ASEPTIC PROCESSING UNLOCKS SUSTAINABLE BENEFITS AT

Automation saves labor at Sazón Goya

Back to basics: understanding conveyors

When to choose a co-manufacturer

Automation saves labor at Sazón Goya

Back to basics: understanding conveyors

When to choose a co-manufacturer

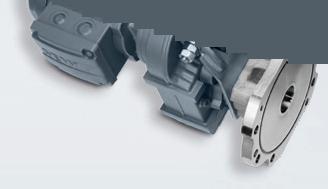

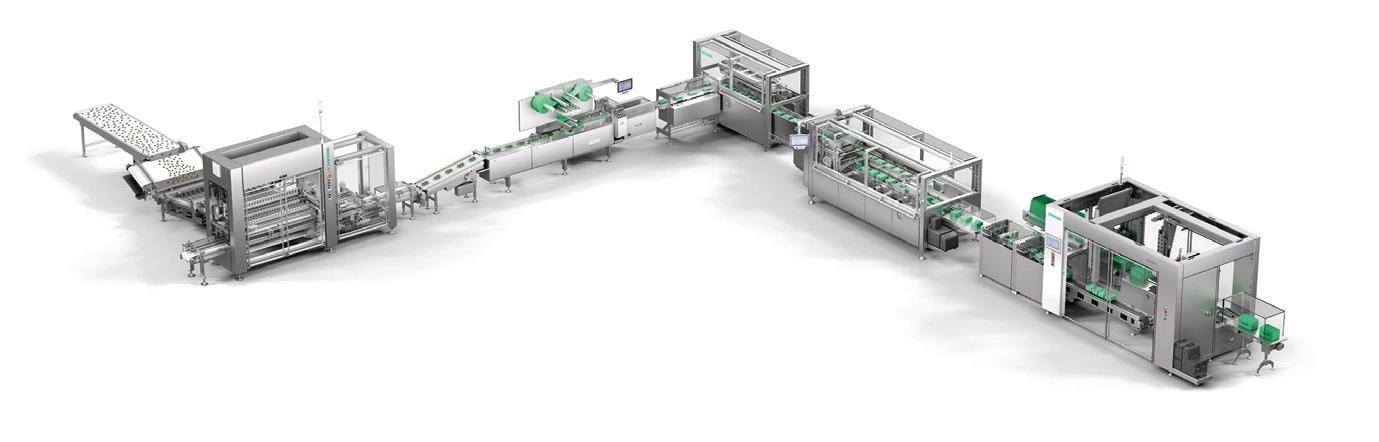

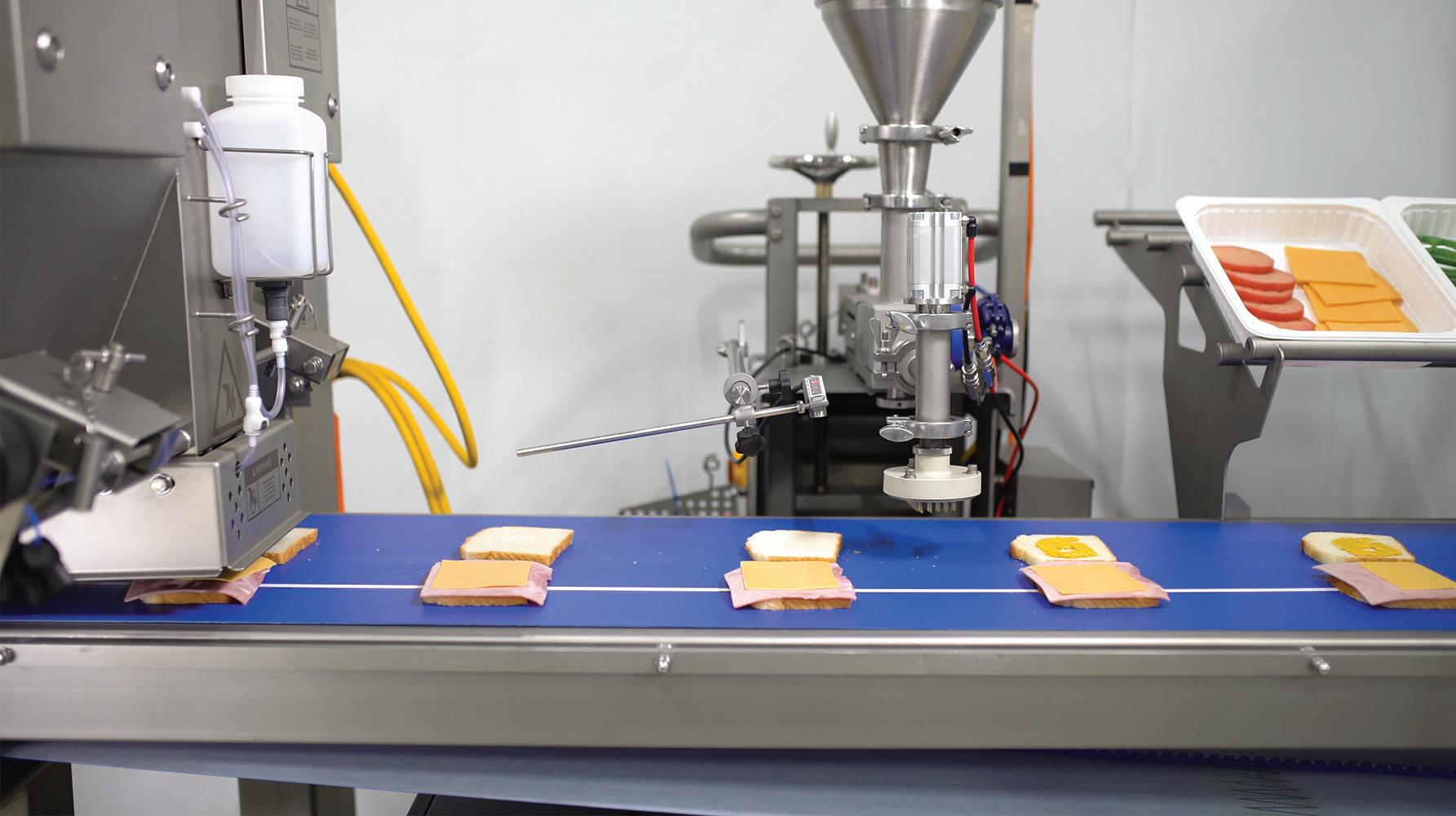

For high volume deli products, our fully automated One Line concept provides all the capacity and productivity you need in a relatively small footprint. It starts with our OptiSlicer which seamlessly connects to a scanner, loader and thermoformer. Designed to provide high levels of hygiene, the complete GEA line is easy to clean and maintain.

Our One Line concept adapts to each type of deli product processed, so each and every result is optimized. See the complete line at PACK EXPO International – Booth S-4166. GEA North America gea.com/unitedstates sales.northamerica@gea.com

06 From the Editor

Recalls are wake-up calls for the industry

09 In the News

Boar’s Head closes Virginia plant after deadly Listeria outbreak

The factors slowing AI adoption in processing

Five AI solutions currently helping food processors

18 OpX Intel

Why business plans fail and what you can do about it

25 Packaging Technology

Kraft Heinz Transitions to 100% rPET for condiments

New look for Chips Ahoy! packaging aims to increase shelf recognition

Stonyfield is First with All-PE Spouted Pouch

60 Dry Processing Products

62 Plant Floor Products

Aseptic Processing Unlocks Sustainable Benefits at Suntado

The vertically integrated contract manufacturer opened its greenfield plant in Idaho this year, with the latest technology for aseptic and ESL beverage processing, and an eye toward serving an international customer base.

43 Tech Today: Conveyors for Food Processing

Conveyors are the workhorses that keep food facilities moving, but some operations require specialized applications to succeed.

89 Contract or Self-Manufacturing? How to Choose

A processor’s goals can be the deciding factor for producing in-house or sending that work to a co-manufacturer.

55 Case Study: Sazón Goya

Goya’s Sazón brand reduced worker fatigue while elevating productivity by adding automated weigh batching systems.

73 Case Study: Sandwich King

A new depositor helped the U.K. brand solve workforce challenges while increasing output and reducing food waste.

77 Case Study: Rumiano Cheese

Employees used to hand-label cheese until a weigh price labeler was installed, elevating throughput and reducing labor.

81 Case Study: La Huerta

The company used to rely on manual vegetable inspection until it installed an optical sorter, decreasing labor and the volume of good product in its reject stream.

Pneumatically conveyed materials heat up, releasing moisture that can cause sweating on storage surfaces.

Xchanger has proven designs that will cool conveying air and eliminate the problem.

EDITOR-IN-CHIEF MICHAEL COSTA mcosta@pmmimediagroup.com

CONTRIBUTING WRITERS

MAURA KELLER, STEPHEN PERRY, STEPHEN SCHLEGEL, JAMIE VALENTI-JORDAN

ART DIRECTOR KATHY TRAVIS

CREATIVE DIRECTOR DAVID BACHO

VICE PRESIDENT, SALES JOHN SCHREI jschrei@pmmimediagroup.com • 248/613-8672

PUBLISHER PATRICK YOUNG pyoung@pmmimediagroup.com • 610/251-2579

ACCOUNT EXECUTIVE BRIAN J. GRONOWSKI bgronowski@pmmimediagroup.com 440/564-5920

SENIOR MANAGER, PRINT OPERATIONS LARA KRIEGER lkrieger@pmmimediagroup.com

FINANCIAL SERVICES MANAGER JANET FABIANO jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

PRESIDENT DAVID NEWCORN

VICE PRESIDENT, DIGITAL ELIZABETH KACHORIS

SENIOR DIRECTOR, MEDIA OPERATIONS KELLY GREEBY

Talk Directly with Design Engineers!

Talk Directly with Design Engineers!

n For Gases & Liquids Talk Directly with Design Engineers!

DIRECTOR, DIGITAL MEDIA JEN KREPELKA

DIRECTOR OF CONTENT KIM OVERSTREET

SENIOR DIRECTOR, EVENTS TREY SMITH

FOUNDING PARTNER AND EXECUTIVE VICE PRESIDENT, INDUSTRY OUTREACH, PMMI JOSEPH ANGEL

n

n Over 25,000 Units

n Over 25,000 Units

n

n 75 Countries

n 75 Countries

n 75 Countries

n 75 Countries

n Customize to your specs.

n Customize to your specs.

n Customize to your specs.

n Customize to your specs.

n 10 Std. Models.

n 10 Std. Models.

n 10 Std. Models.

n 10 Std. Models.

n

n For Gases & Liquids

n For Gases & Liquids

Processing Technologies 12930 Worldgate Drive, Suite 200, Herndon, VA 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org @ ProFoodWorld CONNECT WITH US @ProFoodWorld www.linkedin.com/ showcase/profoodworld

T F d, H l d N v b g g w ld’ d l gy b d d b w d d y x d g g x ll v lv g d d w ldw d .

’ v y ld l d, lly g d solutions – flexible, streamlined systems, backed by some of the best experts you’ll find anywhere. Please scan the QR code to find out what we can do for you.

PACK EXPO

3-6 N v b 2024 g , ll

Booth N5449

Sy Au

> Gabler > Shick Esteve

Booth N6124 M x v

> Coperion > Unifiller

> Peerless > Baker Perkins

MICHAEL COSTA | EDITOR-IN-CHIEF

As we go to press for this issue, Boar’s Head has decided to shutter its plant in Jarratt, Va., as the result of a Listeria outbreak linked to that facility and food produced there that has left nine people dead and hospitalized 57 so far.

You can read further details about this story on P. 9, but the USDA cites a list of food safety violations that, if you work in food processing, should make you double-check every part of your own operation to ensure nothing like this ever happens under your own roof, and by association, to your brand.

The number of recalls from food processors is not receding. I’m reminded of a conference I attended earlier this year where the topic of recalls came up during the audience Q&A. The speaker (an industry professional) dismissed the notable increase in recalls as a concoction of the media overplaying it, and overzealous government inspectors looking for every miniscule violation they can find.

This deflective approach to dealing with the critical questions that arise when a recall happens is not productive. Concerned companies might want to start by looking closely at their workforce. I have long thought that as the industry perpetually struggles to hire and retain employees, that standard operating procedures (SOPs) crucial to food safety can get lost.

Even if an inexperienced worker or new-hire has food safety training, are they dedicated enough to carry those rules out to the letter every day? Is a manager there to vigilantly oversee those procedures? Are maintenance technicians proactive enough to spot issues with machinery that can impact food safety before they become a problem?

I believe food safety begins with people, and that recalls aren’t a fantasy created by the media and government inspectors. Recalls are real, and at their worst, they can result in people dying, and your brand dying too.

Think today about what areas of your food safety program you can improve, and how you can ensure employees are executing your SOPs every day without cutting corners. This won’t just help your operation, but will help the industry as a whole by reducing the potential for future recalls.

EDITORIAL ADVISORY BOARD

CHRISTINE BENSE

CHIEF SUPPLY CHAIN OFFICER

Turkey Hill

GREG FLICKINGER

CHIEF EXECUTIVE OFFICER American Botanicals

JOHN HILKER

SENIOR VP, OPERATIONS Kite Hill

VINCE NASTI VP, OPERATIONS

Nation Pizza & Foods

JIM PRUNESTI VP, ENGINEERING Conagra Brands

LISA RATHBURN VP, ENGINEERING T. Marzetti

SCOTT SPENCER CEO

Quality Harvest Foods

TONY VANDENOEVER CONSULTANT, FOOD MANUFACTURING ENGINEERING Waterfall Ventures

DIANE WOLF FORMER VP, ENGINEERING AND OPERATIONS

Kraft Foods

BROOKE WYNN SENIOR DIRECTOR, SUSTAINABILITY

Smithfield Foods

mcosta@pmmimediagroup.com

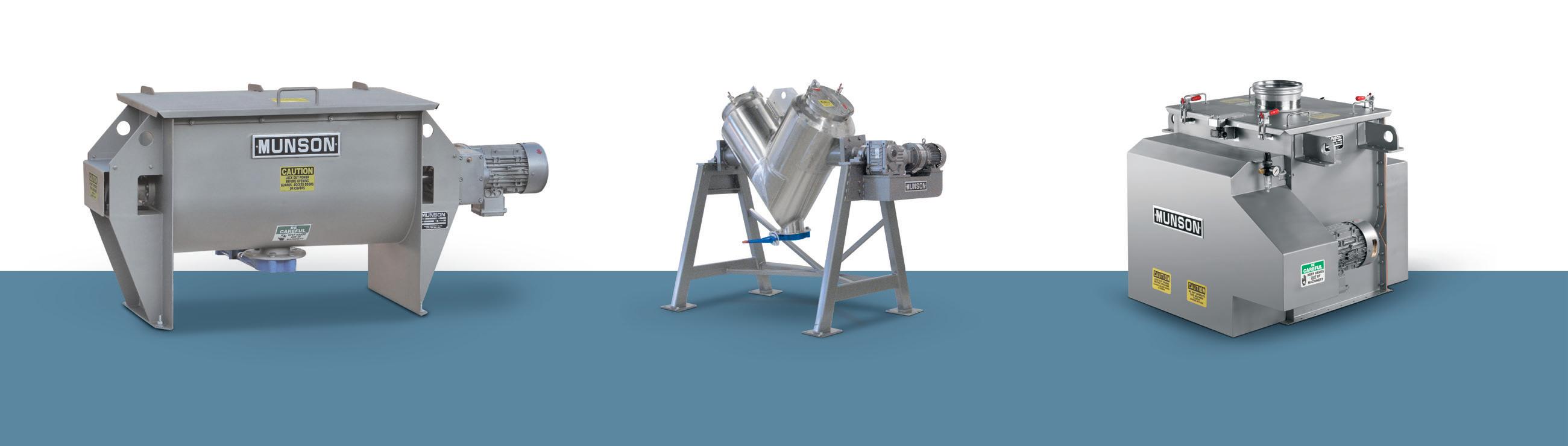

RIBBON/PADDLE/PLOW BLENDERS HANDLE POWDERS TO PASTES

Agitators forced through stationary materials impart shear needed to reduce agglomerates and blend pastes and slurries. Basic industrial units to state-of-the-art sanitary designs with heating/cooling jackets, liquid spray additions, and high-speed choppers/intensifiers. Capacities from 1 to 1,150 cu ft (.03 to 32 m3).

SANITIZE ULTRA-FAST, THOROUGHLY

Smooth internal surfaces free of baffles, shafts and bearings allow unobstructed material flow, plus complete discharge through a gate valve for rapid cleaning or sanitizing of the easy-access interior. Uniform blends are typically achieved in as little as 15 minutes with equal efficiency at fill volumes from 100% to 25% of capacity. Ideal for dry and granular materials.

n 100% Uniform blending and/or liquid additions in one to 2–1/2 minutes

n Total discharge with no segregation

n Ultra-gentle tumbling action (versus blades forced through batch)

n Ultra-low energy usage

n Equal efficiency from 100% to 15% of capacity

n No internal shaft or seals contacting material unlike other rotary mixers

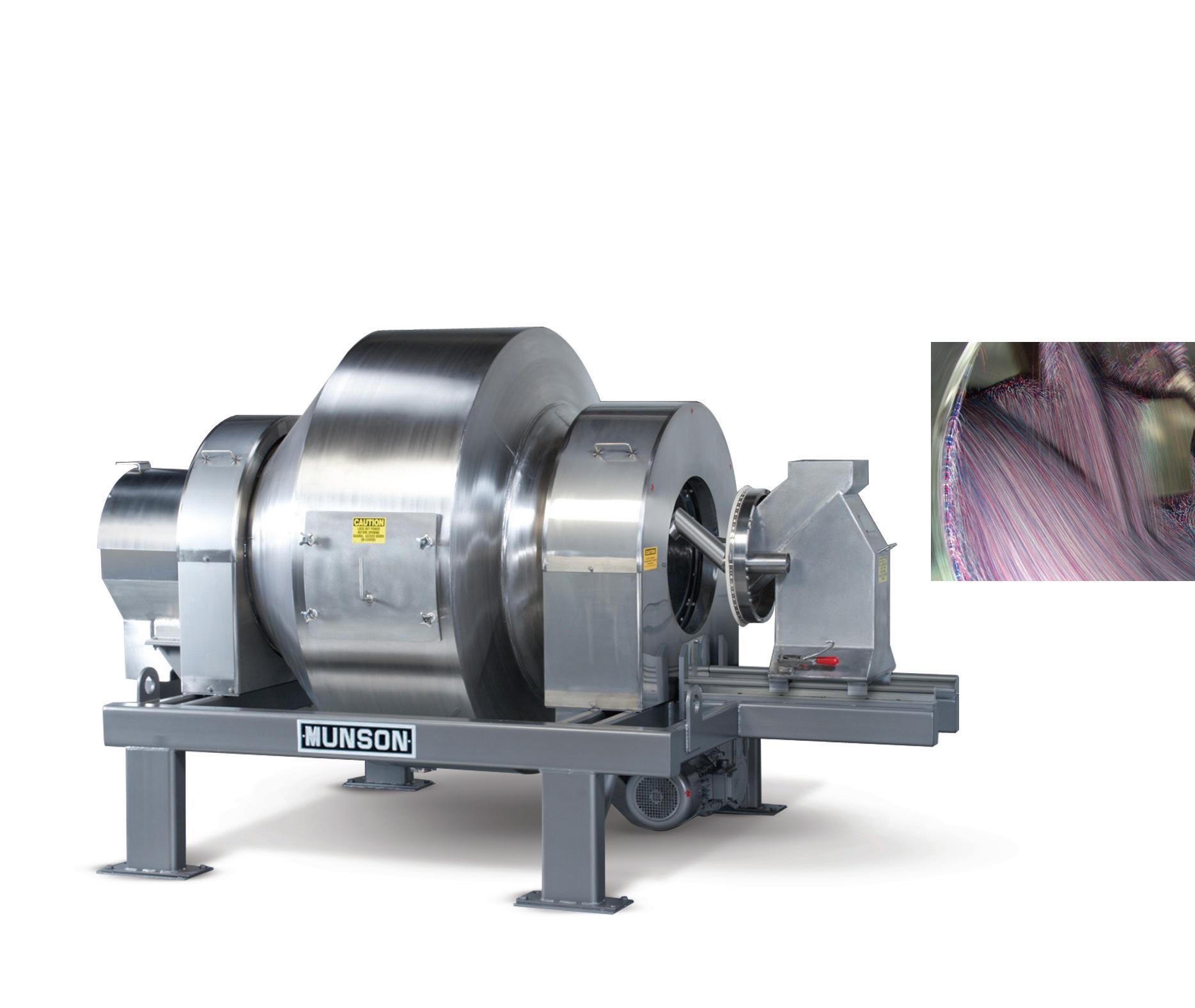

FLUIDIZED BED MIXERS BLEND ULTRA-FAST, GENTLY

MUNSON® Fluidized Bed Mixers feature two shafts with paddles that counter-rotate at high speeds to fluidize material, achieving homogeneous blends in 10 seconds to 2 minutes. Low shear forces minimize friction with little or no degradation and insignificant heat generation. Drop-bottom gates provide rapid discharge. Capacities from 0.21 to 283 cu ft (6 L to 8 m3).

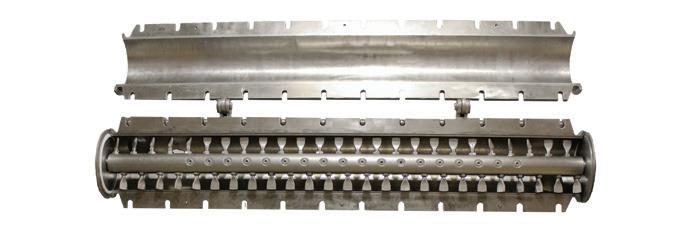

LUMP BREAKERS REDUCE AGGLOMERATES, FRIABLE MATERIALS

Remove lumps and agglomerates from bulk foods. Dual rotors with three-point, singlepiece breaking heads rotate with minimum clearance inside a curved, perforated bedscreen. On-size material exits through bedscreen apertures from 1/32 to 2–1/2 in. (0.8 to 63.5 mm) in diameter. Fits tight spaces between upstream and downstream process equipment.

PIN MILLS REDUCE FRIABLE SOLIDS IN CONTROLLED SIZE RANGES

Coarse to fine grinding of friable powders, flakes and granules into controlled particle sizes at high rates per HP/kW. High-speed rotation of the inner disc creates centrifugal force that accelerates bulk material entering the central inlet of the opposing stationary disc through five intermeshing rows of pins. Desired tight particle size distribution obtained by controlling the rotor speed.

Recalled deli products produced at the facility have resulted in a reported 57 hospitalizations and nine deaths due to Listeria infection. The brand is implementing company-wide food safety measures as a result.

DELI MEAT PRODUCER BOAR’S HEAD has closed its Jarratt, Va., plant after a Listeria outbreak linked to the plant hospitalized dozens across 18 states. The company cites production processes at the facility as the root cause of the contamination.

The closure comes after Boar’s Head ready-to-eat liverwurst products and other deli products produced at the plant were linked to a Listeria outbreak that has hospitalized 57 and killed 9 thus far, according to the CDC. In July, Boar’s Head recalled over 7.2 million pounds of ready-to-eat meat and poultry products under the Boar’s Head and Old Country brand names.

The company announced the closure in September as a part of its measures to “prevent such an incident from ever happening again,” it explained in a release. About 500 employees are impacted by the shutdown, according to a union spokesperson.

The facility has not been operational since the recall was fi rst enacted in July. The decision to close the plant comes after Boar’s Head’s investigation “identifi ed the root cause of the contamination as a specifi c production process that only existed at the Jarratt facility and was used only for liverwurst,” the company said in its announcement.

This Boar’s Head plant in Jarratt, Va., is now closed due to numerous food safety issues identified by the USDA at the facility.

As a result of the Listeria outbreak at its Virginia plant, Boar’s Head is discontinuing production of liverwurst.

Boar’s Head is also permanently discontinuing its liverwurst production after this discovery.

A USDA Food Safety and Inspection Service (FSIS) notice of suspension shared in the company’s announcement notes “insanitary conditions” including beaded condensation on a door opening dripping over products, as well as inadequate sanitation procedures that could have resulted in staff and equipment spreading bacteria. The notice cites positive test results for Listeria monocytogenes both in an unopened liverwurst product and on a pallet jack used to move racks of product around the facility.

Facility reports from the FSIS have also described insanitary conditions including mold, rancid smells, chipping and flaking paint, rusty equipment, and insects among other various instances of noncompliance since 2022.

“This is a dark moment in our company’s history, but we intend to use this as an opportunity to enhance food safety programs not just for our company, but for the entire industry,” Boar’s Head said in its announcement.

Boar’s Head explained in its announcement a plan to prevent future food safety incidents and enhancing its food safety and quality measures across the country.

The company is currently recruiting to appoint a new chief food safety and quality assurance officer, who will report directly to the company’s president.

A new “Boar’s Head Food Safety Council” will also help the company in adoption and implementation of enhanced quality assurance programs. The council will be made up of independent food safety experts, who will serve as advisors to the new chief food safety officer and to the company overall. Some of these experts have already been contributing to the Jarratt facility investigation.

Boar’s Head also plans to create an enhanced company-wide food safety and quality assurance program. Says the announcement, “Our company’s goal is to develop and industry-leading program that addresses food safety standards and strengthens a culture of food safety throughout the supply chain.”

Manufacturing food and beverages require robust, reliable, and durable equipment solutions. In addition, ingredients must be handled gently, added precisely, and mixed efficiently. We have extensive knowledge of food and beverage production, and our application experts can develop and deliver a solution to handle your most demanding applications. Scott Mixers is a proud brand of EBARA Mixers. www.scottmixers.com

Despite the buzz around AI in food and beverage processing, concerns like security and data hallucinations are causing hesitation about the technology.

CASEY FLANAGAN | DIGITAL EDITOR, PMMI MEDIA GROUP

ARTIFICIAL INTELLIGENCE (AI) has the potential to be a transformative tool for the food and beverage processing industry, but the technology includes a few significant drawbacks to consider.

That’s according to PMMI Business Intelligence’s 2024 report, “The AI Advantage in Equipment: Boosting Performance and Bridging Skills Gaps,” where Business Intelligence researchers interviewed industry stakeholders to understand current applications, ambitions, and attitudes on AI in processing and packaging.

Cybersecurity concerns

AI models require data for training, and how much customer data is required depends on the technology.

Predictive maintenance, for example, requires continuous monitoring of end users’ data to func-

tion and data ownership varies between solutions. Digital twin simulations, however, can perform their function with just the machine parameters.

Navigating cybersecurity issues is always a challenge, but as data security and technology improve, legislation changes, and public trust in these tools increases, it may be possible to overcome many of these concerns.

A key issue that can slow down the integration of AI within a company is the state of its data collection infrastructure.

To function optimally, AI models require the collection and storage of relevant data, and the level of this can vary substantially between CPG end users.

Some CPG stakeholders are hesitant to adopt AI technologies due to concerns including employee pushback and data security.

As with most new technologies, reluctance to utilize AI tools can be generational.

This has been reported to be especially true with AI assistants, where some users tend to prefer completing tasks the way they have always done them.

“I think there’s an element of distrust about [AI]. But there’s absolutely an element of newness and not great clarity on what it is and what it can do,” says one interviewed representative of a food and beverage CPG.

Some interviewees mentioned job security as a common concern with AI integration.

Utilizing AI for machine vision has allowed more complex processes to be automated and has put some jobs at risk of being replaced.

Some other AI applications, like AI assistants or connected worker platforms, are less likely to risk job security. These are not replacing the staff completing tasks, but rather increasing the speed at which tasks are completed.

“I think there’s an element of distrust about [AI]. But there’s absolutely an element of newness and not great clarity on what it is and what it can do.”

Large language models (LLMs) can occasionally provide incorrect information, which is known as a data hallucination.

Understandably, this makes users reluctant to trust the outputs of AI assistants. Mistakes in applications, such as maintenance, could potentially cause machine downtime or even serious injury.

However, this concern can be overcome by having the AI verify its own outputs against either a machine manual or a highly skilled employee.

SOURCE: PMMI Business Intelligence: 2024 The AI Advantage in Equipment: Boosting Performance and Bridging Skills Gaps

Expert slicing.

Proven productivity.

Interchangeable, 20-inch diameter wheels offer sharp, precision slices down to .020" (.5 mm).

Self-draining frame provides drip, draw, and drain principles.

Sanitary design.

Stainless steel motors.

Equipped with two VFD’s (variable frequency drives) to synchronize controlled feeding and the speed of the slicing wheel.

Food zone separate from the mechanical zone.

PMMI White Paper highlights AI applications expected to have the most significant impact within the processing and packaging industry.

SEAN RILEY | SENIOR NEWS DIRECTOR, PMMI MEDIA GROUP

WHILE MANY AI-ENHANCED PRODUCTS are on the market, PMMI Business Intelligence’s 2024 report, “The AI Advantage in Equipment: Boosting Performance and Bridging Skills Gaps” highlights five that are or will have the most significant impact on processing and packaging operations.

A relatively new tool developed by multiple automation vendors and solutions providers, AI assistants are large language models (LLMs) that can assist individuals in performing a wide variety of functions. They employ the same concept used by ChatGPT but have been trained on data specific to the indus-

try so they can provide more useful and reliable outputs. Some of the most common uses include coding, admin, customer service, machine manual creation, and brainstorming.

Integrating AI software within vision systems has improved existing applications and aided new ones, such as pick-and-place operations and palletizing. The additional complexity of pick-and-place benefits from an AI solution if the products are inconsistent and require additional decision-making by the system. AI solutions have much better accuracy rates compared with traditional rule-based vision inspection.

SOURCE: PMMI BUSINESS INTELLIGENCE: 2024 THE AI ADVANTAGE IN EQUIPMENT: BOOSTING PERFORMANCE AND BRIDGING SKILLS GAPS

AI models can be trained using manuals, maintenance practices, and customer feedback in response to system alerts. The software can provide users with possible explanations for the reasons behind the alert. Additionally, users can ask questions about recent

maintenance or similar historic alerts and receive solutions from the manual or past experiences.

A digital twin is a virtual representation of a physical process, machine, or plant designed to reflect its real-world counterpart. These simulations are key for optimizing plant/warehouse layout for end users (CPGs) and machine design for OEMs.

Connected worker platforms generally feature a cloud-based management system that operations management or production supervisors use to create, assign, manage, and monitor tasks. These systems are currently used by some of the largest end users (CPGs) in the US and are often integrated with an AI assistant. It monitors workers’ performances by collecting data, such as speed of task completion and linking metrics. This can determine whether a quality issue is related to a particular process in the plant.

SOURCE: PMMI Business Intelligence: 2024 The AI Advantage in Equipment: Boosting Performance and Bridging Skills Gaps

STEPHEN M. PERRY PH.D. | CO-FOUNDER + COACH, FSO INSTITUTE

CONTRIBUTOR:

Dan Sileo, Chief Manufacturing Coach, FSO Institute

The first step to successful execution of a plan is the existence of a clear, concise one in the first place— whether it be a strategic plan, an action plan, an annual operating plan, or any other plan variation.

IN A RECENT PROFOOD WORLD ARTICLE by FSO Institute, we focused on the importance of developing a robust strategic plan to help manufacturers create direction clarity in their organization. The premise is simple: if you don’t know where you’re going, any road will take you there.

So, the first step to successful execution of a plan is the existence of a clear, concise one in the first place—whether it be a strategic plan, an action plan, an annual operating plan, or any other plan variation. That article provided guidance from FSO Institute’s Manufacturing Health Roundtable (MHRT) on just how to develop such a plan.

During their recent monthly virtual meeting, the MHRT followed up on their plan creation discussion by sharing some of their thoughts on why these plans often don’t get executed and what can be done about it. What follows are the highlights of the discussion and some color commentary and opera-

tional insights by FSO Institute Chief Manufacturing Coach Dan Sileo, formerly of Procter & Gamble, Sunny Delight, and Sugar Creek Foods.

FSO INSTITUTE: Some of the reasons why plans don’t get executed include no alignment at the top (no direction clarity), frequent direction changes (shifts in clarity), top team is aligned but no one else knows, no effort to share plans throughout the company to get buy-in, ownership and advocacy (BOA), no connection to individual roles (no role clarity), employees already too busy and no common processes and procedures for optimizing plans.

In your experience, how does this list sound to you and which are the most significant? Are there reasons you’d add that are not included in this list?

SILEO: You have an extensive list of which there is usually more than one factor in play. The only addi-

If a plan is well communicated and a leader gives credit to the team or individuals for successes, supports when there are failures, and delivers on any commitments they made, the team becomes excited to perform.

tion I would make, which is perhaps one of the most important ones, is when leadership actions and communications in the day-to-day operations do not match the stated plan. Even if the plan is well communicated, people at the point of execution adjust to the daily feedback they receive and will view the plan as just another “program of the month” to be managed somehow. Leadership needs to be self-aware of how they are impacting their people and intentional in supporting them in delivering the plan—they have to walk the talk.

FSO INSTITUTE: It seems that there are some standard responses to these challenges – rounding up the usual suspects, if you will – that include focusing on the fewest, most important tasks; developing scorecards, KPIs, RACI charts; and working on the most important issues first – addressing the burning platforms and working on cultural change.

No doubt these are extremely important, but since they are people-dependent couldn’t they all benefit from better leadership, better teamwork and better individual performance?

SILEO: Absolutely. And it is the interconnectedness of these three that really makes it powerful. A good servant leader through coaching and barrier removal fosters better individual and team performance which frees up time for the leader to invest more in them as well as PDCA (Plan, Do, Check, Act) the plan. So many times, particularly at the plant level, the focus is on equipment, lines, supplies, etc. and not on people. For most, it seems easier to work on these things than on the people challenges they face. These are the harder things to do so not sure why they’re always referred to as soft skills.

FSO INSTITUTE: Let’s drill down on these three pillars of execution starting with individual performance. The focus here is on the most essential elements of individual performance improvement including understanding of self and others (Emotional Intelligence), personality traits that count the most (Big 5 Personality Factors) and doing what high performers do (key characteristics).

Can you provide an example or two of just how these elements can play out at the plant level and improve individual performance and overall plant operations?

SILEO: Think about the Big 5 Personality Traits (conscientiousness, extroversion, agreeableness, emotional stability, and openness to experience) and how a team member who seeks out and values feedback on how they perform on a team cuts across all the factors. Not only do these traits drive better personal performance but typically breaks down walls to acceptance for others who may not be as open since they “exposed” themselves first. A few champions who exhibit these traits on the plant floor can go a long way in inspiring others to do so as well. This helps build a level of trust that it’s not about “me” but about “we” on the team.

FSO INSTITUTE: Let’s talk about better leadership. The focus here is on what’s expected of great leaders and what’s required to become one including saying goodbye to command and control leadership (Servant Leadership), leadership traits that matter most (8 Traits of Authentic Leaders) and doing what leaders you like the most do (Leadership Green Flags).

Can you give a couple of examples of how better leadership at plant level contributes to improvement in overall plant operations?

SILEO: As we talked in the previous example about the Big 5 Personality Traits, this is most important for the leader who must exemplify the factors showing the team members what they expect. I have seen good leaders begin to transform underperforming teams just by moving from command and control to a servant leadership style that incorporates the Big 5. The 8 Traits of Authentic Leaders (honest, selfaware, genuine, consistent, purpose-driven, humble, and ethical) now become the propellant that moves the team forward. So, if the plan is well communicated and the leader is constantly driving the team to deliver, giving credit to the team or individuals for

successes, supporting when there are failures, and delivering on any commitments they made, the team becomes excited to perform.

FSO INSTITUTE: Finally, let’s talk about better teamwork. The focus here is on the cultural components that create the greatest likelihood of getting things done including cultural change that everyone wants (Culture of Collaboration), making dysfunctional teams functional (5 Dysfunctions of Teams) and if it’s not safe, it’s not functional (Psychological Safety).

How does better teamwork at the plant level contribute to overall plant operations?

SILEO: We have all seen individual pockets of excellence or departments that seem to perform well above the norm because they operate well as a team. When you get the leaders across the facility employing all the tools we have talked about and they collaborate instead of driving their team to win at the expense of others, we typically see results take off. This requires that plant leadership foster psychological safety, the open communication, respect, shared goals, and trust across the organization. Psychological

safety enables engagement, fear diminishes it. Simple tools like an effective Managing for Daily Improvement (MDI) process often provide a framework at all levels and across all functions of the organization to build this culture and provide a safe way to contribute to the overall plan.

PMMI’s OpX Leadership Network has produced more than 20 manufacturing process-improvement documents for CPGs and OEMs. The FSO Institute has facilitated the adoption and implementation of these documents, especially for food and beverage manufacturers. This series of articles shows how CPGs are using OpX and FSO documents to improve their overall manufacturing health and collaboration with OEMs and other suppliers. Learn more at opxleadershipnetwork.org and fsoinstitute.com .

Helping you bring your

products

Delivering Results. With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

• Potato and vegetable preparation

• Frying and oil management

• Drying and roasting

• Seasoning and flavoring

• Conveying and product handling

• Weighing, bagmaking, and casepacking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

ANNE MARIE MOHAN | SENIOR EDITOR, PACKAGING WORLD

The change will help Kraft Heinz reduce the use of virgin plastic and reduce greenhouse gas emissions by up to a 43%.

KRAFT HEINZ has introduced 100% recycled PET (rPET) bottles for its 12- and 22-oz sizes of Kraft Real Mayo, Aioli, and Miracle Whip, with the balance of its container sizes scheduled to launch in the new packaging by year-end. The move comes following the company’s announcement last year of a new goal to reduce the use of virgin plastic in its global packaging portfolio by 20% by 2030.

According to those at Kraft Heinz, the switch to 100% rPET for its full range of container sizes will result in the elimination of about 14 million lb of virgin plastic. In addition, depending on the size, the transition to the new container will result in a 36 to 43% reduction in greenhouse gas emissions (GHGs) versus the current packaging, based on 2022 volumes.

To make the change, Kraft Heinz worked with long-time packaging partner Plastipak, a designer, manufacturer, and recycler of plastic containers. Says Chris Max, research lead, R&D/packaging development for Kraft Heinz, “For nearly four decades, they’ve helped us design and manufacture packaging that protects the product from our production facilities all the way to consumers’ tables.”

According to Max, there's a lot to consider when developing a new packaging solution. “First and foremost, packaging is about protecting the product, so it must deliver against our food-safety requirements,” he says.

“Packaging must also fulfill consumer expectations and function the way they have come to trust. And finally, we need to make sure we have the internal infrastructure to support the changes, meaning any new packaging developments need to fit seam-

s

“We need to make sure we have the internal infrastructure to support the changes, meaning any new packaging developments need to fit seamlessly into our production lines,” says Chris Max (foreground), research lead, R&D/ packaging development for Kraft Heinz.

Kraft Heinz’s switch to 100% rPET for its full range of container sizes will result in the elimination of about 14 million lb of virgin plastic.

lessly into our production lines.”

For the new Real Mayo, Aioli, and Miracle Whip containers, Plastipak optimized its manufacturing process to ensure the performance of the packaging remained uncompromised after the transition to recycled content and worked with Kraft Heinz to leverage best-practice quality protocols.

One concern with recycled content is whether it contains contaminants that may affect product safety. For Kraft Heinz, delivering high-quality, safe foods is understandably one of its biggest priorities. “All materials used in our packaging must meet FDA requirements for food contact and be safe and suitable for the intended use,” Max explains. “At Kraft Heinz, we also mandate all recycled material be certified by an Association of Plastic Recyclers [APR]approved body.”

MATT REYNOLDS | CHIEF EDITOR, PACKAGING WORLD

AHOY! has been launching some new recipes lately, including an update to its original cookie recipe alongside its first certified gluten-free chocolate chip cookie. A pair of new packaging designs with a combination of improvements including updates to the logo, an updated image of the cookies themselves, and more prominent background graffiti reflecting the brand personality with a matte packaging finish that all together makes it a more modern and fun design, the company says.

Gluten-free Chips Ahoy features light blue on a white background instead of the white and light blue on darker blue for original Chips Ahoy. This helps to signal to consumers which cookies are gluten free and which are not when shopping.

“The overall objective of the Chips Ahoy pack redesign was to evolve the visual language to be relevant with the target consumer, double down on the taste appeal of the cookie and to communicate the product improvements. We crafted the logo to ensure modernity and boldness against the backdrop. We amped up the graffiti to add personality and visual texture. We photographed our product as the hero on pack to drive the

yum-factor. All of these elements work together to deliver an iconic experience at shelf for our Chips Ahoy consumers,” says Samantha Zellefrow, Global Design Excellence lead at Mondelēz.

Specific to the even more recent gluten-free launch, packaging colors are reversed to light blue on a white background instead of the white and light blue on darker blue. This will help to make it immediately obvious which cookies are gluten free, and which are not, by a simple glance at the shelf.

The overall objective of the Chips Ahoy pack redesign, according to those at Mondelēz, was to evolve the visual language to be relevant with the target consumer, double down on the taste appeal of the cookie, and to communicate the product improvements.

“For the packaging, this is the existing adhesive laminated peel and reseal film structure with a rotogravure print method. Utilizing the existing printing technology, a matte over lacquer is applied to create differentiation on shelf and complement the new graphics. The metalized film layer provides the barrier required to achieve the appropriate shelf life of the new cookie formula,” notes Andy Clark, North American Biscuit Packaging lead, Mondelēz.

Mid-Tube Housings (MTH™) incorporates 2 inch diameter Rare Earth magnetic tubes on 4 inch centers into our proven Drawer-In-Housing configuration for optimum ferrous metal separation for difficult flowing products in high-flow rate applications.

ANNE MARIE MOHAN | SENIOR EDITOR, PACKAGING WORLD

STONYFIELD, known for its commitment to producing high-quality, organic yogurt, as well as its attention to sustainable packaging, has become the first to use the CHEERCircle all-polyethylene spouted pouch. Although the recycle-ready pouch is not currently able to be recycled in the U.S., it is said to provide significant environmental benefits versus a typical multi-laminate spouted pouch. It’s also well positioned for recyclability when the infrastructure becomes available. Stonyfield developed the pouch in collaboration with Amcor and Cheer Pack North America for its YoBaby refrigerated yogurt.

Spouted pouches are traditionally made from a multilayer, multi-material structure. The most common construction, according to Tom Schell, senior director – R&D, Amcor Flexibles North America, is an aluminum oxide-coated oriented PET/biaxially oriented nylon/PE structure, whereby the AlOxcoated OPET provides the barrier and a printing substrate, the BON provides toughness, and the PE provides the sealing surface.

In contrast, the new Stonyfield package uses Amcor’s AmPrima PE Plus, an all-PE film that meets the APR Design Guide for recyclability. According to Amcor, high-barrier, heat-resistant AmPrima PE Plus flexible film was engineered to address the challenges with producing an all-PE spouted pouch.

To allow for sealing and fitment insertion without distortion, AmPrima PE Plus features a heat-resistant outer web. For the Stonyfield yogurt application, the required oxygen barrier is delivered through the inclusion of ethylene vinyl alcohol, which is compatible in the PE recycling stream, while HDPE is used to enhance the moisture barrier to the appropriate level.

Also important for the project was the selection of the pouch fitment. The team chose the Cheer Pack Vizi PE cap to ensure the entire pouch would pass critical guidance testing as defined by APR. The Vizi Cap is said to improve tamper-evidence, as well as significantly reduce plastic use when compared with traditional pouch fitments. According to Cheer Pack, use of the Vizi Cap can result in a reduction of five-plus tons per 10 million caps, or the equivalent of 15,460 lb of CO2

To validate the AmPrima Plus structure in pro-

A multi-company collaboration resulted in a package that achieved all customer expectations, including standard line speeds for converting at Cheer Pack North America and filling lines at Stonyfield Organic.

duction environments, Amcor R&D worked closely with Cheer Pack North America’s pouching and spouting experts. Says Laura Stevenson, marketing manager for Amcor Flexibles North America, “This open collaboration resulted in a package that achieved all customer expectations, including standard line speeds for converting at Cheer Pack North America and filling lines at Stonyfield Organic.”

As noted, although the pouch is designated as recycle-ready, Stevenson explains that at present, the infrastructure to recycle flexible packaging via MRFs (municipal recycling facilities) in the U.S. is insu cient. “The AmPrima portfolio provides customers with a packaging solution that is designed to be recycled, if clean and dry, through existing store drop-o s,” she says. “Today, that is di cult for liquid products as materials need to be clean and dry prior to going into the PE-recycling stream. However, the recycling industry along with Amcor, are working to change that.”

Even when not recycled, significant sustainability benefits accrue from the use of AmPrima PE Plus film versus a three-ply foil structure incumbent, shares Amcor. These include a 5% reduction in non-renewable energy use, a 22% reduction in carbon footprint, and a 51% reduction in water consumption. Those numbers rise to 53%, 49%, and 66%, respectively, if the film were to be recycled.

Slash mixing times by up to 90% for increased productivity

Effortlessly hydrate even the most challenging gums & thickeners

Maximize yields & achieve consistent results

Ready to optimize your food or beverage production process?

Explore our comprehensive mixing application guides & how-to videos to find the ideal solution for your mix >>

The vertically integrated contract manufacturer opened its greenfield plant in Idaho this year, with the latest technology for aseptic and ESL beverage processing, and an eye toward serving an international customer base.

TMICHAEL COSTA | EDITOR-IN-CHIEF

The 190,000-sq-ft Suntado facility was built with expansion in mind. It currently houses two processing lines and six filling lines, but has room to expand to six processing lines and 18 filling lines in the future.

TIME (HTST) MILK PRODUCTION has often been limited by its relatively short expiration date—just a few weeks—and the need to be refrigerated throughout the entirety of the cold foods supply chain. That short shelf life keeps HTST milk produced in the U.S. from making its way to regional areas like Mexico and South America, and far-o markets like China and Taiwan, for example.

After being filled, aseptic and ESL containers are conveyed into this automated end-ofline space where they are packed into cases and palletized before shipping.

Aseptic dairy processing and packaging changed that scenario, with milk produced through ultrahigh temperatures (UHT) and filled into sterile, oxygen-free aseptic packaging. That milk has a shelf-life of up to 12 months, which means those far-away markets are now accessible for U.S. dairy manufacturers, since refrigeration is not required once the milk is sealed in aseptic containers. This opens the door to distribution in emerging economies as well,

where refrigeration may be inconsistent or scarce. Another variation with a shorter shelf life—about 80 to 100 days—is extended shelf life (ESL) processing and packaging. ESL milk lasts much longer than HTST milk but requires end-to-end refrigeration throughout its lifespan.

Suntado uses rollfed packaging, which contains more unfinished cartons per pallet than blank-fed packaging, reducing the number of trucks needed to deliver packaging to the plant.

Both aseptic and ESL milk are produced at the new Suntado plant in Burley, Idaho, located in the dairy-rich Magic Valley region of the state. Suntado is a new, vertically integrated processor specializing in contract manufacturing of aseptic and ESL organic and conventional milk products, along with plantbased beverages, with options for value-added blending of flavors, and lactose-free and vitamin dosing for functional drinks.

The name Suntado comes from its two founders, Dirk Reitsma, owner and manager of Sunrise Organic Dairy, and Jesus Hurtado, owner of Hurtado Dairy. Sunrise + Hurtado = Suntado. Both farms are approxSuntado Plant Manager Russ Lucas stands next to a milk tanker truck that only needed to travel 20 miles from farm to factory for processing. This vertically integrated business model ensures fresher product and a lower carbon footprint for transportation.

Why contract manufacturers need to be fully certified before producing any food or beverage items. What You Will Learn in This Story:

Why aseptic milk production creates the potential for international sales. How aseptic processing can cut the cost of cold storage and refrigeration.

Milk is stored in stainless-steel silos until it’s ready for separation, standardization, or processing. Once milk is processed through UHT it’s stored in aseptic surge tanks and can be routed to aseptic filling lines.

Suntado currently has six fillers—four aseptic and two ESL—and finished cartons are conveyed to the left into the end-of-line space on the other side of the wall.

imately 20 miles from the Suntado facility. Reitsma’s farm has 5,500 cows and can produce 400,000 lbs of organic milk daily. Hurtado oversees 28,000 cows, and can produce 2 million lbs of conventional milk daily.

Combined, this vertically integrated business model not only supplies Suntado with a steady stream of fresh milk—which can be processed and packaged the same day—but the short distance to travel from farm to factory helps keep Suntado’s carbon footprint low.

“Before Suntado, Dirk and Jesus would ship their

milk to customers in other states, and in some instances, as far away as the East Coast,” says Tory Nichols, office of the CEO, business development at Suntado. “Now they’re just driving it 20 miles to their own facility, so there’s a strong sustainability point just around the transportation of milk from the dairies to the plant.”

Eco-friendly initiatives and efficiencies throughout Suntado’s plant help position it as a potential leader in the marketplace as the company ramps up its first year of business. Here, we’ll take a detailed look inside the greenfield facility, which was designed and built by Big-D Construction and E.A. Bonelli + Associates.

Suntado currently has two processing lines and six fillers: four aseptic and one ESL from Tetra Pak, and one ESL from Pactiv Evergreen. The 190,000-sq-ft plant was built with extra space to house up to six processors and 18 filling lines operating in the facility—three times what is currently in place now. At full capacity currently, Suntado can produce more than 33 million gallons a year, and after expansion, about 100 million gallons annually.

The process starts when milk is trucked in by tanker to a receiving area. Milk is stored in stainless-steel silos until it’s ready for separation, standardization, or processing. Once milk is processed through UHT it’s stored in aseptic surge tanks and can be routed to the aseptic filling lines where cartons are filled and sealed, then conveyed to Robopac case packers and TopTier palletizers for eventual distribution.

“There’s a substantial amount of effort that goes into making a sterile product,” says Russ Lucas, Suntado’s plant manager. “You need the boilers going, and then the chillers need to be operating as well. You turn the temperature up to the 285-degree range [for UHT processing] then you need to cool it back down to 80 degrees. Or, if the milk is going out to ESL, then down to 36 degrees. So, there’s a lot of change in temperature and a lot of movement of product around.”

on their new vertically integrated, state-of-the-art aseptic beverage facility! We are honored to be their ESL/Aseptic processing partner!

LOW ACID PRODUCTS

When you choose Statco-DSI for your ESL/Aseptic processing solutions, you’ll benefit from the most innovative and robust operating solutions available in today’s market.

THERMA-STAT ESL/ASEPTIC PROCESSING SYSTEMS are built with readily available, domestically supplied components for long term ease-of-maintenance and reduced downtime. We build our systems in-house to control the project timeline and ensure on-time delivery. In addition to these key advantages, our systems offer exclusive features:

• Fluid Milk & Flavored Milks • Heavy Whipping Cream

• Ice Cream Mixes • Dairy Creamers & Non-Dairy Creamers

• Protein Enhanced Dairy Products

• Plant-Based Products: Oat, Nut, Flax, Pea, Soy

• Product-to-product regeneration: raw product heated with ultra-pasteurized product significantly reduces energy usage and system complexity

• Seamless, unrestricted routing to multiple destinations maximizes production runs and minimizes scheduling conflicts

• Optimized design performance reduces utility costs and environmental impact

• Specialized HMI screen graphics and event logging aids in system troubleshooting

Because aseptic milk doesn’t require refrigeration after being sealed in containers, Suntado uses onsite ambient storage like this for inventory—saving energy costs as a result.

As noted earlier, aseptic containers give Suntado a chance to manufacture milk and other beverages for customers around the world because it doesn’t need to be refrigerated until the container is opened. This means Suntado can schedule longer continuous production runs with less waste in the end.

“I’m not going to be squeezed into a 25- or 30-day window to get product out the door before it goes past its best-by date,” says Lucas. “[Aseptic] gives us a certain amount of flexibility, and our plan is to get as close as we can to 24-hour [production] runs. “Our strategy is to plan ahead to manage our product mix so that we don’t have multiple changeovers and force extra CIPs (clean-in-place) and the associated downtime.”

Mat Rutz, VP of contract manufacturing for Tetra Pak in the U.S. and Canada, adds, “Aseptic lines run faster than the alternative packaging technologies, and you can schedule your production around to get the maximum benefit out of the technology,” he says. “In principle, because the [aseptic] product will last longer as opposed to a traditional dairy environment—where the milk is going to spoil in a few weeks so you have to build that into your scheduling on a weekly basis—you can lengthen your runs

and reduce your CIPs, which means you eventually reduce the amount of product down the drain.”

Another advantage to aseptic processing is less energy usage over time in the form of refrigeration. Because aseptic milk is shelf stable for up to a year, the finished product doesn’t need to be put into a cooler and stored. ESL products need to stay chilled, but overall, “the cold storage areas here are substantially smaller than the ambient,” notes Lucas.

“That’s less square footage just draining money to keep our storage areas cold.” Lucas adds that Suntado has an offsite warehouse under construction that has 8,000 additional pallet spaces in an ambient environment for extra aseptic storage capacity.

Suntado also utilizes an onsite water filtration system that treats wastewater before releasing it back into the city’s system. “We have a DAF (dissolved air flotation) unit out on the northeast corner of our property that removes the solids from our wastewater,” Lucas explains. “The effluent out of the plant gets cleaned up and has a very limited impact on the city’s wastewater system once it goes out after we treat it here.”

Suntado employs a highly skilled workforce, many of whom have extensive experience in dairy processing due to the high number of dairies in Idaho. Nichols estimates about 25% of the core staff also have specialized experience in aseptic processing, and the company has been attracting talent with the promise of a modern, efficient workplace.

The company currently employs approximately 70 people, and will expand to 120 as Suntado grows its operation. One of the perks for workers is a 2-2-3 work schedule, where employees work two day shifts in a row, followed by two days off, and then back on for three more days of work.

“It’s nice to be the new kid on the block,” Lucas says. “We have some great talent here, but we’re also having to teach and train that aseptic is different than what some of them may be used to in traditional dairy

plants. There’s more discipline required, and extra care for sanitation as well as packaging.”

Speaking of packaging, Suntado utilizes roll-fed packaging, which allows for more cartons per pallet to be shipped to the plant compared to traditional blank-fed packaging. This not only reduces the number of trucks needed for transportation—lowering Suntado’s carbon footprint—but also enhances storage efficiency.

“Blank-fed packaging would be somewhere around 24,000 packs per pallet,” notes Rutz. “Roll-fed material would be upwards to 36,000 packs per pallet. So Suntado is bringing in more unfinished packs per pallet than the alternative, which means they’re essentially pulling trucks off the road in order to deliver the same amount of material for the business needs of Suntado.”

Nichols says if a food or beverage brand self-manufactures, that company can make its products while it goes through the certification process for food quality, food safety, kosher, halal, and other requirements, depending on what’s being produced. However, a contract manufacturer like Suntado has

a stricter path when it comes to being certified and must have all of their certifications in place before any production can begin.

“It’s different when you’re a co-packer because when you’re making someone else’s brand, you have to start certified. Retailers and grocers are trusting that the plant is certified, and that we will uphold the reputation of our customers,” Nichols says. “Establishing those certifications can be a challenge as a co-packer, but it’s something we have overcome. Getting all those initial certifications was a big deal.”

Like several other food and beverage facilities built since the pandemic, Suntado experienced many of the prevalent supply chain headaches in today’s design/ build landscape, but conquered them to open the plant in less than two years from the start of construction.

“We needed to have weekly calls with Big-D Construction about long lead times for things like 60,000-gallon tanks, electrical gear, boilers, and stainless-steel beams,” remembers Nichols. “We were very fortunate that a large brand was building several warehouses and stopped for a while, so we were able to pick up their steel.”

Get to know Kovalus. A new name. Decades of experience.

From Gelatin, Plant Proteins to Collagen, Eggs and more: Our comprehensive Separation Solutions extract value in food with Advanced Membrane Elements, Filtration Systems, Evaporation, Drying, and Powder Handling technologies.

Employee-owned and operated with a legacy spanning over 180 years, ROSS is synonymous with innovation and quality in manufacturing mixing, blending, drying, and dispersion equipment.

Our commitment to excellence is evident in our five state-of-the-art manufacturing facilities across the U.S.A., complemented by an 8,000 sq. ft. Test & Development Center and three international plants, ensuring we serve customers worldwide with precision and reliability.

From standard models to custom solutions tailored to your unique processing needs, ROSS mixing equipment is engineered for decades of trouble-free operation, empowering industries and fostering economic growth.

Proudly engineered and fabricated in the USA, we’re driving the future of manufacturing, supporting American jobs, and fortifying supply chains for generations to come.

Seth Teply, president and CEO of Tetra Pak U.S. and Canada, says the vertically integrated Suntado and its focus on producing aseptic and ESL beverages can help address several nutrition issues impacting populations around the world.

“Today, there are 700 million people that are food insecure, meaning they don’t have access to safe and nutritious food. So, the U.S. dairy industry has a huge role to play in helping to feed the world,” he says. “We believe that shelf-stable and ESL technologies can play a key role in this by helping to reduce food waste globally. About 30% of all food produced is wasted, and in the U.S. there are studies that place it as high as 40%. So, shelf-stable and ESL production of liquid dairy products and other beverages like what Suntado is doing here can be a leading edge to help combat food insecurity in a sustainable way.”

From an economic standpoint, Suntado has already attracted the attention of those countries and regions mentioned at the top of this story, using aseptic processing to help create a truly global customer base for its products.

“We’ve hosted trade organizations from Mexico, Taiwan, China and other parts of Asia, and we are in talks with multiple international customers,” says Nichols. “They’re very interested in having USDA Grade A milk. When you think of countries like Singapore or Taiwan, where many items are expensive, being able to export into those markets from a plant like ours—whether it’s UHT or ESL—is economically viable. For example, a quart container of heavy whipping cream in the U.S. is around $6. In Singapore, you can get $18 for it. So, it makes a lot of sense to export to those markets, and if we build those international relationships it’s going to help Suntado, and the U.S. dairy industry too.”

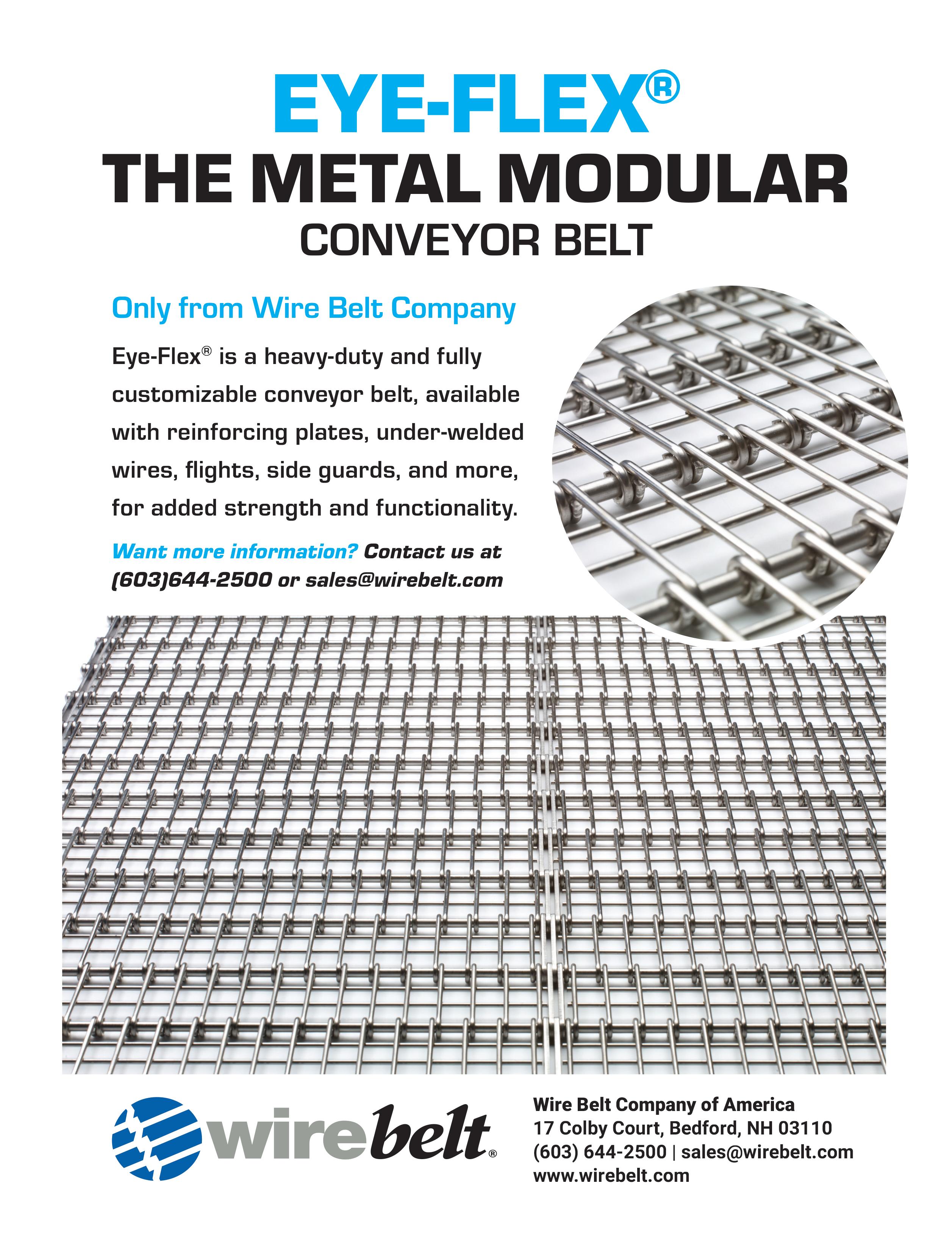

Conveyors are the workhorses that keep food facilities moving, but some operations require specialized conveying applications to reach their potential. Today’s technology has made conveyors more customizable than ever to help meet those needs.

“HORSES FOR COURSES” is a well-known idiom that means a specialized skill or application is often the best route to complete a particular task. In food processing, conveyors could be considered the workhorses of the plant, transporting products through each stage of manufacturing and eventually into packaging.

An ideal way for a manufacturer to assess their conveying needs is to view conveyors through the lens of “horses for courses” and understand that every operation—including their own—has unique products that require specialized handling as food moves through their facility.

With so many di erent types of conveyors on the market today, a food manufacturer can target a specifi c conveying option as a perfect fit to help maximize productivity, e ciency, product quality, food safety, labor savings, energy conservation, and more.

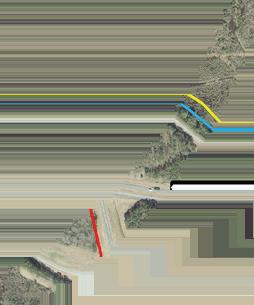

Spiral conveyors like this one allow long lengths of belt to travel in a helical path, often allowing processing in a facility footprint using only 10% of the square footage required of a long, straight-running conveyor.

PHOTO COURTESY OF ASHWORTH

“Conveyors are the connective tissue that many operations require to generate a continuous product flow from one key process to the next.”

Here, we’ll look at some of the most common types of conveyors for food processing, along with the latest innovations propelling this equipment beyond just transporting products. If chosen correctly, conveyors can have a substantial impact on a company’s bottom line as well.

“Conveyors are the connective tissue that many operations require to generate a continuous product flow from one key process to the next,” says Adam Bannerman, food team, new product development, lead engineer at Intralox .

Without that “connective tissue” in a food processing facility, very little would be accomplished. Conveyors reduce labor requirements, enhance efficiencies, and ensure food safety by minimizing manual handling. Conveyors also optimize space utilization, allowing for both vertical and horizontal transport of products, depending on the application.

“If conveyors disappeared, F&B processing would resort back 150 years to fully manual pro -

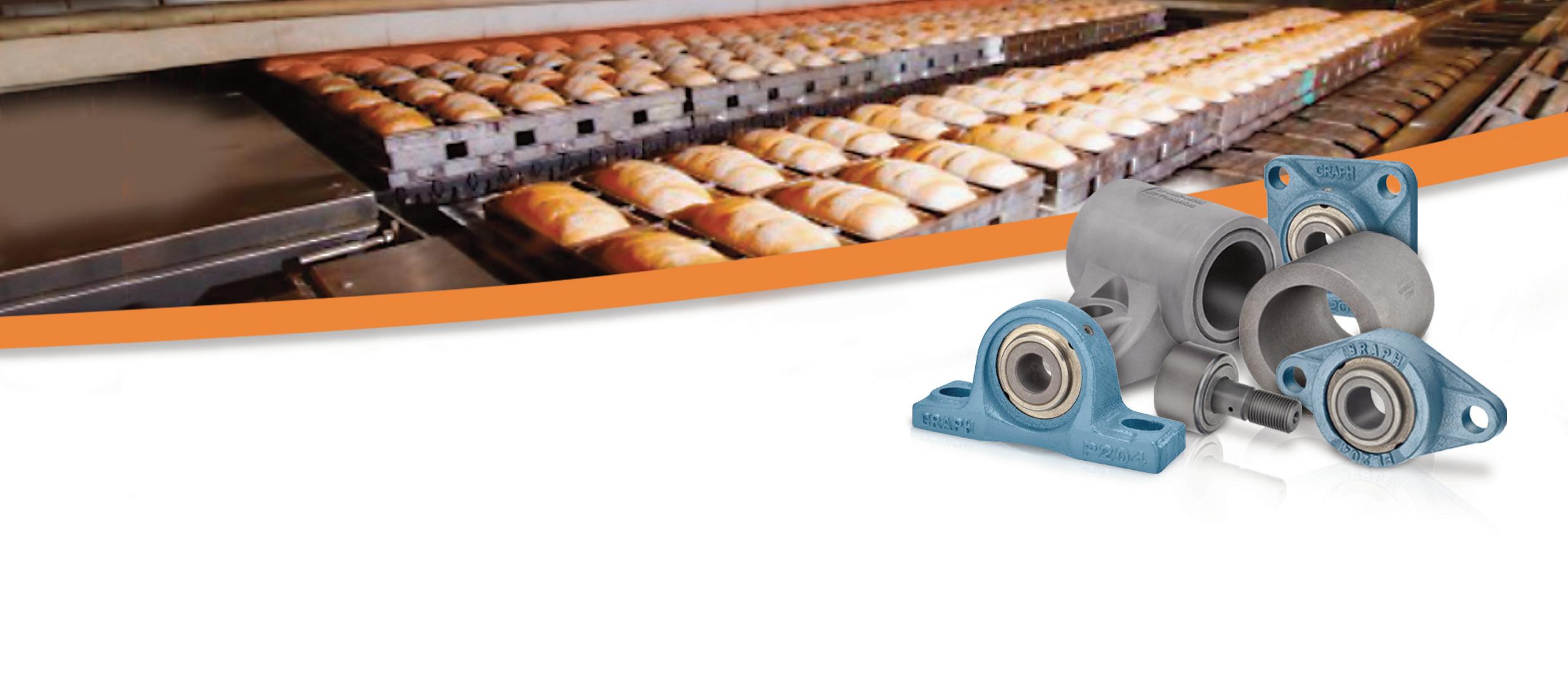

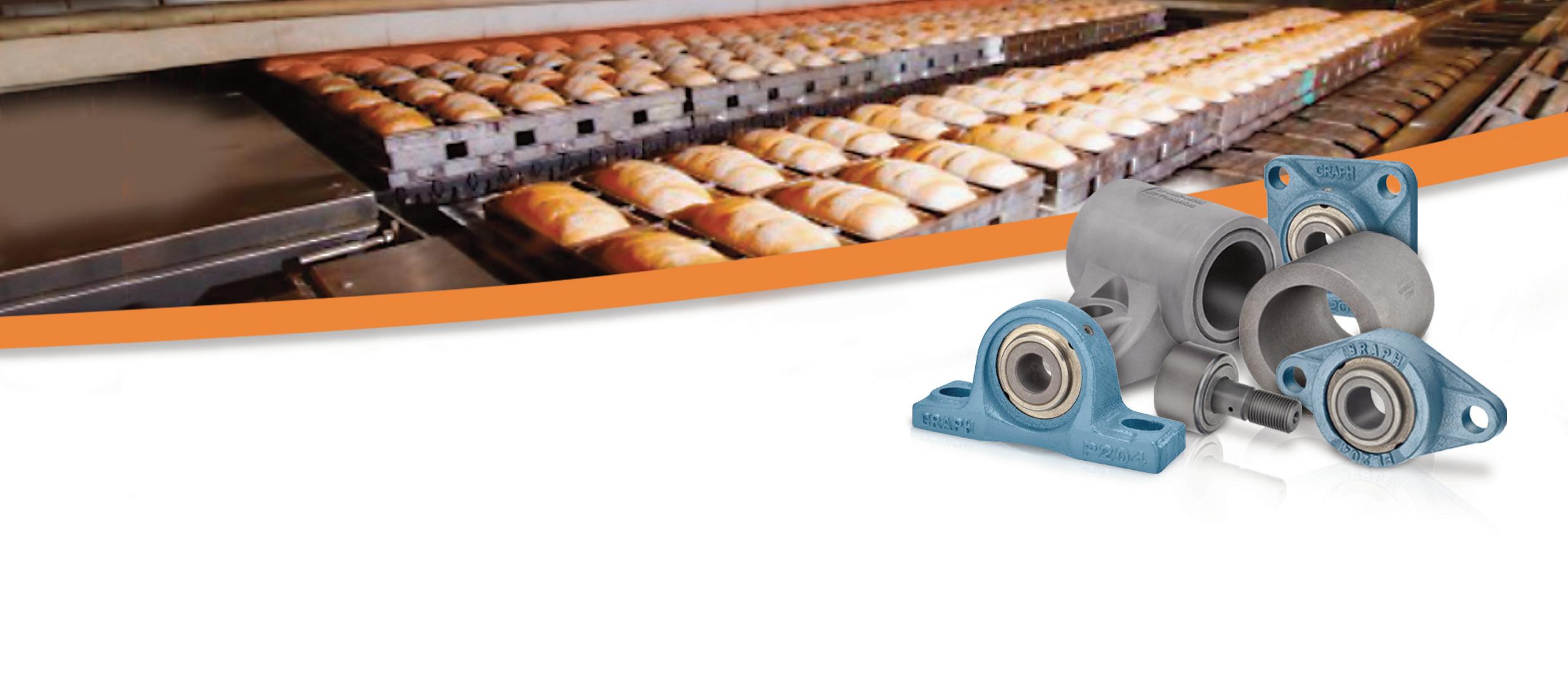

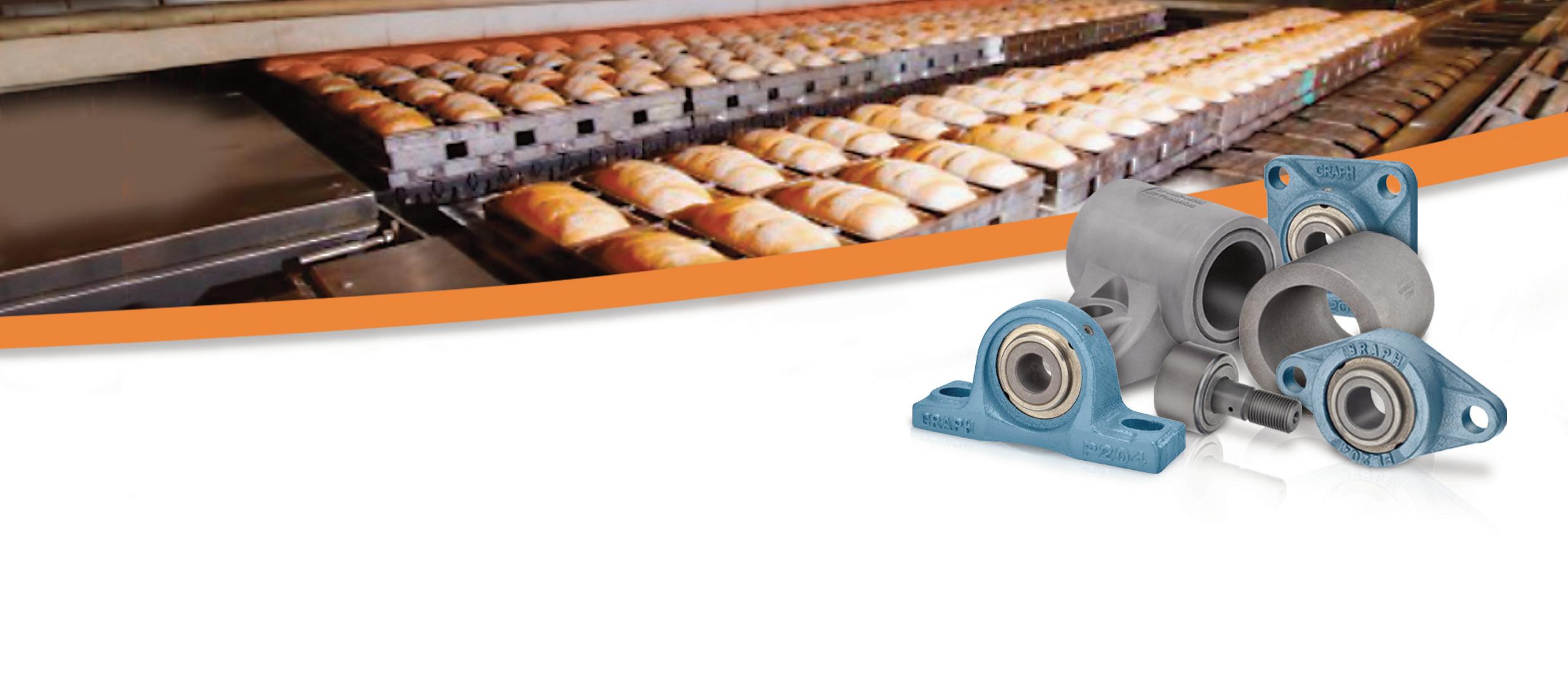

Baked goods like these muffins can go through multiple phases of conveying, from cooling on stainless-steel wire to being shuttled on plastic belting to packaging. Throughout each step, foodsafe, hygienic surfaces are crucial to maintain food safety.

cesses, labor costs would skyrocket, and OEE and production output would plummet, all resulting in catastrophic effects on the overall supply chain and unimaginable consumer price increases and vast shortages,” says Ken Lento, SBU manager, West, at FlexLink.

Fortunately, that scenario cannot come true today because food processors have more conveyor choices and customizable options to choose from than ever before. Lento details a few of the most common types of conveyors and conveying surfaces for processing—and their intended applications—as:

• Stainless steel for direct food contact and products necessitating hygienic washdowns.

• Aluminum for non-washdown applications and where easy modification and installation are required.

• Hygienic flat belt for direct food contact, bulk product, and raw product, typically with a stainless-steel framework.

• Stainless-steel chain for baking, cooling, and raw product handling.

Conveyors in food processing reduce labor requirements, enhance efficiencies, and ensure food safety by minimizing manual handling. Conveyors also optimize space utilization, allowing for both vertical and horizontal transport of products.

One example of identifying an exact conveyor match for specific processing needs comes from G&S Foods—a Pennsylvania-based snack maker that originally used stainless-steel, beltless vibratory conveyors, which are common in the snack industry. Like their name indicates, those conveyors vibrate, shaking products like pretzels and potato chips incrementally forward down the production line.

According to Wade Fitzkee, VP of operations at G&S Foods, the vibratory conveyors they were using would “shake the salt and seasoning off the product.” The company solved this problem by switching to horizontal motion conveyors, which uses a gentler forward-and-back motion that helps maintain the quality of the products produced at G&S Foods. “They were easier to clean for us too. The salt and seasoning stays on the product, and therefore it’s not all over the pan. It doesn’t make a mess that you have to clean up, and that smooth stainless-steel surface is easier to wipe down and it’s easier to sanitize,” he says.

Conveyors used in bakery or snack operations—

like G&S Foods—that are tasked with gentle handling to preserve product integrity is just one example that addresses the unique needs of operators within food processing. Another example might include conveyors designed for meat processing or frozen vegetables that feature temperature-control capabilities. The varying levels of customization ensure that each conveyor system can be optimized for its intended application, enhancing overall user efficiency and product quality.

While the stainless-steel horizontal conveyors used at G&S Foods can be easy to clean due to the open metal surface and lack of cracks or crevices that can harbor bacteria, conveyors of all types today are hygienically designed to elevate food safety regardless of the environment, and use materials like food-grade metal and plastic that ensure sanitation is maintained and can withstand harsh cleaning agents without compromising the longevity of the equipment.

Choosing the right conveying surface for a partic-

With over 2,000 food industry projects completed in 15 years— Hapman is the name food manufacturers trust for bulk material handling solutions.

Your ingredients flow precisely where, when, and how you need them— without fail. Our specialized equipment is designed for the food industry, offering sealed conveyors, dust containment, easy cleanability, and food-grade components. Need a full system layout? Our expert engineers are ready to support your complete project requirements.

ular operation is also crucial to maximize productivity and maintain sanitation. For certain types of food production like proteins or baked goods, identifying the right belt or chain is essential to success.

“A conveyor belt is often the largest single component of any conveyor system,” says Jonathan Lasecki, director of engineering at Ashworth. “Products such as poultry or items baked directly on a belt need more product support, requiring belting with a denser surface.”

Bannerman adds, “There are many applications, food types, processes, and environments that influence belt selection. The truth is there’s no onesize-fits-all option,” he says. “Many food products are conveyed directly on a belt surface and these operations vary widely from bakeries to ready-to-eat meals. However, everyone needs a reliable process to make quality products that are safe for their cus-

tomers at the end of the day. Reliability and hygiene are two primary categories, with many levels of consideration below each of these including durability, abrasion, chemical compatibility, and ease of product release.”

The footprint within a processing facility to house conveying lines can often be a challenge, as it is with any other type of equipment. Since space can be limited for conveying lines, vertical conveying solutions—like spiral and bucket conveyors—make use of an abundance of vertical square footage.

“Spiral conveyors allow long lengths of belt to travel in a helical path, often allowing processing in a facility footprint using only 10% of the square footage required of a long straight running conveyor,” says Lasecki. Spiral conveyors are frequently used to

That fits within your budget and footprint.

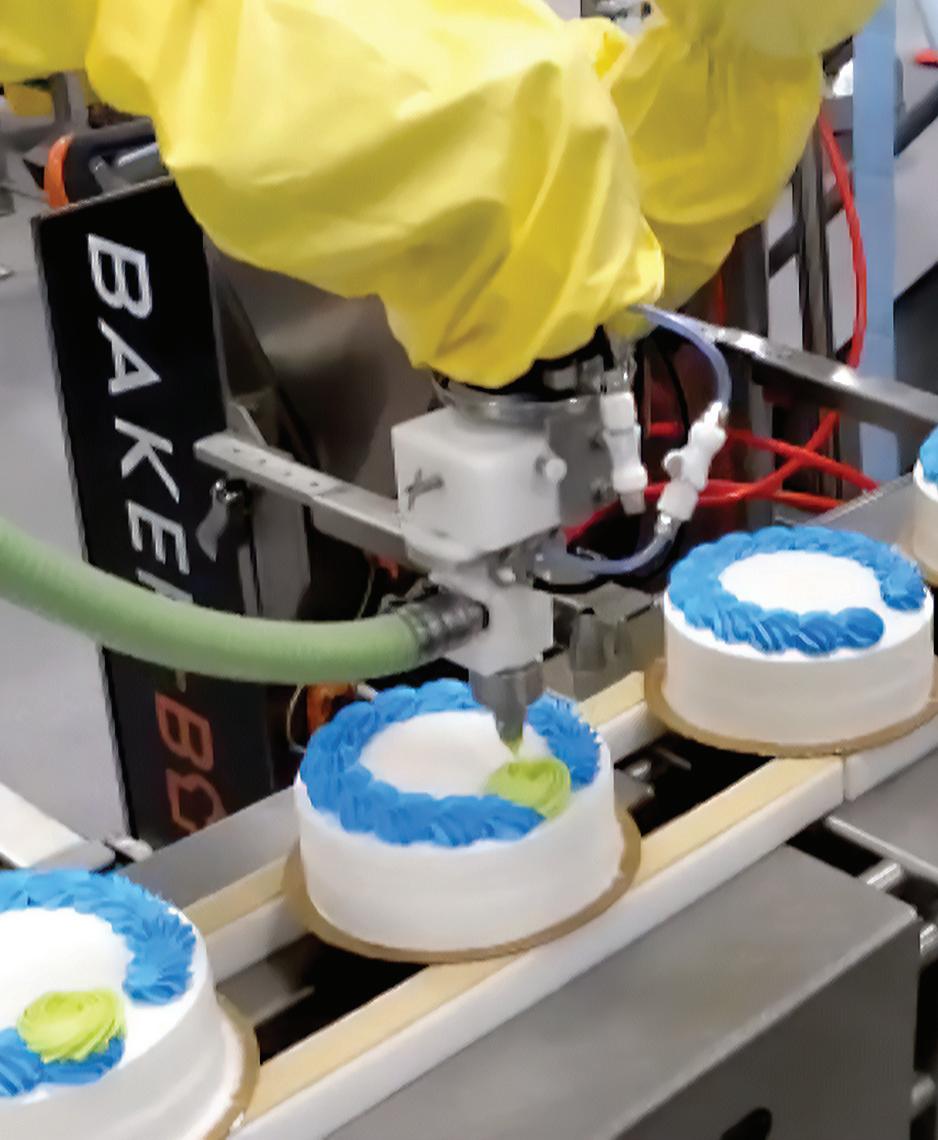

Automatically move pans, trays and boards from, or to conveyors and racks, or auto feed pans to conveyors.

Base ice top & sides, cake border top and bottom, drizzle & draw for round cakes, sheet cakes, cupcakes and cookies.

Primary packaging, secondary packaging, end of line palletizing and depalletizing.

chill or freeze food as a required step for processing, and the amount of vertical space used helps to free up a considerable amount of square footage elsewhere in a facility.

“Conveyor manufacturers are very creative today in offering overhead, ceiling mount, or floor supported conveyors,” adds Jim Dodd, SBU manager, South, at FlexLink. “Spirals and wedge conveyors also offer small footprint elevation inclines and declines, and conveyors are often stacked as well to minimize footprint.”

G&S Foods utilizes ceiling mounted horizontal conveyors above other conveying lines, which Fitzkee says helps the company manufacture more product volume compared to their previous setup, especially since the horizontal conveyors they use are larger and deeper than the previous vibratory conveyor setup.

Space saving also comes in the form of flexible, scalable modular conveyors and tighter product transfers on the line, allowing processors to adapt to changing production needs without significant overhauls. Modular designs enable quick reconfiguration of production lines, accommodating new products

Since space can be limited for conveying lines, vertical conveying solutions like this spiral elevator conveyor can utilize an abundance of vertical square footage in a facility.

“Spiral conveyors allow long lengths of belt to travel in a helical path, often allowing processing in a

facility footprint

using only 10% of the square footage required of a long, straight-running conveyor.”

or changes in demand. This adaptability is crucial in an industry where market trends can shift rapidly, and processors must be able to respond swiftly to maintain their competitive edge.

“We get customer requests for better and tighter transfers all the time,” says Bannerman. “Product transfers can change your line performance and reduce waste if done correctly. Trends for small-

er products, line flexibility, and changing market demands are making this even more important to future-proof production lines.”

On the subject of reducing waste, energy efficiency is also a focal point in today’s conveyor design. As processors aim to reduce their carbon footprint and operational costs, conveyors that consume less energy while maintaining high performance are in demand. Advances in variable speed motor technology that drive conveyors, lightweight materials, and streamlined designs contribute to lower energy consumption. These improvements not only benefit the environment but also provide cost savings for processors, making their operations more sustainable in the long run.

“Food manufacturers are increasingly realizing that conveyors offer far more than just transport between processes,” notes Lento. “When smartly designed, they increase OEE by supporting line optimization and line balancing by providing dynamic buffering and accumulation options to protect critical path process and prevent choking and starving of each part of the line. Real-time automated diverts and merges

Eriez offers a wide range of magnetic separators to get metal out

s

In-line sensors, vision inspection, product sorting, and IoT (Internet of Things) devices embedded in conveyor systems provide operators with real-time data on performance, product quality, and maintenance needs. That data can help processors save money over time.

also offer efficient ways to move products between lines in response to downtime, SKU changeovers, and increased or decreased production demands.”

Lento adds that accumulation tables in particular—where products can gather to the side of the conveyor if there is a problem on the line downstream affecting flow—are becoming an increasingly important part of a conveyor system, especially with the pressure to increase production and reduce downtime in many operations.

Automated labor savings

Conveyors are by design intended to increase production speed while decreasing the need for labor. Today’s conveyors reflect the ongoing labor shortage by incorporating simplified controls so operators can use them more easily—particularly important for entry-level or inexperienced workers—and the conveyors are also built with advanced safety features that help protect staff from accidents.

“Our customers tell us one of the bigger chal-

Miura is dedicated to producing reliable, efficient, and safe steam generation systems for pet food processing companies. Our complete solutions approach ensures your facility operates at peak efficiency, addressing all aspects of your boiler room.

Miura is dedicated to producing reliable, efficient, and safe steam generation systems for pet food processing companies. Our complete solutions approach ensures your facility operates at peak efficiency, addressing all aspects of your boiler room. We invite you to experience unparalleled efficiency and savings with Miura during our limited-time Summertime Savings event.

We invite you to experience unparalleled efficiency and savings with Miura’s Multiple Installation System.

lenges they face is related to securing a reliable labor force amid increasing demands for throughput,” says Bannerman. “This puts pressure on the [conveying] equipment to be reliable, safe, and easy to maintain.”

Dodd adds that bar codes are also an option on conveying lines today so operators can easily access machine specs, service manuals, and order parts on the spot to minimize downtime. He also envisions increased use of collaborative robots to further automate primary, secondary, and end-ofline processes along conveyors.

Advanced technology in today’s conveyors is another element that increases efficiency on the line while leading to significant cost savings. In-line sensors, AI, vision inspection, product sorting, and IoT (Internet of Things) devices embedded in conveyor systems provide real-time data on performance, product quality and consistency, and maintenance needs.

This data-driven approach allows for predictive maintenance, reducing downtime and extending the lifespan of the equipment. By leveraging these technologies, processors can achieve greater effi -

ciency and reliability, ensuring that their production lines run smoothly. Additionally, real-time dashboards provide operators with instant access to critical data, enabling quicker decision-making and more responsive management.

“Processors today want to validate what they are going to purchase, and monitor their production efficiency,” Lento explains. “[Conveyor] systems can be simulated with software to see how they will work and what to provide as a final solution for an operation.”

As food processing continues to evolve, the role of conveyors will remain pivotal. Balancing efficiency and flexibility, while embracing new technologies, will be key to navigating the complexities of modern manufacturing. By staying ahead of market trends and technological advancements for conveyors, processors can ensure their operations remain competitive, efficient, and capable of meeting the always-changing demands of the industry.

Ashworth www.ashworth.com FlexLink www.flexlink.com

FPS Food Process Solutions www.fpscorp.ca

Intralox www.intralox.com

Compact pressure sensors and switches with 360° custom-color status display

www.vega.com/vegabar

256 colors

Individually selectable:

Measurement in progress

Sensor switching

Process malfunction

MICHAEL COSTA | EDITOR-IN-CHIEF

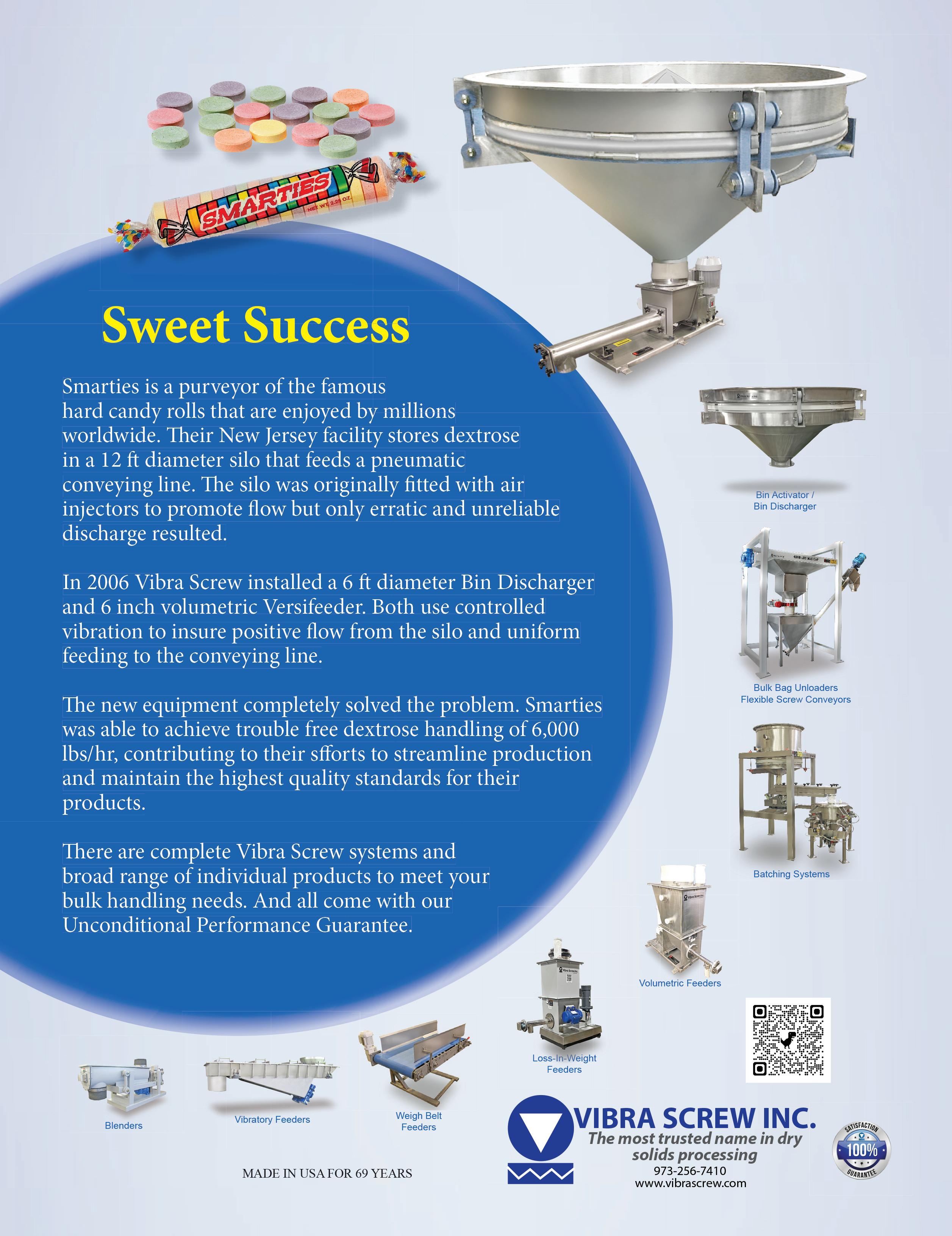

Goya’s Sazón brand reduced workforce fatigue while elevating productivity by adding automated weigh batching systems, resulting in a 12.5% production increase per shift.

SAZÓN PRODUCES bouillon powders and varieties of Sazón Goya seasonings for Goya Foods, the largest Hispanic-owned food company in the U.S. The original product line was launched in Puerto Rico in 1973 and moved to Goya’s Miami-area facility in 1983.

Workers at that Miami plant previously loaded herbs, spices, salt and seasonings manually into three ribbon blenders, each with a working capacity of nearly 3,000 lb. The job required lifting, cutting, and dumping several dozen bags per batch, for 21 batches over an eight-hour shift. “Dumping 50 lb bags of seasoning for every batch is not easy work,” says Hiram Carlo, plant manager at the Sazón facility.

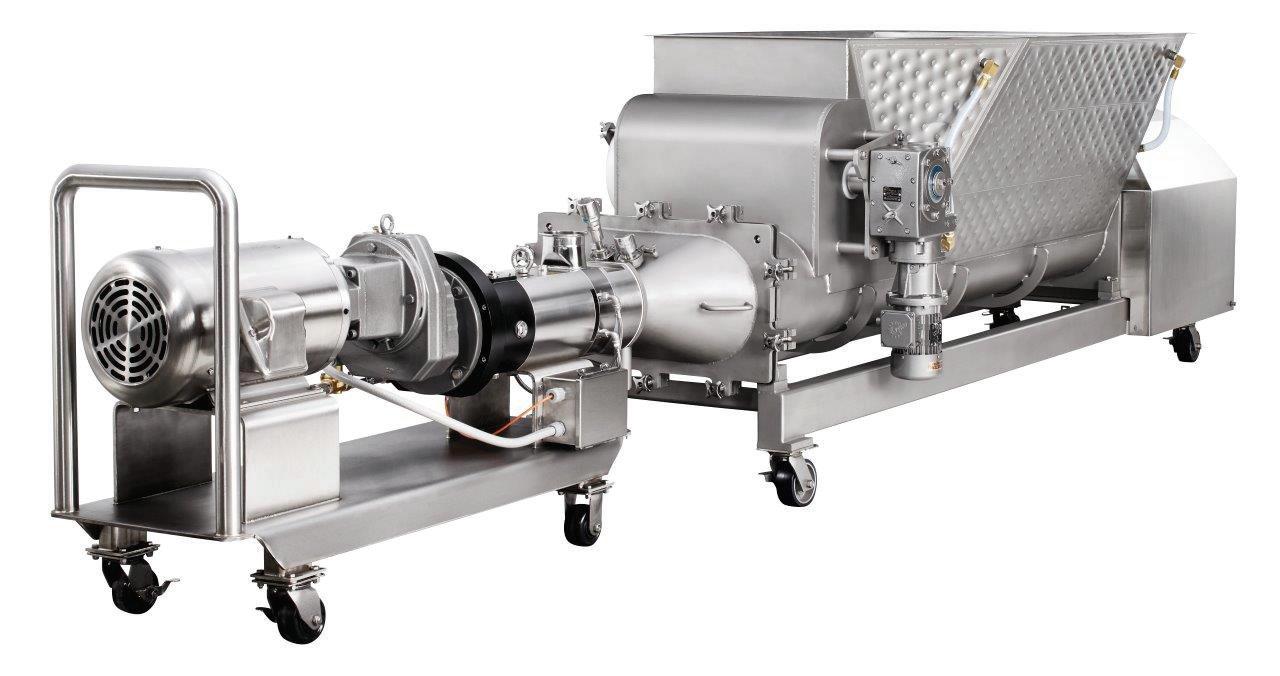

Due to ongoing sales growth, Sazón added two more packaging lines and two blenders to the operation in 2019. The company also installed five identical bulk weighing and batching systems from Flexicon Corporation—one for each blender—to add high-volume ingredients in many of the 19 seasoning and bouillon recipes.

Goya’s Miami-area Sazón plant produces more than a billion seasoning and bouillon packets per year.

discharger, which is mounted on load cells. The operator connects the bag loops to a lifting frame at floor level and, using a pendant controller, loads the bag into the discharger frame by means of a hoist and trolley traveling on a cantilevered I-beam.

Each of the batching systems combines a bulk bag discharger and a flexible screw conveyor that feeds the ingredient into a pneumatic conveying line 55 ft long. The result of adding Flexicon’s efficient, labor-saving equipment has been an increase of 12.5% in production of blends per shift.

The process begins when one-ton bulk bags of seasoning are delivered by forklift to the bulk bag

The operator then makes a dust-tight connection to a clamp ring atop a telescoping tube, and unties the spout drawstring. The telescoping tube applies continuous downward tension on the bag as it empties and elongates, promoting flow and evacuation of the seasoning.

The seasoning, comprised of fine white crystals, flows into a 5-cu-ft floor hopper charging an integral 5 ft long, 3.5 in. diameter flexible screw conveyor. The conveyor propels the product at an incline, discharging through flexible downspouting

Here, an operator at Sazón uses a pendant to hoist a Flexicon bulk bag and roll it into position.

Here are three of the five bulk weighing and batching systems at Sazón’s Miami-area plant, each comprised of a bulk bag discharger on load cells, that move seasoning from bulk bags through a pneumatic conveying line to five blenders.

Blended batches of seasoning and bouillon powder are gravity discharged into a polymer surge hopper and flexible screw conveyor that feeds a packaging machine. The fully enclosed system prevents contamination of the product and facility environment.

into a pickup adapter feeding a 2.5 in. diameter pneumatic conveying line.

Load cells supporting the bulk bag discharger transmit loss-of-weight signals to a PLC that controls the batch weight of the seasoning. “We just input the information into the panel, say 2,000 pounds, and that’s it,” Carlo says.

Upon receiving the signal, the inclined flexible screw conveyor feeds the seasoning into the pickup adapter. From there, the material travels 55 ft horizontally and 15 ft vertically to a 24 in. diameter filter-receiver that discharges into a 2.5 cu ft hopper.

Delivery of the seasoning slows and stops automatically when the weight lost from the bulk bag reaches the target batch weight. A rotary airlock valve simultaneously discharges the batch into the blender through downspouting, as minor ingredients are added manually.

After 30-minute blending cycles, the batch gravity discharges through a slide gate and passes through a check-sifter before flowing into a hopper from which a flexible screw conveyor

In this photo, an operator at Sazón ensures a clamp ring makes a dust-tight connection while a telescoping tube applies downward tension on the bulk bag, promoting flow and release of powder.

feeds a packaging line. Foil-lined packets of seasoning and bouillon are formed and filled with 5 to 10 g of material and heat-sealed at rates of 1,000 to 1,500 per minute.

A lot of our customers can’t talk about their secret to safe, smooth, gentle conveying but everyone knows the secret is Volkmann. Our patented pneumatic vacuum conveyors automatically transfer powders and other bulk materials from one point to another in fully enclosed, dust-tight, explosionproof systems.

Automated, hygienic and quiet

Easy to use, easy to clean

No tools disassembly

Stainless steel as standard

Fast lead times, easy to install

The packets are inserted into a carton that passes through a checkweigher, is coded, and moves to an accumulator for placement into a master case. In the final step, two palletizers consolidate the master cases for shipment.

By adding five Flexicon weighing and batching systems, Sazón can operate two shifts that process 35 seasoning and bouillon batches per shift—compared to 21 batches previously—with only five operators needed for batching, blending, packaging, and shipping.

“We package more than a billion [seasoning and bouillon] packets a year now, and we’re much more comfortable,” notes Carlo. “No worker fatigue, and far less time dumping bags manually. It’s a more efficient way to make our products and it’s making our lives easier.”

Looking ahead, Carlo says Goya has identified a satellite facility near the Miami-area plant, where Sazón can add production capacity, “and build on the automation work done with Flexicon to test new procedures that will reduce material handling and enhance food safety and quality control initiatives.”

Flexicon Corporation www.flexicon.com

The ROSS CDA-300 Dual Shaft Mixer is designed for efficient and consistent processing of various formulations. Featuring a powerful anchor agitator and highspeed disperser, it ensures thorough mixing and dispersion of ingredients, even in high-viscosity batches. The mixer’s versatile design, including interchangeable mix cans with heating/cooling capabilities and a userfriendly control panel, makes it suitable for a wide range of applications. With its vacuum operation and safety features, the CDA-300 delivers high-quality products with precise control and reliability.

Charles Ross & Son Company mixers.com