8 minute read

Tech Perspective

JOYCE FASSL | EDITOR IN CHIEF

Advanced Weigh Cell Technology Boosts Ef ciency in Packaging Applications

Compared to conventional weighing methods, electromagnetic force restoration-based solutions help ensure mission-critical quality control and faster throughput while providing space-saving e ciencies.

RECENT TECHNOLOGICAL In addition, active vibration compensation (AVC) ADVANCEMENTS have made is incorporated into some EMFR weigh cells to elecin-motion weighing operations tronically reduce or eliminate the e ect that low-fremore precise and profitable for food quency vibrations may have on the weighing results packaging operations. Typically, check- obtained by other checkweighers. These environweighers used for food packaging pre- mental vibrations are common in production facilities vent both underfilling and overfilling of and warehouse distribution centers, typically with products, resulting in brand protection conveyors, mechanical sorters, forklift trucks, and and cost reduction due to less prod- other machinery. uct giveaway, which is eliminated by a checkweigher’s filler feedback technol- PFW: Please explain how EMFR technology works. Jim Renehan, senior ogy. This usually results in a machine’s Renehan: EMFR systems can be compared to a simmarketing manager for return on investment (ROI) of well ple beam balance—though the intricacies are anyWipotec-OCS. under a year. thing but. Incoming weight on the load plate causes The latest checkweighers incorpo- the lever arm to leave its nominal resting position. rate weigh cells featuring electromagnetic force res- A position detector recognizes this slight position toration (EMFR), according to Jim Renehan, senior change and forces a coil on the other side of the lever marketing manager for Wipotec-OCS, a manufactur- arm to move out of the magnetic field. er and supplier of in-motion product weighing, X-ray When this occurs, a photoelectrical beam recogscanning, product inspection, parcel dimensioning, nizes any minute deviations in the lever arm position package marking, and serialization and aggregation and immediately sends its findings through a meaequipment. Wipotec-OCS’s weighing, inspection, surement resistor, transforming this data into a digiand track-and-trace solutions serve a broad array of tal signal via an analog-to-digital (A/D) converter. industries, including food. The resulting digital weight value is determined EMFR technology has proven e ective in tough by an advanced digital signal processor at excepin-motion weighing applications, according to tionally fast speeds with an internal sampling rate of Wipotec-OCS. It eliminates the reliance on bending 1 ms, or 1,000 weight values per second. The weigh metal as a primary means of gathering weight data. cell’s digital signal processor output is sent to the The optical and electronic methodology approach interface connection on the checkweigher or another employed in EMFR weigh cells results in faster settling third-party OEM device or machine. times and captures more weigh samples as products With their quick sampling rates, EMFR-based move over the weigh cells. These checkweighers can weigh cells enable extremely accurate weighing deliver more accurate, repeatable weighing results at results that provide space and cost savings when faster production line speeds compared to conven- integrated into existing systems. They also postional strain gauge-based checkweighers. sess high throughput rates, suitable for high-speed

checkweighers that can capture product weights at rates up to 600 units per minute. Small and midrange checkweighers with EMFR-based weigh cells o er attractive price-to-performance ratios, and all EMFR scales deliver increased plant e ciency, thanks to precise and reliable weighing results.

PFW: What are the benefits of EMFR technology?

Renehan: Compared to conventional strain gauge scales, EMFR weighing o ers a number of benefits. When compensating for a dead load, traditional strain gauge-based checkweighers require a sti er load cell to process the weight. With strain gauge checkweighers, the resolution of the weighing range declines. Since many load cells like the one illustrated in Figure 1 rely on a relatively large amount of metal bending, they all exhibit a spring-like operational behavior called “ringing.” These types of cells cannot tolerate fast weight changes, because the ringing action must be compensated within the load cell. Dead load weight also needs to be compensated.

Since EMFR weigh cells do not rely on large degrees of metal deflection, ringing is not a major concern. EMFR scales balance dead load with far less cumbersome software commands, keeping the weighing range available and the resolution intact.

When measuring dynamic performance, EMFR checkweighers have a short settling time and active attenuation provided by the electronic controller, while preventing sensitivity and resolution from changing. This eliminates the need for constant calibration checks. As seen in Figure 2, strain gauge checkweighers generally possess less e ective dampening oscillatory systems and a higher resonance frequency when settling, while the sti load cell reduces sensitivity and resolution, requiring consistent calibration and maintenance.

By contrast, EMFR scales are faster, more e cient, and more precise, and require less maintenance than conventional weigh cells. Since EMFR modules accurately acquire product information faster than a load cell, more weight samples per unit of time are achieved. This is one of the reasons EMFR-based checkweighers provide more precise product weigh information at faster throughput speeds.

PFW: Can you provide an example?

Renehan: The EMFR weigh cell in the checkweigher types, shown in the photo on page 56, is frequently found in the center of the machine, just under the centrally located weight bed conveyor. Checkweighers used in food packaging applications take advantage of the high sample rates of EMFR weigh cells to deliver accurate package weights at throughput speeds as high as 600 packages per minute.

This allows the checkweigher to make quick reject decisions if an item is over- or underweight. Frequently, checkweighers in food packaging applications are placed after the package filler. This allows the user to take advantage of the checkweigher’s filler feedback technology. If the checkweigher sees a series of over- or underweight measurements, the filler feedback loop enables automatic adjustments to the filler to bring the package fill weight back into the acceptable tolerance range. This capability prevents expensive product giveaway errors in the case of package overweight conditions, or dissatisfied customers and/or product recalls due to product underweight situations.

Multiple EMFR weigh cells are also incorporated into belted checkweigher designs. The compact design

IMAGE COURTESY OF WIPOTEC-OCS

Figure 1 shows a bending beam load cell with strain gauges.

IMAGE COURTESY OF WIPOTEC-OCS

Figure 2 shows an EMFR weigh load cell vs. the load cell setting time.

possible with EMFR weigh cells makes it a good choice for food packaging applications. The custom checkweigher shown on the left was designed for a cheese packaging application. Each of the five belt lanes has an EMFR weigh cell under the individual weigh bed conveyors, and they operate somewhat independently of each other. However, per the customer’s request, if one package is over- or underweight, then all five packages in that batch are rejected.

Also notice the metal detector incorporated into this multitrack checkweigher design. In food packaging applications, it is common to see a checkweigher integrated with a metal detector. The metal detector interface is controlled using the machine’s common HMI, which controls both the checkweigher and metal detector functions for simplified operation. Like the checkweighing function, if any one package is found to have metal present, then all five packages in that batch are rejected.

PFW: What is AVC, and how does it enhance EMFR technology?

Renehan: AVC is based on fast-sampling (FS) EMFR technology and is an electronic method of removing the key portion of the ambient noise spectrum from a product weight signal using internal software tools. These noise sources are commonly found in factory and warehouse environments and include conveyor sorters and forklift trucks.

In just about every distribution warehouse, all available space is used. This means that there are multi-level sorting conveyors placed on mezzanines, and often, the dynamic industrial scale or catchweigher is mounted o the ground in one of these vertical mezzanine levels. Super-rigid mounting platforms are necessary for the dynamic scale to reduce vibrations; an AVC-equipped scale can be mounted using less expensive mechanical mounting options, because the weigh cell will compensate for the vibrations electronically.

Similar mounting advantages come into play with checkweighers equipped with EMFR weigh cells with built-in AVC used in food packaging quality control. Combining EMFR weigh cell technology with AVC sensors enables accurate product weight measurements.

A typical AVC implementation involves two weigh cells located inside the EMFR housing, where one of the cells senses ambient vibrations of a certain frequency range.

PFW: How does AVC work?

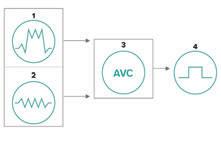

Renehan: As illustrated in Figure 3, two weigh cells are mounted inside one EMFR housing; one weigh cell measures vibrations including the load to be weighed (1), while the other measures vibrations only (2). Vibration-based interfering variables are calculated by comparing the two measurement curves in the signal processing section of the EMFR weigh cell (3), where the major vibration components of the load signal are removed. Due to the FS technology, we are able to deduct the disturbing signal from the load weight signal and come up with a “compensated weight value.” The resultant measurement signal is very close to a load signal that would be achieved without any influence through vibration (4). This final weight measurement signal shows a major reduction, if not complete removal, of the negative e ects caused by interfering vibrations present in the in-motion checkweigher installation environment. Unlike filtering technology common in strain gauge-based weigh cells, the AVC approach used in Wipotec’s EMFR weigh cells is una ected when the disturbing signal (i.e., vibration component) occurs within the same frequency range as the information signal or load weight signal.

Figure 3 shows an active vibration compensation (AVC) schematic.

IMAGE COURTESY OF WIPOTEC-OCS

The EMFR weigh cell in the Wipotec-OCS checkweigher models HC-M and C-A shown above is found in the center of the machines, just under the centrally located weight bed conveyor.

Wipotec-OCS

www.wipotec-ocs.com/us/