PONSSE NEWS

THE POPULAR H7 HARVESTER HEAD RENEWED

PONSSE FOREST MACHINES WORKING AT GERMAN AND FRENCH LOGGING SITES

PONSSE’S SERVICE MECHANICS IN INTERNATIONAL EXCHANGE

AT PONSSE’S FACTORY LIQUEFIED GAS REPLACED WITH BIOGAS

PONSSE WISENT AND ELK

THE POPULAR H7 HARVESTER HEAD RENEWED

PONSSE FOREST MACHINES WORKING AT GERMAN AND FRENCH LOGGING SITES

PONSSE’S SERVICE MECHANICS IN INTERNATIONAL EXCHANGE

AT PONSSE’S FACTORY LIQUEFIED GAS REPLACED WITH BIOGAS

PONSSE WISENT AND ELK

CUSTOMER AND STAKEHOLDER MAGAZINE 2/2024

PUBLISHER

Ponsse Oyj, Ponssentie 22, FI-74200

Vieremä, Finland

EDITOR-IN-CHIEF

Hanna Lehtonen

EDITORS & CONTENT

Ponsse Plc

ISSN 2489-9488 (print)

ISSN 2489-9496 (online publication)

EDITORIAL STAFF

Juho Nummela, Hanna Lehtonen, Mari Komulainen, Marika Ryytty, Jarmo Vidgren, Marko Mattila ja Jussi Hentunen

LAYOUT

Luova Työmaa

COVER PHOTO

Ponsse Plc

ILLUSTRATIONS (PONSSE KIDS)

Henna Ryynänen

Painotalo Seiska

PAPER

Cover: MaxiSilk 150 g/m2 and pages Galerie Art Matt 100 g/m2

ADDRESS SOURCE

Mailing list of Ponsse News and Ponsse customer register

4 NEW SOLUTIONS 2024

Responsible solutions by listening to customers 10 WALD JACOB, PONSSE IS THE NUMBER ONE 13 JÉRÔME RIGOULET, FORESTER BY TRADE, COMPETITOR AT HEART 16 THE POPULAR H7 HARVESTER HEAD RENEWED 18 PONSSE MOMENT

20 A STRONGER NEW PONSSE NETWORK

22 THE BEST SERVICE WITH OUR DEALERS

24 LIQUEFIED GAS REPLACED WITH BIOGAS AT PONSSE'S FACTORY

Ponsse seeks to achieve carbon neutrality at its factory in Vieremä by 2025

26 VARIOUS ASSORTMENTS ACCURATELY AS ORDERED

The CTL method enables high-quality harvesting and forest management on every site

Ponsse PLC customer and stakeholder magazine.

Ponsse News is published twice a year.

Please send feedback, subscriptions and changes of address by email to ponssenews@ponsse.com. The magazine is free of charge.

FOLLOW US:

Economic and geopolitical fluctuations have increased business uncertainty in recent years. Ponsse and our customers have adapted to the new routes of global wood flows, suffered from high inflation and become accustomed to a situation in which visibility into the future is more limited than before and characterised by uncertainty.

At Ponsse, this has been a time for organisational development. With our existing structures and ways of working, we would no longer have been able to respond to the changed requirements of the market effectively enough. In June, we introduced an organisational structure that is in line with our new operating model. In the new operating model, we have divided the world into five geographical areas, where local customer needs guide our sales and service operations. The areas’ country organisations and dealers form a consistent global Ponsse network, which provides our customers with the best possible support for their business operations.

We will continue to rely on our strong values, traditions and customer orientation. Ponsse’s strong culture is one of our most important success factors.

In connection with this, the roles, responsibilities and structures of the support functions that ensure that our operations run smoothly have been made global. The support function teams have members from different parts of the Ponsse network. This has further enhanced cooperation within our network, and we understand the needs of different market areas even better than before. We hope that this cooperation and operational development is visible all the way to our customers.

Amidst the reforms, it has also been important to identify the aspects that we want to hold on to – the aspects that have enabled Ponsse’s success and our customers’ trust. We will continue to rely on our strong values, traditions and customer orientation. These cornerstones, combined with our uncomplicated way of working together, always to the best of our abilities, are the essence of the Ponsse spirit. Ponsse’s strong culture is one of our most important success factors.

Ponsse, and the forest sector in general, is once again facing something new. The demand for renewable raw material is perhaps greater than ever before, and the development of forest machines is progressing in leaps and bounds, taking account of the forest sector’s and customers’ needs more and more comprehensively. For us at Ponsse, the changes provide an opportunity for growth and learning, enabling us to serve our customers even better than before.

Juho Nummela President and CEO, Ponsse Plc

PONSSE Wisent forwarder offers load-carrying capacity, agility and productivity on diverse harvesting sites.

The smallest loader, Elk and Wisent, have been renewed. Both have completely new frame structures, and the frame joints have been changed from welded to cast.

“A simpler structure has been obtained that increases durability and versatility. For example, in terms of profitability, it is important that thanks to the change in the centre of gravity and the design of the cargo space, with Wisent, you can now transport two or three metres a batch,” says Ponsse´s Director of Product Management and PMO, Ville Hukkanen.

IMPROVED ERGONOMICS SUPPORTS THE FOREST MACHINE OPERATOR’S DAILY WORK

PONSSE Wisent forwarder offers load-carrying capacity, agility and productivity on diverse harvesting sites. The excellent weight distribution and geometry of the PONSSE Wisent also make it easy to transport stems on thinning sites with dense and bendy trees.

PONSSE Elk forwarder also operates reliably in changing conditions and on sites with long distances. The new Elk is an efficient and agile forwarder with an excellent load-carrying capacity relative to the machine weight.

The new forwarders feature a big cabin, large windows and thin window pillars, ensuring excellent visibility in every direction. The cabin can also be equipped with the PONSSE Seat, which effectively reduces swaying and impact directed at the operator during the working day.

PONSSE Active Cabin, a cabin suspension system which improves driving comfort, is the most recent addition to the range of optional equipment available for both PONSSE Elk and Wisent. On uneven forest trails and in demanding terrain, ergonomics and productivity improve when the system effectively suspends any strain directed at the cabin.

PONSSE Elk forwarder also operates reliably in changing conditions and on sites with long distances.

The new PONSSE H7 harvester head features a powerful feed and an excellent power-to-weight ratio that improve productivity. Thanks to its improved geometry, the new H7 can process large stems with ease. The advanced PONSSE Active Speed function is a new feature of the H7 harvester head. It allows the speed of the feeding to be adjusted according to the tree species and stem diameter.

ABOUT H7 ON PAGE 16

PONSSE Active Crane makes the crane even easier to use. The operator does not need to control different joint movements: they only need to move the harvester head in the desired direction at the desired speed. End damping makes operations even smoother.

“Active Crane will now be available in Central Europe and is popular in the mountains for C5 and C6 loaders.

The biggest benefit of Active Crane lies precisely in these telescopic cranes

because they give the driver more trajectory to control than in conveyor cranes.”

Ville Hukkanen says Active Crane is also for coordinate control because the driver does not control the different joints of the crane but moves the crane’s head in the direction they want in the coordinate system, and automation takes care of the rest.

Active Crane, available as an option, requires the Opti 5G control system. Available from Q1/2025.

Adjustable armrests are new solutions for improved ergonomics. Adjusted according to the forest machine operator’s dimensions and driving style, the armrests significantly reduce any stress directed at the nape and shoulders while working. As the adjustments are stored in the armrest’s memory, the operator does not need to adjust the armrests again at the beginning of each shift.

Hukkanen is particularly pleased with the renewed armrests.

“Before, the handles were at the end of the ball joint, and adjusting them was a little difficult. Now, the handles slide vertically and horizontally in the slide guides, making it easy to lock them in the right position. The new electronic adjustment is an accessory that enables the manual armrest’s height, length, rotation, tilt, width, and wrist angle to be adjusted. In addition, the electrically operated armrests can be adjusted in height and length, and the driver can return the seat and handles to their desired settings at the start of their shift with a single touch of a button.”

PONSSE Armrests are available as standard equipment for harvesters and forwarders, and PONSSE eArmrests electrically operated armrests are available as optional equipment for all harvesters and forwarders. PONSSE armrests are also available as retrofit packages through Ponsse spare parts (Q1/2025).

PONSSE Scale is a wireless loader scale system that weighs the load and sorts, saves and manages load data during all work stages. Accurate weight measurements ensure optimal loads. Weighing is fully automatic during both loading and unloading, and detailed data on each load is registered. Load data, logs and the measuring accuracy are available

in easily readable reports. PONSSE Scale has excellent weather resistance and produces accurate results in all conditions, ranging from hot summer to freezing cold winter days.

PONSSE Scale can be installed in all new PONSSE forwarder models.

PONSSE Manager 2.0 is a platform for next-generation digital services and is a forest machine management system. The system allows customers to track the location, productivity and fuel consumption of their machines. It also monitors the growth of stands and the progress of plans. In addition, it can be used to machine transports, monitor, monitor the production volumes of machines by assortment and print measuring certificates.

The digital platform allows users to create a custom landing page or dashboard, with immediate access to vital data. Important information can be read quickly, and changes are easy to spot.

PONSSE High-Precision Positioning is a solution that helps the machine operator know the exact location of the machine and the harvester head. This enables the effectiveness of logging operations to be maintained, even in changing conditions.

Utilising industry-leading navigation and location tools, as well as Ponsse’s own advanced technologies such as Active Crane, High-Precision Positioning can raise the reliability bar to a level conventional positioning systems often don’t reach.

By defining the exact location of the harvester head and presenting it in map view, High-Precision Positioning can significantly improve harvesting productivity. The solution clearly shows where the operator should harvest and the areas that should be avoided. Every stump location is saved in the production file, and the driving path the harvester creates is clearly visible to the forwarder.

The new solutions will improve your operations’ productivity and safety. They will also ensure that the site is most reliably and responsibly completed on time and on budget.

High-Precision Positioning is available in Finland, Sweden and Germany for all PONSSE harvesters equipped with Active Crane, and it can also be retrofitted. Availability for other markets will be specified later.

You can start using the free PONSSE Manager 2.0 by contacting us through the form available on our website (manager2.ponsse.com) or by reaching out to your nearest Ponsse sales.

PONSSE MANAGER 1.0 WILL BE DISCONTINUED FOR CUSTOMER USE ON 30/11/24

WALD JACOB

Trees in the forest – from planting to harvesting – are just one of the activities at Wald Jacob. In addition, the company produces 25 hectares of Christmas trees. The family also organises a large Christmas market every year in December.

The Saxon Vogtland is a densely wooded region in eastern Germany. The headquarters of the Wald Jacob forestry company is located just a few kilometres from the Czech border.

“We mainly work in Germany in a range of up to 100 kilometres,” explains Ronny Jacob, head of the company.

“Around 80% of our customers are private forest owners, local authorities and corporations. We have base capacity utilisation thanks to orders from the state forests in Saxony, Thuringia and Bavaria, where we participate in tenders. Beyond the state forest, the price pressure is somewhat lower, yet the smaller structures mean that we have a significantly higher workload in terms of order acquisition, organisation, processing and timber sales. But timber sales allow us to generate some additional margin. Because, as we all know, there is more to earn in the retail sector,” the forestry contractor adds with a laugh.

“However, we had to organise ourselves accordingly. We have four qualified foresters on our team who are responsible for customer contacts, consultations with the district foresters and managing operations. In addition, we have the appropriate capacities in the back office. The concentration of forestry contractors in our region is very high. However, what sets us apart from others is that we offer a very comprehensive portfolio of services. It all starts with planting, maintenance and forest protection, continues with timber harvesting and trading, and ends with special tree felling. Consulting and support are our especially strong points. We can even prepare forest appraisals.”

short logging technology – a forwarder, followed later by a harvester.

“We now have five harvesters and five forwarders. We also have two short timber lorries, a lowbed, a T-winch, two cable tractors, and various agricultural and forestry machines,” says Ronny Jacob. One special feature is that we have never gone with brand loyalty. My father would say that 'We test the machines ourselves and create our own opinion!' This is how we have used and still use all the different colours in the company. However, PONSSE is number one. We have two PONSSE Bears – one of them brand new – a PONSSE Bison and a PONSSE Buffalo. Of course, technology and performance are the primary concern when we make an investment decision. But what I particularly like about both PONSSE and Wahlers Forsttechnik is that they are both family businesses. Just like us. It's a completely different kind of collaboration.”

PONSSE is number one.

We have two PONSSE Bears – one of them brand new – a PONSSE Bison and a PONSSE Buffalo.

Whenever possible, the company carries out the service and repair of the machines themselves. To this end, it has a well-equipped workshop including a gantry crane. Along with an equipment shop with centralised oil supply. Operators have a chip which always give them access for refuelling. The large diesel tank is outside. Once a year or after 1,000 hours, the machines come into the workshop for a major service, while the ongoing work is carried out outside in the forest.

Wald Jacob was founded in 1990 by Hartmut Jacob. He was the manager of a forestry machinery company in the GDR, which was dissolved after German reunification. Because he always had a market economy perspective, he seized the opportunity to set up his own business. With a handful of employees and two LKT 81. They were the standard long timber cable tractors in GDR forestry at the time. The company saw growth. In the mid-1990s, the company started using

“We generally aim for the long term,” says Ronny Jacob. “We are looking at 12,000 to 15,000 hours for the harvester and over 20,000 hours for the forwarder. However, this approach only works with regular good care. And halfway through the service life, a more extensive investment is required to make the machines fit for the remaining service life.”

Wald Jacob is proud of the company’s status as a training centre for foresters. In each of the three apprenticeship years, one to three young people learn this profession, which is particularly demanding and

Jacob's family: On the left, the founding generation Maria and Hartmut. From the right: Head manager Ronny, Sandra and Gina Maria Jacob, son-in-law Hans Hellfritzsch, and son Ernst-Moritz Jacob.

varied. Apprentices who are interested will have the opportunity to work on machines in their final year. This way, the company secures qualified labour.

Out in the forest, Ernst-Moritz Jacob drives the new PONSSE Bear with a C6 crane and H8 power pack.

“I am particularly impressed by the boom extension,” says the forester. “Especially in stands with natural regeneration, it is strong enough to gently lift out even heavy trunks.” Ernst-Moritz previously worked mainly with a chainsaw and has been using the machine for around two years. Today, he is supported by forester Louis and apprentice Lisa as assistant fellers. The surface is quite steep, but thanks to the straps on the front axle, the Bear climbs the hill with ease. The good stability of the machine is noticeable during felling and processing. The crane's automatic tilt mechanism is a great help in this terrain, ensuring that the lifting force is always at its maximum. "We have again invested in a heavy timber harvester because we assume that this type of work will continue to dominate in the region's overaged stands for the next few years. The conversion to stable mixed forests is still in full swing here. However, if the focus later on will be on maintenance and thinning, we may have to make a different decision.”

We return to the depot for another special surprise from Wald Jacob. The family produces Christmas trees on 25 hectares, but that’s not all: most of them are marketed themselves during a four-week Christmas market in December.

“For us, everything revolves around the tree. There are also attractions such as a petting zoo with a variety of different animals and horse-drawn carriage rides. We round off the concept by serving venison from our own hunt. After all, this is also part of holistic forestry. And most of the members of the Jacob family are indeed passionate hunters.

• Owner: Ronny Jacob

• Headquarters: Markneukirchen-Wohlhausen, Saxony, Germany

• Personnel: 40 employees

• Machinery: 5 harvesters, 5 forwarders, 2 short timber lorries, lowbed, T-winch, 2 cable tractors

• PONSSE machines: 2 Bear harvesters, Bison forwarder, Buffalo forwarder

• Company history: Founded in 1990 by Harmut Jacob and his wife Maria. Managed today by Ronny Jacob and Sandra. The third generation – daughter Gina Maria, son Ernst-Moritz and son-in-law Hans – also work in the business.

JÉRÔME RIGOULET

French contractor Jérôme Rigoulet has developed his business over the long term. He is also a championship-winning racing driver in his spare time, and the winner’s choice of machinery is Ponsse.

Jérôme Rigoulet is a forestry contractor in Jura, Eastern France, close to Switzerland. The name Jura means "mountain forest" in Gaulish, an old language. 250,000 hectares of the area, 50% of its territory, is covered by forest.

This is Jérôme Rigoulet's playground, where he harvests 100,000 m3 of timber a year with his PONSSE machines. The harvested timber comprises almost exclusively softwood, and 90% of it is "small wood", as he calls it, with diameters of up to 50 cm. These conditions have led Jérôme to choose the PONSSE Scorpion Giant and its H8 head as his next piece of equipment.

A PIONEERING CONTRACTOR

Jérôme Rigoulet began his forestry career in the 1990s, starting with chainsaw felling, hand planting of tree seedlings, and forest clearing in his father's forestry contractor business. The time he spent as an apprentice not only inspired him to set up his own business but also to bring more mechanisation to the sites in his region.

So in 2001, Jérôme started out with a second-hand forwarder – with great success. Not necessarily because of the machine, but

rather thanks to his welcoming approach and friendly attitude toward customers. Six months later, he was able to buy his first new forwarder, a new one this time, followed by a second and then a third, and at the same time hire two employees.

As the years went by, Jérôme was still driving his forwarder and organising the worksites. As an enterprising man, he seized the opportunity to buy a harvester in 2007. Driving this new machine immediately added an extra dimension to his business. With 3 forwarders and 2 harvesters, supported by 5 employees, his company really took off in 2011.

Now Jérôme is successfully concentrating especially on the commercial side of his business, to make the most out of his customers' pulpwood and pallet timber. Yet another winning bet.

“We still have the same customers today, and we still work in the same way as before,” he says with satisfaction.

The company works for all kinds of forest owners such as private individuals, local authorities, the Ministry of Forestry (ONF), sawmills, managers of natural areas and roads, and forestry operators.

• Founder, owner: Jérôme Rigoulet

• Year of foundation: 2001

• Registered office: Thesy, France

• Employees: 6

• Area of operation: Jura/Doubs, Eastern France

• Ponsse machines: Currently using two PONSSE Ergos, but two PONSSE Scorpion Giants and one PONSSE Buffalo are on order for next year.

Jérôme’s company has evolved even more since then. It now has just one forwarder, but three more harvesters have been acquired, and two lorries are used for transporting timber.

Jérôme is not working the machines as much now, as he is focusing on adding value to the timber. He is still keeping busy though, as one must stay up to date with the development of customers and the market to deliver the best products from the forest.

This work is supported by Jérôme’s recently launched partnership with Ponsse.

“I wanted to work with a major brand and be able to count on local high-quality service,” he explains.

Ponsse was a natural choice in the wooded terrain of Jura. The PONSSE Ergo harvester immediately won Jérôme over with its reliability, comfort and speed. With Ponsse as his partner, the entrepreneur was clearly achieving a higher level of performance in harvesting and trunk processing. Thanks to the increased productivity, the company has become much more responsive in the field.

With the added arrival of the PONSSE Manager system to help manage sites and equipment, the back office operations have a whole new dimension.

“It's a great tool to work with, and I couldn't live without it,” Jérôme says.

The company’s two PONSSE Ergo harvesters with H7 heads are equipped with the system. These machines will soon be replaced by two forthcoming Ponsse Scorpion Giant harvesters with H8 heads. They, too, come with Ponsse Manager functionality.

Jérôme is planning to change his two harvesters simultaneously, so that his two drivers, Guillaume and Yannick, can learn how to use the new machines together and help each other to progress. The simulta-

neous switch also greatly simplifies building up the stock of parts and consumables.

“This is a regular part of the work, because the machines need to withstand a working rhythm of 1,800 h/year with a minimum of break time. This can only be achieved with regularly renewed equipment,” Jérôme explains.

“We're meeting our deadlines thanks to our new machines,” he says.

Jérôme knows that the new Ponsse Scorpion Giant will soon give him even more stability when working on slopes. He can also achieve more crane reach. The H8 harvester head gives much greater processing speed and allows for even bigger diameters.

These are real pluses in the field, not to mention the harvester’s design and interior,

which have won over the drivers. What is more, the ease of service and maintenance is much appreciated. The blend of performance and quality is perfectly suited to the terrain of Jura.

When starting his career as a forester in his twenties, Jérôme Rigoulet also tried his hand at competitive karting. His talent was even spotted by an esteemed racing team. However, the demands of everyday life kept Jérôme away from the circuits after he set up his company.

A self-confessed mechanic and competition enthusiast, Jérôme has always wanted to return to motor sports. He did finish first at a competition for forwarders at Fougerolles

a few years ago, but nothing can replace the thrill of car racing.

Three years ago, Jérôme made his comeback on the tarmac. Now driving Mitsubishi Evo 5 and Evo 9 cars, the contractor has launched himself into regional and national rallies in the Coupe de France and Championnat de France series. Embarking on his third season, he is the reigning French champion in the A8 class. What better match for a champion than Ponsse – the best forest machine in the world!

As with his job as a forester, Jérôme prepares for his rallies in the best possible way by fine-tuning the mechanics and anticipating maintenance as much as possible. But in the end, he knows that it is the driver who makes the difference.

"I wanted to work with a major brand and be able to count on local high-quality service," says Jérôme Rigoulet.

The new PONSSE H7 harvester head features a powerful feed and an excellent power-to-weight ratio that improve productivity. Thanks to its improved geometry, the new H7 can process large stems with ease. The advanced PONSSE Active Speed function is a new feature of the H7 harvester head. It allows the speed of the feeding to be adjusted according to the tree species and stem diameter.

Ponsse’s traditional H7 harvester head is one of the most popular in the product line. It is used all over the world for both thinning and clear cutting. Suitable for both hard and soft woods, it is available for all PONSSE harvesters except the PONSSE Beaver.

“The H7 has been in production since the beginning of the 2000s, and it has never received such major updates until now. The H7 is placed between the H6 and H8 in the product line. Before the updates, the H7 was closer to the H6, but now its features are truly halfway between the H6 and the H8,” says Ville Hukkanen, Director of Product Management and PMO at Ponsse.

Although the new H7 cannot handle trunks with a larger diameter than the previous model, in practice it can now process larger trunks much more efficiently.

According to Ville Hukkanen, Director of Product Management and PMO at Ponsse, the new H7 harvester head has been tested in several different countries, in different tasks, with different types of trees and in different conditions – from freezing cold to extreme heat and from dusty conditions to rain.

Giedrius Cicénas, Department Manager of Baltic Agro Machinery (on the left in the picture) and Renigijus Lukas, Remigijus Zdanavicius, Mindaugas Lukas and Algis Zulpa from Lithuania, UAB Gerilita (pictured above) visited Ponsse´s fair stand at the FinnMETKO 2024 exhibition. In the new H7 harvester head, they were interested in, for example, efficient Active Speed control and improved geometry for large and winding trees.

it possible to process even small thinning trees quickly with a relatively large harvester head. Active Speed has been a popular feature on the H8, and now it is available on the H7 as well.”

accuracy of the measurement. The spikes of the measuring wheel remain in contact with the tree for a longer distance, so the traces of the individual spikes are smaller.”

The updates to the H7 do not only make it easier to process large trees. For example, the Active Speed function feeds the thick base of the tree through the harvester head more slowly and with greater force. The thinner top, on the other hand, goes through the harvester head faster and with less force. The feed speed changes during sawing, and the operator can adjust it to their liking. This optimises the processing of the entire trunk and also reduces fuel consumption

“Active Speed facilitates both clear cutting and thinning, making

The general design of the harvester head has been revised so that snow or logging residues can no longer get packed between are easy to change if necessary. Likewise, all the hydraulic cylinders

The connection hoses on the H7 no longer have a feed-through block, but the hoses continue directly from the harvester head to the

“The new hydraulics also save energy and produce less waste heat.

The updated H7 harvester head is the result of years of engineering and testing. The starting point has been customer feedback from different

“Our harvester heads are designed as a product family, so many features previously made for larger or smaller harvester heads have now been utilised in the H7, such as the Active Speed feature. The product family approach also allows us to use the same production methods as much as possible and even the same components in different harvester

Production methods have also been refined. For example, the share of robot welding has been increased. The updated production methods save time, materials and the environment, and they usually also improve the quality of the final product.

The new H7 will replace the old H7 in production in the near future. Customers have been eagerly anticipating the new harvester head.

“The new H7 is interesting, especially the Active Speed function and the new body design,” says Mindaugas Lukas, who was with Remigijus Zdanavicius, Renigijus Lukas, and Algis Zulpa from the Lithuanian company UAB Gerilita at the FinnMETKO trade fair, where the new H7 was presented for the first time at the turn of August and September.

Ponsse has renewed its global organisation, which focuses on serving customers better and more efficiently.

Ponsse wants to be close to its customers and grow with them. Focused on sales and service, the new organisation has been divided into five market areas and supports customers even better than before. Customers and the aim to support their operations are at the core of the new, even stronger, Ponsse network. The market areas are the Nordic countries (including the Baltics), Europe, South America, North America, and Asia, Australia and Africa. Ponsse serves its customers in more than 40 countries through its local organisations and dealers.

The aim of the new areas and operating model is to ensure a globally harmonised way of working to meet future customer needs. The goal is also a more uniform way of doing things globally. The new model seeks more uniform operating methods and cost-effectiveness. The change is based on a changed operating environment and the need to strengthen Ponsse's long-term competitiveness and profitability. At the heart of everything is the customer and better customer service.

Ville Mansikkamäki Vice President, Europe

PONSSE CZECH S.R.O. CZECH REPUBLIC

PONSSE S.A.S FRANCE

PONSSE MACHINES IRELAND LTD. IRELAND

PONSSE UK LTD. UNITED KINGDOM

WAHLERS FORSTTECHNIK ÖSTERREICH GMBH AUSTRIA

PROGRESS TECHNIK OOD BULGARIA

DYNA TOURAINE FRANCE

WAHLERS FORSTTECHNIK GMBH GERMANY

FOREST POWER KFT. HUNGARY

TECNOAMBIENTE SRL ITALY

CDN ERGO SP. Z O.O. POLAND

ASCENDUM MAQUINÁS PORTUGAL

SC IRUM SA ROMANIA

FLEXIM SPOL. S.R.O. SLOVAKIA

INTEREXPORT D.O.O. SLOVENIA, CROATIA, SERBIA

HNOS. TOIMIL GARCÍA, S.L. SPAIN

Jaakko Laurila Vice President, Nordics

Jussi Hentunen Vice President, Asia, Australia and Africa

PONSSE PLC FINLAND

EPEC OY FINLAND

PONSSE AS NORWAY

PONSSE AB SWEDEN, DENMARK

BALTIC AGRO MACHINERY AS ESTONIA

BALTIC AGRO MACHINERY SIA LATVIA

BALTIC AGRO MACHINERY UAB LITHUANIA

PONSSE CHINA LTD. CHINA

RANDALLS EQUIPMENT COMPANY AUSTRALIA

GUANGXI PANGSAI FORESTRY MACHINERY CO LTD. CHINA

SHINGU SHOKO LTD. JAPAN

RANDALLS EQUIPMENT COMPANY NEW ZEALAND

M.T.S. PARTS CC SOUTH AFRICA

We want to support our network better, so that they can serve our customers even better than before.

Our goal is the best customer experience every day.

MARKO MATTILA

Chief Sales, Service & Marketing Officer

Our new organisation is divided into five different areas. The Vice Presidents of each area ensures that customers' business needs are supported in the best possible way.

Martin Toledo Vice President, South America

PONSSE LATIN AMERICA LTDA BRAZIL

PONSSE URUGUAY S.A. URUGUAY

PONSSE CHILE SPA CHILE

MAQUINARIAS GEIER ARGENTINA

SOTREQ S.A. BRAZIL

TIMBER FOREST BRAZIL

MDETEC S.A.S COLOMBIA

H. PETERSEN PARAGUAY

Marko Mattila* Vice President, North America

PONSSE NORTH AMERICA, INC. USA

A.L.P.A EQUIPMENT LTD. CANADA

HYDROMEC INC. CANADA

READYQUIP SALES AND SERVICE LTD. CANADA

VALHALLA EQUIPMENT INC. CANADA

CHADWICK-BAROSS INC. USA

KLEIS EQUIPMENT LLC USA

PACWEST MACHINERY LLC USA

BAILEY’S USA

*Interim

Ponsse is constantly developing its services across the world with its customers and partners. Dealers’ expertise in local markets helps Ponsse respond to customer needs even better. We met one of the latest additions to our dealer network, as well as our long-term partners in South Africa and Australia.

• France has the fourth largest forest area in Europe, with forests covering more than 16 million hectares.

• Central France is home to highly diverse forests and more than 30 different tree species. The land is mainly flat in the central parts of the country.

• Deciduous trees account for roughly 70 per cent of all trees, with oak, beech and pine being the most significant species.

• France has some 3.3 million private forest owners who own approximately 12 million hectares of forests. A single forest owner usually owns less than a hectare of forest land.

• There are some 800,000 major forest owners.

Starting its partnership with Ponsse in the spring of 2024, Dyna Touraine from France is one of the latest additions to Ponsse’s dealer network. At the bustle of the FinnMETKO 2024 exhibition, we met Nicolas and Romain Boussion, the founders of Dyna Touraine.

“Our company is based in Le Mans in Central France, some 200 kilometres from Paris. My brother Romain and I established the company in 2008, and we are a family-run company like Ponsse,” says Nicolas Boussion, who currently works as a director of the company. Dyna Touraine specialises in forest and earth-moving machines, excavators, chippers and transport vehicles for them. Its customer base extends from the northwest to Central France.

Ville Mansikkamäki, Ponsse’s Area Vice President, Europe; Timo Savornin, Area Marketing Manager, Europe & North America; Director Nicolas Boussion and Managing Director Romain Boussion from Dyna Touraine; and Jean Sionneau, Ponsse’s Country Manager, France, enjoying the exhibition.

“Currently, our company employs roughly 30 people, and we are looking for new employees. We believe in growth, even though the market situation is slightly challenging,” Nicolas says. “We are really enjoying this event – there are many exhibitors, and Ponsse’s exhibition area is very impressive”.

The partnership has got off to a good start, and people from both Ponsse and Dyna Touraine are highly motivated and very excited about their cooperation. “The company operates in first-rate new facilities, and Ponsse’s machines are proving their worth – we are in a good place to move forward,” says Ville Mansikkamäki, Ponsse’s Area Vice President for Europe.

Established in 2007, MTS Parts from South Africa has been a Ponsse dealer since 2016. The company is based in Nelspruit in the north-eastern part of the country, some 300 kilometres from Johannesburg. It employs close to 20 people and delivers forest machines not only in South Africa but also in its neighbouring countries.

“Ponsse has been the best partner for us in forest machine trading, and our cooperation has always been smooth,” says Chris Odendaal, the company’s Managing Director, with Erica Odendaal, his wife and the company owner. “We hope that our partnership continues to improve and grow in the future.”

“We just got here, and everything’s looking good. Ponsse’s machines are impressively on display, and we can’t wait to see the work demonstrations. Finland’s forests and terrain are so different – for that reason alone, it’ll be interesting to see the machines at work.”

Based in Melbourne, Randalls is the oldest still-operating dealer specialising in forest machines in Australia. The company started operating in 1968 and has been a Ponsse dealer since 2014. In addition to its head office in Melbourne, Randalls has branches across South Australia and in Tasmania and New Zealand.

“Currently, we have some 80 employees and operate in a very large geographical area,” says David Waldron, Managing Director of Randalls.

“Our range consists not only of Ponsse’s products but also of a large mix of harvester heads, excavators, track-based machines and seeders. We also make certain products ourselves.”

“The general increase in interest rates and the decelerated exports of timber to China can clearly be seen in the markets. Our customers are now operating at 80–90 per cent compared to the situation a year before. Most of our customers operate on forest plantations, harvesting pine and eucalyptus. However, we believe the situation will improve towards the end of this year,” David says.

“The CTL method landed in Australia more than 40 years ago and is slowly gaining a foothold in harvesting. Those operating in the forest machine market are slowly starting to understand the significance of smaller, yet efficient and terrain-sparing, forest tractors and harvesters,” David says.

“This has been a challenging year for machine sales due to the geopolitical situation.

As Ponsse has launched very interesting new products, we can’t wait to see what the future has in store for us,” Chris says.

• The north-eastern parts of South Africa are home to vast forest areas. The country’s total forest resources consist of some 40 million hectares, of which commercial forests only account for some two per cent.

• Key tree species include pine, eucalyptus and acacia.

• Wood for industrial uses is mainly grown on plantations.

• The terrain is varied, ranging from flat land to steep slopes. Contractors and machines must be able to work in both conditions.

• Australia has the world’s seventh largest forest area, accounting for roughly three per cent of the total forest area in the world.

• Australia’s forest resources consist of roughly 134 million hectares. Old-growth forests account for 98 per cent of all forests.

• Eucalyptus (77 per cent) and acacia (eight per cent) dominate Australia’s indigenous forests.

• Radiata pine (1.1 million hectares) and deciduous trees, mainly eucalyptus (0.7 million hectares), are primarily grown on plantations.

• Of the forest area, 32 per cent is under private ownership, and 17 per cent comprises nature reserves.

Ponsse seeks to achieve carbon neutrality at its factory in Vieremä by 2025. Considering this goal, the most significant part of emissions comes from the use of liquefied gas as a fuel in the surface treatment process in production. Ponsse is close to achieving this goal, as liquefied gas was replaced with renewable biogas at its factory in Vieremä in August.

Ponsse’s factory in Vieremä has shifted to the use of biogas supplied from a local biogas terminal. Commissioned at the beginning of 2024, the Vieremä biogas plant distributes liquefied and pressurised biogas for use in industry and transport. At the beginning of its operations, biogas will be acquired from Gasum, a Nordic energy company, but the supplier will be changed to Hankkija at the end of 2024 when Demeca’s gFuel Upgrade 100 biogas processing unit will be built in Vieremä. The unit will process raw biogas into pure biomethane. The municipality of Vieremä built a raw gas collection pipe across local farms and a connecting pipe for Ponsse, with related modifications being completed during the summer and early autumn of 2024, when the factory was closed for the summer.

“The use of biogas at the factory started without any problems, and gas is now used in all planned locations. Users cannot see any difference. The new gas burners are effective and heat up the water used in the paintshop’s washing machine and the drying chamber. Biogas will also be used in winter for heating the welding unit’s beam storage,” says Esa Penttinen, Ponsse´s Production Director.

“The gas burners can also be adjusted according to needs. This is an excellent feature given that the previous burners were either fully on or completely off,” says Penttinen.

Ponsse’s annual consumption of liquefied gas has been approximately 70,000 kg, or 900 MWh. Last year, the consumption of liquefied gas accounted for more than 90 per cent of the carbon footprint of production in Vieremä. The shift to biogas will reduce Ponsse’s carbon footprint by roughly 215 t CO2-eq. (tonnes of carbon dioxide equiva-

lents) and marks a significant step towards achieving the carbon neutrality goal set for Ponsse’s production.

While biogas links local agriculture in Vieremä to the technology industry, it is not intended for industrial consumption alone. A refuelling station for pressurised biomethane is already in operation in Vieremä. The municipality already has ten biogas-fuelled vehicles and tractors. This also provides Ponsse with the opportunity to use biomethane in the future.

“The municipality of Vieremä is also using biogas as an auxiliary source of district heating. Ponsse’s factory is connect-

The new gas burners are effective and heat up the water used in the paintshop’s washing machine and the drying chamber. Biogas will also be used in winter for heating the welding unit’s beam storage

ESA PENTTINEN Production Director

ed to the municipal district heating network, in which woodchips are used as the primary energy source. In addition to allowing us to replace the fuel used in surface treatment, biogas will also reduce the annual emissions generated in our production by roughly 5 t CO2-eq. through district heating,” says Katja Paananen, Chief Responsibility Officer at Ponsse.

Biogas production represents the circular economy at its best. In its production process, the energy content of waste raw materials can be utilised. In addition, the organic nutrients remaining after biogas production can be used as fertilisers in crop production, for example.

Biogas is produced in an anaerobic digestion process at biogas plants at effluent treatment plants and on farms, in addition to which it is recovered from landfill sites. It can be produced from organic matter such as biowaste, industrial sidestreams, sludge, manure and field biomass. The material generated in the anaerobic digestion process is rich in nutrients and can be used as a recycled fertiliser on fields, among other uses.

Biogas is wholly renewable, and its total lifecycle emissions are as much as 90 per cent lower than those of fossil fuels on average. Biogas is ecological because, when growing, biomass sequesters the same amount of carbon dioxide as is released into the atmosphere through its use. “Local production also strengthens the use of local domestic energy and increases energy self-sufficiency, while reducing dependence on fossil fuels,” says Paananen.

Ponsse's Production Director Esa Penttinen and Chief Responsibility Officer Katja Paananen have been satisfied with the introduction of biogas at the Vieremä factory.

The cut-to-length (CTL) harvesting method serves to directly produce high-quality timber cut to the required length based on demand. It is based on users’ actual needs – only the trees required are harvested.

Assortment refers to the different types of products cut from a single felled stem, including sawn wood, plywood and small logs, pulpwood, and wood used to generate bioenergy. In CTL harvesting, we are talking about a machine chain, consisting of a harvester and forwarder.

The harvester fells, delimbs, measures, optimises and cuts stems directly into the assortments ordered by the user, normally a forest company. In the CTL method, trees are processed in the forest into different assortments, based on the requested purpose of use. All the assortments required are produced from each stem by processing it once – in the same place in which it was felled. The forest company sends its raw material needs, i.e. places its order, directly to the harvester, detailing the assortment,

length and quality requirements. The harvester receives cutting instructions from the forest company and helps the operator produce the assortments ordered. In addition, the harvester optimises each stem based on the order and cuts them to the specified lengths. As a result, the valuable raw material can be used as fully as possible, without generating any waste. The volume of the assortments produced can be monitored automatically in real time.

The forwarder carries the assortments to the side of the forest road, placing each assortment into a separate pile. A timber truck will then transport the assortments to the mill for further processing. Each assortment is transported directly to its correct destination: logs to sawmills; plywood logs to the plywood mill; and pulpwood to the paper or pulp mill. They

will then continue their journey to fulfil various purposes in buildings, furniture and various bioproducts.

The aim of harvesting is to minimise machine trails. Eight-wheeled PONSSE forest machines have a balanced weight distribution, and correctly selected tracks can have a significant impact on machine trails. Forwarders have the greatest impact on trails because they drive over the same path multiple times. As it moves and works in the forest, the PONSSE harvester spreads delimbed branches and treetops over trails. This decreases surface pressure and reduces soil damage. In addition, the nutrient-rich leaves, needles, limbs and tops remain in the forest for the next tree generation. A large load space also helps reduce soil damage, as fewer runs are required.

The CTL method enables high-quality harvesting and forest management at all sites, ranging from thinning to regeneration felling. CTL is the best option for thinning and continuous cover forestry.

Eucalyptus bark contains roughly 70 per cent of the total calcium content of a eucalyptus tree. The CTL method leaves the nutrient- and calcium-rich bark in the forest, reducing the need for fertilisers.

TENDED FORESTS GROW MORE QUICKLY AND PRODUCE HIGHER-QUALITY WOOD

Forests sequester carbon dioxide from the atmosphere and slow the progress of the greenhouse effect. This is why forests are carbon sinks. Forests are kept healthy through well-executed thinning, which increases the amount of carbon dioxide they sequester. Furthermore, correctly timed thinning reduces the risk of snow and storm damage, wildfires and insect damage. Managed forests grow more quickly and produce higher-quality wood. A fully-grown forest keeps the carbon dioxide it has sequestered, but cannot sequester more carbon dioxide as effectively as a young, growing forest. Systematic and long-term forest management produces the best results. The more sustainable products are made from wood, the more slowly the carbon dioxide sequestered in trees is released. Durable wood products such as timber buildings and wooden furniture can be regarded as small carbon stocks. When a larger part of felled trees is used in these products with a slow carbon cycle, the amount of carbon dioxide in the atmosphere decreases. In the CTL method, the largest possible part of felled trees can be processed into valuable and durable logs and subsequently into products with a slow carbon cycle.

CTL forest machines can be used in all

harvesting methods, from first thinning to continuous cover forestry and regeneration felling. The fast and reliable regeneration is addressed in all harvesting methods. After all, only the healthy growth of the next tree generation enables the continuation of the forest cycle and the regeneration of the raw material. To enable different harvesting methods, machines must be balanced and strong so that they can use their long crate reach on thinning sites, for example. PONSSE forest machines operate effectively in all conditions – regardless of the weather, time of year or ground surface. The advanced computing capacity of forest machines allows the best possible value to be extracted from forests. This means more than financial gain. By optimising the yield and processing value of the raw material, the maximum amount of sawn timber with a long-term carbon sequestration capacity can be produced.

Where the CTL method is not yet used in mechanised harvesting, the tree-length method is usually used. Compared to the tree-length method, CTL is a more effective and environmentally friendly method as a result of such factors as fuel economy and the

processing times and work stages required. In addition, less cutting damage and timber contamination, combined with fewer top breaks, mean that the timber quality is higher. In the CTL method, the machine chain usually consists of a harvester and a forwarder, whereas the tree-length method requires up to four machines. In the tree-length method, all stems are delivered as whole stems to the roadside storage, from where they are usually transported first to a sawmill or interim storage. There, the stems are unloaded and cut for sawing. In other words, stems are not processed into assortments until they have been delivered to the sawmill or interim storage. After this, the stems are loaded once again for transport to various production facilities. The same stems go through several processing cycles, each resulting in more costs and adverse environmental impacts. In the CTL method, stems are already processed into assortments in forests based on their intended use, and logs are transported directly from forests to their correct destinations, without any interim storage or back-and-forth driving. While CTL is the most common harvesting method in the Nordic countries, the tree-length method is still used widely in other parts of the world, including Canada, the United States and Italy.

For more than five decades, Ponsse has focused on manufacturing forest machines of the effective and environmentally friendly CTL method. Machines have been developed to use the highly valuable wood raw material and cause the least harm on logging sites.

The Einari Vidgrén Foundation awarded the Huequecura company from Chile the first-ever Global CTL recognition. With the recognition, the Einari Vidgrén Foundation seeks to encourage and promote sustainable silviculture and the diverse uses of valuable wood raw materials using the cut-to-length (CTL) method.

“The company has been engaged in systematic high-quality harvesting in Chile. It’s important to see how the Nordic CTL method is spreading across the world,” says Juha Vidgrén, Chair of the foundation.

Radiata pine accounts for some 60 per cent and various eucalyptus species for 22 per cent of all planted forests in Chile. Around 40–45 million cubic metres of wood are harvested per year. In Chile, the tree-length method is more common, whereas only about 15 per cent of forest contractors use the CTL method. CTL forest machines were introduced to the Chilean markets in the 1990s.

Established in 2002, Constructora Huequecura Ltda. provides services in forests and civilian areas. The company’s founders have more than 40 years of experience in the forest industry.

In 2022, Ponsse was looking for service mechanics for Ponsse’s internal exchange programme. Ponsse’s employees attracted by the idea of working abroad applied for the programme, some of whom have already tried what it is like to work in other Ponsse locations across the world.

The idea of an exchange programme for service mechanics was already raised before the coronavirus pandemic, but the application process was not started until a couple of years ago.

The long-term goal is to gather a group of mechanics who, if required, can temporarily provide extra hands for the needs of Ponsse’s local maintenance organisations. There is a global demand for skilled service mechanics.

In the exchange programme, service mechanics can work for shorter periods abroad, ranging from a couple of weeks to a few months. This lowers the threshold for working abroad.

“Our service mechanics have the opportunity to experience different cultures and conditions and share their expertise with local organisations,” says Tapio Mertanen,

Ponsse’s Chief Service Business Officer.

“Positive feedback received while working abroad strengthens service mechanics’ pro fessional mindset and increases appreciation towards their work,” Mertanen says.

Different working environments and cul tures also teach creativity. In the destination country, the content of the toolbox may not necessarily be the same as what a mechanic is used to, and field conditions may differ significantly. Furthermore, distances between service centres and machines may be longer than in the Nordic countries.

“The opportunity to work abroad seems to motivate service mechanics and helps them develop their professional skills. This will hopefully result in longer employment relationships with Ponsse over time,” says Mertanen.

The opportunity to work abroad seems to motivate service mechanics and helps them develop their professional skills.

– Tapio Mertanen, Ponsse's Chief Service Business Officer

Hailing from Jyväskylä, Juha Kahelin has always wanted to try a work period abroad. With this exchange programme, he decided to make his dream come true, and he was accepted to work in France for four months.

Juha was able to reach the best possible agreement for a family man with his employer. “I was a bit nervous at first about going and being separated from my family, but it all went well,” Juha says. He worked in France in fourweek periods, spending two weeks at home in Jyväskylä between them.

What kinds of experiences did you get in your toolbox? Did the way of working differ from the Finnish way?

“The amazing scenery and the opportunity to learn more about a different culture were the best parts. The work itself wasn’t that different,” Juha says. “The custom of shaking hands has especially stuck to my mind. Anyone, from customers to colleagues, was always greeted by shaking hands,” says Juha. “Working hours also took some time to get used to. I like to start my day at 7 am, so working from 8 am to 5:30 pm with a lunch break of 1.5–2 hours in between differed from my routines.”

Did you learn any French?

“We mainly spoke English, but I know a few greetings and pleasantries in French. While some of my colleagues spoke English, sometimes we had to use body language to understand each other.”

Inspired by the experience, Juha will be going on a new six-month work period in Ireland.

235

“I’d encourage everyone interested to use the exchange programme! It offers educational experiences and makes you see things from a new perspective,” Juha says encouragingly.

Working in Örnsköldsvik in Sweden, Dennis Viberg is a veteran globetrotter. The idea of working abroad was sparked when he was offered the opportunity to go to Brazil. Dennis decided to accept the challenge.

“After the first work period, I wanted to see the world and all the different logging sites,” says Dennis. Following Brazil, he has already worked in France and Ireland.

What makes you want to work abroad?

“It’s interesting to see different work cultures – and cultures in general. Meeting new people and seeing different ways of working are highly educational experiences.”

What differences have you seen while working in different countries?

“As there are significant differences not only in ways of working but also in cultures in general, it’s difficult to point out any single factor. What all of these places have in common is the will to keep customers happy by helping them as quickly as possible and in the best possible way.”

“I’d definitely recommend the exchange programme if you want to challenge yourself, meet new people and learn more about their culture,” Dennis says encouragingly before heading off for a new work period abroad later this autumn.

>2,200

650

The exchange programme was customised for a family man.

– Juha Kahelin

Everywhere I’ve been, there’s always been the will to help customers in the best possible way.

– Dennis Viberg

379

Maintenance services close to customers reduce machine downtime. This results in more machine operating hours and larger harvesting volumes.

Our professional and systematic maintenance service network works every day while taking care of the personnel, occupational safety and health, and the environment.

Addressing the environment is particularly important given that oils are handled during machine maintenance, and services are also provided in the field. For example, hazardous waste is handled in accordance with requirements and good practices. We take pride in the responsible maintenance of PONSSE forest machines, while taking care of the environment.

Every year, Ponsse rewards its most merited subsidiary and dealer. In 2023, Ponsse Czech was selected as the Subsidiary of the Year, while the Dealer of the Year award was given to Wahlers Forsttechnik from Germany.

The evaluation criteria have remained unchanged from one year to the next, including the growth and development of business operations and financial key figures from the previous year. The development of customer and employee experiences (NPS and eNPS) is also considered. Ponsse has had a local subsidiary in the Czech Republic since 2022.

The Dealer of the Year was selected from the network of 30 Ponsse dealers. The selection criteria include accomplishments in sales, after-sales services and customer satisfaction, as well as scores given for training, marketing, warranty processes and spare parts. Established in 1935, the family-run company Wahlers Forsttechnik GmbH & Co. KG has been a Ponsse dealer in Germany since 1993 and has operated in Austria since 2019 through its own subsidiary.

According to the new operating model, in the future, Ponsse will reward the country organization of the year instead of subsidiary of the year.

Ponsse is expanding its dealer network in the United States. Ponsse has signed a dealer agreement with Bailey’s, a company based in Woodlands in California. The new dealer will focus on the sales and services of PONSSE forest machines, as well as the provision of maintenance and training, in the states of California and Nevada.

Established by Bill and Judith Bailey in 1975, the family business is already run by the second generation – Bill’s sons Nik and Sam Bailey. Bailey’s has operated in the forest industry since the beginning.

“We are thrilled to partner with Ponsse and bring their exceptional forest machines to our customers in California. Ponsse’s equipment is synonymous with quality and innovation,” says Nik Bailey,

CEO of Bailey’s.

“To celebrate the new partnership, Bailey’s will host a series of launch events across California, allowing its customers to learn more about PONSSE machinery, meet with experts and see demonstrations of the equipment in action,” Nik continues.

“This partnership with Bailey’s provides Ponsse with an excellent opportunity to expand to a new market area. In California, harvesting has mainly been based on traditional methods, but there are also signs of the CTL method starting to attract interest in the region. Bailey’s has established close ties with the local forest industry, and its culture as a family business makes it an excellent partner for Ponsse,” says Samuel Vidgrén, Area Manager, USA, Dealers.

The Einari Vidgrén Foundation recognised merited forestry professionals for the 19th time at the award ceremony held in Rientola in Vieremä. The awards totalled EUR 180,000.

The Einari Award, the Einari Vidgrén Foundation’s key recognition, was given to Roger Lejeune from Belgium. During his more than 30-year career in forestry, Lejeune has promoted CTL harvesting by setting an example.

Lifetime achievement awards were given to Tapio Lahikainen and Ari Siltala, forestry professionals with a long history in harvesting. Lahikainen and Siltala share a passion for the forest machine industry, even after their decade-long careers. The high quality of work and

outdoor life have been an innate part of both of their lives, starting from their earliest logging sites.

In addition to the Einari Award and the lifetime achievement awards, the Einari Vidgrén Foundation gave recognitions in four categories: Special Recognition awards; Operator Awards; Student Scholarships; and the first-ever Global CTL recognition for promoting CTL harvesting.

Interviews with the award recipients are available at news.ponsse.com/en/logging-news/

The load space of the PONSSE Buffalo forwarder made from SSAB’s fossil-free steel at Ponsse’s factory in Vieremä was demonstrated at Ponsse Show Sweden at the beginning of June and at the FinnMETKO exhibition. This material concept focuses on the machining capabilities, behaviour and properties of the new material used in forest machine manufacturing. The load space was built to test the material, and the material concept is part of the FORWARD27 ecosystem project.

The project’s goal is to develop innovative technological solutions for challenging mobile machines to support the use of sustainable solutions in the heavy machinery industry.

The 20th FinnMETKO exhibition was held in Jämsä during the final week of August. This year, the three-day event had 30,700 visitors. People from almost 30 countries added an international atmosphere to Ponsse’s exhibition area! For more information about our launches at FinnMETKO, see the “Responsible solutions by listening to customers” article.

In the Ponsse News online magazine, you can read stories from logging sites across the world. The online magazine is published in Finnish, English and now also in Swedish. You can send us ideas and feedback at https://news.ponsse.com/ en/contact-us/ or by emailing ponssenews@ponsse.com

TOP 5 ONLINE MAGAZINE STORIES

1. Ponsse’s new solutions for sustainable harvesting

2. UAB Gerilita relies on its Ponsse fleet to harvest wood for export and bioenergy in Lithuania

3. Einari Vidgren Foundation rewarded forestry professionals

4. According to Finnish private investors, Ponsse is the most reputable listed company in Finland

5. FinnMETKO 2024

Ponsse’s exhibition area was filled with happy get-togethers and was humming with visitors. Ponsse Ladies celebrated their 20th anniversary at the event. Read more about the exhibition and check the Ladies’ stories at news.ponsse.com.

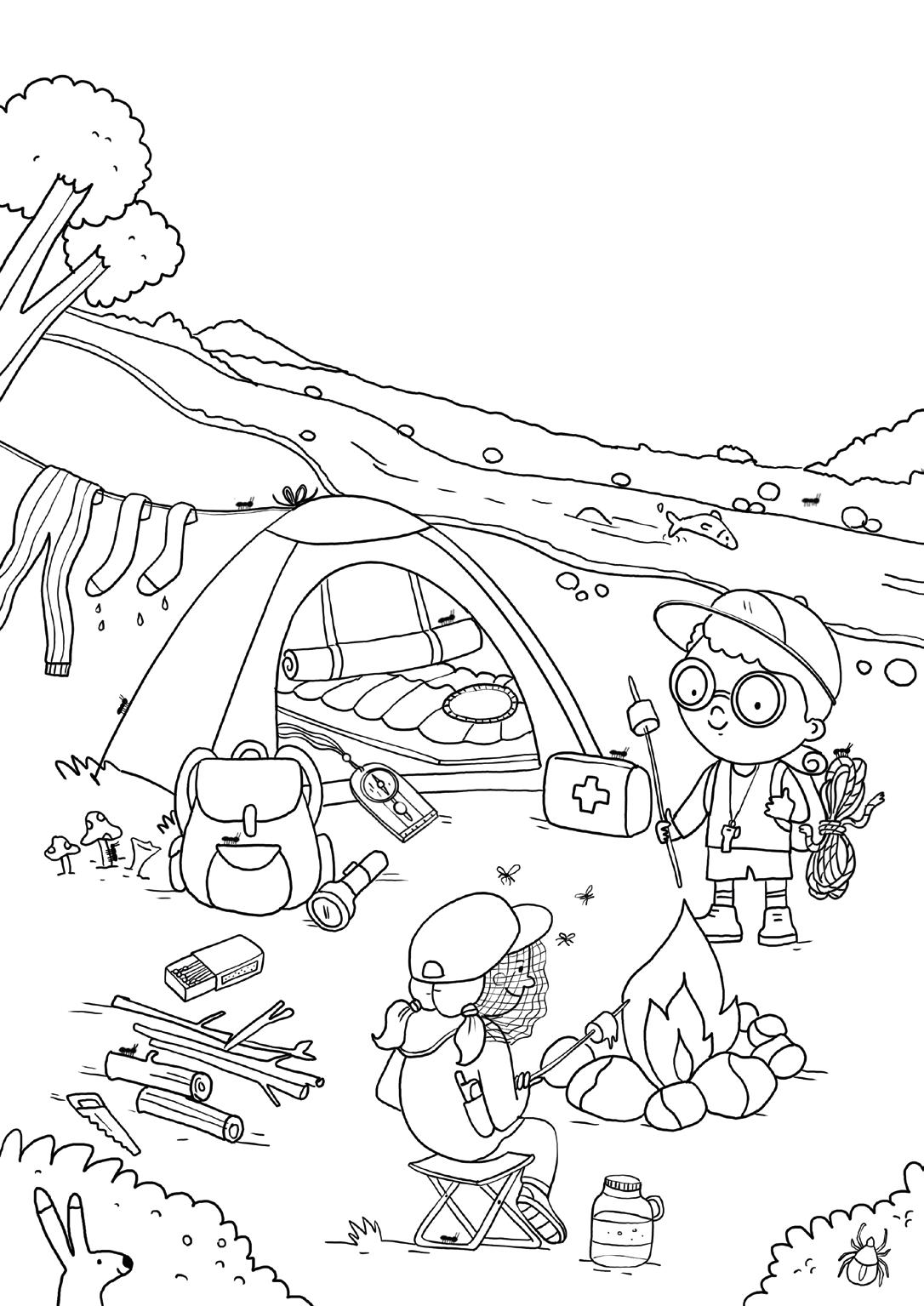

Don't pick or eat anything that you don't recognize!

Circle the items in the picture that are related to the hiker's safety. Afterward, you can color the picture. Think about what makes a good campsite and how to behave near a campfire. How do you protect yourself from mosquitoes or ticks?