PONSSE & WAHLERS TEAM FOR 30 YEARS

TECHNOLOGY CONCEPT THINNING DENSITY ASSISTANT PONSSE SOLUTIONS HOW TO CHOOSE YOUR NEXT USED FOREST MACHINE?

NEW INNOVATION

PONSSE HH360 ROTATOR

PONSSE & WAHLERS TEAM FOR 30 YEARS

TECHNOLOGY CONCEPT THINNING DENSITY ASSISTANT PONSSE SOLUTIONS HOW TO CHOOSE YOUR NEXT USED FOREST MACHINE?

NEW INNOVATION

PONSSE HH360 ROTATOR

PUBLISHER

Ponsse Oyj, Ponssentie 22, FI-74200 Vieremä, Finland

EDITOR-IN-CHIEF

Hanna Lehtonen

EDITORS & CONTENT

Ponsse Plc

ISSN 2489-9488 (print)

ISSN 2489-9496 (online publication)

EDITORIAL STAFF

Juho Nummela, Hanna Lehtonen, Jenny Huttunen, Juha-Matti Raatikainen, Marika Ryytty, Jarmo Vidgren, Marko Mattila and Jussi Hentunen

LAYOUT

Luova Työmaa

COVER PHOTO

Ponsse Plc

ILLUSTRATIONS (PONSSE KIDS)

Ponsse Plc

Painotalo Seiska

PAPER

Cover: MaxiSilk 150 g/m2 and pages Galerie Art Matt 100 g/m2.

ADDRESS SOURCE

Mailing list of Ponsse News and Ponsse customer register

4 AN HONEST AND APPROACHABLE MAN OF THE PEOPLE Stories of Ponsse’s founder Einari Vidgren

8 PONSSE TRAINING SOLUTIONS Training is part of Ponsse’s comprehensive solution for customers

10 PONSSE & WAHLERS Three decades — three generations

13 WAHLERS LADIES LOUNGE

14 PONSSE FINANCING SOLUTIONS

15 PONSSE’S 19,000TH FOREST MACHINE

16 HOW TO CHOOSE YOUR NEXT USED FOREST MACHINE?

18 PONSSE MOMENT

20 TECHNOLOGY CONCEPT Thinning Density Assistant

22 OPERATOR TALENT Training operators and mechanics for the needs of our customers

24 PONSSE HH360 ROTATOR

Ponsse PLC customer and stakeholder magazine.

Ponsse News is published twice a year.

Please send feedback, subscriptions and changes of address by email to ponssenews@ponsse.com. The magazine is free of charge.

FOLLOW US:

At the end of February, we celebrated the delivery of the 19,000th forest machine, PONSSE Scorpion Giant, to Elliot Henderson Ltd in Scotland with Ponsse’s employees, Ponsse Seniors and our customers.

It was a festive day with the machine delivery, some coffee and cake, and not least because of Scottish bagpipes. This exotic music was also heard by pupils and students at Vieremä’s municipal school. As requested by our customers, the same music was also heard at the Vieremä cemetery, next to Einari’s headstone.

That day, close to Einari’s 80th birthday, epitomised the essence of the Ponsse spirit.

During its history, Ponsse has experienced various challenges. Its more than five decades have featured both ups and downs – just like the manufacturing of the Scorpion Giant delivered to Scotland: the shortage of components, drastic inflation, rising interest rates, not to mention the challenges brought by the coronavirus pandemic and the war in Ukraine during this decade.

It was not easy for Einari at the beginning, nor has it been any easier in recent years.

Ponsse employees who feel well throughout our Ponsse network are our most important assets and the prerequisites for all development. It is important to us that Ponsse is a good and safe place to work for all of us.

We have still been able to complete all machines, delivered them to customers, and kept the wheels turning in more than 40 countries. Ponsse’s way of working is deep-rooted, for which I would like to thank our customers, stakeholders, suppliers and above all our amazing personnel! Working together has always been one of our strengths, and we must continue to hold onto it.

Einari’s legacy lives on in many ways, both at Ponsse and in the forest sector. The Einari Vidgén Foundation is looking for responsible forestry professionals this year as well. Einari saw that people doing good deeds in the forest machine industry deserve to be rewarded. We are continuing this tradition.

No one will come from the outside to lift up the image and skills of machine contracting and forest management – we need to do it ourselves. Let’s be truly proud of our forest expertise – we are leading the way globally and to this we should raise a glass!

JUHA VIDGREN Public relations Advisor

JUHA VIDGREN Public relations Advisor

Once upon a time, a stray mixed-breed dog lived in the village of Vieremä. The dog was grey, had a long body, and was rather ugly. The dog was called Ponsse. Ponsse was good at hunting hares and persistent too. No matter the weather, Ponsse would hunt – in heaths, swamps, clumps of spruce or nearly impenetrable coppices. When hunters went out with Ponsse, they never came back empty-handed.

While Ponsse roamed around the village, the young forest machine entrepreneur Einari Vidgrén and his friends had started building their first forest machine. Einari’s brother-in-law, a skilled local blacksmith, had lent his forge to the group of friends. They worked

with purpose from morning till night. Lauri Uuksunen was the ultimate expert when it came to welding. The goal was to build a forest machine that would work throughout the winter and not break down.

Their days were filled with planning and experimenting with options. The axles were taken from an old wheel loader, a powerful engine was attached to the frame, and a Wärtsilä loader was installed on top. The villagers were eager to see how the work was going, and upon seeing the machine, they wondered, “What sort of a ‘Ponsse’ are they making?” When Einari heard this, he laughed and said, “Well, now it has a name too! We’ll call it Ponsse.”

After nine months of hard work, in the late winter of 1969, a grey – and many thought ugly – load-bearing forest tractor was driven

out of the village forge. It was the first Ponsse machine. At first, the machine was put to use at the Tehdaspuu logging site, but after a year of use, the people from Tehdaspuu called and said, “Why don’t you make more of these forest tractors? It’s seen the most action and required the least servicing.” Upon hearing that request, Einari jumped up and said to his wife, “I’m going to start a factory!” “A factory?” asked his wife, surprised. “That’s right,” Einari said and set off in his car towards the Vieremä village.

And that is the story behind the name –Ponsse was named after a mutt that may have been ugly, but was also tenacious and reliable. The stray running around the Vieremä village could not have guessed that his name would be remembered for decades around the world.

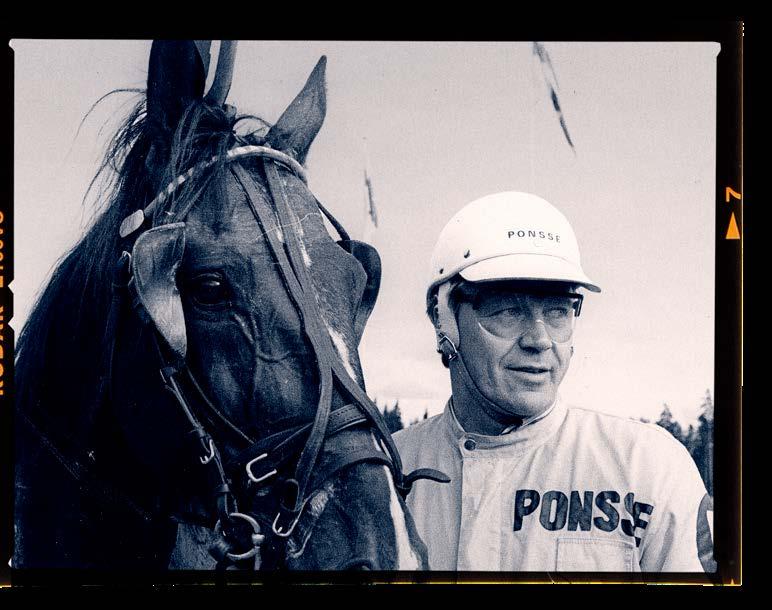

Einari and Barbo Assassin.

Barbo was by far Einari’s favorite animal, remembers Jarmo Vidgren.

Einari and Barbo Assassin.

Barbo was by far Einari’s favorite animal, remembers Jarmo Vidgren.

Forest machine entrepreneur Einari Vidgren would have celebrated his 80th birthday this year. Ponsse’s founder is remembered as a persistent entrepreneur and an approachable man of the people who treated all Ponsse employees equally, without elevating himself above anyone else. To celebrate his anniversary, we have collected stories and memories of Einari from various years. These memories continue to live on at Ponsse to this very day.

“While working as a area sales manager in Lapland, I invited guidance counsellors from Northern Finland to visit Ponsse’s factory,” says Sampo Pulju, who currently works in sales training and technical support at Ponsse in Rovaniemi.

“The visitors hoped that Einari would join us for lunch at the factory’s cafeteria. The cafeteria was full of employees at the time. Einari unexpectedly left the queue to talk to people at different tables. One of the guidance counsellors wondered why Einari did that and what he discussed with this handful of employees. ‘Does Einari know them by name?’ the guidance counsellor asked me. I said that he may not know everyone’s name, but everyone at Ponsse is important to Einari. People were important to Einari,” emphasises Pulju.

Konehuolto P.Kula, Ponsse’s contractual service partner in Pöytyä, Finland, opened its new facilities in spring 2003.

“Einari participated to declare the new building open for business. Einari admired it, saying that not even Ponsse has such a grand building. He must have added some colour to his words,” laughs Petri Kula, owner of Konehuolto P.Kula.

Kula remembers that Einari was sitting in the office upstairs closing a machine deal during the opening.

“He gave a few speeches during the day, also mentioning that he had just completed a deal for two machines, a PONSSE Ergo and a Wisent, with Pekka and Kalle Ali-Raatikainen from Pöytyä,” Kula recalls.

Owner of P. Kula Oy Petri Kula and Einari Vidgren in 2003.

Owner of P. Kula Oy Petri Kula and Einari Vidgren in 2003.

“I started in the assembly department in 1987 after I completed my military service. I only worked there for three months before transferring to another department. Einari called me and asked if I’d have time to take a look at the wiring of a machine being repaired. When I went there, I doubted my skills at first, but we got the machine running. The following Monday when I went to my usual place in the assembly line, they told me to go to the maintenance unit. It’s hard to say whether I was promoted or demoted, but I guess Einari considered my work a success by relocating me,” notes Juha Reis, who currently works as a service engineer.

Area spare parts manager Janne Lavonen had his first day at Ponsse in spring 2006.

“I was familiarising myself with the work of a spare parts salesperson in Iisalmi, Finland, but otherwise I worked at Ponsse’s service centre in Kouvola, Finland.

Einari came to the spare parts shop around the time we were having our first coffee in the morning and said ‘good morning’ to everyone. After I responded to his greeting, he said: ‘Look at that, we have a new guy in our team!’ Einari talked to me like he’d known me for ages and welcomed me to the company. Finally, he said something I will never forget: ‘Do your job well, son, and stay here until you retire.’ I’ve felt part of the team from day one, and I’ve been given the strength to work for our customers and my colleagues.”

”Einari had a helicopter that day and wanted to give everyone interested a ride over Vieremä.

“It was 2008 or 2009 when one day Einari asked people at the factory to gather in the backyard. Einari had a helicopter that day and wanted to give everyone interested a ride over Vieremä. It was an unforgettable day for many!” notes Sari Kiiskinen, who currently works as an HR manager at Ponsse.

“Einari’s genuine will to take care of the personnel’s wellbeing and provide a good employee experience is still being fostered at Ponsse today,” adds Kiiskinen.

Since the beginning of Ponsse’s history, the employees have played cards during breaks, and the tradition continues.

In 1983, the launch of the new S15 forest machine was celebrated.

In 1983, the launch of the new S15 forest machine was celebrated.

“In 1982, I worked in spare parts sales and the Vieremä factory’s collection unit. My day started at seven in the morning.

When Einari started his day at the factory, he came to greet Ponsse’s spare parts salespeople almost every morning, often wishing us a good morning in his booming voice. He also may have banged his fist against the counter, in a positive spirit of course! It was a great way to start the day,” shares Matti Tenhunen, who currently works as a product group manager and who remembers that Einari gave everyone a boost every morning.

“The new machine models of the 2000s had been launched the previous year, although we office ladies didn’t see any machines very often at the time. We talked about this with Einari, who took our message to heart and right away organised a day at the logging site.

We left the office around noon. At the logging site, we cooked sausages over an open fire, and everyone interested was able to ride in forest machines to see them in action.

After the nice afternoon in the forest, we headed to the Ponsse Club, where a magnificent smoke sauna had just been built. Like Einari said, ‘the ladies have to test it’, and that’s what we did!” reminisces Tiina Nissinen, who currently works as a financial manager at Ponsse.

One evening in 1987, Seppo Karvonen received a call: Ponsse’s repair shop had a vacancy. That was how Karvonen’s career at Ponsse began.

“The next thing you know, we just started doing this and that at the repair shop. Einari came by every morning at 7 am and often said that ‘It’s almost finished!’, even though it would still need a moment or two,” Karvonen remembers. These days, Karvonen refurbishes Ponsse’s Reman Parts.

“Ponsse lets its employees take responsibility for their work, and it also feels good that I’ve been able to enjoy the trust of my managers and colleagues, starting from Einari. Just like Einari used to say: ‘Make it so that it’s good!’” reminisces Jorma Hyvönen, who works in research and development at Ponsse. Hyvönen originally came to Ponsse as a summer employee in 1985.

Ponsse’s training team, which consists of a versatile group of different specialists, ensures that PONSSE forest machines can be used effectively, safely and economically at logging sites around the world. The work done by the team pays off in the long term after new knowledge turns into practical routines.

When a new Ponsse machine is delivered, the delivery includes comprehensive operator training. The main goal of operator training is to provide customers and their drivers with knowledge and expertise about new solutions and the use of machines.

Ponsse has an extensive network of operating trainers in different countries who continuously train machine users to operate safely and energy-efficiently with Ponsse’s forest machines. Operator training is

often given by the forest machine on site, but nowadays PONSSE simulators are also often used, which make it easy to update skills.

Ponsse factory’s 11 operating trainers handle the task of teaching essential skills to the Ponsse network’s operating trainers.

Operator training focuses on ensuring competence. Whenever a customer acquires their first PONSSE forest

TRAINING

Trainers ensure that operators’ skills are at a sufficient level, and improve them if required, so that machines can be operated safely and effectively.

machine, they will be taught everything they need to know about the new machine model. Otherwise if an operator has years of experience with PONSSE machines, their previous skills will be updated.

Operator training covers the safe way of working, machine maintenance and servicing, data transfer systems and their use, reporting, machine and operator adjustments, as well as automation. Its other areas include the working methods required when using different machine models at different logging sites.

While new operators can be provided with simulator training, training is otherwise provided during the machine delivery. If required, training can also be continued remotely online or by telephone.

“Trainers ensure that operators’ skills are at a sufficient level, and improve them if required, so that machines can be operated safely and effectively,” says product trainer Hannu Vauhkonen.

Ponsse provides not only operator training, but also product and additional training, including effective machine operations in the hands of professional operators.

Ergonomics and wellbeing are important elements of training. Operators are taught how to adjust the seat and controls and how to use different automated functions to reduce physical stress. As a result, operators will have more energy during their time off. Working methods develop and become easier as the machines and their technology develop, highlighting the continuous development of expertise.

Ponsse wants to provide its customers with a comprehensive solution, and training is an important part of that.

“When our customer buys a machine, that is not the apex of our cooperation, but rather the starting point of the story,” notes Jussi Jurvanen, training manager at Ponsse. ■

Ponsse’s training day was held for the personnel of Kimmo Kulojärvi Oy, a company operating in Eastern Lapland and the Koillismaa region. As many as 15 employees, from harvester to forwarder operators, participated in the event alongside employees of subcontractors.

“Everyone was excited about the training day. The training provided the professionals with new ideas about harvesting methods. They really understood that work does not always need to be done in the same way it has been done before,” notes managing director Kimmo Kulojärvi.

For Kulojärvi, wellbeing at work and the energy-efficient way of working were the most significant parts of the training.

“All new knowledge that operators learn is always a good thing. The best part was learning how operators can keep getting better throughout the working day. If work can be made lighter through training, operators will have more energy when they go home at the end of the day. This would be a major incentive for me,” says Kulojärvi.

The training covered such factors as crane adjustments and strengthening the operators’ current skills. The training made the operators think about their work, and the aim is to hold another training day shortly regarding the use of the measuring device and all its features.

Ponsse and the German dealer Wahlers Forsttechnik have grown together during their 30-year cooperation. The foundation for this was laid by Einari Vidgrén and Hans Wahlers.

The linear distance between Stemmen, Wahlers Forsttechnik’s headquarters, and Vieremä, Finland, is 1,540 km. By land, this is a driving distance of 2,318 km. When a partnership works over such a long distance, it is mainly due to the people involved.

In 1934, Johann Wahlers and his wife Erna founded a blacksmith shop in a small

village called Lauenbrück in Lower Saxony. Especially in the period after the Second World War, this was a tough business. It took a lot of improvisational talent to keep the farmers’ machines operational. His son, Hans Wahlers, worked in the blacksmith shop as a child. He trained in this profession, gained outside experience, and returned to his parents’ business and passed his master craftsman’s examination. The times were eventful. Technology was developing rapidly. And the blacksmith’s job description changed:

the focus was no longer on shoeing horses and the manufacture or repair of simple agricultural equipment, but on the sale and maintenance of complex machines, such as loading equipment. In addition, Wahlers took over a representation of the tractor manufacturer Deutz. Wahlers also specialised in the construction of fairground vehicles.

Hans Wahlers took over his father’s well-established business in 1971. The reason he got involved in forestry technology was a fully equipped service vehicle that enabled him to carry out difficult repairs directly on site. It was just what he needed to help the Scandinavian forestry contractors who were working with their machines in northern Germany to clear the damage caused by a large storm. The occasion was a severe hurricane named Quimburga, which raged across northern Germany in November 1972.

When the era of mechanized logging began in Germany in the mid-1980s, Hans Wahlers designed a compact harvester, the Wahlers Biber, that was precisely tailored to local conditions. It was based on a two-axle Atlas wheel loader, equipped with a Mowi parallel crane, a Grangärde unit and its own control and measurement technology. But he also realized: that’s not the end of the road. Larger technology was needed.

It was the strongest hurricane of the 20th century, destroying 17 million cubic meters of timber in Central Europe. Incidentally, among those forestry contractors was one certain Einari Vidgrén from Vieremä, Finland, who had made his way to Germany with his first forwarder.

When the storm wood had been processed, reforestation began. This proved to be very difficult due to the large mass of logging residue. Hans Wahlers knew how to remedy the situation. He developed the Räumfix for mounting on forestry tractors—a device that is still built today and sold worldwide.

It was a good thing that Einari Vidgrén had made the move from being a forestry contractor to being a manufacturer of forestry machines. At the Elmia Wood Exhibition 1993 in Sweden, the two signed a partnership agreement between Ponsse

and Wahlers Forsttechnik. When production of the Beaver discontinued, the import, sale and service of Ponsse harvesters and forwarders became the basis of the business. An important and unique selling point was the Ponsse Opti, which was the only system on the market that met the requirements of commercial class sorting that were valid at the time.

Hans and his wife Lola Wahlers were very lucky with their daughters. Anne and Monika both saw their future in the family business. However, he was just as lucky with his sons-in-law Ralf Dreeke and Michael Rathjen, who also saw it the same way. They took over the management of Wahlers Forsttechnik in 1999. A significant step in the same year was the construction and opening of a second company headquarters in Uffenheim-Langensteinach, conveniently

located on the A7 highway. From there, Wahlers Forsttechnik took care of the southern German market. In 2007, the company was rebuilt in Stemmen in the north, and both locations have since been modernised and expanded several times. In 2015, a third location was added in Ilmenau, Thuringia

Under the forward-thinking leadership of Ralf Dreeke and Michael Rathjen, Wahlers Forsttechnik has grown into a company with 130 employees and is the largest Pons se dealer worldwide.

The two companies fit together very well: both are family-owned, and both always focus on the customer. Germany is a particularly interesting market for Ponsse. From timber harvesting in wet areas to steep slopes, everything occurs there. The contact with the developers in Finland is correspondingly close, and they value the opinion of their German sales partner. In addition, many components for the Ponsse machines come from Germany.

Ralf Dreeke and Michael Rathjen are gradually withdrawing from day-to-day business. However, they continue to work

for the industry and maintain customer contacts. Marius Dreeke, son of Anne and Ralf, and Gerit Koch, husband of Marlene Rathjen-Koch, daughter of Monika and Michael, have taken over as managing partners. Both have been working in the business for a long time. Gerit is primarily responsible for sales, Marius for administration and internal processes.

The course for this was set last year by changing the managing partners. A current project is the even better development of the Austrian market, which already belonged to the Wahlers sales territory, but was also served by service partners. In 2019, a subsidiary was founded there, which moved into a larger workshop a year later. A salesperson and six service employees now work here, largely independent of their German colleagues.

Ralf Dreeke, Einari Vidgren, Hans Wahlers ja Michael Rathjen Wahlers-Ponssen celebrating Ponsse´s and Wahlers 10 years cooperation in 2003

In addition, a decentralised service structure is currently being established. The IT required for this was no small investment. At present, four mobile mechanics start their tours from where they live. They receive work orders directly on their computers. They also keep a small spare parts warehouse.

Wahlers and Ponsse is a partnership that fits. Across all generations, this has resulted in something that is not just a business relationship, but a friendship with a common goal.

What Hans Wahlers started is being continued by the third generation—much to the delight of senior boss Lola Wahlers also in view of the upcoming 90th Wahlers anniversary in 2024. ■

After a two-year break, the time has come again! “I really wanted this trip to happen after the Covid time-out, and everything fell into place perfectly after the Interforst Trade Fair in July 2022,” explains Anne Wahlers-Dreeke. So, in November 2022, another 22 women customers from Germany and Austria had the opportunity to travel to Finland with Anne Wahlers-Dreeke and Monika Rathjen to visit sales partner PONSSE.

“With each new trip since 2002, and thanks to the positive experiences and acknowledgements shared by participants, we keep planning the next trip each year, to this day,” A. Wahlers-Dreeke explains; the ideas generated suggest new items for the agenda, such as the recent visit to the KEITELE Sawmill, and the itinerary always includes an attraction or building in Vieremä. A particular concern for her was to provide a space

At the Wahlers Ladies Lounge, participants present interesting and informative short lectures on a variety of sector-specific topics, including machine leasing and insurance training for women in the forestry sector, current project information from the KwF - the German Board of Trustees for Forestry Work and Technology (Kuratorium für Waldarbeit und Forsttechnik), issues regarding occupational safety, and of course Wahler’s in-house customer software.

During the introduction round on one of these trips, an idea was presented to offer forwarder training for women. The training sessions have been organised by Anne Wahlers-Dreeke on a regular basis since 2011 in cooperation with the forestry training centre (Forstlichen Bildungszentrum) in Seesen/ Münchehof, near Göttingen in Lower Saxony, with the support of the Einari Vidgren Foundation. At the request of a woman forester, Wahlers is currently organising initial training for women; the focus is on digitalisation and processing of produced machine data in forestry operations, and is especially geared towards motivating the younger generation to get into the business!

The women of the family business have been involved for generations in the company’s operations in one way or the other, and Anne

and Monika do not deviate from here.

Monika trained as a blacksmith in her parents’ business, became the best in her guild and even earned her master’s title in this profession and has been working in the company ever since. This was a rarity for a woman at that time. Anne also started early in her parents’ business and took on office work.

Anne has now also been organising training courses for women in forestry for over 20 years, whether for drivers, entrepreneurs, or those interested in machine technology. The ”Wahlers Ladies Lounge” connects these women with each other. To date, Anne Wahlers-Dreeke has received two awards for this commitment, including one from the German Forestry Council. ■

German Ladies have organised trips to Finland for more than 20 years. In March 2023 ladies went to a logging site in beautiful spring weather.

Most of our customers already aim to balance the finances of their business operations, which is why they make their investments using financing services. We have developed solutions for respon-

sible harvesting for more than 50 years and have provided financing for nearly as long. Through our partners, we provide financing solutions for the acquisition of new forest machines and investments in used machines. ■

»For more information, contact your regional salesperson.

The 19,000th PONSSE forest machine was handed over to Scottish long-term customer Elliot Henderson Ltd. The PONSSE Scorpion Giant harvester with an H8 harvester head will work at logging sites in the Scottish Borders and Scottish Lowlands.

Elliot Henderson Ltd is based in Selkirk in Scotland. The company started more than 35 years ago, planting trees with a small squad of men. Over the years, the business has grown and diversified into forestry, construction,

and scaffolding. Today, Elliot Henderson Ltd comprises more than 40 forest machines which can undertake clear fell, thinning, steep ground harvesting operations, ground preparation or the construction of forest roads. Elliot Henderson Ltd also has the capability for site brash clearance, stump removal and servicing the biomass industry. The company is also a founding member of the Forest Industry Safety Accord and is a member of the Forestry Contractors Association.

With Elliot Henderson Ltd being a long-standing customer for well over 20 years, it’s a fitting tribute to the relationship between the customer and manufacturer that the land-

Ponsse UK was established at 1996, and since 2017, the company has operated at Annan, Scotland. The first PONSSE forest machine was delivered to the country in 1994, and the fleet now comprises nearly 400 Ponsse machines. The Annan service centre is a workplace for about 30 Ponsse professionals.

mark 19,000th machine is joining the fleet.

“Elliot Henderson Ltd has always been at the forefront of new machine releases over the years, which in turn keeps the harvesting fleet productive and at the vanguard of innovation. We are excited to be adding this Scorpion Giant to the fleet. This machine will go straight to work in the windblow resulting from Storm Arwen and we feel the extra power and H8 head will benefit us in this application. We look forward to seeing what it can do! We are currently running PONSSE Scorpion, Ergo, three Elephants and one Buffalo.” says Neil Purves, Director of Harvesting for the Elliot Henderson Group. ■

Scotland is ideal for growing trees: it has mild winters, plentiful rainfall, fertile soil, and a hill-sheltered topography. Scotland’s forests and woodland area covers more than 1.4 million hectares; 18.5% of the country is covered by trees. Forestry contributes almost £1 billion to the Scottish economy, and the industry employs more than 25,000 people. Overall, 81.6% of Scotland’s woodland consists of plantations of non-native conifers like Sitka spruce, lodgepole pine, larch, and Norway spruce. The native Scots pine covers 11.6% of Scotland’s forest land.

Buying a used forest machine, is in many cases a first investment and the most important decision when starting a new business. To minimise risks that can compromise the success of your plan, we have collected some tips to help you to choose your next used machine.

This is our recommendation. Avoid buying a machine from a seller who has no experience of the business. At Ponsse we want longterm relationships and our team’s support is there even after the deal is closed. Our global sales team knows forest machines and they will find the best possible solutions from more than 250 used machines in stock for you.

When you are starting a business, you may not know your monthly production volumes exactly. But there is some information you should get from your customers:

Harvester: What are the average sizes of the trees you will cut and is it hardwood or softwood, what kind of terrain will the work be

done in (slopes, wet area), will it be more thinning or clearcut work?

Forwarder: Are the transportation distances long, what about the lengths of the assortment, do you have some constraints for the width of the machine?

It is also good to estimate how many hours you will work with the forest machine in a year. When you share this information with us, we will find a machine suitable for your needs.

We are talking about a professional working machine: it will need service or spare parts sooner or later. When the machine stops, you may need to change some parts or at least do some service work, which means that you will need some extra money to continue your work in the forest. When you need help? Our global service centre network and service cars around the world are there for you.

How many different owners have there been? Where were the machines working in the past? Why is the machine for sale? Do not assume things, you need to ask! If you are looking at the harvesters’ tyres and they are really worn out even though the machine has been working for less than 10,000 hours, ask for a clear explanation. Today at Ponsse network we sell machines with service agreements. When you are buying a used machine which has had a service agreement, you can easily follow what the machine has worked on and where the machine has worked from the system, and we can estimate what kind of service might come up soon.

In some cases, we can offer you a warranty, ask your local salesperson about this. We know what we are selling, and we can evaluate the risks with you and support you to make the best decision.

The head is the sensible point on the machine. It grabs the trees and trunks are rolling through it all day long. If you have a reliable harvester head, you will avoid many breakdowns as the base machines from competent manufacturers are quite reliable. If you do not have access to the total volume of the harvester heads, examine the condition of the blades. Additionally, an important thing is the condition of the frame itself. We appreciate the condition of the measuring system, and we can update it if needed. Our harvester heads are well known for their high quality.

The forwarder is loaded and unloaded day after day. For this reason, you need a strong and reliable crane. At Ponsse, we have good experience of cranes because we manufacture our own cranes. You need to rely on the transmission system of the forwarder, and you cannot doubt the braking system. This is a matter of safety.

Remember that we are talking about used forest machines. There might be some worn paintwork on the surface, and the tyres could be worn, and there might some small bumps on the machine. Do not worry! These are all reparable if the basics of the machine are in good condition.

When you find a suitable machine, reserve some time for repair and transportation. Take part in the training we offer to get the best out of the forest machine. Preparing a used machine for delivery to a customer is not a story written in advance. It can take more time than a first estimation, even by experienced mechanics. We are starting a long-term relationship, so let’s be patient to make get best of it.

When starting a new business, you might not think first of selling the machine you have just bought. But it is a key point, as your investment will be different if you are looking for a machine for 6 months or 3 years. Take good care of your used machine, and you will get the investment at least party back when when you sell it or trade it in. ■

Our common goal is to preserve forests for future generations. This is why we need to take care of them sustainably and responsibly. Appropriate forest management ensures that forests remain productive throughout their cycle.

The profession of a forest machine operator is both responsible and demanding. Operators must be skilled in tree species, machine operation and technology, as well as work planning. They must also have knowledge of the Forest Act, the Nature Conservation Act and other criteria presented by forest certifications, all of which guide harvesting activities.

Thinning plays a significant role in forest productivity. This is why forest machine

operators need to know what trees to leave standing and what to remove. Technologies are being developed to help operators make these selections and decisions.

Last autumn, we presented the Thinning Density Assistant, a technological concept which is not yet commercially available, but is being studied and tested actively.

The concept uses the lidar technology to iden-

tify trees around the machine and generate a tree map of the logging site. The technology draws an image of the exact location of the machine relative to trees and the adjacent trail on a computer screen.

“As the system does not select any stems for processing, the forest machine operator’s expertise will still be needed in the future,” says Markku Savolainen from Ponsse.

With the technology being developed, the number of standing trees can be measured for the first time in addition to felled trees. The

data collected helps operators achieve the correct and best possible thinning density for forest management, which is also documented.

“A stand-specific stem density –stems per hectare – is given for the system, which the system then starts to teach the operator. As the system operates in real time, no calculations are made afterwards, and the operator sees the situation as it is. The thinning density can be checked on the Opti screen during normal operations,” says Savolainen.

When the operator drives the machine forward on the trail, the view will be updated with new stems. If there is another trail next to the machine, the Thinning Density Assistant shows its

The machine has processed the grey area in the front. When the machine moves, an arrow will be shown to indicate the distance between trails, which is 23.5 m in this example.

Standing trees

Felled trees

A group of trees that should be felled to achieve the optimal thinning density.

location and the exact distance between the two trails. As a result, the system also guides the operator if the distance between trails is too long or short. ■

The Thinning Density Assistant concept uses several technologies.

• The lidar technology helps identify the area around the machine and trees close to it.

• The position of the forest machine is identified using satellites.

• The location of the harvester head on the tree map is determined based on sensor data provided by the Active Crane management system. In addition, the system uses PONSSE Scorpion’s numerous sensors.

Markku Savolainen, Product Manager, machine automation

Markku Savolainen, Product Manager, machine automation

The Operator Talent training programme started from Ponsse Uruguay’s initiative to meet customer needs by starting a training tour. The programme finds, selects, and trains forest machine operators and service mechanics.

Both operators and service mechanics are vital for logging. As a market grows, so does the need for competent workers. This may pose a great challenge for finding trained and skilled employees.

Ponsse has always sought to provide its customers with solutions and services that meet the needs of sustainable forestry. For many years, one of our solutions has been the Ponsse Academy, which is our internal training system for operators and mechanics.

With the upcoming opening of the second pulp mill of UPM, potential was seen in preparing for the coming situation. This gave rise to the idea of the Operator Talent programme. The training programme was to be open for all: anyone who wished to train as a forest machine operator or service mechanic could sign up. The first part was for testing the participants to select the candidates who could complete the full programme and training.

Training tours were organised in 2021

and 2022 by the Ponsse Uruguay training team, who visited locations important for our customers’ operations to offer the training programme. More than 1,200 people signed up during these two years and tours.

THREE STAGES

The training programme had three stages. The first stage included a psychological test that gauged the aptitude of the candidates for the work. Those who qualified for the second stage could demonstrate their abilities in a

forest machine simulator. The candidates who made it to the third stage received training. They were given a choice between two free training courses: forest machine operator or service mechanic. So far, 135 people have completed the training and many of them now work for Ponsse customers in different parts of Uruguay.

Equality was given priority in the training’s implementation. Every part of the training was organised so that the participants did not have to travel anywhere in order to participate. This was done to offer every candidate an equal opportunity to take part in the training.■

Operator Talent was a unique and innovative solution to a challenge. It was our first time participating in a project like this and our experiences were really good. We found skilled employees through the programme and today we have seven forest machine operators who are graduates of the Ponsse programme. We hired them eight months ago and everything has gone smoothly. Their skills are almost on par with our most experienced operators. This was without a doubt a useful solution for us: we found skilled operators, and the Ponsse team provided helpful support during the process.

I’m Leonardo Aparicio from the city of Polanco, close to the city of Lavalleja in Uruguay. Currently, I work as a forest machine operator for Lecal SRL thanks to the Operator Talent programme organised by Ponsse Uruguay in 2021.

I found out about the training tour through social media and decided to sign up. The stages of the programme were challenging. The experience was very important for me and the community of my hometown: even people from small towns could participate in the programme without having to travel a long way or pay to participate. This was unprecedented. The trainers and the work done by the Ponsse team were impressive, as was the content of the training. It was an unforgettable experience!

Walter Calcerrada is a fleet customer who has around 25 Ponsse machines. He works as a contractor for pulp mills and sawmills.

Leonardo Aparicio participated in the Operator Talent programme in 2021.

Walter Calcerrada is a fleet customer who has around 25 Ponsse machines. He works as a contractor for pulp mills and sawmills.

Leonardo Aparicio participated in the Operator Talent programme in 2021.

Demonstrated to the public for the first time at the Expocorma trade fair in Chile, the HH360 rotator has aroused much interest among customers. The rotator is an innovative solution co-developed with Black Bruin that makes it possible for the harvester head to rotate a full, unlimited 360 degrees. The rotator allows the hoses coming from the crane to stay put and the harvester head to rotate freely without unexpected interruptions of production due to kinked hoses.

“We began to develop this solution based on our customers’ needs. The new product allows the harvester head to rotate 360 degrees without twisting its hoses. Free harvester head rotation speeds up stem processing, aids the operator, and reduces hose-related issues,” says Janne Loponen, product manager in charge of harvester heads.

“Compared to our competitors’ products, our solution is robust, powerful, and, above all, energy-efficient, and Ponsse has exclusive rights to use the product in forest machines,” says Loponen.

The rotator is available for Ponsse harvester head models H6, H7, H8, H7 HD, H8 HD, H7 HD Euca, and H8 HD Euca as a separate harvester head attachment. ■

”We have had the new rotator in use now for five months and we have reaped great advantages in terms of maintenance costs. Well, the new Rotator PONSSE HH360, as it rotates freely, has helped us to reduce twisted burst hoses, thus improving our operational performance and reducing forestry harvest costs”.

José Claudio Stanieski, Forestry Manager at Florestal Segundo Planalto, the forestry branch of Brazilian plywood Berneck.Ponsse has opened a new service centre in Joensuu to better serve its customers in Eastern Finland. With about 1,000 square metres of floor space, the service centre features field and information system maintenance, spare parts and machine sales, technical support, ample stocks of individual parts, and a Ponsse Shop.

“The new service centre enables us to provide an even higher level of service for our customers. With a repair shop and spare parts warehouse in the same facility, maintenance turnaround times are also shortened, leaving more time for uninterrupted harvesting,” says Jani Liukkonen, Country Manager for Ponsse Finland.

“On the spare parts side, we can now provide a delivery service, making it possible for our customers to sign a service agreement on equipment purchases,” adds Liukkonen.

Along with the new facilities, we will focus more on personnel training with an option to increase our number of personnel if necessary. Currently, the service centre has 13 employees.

The service centre in Joensuu is located roughly six kilometres south of the city centre. Ponsse chose a location that is easy for customers to access from any direction.

Currently, the service network in Finland consists of 26 locations, with a total of roughly 190 professionals. Ponsse’s market share in Finland is 53 per cent.

The international PONSSE maintenance network consists of 235 service centres. All PONSSE service centres are situated in central locations considering customers’ operations and logistics. ■

PONSSE Parts Online provides an impressive amount of information on your machine and compatible spare parts. Find the correct parts and check their real time prices and availability at any time of the day. You can order the parts to be delivered from the PONSSE service centre of your choosing to any location you want.

The easy-to-use PONSSE PARTS ONLINE works on all devices. Machine-specific information, order history and exploded-view drawings can all be found in PONSSE Parts Online. The service also provides easy access to Instruction Manuals and spare parts manuals when required, which makes PONSSE Parts Online much more than just an application for ordering spare parts. And best of all – it’s completely free!

The PONSSE PARTS OFFLINE feature works when you do not have an internet connection, or your connection is poor. You can place your order any time you want, and the order will be sent as soon as your device reconnects. Parts Offline ensures that your order is not erased even if you lose your connection. The feature is integrated into the Parts Online application and does not need to be installed separately.

WWW.PONSSE.COM/EN/SERVICES

1. ORDER YOUR PONSSE MANAGER IDS

2. INTRODUCTION TO THE SYSTEM

3. ACTIVATE YOUR USER ID

Would you like to share your own story from the forest sector with us?

Stories can be published in our customer magazine or on social media. The story with pictures can be sent to ponssenews@ponsse.com.

In 2019, Arvo Taipale from Kangasala, Finland decided to leave his homeland and he headed to Canada to work as a forest machine driver. In July, he will mark four years of working in the rugged landscapes of Canada.

Arvo's first job was at JD Irving on the east coast in New Brunswick. A couple of years later, after receiving permanent residency in Canada, Arvo ended up working in Ontario for a while. In the end, however, he drove 5,500 kilometres across the country and started working in British Columbia with Freya Logging.

“I have worked at Freya Logging for about 1.5 years. The work sites are usually in the Prince George area, but now in the spring time, I’m working about 400 kilometers away from home in the Jasper area, in the west of the province of Alberta,” Arvo notes.

The current employer's PONSSE fleet includes four Elephant King forwarders and Bear and Scorpion harvesters. The company also has machines from other manufacturers.

For 24,000 hours, Freya Logging have also operated Buffalo King, which was the company’s first purchased machine.

Even in his free time, Arvo likes to tinker with machines.

“ In the summer, I ride an enduro bike and in the winter, I go snowmobiling. In Canada, there are many routes defined by the government, so it's easy to move around in nature with different means both in summer and winter,” shares Arvo.

Many of Freya Loggining´s forest machine operators, like Arvo, have European ancestry. British Columbia has a shortage of skilled harvester and forwarder operators who are proficient in the cut-to-length method of forestry. Valhalla Equipment Inc. is Ponsse´s authorised dealer for British Columbia, Canada.

In addition to renewal felling, Freya Logging also does thinning. The company's owners are familiar with the cut-to-length method due to their backgrounds in Europe, and the company has promoted the use of the commodity method in British Columbia, Canada.

• Location: Prince George, British Columbia, Canada

• Founded in 2016

• The company is owned by Sofia Parfit and her husband Liam, Mirko and Susanne Jansen and Sebastian Mayer

• Repairs approximately 350,000 cubic metres

• Wood species: cedar, hemlock, pine, spruce, noble fir, aspen and birch

• The company employs approximately 25 people and subcontracts another 30-35 truck drivers and mechanics

• During the spring planting season, the company employs up to 20 tree planters

Ponsse North America, Inc. expanded its operations and opened up a new service centre in Tallahassee, Florida, at the end of last year. The expansion was motivated by the region’s increasing demand for timber and growing machine sales in the southern United States.

“We are more than excited about our new location, and its operations have gotten off to a good start. In the southern US, the cut-tolength (CTL) method is not yet as popular as it is in the United States as a whole, and we also wanted to help spread this environmentally friendly method here to the southern parts as well,” says Pekka Ruuskanen, Managing Director of Ponsse North America, Inc.

“In industrial harvesting, the CTL method offers various benefits compared to conven-

tional tree-length harvesting, which remains the most popular method in the United States today. In the CTL method, the harvester fells, delimbs, measures, optimises and cuts stems to make the assortments the forest company has ordered. In addition, harvesting is possible round the year, regardless of weather conditions, which ensures a higher productivity for machine owners,” explains Ruuskanen.

Established in 1995, Ponsse North America, Inc. is Ponsse’s subsidiary with its head office in Rhinelander, Wisconsin. Currently, the company has 89 employees. In addition to the new location in Florida, it has service centres in Wisconsin, Michigan, Minnesota and Oregon. Today Ponsse has altogether 14 dealers and service outlets across the United States. ■

We also wanted to help spread the environmentally friendly method here to the southern parts as well.

In the cut-to-length (CTL) method, trees are already processed in the forest according to their end use, and branches and crowns are left on the ground to nourish the next generation of trees.

Ponsse has dedicated the last five decades and more to the manufacturing, sale, maintenance, and R&D of effective and environmentally friendly CTL forest machines.

Pekka Ruuskanen, CEO, Ponsse North America, Inc.

Pekka Ruuskanen, CEO, Ponsse North America, Inc.

Colour the picture and send it to us!

Ponsse Plc, Ponssentie 22, FI-74200 Vieremä, Finland. You can also take a photo of the picture and send it to ponssenews@ponsse.com. Rememeber to add your name and address and you can win prizes.

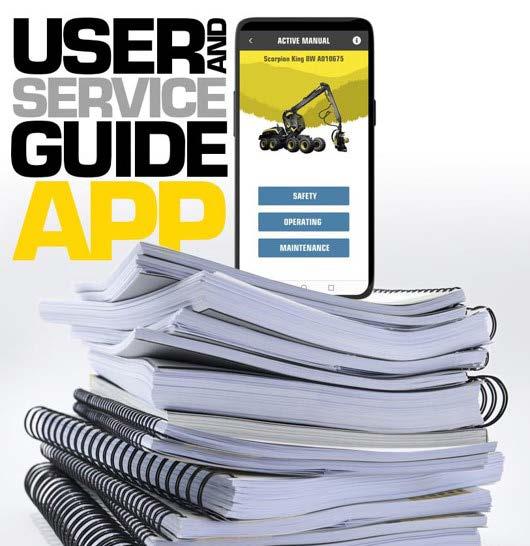

Using animations and videos, The PONSSE Active Manual is a visual way to guide the operator in machine usage and daily maintenance. The application includes highly instructive videos on everyday use and maintenance tips and makes them easy to access in one place.

The videos’ subtitles have been translated into 15 languages: Brazilian Portuguese, Estonian, English, Chinese, Latvian, Lithuanian, Norwegian, French, Swedish, German, Finnish, Czech, Hungarian, Spanish, and Russian. New instructions and videos are constantly being added to the service.

Download the application from the Google Play store App Store free of charge.

Tiina Kautonen has been appointed Ponsse Plc’s new Chief Human Resources Officer and a member of the Management Team starting from the beginning of 2023.

In her position, Kautonen will be responsible for the Ponsse Group’s HR management and the planning and execution of its personnel strategy.

Tiina Kautonen transferred to Ponsse Group from KONE Corporation.

Katja Paananen has been appointed the Chief Responsibility Officer of Ponsse Plc and a member of the Management Team starting from January 2023.

Katja Paananen has more than 20 years of work experience at Ponsse Plc in responsibility, communication, and marketing duties. Paananen will transfer to the new position from her previous post as Sustainability Manager at Ponsse Plc, which she has held since April 2021.

Before this, Paananen was responsible for the Ponsse Group’s communications.

Ponsse’s technology company Epec invests in a responsible new electronics factory in Seinäjoki Finland, aiming for carbon neutrality.

ESF1 (Epec Smart Factory 1) will include a three-story office space and a total of 8,500 m2 of factory space. Epec’s headquarters with its R&D, engineering, support and production functions will move to new premises from its current premises on the Seinäjoki campus.

In addition to Seinäjoki, the company also has offices in Tampere, Turku and Kuopio in Finland, and Shanghai in China. The construction of ESF1 started in spring 2022 and the new facilities will be operational towards the end of 2023.

Ponsse dealer Interexport d.o.o. opened a new center in Davoka, Croatia in February 2023. The centre is Interexport’s fifth location and the first in Croatia. Interexport is the only company that sells Ponsse machines in Croatia.

The company focuses on selling new machines, maintenance services and spare parts sales are also an important part of the business. The 5,000-square-meter center has the company’s administration facilities, sales premises, a central warehouse for spare parts and, in addition, a 900-square-meter workshop hall.

Interexport d.o.o. has been a Ponsse dealer since 2019 in the regions of Slovenia and Serbia, and now also in Croatia.

”Esapekka’s career continues in the new team, and we can now enjoy the speed for the whole season. Rally at that level requires extremely high skills, but we believe that Esepekka will be able to showcase his skills there - in terms of Finns, a great rally season is coming!” commented Public relations Advisor Juha Vidgren from Ponsse.

”Life is full of surprises! Getting a chance to join Hyundai Motorsport and to drive a full-calendar WRC program was something we didn’t expect. This is truly a dream and a unique opportunity; we are very happy to join the Hyundai Motorsport family,” Esapekka says.

PONSSE’S ANNUAL REPORT AND SUSTAINABILITY REPORT 2022 HAVE NOW BEEN PUBLISHED

Ponsse Plc’s annual report for 2022, including the financial statements and the board’s activity report, as well as the sustainability report for 2022, can now be found on our website.

The printed annual report and sustainability report are sent by post to those who have ordered them. Easy-to-read pdfs are available for everyone to read at www.ponsse.com.

The first Ponsse machine began being built in 1969. Originally, the intention was only to build a forest machine that would last even one winter without needing to be fixed all time.

Every year, Ponsse selects a service centre of the year from among Finnish service centers. Mikkeli was chosen as the service center of the year 2022, and it received special praise for its level of customer satisfaction and safety thinking.

The evaluation criteria are based on customer feedback, criteria based on operational development and profitability, and evaluations made by Ponsse’s own expert council.

The Oregon Logging Conference was held in Eugene, Oregon in the United States at the end of February 2023. In the Ponsse event area the PONSSE Manager Satellite and the new PONSSE H8 harvester head were on display.

Ponsse has had service operations in the Mikkeli area since 1989.

Ponsse’s first harvester, the PONSSE HS15, engaged in forest work in 1986. In the ‘80s, the colour green was often used for the exterior of Ponsse machines, but yellow began to be used again in 2005.

Information technology started to arrive in Ponsse’s machines in the ’80s. The photo above features Kajaani Automatiikka’s measuring device from 1987.

Ponsse’s globalization began in the ‘90s and the company was listed on the Helsinki Stock Exchange in 1995. Our history tells us that all the funds received from the listing went to the company’s globalisation. This picture features a Ponsse model from 1994.

BLACK T-SHIRT

Product number 3065 / Sizes: XS–4XL

Black T-shirt with a matching printed Ponsse logo.

Material: 100% organic Fairtrade cotton, 155 g/m2

Certifications: GOTS, EU Ecolabel, Fairtrade, SA8000, Oeko-Tex and Neutral Responsibility.

BLACK T-SHIRT

Product number 3066 / Sizes: XS–4XL

Black T-shirt with a stylish yellow print.

Material: 100% organic Fairtrade cotton, 155 g/m2

Certifications: GOTS, EU Ecolabel, Fairtrade, SA8000, Oeko-Tex, Neutral Responsibility

YELLOW T-SHIRT

Product number 3038 / Sizes: XS–4XL

Unisex T-shirt with a relaxed and oversized fit. The knitted tag on the shirt hem is a sign of sustainability.

Material: 60% recycled cotton, 40% recycled polyester

BLACK CORDUROY CAP

Product number: 3041 / Size: 58

Black corduroy 5-panel cap. Black 3D Ponsse print on the front, black and yellow embroidery on the back. Faux leather strap with a metal buckle.

Material: 100% cotton.

Designed in Finland. Made at an BSCI-audited factory in China.

CHEQUERED CAP

Product number: 3040 / Size: 58

Trendy chequered cap with a stylish faux leather Ponsse coat of arms on the front. Black and white Ponsse embroidery on the back. The size can be adjusted with the faux leather strap that has a metal buckle.

Material: 70% polyester, 27% rayon, 3% spandex

Designed in Finland. Made at an BSCI-audited factory in China.

Product number: 3036 / Sizes: XS–3XL

Relaxed and trendy grey sweater jacket for everyday use made of a soft and comfortable material. Two pockets with zippers on the side, rubber prints on the sides of the pockets and a matching black Ponsse print on the left side of the chest. Knitted Ponsse tag on the side seam. Attractive cut, and the zipper is covered to protect your chin.

Material: 70% recycled polyester, 26% rayon and 4% spandex

Product number: 3035 / Sizes: S–4XL

Relaxed and trendy grey sweater jacket for everyday use made of a soft and comfortable material. Two pockets with zippers on the side, rubber prints on the sides of the pockets and a matching black Ponsse print on the left side of the chest. Knitted Ponsse tag on the side seam. Attractive cut, and the zipper is covered to protect your chin.

Material: 70% recycled polyester, 26% rayon and 4% spandex

Product number: 1802 / Sizes: XS–3XL

The perfect middle layer for everyday use and outdoor activities. The soft brushed fleece is made from recycled polyester. The two pockets with zippers keep your belongings safe. The jacket transfers moisture to the next layer well, dries fast and protects you from the wind. Printed Ponsse logo on the chest and a knitted Ponsse tag on the side seam.

Material: 100% recycled polyester

Certifications: GRS (Global Recycled Standard)

Made at an amfori BSCI-audited factory in China.

Product number: 1801 / Sizes: S–4XL

The perfect middle layer for everyday use and outdoor activities. The soft brushed fleece is made from recycled polyester. The two pockets with zippers keep your belongings safe. The jacket transfers moisture to the next layer well, dries fast and protects you from the wind. Printed Ponsse logo on the chest and a knitted Ponsse tag on the side seam.

Material: 100% recycled polyester

Certifications: GRS (Global Recycled Standard)

Made at an amfori BSCI-audited factory in China.

All the Ponsse Collection products can be found on our online store www.ponsseshop.com

BEING CUSTOMER-ORIENTED is a way of life for us, and we work together with our customers’ best interests at heart.

We work hard, but not too seriously. We always aim for the best possible results while also considering the environment.