WEDNESDAY SEPTEMBER 13, 2023

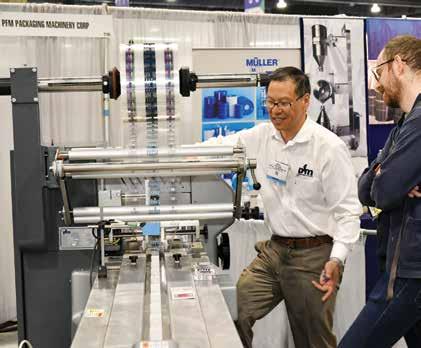

Booth C-2800 SHOW DAILY

NEWS BRIEF

Printing, robotics, pneumatics

Hitachi (Booth N-9520) displays live printing stations, robotic integration and its new DS45 oil-free air compressor to showcase end-to-end solutions for the industry. Visit JR Automation (Booth N-9163) for a chance to Beat the Bot at blackjack. The robotic dealer integrates the technology of Hitachi’s continuous inkjet printer with a CRX-5iA robot from FANUC America (BoothC-5233). Learn more at hitachifusion.com sustainability. SD

Streamlined automation

Bosch Rexroth (Booth SL-5964) demonstrates streamlined automation with a ctrlX AUTOMATION-powered, multitech layout consisting of a VarioFlow plus conveyor, which delivers high accuracy with unprecedented speed, and a Kassow collaborative robot. With more than 225 years of engineering expertise, the company’s comprehensive, harmonized factory automation portfolio offers advanced yet easy-to-use components and digital engineering tools. Customized support addresses the most intricate engineering challenges. SD

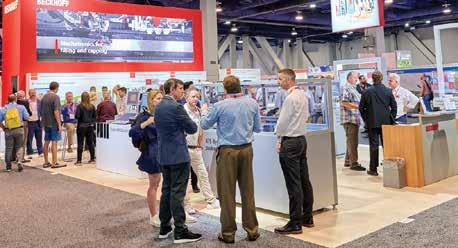

Integrated vision debuts

Beckhoff Automation (Booth SL-6335) launches fully integrated Beckhoff Vision portfolio in North America. New cameras, lighting and lensing allow engineers to implement robust image processing directly in a standard PLC environment with perfectly paired hardware and complementary TwinCAT 3 software. The integration of vision into control architecture, along with EtherCAT communication, powers real-time reactions and greater data transparency for better quality control, traceability and other functions. SD

Sustainable tray

Marchesini Group USA (Booth SL-6701) displays a Paperboard Tray Line and its newly designed tray. This innovative tray design generates a saving of around 50% in paperboard and glue and an estimated 30% of space in the final carton/shipper pack configuration, compared to current designs on the market. SD

Build on this year’s success Plan now for PACK EXPOs in Philly, Chicago and Atlanta.

As PACK EXPO Las Vegas draws to a successful close, attention turns to PACK EXPO East (March 18–20, 2024; Pennsylvania Convention Center; Philadelphia) and PACK EXPO International (Nov. 3–6, 2024; McCormick Place; Chicago) and the launch of PACK EXPO Southeast (March 10–12, 2025; Georgia World Congress Center, Atlanta).

At PACK EXPO shows, attendees:

• See new packaging and processing technology in action for 40 vertical markets

• Get crossover ideas from other industries

• Make new connections via networking events like the Young Professionals Networking Reception and programs sponsored by the Packaging & Processing Women’s Leadership Network

• Participate in free educational programs to gain actionable information to put to use right away

4 win Technology Excellence Awards

Voting closed at noon yesterday for the Technology Excellence Award (TEA) competition, which honors technology never seen before at a PACK EXPO. Voters narrowed the field of 12 finalists down to four winners, one in each category.

FOOD/BEVERAGE WINNER

Designed to quickly empty drums, barrels or jerricans of concentrated liquids, the Aneko Emsys system from Aneko (Booth N-10165) is ideal for syrup preparation rooms with sanitary construction, simple operation and an integrated weighing system. After the operator selects the product, the unit automatically detects the opening and empties the container. Once empty, the container is rinsed, and the system returns to home position for automatic cleaning in place.

(Continued on page 8)

• Move projects forward faster by talking to experts and assessing options side-by-side.

PACK EXPO EAST

As it prepares to present its sixth edition, this well-attended show has grown since its inception

(Continued on page 8)

Manjit Minhas inspires crowd

Manjit Minhas, entrepreneur, beer baroness and television personality, shared insights, experiences and valuable lessons to an audience of 750 at yesterday’s Packaging & Processing Women’s Leadership Network (PPWLN) Breakfast.

In a dialog with Stephanie Neil, PPWLN leader and editor of OEM, Minhas stressed the importance of negotiating skills. “You don’t get what you deserve, you get what you negotiate,” she said, noting everyone who joins her company takes a negotiating course. She also encouraged the audience to set goals and write them down. “This opens the mind to opportunities,” she explained.

At the age of 19, Minhas co-founded the

(Continued on page 16)

It is time to experience

Cartoner handles multiple formats

Using manual or automatic feeding, the Cariba C221 intermittent-motion horizontal cartoner from MG America (Booth SL-6534) accommodates most primary pharmaceutical, nutraceutical and cosmetics packaging formats, including blister packs, round/shaped glass and plastic bottles, jars, soft tubes and flow packs at up to 120 cartons/min. SD

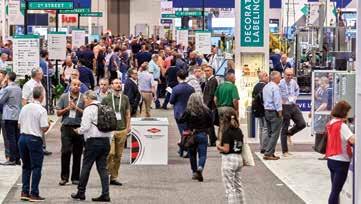

Students compete in show floor tasks

Emerson continues as sponsor of Amazing Packaging Race.

Teams of college students and exhibitors come together this morning in the Amazing Packaging Race, a popular last-day-ofthe-show tradition, sponsored by Emerson Discrete Automation (Booth SL-6107). In this competition, student teams dash around the show floor to take on tasks assigned by participating exhibitors.

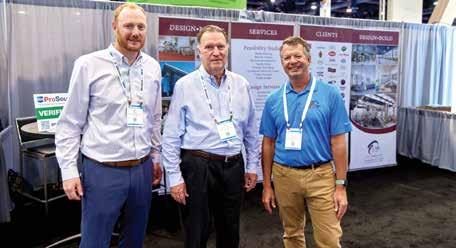

NJM reps Steelco

As its exclusive North American representative, NJM, a ProMach product brand (Booth C-3225, SL-6501), is responsible for sales and service of Steelco Group’s cleaning and sterilization systems for the pharmaceutical, biotech, nutraceutical and medical device industries in the U.S. and Canada. “With the addition of Steelco, we’re expanding our portfolio to include related systems that complement the complete, turnkey packaging solutions we’ve been providing for decades,” says Steve Leduc, vice president & GM of NJM. SD

IP rebrands for 125th birthday

To celebrate its 125th year in business, International Paper (Booth N-9305) has unveiled a new visual identity and corporate website that highlight the sustainability of its mission and its commitment to creating what’s next in meeting industry needs for renewable, fiber-based packaging and pulp. SD

Rockwell expands robotics holdings

Rockwell Automation (Booth SL-6127) complements its advanced material handling capabilities with the planned acquisition of Clearpath Robotics and its OTTO Motors Division (Booth SU-8083), a supplier of autonomous mobile robots, fleet management and navigation software. These technologies dramatically increase throughput and reduce costs by eliminating bottlenecks, ensuring product and packaging are in place when needed and transporting finished goods to a truck or warehouse, creating a safer, more productive workplace. SD

The race concludes with the announcement of first, second and third place teams, who win $1,000, $500, and $250, respectively, for each team member.

“We are extremely grateful for Emerson’s support and commitment to offering educational opportunities for students in the packaging industry,” says Jim Pittas, president & CEO, PMMI, The Association for Packaging and Processing Technologies (Central Lobby), organizer of the PACK EXPO family of trade shows. “Throughout the years, Emerson’s consistent sponsorship has played a crucial role in the success of this program, making it possible to provide valuable experiences for students. This is one of our most popular events, and we couldn’t do it without the continued support of Emerson.”

“We are thrilled to be part of this hands-on event that celebrates problem solvers and innovative technology, two principles deeply rooted in Emerson’s heritage,” says Jay Gatz, vice president Commercial Execution & Strategy, Discrete Automation, at Emerson. He concludes, “Our passion and unwavering

support for STEM education is driven by these core values. We’re excited to cheer on this year’s collegiate teams as they solve processing and packaging challenges across the PACK EXPO floor.”

Registration for The Amazing Packaging Race is free for students and $600 for exhibitors. Participating exhibitors include: 3M (Booth C-3243), AllenField (Booth SU-8313), B+R Industrial Automation (Booth C-4343), Baumer HHS (Booth C-5603), Beckhoff Automation (Booth SL-6335), Duravant (Booth C-4230), Econocorp (Booth C-4422), Fallas Automation (Booth C-4214), FOX IV Technologies (Booth SL-6301), Fresh-Lock By Presto Products (Booth C-3003), Hoosier Feeder (Booth SL5925), Institute of Packaging Professionals (Booth C-1154), Lenze Americas (Booth C-4803), LinMot USA (Booth C-5414), Morrison Container Handling Solutions (Booth C-1651), OMAC - The Organization for Machine Automation and Control (Booth C-1255), Paper Machinery (Booth C-1361), Plastipak Packaging (Booth N-9357), Schneider Packaging Equipment/Pacteon (Booth C-2223, SL-6604), Shurtape Technologies (Booth SL-5923), SICK (Booth C-5128), Siemens Digital Industries (Booth SL-6351), Starview Packaging Machinery (Booth C-3600), and WLS, a ProMach product brand (Booth C-3225, SL-6501)

For more info, visit www.packexpolasvegas.com. SD

Hitachi donation supports research Equipment auction raises funds for breast cancer research.

Hitachi Industrial Equipment & Solutions America (Booth N-9520) has donated two UX2 continuous inkjet (CIJ) printers and two WJ200 Series variable frequency drives for an online auction to raise money for the Breast Cancer Research Foundation.

The CIJ printers are equipped with a sealed SafeClean-Station, which cleans and dries in a single operation, consumes less solvent than manual cleaning and reduces downtime caused by a dirty nozzle.

Bids may be placed until 5 p.m. UTC (1 p.m. EDT) on Sept. 30, 2023. Winners will be contacted at the conclusion of the auction.

For more info, visit givebutter.com/c/hitachi, hitachi-iesa.com. SD

Secondary & End of line

When the choice is yours, why not choose more? A leading provider of primary, secondary, and end-of-line packaging machines, Paxiom has more than 30 years of industry expertise. Operating from seven global facilities, with a passionate and focused staff of professionals with the strongest national service presence, the ability to provide systems integration, and an installed base that included more than 7,000 machines across the world. Paxiom. Get more.

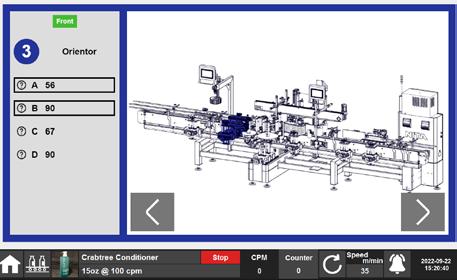

One-button changeover

PLC-controlled, servo-driven, fully automatic labeler from Quadrel Labeling Systems (Booth C-1655) changes over with the press of a button. The new design reduces changeover time to less than 2 min. and is available on ProLine models. SD

Robotic unscrambler debuts

A parallel-kinematic, multi-axis, pick-and-place robot module on the fully automatic robotic unscrambler from Omega Design (Booth C-3836) separates, orients and positions bottles onto a conveyor or into stabilizing pucks. Dual infeed presents two containers at once to the robotic arms from the integrated hopper. Designed with minimal changeover points for applications running complex or multiple bottle shapes, unit handles a broad array of containers, bottles, tottles, jars, vials, jugs and tubes. SD

ROPP capper offers up to 4 heads

An automatic roll-on-pilfer-proof (ROPP) cappers from E-PAK Machinery (Booth C-4614a) accommodate one to four capping heads. Servo feedscrew indexing ensures proper bottle alignment, and a height-adjustment feature accommodates different container sizes. The sorter and capper can handle caps with various diameters, and the cap feed chute has a wide adjustment range to meet specific cap and container combinations with minimal change parts. SD

Weigh cannabis precisely

A fully automatic, high-precision cannabis weighing and filling system from MULTIPOND America (Booth SL-6567) combines product protection, easy operation and minimal giveaway with a tamper-proof system. An integrated pre- and post-weighing device continuously checks the weighed weight. SD

Software optimizes

Cloud-enabled PackNet® production and optimization software seamlessly integrates with Packsize’s (Booth SU-7407) On Demand Packaging® machines to manage machine, box production and packaging workflow integrations. Key features include support for multi-tenant environments, reporting, cube optimization and dimensioning. Comprehensive approach provides data to minimize material waste and enhance sustainability practices in real-time. SD

SEPTEMBER 13, 2023

OpX enhances FAT work product

SAT Addendum guides next step in acceptance testing.

An Addendum for site acceptance tests (SATs) will join the One Voice Factory Acceptance Tests (FATs) work product early in the fourth quarter of 2023.

Published by the OpX Leadership Network (Central Lobby) in 2022, the original document, plus a Virtual FAT Addendum, guides consumer packaged goods companies through the FAT process via a playbook and checklist. The SAT Addendum does the same for the SAT process. “Although the FAT and SAT perform many of the same tests, the OpX Leadership Network’s Capital Projects Solutions Group felt a SAT Addendum would be helpful to CPG companies and OEMs,” reports Bryan Griffen, director, Industry Services, PMMI, The Association for Packaging and Processing Technologies (Central Lobby), and convener of the OpX Leadership Network. Machinery buyers rely on FATs to ensure a machine will perform as specified. The tests are performed by the OEM at its facility and typically runs the machine in short bursts to show functionality. The end user may be onsite or observe virtually. At

the end of the FAT, a punch list of what needs to be corrected or reworked is made and completed.

After installation of a machine, the SAT occurs. This involves running the machine at full speed for a specified period to confirm any issues identified at the FAT have been resolved, work out kinks and verify performance is as expected. If the machine will run different formats or sizes, changeovers are made to run each variation. This ensures changeovers go smoothly and that the operators understand how to do them. “If the FAT was done virtually, the SAT also will check physical aspects of the machine like pinch points and sharp edges, which couldn’t be done virtually,” says Griffen.

Once the SAT is completed, the machine is integrated with up- and downstream equipment and a line test is run to synchronize the line and achieve the desired OEE.

The SAT Addendum will be available for free download on the OpX Leadership Network website in a few weeks.

For more info, visit opxleadershipnetwork.org. SD

PACK

Publisher PMMI Media Group

Editorial Director

Hallie Forcinio

Associate Editor

Barbara Rook

Production Manager

Mary Thorne

Art Director

Debi Friedmann

IT/Production Support

Manny Dominguez and Olga Minkevich

Photographers

Miles Boone and Edina Dibusz

Advertising Sales Management

Dave Newcorn, President, PMMI Media Group

John Schrei, Vice President, Sales, PMMI Media Group

SEPTEMBER 13, 2023

(PACK EXPOs Continued from page 1) DISCOVER THE FUTURE OF

PACKAGING SUSTAINABILITY

but retains an intimate feel with approximately 100,000 net sq. ft. of exhibits, 400 exhibitors and 6,000 attendees. Conveniently located in Philadelphia, the show is a quick trip by train or car from most anywhere on the East Coast.

PACK EXPO INTERNATIONAL

PACK EXPO International will be the biggest packaging and processing show on the planet in 2024. With 45,000 attendees expected and 2,500 exhibitors spread across more than 1 million sq. ft. of floor space, it will connect more packaging and processing end users and suppliers than any other event in 2024.

PACK EXPO SOUTHEAST

This show will bring the industry together in a region of the country that is not currently served by a trade show focused on packaging and processing. Atlanta represents an ideal location. Not only is it home to some of the top manufacturing industries in the region, but it’s also located a mere two-hour flight from 80% of the U.S. population.

NORTH HALL, Booth N-9455

Attain a complete understanding of packaging sustainability and what that means for your brand.

Reshape Your Brands Impact

Explore 6 key areas of packaging sustainability encouraging you to think outside the box.

• Manufacturing

• Material

• Design

• Logistics

• Recovery

• Analytics

Find Inspired Ideas

Talk with top universities about their projects centered around sustainability and the circular economy.

• Michigan State University

• Wisconsin Stout

• Indiana State University

Booth: N-9967

Get Insights from Experts

FREE sessions on how to make your brand more sustainable.

PACK EXPO LAS VEGAS 2025

PACK EXPO Las Vegas (Sept. 29–Oct. 1, 2025; Las Vegas Convention Center) returns for its 16th edition.

For more info, visit www.packexpo.com. SD

( TEA Continued from page 1)

GENERAL PACKAGING & PROCESSING WINNER

This augmented reality system from Harpak-ULMA Packaging (Booth SL6188, SL-6101) utilizes AI to identify patterns, predict outcomes, optimize decision-making processes and transform packaging operations.

PERSONAL CARE/PHARMA WINNER

The patent-pending Digital LineClearance Assistant™ from Catalyx (Booth SL-6185), formerly CXV Global and Panacea Technologies, deploys a network of fixed-position cameras to ensure coverage of hard-to-reach areas and inspects the entire line in seconds.

SUSTAINABILITY WINNER

Recycle-ready sachet from Amcor Healthcare Packaging (Booth SL-6635) replaces difficult-to-recycle foil laminations with a metallized polyolefin/AmPrima™ film, which is compatible with the polyethylene film recycling stream. For more info, visit www.packexpolasvegas.com. SD

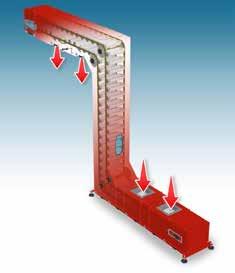

Vertical Conveying. Simplified.

Spiral Conveyors & Bucket Elevators

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, wet environment and freezer versions.

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2,000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Narrow Trak Spirals are super compact and designed to handle smaller loads. Our 6” and 9” wide nesting slats can end-transfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 220 FPM.

Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit.

Our Bucket Elevators are designed for gentle handling and well-suited to transport a broad range of bulk products. They are completely enclosed with overlapping pivoting buckets, that prevent spillage and helps mitigate foreign debris.

They can be configured with multiple inlets or outlets that can be controlled individually. Available in three standard bucket sizes, yielding capacities up to 300, 700 or 1,800 cubic feet per hour. They can also be delivered in powder-coated carbon-steel, or stainless-steel for wet environments.

All Ryson equipment is modular and built to order. No matter the application, the Ryson team is up to the challenge of finding solutions for your conveying needs. For application assistance or more information, give us a call or visit www.ryson.com

Check out our running equipment at Pack Expo | Booth C-4736

www.ryson.com

(757) 898-1530

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

hotspots find targeted solutions

NORTH HALL

The Containers and Materials Pavilion

Find new sustainable materials, flexible packaging, printable films and more. Also see award winning packages at:

PACKage Printing Pavilion

Explore technology that makes customization, promotions, small runs, on-demand production and smart packaging cost effective.

The Logistics Pavilion

Find supply chain solutions including warehousing and dock equipment and systems, inventory management and control, distribution logistics services and transportation.

The Processing Zone

Find front-of-the-line solutions for food and beverage processing and discover ways to increase safety, improve efficiency and achieve total system integration.

SOUTH

UPPER HALL

The Confectionery Pavilion

Uncover specialized equipment and integrated systems for your candy, chocolate, mints and gum production lines.

Sponsored by:

The Reusable Packaging Pavilion

Discover reusable assets that not only reduce waste but also provide more reliable protection for your production and can be part of a smart supply chain.

Sponsored by:

SOUTH

LOWER HALL

The Healthcare Packaging Pavilion

A one stop shop for solutions targeted to pharmaceuticals, biologics, nutraceuticals, medical devices and more.

Awards honor sustainability efforts Conagra,

Hormel,

Red Mill

Winners in the ninth annual Sustainability Excellence in Manufacturing Awards (SEMA), sponsored by ProFood World, a publication of PMMI Media Group (Central Lobby), a division of PMMI, the Association for Packaging and Processing Technologies, were honored on Monday in a presentation at the Processing Innovation Stage (Booth N-10511)

The award-winning programs and projects were completed and operational between November 2021 and December 2022.

PROGRAM CATEGORY

• First Place: Conagra Brands, Fayetteville, AR, Certified Carbon Neutral Made in a Zero-Waste Facility.

PROJECT CATEGORY

• First Place: Hormel Foods, Dubuque, IA, Reverse Osmosis Concentrate Reuse

• Second Place: Conagra Brands, Imlay City, MI, Steam Trap Optimization

• Third Place: Bob’s Red Mill, Milwaukie, OR, Food Waste Reduction

• Fourth Place: Smithfield Packaged Meats, Kinston, NC, Plastic/Film Waste Reduction. The peer-reviewed awards recognize facilities for

projects or programs that improve sustainability efforts in food and beverage manufacturing operations, focusing on pollution prevention, compliance assurance and environmental protection. Recipients are awarded for reducing water and energy use, waste conservation, pollution prevention and packaging reductions.

“Sustainability is more important than ever for both food and beverage manufacturers and their customers,” says Aaron Hand, editor-in-chief of ProFood World. “As shown by the depth of entries in the Project Category, processors are often chipping away at sustainability efforts on a project-by-project basis, in many cases getting inspiration from their employees who have firsthand knowledge of where waste is occurring and ideas about how operations could be optimized.”

Past award winners include B&G Foods, Pepperidge Farm, Sierra Nevada Brewing, Campbell Soup, McCormick, Hormel, Hiland Dairy and Land O’Lakes.

For more info, visit pfwgo.to/sema. SD

Editor’s Note: Award winners are described in the cover story in the August 2023 issue of ProFood World

SEPTEMBER 13, 2023

Schubert North America turns 25

Kick back and dine for leSS!

Kick back and dine for leSS!

Visit the North Hall Backyard Bistro with lunch options at discounted rates

Schubert North America (Booth SL-6820, SU-7654) marked its 25th anniversary with a reception yesterday afternoon, which featured traditional German refreshments in honor of its parent company, Gerhard Schubert, which is headquartered in Crailsheim, Germany, and was founded in 1966.

In 1998, the Schubert family set up its first North American location in Dallas, TX, expanding the company’s international presence. A Canadian operation opened a few years later.

Open Daily Open Daily In North Hall

back of the show floor

11:00 AM - 3:00 PM Monday - Wednesday

Refuel Relax Return

FIRST-TIME ATTENDEE LOUNGE

South Upper Hall Room S-220

HOURS OF OPERATION:

Monday – Tuesday: 8:00 am – 5:00 pm

Wednesday: 8:00 am – 3:00 pm

If your badge says “First-Time Attendee” stop by to:

• Ask questions of show staff

• Access product locators

• Enjoy refreshments and comfortable seating

MONDAY, SEPTEMBER 11

8:30 am PACK EXPO 101: Navigate the Show Like a Pro

1:30 pm Bringing Your Products to Market Using Contract Packagers & Manufacturers

TUESDAY, SEPTEMBER 12

8:30 am PACK EXPO 101: Navigate the Show Like a Pro

• Attend special sessions PLUS, an Exclusive Networking Reception on Tuesday 4:30 pm – 5:30 pm. Your First-Time Attendee Badge is your access pass.

In 2015, Schubert established its North American headquarters in Charlotte, NC. Due to continued growth, the company recently acquired seven acres of land in Charlotte to further expand its operations. The new headquarters building, which occupies approximately 45,000 sq. ft., will include sales, engineering, service, final assembly and a customer training center. Today, North American customers also are served from a facility near Toronto in Mississauga, Ontario, Canada.

For more info, visit schubert.group. SD

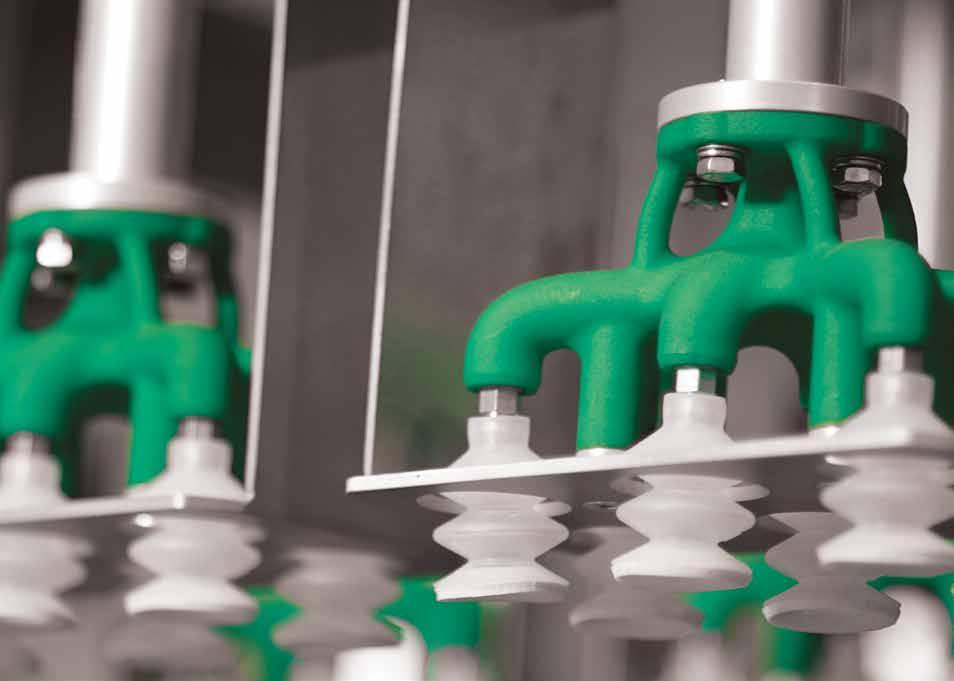

Automate Floor to Cloud™

Floor to Cloud™ solutions from Emerson Discrete Automation (Booth SL-6107) empower smarter packaging lines and more efficient processes, enabling continuous improvement of productivity, sustainability and safety. Products on display include AVENTICS Series AF2 flow sensors and multimedia monitoring technology.

By monitoring air consumption in pneumatic systems, AVENTICS Series AF2 flow sensors enable rapid intervention if a leak occurs and help optimize energy consumption, reach net-zero targets, prevent machine downtime and reduce costs. A high-flow model propels compressed air monitoring beyond individual machines to benefit larger air lines and systems.

1:30 pm How to Make Your Product’s Packaging Environmentally Friendly

WEDNESDAY, SEPTEMBER 13

8:30 am PACK EXPO 101: Navigate the Show Like a Pro

Sponsored by: Booth C-3222

Multimedia monitoring, including CoreTigo wireless communication, analyzes water, compressed air, gases, electricity, steam and other utilities. The Edge Analytics Dashboard measures efficiency, optimizes productivity, avoids or reduces downtime and helps meet sustainability goals.

For more info, visit www.emerson.com/en-us/catalog/aventics-af2, Emerson.com/ Sustainable-Automation. SD

PMMI

exhibitors can take a break from the show floor in dedicated lounges (Room S-215; S-222 / N-101, N-114), sponsored by Lenze Americas (Booth C-4803), where they will be welcomed by ambassa-

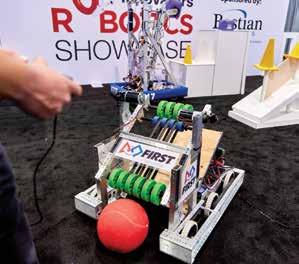

Students from area high schools show off their robots at the Future Innovators - Robotics Showcase (Booth N-9769), sponsored by Bastian Solutions (Booth N-10343)

The Candy Bar Lounge (Booth SU-7201), sponsored by Syntegon (Booth C-2800), offers a space to recharge and network with peers and clients.

At the Showcase of Packaging Innovations™ (Booth N-955), sponsored by WestRock (Booth C-2023), attendees can examine award-winning packages from competitions around the world.

Have you been able to navigate your way around the show? Thank Festo (Booth SL-6160) and SMC (Booth C-4839) for sponsoring the aisle banners.

The Amazing Packaging Race, sponsored by Emerson Discrete Automation (Booth SL-6107), pits college, trade school and university students against each other to take on tasks assigned by show exhibitors.

members and

dors like Charlene Gove.

Lanyards, sponsored by ORBIS (Booth SU-8001), help you keep track of your show badge, which is your passport to the show floor and events.

Hotel key cards were sponsored by Frain Industries (Booth SL-5963)

Students from area high schools show off their robots at the Future Innovators - Robotics Showcase (Booth N-9769), sponsored by Bastian Solutions (Booth N-10343)

The Candy Bar Lounge (Booth SU-7201), sponsored by Syntegon (Booth C-2800), offers a space to recharge and network with peers and clients.

At the Showcase of Packaging Innovations™ (Booth N-955), sponsored by WestRock (Booth C-2023), attendees can examine award-winning packages from competitions around the world.

Have you been able to navigate your way around the show? Thank Festo (Booth SL-6160) and SMC (Booth C-4839) for sponsoring the aisle banners.

The Amazing Packaging Race, sponsored by Emerson Discrete Automation (Booth SL-6107), pits college, trade school and university students against each other to take on tasks assigned by show exhibitors.

members and

dors like Charlene Gove.

Lanyards, sponsored by ORBIS (Booth SU-8001), help you keep track of your show badge, which is your passport to the show floor and events.

Hotel key cards were sponsored by Frain Industries (Booth SL-5963)

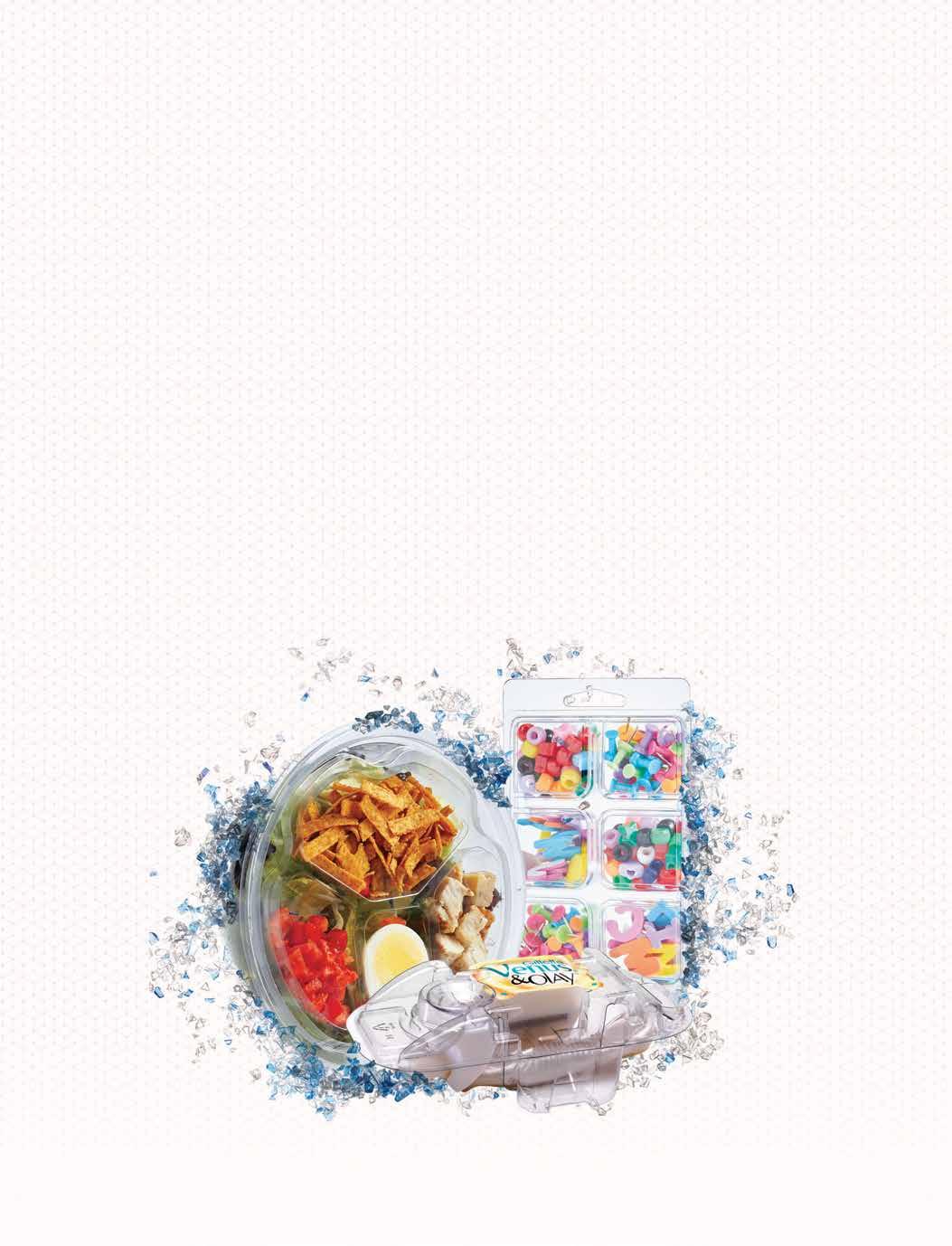

We s et the st a nd a rd fo r susta i nable therm oforme d pac kagin g. Rea c h you r goals quic ke r with ou r SC S Global c ertified 100% pos t- c onsume r re cycled m a ter ia l .

We s et the st and ard fo r susta inable therm oforme d pac kagin g. Rea ch you r goals quic ke r with ou r SC S Global certified 100% pos t- consume r re cycled m ater ial .

Per fec t i n b oth the food and reta i l mar kets , we h ave an in-s toc k o rcus tom solution fo r you r pac kaging needs .

Per fec t i n b oth the food and reta il mar kets , we h ave an in-s toc k o rcus tom solution fo r you r pac kaging needs .

SEPTEMBER 13, 2023

Sustainability Stage debuts

Anew show feature, Sustainability Central in the North Hall, houses the Sustainability Stage (Booth N-9967) where attendees will learn from more than a dozen industry experts about how to improve the environmental profile of their brands.

Topics include logistics, labeling, waste reduction, sustainable design and transitioning to more sustainable materials. with an opening presentation on Monday by Daniella Souza Miranda, global business director, Circular & Renewable Solutions at Dow (Room S-116), the show’s official Sustainability Partner. Session descriptions, times and locations are listed below. Updated schedules

LEVERAGING SUSTAINABILITY IN PACKAGING COST OPTIMIZATION: HOW TO CAPTURE SUSTAINABILITY VALUE WHILE SAVING COSTS

10:00-10:30 AM

As the consumer goods and packaging industry faces several headwinds coming out of COVID, including an uncertain economic situation, softening demand, supply chain challenges that haven’t fully been resolved, etc., sustainability often takes a back seat to cost optimization and other performance improvement levers. There are, however, ways to incorporate sustainability into these initiatives to continue to make progress against goals and commitments, as well as not have to sacrifice either objective. Join the Roland Berger team as they discuss how to incorporate sustainability thinking into cost optimization and provide examples of its value creation.

Rebecca MarciniakDilhani de Silva

Roland Berger

(Minhas/PPWLN Continued from page 1)

Minhas Brewery, Distillery, and Winery in Alberta, Canada, alongside her brother Ravinder Minhas. Since then, her companies have evolved into a significant player in the Canadian and US markets with revenues exceeding $220 million and a portfolio of about 120 brands of beers, spirits, liqueurs and wines.

Minhas is committed to sustainability and social responsibility. A special 48-can pack for COSTCO, significantly reduces packaging materials, and she was the first brewer in Canada to add a Management Warning on beer cans, urging against drinking and driving, advising expectant mothers to avoid alcoholic products and promoting responsible consumption.

The PPWLN Breakfast was sponsored by Emerson Discrete Automation (Booth SL-6107), Septimatech Group (Booth C-2836), ID Technology (Booth C-3414), BW Packaging (Booth C-1800), WestRock (Booth C-2023), SMC (Booth C-4839), Morrison Container Handling Solutions (Booth C-1651), Plexpack (Booth C-3036) and POWHER (ProMach Womens Resource Group).

For more info, visit pmmi.org/ppwln. SD

Sustainability STAGE

may be found on the show website or via the show App, sponsored by ProMach (Booth C-3222)

Other free educational opportunities on the show floor include the new Industry Speaks Stage (Booth C-1141) (see schedule, p. 24), the Innovation Stage (Booths C-2051, C-2058, C-2151) and the Processing Innovation Stage (Booth N-10511) (see schedule, p. 30), plus The Forum — An Industry Knowledge Exchange (Booth C-2158) (see schedule, p. 58)

Schedule as of August 23, 2023.

For more info, visit packexpolasvegas.com. SD

WEDNESDAY, SEPTEMBER 13, 2023

ALL TOGETHER NOW: UNLOCKING PACKAGING’S CIRCULAR FUTURE

11:00-11:30 AM

It’s time to go beyond broad recyclability claims and design packaging that is actually being recycled into valuable post-consumer recycled material. But how can brands transform from passive producers of waste to active participants in a circular economy? By embracing a systems approach that engages materials suppliers, reprocessors, materials recovery facilities (MRFs) and machinery makers to shed light on all the links of the circular supply chain. From advanced recycling to reuse and refill and monolayer materials, we’ll explore the ways stakeholders can take their recyclability claims from promise to reality.

Matt Reynolds

Chief Editor, Packaging World

Anne Marie Mohan

Senior Editor, Packaging World

Sean Riley

News Editor, Packaging World PMMI Media Group

INTENTIONAL DESIGN FOR SUSTAINABLE AND RECYCLABLE PACKAGING STRUCTURES

12:00-12:30 PM

To meet the combination of growing consumer demand and an escalating regulatory environment, Michelman helps customers transition to more sustainable solutions for their packaging needs. We will discuss how to transition from film-based substrates to fiber-based substrates that will enable improved end-of-life options for final structures in existing recycling streams – all while maintaining excellent barrier performance!

Talia Collins

Mgr, Global Research & Development

Michelman

Toby Corey

Exec Chairman & COO

Cruz Foam SD

MAKE IT SMARTER AT PACK EXPO 2023

BOOTH C-5033

PRIMARY

CASEPACKING

TRAYPACKING

CARTONING PALLETIZING

PRIMARY

CASEPACKING

TRAYPACKING

CARTONING PALLETIZING

PMMI partners with Festo Didactic

Workforce development effort aims to close STEM skills gap.

Apartnership between PMMI, The Association for Packaging and Processing Technologies (Central Lobby), and Festo Didactic North America, a subsidiary of Festo (Booth SL-6160), seeks to support PMMI members and educators nationwide with advanced technical education, hands-on training and certifications to close the STEM skills gap. Together, the two organizations bring highly customizable training options to packaging and processing companies.

“Packaging and processing is a uniquely innovative industry, with endless career opportunities—but we are seeing the skills gap continue to grow. This collaboration presents a significant opportunity to provide critical resources to PMMI members and educators who need support to meet the technical workforce needs of the industry,” says Stephan Girard, senior director of Workforce Development, PMMI.

MECHATRONICS CERTIFICATIONS

Manufacturing employers need skilled workers who can operate, maintain and troubleshoot equipment. To achieve this, employees must have the right mechatronics skills. The PMMI Mechatronics

Certification program helps educational institutions create industrial maintenance programs that align with the technical needs of manufacturers and prepare students for careers in advanced manufacturing. Through a series of online tests based on industry-developed skill standards, PMMI’s Mechatronics Certification program helps employers assess the core skills of prospective and current workers.

Festo Didactic, an education company with deep roots in manufacturing automation, offers lab equipment and educational content aligned with PMMI’s Mechatronics Certifications. This provides a turnkey solution for high schools, colleges and universities looking to provide mechatronics training that meets the needs of the industry. Festo’s factory automation learning systems simulate the most technically advanced processing plants, focusing first on individual stations with the option to scale to more complex Industry 4.0 cyber-physical systems.

CUSTOMIZED TRAINING

The customized curriculum and hands-on training offer a wide range of topics and skills related to mechatronics and factory automation such as robotics, CAD/

CAM/CNC and PLC.

Benefits for industry:

• Improve workforce readiness

• Upskill employees quickly

• Reduce turnover

• Close skills gap with continued learning and professional-development courses

• Highest-quality industry standards.

“As a long-standing member of PMMI, with similar goals and approaches to workforce development, stepping into the role of Preferred Technical Learning Collaborator is a natural fit,” says John Holmes, vice president of Sales for Festo North America. “This partnership was forged in response to the industry’s ongoing hiring and upskilling challenges, and we’re eager to see how our combined expertise and resources positively impact the schools and companies PMMI serves.”

Tony Oran, vice president of Festo Didactic North America, concludes, “We’re committed to setting people up for success in their careers as individuals while looking for smart ways to come together so industry can thrive as a whole.”

For more info, visit PMMI.org, festo.com. SD

Wherever you are and whatever your industry, there’s a PACK EXPO event to provide solutions you need today and the inspiration for tomorrow.

March 18-20, 2024

Philadelphia, USA

June 4-7, 2024

Mexico City, Mex.

Nov. 3-6, 2024

Chicago, USA

March

June

Sept.

Partners bring knowledge to show Partner

Program links attendees to wide array of organizations.

Approximately 30 organizations are partnering with show organizer PMMI, The Association for Packaging and Processing Technologies (Central Lobby), for PACK EXPO Las Vegas, connecting attendees to leading associations from all segments of packaging and processing.

“The Partner Program is one reason why PACK EXPO Las Vegas is the most comprehensive packaging and processing event in North America in 2023,” says Jim Pittas, president & CEO, PMMI. “These organizations bring targeted knowledge to the show floor and give attendees actionable information to improve their operations.”

Participants in the PACK EXPO Partner Program exhibit in the Partner Pavilion or elsewhere on the show floor.

New this year, the PACK EXPO Las Vegas Partner Plus Program gives groups the opportunity to present sessions on the Industry Speaks Stage (Booth C-1141) (see schedule, p. 24) or to co-locate meetings with the show under the banner, Industry Meets. For example, the Cold Pressure Council (Booth C-1153) has scheduled its Annual Conference on Tuesday, Sept. 12, 2023, at the Las Vegas Convention Center and a Board of Directors meeting the next day. Other Industry Meets participants include: the International Bottled Water Association (offsite);

MHI Automation Industry Groups; Composite Can & Tube Institute (Booth C-1350); Contract Packaging Association (Booth C-1256); Institute of Packaging Professionals (Booth C-1154); and OMAC - The Organization for Machine Automation and Control (Booth C-1255). The latter plans a public General Session and a Workgroup meeting at 10:00 a.m. and 11:00 a.m., respectively, on Tuesday, Sept. 12.

The Industry Speaks Stage, another first for PACK EXPO Las Vegas, offers an opportunity to hear experts representing Partner Program participants discuss hot topics and trends including automation, high-pressure pasteurization, digital transformation, contract manufacturing/packaging, flexible packaging, modern warehousing and logistics, machinery standards and sustainability.

“As part of the PACK EXPO Partner Program, we are looking forward to seeing our members and meeting potential members while talking to brand owners, packaging designers, label printers, molders and others who are learning more about the advantages of in-mold labeling and decorating technology,” says Dianna Brodine, managing director at the In-Mold Decorating Association (Booth C-1347). “In addition, we are releasing white papers about the sustainability and recyclability of in-mold labeling/dec-

INDUSTRY MEETS

Cold Pressure Council (Booth C-1153)

Composite Can & Tube Institute (Booth C-1350)

Contract Packaging Association (Booth C-1256)

Institute of Packaging Professionals (Booth C-1154)

International Bottled Water Association

MHI Automation Industry Groups

OMAC - The Organization for Machine Automation and Control (Booth C-1255)

orating processes and presenting an Industry Speaks session on the subject [4:30 p.m., Monday, Sept. 11].”

For up-to-date schedules and Partner Program Pavilion details, check the PACK EXPO Las Vegas mobile App, sponsored by ProMach (Booth C-3222), or the show website.

For more info, visit packexpolasvegas.com, promach.com. SD

PARTNER PROGRAM PARTICIPANTS

3-A Sanitary Standards (Booth C-1353)

AIM (Booth SU-8306)

AMERIPEN (Booth C-1151)

Anuga FoodTec Family (Booth C-1158)

ASD Turkish Packaging Manufacturers (Booth C-1145)

Association for Roll-to-Roll Converters (Booth C-1351)

Association of Plastic Recyclers (Booth C-1157)

Australian Packaging and Processing Machinery Association (Booth C-1150)

CANAINCA

Cold Pressure Council (Booth C-1153)

Composite Can and Tube Institute (Booth C-1350)

Consumer Brands Association (Booth C-1248)

Contract Packaging Association (Booth C-1256)

Flexible Packaging Association* (Booth C-1348)

Foil & Specialty Effects Association* (Booth C-1346)

Foundation for Supply Solutions (Booth C-1152)

International Bottled Water Association

In-Mold Decorating Association* (Booth C-1347)

Institute of Packaging Professionals* (Booth C-1154)

Instituto Argentino del Envase (Booth SU-8135)

International Society of Beverage Technologists (Booth C-1354)

MHI Automation Industry Groups

National Confectioner’s Association (Booth SU-7201)

OMAC – The Organization for Machine Automation and Control (Booth C-1255)

OPC Foundation (Booth C-1250)

PLCopen (Booth C-1253)

Reusable Packaging Association* (Booth SU-8000)

SNAC International (Booth C-1146)

The Tube Council of North America*

UCIMA – Italian Packaging Machinery Manufacturers Association (Booth C-1149)

U.S. Department of Commerce (Booth C-1159)

World Packaging Organisation* (Booth C-1246)

SEPTEMBER 13, 2023

Showcase displays award winners

Visit The Showcase of Packaging Innovations®, sponsored by WestRock.

The Showcase of Packaging Innovations® (Booth N-9550), sponsored exclusively by WestRock (Booth C-2023), features award-winning packages from competitions around the world.

“The Showcase of Packaging Innovations is a traditional and treasured component of PACK EXPO,” says Jim Pittas, president & CEO of PMMI, The Association for Packaging and Processing Technologies (Central Lobby), the show organizer. “We are most grateful to WestRock for sponsoring this facet of the show once again. Being able to view an array of innovative packaging in one place is inspiring and gives attendees ideas to take home and adopt to make their packaging more environmentally-friendly and consumer-friendly.”

Ten organizations are participating in this year‘s

Showcase, which is located in the North Hall straddling the boundary between the Containers and Materials Pavlion and the PACKage Printing Pavilion.

Sustainability plays a role in many of the award winners. A judge for the Flexible Packaging Association competition, Gary Borges, associate professor, University of Wisconsin-Stout, explains, “Sustainability is growing tremendously . . . Post-consumer recycling is a trend that we saw. And we’re seeing an increase in paper structures that . . . we can send to our paper waste streams at home. So, we’re seeing all of these innovations taking place. It is pretty impressive.”

For more info, visit packexpolasvegas.com, westrock. com, dow.com, flexpack.org, fsea.com, imdassociation. com, iopp.org, profoodworld.com, reusables.org, tube.org, worldpackaging.org. SD

At the Flexible Packaging Association, the RESCUE!® Outdoor Disposable Fly Trap earned the Highest Achievement Award. It also won a Packaging Excellence Gold Award, a Technical Innovation Silver Award and an Expanding the Use of Flexible Packaging Award. The flexible packaging, produced by Glenroy for Sterling International, is easy to use: Cut along the dotted line at the top to expose the trap entrance, add water and hang. The pouch construction protects the consumer from the powerful attractant inside. Once the trap is full (collecting up to 20,000 flies), the consumer simply discards it.

In the ninth annual Sustainability Excellence in Manufacturing Awards, organized by ProFood World, a PMMI Media Group (Central Lobby) publication, First Place in the Program Category honors a certified carbon-neutral brand made in a zero-waste Conagra Brands facility in Fayetteville, AR.

PARTICIPANTS

Dow (Room S-116)

Dow Packaging Innovation Awards

Flexible Packaging Association (Booth C-1348)

Foil and Specialty Effects Association (Booth C-1346)

In-Mold Decorating Association (Booth C-1347)

Institute of Packaging Professionals (Booth C-1154)

ProFood World (Central Lobby)

Sustainability Excellence in Manufacturing Awards

Reusable Packaging Association (Booth SU-8000)

The Tube Council of North Ameria WestRock (Booth C-2023)

World Packaging Organisation (Booth C-1246)

In a competition sponsored by the In-Mold Decorating Association, label supplier MCC Verstraete and molder Jokey Group were honored with the Best In-Mold Label Award for an interactive in-mold label with a digital watermark. Designed for De Dames van Akkkerlust, a new ice cream brand, the intelligent feature adds value in the packaging journey—from tracking and authenticating products to boosting customer engagement to digitally sorting the package for recycling. The sustainable packaging is designed to reflect the nature of the ice cream, which is made on a sustainable farm from 100% organic milk.

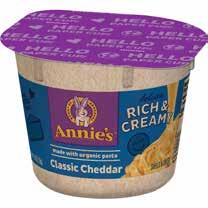

The Best of Show Award in the 2023 AmeriStar competition, sponsored by the Institute of Packaging Professionals, revolutionizes single-use packaging with a focus on sustainability and consumer satisfaction. Annie’s certified industrially-ompostable molded fiber cup offers functionality equal to a plastic thermoform and broadens the use of molded fiber into shelf-stable products. The packaging offers a 45% reduction in carbon footprint and is direct-printed via a flexographic process. A spray coating made from a renewable formula offers grease and water protection. Improved convenience and warmth retention enhance the consumer experience. The package also won an AmeriStar Award in the Sustainable Packaging category.

The top prize in the Dow Packaging Innovation Awards, the Diamond Award, went to Procter & Gamble for its G ECOCLIC® box for liquid laundry capsules. The patent-pending cardboard packaging scores for sustainability and child safety. The carton consists of FSC-certified materials with a minimum of 70% recycled fibers, and its dimensions and design fit 50% more packs per pallet. The certified child-resistant design also is easy to open even for people with dexterity limitations and sight or cognitive impairments. A reassuringly loud ‘one click’ closure signals the pack is closed.

IMA creates eCommerce division

E-CO Flex machine right-sizes boxes, conserves corrugated.

Anew division established by the parent company of IMA NorthAmerica (Booth C-3200, C-3400) serves the increasing demand for online shopping with technologies to automate the packaging process.

The first model in the IMA E-COMMERCE line, the E-CO Flex machine, simplifies e-fulfillment packaging by connecting to the end user’s warehouse management system and selecting the best fit-to-size box for the products to be packed.

Once the most suitable box is identified, the blank is automatically picked from the magazine, erected and bottom-sealed using water-activated tape. Tape is applied on an integrated, proprietary water-activated tape dispenser from Intertape Polymer Group, which serves as the exclusive distributor of the E-CO Flex machine in the U.S. and Canada.

The pre-assembled container is presented to the operator, who simply inserts the items to be shipped and secures them with the required amount of dunnage. The operator reinserts the open-faced box into the machine where the remaining void is measured. If necessary, the E-CO Flex machine is capable of automatically reducing the height of the box and then closing it, adapting flap-folding to the new box dimensions.

Automated packaging solutions, such as the E-CO Flex machine with right-sizing capabilities, allow e-tailers to combine multiple stations into one unit. By reducing the cubic footage of cases to a minimum, dimensional (DIM) weight pricing can be safely implemented, resulting in reduced material usage. This can reduce corrugate consumption while eliminating the need for void fill in compliance with the latest sustainability policies adopted by IMA Group.

For more info, visit ima.it. SD

Editor’s Note: The original version of this article was posted on March 20, 2023 by Packaging World.

Industry Speaks Stage features PACK EXPO Partners

Anewcomer to the free educational programming at PACK EXPO, the Industry Speaks Stage (Booth C-1141), located in the Central Hall, draws experts from the PACK EXPO Partner Program, which includes various technical and industry groups.

The 30-min. presentations focus on topics such as automation, standards, developments in high-pressure processing, sustainability, flexible packaging, contract manufacturing/packaging, warehouse automation, in-mold labeling/ decorating, metallic labels/cartons, automatic identification and data capture, beverages and snack food.

THE PACKAGING POLICY PRECIPICE— CHALLENGES

OR OPPORTUNITIES

10:30-11:00 AM

The U.S. remains at a critical precipice on packaging and environment policy with significant new laws continuing to be passed and implemented on packaging producer responsibility, labeling, recycled-content mandates and more. Join a fast-paced discussion about what’s happening and how to engage with the ensuing challenges and opportunities.

Dan Felton Exec Dir AMERIPENSession descriptions, times and locations are listed below. Updated schedules may be found on the show website or via the show App, sponsored by ProMach (Booth C-3222)

Other free educational opportunities on the show floor include the new Sustainability Stage (Booth N-9967) (see schedule, p. 16), the Innovation Stage (Booths C-2051, C-2058, C-2151)/Processing Innovation Stage (Booth N-10511) (see schedule, p. 30), plus The Forum — An Industry Knowledge Exchange (Booth C-2158) (see schedule, p. 58). Schedule as of August 23, 2023.

For more info, visit packexpolasvegas.com. SD

WEDNESDAY, SEPTEMBER 13, 2023

SUSTAINABILITY INTO PACKAGING AND PROCESSING MACHINERY

11:30-12:00 PM

Examine the global and regional perspectives of sustainability and circular design, showcasing initiatives, programs, regulations and roadmaps from Italian packaging machinery manufacturers.

Riccardo Cavanna

Pres

UCIMA - Italian Packaging Machinery Manufacturers’ Association

PMMI adds 47 members

all are exhibiting at PACK EXPO Las Vegas.

PMMI, The Association for Packaging and Processing Technologies (Central Lobby), continues to grow, with the acceptance of 47 new members at its Spring Board of Directors Meeting. The ongoing expansion of PMMI’s membership reflects the trust and confidence that packaging and processing companies have in the association’s resources, networking opportunities and industry expertise.

NEW GENERAL MEMBERS

Advanced Equipment (Booth N-10537)

AGC Heat Transfer (Booth N-10516)

American-Newlong (Booth SU-8046)

CMES Robotics (Booth N-9925)

DCC Automation (Booth SL-6269)

Dispac

Husky Technologies

Kinematics & Controls

Material Transfer and Storage (Booth N-10546)

Matiss (Booth SL-5869)

MXD Process (Booth N-10530)

Pennsylvania Scale (Booth SU-8275)

PSnC/Avanti (Booth SL-6669)

Robotiq (Booth SL-6870)

Silgan

Tronics America (Booth N-9709)

Vecoplan (Booth SU-8281)

WHAT CAN THE ISBT OFFER THE BEVERAGE INDUSTRY PROFESSIONAL?

12:30-1:00 PM

The vision of the International Society of Beverage Technologies (ISBT) is to be the premier global beverage industry technical association, which drives sustainable growth, resolves challenges and leads productivity innovations. ISBT offers the global industry a platform to network and help the industry thrive. Come learn what this 75-year-old society offers its members and their companies in a global format.

Ron PuvakMktg Committee Chair

Int’l Society of Beverage Technologists SD

“We are thrilled to welcome these new members to our community,” says Andrew Dougherty, vice president of Member Services at PMMI. “As the industry continues to evolve and grow rapidly, so does PMMI. And we remain committed to providing the resources our members need to thrive and succeed.” Newcomers include General, Associate, Affiliated Supplier, Component Supplier and Material Supplier members.

NEW ASSOCIATE MEMBERS

American Sleeve Technology (Booth C-5530)

Bairespack USA

Boix Machinery USA (Booth SU-7280)

Canon USA (Booth N-9736)

Elopak (Booth N-9359)

Epson America (Booth SL-6664)

INNOVA GROUP (Booth SL-5903)

Keyence Corporation of America (Booth N-9745)

Sanko Kikai (Booth SL-6550)

Tecma Aries America (Booth SU-7448)

NEW AFFILIATED SUPPLIER MEMBERS

BEXP USA (Booth SL-6529)

Holt Logistics

Mingo (Booth SU-8450)

New Age Industrial (Booth N-9441, SL-6830)

NorthWind Technical Services (Booth N-10733)

POWER Engineers (Booth SU-7236)

SafetyChain Software (Booth N-10451)

Sigma Robotics

Sneed Coding Solutions (Booth N-9530)

NEW COMPONENT SUPPLIER MEMBERS

Bihl + Wiedemann (Booth SL-6029)

nVent - Hoffman

SEW-EURODRIVE (Booth N-10371, N-10453)

VtecUSA (Booth SL-6848)

NEW MATERIAL SUPPLIER MEMBERS

Chicago Tag & Label (Booth N-9817)

ePac Flexibles

Industrias Tuk / HyStik (Booth SL-6463)

Jadex (Booth SL-6835)

Metsä Board (Booth N-9216)

TigerPress (Booth N-9844)

Vibac Americas (Booth N-11231)

For more info, visit pmmi.org. SD

Nearly

NEVER BEEN SO EASY

SEE US AT BOOTH SU-7412

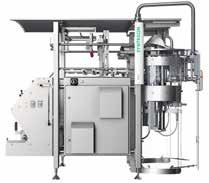

TOTALLY AMERICAN WITH AN ITALIAN HEART

Ronchi America proudly presents the SIRIO/S capper, built in Atlanta, GA. This SIRIO/S capper includes all of the Ronchi features and is FAT ready within 12 weeks or less. The SIRIO/S capper is also capable of being synchronized with the US built Ronchi EXACTA/R 18 filler.

Integrated systems run on show floor

Tabletop vertical form/fill/seal machine debuts.

Demonstrations at Paxiom Automation (Booth C-5006) include integrated systems for filling cannabis flower and edibles, packaging vitamin gummies, and horizontal flow wrapping using equipment from subsidiaries, WeighPack Systems, ValTara and Canapa Solutions. Attendees also may view WeighPack’s newest VersaPak™ vertical form/fill/seal (V/F/F/S) machine.

The line from Canapa by Paxiom, a specialist in cannabis packaging systems, fills flowers or edibles into jars. This turnkey operation includes the NTEP-certified PrimoCombi weigh filler, NTEP-certified Pre-CheQ weight analyzer, jar filling conveyor, KAPR rotary chuck style capper, LBLR adhesive label applicator and automatic unscrambling and accumulation rotary tables.

third party traceability software. Simple, compact and easy to use with intuitive controls and a streamlined interface, operators quickly become proficient, reducing training time and maximizing productivity.

Vitamin gummies are being packaged on a PrimoCombi® count-by-weight filler from WeighPack integrated with a high speed SpinDexer® rotary bottle filler. The integrated system can accommodate gelatin or pectin gummies as well as sanded, sugared, oiled and waxed formats. The filler design allows for sticky gummies to be filled into narrow-neck containers by eliminating bridging and ensuring optimal bottle transfer from each traveling funnel.

The SpinDexer rotary bottle filler is available in several models including its base model, rated at up to 60 bottles/min., its HS model for high-speed applications up to 150 bottles/min. and its XL model for large-format club sizes.

In the PKR™-Scara robot demo, the robot picks and places products directly onto the SleekWrapper F65 horizontal flow wrapper. Offering an immediate ROI, this pick-and-place system replaces up to three people hand loading.

The PKR-Scara robot can be integrated into any new SleekWrapper from ValTara or any third-party flow-wrapping machine in the field or in-house. Standard features include integrated infeed and out-

feed conveyors, robust stainless-steel frame and easyto-program parameters with recipe recall. The robot, vision guidance and PLC controls with color touchscreen are based on technology from OMRON.

Engineered to fill grams, eighths and ounces, this system features complete stainless-steel construction, includes free online support via digital cameras and a full production suite of reporting that integrates with

An OMRON PLC also controls WeighPack’s newest and most compact VersaPak™ V/F/F/S machine. With its small footprint, the unit can sit on a tabletop or floor stand and is well-suited for businesses with limited space as well as schools, hospitals, kitchens and homes. Easily integrated into existing packaging processes, the automatic bagging system uses non-proprietary rollstock. Producing up to 20 packages/min., the VersaPak machine can fill pouches from 2–8 in. (50–200mm) wide. Standard features include large color touchscreen, bag-forming collar with tube, recipe recall and automatic bag length adjustment. Applications include eCommerce, hardware, food and home goods.

For more info, visit paxiom.com, canapasolutions.com, valtaratec.com, weighpack.com. SD

ATS serves dairy and food industries

Anthony Subryan, general manager and CEO at Brampton, Ontario-based ATS Engineering (Booth SL-6238), talks with the PACK EXPO Show Daily (SD) about the state of the industry and what drives his company to excel at designing and manufacturing packaging machinery.

SD: What is impacting the industry today?

Subryan: The pace of packaging and product development has increased to a level never seen before in the food and dairy industry. New filling technology is being driven by the variety of new styles of containers that our customers are bringing to market. To be more competitive and stand out on the shelf, the variation of container shapes being produced keeps changing. This drives us to continuously innovate in order to fill, seal and overcap these unique container geometries in the most efficient manner possible. ATS Engineering has a long history of innovation in building filling machines for our dairy customers.

SD: How important is flexibility?

Subryan: In addition to designing for innovative new packaging, the machinery we build needs to be flexible. When a customer runs an assortment of containers, the machinery needs to have a fast and efficient changeover system. ATS has always designed this into every machine. Uptime is critical, so

less time spent swapping parts and preparing for the next product is extremely valuable.

The speed and efficiency of our fillers is paramount. By keeping downtime to an absolute minimum, our customers get maximum throughput. Speed is not the only thing that maximizes production. Customers are always aiming for the greatest efficiencies on their plant floors, so having a machine that is adaptable to a number of container styles and/ or product variations is the best investment for them.

SD: How does ATS address the need for hygienic equipment?

Subryan: One of ATS’ key goals as a machinery manufacturer is to design fillers that have no place for bacteria to hide when the machines are properly washed down and sanitized. This is achieved with the highest-quality grades of stainless steel, as well as all electrical and electronic components, to ensure that everything mechanical and electrical on our machines can operate without failure in these kinds of harsh sanitizing conditions.

Every ATS machine exceeds USDA, FDA and 3-A Sanitary Standards.

Flexible Automation TO IMPROVE YOUR THROUGHPUT SOLUTIONS

SD: How does ATS collaborate with customers?

Subryan: Working closely with customers from the start of each machine’s design has helped ATS design the optimal systems for clients’ facilities and budgets. No matter what the next development in dairy packaging is, ATS will be there, developing high-speed, flexible machinery that delivers superb results for our customers.

For more info, visit atseng.ca. SD

Product portfolio includes fillers, sealers and overcappers.Hygienic rotary and straight-line machines fill liquid or viscous food products, seal containers and then apply overcaps.

Tetra Pak works toward circularity

Recycling efforts send fewer cartons to

Prior to Earth Day 2023, Tetra Pak (Booth C-4340) unveiled recycling initiatives that are helping to turn all components of a used carton package into quality materials and goods. These initiatives are part of the investments the

landfill.

company has been making for decades to support collection and recycling infrastructure across the world and grow the number of recycling operations handling cartons worldwide from 40 in 2010 to more than 200 today.

According to the World Bank, global waste will increase 70% by 2050, unless immediate and significant action is taken. Despite its essential role in feeding a growing global population, food packaging can add to the issue if not properly collected and recycled. Tetra Pak’s recent collaborations are focused on creating recycling capacity, increasing collection rates and ensuring that materials from post-consumer beverage cartons can re-enter the economy.

Markus Pfanner, vice president Sustainability Operations at Tetra Pak, emphasizes that building a circular economy requires system-wide action and cooperation, supported by a regulatory framework that creates the conditions to turn challenges into opportunities. “We need to move away from a linear ‘take-make-waste’ model toward a more connected circular economy,” Pfanner comments. “But being part of a circular solution can’t be driven single-handedly by one individual or entity. Scientists, policy makers, recyclers and industry players and citizens must work together.”

Thank

Academic scholarships to students pursuing careers in the industry.

Summer Manufacturing Camps

To educate and inspire the future manufacturing workforce.

Financial assistance for educational programs

such as FIRST robotics teams and curriculum development at local colleges and universities.

and more…

In 2022, Tetra Pak invested nearly €30 million ($33.3 million) into projects worldwide, with plans to invest up to €40 million ($44.5 million) annually in coming years. As part of the Alliance for Beverage Cartons and the Environment, the company supports the industry ambition to increase the collection of beverage cartons for recycling to 90% and the recycling rate to 70% in the E.U. by 2030.

The company’s goals also include realizing the national recyclability criteria for its packages in all countries where it operates and fulfilling the Ellen MacArthur Foundation’s Global Commitment, a common vision of a circular economy for plastics.

“Three principles are guiding our circularity agenda: designing out waste and pollution; keeping products and materials in use; and regenerating natural systems,” adds Christine Levêque, vice president Collection and Recycling at Tetra Pak. “These initiatives showcase how innovation and a clear drive to change the status quo are key to keeping quality materials in circulation and minimizing the use of new ones. None of these developments could be realized without our 70 experts around the globe, who are collaborating every day with recyclers, local authorities and food and beverage manufacturers to drive the transformation needed to scale up collection and recycling.”

For more info, visit tetrapak.com. SD

Editor’s Note: The original version of this article was posted by Packaging World on April 5, 2023.

According to the World Bank, global waste will increase 70% by 2050, unless immediate and significant action is taken.

Lenze sponsors lounges

Once again, Lenze Americas (Booth C-4803) is sponsoring lounges for exhibitors and PMMI members at PACK EXPO Las Vegas. The lounges provide meeting space, seating, refreshments and a chance to take a break away from the busy show floor.

The Exhibitor Lounges are located in rooms S-215 and N-114. The two PMMI Member Lounges are located in rooms S-222 and N-101.

“Lenze Americas understands the significance of providing members and exhibitors with a dedicated space to rejuvenate amidst networking with attend ees at their booths. We take pride in our continued sponsorship of these lounges this year,” says Paul O’Connor, Lenze Americas.

“We are grateful to Lenze Americas for support ing this resource again,” says Jim Pittas, president & CEO, Processing Technologies (Central Lobby) nizer of the PACK EXPO family of trade shows.

Future Innovators

SHOWCASE

Students demo self-built robots

Robotics teams from Las Vegas-area high schools are demonstrating the robots they have built along with design, engineering, assembly and troubleshooting skills at The Future Innovators - Robotics Showcase (Booth N-9769), sponsored by Bastian Solutions (Booth N-10343)

Come see Vegas-area high school students showcase their “bot skills”. Interact with the bright minds of the future and ask questions about their innovative robot designs.

He explains, “This year’s industry growth and numerous new features at PACK EXPO Las Vegas will make the show floor incredibly busy. As a result, these lounges will be highly sought after by exhibitors and PMMI members as a valuable space to relax and network.”

The respite space will be especially welcome this year as the PACK EXPO Las Vegas show floor is expected to be extra busy with 30,000 attendees touring nearly 1 million sq. ft. of floor space to visit more than 2,300 exhibitors.

For more info, visit packexpolasvegas.com, lenze.com. SD

MetsäBoard Pro FBB Bright is up to 35% lighter than conventional paperboards, while retaining the same quality and rigidity.

Located in the North Hall in Booth N-9769

Monday - Tuesday | 9:00 am - 5:00 pm

Wednesday | 9:00 am - 3:00 pm

Demos are scheduled throughout each day of the show. Stop by to see what these teams have built, watch their robot in action, ask questions and tell the students about career opportunities in manufacturing and engineering.

This annual event is designed to open doors for a new generation of packaging professionals and encourage participation in STEM studies. It’s one of many student-based activities at PACK EXPO Las Vegas, which also includes the winners of the 2022 PACK Challenge (Booth N-9026) from Waterford Union High School and the Amazing Packaging Race, which is sponsored by Emerson Discrete Automation (Booth SL-6107) and occurs on the final day of the show.

For more information about supporting student programs, visit the PMMI U booth at N-9000.

Produced by:

For more info, visit packexpolasvegas.com, bastiansolutions.com, emerson.com/en-us/industries/automation/ food-beverage. SD

THE ‘BOTS ARE TAKING OVER PACK EXPO Las Vegas!

Innovation Stages offer free educational sessions

The always-popular Innovation Stage program returns to PACK EXPO Las Vegas with four platforms: the Processing Innovation Stage (Booth N-10511) in the North Hall, plus three Innovation Stages (Booth C-2051, C-2058, C-2151) in the Central Hall. Exhibitors and subject matter experts will present more than 60, 30-min. sessions about the latest technology breakthroughs and best practices.

Topics range from automation, digitalization, artificial intelligence (AI) and cybersecurity to food

LEVERAGING DATA TO ENABLE CRITICAL SUPPORT FROM YOUR OEM

10:00–10:30 AM

Innovation Stage 2 | C-2151

In today’s challenging environment, it is becoming critical to leverage your OEMs for your operational success. How do we capture, organize and make data available outside manufacturing equipment to enable this much-needed support from machine builders? Let’s start with the basics: data-ready machines supporting performance management.

Steve MulderAmericas OEM Mgr

Rockwell Automation

HIGH-BARRIER RETORTABLE POLYPROPYLENE SOLUTIONS

10:00–10:30 AM

Innovation Stage 3 | C-2058

“Monomaterial packaging” is one of the buzzwords in the flexible packaging industry, since current multi-material packaging is not easy to recycle. PP GL Barrier film is a key component to make recyclable retort pouches.

Chris WardVP, Toppan Packaging Innovation Ctr

Toppan Group

THE JOURNEY TOWARD SUSTAINABLE PACKAGING WITH ONEBARRIER

10:00–10:30 AM

Processing Innovation Stage | N-10511

The journey toward sustainable packaging progresses with oneBARRIER monomaterials, a family of recyclable polymer- or paper-based substrates.

Chris Marshall Area Sales Mgr BOBSTsafety, workforce challenges, sustainability and technology innovations. Highlights include sessions by WestRock (Booth C-2023) (sustainability), Syntegon Packaging Technology (Booth C-2800) (gloveless fill/finish), Siemens Digital Industries (Booth SL-6351) (digital twins), Delkor Systems (Booth C-3840) (robots), Soft Robotics (Booth N-10311) (AI-enabled food picking) and Metsä Board (Booth N-9216) (zero-waste packaging). Session descriptions, times and locations are listed on the following pages. Updated schedules may be

WEDNESDAY, SEPTEMBER 13, 2023

AI IS TRENDING, BUT FIRST YOU NEED GOOD DATA

10:30–11:00 AM

Innovation Stage 1 | C-2051

Before packaging operators look to artificial intelligence or machine learning to solve their most pressing problems, they need a strong product and packaging data foundation through digitized specifications.

Matthew Wright CEO & Founder Specright PACKAGING SUSTAINABILITY INTO YOUR LINE EFFICIENCY

11:00–11:30 AM

Innovation Stage 2 | C-2151

Industrial digital transformation enables new approaches to efficiency. Whereas traditional approaches break out production efficiency (measured in OEE) from energy management key performance indicators, a sustainability-oriented OEE integrates the two. Currently being tested, this approach offers significant promise in driving decarbonization.

Miguel Najerafound on the show website or via the show App, sponsored by ProMach (Booth C-3222).

Other free educational opportunities on the show floor include the new Sustainability Stage (Booth N-9967) (see schedule, p. 16), the new Industry Speaks Stage (Booth C-1141) (see schedule, p. 24) and another popular standby, The Forum—An Industry Knowledge Exchange (Booth C-2158) (see schedule, p. 58).

Schedule as of August 23, 2023.

For more info, visit packexpolasvegas.com. SD

WAREHOUSE AUTOMATION 2024 TRENDS AND INNOVATION

11:00–11:30 AM

Processing Innovation Stage | N-10511

2024 will be the year automation comes into its own. Warehouses are ready, the technology is falling into place, and all that’s left is for you to jump in and start benefiting. But, before making any investment, it’s good to know where we are today, and what’s coming.

Sriram Sridhar Chief Revenue OfficerAddverb

SUSTAINABILITY — WHAT DOES IT MEAN IN PACKAGING MATERIALS?

11:30–12:00 PM

Innovation Stage 1 | C-2051

Sustainability continues to be a hot topic. Understanding how materials can affect the sustainability curve is challenging and requires a holistic approach. Hear about new developments and improvements of materials specific to thermoforming and tray-sealed package design for food.

VP,

CPG Schneider ElectricTRANSPORT SYSTEMS EVOLVE, TAKE ON PICK-AND-PLACE FUNCTIONS

11:00–11:30 AM

Innovation Stage 3 | C-2058

An entirely new way to think about robotics relies on intelligent linear transport systems. Wireless movers can be equipped with powered end effectors that result in a low-profile, flat multi-robot system that’s fully embedded into packaging machinery instead of attached as a separate, standalone robot module.

Jeff JohnsonU.S. Mechatronics Product Mgr Beckhoff Automation

Gregg Poffenbarger

Business Unit Dir - Materials

Multivac

PACKAGING DESIGN AND QUALIFICATION FOR A CIRCULAR ECONOMY

12:00–12:30 PM

Innovation Stage 3 | C-2058

Address the impact consumer demand for sustainable products has had on CPG and retail. Get your roadmap to use Virtual Twin technology to accelerate sustainable and profitable packaging models to plan the circular logistical journey to develop and qualify packaging of the future.

Raymond WodarGlobal Dir, Business Consulting, CPG & Retail Industry

Dassault Systèmes

Wednesday, Sept. 13

THE PARTICIPANTS

Packaging and engineering students from across the country.

THE MISSION

Tour the PACK EXPO show floor, visit participating exhibitor booths and complete challenges.

THE GOAL

Learn about new technologies and interact with industry professionals, while earning points for packaging-related challenges. Members of the winning teams will receive cash prizes, courtesy of Emerson.

Brought to you by:

Sponsored by:

SEPTEMBER 13, 2023

WEDNESDAY, SEPTEMBER 13, 2023 (CONT’D)

DIGITAL READINESS: HOW TO UTILIZE THE RIGHT TECHNOLOGY

12:00–12:30 PM

Processing Innovation Stage | N-10511

The food and beverage industry has shifted focus to Cloud-based software. This shift has delivered decisive benefits as roughly 75% of food and beverage companies have seen key performance indicator improvements. Digital readiness is essential.

Jack Payne Solution Consulting Dir, Food & BeverageAptean

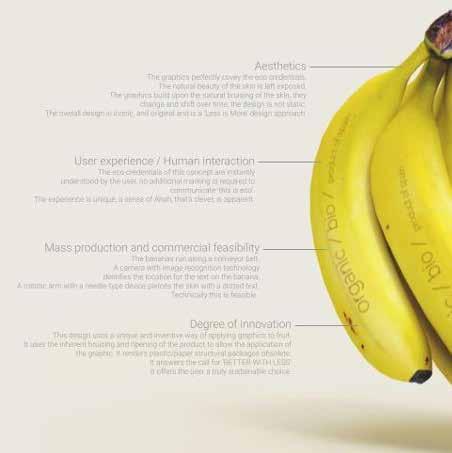

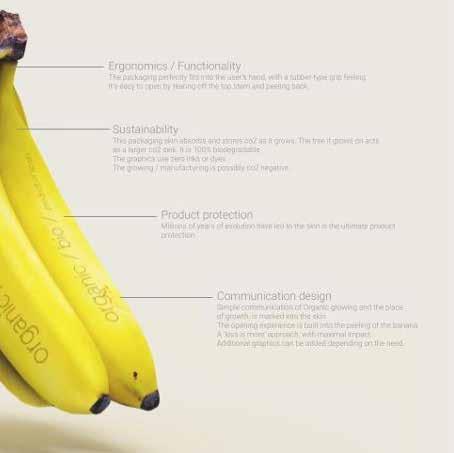

REDESIGN. REPURPOSE. REVOLUTIONIZE: INNOVATIONS FOR ZERO-WASTE PACKAGING

12:30–1:00 PM

Innovation Stage 1 | C-2051

The circular economy will soon guide all consumption. As the need for packaging grows, we must use design for easy recycling or purposeful re-use. Learn from winners in this year’s Better With Less—Design Challenge.

Nathan Pajka Sustainability Mgr Metsä Board SDBulk printhead prints wider areas

Preview the new high-speed HP 108mm bulk printhead at a demo at HP (Booth N-10054). Built to meet the future needs for coding and marking on secondary and latestage packaging, HP’s continued innovation of thermal inkjet (TIJ) technology is enabling highspeed, high-resolution print on wider swaths without the need for stitching, making production lines run seamlessly, faster and more efficiently.

Booth SL-6107

For more information, visit pmmi.org/pmmiu-packexpo

HP is showcasing its upcoming 108mm bulk printhead with Smart Servicing Solution that mitigates decap for optimal performance and uptime, which is ideal to address labor shortage issues. Bulk systems also significantly lower ink costs.

This innovative technology for TIJ not only allows companies to shift away from having to apply labels on packaging but also reduces cost and streamlines the production line by direct printing the outside of the case.

The HP 108mm bulk printhead also helps companies meet the ever-growing demands from consumers and regulators for greater sustainability by using water-based ink for low environmental impact and improved recyclability.

For HP Partners, the HP enabler kit ensures easy, hassle-free integration of the HP 108mm printhead.

For more info, visit hp.com/thermalinkjet. SD

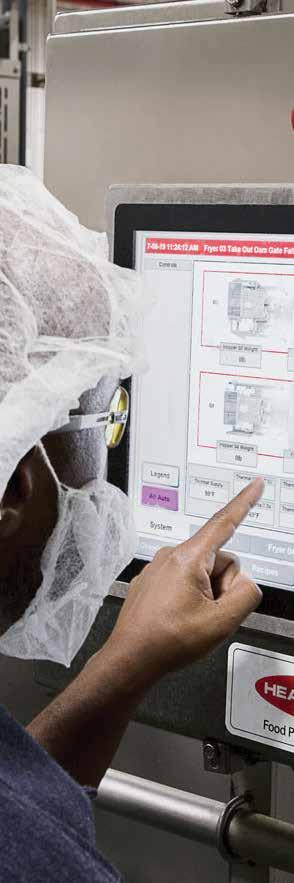

Heat and Control expands globally

New operations open in South Africa and Mexico.

To support customers in Africa, Mexico and Latin America, trol (Booth C-1623) has set up operations in South Africa and Mexico. With a long-established customer base in Africa, the new office in the Stikland, Bellville area of Cape Town, South Africa, confirms its commitment to the region and its customers in Africa, which include small, local food manufac turers as well as larger multinational companies.

Heat and Control South Africa designs, manufactures and supplies equip ment for a vast range of food-processing operations and represents industry partners such as Ishida, Ceia, Key Technology (Booth C-4225) Laboratories (Booth N-10241) in Africa.

The equipment helps end users achieve higher capacity, lower production costs, greater efficiency and improved product quality. Applications include value-added products such as meat, seafood, poultry, meat-alternative products, ready meals, fruits and vegetables, cereals and pet foods.

“In the last five years, we’ve expanded our personnel in this region by 50%, and we have a direct presence in Nairobi, Kenya, as well,” reports Heat and Control GM (Africa) Jeff Rossouw.

Heat and Control’s new location in Jalisco, Mexico, serves as the headquarters for its operations in Mexico and Latin America and significantly expands the company’s ability to serve new and existing customers.