Voice of the Customer | 8 End user hesitations about remote services. Sales Focus | 36 Post PACK EXPO is the time to revisit potential customers. Perspectives | 44 Revolutionizing OEM manufacturing with AI Women in Packaging | 46 Negotiating as a woman in a man’s world. SPRING 2024 Can Humanoid Robots Aid in the Labor Crisis? Advanced AI and full-body mobility could allow general- purpose robots to fill in on packaging and processing lines | 16

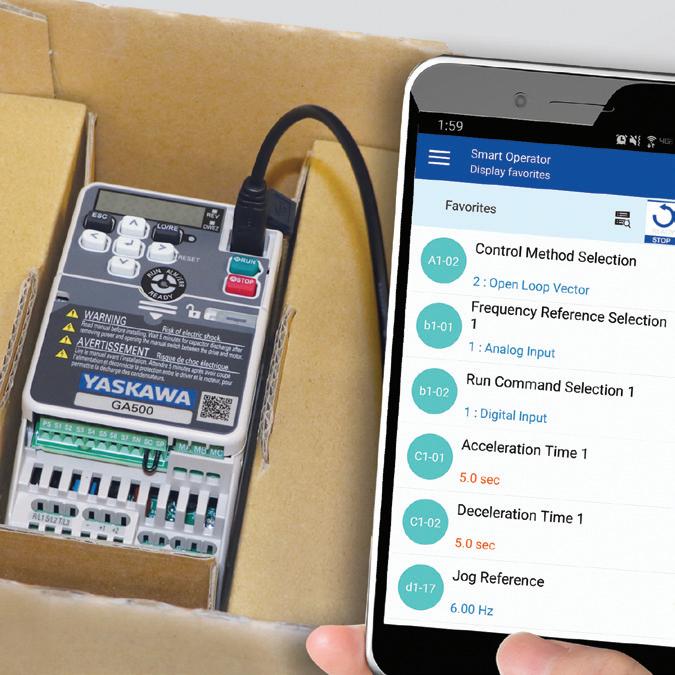

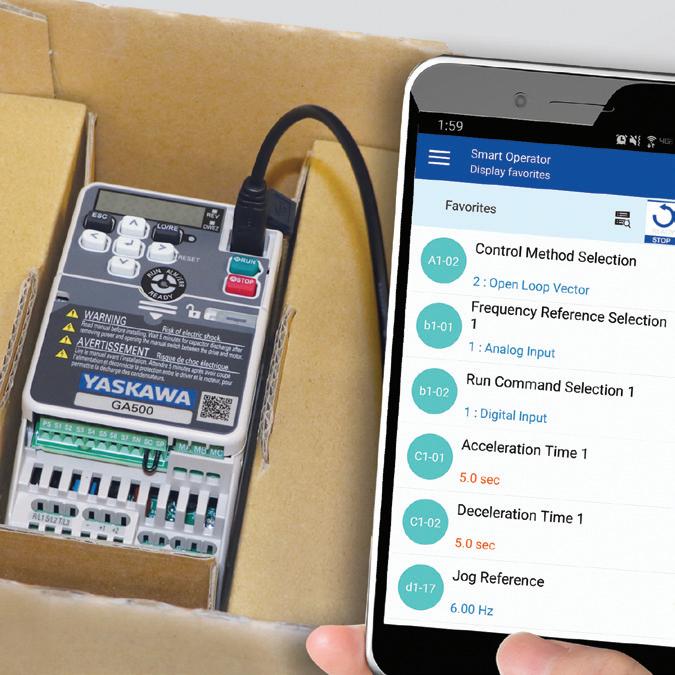

YOU’RE NOT STANDING STILL

You need automation technology that can keep pace with you and your company.

i3 Control is open-sourced so you can scale and collaborate the way you want, without limits. The technology works as one, with one controller, giving you flexibility while maximizing performance. With i3 Control, you’re in total control.

i3 CONTROLTM AS INDIVIDUAL AS YOUR NEEDS Yaskawa America, Inc. 1-800-YASKAWA Email: info@yaskawa.com | yaskawa.com Learn more at icubecontrol.com

Stays up late answering work emails Is in total control with i3 Control Collaborates with teammates in Asia and Europe Tests everything Is connected 24-hours a day Drinks 3 cups every morning

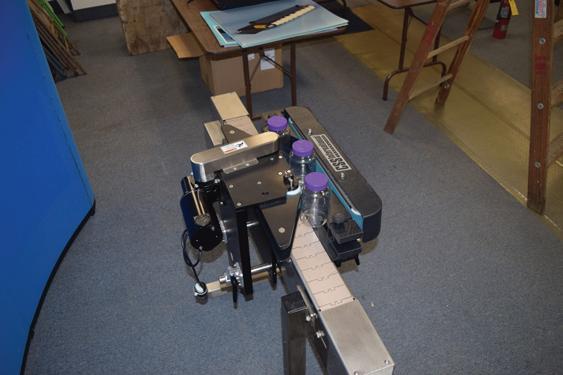

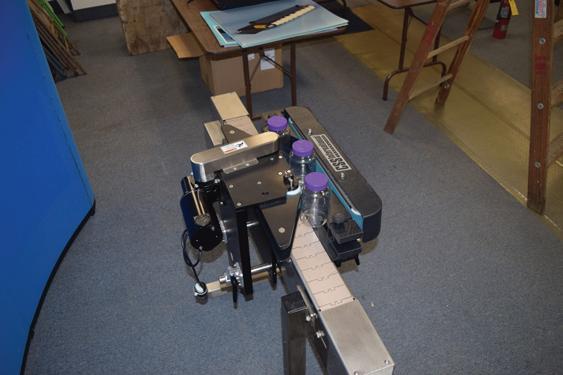

WHY CHOOSE SPAN TECH?

Our conveyor systems seamlessly integrate into your existing setup, streamlining your production processes and reducing manual labor. Trust Span Tech to be your long-term partner in success.

• Tailored Solutions: Our team of experts understands the unique challenges of OEMs. We customize conveyor systems to perfectly fit your manufacturing processes, ensuring optimal performance.

• Advanced Technology: Stay ahead in the industry with our state-of-the-art conveyor technology. From automated sorting to precision handling, our solutions integrate the latest innovations to enhance your production lines.

• Robust and Reliable: Downtime is not an option. Our conveyor systems are built to withstand the toughest conditions, guaranteeing a continuous and reliable workflow for your operations.

• Proven Track Record: Trusted by leading OEMs, we have a proven track record of delivering excellence. Join the ranks of satisfied clients who have experienced unparalleled success with our conveyor solutions.

SPANTECHCONVEYORS.COM | 270.651.9166

YOUR GO-TO PARTNER FOR CONVEYORS OEM’S, YOUR SOURCING STOPS HERE!

CONNECT WITH US:

OEMmagazine.org

With

The

BUSINESS INTELLIGENCE

8 Remote Services

End users weigh the benefits and drawbacks.

INDUSTRY NEWS

12 Potential Tax Breaks

NAM-backed tax package passes House.

MARKETING INSIGHTS

14 Research-Driven Marketing

Three key research areas can support marketing e orts.

SALES FOCUS

36 Post-Show Outreach

Beast practices for following up a er PACK EXPO.

ASSOCIATION NEWS

38 Register for the Executive Leadership Conference

Learn how to leverage your membership.

PERSPECTIVES

44 AI in Manufacturing

A historical perspective and current limitations

WOMEN’S LEADERSHIP

46 Learning Circles

The nuance of negotiation

EXHIBITOR’S CORNER

48 The Year Ahead

Important deadlines for upcoming shows

NEW PRODUCTS

81 OEM MACHINE TECHNOLOGY

Check out the latest product innovations.

FINAL THOUGHTS

84 PMMI Advantage

Straight from the President’s desk.

CONTENTS FEATURES

DEPARTMENTS

@OEMmagazine

facebook.com/OEMmagazine

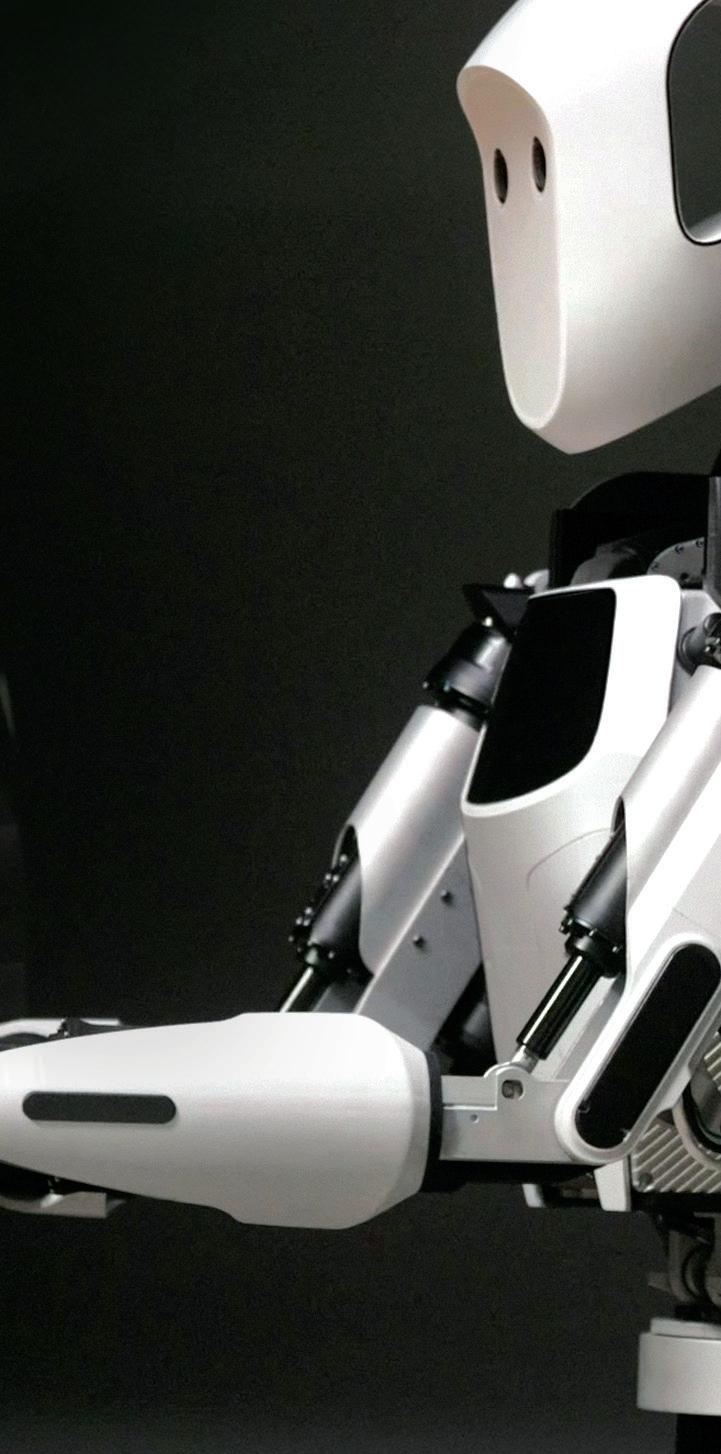

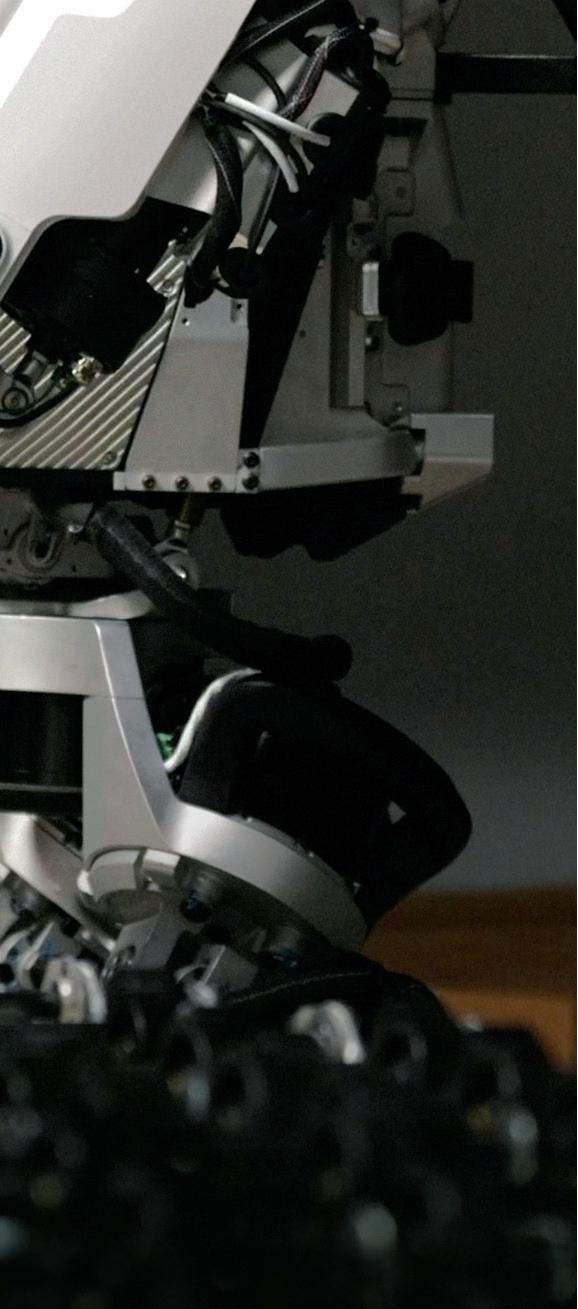

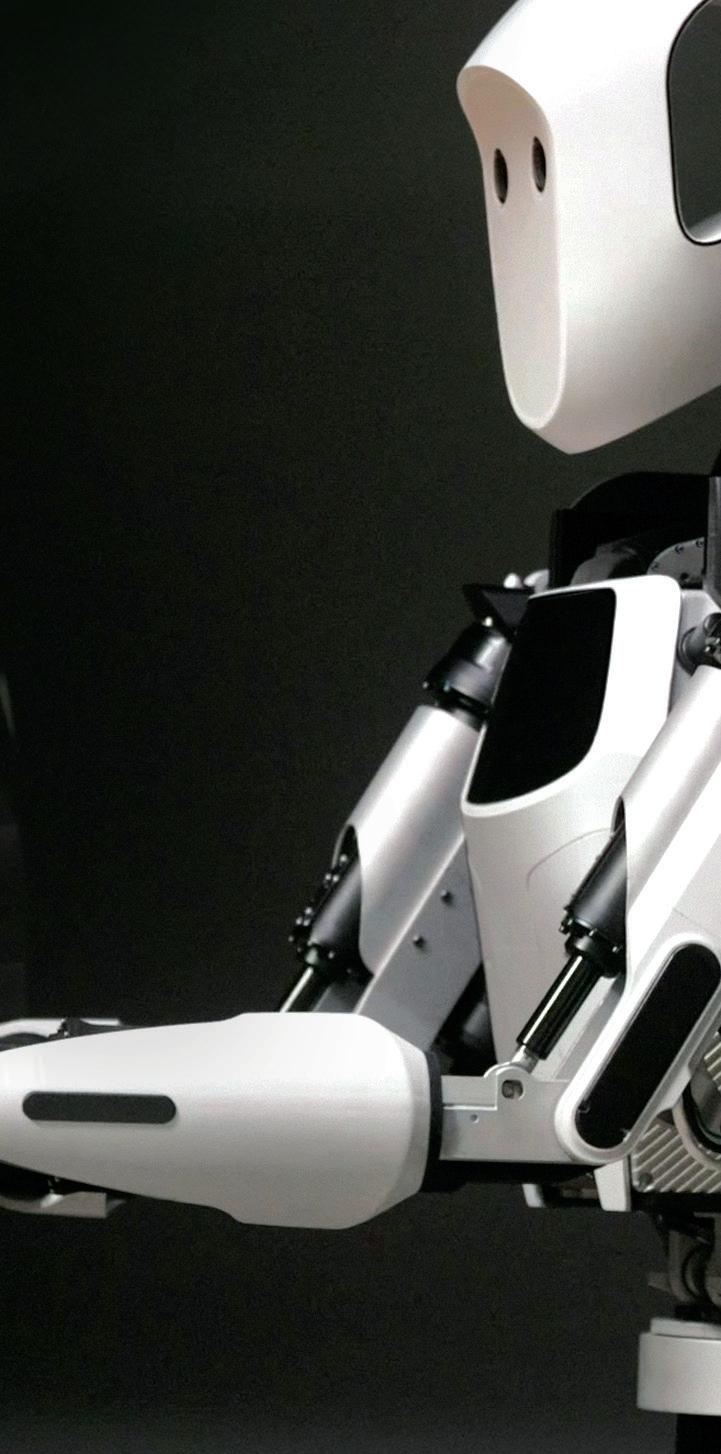

SPRING 2024 2 MANAGEMENT 16 Humanoid Robots

advanced AI so ware, dexterous “hands,” and full body mobility, could humanoid robots answer the labor shortage on the packaging line? OEM PROFILE 28 Robopac USA

voice of the customer drives R&D innovation across a range of case packers, palletizers, stretch wrappers, and laserguided vehicles. NEW MEMBER PROFILE 32 PharmaMed Tackling old pharma and medical device problems with new ideas. 2023 PARTNER LEADERS 49 Automation Supplier Profiles Companies specializing in bringing OEMs the innovative products and services they need. 28 16 VOLUME 7 • ISSUE 1 32

15

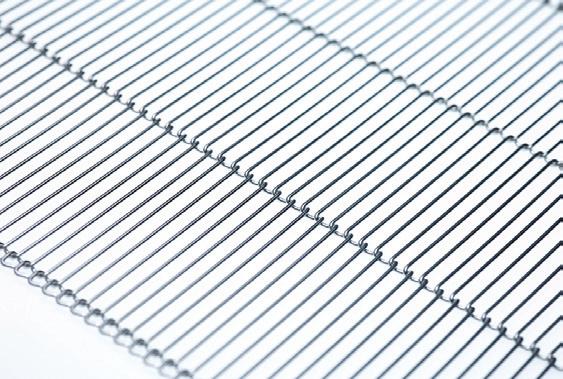

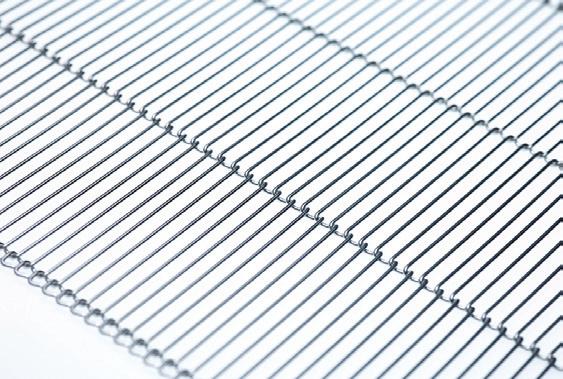

Compact-Grid™ USDA-Accepted Conveyor Belt from Wire Belt Company

Maximum support for small products • Belt installation is fast and simple! • Clean-in-place, USDA-Accepted • Excellent belt tracking, positive drive design

70% open area allows for excellent flow-through

Available in 10mm and 15mm meshes Wire Belt Company of America 17 Colby Court, Bedford, NH 03110 (603) 644-2500 | sales@wirebelt.com | www.wirebelt.com

•

•

•

MM

10

MM Flights available for moving product up an incline u

The official publication of PMMI OEMMAGAZINE.ORG

CONTENT

Sean Riley Editor-in-Chief sriley@pmmimediagroup.com | 571 266 4419

Casey Flanagan Digital Editor

Michael Smith Art Director

David Bacho Creative Director

ADVERTISING

John Schrei Vice President, Sales jschrei@pmmimediagroup.com

Lara Krieger Senior Manager, Print Operations lkrieger@pmmimediagroup.com

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com

PMMI Media Group

401 N. Michigan Ave., Suite 1700, Chicago, IL 60611

Phone: 312 222 1010 | Fax: 312 222 1310

www.pmmimediagroup.com

David Newcorn President

Elizabeth Kachoris Vice President, Digital

Kelly Greeby Senior Director, Media Operations

Jen Krepelka Director, Digital Media

Trey Smith Senior Director, Events

PMMI, The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170

Phone: 571 612 3200 | Fax: 703 243 8556 www.pmmi.org

Jim Pittas President and CEO

Joe Angel Executive Vice President, Industry Outreach, PMMI

Glen Long Senior VP

Tracy Stout VP, Marketing and Communications

Laura Thompson VP, Trade Shows

Andrew Dougherty Vice President, Member Services

SUBSCRIPTIONS

To subscribe to OEM visit: www.OEMmagazine.org/subscribe

To change or modify a subscription, please contact circulation@OEMmagazine.org

OEM EDITORIAL ADVISORY BOARD

Lisa Hunt CEO, Plexpack

Greg Berguig VP, Sales and Marketing, PAC Machinery

Rick Fox III Director, Engineering Services, Fox IV Technology

Brian Ormanic Senior Applications Engineer, Pearson Packaging Systems

Colin Warnes Director Sales Engineering & Project Management, ADCO Manufacturing

Tom Ivy CEO, FoodFlow Automation Solutions

Stacy Johnson VP Business Development, Hoosier Feeder Company

ACOPOS P3

Big impact, small footprint

With the ACOPOS P3, B&R is setting new standards for motion control. This 3-axis servo drive offers a power density of 4 amps per liter, making it one of the most efficient servo drives with integrated safety functions on the market. It also offers unrivaled dynamics and precision, with a sampling time of just 50 µs for the entire controller cascade.

• 69% smaller footprint with highest power density

• No additional fans in the control cabinet

• The right solution for every machine

| A member of the ABB Group

B&R

br-automation.com

Nothing to Fear

Sean Riley, Editor-in-Chief

As I was finishing up my first issue of OEM Magazine since Stephanie Neil’s passing of the proverbial torch, I can’t help but think how this and all jobs will look in the future. Not a news cycle goes by in the mainstream media that doesn’t contain a look at the rise of Artificial Intelligence. For someone who uses writing to put food on the table and a roof over my family’s head, I’ll fully admit that Generative AI like Chat GPT bordered on terrifying when it first arrived on the scene.

Not long after, I saw a presentation from new OEM contributor David McGraw (Revolutionizing OEM Manufacturing with AI, Pg. 44), where he explained that those who aren’t embracing AI as a tool in their toolkit are actually at risk of falling behind the competition.

Our cover story takes a fascinating look at how robots, once confined to cages on packaging and

processing lines, are quickly evolving even beyond collaborative robots. These humanoid robots use artificial intelligence—there are those words again—and human-like features to offer the possibility of truly working alongside a human worker. Will it happen overnight? Of course not. But Liz Cuneo (Are Humanoid Robots the Processing and Packaging Labor Force of The Future? Pg. 16) lays out a very compelling case that it may not be as far off as we think. I’m old enough to remember when society was worried that robots were coming to replace humans and leave people out of work. At a time when hundreds of thousands of manufacturing jobs continue to remain unfilled, it’s ironic that one of the potential solutions is the very solution we all feared.

I hope you enjoy the look and feel of my first foray as the leader of OEM Magazine. If you have any story ideas or any comments, good or bad, please don’t hesitate to reach out at sriley@pmmimediagroup.com.

FOR OPENERS SPRING 2024 6

PROTECTED PROTECTING CRITICAL EQUIPMENT WORLDWIDE FIND OUT MORE AT JAX.COM JAX INC. Menomonee Falls, WI

JAX

BY

LUBRICANTS

End-Users Weigh Benefits and Drawbacks of Remote Services Technology

Remote services can help smooth end-user operations and simplify training, but current drawbacks like cost and cybersecurity concerns are slowing investment.

Casey Flanagan, Digital Editor, PMMI Media Group

End-users are flocking to remote services technology for machinery support, training, and maintenance at the click of a button, but OEMs need to grapple with the technology’s drawbacks to support further adoption.

That’s according to PMMI Business Intelligence’s 2024 “Trends in Remote Services and Monitoring” report.

Remote services are a set of services and tools that end-users can use to support their operations remotely, either internally or through a connection with equipment suppliers.

The technology can be delivered with a variety of methods, including real-time video streaming and augmented reality (AR). This allows suppliers to provide support when needed rather than making CPGs wait for costly in-person appointments.

Remote services use cases for end-users

The most crucial reason behind end-users choosing to invest in remote services is reducing machinery downtime, with around 92% of those surveyed saying it is either somewhat or very important.

“Any downtime is very [expensive] and very critical, so being as quick as possible is key,” says one representative of a large food CPG.

Optimizing machine and operation performance is the second

“

43% of end-users say cybersecurity is a main barrier. . . along with 90% of OEMs.”

most popular reason for end-users to invest in remote services, with about 90% saying it is somewhat or very important. That’s followed by increased speed of support, which about 87% of respondents claim is at least somewhat important.

Combining tools such as remote monitoring and predictive maintenance can dramatically reduce the frequency of stoppages, while remote support provides the means to solve issues quickly.

The ability to use predictive maintenance is considered somewhat or very important by about 83% of end-users. This indicates that the appetite for this service exists for end-users and presents a great

opportunity for the 75% of surveyed OEMs who do not currently offer it.

Investment reasons, with between 75% and 95% finding them important, include limiting the impact of skills gaps and workforce shortages, decreased reliance on on-site technicians, and less cost and time spent on travel.

Decreased cost of ownership, usually a very important metric for end-users, is seen as the least important attribute when looking to invest in remote services and monitoring. About 75% of survey respondents still find this important, though.

Remote services as a skills gap solution

For many end-users, skills gaps have meant they have had to rely more heavily on support from OEMs for simple mechanical and technical problems that would have previously been handled in-house.

Neither end-users nor equipment suppliers want to waste time and money on OEMs sending technicians to plants for minor issues. This is a significant driving force behind the rising use of remote support, with over 87% of end-users finding the technology very effective in helping address skills gaps, along with about 97% of OEMs.

Remote training is a major aspect of remote services as a skills gap solution. About 89% of endusers think that remote training is

BUSINESS INTELLIGENCE SPRING 2024 8

INTELLIGENCE

BUSINESS

BUSINESS INTELLIGENCE

either somewhat or very effective at mitigating skills gaps in their operations.

Augmented reality is an emerging technology with the potential to bridge the gap between remote and in-person training.

End-user technicians and operators can be given on-screen special markers, step-by-step instructions, and real-time videos while being trained on machinery. Just under three-quarters (70%) of end-users see this technology as either somewhat or very efficient for remote training.

Reasons given for end-user reluctance to embrace AR technology for all training included older staff members (often the leaders of maintenance teams) being less enthusiastic about its use.

A hybrid approach is likely to be the most popular option soon. This will involve a combination of initial in-person training, where technicians and operators can get involved with the machinery and ask questions directly to the equipment supplier’s team. Subsequent instructor-led or self-paced online sessions will consolidate learning.

End-users are hesitant about the cost of remote services

Most end-users are aware of the benefits of remote services and monitoring, but significant barriers still keep some from adopting the technology.

Cost of service is the most common barrier for end-users, who cite it as over 10% more than other barriers like limited IT skills and cybersecurity risks.

The additional cost of remote services is small compared with the cost of purchasing new packaging machinery. Despite this, about 60% of end-users see it as a barrier to investment.

Cybersecurity is also a top concern

End-users are also wary of taking on the risk of cyberattacks through remote services investments. About 43% of surveyed end-users say cybersecurity is a main barrier to investment in remote services, along with 90% of OEMs.

The main fear among end-users regarding cybersecurity is malware, cited by about 77% of respondents. Most surveyed OEMs agree, with nearly 90% saying they are somewhat or very concerned about malware.

Although it is possible to retrofit old machinery and update operational technology (OT) systems, this can take a long time due to the technical complications, running the risk of an extended period of machine downtime.

There is also the incompatibility issue with some machines, particularly older ones.

As one medium-sized enduser explains, “We have a couple (machines) on our system that are over 40 years old. You’re not going to be able to retrofit that with […] anything digital because it just wasn’t built with that capacity.”

Some end-users would rather wait for machines to run through their lifecycle and replace them with updated models that already have remote services and monitoring capabilities installed rather than commit to the cost of retrofitting.

As machinery reaches the end of its lifecycle, Business Intelligence researchers expect end-users to explore replacements fi tted with remote services and monitoring capabilities.

Supply chain attacks are another top concern among end-users, with about 73% saying they are somewhat or very concerned with the threat. About 85% of OEMs feel the same.

Close behind in end-user concerns are data theft and tampering, which about 72% cite as a concern. About 90% of OEMs also worry about data theft and tampering.

What the future holds for remote services

The landscape of remote services is evolving rapidly in reaction to opportunities presented by the COVID-19 pandemic. The adoption of various remote services has increased significantly, reflecting the industry’s response to workforce challenges or adaptation to the new normal.

Despite the evident benefits, barriers to adoption, like the cost of service and cybersecurity concerns, persist.

The future of remote services appears to be a hybrid model. While certain functions, like remote troubleshooting, may become more prevalent in years ahead, in-person interactions remain crucial for tasks like FATs, commissioning, and initial training. ■

BUSINESS INTELLIGENCE SPRING 2024 10

For the full report, visit pmmi.org/report/2024-trends-remoteservicesmonitoring.

256 colors

Individually selectable:

Measurement in progress

Sensor switching

Process malfunction

We bring color into view! Compact pressure sensors and switches with 360° custom-color status display www.vega.com/vegabar Adjustment via smartphone $518 VEGABAR 39 Clamp 1" Hygienic adapter system Compact design 15 cm

House Passes NAM-Supported Tax Package

The critical bill for manufacturers now goes to the Senate for review.

Packaging and processing OEMS, as well as manufacturers in general, secured a major victory on Jan. 31 when the House of Representatives passed a bipartisan tax package containing provisions critical to the industry, according to the National Association of Manufacturers.

What’s going on:

The House voted 357–70 to pass the bipartisan Tax Relief for American Families and Workers Act. The bill includes three important manufacturing priorities:

• Restoring immediate R&D expensing for domestic research.

• Reinstating full expensing (also known as 100% accelerated depreciation) for businesses’ capital investments.

• Returning the U.S. to a pro-growth interest deductibility standard.

What it means:

The measure will enable manufacturers to invest in their businesses, create jobs and compete in the global marketplace.

• The bill is particularly important for small and medium-sized manufacturers, many of which experienced significant tax increases as a result of the expiration of these pro-growth provisions.

• “While it was once a paid expense, R&D is now a cost that many small businesses cannot afford,” said Rep. Carol Miller (R-WV), in a speech on the House floor last month.

• The overwhelming majority—89%—of respondents to the NAM’s Q4 2023 Manufacturers’ Outlook Survey said higher tax burdens on manufacturing would make it more difficult for them to hire, buy new equipment and expand their facilities.

What’s next:

It’s critical that the Senate now also pass the measure, the NAM said.

• “Manufacturers thank [House Speaker Mike Johnson (R-LA)] and [House Ways and Means Committee Chairman Jason Smith (R-MO)] for their leadership in passing the Tax Relief for American Families and Workers Act—and the bipartisan work in the House and Senate to secure progress for America’s manufacturing workers,” NAM President and CEO Jay Timmons said in a social post after the House voted.

• “Manufacturers are now counting on the Senate to act quickly to restore these provisions that are absolutely critical to strengthening America’s competitiveness and growth of manufacturing in America.”

• Added Ketchie President and Owner and NAM Small and Medium Manufacturers Group Chair Courtney Silver, “This just isn’t about numbers on my financial statements and my tax returns—this is about taking care of the people here [at Ketchie] and in communities across this country…. Let’s restore some common-sense tax provisions, and let’s support our American manufacturers across our country.” ■

CISA Recommends Getting Rid of Default Passwords

The Cybersecurity & Infrastructure Security Agency (CISA) is urging manufacturers to change or even get rid of default passwords altogether on the equipment and so ware they manufacture. The agency said that “studies by CISA show that the use of default credentials, such as passwords, is a top weakness that threat actors exploit to gain access to systems, including those within U.S. critical infrastructure.”

CISA has also released a new work product that guides secure-by-design open-source so ware development in a broader e ort to secure the so ware supply chain.

The document focuses on recommended practices for implementing open-source so ware as well as tracking the use of open-source code through a concept known as a “so ware bill of materials.” The document also provides guidance on how to select open-source so ware, conduct risk assessments, maintain open-source so ware, and respond to vulnerabilities and threats.

For more information, visit h ps://bit.ly/3UcwI3N.

INDUSTRY NEWS SPRING 2024 12

INDUSTRY

Sean Riley, Senior News Director

NEWS

Research-Driven Marketing: Unlocking Success in Three Key Areas

Three key research areas - market trends, benchmarking, and customer feedback – can strategically support your marketing efforts.

Sharon Taylor, Principal Marketing Strategist, PMMI Media Group

Are you harnessing the full power of research to fuel your marketing strategy and drive your company’s growth? We’ll delve into three key research areas - market trends, benchmarking, and customer feedback - and show you how to apply it strategically to support your marketing efforts.

Market trends

Marketing research that identifies industry trends and market growth can help you plan where to invest your sales, marketing, and product development dollars.

Market trend data may be freely accessible, or it may require a subscription or fee to access.

Within packaging and processing, PMMI Business Intelligence reports are an excellent source of industry insights. All reports are free to access by any employee of PMMI member companies. By leveraging the information in these reports and other industry resources, you can make informed decisions about entering new markets, setting growth goals, and targeting new customer segments.

Benchmarking

Benchmarking reports are a valuable tool for assessing your performance and identifying areas for improvement within your industry. One way to start is by measuring your performance across different marketing channels.

To access benchmark reports, you can search for publicly available marketing channel benchmark reports specific that cover marketing as a whole or focus on a specific channel like email, social media, or websites. It’s important to note that benchmark data may vary from source to source, so it’s best to consistently use the same data source.

To gain more specific insights and compare yourself to your competitors, consider investing in a PMMI Media Group custom research project. Another option is participating in a Packaging World ad effectiveness study, where your ad will be included in a reader study measuring ad recall and interest against all participating ads.

In addition to marketing channel benchmarks, sales performance benchmarks are valuable for evaluating your market share and validating your return on investment.

Customer feedback

In addition to external benchmarking reports, don’t forget to tap into the primary research available through your own customer database, website, and social media channels. Customers and prospects are often willing to share their feedback if they see value in it.

When asking participants to complete longer surveys (10 questions or more), it’s essential to offer something of value in exchange. This can be a small incentive for each participant or the first X number of participants, a raffle entry for a larger prize, or access to the survey results when published.

Another effective approach is to survey contacts more frequently with fewer questions. You can integrate single-question surveys into your emails, ask for feedback via social media, or add to your website forms or pop-ups. Consider asking participants about recent promotions, their interest in specific products, or their plans to attend upcoming events.

By leveraging primary research and engaging with your audience directly, you can gather valuable insights, keep your data up to date, and make informed decisions for your business.

In conclusion, research-driven marketing is a powerful tool that can fuel your marketing strategy and drive your company’s growth. ■

SALES & MARKETING SPRING 2024 14

MARKETING INSIGHTS

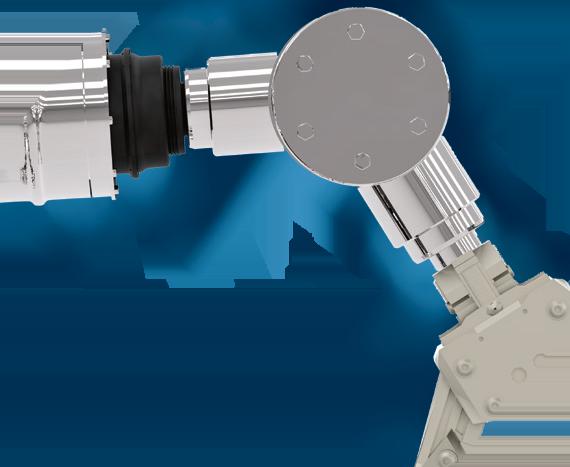

In the sophisticated world of industrial automation, X Platform is a confident presence ready to bridge the gap between the complex aspirations of machine builders and the practical necessities of factory operations.

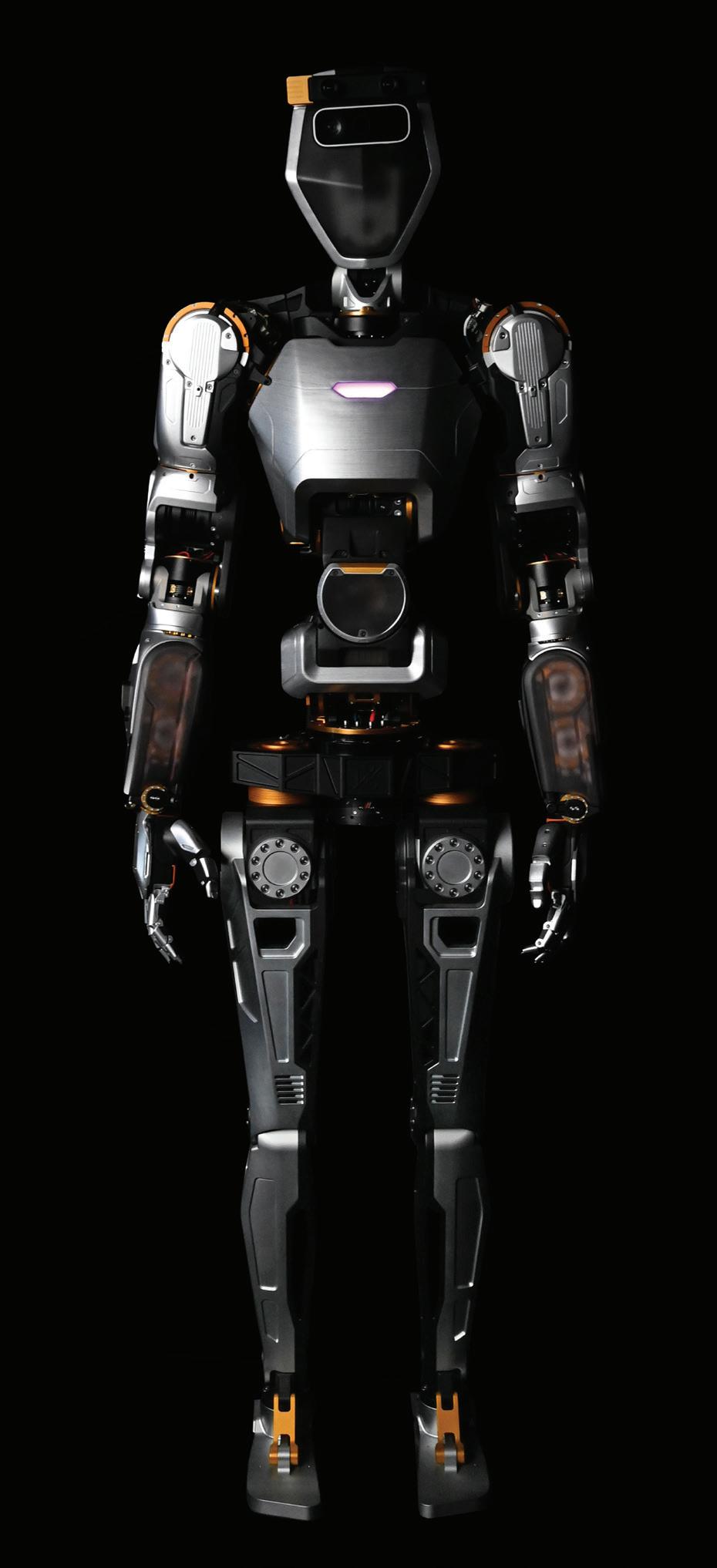

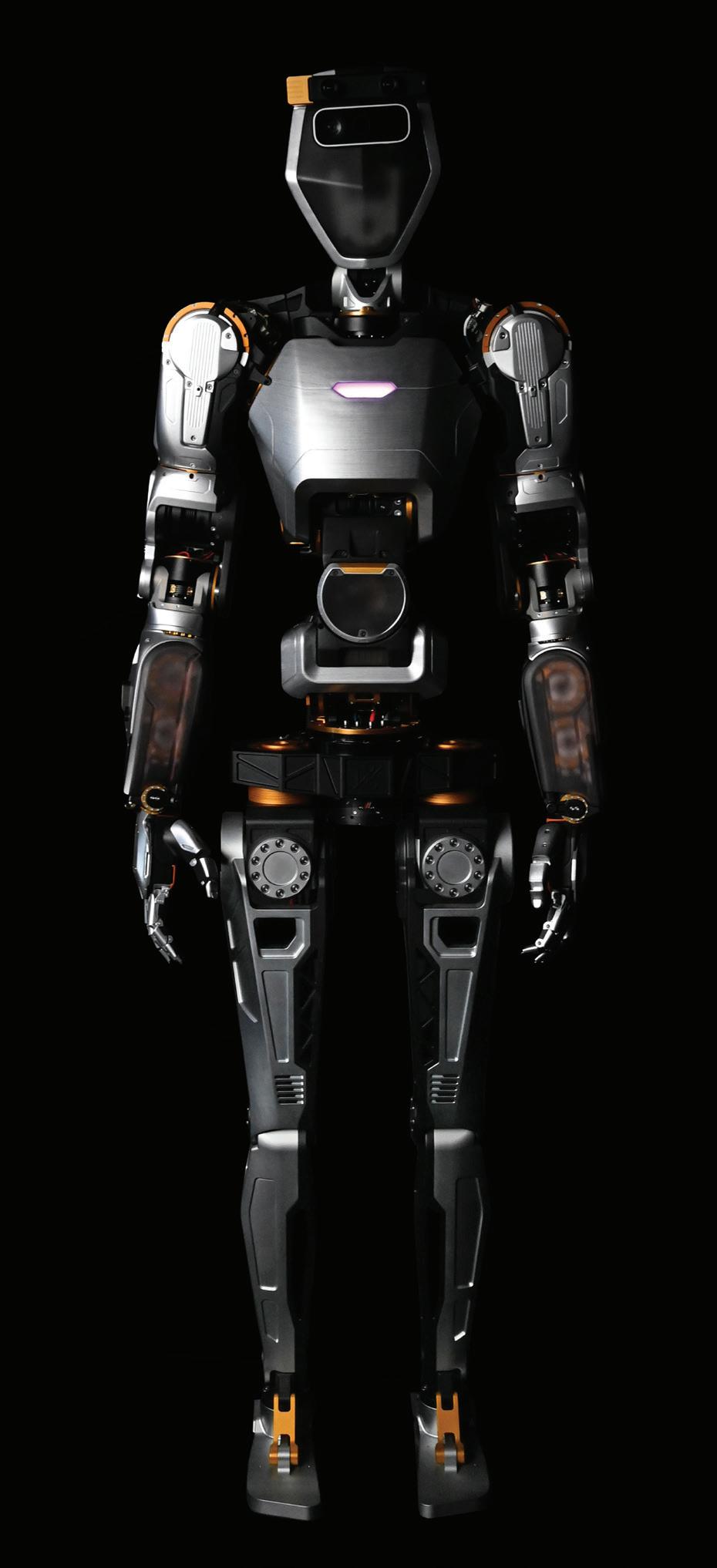

Are Humanoid Robots the Processing and Packaging Labor Force of The Future?

With advanced AI so ware, dexterous “hands,” and full body mobility, will humanoid robots be the answer to the shortage of labor on the packaging line?

By Liz Cuneo, Senior Editor

What exactly are humanoid robots, and are they a viable labor force solution? Can they operate sophisticated equipment or only perform simple tasks? How much faster are they than human workers?

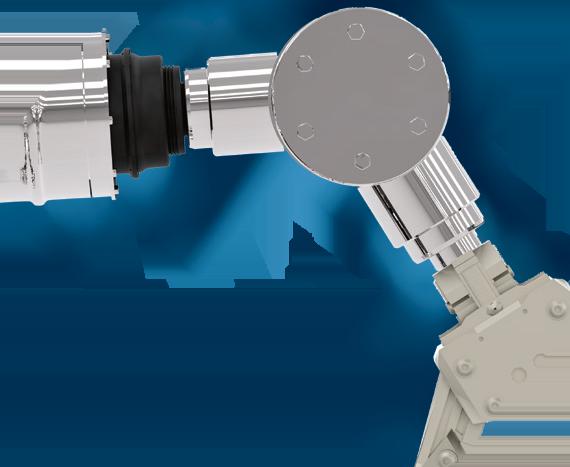

Humanoid robots, or robots that look and move like humans, still look like a thing of the future, but they’re already being used in some industries today and have the potential to report for duty on the packaging line in the near term. General-purpose robots like humanoids differ from the robotics and automation we typically write about. We’re not talking about one piece of equipment that does one thing (albeit very fast and efficiently). We’re talking about a robot that can be programmed and “taught” to do many things, like kitting, material replenishment, order picking, palletizing, and lifting/loading. Is there a place for a general-purpose robot in packaging facilities today?

General purpose means greater functionality

Apollo shines in tasks that are considered “gross manipulation,” or gross motor function, like grabbing something with both hands. Photo courtesy of Apptronik.

The robots mentioned above are programmed to do one task and do it well. General-purpose humanoid robots such as Phoenix, from Sanctuary AI, a Canadabased robotics company, can handle a variety of tasks thanks to its full body mobility. This gives users the flexibility of using the humanoid robot to automate any pressing task at any pressing time.

Phoenix is the company’s sixth-generation robot designed to overcome the challenge of bringing a general-purpose robot to market. Phoenix can

perform daily tasks such as picking and can work alongside humans. Phoenix is 5’7”, weighs 155 pounds, and can lift up to 55 pounds. Perhaps the robot’s most impressive feature is its hands, which feature “20 degrees of freedom and haptic sensors” that allow it to perform tasks that require dexterity.

“A critical component needed to make robots truly general-purpose is dexterous hands,” says Geordie Rose, CEO & co-founder of Sanctuary AI. “This is an area that Sanctuary AI has been intently focusing on. Each with 20 degrees of freedom and proprietary haptic technology, Phoenix’s hands are designed to be as close as possible to human hands in their dexterity and fine manipulation capabilities. Our haptic technology provides the robots with a sense of touch which is essential to perform tasks successfully.”

Sanctuary AI isn’t the only robotics company with

MANAGEMENT SPRING 2024 16

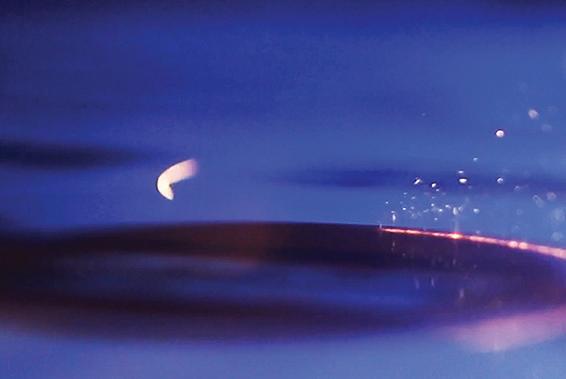

A PULSED LASER FOR SENSITIVE MATERIALS

The p150 designed for OEM integration delivers improved processing speeds and high quality results on difficult to process materials. Fast pulse rise time, best-inclass 600 watts peak power, and excellent beam quality opens up new capabilities to process thin films, and modern plastics. Melt lips, burn marks, and over melt can be greatly reduced and even eliminated.

Learn more about the p150:

out more at:

https://novantaphotonics.com/ Find

“You’ve got about a million jobs unfilled in logistics, material handling, [and] manufacturing.”

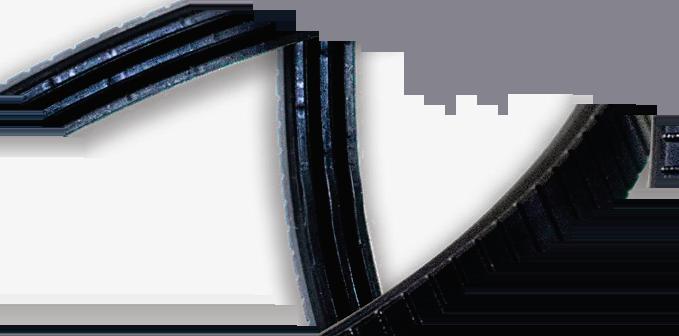

a humanoid in the market. Apollo, from Apptronik, an Austin, TX-based robotics company, is a humanlike robot that is designed for use in manufacturing. Apollo is 5’8”, can lift up to 55 pounds, and can operate for four consecutive hours.

“Apollo will solve many of the near-term manufacturing and logistics use cases that have not been addressed by special-purpose automation solutions to date. This includes automated lineside/work cell delivery or machine tending of totes in manufacturing as well as trailer unloading, case picking, or palletizing,” says Jeff Cardenas, co-founder and CEO of Apptronik.

According to the company, Apollo shines in tasks that are considered “gross manipulation,” or gross motor function, like grabbing something with both hands. As technology develops, Cardenas predicts that

MANAGEMENT SPRING 2024 18

Digit uses its claw-like hands to grab and move empty tote boxes, removing this mundane and repetitive task off human workers. Photo courtesy of Agility Robotics.

www.dornerconveyors.com Great for: Machine Infeed/Outfeed Food & Beverage Carton/Case Handling Packaged Goods Scan to Learn More High Speeds up to 267 fpm Inclines & Declines +/-10° Loads up to 700 lbs. NEW PRODUCT

BOOST YOUR CONVEYING PERFORMANCE

Fenner Drives Performance Boosters

Power up your conveyor performance with these offerings from Fenner Drives:

LONGEVITY

Get longer belt life than rubber poly-V belts

Product Features

Abrasion-resistant polyurethane

High-friction polyurethane

Elastic reinforcement

Oil, grease and chemical resistant

PERFORMANCE

Increase performance on curves

Benefit

Eliminate slip and “walk off” of belts from dust build up

Lower running tension needed, reducing belt fatigue

Self-tensioning for consistent performance

Longer belt life

Connect with the Fenner Drives team to find out how Eagle Poly-V or any of our standard products can address your application needs: fennerdrives.com/eagle-poly-v

Fenner Drives

PRODUCTIVITY

Less down time keeps your line running for optimal throughput

Competitors

A Fenner Precision Polymers Company

the robots will be able to move to finer dexterity tasks (complex tasks) over time. Specific to the packaging line, Cardenas says that Apollo would excel at material replenishment tasks like loading blank cartons into a cartoner, adding a new roll of film to a form/fill/

seal machine, and even handling simple packaging machine changeover.

Look at real-life applications

Another robot in market today is Digit from Agility Robotics, an Oregon-based robotics company. This humanoid robot can unload and load totes (up to 35 pounds) and put them on a conveyor. Amazon is already experimenting with Digit in its warehouses today. Digit uses its claw-like hands to grab and move empty tote boxes. According to Melonee Wise, CTO of Agility, Digit could also handle material replenishment tasks like picking up a box of containers and dumping it into an unscrambler. However, loading several containers by hand into a case would prove more difficult.

“Digit is really good at moving box-like or tote-like containers; that’s Digit’s superpower. It gets trickier when we talk about stacks of things or individual objects that we have to potentially pinch. A lot of Digit’s manipulation is more like tongs, less like bi-manual hands,” says Wise.

Sanctuary AI says that Phoenix is in the pilot stage, yet is ready for real-life application and can learn from demonstration by users wearing a VR headset to

MANAGEMENT SPRING 2024 20

Feeders & Conveyors Eriez.com | 814.835.6000 Mechanical & Electromagnetic Conveyors •Low profile models •Wide range of screener options •Models for every application Compact Feeders •Energy efficient electromagnetic drives •High Speed models for rapid On/Off cycling •High Deflection models for fine powders, leafy, and sticky products for Every Challenge

A critical component needed to make robots truly generalpurpose, is dexterous hands. Photo courtesy of Sanctuary AI.

Thank You

Thank You to our OpX Leadership Network 2023 Sponsors. Your continued support allows the OpX Leadership Network to bring solutions on topics such as OEE, Total Cost of Ownership, Remote Equipment Access, Virtual FAT, RFP for CPG Industry and more to our growing audience of food and beverage companies.

Platinum Sponsor

Gold Sponsors

Silver Sponsor

For more information on the OpX Leadership Network visit opxleadershipnetwork.org

“. . . we’re building generalpurpose robots that can do any work a person might be reasonably expected to do.”

“show” the robot a new task. This remote control allows workers to operate the robot from home, decreasing their need to be on site, or from handling the task themselves. Sanctuary demonstrated the potential of robot remote work with a pilot test at a retail store in January where a human guided the robot through 100 tasks.

“Not only could Phoenix fill one of those roles, it could be used to perform any and all of them, which is unique,” says Sanctuary AI’s Rose. “Historically, many of the popular and successful robots that we’ve seen over the last several years have been on the special-purpose end of the spectrum. For example, an automated case labeling machine could perform the singular task of labeling boxes repeatedly, but by design these use cases are exclusive. At Sanctuary AI, we’re doing something entirely different — we’re building general-purpose robots that can do any work a person might be reasonably expected to do.”

It turns out many humanoid robots can handle both changeover and operating an HMI. These general-purpose robots, like Apollo, have the capability to manage the HMI interface (depending on what’s on the screen) and handle changeover, but due to its sophisticated technology, may not need to interface with the HMI like us humans.

“The robot can directly connect to the back end… it doesn’t necessarily need a touchscreen interface like we do because it can just connect to the computer,” says Cardenas.

When I reached out to Melonee Wise of Agility Robotics, she expressed the same idea.

“Most likely Digit would just do it telepathically… Digit would most likely look at a system without even having to look at the touchscreen, and just ask the system and the network it’s connected to. That’s how we do it today,” says Wise.

Robots as a labor solution

So, what’s driving the adoption of humanoids in the workplace? Experts agree that the number one motivator is labor shortages, followed by the desire to remove ergonomically challenging tasks from human workers.

MANAGEMENT SPRING 2024 22

2023 HIGHLIGHTS Realize the Power of PMMI to Move Your Business Forward! Celebrate PMMI’s 90th Year Connecting the Industry Throughout 2023, PMMI connected the industry and served as a critical link, bringing together thought-leaders and resources to advance our industry and help it grow stronger. PATRICIA ANDERSEN Vice President of Human Resources & Aftermarket Services, Delkor Systems, Inc. Chairwoman of the Board, PMMI Review the 2023 programs that impacted your business Check out 2023 Highlights pmmi.org/2023-highlights ❝ Experience the success of our record-breaking trade shows and meetings Learn how we connected the industry to advance your business ❝

“It comes down to the labor gap. You’ve got about a million jobs unfilled in logistics, material handling, and manufacturing. And when we talk to customers, their big pain point is that 1 in 3 people don’t show up for a shift, and they have 20 open jobs… they just need to get the work done,” says Wise.

“We see a massive opportunity here, given there’s such a clear need for labor in manufacturing,” says Sanctuary AI’s Rose. “At the onset of the pandemic, the manufacturing industry lost roughly 1.4 million jobs and currently has around 700,000 job openings, representing 7% of the overall 9.9 million job vacancies in the U.S. Our robots are designed to help address labor shortages across industries, including manufacturing and packaging, as well as take on roles that are boring or unsafe for people.”

“Based on a 10-hr, two-shift operation that runs 5-6 days a week, we can achieve a payback, or ROI, of less than two years.”

while one is charging, others are working.

Are humanoid robots the future of packaging?

The functionality and capabilities are clearly there for humanoids to be deployed successfully in various places along the packaging line, and the evidence supports that they can help solve today’s workforce issues and provide automated labor where needed.

So, the final question is this. Is there a future where humanoid robots are used more and more in packaging facilities? While not too surprisingly, the robot manufacturers are more optimistic about this future than the CPGs I spoke with.

Removing dangerous tasks and filling the labor gap is one thing, but then there’s increasing throughput. Since robots can perform strenuous or repetitive tasks longer than humans, without the need for a break, Wise says that the general throughput of humanoid robots is higher than that of human workers. But there is the issue of battery life and charge time. While some companies I researched report four hours of battery life, Digit lasts about two hours, depending on what Digit is doing, and it takes about one hour to charge. Agility says that it is working on improving the battery life but also pointed out that typically, companies deploy a fleet of Digits so that

“The idea of using humanoid robots in the packaging facilities has not crossed my mind but humanoid robots do present good opportunity,” says Daniela Garcia, a packaging engineer in the dairy industry. “They have potential for implementation in areas where repetitive motions that cause fatigue over time are common. My mind goes to the loading of case packer magazines or the general replenishing of materials for equipment that is manually loaded today. Although this is the initial thought, such implementation requires thorough understanding of the limits and capabilities of humanoid robots.”

Camron Franklin, senior parcel account manager, Conveyor Solutions, agrees that there is value in tak-

Better Than a Load Cell Fast Weight Captures and Easy Integration MMS 2 wipotec.com/us Our show truck will come to you. Scan here to learn more. Visit us at Pack Expo East in Philadelphia, PA March 18-20, 2024 Booth# 721 Wipotec Technology‘s new MMS 2 is an ideal weigh cell for production lines in a variety of settings, including quality control scenerios for vial and syringe filling. The MMS2 offers IP65 protection for safe guarding components against dust, foreign materials, water, and other environmental factors.

MANAGEMENT SPRING 2024 24

ing repetitive motions off human workers, but the question on everybody’s mind is cost.

Many robot manufacturers like Sanctuary AI and Apptronik will be deploying their robots through a Robotics-as-a-Service (RaaS) model where customers can lease the robots for an ongoing fee. Pricing varies based on the size of the operation and complexity of the tasks being performed and companies I spoke with are not eager to give out exact numbers. Even a Google search won’t net you exact numbers on humanoid robot pricing.

• Choose from custom designed or standard, 24/7 workhorse conveyors for simplistic to complex packaging applications.

• Our goal? Maximize productivity; increase throughput; minimize footprint; factor in future growth.

• We connect mechanical engineering & electrical so your OEM equipment “talks”.

• Accumulate, rotate, elevate, decline, merge, curve, divert, reject, flip, grip, hand pack, stack, sanitary, what’s that? Just tell us what you need. It’s that simple.

www.multi-conveyor.com

MANAGEMENT SPRING 2024 25

Humanoid robots like Phoenix o er users the flexibility of deploying the robot to automate any pressing task at any pressing time. Photo courtesy of Sanctuary AI.

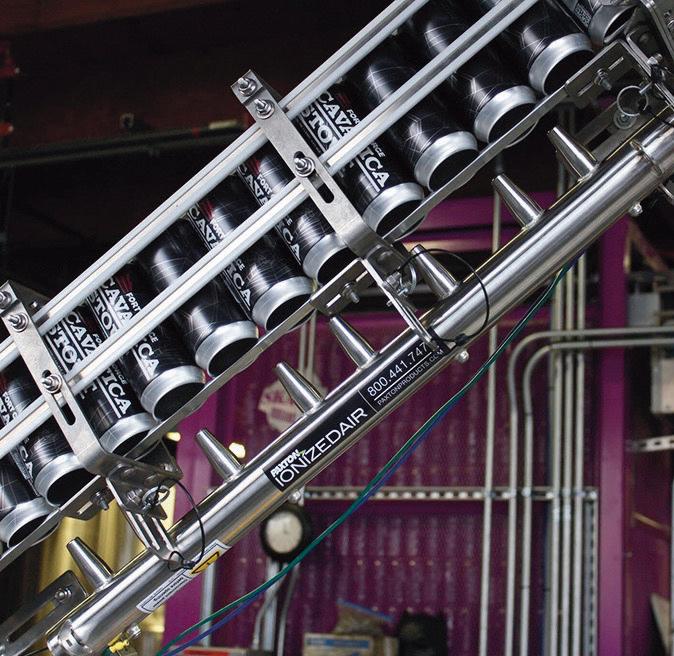

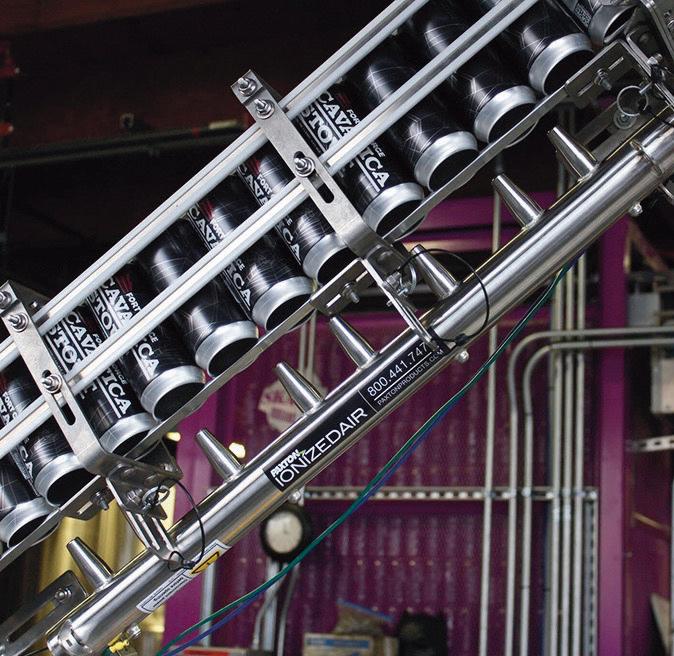

Paxton’s high efficiency drying and blow off solutions improve the drying of cans and bottles for high quality labelling and coding, while using 60–80% less energy – typically giving a one year ROI. And with Paxton’s PowerDry™ Drying System, you can significally reduce downtime and quality rejects.

DUST AND DEBRIS BLOW OFF

“Our robots are designed to help address labor shortages across industries, including manufacturing and packaging . . .”

Cardenas from Apptronik says that deploying them as RaaS is meant to offer the robots at a price comparable with the “rates of existing workers” by offering them at a “salaried” rate.

“The target is, long-term, to produce a system that costs less than $50,000 per year—and what that does is open up the range of different opportunities, but we’re not there yet today. That’s the goal, and that’s part of the design of Apollo to enable that,” says Cardenas.

Paxton’s powerful air delivery devices and systems remove dust, particulates, and debris effectively and efficiently. And if static cling is an issue, Paxton’s Ionizing Rinsing Systems dissipate the static charges on the targeted surfaces and then blasts the contaminants away using a Paxton PX-Series Blower.

INDUSTRY LEADING BLOWERS

Robots-as-service is helpful for companies and allows them to try the robots out and learn their capabilities without a large upfront investment.

Right now, Agility is selling Digit CapX plus Saas, but will go to a RaaS model in the future. According to Wise, as expected, the robots are “pretty expensive,” and she cannot publicly talk about price at this time.

What about repair and maintenance? Apptronik says that right now it is doing all its own service and maintenance but is looking to partner with third party providers that are already doing a lot of maintenance for other automation systems at scale. But general-purpose robots like Apollo and Digit are created to be easy to maintain.

“One of the keys for a robot like Apollo is for it to be easy to maintain, easy to swap out parts, and modularity is a big focus for us as we move ahead to enable that,” says Cardenas.

The PX-series of centrifugal blowers, by Paxton Products, offers unmatched blower efficiencies as high as 80% – meaning you’ll use 33% less energy overall. In addition to this, Paxton blowers come with an unmatched three-year warranty.

Wise also says Digit was created to easily change out parts on the robots, simplifying maintenance and service. But what about TCO (total cost of ownership) or ROI?

“Based on a 10-hr, two-shift operation that runs 5-6 days a week, we can achieve a payback, or ROI, of less than two years,” says Wise.

If labor shortages continue and robot prices decrease, a robotic humanoid future becomes a little more plausible. While exactly what humanoid robot adoption will look like remains to be seen, the interviews I conducted helped me to realize a not-so-far-off future where these robots can fill in gaps along the packaging line.

We’re clearly in the early days for general-purpose robots as most are not yet available for purchase or hire in large quantities or with the exact skillset CPGs may be looking for. But these robotics companies are working hard on the technology to get them ready for scale and improve functionality in manufacturing, logistics, and even packaging.

As with all trends and new technology, time will have to tell us how broadly this will be adopted and in what capacity. ■

513-891-7485 PAXTONPRODUCTS.COM SCAN QR CODE TO LEARN MORE

ENERGY EFFICIENT DRYING

MANAGEMENT SPRING 2024 26

REACH WHO YOU WANT

did you know?

Display your latest products and technology at PACK EXPO International - the ONLY place in 2024 where you can get your brand in front of 45,000 packaging and processing buyers.

88% of attendees are looking to see new types of machinery, technology, materials and containers.

November 3-6, 2024 | Chicago, Illinois RESERVE YOUR BOOTH TODAY AT PACKEXPOINTERNATIONAL.COM

Derek Jones, Marketing Manager

Derek Jones, Marketing Manager

Rodney Grounds, Vice President of Sales

Rodney Grounds, Vice President of Sales

Company Background

When established: 2001

Leadership: Filippo Gremese, CEO; Rodney Grounds, VP of Sales; David Brooks, National Distribution Sales Manager; Andrea Mantovani, After Sales Manager; Brad Dodrill, Controller; Derek Jones, Marketing Manager

Range of products: Automatic and semi-automatic stretch wrappers; Case packers; Palletizers; Laser Guided Vehicles

Production/shipping volume per year: $450M+ globally

Headquarters/manufacturing location(s): Global headquarters are in Bologna Italy; U.S. HQ is located in Duluth Georgia; 10 production facilities including one in Portland Oregon (for the TopTier palletizers)

Number of employees: 2000+ worldwide

Number of field service personnel: Globally: 280+; U.S.: 50+

Facility square footage:80,000

Geographic sales and support areas: Italy corporate office and manufacturing facilities; Subsidiaries located in U.S., Germany, France, Spain, UK, Russia, Brazil, and China

Company website: www.robopacusa.com

Annual revenues: over $100 million

Robopac USA’s End-of-Line Advantage

The company listens to the voice of the customer to drive R&D innovation across a range of case packers, palletizers, stretch wrappers, and laser-guided vehicles.

Stephanie Neil, Contributing Editor

Founded in 2001, secondary packaging provider Robopac USA is based in Duluth, Georgia, but it has deep roots in the packaging valley of Bologna, Italy. As a subsidiary of the Italianbased Aetna Group that started as a foundry casting aluminum in the 1930s, the company is built on a customer-centric partnership approach, delivering the end-ofline packaging equipment needed downstream to pack cases and stack pallets.

Robopac USA is best known for its portable semi-automatic stretch wrap machine, called Robot S7, now in its seventh generation, but the company offers everything downstream from the product being made.

“We manufacture, service, and support a complete line of end-ofline packaging equipment,” said Robopac USA marketing manager Derek Jones, noting the company provides the widest range of machines and technological capabilities across all of its product lines,

including case packing, palletizing, stretch wrapping, and laser-guided vehicles.

Customizable machines

Most of the case packing, stretch wrapping, and laser-guided vehicles are manufactured in Italy, but Robopac USA does have facilities in Portland, Oregon, where palletizing equipment and entry-level automatic stretch wrappers (LT Automatic) are made. In addition, on the semi-automatic stretch wrapping side of the business, they have around 250-300 of those machines in stock to keep lead times short. “Most semi-automatic stretch wrappers ship within 72 hours from receipt of the purchase order. Robopac also has over $2 million in spare parts with over 90% shipping the same day,” Jones said.

And the equipment is designed to be adaptable. For example, while its semi-automatic stretch wrapping equipment comes in different configurations, if a customer wants to add on capabilities, like roping

OEM PROFILE – ROBOPAC SPRING 2024 28

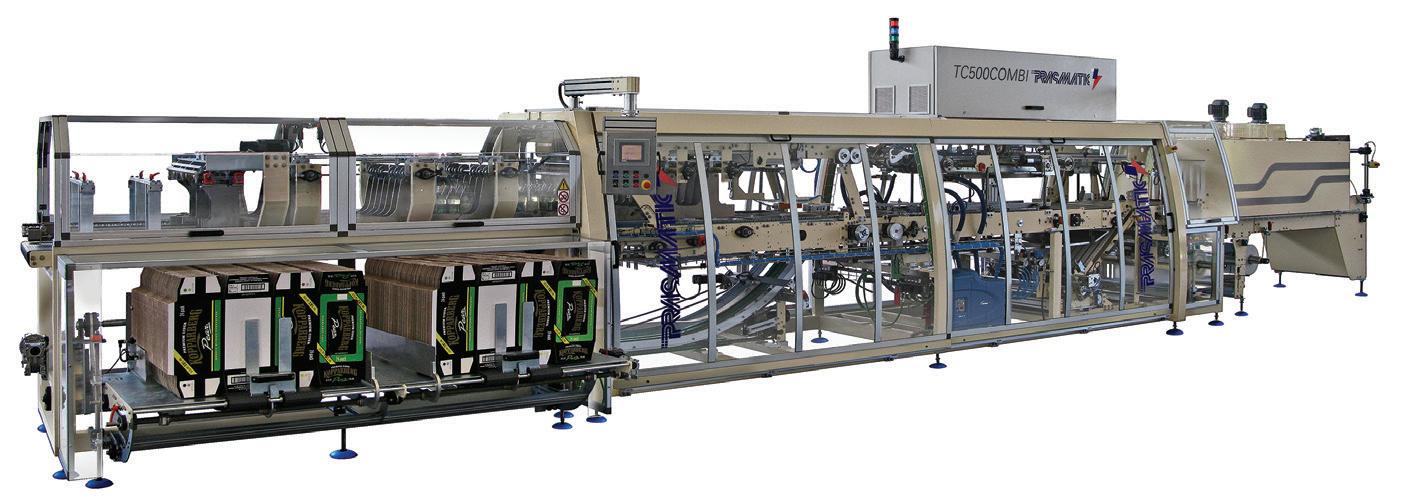

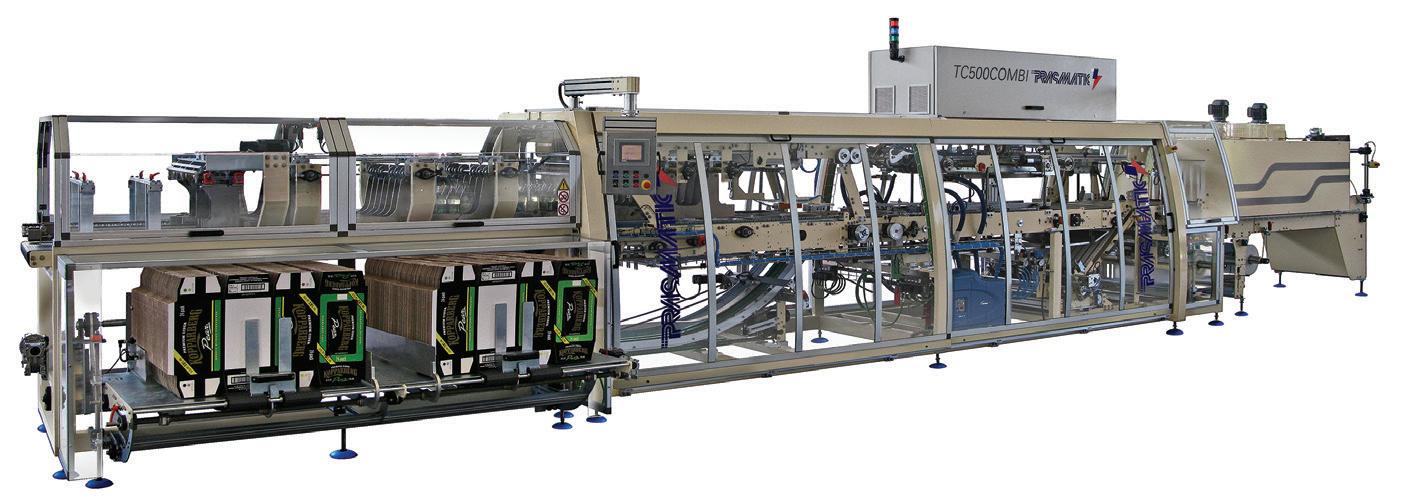

Prasmatic TC 500

Combination shrink wrapper and case packer

devices, Robopac is able to upgrade the equipment at its Georgia facility prior to shipping. In addition, the machines that go through an RFQ process—including case packing, palletizing, automatic stretch wrapping, and laser-guided vehicles—can be customized based on enduser requirements.

This level of flexibility, coupled with an increased demand for more automated end-of-line equipment due to a labor shortage in the industry, is why Robopac USA has experienced 30% to 40% revenue growth annually in the North American market over the past four years.

The company also continues to evolve its products, as Robopac invests over 6% of revenues annually into research and development. “New product development is often a matter of designing new options to fit a particular market need,” Jones said. “Oftentimes, our customers come to us with new primary packaging designs which require adaptations of our equipment to meet those needs. If these new product designs are believed to be a market trend, the Robopac engineering team will start developing these adaptations.”

Other times, it is a matter of listening to the voice of the customer, many of whom are asking Robopac to make the machines more user-friendly. For example, more people want “hands-off” experiences with the machines, but the automatic stretch wrappers would require someone to change the roll. As a result, the company created an automatic roll changing (ARC) device that can detect when the film has run out. It then automatically switches the roll itself, and when another load comes down the conveyor and enters the wrapping zone, it will trigger the photo eye sensor, and the machine will start back up and wrap another load.

Meeting market changes

There are other trends in the CPG industry currently happening around changes in shelf-ready packaging and materials that are impacting how Robopac is designing its machines.

Shelf-ready packaging is driven by the labor shortage in retail, where there is a need for more efficiency in the stocking of products on the store shelves.

OEM PROFILE – ROBOPAC SPRING 2024 30 From handles, knobs, ergonomic control elements to precision rotary controls Elesa is a single-source manufacturer with a wide range of innovative, award-winning products available in inch and metric sizes. Shop elesa.com

Helix 1 EVO rotary arm wrapper

“Robopac has worked with corrugate manufacturers to come up with unique wrap-around case designs that provide a shelf-ready solution,” said Rodney Grounds, Vice President of Sales at Robopac USA. “Because the cases are designed as a wrap-around, our customers will see a reduction in corrugate use over traditional shelf-ready case designs. Typically, a customer can reduce the corrugate by 5-to-7% using this method.”

Another trend Grounds is seeing from the large consumer products companies is the reduction of plastics in their packaging materials. By using Robopac’s patented Cube film delivery system, they have consistently been able to show a 20-to-50% reduction in stretch film consumption while maintaining superior load containment, he said.

In addition, Robopac is on its own digital transformation path, using a stage-gate approach to new product development. One of the stages includes the use of digital twins, which allows engineers to simulate new product development to ensure the legitimacy of the prototype. But that is just one way the technology could potentially be used. “Robopac sees that in the future digital twins could be used as an artificial intelligence platform for maintenance and repair,” said Grounds.

The glo-cal advantage

Because this U.S.-based company is headquartered in Italy, there is a cross-culture influence. For example, Robopac USA has an Italian CEO who provides a nice balance of the Italian culture with the U.S. expectations around speed and service.

“We use a term called ‘glo-cal,’ that is global and local, a combination of how we want to present ourselves as an organization around the world, but also understanding that each market is different and we need to know what the needs are of the local area,” Jones said.

To that end, the company believes it is important to be present in the customers’ local markets. Therefore, they have regional sales engineers based geographically in North America. These sales engineers are assisted by a team of application engineers, each specializing in an equipment sector. In addition, each global business unit has a team of specialized project managers to make sure local customers are served properly.

This commitment to customers has been an important part of the company’s Italian history, and it will also lead the North American operations into the future as it continues to grow and expand operations. ■

OEM PROFILE – ROBOPAC SPRING 2024 31 Create your next packaging line layout in minutes with CAD360 from mk. www.mkcad360.com | mk North America, Inc. | (860) 769-5500 CAD360!

Company Background

When established: 2012

Range of products: Custom automation. Also, a line of standard products: blister sleever, blister accumulator, brush washer/dryer, vial tray loader, wallet sealer, compact case packer, robotic syringe de-nester.

Executive team: Dustin Hanson, President. Walt Stewart, Exec VP of Sales. Ryan Sorkness, VP. Mark Jenson, Project Manager.

Production/shipping volume

per year: 15-20 medium to large systems

Headquarters/manufacturing location(s): Fargo, ND.

Number of employees: 25

Number of field service personnel: Five service technicians

Facility square footage: 30,000 sq ft facility

Geographic sales and support areas: National and International

Company website: pharmamedinc.com

Annual revenues: 5 to 10 million

PharmaMed: Pharma-grade Automation

Tackling old pharma and medical device problems with new ideas.

Sean Riley, Senior News Director

Arecent addition to PMMI, PharmaMed has been the pharma and medical automation pride of Fargo, North Dakota, for over a decade. OEM Magazine recently spoke with its leadership team to help introduce the company to its fellow association members.

Can you provide a brief history of your company?

PharmaMed was founded in 2012 by Walt Stewart and Dustin Hanson. Both had extensive experience in custom automation in the pharma and medical industries. Their vision was to build a company focused on great customer service and where their employees were treated like family.

What sets your company apart in the industry—what makes it shine?

PharmaMed employs Passionate Problem Solvers who can solve even the most complex issues. Their dedication to customers sets them apart from the rest. PharmaMed doesn’t give up and is always willing to work with its customers to get things right.

What went into the decision to join PMMI?

At PharmaMed, we like the idea of doing things to benefit our employees and our business. We saw the many advantages of PMMI for our employees, like training reimbursement for our employees, name recognition, networking opportunities, and discounts for tradeshows we already attended.

Have you participated in any PMMI programs since becoming a member or have plans to in the future?

We bought our PACK EXPO 2024 International Booth since becoming a member. While we have not participated in any other programs yet, we plan to take advantage of the employee training and the tuition benefit for continued education in the near future.

What’s your approach to new product development? How do you come up with ideas for new machines and market-test them?

We are always paying attention to the products currently offered by other companies, and we listen to our customers’ needs. This helps us see gaps in the market. When we go to trade shows with sample machines, potential customers always ask us, “Where can we get one of those?”

OEM NEW MEMBER SPRING 2024 32

Ready to take your workforce to the next level?

Don’t miss these upcoming training and development opportunities!

Packaging and Processing Equipment Selling in Today’s Market

Become a trusted advisor to customers purchasing packaging, processing, and automation equipment.

MAY 8-9, 2024

nVenia; Chicago, IL

Field Service Essentials

Transitioning from proficiency to excellence as a technician involves more than technical skills. Discover the nontechnical knowledge and skills essential for moving from good to great.

JUNE 18-19, 2024

BellatRx Inc.; Montreal, QC, Canada

Certified Trainer Workshop

Learn the most effective strategies and tactics to deliver exceptional training across all employee skill levels with this leading train-the-trainer program for the industry.

JUNE 20-21, 2024

BellatRx Inc.; Montreal, QC, Canada

For more information or to register for our upcoming workshops, visit pmmiu.org

PMMI MEMBERS ONLY

PMMI MEMBERS ONLY

PMMI MEMBERS ONLY

PMMI MEMBERS ONLY

How has your product line broadened over the years?

We started with one small machine, a brush washer/ dryer. Over the past 11 years we have now expanded to offer seven standard products, including the brush washer/dryer, a blister sleever, blister accumulator, vial tray loader, wallet sealer, compact case packer, and robotic syringe denester.

Can you share your annual investment in R+D (% of sales)?

We always research new technologies and processes when running a custom automation company. We estimate that, on average, 10-20% of sales is directed toward R&D.

Where do you find most of your employees?

What sort of background or specific talents/skills do you look for?

Our philosophy has always been to hire someone with quality personality traits and train them to do the job. We find our employees through multiple channels, including North Dakota State University engineering interns. We look for people with good character traits like integrity and respect for others and people who are team players and hard workers.

Why do employees love working for your company?

At PharmaMed, we offer flexible schedules, a caring leadership team, challenging design projects, and a team-oriented atmosphere. We all work together to accomplish each project, and the leadership team works hard to make sure everyone knows their role is important.

How do you balance standardized machine configurations with those requiring customization?

We do mostly custom automation and bring in our other standard products as needed to fit into product lines. Our team of “Passionate Problem Solvers” does an outstanding job merging these together to make one functional line.

Are you incorporating lean manufacturing?

Yes, we incorporate lean manufacturing. PharmaMed has just moved into its new corporate headquarters, and so we have implemented protocols and SOPs to support a more efficient approach to running our business. As a facility, we recycle everything, including in our manufacturing process and operations. We recycle metal shavings, reuse metal that can be repurposed, and other similar things.

How do you approach project management?

We have a dedicated Project Manager for all projects. This person follows the machine design/build and is part of all discussions/communications with the customer throughout the entire project.

What’s your process for handling a customer’s initial inquiry and needs assessment?

When a customer reaches out to us initially and inquires about our products, we listen to their needs. If there is a potential match between the challenge and the solution, we write up a quote and give them an estimated timeline.

Once a customer issues a P.O., what happens next? What can they expect?

Once the P.O. is issued, we have a five-step process for our customers:

1. Discovery – This is where we learn what our customers’ needs are – because we do custom automation, this is a process where we must come up with a custom solution. This is where our Passionate Problem Solvers really shine.

2. Design and Engineering –

• Project Schedule

• Engineering

• Presentation of design

• Revision

• Procurement

3. Assembly and Debug

4. Delivery and Set up

5. Ongoing Support

How do you handle field service and training?

Do you have dedicated training personnel, or do Service Technicians typically conduct training?

All PharmaMed machines use our S/S/T Program (Setup, Startup, Training). Field service and training are done by our Service Technicians onsite with the majority of installations.

Do you have PMMI Certified Trainers?

We don’t currently have PMMI Certified Trainers, but it is one of the PMMI offerings that has piqued our interest. Now that we are members, we can work toward it. ■

OEM NEW MEMBER SPRING 2024 34

Great managers are key to a great workplace! Do you have an employee who shows potential for leadership? Equip them with the skills today to become the leaders of tomorrow!

Whether new to leading a team or an emerging talent, PMMI’s Leadership Development Program equips employees with the skills to lead with impact. From mastering strategic decisionmaking to team management, we provide the knowledge and confidence to succeed.

more information, visit pmmi.org/young-professionals/program Join

Program

May 1 Registration Deadline May 10 Program Begins Apply Now! Limited Spaces Available. Organizations with effective leaders outperform competitors! FACT:

For

PMMI’s Leadership Development

Where Leaders Are Born, and Futures Are Defined.

Maximizing PACK EXPO Momentum: Renewed Outreach Post Show

Best practices for the post-show follow-up.

Matthew Neuberger, President, Neuberger & Company, Inc.

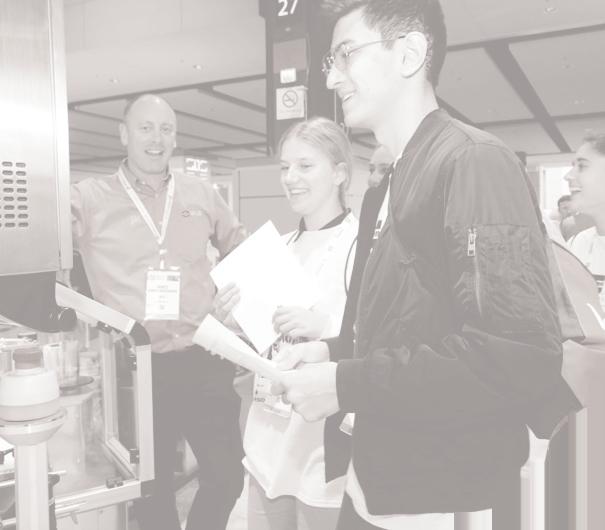

As we move from another successful PACK EXPO event, attendees must reflect on the valuable connections and opportunities discovered during the exhibition. It’s tempting to do an initial follow-up and then slowly let those contacts drift from our minds. But that ignores ongoing opportunities for transforming promising leads into meaningful business relationships. Explore the importance of diligent follow-up, how artificial intelligence (AI) can enhance this process, and why the start of the new year presents a golden opportunity for rekindling connections.

Attending PACK EXPO is about more than just the products and innovations showcased on the exhibition floor. It’s a melting pot of industry professionals, decision-makers, and potential collaborators. However, the real magic happens after the event and not just in the immediate follow-up phase. Many opportunities may slip through the cracks if the leads gathered are not nurtured and developed through strategic initiatives.

The follow-up process is a crucial aspect of lead development. Continued involvement shows dedication, professionalism, and a genuine interest in potential collaborations. In a competitive market, the extra effort in the follow-up often sets successful businesses apart.

Are you still working the leads?

As we enter the post-PACK EXPO period, it’s crucial to ask: Are you still working on the leads you gathered during the event? With the hustle and bustle of daily operations, it’s easy for those promising connections to get an immediate follow-up and then be put on the back burner. However, consistent follow-up is critical to maintaining the momentum gained at PACK EXPO.

Are you utilizing all available channels, such as email, phone calls, and social media, to reconnect with potential collaborators? Establishing a systematic follow-up

approach ensures no lead is left untouched and allows you to prioritize and personalize your engagement based on each contact’s unique needs and interests.

AI-powered follow-up:

Incorporating AI into your follow-up strategy can be a game-changer in the digital transformation era. AI-powered tools can analyze vast amounts of data to identify patterns, predict behaviors, and provide valuable insights into your leads’ preferences. This enables a more personalized and efficient follow-up process, increasing the likelihood of converting leads into meaningful partnerships.

Consider employing AI prompts to automate routine follow-up tasks, such as sending personalized emails or scheduling follow-up calls. By leveraging AI, you can streamline your follow-up efforts, allowing you to focus on building authentic relationships and exploring collaborative opportunities.

The new year: a fresh start for follow-up:

As we approach the new year, it’s an opportune moment to rekindle connections and set the stage for future collaborations. The start of the year brings a renewed sense of energy and optimism, making it an ideal time to reconnect with leads and prospects. Perhaps your immediate follow-up did not sync with potential projects or budget cycles? The new year is a fresh reason to check in with your leads. Previously inopportune timing might sync up in the new year, and your outreach reinforces your interest in working with that prospect. The new year provides a clean slate for building relationships and exploring new business ventures.

By investing time and effort into a thoughtful follow-up process, attendees can continue nurturing the promising PACK EXPO leads into long-lasting and mutually beneficial partnerships rather than biding time until next year’s event. ■

Learn more about PMMI’s Certified Technical Sales Professional Program here: oemgo.to/ctsp2023

SALES & MARKETING SPRING 2024 36

SALES FOCUS

“With the market expansions that are happening in the Southeast, it makes so much sense to bring all the benefits of PACK EXPO to Atlanta so we can connect directly with customers. We’re looking forward to a successful first show in Atlanta in 2025!”

Allison Wagner, Business Strategy Manager, Morrison

Container Handling Solutions

food processing facilities in Georgia

of PACK EXPO attendees are decision makers

life sciences companies headquartered in Georgia

MARCH 10–12, 2025 / ATLANTA, GA

WORLD CONGRESS CENTER Reserve your booth today! PACKEXPOSOUTHEAST.COM

GEORGIA

ATLANTA IS THE PLACE TO BE TO GROW YOUR SALES

2025 DEBUT!

1,586 75% 4,000

ASSOCIATION NEWS

Sean Riley Senior News Director

Celebrate PMMI’s 90th Year Connecting the Industry

DON’T MISS PMMI’s 2023 Highlights – a digital look back on PMMI’s major accomplishments throughout the year. Through this interactive webpage, you and your team will gain a deeper understanding of the power of PMMI to help you move your business forward. Review the 2023 programs that impacted your business. Experience the success of our record-breaking PACK EXPO trade shows and meetings. Learn how we connected the industry to advance your business. Check out the site and share it with your team. Access 2023 Highlights at pmmi.org/2023-highlights.

Join Top Leaders and Elevate Your Business at Executive Leadership Conference

Kickstart Your Business in 2024 – Register Today

Join other packaging and processing leaders in Cancun, Mexico, April 14-17, 2024, for PMMI’s Executive Leadership Conference where you will:

• Exchange ideas with peers – Share best practices with 125+ like-minded, C-suite industry executives.

• Learn from top leaders - Hear from exceptional keynote speakers such as Brian Beaulieu of ITR Economics and gain insights to take your business to the next level in 2024.

• Grow your connections - Participate in over 15 networking events, providing opportunities to expand and share knowledge with fellow leaders.

Hear from expert speakers on topics that will move your business forward, such as:

- Economic Outlook – Brian Beaulieu, CEO and Chief Economist, Institute for Trend Research (ITR) Economics

- AI in Manufacturing – Tom Morrison, President & CEO, Tom Morrison & Associates, Inc.

- Workforces Across the Generational Divide –Jaime Notter, Co-Founder & Cultural Designer, PROPEL

Check out the full schedule at pmmi.org/elc.

Secure Your Spot in the 2024 Leadership Development Program

Available exclusively for PMMI member companies

The PMMI U Leadership Development Program supports PMMI member companies in developing the next generation of leaders and managers. This six-month program offers a comprehensive approach to leadership development, focusing on critical areas such as mastering strategic decision-making and team management skills.

Each participant will receive a personalized development plan, based on a multi-dimensional assessment measuring behavior, motivation, and leadership attributes.

Apply Now! Limited Spaces Available.

Registration Deadline: May 1

Program Begins: May 10

For more information, visit pmmi.org/young-professionals/program ■

2023 HIGHLIGHTS

ASSOCIATION NEWS SPRING 2024 38

Master Proven Selling Techniques with PMMI’s Onsite Sales Training

Take your sales to the next level and equip your sales professionals with industry-leading knowledge when you register your team for our member-exclusive Packaging & Processing Equipment Selling in Today’s Market workshop, May 8 – 9, Chicago, IL.

During this two-day, in-person training, your capital equipment sales professionals will learn systematic consultative selling techniques that will position them as trusted advisors to customers seeking packaging, processing, and automation equipment.

Hurry, seats are filling fast! Register today at pmmiu.org.

Don’t Miss These Workshops Happening in Montreal, Quebec

Field Service Essentials

June 18–19 (BellatRx Inc., Montreal, Quebec)

Field service technicians are the face of your organization. They spend more time with your customers than anyone from your operation. This two-day workshop explores the nontechnical knowledge and skills needed to be a great technician.

Certified Trainer program

June 20–21 (BellatRx Inc., Montreal, Quebec)

This workshop gives your company the strategies and tactics to become an effective and successful trainer across all employee skill levels.

Learn more and register for these workshops today at pmmiu.org

Maximize Your Exposure to Reach Target Customers in 2024

Are you prepared to optimize your competitive edge and present your solutions to the right audience? It’s time to update your PMMI ProSource profile!

With 75% of site visits involving filter-based searches, it’s crucial to ensure your company appears in relevant search results. By updating your PMMI ProSource profile and using applicable search filter checkboxes, such as automatic, semi-automatic, inline, rotary, and more, you’ll make it easier for potential customers to discover your business.

Your updated profile listing enables you to increase your company’s visibility, highlight your areas of expertise, and drive traffic to your company’s profile. Visit pmmi.org/prosource to learn more.

UnPACKed with PMMI’s Best of 2023

Did you miss out on our most downloaded podcasts of 2023? Don’t worry – you can catch up on all our podcast episodes anytime, anywhere. Tune in on Apple Podcasts, Spotify, or wherever you get your pods –search for “unPACKed with PMMI” and start finding solutions to your operational challenges today!

Top 3 from 2023:

• PepsiCo Empowers Next Gen Workforce

• Special Six-Part Sustainability Series: Pt. 1 - Advanced Recycling

• Tackling PACK EXPO Las Vegas: Insider Tips for Attendees

Business Intelligence –Webinar Library

DIVE DEEPER into the latest industry research and hear from industry leaders with the Business Intelligence Webinar Library. These insights, found in the newest industry reports, provide a detailed look into the challenges and solutions in the packaging and processing industry.

View the full Webinar Library today: https://www.pmmi.org/webinars.

2024 Trends in Remote Services & Monitoring

Read the most recent insights on remote services and monitoring in the newly released 2024 Trends in Remote Services & Monitoring report. This report covers services

ASSOCIATION NEWS SPRING 2024 39

offered to customers, recommended attributes, and barriers your customers face, all discussed by key leaders in the industry. This report provides answers to remote services challenges, valuable industry benchmarks, strategic planning insights, and a better understanding of which remote services offer the greatest potential for revenue growth.

Read Full Report:

https://www.pmmi.org/report/2024-trendsremote-services-monitoring

View Full Report:

Moving to Sustainable Packaging:

Closing the

Innovation Gap

Global sustainable packaging policies and swiftly changing domestic legislation are impacting the rate at which manufacturers need to change packaging materials. Discussions reveal a clear movement toward more sustainable packaging and practices, such as reducing carbon footprints.

https://www.pmmi.org/report/2023-movingsustainable-packaging-closing-innovation-gap

Achieving Vertical Strategies

Successful vertical startups depend on several key factors: communication, involving all relevant stakeholders early in the process, ownership of tasks, and robust planning.

View Full Report: https://www.pmmi.org/ report/2023-achievingvertical-startups

Global Marketing – International Shows

In 2024, PMMI Global Marketing is ready to make a significant impact on the international stage with participation in key international shows. With collaboration, industry insights, and strong connections within the international packaging and processing community, PMMI Global Marketing is focused on helping our members succeed in the international sphere.

• Anuga FoodTec, March 19–22, 2024, Cologne, Germany

• EXPO PACK Mexico, June 4–7, 2024, Mexico City, Mexico

• ProPak Asia, June 12–15, 2024, Bangkok, Thailand

• Anuga FoodTec India, Aug. 28–30, 2024, Mumbai, India

Learn more about the 2024 show lineup and member resources at: https://www.pmmi.org/goglobal.

10 Things the PMMI Leadership Program Has Taught Me

A RECENT graduate reveals the benefits of participating in the PMMI platform.

By Mia Stevens, Marketing Coordinator, Morrison Container Handling Solutions

I have been the marketing coordinator at Morrison Container Handling Solutions for about a year and a half. I joined the team after graduating from Purdue Northwest. My role at Morrison allows me to challenge my creative side and build on my strategic skills while shaping what our message is to the industry and our customers.

With my goals focused on continuing to grow while providing value to my company, I was allowed to participate in the PMMI Leadership Development

ASSOCIATION NEWS SPRING 2024 40

Full Page 8.375” x 10.875”

Program, and my journey has been nothing but transformative. Not only did this course provide me with a platform to refine my skills, but it also instilled new perspectives that have reshaped my approach to leadership. Here are ten things I learned in the process.

1. My Personality Breakdown:

As I started this class, I underwent an in-depth analysis that shed light on my personality type from many different angles, such as how I handle:

• Problems & Challenges

• People & Contacts

• Procedures & Constraints

• Pace & Consistency

Having this as a resource has been invaluable not only in my career but also in my home life. I can now take a step back, recognize my patterns, and address them in real-time.

2. How to Navigate Leadership Styles:

Exploring various leadership styles has broadened my toolkit, enabling me to adapt to different situations. Although, it’s not just about adapting to situations; it’s about understanding what resonates with me. This journey has given me the tools to recognize what I truly value in a leader and how I respond best in different scenarios.

3. Embracing My Strengths and Weaknesses:

In the business world, we are often advised to keep our weaknesses under wraps. However, this course was a game-changer for me. It gave me the tools to recognize my strengths and weaknesses and play them strategically. What surprised me most? Traits I used to see as weaknesses unfolded into unexpected strengths as the course progressed.

4. Mastering Communication Dynamics:

We all understand the significance of communication, but this course elevated my ability to communicate both within my team and with the world outside it. This program highlighted internal and external communication strategies and sharpened my skill in articulating ideas effectively.

A key lesson I wish I had known sooner is to become an active listener.

5. Leadership vs Management:

Plot twist – they’re not the same thing! Exploring the nuances of leadership versus management has been a personal value, but this course has elevated it to a lived principle. It’s not just about understanding; it’s about embodying a standard that has enhanced my leadership skills and shaped me into a more conscientious individual.

6. The Power of Presence:

Recognizing the importance of being physically and mentally present has changed how I look at most things. I often find myself repeating the expression “be where your feet are” as a reminder to live in the moment and give 100% of my effort to the task at hand. In our fast-paced world, getting caught up in a project or something said in a meeting is easy. If you constantly worry about what happened yesterday, you will miss the chance to conquer today!

7. Strategic Decision-Making:

Delving into effective decision-making strategies has empowered me to navigate challenges with confidence and clarity and elevated my value as an asset to my company. Trusting my decision-making skills, I now approach choices holistically, considering the bigger picture for impactful outcomes.

8. Adaptability and Resilience:

This program didn’t just teach me about adaptability and resilience in leadership; it became my guide to navigating change with agility. As a newcomer in this industry, I wasn’t always the loudest voice, but this course revealed something crucial – this industry is built on different perspectives, and this is what drives innovation! We need people who see things from different angles, or we will never evolve.

9. Networking:

Through this course, I had the privilege of connecting with incredible individuals who have become a valuable network of resources who understand my industry and its demands.

10. Fostering a Culture of Continuous Learning: