How Versatile Packagers Stays Versatile

Contract Packaging Solutions

Suited to Meet Your Demands

CSS Series Continuous Motion Side Sealers –High throughput speeds with patented Motion Trim Technology™. Accommodates randomly fed or spaced product and separates them into reliable, consistent packages using the absolute minimum amount of film.

Kayat SRX Series Shrink Bundler

Bundle pre-formed trays on the SRX-CTF or loose packaged food and beverage products on the new SRX-CUF. Both machines accommodate clear or print registered shrink film and speeds of up to 60 cycles per minute.

BVS Series Continuous Motion Vertical Wrappers

Multipack products in an upright position including bottles, canisters, aerosols, or jars directly from a filler.

Tekkra In-Line Wrappers

Designed for shrink bundling products that can stand by themselves, this machine provides options for shrink bundling product on corrugated pads, in trays, or loose.

After a devastating fire, Illinois co-packer stays resilient and innovative in niche markets without losing its commitment to customers.

Automation, combined with an upskilled workforce and reduced water consumption, writes a new chapter in canned protein company’s 80-year history.

During a refocus of its core business, Indiana co-packer plugs in a pre-made rotary pouch machine, boosting productivity by 15%.

Versatile Packagers, which celebrates its 25th year working with Signature Brands, shares the keys to building long-lasting co-packing partnerships.

Joseph Derr EDITOR jderr@pmmi.org

David Bacho CREATIVE DIRECTOR

John Schrei VICE PRESIDENT, SALES jschrei@pmmimediagroup.com

Lara Krieger SENIOR MANAGER, PRINT OPERATIONS lkrieger@pmmimediagroup.com

Janet Fabiano FINANCIAL SERVICES MANAGER jfabiano@pmmimediagroup.com

David Newcorn PRESIDENT

Elizabeth Kachoris VICE PRESIDENT, DIGITAL

Kelly Greeby SENIOR DIRECTOR, MEDIA OPERATIONS

Jen Krepelka DIRECTOR, DIGITAL MEDIA

Kim Overstreet DIRECTOR OF CONTENT

Trey Smith SENIOR DIRECTOR, EVENTS

Have a question or an idea for an article? Contact Joseph Derr, Editor. Contract Manufacturing and Packaging magazine prefers to receive press releases by e-mail. Send to jderr@pmmi.org.

PMMI MEDIA GROUP 401 N. Michigan Ave., Suite 1700, Chicago, IL 60611 WEB www.pmmimediagroup.com

PMMI THE ASSOCIATION FOR PACKAGING AND PROCESSING TECHNOLOGIES 12930 Woodgate Dr., Suite 200, Herndon, VA 20170 PHONE 571/612-3200 • FAX 703/243-8556 WEB www.pmmi.org

PUBLICATIONS MAIL AGREEMENT NO. 40064408

Return undeliverable Canadian addresses to Express Messenger International, P.O. Box 25058, London Brc, Ontario, Canada N6C 6A8

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com.

Contract Manufacturing and Packaging magazine is the official publication of the CPA, The Association for Contract Packagers and Manufacturers. The association provides business development support, industry education, networking opportunities, and industry intelligence for contract packagers and contract manufacturers. For more information on becoming a CPA member, contact Paige Jarvi, 571/287-6818, pjarvi@contractpackaging. org, or visit www.contractpackaging.org

BY JOSEPH DERR, Editor

As the new editor of Contract Manufacturing and Packaging (CM+P), I’m excited to say hello—and I hope this isn’t the end of our conversation.

For nearly four years, I’ve been the editor of the PMMI ProSource directory, contributing articles, videos, and more for PMMI Media Group. But I have been in packaging for longer than that. My first jobs out of college were working at converting and packaging trade magazines, before moving on to nonprofits and other odd jobs.

I wouldn’t be here if it weren’t for networking: it was a chance reencounter at the local grocery store with a longtime

friend, Dave Newcorn (now president of PMMI Media Group), that kickstarted my return to B2B publishing after a 20-year hiatus.

So, it’s fitting that networking and cultivating long-lasting business relationships are key themes in my first issue as editor of CM+P

On p. 6, we profile MattPak, a co-packer that leaned on its network to recover after a fire. In my Q&A with Bob Vande Weghe of Versatile Packagers (p. 16), he shares how transparency helped build a 25-year partnership with Signature Brands. Columnist Robby Martin (p. 4) talks about the flipside of that dynamic with an anecdote of how poor communication can end co-packing deals—and offers steps to avoid that outcome.

On the co-man side, we feature how Crider Foods’ switch to an automated

retort system has propelled the meat packing contractor to new heights (p. 10).

We also have some good news to report for you: the forecast for contract packaging is very strong. Two independent reports seem to be saying the same thing you are probably feeling these days in your facilities: contracting is in high demand, providing critical services that brands need right now. Read the summary on p. 5

Before you dive in, just one request: Let’s keep the conversation going! I want CM+P to be a hub for co-packers and comans to connect and thrive. So, write in, find me on LinkedIn, share your ideas, and tell me what keeps you up at night.

Let’s talk soon!

jderr@pmmi.org

BY JERRY THOMPSON, President, CPA

As the crisp air of late fall sets in and the ending of another year draws closer, I’m reflecting on the highlights of 2024. One for me was attending the Packaging Recycling Summit, presented by Packaging World in Anaheim in September—a trip I somehow managed to fit into my already packed schedule of work, travel, and the start of my child’s senior year with college visits and applications.

During the Packaging Recycling Summit, I gained some valuable insights into the latest efforts and innovations in recycling. It’s an issue that remains close to my heart, as many of you know.

It was inspiring to attend this event and learn about the current recycling efforts happening across the country. Despite the numerous setbacks in recycling and waste management, as well as the slow rate of progress in the U.S., it was encouraging to witness the perseverance of so many leaders who are tackling these challenges. I left the summit feeling motivated and optimistic about the advancement of packaging recycling.

Our industry appears to be making strides in nearly every packaging medium and waste stream discussed at the summit. I had the privilege of hearing from speakers like Myles Cohen, the founder of Circular Ventures, who shared insights into the pros and cons of paper versus plastic recycling. We learned both impressive and frustrating statistics about recycling rates and the costs involved, for both industry and consumers, like this one: Did you know that the cost of recycling for consumers is at least three times higher than it is for industrial waste?

While Cohen’s talk may have been discouraging to some, given the costs and the relatively low rates of actual recycling, I found it inspiring. It pushed me to set new goals, and I encourage you to do the same.

We also heard from Yale research scholar Reid Lifset, who spoke on Extended Producer Responsibility (EPR) and its history, a topic he has studied for most of his academic career. I greatly admire his dedication, though I wish we didn’t need his expertise to address the growing challenges our society has created. If only we had started working toward waste reduction and recycling 25 years ago! Whatever happened to the reduce, reuse, and recycle movement?

I believe the EPR movement represents a final tipping point, compelling us to reflect on the waste streams we generate and the associated costs. It’s a driving force that makes us consider the end-of-life impact of the products we purchase every day…and that we manufacture.

PACK EXPO was, of course, another highlight of the year, and as always, it was great to catch up with many of you there. I look forward to reconnecting with you all at what I know will be a memorable event for all of us in 2025: ENGAGE. I’ll see you in Clearwater, February 4-6! CM+P

Jerry Thompson is president of Combined Technologies, Inc.

Editor’s Note: If you missed the Packaging Recycling Summit, you can still access the video archive. See p. 5 for more.

• Made at fixed angles of 30, 45, and 60 degrees

• Reduced footprint

• Eliminate changeover adjustments

• Accessibility layout for operator and fork truck traffic

BY ROBBY MARTIN, Principle, 3-Fold Consulting

Sustainability—in the environmental sense—continues to be a hot topic at conferences and trade shows. But in addition to environmental sustainability, I keep being reminded that sustainability in our supply chains goes far beyond environmental and packaging materials considerations.

By supply chain sustainability, I mean keeping our supply chains in good shape. But when we factor in workforce challenges that have existed since the pandemic, it becomes clear that threats to the supply chain can come from multiple sources. In my opinion, this puts contract manufacturers (co-mans) and contract packagers (co-packers) in a tricky spot between opportunity and risk.

Here’s an example of such a situation. A co-man I know well recently shared an experience. After a year of productive conversations with a large brand owner, his team worked at risk to develop six product SKUs to suit the brand owner. Just when they were about to finalize the paperwork to start ordering materials for production, the brand owner canceled the project. Why the sudden change in direction? The brand owner switched buyers for their co-manufactured products. The new buyer, likely with a new set of sourcing criteria, deemed the quoted costs too high for the products my friend developed. Meanwhile, based on productive and forward-looking conversations with the previous buyer, my friend was on the verge of committing to a new facility lease

at a new location with new line layouts. All of this was to support the acquired new business.

Here’s the really bad part: after notifying my friend that they were canceling the project, the brand owner was unwilling to compensate my friend’s business for their development time, trial time, or even for third-party testing and other services the co-man employed in pursuit of the brand owner’s business. It’s worth noting that the products in this story are in a niche where my friend’s company is among the most qualified producers.

I could go further, but I’ll spare you the details. The point of telling this story is to underscore the need for clear communication and well-defined “working rules” between the brand owner and the co-man/co-packer. While I am a huge proponent of companies being “easy to work with,” no provider should be forced to bear the full burden of a development project without protections for their investments and risks. To do so can put the co-man/co-packer supply chain at the highest possible risk—and that is not sustainable.

In my experience, smooth interactions between parties almost always boil down to clear, effective, and well-understood communication. Here are three tools to help keep communication fluid and welldocumented.

NDAs are often the first step in many engagements. They protect confidential information shared between the parties and set expectations for its use. While they safeguard shared information, they also offer the first opportunity to address how engagement details will be handled. Identifying issues early can prevent disruptions later.

When I worked with a brand owner, we were introduced to development agreements by a contract manufacturing partner. Once we learned how to work with development agreements, these documents became a standard part of our engagement with contract providers, especially when working with co-mans. While development agreements may overlap with some elements of the NDAs, they go further into how parties work together, answering questions like:

• How will costs be managed?

• How will line time and lab time be managed?

• How will material costs be accounted for and/or reimbursed?

• How will the project be ended, if that becomes necessary?

• How do we transition to full-scale, permanent production if the project moves forward?

I could write volumes on this. The key point is that they should outline expectations, including WHO PAYS! This helps protect contractors from disruptive project surprises like the one my friend experienced.

Stage-Gate® is a great tool for evaluating projects in terms of size, scope, and capability. Even a simple set of checkpoints can help service providers evaluate whether a project is on the right track. Both parties should ask “big picture” questions along the way to avoid misaligned expectations. The bigger or more complex the project is, the more important structured checkpoints become. One final thought: co-mans and copackers are providers, but they also have their own supply chains to manage. Don’t be shy about protecting your right to do that well! CM+P

PMMI’s Business Intelligence report, “Contract Packaging & Manufacturing: Drivers of Machinery Investments,” published in October, highlights strong growth on both the brand and contractor sides. The report, compiled from interviews across the sector, reveals that 67% of brand owners plan to maintain or increase their reliance on outsourced services, while three-quarters of contract packaging/manufacturing (CP/CM) companies expect significant business expansion over the next three years.

One highlight of the report explains the main reasons brands seek contracted services. Fifty-nine percent of respondents said that CP/CMs offer brands access to machinery and packaging formats not available in-house. Brands also say that contractors assist with testing new products or packaging (48%), provide customized solutions for short or limited production runs (48%), and support brands in meeting surges in sales volume (43%). CP/CM services also help brands better serve the e-commerce channel, though this is a smaller factor at 7%.

The 51-page report, produced with DDR/REACH, outlines the capabilities CP/CM providers need and the challenges they face to succeed. Download the full report at www.pmmi.org/business-intelligence

Another recent report from Mordor Intelligence forecasts that the contract packaging market will grow from $73.32 billion in 2024 to $111.22 billion by 2029, reflecting a compound annual growth rate (CAGR) of 8.69%.

Mordor Intelligence attributes this growth to brands’ appeal of outsourcing, as co-packers offer consistent quality and cost savings. The report highlighted the pharmaceutical and cosmetics sectors in particular, predicting strong growth, as strict regulations drive the demand for co-packing services.

Also featured in the report: how growing consumer interest in eco-friendly packaging presents an opportunity for co-packers to provide sustainable solutions to their partner brands. CM+P

Did you miss Packaging World ’s Packaging Recycling Summit (PRS) in September? Don’t worry—you can still catch all the insights virtually and for free by registering after the fact.

Leading retailers, reprocessors, materials recovery facilities (MRFs), and solution providers joined top brands including Google, Amazon, General Mills, Colgate-Palmolive, Coca-Cola, Danone, and McCormick to share their experiences.

Watch videos about the top drivers in packaging recyclability today, including regulatory changes like Extended Producer Responsibility (EPR) and post-consumer recycled content (PCR), advanced recycling, consumer behavior, and designing for recyclability. Sessions also explored integrating recyclable materials with both new and legacy machinery.

To watch the PRS video archive, scan the QR code or visit www.packagingrecyclingsummit.com and register for free now.

This mobile pail filler was created for batch filling operations at multiple locations. It is top and sub-surface pail filler that moves around on casters. This filler will handle 1 to 7 gallon containers and only requires 25 lbs. of inertia to move it.

Increase Production & Maximize Uptime

Heavy-Duty & Long Lasting

After a devastating fire, Illinois co-packer stays resilient and innovative in niche markets without losing its commitment to customers.

BY JOSEPH DERR, Editor

Based in the Chicago suburbs, MattPak, Inc. prides itself on satisfying its customers, embracing innovation, and investing in its people. After a devastating fire in 2008, the company quickly rebuilt itself through close-knit relationships to thrive as the successful co-packer it is today.

It all started as a conversation between friends in 2001. Ted Kunach and Jeff Graham both had extensive experience working at co-packer Cloud Corporation before it was sold to private equity. (It is now a part of Mespack .)

“Chuck Cloud, the founder of Cloud Corporation, was the man who invented the water-soluble pouch machine back in 1962,” says Jeff Graham, now vice president of sales and partner at MattPak. “He told me, ‘Go create a market,’ and that’s what I

Year started: 2001

Location: Franklin Park, Ill.

Number of employees: 120 employees (2 shifts)

Main industries served: Food, beverage, food service, household goods, professional cleaning products

Types of products handled: Laundry

did for these pods in the 1990s.”

Ted Kunach, now president and partner at MattPak, had a knack for building and rebuilding machinery, taking after his father. In his youth, Kunach would

detergent powders and liquids, household and professional soaps and cleaners, condiments, spices, ingredient mixes, drink mixes, etc.

Packaging services offered: Filling and packing

Additional services offered: Machine parts and service, machine sales

Certifications and capabilities: Safe Quality Food (SQF), organic, kosher

Types of packaging equipment in facility: Horizontal form/fill/seal machines (for pouches and sachets), custom high-speed rotary style drum machine (for watersoluble pouches), and robotic palletizers

Website: www.mattpak.com

visit and help move pallets in the factory where his dad worked. “He could make any machine whistle, sing, and dance, and he’d make the most intricate parts for the machines,” says Kunach. “I just watched the machines and was fascinated by them.”

‘Let’s make some pouches and pods’

Combining their experience, Kunach and Graham had a solid foundation to start a new venture together. “Ted can fix any machine or find any machine to buy,” says Graham. “And we can provide pouches and pods to many companies.”

When they left Cloud, the two got to thinking. “How difficult can it be?” Graham recalls their conversation at the time. “It will be fun—let’s start our own company and make some pouches and pods.”

Those formats—water-soluble polyvinyl alcohol (PVA) pods and singleserve powders in paper, film, or foil sachets—remain the core of MattPak’s co-packing operation to this day.

The partners leased a building in Franklin Park, Ill., and began assembling

equipment for their new business.

MattPak’s first big contract was packing instant potatoes in stand-up pouches for Idahoan Foods, one that helped the copacker build its first PVA filling machine. Naming the company after Kunach’s then toddler son, Matthew, in 2001, MattPak was born.

By the mid-2000s, the operation was taking on contracts to produce pods for major detergent and household cleaner brands as well as pouches and sachets for food brands. But not long after MattPak’s seventh birthday came a devastating setback.

In June 2008, a fire, ignited by a chemical reaction in a laundry booster product, destroyed a large part of the facility. The fire brought the MattPak team closer together: Kunach remembers how MattPak’s employees worked to salvage what they could.

“We rebuilt from scratch, using the support of our industry partners and the hard work of our team,” Kunach says.

One of MattPak’s largest customers even offered space in their plant to help

MattPak uses a high-speed rotary style drum machine it designed and built to produce single-fill pods for both liquid and powder products.

keep the co-packer’s operations running as the company rebuilt itself—an unusual move that attests to the strong relationships MattPak had built in a short time.

“They didn’t charge us anything. They just said, ‘We need you to keep packing for us, so come use our space,’” Kunach recalls.

To keep product rolling during the rebuild, MattPak also outsourced some jobs to other co-packers, but those contracts would return to MattPak once it was back on its feet. “We didn’t lose a single customer—in fact, we even gained new business during that time,” Graham says.

By August 2009, MattPak was fully operational back in the original facility, stronger than ever. “We didn’t just rebuild, we expanded,” Kunach explains. “We went from 20,000 to 50,000 square feet, adding new production lines and building a second floor to accommodate more equipment.”

Today, MattPak’s commitment to its customers lies at the heart of its success (the company’s motto is “Excellence in Contract Packaging”).

“We go above and beyond for our customers,” Kunach says. “If we can’t do a job, we’ll point them in the right direction. That’s why they keep coming back.”

The co-packer has two main production processes: one for water-soluble pods

and the other for powders in sachets, with each side representing approximately 50% of the business. Each production room is enclosed with its own air handling system to avoid cross-contamination.

For the water-soluble pod side of the business, MattPak uses custom, inhouse designed and built high-speed rotary style drum machines that produce single-fill pods for both liquid and powder products. These pods are typically used in laundry detergents but have many other applications.

Liquid or powder products for the pod lines are gravity-fed through a hopper, with powders screened via magnet. As product enters MattPak’s custom filling machine, two rolls of PVA are fed to form the pods. One roll is vacuum-formed to become the cavity and the other for the lidding. The two rolls are filled with a single-serve portion before being sealed using water, heat, and pressure. The roll is cut in the machine direction before the pods move into bulk lined cases and then on to two Formic robotic palletizers.

On the food side, MattPak handles a variety of products including sweeteners, spices, seasoning mixes, instant coffee, hot chocolate, grated cheese, and drink mixes. All products run on horizontal form/fill/seal pouch equipment from either Bartelt , R.A Jones or Cloud, which fill pouches or sachets using either intermittent or continuous motion.

Innovative applications

Beyond detergent and professional cleaning products, MattPak already packs proteins for health and fitness stores in edible, water-soluble pods. The company is also exploring edible, water-soluble pods for drink mixes.

“We’re looking to move into hot cocoa and drink mixes, where you drop a pod in your water bottle instead of tearing a pouch open and pouring,” Graham says.

One of MattPak’s most notable innovations combines its two fortes in a single package: a pod-within-a-pouch design. MattPak collaborated with Brook + Whittle for the Degreaser and Cleaner from WD-40 Company in a flexible packaging format (pictured at left). The product is packaged in stick pack-like pods that dissolve when mixed with water in any pre-existing bottle sprayer.

“You just drop the liquid pod into your sprayer, shake it up, and you’re good to go,” says Michael McCann, MattPak’s inside sales manager. “The pouch and pod combo eliminates the need for full bottles of liquid.”

MattPak also hopes to expand further, by venturing into sustainable packaging solutions that use more bio-based materials when the time is right.

MattPak’s horizontal form/fill/seal pouching machine packs crushed pepper in single serve sachets.

MattPak’s membership in CPA has also been a part of the co-packer’s growth, says Jeff Graham.

“Through CPA, we’ve built a lot of relationships and found new business opportunities – it’s a great bunch of people,” says Graham. “You build relationships with people who can be friends for life, and you grow your business in ways you might not even have thought of.”

Networking at CPA events has led to collaborations for MattPak with companies like Nulogy, which helped the co-packer adopt an ERP system for inventory and quality control.

While its members sometimes may be direct competitors, the networking benefits and learning opportunities that the CPA offers outweigh any rivalries. “Even though we’re all technically competitors, at the end of the day, we are contract packaging—we’re a family,” says Ted Kunach. CM+P

Another key to MattPak’s success is its strong company culture. Employees are treated like family, and management—led by co-owners Ted Kunach, Jeff Graham, and Matthew Kunach—fosters open communication and employee development. “They are always walking the floor, talking to employees, and listening to their ideas,” says McCann.

Another key to keeping good workers at MattPak has been an emphasis on promoting from within. “Many of our managers and team leaders started out running lines and working in the plant and now they’re managing operations,” Graham says.

The company is undergoing another major expansion: an annex that will run new production lines to meet growing demand. They are also expanding stand-up pouches with zipper capability.

MattPak will also venture into an ESG social audit for the first time next year. “It’s the next thing coming, and our customers want these audits,” says Graham.

Matthew Kunach—the company’s namesake and today its operations manager—looks forward to the future but says there is also a deep sense of pride in the work MattPak is doing today.

“It’s pretty cool walking in here every day and being able to see your name on the door and know that you’ll keep it growing for years to come,” he says. CM+P

Automation, combined with an upskilled workforce and reduced water consumption, writes a new chapter in canned protein company’s 80-year history.

BY JOSEPH DERR, Editor

Crider Foods , a contract food manufacturer and packager in Stillmore, Ga., is the leading U.S. producer of canned chicken, turkey, ham, pork, and beef products. Through automation of its retort system, Crider Foods has transformed its operations and, in the process, upskilled its workforce while taking a great leap in environmental sustainability through reduced water

The path to automated packaging began in 2010 at an inflection point for the company. From 2008 to 2010, the Crider Foods retorting operation neared production capacity. The simple answer for increasing capacity at the time seemed to be to purchase cost-effective retorts, expand the retort room, and hire additional employees for loading and unloading baskets and retorts by hand as well as for palletizing.

consumption. The company has also endowed university-level technical education to prepare the next generation of process engineers.

From its beginnings in 1944 as a family fish and poultry market in Douglas, Ga., Crider Foods today centers its business around canned chicken as its lead product. Now, as it annually packs millions of pounds of canned protein, there is no manual handling of cans at the Crider plant from the time the cans enter the facility to when they leave.

While there were islands of automation in the 250,000-sq-ft poultry operation at the plant for processing, canning, and fully cooked frozen lines, most procedures required direct labor. And workers were not trained in advanced technology.

Then, Crider began working with Allpax , a product brand of ProMach, a leading U.S. manufacturer of retorts and automated batch retort systems (ABRS). After touring the Stillmore plant and listening to Crider’s goals, Allpax proposed a fully automated retort

system that would cut down on manual operations and significantly increase capacity. The higher cost of the proposed system, not to mention the worker upskilling issue, left the Crider evaluation team intrigued but cautious.

Allpax invited key managers, including second-generation owner and present chairman William (Billy) Crider Jr., to tour a recently installed ABRS-based canning operation in Illinois. The Allpax technical sales team wanted Crider Foods to experience the benefits of automation and have the opportunity to talk with end-users about their experience with the recently installed automated batch retort system.

“It felt like I had stepped into the future,” Crider said later about the tour. “I saw in my mind’s eye high-speed canning lines at our Stillmore plant feeding a similar automated retort system, and I understood what that would mean for transforming our family-owned business. At the end of the tour, I said to the Allpax sales team we wanted an automated system like the one we just saw.”

During the tour, Crider and his team saw a single operator running 8 Allpax jumbo retorts from a control platform overlooking the room. Cans were automatically swept in layers into and out of retort baskets. An automated shuttle traveling at 270 fpm loaded and unloaded the bank of eight retorts and the system tracked the baskets, ensuring that every can went through the correct cooking process.

The ABRS system could load/unload baskets at a rate of 550 cans per minute,

Upstream of the retort room, Crider Foods upgraded fillers and seamers on its canning lines and ran those lines at a higher speed to accommodate the increased capacity in the retort room.

depending on can size with smaller cans running faster than 550. The Allpax operation and record-keeping software complied with FDA guidelines. Allpax provided this customer 24/7 remote technical support via a secure virtual private network.

“Plant personnel informed us that production was up with the new automated system and labor input virtually disappeared,” Crider says.

Shortly after the tour, Allpax designed a retort operation for Crider with eight sixbasket saturated steam vessels with the option of adding water spray capabilities later. The ABRS portion of the system consisted of two loading/unloading stations for the baskets and a threebasket shuttle.

The shuttle automatically traveled to the retorts to load and unload baskets, meaning that the days of employees

pushing baskets—each carrying more than 2,000 filled cans—into and out of retorts were in the past. A cook responsible for following FDA guidelines would monitor the entire sterilization process from a bank of computer screens overlooking the retorts. Before the new system shipped to Stillmore, Allpax staged a thorough factory acceptance test complete with documentation.

Installation in Stillmore went smoothly as Allpax manufactured all the equipment. Crider Foods reports there were no issues with components not integrating properly, which they chalk up to being an advantage of working with a single-source supplier. Retort room staff decreased from approximately 20 down to three or four. New employees were hired for some of the more specialized jobs and other personnel were reassigned to various departments within the plant.

On the downstream end, Crider transformed 40,000 sq ft of warehouse space into a new end-of-line packaging room with new high-speed packaging lines featuring automated inspection, labeling, tray packaging, and palletizing equipment. Like the canning lines, end-ofline operations saw a significant reduction in staffing needs.

Having additional personnel available for other departments eased staffing issues in those departments. Today, there is one operator and one recorder per canning and packaging line and one operator and one recorder for the palletizing operation.

The Crider retort room now features 15 Allpax static retorts for cans and 5 dual-mode retorts capable of saturated steam and water spray with overpressure, which are used for cans or for the new pouch lines of ready-to-eat chicken products. From the time the empty cans are depalletized to the time the full cans are packed into trays and palletized, no human touches them.

During and after the installation in 2011, Crider Foods launched an intensive

training program. The state of Georgia supported training through its Quick Start program, where technical colleges provide customized workforce training for companies creating jobs. Crider also hired a private training organization to assist in multi-skills training.

The maintenance staff was given extensive training in all aspects of automation, including best practices in preventive maintenance. Preventive maintenance keeps the automated systems running in like-new condition. Maintenance personnel were involved in the planning for the new lines and provided important insights about what was needed in a new high-speed/highcapacity environment.

“This gift will help apply and develop technology to solve problems due to labor shortages, processing inefficiencies, and supply chain disruptions, while establishing an experienced high-tech workforce in southeast Georgia,” says Mohammad Davoud, dean of the Allen E. Paulson College of Engineering and Computing.

Crider regularly arranges tours of the plant for high school students. Students are surprised and intrigued by the high level of technology, especially when they witness technicians walking the floors with tablets held in their hands. The company hopes to show students that 21st-century food production can offer fulfilling and well-paying careers.

The concerted effort of upskilling the workforce paid off in optimal overall equipment effectiveness, quality, and safety. For example, the plant recently held a month-long celebration when it reached 2 million hours without lost time due to accident or injury.

In 2022, Crider Foods endowed $1 million to Georgia Southern University’s Allen E. Paulson College of Engineering and Computing to develop the Advanced Processing Research Network (APRN).

“We wanted to help develop a program that will produce more of the fantastic engineering talent we’ve already been hiring from Georgia Southern and help the University become a source of engineering talent for the entire Southeast,” says William (Billy) Crider III, CEO.

In 2011, Stillmore phased out poultry processing to make more room for canning, fully cooked frozen chicken, and warehouse space and today purchases poultry and other meats from leading processors. The plant increased from a quarter of a million sq ft to half a million. The Crider Foods operation in Stillmore is staffed by more than 700 people. Employee retention and morale are high, Crider reports. Further, values of supporting co-workers run throughout the organization.

Quality assurance and value are Crider’s benchmarks and constant improvement defines its culture.

Investment in training allows Crider to make sure quality and safety exceed expectations. Key quality assurance processes include:

• All incoming meat is checked to raw material quality specifications and temperature requirements. All raw material is X-rayed for bones and foreign material

• All raw material is weighed before and after marination to ensure consistent results

• All can labels are scanned and validated to match the inkjet code on the can to ensure the correct label has been applied

• All cans are given a final X-ray to remove any dented cans or cans with potential bones or foreign material

• Can seams are verified through digital imaging equipment

• Crider’s onsite lab samples all production runs to ensure sodium, fat, and protein levels are consistent.

Employees closely monitor every production run. The plant holds a Level 3 SQF Certification and has received numerous SQF “excellent” ratings. The plant has a GOLD Certificate of Recognition from Silliker, the leading international network of accredited food testing and consulting laboratories.

Stillmore also has a 6,000-sq-ft pilot plant. Most of the pieces of equipment in the pilot facility are smaller versions of equipment on the line, from marination injectors, to tumblers, ovens, and fillers. Similar equipment aids in scaling up from pilot lines to full production.

An Allpax 2402 Multi-Mode laboratory retort is an essential piece of equipment for R&D and piloting as it has the same software as the production system, so the plant is assured of quality once the parameters are set. The machine’s various modes can be used to find the optimum recipe.

Retorts are the largest consumers of water at Stillmore, mostly from cooling the cans after processing. The plant added filtration/recycling systems and

has reduced water consumption by 66%. Outside the retort room, washing cans offers another opportunity to cut consumption and operation is examining other ways to cut down on use.

Heat exchangers capturing heat from the retorts are being used to heat water for the plant’s boilers and to feed into the sanitation system. The control system is making boilers more efficient and has decreased natural gas usage by roughly 10 percent. The plant utilizes an energyefficient ammonia-based refrigeration system to maintain the cold parts of the operation at 58 degrees year-round.

Water leaving the plant is screened for meat particles and any protein captured is collected and sent to a rendering plant. Water then goes through a Dissolved Air Flotation (DAF) water treatment process that clarifies wastewater by removal of fats, phosphates, starches, proteins, and other suspended solids, oils, and greases. Phosphate and other useful chemicals

are collected and used as a natural agricultural fertilizer for the company’s 500 acres of farmland where Rey grass is grown in the winter and Bermuda grass in the summer.

Following the DAF process, water

passes through an aeration facultative pond, then an aeration pond, which further cleans the H20. A holding pond of clean water supplies an irrigation system for the grass-growing operation.

In addition to making the plant more energy efficient, water reduction at the plant is also a step towards sustainability, which Crider Jr. says is good for the environment and business.

“The majority of our brand owners and retailer customers have supplier sustainability goals, and we are proud to show them our accomplishments,” says Crider Jr. “Making these investments is the right thing to do in terms of looking to the future and what we are leaving for those who come after us.”

A vision of the future where automation paved a new path for Crider Foods has in the years since transformed the company. Crider Foods has been feeding families for 80 years and confidently knows it will continue to do so in the future. CM+P

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies,

Mar. 10-12, 2025

During a refocus of its core business, Indiana co-packer plugs in a pre-made rotary pouch machine, boosting productivity by 15%.

BY JOSEPH DERR, Editor

Midwest Service Warehouse (MSW) Packaging, established in 1991, operates two facilities in Lawrenceburg and Batesville, Ind., totaling approximately 100,000 square feet and employing 60 people. A provider of contract packaging and repacking services to globally recognized brands, MSW Packaging’s portfolio includes pouching, cartoning, registered shrink-wrapping, hand packing, kitting, and e-commerce fulfillment.

For most of its time in business, MSW engaged in contract manufacturing of products such as granolas, spiced nut mixes, and pet treats.

lines is dedicated to bagging pretzels/ snacks and candies sold in club stores.

MSW also packs numerous club variety packs for beverages, candy and snacks, and protein bars.

Besides its new premade pouch machine, MSW also installed equipment including a bucket elevator and combination scale. MSW Packaging’s new line runs dry goods for its clients.

product line of candies, salty snacks, and chocolates. “We’re running various sizes of standard retail and club pouches with fills from 1 to 26 oz,” says DeAngelis.

“We had clients that were looking for us to have increased capacity in the straight co-packing segment,” says David DeAngelis, vice president of sales and marketing at MSW. “In early 2022, we did a deep dive into our business and decided to focus exclusively on the co-packing side.”

First, MSW notified its contract manufacturing customers of the phaseout, giving them eight months of lead time to find a new manufacturer. During that transitional time, MSW also prepared its facility for the next phase by restructuring their space to accommodate the new focus on the growing co-packing business.

“We knocked down some walls and built new ones to prepare our space for the new line,” says DeAngelis.

A significant part of their co-packing

MSW knew it was also time to upgrade a pre-made pouch machine that was about a decade old. They approached Viking Masek Packaging Technologies at a PACK EXPO show, drawn by the manufacturer’s reputation in the contract packaging space. “We had known about Viking Masek for a long time, and we wanted to explore more.”

That exploration led to MSW’s purchase of what was soon to become the star of its new packaging line: Viking Masek’s 8S-285, a single-lane, automatic, rotary pre-made pouch machine. This filler and sealer, designed for dry goods and powders, was a perfect fit for MSW’s

MSW liked this pouch machine not only because of its production capacity (Viking Masek reports on its website that the machine can run at a maximum of 60 bpm) but also for its fast changeover time to handle the varying needs of its clients. DeAngelis says that one client has five different SKUs running on the same line. “We’re running five of the same product, just different flavors,” he says. “Changeover time is so minimal, and it’s greatly improved our productivity.”

The 8S-285 allows MSW to run 42-48 bags per minute with 3-5 products at a time, significantly enhancing their capabilities. “We consistently see a 15% improvement in productivity compared to our older lines,” DeAngelis added.

Because of the need to transition quickly to its new focus on co-packing, MSW was

concerned about implementation time, but the supplier delivered ahead of schedule.

“Viking Masek went above and beyond to pull together all the components needed for this line,” DeAngelis remarked. “I think implementation was 14 weeks, which was about eight weeks sooner than we were originally looking at, and it’s a very consistent, reliable line.”

The new line also features a bucket elevator from Frazier & Son that Viking Masek helped specify. Other equipment that is part of the new line includes a Yamato Corp. combination scale, a Fortress Technology metal detector, and case erectors supplied by Cleveland Equipment

To maintain uniformity with end-ofline processes, MSW sourced specific equipment that the Viking Masek team seamlessly integrated into the overall buildout, says DeAngelis. Getting the new line up and running went so well

that MSW is considering extending its partnership with the supplier.

“It has helped us move forward with our three-to-five-year expansion plans, which is why we’ve reached out to Viking Masek about some other lines to support existing and new customer requirements,” says DeAngelis.

He credits this overall success not only to the machine’s features but also to Viking Masek’s customer-centric approach. “We felt like they really treated our business as their own and made recommendations based on what we were looking to achieve, not necessarily so Viking Masek could sell more equipment.”

Besides productivity, MSW’s investment in the automated packaging solution also had a visible impact on operations. With higher output, MSW can now focus

on other areas of the plant, reassigning workers to other skill-oriented positions.

“We’re not changing the headcount of our organization,” says DeAngelis. “We’re just allowing people to develop new skills on new equipment.”

MSW rotates its workers between lines, and teams enjoy getting to work with the new pouch machine. “We know people are excited that it’s their turn to be in the room because it’s air-conditioned and less strenuous work.”

DeAngelis added that workforce turnover is also dropping.

MSW’s partnership with Viking Masek has also had a positive ripple effect beyond the plant walls—with MSW’s clients. “When they see or hear that we were running something on a Viking Masek line, it gives them a certain comfort, recognizing that it’s quality equipment on a quality line, and they’re happy to hear that.” CM+P

Versatile Packagers, which celebrates its 25th year working with Signature Brands, shares the keys to building long-lasting co-packing partnerships.

BY JOSEPH DERR, Editor

Versatile Packagers, headquartered in Tampa, is part of the Wheelhouse family, with locations in North Carolina, Indiana, Pennsylvania, and Texas. Priding itself on building lasting co-packing partnerships, Versatile celebrates 25 years with Signature Brands, the dessert decoration and holiday goods company, this year.

Contract Manufacturing and Packaging (CMP) caught up with Executive Director Bob Vande Weghe, who explained how Versatile builds those partnerships and why tactics like taking an end-to-end cost mindset, staying agile amidst fluctuating demand, and fostering innovation are critical.

CM+P: Versatile Packagers went from a 15,000-square-meter facility to one ten times that size today. How?

Bob Vande Weghe: Versatile Packagers started in 1992 with Tropicana. We were co-packing for them, handling multi-packs of products on both the refrigerated and ambient sides. This launched our company. From there, we diversified and grew by adding more services and equipment to handle different types of packaging. Since Florida isn’t a huge manufacturing state, we have to stay agile to manage a lot of different types of jobs. Most of our jobs aren’t large, so agility in our location is essential as we’re constantly handling a bit of everything for everyone.

What kinds of jobs do you take on nowadays?

We’ve expanded into various types of packaging, including blister packaging,

cartoning, and beverage containers. In 2019, we were purchased by South Atlantic Packaging and Wheelhouse Corporation, which opened new opportunities to serve our customer base across multiple locations, reducing freight costs for those with out-of-state locations. We now have five locations across the U.S. Now, we’re involved in the automotive, medical, nutraceutical, skincare, and haircare industries. I think the only area we don’t cover is pharmaceuticals.

How does Versatile Packagers stand apart from the competition?

Our focus is on developing long-term customer relationships. I often talk about “yes sir/yes ma’am” accounts—customers that simply want us to execute without collaboration. While those are fine, we prefer partnerships where we can collaborate and look for improvements

in design, labor, equipment, and people. Those are the four areas we focused on over the years.

Once a customer is onboard, we aim to sit down with them and suggest ways to reduce costs and improve processes. We prefer to be involved early in a project rather than after everything is finalized. By then, it can be too late to make improvements or reduce costs, and it becomes a “yes sir/yes ma’am” scenario.

Tell us how the partnership with Signature Brands grew over the years.

Initially, Signature Brands brought us a “yes sir/yes ma’am” project to assemble components, which was easy to execute. As we built trust, they asked us to handle more complex tasks. We like to ask questions like: “What can we do better with those projects? How can we reduce those costs?” We don’t just work with the customer, but we also work with the manufacturers that may be making the materials themselves and ask questions like: “Can we go from a .25-point board down to a .24-point board and still

accomplish the same goal?”

We also tend to think end-to-end about costs. With Signature’s cupcake paper liner business, they asked if we could match the price of another copacker. I told them that we have a piece of equipment here that can do it twice as fast, but that it would be a different concept, a different look and feel. We helped them reduce the package by about half and reduce their cost by about twothirds.

In that example, what was your concept?

Originally, the cupcake liner package was a header card stapled to a poly bag. We changed it to a flow-wrap bag with a header card and then moved to a fully printed flow-wrap with a hang hole. Afterward, we began manufacturing the liners ourselves, forming and packaging them, which allowed us to increase production and cut costs dramatically.

Over the years, our collaboration has led to more cost reductions, increased production speed, and process improvements.

What does a good co-packing partnership look like to you?

It is about constant communication and transparency. All our systems allow customers to see real-time data, so our customers trust what we’re doing. When they have that trust factor of knowing what we’re doing and seeing what we’re doing, they know we’re producing a good product for them. And year after year of working closely together like that produces great results. Then they are going to give you more and more responsibilities.

It’s also about continuous improvement. We don’t rest on past successes. We’re always looking for ways to reduce costs and increase sustainability. The world changes constantly, and we have to adapt with it. We’ve worked closely with Signature Brands to develop new packaging, like a nesting cup design that increased efficiency and reduced costs. Our relationship with Signature Brands has been successful because of collaboration and listening on both sides. That’s the key for any contract packager: listening and acting on what’s discussed.

Can you go the extra mile for one customer without neglecting the others?

It all starts with not getting overloaded by any one customer. You can’t be everything to everybody. We assign key roles for each account. Personally, I manage five to seven accounts, which allows me to spend quality time with them and focus on developing their products. We meet with one customer regularly to discuss projects and test materials to find ways to reduce costs. It’s about collaboration, and customers also need to be open to spending time finding improvements.

What do you do in challenging times when there are fluctuations in consumer demand?

Our versatility lies in two strengths. First is our ability to manage labor really well. Second is having multifunctional equipment that can handle various jobs. We try to work with the equipment

we already have so that we’re not increasing costs by adding more and more equipment. For example, we have equipment that can run 10 pieces a minute, but we also have equipment that can run 150 pieces a minute. When you can move from job to job quickly, it allows you to be that agile type of vendor that you need to be. I think this flexibility helps us remain competitive to handle fluctuations in demand that our customers experience daily from retailers.

As a contract packager, we see a lot of volatility with supply chains and uncertainty with new product launches. But I think that’s part of our business. When you have a good relationship with your customer, you’re able to work through the challenges associated with change and unpredictability.

What would you say is your approach to innovation?

The Wheelhouse management team meets weekly across all our locations to discuss projects. It’s great to have team members with different expertise to bounce ideas off each other. My business partner in Tampa and I constantly talk

about ways to reduce costs and improve processes. Innovation and sustainability are key topics every week. One of the benefits of having five locations is that if one facility doesn’t need a piece of equipment, another might. We can pack it up and move it where it’s needed, allowing us to maximize the use of our assets.

What’s next for Versatile Packagers?

Sustainability is our biggest focus right now. Paper blisters and paper packaging in general for non-food packaging, as well as trying to control rising costs, are some of the upcoming processes we’re developing in-house with some help from our vendors. This type of paper packaging is already happening in the industry, and we have been doing this for years, but we plan to expand further and try to find ways to bring costs down and help create a greener environment. CM+P

Register for ENGAGE now Registration for CPA’s ENGAGE conference is now open. Scheduled for February 4-6, 2025, at the Sheraton Sand Key Resort in Clearwater, Fla., ENGAGE is the premier annual event for contract packagers and manufacturers. Sign up today so you won’t miss out on three days packed with learning and networking opportunities. Register at www.contractpackaging.org/engage.

Did you know that CPA is not just for contract packagers and manufacturers? The association connects OEM suppliers and packaging material suppliers to its member base through its Associate Member program. As an Associate Member, you get to network with our expanding membership of CP/CM and brand members, share news with our members, and enjoy exclusive sponsorship programs. Our CP/CM members prefer to do business with CPA Associate Members, so join today at www.contractpackaging.org/membership

Since 1995, CPA has been connecting brands and manufacturers, and it recently debuted its latest tool to drive that mission forward. CPA’s new AI-driven RFQ tool, unveiled at PACK EXPO International in November, is designed to revolutionize the way brands connect with the most suitable providers for project success. CPA members will benefit from enhanced interaction, and there will be no charge for brands to use the tool. Look for more details on the CPA website and at ENGAGE.

With another successful PACK EXPO International in the books, CPA will kick off a busy 2025 tradeshow season in January at the Winter Fancy Food Show in Las Vegas. The team will then travel to the Natural Products Expo and SNAXPO in March, Cosmopack North America in July, and PACK EXPO Las Vegas in September. CPA CP/CM members are encouraged to maximize their marketing dollars by becoming Tower Sponsors, allowing them to showcase their capabilities at these shows for a fraction of the usual cost. Learn more at www.contractpackaging.org/ sponsorships. CM+P

301 Grove Street, Vancouver, WA 98661

Phone: +1 877 204 7444 E mail: www.columbiaokura.com

Columbia/Okura LLC is a robotic palletizing integrator, applying expert knowledge and tools to solve customers’ “End of Line” production challenges for a diverse range of businesses, products, and applications. The historical success of our company can be attributed to an exclusive focus on end of line palletizing systems and applications. Columbia/Okura LLC offers robotic palletizing solutions comprised of dynamic products and services aimed at increasing our customers end-of-line packaging efficiency, promoting safety, and reducing their overall cost of production.

Like all industrial robots, Columbia/Okura robots are programmable, automating tasks that are often repetitive or harmful to workers. They have the ability to lift and move heavy loads quickly while keeping products safe and stacking them to be shipped or even neatly to be sold in stores.

The Columbia/Okura miniPAL® is a collaborative palletizing robot built for flexibility and ease of use. It features a range of cobots by Universal Robots, that can handle up to 30KG. The miniPAL® is equipped with Pally software, an intuitive pattern-building program—created in partnership with Rocketfarm—that is easy to operate and program for various product types, including cases, spot packs, trays, bundles, and plastic bags.

With 25 years of equipment design and system integration experience, we have the knowledge to offer the right solution for the job. We offer complete and professional services; from initial system design proposals through project startup and commissioning, as well as after sales support. Our integrated lines offer an end-to-end solution for fully automated bagging and robotic palletizing line solutions from a single, US-based, OEM provider. Our service offering includes integration of manual bagging machines, open-mouth bagging machines, valve bag fillers, air packers, impeller packers, and pallet dispensers.

Phone: 269-637-1112

www.do-it.com

Email: sales@do-it.com

For over 50 years Do-It Corporation has been designing and making hang tabs for the packaging and merchandising display industries. Do-It also manufacturers merchandising display strips, printed hang tabs, carry handles, on-product instantly redeemable coupons (IRCs), shelf wobblers, and promotional bottle neck hang tabs. All Do-It products are designed to get your products noticed in the retail environment and increase sales. Do-It Corporation is a certified Walmart Impulse Strip Supplier.

Do-It Hang Tabs can be provided in clear plastic or can be printed. All products can be produced in several plastic and adhesive choices, depending on the performance requirement and customer preference. Do-It Products are safe and FDA approved for non-food contact.

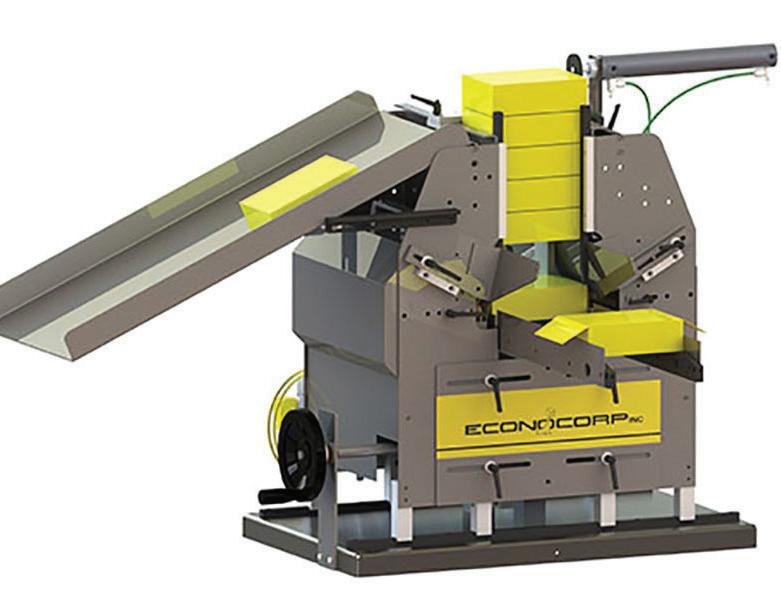

72 Pacella Park Drive, Randolph, MA 02368

Phone: 781/986-7500

www.econocorp.com

Email: info@econocorp.com

Since 1964, Econocorp has been at the forefront of secondary packaging innovation. Our mission? To unlock the power of automation for businesses that crave flexibility in their operations and have an eye for growth.

Specializing in low- to moderate-speed cartoning, case packing, and tray forming solutions, we’ve got all your secondary packaging needs covered. From single machines to integrated systems, Econocorp delivers excellence, every time.

Our solutions cater to a diverse range of industries, including:

• Contract packaging

• Craft beverages & beer

• Dairy, snacks, cereals & frozen foods

• Industrial goods & household items

• Personal care & cosmetics

• Electronics & games

• And more!

The types of solutions we provide include:

Whether you’re end loading or top loading cartons, or a mix of both, we’ve got your needs covered. From countertop carton sealers to continuous-motion cartoners, our economical cartoning machines are developed with the highest quality standards and are easy to operate and maintain.

Our case packing solutions are designed to meet your unique needs. Some of our products include semi-automatic horizontal case packers, automatic carton packers, and wrap-around systems for cartons, trays and cases. They focus on user-friendly functions that are simple to operate and provide cost-effective maintenance.

Econocorp tray formers can form corner glue, corner lock or simplex style locking trays with a hinged cover, and seal them using hot melt glue. When it comes to secondary packaging, Econocorp has your back with solutions designed to move at the speed of your businesses’ changing needs.

21121 Cabot Boulevard, Hayward, CA 94545

Phone: 800/227-5980

www.heatandcontrol.com

Email: info@heatandcontrol.com

Heat and Control®, a world-leading equipment manufacturer, offers the latest technology and the highest quality equipment for packaging, processing, coating and seasoning, conveying, weighing, inspection, and controls/ information systems. Established in 1950, our brands include FastBack® (horizontal motion conveyors and on-machine seasoning), Mastermatic (fryers), and Spray Dynamics® (coating and seasoning application systems), and we partner with other global manufacturing leaders, including Ishida (weighing, packaging and inspection) and CEIA® (metal detection).

Packaging–From tray and container filling to fully automated and integrated Ishida snack food packaging systems, we provide end-of-line solutions, including the industry’s best performing VFFS snack bagmaker, Inspira.

Food Processing–Choose from our vast range of integrated processing solutions including fryers, oil management, ovens, and coating systems.

Seasoning Application–Our comprehensive range of seasoning solutions for on-machine or process area deliver top performance, efficiency, application accuracy, and flavor.

Conveying and Product Handling–We provide a wide variety of conveying and product handling systems to move product through the line efficiently.

Weighing/Combination Scales–Ishida has revolutionized the industry with the ultra-precise computer combination weigher (CCW).

Inspection and Quality Assurance–Protect your consumer and your equipment with detection technology, including Ishida x-ray machines and checkweighers, and CEIA metal detection equipment.

P.O. Box 7281 Reno, NV 89510

Phone: 775-356-6111

www.McKernan.com

Email: Sales@McKernan.com

Over 65 years ago, McKernan began buying and selling surplus packaging (Best Value), later adding a complete Wholesale line. This allows McKernan to offer the highest quality packaging and the lowest minimums. With millions of these package components in stock, most orders ship in less than 48 hours. Search our online inventory at McKernan.com.

McKernan’s Best Value line includes top quality, unbranded packaging components at discounted prices. Our buyers negotiate the best deals, passing on the extra savings to you. New shipments arrive daily. While there is always something new, you may need to move fast as these deals sell out quickly.

McKernan’s PRECYCLE®, or pre-consumer recycling, buys unbranded excess packaging inventory. Plus, we pay the freight to move it out of your warehouse. McKernan is an environmentally responsible and smart solution to scrapping or traditional recycling. Visit WeBuyPackaging.com for more.

McKernan was a pioneer in the green movement with our PRECYCLE® program. Wanting to continue with sustainable packaging, we are proud to carry a new line of PCR that supersedes the quality of previous PCR options.

Whether buying or selling, when you call McKernan, you will speak with a real person. Call 1-800-787-7587 or 775-356-6111 and the front desk staff will connect you with a sales representative or surplus specialist for further assistance.

600 S. Commercial Street, Neenah, WI 54956

Phone: 844/293-2814

www.nerconconveyors.com

Nercon Conveyor Systems is a leading manufacturer of conveyor systems for raw and packaged goods. Nercon solutions are Designed with a Purpose, which means you get the benefit of top quality design, engineering, and production offering the best value in the industry. Conveyor systems are what we do. In fact, it’s the only thing we do so we are industry EXPERTS. Whether it’s for food and beverage applications, pet food, pharmaceuticals, or anything else that consumers put in their shopping cart, we tap into our extensive, decades long experience to provide the right solution for your production line. We look at every project holistically. You might have an idea of the solution you think is right for your line. We’ll evaluate that solution and move forward with it if it truly is the best option, or we’ll offer an alternative solution that may work better and be more budget-friendly. Once that solution is agreed upon, our expert fabricators and assembly teams take over to build you the most reliable systems available. Unlike other OEMs, Nercon owns the entire project from start to finish, including the manufacturing of a majority of the parts used in your system. That allows us to optimize cost, efficiency, and lead times because we’re not waiting for all the components to be delivered from outside vendors. That also means we will stand behind our solutions. If we designed it, engineered it, manufactured the components, assembled it and tested the final solution including the controls, we have no doubt you will have a solution that will last.

Phone: (416) 204-0427

www.Nulogy.com

Email: info@nulogy.com

Nulogy is the leading platform for co-packers, contract manufacturers, and value-added logistics providers, and is purpose-built to optimize operations and enable the real-time data visibility needed to thrive in today’s challenging market conditions. For more than 20 years, Nulogy has been the gold standard for external supply chain operations—preferred by contract suppliers and their brand customers alike.

- Optimize spend: Leverage real-time data from your production operations to get the most out of every dollar spent on inventory and labor.

- Higher Attainment Rates: By accurately capturing your production data, minimize errors and inaccuracies for faster, better order fulfillment.

- Improve customer service: Deliver stronger results and better communication with your customers for mutual trust and growth.

Nulogy powers the operations of the industry’s leading contract packaging and manufacturing providers, including AmeriPac, Crescent, DHL Supply Chain, FedEx, MSI Express, and Summit Packaging Solutions.

In today’s fast-paced market, co-packers and contract manufacturers need real-time insights, operational efficiency, and seamless collaboration to stay ahead. Nulogy’s purpose-built platform provides the tools to overcome industry challenges, reduce waste, and enhance performance.

Scan the QR code to discover how Nulogy can enhance your co-pack operations.

Phone: 417-673-5551

www.prosysfill.com

Email: info@prosysfill.com

ProSys is a premier manufacturer of semiautomatic and fully automatic equipment for filling, Squeeze Tubes, Syringes, Airless Pumps, Cartridges, Jars, Custom Containers & Hot Melt applications for the Pharmaceutical, Cosmetic, Lubricant, Food, Sealant and Adhesive industries. A global supplier of filling equipment since 1985 with U.S. sales, manufacturing and customer service facilities located in Southwest Missouri.

FLEXIBLE COMBINATION FILLING SYSTEMS

• Plastic & Metal Tube Filling Systems

• Tube & Airless Pump Filling Systems

• Tube & Cartridge Filling Systems

FEATURES & BENEFITS

• Fill Accuracy of +/- 0.1% by Volume

• Turnkey & Custom Designs

• Air-Free Vertical Bottom-Up Filling

• Custom Mix Solutions (Eliminates Batching)

• Drum & Pail Presses

• SERVO Solutions

• Explosion Proof Controls (Class 1 Division 1&2, ATEX 0&1)

• Tool-free Release System for Simple Changeovers

• “Digital Readout Indicators” for Fast & Accurate Adjustments

• Multiple Service Technicians for Less Down Time & Preventive Maintenance

• On-line Service & Support

• Recipe Storage & Recall

• Creams, Lotions & Viscous Pastes to 3 Million Centipoise

• Designed & Built in the U.S.A.

www.specialtyequipment.com

Since 1969, at Specialty Equipment Corporation, we have positioned ourselves as the leading manufacturer and provider of liquid filling systems in North America. Headquartered in Houston, Texas we have built our reputation on manufacturing and providing high-end packaging machinery and material handling systems including:

• Liquid fillers for Pails, Drums, Totes and Bottles

• Drum and Pallet Conveyors

• Palletizers for Boxes, Pails and Drums

• Solids fillers for Pails, Drums and Supersacks

• IIoT Software

Over our 50-plus years in business, we have developed a full product offering of automatic and semi-automatic filling machines, conveyors, and packaging machines for drums, pails, IBCs, bottles, jugs, rubber bales, and pallets. We serve a wide range of industries including lubricants, sealants, agriculture, chemical, cleaners, coatings, flavors, and food additives manufacturers.

Contact us now for more information.

1360 Grandview Parkway, Sturtevant, WI 53177

Phone: 877/375-2121

www.spee-dee.com

Email: info@spee-dee.com

Spee-Dee® is known for reliable, accurate and durable filling and checkweighing systems. Contract Packagers and CPGs trust us to improve efficiency, productivity and profitability. Our test lab simulates a full production line at our facility to verify the accuracy of your equipment.

Fast and reliable, our fillers are the ultimate dry filling solution for products ranging from coffee to protein powder. Accurately fill flexible packages such as pillow bags and stand-up pouches as well as rigid containers and single-serve cups.

Fill snacks, candy, spices, coffee, nutraceuticals and more into rigid containers with ease and accuracy. Patented magnetic funnels and tool-less change parts reduce downtime. Easily integrate with Spee-Dee augers or cup fillers in addition to multihead weighers or electronic counters. High-speed and economical options available. All in a small footprint.

Accurately fill rice, beans, cereal, candy, popcorn, nuts and more. High-speed Spee-Dee cup fillers feature quick-change telescoping cups that are easily inserted in minutes. Industry’s most durable, low-maintenance option.

Verify product weight at high speeds. Reduce costly product giveaway. With Electro-Magnetic Force Restoration (EMFR) technology, our checkweighers are more accurate than traditional strain gauge models. Multiple configurations available including incline for small footprint installs.

525 Vossbrink Drive, Washington, MO 63090

Phone: 636/239-7424

Texwrap stands as the industry leader and design manufacture of cutting-edge, fully automated shrinking wrapping and shrink bundling systems. The Kayat SRX and DX line of shrinking bundlers help round out our shrink-packaging solutions with intermittent motion, continuous motion and custom bundling systems, and options for clear and print registered film.

With our latest innovation the Kayat SRX product series can effectively shrink wrap products in trays, or loose/bulk products.

The Kayat SRX features include:

• Slide out film feed and cut assembly for easy maintenance

• Toolless adjustable wrap bar assembly

• Updated Aleen-Bradley controls package with predictive maintenance flags

• Clear or print registered film capability

• Speeds up to 60 cycles per minute.

The DX-130 delivers workhorse productivity in a compact footprint designed to fit in most any production line. The Texwrap badge symbolizes commitment to quality and product support second to none.

The DX features include:

• Linear Slide Design - Used in both the seal jaw closure and carriage travel assembly mean longer life and less maintenance over time.

• Ergonomic Powered Film Cradles - Film cradles are ergonomically designed to enable faster film changeovers.

• Robust Construction - Heavy-duty welded, tubular frame construction.

Our mission is to provide our customers with the latest technological advances while maintaining our commitment to a user-friendly machine that is efficient and easy to maintain. The quality construction, flexibility, easy changeover, and low maintenance features of our systems give Texwrap and Kayat SRX machinery the lowest total cost of ownership available in the market.

For in-depth searches on individual members’ capabilities, visit pmmimediagroup.com/go/contract-manufacturing-and-packaging

Aaron Kendell Packaging Equipment (AEK) www.aekpack.com

KC Christensen (630) 238-2660

ADCO Manufacturing www.adcomfg.com

Jason Chevalier (888) 608-5946

Aesus Inc.

www.aesus.com

Andreas Pollmueller (888) 918-7777

Allegiance Staffing www.allegiancestaffing.com

Danny Minor (281) 355-9222

ALLIEDFLEX Technologies, Inc. www.alliedflex.com

Dennis Calamusa (194) 923-1181

American Specialty Oil Co www.americanspecialtyoils.com

Ann Marie Galbo (734) 522-6333

Barry-Wehmiller www.bwpackagingsolutions.com/, www.bwflexiblesystems.com

Nick Pacak (864) 486-4000

BellatRx Inc.

www.bellatrx.com

Brandy di Tomasso (514) 630-0939

Berlin Packaging www.berlinpackaging.com

Rick Brandt (312) 876-9292

CAM Packaging Systems www.cam-systems.ca

Melinda Mantel (905) 737-5400

Clevertech North America www.clevertech-group.com/en-us

Maria Morales Randall (239) 301-4445

CMCO/Dorner/Garvey www.dornerconveyors.com / www. garvey.com

Michael Earling (800) 397-8664

CMG Plastics www.cmgplastics.com

Jens Duerr (908) 218-7997

Comgraphx www.comgraphx.com

Sie Roe (918) 258-6502

Consolidated Label Co. www.consolidatedlabel.com

Joel Carmany (800) 475-2235

Cremer Speciaalmachines B.V. www.cremer.com

Rene Stuijt +3-125-241-9038

Delkor Systems, Inc. www.delkorsystems.com

Dan Altman (800) 328-5558

DNP Imagingcomm America www.am.dnpribbons.com

Ashley Rothey (724) 696-8932

Douglas Machine www.douglas-machine.com

Sara Hoidahl (320) 763-6587

Econocorp www.econocorp.com

Brooke Kuzmich (781) 986-7500

Elum, Inc. www.eluminc.com

Stephen Mendes (401) 954-7938

Formic www.formic.co

Misa Ilkhechi (775) 436-7642

Fortis Solutions Group www.fortissolutionsgroup.com

Marygrace Quigley (844) 374-5257

Frain Industries www.frain.com

Mary Woodrick (630) 629-9900

Frazier & Son www.frazierandson.com

Jillian Kniffen (936) 494-4040

Gallant Engineering USA LLC www.gallantengg.com

Rakshita Chowdhary (217) 200-1183

Garrido Printing Equipment, Inc www.garridousa.com

Nicolas Garrido (305) 593-9030

Gigantic Bag www.giganticbag.com

Mike Posusney (601) 600-2414

Graphic Packaging International, Inc. www.graphicpkg.com

Faye Milliner (678) 767-2299

Herrmann Ultrasonics www.herrmannultrasonics.com

Erica Perry (630) 626-1626

Hub Labels, Inc. www.hublabels.com

Marketing (301) 790-1660

ID Logistics www.id-logistics.com

David Nye (570) 575-4765

Inergroup Insourcing Solutions www.inergroup.com

John Powell (214) 493-8458

JLS Automation www.jlsautomation.com

Ray Kondracki (717) 505-3800

Lako Tool & Manufacturing, Inc. www.lakotool.com

John Bialecki (419) 662-5256

Loma Systems, An ITW Company www.loma.com

Alice Maniev (800) 872-5662

MASSMAN Automation Designs, LLC www.massmanllc.com

Mark Suchy (320) 554-3611

Matrix Packaging www.matrixpm.com

Marc Wolf (262) 268-8300

MJS Packaging www.mjspackaging.com

Sales Vogel (734) 744-4900

Morrison Container Handling Solutions www.morrison-chs.com

Dustin Lee (708) 756-6660

Nalbach Engineering/ Container Handling Systems www.nalbach.com

Misty Melvin (708) 579-9100

Nulogy Corporation www.nulogy.com

Wendy Phua (416) 204-0427

OMNI Systems www.omnisystem.com

Dean Ketchum (800) 252-2533

Parker Plastics, Inc. www.parker-plastics.com

Cameron Coyle (262) 947-3344

Plastic Bottle Corporation www.plasticbottle.com

Stuart Feen (888) 722-7465

PMI KYOTO www.pmikyoto.com

Branko Vukotic (847) 437-1427

Polymerall Flexible Packaging www.polymerall.com

Oscar Perez-Galicia (682) 237-1130

Polypack, Inc. www.polypack.com

Brian McCann (727) 578-5000

Power Central LLC www.thepowercentral.com

Viswanath Puttagunta (972) 342-0205

Priority Plastics, Inc. www.priorityplastics.com

Stephanie Oliva (260) 726-7000

Quad Packaging, Inc. www.quad.com/solutions/ production/packaging

David Phillipes (610) 360-2455

QUAD Redzone www.rzsoftware.com

John Ponte (305) 908-4479

R.A Jones

www.rajones.com

Rich Clifton (513) 382-4544

Roberts PolyPro Inc. www.robertspolypro.com

Roy Tetreault (704) 588-1794

Ronchi America, LLC www.ronchipackaging.com

Andrew Yang (678) 398-7413

Ropak Manufacturing Company www.ropak.com

Chuck Garrett (256) 350-4241

Septimatech Group Inc septimatech.com

Quinn Martin (519) 746-7463

Shrink Packaging Systems Corporation www.sps70.com

Diane Lamb (800) 944-9689

Sidel www.sidel.com

Nellie Oprikova (678) 221-3000

Smurfit Westrock westrock.com

Jennifer Madison (770) 448-2193

Spee-Dee Packaging Machinery, Inc. www.spee-dee.com

Terri Fountain (262) 886-4402

TEXWRAP Packaging Systems www.texwrap.com

David Nettles (636) 239-7424

The Melville Group, LLC www.melvillegroup.com

Carl Melville (760) 671-1110

Thomas Blaige & Company LLC dba

Blaige & Company www.blaige.com

Thomas Blaige (312) 337-5200

TNA North America, Inc. www.tnasolutions.com

Mukul Shukla (972) 462-6500

Tripack, LLC www.tripack.net

Marc Tredo (866) 900-1255

Tronics America, Inc. www.tronicsamerica.com

Richard Dew (219) 769-0876

Viking Masek www.vikingmasek.com

Alexandria Sielaff (920) 564-5051

Visstun www.visstuncups.com

Berlin Lopez (702) 251-8809

Weber Packaging Solutions Inc. www.weberpackaging.com

Harrison Chien (847) 364-8500

Winpak www.winpak.com

Nate McCord (708) 753-5700

Zacros America, Inc. www.zacrosamerica.com

Sales RFQ (800) 890-1183