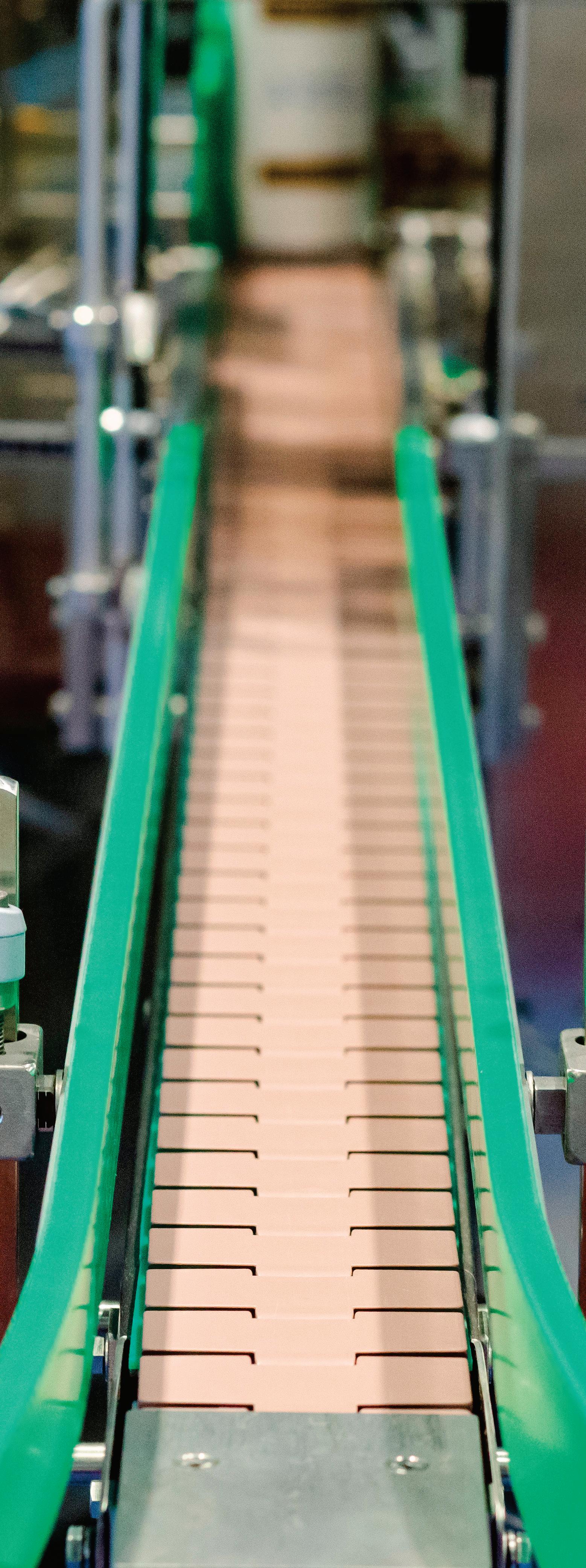

Our conveyor systems seamlessly integrate into your existing setup, streamlining your production processes and reducing manual labor. Trust Span Tech to be your long-term partner in success.

• Tailored Solutions: Our team of experts understands the unique challenges of OEMs. We customize conveyor systems to perfectly fit your manufacturing processes, ensuring optimal performance.

• Advanced Technology: Stay ahead in the industry with our state-of-the-art conveyor technology. From automated sorting to precision handling, our solutions integrate the latest innovations to enhance your production lines.

• Robust and Reliable: Downtime is not an option. Our conveyor systems are built to withstand the toughest conditions, guaranteeing a continuous and reliable workflow for your operations.

• Proven Track Record: Trusted by leading OEMs, we have a proven track record of delivering excellence. Join the ranks of satisfied clients who have experienced unparalleled success with our conveyor solutions.

Packaging Three takeaways from PMMI’s 2024

to Top Report INDUSTRY

1/2 of new manufacturing jobs to remain open by 2033

MARKETING

12

Three strategies to achieve success. SALES

AI

The impact on OEM innovation and design

ASSOCIATION

32 PMMI Member Round-up

Another

EXHIBITOR’S

”

—Michelle Bryson, pg 20

PACK EXPO

38 Elevating Show Strategies How to 10x your PACK EXPO investment

PERSPECTIVES 40 From PC to iPC New demands on iPCs WOMEN’S LEADERSHIP 41 Communications

Three barriers that sabotage interactions WORKFORCE DEVELOPMENT 42 From Strategy to Action An X-factor in employee engagement NEW

Compact pressure sensors and switches with 360° custom-color status display

www.vega.com/vegabar

256 colors

Individually selectable:

Measurement in progress

Sensor switching

Process malfunction

The official publication of PMMI OEMMAGAZINE.ORG

CONTENT

Sean Riley Editor-in-Chief sriley@pmmimediagroup.com | 571 266 4419

Casey Flanagan Digital Editor

Michael Smith Art Director

David Bacho Creative Director

ADVERTISING

John Schrei Vice President, Sales jschrei@pmmimediagroup.com

Lara Krieger Senior Manager, Print Operations lkrieger@pmmimediagroup.com

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com

PMMI Media Group

401 N. Michigan Ave., Suite 1700, Chicago, IL 60611

Phone: 312 222 1010 | Fax: 312 222 1310 www.pmmimediagroup.com

David Newcorn President

Elizabeth Kachoris Vice President, Digital

Kelly Greeby Senior Director, Media Operations

Jen Krepelka Director, Digital Media

Trey Smith Senior Director, Events

PMMI, The Association for Packaging and Processing Technologies

12930 Worldgate Dr., Suite 200, Herndon VA, 20170

Phone: 571 612 3200 | Fax: 703 243 8556 www.pmmi.org

Jim Pittas President and CEO

Joe Angel Executive Vice President, Industry Outreach, PMMI

Glen Long Senior VP

Tracy Stout VP, Marketing and Communications

Laura Thompson VP, Trade Shows

Andrew Dougherty Vice President, Member Services

SUBSCRIPTIONS

To subscribe to OEM visit: www.OEMmagazine.org/subscribe

To change or modify a subscription, please contact circulation@OEMmagazine.org

OEM EDITORIAL ADVISORY BOARD

Lisa Hunt CEO, Plexpack

Greg Berguig VP, Sales and Marketing, PAC Machinery

Rick Fox III Director, Engineering Services, Fox IV Technology

Brian Ormanic Senior Applications Engineer, Pearson Packaging Systems

Colin Warnes Director Sales Engineering & Project Management, ADCO Manufacturing

Tom Ivy CEO, FoodFlow Automation Solutions

Stacy Johnson VP Business Development, Hoosier Feeder Company

• Maximum support for small products

• Belt installation is fast and simple!

• Clean-in-place, USDA-Accepted

• Excellent belt tracking, positive drive design

Flights available for moving product up an incline u

• 70% open area allows for excellent flow-through

• Available in 10mm and 15mm meshes

Economists, by nature, are not the most entertaining sorts. Fortunately for attendees of PMMI’s Executive Leadership Conference, Brian Beaulieu, CEO and Chief Economist of the Institute for Trend Research (ITR) Economics, has a knack for mixing humor with the ups and downs that are part and parcel of the U.S. and global economies. I was fortunate to sit down with Brian for a podcast that we partially transcribed for OEM Magazine (Economic Insights for Tomorrow p. 16) because of the powerful messages he has on the future into the 2030s.

It is an important story to share, as well as Brian’s comment that he doesn’t reveal these things to scare everyone but rather to prepare for what could be some pretty rough times as we exit this decade. Let’s just say we should all make sure we have our houses in order when the calendar switches into the 30s.

This issue also continues our AI in Manufacturing coverage with Exploring AI’s Possibilities p. 30. Love it or hate it, AI is here to stay, and author David McGraw explores the possibilities for the ever-changing technology’s impact on OEM product innovation and design.

In fact, our OEM Profile on IPM Automation (IPM: Over-Delivery in the Name of Uptime, p.24) includes ways that the Michigan-based dairy, food, and beverage packaging systems integrator is already using AI and plans to expand its role. Finally, don’t miss our New Member Profile on PSR Automation (p. 28), a classic American tale of an immigrant who brought his family from Guyana and eventually started his own packaging company.

I hope you enjoy the issue. If you have any story ideas or any comments at all, please don’t hesitate to reach out at sriley@pmmimediagroup.com. ■

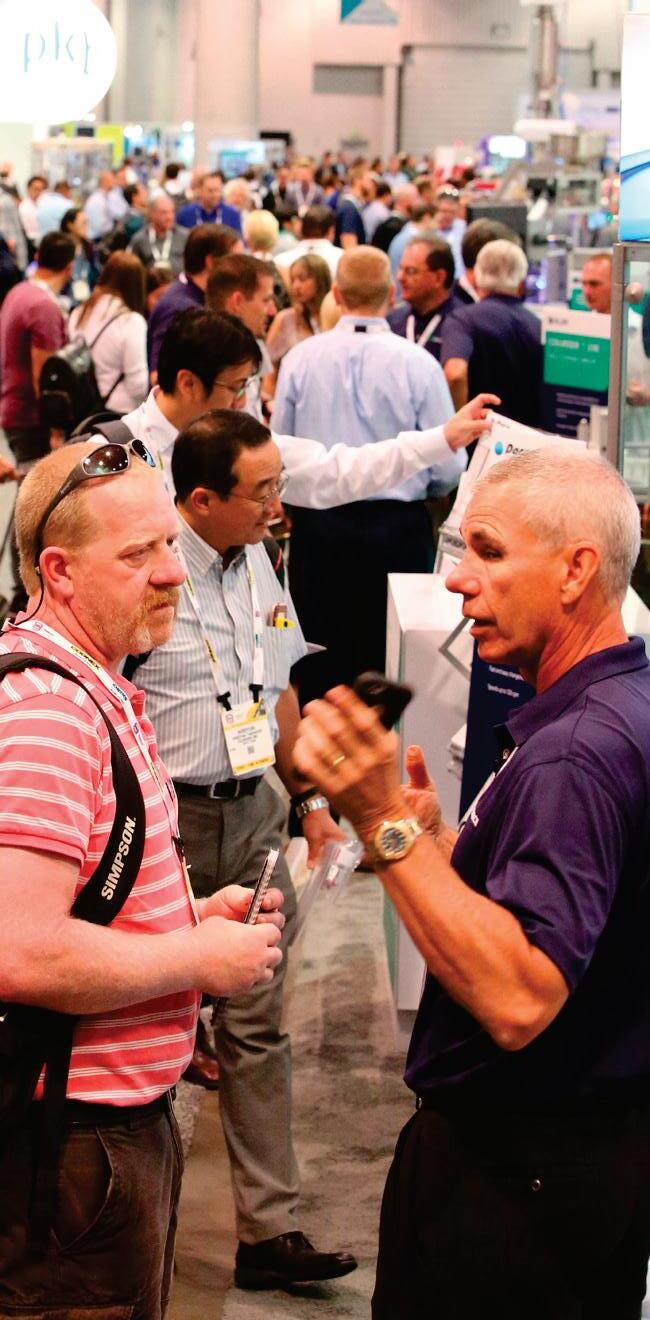

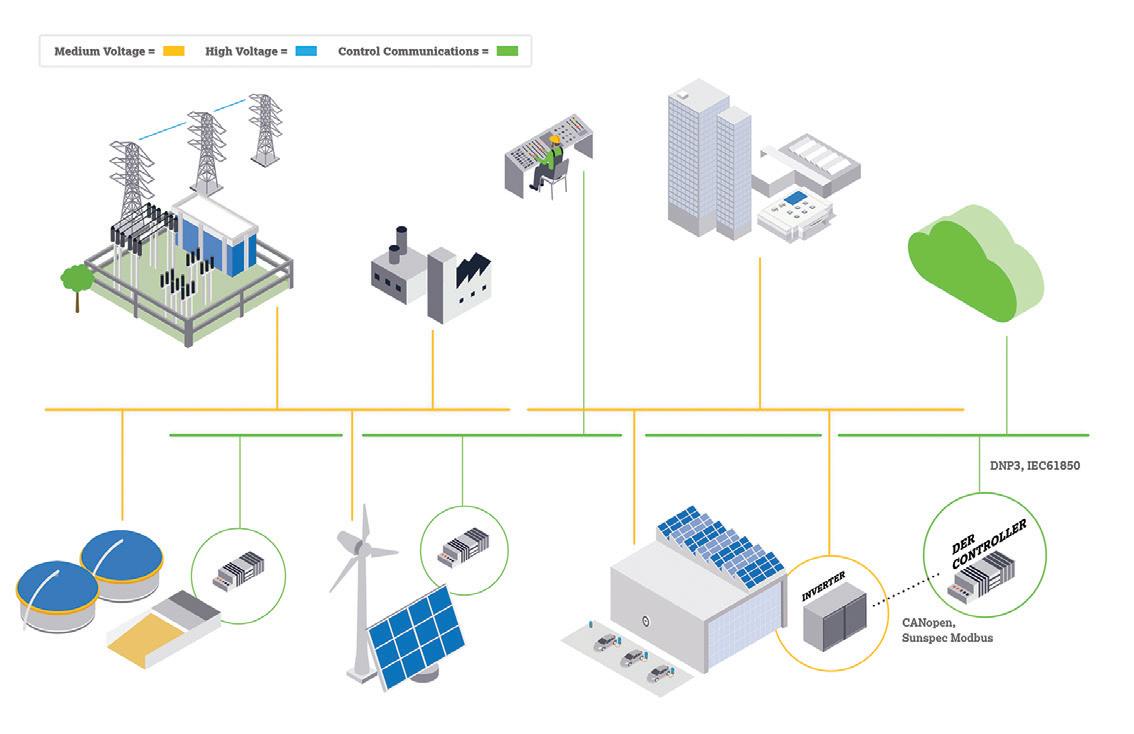

Exhibit space for PACK EXPO International 2024 is selling fast! Connect with 45,000 industry professionals from 40+ vertical markets looking for your solutions to get ahead of trends, move projects forward and solve their industry challenges.

of attendees attend the show to develop relationships with new suppliers like you!* of attendees are likely to make a purchase within 3-6 months of the close of the show* 88% 61%

*NOTE: Numbers based on PACK EXPO International 2022 Attendee Survey

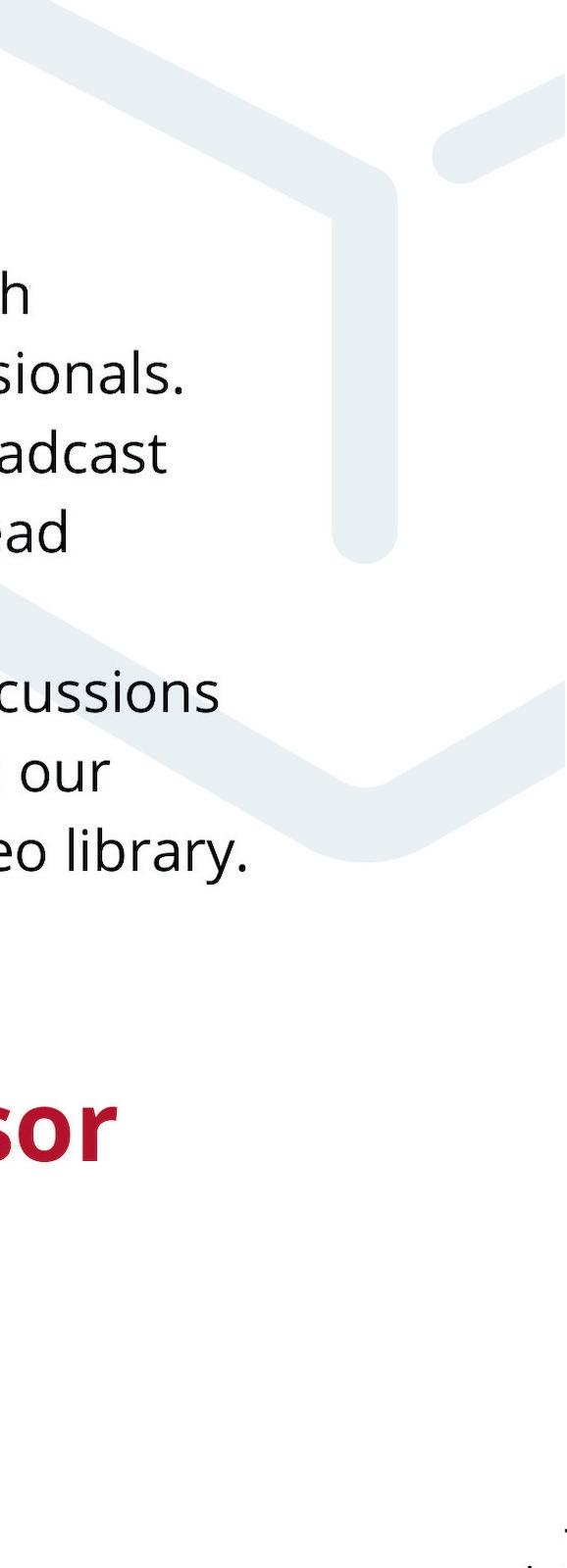

From data management strategies to the rise of artificial intelligence, packaging and processing executives are targeting a digital future for their industry.

By Casey Flanagan, Digital Editor, PMMI Media GroupIf you are looking for a snapshot of current attitudes and priorities in packaging and processing, look no further than the 2024 Top to Top Summit.

In March, executives from across packaging and processing sectors, including end-users and OEMs across several industries, gathered to focus on the key themes affecting packaging and processing.

The subsequent report, PMMI Business Intelligence’s “2024 Transforming Packaging and Processing Operations,” details their responses to shine a light on the industry’s biggest trends, from data and analytics best practices to experiments with artificial intelligence (AI).

Data and analytics can be the key to major improvements in packaging and processing operations, but as industry executives at the Summit indicated, there are several routes to consider in managing this data.

Data management methods can range from manual entry into spreadsheets uploaded to the cloud to advanced analytics. Companies often manage on-site data using their warehouse management systems (WMS), enterprise resource planning (ERP), and material requirements planning (MRP) systems.

External data storage and analytics solutions cited by executive participants included SAP, Siemens, MVI, PowerBI, Microsoft SharePoint, MasterControl, DataBricks, and SolidWorks.

External maintenance and support are often used to ensure that data is stored and managed properly, and not all businesses had a single data management approach, with one end-user saying data is “separately managed for each division.”

“They still need to understand how to apply [AI] and ensure security of information.”

The use of the cloud for data management varies, but as one end user put it, companies are “moving into the cloud.”

About half of respondents use a combination of cloud services and on-site data storage. More than a third say they store data entirely in the cloud, and just under one-fifth keep all their data on-site.

Many of those saying they use a combination of on-site and cloudbased data storage are migrating to cloud-based systems. In some cases, this is because data is being consolidated, integrated,

and managed more effectively to leverage its value using analytics.

The cloud is also often used for data storage as an additional backup for disaster recovery. However, the importance of security was raised. One respondent said their company is “following the strictest safety process and legal rules,” and another noted there are “checks and balances before [data] goes into the cloud.”

One representative among the 20% of companies that keeps their data on-site explained, “we own the entire technology stack, hardware, software, and everything in between. We store our data in multiple physical locations and we air-gap our backups regularly.”

Cloud storage and easy accessibility of company data can bring major benefits, but some executives at the Summit were wary about its potential risk to security.

Data governance and security challenges emphasize the need for robust strategies to manage and protect collected and stored in data lakes. This includes concerns about interoperability and sharing data across different platforms and stakeholders.

One panelist at the Summit pointed to the importance of storing data in the cloud so it can be shared across organizations.

“The more data you have, the more value you’ll create at the data lake. The more people who have access to the data, the more that value can actually be realized,” the panelist said.

However, concerns over data security and confidentiality can prevent data from being shared and fully leveraged. These are often most acute within IT teams in factories and can lead to tension between IT and OT teams.

It was suggested at the Summit that action is needed to bring together IT and OT leaders and involve IT specialists more in discussions about data analytics.

AI advancements are a seemingly inescapable trend in modern culture, and as executives at the Summit indicated, it isn’t going away anytime soon in packaging and processing. There’s one question on the mind for many in the industry though – how to use it?

Summit participants indicated that most AI projects are still in their infancy, often in the research and planning stages.

Asked about whether they were using or looking to use AI within their operations, most respondents said yes. Projects range from initial research to adoption of various AI systems across several different departments.

More than a third of respondents are not currently using AI, with many planning to do so in the future of keen to learn more about it. However, others remain skeptical. One respondent said they are “currently drafting a corporate policy governing the use of AI for work and/or on work computers.”

Another participant explained

they “still need to understand how to apply [AI] and ensure security of information.”

In many cases, AI is not used in manufacturing operations, but is employed by other departments for tasks such as customer service and support, marketing, sales for business intelligence, and in HR to write job descriptions. Many of those using AI are utilizing it in production demand, planning and forecasting, and some respondents are employing it in data processing and analysis.

When AI is being used on the factory floor, it can include automation of repetitive tasks, machine vision and quality control, predictive maintenance, remote services and monitoring, and inventory management.

“We are actively using AI as a co-pilot to positions involving repetitive and in-depth data processing and analysis,” one respondent said.

Packaging and processing professionals are finding myriad applications for AI, and as respondents indicated, the success tends

to snowball. As AI projects have proven successful, some companies have started plans to expand its use beyond initial applications.

“We are leveraging AI and data analytics for vibration analysis today,” one respondent explained. “We will be leveraging AI to help our Reliability Engineering team move towards prescriptive maintenance in the future.”

One respondent already using machine vision AI added, “We are working with different solution providers to be able to implement this type of tool to optimize the supply chain and address energy efficiency issues. However, we are at a very experimental level.”

When asked about potential future uses of AI technology, responses at the Top to Top session included:

• Process optimization

• Reducing time to resolution and/or development

• Predictive maintenance

• Flow management and simulation/virtual twin manufacturing environments

• Machine vision inspection and quality control

• Modeling line performance and control strategies

• Production planning and forecasting

• Optimizing production equipment performance

• Operational improvements

• Logistics optimization

• Remote service

Whether through proper data management or experimental AI applications, the insights gathered from the 2024 Top to Top Summit underscore the pivotal role of digital tools in packaging and processing. ■

L.C. Bird High School’s RoboHawks robotics team leveraged industry sponsorships from BluePrint Automation and PMMI to compete globally.

By Casey Flanagan, Digital Editor, PMMI Media GroupThe L.C. Bird High School RoboHawks are gearing up for the challenge of a lifetime at the FIRST Robotics Championship, thanks in part to support from BluePrint Automation (BPA), PMMI, and the PMMI U Skills Fund.

The Virginia-based robotics team paved its path to the upcoming “Worlds” Championship in Houston, Texas, with an impressive performance in the Chesapeake District Championship, where it secured third place.

“The excitement is real,” says Katy Clarke, RoboHawks faculty sponsor and teacher at L.C. Bird, as the students prepare for their trip to the April 17-20 competition.

“Our robot hit challenges it has never hit before; we were down in 22nd place at one point, and it got very dicey,” Clarke recalls from the District Championship. “It was definitely a tale of perseverance.”

The RoboHawks’ journey to Worlds was made possible by a collaborative sponsorship between BluePrint Automation (BPA) and PMMI.

Just before the District Championship, three RoboHawks team members presented their robot design and the challenge ahead to BPA executives. At the end of the presentation, BPA offered $12,500 to help the team on its trip to Worlds. PMMI matched that donation through the PMMI U Skills Fund for a total of $25,000 to assist the RoboHawks.

“Without that [financial support], I genuinely can tell you we would not have the number of students going that we have,” Clarke says. We have 24 students going to Houston, and many of them are flying for the first time, so we’re very excited and grateful for it.”

BPA is continuing to back the team in the long term by offering its manufacturing capabilities for next year’s competition. As the team designs its robot for

next year, it can send CAD drawings to BPA, and the company will manufacture the parts at no cost.

The partnership between the RoboHawks and their industry sponsors is a prime example of how external support can propel educational programs to new heights and inspire the next generation of engineers.

“PMMI has a very strong ownership in developing the future workforce through the PMMI U Skills Fund,” explains Dana Greenly, director of member outreach at PMMI. “The goal is to equate what Katy’s team is doing to robotics and packaging and to make sure that we have a talent pool that is available to our member companies. We hope that through this, [students] will remember PMMI and the companies that are sponsoring their team as they go out and look for employment.”

With backing from BPA and PMMI, the RoboHawks are poised for success at the FIRST Robotics Championship, showcasing the tangible impact of industry support on educational initiatives and student inspiration. ■

uMANUFACTURING—which includes packaging and processing OEMs—is on the precipice of a large percentage of skilled jobs remaining unfilled, beyond even the dire circumstances the industry has faced since 2017.

At the current pace and without significant changes to address workforce challenges, half of the 3.8 million jobs expected between 2024 and 2033 will remain vacant, according to Deloitte and The Manufacturing Institute’s new report, “Taking charge: Manufacturers support growth with active workforce strategies.” The report is based on an online survey of more than 200 U.S. manufacturers, interviews with senior executives from manufacturing organizations of all sizes and across all sectors, extensive analysis of secondary data on labor supply and demand, and analysis from Deloitte’s economic team.

This isn’t a new revelation by any means, but with the U.S. manufacturing industry emerging from the pandemic on a strong growth trajectory, continued growth is expected over the next 10 years as companies meet evolving customer demands, de-risk their supply chains, and leverage government incentives and policies, unfulfilled positions could reach a breaking point.

Manufacturing is aware of the crisis, as 65% of respondents in the National Association of Manufacturers’ 2024 Q1 outlook pointed to attracting and retaining talent as their primary business challenge.

The demand for digital skills is accelerating as operations and products become more complex and information from smart connected devices and systems needs to be integrated and analyzed.

“Manufacturers recognize that the workforce is evolving,” says — Carolyn Lee, president and executive director, The Manufacturing Institute. “Pandemic-driven shifts have already created hundreds of thousands of new jobs, and now we are seeing increased demand for digital skills that need to be met or risk further widening of the talent gap.”

“Companies must prioritize technology, training and talent development, and the investments that are

PMMI has joined Ameripen as an Associate Member, strengthening the relationship between the two organizations. The announcement was made in April at PMMI’s Executive Leadership Conference and Ameripen’s Annual Summit. This will translate into more coordinated work on legislation and other initiatives related to Extended Producer Responsibility. This will also strengthen PMMI’s existing work with Ameripen and the value the relationship brings to PMMI Members, for example:

• Ameripen is a valued presenter at several PMMI events

• Dan Felton, Executive Director, brings his expertise to the advisory committee for PMMI Media Group’s Packaging Recycling Summit (Sept. 16-18; Anaheim, California)

• PMMI and Ameripen collaborated on the Packaging Compass project, released in early 2023 and is set to be updated this year

• Ameripen will participate in the Sustainability Central Stage at PACK EXPO International 2024. ■

driving growth will also require the industry to build out a talent ecosystem,” says Lee. “With investments in partnerships, apprenticeships, and education, and prioritizing a more diverse and inclusive workforce, a whole host of new talent will be on the factory floor and driving the next wave of growth.”

More than 9 in 10 surveyed manufacturers said they are forming at least one partnership to improve job attraction and retention, and on average, they are partnering with four or more. The top five partnership types among respondents are with technical colleges (73%), industry associations (58%), universities (48%), state and regional economic development agencies (47%), and K-12 schools (44%).

Many partnerships are geared towards building, leveraging, and supporting training programs — helping address the need to develop new talent. Nearly half (47%) of those surveyed in research by Deloitte and the MI indicated that apprenticeships, work studies, or internships at manufacturing companies would be the most effective way to increase interest in manufacturing as a career choice. ■

Most packaging and processing marketing teams are minimally sta ed; discover three e ective strategies to help succeed and reduce stress.

Sharon Taylor, Principal Marketing Strategist, PMMI Media Group

Are you a part of a small marketing team? You’re not alone! According to a recent survey of PMMI members, the average size of marketing departments at companies up to $50 million is just 1.5 marketers. But don’t let your limited resources hold you back. Discover three effective strategies to help you achieve success and reduce stress in your role. Keep reading to learn more.

In a fast-paced work environment, it’s all too common to find yourself juggling multiple responsibilities without making significant progress on any single task. This scattered approach can lead to inefficiency and increased stress. To address this challenge, it’s essential to establish a more organized and systematic approach to your workload.

Start by creating a comprehensive list of all your tasks and responsibilities. While handwritten lists can be effective, using online project management tools such as Asana, Monday.com, or Notion can provide enhanced organization and collaboration capabilities, especially as your team grows. These tools offer a range of features to help you track tasks, allocate resources, and prioritize assignments effectively.

Once you have your tasks outlined, prioritization is key. Apply the principles of the Eisenhower Matrix to categorize your tasks based on their urgency and importance. This method allows you to identify which tasks require immediate attention, which can be scheduled for later, what can be delegated to others, and what can be eliminated from your workload.

To ensure that you have dedicated time to complete your tasks, consider implementing time-block scheduling. By setting aside specific time slots for focused work, you can guard against distractions and

interruptions, ultimately improving your productivity. Additionally, this method provides valuable insights into how long different tasks take to complete, helping you better manage your time in the future.

In addition to these organizational strategies, consider leveraging AI-powered note-taking tools, which are increasingly integrated into many video conferencing platforms. These tools can be valuable for summarizing meetings and capturing key action items, saving you time and providing clarity on your tasks.

QUICK TIP: Try recording a meeting with just yourself and use the AI notetaking feature to create a summary of your thoughts and ideas. This hack can help bring clarity to planning projects or drafting content.

Managing digital clutter is another essential aspect of improving efficiency. Consider using a dedicated notetaking app to save inspiring articles, creative examples, and marketing resources, allowing you to review them at a later, scheduled time. Similarly, create email folders and rules to automatically categorize incoming messages, making managing and prioritizing your communications easier.

Implementing these strategies can create a more streamlined and efficient workflow.

Outsourcing can give your marketing team additional skills, perspective, and manpower. However, choosing what to outsource and who to hire can be challenging.

Agencies offer value for expertise that you may not have internally. Smaller companies should note that agencies have minimum spending requirements. However, if you have the budget, agencies can be valuable partners worth investing in. They have solid project management processes that keep you and your team on track.

Hiring an independent consultant who functions as their own agency is a lower-cost option for companies on a budget. However, independent contractors may take longer to complete your project and require more participation.

Freelance or contract support can also help meet a specific ongoing need, such as copywriting or design. It may also serve as a way to test whether a full-time employee role is needed. Leverage your network or use resources such as Fiverr, UpWork, or 99Designs.

Regardless of your chosen outsourcing option, it will require planning and ongoing support. If you have the need and budget, outsourcing can free up your time, provide a better output, and be a valuable investment.

Networking is not just for job seekers or those with extra time on their hands. It offers numerous benefits for small marketing teams. Building a strong network provides access to advisors and mentors who can offer valuable insights and solutions.

Mentorship can be formal or informal, and it’s not as daunting as it may seem. You can find mentors within your organization’s mentorship program, among former managers, colleagues, or connections in your network. Joining an official mentorship program is another option, as these programs often pair you with a suitable mentor.

Associations, such as PMMI, are valuable networking, mentorship, and professional development resources. PMMI hosts events like the upcoming PMMI Roadshow and offers networking groups like the MaX Marketing Share Group.

Beyond PMMI, look to industry associations, local communities, and marketing-specific organizations like the American Marketing Association for networking opportunities. Additionally, consider joining user groups for the technologies your team uses, such as Adobe or Salesforce.

Finally, always connect with individuals on LinkedIn to centralize your network and easily communicate with them. Building and nurturing your network can lead to valuable insights and recommendations when needed. ■

The art of understanding customer needs beyond the traditional product-focused sales pitch.

Matthew Neuberger, President, Neuberger & Company, Inc.

In the competitive landscape of the packaging industry, sales professionals are constantly seeking innovative strategies to enhance their effectiveness and drive more sales. One emerging transformative approach involves a deep understanding of customer needs beyond the traditional product-focused sales pitch. This article draws inspiration from rethinking what the term value proposition means.

Traditionally, sales efforts in the packaging industry have been heavily centered around the specifications of the products - their “speeds and feeds.” This approach, however, often falls short of addressing the deeper needs of customers, particularly those in companies dealing with consumer packaged goods (CPGs) and similar sectors. A pivotal realization came from a story about a paint manufacturer that understood its products’ actual value lay not just in the quality of the paint, but in the labor hours, it saved companies. This insight shifted their sales narrative from merely highlighting product features to demonstrating how their paint could alleviate the frustration of labor management and costs. The less they talked to their customers about paint and the more they spoke of labor management, the more they sold.

At the heart of this customer-centric approach is understanding the “job to be done” - a principle emphasizing the importance of grasping what the customer is ultimately trying to achieve and the obstacles they face.

This method requires a departure from the conventional sales script focused on product capabilities, urging sales teams to engage in more meaningful conversations with their clients. Your PowerPoint presentations will get you in the door. However, they will not sell your equipment. In fact, they will make you look more like your competitor – yes, YOU could be inserting competition, indecision, and pricing pressure simply by sharing your information without the correct value proposition attached. How would you know? Look at what’s stuck in your pipeline.

Evaluate the dollar value of annual discounts and concessions provided.

When sales professionals master the art of understanding and articulating the customer’s job to be done, they transcend the role of mere vendors to become trusted advisors. This transition is crucial in a market where purchasers increasingly ask for engineers instead of salespeople. They perceive engineers as problem-solvers who grasp their challenges’ technical and operational nuances, unlike traditional sales representatives whose pitches might seem superficial.

A standard indicator that a sales approach is misaligned with customer needs is when discussions quickly pivot to price comparisons with competitors. This scenario often signifies that the sales message has failed to resonate deeper, leaving the customer to default to price as the primary decision criterion.

Conversely, price becomes a secondary consideration when a sales professional successfully communicates how their solutions can address the customer’s specific challenges and aspirations. The essence of this customer-centric sales philosophy is empathytaking the time to understand not only the technical specifications of the customer’s challenges but also how they affect them personally and professionally.

This approach offers a powerful paradigm shift for sales professionals in the packaging industry. By focusing on the customer’s broader objectives and becoming a source of valued advice and solutions, sales teams can build deeper relationships, differentiate themselves from competitors, and ultimately achieve tremendous success.

Sales professionals are responsible for bridging the gap between the customer’s challenges and how their products or services can make a meaningful difference. This elevates the sales conversation and positions sales professionals as indispensable partners in their customers’ success. ■

Learn more about PMMI’s Certified Technical Sales Professional Program here: oemgo.to/ctsp2023

A candid discussion on the impact of elections, inflation, and uncertainties with the global economy on packaging and processing.By Sean Riley, Editor-In-Chief

This Spring, PMMI held its Executive Leadership Conference (ELC). One of the highlights of the conference is the ITR Economic Outlook, which provides a roadmap for 2024 and beyond, both in packaging and processing and around the globe. After the ELC, OEM Magazine Editor-in-Chief Sean Riley sat down with Brian Beaulieu, CEO and Chief Economist of the Institute for Trend Research (ITR) Economics, for an unPACKed with PMMI podcast. The following is a portion of their discussion edited for space and clarity. The entire podcast is available at pmmi.org/ podcasts.

Sean Riley: You spoke at the Executive Leadership Conference, and right up front, you said that the economy is going to skate by in ‘24, but then you have 25 through 28 as good years that are looking up. What exactly is going to happen there?

Brian Beaulieu: It’s tough to talk about what exactly will happen there, but the general trend is that the economy will improve in ‘25, ‘26, ‘27, ‘28 because we don’t see any major stumbling blocks. In my world, we look for economic imbalances and don’t see any imbalances.

We see consumer incomes continuing to go up. The trouble spots, like deficit spending, are future problems. They’re not likely to impact us in that short period. The Fed looks like they’re done with quantitative tightening. I’m not sure they’re going to go into quantitative easing, but the tightening portion is behind, which is how we’re reading the trends.

projecting to be a massive downtick once we hit the 2030s.

Brian Beaulieu: One of the things that everybody needs to do is figure out how they can obviate labor in economic speak, which is how we can employ technology, not only on the processing floor or distribution floor but in information systems and information flows in the office. AI is just a small part of it. It’s not just AI, but the more I can get automation to replace people, the stronger I am going to be going forward because people are going to be the single most expensive and limited in supply element to what we do.

Sean Riley: You noted an interesting trend: as you said, manufacturing is paying almost too high or very high wages. On the other hand, manufacturing is having a very hard time getting labor. How do you balance those two elements where they need to pay these higher wages to retain labor, but they can’t find any labor to begin with?

Brian Beaulieu: A lot of it can be circumvented by having some sort of career path available to people, even on the manufacturing floor. If you can show them, they’ll learn these skills, which will get them into the higher wages. Then, at least, you’re matching what they can do with the higher wages instead of just throwing money at a very serious problem. Culture has a lot to do with retaining people, and the geographic market you’re talking about also does. So there’s no one fix, but culture is extremely important.

Sean Riley: I was thinking about how packaging and processing can prepare for that or make the most of that little uptick before what ITR is

I believe affordable housing in the area where you’re manufacturing is absolutely important. And there are some political things you can do there. Some

“. . . people are going to be the single most expensive and limited in supply element to what we do.”

of the folks I know are even investing in that. They are investing in housing infrastructure along with the cities or the towns to make some things happen in that regard.

Those aren’t things that we used to have to contend with in the 1970s, 1980s, and 1990s. This is just a whole new paradigm.

Sean Riley: That’s very interesting. I hadn’t thought of housing and things like that as part of the whole package.

Brian Beaulieu: I tell you what some other successful companies are doing as a best practice: they’re subsidizing childcare right near their facilities. Moms and dads can bring their kids, work their shift and then pick up the kids and go home. They’re also subsidizing healthcare facilities with physician assistants (PA) and nursing assistants near the facility just to make it a lot easier to come to work for me as opposed to this other person.

Sean Riley: We have an election coming up. How will the results impact the economy?

Brian Beaulieu: It’s a very interesting question, to be sure. Let me step back and tell you we’re numbersbased. The numbers are the numbers. When I look back, we look back at Republicans versus Democrats over the years in post-World War II history, who was in the Oval Office.

You couldn’t say under blue or under red that you will have slower or faster growth. Let’s fast-forward to after Bill Clinton, when George W. Bush was in office. The average GDP growth parameter was 1.9%. You go to President Obama, and it was 2.0%, and you go to Donald Trump, and it was 1.8%.

These are very different administrations, different focuses, and different social ideas. Yet the rate of growth in the economy was very stable. And that’s the point. These politicians will change where we spend money. They will change who is going to be the beneficiary of the money. So it’s really how much deficit spending they are willing to engage in that moves the needle in terms of economic growth.

However, understand that moving that needle in the short term gets you reelected, but it harms the economy in the long term. They can change their policies, but those are social policies that don’t change the economic outcome at the end of the day.

Sean Riley: You said when speaking at the ELC that China is going to be a problem in the near future. Why, and what is the problem going to be there?

Brian Beaulieu: The problem is really twofold. First, their demographics are in a negative trend. Their population is getting smaller, and that is an exceedingly difficult situation for an economy to find itself in. It makes growth very difficult.

The second issue is that their whole economy has been propped up based on leverage since about 2012. And that’s not a stable platform—it’s a house of cards. And you’re seeing that leverage just collapsing. When you look at the housing market and another big developer has gone under, you look at how much money state-owned enterprises owe that will never get paid back.

It’s just a treadmill that is totally unsustainable. When you have fewer and fewer consumers in your economy, that leverage only becomes more and more burdensome, which is why their government has to become more dictatorial. I know that’s a politically sensitive term, but they’re pulling back in finding ways to become capitalists in their economy. It’s becoming increasingly state-run and state-determined because the government needs to exert more command and control, and the economy is fraying rapidly around the edges.

Sean Riley: We hear all the time, and I don’t know if it’s a media thing, but we hear all the time that the U.S. Economy is struggling. But you seem to say, and you’ve stuck to this, that it’s going to remain the dominant, largest economy in the world for the next 50 to 100 years. Why is it always perceived as negative?

Brian Beaulieu: It is a political exercise. I’m not a politician, but I’ve studied politics and reassociation with economics, among other things. And if the

here in the United States. Our geography is amazing. Third, we still have the rule of law. The simplest way to express that is that we have intellectual property rights, private property rights, and bankruptcy laws that allow us to fail, get back on our feet and try again. There’s no place on this planet outside of the United States where you’re going to find all three of those factors in existence at the same time in the same geography. This is a unique American experience.

Sean Riley: I know this is the elephant in the room we’ve been discussing for a little while, as you’ve given presentations at various PMMI events. ITR has highlighted a depression that’s coming in the 2030s. It’s not going to be pretty. So, is there anything that we can do to avoid it? I think I know the answer to that. And what can companies do to prepare for it?

Brian Beaulieu: You can always do something if we mean the government, but they’re not going to because that would not get them reelected. That’s not going to happen. I think we can safely rule that one out.

So, I’m going to focus more on businesses and individuals. Businesses need to start figuring out, and we help them with this, what markets will be relatively safe during the 2030s and what markets will be absolutely clobbered. It doesn’t matter if I’m not currently involved with the relatively safe ones; I have five or six years to get something going and start gaining market share in those relatively safe areas. And really downplay the areas that we think are going to get hurt and hurt. You can rebalance your company. You still have time to do that.

“ The whole reason we do this is not to scare people but to forewarn them.”

politicians can create pain in your mind, then they can position themselves as the solution to that pain or that problem. And that’s why you’re going to vote for them. Americans vote for people who say, I can fix this problem for you. Not, let’s work together because we’re the best there is.

Sean Riley: With that in mind from a positive standpoint then, you’re stating that the economy is going to remain the largest in the world going forward, correct?

Brian Beaulieu: Correct. For three very good reasons. One, our demographic trend is positive—it could be even better, obviously—but it is positive. Second, we have been mightily blessed with natural resources

The larger the company, the more difficult that is. Although I guess if you get really large, you can always make an acquisition into a safer space. We described it at the [ELC] as a financial bunker program. Get these things about your life in order before we hit the 2030s. And my goodness, talk to your kids about what they’re studying and what career paths they should be thinking about if they’re graduating anytime near the 30s or in the 2030s. Because that’s critically important to their long-term well-being.

The whole reason we do this is not to scare people but to forewarn them. If you’re forewarned, you’re forearmed. More people become millionaires during bad times than during good times. And those who become millionaires are the ones who can see what’s happening, change their course, and use the trends to their advantage. ■

MARCH 10–12, 2025 / ATLANTA, GA

GEORGIA WORLD CONGRESS CENTER

Place your company at the core of the Southeast’s dynamic manufacturing hub by participating in PACK EXPO Southeast. Distinguish yourself among 400 innovative exhibitors and interact with 6,000 high-quality buyers eager to discover your cutting-edge materials and see your machinery in action.

Reserve your booth today!

Michelle Bryson, Global Sustainable Packaging Leader for BW Packaging, discusses her role and her company’s drive to sustainability.

Sean Riley, Editor-in-ChiefWith the exception of perhaps the workforce, no current topic dominates packaging and processing operations to the extent of sustainability. After years of materials dominating the conversation, OEMs like BW Packaging began recognizing the importance of a dedicated sustainability strategy for machinery builders. Enter Michelle Bryson, Global Sustainable Packaging Leader for BW Packaging, who was kind enough to sit down with OEM Magazine to discuss her position and a little about BW Packaging’s sustainability initiative.

OEM: How does a packaging engineer for high-level CPGs become the Global Sustainable Packaging Leader for an OEM?

“ I use my position as a platform to convey the often-overlooked importance of machinery in sustainable packaging.”

Michelle Bryson: My career journey has been driven by my desire to fully immerse myself in sustainability. After 31 years in the brand owner space at companies like PepsiCo and Wells Enterprises, I realized that I wanted to control my own destiny and focus full-time on sustainability. I didn’t feel I was able to focus on sustainability like I wanted to [when I was] working as a Packaging Leader in the CPG space; for one company, that space was crowded; for another, it was deprioritized. BW Packaging’s Global Sustainable Packaging Leader role represents a perfect intersection of my career goals and the company’s commitment to a dedicated focus on sustainability.

OEM: Machinery is usually the last thing people think of when the issue of sustainability in packaging comes up. What was BW trying to accomplish by establishing your position, and how do you think your unique background helps in your role?

Bryson: Carol O’Neill, BW Packaging’s President, recognized the need for a dedicated focus

on sustainability. She understood that while BW Packaging had experts designing equipment, there was a gap in addressing the sustainable material solutions customers were increasingly demanding and needed dedicated focus to customer requests for reporting. The establishment of my position was aimed at providing focused support to align with and advance our customers’ sustainability goals. Carol and the other Packaging leaders saw the importance of having someone dedicated to thinking about materials, understanding customer needs from a sustainability perspective, and supporting those goals fulltime.

Today, I lean on my experiences as a packaging engineer for CPGs and use my position as a platform to convey the often-overlooked importance of machinery in sustainable packaging. Having been in the shoes of many of our customers, I appreciate the need to de-risk and thoroughly test sustainable materials during the packaging development process with as much leeway as possible. Once the product, package, and equipment come together for that critical start-up for sales, that is often too late. I actively engage in conversations with material suppliers and product line leaders to ensure that our machinery complements these new materials effectively.

I believe that by encouraging our customers to involve their OEMs early in the development process, we can establish a more productive, collaborative approach. This synergy is vital. The success of sustainable packaging relies on the harmonious integration of product, material, and equipment. My goal is to help our customers see this interconnection and navigate it with our support, ensuring that the machinery does not become a limiting factor in their sustainable packaging journey. Our applications engineers understand how to make adjust-

ments to the machines and know when change parts may be needed; we are collaborating with material suppliers that may offer insights into what they’ve seen, what customers are seeing, and suggestions they are considering. I can’t stress enough that the collaboration will bring great insights.

OEM: What have BW and you accomplished in the sustainability space under your stewardship so far?

Bryson: Since our journey together began in late 2021, my BW Packaging team members and I have made significant strides in sustainability. We conducted a thorough internal and external stakeholder analysis, focusing our efforts on customer sustainability goals and reporting through frameworks like CDP and EcoVadis. We’ve initiated extensive training for our team members to infuse sustainability throughout our operations, from innovation to sales.

greenhouse gas reduction goals, which are crucial for both our customers and the planet. We now have alignment to these goals within the packaging platform per our commitment to the CDP. I see my role as an opportunity to make a significant impact on sustainability, far beyond what I could have achieved in my previous positions.

I also take enjoyment from the opportunity to collaborate with the diverse team at BW Packaging to develop a comprehensive sustainability strategy that invites everyone to get involved. The collaboration and buy-in I’ve had from our team is what enables us to ensure our equipment can reliably run sustainable materials. It requires a deep understanding of these materials and the willingness of our team members to take an active role in validating those materials through rigorous testing on our machines.

“ . . . by encouraging our customers to involve their OEMs early in the development process, we can establish a more productive, collaborative approach.”

Our efforts have also been acknowledged industry-wide, highlighted by our Synerlink team’s nomination for the Packaging Europe Sustainability Awards in 2022 for their SnapCut PET cutting technology and Synerlink’s subsequent victory in the Pre-Commercialize Recyclable Packaging category in 2023 for their contributions to a collaboration focusing on sustainable materials for dairy cups. Of course, our pursuit of sustainability is not driven by a desire for awards and recognition, but these accolades reflect our team’s hard work and dedication to advancing sustainable manufacturing and offering more responsible solutions to our customers.

OEM: What do you personally want to accomplish as Global Sustainable Packaging Leader?

Bryson: Personally, I have found the process of developing BW Packaging’s sustainability strategy from the ground up to be very fulfilling. A key focus for me has been establishing and achieving

OEM: What are some of the biggest challenges you have faced, making sustainability front of mind at a machinery builder?

Bryson: One of the main challenges has been helping various departments understand the connection between their work and sustainability, especially how climate change impacts us. To overcome this, I’ve focused on helping various departments, like sales and operations, understand and personally connect with sustainability. It’s about making sustainability relatable and engaging for them. The key is to bridge the gap between the world of sustainability, our customers’ goals, and our daily operations. It’s crucial to demonstrate that what matters to our customers also matters deeply to us at BW Packaging. I’m proud to say that we truly are living the words that we’ve included in BW Packaging’s sustainability commitment.

OEM: What are some of the low-hanging fruit other OEMs can check off the list in the drive towards becoming more sustainable?

“. . . the U.S. is not as quick as in Europe, but the trend is definitely moving towards more stringent sustainability legislation.”

Bryson: The idea of ‘lowhanging fruit’ in sustainability might be misleading as it suggests easy wins without a fundamental shift in approach. Sustainable practices require both top-down leadership and bottom-up engagement. For immediate action, OEMs can focus on testing sustainable materials, but in the long term, a comprehensive organizational commitment to sustainability, encompassing leadership, innovation, and compliance with legislation, is essential. Everyone can be a sustainability leader in their own sphere of influence. I’m very passionate about this! I encourage anyone struggling with the mindset shift that’s required to read my post about sustainable packaging and OEM engagement.

OEM: Finally, on a larger scale, when do you think the U.S. will catch up with Europe regarding EPR or taxes on carbon footprint? Is that something you see

happening in the near future? Why or why not?

The U.S. is gradually moving towards European standards in sustainability, especially in Extended Producer Responsibility (EPR) and carbon footprint taxes. This shift is evidenced by the increasing number of states introducing EPR legislation. While it can be challenging due to varying state laws, seeing a broader acceptance of the responsibility brands must take for their materials is encouraging. The pace of change in the U.S. is not as quick as in Europe, but the trend is definitely moving towards more stringent sustainability legislation. To keep atop of that effort, look up the SPC (Sustainable Packaging Coalition) website page tracking EPR status in the US. For more information, visit Extended Producer Responsibility - SPC’s Guide at sustainablepackaging.org. ■

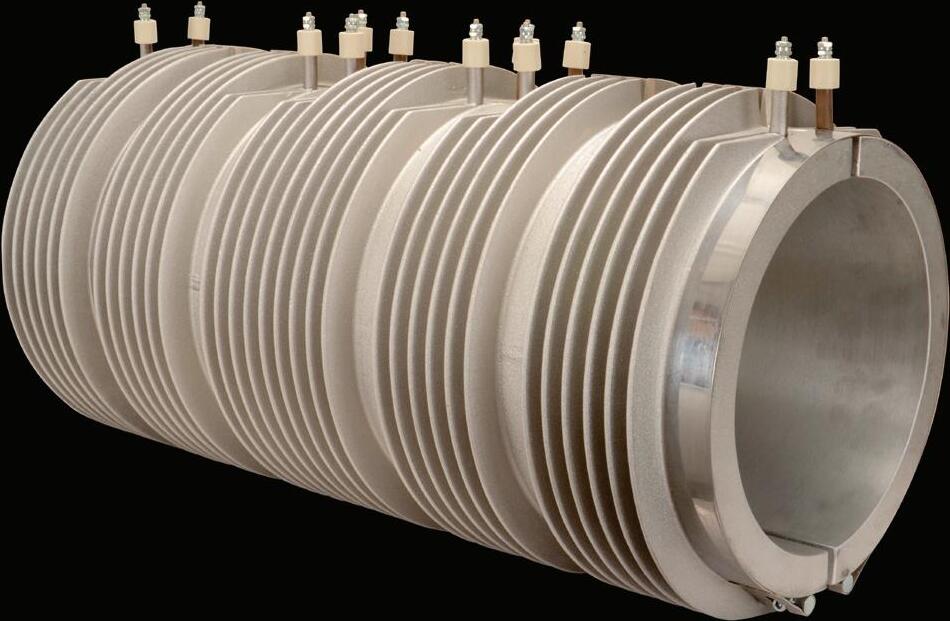

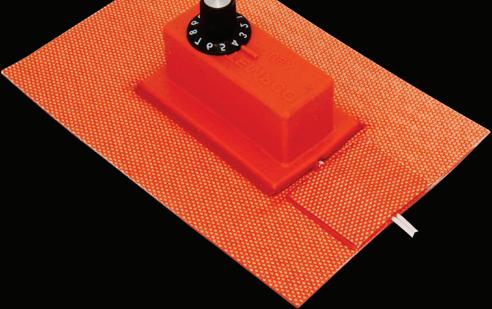

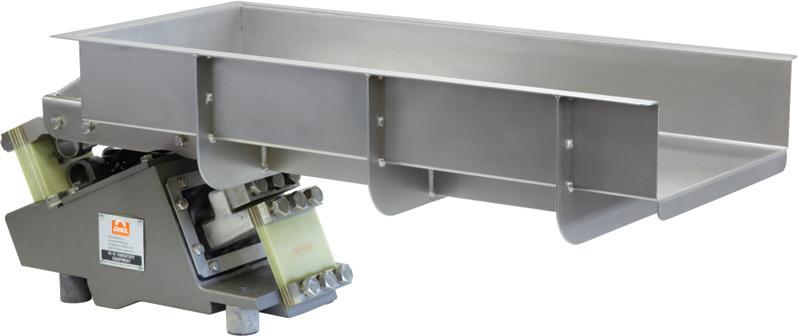

•Energy efficient electromagnetic drives

•High Speed models for rapid On/Off cycling

•High Deflection models for fine powders, leafy, and sticky products

Mechanical & Electromagnetic

•Low profile models

•Wide range of screener options

•Models for every application

Today’s CPG companies are eager to find solution providers who can advance their success in the circular supply chain. Connect with these decision-makers and other packaging recycling stakeholders at the Packaging Recycling Summit 2024.

Keynote Speaker | Jim Velky, Sr. Director of Sustainability The Coca-Cola Company

Speaking and promotional branding opportunities for suppliers

Schedule pre-qualified 1-on-1 meetings with attendees

Attendees will hear from household names like Danone, General Mills, WM and more

Multiple networking opportunities throughout all three days

When established: 1998

Range of products: Design, engineering, integration, automation, control and installation of Secondary Packaging systems and subsystems.

Executive team: Erv Fringer, President; Dan Breuker, Director of Engineering, Integration and Project Management, Brad Breuker, Sales Manager; Scott Ash, Director of Onsite Services

Headquarters / manufacturing location(s): Two facilities in Rockford, Michigan

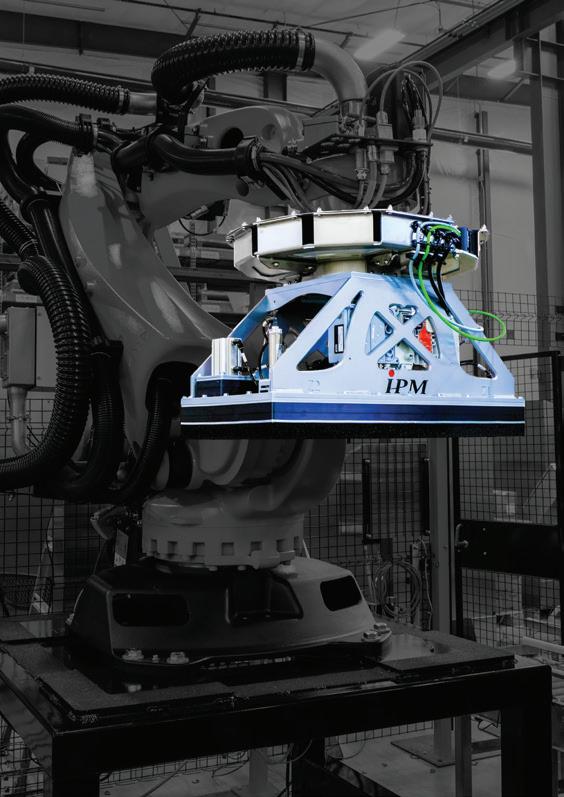

Number of employees: 141

Number of field service personnel: 36

Facility square footage: Two facilities totaling 178,000 SF

Geographic sales and support areas: North America

Company website: www.callipm.com

Annual revenues: over 50 million

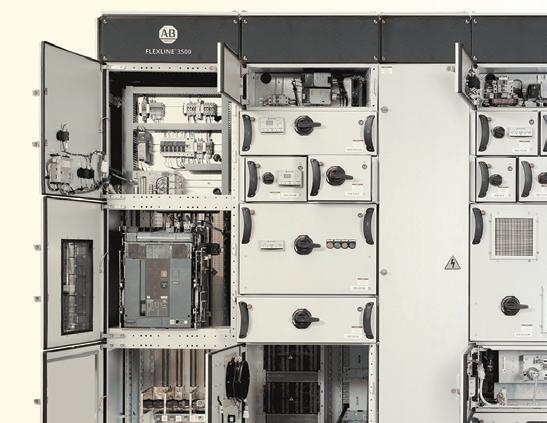

IPM’s emphasis on machine runnability and continued service is driven by its positioning statement that “uptime is the only time that matters.”

By Casey Flanagan, Digital Editor, PMMI Media GroupIf one word could describe the team at Integrated Packaging Machinery (IPM), it would be “dedicated.”

The Michigan-based dairy, food, and beverage packaging systems integrator tackles every project with a specialized and customerfocused approach, where uptime is king, and every decision is made with practical runnability in mind.

This holistic approach to meeting its customers’ targets “may seem far too aspirational,” explains Tom Wiersma, business development manager at IPM. “But the truth is, there are ways to do what needs to be done.”

IPM’s dedication to its customers’ needs stems from its employees’ own dedication to the company. Running under an employee stock ownership plan (ESOP), every IPM employee is committed to the company’s success.

“The culture is such that nobody ever says anything along the lines of ‘that’s not my job,’” Wiersma says. “Our employees will find a way to get it done or find somebody who can get it done, because when the company succeeds, they succeed.”

The story of IPM begins in 1998, with two colleagues who worked together at a conveyor supplier— Brad Lamb, IPM’s president until his retirement two months ago, and Kendall Malstrom, who still works at

IPM as vice president.

The duo decided they could excel at designing packaging systems and started the company with that goal in mind. Without the means to build their own machines, they decided to work with those who could.

“That’s been the model ever since. We’ll buy the best solution from outside, and integrate it into a single packaging ecosystem,” says Wiersma.

Part of what makes IPM unique is its OEM-neutral approach to designing secondary packaging lines. When choosing machines for a project, it prioritizes optimal performance over any specific OEM product line.

When designing a highly customized line to fit both the dimensions and performance metrics required by its customers, “not every OEM can do it, and not everyone has a good price,” Wiersma explains. “We have to find the OEM that solves all the right problems, and no single company does that.”

The company instead approaches each project with a fresh perspective, informing its decisions with an “uptime audit” in the early planning stages. This includes an on-site meeting to gather all the available data about the customers’ current and desired production rates, packaging dimensions, and other

necessary information.

“If it’s an existing system they want to modernize, we’ll assess that system and its uptime capabilities, asking ‘what do we need to do to make this work better?’” explains Wiersma. “When it’s a new project, we’ll spend time with our customers to figure out what they need, what their aspirations are for this plant, and we’ll help them unearth all that.”

This assessment and subsequent project phases are guided by IPM’s SURE-thing approach (Specified for Uptime + Runnability Engineered).

In the eyes of IPM, uptime is an essential consideration for the success of its customers, and it must be strategically achieved rather than being left to happenstance.

While in operation, “it’s okay if a line slows down, but then it has to be designed to auto-accumulate cartons, and speed up again when the time comes,” says Wiersma. “Runnability is key, and that’s also an engineered solution.”

With these principles in mind, IPM completes its design phase with an evaluation of several options to reach scope freeze, or a solidification of the project’s requirements.

As the process continues, scope freeze may be malleable, “but the point of the first phases is to do all that we can to ensure that scope freeze doesn’t move,” Wiersma says.

Once IPM starts connecting machinery, it follows a rigorous factory acceptance test (FAT) protocol, closely adhering to PMMIsuggested standards, to ensure the various machinery operates as intended.

IPM can take two different routes for its FAT, depending on the project.

In more straightforward cases, the company can confidently go to an OEM site with the customer’s

machine requirements in mind, observe the machine in action, and give it the stamp of approval.

For more complex projects, though, like a recent case Wiersma cited where three robots would be working together, IPM may need to take matters into its own hands.

“There’s no way we could have done that at three different OEM locations, so we had to bring the robots into our own plant, set it up, and make sure it is programmed accurately and works as intended,” Wiersma says. “It’s expensive, so we don’t want to do it if we don’t have to, but sometimes you have to. Our customers know that, and it’s baked into the price.”

IPM then puts the whole system together at the customer’s plant and runs a demanding site acceptance test (SAT).

“We’ve installed and commissioned it, programmed it, automated it, but we don’t leave until it’s operating precisely as the customer wanted,” Wiersma says.

As a packaging systems integrator, IPM generally leaves the machine building to the OEMs. But with its “bias for over-delivering,” as Wiersma says, the company will design machine components when the situation necessitates.

One such example came with IPM’s development of its AccuTURRET end-of-arm-tool (EOAT) cable management system.

Customers had reported to IPM that the cables running into the EOAT were wearing down from repeated use, and eventually causing downtime.

IPM developed the cable management system to solve this problem, with an emphasis on difficult pallet building operations and space-limited applications. The system features 220° rotation to accelerate cycle functions, improve accuracy, and reduce stress on the energy, communications, and vacuum supply of the EOAT.

“Although we don’t manufacture machinery as a rule, if we can’t find it, we’ll find a way,” says Wiersma.

Also unique to IPM is its approach toward training; the company’s focus on the entire packaging line as a cohesive system extends into its training philosophy.

With anywhere between six to 10 different machine centers or functions on a given packaging line, it’s easy to develop gaps in expertise by studying each machine as an individual unit.

Instead of an OEM technician coming to train employees on individual machines, “we work very closely with those OEMs, take their information, and design a curriculum for the entire packaging line,” Wiersma says.

IPM trains its educators on-site at customer facilities.

The AccuTURRET system improves EOAT efficiency while protecting the machine’s wiring.

IPM’s staff includes four “adult educators” to gather this information and craft a comprehensive curriculum, says Wiersma. When the company installs a new line at a customer site, these educators will visit the plant and offer training across all shifts, sometimes staying for two days to cover all employees.

Further, the educators compile the information into an e-learning tool for future reference.

“After we leave, people need to be reminded or re-educated, or people leave and more come in. So, we convert that line curriculum into an e-learning tool that people can spend time on and learn from,” Wiersma says.

Looking forward, IPM is placing an emphasis on emerging digital technology in the name of continued customer support.

The company already employs 36 field technicians to install, optimize, and maintain the systems at its customers’ sites, but its development focus now includes technology to streamline and digitize maintenance.

Currently in development is digital twin capability, or a real-time, exact digital replica of a customer’s packaging line. Once operational, IPM will be able to troubleshoot issues for customers without requiring an on-site technician.

“We will be able to help customers via remote access, to troubleshoot issues or even augment our earlier training by having an instructor use that digital twin with new employees,” says Wiersma.

IPM is also in the process of implementing artificial intelligence (AI) for use in predictive maintenance.

“If we can predict some of those issues with AI, we can do predictive maintenance more intelligently, more timely, more relevant, and less expensively,” says Wiersma.

Additionally, IPM has already had some success in implementing AI for training.

“The cohort of five or six employees at a customer location will have their AI device on, and we can do training on-site, in the plants, using AI as a medium,” says Wiersma. ■

Are you looking to engage your customers with insight-driven strategies? Discover the power of actionable intelligence with PMMI’s member-exclusive resources.

Our Business Intelligence, Custom Research, Global Marketing, and specialized Workforce Development programs, including Packaging & Processing Selling in Today’s Market and Field Service Essentials, are designed to not only navigate industry challenges but also to uncover deep insights that empower you to guide your customers with confidence and precision and meet their evolving needs.

PMMI is your answer, connecting you to customers and providing the support and resources you need 365 days a year.

Learn more at pmmi.org/pmmi365

When established: 1993

Range of products: 35+

Executive team: David Ramnarain (President), Chris Ramnarain (V. Presidrent), Brian Ramnarain (CEO)

Production/shipping volume per year: 100+

Headquarters / manufacturing location(s): Shakopee, MN

Number of employees: 10+

Number of field service personnel: N/A

Facility square footage: 30,000 sq

Geographic sales and support areas: USA

Company website: www.psrautomation.com

Annual revenuesPick a range: $3-6 million

PSR Automation is a family packaging company that expanded along with the family.

By Casey Flanagan, Digital Editor, PMMI Media GroupOne of PMMI’s newer members, PSR Automation, is a unique story about a family in Shakopee, Minnesota, that literally goes down the packaging line and learns how to manufacture the different pieces of equipment it produces. OEM spoke with patriarch David Ramnarain about PSR’s evolution. The full interview is available at oemmagazine.com. The following are some highlights.

OEM: Can you provide a brief history of your company?

PSR: I came from Guyana, South America, with a mechanical engineering degree, and I started working at a contract packaging company in Minneapolis. I worked for that company for 20 years, when I decided I could make a difference in the industry by developing brandnew technologies.

In 1993, PSR Automation Inc. started in a two-car garage and is now operating out of a 30,000 sq ft building. PSR Automation Inc. is now a thriving engineering and automation enterprise.

In addition to providing engineering solutions and quality packaging machines for 30 years, PSR believes in supporting local

businesses and contributes to improving customers growth. PSR stands as an example of hard work, perseverance, and the American dream

OEM: What sets your company apart in the industry—what makes it shine?

We take one part at a time. We did the filling part, and we got very good at that for the past 15 years, and we offer top-of-the-line servo fillers. We did capping, and we have the top-of-the-line there. Now we’re doing the pump inserters, with finger pumps and trigger pumps.

The next approach will be going to the end of the line, where robotics is a big aspect. We’ll have to develop a strategy to change how packaging is done at the end of the line. We’ll go about it more efficiently to accommodate the space available for packaging companies. That sets us apart in engineering and technology; we try to change the industry.

We can also make changes very fast; we’re not top-heavy. Developing a new machine only takes about two or three months from the initial idea to when the machine is shipped. Machine lead time is about eight to 12 weeks, which is very good for the industry.

OEM: What made the decision to join PMMI come about?

PSR: PSR has grown to a point where we have all these products, but there’s no way that companies around the country know about us. We know PMMI is in the business of marketing for packaging companies. Without being part of a big membership, you can isolate yourself. For our company right now, we don’t want to do that, we want to be involved with everything happening.

OEM: Have you participated in any PMMI programs since becoming a member or have plans to in the future?

PSR: We’re looking forward to attending more PMMI trade shows. Marketing will also be a big deal for us because we don’t have anybody in-house to do that for us. I think it’s time for a professional marketing plan, and that’s where PMMI comes in with insights from years of marketing experience.

OEM: What’s your approach to new product development? How do you come up with ideas for new machines and markettest them?

PSR: We have about 77 different products that go on the packaging line, but we don’t manufacture all of them; we just manufacture seven products in our facility right now. Those are manufactured constantly, so they’re on the floor ready to go. Innovation-wise, if a customer requests a custom solution for the packaging line, we’ll analyze whether that would be something we would want to invest engineering and resources and, in turn, be able to market that. If the customer comes to us and we see a future use for that product, then we’ll

The PI5000 Pump/ Trigger Inserter is controlled by nine servo motors for maximum flexibility.

get into that area. That’s how we develop a brand-new system.

On a day-to-day basis, we look at the whole packaging line and see what the industry is doing, and we’ll allocate resources from there. PSR has captured most of the packaging line, so we can complete the whole filling line, almost the whole packaging line, from start to finish. We don’t currently make a bottle scrambler, which we can do, but somebody else is doing a good job at it, so we don’t want to just copy that. We want to come up with brand-new ideas.

OEM: How has your product line broadened over the years?

PSR: Back in 1993, I started out making change parts and doing machining jobs. I had a lathe and a mill in the garage to fill those customer orders. Then, finally, I decided to do a filling line due to a customer request.

The first filling machine was the pressure filler. Since everybody was making pressure fillers, I tried to be competitive and create one. After 30 years, we still have pressure fillers running in factories, so the quality is built in. We did that for about seven or eight years, sustaining the business. But then my oldest son came in as an electrical engineer, while PLCs and other tech came in. That

made a big difference in our company; he came and revolutionized the whole electrical system, replacing mechanical movements with servos. That came about in about 2005.

Two years later, my youngest son came in with a mechanical engineering degree, and he took everything from hand-drawing machines to using technology. The two came at the right time, and the company took off from then on.

OEM: Do you have any plans for facility expansion or new operations?

PSR: In the past year, we have completed three brandnew projects. Those need to be manufactured and brought to the market. Right now, we have new carbonation machinery. Because it’s brand-new, we are applying for patents. I know for sure that it’s going to take off.

Then we want to manufacture other product lines, too, but the way the factory is set up right now—we have seven different product lines—it’s already filled up. Expansion is coming very soon. PSR’s track record is that we go to a new facility every 10 years. I’m looking into a new facility already, and it’s only been five years. We’re outgrowing this building already. ■

Reflecting on our previous exploration of AI’s historical progression within the OEM manufacturing sector (OEM Spring 2024), we now venture into the burgeoning field of Generative AI. This article delves into its speculative yet promising impact on product design and innovation within the OEM industry, envisioning future possibilities.

Generative AI, distinguished by its capability to create and innovate, involves sophisticated algorithms that learn from extensive datasets to generate new concepts. This form of AI stands to revolutionize the approach to product design by not just analyzing data but actively generating innovative solutions.

Generative AI redefines OEM product design by automating processes and fostering creativity. This technology autonomously generates and iterates on designs, fostering innovative industrial design methods. For example, in automotive sectors, it devises solutions that synergize aerodynamics with aesthetics, areas traditionally dominated by manual effort. Additionally, it produces multiple design alternatives quickly, expanding the creative scope for designers.

This AI technology also works in conjunction with simulation tools, allowing for the rapid testing of designs under simulated conditions. This capability not only speeds up the design process but also improves its accuracy and reliability. It plays a critical role in industries requiring quick innovation cycles such as electronics, streamlining prototyping and refinement processes.

Generative AI promises to revolutionize how OEMs craft products by enhancing customization and personalization. At present, its application in production is exploratory, but it aims to tailor products to individual preferences efficiently, surpassing traditional methods. It leverages deep learning to analyze various

“ . . . it is poised to become a cornerstone technology in OEM design processes.”

data points, including consumer purchases and social media trends, to create designs that resonate with current and future market demands.

Moreover, Generative AI’s capabilities extend to crafting products uniquely designed for individual users, exemplified by personalized vehicle designs in the automotive industry. It supports a dynamic design process, continuously refining products based on user feedback and performance data. Virtual prototyping, enabled by AI, streamlines design validation by minimizing the need for physical prototypes, reducing costs and environmental impact. This approach also emphasizes sustainable design practices, ensuring that personalized products are as eco-friendly as they are innovative.

Generative AI’s ability to process and analyze vast amounts of data can lead to innovative solutions for complex design challenges that would

typically require extensive R&D resources. It can identify non-intuitive design options that improve performance and durability by analyzing factors such as material properties, environmental impacts, and usage patterns simultaneously. In aerospace, for instance, this might involve developing more efficient wing designs that optimize aerodynamics and reduce fuel consumption without compromising on safety or cost.

The potential applications of Generative AI in OEM product design span across industries. In the electronics sector, for example, Generative AI could be used to design circuit layouts that optimize space and power consumption while enhancing capabilities. In furniture manufacturing, AI could generate designs that optimize material use and comfort, catering to ergonomic standards and consumer preferences, potentially reducing costs and environmental impact.

As Generative AI continues to evolve, it is poised to become a cornerstone technology in OEM design processes. However, harnessing its full potential will require overcoming significant challenges, including ethical concerns related to automated decision-making and the need for robust data privacy protections. Future advancements in AI will need to address these issues head-on, ensuring that AI-driven designs are not only innovative but also aligned with broader societal values and regulatory standards.

Generative AI represents a frontier in OEM product design and innovation. With its ability to enhance creativity, drive efficiency, and enable unprecedented levels of customization, it holds the promise of profoundly transforming the industry. As we look ahead, it is clear that integrating Generative AI into OEM design processes will not only redefine product innovation but also set new benchmarks for the future of manufacturing. ■

David McGraw is a Senior Director at Alvarez & Marsal Private Equity Performance Group L.L.C.

THIS COLLABORATION offers PMMI members exclusive benefits aimed at strengthening their workforce. PMMI members can attend exclusive recruitment events, including virtual and in-person career fairs, workshops, and Heroes Connect events. These events provide opportunities for PMMI companies to interact with veterans in training programs and discuss the industry, their companies, and potential career paths.

This initiative gives PMMI member companies a strategic advantage in workforce development, which can enhance productivity and competitive edge in the global market. For more information on how to engage with this initiative, visit pmmi.org/ heroesmakeamerica.

July 24 – 25

(AC Hotel Vancouver Waterfront, Vancouver)

This free event promises to be a game-changer –offering an exciting agenda, including speakers from Bob’s Red Mill Natural Foods and a Plant Tour of their processing and packaging facility. Hear from Industry experts and expand your network. Whether you’re interested in the latest industry trends, best practices, or sales strategies, there’s something for everyone.

For more details and to register, visit pmmi.org/roadshow.

SheLeads: Navigation Leadership for Women (New!)

July 10–11 (PMMI, Herndon, Virginia)

October 8–9 (PMMI, Chicago)

This course is designed specifically for women leaders in manufacturing who are looking to enhance their self-awareness and leadership skills. This interactive program provides a platform for participants to explore new ideas, reflect, share experiences, practice new skills, and build new relationships with other leaders to support their growth.

Registration details are coming soon! For more information, visit pmmi.org/sheleads.

July 30 – 31, (PMMI, Chicago)

August 28 – 29, (PMMI, Chicago)

December 11–12 (PMMI, Las Vegas)

This two-day workshop is specifically designed for packaging and processing equipment sales professionals who are looking to maximize sales at PACK EXPO through pre-show preparation, effective selling strategies during the event, and post-show follow-up techniques.

August 20–21 (Delkor Systems, Minneapolis)

November 3–4 (PACK EXPO International, Chicago)

Field service technicians are the face of your organization. They spend more time with your customers than anyone from your operation. This two-day workshop explores the non-technical knowledge and skills needed to be a great technician.

Certified Trainer

August 22–23

(Delkor Systems, Minneapolis)

November 3–4

(PACK EXPO International, Chicago)

This workshop gives your company the strategies and tactics to become an effective and successful trainer across all employee skill levels.

Packaging & Processing Equipment Selling in Today’s Market

September 26–27

PMMI Annual Meeting and Young Professionals Conference

The 2024 Young Professionals Conference (YPC) will be held on the last day of the PMMI Annual Meeting. The YPC is an opportunity for emerging leaders in packaging and processing to get expert career advice, explore industry hot topics, and network with peers.

(PMMI Annual Meeting, Hershey, Pennsylvania)

This workshop will help capital equipment sales professionals and their managers learn systematic consultative selling techniques to make them trusted advisors to customers purchasing packaging, processing, and automation equipment.

Risk Assessment

November 3–4

(PACK EXPO International, Chicago)

Risk assessment is a process that manufacturers use to evaluate their equipment before an accident or incident occurs. Many end users now require risk assessment as part of the procurement process. This workshop provides valuable insights and strategies for maximizing safety and minimizing liability in machinery-related accidents.

Learn more and register for these workshops today at pmmiu.org

On the Rise Awards - Nominations Due July 15

NOMINATE outstanding young professionals for PMMI’s On the Rise Awards. This program, hosted by the Young Professionals Network, supports career growth in packaging and processing. Nominations open May 1 - July 15.

Visit pmmi.org/youngprofessionals/awards to nominate your young professional.

September 25, 1:00 PM - 5:00 PM Hershey Lodge Hershey, Pennsylvania

Visit pmmi.org/young-professionals/events to register.

Young Professionals Networking Reception at PACK EXPO International

(November 3 - 6, McCormick Place, Chicago) November 4, 2024

Details forthcoming at pmmi.org/young-professionals/events.

PMMI’S Expert Connect program provides the hard-to-get business support you need in two key areas: legal counsel and exporting advice.

Need advice regarding contracts, labor law, or regulatory issues? PMMI has the answer. We can connect you with legal expert Eric Greenberg, from Croke Fairchild Duarte & Beres, LLC. Eric has extensive experience in our industry and can provide significant value to PMMI members. PMMI will cover the first hour of Eric’s time. If your question requires additional time, you can engage Eric’s firm at their cost.

Services include:

• General Corporate Advice

• Finance & Liquidity Solutions

• Venture Capital & Founders

• Employment & Labor

• Litigation & Investigations

• Mergers & Acquisitions

• Outside General Counsel

• Food and Drug Law

• Government Affairs & Regulatory Law

• Taxation