8 minute read

Case Study: Tree Top

AARON HAND | EXECUTIVE EDITOR

Decanter Helps Optimize Fruit Juice Concentrate Process

Moving to a new style of decanter largely because of maintenance issues with older machines, a fruit processor found several ways the new system improved production, including sanitation and fl exibility.

WITH ITS HEADQUARTERS in Selah, Wash.—in the heart of the state’s apple country—it’s no surprise that Tree Top got its start in apples. These days, the grower-owned cooperative, representing orchards throughout Washington, Oregon, and Idaho, still focuses on making high-quality apple juice, but also a range of other fruit products as well.

At its facility in Prosser, Wash., Tree Top makes a variety of fruit juice concentrates. The majority of the year is focused on apples and pears, but the plant processes a wide range of fruit on a seasonal basis, including strawberries, blueberries, blackberries, cranberries, mangoes, and plums.

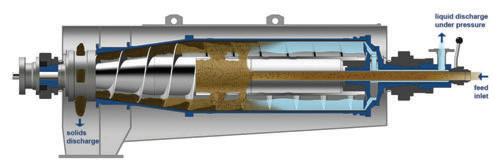

Decanters, used to extract fi nely solubilized fruit, are an important part of the juice concentrate process. “We bring the fruit into the plant, inspect it, it gets milled into the consistency of apple sauce, we depectinize it, and then we run it through decanters to pull out the solids,” explains Brian Curtis, plant manager at the Prosser facility.

Tree Top had some old decanters, some built in the early 1990s, that were beginning to be more trouble than they were worth. “We were reaching a point where they were becoming obsolete and the maintenance was incredibly expensive and frequent,” Curtis says. “Tree Top decided it was time to upgrade those decanters.”

The processor bought its fi rst Flottweg decanter in 2012 at its headquarters in Selah, Wash., and then the Prosser facility got its fi rst the next year. Prosser

▲ Though apple juices and other products are the company’s mainstay most of the year, Tree Top makes seasonal products from a range of other fruits as well.

PHOTO COURTESY OF TREE TOP

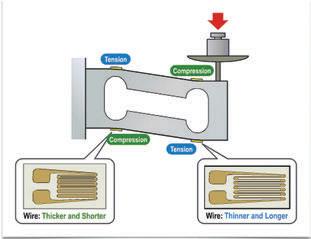

ILLUSTRATION COURTESY OF FLOTTWEG

Decanters separate fruit solids from liquids in Tree Top’s production of juice and juice concentrates.

got another in 2015, and a third one last year. With the di erent style of the Flottweg decanters, maintenance is easier and less expensive, according to Curtis. “They’re very, very low maintenance,” Curtis says. “For the most part, we pretty much do preventative maintenance on the lubrication system, and that’s about it. We haven’t had any of them crash. None of them have failed.”

Even annual overhauls are faster and cheaper. “The way it’s designed, for the annual overhaul, it’s really easy to access the components that you need to do your annual maintenance on,” Curtis says. “Also, the way it’s designed, the components aren’t as expensive to replace as some of the other styles.”

Optimizing sanitation, exiblity

The Flottweg decanters have some other benefits that help to optimize production for Tree Top. Sanitation has been one of the most noteworthy, according to Curtis. “Decanters by nature are pushing solids out to the edge of the bowl with centrifugal force, so it creates kind of this cake of solids. When you go to clean them, if you can’t change that G-force, basically, then you’re not able to get the cake o the bowl,” Curtis explains. “So, with the old machines, we didn’t have the ability to get the cake o . We’d have to run them and shut them down, and just hope that the cake would fall, then start them back up and do that a couple times.”

The Flottweg decanters have a clean-in-place (CIP) program that changes the flows from high and low, and they also slow down and speed up the bowl. “That helps drop the cake so we get the machines nice and clean,” Curtis says.

That Simp Drive feature, which o ers the ability to optimize the bowl speed, also provides a high separation e ciency that ultimately lets Tree Top use about 25% less energy, notes Jon Kingston, food and beverage manager for Flottweg.

The adjustable impeller is another feature of the Flottweg decanter, making it flexible and easy to adapt to various types of fruits. “It allows that machine to be used in multiple applications,” Curtis says. “We’ve found a sweet spot, though, so we don’t adjust the impeller for di erent fruits.” However, it does get manipulated during CIP processes, he adds.

It provides optimized separation because it enables the pool depth inside the decanter centrifuge to be changed while it is running, Curtis notes. Tree Top’s old decanter had a fixed dam, which could potentially overflood the machine. The Flottweg is a closed system so that it can’t pick up any air or foam.

Also of note are the decanter’s outboard bearings, which are completely outside of the product zone, Kingston notes. On Tree Top’s previous machines, the bearings were in the product zone, and were notorious for failure. With the new bearings, no product or excess water can get in there, and they typically need to be changed out just once a year.

Future plans

Tree Top has been able to recover 38% of the cost of the latest Flottweg decanter in the first year, so Curtis expects about a three-year ROI.

The Prosser facility is in the planning stages to get another Flottweg decanter—this time a smaller one for a separate side stream of slurry that it receives as a byproduct from other facilities.

Flottweg

www.flottweg.com

COMPANY / WEBSITE

ABB Motors & Mechanical www.new.abb.com/drives/energy-e ciency

Atkore Calbrite www.calbrite.com/flex-conduit-and-fittings

Bunting Magnetics www.buntingmagnetics.com

Cablevey Conveyors www.cableveyconveyors.com

Clayton Industries www.claytonindustries.com

Cleveland Gear www.clevelandgear.com

Coppice Allupack www.drbsales.com

Eriez www.eriez.com

ESI Group USA www.esigroupusa.com/about-esi/events/

Festo Corp. www.festo.us

Flexicon www.flexicon.com

Gericke USA, Inc. www.GerickeGroup.com

Graphalloy www.Graphalloy.com

Hapman www.hapman.com/profood

Heat and Control, Inc. www.heatandcontrol.com

Industrial Magnetics, Inc. www.magnetics.com

Klöckner Pentaplast www.kpfilms.com

PAGE COMPANY / WEBSITE

1

40

11

Cov-3

43

15

16

37

12-A (select issues)

39

Cover-2

2

42

8

44

34

5 Kollmorgen www.kollmorgen.com/uptime

Linde www.lindefood.com/vision

Lubriplate Lubricants www.lubriplate.com

Mennekes www.Mennekes.com

Munson Machinery www.munsonmachinery.com

PACK EXPO Trade Shows www.PackExpo.com

P.E. North America www.PENorthAmerica.com • www.AxonCorp.com

ProFood 2021 World Leaders In Processing www.profoodworld.com

ROSS Mixers www.mixers.com

SEW Eurodrive, Inc. www.seweurodrive.com

Shick Esteve www.shickesteve.com

Spokane Industries, Inc. www.spokaneindustries.com

Urschel Laboratories, Inc. www.urschel.com

Van der Graaf www.vandergraaf.com/PF

Volkmann, Inc. www.volkmannUSA.com

Wire Belt www.wirebelt.com

PAGE

46

31

27

26

4

49

18

53

23

Cov-4

7

10

25

Cov-1

45

19

ProFood World ® (ISSN 2476-06760, USPS 22310) is a registered trademark of PMMI, The Association for Packaging and Processing Technologies. ProFood World ® is published 6x a year (February, April, June, August, October, December) by PMMI Media Group, 401 North Michigan Avenue Suite 300, Chicago, IL 60611; 312.222.1010; Fax: 312.222.1310. Periodical postage paid at Chicago, IL, and additional mailing offices. Copyright 2021 by PMMI. All rights reserved. Materials in this publication must not be reproduced in any form without written permission of the publisher. Applications for a free subscription may be made online at www.profoodworld.com. Paid subscription rates per year are $55 in the U.S., $80 Canada and Mexico by surface mail; $130 Europe and South America. $200 in all other areas. To subscribe or manage your subscription to ProFood World, visit ProFoodWorld.com/subscribe. Free digital edition available to qualified individuals. POSTMASTER: Send address corrections to: ProFood World, 401 North Michigan Avenue, Suite 300, Chicago, IL 60611. PRINTED IN USA by Quad Graphics. The opinions expressed in articles are those of the authors and not necessarily those of PMMI. Comments, questions and letters to the editor are welcome and can be sent to: jfassl@pmmimediagroup.com. We make a portion of our mailing list available to reputable firms. If you would prefer that we don’t include your name, please write us at the Chicago, IL address. Volume 5, Number 2.

Each of the following market leading companies participates in ProFood World’s Leaders in Processing program. Leaders in Processing companies receive prominent, year-round exposure on ProFoodWorld.com. ProFood World sincerely thanks its participants!

LEADERS

IN PROCESSING 2019

Advertisement

CLEANING/SANITIZING/CIP COATING/ENROBING TANK CLEANING EQUIPMENT

Spraying Systems Co.

North Avenue and Schmale Road • P.O. Box 7900 • Wheaton , IL 60187-7901 • USA Phone: 630/665.5000 Email: info@spray.com

www.spray.com

Spraying Systems Co., the global leader in spray technology, has been providing food and beverage processors with solutions to cleaning, coating, lubricating, drying and other challenges for more than 80 years. Our spray nozzles, tank cleaners and automated systems help processors ensure food safety, minimize waste, boost productivity and improve worker safety.

Cleaning and sanitizing systems include dozens of TankJet® tank cleaners for fast, thorough cleaning of tanks, vats and mixers up to 100’ in dia. TankJet tank cleaners reduce water and chemical use, eliminate the need for workers to enter tanks and minimize downtime.

Our Klarion™ system enables food processors to clean and sanitize equipment without the use of harsh chemicals, dramatically improving worker safety and eliminating the need for PPE. This unique on-site generation system produces powerful, safe, drainfriendly cleaning solutions in ready-to-use concentrations. Plus, customers report cost savings up to 30% with Klarion compared to traditional chemicals, making the system a smart way to advance your sustainability initiatives while improving worker safety.

Applying viscous coatings, fl avorings, lubricants and additives is often wasteful, messy and costly. Our AutoJet® Spray Systems apply coatings directly on the target and nowhere else. Products are coated uniformly and consistently – even when operating conditions change. AutoJet systems are ideal for butter, slurries, egg wash, release agents, antimicrobials, mold inhibitors and more.

Other product solutions include handheld GunJet® spray guns, SprayDry® nozzles, WindJet® air nozzles, conveyor and equipment cleaning nozzles and more.

Our local experts and Spray Technology Centers are right where you need them – in your area.

We’re standing by and ready to help you improve e ciency and operate more sustainably. Call 1-800-95-SPRAY for immediate assistance.

Read more about Spraying Systems Co. in ProFood World : www.profoodworld.com/companies/spraying-systems-co

Spraying_LIP_2019.indd 1 www.profoodworld.com l February 2019 l ProFood World l 1

1/29/19 8:47 AM