SHOW DAILY

NEWS BRIEF

Pacteon Power!

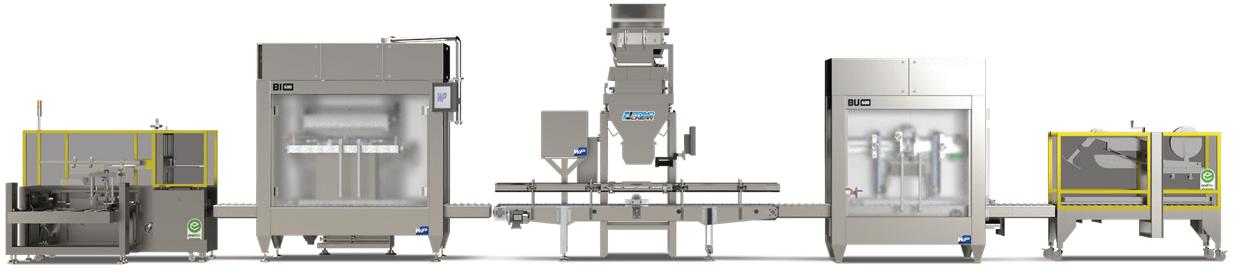

The Pacteon Group (Booths S-3300, W-16041), currently Schneider Packaging Equipment, ESS Technologies, Phoenix Wrappers, and Descon Conveyor Systems is your one source for end-of-line packaging solutions. ■

Collaboration Revealed at PACK EXPO International

Catalyx (Booth W-13047) and INEL chose PACK EXPO International to announce they have formed a strategic partnership to deliver innovative, end-to-end packaging solutions. The collaboration will improve inspection, veri cation, serialization, and labeling processes to drive greater e ciency and regulatory compliance. By joining forces, Catalyx and INEL aim to streamline high-volume manufacturing tools, ensuring the next generation of pharmaceutical production meets stringent standards while driving industry innovation. ■

Corrections

The PMMI Show Daily sta inadvertently listed incorrect anniversaries on some of yesterday’s photos. We regret this error and are rerunning the collection today with the correct dates on p. 6. ■

PMMI Reveals State of the Industry

U.S. packaging machinery market is projected to exceed $11 billion in 2024

At a media breakfast yesterday, PMMI, e Association for Packaging and Processing Technologies (Booth N-4550) unveiled a deep dive into the ndings of the 2024 State of the Industry Report with Jorge Izquierdo, vice president, market development, PMMI, and o ered news from the PACK EXPO portfolio of trade shows with Jim Pittas, president and CEO, PMMI.

e packaging machinery industry has shown resilience and adaptability in the face of global economic pressures. According to the report, the U.S. packaging machinery market is projected to reach $11.1 billion in 2024, driven by automation and sustainability. Industry growth is expected to peak in 2027, with a continued focus on innovative solutions to meet evolving consumer and regulatory demands. ■

Last Chance to Vote for TEA

Voting for the Technology Excellence Awards return this year is quickly approaching. Get your last-minute selections in before voting closes today at noon. ere are three ways to vote: onsite, on the o cial show mobile app, and online. e winner of each category will be announced via a press release a er voting closes this a ernoon. Be sure to take the time to check out the nalists and the winners at their booths. All attendees are encouraged to vote for their favorite product in each category. ■

For more information on the Technology Excellence Awards Finalists, see p. 28.

Students Win PACK EXPO Scholarships

e PMMI Foundation, the charitable arm of PMMI, e Association for Packaging and Processing Technologies, proudly announces the recipients of the 2024 PACK EXPO scholarships. is year, six exceptional students from North American colleges and universities have each been awarded a $5,000 scholarship to support their academic pursuits and career development in the packaging and processing industries.

—Continued on page 4

Amcor Showcases On-Demand Sustainable Solutions

Daily demonstrations of equipment for liquid products and proteins will be featured.

Inspired by the promise of responsible packaging for a brilliant future, Amcor’s responsible packaging solutions are displayed in an interactive and engaging exhibit at PACK EXPO International in Booth S-3705. Daily demonstrations of packaging equipment for liquid products and proteins will be featured, as will more than 130 on-demand life cycle assessment comparisons for data-driven decisionmakers looking to measure carbon impact.

Brands focused on improving their sustainability will find drop-in solutions for over 85% of Amcor’s product portfolio, ready to run today and meeting the performance needs that customers’ production environments demand.

Amcor is excited to bring to PACK EXPO visitors an on-demand application that compares over 130 packages with a more sustainable solution, quantifying reductions in energy use, carbon footprint, and water requirements. Amcor’s diverse portfolio of packaging solutions is designed to be recycled, reduce resource waste, and increase the use of recycled content across packaging formats.

New this year, Amcor will share more examples of fiber-based packaging. The AmFiber™ portfolio includes cold-seal bar wrap, dry mix pouches, and home care product sachets. AmFiber™ is curbside recyclable, reduces demands on virgin plastic, and meets product needs for barrier and shelf-life.

The company’s award-winning AmPrima® portfolio of solutions is designed to be recycled – if clean and dry – at existing store drop-off locations or curbside where available. AmPrima® films meet or exceed the performance demands of current nonrecyclable alternatives.

Consumer health brands will see numerous solutions, including the AmSky™ thermoform blister system, a recycle-ready alternative that is vinyl and aluminum free.

Live

Amcor equipment/film packaging system demonstrations

Liquiflex® VFFS pouch demonstration for 67% carbon reduction compared to cans

Liquiflex is a fast, flexible packaging technology for food service products such as soups, sauces, dressings and condiments. Liquiflex® intermittent or continuous motion VFFS pouching machines create strong, abuse-resistant, zero headspace pouches with superb seal integrity. Liquiflex® features a programmable 200-function memory, rapid changeovers and clean up, and accurate weight control to eliminate variability and profit loss.

Liquiflex® pouches reduce carbon footprint by 67% compared to metal cans and provide up to 30% reduction in material thickness over competitive structures.

Amcor’s Moda Bag vacuum packaging system demonstration with Amcor shrink tubing

A compact, all-in-one, on-demand bag-making and printing system for boneless or bone-in meats and cheese. This single, in-line, bag-making system significantly reduces material and labor costs, and allows packagers to pivot production quickly to meet changing SKUs, product sizes and labeling needs through on-site printing technology.

The Moda Bag system vacuum-packages products from rolls of shrink tubing up to 17”. High-resolution thermal transfer printing delivers crisp brand graphics in-line and eliminates the need to keep individual SKUs of printed shrink bags or labels in inventory.

Film + machinery testimonials running in all halls

Amcor film is running in machinery company booths throughout all halls of PACK EXPO. Over 60 film specs will demonstrate the efficiencies created between machinery and packaging film. Attendees can stop at the Amcor booth for a map handout to guide their trip through the show. ■

NEWS BRIEF

on the

Silent Auction – PMMI Foundation Fundraiser

The PMMI Foundation Silent Auction is new to the show and takes place daily via virtual bidding. Notable items up for bid include accommodations at premier Chicago-area hotels, including the Langham, Sheraton Grand Riverwalk, LondonHouse, Loews, and the InterContinental Magnificent Mile. In addition, premium wine and spirits, gift cards, and more are available. Items will be displayed on the Grand Concourse, Level 2.5. All proceeds benefit the PMMI Foundation. ■

An Encoder Products (Booth W-16005) sponsored reception wrapped up the first day of PACK CHALLENGE, sponsored by Pepsico. Stop by and see a real-world, endto-end student competition that requires collaboration, creativity, conception, process, design, build, programming, debug, marketing and field installation knowledge. ■

—continued from page 1

The scholarships, made possible through the PACK gives BACK™ events at PACK EXPO International and PACK EXPO Las Vegas, are part of PMMI’s commitment to investing in the future workforce.

“Supporting the next generation of industry leaders is central to our mission,” says Jim Pittas, president and CEO, PMMI, producer of the PACK EXPO portfolio of trade shows. “Thanks to the incredible support of our sponsors and partners, we can continue to provide resources that inspire innovation and growth in the packaging and processing sectors. We extend our gratitude to everyone who contributes to this initiative.”

Each year, the PMMI Foundation awards over $200,000 in scholarships to students pursuing degrees in fields such as packaging, food processing, engineering, and mechatronics. Since its establishment in 1998, the Foundation has awarded over $3.8 million to strengthen the future workforce, demonstrating its ongoing commitment to fostering industry talent.

To be eligible for the $5,000 scholarship, students must demonstrate academic excellence, major in engineering, packaging, processing, mechatronics, or a related field, and show a strong commitment to advancing the industry.

Congratulations to the 2024 PACK EXPO Scholarship recipients:

• Morgan Bartholomew, Pennsylvania College of Technology, Polymer & Plastics Engineering

• Amy Foo, California Polytechnic State University, San Luis Obispo, Industrial Technology and Packaging

• Matthias Fowler, Hennepin Technical College, Mechatronics

• Madison Roberts, Michigan State University, Packaging Science

• Ethan Sawyer, Tennessee Technological University, Mechanical Engineering

• Blake Strickland, Cape Fear Community College, Industrial Engineering Technology ■

See Your “Selfie” in Show Daily’s Booth Happenings!

Exhibitors can submit smartphone photos of their booth—whether it’s an innovation or your team—by uploading an image and caption through our simple form for a chance to be featured in PMMI’s Official Show Daily.

Anniversaries

Emerging Brands Accelerate Growth at PACK EXPO International

New show feature, Emerging Brands Central, offers free educational sessions and one-on-one consultations for businesses looking to scale up

Growing brands seeking to scale up and expand operations can find valuable information and resources at the new Emerging Brands Central at PACK EXPO International 2024.

Emerging Brands Central, located in Booth W-20049, features free educational sessions with industry experts designed for brands growing their manufacturing operations. The free 30-minute sessions will cover topics such as:

• Brand Growth Strategies: How companies can effectively scale operations through value engineering and incremental automation.

• Sustainability and Innovation: Focused discussions on sustainable packaging, materials, and processes, plus utilizing innovations in manufacturing and packaging.

• Navigating Market Challenges: Insights into market trends, overcoming entry barriers and supply chain challenges for new brands.

A complete list of sessions can be found under the Education tab in Map Your Show or at www.packexpointernational.com/education/emerging-brands-central.

Expert advisors also will be available for complimentary one-on-one consultations on-site during the show. The advisors have decades of combined consumer packaged goods experience with companies like PepsiCo, Dannon, General Mills, Del Monte, Nestlé, and Kraft. Meet the advisors and schedule appointments at www.packexpointernational.com/education/emerging-brands-central

“The addition of Emerging Brands Central to PACK EXPO International shows that companies of all sizes and backgrounds have a place at the largest packaging and processing event in the manufacturing industry,” says Laura Thompson, vice president of trade shows, PMMI. “Growing brands seeking to expand can use this time to learn, get expert advice, and network with their peers. The possibilities of the types of connections that can be made are endless.”

Emerging brands can also take advantage of being introduced to thousands of manufacturing solutions located within seven specialty pavilions that can help them scale up and expand operations. In addition, there are 150+ educational sessions available at the show featuring topics such as sustainability, AI, automation, robotics, food safety, production, and more. Brands also have ample opportunity to connect with other businesses at the many networking and special events.

Emerging Brands Central is sponsored by Accredo Packaging Inc. (Booth W-24049), Bizerba USA, Inc. (Booth S-2066), Esko (Booth W-13051), Formic (Booth N-5069), Matthews Marking Systems (Booth S-2272), Oxipital AI (Booth LU-7243), Patterson Fan Co. (Booth LU-7127), PMMI ProSource (Booth N-4550), ProSys Fill LLC (Booth S-3656), Selig Group (N-5881), Sonoco (Booth S-2666), and Smurfit Westrock (Booth S-2830) ■

Innovation Unveiled from the Massman Companies

As you navigate the immense 1.3 million square feet of PACK EXPO, something catches your eye at the Massman Companies booth. You can’t help but step into Booth S-2530 as the buzz of excitement pulls you in. You’re immediately greeted by a lineup of connected machinery running continuously as if it’s straight o a production line.

You may be drawn into this booth by an entertaining machine throwing containers, but what keeps you there are new, innovative packaging solutions.

Innovations like the new Auto Gantry Drum and Tote Filler brought by Ideal Pase. is cuttingedge, hands-free solution is equipped with an

advanced vision system for precise lance placement, o ering high accuracy and scalability with features tailored to meet the requirements of hazardous environments. Or the new concept Vertical Feed Unscrambler integrated with a labeler brought by New England Machinery. is space-saving machine streamlines bottle sorting and labeling into one compact footprint, eliminating the need for additional downstream labeling equipment and enhancing overall e ciency. is machine is located in Massman Companies HealthCare Booth in the West Hall, Booth W-15015.

Here is a quick list of more must-see machines on display:

1. Massman Automation’s Flexible Pouch Filler - this high-speed machine handles a variety of pouch sizes with precision. is versatile solution o ers adaptability to evolving production demands, ensuring e ciency and accuracy across di erent applications.

2. Massman Automation’s Bottom Loading Case Packer - this robust machine was engineered for superior exibility and seamless integration into modern production lines.

3. EDL Packaging’s Single Roll Wrapper and high-e ciency Shrink Tunnel - designed to deliver reliable, precise bundling and wrapping solutions for even the most challenging production environments. ese systems o er superior product protection and optimal presentation.

4. DTM Packaging’s Pure l 2000 - a high-speed liquid lling machine designed to deliver accuracy and e ciency across a wide range of liquid applications, making it ideal for industries with high-demand production schedules.

5. New England Machinery’s Compact Unscrambler & Rotary Capper – both machines are capable of handling a variety of container sizes and shapes and o ers quick changeovers. ■

Boundless Educational Opportunities Available at PACK EXPO International 2024

Attendees can explore over 150 free educational sessions, engage with industry experts, and experience new show features that offer the latest strategies and innovations shaping the future of packaging and processing.

PACK EXPO International 2024 is proud to host unmatched educational opportunities designed to empower industry professionals from around the world. With over 150 free educational sessions available, attendees will have access to a wealth of knowledge, insights, and resources essential for navigating today’s rapidly evolving manufacturing landscape.

This year, two exciting new show features— Emerging Brands Central and Sustainability Central—will take center stage, offering attendees cutting-edge insights and strategies to propel their businesses forward.

Emerging Brands Central

Located in the West Hall at Booth W-20049, Emerging Brands Central is a must-visit destination for rising brands looking to scale their operations and expand their reach. This educational hub, an evolution

of the Emerging Brands Summit, will host 30-minute sessions led by industry experts.

These sessions will cover a range of topics including packaging machinery and innovation and scaling strategies, providing actionable advice for brands eager

Sustainability Central

to grow. Attendees will be uniquely able to engage with thought leaders and gain the practical knowledge needed to overcome growth challenges. Brands can also take advantage of an opportunity to meet industry expert advisors one-on-one at Emerging Brands Central. Advisors are available for complimentary oneon-one private consultations to provide personalized advice for each brand’s specific need.

Making its debut at PACK EXPO International 2024, Sustainability Central is set to become the epicenter of sustainable packaging innovation. Located in the West Hall at Booth W-21020, this new feature provides a comprehensive look at what sustainability means for brands today. Industry experts will lead discussions on a wide array of topics, including sustainable packaging, design, EPR, and circularity. Attendees will walk away with actionable insights on enhancing their sustainability initiatives, making their brands more eco-friendly and competitive in an increasingly environmentally

Safety & Efficiency

Halo Automatic Testing System reduces time spent on manual quality control checks, cuts costs and elevates product quality—minimizing risks in even the most challenging environments.

conscious marketplace. In addition, the latest research and best practices in sustainable packaging from leading colleges and universities, PMMI Business Intelligence, and AMERIPEN will be on display.

“PACK EXPO International 2024 is not just an exhibition; it’s a global hub for innovation and education,” says Laura Thompson, vice president, trade shows, PMMI. “With the introduction of Emerging Brands Central and Sustainability Central, we’re providing attendees with unparalleled access to cuttingedge strategies and solutions that are shaping the future of our industry. This is the place where ideas become reality and where professionals come to expand their knowledge and drive their businesses forward.”

A World of Learning at Your Fingertips

In addition to these new features, PACK EXPO International hosts a multitude of educational stages and pavilions where attendees can dive into specialized topics and learn from global industry leaders. Highlights include:

Reusable Packaging Learning Center: Sponsored by the Reusable Packaging Association, the Reusable Packaging Learning Center (Booth LU-6737) offers insights into how reusable packaging systems can

drive efficiency and sustainability in the supply chain and cover topics such as logistics, improving material handling performance, and value assessment.

PACK EXPO International 2024 is more than just a trade show—it’s a dynamic educational experience that equips packaging and processing professionals with the knowledge and skills needed to excel in today’s competitive environment.

Whether you are a seasoned expert or an emerging brand, the opportunities for growth and learning at this year’s event are unparalleled. ■

Innovation Stages: On three stages in the North Hall (Booths N-4560, N-4580, N-4585) exhibitors and subject matter experts present free 30-minute seminars on breakthrough technologies and solutions such as AI, robotics, design, and sustainability.

Processing Innovation Stage: Focused on food and beverage processing advancements, experts on this stage cover topics such as food safety and sustainability in 30-minute sessions at Lakeside Upper Hall, Booth LU-7147.

Industry Speaks: Experts from the PACK EXPO International Partner Program, covering multiple industry verticals, address the latest hot topics and industry trends such as sustainability, safety, AI, automation, design, and robotics. Located at Booth N-4544 in the North Hall.

Morrison Container Handling Solutions and Hamrick Packaging Systems

Showcase Turnkey Case Packing Solution

Morrison and Hamrick will demonstrate their collaborative Hamrick 600D-S case packer equipped with a Morrison Turning Timing Screw Drive Unit.

Morrison Container Handling Solutions (Booth N-4906), an expert in container handling technology and custom automated container handling solutions, collaborated with Hamrick Packaging Systems (Booth N-5619) and is showcasing a turnkey case packing solution.

The Hamrick 600D-S case packer will be on display in Booth N-5619 and features a Morrison Turning Timing Screw Drive Unit ahead of the case packer to position the containers in a proper orientation for the case packing pattern. The Hamrick model 600DS Servo Case Packer with 8’ extended product infeed is capable of running up to 30+ cycles per minute, while the Morrison timing screw system complete with perimeter guarding can run speeds over 500 containers per minute.

This particular application being showcased will be operating at 150 containers per minute, turning containers 90 degrees prior to the Hamrick case packer to be wide side leading, simplifying the case packer container handling requirements.

—Continued on page 16

ATLANTA, USA

March 10-12, 2025

GUADALAJARA, MEXICO

June 10-12, 2025

LAS VEGAS, USA

Sept. 29-Oct. 1, 2025

PACK EXPO Premier Packaging and Processing Events

PHILADELPHIA, USA

Feb. 17-19, 2026

Wherever you are and whatever your industry, there’s a PACK EXPO event to provide solutions you need today and the inspiration for tomorrow.

MEXICO CITY, MEXICO

June 2-5, 2026

CHICAGO, USA

October 18-21, 2026

—Continued from page 14

“ e Hamrick 600D-S case packer is our fastest and most exible option designed to run high rates of speed, while accommodating undersized to oversized case/tray styles,” Frank Skerl, Hamrick Vice President of Sales, said. “ ese machines can pack in tandem operation at speeds up to 50+ cases per minute and can be highly customized to handle most rigid container types.

“Ideal for PET/HDPE, the 600D-S includes an onboard servo lane divider to handle non-round products.”

Morrison and Hamrick have developed a long-

time OEM partnership. Hamrick looks to Morrison to supply their expertise in container handling ahead of the Hamrick systems for e ciency and continuous motion applications.

“We have chosen the Morrison bottle turning screws as the preferred method to change the orientation of the bottles from narrow side leading to broad side leading when packing 2-pack and 3-pack cases of product for Colgate Palmolive,” Skerl said. “ e accuracy and reliability of the Morrison unit makes them an easy selection as partner for this project.”

Morrison will have various other container

handling equipment on display, and is excited this particular turning system will be showcased in Hamrick’s booth, as it provides a great example of how the custom solution provider can work with other OEMs to provide solutions for their equipment.

“If you walk around PACK EXPO International, you’ll nd dozens of Morrison systems in other OEM’s booths, which highlights our commitment to work with OEMs and end users alike and improve e ciency in container handling,” Dustin Lee, Morrison’s Vice President of Sales, said. “We are always honored when our OEM partners show our equipment integrated into theirs as we know it is an important choice for them to make.”

Equipment features for Morrison’s systems:

• Dual Timing Screws

• Tool-less Quick Change Infeed Guides and Screws

• Deluxe adjusters to speed up changeover between container sizes

• Full Perimeter Safety Guarding

• Flexible for Multiple Container Sizes

• Servo driven

• Equipment features for the Hamrick system:

• Morrison Inline Orienting Custom Drive Assembly- to turn incoming bottles 90 degrees prior to packing.

• Servo Lane Divider for non-round containers

• Heavy Duty Servo controlled case li with dual rack and pinion gears

• Optional: Extended Case Li Option to run cases in tandem

• Servo Controlled case advance lugged chain

• Allen Bradley Controls Package

• Optional: Te on coated lane guides

• Optional: LED Lighting package

“Morrison is our rst call whenever our customer has product orientation or handling requirements. eir attention to detail and ability to collaborate has led to many successful joint projects together,” Jordan Hamrick, President at Hamrick Packaging Systems, said. “ ey are a true partner in every sense of the

is system will be supplied to Colgate-Palmolive at the end of the trade show. To see it on display, Booth N-5916, then visit N-4906 to see more container handling solutions.

“At PACK EXPO, we o en showcase concepts of how we handle containers,” Morrison’s CEO Nancy Wilson said. “What’s great about having our equipment in other OEMs booths is we can showcase the nal solution and how it interacts on a packaging

“Partnerships like the one we have with Hamrick Packaging Systems are important in our business, and we hope attendees enjoy seeing these two great pieces of equipment in action together.”

For more information about the companies, visits their websites at www.morrison-chs.com and www.hamrickmfg.com. Both companies have been providing state-of-the-art packaging solutions for more than 50 years. ■

AS FAR AS YOUR EYES CAN SEE: INFINITE OPTIONS FOR PACKAGING FOOD. BROUGHT TO LIFE WITH SCHUBERT. PACKEXPO CHICAGO

NOV 03 - 06, 2024

SCHUBERT NORTH AMERICA NORTH HALL BOOTH 6151

SCHUBERT PHARMA WEST HALL BOOTH 16095 WELCOME

Being flexible is good, being fast and flexible is even better. Schubert packaging machines are leading the way. Intelligent control and precise robotics can now replace complex mechanics to ensure maximum flexibility in all packaging processes. In fact, 80% of the leading FMCG companies count on us and our flawless packaging combined with the lowest possible consumption. In line with our Mission Blue Sustainability Initiative: A winning proposition – for our planet and for you. www.schubert.group/en/food.html

Emerson Renews Commitment to Amazing Packaging Race

Emerson Discrete Automation Group (Booth N-5345) reaffirmed its support for The Amazing Packaging Race at PACK EXPO International, continuing a partnership with show producer PMMI, The Association for Packaging and Processing Technologies, for over a decade.

Laura Thompson, vice president, trade shows at

PMMI, emphasized the significance of education and workforce development, stating, “PMMI is committed to engaging students and fostering their enthusiasm for our industry. The return of The Amazing Packaging Race to Chicago this year underscores our dedication to this cause.”

The event, which sees student teams solve

challenges set by exhibitors across all four halls of the show floor, will culminate on Nov. 6 with prize presentations to the top three teams. Each winning team member will be awarded $1,000, with second and third-place teams receiving $500 and $250 per member, respectively.

RE Packaging-Filling Machines

Jim Pittas, president and CEO of PMMI, commended Emerson’s ongoing support, noting its pivotal role in sustaining programs like The Amazing Packaging Race and contributing significantly to the PMMI Foundation. “Our partnership with Emerson Discrete Automation Group is a source of immense pride, enabling us to collectively shape the industry’s future,” Pittas remarked.

The Amazing Packaging Race is one of several student activities designed to attract the next generation of packaging and processing professionals. Additional programs include PACK Challenge (Booth W-16005), sponsored by PepsiCo, a machinebuilding competition among high school teams; the Future Innovators Robotics Showcase (Booth W-21054), sponsored by Schneider Electric (Booth N-6030), displaying designs from Chicago-area high school teams; and the Workforce Development Pavilion (Booth W-20022), where companies can connect with students from PMMI education partner schools.

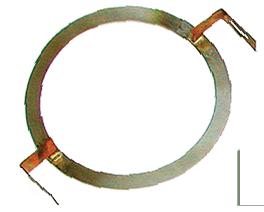

IMPULSE HEAT SEALING

5 Star Rating

Truly are the EXPERTS AT IMPULSE HEAT SEALING!

15 minutes with a TOSS engineer and I learned more about impulse heat sealing than I have in my 30 years of designing V/F/F/S machines... THANKS TOSS!!

Technology is simply Fantastic.

The PIREG® Temperature Controller controls the time and temperature of the impulse heat seal band flawlessly on every cycle. TOSS Technology truly performs as advertised…

Alloy-20 ® Impulse Heat Seal Bands are far Superior. TOSS designed custom impulse heat seal bands for me to replace my current NiChrome bands. Now I’m getting longer life and cleaner seals. I’m a true believer! Only GENUINE TOSS Alloy-20 ® impulse heat seal bands from now on.

Fortress Technology Touts Star Quality with Icon X-Ray

Already winning over food processors with top-shelf productivity and detection accuracy.

Fortress Technology (Booth S-1758) has launched a fully integrated, super-hygienic X-ray inspection system equipped with internal view cameras and an integrated automatic reject device to optimize floor space.

Founder and President of Fortress Technology, Steve Gidman, is unveiling how the Icon X-ray is

already winning over food processors with its unparalleled productivity while simultaneously reassuring consumers with exceptional contaminant detection accuracy. Discover the innovative features of this highspeed X-ray system, designed to significantly enhance processing efficiency, consumer safety, and contaminant detection in high-care food production facilities.

The hygienic Icon X-ray (above) includes an integrated reject device, with the option to add other features, e.g. shielded sliding doors. The Icon X-ray uses Fortress Technology’s proprietary IA+ algorithm to adapt to variable-density products that present with metal, ceramic, glass and high- density plastic contaminants (below).

Experience how leading brands are paving the way towards a sustainable future. Expertled sessions and informational displays will help you understand packaging sustainability and what that means for your brand.

Learn From the Best

Hear from companies leading by example. Amazon, Conagra Brands, Dr. Bronners, Merck and more on topics such as:

• How to drive sustainability in your organization

• Innovative collaborations and packaging solutions

• Designing for e-commerce packaging

• Pursuing the circular economy

Get Inspired

See firsthand innovative projects from academic institutions like Clemson University, University of Florida, and Virginia Tech, along with critical research from PMMI Business Intelligence and Ameripen

“The Icon is truly an inspection game-changer. Especially in the New Era of Smarter Food Safety. It adds a new level of food safety and traceability that is no longer reserved for the most elite food brands,” said Gidman.

The Icon X-ray inspects and rejects packaged chilled, baked, and confectionery products using Fortress Technology’s proprietary IA+ algorithm. This algorithm provides unparalleled processing and detection power to adapt to variable-density products containing metal, ceramic, glass, and high-density plastic contaminants. In addition, IA+ allows for instant adaptation to future machine learning features.

Prioritizing user safety and with a constant inspection throughput of up to 200ppm, the Icon X-ray features internal cameras to vigilantly monitor product status and immediately address operational bottlenecks. Processors can select optional

INNOVATIONS THAT TRANSFORM OPERATIONS

Boost your bottom line with the industry’s most advanced foodservice packaging solution, Liquiflex®.

• Liquiflex® packaging equipment guarantees lightning-fast setups and changeovers, increased throughput, and reduced operating costs.

• Liquiflex® Advance™ films offer unmatched package strength, exceptional abuse resistance, and optimized materials for reduced waste. Together, they deliver next-generation liquid packaging solutions that enhance versatility and optimize operations.

DAILY DEMOS OF LIQUIFLEX® FOODSERVICE PACKAGING EQUIPMENT

Responsible packaging for a brilliant future. e

Visit us in South Hall, booth 3705, for an up-close look at the game-changing Liquiflex® technology. amcor.com/pack-expo

—Continued from page 20

transparent high-density windows on the sliding access panels that fully shield operators from X-rays as they observe the inspection process. The X-ray cabinet comes equipped with all required shielding, mitigating the costs associated with postpurchase safety modifications.

Robust and hygienic, the Icon X-ray comprises a fully enclosed, maintenance-free, air-cooled generator. Unlike other food X-ray systems, the Fortress Icon X-ray doesn’t use an energy-intensive air conditioning unit.

Visit the Lakeside Backyard Bistro, an oasis themed destination with delicious lunch options at discounted rates. Enjoy fun backyard style games and a place to kick back.

of the show floor

The Icon X-ray’s ultra-hygienic design supports sanitation processes. It increases plant productivity and food safety, with beveled, easy-clean surfaces to promote water run-off, speed up drying time, and prevent cross-contact contamination. Created for high-care food environments, fully-sealed panels ensure that no cables are exposed to dust and other particulates. As a result, the Icon’s framework can withstand repeatable, high-pressure, high-temperature jet sprays, wash-downs, or steam-cleaning procedures. Additional time-saving sanitation features include easily removable magnetic X-ray curtains, a quick-release tight-fitting conveyor, and IP69krated sensors.

The Icon X-ray offers networked data integration and reporting as standard features. For enhanced connectivity, processors can incorporate network communication adapters to integrate with existing systems and support real-time data sharing and analysis in various formats.

The Icon X-ray’s 10-point touch industrial capacitive touchscreen display is responsive and intuitive, facilitating seamless user interactions. The ability to swipe, zoom, and easily select an instruction saves time, minimizes stoppages, and increases productivity.

The product comes with Fortress Technology’s highly valued Never Obsolete guarantee, ensuring equipment longevity and cost savings for customers. It is one of 16 machines being showcased by Fortress, making Booth S-1758 Fortress’s biggest equipment presentation in its history. ■

PACK EXPO International 2024 Offers Robust Sustainability Education

Companies will share best practices in Sustainability Central.

PACK EXPO International 2024 spotlights sustainability with new and expanded show resources to help brands lessen energy consumption, minimize waste, and reduce overall carbon footprint.

Debuting at PACK EXPO International, Sustainability Central (Booth W-21020) is a unique opportunity for attendees to delve into packaging sustainability and its implications. This show floor destination, featuring expert speakers and a showcase of actionable, sustainable solutions in manufacturing, materials, recovery, logistics, analytics, and design, offers over 20 educational sessions. These sessions, led by experts from Amazon, Conagra, Clorox, Dow, Merck, Mars Wrigley, the Consumer Brands Association, and other major industry players, provide insights on a range of topics.

Additionally, Sustainability Central features displays from Virginia Tech, Consortium for Waste Circularity, Clemson University, PMMI Business Intelligence, U.S. Plastics Pact, and AMERIPEN, among others, sharing their latest planet-friendly innovations, research, and best practices.

As a testament to its commitment to a seamless and productive event, show producer PMMI, The Association for Packaging and Processing Technologies, is expanding resources to assist attendees in efficiently navigating the show. This initiative is designed to ensure that attendees can make the most of the show’s exhibition space, where they can witness sustainability-enhancing solutions in action.

• For advanced online planning, attendees can use the Sustainability Solutions Finder, a professionally vetted and searchable tool, to locate exhibitors with environmentally friendly products and machinery. A kiosk is also located in Sustainability Central.

• On-site, attendees can look for the PACK EXPO Green icon to identify sustainable materials and machinery suppliers and educational sessions focused on sustainability. The online exhibitor directory has a complete list of current PACK EXPO Green exhibitors.

“We’ve intentionally partnered with companies, exhibitors, and vendors to integrate sustainability into every component of PACK EXPO International, including educational programming, show features, and how we do business as the largest packaging and processing event this year,” says Laura Thompson, PMMI’s vice president, trade shows.

In addition to the new and expanded education and show navigation resources, attendees can experience the returning features and initiatives that support their ecoconscious efforts:

• Sustainability-focused educational sessions occur at the Innovation Stage, Processing Innovation Stage, and Industry Speaks.

• The Reusable Packaging Pavilion (Upper Lakeside) features Reusable

Packaging Association member companies demonstrating sustainable packaging solutions to help reduce waste, cut costs, and gain supply chain efficiency. Attendees can explore reusable transport packaging products and services and see innovative reuse solutions.

• Sponsored by Smurfit WestRock (Booth S-2830), The Showcase of Packaging Innovations® (Booth W-21030), located within the Containers and Materials Pavilion, displays award-winning packaging from around the world.

Additionally, PMMI worked with Dow (Booth W-21062), the Official Sustainability Partner and the Official Sponsor of Show Floor Recycling at PACK EXPO International, to minimize the event’s environmental impact and divert as much waste as possible from landfills. PMMI is also proud to host PACK EXPO International 2024 at McCormick Place, recognized by independent thirdparty organizations such as LEED, APEX, Green Seal, and the U.S. Environmental Protection Agency for its innovative strategies to reduce its carbon footprint.

Learn more about PACK EXPO International’s Sustainability Commitment at packexpointernational.com. ■

Experience matters.

• Technical support up front - when it matters most

• In-house OEM equipment integration*

• Electrical communications for synchronization

• 24/7 workhorse conveyors, standard or custom

• Maximize productivity, minimize footprint

*X-Ray; Metal Detection; Check-Weighers; Coders; Labelers; etc.

PROVEN CONVEYOR EXPERTISE:

Accumulate, Rotate, Elevate, Integrate, Lift-gate, Incline, Combine, Decline, Alpine, In-line, Grip, Flip, Split, Invert, Divert, Merge, Twist, Turn, Curves, Transfer, Push, Custom, Stack, Hand pack, Serpentine, Servos, Starwheels ... and more.

Mettler-Toledo Introduces Next-Level Flexibility with New Combination Inspection Systems

Mettler-Toledo Product Inspection has extended its combination inspection portfolio with advances to the new CM (checkweighing and metal detection) and CX (checkweighing and x-ray) combination systems. is signi cant advancement integrates the new M30 R-Series metal detectors and X2 Series of high performing x-ray inspection systems into high-precision C-Series checkweighers, providing customers with maximum exibility to choose the right system to suit their individual application, packaging and budget requirements. Both systems, as well as a CV (checkweighing and vision) combination system, will be demonstrated in Booth S-2939

Powerful 2-in-1 Solutions

With the introduction of the next generation of the CM and CX combination systems, Mettler-Toledo delivers powerful 2-in-1 inspection solutions that manage Critical Control Points (CCPs) by combining precision weighing with contamination detection in an integrated solution. ese new systems o er simpli ed operation, a space-saving design and reduced total cost of ownership. e integration of the new M30 R-Series and X2 Series also o ers higher detection sensitivity, providing an added layer of security and quality control.

Key Bene ts of Combination Systems

• Maximum Con guration Flexibility: Multiple inspection combination options provide manufacturers with maximum exibility to nd the right solution for their packaging, application and budget needs.

• Enhanced Operator E ciency: One-touch operation via the checkweigher supports easy and automated product changeovers. Statistical and status information for the contamination detection solution and checkweigher are available with a single HMI, reducing operator training requirements and minimizing the risk of user errors. e advanced HMI design improves usability, making the combination system user-friendly.

• Space Saving Design: Shared components, such as conveyors, provide space savings, and having less feet on the oor facilitates easy cleaning.

• Reduced Total Cost of Ownership: A single vendor solution provides documentation, installation, con guration support, training and service for two technologies in one, reducing costs over the long term.

• Additional Quality Assurance Checks: Vision inspection technology is available as an additional option, making a powerful 3-in1 system that can provide comprehensive quality control by detecting packaging defects, verifying label information and maintaining product integrity. 4-in-1 solutions are also available integrating checkweighing, metal detection, x-ray and vision inspection.

• Industry 4.0 Ready: All combination systems can be connected to ProdX™, a state-of-the-art product inspection management so ware. is complete quality inspection data management system delivers full digital management of product inspection equipment for real-time monitoring and food safety compliance. Visibility of the data can help improve productivity, food safety traceability and facilitate regulatory compliance.

Joern Migge, Head of Product and Market Management, Mettler-Toledo, says, “We are excited to introduce the latest advances of the CM and CX Combination Systems to our customers. ese innovative solutions provide unparalleled exibility, enhanced e ciency and signi cant cost savings. By integrating the latest M30 R-Series metal detectors and X2 Series x-ray inspection systems, we are able to deliver maximum protection and

assurance for our customers’

Rychiger

Booth #S-2153

As a key player in the packaging industry, RYCHIGER Canada formerly known as Nuspark Inc. is excited for you to come by our booth and discuss firsthand the power of our state-of-the-art packaging automation solutions. We specialize in delivering complete packaging lines, standalone machines, and customized solutions for primary, secondary, and tertiary equipment. To continue setting industry benchmarks, we will be showcasing our new innovative Tray Packer with our new nesting solution, smart linear track tray handling system, our small footprint vertical cartoner, and a collaborative robot palletizer.

Come by our Booth #S-2153 on November 3rd – 6th for a chance to WIN some amazing prizes by participating in our “pronunciation”. We are eager to connect with you and discuss opportunities, share insights and experience in the packaging industry.

We’ll see you at our booth #S-2153 www.rychiger.com

Vote Now for Technology Excellence Awards

Recognize PACK EXPO debuts by selecting winners in four categories.

New this year, voting began online on Oct. 28 and runs through noon on Tuesday, Nov. 5. In-person attendees are encouraged to visit the nalist’s booths and vote via the o cial show app or online. Winners will be announced a er noon on Nov. 5.

More than 100 solutions suppliers submitted nominations for this year’s awards, which were reviewed by a panel of top industry professionals and narrowed down to three nalists in four categories.

e Technology Excellence Awards Panelists are:

• Anne Marie Mohan, senior editor, Packaging World

Voting remains open for the 2024 Technology Excellence Awards (TEA), which recognize the best innovations in packaging and processing being presented for the rst time at a PACK EXPO event.

Detecting the Invisible — The Only Proven Detection Technology for Soft Plastic Food Radar (Booth LU-7464)

e patented Food Radar® technology was born out of a need to detect common food contaminants that existing technologies could not detect. Food safety must always be at the top of the industry’s agenda, and removing physical contamination is central to achieving that goal. Low-density foreign bodies, such as so and hard plastics, rubber, wood, and pit fragments, have always caused problems for the industry. e traditional methods are insu cient to address this issue going forward, so the Food Radar® represents a new opportunity for the food industry. Foreign bodies are detected by transmitting

• David Smith, principal, David S. Smith & Associates

• Matt Reynolds, editor, Packaging World

• Michael Costa, editor-in-chief, ProFood World

Food/Beverage

low power microwaves through the food product. e system uses a microwave sensor designed for emulsions and pumpable products and measures the dielectric properties of the food. Foreign bodies produce a deviation from the norm, activating a very fast pneumatic rejection, controlled by a proprietary automatic algorithm. e system can also detect denser foreign objects such as glass and metal but is particularly well-suited to less dense foreign objects such as wood splinters, hard and so plastics, rubber, extraneous vegetable matter, fruit, stones and starch lumps.

Now boasting a client list of major international food manufacturers, the Food Radar® technology is continuously proving its value.

PMMI Vice President of Trade Shows Laura ompson announced the nalists for each category in a series of videos available at www.packexpointernational.com/tea “ e Technology Excellence Awards at PACK EXPO International are a testament to the incredible innovations shaping the future of the packaging and processing industries,” says ompson. “ ese nalists represent the forefront of technology, driving advancements in sustainability, e ciency, and safety across multiple sectors. We are excited to give attendees the opportunity to engage with these trailblazing solutions and vote for their favorites both online and in person.”

Read more about the 2024 Technology Excellence Award nalists below.

Food Safety Solution

Antares Vision Group (Booths LU-6816, S-3754) is comprehensive solution allows manufacturers and distributors to track the origin of raw materials, manage purchase orders, track statuses and deliveries with subcontractors, while providing a labeling solution with all required attributes to meet regulatory compliance, particularly addressing FSMA regulations.

Challenges Solved:

• Traceability: Ensures full traceability of raw materials and ingredients to verify authenticity and origin.

• Regulatory Compliance: Addresses stringent FSMA regulations by providing comprehensive labeling solutions.

• Supply Chain Management: Streamlines procurement, production, and delivery processes to meet consumer demands and regulatory requirements.

• Transparency: Enhances transparency across the supply chain to satisfy consumer demands for information and veri cation.

• Data Accuracy: Ensures accurate recording and reporting of food safety data to drive informed decision-making.

Bene ts:

• Enhanced Food Safety: Guarantees the safety and quality of food products by tracing their origins and complying with FSMA regulations.

• Regulatory Compliance: Meets regulatory requirements e ortlessly with comprehensive labeling solutions and accurate data reporting.

• E cient Supply Chain Management: Streamlines supply chain operations for improved e ciency and reduced risks.

• Improved Transparency: Enhances transparency across the supply chain, enabling quick response to food safety incidents and consumer inquiries.

Automation Solutions from Washdown to Warehousing

Let Turck tackle whatever packaging automation challenges you are facing. Our wide range of reliable automation solutions – including sensors, industrial cordsets, distributed I/O products, and RFID stand up to the toughest packaging environments. From improving high-speed cap and can detection to cost-effective machine control with a combined HMI/PLC, or more rugged washdown-rated cables, Turck has a solution. Optimize your packaging machines and lines with Turck.

Visit us in booth N-5719

Booth # N-5041

—Continued from page 28

Visual AI — Setting the New Standard for Resilient, E cient, and Sustainable Manufacturing Oxipital AI™ (Booth LU-7243)

Food/Beverage

By unraveling the challenges of high-variability manufacturing environments, Oxipital AI™ visual AI presents manufacturers with actionable insights to drive more resilient and sustainable manufacturing. Inspection data unveils essential intelligence for:

Magnetic Liquid Traps

• Defect Detection: Identify and classify defects at any production stage to pinpoint origin, optimize quality, reduce waste, and improve margins.

•All models have 316 stainless-steel construction.

or data labeling is required to deploy these solutions, leading to immediate and transformative impact for manufacturers.

•Removes ferrous tramp from your liquid processing and conveying lines.

•Equipped with high-strength and high-temperature rated magnets.

• Attribute Tracking: Identify, measure, and track a vast range of product attributes to ensure your products are in spec at any point in production.

• Live Monitoring: Gain real-time insight into production quality to respond faster, minimize downtime, and improve e ciency.

• Trend Analysis: Identify and analyze production trends to make data-driven decisions, anticipate future issues, and drive continuous improvement e AI-enabled inspection solution seamlessly. integrates into manufacturers’ existing work ows without process disruption or upstream product presentation requirements. No code, machine vision,

Oxipital AI™’s visual AI solutions combine reliable hardware with intuitive so ware and pre-trained object models to deliver a holistic experience to users. A camera captures images, which are then processed on the edge in real-time to recognize patterns, anomalies, and deviations, agging those that don’t meet desired quality standards. User-friendly webbased dashboards deliver actionable insights, allowing process and quality engineers to uncover trouble areas in production and make data-driven process changes, resulting in increased yield, reduced waste, improved quality, and pro tability.

General Packaging & Processing

Pipeline Style Metal Separators

•Remove ferrous and non-ferrous metals from liquids, pastes, or slurries.

•3-way separation mechanism is suitable for both pneumatically-driven pig cleaning and Clean in Place (CIP).

Amcor Revolution™ APET Packaging Solution — Revolutionizing Recycling

Amcor Flexibles North America (Booth S-3705)

sales@buntingmagnetics.com buntingmagnetics.com

When disposed of in curbside recycling containers, this innovative packaging is sorted into PET bales and processed by plastics recyclers. e wash tank method separates the PE layer from the PET, allowing the PE sealant to oat and be collected with other components, while the PET sinks for recycling within the PET stream. is technology is designed so existing infrastructure separates the PE from the PET so consumers do not need to separate the PE sealant prior to recycling the package. is design maintains optimal peel strengths, tailored sealant layers, and consistent oxygen barrier performance. Recycling Revolution™ Sortable Barrier APET packaging dramatically lessens the

environmental impact when recycled compared to baseline packaging sent to land ll. According to an Amcor ASSET™ life cycle assessment, it reduces nonrenewable energy use by 71%, cuts the fossil carbon footprint by 57%, and uses 51% less water. ese savings are comparable to the energy use of burning a CFL light bulb for a year, the emissions of driving a car for a year, and the water used in numerous showers. Amcor Revolution™ APET has received Critical Guidance Recognition from the Association of Plastic Recyclers (APR) for meeting or exceeding Critical Guidance criteria, is prequali ed with How2Recycle® for “check locally” in the U.S. and “widely recycled” in Canada, and is listed on Walmart’s ‘Circular Connector’ platform. ese achievements underscore Amcor’s commitment to sustainability and innovative solutions that facilitate a circular economy.

PAVILION HOTSPOTS

FIND TARGETED SOLUTIONS

LAKESIDE UPPER HALL

The Processing Zone

Find front-of-the-line solutions for food and beverage processing and discover ways to increase safety, improve efficiency, and achieve total system integration.

The Reusable Packaging Pavilion

Discover reusable assets that reduce waste, provide more reliable protection for your production, and can be part of a smart supply chain.

Sponsored by:

NORTH HALL

The Logistics Pavilion

Find supply chain solutions that include equipment and systems for warehousing and material handling, dock and warehouse, inventory management and control, distribution logistics services and transportation providers.

SOUTH HALL

The Confectionery Pavilion

Uncover specialized equipment and integrated systems for your candy, chocolate, mints, and gum production lines.

Sponsored by:

PACKage Printing Pavilion

Explore technology that makes customization, promotions, small runs, on-demand production, and smart packaging cost-effective.

WEST HALL

The Containers and Materials Pavilion

Find new sustainable materials, flexible packaging, printable films, and more. Also, see award-winning packages at:

—Continued from page 30

General

Packaging & Processing

The Healthcare Packaging Pavilion

Visit your one-stop shop for solutions targeted to pharmaceuticals, biologics, nutraceuticals, medical devices and more.

Syntegon Cookie Tray Loading System

Syntegon Packaging Technology, LLC (Booth S-2914)

e integrated cookie tray packaging system features an FGCT Tray Loader, a FIT/202 Tray Overwrapper and a MagTrac/BEC Cartoner.

e all-new FGCT (Feeding Grouping Counting Turbo) is a high-speed tray loader providing a multilane high-speed counting operation. e rotary stacker precisely counts the cookies, which are then placed into a cross-chain for downstream trayloading. e new FGCT can achieve a rate of up to 3,000 cookies per min.

e FGCT system is complemented by the FIT linear motor infeed system and Pack 202 wrapper.

e FIT enables contactless synchronization of trays, surpassing the speed of traditional chain solutions

Fogg’s PF Series Pressure Filler

Fogg Filler Company (Booth S-3614)

Fogg’s PF pressure ller series is a complete rethink of lling technology engineered as a hybrid system to o er signi cant advantages over current gravity bowl and pressure gravity lling designs. It is a technological hybrid pairing that integrates the precision and the product supply pressure of contactless electronic metering valves with the closed loop bypass process controls and clean/sterilize-inplace (CIP/SIP) cleanability in a contact- lling valve.

In place of exible hoses, this system is comprised of downward-sloped stainless-steel plumbing for a more direct and hygienic product path. is makes for a fully CIP/SIP-able system that will increase speed and cleanliness in the lling process and greatly reduce the opportunity for temperature loss in hot- lled products. ese stainless tubes are in a xed position, minimizing the total moving parts on the ller. e technology is simpler to operate and maintain, with fewer parts and controls than non contact electronic or vacuum- lling solutions. Technicians can easily understand the operation without a lengthy and costly training process.

and reducing infeed lengths. is will be the rst time the FIT “smart” infeed is joined with the Pack 202 horizontal ow wrapper, further pushing the advanced linear motion technology to lower-priced machines. e new FIT/202 can achieve a tray overwrapping rate of up to 150 trays per min. Once wrapped, the trays enter the all-new MagTRAC production feed, capable of handling a wide range of products, from wrapped bars to pre-formed trays, e ciently staging the products for automatic loading. e new Kliklok BEC endload cartoner o ers the bene ts of the proven machine series combined with the latest technological advancements to meet the requirements of automated production processes. e MagTRAC/BEC can achieve up to 400 products per minute infeed rate and up to 170 cartons per min.

ese lling systems dramatically improve the speed and e ectiveness of lling in distilled spirits and hot- ll beverage processes, among other food and beverage products, given creative new valve designs, valve product supply and venting systems, and precision “predictive pumping” technology. is new lling technology exempli es Fogg’s innovative reputation in the food and beverage lling industries. It represents long-awaited features and bene ts integrated into a machine that is historically discrete from multiple machine technologies.

N -O -LIN

IN SOLU IONS

IPacteon works with you and for you as your single source solution to design, integrate, and service your product handling and automation needs. Your success matters.

—Continued from page 32

Unique Medical Lea et — Thin Bible Paper Booklet

ThinPrinting by St Michel Print (Booth W-13062)

e in Bible Paper Booklet is a new standard for pharmaceutical packaging. It provides an outstanding patient experience on their treatment journey, a shallow carbon footprint, and maybe the lowest cost. It is easy to open, close, and nd correct information (e.g., table of contents with page numbers and larger font size) compared to the standard lea et. In addition, it can be tailored to customer needs, and therefore, the size is suitable for the current package, and the content will be as needed. Because there is no folding, the booklet is extremely easy to remove from the package and vice versa. At the same time, it is highly environmentally friendly (~30 – 50% less paperweight than standard lea ets), and the price is signi cantly lower (~20%) with high volume. Due to lower weight, a package is lighter weight, and if needed, smaller in size, and transportation will have lower CO2 emissions (lighter containers and less transportation). For the same paper volume, as with the standard lea et, it can include at least three-to-four times more information (e.g., more languages). When several languages are included, the logistics and warehouse costs will also decrease (stock item numbers and the need of warehouse space will decrease).

Personal Care/Pharma

Omni-IR™

Pace Packaging, LLC (Booth S-3506)

e Omni-IR™ is the new generation of Pace’s linear technology. Employed in a wide range of industries, these unscramblers excel at e ciently unscrambling a wide range of container types, including round, rectangular, square, and oval PET, HDPE, PP, PS, and PVC bottles, with and without handles, as well as spiral-wound ber containers. Capable of achieving speeds ranging from 250 to 650 bottles per min., the Omni-IR™ series o ers manufacturers of all sizes a customizable solution to meet speci c production demands while adhering to budgetary constraints. Applications include personal care, ready-to-drink beverages, bottled water, automotive, laundry, household cleaning, and container decorating.

Amcor Opening Feature

Amcor Flexibles Healthcare (Booth S-3705)

Amcor’s Opening Feature (AOF) technology is a proprietary tear initiation technology incorporated into a variety of pharmaceutical packaging formats. e AOF technology is a notch-less opening feature that provides both child-resistance and senior-friendly performance, facilitating controlled dosing of pharmaceutical powders, granules, creams, gels, and liquids. Common package formats using the AOF technology include sachets, stickpacks, and blister lidding. e AOF technology is incorporated into the packaging material during the manufacturing process and is compatible with a variety of laminate technologies. e AOF technology is applied in register with the graphics. e package tears at the printed indicator only and is not evident to a child. e AOF technology can be adapted to each individual package format for maximum e ectiveness. e AOF technology does not impact the package’s barrier properties, seal strength, integrity, or aesthetics. It is essentially invisible to the consumer, making it an ideal technology for use in child-resistant, senior-friendly packaging formats.

TUESDAY SHOW DAILY

—Continued from page 34

EnduraGrip®

Omada™ — Automating Application of Paper-based Handles at Scale Smur t Westrock (Booth S-2830)

e automated application of EnduraGrip® Omada™ allows brands to e ciently and e ectively replace plastic clips with a more sustainable, recyclable alternative. e use of these paper-based clips also increases shelf impact thanks to their fully printable surface.

Omada delivers e cient throughput and minimal

Sustainability

product movement, even with products in low-walled trays, by o ering a continuous product ow through the machine. Since intermittent stoppage can jostle bottles, Omada’s continuous product motion ensures the accurate placement of handles onto the primary products in the case.

Omada’s servo-driven application enables the machine to operate at a high speed with highly repeatable accuracy while carefully controlling the application pressure and positioning—critical

Carbon footprint reduction

factors for successfully placing paper-based handles. Traditional pneumatic systems are powered by compressed air, while Omada’s servos operate on electricity. is is both e cient and cost-e ective and provides control over force and torque. e machine also utilizes an automatic magazine changeover system for seamless operation.

During the design process for Omada, Smur t Westrock used a digital twin to design and validate the machine virtually—for a more sustainable and e cient process that minimized unnecessary waste.

PPK Natura — World’s First PET Resin Made from Waste Carbon

Plastipak Packaging, Inc. (Booth W-24100)

PPKNatura is the world’s rst polyethylene terephthalate (PET) resin made from captured carbon emissions. e innovative carbon capture and transformation (CCT) technology from LanzaTech converts waste carbon into materials such as sustainable fuels, fabrics, packaging, and other products that people use in their daily lives. e resin is suitable for food, personal care, pharmaceutical packaging, and other non-packaging applications.

PPK Natural resin reduces greenhouse gas emissions, and its production process does not require land or food resources. In addition, packaging made from this material can be fully recycled at the end of its life, keeping the carbon in a circular material cycle. Proprietary bacteria are applied to consume a variety of waste feedstocks and convert them into new chemicals, which can be turned into packaging, clothing, laundry detergent, aviation fuel, and more. e company explains that while PET resin contains 30% monoethylene glycol (MEG) traditionally sourced from petroleum, PPK Natura utilizes LanzaTech’s carbon capture technology to produce CarbonSmart MEG.

Innovating Circular Sustainability

Harpak-ULMA Packaging, LLC (Booths N-4736, N-4643, and N-5043)

Balancing packaging functionality with environmental responsibility is a key tenent of #ULMAweCare, driving technological innovations that support an increasingly circular production model. Transitioning to more sustainable materials, such as mono-material lms, is di cult as many packaging machines were not designed to handle these newer, more environmentally friendly lms. ese lms require precise temperature control and specialized forming processes to ensure optimal performance and recyclability. ULMA Packaging has developed two groundbreaking technologies, BETTER-SEAL™ and ECO-FORM™, each representing signi cant advancements in handling these new lm types. ■

Improving Processing Plant Uptime

Major poultry processor solves its most di cult challenge.

Within the food processing space, maintaining production speeds and throughput with minimal interruptions is crucial to meet the ever-increasing rise in consumer demand for a variety of di erent products. E ciency and hygiene are critical, requiring equipment made to withstand rigorous conditions to keep production lines moving smoothly. is is

particularly true in the poultry processing industry, where machinery faces unique challenges, from high torque demands to frequent, intense washdowns.

Transforming poultry processing e ciency with the gen2

A major poultry processing plant in North Carolina faced a di cult challenge on its toughest application—a solid 90-degree transfer. As the conveyor separated whole birds from the main line, birds would bunch up at the 90-degree turn, drastically increasing the torque demand on the conveyor’s motor and speed reducer. Due to direct contact between the partially processed birds and the transfer line, the entire conveyor was also subject to rigorous washdown, adding even more strain. As a result of the high torque demands and frequent washdowns, the conveyor’s existing competitor speed reducer began to fail every other month.

In December of 2022, the facility maintenance manager contacted Regal Rexnard’s (Booth LL-10014) Boston Gear to help solve the problem. Boston Gear replaced the plant’s failing speed reducer to meet the challenging application with the SS700 Series Gen2. e Gen2 (2nd Generation) of Boston Gear’s SS700 Series Speed Reducers package the t-form function of the original IP69K Rated stainless steel speed reducers with several key upgrades and improvements.

Today, the customer reports zero issues with the new speed reducer and the Gen2 maintains its pristine and corrosion-free exterior. In just six months, the Gen2 increased its operating life by 300%. e new design also incorporates features for quick and easy installation and maintenance.

8 key reasons why the gen2 is ideal for food processors

1. e Domed Crown™ Curved Design reduces uid pooling and improves chemical runo , lowering the risk of pathogen formation and ensuring the food processing operation remains safe and compliant.

2. e Larger Output Sha Bore allows for the selection of a smaller reducer, especially in low-torque or low-duty applications, if the sha size is dictating the selection, providing the opportunity to downsize product selection (weight, envelope size, cost) and standardize conveyors throughout the facility.

3. e IP69K Rated Stainless Steel Enclosures are compliant with IEC 60529 and can withstand washdown nozzle pressure of up to 1450psi as close

South Building, Room S-102

Lounge Hours: Sunday – Tuesday: Wednesday: 8:00 am – 3:00 pm

If your badge says, “First-Time Attendee,” stop by to:

Get expert assistance

Access product locators

Enjoy refreshments and comfortable seating

Attend a special session just for newbies

Special Session: Sun – Tues at 8:30 am How to Navigate the Show Like a Pro

Your First-Time Attendee Badge is your access pass.

—Continued from page 40

4. e Field-Installed Sha Covers protect against potential food traps and rotating elements that pose hazards to operator safety. Compliant with both FSMA and OSHA regulations, installing these covers ensures products meet the highest safety standards.

5. Using the Lowest Operating Temperatures ensures a greater ability to maintain required temperature ranges within the processing area. is also ensures a reduced risk of operator injury due to incidental skin contact and a lower risk of oil leaks due to minimized internal pressure build-up.

6. With guaranteed High Operating E ciencies, rigorous testing against competitive models demonstrated that the Gen2 operates food processing equipment using less electricity, generating cost savings over time.

7. Its NSF Certi cation assures a hygienic design that meets the most stringent food-safety requirements. Boston Gear speed reducers with NSF laser marking meet or surpass USDA or any other food regulatory guidelines.

8. e Tapered Bushing Option eliminates the need for an output keyway by using a clamping force to transmit torque. is results in the elimination of keyway food traps, which removes opportunity for pathogen formation, as well as the mitigation of customer sha damage costs from galling damage that can occur over time and the removal of sharp edge safety hazards.

8:00 am — 9:00 am as 4 inches, making the Gen2 highly resistant to water ingress during high-pressure washdown.

By embracing innovative solutions like the SS700 Series Gen2, poultry processing plants can overcome even the toughest operational challenges. Investing in advanced, durable equipment designed to meet the industry’s unique demands ensures not only enhanced e ciency and productivity but also the highest standards of hygiene and food safety. is forward-thinking approach is crucial for facilities aiming to thrive in the competitive food processing space while consistently meeting consumer expectations. ■

Industry Training

Elevate your talent through PMMI’s convenient training and development opportunities.

Certified Technical Sales Professional (CTSP) Certification (for PMMI members only)

Be a trusted advisor to your customers.

Certified Trainer Workshops

Develop your team’s training skills.

Field Service Essentials (for PMMI members only)

Give your technicians the non-technical skills they need to provide great customer service.

Mechatronic Certifications

Identify multi-skilled workers to troubleshoot and repair automated equipment on the plant floor.

Risk Assessment Workshops

Improve productivity and ensure worker safety.

SheLeads: Navigating Leadership for Women

Take your leadership skills to the next level.

Successful Selling @ PACK EXPO

Maximize sales from trade shows.

Show Floor Education O ers

Insight from Industry Insiders

Session descriptions, times, and locations can be accessed by scanning the QR codes or via the show app sponsored by ProMach (Booth S-3500).

Emerging Brands Central Debuts in Chicago

PACK EXPO International’s Emerging Brands Central is a new show feature debuting in the West Hall. Emerging Brands Central features free educational sessions with industry experts, designed for brands who are scaling their manufacturing operations.

Education session topics in Booth W-20049 include:

• How to E ectively Scale Your Operations rough Methods Like Value Engineering and Incremental Automation

• Responding to Consumer Demand for Product Innovation

• Developing a Smart Growth Strategy for Manageable and Controlled Scalability

Plus, take advantage of our free expert advisors who will be on-site during the show.

Sustainability Central Unveiled in Chicago

PACK EXPO International’s Sustainability Central is a new show feature debuting in the West Hall. Within Sustainability Central, attendees get di erent takes on sustainability from industry experts and gain insight into making brands more sustainable for the future.

Education session topics in Booth W-21020 include:

• Catalyzing Circularity

• Toward Global Recyclability Design Guidance

• Sustainability in Biopharmaceutical Packaging

• Enabling Circularity with Smart Packaging

• Sustainable Innovation: Collaborations Drive Decarbonization

• Creating a Business Case to Drive Sustainability

• Design E-commerce Packaging to Enhance Customer Experience

VDG Drum Motors

Reliable and Efficient Conveyor Drive Solutions

SSV Series Drum Motors drive modular, wire mesh, and monolithic thermoplastic conveyor belts without using sprockets, eliminating gaps and crevices, and reducing washdown time and water usage by 50%.

Designed for 80,000 hours of continuous operation before maintenance, SSV Drum Motors increase throughput and reduce operational maintenance costs.

IP69K-rated sealing system

Washdown up to 3,000 psi

Premium-efficiency electric motor

With all drive components enclosed and protected inside the drive drum, VDG Drum Motors provide a safe, efficient, and space-optimized conveyor belt drive solution for material handling applications while minimizing downtime.

INCREASES Tracking Traction by 40% the Life of the Belt VDG IronGrip™ Lagging

TUESDAY

5, 2024

Innovation Stages for Free Cutting-Edge Education Sessions

For up-to-the-minute content, head to the always-popular Innovation Stages (Booths N-4560, N-4580, and N-4585). Exhibitors and subject matter experts present packaging industry breakthroughs, new products, and best practices during fast-paced, 30-minute seminars presented on three stages.

Education session topics include:

• Designing the Future of Packaging

• Ensuring Food Safety

• AI Strategies to Meet Packaging Circularity

• 2024 Maintenance Trends & Challenges

• Accelerating Digitalization

• Leveraging Data for Predictive Maintenance

THE CANDY BAR LOUNGE

Indulge in fruitful conversations. Connect, learn and idea share with fellow confectionery enthusiasts.

Hosted by: Sponsored by:

CONFECTIONERY INDUSTRY NETWORKING RECEPTION

Tuesday, November 5 4:00 pm – 5:30 pm

Education for Improving Food and Beverage Operations

Got 30 minutes? Take a seat at the Processing Innovation Stage (Booth LU7147) to hear about the latest food and beverage processing breakthroughs and improvements to make in operations. Content is targeted to food and beverage manufacturers. Exhibitors and subject matter experts present packaging industry breakthroughs, new products, and best practices during fast-paced seminars.

Education session topics include:

• Advances in HPP

• Transformative Waste Management

• AI-Enabled Vision

• Demystifying Automation

• Next Gen PEF Technology

PACK EXPO Partners Offer Perspective at Industry Speaks Stage

Thought leaders hailing from PACK EXPO International Partner Associations will bring you intriguing views from various vertical industries, address hotbutton topics, and share their thoughts on industry trends at the Industry Speaks Stage (Booth N-4544). Nearly 20 associations are scheduled to speak, including the Cold Pressure Council (Booth N-4512), CPA—Contract Packaging Association (Booth N-4511); IoPP—Institute of Packaging Professionals (Booth N-4513); and F4SS—Foundation for Supply Chain Solutions (Booth N-4510)

The free 30-minute presentations focus on topics including:

• Key Robotic Trends and Their Impact on Industry

• Find Your Perfect Contract Manufacturer

• BEMA Intel: Trending Data that Matters

• State of the Snack Category

NEW Technologies on Exhibit

See our NEW UNISPLICE™, the automatic label web splicing system that provides automatic execution of an end-to-end splice without an operator being present.

See our NEW Recipe Driven Automatic Setup Feature exhibited at the show on the following:

• BRONCO® 130 Labeler

• Beltorque® Capper BT-IC

The World’s Largest Packaging and Processing Classroom

PACK EXPO International features programs designed to engage and inspire the next generation of talent in the packaging and processing sectors.

As the manufacturing industry faces a critical skills shortage, with the U.S. Bureau of Labor Statistics projecting the addition of 3.1 million jobs in maintenance and repair occupations by 2031, PACK EXPO International 2024 plays a pivotal role in addressing this challenge. The event features comprehensive programs designed to engage and inspire the next generation of talent in the packaging and processing sectors.

Student-Focused Initiatives

Recognizing the acute need to attract and retain a skilled workforce, PACK EXPO International, produced by PMMI, The Association for Packaging and Processing Technologies, prioritizes educational outreach to students.

“PACK EXPO International’s student activities are a bridge that connects today’s students to tomorrow’s workforce, empowering them with the skills, knowledge, and experiences needed to thrive in an ever-evolving world,” said Kate Fioranti, director,

workforce development, PMMI

The event features a variety of activities aimed at introducing high school and college students to opportunities within the industry:

Girl Scout Event: New to the show, local Chicago Girl Scout Troops will receive credit for their Sustainable Packaging Patch. Scouts will meet in the Student Lounge on Sunday, Nov. 3, at 11:00 a.m. for a hands-on project focusing on sustainability. Lunch will be provided, followed by a panel and show floor tour from industry professionals.

Silent Auction - Foundation Fundraiser: Also new to the show, the Silent Auction will take place Sunday through Wednesday. Notable items up for bid include accommodations at premier Chicagoarea hotels, including the Langham, Sheraton Grand Riverwalk, LondonHouse, Loews, and the InterContinental Magnificent Mile. In addition, premium wine and spirits, gift cards, and more are available. All bidding will occur virtually, and items will be displayed on the Grand Concourse, Level 2.5.

Packaging Solutions That Work!

Proceeds will benefit the PMMI Foundation. PACK Challenge: Returning for its second year, the PACK Challenge, sponsored by PepsiCo, invites five high school teams to participate in a machine-building competition. Competitors will demonstrate their skills by constructing full-scale material-handling machines capable of denesting