OCT2023 packworld.com 18 How ColgatePalmolive Cuts Packaging CO2 26 Robots Handle Cartons, Cases for T. Marzetti 34 Hyper-local Automated Micro-factory Packages Ice 42 Best Practices for CM/CP Selection 24 Cartons Re ll Durable Glass in Reusable Cleaner System Learn more about our automation solutions at www westrock.com/ automation

v yda s r v � B -in-class blow logy � ys � v ch your s

xiLid

NEW INTRALOX® SERIES 2300 DUAL TURNING BELT ELIMINATE DEAD PLATES ON YOUR S-CURVES. © 2022 Intralox, L.L.C. 5011190_EN Scan QR code to learn more.

26

Robotics Bring Big Benefits to Bakery

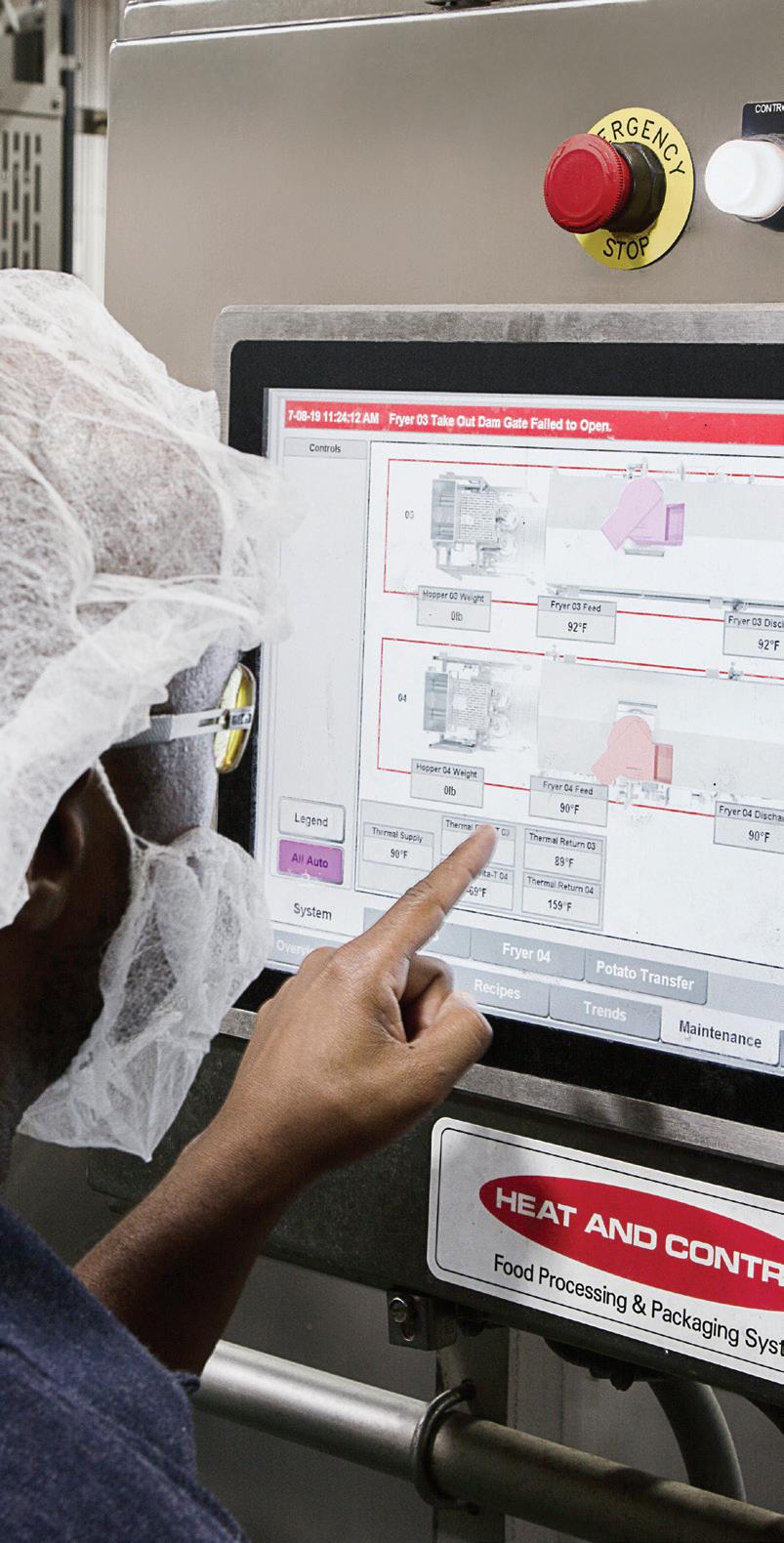

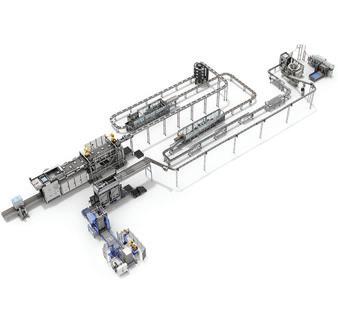

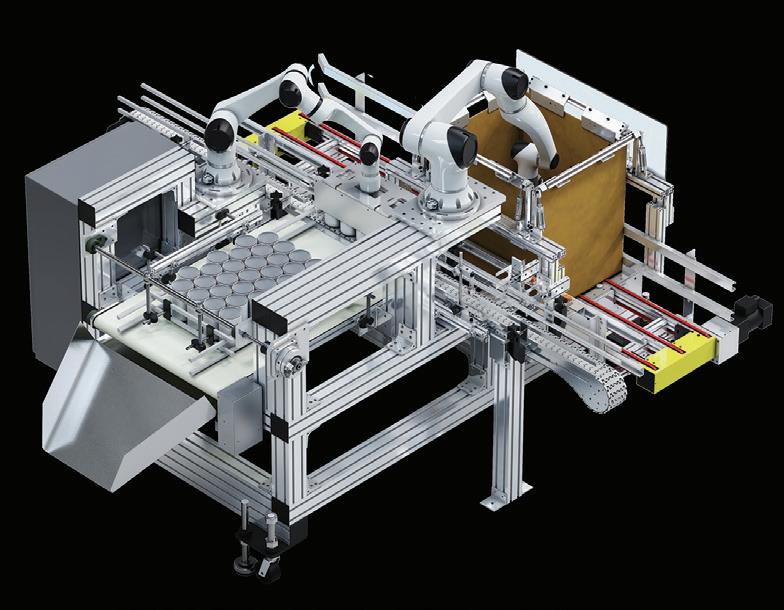

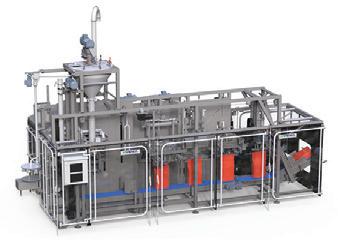

Two identical monoblock cartoning/case packing systems produce a number of secondary and tertiary packaging formats, while robotic palletizing brings the automated line to a close.

34 AUTOMATION

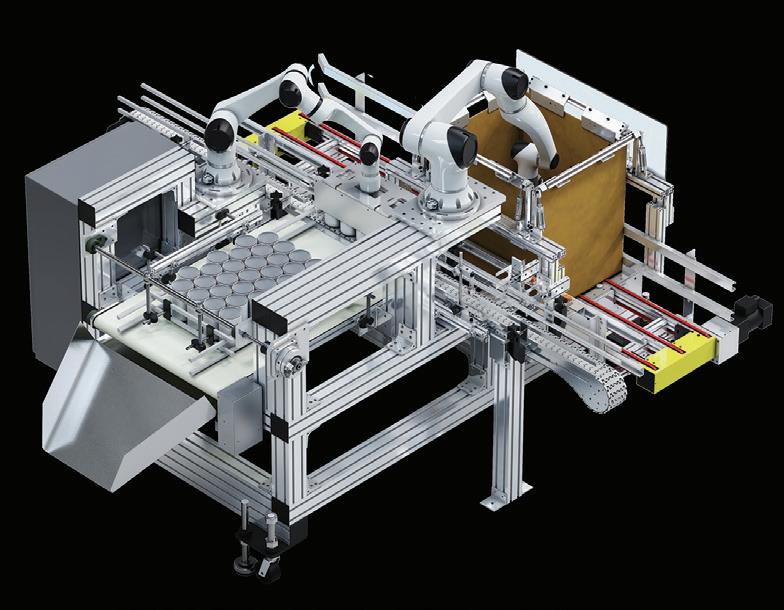

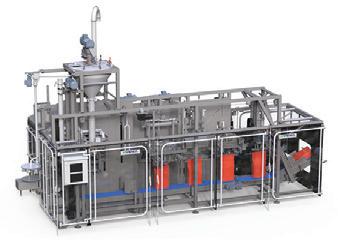

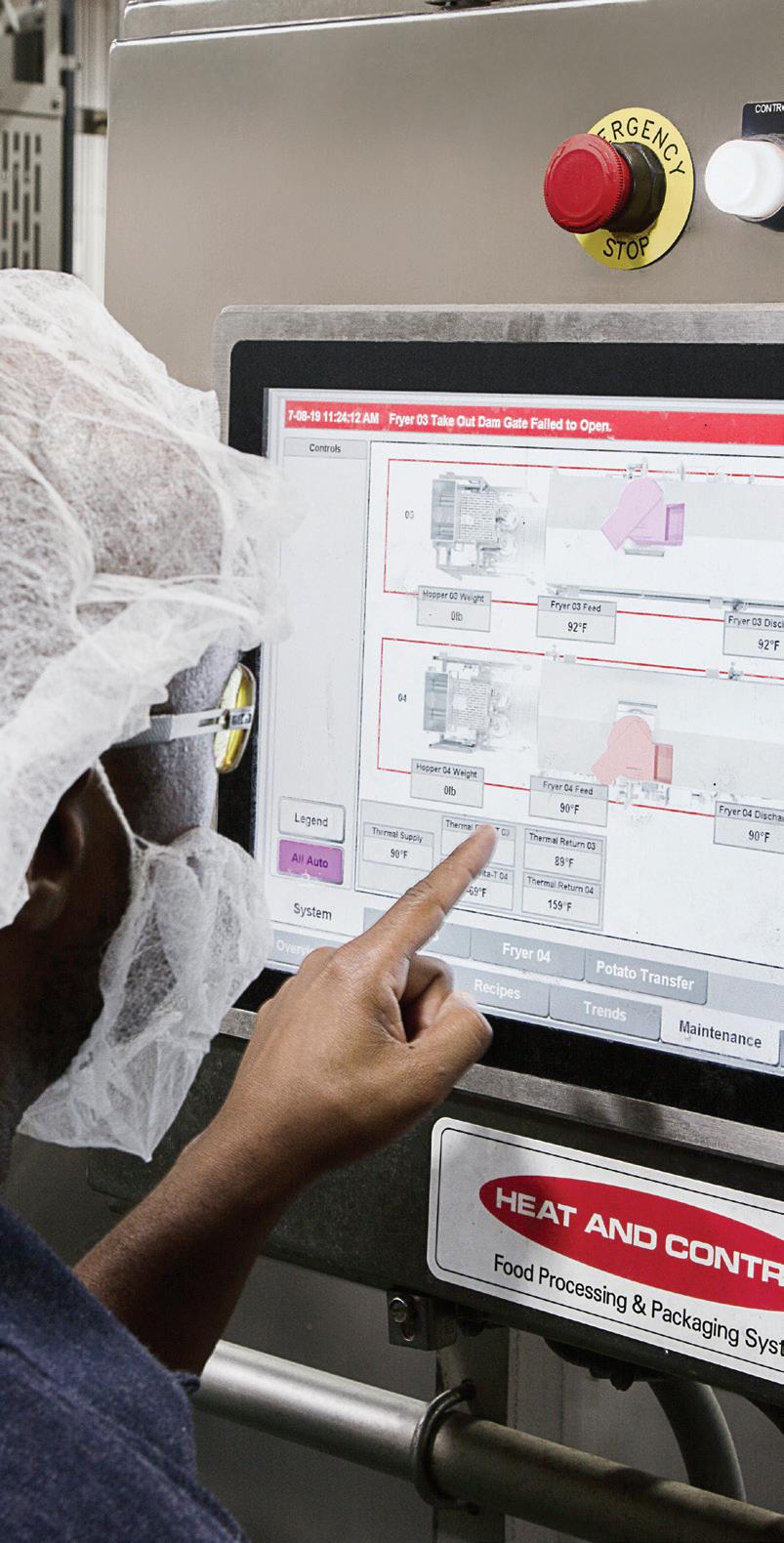

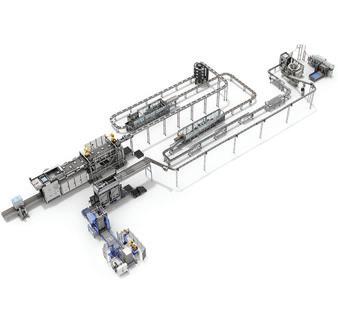

Grocer Pilots Autonomous Micro-Factory for More Sustainable Ice

Relocalize, a provider of hyper-local automated micro-factories, partners with Southeastern Grocers in a pilot to produce a more sustainable, high-quality ice product manufactured and packaged near the point of distribution.

42 Contract Packager Selection Best Practices for Scaling Brands

Could your fast-scaling brand benefit from product packaging expertise and equipment capacity from a co-manufacturer/co-packer? Experts discuss how to know whether your emerging CPG is ready, and if you are, what your next steps should be.

50 CPA Membership Directory

A company listing of members of the Association for

Cleancult’s packaging system comprises a refillable, reusable, shatter-resistant glass bottle paired with Eco Refills in 32-oz cartons that together are said by the company to reduce plastic waste by 90%. In addition, by using this packaging system, consumers can save up to 55.8 lb of plastic per year, according to the company.

DEPARTMENTS

56

Aladin Alkhawam Supply Chain Security Director, Endo International plc

Jan Brücklmeier Technical Application Group Packaging Technology Expert, Nestlé

M. Shawn French Director – Innovation & Packaging Engineering (Beverage), Danone North America

Patrick Keenan R&D Packaging Engineer, General Mills/Annie’s Organic Snacks

Mike Marcinkowski Global R&D Officer, GPA Global & Hub Folding Box Co.

David Smith, PhD Principal, David S. Smith & Associates

Brian Stepowany Packaging R&D, Senior Manager, B&G Foods, Inc.

Jasmine Sutherland President, Texas Food Solutions; Vice President, Perfect Fit Meals

Contract Packagers

Manufacturers.

VOL30 NO10 Packaging World® (ISSN # 1073-7367) is a registered trademark of PMMI, The Association for Packaging and Processing Technologies. Packaging World® is published monthly by PMMI with its publishing office, PMMI Media Group, located at 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611; 312.222.1010; Fax: 312.222.1310. Periodicals postage paid at Chicago, IL, and additional mailing offices. Copyright 2023 by PMMI. All rights reserved. Materials in this publication must not be reproduced in any form without written permission of the publisher. Applications for a free subscription may be made online at www.packworld.com/subscribe. Paid subscription rates per year are $254 in the U.S., $363 Canada and Mexico by surface mail; $605 Europe and South America; $907 Far East, Australia, and other countries by air mail. Single copy price in U.S. is $20. To subscribe or manage your subscription to Packaging World, visit Packworld.com/subscribe. Free digital edition available to qualified individuals outside the United States. POSTMASTER; Send address changes to Packaging World®, 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611. PRINTED IN USA by Quad. The opinions expressed in articles are those of the authors and not necessarily those of PMMI. Comments, questions and letters to the editor are welcome and can be sent to: editors@packworld.com. Mailing List: We make a portion of our mailing list available to reputable firms. If you would prefer that we don’t include your name, please write us at the Chicago, IL address.

Lead

&

FEATURES

COLUMNS 5

Off 20 The Legal Side

22 The Big Picture 24 Sustainable Packaging

The Insider NEWS/EVENTS 6 News 16 Quotables/By the Numbers INTERVIEW 18 First Person PRODUCTS 52 Technology ADVERTISING 55 Advertiser Index

EDITORIAL ADVISORY BOARD

24

2 PW OCT 2023

800.621.4170 | trianglepackage.com 100 YEARS OF KEEPING FOOD SAFE

FROM COFFEE TO PROTEIN POWDER,

if you make it, Spee-Dee ® augers can fill it.

Matt Reynolds Chief Editor

Anne Marie Mohan Senior Editor

Iris Zavala Managing Editor

Sean Riley Senior News Director

Pat Reynolds, Sterling Anthony, Eric F. Greenberg, Ben Miyares Contributing Editors

David Bacho Creative Director

ADVERTISING

John Schrei Vice President, Sales jschrei@pmmimediagroup.com

Lara Krieger Senior Manager, Print Operations lkrieger@pmmimediagroup.com

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

David Newcorn President

Elizabeth Kachoris Vice President, Digital

Kelly Greeby Senior Director, Client Success & Media Operations

Jen Krepelka Director, Digital Media

Trey Smith Senior Director, Events

Sharon Taylor Director, Marketing

Joseph Angel Founding Partner and Executive Vice President, Industry Outreach, PMMI

Lloyd Ferguson Founding Partner

Spee-Dee will help find the right solution even for new formulations like plant-based protein powders, sugar substitutes and gluten-free flours. Our fillers easily integrate with all formats of bag makers, conveyor lines and cup and tray equipment. Optional vacuum tooling eliminates product drip for clean seals with all packaging types.

Staff at PMMI Media Group can be contacted at info@pmmimediagroup.com

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com.

Packaging World • PMMI Media Group 401 N. Michigan Ave., Suite 1700, Chicago, IL 60611 Phone: 312/222-1010 • Fax: 312/222-1310

info@packworld.com • Web: www.packworld.com

The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170 Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

E-Mail:

PMMI

CONTENT

4 PW OCT 2023 spee-dee.com | 877.375.2121

Follow us

Work/Study Co-Op Pays Off

Me and 32,000 of my closest friends just attended a mighty energizing PACK EXPO Las Vegas 2023—the biggest ever, by the way. Needless to say, there was no shortage of advanced technology to dazzle us. But I also had an encouraging conversation on the subject of workforce development with Fanuc engineering manager Jessica Juhasz (pictured below), who has a fascinating work/study backstory that’s more like what we see in Germany than what we see in the U.S.

Juhasz earned her B.S. in electrical engineering at Kettering University, which was founded in 1919 as a night school for engineers, managers, designers, and technicians in the rapidly-evolving automobile industry. In 1923 it was acquired by General Motors and became known as GMI, General Motors Institute. The Kettering name came in 1998. Located in Flint, Mich., and having a total enrollment of about 2,237 (1,516 undergrads), Kettering’s concept of education is unique in the way that it blends practice with theory in equal measure. In fact, all undergraduate students are required to complete at least five co-op terms with one of Kettering’s many employer partners. For Juhasz, that partner was Fanuc.

During the 4.5 years it took to earn her B.S., Juhasz spent the months of July, August, September in a Kettering classroom. October, November, December she worked 40-hour weeks at Fanuc. January to March it was back to the Kettering classroom, and April to June it was back to Fanuc. “At the very beginning they started me off in operations, purchasing to be more specific,” says Juhasz. “Having never had a corporate job, it was a good way to get the big picture, to learn about the nature of the business, about how things that go into robots got purchased. But by sophomore year I was able to work in our manufacturing and engineering department, so it was being out on the floor, doing time studies, helping improve processes within our manufacturing department, and so on.”

Upon graduation, Juhasz became a full-time Fanuc engineer. And get this. In addition to gaining 2.5 years of invaluable work experience at the same time she was earning a B.S. in electrical engineering, she was paid a salary during the months she worked at Fanuc throughout her undergraduate years. According to the Kettering web site, today the average hourly co-op earnings for first-year students is $15.38. And for seniors it’s $18.72.

Looking back now, Juhasz sums up her co-op experience this way: “It was a unique way of learning and understanding what I wanted to do in my career. You just can’t get that in a conventional academic program because it’s all purely theoretical.”

Denise Scanlon, university and early career talent acquisition partner at Fanuc, is equally impressed with what Kettering offers. “It’s so well organized,” she notes. “And they don’t make it a hardship on the manufacturer employing the student.” Worth noting is that Scanlon is the one who brought Juhasz into the Kettering/Fanuc fold way back in 2005.

Also intrigued by the Kettering/Fanuc relationship is Stephan Girard, senior director workforce development at PMMI. “Co-ops are great because they are similar to registered apprenticeships, but they don’t have as many strings attached since they are not affiliated with the Department of Labor,” says Girard. “What’s so important about a co-op is the hands-on experience that’s gained. A student in a conventional engineering program typically doesn’t get beyond the theoretical. But a student coming out of a co-op is ready to hit the ground running. I would love to see more of these types of programs.”

While we’re on the subject of workforce development, be sure to visit https://pmmiu.org to see what PMMI U offers to help the development of the future workforce. Finally, here’s the at-booth video (pwgo.to/8097) of Juhasz demonstrating Fanuc’s latest food-packaging robot. PW

LEAD OFF reynolds@packworld.com 5 844-293-2814 Draper Z Incline Conveyor NEW Contact Us for Details CONVEYOR EQUIPMENT IN 6 - 8 WEEKS • Made at fixed angles of 30, 45, and 60 degrees • Reduced footprint • Eliminate changeover adjustments • Low maintenance • Accessibility layout for operator and fork truck traffic

Pouches Prove More Sustainable than Cartons for Cocktail Tea Bags

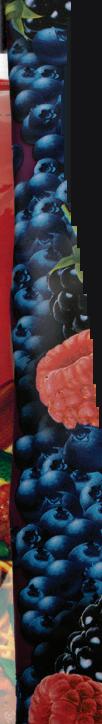

Sayso, the “first-ever craft cocktail tea bag” brand, is celebrating its first anniversary with a move to new carbon footprint-lowering secondary packaging and new graphics that clearly communicate the product’s purpose: to create craft cocktails and mocktails with real ingredients in mere minutes without the shaking, blending, or mess.

Brooklyn, N.Y.-based Sayso was co-founded by Chloe Bergson and Alison Evans. The two women, who met at Harvard Business School, were looking for a way to duplicate at home the craft cocktails they so enjoyed in New York City restaurants and bars, but were frustrated with the disappointing results they achieved with cocktail kits and liquid mixers that

Chemical Recycling Pilot Closes the Loop for Arla’s Cheese Maturing Bags

Keeping plastic in the loop is the goal of a new pilot undertaken by international dairy foods company Arla Foods and film producer Südpack whereby a portion of the cheese maturing bags used in Arla’s cheese production process are being chemically recycled and made into new packaging. The pilot relies on Recenso’s Carboliq chemical recycling process, which is being done at an industrial-scale pilot facility in Ennigerloh, Germany, jointly operated by Südpack, Clean Cycle Investments, and Recenso’s subsidiary, which also goes by the name Carboliq Cheese maturation is a scientific process that develops the flavor and texture of cheese over time. At its Rødkaersbro dairy in Denmark, Arla matures its mozzarella cheese by placing it in specially designed maturing bags for about two weeks. The plastic bags are made of multiple film layers that act as a barrier

were full of excessive sugar, preservatives, and artificial flavors. Their solution was to develop a line of dry mixes packaged in tea bags that could be steeped in spirits to create one of four craft cocktails (or in a non-alcoholic beverage for a mocktail): a Skinny Spicy Margarita, a Skinny Cardamom Paloma, a Honey Rosemary Moscow Mule, or an Old Fashioned.

Sayso’s cocktail mixes are non-GMO, vegan, gluten-free, kosher, and/ or plant-based and include such vibrant ingredients as orange and grapefruit peel, jalapeno, ginger, smoked salt, cardamom seeds, and honey.

Explaining how Sayso came up with the idea to package the ingredients in tea bags, Bergson says that it was important for consumers to be able to see the real ingredients that make up the product. “The tea bag helped us to achieve this by containing the pieces of ingredients so that they were not floating around, and at the same time providing visual transparency,” she says.

It was also important to Sayso to weave sustainability into the fabric of the company early on, including in the selection of its packaging materials. The tea bags, from Nasa Corp., range in weight from 0.16 to 0.57 oz,

to oxygen, preventing the formation of mildew and the emergence of pathogens and harmful microflora. Because of their multilayer construction, the bags cannot be recycled through mechanical means. Instead, the 220 metric tons of maturing film used by Arla each year are incinerated.

“At Arla Foods, we have a 360-degree approach to packaging—how was the material sourced, what qualities does it possess, and how can it be disposed of after its functional use,” says Grane Maaløe, lead packaging development manager at Arla.

“In this pilot, we are finding a new use for our maturing film previously sent to incineration and are closing the loop by applying the recycled material into new food packaging, improving circularity, which is one of the cornerstones in our sustainable packaging strategy.”

For the pilot, Arla is sending 80 metric tons per year—the volume that can currently be accommodated by the Carboliq pilot facility—to Ennigerloh where it undergoes a proprietary one-stage conversion process that liquefies solid hydrocarbons, resulting in Carboliq’s CRL (Circular Liquid Resource), or a high-yield oil that can be used to manufacture new high-end polymers. According to Carboliq, its process is characterized by the application of thermal, catalytic, and physical

NEWS 6 PW OCT 2023

depending on ingredients, and are constructed of a compostable, non-woven fabric made from PLA (polylactic acid) bioplastic with a 100% PLA thread. The tag for the tea bag is made from a lamination of uncoated paper and PLA.

When first launched, Sayso’s Ready-to-Make Cocktail Sachet products were sold in an eight-count carton, with each tea bag individually packaged in a film/foil three side-seal pouch. This summer, the company switched from the carton to a flexible film stand-up pouch with zipper closure that Bergson says “significantly” reduces Sayso’s carbon footprint by negating the need for individual packaging for each tea bag. This also allowed the company to significantly reduce the cost of the product, from $24/unit ($3/serving) for the carton to $16/unit ($2/ serving) for the pouch.

Supplied by ePac Flexible Packaging, the new SUP is made from 0.56-mil post-consumer recycled soft-touch matte PET/0.48 mil PCR metallized PET/3.50 mil PCR white polyethylene, for an overall PCR content of 43.5%.

With the new pouch came new packaging graphics as well. While the logo and color palettes remain the same, Sayso has made the finished product the focal point of the package. “On the new package, we hero a real photo of our product,” says Bergson. “Because we are introducing a new product category, we realized how important customer education is. Despite using the tea bag form factor, we are not a tea product—we are a cocktail and mocktail product.”

In addition to the new packaging, Sayso has added two new flavors, Espresso Martini and Hibiscus Cosmopolitan. The products are available online through the company’s website and Amazon.com as well as in select retailers in California and the Northeast, including Citarella, Gourmet Garage, Fairway, Morton Williams, and others.

—Anne Marie Mohan

forces for cracking hydrocarbon and by its ability to use a wide range of mixed-waste plastic or agricultural waste biomass as feedstock.

Says Dirk Hardow, business unit manager, Functional Films and Compounds for Südpack, while one metric ton of mixed plastic waste does not equal one metric ton of new packaging, “it does reduce the need for fossil feedstock, and it paves the way for increased investing in this infrastructure moving forward.”

Furthermore, reports Südpack, factoring in the loss of electricity and thermal energy that incineration delivers, and the negative impact of transporting the films from Denmark to Germany, the calculation behind the test still comes out in favor of chemical recycling when it comes to overall carbon emissions. Per metric ton of plastic waste, the full processing, including the chemical recycling process, emits up to 50% less than sending the maturing film to incineration, the company says.

The pilot began in 2021. Upon conclusion of the pilot, Südpack and Arla will evaluate and plan the next steps. “The aim is to create a business case comparing the economic, practical, and environmental impact of the process,” says Maaløe. “We will use the results not only internally, but also share our findings with national waste sorting shareholders to make sure we work bilaterally to create the best recycling infrastructure for the future.”

—Anne Marie Mohan

—Anne Marie Mohan

7

PMMI Releases Overhauled Packaging Equipment Safety Standard

On Aug. 31, PMMI unveiled the newly approved American National Standard on the Safety of Packaging and Processing Machinery, ANSI/PMMI B155.1-2023. This new edition marks an overhaul of the standard, introducing critical changes that prioritize user safety and reflect industry advancements.

Guided by a panel of experts convened by standard-developer PMMI, the ANSI/ PMMI B155.1-2023 standard underwent a comprehensive revision to address evolving safety concerns, technological advancements, and changing operational landscapes. The development committee includes new contributors providing insights from machine builders, CPGs, and controls and automation suppliers.

“By introducing these comprehensive updates, the ANSI/PMMI B155.1-2023 standard sets a new benchmark for safety in the packaging and processing machinery industry,” says Tom Egan, vice president, industry services, PMMI. “This revised standard reaffirms the commitment of PMMI to the safety and well-being of industry professionals, ensuring that technological advancements go hand-in-hand with the highest levels of safety.”

The standard guides packaging and processing machinery suppliers and users through a formal, documented risk assessment process designed to ensure that reasonably foreseeable hazards are identified, and corresponding risks are reduced to an acceptable level.

“Safety is critical to all operators. With an evolving work landscape, having industry standards that are rigorously evaluated on a consistent basis allows us to stay vigilant in mitigating risk,” says John Uber, head of product compliance for PMMI member company Mettler Toledo.

A few key highlights of the standard’s updates include:

• Refined responsibilities. The revised text explicitly outlines the responsibilities of machinery suppliers, users, modifiers, purchasers of used machinery, and other stakeholders, fostering a safer working environment through increased accountability. The update addresses machinery-as-a-service (MaaS), including equipment loaned or provided by a third party and located in a user facility, as well as mobile platforms, robots used for logistics, cleaning, and more.

• Introduction of CM/CP concepts. The new edition introduces the concept of copackers and co-manufacturers, delineating their associated responsibilities within the framework of safety regulations.

• Updated legacy machinery requirements. The responsibilities for existing (legacy) machinery have been updated and clarified to ensure that older equipment is brought in line with the latest safety standards in a practical, cost-effective, and appropriate way.

• Clarified scope. The scope of the standard has been clarified to provide a more precise understanding of its applicability, reducing ambiguity and allowing for improved implementation.

• Remote/tele-operation enhancements. With the advancement of remote operations, the standard now offers improved information and guidelines for safely operating machinery through remote means.

• Reorganized clauses 4 and 5. The standard now features a restructured layout for enhanced clarity and ease of reference, streamlining the reading experience for professionals in the field.

• Whole body access requirements. The standard now includes comprehensive requirements for situations where whole body access is applicable, safeguarding operators from potential hazards.

Packaging World recently previewed the long-awaited acceptance and release of updates to this standard. Visit pwgo.to/8090 to read more.

The ANSI/PMMI B155.1-2023 standard will be available for purchase through the ANSI webstore. —Matt Reynolds

NEWS 8 PW OCT 2023 build your best conveyor business BI-DIRECTIONAL ACCUMULATION TABLE DISTRIBUTORS modularconveyor.com 844.293.2816 • Product Flexibility: Quickly introduce new products into inventory • Process Flexibility: Modular conveyor systems with standard designs • Cost Flexibility: Quote solutions with options for every project blueprint represent Modular Conveyor Express and get your conveyor systems and equipment in 3-4 weeks! Conveyors designed by Nercon

Madura Tea Shifts from Metalized OPP to Barrier Paper Packaging

Australia is leading the charge in a recent shift toward barrier paper packaging. Not long after Mars unveiled an Australian barrier paper pack pilot with candy bars—and Nestlé did the same with its KitKat bars—Australian brand Madura Tea shifted packaging materials from metalized oriented polypropylene (OPP) to flexible paper packaging.

“Madura Tea has made the right decision in demonstrating its environmental responsibility by using recyclable materials from sustainable sources,” says Carsten Loemker, lead, engineering/technology, Madura Tea says of the company’s motivation for the switch.

With help from German suppliers Gundlach Packaging Group and Koehler Paper, Madura believes it has found an ideal packaging format for its products in a specific material called Koehler NexPlus Seal Pure MOB 72 gsm. The supplier notes this paper material has a mineral oil barrier and offers protection against mineral oil hydrocarbons MOSH and MOAH. Gundlach Packaging Group and Koehler Paper provided the brand owner with a range of test materials from the Koehler NexFlex product range, and after several promising tests landed on this specific material. Koehler Paper says that Koehler NexPlus Seal Pure MOB is a packaging paper with a significantly reduced carbon footprint in comparison to conventional plastic packaging, and is also 100% recyclable.

“Koehler NexPlus Seal Pure MOB—which is made from 100% virgin fiber pulp and is therefore suitable for contact with food—impressed everyone involved thanks to its outstanding barrier properties,” says Yevgen Zolotkovski, sales manager for Flexible Packaging Papers at Koehler Paper.

Like all other NexPlus papers, NexPlus Seal Pure MOB is also heatsealable, and its high-strength properties make it ideally suited for further processing on all commercially available packaging machines, the company says.

“Although it’s an uncoated paper, the printing results are excellent and highlight the new environmentally friendly concept,” adds Rüdiger Brinkmann, senior sales manager at Gundlach. —Matt Reynolds

TriWraptor Ultimate Tray/Shrink Performance UP TO 120 TRAYS/MINUTE 63 Pickering Street, Portland, CT info@standard-knapp.com • (860) 342-1100 standard-knapp.com • eol.group Discover the the TriWraptor™ line of Tray/Shrink/Bundlers from Standard-Knapp: standard-knapp.com/ts 9

Fiber-based, Snap-closing Lid Launched at Picadeli

Swedish healthy eating pioneer Picadeli Salad Bar, a new concept salad bar destination located in-store at grocery retailers in Europe and more recently, the Midwest U.S. at Schnucks and Eatwell, will replace its entire line of plastic lids with paper-based lids. The company says the move will eliminate 250 metric tons of plastic from its supply chain every year. The new lids are recyclable in household paper waste streams and are made from renewable plant-based fiber sourced from sustainably managed forests, the company says.

“We value the health of our planet as much as we value healthy eating,” says Henrik Åkerman, head of sourcing and supply chain at Picadeli. “We are committed to preserving as many of our planet’s precious resources as possible, while also producing high-quality, functional packaging for our consumers to enjoy. With that in mind, we are delighted to introduce this new lid to our packaging. It fulfills all our needs and helps us reduce the amount of plastic in our portfolio, in line with modern consumer demands.”

The packaging format offers a secure snap closure system that represents an upgrade on the performance of Picadeli’s previous solution. Graphic Packaging International worked with Picadeli to achieve the familiar, functional, and tactile ‘snap’ that consumers know and expect.

“Everything we do, we do for our customers, and so it’s always pleasing to develop innovations that deliver on our customers’ expectations so emphatically,” says Åke Larsson, managing director of Graphic Packaging Tibro AB–the site involved in designing and producing the innovation.

“The new lids offer the functionality required for Picadeli to eliminate plastic salad bowl lids from their supply chain. They also offer great branding benefits via high-quality printing onto the lid using water-based inks.”

Picadeli used this opportunity to add bold, playful messages to the lids, enticing consumers to engage with the brand–an important benefit as it is the market-leading healthy fast-food outlet in Europe and the U.S., with more than 2000 salad bars across Europe alone. During the development of the new lid solution, Graphic Packaging optimized the design to ensure it remained rigid in chilled and moisture-rich environments.

—Matt Reynolds

NEWS

10 PW OCT 2023

Inside the cabinet? Outside?

You choose with our powerful, ultra-compact IPCs

Small enclosures. Harsh environments. Evolving requirements. As engineers, we know these factors must be addressed constantly. Every new machine presents unique challenges and opportunities to innovate. So our ultra-compact Industrial PC series gives you freedom to choose the perfect controller for every machine. Maybe it’s the C6015 with dimensions of just 82 x 82 x 40 mm and outstanding installation flexibility. Or maybe your machine calls for the IP65/67-rated C7015 for cabinet-free installation. All IPCs in this series deliver powerful control to simultaneously run automation, HMI, edge computing/IoT and other communication – all on one controller. They make ideal gateways to the cloud and support flexible I/O system expansions – inside or outside of the cabinet. The choice is yours

Scan to discover all the IPC installation and application possibilities PC11-51USA

Advanced Recycled Material Finds Circular Home in Fruit Cups

Pacific Coast Producers, an agricultural co-op known for high-quality fruits canned or otherwise packaged for private brands the word over, has made a big shift in one of its more common packages. It will now use Printpack’s diced fruit cups that include 30% ISCC PLUS certified-circular polyethylene from ExxonMobil, an advanced or molecularly recycled material. With this launch, the three companies say they’re working toward a shared goal of reducing plastic waste by supporting a circular economy for plastics.

“Pacific Coast Producers is proud to be associated with the efforts of Printpack to manufacture packaging that is progressively more circular for our earth and our consumers. Together, we are engaged in an ever-evolving venture to provide shelf-stable, single-serve fruit products that are made from 30% ISCC PLUS certified-circular plastic. We will gradually increase the number of cups that include certified-circular content with each seasonal pack. Our collective efforts to reduce landfill deposits, eliminate waste, and diminish pollution is the most important initiative a consumerpackaged goods company can pursue,” says Andrew K. Russick, Pacific Coast Producer’s VP, sales & marketing.

Gabletop Carton for Mouthwash Cuts

Plastic by 80%

Dedicated to making “everything” that helps consumers live more sustainably in their homes, including sustainable personal care and household and cleaning products, German company LUORO has a special place in its heart, and in its product portfolio, for oral care products. The company’s first product, introduced in 2019 on Germany’s version of Shark Tank, was The WingBrush, an interdental brush with refillable heads.

Now, with its Paperdent line, LUORO is taking aim at plastic packaging in the oral care category. “Plastic waste is one of the main threats to our nature and wildlife, and especially in dental care, where an extremely large number of products made of single-use plastic are still being manufactured and used,” says Alexander Kurth, LUORO’s head of communications. “We want to break this trend and show that alternative materials can be used to make products that are at least as good and won’t outlive us by several hundred years.”

In June, LUORO introduced a new alcohol-free, vegan mouthwash product under the Paperdent line in packaging made from, you guessed it, paper. The mouthwash, in Mild Fresh and Mild Herb flavors, comes in a fully recyclable, 500-mL carton, the D-Pak from Elopak. According to Patrick Verhelst, chief marketing officer for Elopak, the D-Pak reduces the overall plastic content used by Paperdent in its mouthwash packaging by up to 80% when compared with traditional rigid plastic mouthwash bottles.

Concern for plastic waste and its potential impact on the environment is growing globally as only a small fraction of plastic is being recycled. ExxonMobil is supporting the circularity of plastics through its Exxtend technology for advanced recycling, sometimes called chemical or molecular recycling. ExxonMobil’s proprietary

Elopak’s D-Pak paper-based gabletop carton has been around since the 1990s and is designed specifically for non-food products. The carton uses sustainably sourced paperboard and is lined with a bio-based plastic

NEWS

12 PW OCT 2023

technology breaks down plastic waste into feedstock that can be used in making new plastics and other valuable products. The amount of plastic waste processed can be attributed through the ISCC PLUS mass balance free attribution approach to new, certified-circular polymers that provide the same quality and performance as virgin plastics. This allows converters like Printpack to use certified-circular ExxonMobil PP in existing converting processes.

“We are excited to be the first to bring ISCC PLUS certifiedcircular material to the diced fruit cup market. This is a significant milestone for Printpack as we continue to expand our portfolio of packaging that offers sustainability benefits. Now in addition to being recyclable, these fruit bowls will have 30% ISCC PLUS certified-circular content. That is an important step towards building a circular plastic economy,” says Dan Sanders, product development manager, Printpack Rigid.

Adds Olivier Lorge, global market development manager, polypropylene, Vistamaxx, and Exact, ExxonMobil, adds that he and his team are also “proud to work with Printpack to develop products that meet customer expectations for high-performance polypropylene products that help protect and keep food safe, while also helping to support the circular plastic economy.” —Matt

Reynolds

made from tall oil, a liquid obtained as a byproduct from pulp and paper manufacturing.

“The tall oil-based feedstock allows Elopak to create cartons entirely made from wood,” says Verhelst. “The wood used to create tall oil is sourced from sustainably managed forests, therefore ensuring the carton is fully renewable, contributing to the circular economy.”

Paperdent’s use of the D-Pak marks the first time this package has been used for mouthwash. According to Kurth, the biggest challenge related to using the gabletop carton is making sure the consumer understands what the product is. “Consumers have so far been used to using mouthwash exclusively in plastic bottles,” he says. “Most customers know paper composite cartons from milk, which is why we have to clearly differentiate ourselves here. That’s why we decided to depict a classic mouthwash bottle on the front of the packaging design to enable easy identification on the shelf.”

The Paperdent product is also among the first to be filled at Elopak’s new full-service facility in Terneuzen, The Netherlands. The facility began operation in Q2-23 and provides turnkey services that include the supply of preprinted blanks and closures, packaging on a dedicated, fit-for-purpose filler, and both pre- and aftermarket launch products. “This enables a partnership with customers across all stages of a product, from ideation to commercial launch in large or small scale,” says Verhelst.

LUORO’s Paperdent mouthwash is available for €4,99 (approximately $5.40), which Kurth says is “on par with suppliers who do not use sustainable packaging.” The product is sold online and at select pharmacies and supermarkets in Germany and Austria.

—Anne Marie Mohan

Compact Spiral lifts your line to a new level

The Compact Spiral elevators give you increased access to the production floor and the possiblity to transport goods vertically. The unique spiral-shape is key to its compact construction, offering 40% smaller footprint.

•Small footprint, using less space

•Gentle product handling

•Compact design

•Continuous product flow avoiding stop losses

Read more at Flexlink.com or contact us at info.us@flexlink.com.

13 FlexLink

is part of Coesia, a group of innovation-based industrial and packaging solutions companies operating globally, headquartered in Bologna, Italy. www.coesia.com�

Record-Breaking

PACK EXPO Las Vegas Exceeds Expectations

Last month, nearly 32,000 attendees engaged with more than 2,300 exhibitors across a million sq ft of exhibit space last in the largest packaging and processing trade show in North America this year, and the best attended in PACK EXPO Las Vegas history.

“PACK EXPO Las Vegas was a huge win for the packaging and processing industry,” says Jim Pittas, president and CEO of PMMI. “From attendance to exhibition space to educational sessions, the show surpassed expectations to provide our largest, most comprehensive show to date. This is proof that the industry continues to thrive and show-up to provide the most innovative, sustainable, effective solutions the world has to offer.”

And show up they did. Brand owners and CPGs attending had this to say about their experiences:

“I came to PACK EXPO Las Vegas to find new packaging and filling equipment and am excited by what I’m seeing on the show floor. This might be the largest PACK EXPO I’ve attended. It’s a well put together event with a good representation of industry suppliers which allows me to see so many solutions live and under one roof,” says Suzanne Dawis, vice president of R&D, Bright Innovation Labs.

Adds Ryan Besai, group chief engineer, Bermudez Group Limited, based in Trinidad and Tobago, “Our group includes several companies and more than 28 brands in cookies, crackers, snacks, and breads. I’m at PACK EXPO Las Vegas to find automation and robotics solutions to take our operations to the next level. While I’m new to the show, I can see that PACK EXPO Las Vegas has a wide variety of suppliers. The Innovation Stage sessions I attended were very enlightening. For businesses based in the Caribbean, the show is relatively close and easy to reach.”

Sustainability remains top of mind and thousands of attendees visited the new Sustainability Central exhibit, as well as the hundreds of exhibitors showcasing sustainable materials and machinery at the show.

“We came to PACK EXPO Las Vegas to find more sustainable packaging options,” says Brooke Ervin, packaging engineer, Mopar (Chrysler Service Parts Division). “Particularly, we’re interested in returnable packaging. We’ve already seen possible solutions on the show floor and visited Sustainability Central. This show is where we need to be.”

PMMI heads east next year with registration now officially open for PACK EXPO East (March 18-20, 2024; Pennsylvania Convention Center). For more information and the register, visit packexpoeast.com PW

NEWS

Wexxar@ProMachBuilt.com | 1.888.565.3219 | www.Wexxar.com The BEL 5150E is designed from the ground up to work with any e-commerce system so it can adapt to your needs. Integrate with any input device or your ERP/e-commerce system to trigger automatic size changes for quick and ergonomic case forming, packing and sealing. Visit our website to book a free virtual demo today! 14 PW OCT 2023

The sustainable alternative to shrink film packs PET bottles and cans packaged without plastic? No problem with the renewable, paper-based packaging solution LitePac Top from Krones! Krones, Inc., 414-409-4000, sales@kronesusa.com, www.kronesusa.com

52%

The number of industry leaders surveyed by Aura about their business’s supply chain who think a genuine circular economy for packaging is still 20 years away; 26% don’t see it happening for 50 years or more

$186.3B

The predicted market value of the reusable packaging market by 2033, growing at a CAGR of 5.5% from $109.09 billion in 2023, according to Future Market Insights

3B

The number of trees that are cut down every year to meet the global demand for packaging, a number that has grown by more than 65% in the past 15 to 20 years, according to Canadian NGO Canopy

85%

The percentage of consumers surveyed by the American Chemistry Council who believe if a new plastic product is made from plastics processed through advanced recycling, the product could have a label saying it contains “recycled content”

“Reusable packaging, or as we call it ‘refill and recharge’ formats, is an essential part of our sustainable packaging development strategy. For example, we know that using refill pouches can lower plastic usage by up to 81% and help drop packaging intensity by as much as 70%. The main challenge lies with the adoption rate and the upgrading of consumer habits. This is why empowering our business ecosystem plays a pivotal role within our ‘L’Oréal for the Future’ strategy. By engaging with our retailers and with consumers, we aim to drive this category of products, which in turn will help us promote more responsible consumption.”

–Erik Troost, sustainability program lead for L’Oréal, in an article from Packaging Europe, “The L’Oréal approach to packaging sustainability”

“Plastics play an important role in the everyday lives of Canadians. However, a significant amount of plastic food packaging is used only once and then ends up in landfills as waste, or in the environment as pollution. By getting rid of problematic plastic food packaging, replacing singleuse packaging with reuse-refill systems, and ensuring that plastics, if needed, are designed to be safely reused, recycled, or composted, we can all help move Canada toward zero plastic waste.”

–Steven Guilbeault, Canada’s environment and climate change minister, as quoted in an article from Global News, “Canada sets sights on next plastic waste target: food packaging”

“We’re taking food waste and then we add certain types of microorganisms, and the bacteria is going to use the nutrients in the food waste and generate the nanocellulose material out of that. One of the most exciting applications is in smart packaging. We can embed food extract pH responsive compounds in the nanocellulose and then create a smart label that reflects the shelf life of food products.”

–Dr. Dylan Liu, lecturer in food science and sustainability at Federation University Australia, in an article from ABC News, “Packaging made from food waste could save millions of tonnes of produce from landfill”

QUOTABLES

BY THE NUMBERS

16 PW OCT 2023

Colgate-Palmolive’s Sustainability Plan Spans Packaging Lifecycle

Cecilia Coates, Sustainability & Digital Transformation, ColgatePalmolive, detailed her company’s plan for a 90% reduction in emissions by 2040 at PACK EXPO Las Vegas 2023. Packaging World was there to learn more.

Colgate-Palmolive’s 2025 Sustainability & Social Impact Strategy (pwgo. to/8098), includes eliminating unnecessary or problematic packaging, a 33% reduction in virgin plastic, and a transition to only use recyclable, reusable, or compostable packaging by 2025. Colgate’s goals span beyond plastic reduction and far beyond 2025 though; the company also aims to reduce scope 1, 2, and 3 greenhouse gas emissions by 90% by 2040, with 2020 as the base point. Here’s how Coates describes these ambitious goals. (Note: Conversational language edited for clarity)

Packaging World:

Can you explain Colgate’s strategy to hit its 2040 emissions goal?

Cecilia Coates:

The three categories from which our emissions come are manufacturing, logistics, and procurement. Here’s how we’re tackling them: For manufacturing, its energy efficiency, renewables, and zero waste. For logistics, it’s greater operational efficiency. It’s how much weight and how much distance we’re moving products across the world. Then for procurement, it’s more about supplier engagement and working in partnership with our suppliers to reduce all the emissions in the upstream supply chain.

How is Colgate-Palmolive manufacturing becoming more sustainable?

Our biggest focus here is energy efficiency, because ultimately, the cheapest megawatt hour is the one you don’t use. We’re really focused on energy efficiency and using as little as possible to make a product and to keep growing the business while using as little energy as possible.

Then, the energy that we do use, we want to focus on making it renewable. Embedded in that carbon target is a specific sub-target of 100% renewable electricity by 2030. A lot of our factories have solar panels on site. That doesn’t mean that we’re going to get to 100% using solar panels because it’s physically impossible considering our energy

load, but that is one example of a tactic that we’re using.

And then there’s our commitment to zero waste. I love this one because it’s not always an intuitive connection for people, but really waste, especially waste that ends up in landfill, has greenhouse gas emissions, either methane or CO2. So as much more waste that we can divert from landfill is less carbon emissions that we are putting out there into the atmosphere. We have a very strong commitment on zero waste, and we’re very proud that many of our factories have been certified TRUE zero waste by the U.S. Green Building Council.

We really like exploring the connection between packaging and climate. Especially, for example, a reusable toothbrush that has an application in terms of carbon emissions. We’re doing studies which basically tell us after using a toothbrush X amount of times and having replaced X amount of plastic toothbrushes, that has an implication on carbon reduction. We haven’t published numbers yet, but we’re making the study so that we know from a very technical life-cycle assessment perspective, the carbon benefits of switching to reusable products.

What role can technology play in meeting Colgate’s emissions targets?

Data and digitization is really a key enabler of how we’re going to become more efficient and reduce energy and achieve net zero. One of the things we’re focused on is using energy sensors, IoT devices, software, platforms that can help us bring visibility to where energy is being consumed. And we have examples, vendors that are present here in [PACK EXPO Las Vegas], and have their devices in our factories, and they’re using those to really empower people with information to guide the strategy and guide the energy production.

What can you do alongside suppliers to help meet emissions targets? I want to really emphasize that this is one of our key focus areas, to engage with our suppliers. Whether they are supplying machinery, raw materials, or packaging materials, we want to talk to all our suppliers and really convey this message. Our chief procurement officers have been messaging through webinars to our suppliers, telling them how important this is for Colgate, and how we value the partnerships that we can do together to reduce our emissions together, and to collect data to make more informed decisions and more informed partnerships to get to net zero together.

Have these changes brought any challenges to profitability?

If so, how do you balance it?

Usually, when we make big goals, we must reassure people that we’re committed to making them cost-neutral. But a lot of these things are expensive. Post-consumer recycled content for example, usually has a premium price. What we do is, because we’ve made a commitment, we say ‘okay, we know and understand, but we’re going to over time make it cost-neutral.’ We try to find efficiencies in other parts of the business so that we can balance it out and ultimately be able to reach our goals while cost-neutral. —Casey

Flanagan

FIRST PERSON

18 PW OCT 2023

DESIGNED

FOR PERFORMANCE AND ADAPTABILITY

VARIABLE HEIGHT CASE AND PALLET LABELING IN MOTION

Designed to integrate into new or existing production lines, Panther’s all-electric Auto-Height Servo Stand accomplishes variable height labeling for cases, trays, and pallets in an all-in-one compact footprint. Ultimately saving you on space while providing greater flexibility, efficiency, and throughput.

AUTOMATED VERTICAL ADJUSTMENT

Programmable variable speed adjustments – up to 12” vertical adjustment per second.

PRINTER APPLICATOR ADAPTABILITY

Can be used with Panther electric and pneumatic print and apply label applicators.

PRECISE MULTI PANEL LABELING Apply labels to single or multiple panels on variable height cases and pallets with precision and speed.

INCREASE YOUR LABELING EFFICIENCY & THROUGHPUT

Panther.Sales@ProMachBuilt.com | Highlands Ranch, CO | 303-703-9876 | PantherLabel.com © 2023 ProMach Inc.

CONTACT US TODAY AT PANTHER.SALES@PROMACHBUILT.COM

By Eric F. Greenberg, Attorney-at-law

Day and Temp Labor Agencies, And Their Clients, Face Legal Changes

New legal requirements that are intended to protect day and temporary workers have toughened obligations on staffing agencies that supply such laborers in two states. That in turn is making life harder for companies who use their services, notably contract packaging and manufacturing businesses. Opponents worry that similar requirements could spread to other states.

Legislators are motivated by the sensible goal of protecting workers from abuses by some problematic staffing providers, but the new law imposes a range of legal obligations on all such providers, both good and bad.

“Coman” and “copack” [CM/CP] companies commonly rely on day and temp workers so that they can quickly and effectively fulfill their clients’ requests, often on short notice. The CM/CP companies’ efficient, flexible responsiveness is a big part of what they are providing to clients.

The Illinois Day and Temporary Labor Services Act has been around for some time, but significant amendments were made to it this year, and a similar law was recently passed in New Jersey. Among the Illinois law’s provisions is a requirement that if day or temp workers work for over 90 days for a company, their pay must equal what’s paid to employees hired directly by the company, and they have to be provided the same benefits, or their cash equivalent. There are reporting and notice requirements that the temp services must fulfill, recordkeeping obligations for the client CM/CP companies, and penalties for violations including, alarmingly, a provision allowing private parties to sue to enforce the law.

Illinois legislators said when passing this new law that there are about 650,000 people who work as day or temporary workers in the state, and about 300 day and temp labor service agencies that are registered to operate there. Legislators suspect that many others operate but are unregistered. They believe that low-wage day and temp workers “are particularly vulnerable to abuse of their labor rights, including unpaid wages, failure to pay for all hours worked, minimum wage and overtime violations, and unlawful deductions

from pay for meals, transportation, equipment, and other items.”

Tom Landry of the national staffing agency Allegiance Staffing says laws like Illinois’ place obligations on agencies to provide things that many reputable staffing agencies already provide. “These are best practices. Good operators have no problem with this,” he says. For example, good staffing agencies already provide benefits to day and temp workers, he notes, and he adds that he himself has called for sensible regulation of the industry for years. What’s more, he says many of the protections the new amendments provide for would have been possible without the amendments, if only the pre-existing law were properly enforced. In addition to his business, Landry serves on the Board of Directors of the Contract Packaging Association (CPA), the most prominent trade association for contract packagers and manufacturers. [The author serves as General Counsel to CPA – Ed.]

But Landry fears that some of the new law’s requirements could be impractical to implement, such as the paycheck reporting obligations, which could cause confusion and lead to inadvertent violations by staffing agencies.

Landry is concerned that the law seems to characterize good staffing agencies as if they’re making “indentured servants” of their employees. He defends such companies, explaining that “Our employees work for us because they like the flexibility. They can pick and choose who they go to work for and on their schedule. They get free job training provided by [CM/CPs], they get exposed to multiple industries and work environments. They gain experience that helps them secure a better life. Good staffing agencies promote conversion [to full-time employees], it helps us recruit more quality employees and builds a better bond with our [CM/CP] clients.”

Landry thinks laws like this are headed for court challenges, and the similar one in New Jersey is already being challenged as unconstitutionally vague. It seems likely that laws like this will be the subject of ongoing debate in coming years, as proponents look for ways to protect workers and the affected businesses advocate for clarity and practicality. PW

THE LEGAL SIDE INFORMATIONAL ONLY, NOT LEGAL ADVICE.

20 PW OCT 2023

Eric Greenberg can be reached at greenberg@efg-law.com. Or visit his firm’s website at www.ericfgreenbergpc.com.

Legislators are motivated by the sensible goal of protecting workers from abuses by some problematic staffing providers, but the new law imposes a range of legal obligations on all such providers, both good and bad.

BUILD IN FLEXIBILITY

For packaging and converting equipment OEMs, a digitally controlled laser processing system offers a repeatable baseline process to manage dynamic production needs with enough processing flexibility to accommodate new materials. Novanta offers unique design and manufacturing expertise of laser sources, beam delivery systems, and software to eliminate component compatibility issues and crosstalk between separate vendors for seamless integration.

LASER PROCESSING SOLUTIONS

https://novantaphotonics.com

Email: photonics@novanta.com

By Sterling Anthony, CPP, Contributing Editor

Choices in Barrier Flexible Packaging

Flexible packaging is a structural characterization referring to a material’s ability to bend and to fold, therefore, to flex. Flexible packaging, compared to rigid packaging like glass and metals, is lightweight. That inherent property results in lower transportation costs for brand owners and convenience-of-handling for consumers. Barrier protection, however, is not an inherent property of flexible packaging. It needs to be bestowed through engineered means.

The need for barrier packaging derives from the need to protect the contained products from the harmful effects of gases, moisture, and light (UV). The aforementioned elements can reduce the quality, efficacy, performance, and aesthetics of products such as food and beverage, pharmaceuticals, medical devices, and cosmetics, among others.

Flexible packaging provides barrier, either as a monolayer or a multilayer substrate. The associated technologies include extrusions, coextrusions, laminations, and coatings, producing structures such as bags, pouches, and thermoforms. The packaging supplier industry segment known as converters offer a wide and imaginative range of offerings. But how does a packaging user decide?

The protection function of flexible packaging (as with any other type of packaging) always should reflect the needs of the product. A given product’s susceptibility to harm establishes the type and the level of barrier that the flexible packaging must provide. As logical and straightforward as that might sound, decisions are complicated by various considerations and chief among them is the targeted shelf life/service life. It sets ramifications throughout the supply chain, notably on inventory levels.

It’s easier to decide on the type of barrier needed than it is to decide on the amount. A powder, for example, needs protection from moisture—a self-imposed requirement. How much protection and for how long, however, are less obvious. Too little protection (underpackaging) and too much protection (overpackaging) are both costly. The former results in consumer dissatisfaction, and the latter results in reduced margins. In the tradition of Goldilocks, comfort resides in the optimal middle. Following are some of the main ways to get there, material-wise.

• Aluminum foil. Foil is the best flexible barrier against gases, moisture, and light. The degree of protection mainly depends on the foil’s thickness, which in turn affects cost. On the debit side, foil is susceptible to pinholes, flex-cracking, and abrasion. Due to its inability to seal, along with its various susceptibilities, foil frequently is sandwiched within laminations. When, however, foil is a visible surface layer, it imparts a sheen (especially when lacquered) that

enhances aesthetics and shelf appeal.

• Metallized films. These structures are the closest rivals to aluminum foil as barriers to gases, moisture, and light. Any film can be metallized (the depositing of a layer of vaporized metal). The task, therefore, is to choose a film of certain inherent barrier properties, then to enhance them with aluminum metallizing. To illustrate, polyethylene terephthalate (PET), polypropylene (PP) in its various orientations, and polyamide (nylon) are modest barriers against gases and moisture, and negligible barriers against light. When metallized, though, their barrier properties increase by multiples.

• Glass-coated films. Silicon oxide, a modification of silicon dioxide (or sand, the main component of glass), is vacuum-vaporized then deposited as a thin coating. Silicon oxide imparts barriers associated with glass, namely against gases and moisture, but not against light (though transparency and the ability to see the contents can be an otherwise advantage). The thusly coated films are best laminated to protect the coating; after all, glass is fragile. Because of cost, glass-coated films see high-end, high-margin applications, such as for some medical devices and some specialty food packaging.

• EVOH. Ethylene vinyl alcohol (EVOH), a copolymer, is a barrier against gases. It’s used in multilayer structures, such as coextrusions and laminations, and can enhance the relatively low gas barriers provided by polyolefins. As another example, nylon’s intermediate barrier against gases is increased by EVOH. But EVOH is hydroscopic, and its barrier properties against gases are reduced in a high-humidity environment. That’s why an EVOH-containing structure might include a material serving as a moisture barrier.

One would be remiss not to include sustainability in the discussion. Source reduction, minimizing converting steps, and conserving energy usage are prime pursuits. Structures that include paper must include a coating or a film, because paper can not otherwise be sealed. Monolayer film structures—polyethylene bags, for example—are sourced from non-renewables and have poor recycling rates. Multilayer structures are difficult (an understatement) to separate into individual layers for recycling. Even those converters that promote their offerings as compostable must admit that the infrastructure for commercial composting has a long way to go.

All of that is par for the course. No packaging has sustainability bona fides that isolate it from criticism. It’s all about trade-offs and arguments about a net environmental footprint. What’s not subject to argument, however, is that barrier flexible packaging is popular with consumers. That fact cements its continued use, now and for the foreseeable future. PW

22 PW OCT 2023

THE BIG PICTURE

The protection function of flexible packaging (as with any other type of packaging) always should reflect the needs of the product.

It is time to experience

By Anne Marie Mohan, Senior Editor

By Anne Marie Mohan, Senior Editor

Company Forms ‘Cult of Clean’ with Refillable, Reusable Cleaner Packaging

The range of refill-at-home options for household cleaning product packaging has so far run the gamut—from concentrates in cartridges, sachets, and tablets to refills in pouches, cans, and bottles. Now, New York City-based brand Cleancult has added another alternative: product refills in paper-based gabletop cartons.

As the story goes, Cleancult was founded in 2019 when founder and CEO Ryan Lupberger looked on the back of his laundry detergent bottle and didn’t recognize one ingredient on the list. This led him, along with co-founder Zachary Bedrosian, to design a cleaning system with zero single-use plastic waste packaging and clean formulations. Shares Lupberger, “Cleancult is dedicated to helping retailers reach their sustainability goals and reduce plastic waste in the cleaning aisle while also making sustainable cleaning options more accessible for customers.”

Cleancult’s packaging system comprises a refillable, reusable, shatter-resistant glass bottle paired with Eco Refills in 32-oz cartons that together are said by the company to reduce plastic waste by 90%. In addition, it says, by using this packaging system, consumers can save up to 55.8 lb of plastic per year.

“Unlike other sustainable alternatives such as concentrates, pouches, etc., Cleancult’s refillable system reduces the need for a user to change their behavior and allows them to easily transition from traditional household cleaning products to a more sustainable alternative,” explains Lupberger. “Once a customer purchases a refill carton and reusable dispenser, they just need to pour the product into the bottle. Unlike other products, such as concentrate tablets that require consumers to add water to create their own cleaning solutions, Cleancult is formulated and ready to use once purchased and transferred into its respective refillable container, ultimately making it easier for customers to swap to a more sustainable cleaning routine.”

To design the system’s triangular, beaker-shaped glass bottle, which Lupberger describes as “a blend of beauty, functionality, and sustainability,” Cleancult worked with industrial design agency Guerrera Office (formerly Vibility). “Every detail was carefully considered, from the geometric

lines and clean silhouettes to the ergonomic design,” says Lupberger. “We also minimized the use of plastic to ensure a more sustainable solution that is even dishwasher safe. From the shatter-resistant glass to the protective silicone sleeve, the bottles are crafted with durability in mind, so they are meant for you to refill continuously and rely on for a lifetime—they are the last bottle you will ever need to buy!”

The cartons, from a proprietary supplier, include layers of polyethylene, aluminum, and paper, with the paper being FSC-certified, “to ensure sustainability and responsible sourcing,” Lupberger notes. The cartons have been categorized by How2Recycle as being “broadly recyclable,” meaning that greater than 60% of the U.S. population has access to carton recycling, and bear the How2Recycle label.

Beginning as a digitally native brand, Cleancult has expanded since 2019 into retail stores that include Kohl’s, CVS, Walgreens, Meijer’s, and others. In March, it announced its products would be rolling out in Walmart, bringing its retail presence to 31,000 points of distribution. With this massive shift from its D2C roots, Cleancult redesigned the graphics for its packaging to ensure they would stand out on shelf while clearly communicating the company’s mission to reduce plastic waste for consumers.

“We teamed up with [brand design agency] Robot Food to help elevate our brand identity and also redesign our packaging to have consumers connect our refill cartons directly with the reusable dispensers while in-store,” says Lupberger. “This resulted in our paper-based refill cartons featuring an image of the corresponding dispenser, and the refillable glass bottles now include a hangtag to visually correlate to the specific refill product.”

With the launch into Walmart, Cleancult also updated its scent portfolio to include fragrances such as Wild Lavender, Lemon Verbena, and Sea Minerals. Its products include liquid dish soap, hand soap, and laundry detergent along with reusable bottles in three sizes with different dispensing closures and in different colors, all available at retail and online at Cleancult.com and Amazon.com. At Walmart, Cleancult’s refill cartons start at $7.48, and the glass dispensers can be purchased for $8.98.

—Anne Marie Mohan

24 PW OCT 2023 SUSTAINABLE PACKAGING

Watch video on Cleancult’s products and packaging at pwgo.to/8074.

Robotics Bring Big Benefits to Bakery

Two identical monoblock cartoning/case packing systems produce a number of secondary and tertiary packaging formats, while robotic palletizing brings the automated line to a close.

By Pat Reynolds, Contributing Editor

Headquartered in Columbus, Ohio, T. Marzetti Company has a plant in Luverne, Ala., that makes frozen bakery products sold in supermarkets under its own Sister Schubert’s brand as well as under numerous private label brands. As demand for its offerings continued to grow, the plant found itself needing a more efficient way to handle manual cartoning, case packing, and palletizing. So management recently turned to robotic automation to reduce its increasingly unsustainable labor costs.

The product itself is dinner rolls in aluminum pans that consumers bake in the oven for 12 minutes or so. “In addition to dinner rolls,” notes Project Manager John Haenszel, “we have sweet goods like cinnamon, lemon, and blueberry rolls, for example. And we also make a sausageand-cheese pinwheel. But the primary package is always a round aluminum pan.”

Primary packaging changed very little. It’s done on a bagger from Kliklok, a Syntegon company, that pulls clear film bags from wickets, inserts a filled pan, and clips the bag closed. The bagged pans then go into a spiral freezer. At this point it’s time for secondary and tertiary packaging, and this is where the transformation has occurred. A key automation upgrade came in the form of a robotic palletizing system from Schneider Packaging Equipment, a Pacteon company. But most impressive are the two upstream monoblock cartoning and case packing systems from Cama Each IF299 monoblock is designed to run 45 bagged pans/min, and each system includes a Model IF315 top-load cartoning system featuring a vision-guided RB590 Triaflex delta style robot.

Cama has been supplying robots for more than 30 years now, offering a robotic loading unit with the latest open-architecture controls technology. In the case of the T. Marzetti machines, the controls are from Rockwell. “The idea is to offer equipment with built-in, custom-

ized robots, not arms that simply pick and place, but solutions conceived for specific packaging operations,” says Billy Goodman, managing director of Cama North America.

The monoblock system is part of Cama’s Breakthrough Generation (BTG) series, which features modular, scalable, and hygienically designed frameworks housing contemporary automation solutions. This includes advanced servo technology tightly coupled to vision systems and Cama’s robotic solutions, which have been developed in house to deal with the specific demands of secondary packaging. The vision system integrated by Cama includes a 3D Cognex camera.

26 PW OCT 2023

For twin-pack cartons, the delta style robot picks bagged pans from the conveyor belt in the foreground, rotates them so that the ponytail is in the 12 o’clock position, and places them into a carton that is erected from a flat blank upstream.

Bundle both ways Trayed or Loose Product

With our latest innovation, the Kayat SRX product Series can effectively shrink wrap products in trays, or loose/bulk products.

The Kayat SRX-CUF tackles the growing demand from both retailers and consumers for bundled loose products, like bottles cans and jars. These products can be configured in a variety of patterns or multipacks.

Other innovation and technological upgrades of the Kayat SRX include:

• Slide out film feed and cut assembly for easy maintenance

• A toolless adjustable wrap bar assembly

• Updated Allen-Bradley controls package with predictive maintenance flags

• Clear or print registered film capability

• Speeds up to 60 cycles per minute

To discuss the Kayat SRX and your next shrink bundling project contact us at: 636.239.7424 or Texwrap@ProMachBuilt.com

PERFORMANCE, PACKAGED

LEARN MORE www.texwrap.com/SRX

KAYAT SRX

Cama’s BTG Series machines are also based on a 100% digital platform that supports full Industry 4.0 capabilities, including Augmented Reality, Virtual Reality, and virtual testing, training, and operation. Furthermore, advanced component-identification systems can deliver rapid format changeovers, sometimes in as little as 15 minutes.

Each IF299 delivered to Marzetti had to be able to do two essential things. First, it had to orient incoming pans, and we’ll see why in a minute. Second, it had to produce either of two formats. Format 1 is twin-pack cartons followed by six cartons into cases. With this format, consumers pick a twin-pack carton from the freezer case. Format 2, on the other hand, is a no-carton approach, where bagged pans go directly into cases in either 6- or 12-count arrangements. In this format, consumers pick as many individual pans from the freezer case as they desire. Let’s look at Format 1 first, where the robotic cartoner puts two pans into wraparound cartons and the case packer puts six twin-pack cartons into wraparound cases.

Exiting the freezer

It starts with bagged pans exiting the spiral freezer about 10 ft above floor level. A decline conveyor takes the pans down to floor level, where manual labor is used to place half the pans on a conveyor leading to one Cama system and the other half on a conveyor leading to the other Cama. Just ahead of both Cama systems are X-ray detection systems from Anritsu that detect foreign objects and cause pans with such objects to be rejected from the line.

Like any plastic bread bag gathered at the neck with a plastic clip closure, the Marzetti packages have a “ponytail.” The orientation of the ponytail is completely random when packages reach the infeed of a Cama system. This was challenge number one for the Cama engineers.

“The ponytail needs to be in the 12 o’clock position if the package graphics are going to be properly aligned with the two display cutouts in the carton,” says Haenszel. “So the Cama solution needs to do more than just put pans into cartons at rate. It needs to put pans into cartons in a specific orientation at rate. It uses a vision system to do that. It identifies the orientation of the ponytail and relays that data to the Rockwell controller, which sends that information to the robotic end

It’s time to expect more.

Thank you to our customers, partners and employees. You’ve helped keep shelves stocked, families fed and the supply chain moving through it all.

Together, we can help every supply network be more sustainable, more efficient and more resilient. Now and for the future.

Expect more with CHEP.

us how we can do more 28 PW OCT 2023

Tell

The tooling on this two-axis robotic pusher presses the top flap closed. Then the pusher slides the finished carton at a right angle to a staging area. In doing so, the pusher pushes the preceding twin-pack carton out of the staging area and onto another right angle conveyor takeaway that leads toward the case packing station.

LET PFLOW DO THE HEAVY LIFTING Material Lifts for Any Application • Ideal for high-capacity, high-cycle automated systems • Capable of 400 FPM vertical travel • Conveys loads up to 10,000 lbs to unlimited floor levels • Continuous-duty cycle motors for higher cycle rates MATERIAL HANDLING SOLUTIONS CONTACT US TODAY! www.pflow.com | (414) 352-9000 100% Employee-Owned

Six cartons in two stacks of three are pushed into the loading station of the wraparound case packer. Then the case is pushed at a right angle beneath folding bars and tooling that closes around the top to compress the top flap shut.

effector, which in turn rotates in whichever direction it needs to get the ponytail in the 12 o’clock position. That was a tall order, because if you think about the end effector putting the pan into a carton that is only slightly bigger than the pan itself, there isn’t a lot of room for error. And it would be an easier fit if the ponytail could be in a corner, where there’s more room. So it was a challenging thing to pull off.”

Pans are fed single file into the Cama monoblock on a continuousmotion belt conveyor. Flat carton blanks are picked from a magazine feed and pass under two Nordson glue nozzles before being pushed down into a forming box. The paperboard cartons, supplied by WestRock, are a 26-point paperboard printed offset in seven colors.

Once formed, the cartons proceed top-flap-open down a conveyor that runs parallel to the conveyor carrying the bagged pans. The carton conveyor pauses periodically so that the Triaflex delta-style robot can pick one pan at a time from its conveyor belt and, after rotating in either direction and as many degrees as needed to orient the ponytail to the 12 o’clock position, place the pan neatly into the carton. As soon as a second pan has been placed on top of the first, that carton is advanced out of the loading station and an empty carton takes its place so the process can be repeated.

REDUCE CAPITAL REQUIREMENTS BY 90% TO START AND MAINTAIN PACKAGING LINES (630) 629-9900 sales@frain.com

30 PW OCT 2023

Leave Your Mark

A coding and marking

We’re exploring packaging and production, hot topics, challenges, and solutions in the coding and marking industry. Get ready for expert interviews, real world case studies, and thought-provoking discussions that drive efficiency, compliance, and profitability for manufacturers of food, beverages, personal care and life science products. Sponsored by

AVAILABLE ON ALL PODCAST PLATFORMS

EPISODES 1& 2 OUT NOW!

NEVER MISS AN EPISODE Sign up now to stay up-to-date on future eisodes!

codingandmarkingpodcast.com

A short distance later, the filled carton has glue applied to its top flap by a Nordson unit and enters a two-axis robotic pusher whose tooling presses the top flap closed. Then the pusher slides the finished carton at a right angle to a staging area. In doing so, the pusher pushes the preceding twin-pack carton out of the staging area and onto another right angle conveyor takeaway that leads toward the case packing station.

At the case packing station, a carton drops into a flighted conveyor that makes yet another right angle turn to a station where a push bar pushes it into an upstacker. As soon as cartons are stacked three high, that stack of three is pushed into a loading station where it sits momentarily until it’s joined by another stack of three cartons. Then all six cartons are pushed into a single-wall C-flute wraparound case that has been pulled from a magazine feed and erected with help from, again, Nordson glue guns. Now the case is pushed again at a right angle beneath folding bars and tooling that closes around the top to compress the top flap shut. As soon as that tooling opens, the finished case is indexed forward onto a right-angle takeaway conveyor, in the process passing a Hitachi ink-jet coder for date coding.

On to Format 2

As mentioned previously, some stores display individual pans of these products in the freezer case as opposed to twin-pack cartons. This can be done in one of two ways. One option is for the store to receive 12 pans in a brown kraft corrugated case and for the store personnel to remove the pans and stand them on end in the freezer case. The other

option is for the store to receive six pans in a white display-ready case that goes into the freezer case after the store personnel opens the case along the perforated score lines.

For both the brown kraft 12-count and the white retail-ready sixcount, the IF299 operates a little differently than when two-pack cartons are being produced. Obviously, the station where cartons are picked, erected, and loaded is inactivated. Pans still enter single file on the same belt conveyor, and they still get picked by the same delta-style robot, and that robot’s end effector still orients the ponytail of each pan—though in this case it orients the ponytail in the 9 o’clock position rather than the 12 o’clock position. Orienting all pans in the same position ensures that the ponytail does not interfere with pan manipulation or case closing.

Also quite different is that once the robot has a pan in its grip, it moves in the exact opposite direction that it takes when loading twinpack cartons. In other words, rather than stroking north to drop pans into cartons on conveyor belt A it strokes south to drop pans onto conveyor belt B that runs parallel to A.

From here on out, the sequence is very similar to what we saw when twin-pack cartons are being case packed. Pans drop into the same flighted conveyor that takes cartons to the upstacker. But in this case

32 PW OCT 2023

Watch a video of the Marzetti Company packaging line in action at pwgo.to/8096

it’s two pans per flight as opposed to one carton per flight. When pans reach the upstacker, they can proceed into corrugated cases in six- or 12-count formats. Whichever format is chosen, top flaps are closed and glued shut and finished cases discharge the same way that cases full of twin-pack cartons do.

WHEN IT COMES TO CONSCIOUSLY CREATING A CLEANER AND GREENER WORLD, YOU ARE NEVER ALONE

With Sidel solutions to support you, going circular needn’t be a burden.

You can reduce with X-Lite, the world’s lightest PET bottle; EvoPack™M and Stryon packers, granting -15% repacking and -50% plastic. You can grow in r-PET leveraging our 20 years’ experience and our new PET recycling pilot plant. You can save up to 60% energy and water with our tunnel machines for refillable PET and returnable glass.

Sidel, Empowering Sustainable Futures.

Robotic palletizing

Cases exiting the two Cama systems merge onto a single conveyor so that a Hitachi ink-jet coder can imprint date code information on each case. Cases then enter the infeed conveyor of a Schneider robotic palletizer equipped with a Fanuc robot with R30iB controller. End of arm tooling includes slip sheet pick-and-place capability.

Running commercially now since late April, the new equipment operates two 10-hour shifts four days a week. Like any leap from a largely manual operation to one that’s highly automated, there was a hiccup or two as installation wound down and commercial production began. But a lot of that had to do with packaging materials needing to be more rigidly in spec. “There’s room for slightly out of spec corrugated, for example, when humans are handling that corrugated,” says Haenszel. “When automation enters the picture, that’s not the case. Automated systems are looking for more standardized and consistent conditions. So we had to tighten up the quality requirements on corrugated cases, for example.”

The paperboard spec for cartons also changed. Because the carton is now a wraparound style formed from a flat blank rather than the pre-glued carton that was formerly erected and filled by hand, the paperboard went from a 28-point to a 26-point stock, which brought a slight cost savings.

Haenszel also notes that when it did come time to bring the new equipment in and make it fit an existing space, it helped that the monoblock Cama systems measured just 8.387 x 2 m (27.5 x 6.5 ft). “There was not a lot of room to spare,” he adds. PW

sidel.com

33

The robotic palletizer includes end-of-arm tooling with slip sheet pick-and-place capability.