instruction, organizing education-relation projects and opportunities, and managing other Navac training personnel. Schwartz initially joined the Navac team in 2020, and prior to his time with Navac, he was senior national training manager for LG Electronics.

Centrotherm welcomes Eckhard Hilscher as the new regional sales manager, responsible for the east coast. He comes to Centrotherm after nearly two decades with Hart & Cooley , where he previously served as national accounts manager of the wholesale division.

Sauermann Americas announces the appointment of Wildon Sales and Marketing Inc. as its Canadian territory representative for combustion products. As the Canadian territory representative, Wildon’s team is set to develop new partnerships and contribute to Sauermann America’s combustion

product sales and business strategies in Canada.

Wolseley Canada opens a new branch in West Kelowna. Located at 1315 Industrial Road, the West Kelowna branch is a 17,000 sq. ft. facility that offers a full range of Wolseley Canada’s roster of plumbing and fire protection products, with HVAC products to be added over time. A formal grand opening was held on Nov. 17, while the new branch has already opened.

Equipco has announced several new associate partners to its team. Adam Hedden, Bryan Jones, Evan Cikaluk, Nick Bérubé , and Pierre Huneault will take on the role of associate partners. “As we celebrate 40 years in business this month, we also are looking ahead and planning for the next 40 years! Please help us congratulate Nick, Adam, Pierre, Evan, and Bryan for being selected as that “next step” and receiving the title of associate partner,” shared Equipco on its social media.

Interest rates have skyrocketed in recent months. Not only that, but the forecast for 2023 showcases further increases.

The good news is that Canada created 108,300 full-time jobs in October 2022.

The bad news is that 42 per cent of small businesses didn’t pay all of their rent in October, and September was almost as bad, according to an Alignable Research Center poll published in October.

A recent study by Statistics Canada shows that the country has a very low unemployment rate and that labour costs are increasing dramatically. These costs get passed on to the consumers and push inflation higher. The government counters this by pushing up interest rates, which in turn causes increases in wages, and so on.

The balance the government is aiming to achieve is to tame inflation without causing a recession. That is an extremely difficult task. We need to ensure that, while we hope for the best, we must plan for the worst.

The beginning of 2020 was very rosy. Nobody had any idea what the next two years were going to bring. Without financial aid from the government, I am sure many would not still be in business. It is highly unlikely that the government is going to bail us out in 2023. We are on our own and must plan accordingly. Running your HVAC or

plumbing business is akin to the feds aiming to balance inflation and recession. Difficult but not impossible.

Let’s explore interest rates first. Normally I advocate businesses and homeowners to go with variable interest rates. But, now that we need a better sense of stability, I would recommend that you lock in as much of your debt as possible for at least three years.

If you are going to borrow money, make sure that it will generate a positive cash flow. Buying new equipment and vehicles is an ongoing investment we make in our businesses. The cost of vehicles is at an alltime high, and operating costs are also rising rapidly. Explore not only the capital cost of a vehicle but the operating costs. We all know that electric vehicles are the way to go. So, buying a gas-powered vehicle now, which you will expect to use for at least five years, might not be the best decision. The availability of electric vehicles will be a lot better in two years. Maybe buy a used vehicle and keep it for two to three years. This also reduces your investment and interest charges and will reduce your operating costs when you get the electric vehicle. Only buy what you really need.

If your need is short-term, then do a short-

term rental or lease. Do an internet search or check with your association as there are companies that specialize in short-term rentals and leases. Can you rent the equipment you need? Can you defer the investment?

Apart from fixed (capital) assets, we also use lines of credit for financing our operations. That’s called working capital. There are several reasons we need working capital in our business. First, look at your current assets. The largest categories are likely accounts receivable and inventory.

Reduce your accounts receivable by being more persistent in your collections and by getting deposits. If you are doing new construction, monitor your holdbacks. Make sure you invoice all work at the earliest date possible.

There are two sides to inventory, which we covered this in a previous article. The balance is between carrying enough to service your customers in a timely manner and maintaining the lowest level to lower borrowing costs.

We need to have a contingency plan in case of a recession. We had enough surprises with COVID-19, we can’t afford anymore.

If you look at your salaries (that excludes wages in direct labour), you will see that

A recession could be coming down the pipeline; set up a preventative maintenance plan for your business now.

Ron Coleman

salaries represent approximately 50 per cent of your overhead. You will also realize that most of your overhead is fixed or very close to fixed. You can make some savings on cost elements such as advertising as long as it doesn’t reduce your income. You do need to look at the cost/benefit of overhead decisions.

The real focus needs to be on your overhead labour. As the owner, maybe you can reduce your salary temporarily. It’s your company, so you’re not really losing anything. You are protecting your investment. Have a strategy for having estimators, project managers and other staff with trade backgrounds being pushed down to direct cost as superintendents. You will retain your good people, reduce your overhead, and likely increase production as these are often people that are very efficient on the job front. Superintendents become foremen, foremen become journeymen and lay off the least productive journeymen.

I know we hate to lay off our top people, but if our numbers are not there, we can’t afford the false economy of hoping things will turn around. Hope is not a strategy.

We also need to look at cost-cutting measures in the field and the shop. Start by looking at areas that can be automated. I hope none of you are still using traditional timesheets. Technology has moved so far in recent years that many steps in our businesses are being automated. Your competitors are doing this, and you are getting left behind if you are not investing in technology.

There are numerous government incentive programs to streamline your technology. We have covered those in a previous article, as well as explored areas around efficiency.

Revisit your estimated costs and your charge-out rates. I recently did a workshop on labour rates and none of the contractors were including a warranty as a cost of labour. MCA Canada recommends that labour costs should be increased by three per cent to cover potential warranty issues.

There is no downside in preparing for a recession. There are several upsides. The first one is it will force you to be more profitable.

That will reduce your need for borrowing and build up your cash reserves to protect you in case of a recession. This will increase the value of your business. You will also feel more secure and less stressed out and know how to protect your key employees.

By streamlining your investment in equipment and vehicles, you will reduce costs.

I am sure all you service contractors constantly tell your customers the importance of preventative maintenance. No heat and burst pipes are never fun. They cost more to fix and are very disruptive. Follow the advice you give to your customers and start your preventative maintenance plan now. :

Ronald Coleman is a Vancouver-based accountant, management consultant, author and educator specializing in the construction industry.

He can be reached by e-mail at ronald@ronaldcoleman.ca.

The balance the government is aiming to achieve is to tame inflation without causing a recession. That is an extremely difficult task.

It’s that time of year again. The National Kitchen and Bath Association (NKBA) is hosting its annual Kitchen and Bath Industry Show (KBIS) from Jan. 31 to Feb. 2 at the Las Vegas Convention Center in Las Vegas, Nevada.

In addition, entries for the show’s 2023 Best of KBIS Awards are now being accepted. The contest recognizes new innovations in the kitchen and bath industries, with a formal ceremony taking place at the KBIS NeXT Stage on Feb. 1.

“The Best of KBIS program celebrates new product innovation among the kitchen and bath industry and assists in elevating the KBIS platform,” said Suzie Williford, executive vice president and chief strategy officer of NKBA. “This program showcases year-after-year, the “best-of-the-best” in our industry. I can’t wait to see what new innovations come to Vegas this year!”

The Best of KBIS is broken down into different categories, including best of show, kitchen (gold and silver), bath (gold and silver), connected home technology, and the impact award (judge's choice). Submissions will be accepted until Dec. 2.

To be eligible for the contest, all products must have been introduced after Feb. 1, 2022. To enter, exhibiting manufacturers must complete a submission form and submit at least two high-resolution images. Products may be entered in multiple categories but require an individual entry form and submission fee for each category.

A judging committee, comprised of five design professionals, will narrow the entries to 50 finalists, which will be judged onsite at the show. Each finalist will have five minutes to present their product to the judges during an in-booth visit. The judges will be announced at a later date.

Nov. 30 – Dec. 2, 2022, The Buildings Show, Metro Toronto Convention Centre, South, Toronto, Ont. For more information, please visit www.informaconnect.com/ the-buildings-show.

Jan. 31 – Feb. 2, 2023, NKBA/KBIS: Las Vegas Convention Center, Las Vegas, Nevada. For more information, please visit www.kbis.com.

Feb. 6 – 9, 2023: AHR Expo 2023, Georgia World Congress Center, Atlanta, Georgia. For more information, please visit www.ahrexpo.com.

This unique series of plumbing products feature an advanced copper alloy finish that exhibits impressive antibacterial properties.

Laboratory testing has shown that when cleaned regularly this surface:

•Reduces bacteria contamination, achieving 99.9% reduction within 2 hours of exposure.

•Delivers continuous and ongoing antibacterial action.

•Helps inhibit the buildup and growth of bacteria within 2 hours of exposure between routine cleaning and sanitizing steps.

As the demand for constant sanitation of high traffic environments continues to rise, so does the need for efficiency and effectiveness in killing bacteria on surfaces.

Research indicates that copper has several modes of action against bacteria. One such mode of action is ion exchange, which researchers believe works like this1:

1.Copper surfaces contain copper ions that are recognized by bacteria as an essential nutrient.

2.The copper ions enter the bacteria providing a lethal dose that interferes with normal cell function and membrane integrity.

3.Cell respiration/metabolism is impeded and DNA damage may occur. The bacteria can no longer consume food or reproduce, and dies.

Clean and sanitize according to standard practice. Healthcare facilities must maintain the product in accordance with infection control guidelines. The use of this surface is a supplement to and not a substitute for standard infection control practices; users must continue to follow all current infection control practices, including those practices related to cleaning and disinfection of environmental surfaces. This surface has been shown to reduce microbial contamination, but does not necessarily prevent cross contamination.

1 Vincent, M., R.E. Duval, P. Hartemann, and M. Engels-Deutsch et al, Contact killing and antimicrobial properties of copper, Journal of Applied Microbiology, December 27, 2017; 124:1032—1046. Source of graphics: Drs. Grass, Keevil, Rensing, and Soliaz courtesy of the Copper Development Association CuVerro® and CuVerro ShieldTM are registered trademarks of Wieland North America, Inc. and are used with permission.